Revision History

Revision Level Revision Date

Rev. A, ECO 539 May 1999

Rev. B, ECO 740 January 2000

Rev. C, ECO 818 August 2000

Rev. D, ECO 1149 May 2001

Rev. E, ECO 1532 May 2002

Rev. F, ECO 1983 April 2003

Rev. G, ECO 2374 September 2003

Rev. H, ECO 3580 November 2005

Rev. J, ECO 5019 December 2007

Rev. K, ECO 5407 July 2008

Contact Information

Pulmonetic Systems, Inc.

17400 Medina Rd., Suite 100

Minneapolis, Minnesota 55447-1341

Phone: (763) 398-8500

Office Fax: (763) 398-8400

Customer Care Center Phone: (800) 754-1914

Customer Care Center Fax: (763) 398-8403

Sales/Marketing E-mail: info@pulmonetic.com

Customer Care Center E-mail: service@pulmonetic.com

Pulmonetic Systems Website: http://www.pulmonetic.com

®

1000, LTV® 950, LTV® 900, LTV® 800 and LTV® are trademarks belonging to

LTV

Pulmonetic Systems, Inc.

©

Copyright

2008 Pulmonetic Systems, Inc., Minneapolis, Minnesota.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page i

User/Owner Responsibility

This manual is intended for use only by service personnel who have been trained and

authorized by Pulmonetic Systems. Pulmonetic Systems does not condone or approve of

service activity on its products by untrained and unauthorized personnel. Pulmonetic

Systems is not responsible for any unauthorized repairs or any repairs made by

unauthorized procedures.

Use of an incorrect part or failure to exercise due care in the installation, removal, servicing,

checkout or calibration of parts and equipment may result in damage or malfunction of the

equipment. This may also result in damage to property and injury including death.

The purchaser and installer of these parts shall bear full responsibility and liability for the

above. All maintenance performed within the applicable warranty period must be authorized

in advance by a Pulmonetic Systems’ Service representative in order to retain the warranty

status of the subject unit.

Warranty

Pulmonetic Systems warrants that the LTV® Series ventilator is free from defects in material

and workmanship for a period of one (1) year from the date of shipment, or 8,800 hours as

measured on the usage meter, whichever comes first, with the following limitations:

Patient circuit components, including tubes, exhalation manifold, and other associated

parts are warranted for sixty (60) days from date of shipment.

The internal battery is warranted for ninety (90) days from date of shipment.

Pulmonetic Systems will, at its option, either repair, replace, or issue credit for products that

prove to be defective during the warranty period.

For warranty service or repair, the product must be returned to Pulmonetic Systems or a

service facility designated by Pulmonetic Systems, shipping prepaid by the Buyer.

LIMITATION OF WARRANTY

Ordinary maintenance, as specified in the LTV

®

Series or LTV® 800 Ventilator Operator’s

and Service Manuals, is not covered under the foregoing warranty

The foregoing warranty does not apply to defects resulting from:

1) Improper or inadequate maintenance of the unit;

2) Improper use or misuse of the unit;

3) Unauthorized modifications or repair to the unit;

4) Use of the unit with unauthorized accessories, e.g. external battery or AC adapter.

5) Operation of the unit outside the specified environment.

NO IMPLIED WARRANTIES

This warranty is exclusive. There are no other warranties expressed or implied.

LIMITATION OF LIABILITY

Pulmonetic Systems shall not be liable for loss of profits, loss of use consequential

damages, or any other claim based on breach of warranty. Pulmonetic Systems, Inc.’s

liability for damages of any kind shall be limited to the purchase price of the defective unit.

Page ii LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Notices

The LTV® Series ventilator complies with limitations as specified in IEC 601-1-2 for Medical

Products. It does however, use and radiate radio frequency energy.

The function of this machine may be adversely affected by the operation of other nearby

equipment, such as high frequency surgical diathermy equipment, short-wave therapy

equipment, defibrillators or MRI equipment.

Notice to Users

Unsafe Operation - Servicing the LTV® Series ventilator without a complete and thorough

understanding of its attributes may result in unsafe operating conditions. It is important that

this manual be read and understood in its entirety before servicing the ventilator.

Warnings and Cautions Section - Read the section on Warnings and Cautions carefully

before attempting to service or operate the LTV® Series ventilators. General warnings and

cautions which apply any time you use the ventilator are listed in the front of this manual.

General and specific warnings and cautions also appear throughout the text where they are

most meaningful.

Use and Maintenance - Any questions regarding installing, setting up, operating, or

maintaining the LTV® Series ventilators, should be directed to a service technician who has

been trained and certified by Pulmonetic Systems or Pulmonetic Systems, Inc. using the

contact information at the front of this manual.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page iii

Contents

Notices .........................................................................................................................................iii

Chapter 1 - Introduction.................................................................................. 1-1

Getting Assistance ....................................................................................................................1-1

Operator’s Safety Information ...................................................................................................1-2

Warnings ...................................................................................................................................1-3

Cautions ....................................................................................................................................1-4

Symbols.....................................................................................................................................1-6

Chapter 2 - Ventilator Checkout Tests .......................................................... 2-1

Alarm Test ................................................................................................................................. 2-4

Display Test...............................................................................................................................2-5

Control Test............................................................................................................................... 2-7

Leak Test...................................................................................................................................2-9

Vent Inop Alarm Test ..............................................................................................................2-11

Exit ..........................................................................................................................................2-12

Chapter 3 - Real Time Transducer Data ........................................................ 3-1

Chapter 4 - Cleaning and Sterilization........................................................... 4-1

Cleaning the Ventilator..............................................................................................................4-1

Cleaning the Exhalation Valve and Reusable Patient Circuit ...................................................4-2

Cleaning the Inlet Filter .............................................................................................................4-7

Cleaning the Fan Filter..............................................................................................................4-8

Chapter 5 - Preventative Maintenance........................................................... 5-1

Recommended Maintenance Schedule .................................................................................... 5-1

Before Initial Use.......................................................................................................................5-2

Storage Maintenance ................................................................................................................ 5-2

Daily Maintenance..................................................................................................................... 5-2

Monthly Maintenance ................................................................................................................ 5-2

10,000 Hour / 2 Year Maintenance ........................................................................................... 5-3

30,000 Hour Maintenance / 6 Year Maintenance .....................................................................5-3

Chapter 6 - Maintenance & Calibration.......................................................... 6-1

Operating Theory ......................................................................................................................6-1

Pneumatic Schematic Detail .................................................................................................6-3

Vent Maintenance .....................................................................................................................6-4

Vent Maintenance Entry........................................................................................................6-5

Vent Maintenance Entry Alarm .............................................................................................6-5

Calibration .................................................................................................................................6-6

Airway Pressure Calibration..................................................................................................6-7

Calibrate the Airway Pressure Transducers .........................................................................6-9

Flow Differential Calibration ................................................................................................6-11

Valve Differential Calibration............................................................................................... 6-14

O

Inlet Pressure Calibration............................................................................................... 6-17

2

Motor Drive Calibration .......................................................................................................6-19

Measure Turbine Speed (T/S).............................................................................................6-21

Vent Maintenance Exit ........................................................................................................6-23

Calibration Worksheet.........................................................................................................6-24

Flow Valve Calibration ............................................................................................................6-25

Flow Valve Calibration Worksheet ......................................................................................6-29

Servo ....................................................................................................................................... 6-30

Solenoid ..................................................................................................................................6-32

Step Test .................................................................................................................................6-33

Watchdog Test ........................................................................................................................6-34

Page iv LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Configuration .......................................................................................................................... 6-35

Model Selection ...................................................................................................................... 6-36

Flow Valve Home Position...................................................................................................... 6-37

Temperature Compensation................................................................................................... 6-39

Analog Board Setting.............................................................................................................. 6-40

O

Blender .............................................................................................................................. 6-42

2

Configuration Menu Exit .........................................................................................................6-43

CLEAR.................................................................................................................................... 6-44

Vent Maintenance Menu Exit.................................................................................................. 6-45

Chapter 7 - Troubleshooting...........................................................................7-1

Displays and Buttons................................................................................................................ 7-2

Ventilator Performance............................................................................................................. 7-6

Advanced Vte Diagnostic Procedures .................................................................................... 7-22

Advanced FiO

Diagnostic Procedures .................................................................................. 7-26

2

Power and Battery Operation ................................................................................................. 7-28

Alarms..................................................................................................................................... 7-31

Checkout Test Failures........................................................................................................... 7-37

Test Lung Operation............................................................................................................... 7-41

Chapter 8 - Component Removal and Replacement.....................................8-1

Training and Authorization........................................................................................................ 8-1

Service Record ......................................................................................................................... 8-1

Tools ......................................................................................................................................... 8-2

Calling for Assistance ............................................................................................................... 8-2

Before removing the back panel............................................................................................... 8-3

Before replacing the back panel............................................................................................... 8-3

After performing any maintenance ........................................................................................... 8-3

Boots, Protective....................................................................................................................... 8-4

Boots, Temporary Removal.................................................................................................. 8-5

Boots, Permanent Removal.................................................................................................. 8-7

Boots, Reinstallation...........................................................................................................8-10

Boots, New Installation ....................................................................................................... 8-13

LTM/LTV mounting assembly installation and removal.......................................................... 8-16

LTM mounting assembly temporary removal (current LTMs) ............................................ 8-17

LTM mounting assembly permanent removal (current LTMs) ........................................... 8-18

LTM mounting assembly re-installation (current LTMs) .............................................. 8-18

LTM mounting assembly re-installation (current LTMs) .............................................. 8-19

LTM mounting assembly installation (current LTMs)................................................... 8-21

LTM/ LTV

LTM/LTV mounting bracket temporary removal (earlier model LTMs)............................... 8-25

LTM/LTV mounting bracket permanent removal (earlier model LTMs).............................. 8-26

LTM/LTV

LTM/LTV

Back Panel.............................................................................................................................. 8-31

Back Panel, Removal ......................................................................................................... 8-31

Dovetail Mounting Bracket, Replacement .......................................................................... 8-32

Back Panel, Reinstallation.................................................................................................. 8-35

Internal Flexible Tube Routing Configurations ....................................................................... 8-39

LTV

LTV

LTV

LTV

Alarm Sounder Assembly ....................................................................................................... 8-45

Analog Board Assembly ......................................................................................................... 8-48

External Inlet Filter.................................................................................................................. 8-51

Fan Assembly ......................................................................................................................... 8-52

Cleaning the Fan Filter ....................................................................................................... 8-54

®

mounting bracket (earlier model LTMs) ........................................................... 8-24

®

mounting bracket, reinstallation (for earlier model LTMs) ................................ 8-27

®

mounting bracket installation (earlier model LTM)............................................ 8-29

®

900, 950 and 1000 Current Version Tube Routing Diagrams................................... 8-40

®

900, 950 and 1000 Earlier Version Tube Routing Diagrams .................................... 8-42

®

800 Current and Earlier Tube Routing Diagram ....................................................... 8-43

®

800 Current and Earlier Tube Routing Diagram ....................................................... 8-44

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page v

Flow Valve Assembly and Cleaning Instructions ....................................................................8-55

Front Panel.............................................................................................................................. 8-64

Internal Battery Pack...............................................................................................................8-69

Internal Inlet Filter ...................................................................................................................8-72

Main Board Assembly .............................................................................................................8-73

Memory Board......................................................................................................................... 8-77

Checking the O2 Blender when upgrading software ..........................................................8-79

Motor Board Assembly............................................................................................................8-80

O2 Blender Assembly / O

O

Blender Filter......................................................................................................................8-89

2

O2 Blender Cap (LTV 1000 Only)........................................................................................... 8-90

O2 Port Cap (Low Pressure)...................................................................................................8-91

Power Board Assembly...........................................................................................................8-92

Right and Left Soft Side Panels ............................................................................................8-102

Rotary Switch (Set Value Knob) Assembly...........................................................................8-103

Solenoid Manifold Assembly................................................................................................. 8-105

Thermo Conductive Motor Board Heatsink Pad ...................................................................8-107

Thermo Conductive Turbine Pad ..........................................................................................8-108

Turbine Manifold ...................................................................................................................8-109

Inlet Block .....................................................................................8-82

2

Chapter 9 - Final Checkout Test..................................................................... 9-1

Checkout Test Selection ...........................................................................................................9-1

General Checkout .....................................................................................................................9-2

General Checkout Worksheet ............................................................................................... 9-8

Power Checkout......................................................................................................................9-12

Power Checkout Worksheet................................................................................................9-14

Performance Checkout ...........................................................................................................9-16

Performance Checkout Worksheet .....................................................................................9-25

24 Hour Burn-in.......................................................................................................................9-30

24 Hour Burn-in Worksheet.................................................................................................9-31

Appendix A - Ventilator Specifications .........................................................A-1

Appendix B - Glossary....................................................................................B-1

Appendix C - Service Record Form ...............................................................C-1

Appendix D - Event Trace...............................................................................D-1

Event Codes............................................................................................................................. D-3

Event Codes by Code # ....................................................................................................... D-3

Event Codes by Event Name ............................................................................................... D-6

Event Trace Data Definitions ............................................................................................... D-9

Appendix E - Reference Information .............................................................E-1

Conversion Factors .................................................................................................................. E-1

Extended Features Map...........................................................................................................E-2

Extended Features Map (continued)........................................................................................ E-3

External Accessories Screw Location, Type and Length......................................................... E-4

Input O

Parts, Replacement.................................................................................................................. E-8

Settings, Dip Switch ............................................................................................................... E-12

Settings, Front Panel Controls and Extended Features ........................................................ E-13

Tools, Required...................................................................................................................... E-14

Transducer Calibration, Acceptable A/D Counts ................................................................... E-15

Torque Values........................................................................................................................ E-16

Flow Chart.................................................................................................................. E-6

2

Appendix F - Index .......................................................................................... F-1

Page vi LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Chapter 1 - I

This manual describes how to perform routine maintenance, troubleshooting, and repairs on

the LTV

trained and authorized by Pulmonetic Systems. Do not perform any of the procedures in

this manual unless you are trained and authorized for service on the LTV

®

Series ventilator. It is designed for use by service personnel who have been

NTRODUCTION

®

Series

ventilators.

This manual contains what you need to know to:

1) Perform preventative maintenance.

2) Calibrate the ventilator.

3) Perform routine troubleshooting.

4) Remove and replace major components of the ventilator.

®

See the LTV

Series or LTV® 800 Ventilator Operator's Manual for more information on

setting up and operating the ventilator.

Getting Assistance

If a problem occurs while maintaining the LTV® Series ventilator or if you require additional

information, contact a service technician who has been trained and certified by Pulmonetic

Systems or Pulmonetic Systems, Inc. at:

Pulmonetic Systems, Inc.

17400 Medina Rd., Suite 100

Minneapolis, Minnesota 55447-1341

Phone: (763) 398-8500

Office Fax: (763) 398-8400

Customer Care Center Phone: (800) 754-1914

Customer Care Center Fax: (763) 398-8403

Sales/Marketing E-mail: info@pulmonetic.com

Customer Care Center E-mail: service@pulmonetic.com

Pulmonetic Systems Website: http://www.pulmonetic.com

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 1-1

Operator’s Safety Information

All Operators are to read and understand the following information about Warning, Caution

and Note statements before operating the LTV

®

Series ventilator.

General warnings and cautions which apply any time you use the ventilator are listed here.

General and specific warnings and cautions also appear throughout this manual where they

are most meaningful.

WARNING

“Warning” statements contain information about circumstances or practices that may cause

serious and undesirable results, or expose the patient or operator to danger.

CAUTION

“Caution” statements contain information about circumstances or practices that may result

in equipment damage.

Note

“Note” statements contain additional information to assist in the proper operation of the

LTV® Series ventilators.

Page 1-2 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Warnings

WARNING

WARNING

Ventilator Service and Repair - Only service technicians who have been trained and

certified by Pulmonetic Systems, Inc. are authorized to perform repairs or maintenance on

the LTV® series ventilators. Do not attempt to repair or replace any part of the ventilator

unless you are trained and certified to do so by Pulmonetic Systems. Personal injury could

result.

Fire or Explosion - Operation of the LTV® Series ventilators in the presence of flammable

gases could cause a fire or explosion. Under no circumstances is the ventilator to be

operated when explosive gases are present. The presence of nitrous oxide or flammable

anesthetics presents a danger to the patient and operator.

Untrained Personnel – Only properly trained personnel should operate the ventilator. The

LTV® Series ventilator is a restricted medical device designed for use by Respiratory

Therapists or other properly trained and qualified personnel under the direction of a

physician and in accordance with applicable state laws and regulations.

Unauthorized Parts or Accessories – Serious harm to the patient may result from the use

of unauthorized parts or accessories. Only items expressly approved by Pulmonetic

Systems may be used in conjunction with the LTV® Series ventilators.

Ventilator Checkout Tests – Be aware that gas is not delivered to the patient during these

tests. Disconnect the patient from the ventilator and ventilate the patient using an alternative

method before running the Ventilator Checkout tests.

Ventilator Checkout and Maintenance Modes - The LTV® Series ventilator does not

deliver gas during the Ventilator Checkout mode (VENT CHECK) or Ventilator Maintenance

mode (VENT MTNCE) and should not be used to ventilate a patient during these tests.

Mounting Screw Use – Internal damage to the ventilator may result if wrong length

mounting screws are used to secure parts or accessories. Refer to the information

contained in Replacement Screws Kit, P/N 11149, to determine the appropriate accessories

mounting screws or accessories replacement screws to use when removing or exchanging

external accessories on an LTV® Series ventilator.

Patient Circuits – Pulmonetic Systems Patient Circuits, Exhalation Valve Assemblies and

Water Traps are shipped clean, not sterile.

Ultra Violet Light Sensitivity – The material used in the tubing of the “Reusable” Patient

Circuits is not UV stable. Avoid exposure of tubing to UV light.

PEEP Valve Rotation – Attempting to adjust the PEEP valve counterclockwise past zero (0)

may damage the PEEP valve assembly and cause circuit leaks.

To avoid damaging the PEEP valve, always depress the yellow lock button on top of the

valve when making adjustments.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 1-3

Cautions

CAUTION

Electrical Grounding – In the event of a loss of electrical protective ground, touching the

ventilator could result in electrical shock. To ensure grounding and avoid this danger, use

only the unmodified power cord originally supplied with the LTV® Series ventilators,

maintained in good condition and connected to a properly wired and grounded electrical

power outlet.

Fuse Fire Hazard – Replacement of existing fuses with fuses with different voltage or

electrical current ratings may cause a fire.

Storage Temperature - Storing the LTV® Series ventilator at temperatures above 60°C

(140°F) for long periods can damage the internal battery and cause expected battery

duration to degrade.

Patient Assist Call Connector – Do not apply more than 25V rms or 32VDC to the Patient

Assist Call connector.

CLEAR Function Cautions - The CLEAR function should be used with great care as once

a section of the memory is cleared, all data in that section of memory is lost and it cannot be

automatically restored.

Electronic and Mechanical Parts - The LTV® Series ventilator contains delicate electronic

and mechanical parts that must be handled properly to avoid damage. Follow the

instructions given in this manual carefully and make sure to observe all instructions.

Opening the ventilator - Always turn the ventilator OFF and remove the external power

before opening the ventilator case or attempting to service the ventilator.

Anti-static Precautions - Always wear a grounded anti-static wrist strap when handling the

ventilator with the case open. Electrostatic discharge can damage the internal electronics.

Verification of Operation - After opening the ventilator and performing any maintenance,

verify proper operation of the ventilator by performing the checks and calibrations

recommended in Chapter 9 - Final Checkout Test.

Ventilator Sterilization – To avoid irreparable damage to the LTV® Series ventilator, do not

attempt to sterilize it.

Cleaning Agents – To avoid damaging the ventilator’s plastic components and Front Panel,

do not use cleaning agents containing ammonium chloride, other chloride compounds, more

than 2% glutaraldehyde, phenols, or abrasive cleaners.

Page 1-4 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

CAUTION

Ventilator Immersion - Do not immerse the ventilator in liquids.

High pressure air nozzle – Only a low-pressure air nozzle with flow less than 10 liters per

minute should be used around the ventilator. High pressure can damage the ventilator, in

particular the differential pressure ports.

Exhalation Valve - Do not pour or spray liquids into the exhalation valve.

Patient Wye Installation – Always install the patient wye in the patient circuit so the

proximal sense lines are oriented up while operating.

Front Panel – Do not pour or spray liquids onto the Front Panel.

Care of Bacterial Filters – If bacterial filters are used in conjunction with the LTV® Series

ventilator, comply with all recommended care procedures as specified by the filter

manufacturer.

Wet or Damp Filters - Do not install any wet or damp filters into the LTV® Series ventilators.

This could damage the ventilator.

Proximal Sense Lines - Do not remove the proximal sense lines from the patient wye.

Software Caution – Never install a version of software lower than the version originally

installed in the ventilator. Erroneous operation may result from the installation of an

incompatible software version. Generally, LTV® ventilator software is designed to be

backwards-compatible with this exception.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 1-5

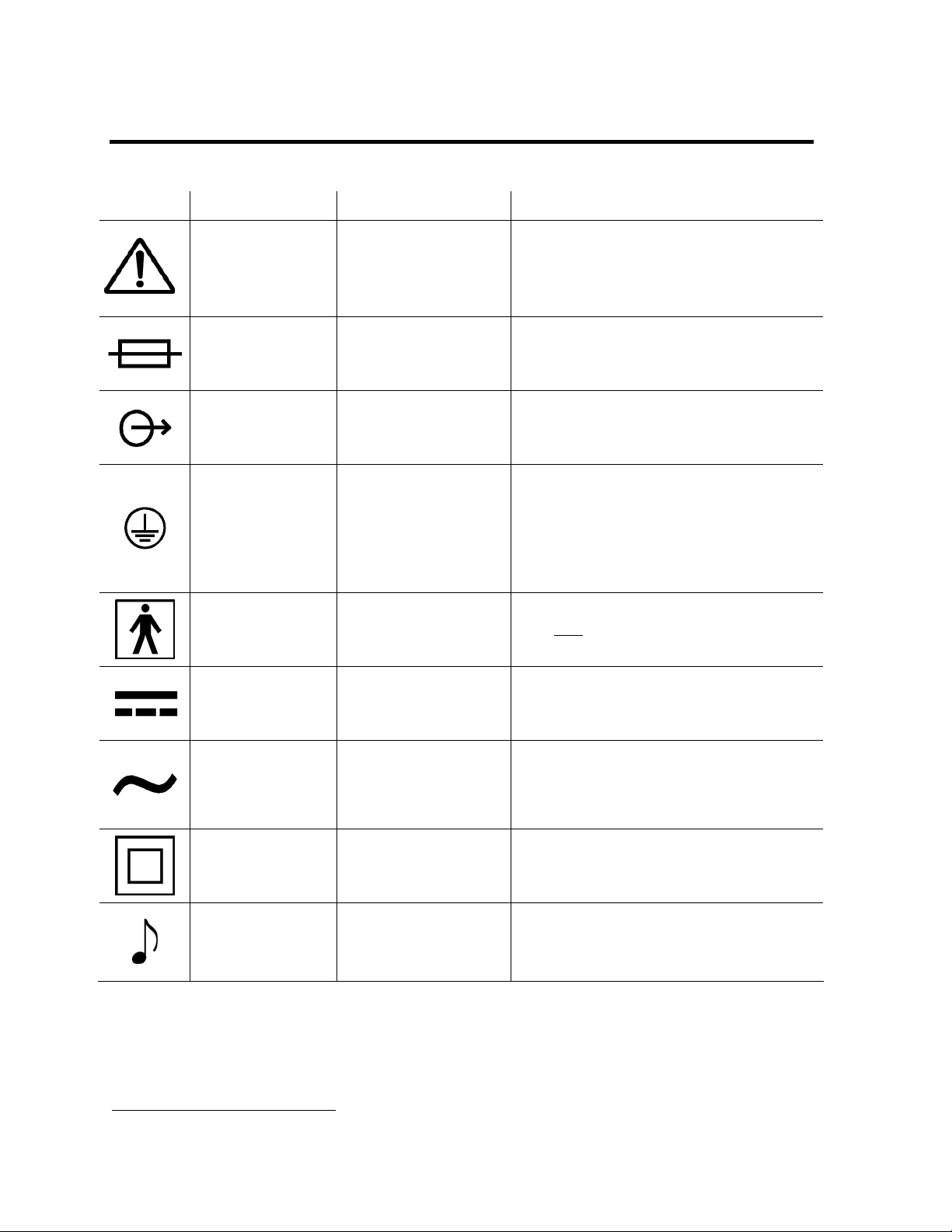

Symbols

Symbol

Compliance

ISO 3864

(Prev. IEC 348)

Symbol No.

B.3.1

1

Caution (refer to

accompanying

documents)

Title Application

Direct the user to the instruction

manual where it is necessary to follow

certain specified instructions where

safety is involved.

IEC 417

Symbol No. 417-

IEC-5016

IEC 417

Symbol No. 417-

IEC-5035

IEC 417

Symbol No. 417-

IEC-5019

IEC 417

Symbol No. 417-

IEC-5333

IEC 417

Symbol No. 417-

IEC-5031

IEC 417

Symbol No. 417-

IEC-5032

Fuse Indicates the location of fuses.

Output Identifies an output terminal when it is

necessary to distinguish between

inputs and outputs.

Protective earth

(ground)

To identify any terminal which is

intended for connection to an external

protective conductor for protection

against electric shock in case of a fault

or the terminal of a protective earth

(ground) electrode.

Type BF equipment. To mark type BF equipment complying

with IEC

Publication 601.

Direct Current Indicates on the rating plate that the

equipment is suitable for direct current

only; to identify relevant terminals.

Alternating current Indicates on the rating plate that the

equipment is suitable for alternating

current only; identifies relevant

terminals.

Class II equipment To identify equipment meeting safety

requirements specified for Class II

equipment.

Sound; audio Identifies controls or terminals related

to audio signals.

Symbol No. 417-

IEC-5172

IEC 60417

Symbol No.

IEC 417

5182

1

Reference IEC Medical Electrical Equipment, 2nd. Edition 1988

Page 1-6 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Chapter 2 - V

This chapter details five test procedures that are initiated through the Vent Check menu and

used to verify the proper operation of the LTV

ENTILATOR CHECKOUT TESTS

®

Series ventilator. These Checkout Tests are

to be performed before using the ventilator on a patient and in accordance with

recommended periodic maintenance and testing of the ventilator. See Chapter 5 -

Preventative Maintenance.

The five test procedures are:

Test Test used to:

Alarm Test Verify that the audible alarm is working correctly.

Display Test Verify that the ventilator displays are working correctly.

Control Test Verify that the ventilator buttons and the Set Value knob are

working correctly.

Leak Test Test the patient circuit for leaks.

Vent Inop Alarm Test Verify that the Inop alarm is working correctly.

The Vent Check Menu is set up as follows:

VENT CHECK

ALARM

DISPLAY

CONTROL

LEAK

EXIT

WARNING

Ventilator Checkout and Maintenance Modes - The LTV® Series ventilator does not

deliver gas during the Ventilator Checkout mode (VENT CHECK) or Ventilator Maintenance

mode (VENT MTNCE) and should not be used to ventilate a patient during these tests.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 2-1

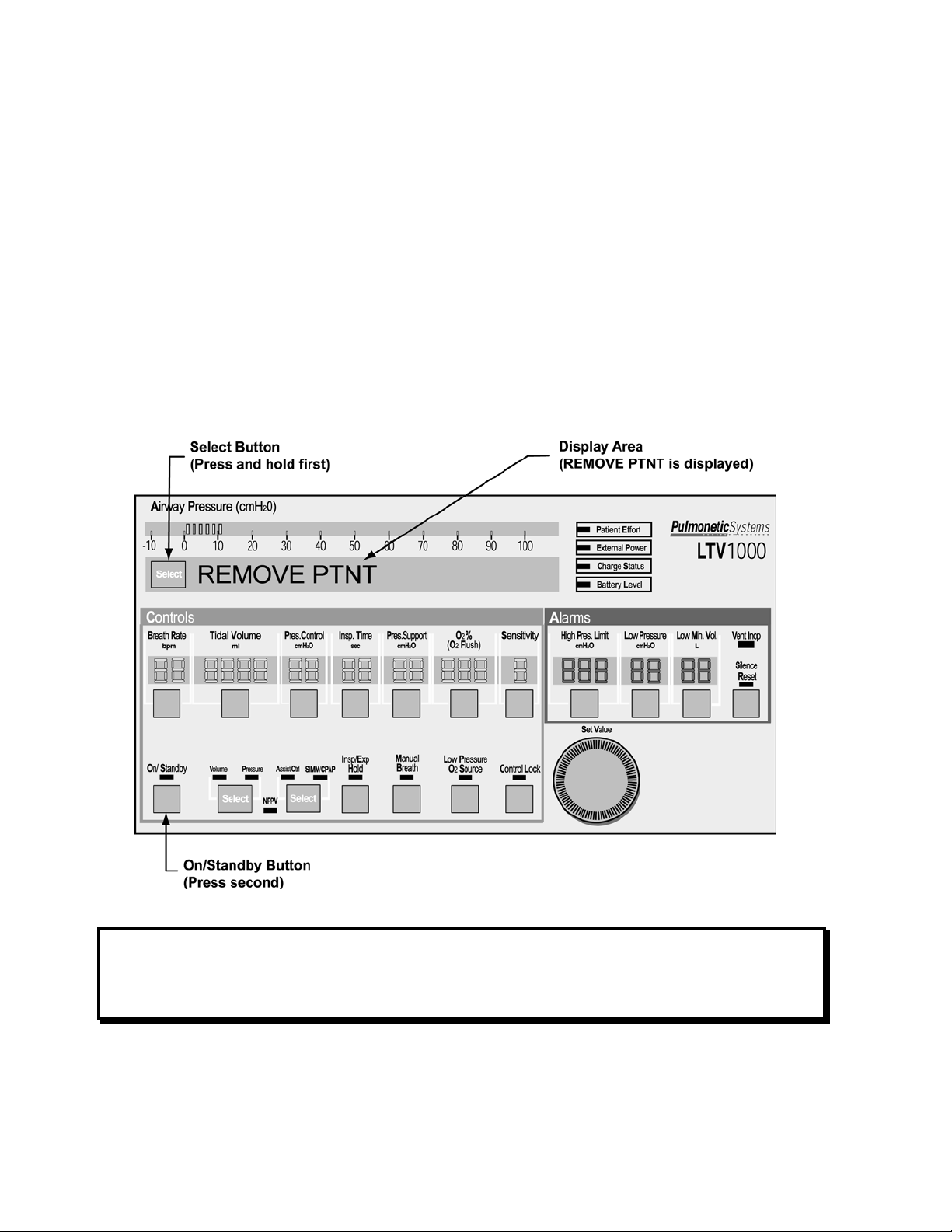

To enable the Ventilator Checkout menu:

To enter the Ventilator Checkout (VENT CHECK) menu, a special power on sequence is

required.

1) Disconnect the patient from the ventilator and ventilate using an alternative method.

2) With the ventilator off, connect the AC Adapter to the ventilator and plug it in to a valid

AC power source. Verify that the External Power and Charge Status LEDs are

illuminated or flashing.

3) Press and hold down the Select button. While holding the Select button, press the

On/Standby button to turn the ventilator on.

• REMOVE PTNT is displayed; if it does not display, repeat steps 2 through 4.

• An audible alarm (alternating on/off tone) will sound while REMOVE PTNT is

displayed.

Note

Although the LTV® 1000 Front Panel is shown, the test is applicable to all LTV® Series

ventilators.

Page 2-2 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

4) Clear the alarm by pressing the Silence/Reset button.

• The audible alarm silences, and the display changes from REMOVE PTNT to

VENT CHECK.

To enter the Ventilator Checkout menu:

1) Push the Select button.

2) The first Ventilator Checkout Test, ALARM is displayed.

Note

Although the LTV® 1000 Front Panel is shown, the test is applicable to all LTV® Series

ventilators.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 2-3

Alarm Test

The alarm test verifies that the audible alarm is working correctly.

To run the alarm test:

1) Press the Select button while ALARM is displayed.

2) Verify that the audible alarm is sounded.

3) When the alarm has sounded for at least 2 seconds, push the Select button again.

• The audible alarm is silenced and the next menu item is displayed.

4) Verify a confirming audible chirp occurs after the alarm is silenced.

Note

Although the LTV® 1000 Front Panel is shown, the test is applicable to all LTV® Series

ventilators.

If the ventilator fails the alarm test, see Chapter 7 - Troubleshooting for more information.

Page 2-4 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Display Test

At the end of the Alarm test, DISPLAY shows in the LED display window. The display test

verifies that the ventilator displays are working correctly.

To run the Display Test:

1) Press the Select button while DISPLAY is showing.

2) All segments of the 7-segment control displays; all dots of the dot-matrix window

displays and all LEDs are illuminated.

Note

Although the LTV® 1000 Front Panel is shown, the test is applicable to all LTV® Series

ventilators.

3) To end the display test, press the Select button again and the next menu item is

displayed.

Note

The displays for the External Power, Vent Inop, and Charge Status LEDs are not tested

by the Display Test.

• The External Power and Charge Status LEDs are tested when the AC adapter is

connected to the ventilator (see page 2-2).

• The Vent Inop LED is tested during the Vent Inop alarm test (see page 2-2).

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 2-5

Displays will be illuminated in the following colors:

Display Color Display Color

Airway Pressure Display Green

Pressure Mode LED

Display Window Red Assist/Control Mode LED Green

Breath Rate Green SIMV/CPAP Mode LED Green

Tidal Volume Green NPPV Mode LED Green

Pressure Control2 Green

Inspiratory / Expiratory Hold LED

Inspiratory Time Green Manual Breath LED Green

Pressure Support Green

Low Pressure O

Source LED3

2

O2 %3 Green Control Lock LED Green

Sensitivity Green Patient Effort LED Green

High Pressure Limit alarm Red External Power LED Not tested

Low Pressure alarm Red Charge Status LED Not tested

Low Minute Volume alarm Red Battery Level LED Amber

On/Standby LED Green Vent Inop LED Not tested

Volume Mode LED3

Green Silence Reset LED Red

2

3

Green

Green

Green

If the ventilator fails the Display Test, see Chapter 7 - Troubleshooting for more information.

2

Not applicable to the LTV® 900 or 800

3

Applicable to the LTV® 1000 only

Page 2-6 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Control Test

At the end of the Display test, CONTROL shows in the LED display window. The Control

Test is used to verify that the ventilator buttons and the Set Values knob are working

correctly.

To run the Control Test:

1) Press the Select button while CONTROL is displayed.

2) SELECT is displayed in the display window.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 2-7

Note

Although the LTV® 1000 Front Panel is shown, the test is applicable to all LTV® Series

ventilators.

3) Test each control by pressing every button, one at a time. When each one is pressed,

verify that the name of the button is displayed in the display window.

Control names are as shown in the table below:

Control Display

Display Select

Breath Rate

Tidal Volume

Pressure Control4

Inspiratory Time

Pressure Support

O2 %5

Sensitivity

High Pressure Alarm

Low Peak Pressure

Low Minute Volume

Silence / Reset

On/Standby

Volume & Pressure4

Assist/Control & SIMV/CPAP

Inspiratory / Expiratory Hold5

Manual Breath

SELECT

BREATH RATE

TIDAL VOLUME

PRES CONTROL

INSP TIME

PRES SUPPORT

O2%

SENSITIVITY

HIGH PRES

LOW PRES

LOW MIN VOL

SILENCE

ON / STNDBY

MODE VOL/PRS

MODE A/C S/C

IE HOLD

MANUAL BRTH

Low Pressure O2 Source5

Control Lock

Set Value Knob rotate Left

Set Value Knob rotate Right

LOW PRES O2

CONTROL LOCK

ROTATE LEFT

ROTATE RIGHT

4) Test the Set Value knob by turning it clockwise and counterclockwise. Verify that the

direction of rotation is displayed in the display window.

5) To exit the control test, press the Select button again and the next menu item is

displayed.

If the ventilator fails the Control Test, see Chapter 7 - Troubleshooting for more information.

4

Not applicable to the LTV® 800 and 900

5

LTV 1000 only

Page 2-8 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Leak Test

The Leak test is used to test the patient circuit for leaks.

To run the Leak Test:

1) At the end of the Control test, LEAK shows in the LED Display window.

2) Attach all patient circuit accessories (such as water traps, heated circuits and humidifiers

to the patient circuit.

®

3) Connect the patient circuit to the LTV

4) With a clean, gloved hand or 4”X4” gauze pad, occlude the proximal end of the patient

circuit.

Series ventilator.

5) Press the Select button while

LEAK is displayed.

Note

The Leak Test cannot be run until the ventilator has been running for 60 seconds. If you

attempt to run the leak test before the warm-up period has completed, a WAITING message

will be displayed. When the warm-up period is complete, the Leak Test menu item is

redisplayed.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 2-9

6) To perform the Leak Test, the ventilator does the following:

a) Closes the exhalation valve and sets the flow valve to a near-closed state. The

display briefly shows HOMING VALVE.

b) Elevates the turbine motor speed. The display shows SET TURBINE.

c) Elevates the circuit pressure. The display shows PRES xx.x cmH

the real-time airway pressure.

d) Sets the flow valve to a near closed position. The display shows FLOW xx.x Lpm

where xx.x is the flow through the flow valve.

e) After several seconds, the display shows

indicating the Leak Test results.

7) The Leak Test will fail if the flow through the flow valve is equal to or greater than 1.0

Lpm.

8) To exit the Leak Test, press the Select button again and the next menu item is

displayed.

LEAK xx.xx PASS or LEAK xx.xx FAIL

O where xx.x is

2

Note

Although the LTV® 1000 Front Panel is shown, the test is applicable to all LTV® Series

ventilators.

If the ventilator fails the Leak Test, see Chapter 7 - Troubleshooting for more information.

Page 2-10 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Vent Inop Alarm Test

The Vent Inop alarm test is used to verify that the Inop alarm is working correctly.

To run the Vent Inop alarm test:

1) To run the Vent Inop alarm test, the ventilator must be on (running) for at least 60

seconds.

2) Turn the ventilator off by pressing and holding the On/Standby button for a minimum of

3 seconds. DO

NOT press the Silence/Reset button.

3) Observe the ventilator for 15 seconds and verify that both

• The alarm tone sounds continuously for a full 15 seconds.

• The Vent Inop LED illuminates continuously for a full 15 seconds.

of the following occur;

4) Silence the alarm by pressing the Silence/Reset button.

5) Verify a confirming audible chirp occurs after the alarm is silenced.

Note

Although the LTV® 1000 Front Panel is shown, the test is applicable to all LTV® Series

ventilators.

If the ventilator fails the Vent Inop alarm test, see Chapter 7 - Troubleshooting for more

information.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 2-11

Exit

To exit VENT CHECK and enter normal ventilation mode:

1) Turn the Set Value Knob to scroll through the main menu entries (VENT OP, ALARM

OP, VENT CHECK, etc.) until EXIT is displayed.

2) Push the Select button while EXIT is displayed.

3) Alternatively, push the Control Lock button until normal ventilation mode is restored.

POST will be performed and the ventilator will begin ventilation using the previously stored

settings.

Page 2-12 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Chapter 3 - R

EAL TIME TRANSDUCER DATA

The Real Time Transducer data allows you to view the real time activity in the ventilator. The

real time transducer menu is set up as follows:

RT XDCR DATA

AP xx.xx

FDb xx.xx

FDw xx.xx

FDn xx.xx

FTw or FTn

xx.xx Lpm

FTb x.xx Lpm

LEAK xx.xx Lpm

FVd xx.xx

c

c

c

c

c

H20

m

H20

m

H20

m

H20

m

H20

m

(Not on LTV

(Not on LTV

(Not on LTV

®

800)

®

800)

®

800)

(Not on LTV® 800)

(Not on LTV

(Not on LTV

®

800)

®

800)

FV xx.xx Lpm

®

FVt xxx.x °F

Optional (Not on LTV

800)

STEP xxxx

TS xxxx rpm

®

(LTV

O2 xx.xx PSIG

1000 only)

BV xx.xx VOLTS

EV xx.xx VOLTS

RT EXIT

Each item displays real time activity in the displayed units. For some items, transducer

counts can also be displayed. Pressing Select while the item is displayed, displays

additional transducer data.

Display Real Time Data

AP xx.xx

c

H20

m

Airway pressure as measured at the patient wye using the high

side proximal sense line.

FDb xx.xx

(Not on LTV

FDw xx.xx

(Not on LTV

c

c

H20

m

m

®

800)

H20

®

800)

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 3-1

Flow differential pressure as measured at the patient wye using

the bi-directional transducer. Differential pressure is measured

between the high and low side proximal sense lines.

Flow differential pressure as measured at the patient wye using

the wide scale transducer. Differential pressure is measured

between the high and low side proximal sense lines.

Display Real Time Data

FDn xx.xx

(Not on LTV

c

m

H20

®

800)

Flow differential pressure as measured at the patient wye using

the narrow scale transducer. Differential pressure is measured

between the high and low side proximal sense lines. The

narrow scale transducer is only used for differential pressures

between -0.35 cmH

Lpm to 15 Lpm).

O and 0.35 cmH2O (approximately -15

2

FTw xx.xx Lpm

or

FTn xx.xx Lpm

(Not on LTV

®

800)

FTb x.xx Lpm

®

(Not on LTV

800)

LEAK xx.xx Lpm

c

m

®

800)

H20

(Not on LTV

FVd xx.xx

FV xx.xx Lpm

FVt xxx.x °F

(Not on LTV

®

800)

Flow in Lpm calculated from the differential pressure measured

at the patient wye. When the value is calculated using the wide

scale differential pressure, FTw is displayed. When the value is

calculated using the narrow scale differential pressure, FTn is

displayed.

When Leak Compensation is on, FTw xx.xx and FTn xx.xx

Lpm values are offset by the value of LEAK xx.xx Lpm.

Transducer count display is not available for this item.

Flow in Lpm calculated from the differential pressure measured

at the patient wye using the bi-directional transducer.

Transducer count display is not available for this item.

Leak flow calculated from the differential pressure transducer,

measured at the patient wye during exhalation.

Differential pressure as measured across the flow valve.

Flow valve flow in Lpm calculated from the differential pressure

measured across the flow valve.

Transducer count display is not available for this item.

Flow valve temperature. Only available on the LTV 900, 950

and 1000 with FVt capability. Not available on the LTV 800.

STEP xxxx

Commanded flow valve motor step position.

Transducer count display is not available for this item.

TS xxxx rpm

O2 xx.xx PSIG

®

(LTV

1000 only)

BV xx.xx VOLTS

EV xx.xx VOLTS

Monitored turbine speed in rpms.

Oxygen inlet pressure in PSIG as measured at the inlet

pressure transducer.

Internal battery voltage.

External power voltage.

Page 3-2 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Chapter 4 - C

LEANING AND STERILIZATION

Cleaning the Ventilator

All ventilator external surfaces should be cleaned before and after each patient use, and as

may be required.

To clean the ventilator:

1) Wipe the exterior surfaces of the ventilator with a clean, damp cloth. The use of an anti-

bacterial cleaning solution is recommended. Be sure to wipe away any residual cleaner.

CAUTION

Ventilator Sterilization – To avoid irreparable damage to the LTV® Series ventilator, do not

attempt to sterilize it.

Cleaning Agents – To avoid damaging the ventilator’s plastic components and Front Panel,

do not use cleaning agents containing ammonium chloride, other chloride compounds, more

than 2% glutaraldehyde, phenols, or abrasive cleaners.

Ventilator Immersion - Do not immerse the ventilator in liquids.

Exhalation Valve Cleaning - Do not pour or spray liquid cleaners into the exhalation valve.

Front Panel Cleaning – Do not pour or spray liquid cleaners onto the Front Panel.

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 4-1

Cleaning the Exhalation Valve and Reusable Patient Circuit

WARNING

Patient Circuits – Pulmonetic Systems Patient Circuits, Exhalation Valve Assemblies and

Water Traps are shipped clean, not sterile.

Ultra Violet Light Sensitivity – The material used in the tubing of the “Reusable” Patient

Circuits is not UV stable. Avoid exposure of tubing to UV light.

PEEP Valve Rotation – Attempting to adjust the PEEP valve counterclockwise past zero (0)

may damage the PEEP valve assembly or cause circuit leaks. To avoid damaging the PEEP

valve, always depress the yellow lock button on top of the valve when making adjustments.

CAUTION

Proximal Sense Lines - Do not remove the proximal sense lines from the patient wye.

Care of the Exhalation Valve - The exhalation valve is a delicate assembly and may be

damaged if;

• Care is not exercised when handling or cleaning it.

• Cleaning instruments or foreign bodies are inserted into it.

• High-pressure gas nozzles are used to dry it.

Care of Bacterial Filters – If bacterial filters are used in conjunction with the LTV® Series

ventilator, comply with all cleaning procedures as specified by the filter manufacturer.

To clean the exhalation valve, wye, sense line(s) and reusable patient circuit:

For purposes of cleaning, the patient circuit with exhalation valve and all accessories must

be detached from the ventilator.

1) Disassemble the exhalation valve as shown (on following pages) and remove the

diaphragm and compression spring. If using a patient circuit with a PEEP valve; remove

the exhalation valve retainer collar (rotate) and pull the PEEP valve assembly off the

exhalation valve body. USE CAUTION: The diaphragm and spring may become

dislodged.

2) Remove exhalation valve diaphragm and compression spring.

Page 4-2 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

LTV® 900, 950 and 1000 Reusable Patient Circuits:

p/n 10665, Rev. K LTV® Series Ventilator Service Manual Page 4-3

LTV® 800 Reusable Patient Circuits:

Page 4-4 LTV® Series Ventilator Service Manual p/n 10665, Rev. K

Loading...

Loading...