Puch 1970-1971 Puch, 1970 Moped, 1971 Moped Maintenance Manual

PUCH

1970 and

1971

MOPED MAINTENANCE

MANUAL

Includes

• Technical Data

• Description

• Maintenance and service

• Trouble Shooting

Steyr - Daimler -

Puch

PUCH

SERVICE-AUSTRIA 907.1.71.033.1

i

PUCH-Motor-Cycles

mm

DESCRIPTION

AND

MAINTENANCE

STEYR - DAIMLER - PUCH AKTIENGESELLSCHAFT

AUSTRIA AUTRICHE

TABLE OF CONTENTS

1.

Technical Data

(see attached data sheet)

2.

Description

3. Maintenance and Service

4. Trouble Shooting

5. Index

V

FIRST READ — THEN DRIVE ! I !

Take this motto to heart and let your vehicle have that

minimum of maintenance and care it needs to give you

full satisfaction and security.

We present you therefore together with your new

PUCH MOTOR-CYCLE

these operating instructions.

The booklet is intended as an introduction to handling,

tending and maintenance of the vehicle.

Should it be your first motor vehicle, we advise you in

your own interest to read these operating instructions

carefully. Most damages are caused by ignorance and

hence could easily be avoided. Regular maintenance will

prevent troubles and repairs which may cost you much

time and money.

The section on trouble shooting will inform you about

many sources of faults. But do not undertake fumbling

things that can only be executed expertly by a reliable

workshop. A widespread service organsiation as well as

our own service department in the works at Graz will

be pleased to be useful to you.

When requesting information or ordering spare parts

please never forget quoting the engine number.

Numbers in brackets within the text refer to the illustrations.

Out of two numbers, the one on the left of the

oblique line indicates the numbers of the figure, the one

on the right of the oblique line refers to the numbers

within the figure.

Now we wish you a good start and a good time with

your PUCH motor-cycle!

STEYR-DAIMLER-PUCH

Aktiengesellschaft

VI

2.

DESCRIPTION

—.., ".-...... ....-—

H

7%

I

2.1

CONTROLS

Location and working of

the controls may be seen

from the data sheet hereto

attached.

2.2 FIRST PUTTING INTO

SERVICE

2.3 BEFORE EVERY TRIP

2.4 DRIVING

INSTRUCTIONS

2—1

2—2 DESCRIPTION

2.2 FIRST PUTTING INTO SERVICE

After final assembly, every PUCH motor-cycle has to

undergo a trial trip, it is therefore ready for use. It is

nonetheless strongly recommendable to carry trough the

following checkings before putting the vehicle into operation for the first time.

2.21 Comparing the charakteristic numbers

Before the first trip, compare the characteristic numbers

of the vehicle with those indicated on the registration

papers.

2.22 Checking the oil level in the gearbox

Are provided for the purpose either an oil control plug

or a dipstick on the right hand side gearbox cover.

a) Oil control plug version

(fig.

1)

With the vehicle in horizontal position (normal

posi-

tion),

oil level in gearbox should come up to the bot-

tom edge of the oil control plug

(1/2,

2a/2). In case

that mark is not reached, take off the oil filler plug

(1/1,

2a/l) and

fill

in motor oil (see section 3.21) until

oil comes out of the oil control hole. The oil control

plug (1/2) should be screwed in again only when no

more oil pours out of the hole.

b) Dipstick version (fig. 2)

Check oil level at horizontal (normal) position. Screw

out dipstick (2/1), wipe it dry and put it and pull

out again. Oil level is correct when between the two

DRIVING INSTRUCTIONS 2—3

marks.

If

oil level is under the lower mark,

fill

in

motor oil (see section

3.21).

If

oil level comes up to over the upper mark, loosen

oil drain

pliug

(2/2) and drain some oil. Before

measuring again, wipe the dipstick dry.

Whenever measuring oil level, screw in entirely the

dipstick!

2.23 Checking the air filter (for location see data sheet)

The intake muffler air filter must be wetted by motor oil

SAE 40 vor 50, except vehicles with dry air filter.

2.24 Checking the inflating pressure

For pressure figures see data sheet.

2.25 Gasoline-oil mixture refuelling

Mix gasoline with branded motor oil SAE 40 or 50 (See

lubricants chart) in a 1 : 25 ratio

(=

4%), that is 40 c.c.

on 1 liter of petrol.

Important! Never fill in pure petrol!

2.3 BEFORE EVERY TRIP

You should check:

0

Fuel provisions

9

Tyre inflating pressure

0

Braking efficiency

•

Lighting

•

Tool kit

2—4 DESCRIPTION

2.4 DRIVING INSTRUCTIONS

2.41 Starting the engine

0

Open fuel cock.

#

Put in ignition key (models with ignition lock).

%

Operate the choke only wen engine

cold,

if neces-

sary,

operate the tickler.

0

When re-starting a hot engine, do not operate either

choke notrickler.

0

In automatic models with pedals watch position of

change lever for treadle (see data sheet).

0

Open the throttle by 1A

(turn throttle twist-grip by one

third of its travel). Attention: in automatic models

open throttle only slightly.

0 In

automatic models with pedals pull lever for release

of starting device (see data sheet).

0

Crank engine by means of pedals or kick-starter.

0 In

case the choke has been operated, push in pro-

portion as engine warms itself up.

0

After a few hundred yards, the choke should be turned

off! (In case of a Bing-carburetter with

14

mm 0 and

17

mm 0, choke turnes off automatically by fully

opening the throttle

manentarily.)

2.42 Moving off (In automatic models just open throttle)

£

Pull clutch control lever; engage 1 st gear.

%

Release clutch lever slowly, simultaneously open

throttle twist grip.

2.43 Gear shifting (In automatic models results automatically according to number of engine revolutions)

DRIVING INSTRUCTIONS 2—5

The bottom gear which you are now using represent the

starting and climbing gear. As soon as circumstances

will allow, you will change up. Proceed as follows:

0

Throttle down.

#

Operate clutch control lever almost at the same time

and engage the next gear.

0

Release clutch control lever.

#

Open throttle.

After reaching maximum speed by fully opening the

throttle twist grip, throttle down to about 3A;

the fall in

speed will be hardly perceptible whereas fuel consumption will thus be considerably reduced. Throttle opening

should be turned to what the engine just needs-sharp

opening of the throttle twist-grip only increases fuel

consumption. When driving speed has to be reduced because of a slope or traffic circumstances, change down.

Proceed as follows:

0 If

necessary, apply the brakes and the same time

0

throttle back,

9

operate clutch control lever and change down,

0

release clutch control lever,

#

give throttle again.

Hint for owners of automatic models

When rapid acceleration requires even quicker gearshift-

ing,

throttle down completely after reaching about

25 km/h and open throttle again shortly afterwards. Thus

second gear shifted more quickly.

2—6 DESCRIPTION

2.44 Applying the brakes

Throttle back,

apply hand and foot-operated brake simultaneously. On

sandy, wet or slippery roads, use primarily the footoperated brake.

Always apply the brakes cautiously. Locking wheels

reduce the braking efficiency and entail skidding and

crashing.

2.45 Stopping and parking

#

Throttle back,

%

apply the brakes,

%

(Inapplicable in automatic models) just before stopp-

ing,

operate the clutch control lever and engage

neutral gear.

In

order to shut off the engine:

0

Press

short-circuiting

button. Pull out ignition key

(models with ignition lock),

%

shut fuel cock,

<0

shut off the vehicle.

2.46 Driving downhill

When driving downhill, the idling engine acts as a brake.

During longer descents, open the throttle every now and

then in order to grease the engine (the lubricant being

in the fuel). If necessary, apply the brakes. When des-

cending steep grades, engage bottom gear.

2.47 Treading with shut-off engine

(Possible

only in models with pedals, in automatic models with pedals

adjust change lever for treadle [see data sheet]).

DRIVING INSTRUCTIONS 2—7

0

Operate clutch control lever and engage 2nd gear

(3rd gear) whilst pedalling.

%

Mount the auto-cycle and set it going like a bicycle

whit pulled-down clutch lever.

%

Before stopping, engage neutral gear.

3. MAINTENANCE AND SERVICE

3.2 LUBRIFYING THE

VEHICLE

3.3 MAINTENANCE

OPERATIONS

3.4 CLEANING THE

VEHICLE

3.5 LAYING UP

3—1

3—2 MAINTENANCE AND SERVICE

SERVICE

A number of maintenance operations are beyond the

amateur's reach as he lacks the special devices necessary

for their execution.

We recommend therefore to entrust such operations to

one

of the many service stations set up by PUCH in

Austria as well as abroad. Their skilled personell dis-

posing of specially tested working methods and every

working facility will carry out any overhauling and repair

work rationally, economically and rapidly.

The PUCH-ORGANIZATION will always be pleased to

give you further information and advice.

SPARE PARTS

Correct and swift execution of all spares orders is

con-

ditioned by the exact quoting of chassis and engine

numbers and full type designation on the order form.

Below will be given a description of the recurrent maintenance works. The lubrication and maintenance schedules

will be found on the data sheet hereto attached.

LUBRIFYING

3—3

3.2 LUBRIFYING THE VEHICLE

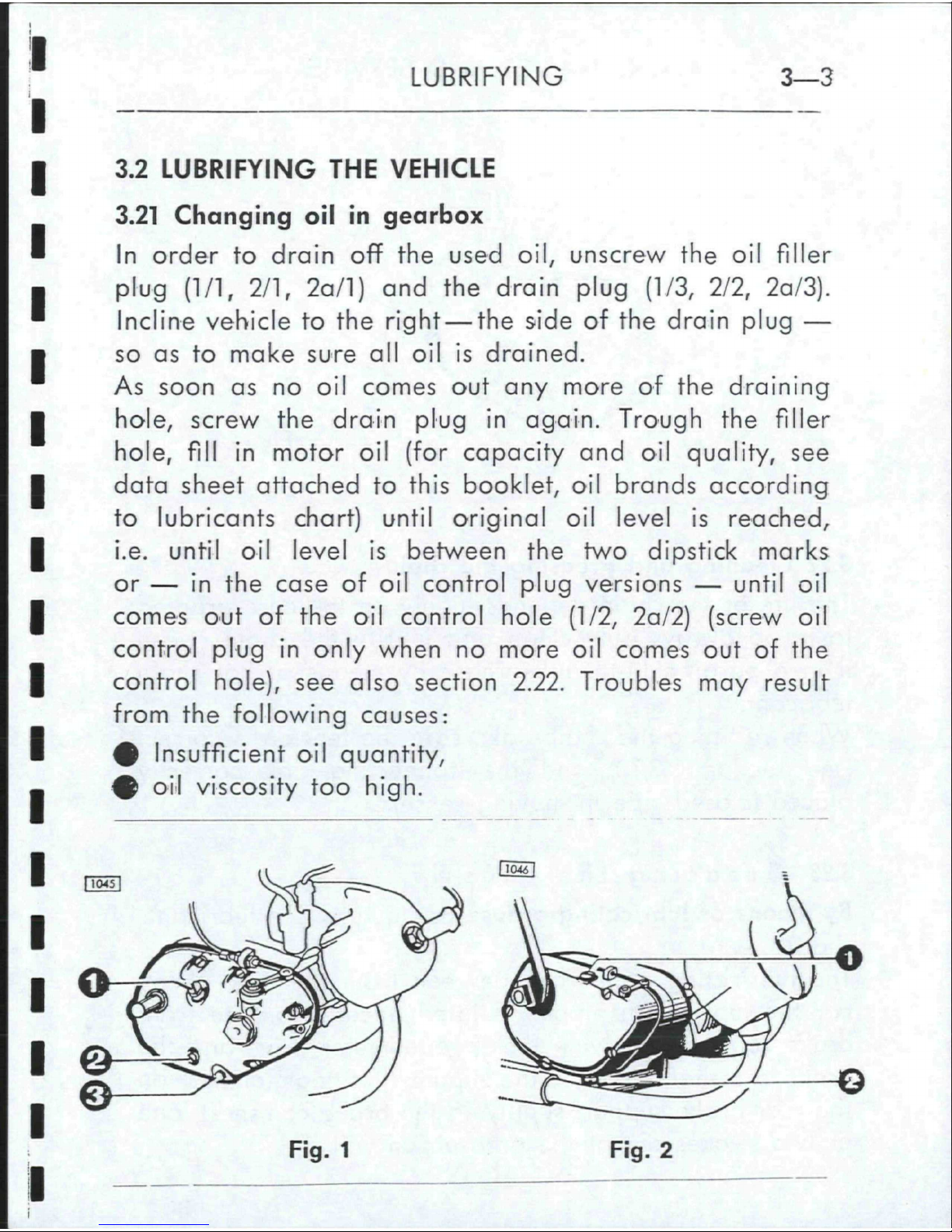

3.21 Changing oil in gearbox

In

order to drain off the used oil, unscrew the oil filler

plug

(1/1,

2/1,

2a/l) and the drain plug (1/3, 2/2, 2a/3).

Incline vehicle to the

right —

the side of the drain plug —

so as to make sure all oil is drained.

As soon as no oil comes out any more of the draining

hole,

screw the drain plug in again. Trough the filler

hole,

fill

in motor oil (for capacity and oil quality, see

data sheet attached to this booklet, oil brands according

to lubricants chart) until original oil level is reached,

i.e. until oil level is between the two dipstick marks

or — in the case of oil control plug versions — until oil

comes out of the oil control hole (1/2, 2a/2) (screw oil

control plug in only when no more oil comes out of the

control hole), see also section 2.22. Troubles may result

from the following causes:

0

Insufficient oil quantity,

%

oil viscosity too

high.

[ToSI

DwU

h

c~-

[

\

0

I

<>

©

3

€>

Fig.

1 Fig. 2

3—4 MAINTENANCE AND SERVICE

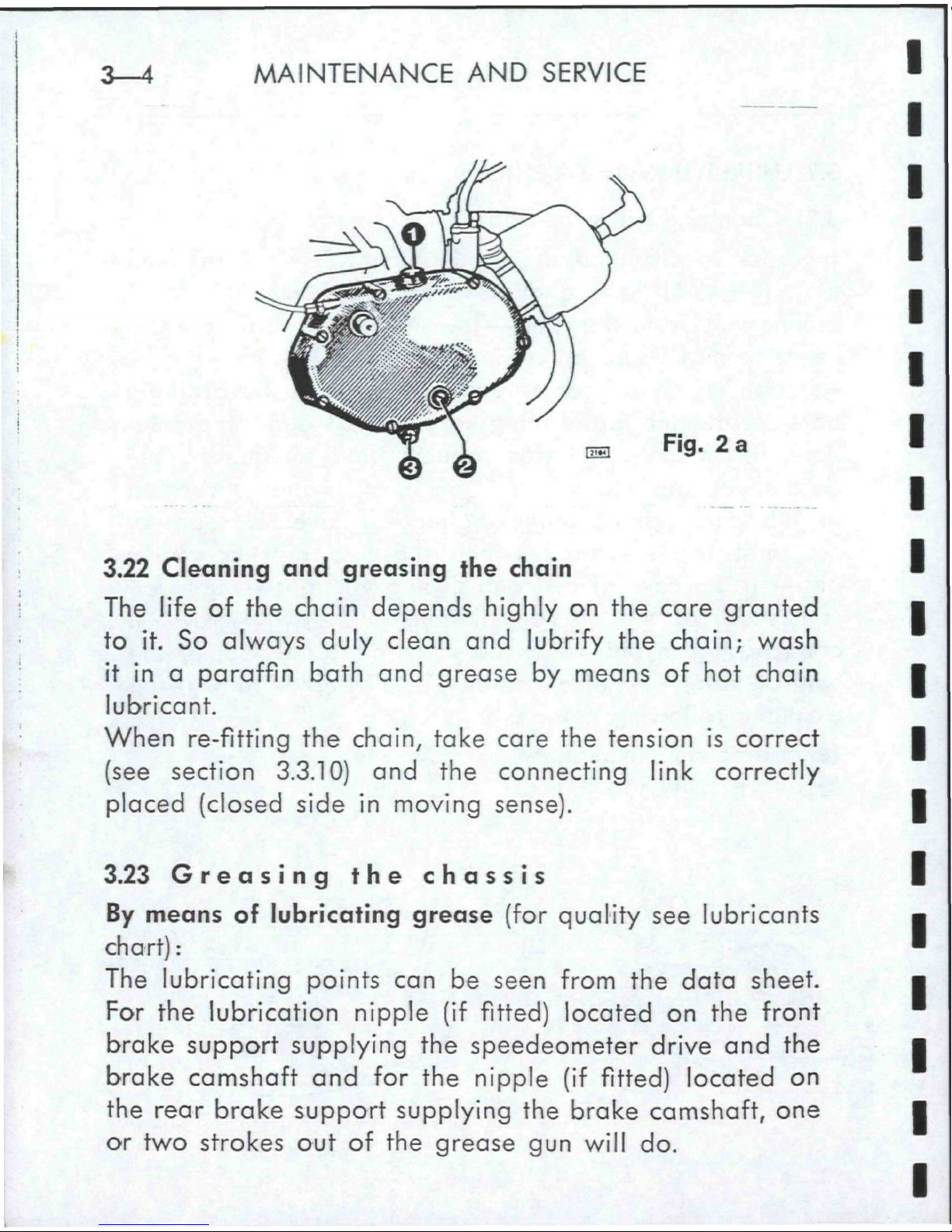

Fig.

2 a

3.22 Cleaning and greasing the chain

The life of the chain depends highly on the care granted

to it. So always duly clean and lubrify the chain; wash

it in a paraffin bath and grease by means of hot chain

lubricant.

When re-fitting the chain, take care the tension is correct

(see section 3.3.10) and the connecting link correctly

placed (closed side in moving sense).

3.23 Greasing the chassis

By means of lubricating grease (for quality see lubricants

chart):

The lubricating points can be seen from the data sheet.

For the lubrication nipple (if fitted) located on the front

brake support supplying the

speedeometer

drive and the

brake camshaft and for the nipple (if fitted) located on

the rear brake support supplying the brake camshaft, one

or two strokes out of the grease gun will do.

MAINTENANCE OPERATIONS 3-5

By means of lubricating oil (quality see lubricants chart):

0

Brake adjusting screw on front and rear wheel

0

Chain tensioning screws

#

Gearshift links and bearing points (if fitted)

4

Central prop bearing

#

Saddle bearing points (if fitted)

0

Brake pedal bearing

#

Working surfaces of brake and clutch control levers

#

Bowden cables (if necessary, take off headlight

bracket)

3.24 Changing oil in rear suspension unit and telescopic

fork

This operation should only be carried out — according to

the instructions given in the repair manual — by a

PUCH

service station (capacities given in the data sheet attached

to this booklet).

3.25 Lubrifying the grease felt supplying the ignition cams

Lubrify the grease felt by means of BOSCH grease

Ft!

v4.

The lubricant must not reach the

make-and-break

contacts

where it would cause excessive wear.

3.3 MAINTENANCE OPERATIONS

Entrust all works that you feel to be out of your reach

to a PUCH representative; he will be pleased to help

and advise you.

3.3.1 Checking the spark-plug

Screw the spark-plug out of the cylinder and hold it by

its threaded end against earth, e.g. the cylinder head

3—6 MAINTENANCE AND SERVICE

(plug

still

being connected with the plug wire). If the

starting device is now operated, a powerful spark should

flash over between the electrodes. Oily plugs or plugs

with dirt deposits between the electrodes will not pro-

duce any spark and must be cleaned (wooden splinter or

steel brush).

When replacing, only use a spark-plug whose thermal

value corresponds to the figure indicated in the data

sheet. The spark gap should be between 0,5 to 0,6 mm.

If

the gap is wider, regap by bending the outer elec-

trode.

When screwing the plug in, take care it

fits

well

into the thread and may easily be turned. Never have

recourse to force when screwing in: Screw in by hand

2 or 3 turns, only then you may use the spark-plug

wrench.

Standard plug according to data sheet.

3.3.2 Decarbonizing the engine

The constitution of deposits on cylinder cover, piston

head and exhaust port is a necessary corollary of the

working of our combustion engines (two-stroke engines),

but a length is a source of troubles. Combustion products originating from oil as well as from fuel must

therefore be removed from time to time.

Cylinder cover and piston head

Removing the carbon deposits from cylinder cover and

piston head must be carried out by means of a blunt

edged instrument (screwdriver or the like). As surface

hardness of light alloys is relatively low, their surfaces

may easily be scratched. Scratching is to be avoided as

every new scratch entails inevitably the constitution of

MAINTENANCE OPERATIONS

3—7

Fig.

3

new carbon deposits. From the piston head, remove only

scaly deposits; a uniformly tenuous layer of oil carbon

need not be removed. Before refitting the cylinder cover,

thoroughly remove all carbon remains from inner side of

cylinder (cloth used should not be ravelling), rub with

motor oil. Then make sure by turning the engine over

a few times that engine runs easily. Clean faying sur-

faces on cylinder ond cylinder cover by wiping them

and re-fit without gasket. Tighten the four cylinder head

nuts crosswise.

Exhaust port

In order to clean the exhaust port, take off the exhaust.

Engage highest speed and turn engine over by means

of the rear wheel (spark-plug unscrewed) till piston

reaches lowest point. In automatic models possible only

by means of starting device. Coutiously remove oil carbon from exhaust port; take care not to damage piston

or cylinder working surfaces. When cleaning the exhaust

port it will be practical also to clean the exhaust muffler

(see following chapter).

Loading...

Loading...