PSV groupe DRC 32, DRC 98, DRC - H22, DRC - H82 User Manual

Mincer

DRC 32/98

User Guide

Usine du berre au Loup – RD147 – BP20 – 95420 Genainville – France

Brand, patents and models registered in France and abroad R.C.S.

Pontoise B 642 033443

NEW EQUIPMENT COVERED BY THE DIRECTIVE

1. CEM 2014 / 30 / UE

2. BT 2014 / 35 / UE

- MACHINE 2006 / 42 / CE

CERTIFICATE OF COMPLIANCE rules of the European

Community.

The Manufacturer hereby PSV Groupe, BP20 95420

Genainville certifies that the new material designated below:

TRADITIONNAL MINCER

TYPE : ..............

Serial number : ...............

Genainville, done on .............

M. Michel PATUREL

CEO

Table of contents

1 Introduction ................................................................................................... 1

2 Installation and Electrical connection ........................................................ 2

3 Features and specifications ......................................................................... 3

4 Description .................................................................................................... 5

4.1 Installing the body .................................................................................... 5

4.2 Mouting plates and knives ....................................................................... 6

4.2.1 SYSTEM 2 CUTTING ELEMENTS (enterprise). .............................. 6

4.2.2 SYSTEM WITH 3 CUTTING ELEMENTS (UNGER). ....................... 7

4.2.3 SYSTEM WITH 5 CUTTING ELEMENTS (UNGER). ....................... 8

4.2.4 PRECAUTIONS FOR INSTALLATION AND MAINTENANCE .......... 8

5 Maintenance .................................................................................................. 9

5.1 Cleanning the machine .......................................................................... 10

5.2 Preliminary cleanning ............................................................................. 10

5.3 Disinfection ............................................................................................. 10

5.4 Rinse ...................................................................................................... 10

5.5 Maintenance ........................................................................................... 10

6 Warning ........................................................................................................ 11

7 Accessories ................................................................................................. 11

8 Customer service .................................................................................... 11

9 Warranty ....................................................................................................... 12

10 DRC 32/98 nomenclature .......................................................................... 13

11 Exploded scheme DRC 32/98 ................................................................... 15

12 Electric Scheme ........................................................................................ 17

1 Introduction

1

DRC 32, DRC 98 mincers can mince all kinds of meat for

the production of hamburgers, meatballs, sausage, etc...

They can be equipped with two cutting elements version

ENTREPRISE 32 (a plate and a knife), and three or five

cutting elements version UNGER 98. (See page 9.10.11)

DRC 32 has one knife single side, self-sharpening.

DRC 98 has one or two knife double side, with

removable blades.

STANDARDS

These devices meet the requirements of the decrees and safety

standards.

General hygiene and safety laid down in Articles 84 to R233R233-106, introduced in the Labour Decree No. 80543 of

July 15, 1980.

French standard NF U66-062, Machine chopping

meat, integrated prevention.

The control devices and signage, exhibit a degree of protection

IP54 as defined in standard NF 20-010.

All devices present a degree of protection IP245.

Continuous sound pressure level equivalent to the

Workstation measured according to standard NF S31 124 P

<70 dB (A) empty and loaded

The hand-protection plate is mandatory and should never

be disconnected from the board.

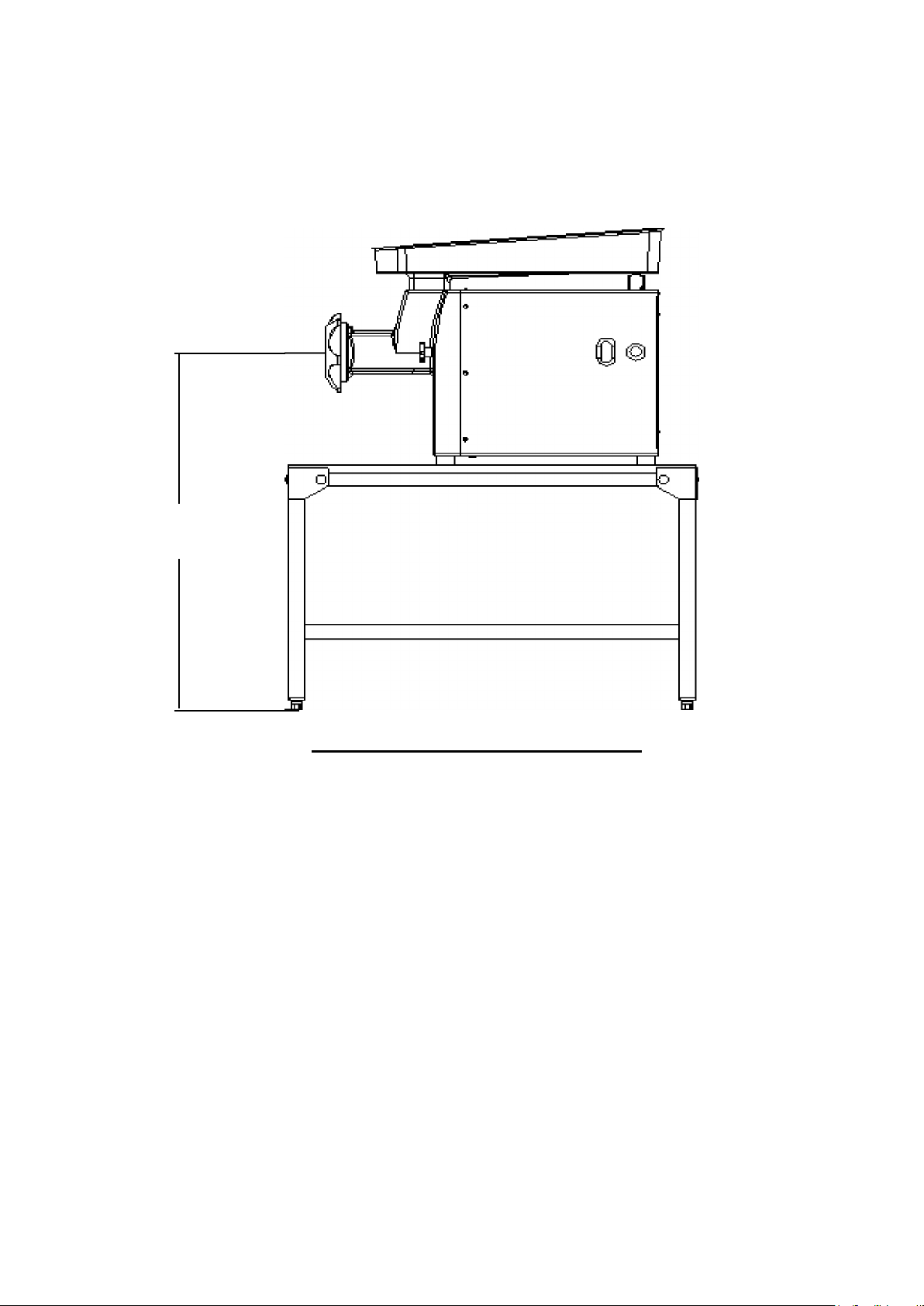

2 Installation and Electrical connection

2

0 Position the machine on a stable and solid work surface.

0 See recommended height of sketches above.

ELECTRICAL CONNECTION

0 The electrical connection must be performed by qualified

personnel and be conducted in compliance with safety

standards in force.

0 The line of the power supply must be carried out using a

cable section adapted to the power of the machine and

must include three phase conductors and a grounding

conductor (voltage machine 400v, 50 Hz) or two phase

conductors and a grounding conductor (voltage machine

230v, 50 Hz) .

0 The power of the machine must be protected by a breaker.

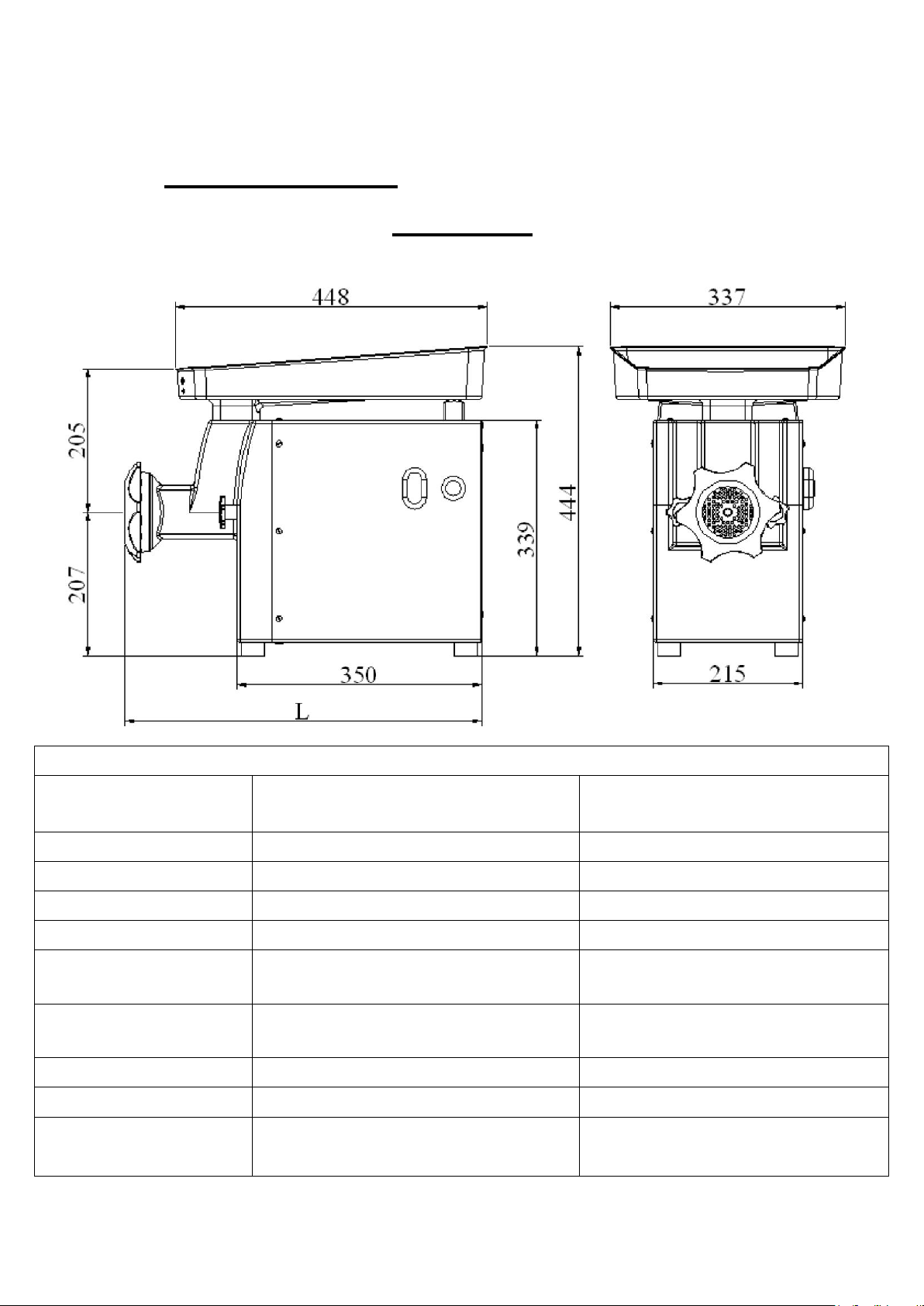

3 Features and specifications

Specifications

Version 98

Version 32

Dimensions

670(L) x 425 x 505

620(L) x 425 x 505

Weight

58kg

55kg

Packing

780 x 670 x 705

780 x 670 x 705

Theorotical flom

600 kg/h

600 kg/h

Engine

3CV / 2.2 KW continuous work

3CV / 2.2 KW continuous

work

Voltage

TRI - 400v - 50 HZ /

MONO - 230V - 50HZ

TRI - 400v - 50 HZ /

MONO - 230V - 50HZ

Reducer

Reducer PSV

Reducer PSV

Cutting system

Double cut B98 SUPINOX

Simple cut N°32 SUPINOX

Standard

equipment

1 knife, 1 plate Ø5, 1cutting-

plate

1 knife, 1 plate Ø5

3

TECHNICAL SHEET

DRC 32 / 98

THIS MACHINE EQUIPPED WITH A SAFETY

4

SYSTEM ELECTROMAGNETIC, only work

when the removable plate IS IN PLACE.

Loading...

Loading...