Page 1

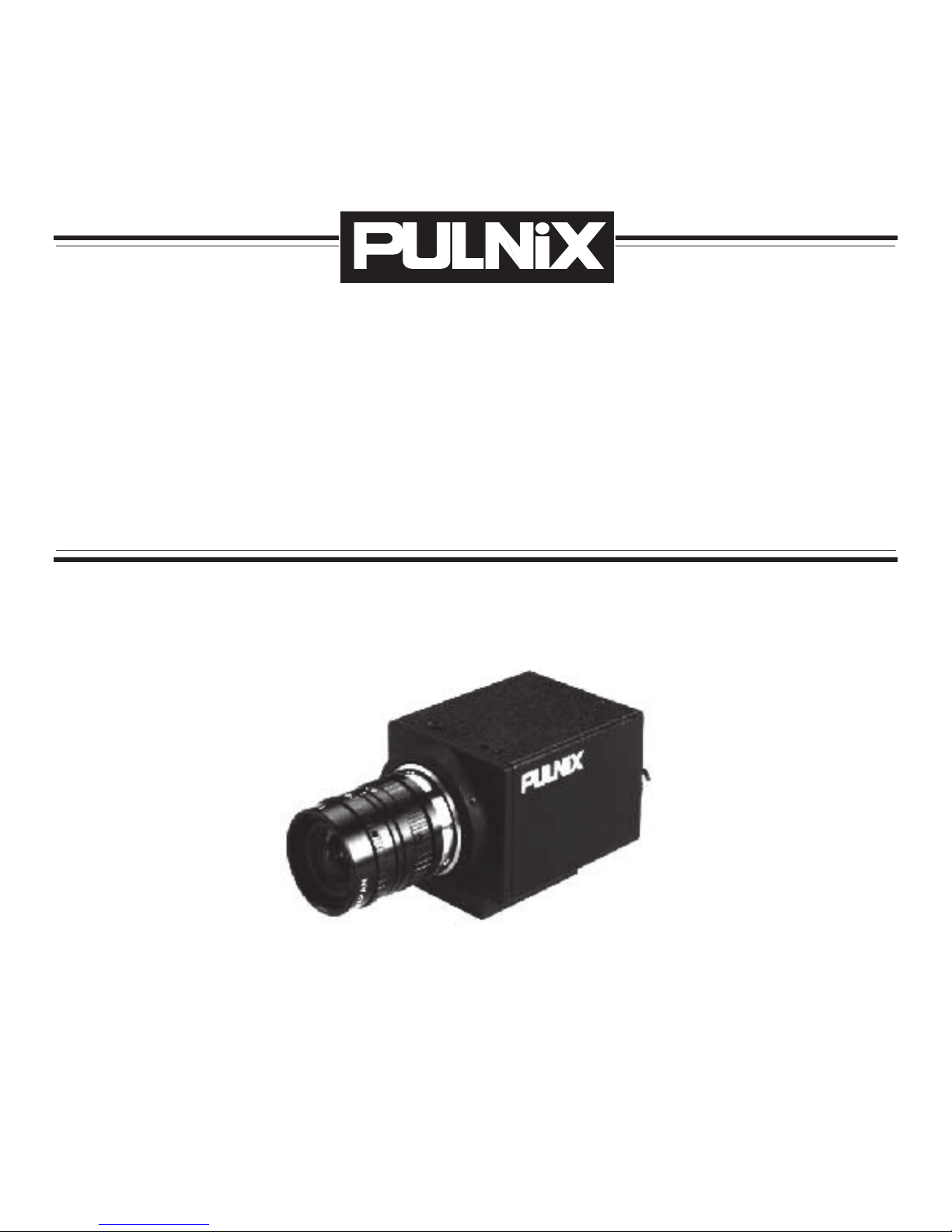

TM-200/TM-300

Miniature CCD Camera

Operation Manual

69-0047

Rev. B

Page 2

Page 3

Notice

The material contained in this manual consists of information that is proprietary to JAI PULNiX , Inc., and may only

be used by the purchasers of the product. JAI PULNiX , Inc. makes no warranty for the use of its product and assumes

no responsibility for any errors which may appear or for damages resulting from the use of the information contained

herein. JAI PULNiX , Inc. reserves the right to make changes without notice.

Warranty

All of our solid state cameras have a full three year warranty. If any such product proves defective during this warranty

period, JAI PULNiX , Inc. will repair the defective product without charge for parts and labor or will provide a

replacement in exchange for the defective product. This warranty shall not apply to any damage, defect or failure caused

by improper use or inadequate maintenance and use.

Certifications

UL

CE

FCC

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

W

ARNING

Changes or modifications to this unit not expressly approved by the party responsible

for FCC compliance could void the user’s authority to operate the equipment.

TM-200 Operation Manual

JAI PULNiX, Inc.

625 River Oaks Parkway

San Jose, CA 95134

Tel: (408) 383-0300

Tel: (800) 445-5444

Fax: (408) 383-0301

Page 4

Page 5

Table of Contents

1 INTRODUCTION ....................................................................1

1.1 Product Description .......................................................................... 1

1.2 Features ...........................................................................................1

1.3 Functional Options ........................................................................... 2

1.4 Applications ...................................................................................... 3

1.5 System Configuration ....................................................................... 3

2 INSTALLATION .....................................................................4

2.1 Getting Started ................................................................................. 4

2.1.1 Unpacking Instructions ........................................................ 4

2.1.2 Components List .................................................................4

2.1.3 Accessories ......................................................................... 4

2.2 Camera Setup ..................................................................................5

2.2.1 Connector Pin Configurations .............................................5

2.2.2 Power Supply and Power Cable Setup ................................ 5

2.2.3 Attaching the Video Output .................................................7

2.2.4 Attaching the Camera Lens ................................................. 7

2.2.5 Back Focusing the Lens ...................................................... 7

2.2.6 Auto-Iris Lens Setup ............................................................ 7

2.2.7 Monitor Display Mode ..........................................................7

2.2.8 Connectors and Cables ....................................................... 8

3 OPERATION ..........................................................................9

3.1 Modes of Operation .......................................................................... 9

3.1.1 External Switches ................................................................ 9

3.1.2 Shutter Control .................................................................... 9

3.1.3 Field and Frame Modes ......................................................9

3.1.4 Integration ...........................................................................10

3.1.5 External Sync ...................................................................... 10

3.1.6 Timing ................................................................................. 11

3.1.7 Interfacing to Frame Grabbers ............................................ 12

3.1.8 Sync Output and Clock Output ............................................ 12

3.2 Board Layout and Adjustment .......................................................... 12

3.2.1 Processor Board ................................................................. 12

3.2.2 Mother Board ...................................................................... 12

4 TROUBLESHOOTING ...........................................................14

4.1 Problems and Solutions ................................................................... 14

4.1.1 Symptom: No Video ............................................................. 14

4.1.2 Symptom: Dark Video .......................................................... 14

4.1.3 Symptom: Non-synchronized Video .................................... 14

4.2 Information and Support Resources ................................................ 15

5 APPENDIX ............................................................................. 16

5.1 Specifications ................................................................................... 16

i

Page 6

Table of Contents

5.1.1 Product Specifications .........................................................16

5.1.2 Physical Dimensions ............................................................17

5.1.3 Glass Specifications ............................................................17

5.1.4 C-Mount Specifications ........................................................17

5.1.5 Front End Detail ...................................................................19

5.2 Spectral Response ...........................................................................20

ii

Page 7

List of Figures

FIGURE 1. TM-200 System Configuration ...................................................3

FIGURE 2. 12P-02 Interface Cable (optional) ..............................................6

FIGURE 3. TM-200 Rear Panel ....................................................................9

FIGURE 4. Shutter Control Settings .............................................................9

FIGURE 5. Input Signals ..............................................................................11

FIGURE 6. TM-200/TM-300 Timing Chart ....................................................11

FIGURE 7. Processor Board ........................................................................12

FIGURE 8. Physical Dimensions ..................................................................17

FIGURE 9. Camera Front End - Glass Specifications ..................................17

FIGURE 10. C-Mount .....................................................................................17

FIGURE 11. Combination With “CS-Mount” Camera ......................................18

FIGURE 12. Front End Detail .........................................................................19

FIGURE 13. Front End Assembly ...................................................................19

FIGURE 14. Spectral Response .....................................................................20

iii

Page 8

Page 9

June 15, 1998

TM-200 / TM-300

Miniature CCD Camera

Operations Manual

1 INTRODUCTION

1.1 Product Description

The TM-200/300 is designed to be a simple yet high quality camera capable of meeting a variety of

application requirements. Featuring an advanced Had-type interline transfer 1/2" CCD imager, this

miniaturized high resolution camera offers many standard and optional features at a very affordable

price. It is available in both EIA (TM-200) and CCIR (TM-300) formats.

1.2 Features

Variable electronic shutter and random CCD integration.

•

The substrate drain-type shutter mechanism provides a superb picture at various speeds without

smearing. The electronic shutter rate can be externally adjusted, from 1/60 to 1/10,000 in discrete

steps, via a manually controlled dial switch.

Miniaturized and lightweight.

•

The use of a CCD image sensor in the video camera module and the development of special mini

C-mount lenses makes it possible to produce a very compact, lightweight and robust camera small

enough to operate just like a remoted head.

•

High sensitivity.

The TM-200/TM-300 camera is one of the most low light sensitive 1/2" CCD cameras available

today. This feature is especially important when using the faster shutter speeds. The CCD detects

images into the near infrared. It requires only 1.0 lux of minimum illumination and 0.5 lux

minimum illumination at maximum gain. In general, this allows use of a higher lens f-value while

providing greater depth of field and sharper images.

Page 1

Page 10

INTRODUCTION

•

Precise image geometry.

On the CCD image sensor, the photosensor elements form exact rows both horizontally and

vertically so that a very precise image geometry may be obtained.

• Low lag/high resistance to image burning.

Since the CCD is highly resistant to image burning, the camera may be exposed to bright objects

for a long period of time. Because a “smear” phenomena may occur when shooting a very bright

object, an infrared cutoff filter is recommended to obtain a clear picture.

•

AGC selection, manual gain control and gamma adjustment.

These adjustments, which are particularly important in vision system applications, are externally

adjustable via switches on the rear plate.

•

Genlock circuit.

A genlock circuit is built in to accept external sync for applications in which external sync is

required.

•

High resistance to magnetic field and vibration/mechanical shock.

Due to its ruggedized design, the CCD imager can withstand strong vibration and shock with little

or no noise appearing in the picture. Since the TM-200/TM-300 is not influenced by a magnetic

field, it will produce stable images even when placed next to objects such as electric furnaces,

welding machines or NMR scanners.

•

Quick start-up and low power consumption.

No more than 2 seconds is needed for the TM-200/TM-300 to warm up, and shooting can begin

within a second after turning on the camera. The power consumption is only 3.0W. This makes the

camera excellent for use with battery operated systems.

•

Three Year Warranty

The CCD solid state image sensor allows the camera to maintain a superior performance level

indefinitely while requiring virtually no maintenance. PULNiX backs all of the TM Series cameras

with a three-year warranty.

Warning: Unscrewing the camera cover or opening the camera in any way

will void this warranty.

1.3 Functional Options

• Internal IR Cut Filter (OP3-1)

Pixel Clock Output (OP7-2)

•

•

Glassless CCD Imager (OP21)

•

DC Coupled (OP72)

Page 2 TM-200 / TM-300 Miniature CCD Camera

Page 11

INTRODUCTION

1.4 Applications

The miniature size of the TM-200/TM-300 camera eliminates the need for a remoted imager camera in

all but the most confined spaces. This camera fits easily, both physically and functionally, into all types

of machine vision, automated inspection, and related applications. Other uses include remotely piloted

vehicles, miniature inspection devices, surveillance, microscopes and medical equipment.

FIGURE 1.

1.5 System Con guration

Figure 1 (below) presents a typical system configuration in which a computer and frame grabber board

are used. A computer and frame grabber board are not required for operation of the TM-200/TM-300

camera.

TM-200 System Con guration

Power

Ext. Sync

SHUTTER

SPEED

0

9

8

7

6

5

VIDEO

FLD

AGC

1.0

GAIN

1

2

3

4

0.45

MGC

POWER

FRM

Integration

Video Output*

Computer with

Frame Grabber

Board

Monitor

TM-200 / TM-300 Miniature CCD Camera Page 3

* Video Output is the

same as BNC connector

Page 12

2 INSTALLATION

The following instructions are provided to help you to set up your video camera system quickly and

easily. It is suggested that you read through these instructions prior to unpacking and setting up your

camera system

2.1 Getting Started

2.1.1 Unpacking Instructions

It is recommended that the original packing cartons for the cameras and lenses be saved in case there is

a need to return or exchange an item.

It is also recommended that any equipment being sent to another location for field installation be bench

tested to assure that everything is fully operational as a system.

INSTALLATION

2.1.2 Components List

Please begin by checking your order against the Components List (below) to assure that you have

received everything as ordered, and that nothing has been overlooked in the packing materials. If any

item is missing, please contact your PULNiX representative immediately.

•

TM-200 camera

•

TM-200 data sheet

•

TM-200 operations manual

2.1.3 Accessories

Following is a list of additional accessories or equipment that may be recommended or required for your

particular application. Please check with your PULNiX representative prior to the installation of your

video system to determine what you might need.

•

Power Cable: 12P-02 Interface Cable

•

Power Supply: PD-12P, PD-12P, DC-12N, or K25-12V

Page 4 TM-200 / TM-300 Miniature CCD Camera

Page 13

INSTALLATION

2.2 Camera Setup

2.2.1 Connector Pin Con gurations

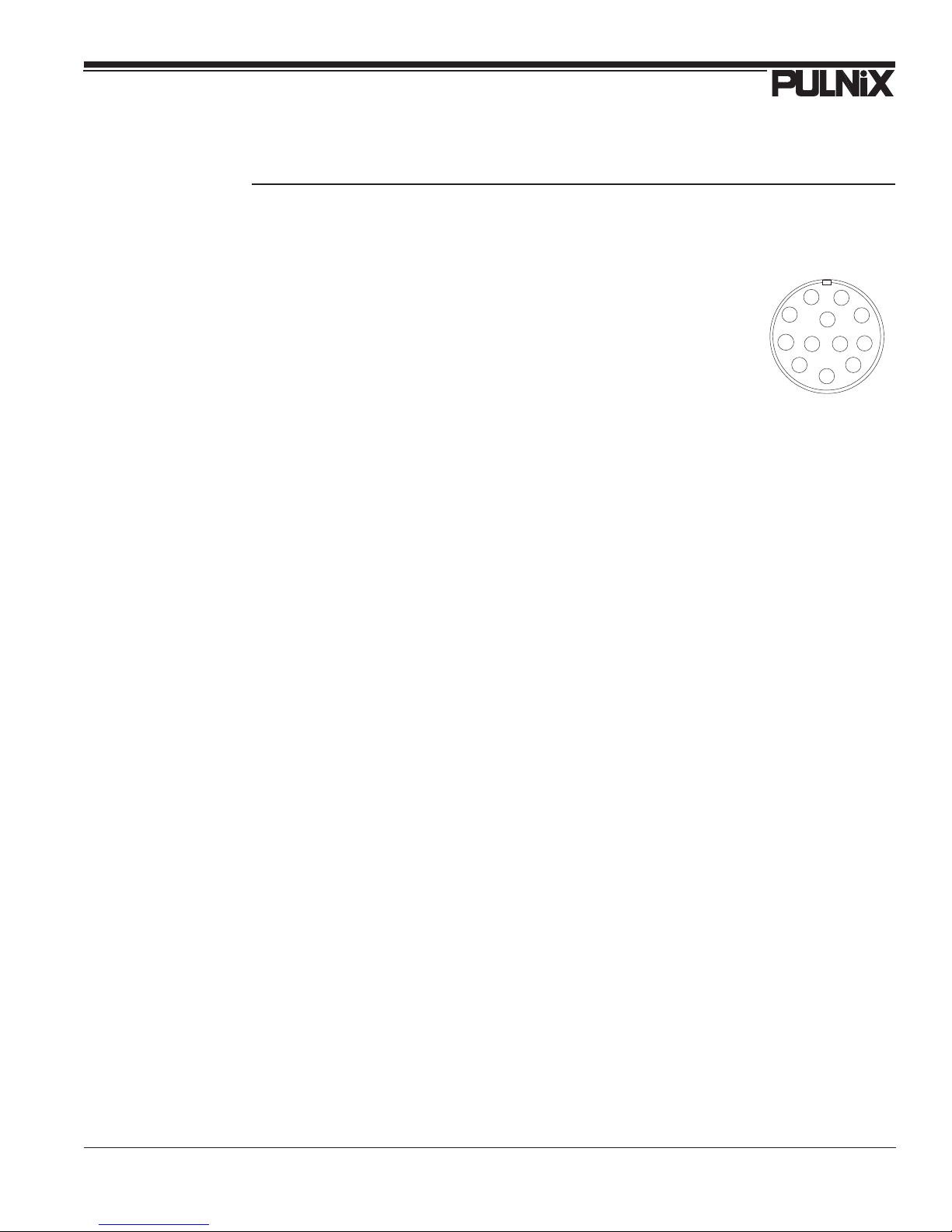

2.2.1 (a) 12-Pin Connector

The TM-200 has a 12-pin connector for power input. Generally, Pin #1 is

Ground and Pin #2 is +12V DC. The other pins handle a number of other input

and output functions, which will be discussed further in other sections.

Pin Description Pin Description

1 GND 7 VD Input

2 +12V DC 8 GND

3 GND 9 HD Input

4 Video Out 10 N/C

5 GND 11 Integration

6 N/C 12 N/C

2.2.2 Power Supply and Power Cable Setup

2.2.2 (a) Power Supplies

PULNiX recommends the following power supplies:

1

9

2

3

11

4

8

10

7

12

6

5

K25-12 110V AC/12V DC 2.1A power supply

P-15-12 220V AC/12V DC 2.1A power supply

K50-12 110V AC/12V DC 4.2A power supply

PD-12P 110V AC/12V DC 0.5A power supply

For users providing power through the 12-pin connector, the PD-12P power supply is available with the

12-pin mating connector already attached to the leads from the power supply. The PD-12 power supply

can be connected to the PULNiX power cable via a terminal strip or directly.

When wiring the PD-12 power supply directly, please note the following:

•

Twist the lead ends together and tin solder for strength and electrical continuity.

•

Use shrink tubing or a similar insulator to prevent exposed leads from touching.

•

The +12V lead is marked with a red stripe or white lettering; be sure not to reverse the leads.

•

Properly insulate all connections to prevent shorting.

2.2.2 (b) PULNiX Power Cables

If you are using PULNiX power cables, such as the 12P-02, KC-10, etc., please refer to the pin-out

diagram. The color coded leads use Grey for Ground and Yellow for +12V DC.

TM-200 / TM-300 Miniature CCD Camera Page 5

Page 14

INSTALLATION

FIGURE 2.

12P-02 Interface Cable (optional)

Flying

1

2,000mm± 10mm

(2 Meters)

PC-12P (Hirose Part #10A-10P-12S/PC12P)

1

12P-02 Interface Cable

Pin# Lead Color Function Pin# Lead Color Function

1 Gray GND 7 Black coax VD Input

2 Yellow +12VCD 8 White coax shield GND

3 Red coax shield GND 9 White coax HD Input

4 Red coax Video 10 Brown N/C

5 Orange coax shield GND 11 Blue Integration

6 Orange coax N/C 12 Black coax shield N/C

Leads

32mm

Note: Make sure that the unused leads are not touching and that there is no possibility that the

leads could short due to exposed wires.

2.2.2 (c) “K” Series Power Supplies

Attach the 110V line cord to the two terminals marked “AC”. Do not plug the cord into a 110V AC

socket until later in the procedure. Next, attach the Grey and Yellow leads of the power cable to the

Ground and 12V DC terminals respectively. Be sure to replace the plastic terminal guard on the power

supply at this time.

Note: The “K” series power supplies are designed primarily for OEM users who will be

mounting the power supply inside a protective enclosure. For use in exposed situations,

the DC-12N and PD-12 are recommended.

2.2.2 (d) Building Your Own Power Cable

Consult the pin-out for the camera purchased. Connect the Ground and +12V power leads of the PC12P power connector to Pin #1 and Pin #2, respectively (power must be DC regulated, and of sufficient

current to properly power the camera).

2.2.2 (e) Attaching the Power Cable to the Connector

The 12-pin connector is keyed and will only fit in one orientation. Rotate the connector while applying

slight pressure until the keyways line up. Press the connector into place until firmly seated.

The power cord may now be plugged into the 100V AC socket, and the camera powered up.

Page 6 TM-200 / TM-300 Miniature CCD Camera

Page 15

INSTALLATION

2.2.3 Attaching the Video Output

Most users utilize the BNC connector for video output from the camera. Connect the output from the

camera to the input of your monitor, VCR or switching device. The input of the monitor should be

balanced for 75Ω termination. Standard RG-59 type coaxial cable should carry a full video signal for up

to 500 feet.

Users wishing to output the video and input the power and sync to a camera over a single cable can use

the PULNiX multi-conductor cables, such as the 12P-02, the KC-10, etc. The mini coaxial leads in

PULNiX multi-conductor cables are designed for short runs of no longer than 100 feet.

Note: Make sure that no extraneous wires are visible which could cause a short.

2.2.4 Attaching the Camera Lens

The TM-200/TM-300 camera accepts 1/2" or larger format size C-mount lenses. To attach the C-mount

lens to the camera, carefully engage the threads and rotate the lens clockwise until it firmly seats on the

mounting ring. Do not force the lens if it does not seat properly. Please note that some lenses with

extremely long flangebacks may exceed the mounting depth of the camera.

2.2.5 Back Focusing the Lens

To backfocus the TM-200 camera, first attach a C-mount lens in the lens mount. Be sure that the lens is

properly mounted.

Set the lens focus to infinity (if the lens is a manual iris, set the iris to a low f-stop while still retaining a

well-illuminated image). Obtain the best focus possible at this setting, then loosen the 3 miniature hex

head set screws locking the focus ring in place. Now turn the entire lens and focus ring assembly back

and forth until the best image is obtained. Tighten the focus ring set screws. Your backfocus is now set.

2.2.6 Auto-Iris Lens Setup

Auto-iris lenses with full video input can be used with the PULNiX TM-200, although this camera

model does not come equipped with auto-iris output.

Note: Make sure that the power is removed from the camera before connecting or disconnecting

the auto-iris lens. There is a small chance that damage could occur to the auto-iris lens by

plugging or unplugging it while the camera is powered up.

Power down the camera before installing the auto-iris lens. To install the auto-iris lens in a PULNiX

camera for which the auto-iris input is not supplied, wire the signal (video) on the lens into the terminal

1 Vp to peak video output on the camera.

Point the camera at a light area and then quickly towards a darker area. If everything is working

properly, the iris should adjust for the light change.

2.2.7 Monitor Display Mode

For monitoring real time video, connect the video output to a video monitor or other device.

TM-200 / TM-300 Miniature CCD Camera Page 7

Page 16

INSTALLATION

2.2.8 Connectors and Cables

12-pin connector and cable: Standard cable is 12P-02 (2m, 8 conductor cable) for power and external

controls.

Page 8 TM-200 / TM-300 Miniature CCD Camera

Page 17

OPERATION

3 OPERATION

3.1 Modes of Operation

3.1.1 External Switches

FIGURE 3. TM-200 Rear Panel

Gamma switch

Up = 1.0

Down = 0.45

AGC/MGC switch

Up = AGC (Automatic Gain Control)

Down = MGC (Manual Gain Control)

* When MGC is selected, the camera gain is adjustable

with the potentiometer on the back plate.

FLD/FRM Switch

Up = FLD (Field Mode)

Down = FRM (Frame Mode)

* Select FRM for strobe applications and FLD for high

shutter speed applications.

SHUTTER

SPEED

0

9

1

8

7

4

6

5

VIDEO

FLD

AGC

1.0

GAIN

2

3

0.45

MGC

POWER

FRM

3.1.2 Shutter Control

FIGURE 4. Shutter Control Settings

Set Shutter Mode

0 1/60

1 1/125

2 1/250

3 1/500

4 1/1,000

5 1/2,000

6 1/4,000

7 1/10,000

8 N/C

9 N/C

3.1.3 Field and Frame Modes

The standard factory setting for the TM-200/TM-300 camera is FIELD MODE. The mode selection is

on the back panel of the camera.

0

9

8

7

6

1

2

3

4

5

Shutter Control Switch

TM-200 / TM-300 Miniature CCD Camera Page 9

Page 18

OPERATION

3.1.3 (a) Field Mode

In Field Mode, two horizontal rows are scanned together, changing the pair at each interlace scan. The

sensitivity of the CCD is doubled for one field of integration, therefore it can obtain the same sensiti vity

as in Frame Mode in half the period of time. This is an advantage when the shutter is used often.

Because of the alternating two row scanning, Moire is almost unnoticeable. While the vertical resolution

is not as good as in Frame Mode, it is sufficient to view the full vertical resolution of the TV format.

Note: Only odd fields are output in this mode. Field Mode cannot provide full frame resolution

with strobe lighting applications.

3.1.3 (b) Frame Mode

In Frame Mode, each horizontal row is scanned as interlace scanning. The integration of each pixel is

one frame period. Vertical pixel resolution is good, and exact location is obtained. A disadvantage as

compared with Field Mode is the tendency to show vertical Moire. For strobe lighting, Frame Mode

must be used to achieve full frame resolution.

3.1.4 Integration

The CCD imager of the TM-200/TM-300 can be exposed longer than normal TV timing (16.7 msec.).

This feature provides high sensitivity for dark environment applications.

Pin #11 of the 12-pin connector is the control pin for integration. It accepts standard TTL inputs. High is

considered 5 Volts and Low is considered 0 Volts. You may enable (i.e., not actually start integrating an

image) integration by applying a high signal to pin #11. Then, when a low v oltage is applied to the same

pin #11, the integration process begins. Integration blocks the transfer gate of the image data out of the

CCD array. Think of a transfer gate(sg) as a floodgate that lets water out of a lake (CCD array). Upon

returning the signal back to high which is required to end the process, the image is output.

Set the camera in frame mode to output two fields of information. In this mode, the output fields appear

to have different exposures, so this may cause problems in some applications. Set to field mode to

output one frame with only one frame of resolution, one field is doubled to obtain one frame (this is not

a true full frame of information).

3.1.5 External Sync

The TM-200/TM-300 can accept external sync from an external sync generator or frame grabber. Input

specifications:

Internal/External auto switch

fH+15.734 KHz ±5%, fV +59.95 Hz ±5%

Note: The TM-300 has a one (1) horizontal line delay between the input VD signal and the

output video. If external vertical drive (VD) is applied to the camera, it may cause the

video output to be delayed 1 HD (1 H = ~64.0 µs). If the imaging system is capable of

automatically detecting the start of video (within a few HD), then no problem will exist.

Otherwise, re-configure the video capturing sequence to delay video acquisition of 1H.

Page 10 TM-200 / TM-300 Miniature CCD Camera

Page 19

OPERATION

FIGURE 5. Input Signals

+5Volts

0 Volts

+5Volts

0 Volts

HD

TTL Level

VD

TTL Level

1/f(horizontal)

3 - 5µsec.

1/60

1 to 9H

3.1.6 Timing

FIGURE 6. TM-200/TM-300 Timing Chart

HD

CCD photo sensors

allocation

69.8nSec

CCD output

signal

Composite video

output

763

6

764

765

22

1.54µSec

6.7µSec

96

45 70 22 5

766

767

768

B1

B45

H register

stop period

Optical

black period

H BLK 10.7µSec

68

H SYNC

4.75µSec

818

768

64

4.47µSec

123456789

B1B2B3B4B5

D1

D22

Optical

black period

Dummy

H register

154

910

63.56µSec (1 horizontal line)

10

757

758

Image sensing period

Effective picture

period

756

52.81µSec

759

760

761

762

763

764

45

765

766

767

768B1B45

TM-200 / TM-300 Miniature CCD Camera Page 11

Page 20

OPERATION

3.1.7 Interfacing to Frame Grabbers

12-pin connector or BNC.

3.1.8 Sync Output and Clock Output

TTL level internal sync and buffered pixel clock output (14.31818MHz) are available from the TM-200/

TM-300 camera. The signal is an emitter follower output requiring a termination resistor at the end of

the cable. The suggested value is from 75Ω to 330Ω.

3.2 Board Layout and Adjustment

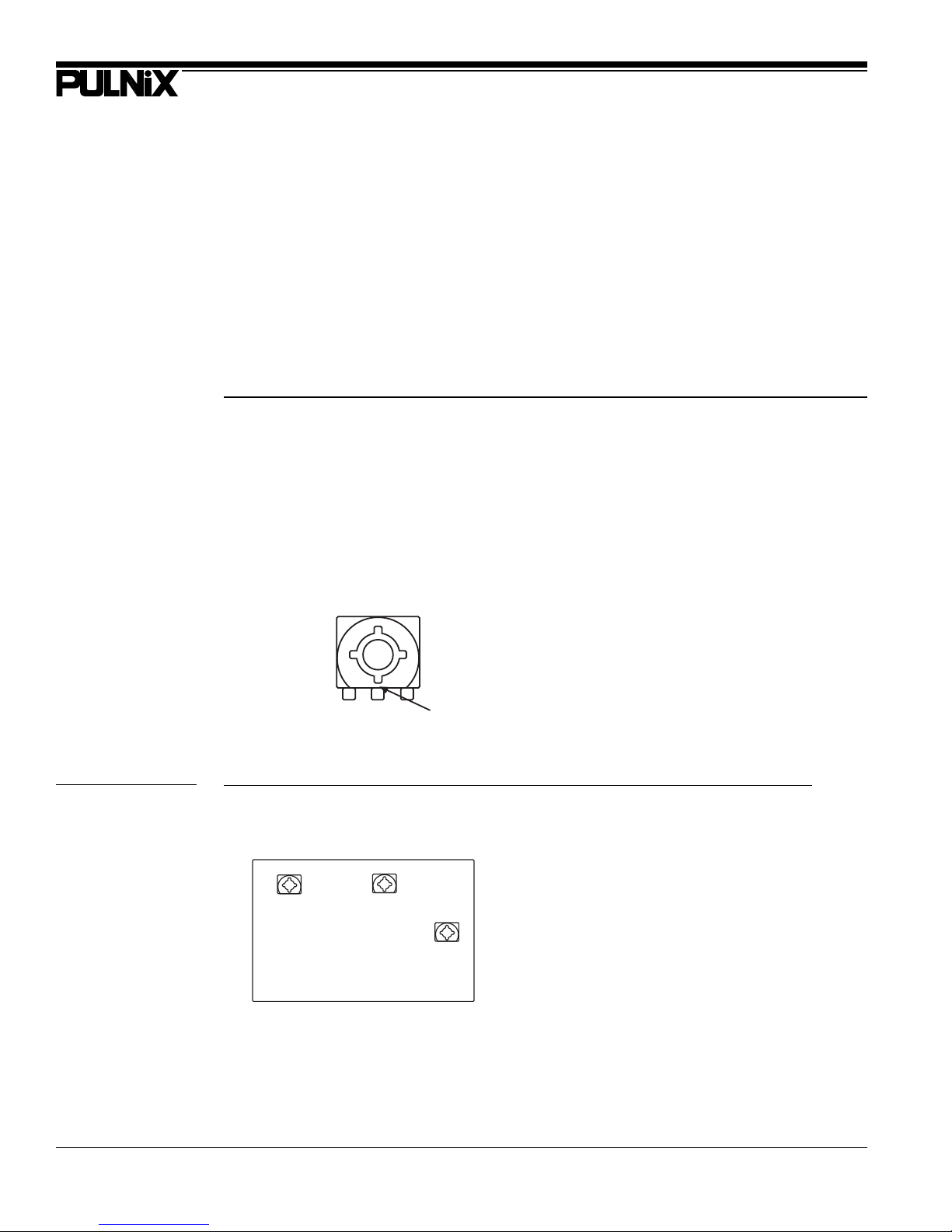

3.2.1 Processor Board

Connect Processor Board to test jig and check all functions.

Voltage Setting

AGC Adjust VR1 (AGC) so that the pot. is 2.0V.

MGC Set VR3 (MGC) at mechanical center (2.5V at pot.). Then set ext. gain pot.

(rear panel) to 3.6V at pot.

Mechanical center

AGC MAX. Adjust VR2 (AGC MAX) to 3.±0.1V at pot.

FIGURE 7. Processor Board

VR1 VR2

AGC MAX

AGC

VR3

MGC

3.2.2 Mother Board

External Sync Specification

Page 12 TM-200 / TM-300 Miniature CCD Camera

Page 21

OPERATION

Sync Internal/External auto-switching

HD in fHD = 15.734 KHz ± 5% (EIA)

fHD = 15.625 KHz ± 5% (CCIR)

VD in fVD = 59.94 Hz ± 5% (EIA)

fVD = 50.00 Hz ± 5% (CCIR)

Input impedance 200Ω

TM-200 / TM-300 Miniature CCD Camera Page 13

Page 22

4 TROUBLESHOOTING

4.1 Problems and Solutions

Following are troubleshooting tips for common problems. Generally, problems can easily be solved by

following these instructions. If the following remedies fail to offer a solution to your problems, please

contact a PULNiX representative.

4.1.1 Symptom: No Video

Remedies: Check that the following are properly connected and operational.

• Power supplies

• Power cables

• Main power source

• Shutter control

• Async mode

• Lens

TROUBLESHOOTING

4.1.2 Symptom: Dark Video

Remedies: Check that the following are properly connected and operational.

• Shutter selection

• Iris opening on the lens

4.1.3 Symptom: Non-synchronized Video

Remedies: Check that the following are properly connected and operational.

• Proper mode output

• Frame grabber software camera selection

Page 14 TM-200 / TM-300 Miniature CCD Camera

Page 23

TROUBLESHOOTING

4.2 Information and Support Resources

For further information and support:

Phone: (408) 383-0300

(800) 445-5444

Fax: (408) 383-0301

E-mail: imaging@jaipulnix.com

Mail: JAI PULNiX Inc.

Sales Department

625 River Oaks Parkway

San Jose, CA 95134

Web Site: www.jaipulnix.com

TM-200 / TM-300 Miniature CCD Camera Page 15

Page 24

5 APPENDIX

APPENDIX

5.1 Speci cations

5.1.1 Product Speci cations

TABLE 1. TM-200/TM-300 Product Speci cations Table

Model TM-200 (EIA) TM-300 (CCIR)

Imager 1/2" Interline transfer CCD, HAD type

Pixels 768(H) x 494(V)

Cell size 8.4µm x 9.8µm 8.6µm x 8.3µm

Scanning 525 lines EIA

Sync Internal/External auto switch

fH=15.734 KHz ±5%,

fV=59.95 Hz ±5%

TV resolution 570(H) x 350(V) 560(H) x420(V)

S/N Ratio 50dB min., 56dB typical, AGC off

Min. illumination 0.5 lux (F=1.4)

Video output 1.0 Vp-p composite video, 75Ω

AGC ON/OFF back panel switch

Gamma 1 or 0.45 back panel switch

Lens mount C-mount

Power requirement 190 mA, 11-15V

Operating temp. -10°C to +50°C

Vibration & Shock Vibration 7Grms/20-2000 Hz, Shock 70G

Size 45.8mm x 39.4mm x 66.3mm

Weight 157g (5.6 oz.)

Power cable 12P-02 (optional)

Power supply k25-12V, DC-12N, PD-12

Functional options 3-1, 3-2, 7-2, 21, 25

Accessories See current price list.

752(H) x 582(V)

625 lines CCIR

fH=15.725 KHz ±5%,

fV=50 Hz ±5%

1.81" x 1.54" x 2.60"

P-15-12

Page 16 TM-200 / TM-300 Miniature CCD Camera

Page 25

APPENDIX

5.1.2 Physical Dimensions

FIGURE 8. Physical Dimensions

45.8 mm

39.4 mm

7.0 mm

5.1.3 Glass Speci cations

FIGURE 9. Camera Front End - Glass Speci cations

78.9 mm

66.3 mm

CCD

2X 11.0 mm

30.4 mm

1/4-20 UNC-2B

2xM3x10

CCD Glass (BK-7) 0.75mm thickness

Refractive Index = 1.5

Glass Cover (BD-65) 1.0mm thickness

Refractive Index = 1.51

2xM6x10

5.1.4 C-Mount Speci cations

FIGURE 10. C-Mount

TM-200 / TM-300 Miniature CCD Camera Page 17

CCD Glass

Page 26

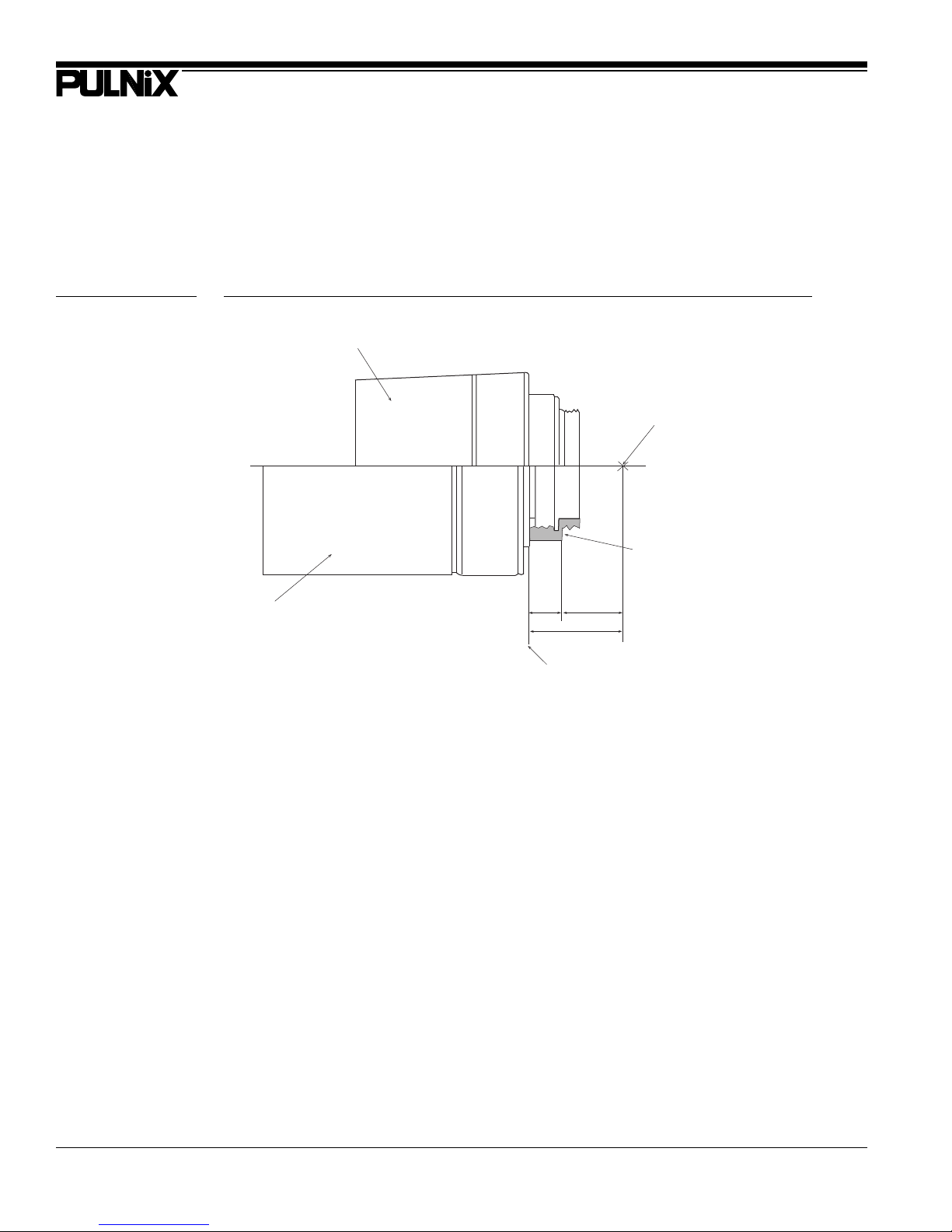

The Flange Back Length of the CS-Mount is 12.5mm versus 17.526 of the C-Mount. The shorter Flange

Back Length of the “CS-Mount” allows room for the stripe filter incorporated in the color camera.

Additionally, the shorter Flange Back Length allows for reduction of the effective diameter of the first

lens and reduces the number of lens elements. The common C-Mount lens is completely compatible

with a CS-Mount camera when a 5mm extension ring is inserted between the lens and the camera.

FIGURE 11. Combination With “CS-Mount” Camera

CS-Mount Lens

APPENDIX

Focal Point

C-Mount Lens

12.5

5

17.526

Flange Surface of

C-Mount

5mm Extension Ring

Page 18 TM-200 / TM-300 Miniature CCD Camera

Page 27

APPENDIX

5.1.5 Front End Detail

FIGURE 12. Front End Detail

1.00

18.20

Front End

Image Plane

CCD Imager

1.41

FIGURE 13. Front End Assembly

C-Mount Ring

16.8

TM-200 / TM-300 Miniature CCD Camera Page 19

2X MOUNTING

HARDWARE

I.C.

PIN 1

FRONT

END

3X C-MOUNT RING

LOCKING SET SCREW

C-MOUNT

RING

Page 28

5.2 Spectral Response

FIGURE 14. Spectral Response

1.0

O.9

0.8

0.7

0.6

0.5

0.4

0.3

Relative Sensitivity

0.2

0.1

0

400

500

APPENDIX

600 700 800 900 1000 1100 1200

Wave Length (nm)

Page 20 TM-200 / TM-300 Miniature CCD Camera

Page 29

Page 30

Page 31

Page 32

Industrial Products Division

JAI PULNiX Inc.

625 River Oaks Parkway

San Jose, CA 95134

Email: imaging@jaipulnix.com

www.pulnix.com

Tel: 408-383-0300

Tel: 800-445-5444

Fax: 408-383-0301

Loading...

Loading...