PSV groupe DRC114 User Manual

1

FFLLO

O

O

O

R

R

STT

S

A

A

D

D

N

N

R

R

DII

D

C

C

1

1

N

N

1

1

G

G

4

4

MII

M

N

N

C

C

E

E

R

R

Uss

U

Usine du berre au Loup – RD147 – BP20 – 95420 Genainville – France

Marques, brevets et modèles déposés France et étranger. R.C.S. Pontoise B 642 033443

« Original manual »

err

e

G

G

uii

u

d

d

e

e

2

Certificate of Conformity to rules of the European Community

The manufacturer hereby GROUPE PSV, BP20 95420 GENAINVILLE

NEW EQUIPMENT COVERED BY FOLLOWING DIRECTIVES

MACHINE 2006 / 42 / CE

CEM 2014 / 30 /UE

BT 2014 / 35 / UE

MODELE : TRADITIONAL MINCER

TYPE : DRC114CS

SERIAL NUMBER :

M. Dominique VILLA

CEO

3

TABLE OF CONTENTS

1/ INTRODUCTION AND NORMALISATION ………………… p.4

2/ INSTALLATION AND ELECTRICAL CONNECTION …… p.5

3/ CHARACTERISTICS AND TECHNICAL SHEET………. p.6

4/ DESCRIPTION ……………………………………………... p.8

A/ INSTALLING THE BODY ………………………………… p.8

B/ PLATES AND KNIVES MOUNTING ………..……… p.9

2/ SYSTEM WITH 3 CUTTING ELEMENTS……………… p.10

3/ SYSTEM WITH 5 CUTTING ELEMENTS……………. p.11

C/ PRECAUTIONS………………………………………. p.12

1/ MOUNTING & MAINTENANCE OF UNGER SYSTEM p.12

2/ UTILISATION DES BOUTONS DE COMMANDE p.13

3/ PRODUCT PUSHER USING ……………………………. p.14

5/ MAINTENANCE…………………………………………........ p.15

A/ CLEANNING OF THE MACHINE…. ..……………….. p.15

B/ PRELIMINARY CLEANNING ………………………… p.15

C/ DISINFECTION…………………. ……………………. p.15

D/ RINSE… …………………………………………………. p.16

E/ MAINTENANCE …………………………………………... p.16

6/ WARNING…….…………………………………………… p.17

7/ ACCESSORIES ……………………………………………… p.17

8/ AFTER SALES SERVICE ………………………………….. p.17

9/ WARRANTY CONDITIONS…. …………………………… p.18

10/ NOMENCLATURE DRC 114………………………….. p.19/20

11/ EXPLODED VIEW DRC 114 …………………………... p.21/22/23/24

12/ ELECTRICAL SCHEME …………………………………. p. 25

4

1/ INTRODUCTION

The mincer DRC 114 can mince all kinds of meat for the production of

hamburgers, meatballs, sausage…

The mincer can be equipped with 3 or 5 cutting elements UNGER.

(See on page 10/11)

The mincer 114 is equipped of one or two knife double side with removable blades.

NORMALISATION

These devices meet the requirements of the decrees and safety standards.

General hygiene and safety laid down in Articles 84 to R233-R233-106, introduced

in the Labour Decree No. 80543 of July 15, 1980.

French standard NF U66-062, Machine chopping meat, integrated

prevention.

The control devices and signage, exhibit a degree of protection IP54 as defined in

standard NF 20-010.

All devices present a degree of protection IP245.

Continuous sound pressure level equivalent to the Workstation measured according

to standard NF S31 124 P <70 dB (A) empty and loaded

The hand-protection plate is mandatory and should never be disconnected from

the board.

5

2/ INSTALLATION

Place the machine on a stable and solid floor

ELECTRICAL CONNECTION

Electrical plug in must be preformed by qualified personnel and be conduced in

compliance with safety standards.

The line of the power supply must be carried out using a cable section adapted to the

power of the machine and must include three phase conductors and a grounding

conductor (voltage machine 400v, 50 Hz) or two phase conductors and a grounding

conductor (voltage machine 230v, 50 Hz) .

Electrical plug in must be protected by a circuit-breaker.

6

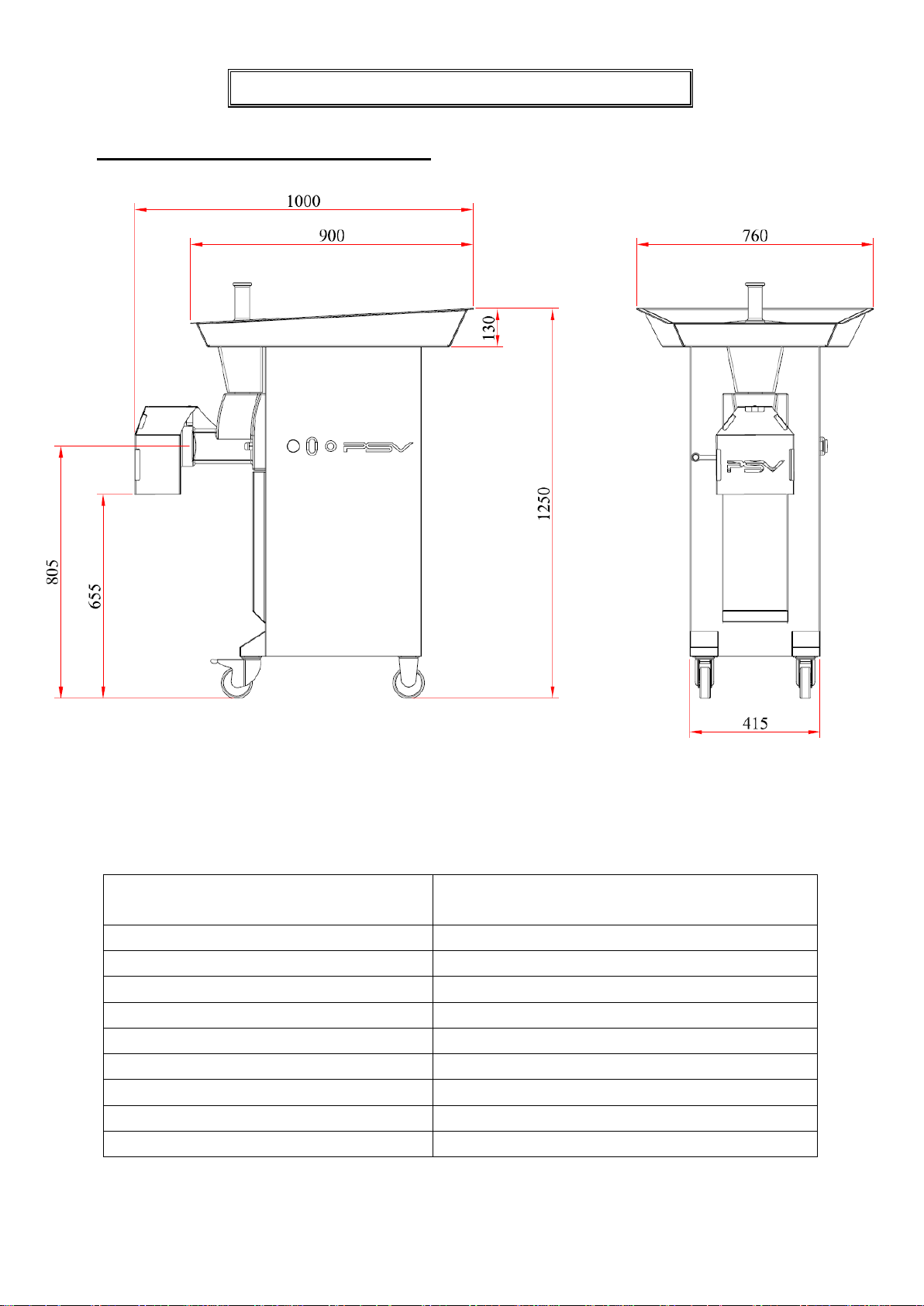

TECHNICAL CHARACTERISTICS

DRC 114

Dimensions

1000 x 760 x 1250

Weight

129 kg

Packing dimensions

1200 X 800 X 1350

Débit théorique

900 Kg/h

Motor

5,5 CV / 4,1 KW

Tension

3 PHASES - 400v - 50 HZ

Gear box

PSV gear box

Cutting system

3 or 5 cutting elements UNGER

Standard equipment

1 knife, 1 plate Ø5, 1plate / knife

3/ CHARACTERISTICS

TECHNICAL SHEET DRC 114

7

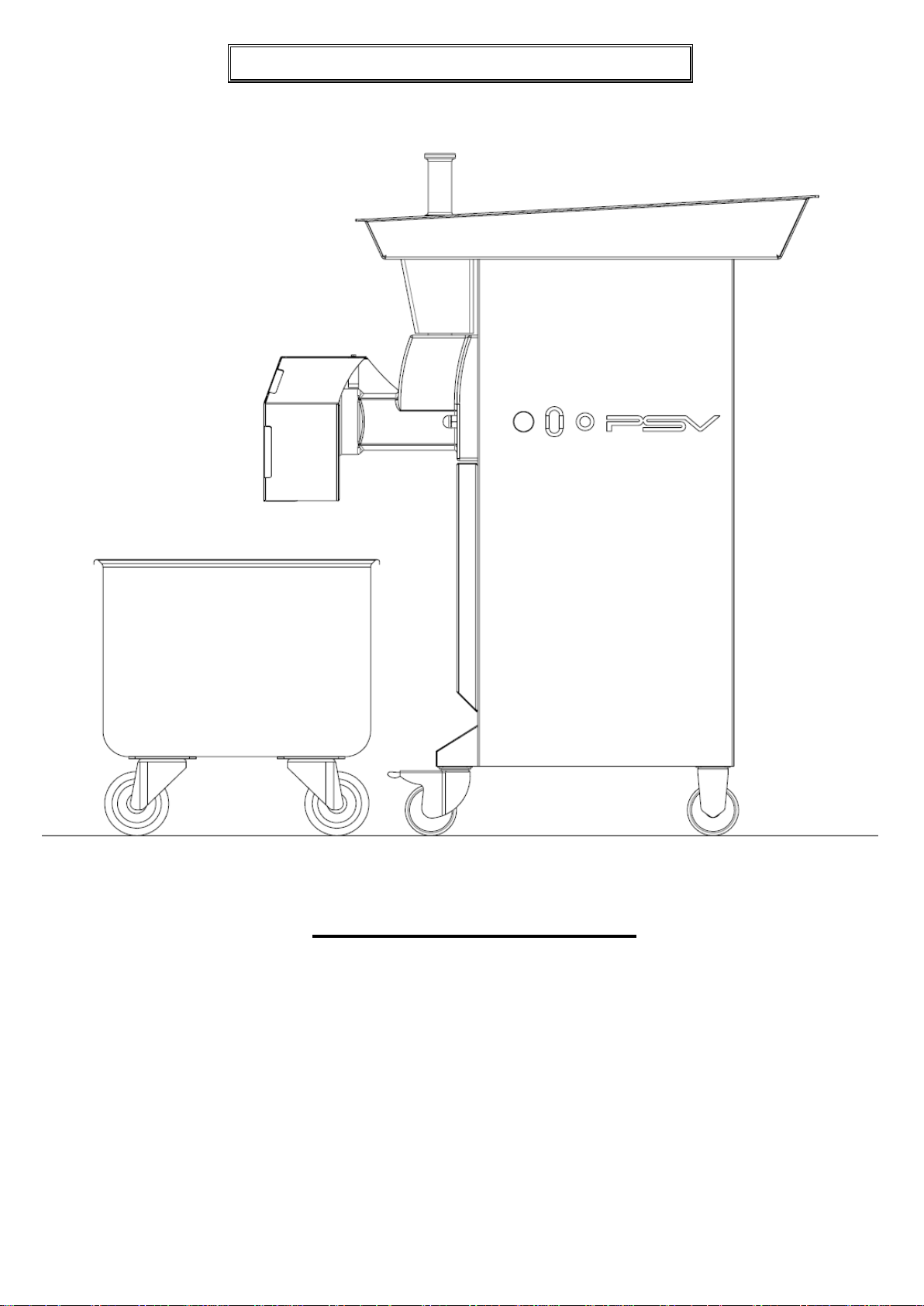

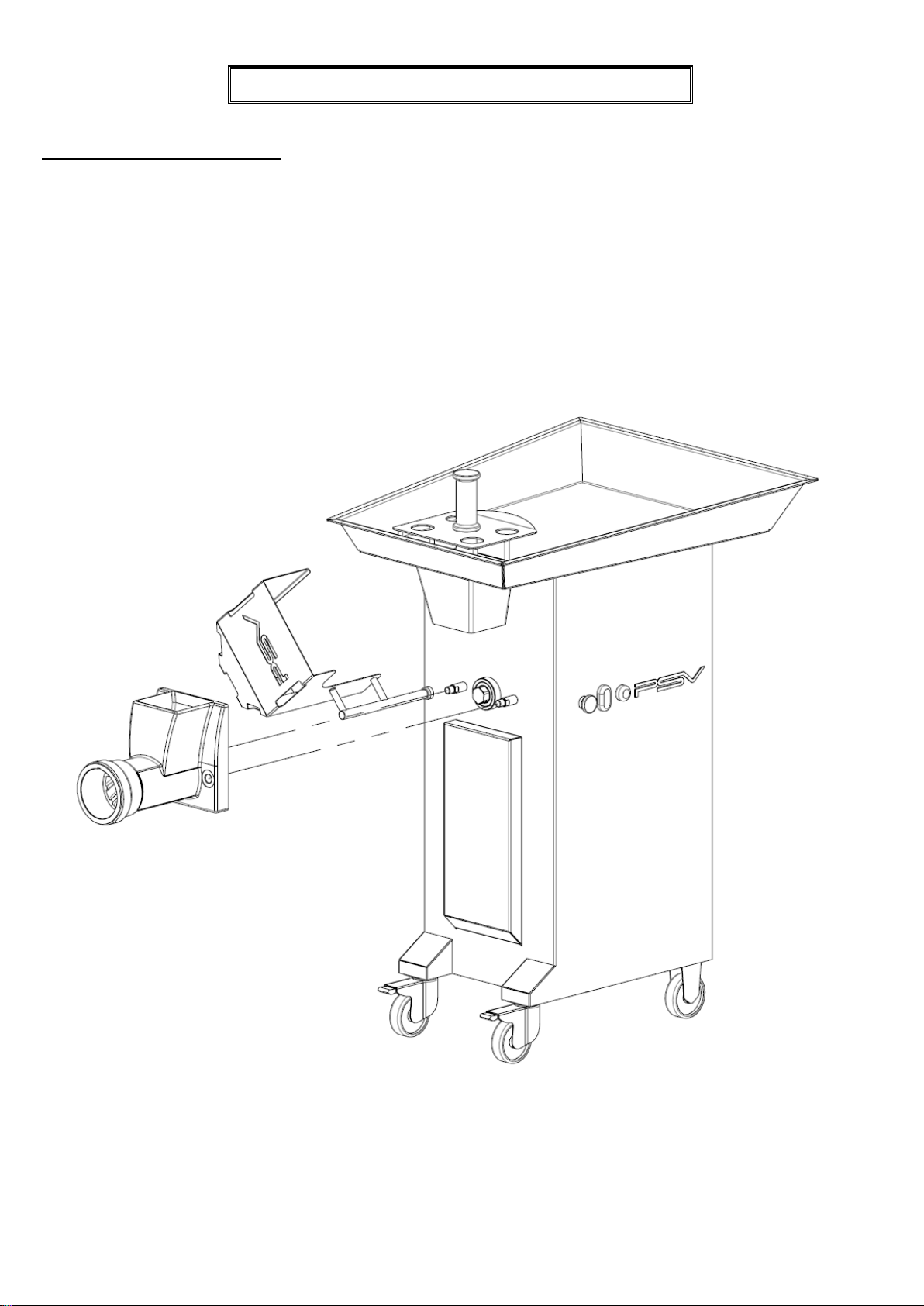

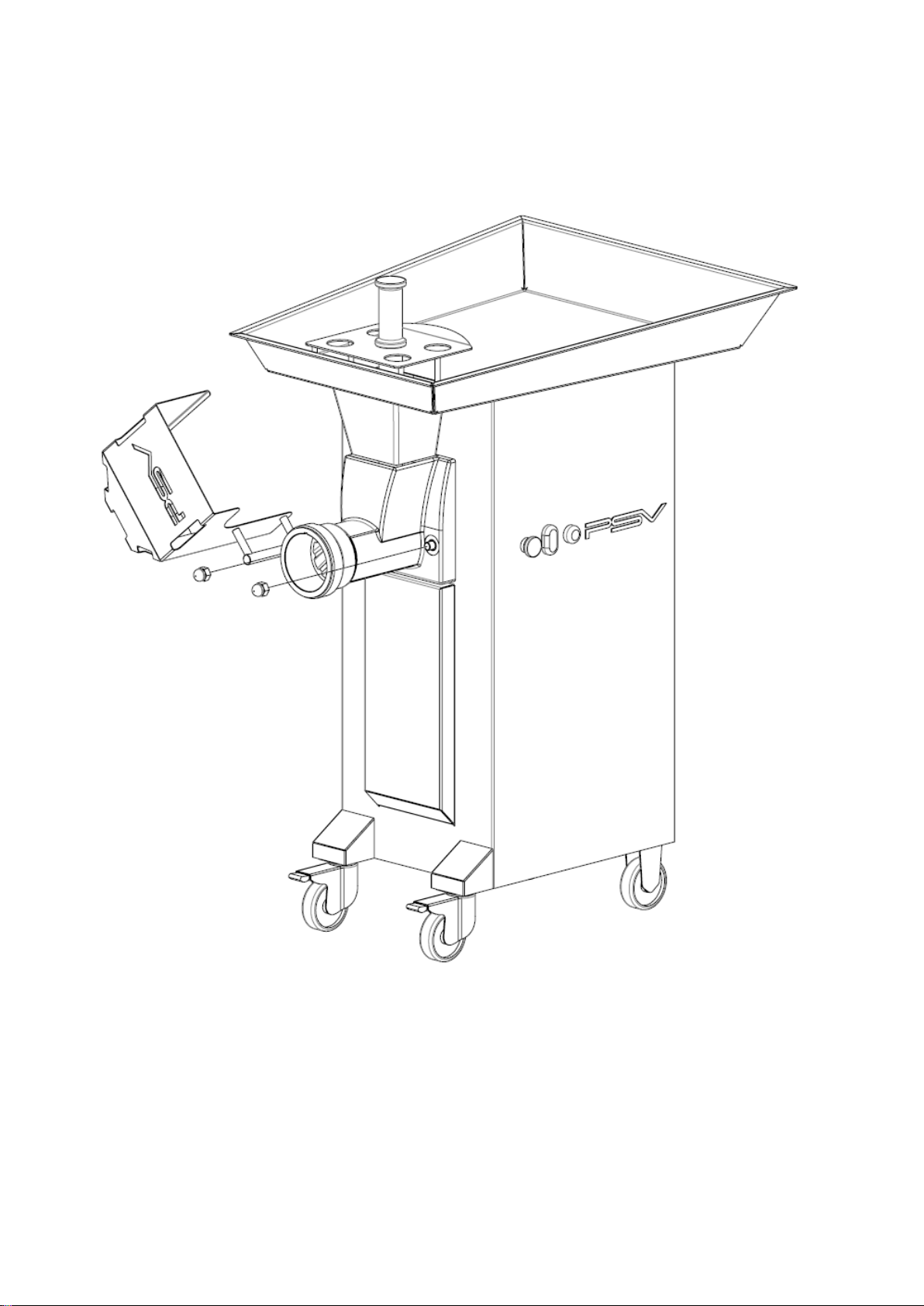

4/ DESCRIPTION

A/ BODY MOUNTING

Rotate the safety guard to place the body

Place the body in front of the machine

8

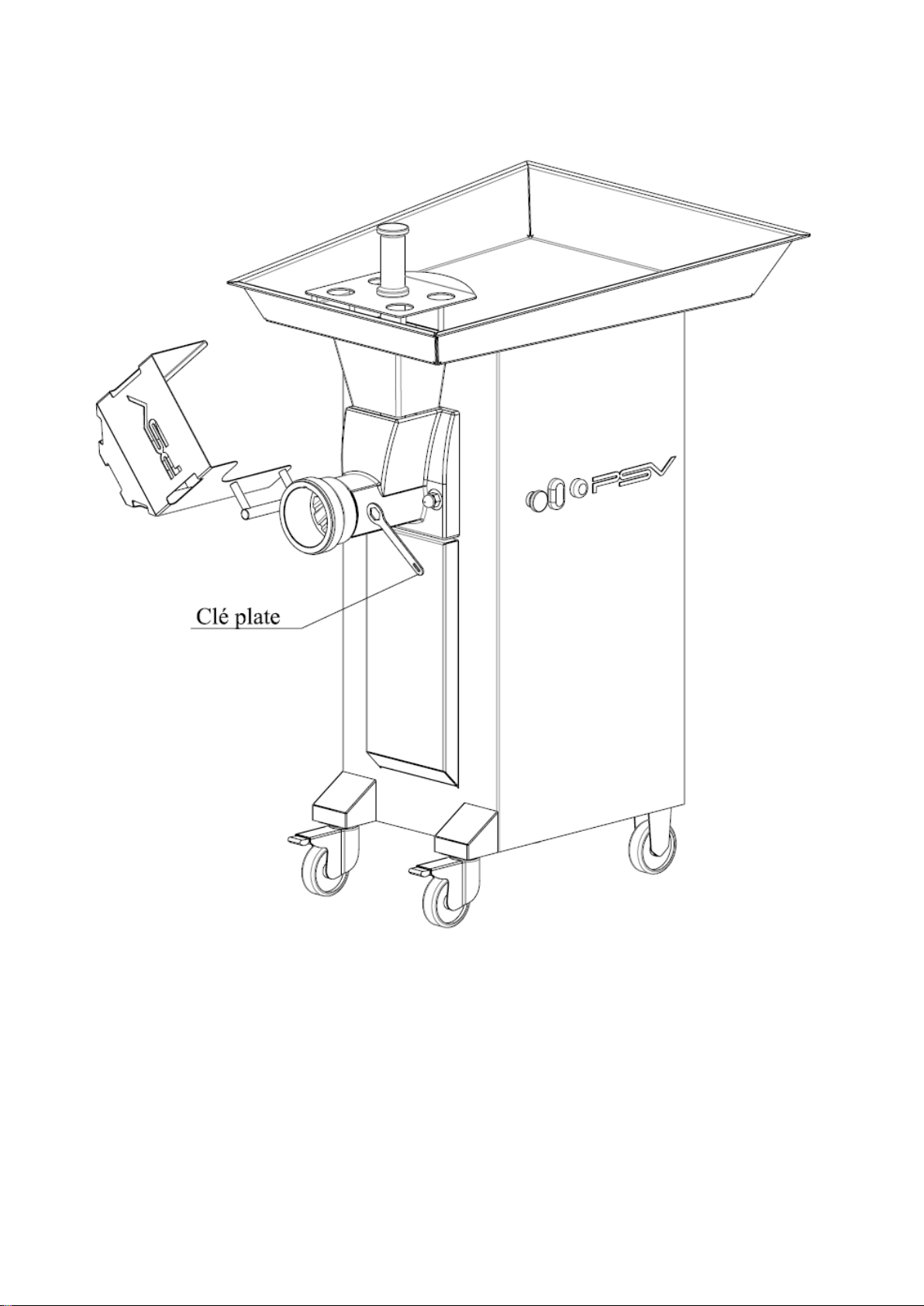

Fit the body in its seats (two blots through).

9

Tighten the two clamp handles setting the body on the machine

Make sure that the body is properly applied against the front

Loading...

Loading...