PTC® INSTRUMENTS

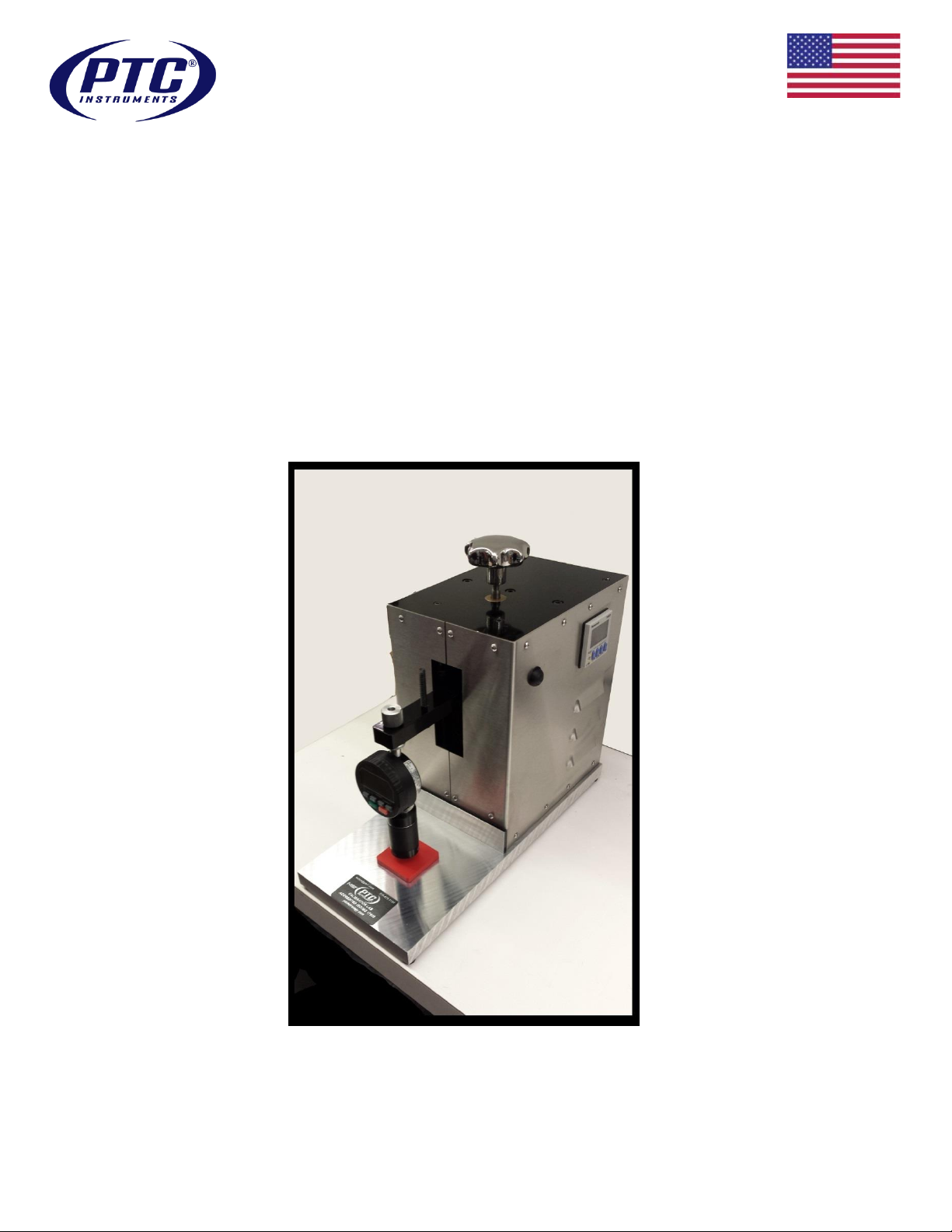

Model 500 Automatic Operating Stand Type 3

The Model 500 automatic operating stand provides constant load, controlled rate-of-descent,

and application velocity, through a geared electric motor and braking mechanism that alternately

lowers the durometer onto the specimen and then raises it in preparation for the next testing

cycle.

The electronic timer adjusts the amount of time the durometer remains in the lowered position

(dwell time), allowing time recording of test determinations. The stand can perform high volume

testing compared to hand-held or manually operated stands.

The versatile Model 500 is compatible with all PTC® 300 (Classic) and 400 (Ergo) series

durometers and most other top mounted durometers, An optional mounting adapter is required

for the PTC® (Pencil) 200 and (e2000) 500 series.

Model 500 Automatic Operating Stand

Find Quality Products Online at: sales@GlobalTestSupply.com

Model 500 Automatic Operating Stand Operating Manual

www.GlobalTestSupply.com

Page 1 of 5

Revision 4.0 5/2015

PTC® INSTRUMENTS

Model 500 Automatic Operating Stand Type 3

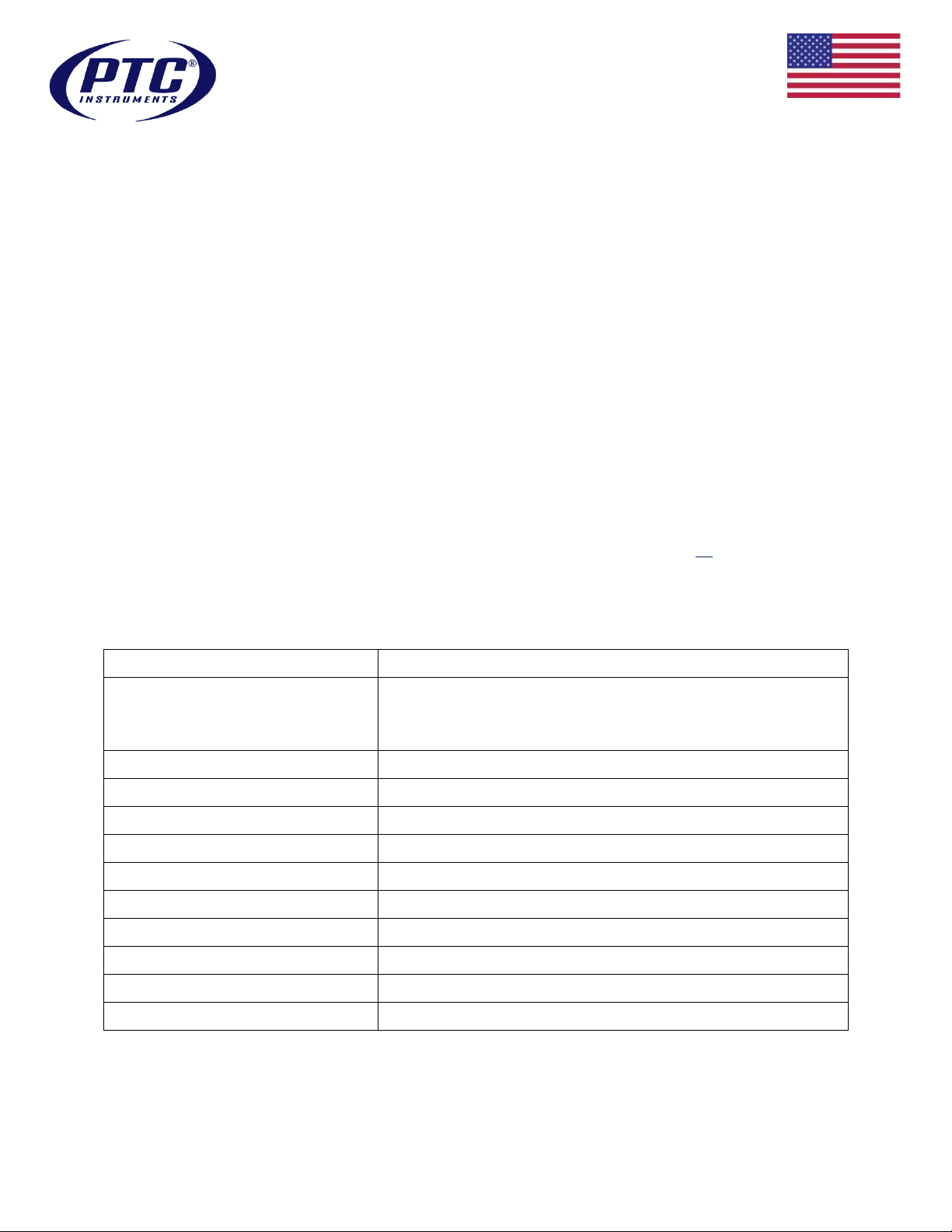

Specification

Description | Value

Accommodates these durometer

scales (both analog and digital):

Polymeric Knob OO, OOO, & OOO-S

Metal Knob A, B, E, & O

Additional Mass: C, D, & DO

Overall Dimensions (D x W x H):

356 x 156 x 248 mm (14 x 6.125 x 9.75 in.)

Specimen Table Dimensions:

177 x 182 mm (7 x 6 in.)

Throat Depth:

83 mm (3.25 in.)

Throat Height:

79 mm (3.125 in.)

Weight (without additional mass)

16 kg (35 lb.)

Minimum Specimen Thickness

6 mm (0.240 in.) per ASTM D2240

Maximum Specimen Thickness

varies with durometer model; ~75 mm (3 in.)

Timer Operation

0 through 9999 seconds

Power Requirements

120 VAC 60 Hz | 240 VAC 50 Hz optional

Operating Temperature

23.0 ± 2.0 °C (73.4 ± 3.6 °F)

FEATURES:

Precision machined aluminum frame provides strength, weight savings, and corrosion

resistance;

Precision machined aluminum base provides a stable, lightweight platform;

Gloss black hybrid powder coated aluminum base, top plate, and specimen platform

provide ease-of-maintenance, durability, and superior service life;

High quality, heavy duty, electric drive motor and servos provide smooth, reliable, long-

term maintenance-free operation;

Dual, precision ground, stainless steel guide rods provide the durometer support arm

and carriage assembly with the most accurate, precise, and stable application of the

durometer of any operating stand;

Dual, precision, long-reach, linear bearings allow for smooth, positive, wobble free,

operational motion;

Durometer mounting device is designed with dual conical spacers to allow for squaring

the durometer to the specimen platform to assure accurate and precise test

determinations;

Additional optional mass allow for the use of this operating stand with all ASTM D2240,

ISO 7619-1, and DIN 53 505 durometers except Type M (micro);

Stainless steel housing provides ease-of-maintenance, durability, corrosion resistance,

and industrial grade service life.

Model 500 Specifications

Find Quality Products Online at: sales@GlobalTestSupply.com

Model 500 Automatic Operating Stand Operating Manual

www.GlobalTestSupply.com

Page 2 of 5

Revision 4.0 5/2015

PTC® INSTRUMENTS

Model 500 Automatic Operating Stand Type 3

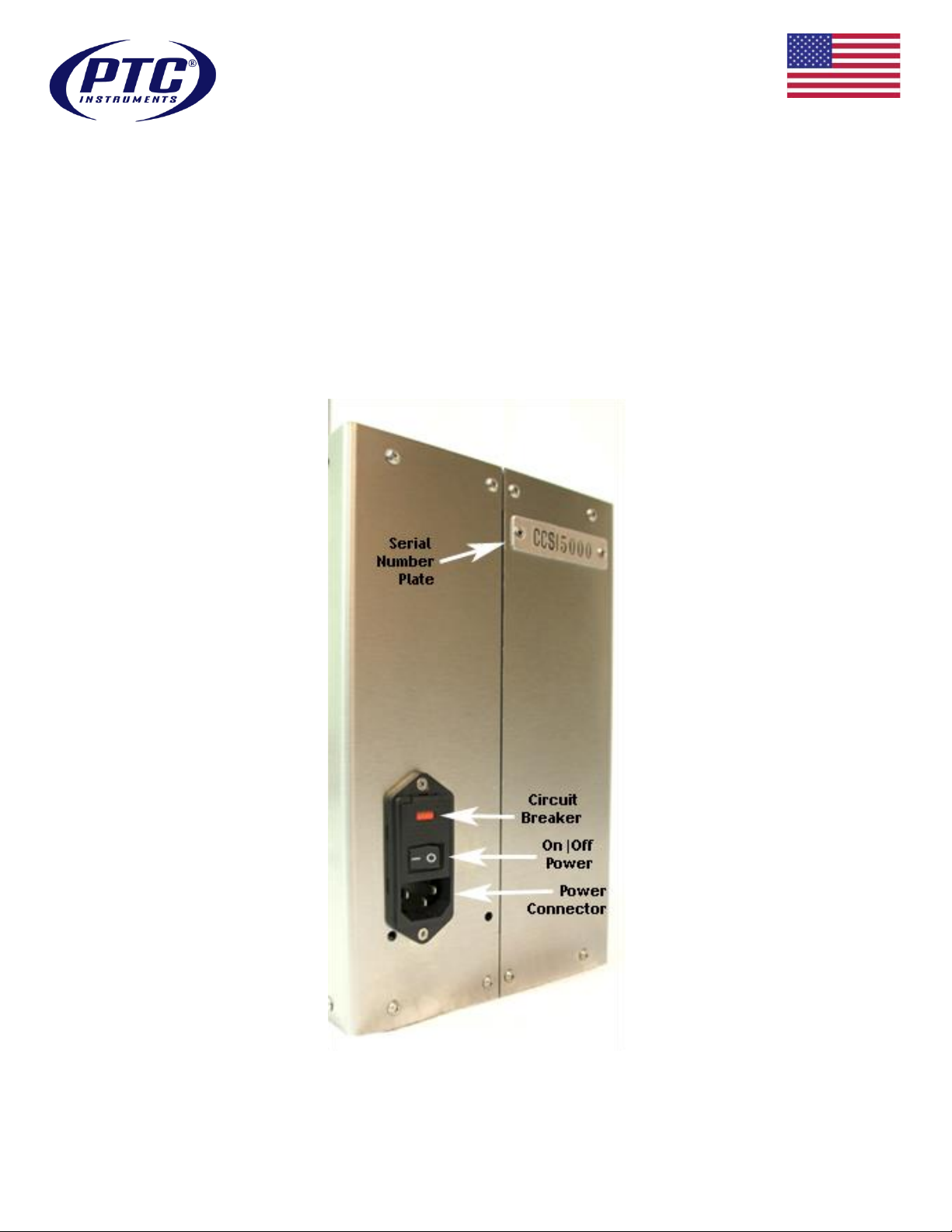

Components and Controls – Rear View

The following diagram shows the components and controls on the rear of the Model 500

automatic operating stand.

Fig. 2. Main Components and Controls of the Model 500 – Rear View

Find Quality Products Online at: sales@GlobalTestSupply.com

Model 500 Automatic Operating Stand Operating Manual

www.GlobalTestSupply.com

Page 3 of 5

Revision 4.0 5/2015

PTC® INSTRUMENTS

Model 500 Automatic Operating Stand Type 3

Mounting Instructions Pencil Style

Remove the set screws from the front mounting bracket. Place the durometer in the rear of the

mounting bracket. Position the durometer in the lowest position, mounting bracket just under the

digital head. Replace the front of the bracket and screws. Snug the set screws with the hex key

just enough to prevent slipping.

Place 2” diameter leveling block between the base of the Test Stand and the presser foot of the

durometer.

Loosen the knob on the mounting adapter holding the durometer in alignment. Maneuver the

durometer by pivoting gently left/right and forward /back mounting assembly, to ensure that the

presser foot is flush with and parallel to the block. Firmly, but gently, tighten the durometer

mounting knob. Run the test stand to the down position to be sure the durometer is now parallel

on the leveling block with the base plate. The durometer when fully engaged should read 98 to

100 on the dial indicator.

Remove the leveling block. The unit is now ready to test.

Performing ASTM D2240 Test Determinations

Turn the power switch to the ‘on’ (I is depressed) position (Fig. 2);

When the durometer mounting arm reaches the highest position (up delay), turn the power

switch off (O is depressed);

Turn the durometer height knob until the bottom of the durometer is approximately one inch

above the specimen;

Turn the power switch on. When the durometer reaches its lowest position (down delay), turn

the power switch off or use the cycle switch (Fig. 3) to halt the movement;

If needed, adjust the durometer mounting knob and durometer height knob to ensure positive

contact with the specimen;

Turn the power switch on. The Model 500 raises the durometer to the up (delay) position

The dwell timer (Fig. 3) on the side of the Model 500 controls how long the durometer remains

at the lowermost position (0 to 999 s), in contact with the specimen before returning to the

uppermost position.

Adjust the dwell timer to meet your testing requirements.

ASTM D2240 specifies a 1s dwell time, however this maybe adjusted to meet other

requirements and reported;

When the durometer returns to the uppermost position it will begin the next test cycle by

actuating the cycle switch located on the side of the 500;

Record each reading for at least five cycles;

When employing a durometer with an analogue maximum indicating hand or digital maximum

reading hold feature, reset it at each up delay cycle;

Find Quality Products Online at: sales@GlobalTestSupply.com

Model 500 Automatic Operating Stand Operating Manual

www.GlobalTestSupply.com

Page 4 of 5

Revision 4.0 5/2015

PTC® INSTRUMENTS

Model 500 Automatic Operating Stand Type 3

Calculate the average or the mean (refer to ASTM D2240) of the readings to obtain the test

result.

CAUTION

Turn off (cycle switch or power switch) the Model 500 only when it is in the up delay or down

delay position. If the Model 500 is turned off while the stand is in motion, it may stall the motor.

If the motor stalls or slows severely, remove any optional mass, turn the power switch off and on, then

use the cycle switch to halt/resume travel until the normal cycle resumes. This may take several

repetitions.

Find Quality Products Online at: sales@GlobalTestSupply.com

Model 500 Automatic Operating Stand Operating Manual

www.GlobalTestSupply.com

Page 5 of 5

Revision 4.0 5/2015

Loading...

Loading...