Puhui MT-602 User Manual

MT-602

User manual

Auto Chip Mounter

Taian Puhui Electric Technology Co., Ltd

Http://www.tech168.cn

MT-602 user manual

Item

specification

product name

auto-mounter machine

product type

MT-602

mounting head

double mounting head

average speed

5000CPH

positioning accuracy

0. 025mm

net weight

151kg

applicable elements

0603-1206 SMD transistors, diodes, capacitors, resistors, chips, etc.

number of rack

56:8mm=50,12mm=4,16mm=2

Number of offline storage files

20

max size of circuit board

300mm×400mm

power supply

220V,50/60Hz,280W

vacuum gas source

-50Kpa,13L/min

operating system

Windows

installation dimension W×D×H

1396*761*480

Number of vacuum pump

2

Number of pump

1

malfunction detection

Suction leak detection, pressure detection

Instruction of installation and commissioning

Introduce of machine

一、 machine parameters

二、 appearance of the machine and basic structure

1 / 32

MT-602 user manual

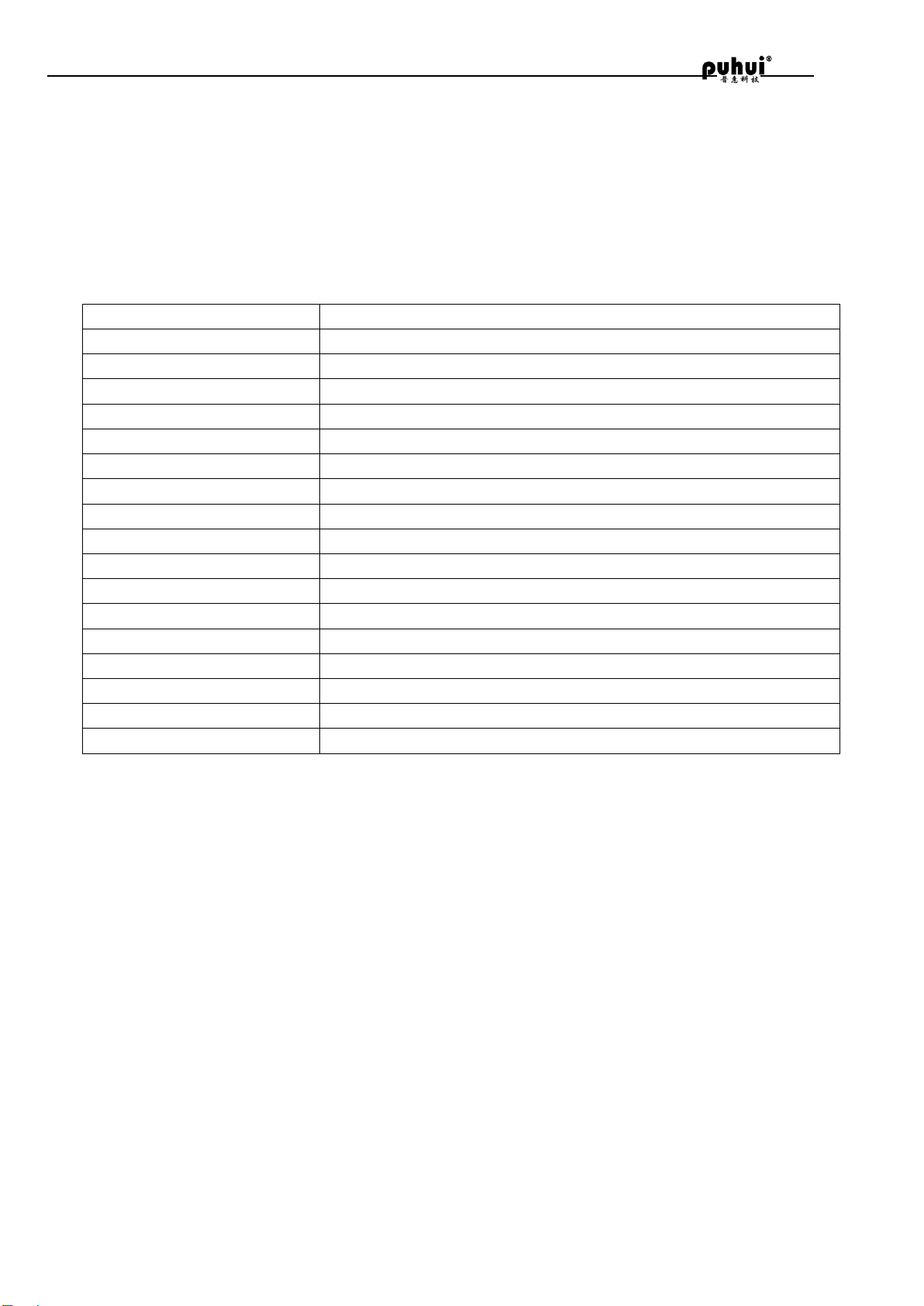

Y-axis motion

components

1, Y-axis plate

2, linear bearings supporting

base

3, linear bearings LM25UU

4, Y synchronous wheel

mounts

5, Y synchronous wheel

6, Y-axis motor mount

7, large X-axis belt fixed tooth

plate

8, shaft belt adjustment block

9, large X-axis belt adjustment

block briquetting

F608ZZ flange bearings

Emergency

stop switch

Suction

mechanism

Pusher

mechanism

Tray moving

mechanism

Feed tray

rack

Operation

panel

Y-axis motion

components

Power

switch

Take belt

mechanis

Rack shaft Motion

components

power

interface

USB

interface

三、 Main Institutions

2 / 32

MT-602 user manual

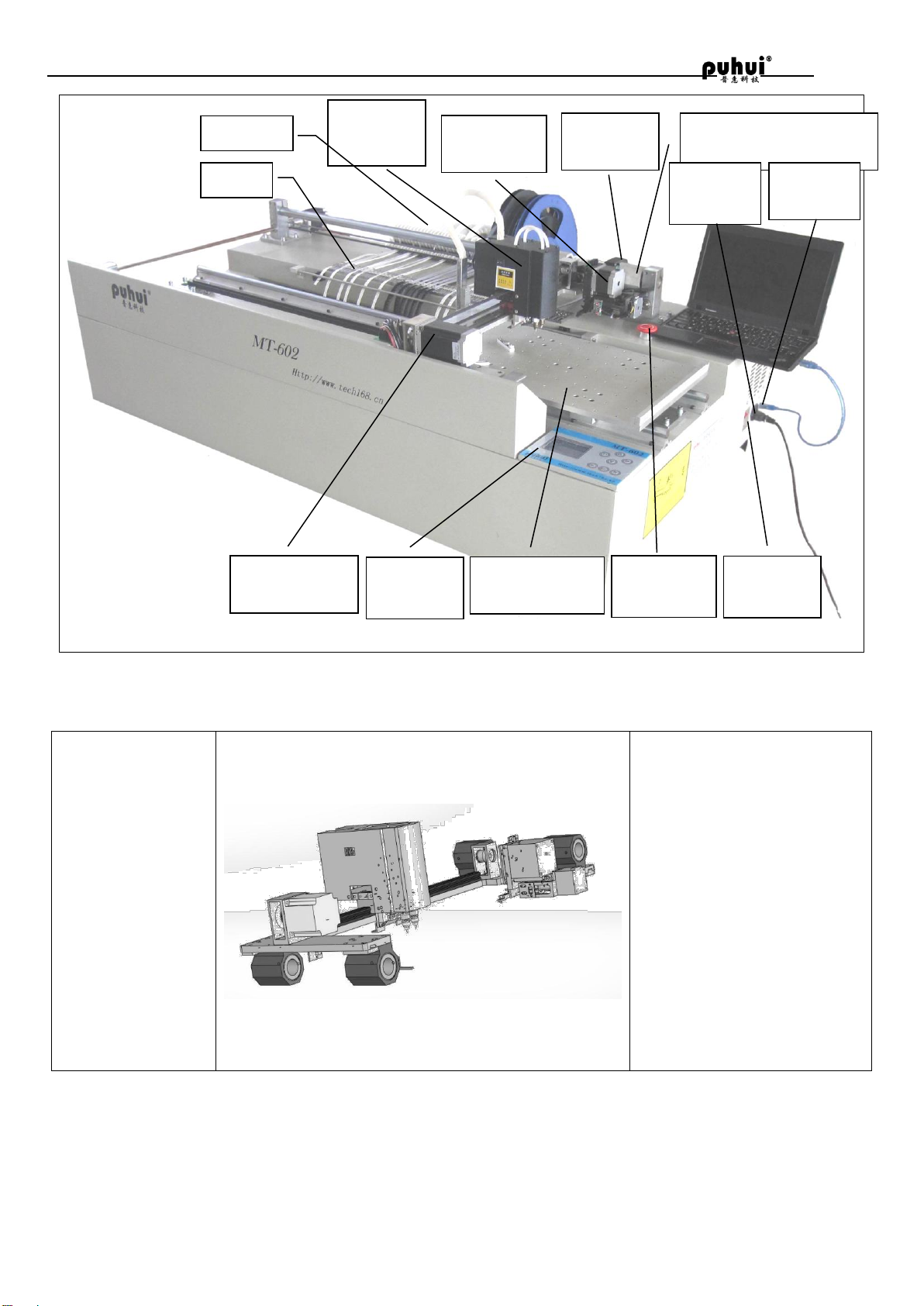

Suction

mechanism

1, the vacuum solenoid valve

2, linear slide MGN9C

3, Z-axis limit switch

4, pick-and-place the drive

motor Z

5, the rotary drive motor Q1,

Q2

6, a nozzle, the nozzle

assembly 2

7, Z-axis suction mounting

plate

8, Y-axis slide mechanism

connecting plate suction

9, Y-axis belt tensioning block

10, Y-axis belt tooth plate

11, motor angle slider stopper

Pusher

mechanism

1, the pusher motor

2, the pusher cam mechanism

component

3, T limit switch

4, the pusher pin

5, the pusher adjustment motor

6, pusher holder

7, pusher slider

Tray moving

mechanism

1,470X300 tray

2, the slider tray

3, the tray belt fixing plate

4, linear slide SBR16UU

5, slider slider

6, the right tray stopper

7. Fixed slider block

Nozzle1

Nozzle2

Pusher

motor

Pusher

adjustment

motor

3 / 32

MT-602 user manual

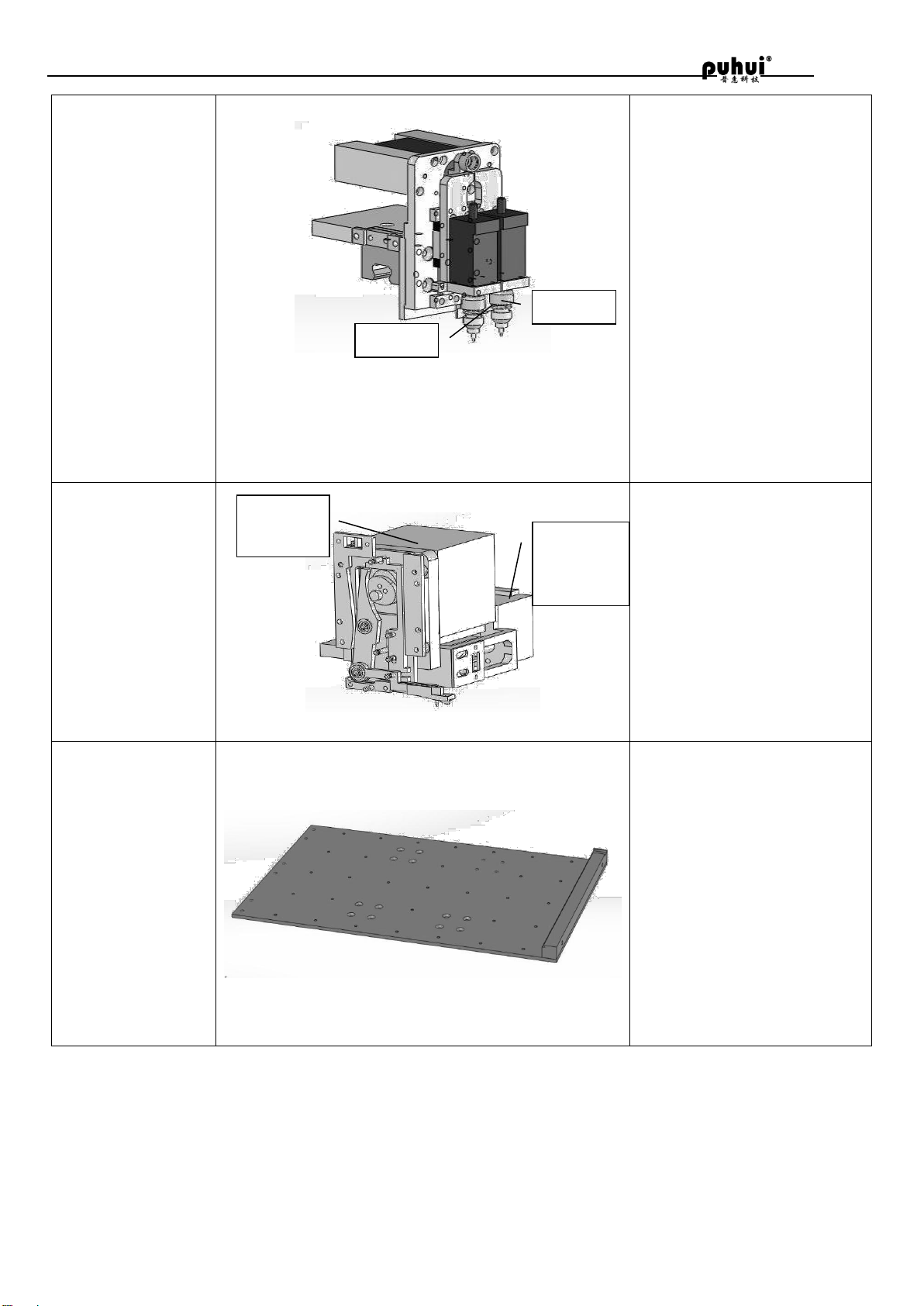

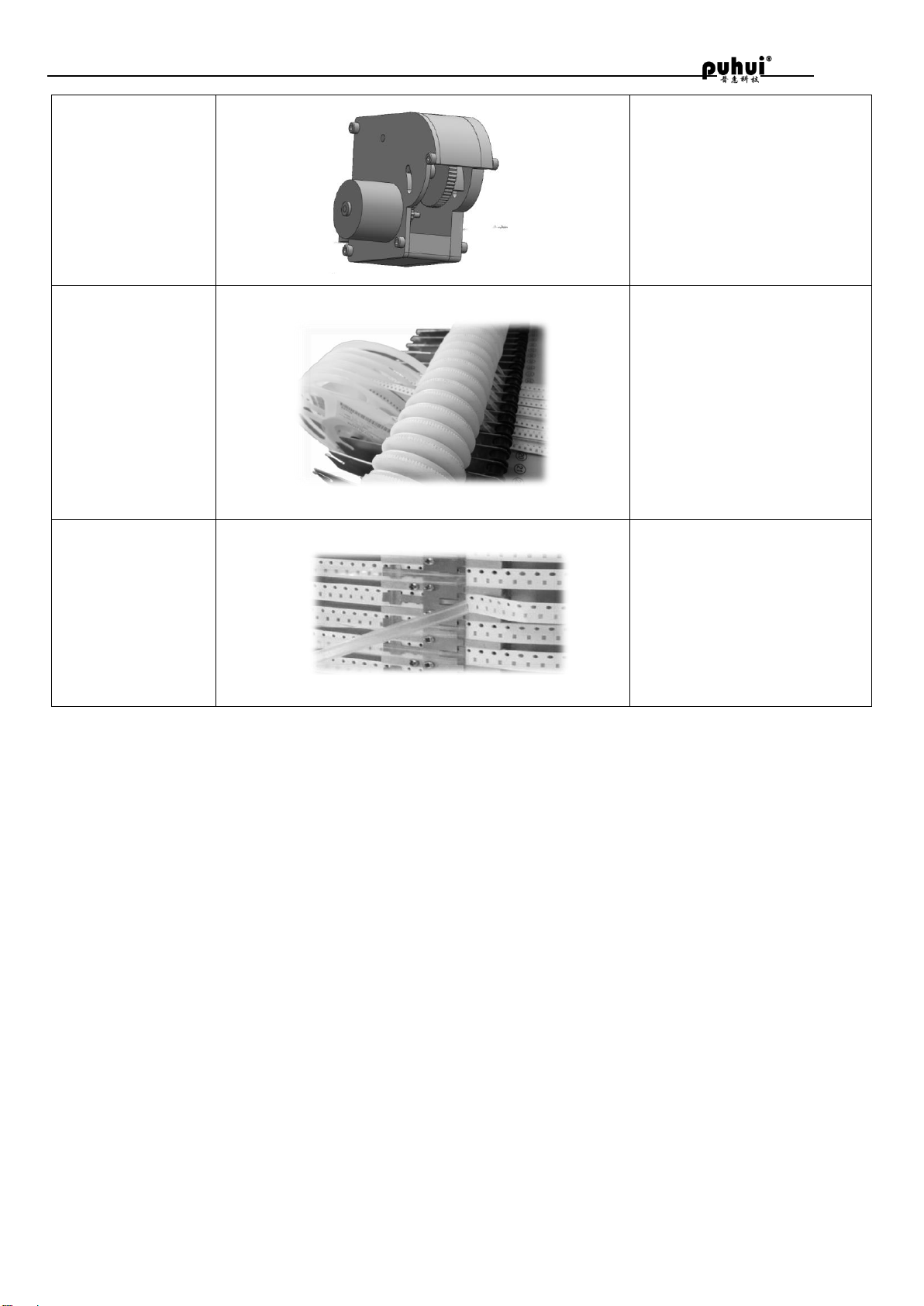

Waste recovery

mechanism

1, closing with gear box

2, the take-up gear assembly

3, take-up motor

4, the take-up motor drive

circuit board

Feed tray

1, tray holder

2, pin for tray

3, waste recycling gear

4, the guide wheel

Rack

1、patch wedge

2、pressing reed

3、discharge pressure bar

1. Preparation and Precaution of installing

(1)Preparation of installing

1. Choose a flat ground to ensure that the machine level

2. Choose firm placement platform to ensure that the machine can not move.

3. Enough space for production operations.

4. Avoid hot and humid environment.

5. Check the power cable if there is breakage.

(2)Precaution for use

1. Electrical Considerations

Use a multimeter to check if the power supply voltage is correct and the connection is reliable.

Ensure that it is earth grounded safely.

Ensure that all hardware connections are secure.

2. Safety Precautions

Before moving the machine, turn the power off, unplug the power cord.

Pay attention to personal safety when transport.

Ensure there is no foreign matter inside of machine before electrifying.

Preparation and installation

4 / 32

MT-602 user manual

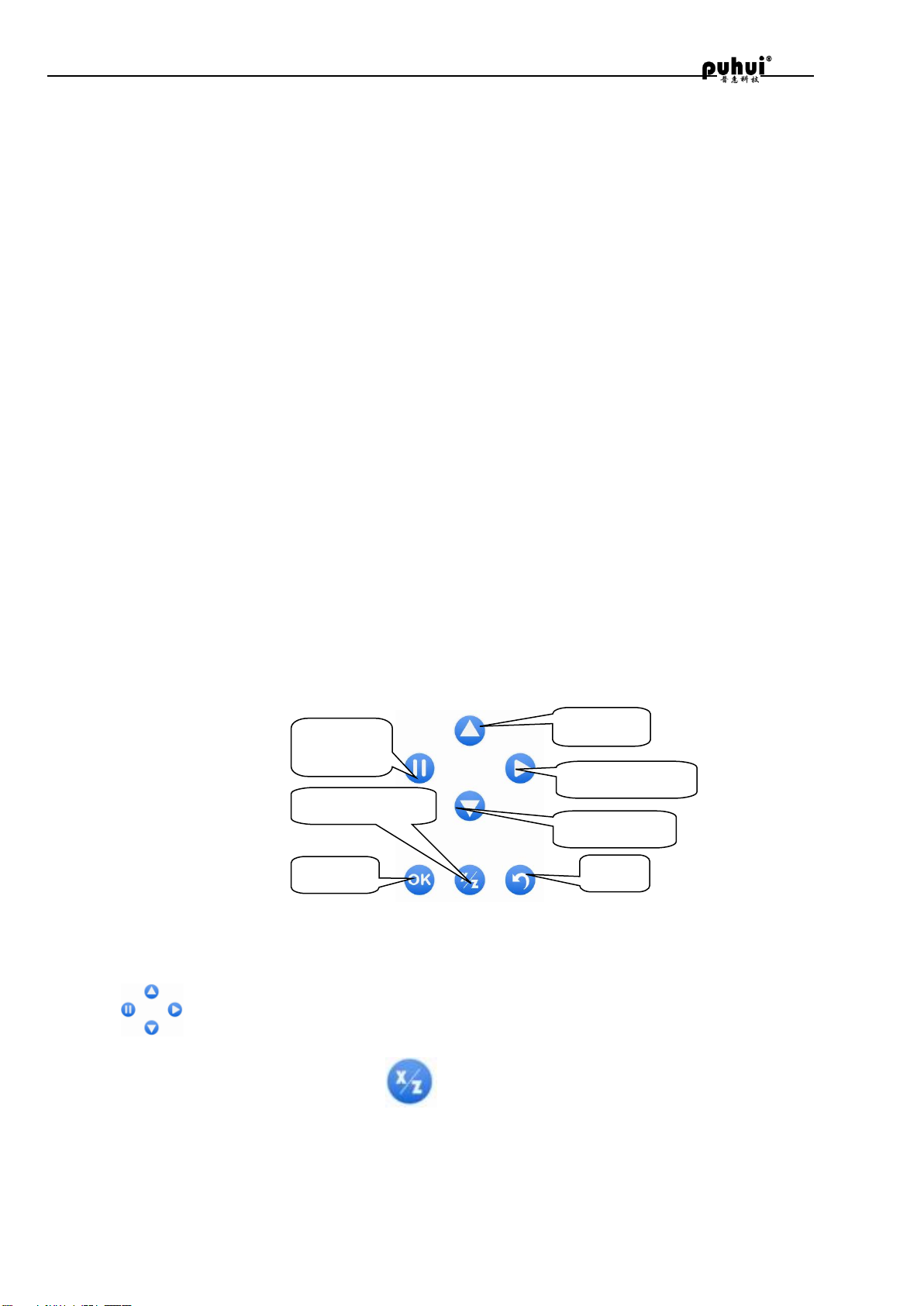

Cursor up

Back

Confirm

Mount Continue

Mount

pause

Cursor down

Tray in and oput

Before electrifying, manual confirmation of the agencies operating normally, without hindrance.

Press the red emergency stop switch, and the system power supply is disconnected when there is

emergency.

Installation of mounter

(1)Select the appropriate operating space for placing Mounter

(2)The SMT machine should be placed in a special support frame.

(3)The machine power should be accessed on the labeled INPUT socket.

Debugging Preparation

1. Safety tips of commissioning test

(1)All of components that are working should not be obstructed when operated.

(2)All of components that are working should not be pushed when stopped.

(3)Ensure that the terminal connection is well.

(4)Restart it after 20 seconds when cut off power.

(5)Press the red emergency stop switch and the system power supply is disconnected if there is emergency.

2. Introduce of operation panel

(1)Above panel

1. Emergency stop switch

Press this switch, power is cut off and all actions of mountor machine are stopped. Clockwise rotation,

button bounces and power is on, following that machine resets and each axis return to the original position.

(2)Main panel

1. LCD

2. Buttons

Description of function keys:

control the moving of mounting head. When the reference point to identify the state, it is uesd for

controlling the nozzle’s up and down movement, while other states, functions as shown above picture.

(3)Side panels

1. Cooling fan outlet

2. Access outlet for main power

When the reference point to identify the state, it is used as the arrow key of mounting head to

5 / 32

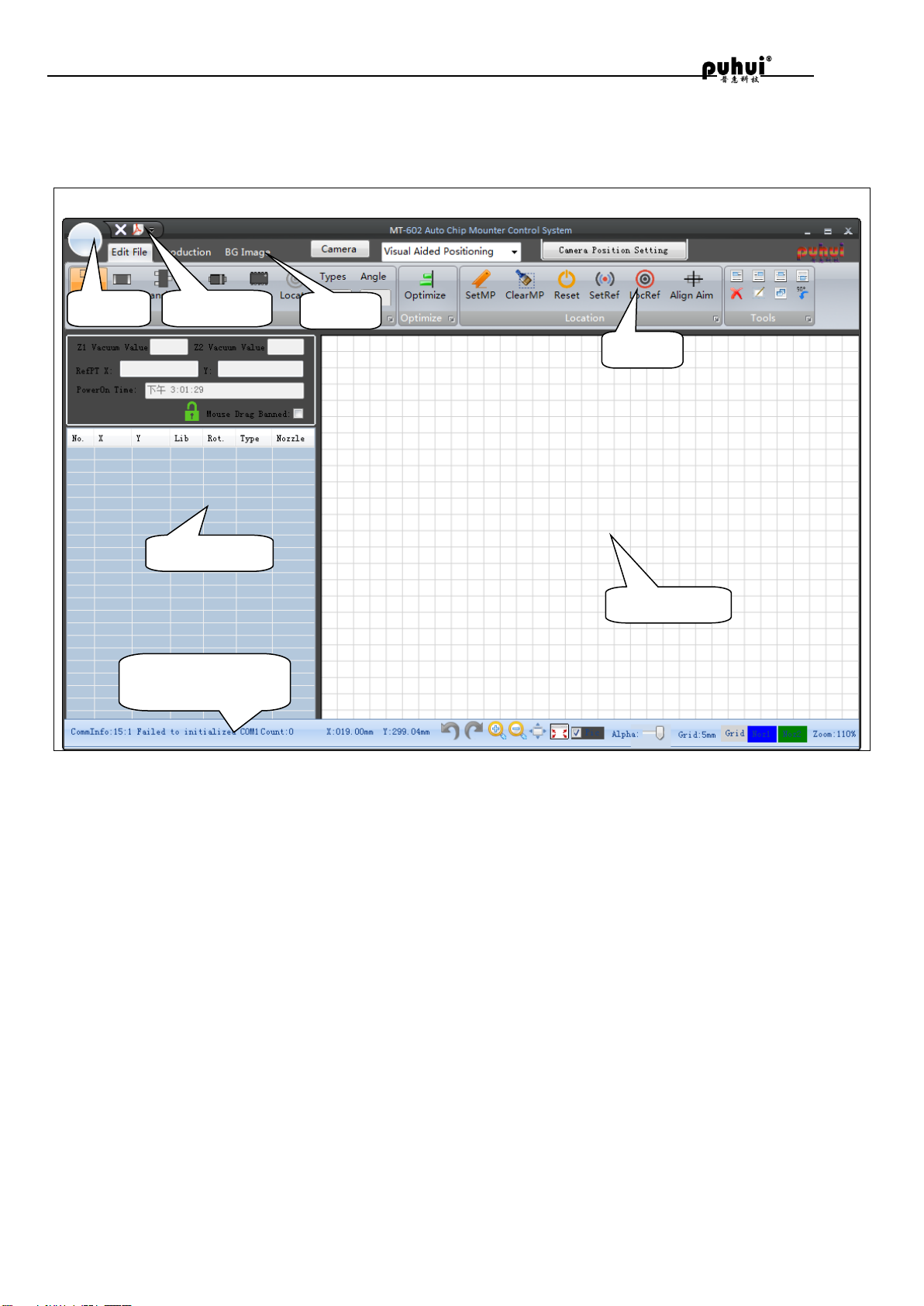

Main interface

Graphing area

Prompt area Status

Element list

Menu

Tab

Instructions

toolbar

3. Power switch

4. USB communication interface

3. Introduce of software interface

MT-602 user manual

6 / 32

MT-602 user manual

Graphical representation

1. No directional element graphical representation 2. Directional element graphical representation 3. Transistor

element 4. Graphical representation of chip components 5. Mark point marker graphic 6. Reference Point logo

graphic 7. Circular array

1

2

3

4

7

5

6

Blue elements using nozzle 1

Green software uses nozzle 2

7 / 32

MT-602 user manual

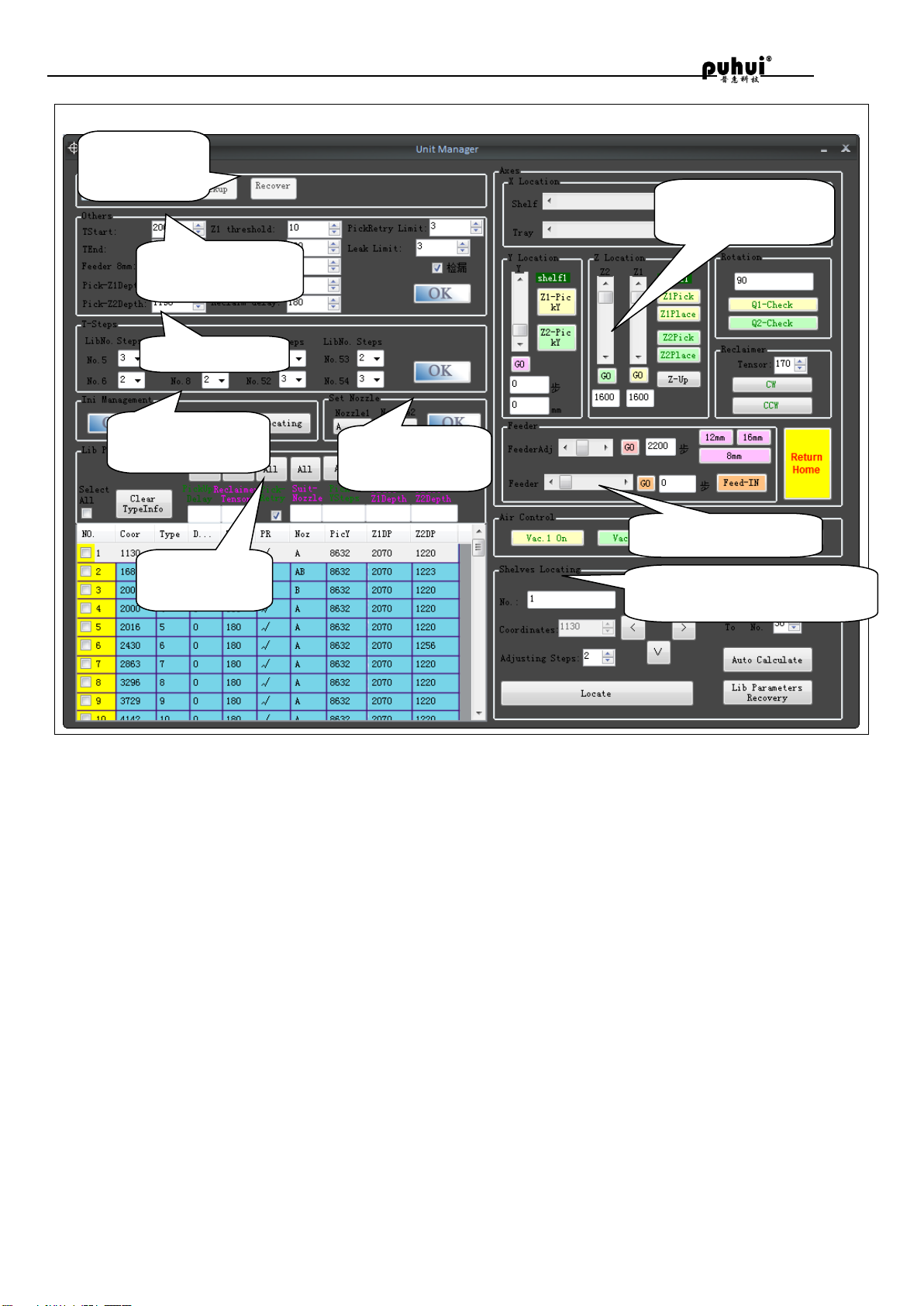

Parameter interface of equipment

Rack parameter

field

Backup and

recovery zone

Each axis positioning

zone

Rack coordinate adjustment

Other parameters

zone

Pusher step zone

Pneumatic control zone

Rack management

zone

Current nozzle

settings area

8 / 32

MT-602 user manual

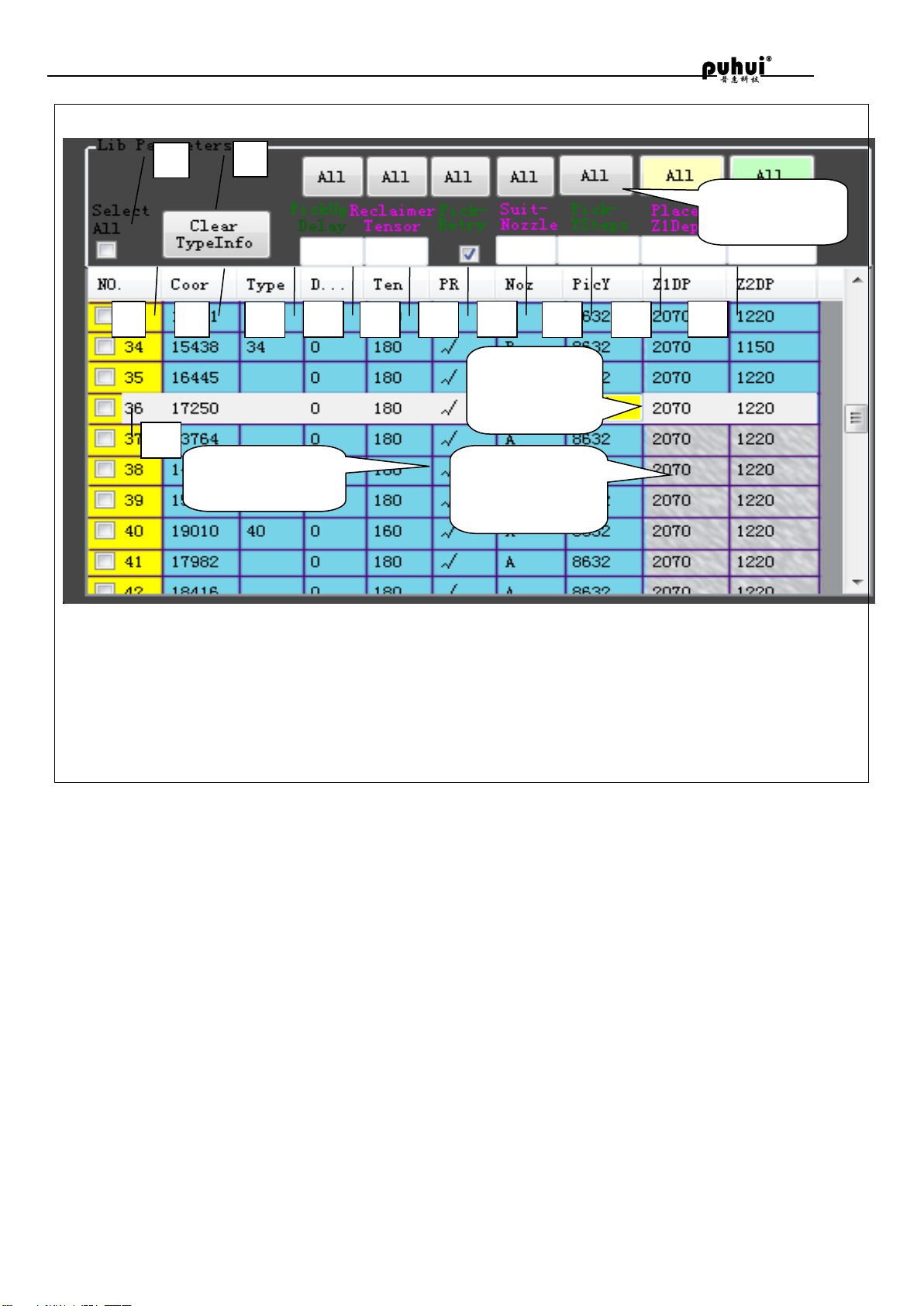

Interface of the device parameters

1. select all of rack 2. Empty rack model column 3. rack Number 4. device coordinates of rack 5. element

models of rack 6stay time on elements when picking element. 7. take-up tension of take-up belt 8. Whether

to check leak of rack element 9. The nozzle type that can be used on rack element. 10. device location

coordinates the feeder element Picking Y 11. Discharge depth of the rack-mount device application when the

nozzle 1, 12Discharge depth of the rack-mount device application when use nozzle 2, 13. Single rack selection

box

Blue area is

editable area

Gray areas is

non-editable

regions alone

yellow area is

current editing

area

2 1 3

5

4

6

7

8 9 10

11

12

Batch edit of

feeder parameters

13

9 / 32

Loading...

Loading...