Page 1

User's Manual

P P 4 0 5 0

P P 4 0 5 0 X P

P P 4 0 5 0 M I C R

P P 4 6 5 0

5112 991 15506

Acknowledgements

PCL is a Trademark of Hewlett-Packard Company.

A Publication of PSi Laser GmbH

Eiserfelder Straße 316

57080 Siegen @ Germany

http://www.psi-laser.de

Version: 5112 991 15506 August 2009

Great care has been taken to ensure that the information in this handbook is accurate and complete.

However, should any errors or omissions be discovered or should any user wish to make suggestions for

improving this handbook, please feel encouraged to send us the relevant details.

The contents of this manual are subject to change without notice.

Copyright © by PSi Laser GmbH.

All rights strictly reserved. Reproduction or issue to third parties in any form is not permitted without

written authorization from the publisher.

Page 2

I

Safety Regulations for the Laser Printer PP 4x50 and

PP 4050XP and the intelligent Paper Stacker iPS 4050E

The LED printers PP 4050, PP 4050MICR, PP 4050XP, PP 4650 and the

intelligent Paper Stacker iPS 4050E fulfils the safety regulations according to

IEC, VDE/GS, and UL / C-UL for information technology equipments (EN 60950,

UL 1950 3rd Edition / CAN/CSA C22.2 No 950-95).

Note: The commercial name of the iPS 4050E is iPS 4050/4060).

The mains cable must be connected to a ground protected wall-socket. The

printer's voltage has to be in accordance with the local mains voltage.

The power plug must be easily accessible at any time so that it can be

disconnected immediately in case of danger or for maintenance purposes.

Before installing the printer, check the surrounding conditions in which the

printer is intended to be used (see next page, Operating Environment).

During thunderstorm you should never attempt to connect or disconnect any

data transfer cable.

The power supply should only be opened and checked by authorized personnel.

Maintenance beyond the descriptions of chapter 5 may only be attempted by

authorized personnel. Repairs done inappropriately may seriously jeopardize

the user's safety.

Attention: This symbol is standing for a hot surface - danger

of burning!

Safety Regulations

II

Electromagnetic Compatibility

We certify that the equipment at issue,

Type: Printer PP 4050, PP 4050MICR, PP 4050XP, PP 4650 and the

intelligent Paper Stacker iPS 4050E

corresponds to the laws and regulations ruling electromagnetic compatibility of

appliances (89/336/EWG) and, therefore, fulfils the requirements for conformity

marking with the CE-sign.

To guarantee that the device stays within the limits according to the approval

regulations for conducted and radiated emission (EN 55022, Class B) and

immunity (EN 55024) in any case shielded interface cables are to be used only.

Note: This equipment has been tested and found to comply with the limits for a

CLASS A digital device pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in wich case the user will be required

to correct the interference at his own expense.

Changes and modifications not explicitly allowed by the equipment's

manufacturer could void the user's authority to operate the equipment.

Operating Environment

Avoid installing the printer where it is exposed to moisture or heat (eg. direct

sunlight).

The printer is designed to operate in a wide range of environmental conditions.

S Temperature: + 15°C to + 35°C (+59°F to + 95°F)

S Humidity: 30% to 50%

For best performance, store and use fanfold paper at 19E to 23° C (68° to 73°F)

and a relative humidity of 33 to 47 percent.

Note: In case of higher values for temperature and humidity the print quality

will degrade!

Page 3

Safety Regulations

III

Power Requirements

S 100 - 110 V (-10/+6%) AC, 12 A (average)

S 100 - 110 V (-10/+6%) AC, 12 A (average)

S 110 - 120 V (-10/+6%) AC, 12 A (average)

S 220 - 240 V (-10/+6%) AC, 6 A (average)

S 50 - 60 Hz

Note: To avoid an overload of the electric circuit support (particularly for 100 to

110 or 110 to 120V) connect the power supply plug of the printer into a

separate protected power wall socket.

Power Consumption

S Operating power < 1.200 Watt average; (<1.650 W peak during

Warming Up)

S Operating current < 100 Watt

S Power save # 45 W

Notes: Slots and openings in the printer's housing are provided for

ventilation. Always ensure that these openings are not obstructed.

Also ensure that the cables of the printer do not interfere with the

output paper path.

During the printing process ozone will be produced. Take care that

the printer is standing in a room with good ventilation. The limt of

ozone concentration should be 0,1 ppm (0,2 mg/m3). Note that the

specific gravity of ozone is higher than that of air.

Caution: Danger of explosation if battery is incorrectly replaced!

Replace only with the same or equivalent type recommended by the

manufacturer. Dispose of used batteries according to the batteries

manufacturer´s instructions.

The intelligent Paper Stacker iPS 4050E can only be used in conjunction with

the printer PP 4050, PP 4050MICR, PP 405XP, PP 4060 or PP 4650.

Caution: Connector not located in limited Power Source! Only for connecting

Paper Stacker (iPS 4050E). Refere to User´s Manual.

Safety Regulations

IV

Moving lift can crush.

Keep feet clear.

See instructions manual.

Caution, the chain of the motor to move the paper exit tray

up and down will start automatically or after pushing the

key at the front side of the table.

Caution, the paper exit tray moves up and down

automatically or after pushing the key at the front

side of the table. Keep your feet clear when the

paper exit tray moves down. Ensure that the cables

at the rear of the printer do not interfere with the

paper path within the stacker.

The feet of the laser printer PP 4050, PP 4050MICR, PP 4050XP or PP 4650

should be positioned into the depressions of the stacker's table.

Note: Open windows, airing, and also draught disturb the paper flow!

Page 4

V

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . XIII

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . XIII

Conventions Used in this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . XIV

1. Installing the Printer and intelligent Paper Stacker . . . . . . . . . . . . . . 1-1

1.1 Requirements to the location of the printer . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 A First Look at the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3 Installing the intelligent Paper Stacker . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.1 Check delivery for Completeness . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4 Installing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.1 Check delivery for Completeness . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.2 Put the Printer onto the intelligent Paper Stacker (iPS) . . . . . . . . 1-6

1.4.3 Interconnect the Printer and iPS 4050/4060 . . . . . . . . . . . . . . . . . 1-8

1.4.4 Mount the Pendulum of the iPS 4050/4060 . . . . . . . . . . . . . . . . . 1-9

1.4.5 Remove the Transport Locks . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.5 Installation of the Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.5.1 Loading the Developer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.5.2 Loading the Toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.5.3 Inserting the Waste Toner Bottle . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.5.4 Inserting the Cleaner Felt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.5.5 Inserting the Ozone Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.5.6 Installing the PC Cartridge (OPC) . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.6 Connection to a Computer or to a Network . . . . . . . . . . . . . . . . . 1-18

1.6.1 PP 4050 Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.6.2 PP 4050XP / PP 4650 Parallel and Ethernet Interface . . . . . . . . 1-18

1.7 Power ON/OFF Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table of Contents

VI

1.8 Handling of the Tractor Cassettes . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.9 Inserting Fanfold Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

- Inserting paper for the first time or changing to another paper width 1-22

1.10 Operating the intelligent Paper Stacker (iPS) . . . . . . . . . . . . . . . 1-23

1.10.1 Adjusting the Paper Exit Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.10.2 Remove Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

2. Printer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Description of the two Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Description of the Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.3 Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2 Menu Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.1 To Activate the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.2 To Confirm and Save Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.3 Example to Change the Language at the Control Panel . . . . . . 2-10

2.3 Status and Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3. Configuring the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 What is Configuring? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

S Profiler 4050 and Profiler 4050/4060 . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 Basic Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.3 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Printout of Standard Configuration . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.1 How to Start the SELF TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 Printout of the Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Page 5

Table of Contents

VII

3.5 Menu Mode Item Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

S OFFLINE Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

S Select Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

S Paper Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

S PCL Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

S Hexdump Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

S General Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

S Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

S Clock Menu (only PP 4050XP/PP 4650) . . . . . . . . . . . . . . . . . . . . . 3-16

S Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

S Info Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.6 Configuration Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

S Profiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

S InterCon-NetTool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

4 Explanation of Individual Menu Items . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Menu Mode SELECT PROFILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 Menu Mode CHANGE PROFILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.1 PAPER MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

S PAPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

S PAPER LENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

S LENGTH FACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

S IMAGE WIDTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

S SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

S DESTINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

S ORIENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

S LANDSCAPE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

S ORIENT. MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

S PAPER EXTENDED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

S PAPER SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

S PAPER PATH SELECT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

S FUSER TEMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

S TONER DENSITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

S VER SHIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

S HOR SHIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

S CUT SHIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Table of Contents

VIII

S INT. LINE REGISTR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.2.2 PCL MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

S FONT NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

S PITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

S POINT SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

S SYMBOL SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

S LINE SPACING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

S TOP MARGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

S LEFT MARGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

S RIGHT MARGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

S TEXT LENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

S PERF. SKIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

S $$ COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.2.3 HEXDUMP MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

S UEL COMMAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.2.4 GENERAL MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

S EMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

S AUTO FORM FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

S AUTOMATIC CUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

S JOB SEPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

S TRACTOR CHANGE CUT . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

S REPRINT LAST PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.3 Menu Mode BASIC SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.3.1 CONFIG. MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

S POWER SAVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

S KEEP TEMP. HIGH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

S ALARM BELL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

S LANGUAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

S MENU ACCESSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

S HOST CHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

S TRACTOR POOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

S CMC7 Bar Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

S RECALL FACTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

S RESET DEVELOPER INFO . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Page 6

Table of Contents

IX

S RESET OPC INFO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

S RESET FUSER INFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.3.2 Clock Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.4 Menu Mode TEST MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.4.1 TEST MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

S PANEL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

S SELF TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

S CONT SELF TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

S CONFIG. PRINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

S PCL TYPEFACE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.4.2 INFO MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

S ENGINE ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

S FIRMWARE VERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

S STACKER VERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

S PANEL VERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

S DEVELOPER INFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

S OPC INFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

S FUSER INFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Installing the Parts of the Toner Kit . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Refilling the Toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.2 Replacing the Waste Toner Bottle . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.1.3 Changing the Cleaner Felt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.1.4 Replacing the Ozone Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.2 Installing the Parts of the Developer Kit . . . . . . . . . . . . . . . . . . . . . 5-8

5.2.1 Replacing the Developer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2.2 Replacing the Transfer Charger Unit . . . . . . . . . . . . . . . . . . . . . 5-10

5.2.3 Replacing the Ozone Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Table of Contents

X

5.3 Installing the Parts of the Fuser Kit . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.3.1 Replacing the Fuser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.4 Replacement of the PC Cartridge (OPC) . . . . . . . . . . . . . . . . . . . . . 5-14

5.5 User Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.5.1 Cleaning the Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.5.2 Cleaning the Transfer Charger Unit . . . . . . . . . . . . . . . . . . . . . . 5-18

5.5.3 Cleaning the Ozone Filter below the Transfer Charger . . . . . . . 5-19

5.5.4 Cleaning the Ozone Filter in the Top Cover . . . . . . . . . . . . . . . . 5-20

5.5.5 Tools for Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.5.6 Cleaning the Corona Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.5.7 Cleaning the TPS Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

6 Trouble Shooting and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

- How to Use this Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Power-related Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Status and Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

7 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Printer Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 Paper Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3.1 Fanfold Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4 Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.5 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

8 Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Basic Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Storing Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.3 Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.4 Guidelines and Specification for Selected Fanfold Paper . . . . . . 8-2

8.4.1 General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

S Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

S Basic weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

S Transport holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

S Perforation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Page 7

Table of Contents

XI

8.4.2 Typical Paper Properties for Laser Printer . . . . . . . . . . . . . . . . . . 8-6

8.4.3 Paper / Form Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.4.4 Label Carrier Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.4.5 Label Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

9 Maintenance / Logbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Toner Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 PC-Cartridge (OPC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.3 Developer Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.4 Fuser Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.5 Inspection Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.6 Customer Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Appendix A Programming Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A-1 Support of Printer Specific Feature and Functions . . . . . . . . . A-2

S A-1.1 Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

S A-1.2 Paper Size Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

S A-1.3 Paper Path Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

S A-1.4 Semigraphics Support under SAP R/3 . . . . . . . . . . . . . . . . . . A-3

A-1.5 EURO Symbol Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A-1.6 Support of Logical and Physical Pages . . . . . . . . . . . . . . . . . . A-4

A-1.7 Support of Job Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A-1.8 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A-2 List of Supported PJL Control Functions . . . . . . . . . . . . . . . . . A-7

A-2.1 Basic Rules for PJL Programming . . . . . . . . . . . . . . . . . . . . . A-7

A-2.1.1 PJL Sytax Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

A-2.1.2 PJL Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

A-2.1.3 List of supported PJL Commands . . . . . . . . . . . . . . . . A-9

A-2.1.4 List of supported PJL Variables and Values . . . . . . . A-12

A-2.1.5 List of supported PJL Variables and Values

for PCL Personality . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

A-3 List of supported PCL5 Control Functions . . . . . . . . . . . . . . . A-16

A-3.1 Job Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

A-3.2 Page Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

A-3.3 Cursor Positions Commands . . . . . . . . . . . . . . . . . . . . . . . . A-19

A-3.4 Font Selection Commands . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

A-3.5 Font Management Commands . . . . . . . . . . . . . . . . . . . . . . . A-22

XII

A-3.6 Macro Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . A-23

A-3.7 Graphic Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

A-3.8 Status Readback Commands . . . . . . . . . . . . . . . . . . . . . . . . A-25

A-4 Support for Semigraphics for SAP/R3 . . . . . . . . . . . . . . . . . . A-26

A-5 Bar Code Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27

A-5.1 Resident Bar Code Font Code 39 HP Compatible . . . . . . . . A-27

A-5.2 Resident Bar Code Controlled by

Private Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . A-28

A-5.2.1 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-29

S Bar code print position . . . . . . . . . . . . . . . . . . . . . . . . . . . A-29

S Bar code print orientation . . . . . . . . . . . . . . . . . . . . . . . . A-29

S Bar code type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-30

S Bar code hight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-31

S Bar code data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-31

S Bar code text control . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-32

S Bar code module width . . . . . . . . . . . . . . . . . . . . . . . . . . A-32

S Bar code ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-33

S Start and Stop characters . . . . . . . . . . . . . . . . . . . . . . . . A-34

S Error checking characters . . . . . . . . . . . . . . . . . . . . . . . . A-34

S Unprinted areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-34

A-5.3 Bar Code Programming Examples . . . . . . . . . . . . . . . . . . . . A-35

S Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-35

S 2 of 5 industrial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-35

S 2 of 5 interleaved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-36

S EAN 8 SC2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-36

S EAN 8 SC6 add 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-37

S EAN 8 SC9 add 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-38

S EAN 13 SC2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-39

S Codabar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-39

S Code 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-40

S Postnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-41

S RMS4SCC / KIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-41

Appendix B Symbol Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Page 8

Preface

XIII

Preface

About this Manual

This manual covers the printer in combination with the interface module, the

Personality Module. The Personality Module (PM) is an integral part of the

printer which determines the functionality of the printer especially regarding the

user and system interface.

The structure of this manual is such that the operator is led step-by-step through

the various procedures. Starting with unpacking and installation of the

consumables it moves on to setting-up configuration parameters and ends with

the mounting of options.

The manual is divided into the following chapters:

1. Installing the Printer and intelligent Paper Stacker

This chapter covers the information about the basic elements of the printer.

The next steps show how to power on the printer, the handling of the tractor

cassettes, inserting fanfold paper, and how to operate the intelligent Paper

Stacker (iPS 4050).

2. Operating the Printer

This chapter discusses in great detail the operation of the control panel, all

menu functions, and the general operation of the menu. General status

messages are also described.

3. Configuring the Printer

This chapter explains how to use the Profiles and to configure the printer so

that it can communicate with the corresponding system environment.

Furtheron this chapter includes a view of the Menu Structure and thoroughly

describes in a short form the printer's operating controls. Finally you will find

a description of the Configuration Programs Profiler 4050 and Profile

Selector 4050. The Profiler 4050 is a menu controlled program and

supported the printer configuration via PC. Different configurations can be

downloaded into the printer.

Profile Selector 4050 is a program for quick access to a profile.

Preface

XIV

4. Explanation of Individual Menu Items

In this chapter are the individual menu items are explained in detail.

5. Maintenance

This chapter explains how to replace the consumables and maintain the

printer.

6. Trouble Shooting and Diagnostics

suggests how to identify and correct simple problems.

7. Technical Data

All technical details or data about the printer can be found here.

8. Paper Specification

Guidelines, Specification, Paper and Label properties are defined in this

chapter.

9. Maintenance / Logbook

All activities of maintenance should be written down here.

Page 9

Preface

XV

Appendix A Programming Guide

This appendix describes command extension of PCL5 and PJL in section 2

and 3. Bar Code Programming is described in section 5.

Appendix B Symbol Sets

All supported Symbol Sets are listed.

Appendix C Miscellaneous

S Order Numbers

S Printer Driver

Preface

XVI

Safe Energy

The PP 4x50 printer models have a special feature to save power. After a

specified period of inactivity, the printer changes to a low power state. W hen a

print job is received, the printer resumes the operating mode. This function is

changeable in the Configuration Menu with the item POWER SAVE. Standard

setting is 15 minutes.

Conventions Used in this Guide

The following conventions are used:

Bold Headlines and important information.

Note: Contains special advice to facilitate handling.

Caution: Contains important information to prevent damage

of the equipment.

[ENTER] Key functions are always depicted in brackets or

indicated by the corresponding symbol e.g. .

The use of LEFT and RIGHT always assumes you are viewing the front i.e. the

control panel of the printer. For instance, the paper input is at the LEFT side of

the printer.

Page 10

16614

1-1

Installing the Printer and intelligent Paper Stacker

1.1 Requirements to the location of the printer

In this chapter the preconditions are described concerning the environment, the

physical prerequisites, and the demand for space which are required for

installation of the printer.

1.1.1 Environmental conditions

S Temperature and Humidity

The following table shows the values of temperature and relative humidity

which are specified for the printer and its consumables.

Temperature Relative Humidity

Print operation *

Optimum range

+ 19 to + 23°C

+ 68 to + 73°F

33 to 47%

Print operation

Extended range

+ 15 to + 35°C

+ 56.5 to + 86°F

30 bis 50%

Transport and Storage

of the printer

- 10 to + 40°C

- 4 to + 104°F

max. 95%

(at + 40°C or + 104°F)

Transport and Storage

of the consumables **

- 10 to + 40°C

- 4 to + 104°F

max. 95%

(at 40°C or 104°F)

Storage of fanfold

paper

+ 19 to + 23°C

+ 68 to + 73°F

33 to 47%

* The photoeletrical process in a laser printer is influenced by the climatic

conditions of the environment. The herewith specified values define a

climate in which an optimal print quality is ensured. Operating the printer

outside this range may lead to a reduction of the print quality.

** It is recommended to store the consumables at a cool and dark location.

S Altitude

The printer can be used at an altitude up to 2,135 m (7,000 ft.).

Installing the Printer and the intelligent Paper Stacker

1-2

S Air circulation

In general there are no restrictions concerning air circulation. However, it is

to be observed that the air flow does not move the fanfold paper heavily at

the paper entry and paper exit of the printer and such may lead to paper

jams.

In conjunction with the paper stacking system care has to be taken that the

air flow does not disturb a proper operation of the stacker.

S Impact of Light and Sunshine

Since the printer is equipped with a light-sensitive photoconductor drum and

optical sensors it shall in generally not be installed at a location which is

exposed to sunlight. If not otherwise possible window shades have to

provide for the necessary protection.

Note: The printer must never be installed such that its right side (paper

exit) points to a window.

If the top cover is opened to clear a paper jam or to perform maintenance

actions sunbeams would directly fall onto the photoconductor drum and

would permanently destroy its surface after an impact period of about 1

minute.

S Acoustical Noise

The upper limits of the acoustical noise are shown below.

S Print Operation < 55 dB(A)

S Stand-by < 48 dB(A)

S Power Dissipation

If an interruption of a print operation occurs the printer can enter the Power

Save mode when for a certain period of time whose duration is selected at

the operator panel the printer does not perform any further operation. In this

mode most of the printer´s subsystems are disconnected from power. The

operating mode is resumed when the printer receives further data from the

host system.

Mode Power Consumption

Operating < 1,200 Watt average

< 1,650 Watt max.

Stand-by < 100 Watt

Sleep Mode (Power Save) < 45 Watt

Page 11

Installing the Printer and the intelligent Paper Stacker

1-3

S Weight and Dimensions

The printer´s weight is 112 kg (247 lbs.) with all consumables included.

The printer and the optional intelligent paper stacker both together weigh

164 kg (361 lbs.).

S Dimensions

Printer Printer incl. Stacker System

Width 810 mm; 32.9 inch 1.040 mm; 40.9 inch

Height 350 mm; 13.8 inch 1.140 mm; 44.9 inch

Depth 780 mm; 30.7 inch 780 mm; 30.7 inch

S Accessability

To facilitate the handling of the printer (and the stacking system) by the

operator the below mentioned distances around the printer should be met

minimally:

S Front 700 mm / 27.6 inch

S Rear 140 mm / 5.5 inch

S Left 480 mm / 18.9 inch

S Right 400 mm / 15.8 inch

Note: The intelligent paper stacker is equipped with castors which allow to

move the entire configuration to an empty space in case of maintenance

activities.

S Preconditions for Installation

Floors and doors must be wide enough that the printer can pass them;

corners and angles must be large enough such that the printer can be

turned if necessary. For example a door must be 80 cm (31.5 inch) wide

minimally.

Elevators must be able to carry the printer and the personnel who transport

it. Doors of the elevators must be wide enough that the printer can pass

them.

It must be ensured that the floor space where the printer is to be installed

does not exceed the following horizontal inclinations:

S from the front to the rear + 1E

S from the left to the right + 2E

It must be safeguarded that an approved mains voltage wall socket is

available which provides for correct and sufficient current; the mains cord

must extend to the wall socket.

Installing the Printer and the intelligent Paper Stacker

1-4

1.2 A First Look at the devices

1 Laser Printer

3 Paper Exit for Cut Sheets

5 Paper Exit for Fanfold Paper

7 Control Panel

9 Upper Tractor

11 Pendulum

13 Shelf for Lower Tractor

15 Castors

2 Rear Cover

4 Top Cover

6 Front Cover

8 Lower Tractor

10 intelligent Paper Stacker (iPS)

12 Paper Exit Tray

14 Shelf for Upper Tractor

Note: The intelligent Paper Stacker (10) - also called iPS 4050/4060 - is an

option!

Note: The Printer drivers for Windows ® are available - see Appendix C Order

Numbers.

Page 12

Installing the Printer and the intelligent Paper Stacker

1-5

1.3 Installing the intelligent Paper Stacker

1.3.1 Check delivery for completeness

When unpacking, check contents of delivery by item against the list detailed

below. Contact your delivery agent immediately if any item is missing or

damaged.

The iPS 4050/4060 package should contain the following:

S iPS 4050/4060 basic unit (1)

S Pendulum (2)

S a box with the left and right Paper Guide (3)

S four Castors

Note: Remove the transport locks and mount the four castors.

Observe that the two castors with locking lever are mounted at

paper entry side.

Installing the Printer and the intelligent Paper Stacker

1-6

S The interface connector and protective

ground cable are packed into a

plastic bag (1).

1.4 Installing the Printer

1.4.1 Check delivery for completeness

When unpacking, check contents of delivery by item against the list detailed

below. Contact your delivery agent immediately if any item is missing or

damaged

The Starter Kit package should contain the following:

S 1 x Developer Unit incl. Toner Cartridge

S 2 x Tractor Cassettes

S 1 x PC-Cartridge

S 1 x Cleaner Felt

S 1 x Ozone Filter

S 1 x Toner Cartridge

S 1 x User´s Manual

S 1 x Mains Cable

S 1 x Waste Toner Bottle

1.4.2 Put the Printer onto the inteligent Paper Stacker (iPS 4050/4060)

S Lift the printer from the pallet using the transport grip points on the left (1)

and the right side (2) of the printer and put it onto the iPS 4050/4060.

Note: Do not attempt to lift the printer in any other manner!

S Position the printer properly (3) into the depressions and make sure the side

covers adequately clear the iPS 4050/4060 frame when opened.

Page 13

Installing the Printer and the intelligent Paper Stacker

1-7

1

Installing the Printer and the intelligent Paper Stacker

1-8

1.4.3 Interconnect the Printer and iPS 4050/4060

SSSS Make sure that the printer and the iPS are powered off

S Plug in the interface connector (1) and fix it properly

SSSS Connect the protective ground cable (2)

Page 14

Installing the Printer and the intelligent Paper Stacker

1-9

1.4.4 Mount the pendulum of the iPS 4050/4060

The printer must be put onto the iPS first before mounting the pendulum. The

pendulum is to be mounted vertically between the bars (1).

S Shift pendulum (2) into the left stacker bearing by compressing the spring

while simultaneously inserting the bolt (3) of the pendulum into the right

bearing (4). Take care that the pin (5) hits the hole (6).

Installing the Printer and the intelligent Paper Stacker

1-10

S Open the extensions (1) of the paper tray.

Page 15

Installing the Printer and the intelligent Paper Stacker

1-11

1.4.5 Remove the Transport Locks

S Open the front cover at the Operator Panel side

S Remove the foil (1) which protects the paper sensors in both paper paths.

S Remove the transport locks (2), (3), (5), (6), (8), and (9) which fix the levers.

S Remove the bubble wrap (4) which protects the rollers at the paper entrance

of the Fuser.

S Remove the foam block (7) which locks the lever of fuser.

Installing the Printer and the intelligent Paper Stacker

1-12

1.5 Installation of the Consumables

1.5.1 Loading the Developer Unit

S Lift the lever (26) upwards to unlock the Developer Unit.

S Pull the Developer Unit (6) about b out of the housing and grasp the grip (7)

with one hand and remove it.

S Remove the plastic bag from the clutch on the rear side.

S Remove plastic and paper safety strips (8) from the area of the toner output

of the Developer Unit (6).

Note: Don´t destroy the small plastic lip above the toner output of the

Developer Unit (6).

S Insert the Developer Unit (6) (step 2.) and secure it by pressing down the

lever (26).

Page 16

Installing the Printer and the intelligent Paper Stacker

1-13

1.5.2 Loading the Toner

There is a Toner Cartridge in the Developer Unit.

S Pull the Toner Cartridge (1) completely off the developer.

Note: An orange tape (2) is visible which is fixed to a foam block that closes

the toner entrance into the developer.

S Remove the foam block (2) from the Developer Unit.

S Shake the Toner Cartridge several times.

S Insert the Toner Cartridge (1) approximate 10 cm, illustrated below, with the

attached plastic seal (3) pointing to the top .

S Remove the stripe (4) from the cardboard roll (5) and fix it at the begin of the

plastic seal tape (3) .

S Turn the cardboard roll (5) to roll up the plastic seal (3) until the seal is

entirely removed and push the toner cartridge until it is fully inserted.

S Turn the Toner Cartridge (1) counter clockwise by about 180 degrees until it

is fully engaged.

Note: The cover of the Toner Cartridge (1) must be locked by the screw (6).

Installing the Printer and the intelligent Paper Stacker

1-14

1.5.3 Inserting the Waste Toner Bottle

The Waste Toner Bottle is in the Starter Kit package 1

S Open the rear (22) cover.

S Press the lever (23) to open the top cover (24), illustrated below.

S Take the Waste Toner Bottle (2) and put it into the compartment.

Note: Please make sure that the cap (2A) is placed onto the cap holder (2B)

and not over the filling hole!

Page 17

Installing the Printer and the intelligent Paper Stacker

1-15

1.5.4 Inserting the Cleaner Felt

The Cleaner Felt (3) is in the Starter Kit package 2

S Insert the Cleaner Felt (3).

S Close the top cover (24).

Note: Depending on paper properties it may be necessary to change the

Cleaner Felt more often than with every second Toner Cartridge.

Installing the Printer and the intelligent Paper Stacker

1-16

1.5.5 Inserting the Ozone Filter

The Ozone Filter is in the Starter Kit package 1

S Insert the Ozone Filter (4) into the slot.

S Close the rear (22) cover.

Note: After printing 20,000 pages it is recommended that the Ozone Filter is

replaced. The box of the Toner Kit contains the Ozone Filter.

Page 18

Installing the Printer and the intelligent Paper Stacker

1-17

1.5.6 Installing the PC Cartridge (OPC)

The Photoconductor (1) is in the Starter Kit package 2

Note: - The Photoconductor is very light-sensitive, so it is wrapped in a

lightproof foil.

S Please do not touch the green part of the Photoconductor with your

fingers. Oil and dirt degrade the print quality.

S Do not expose the light-sensitive Photoconductor to room lighting or

sunlight any longer than necessary.

S Lift the lever (2) upwards to unlock the Developer Unit.

S Carefully remove the drum from its foil container.

S Insert the Photoconductor (1) by using the upper and lower iron band guides

and push it into the printer until you hear a click.

S Attach the electrical connector (3) to position (4).

S Find the orange adhesive tape on the waste toner exit and remove it (5).

S Secure the Developer Unit by pressing down the lever (2).

Installing the Printer and the intelligent Paper Stacker

1-18

1.6 Connection to a Computer or to a Network

Note: The printer must be powered off!

1.6.1 PP 4050 Parallel Interface

At the rear side of the printer you will find the Parallel IEEE 1284 (1) interface

connector.

1.6.2 PP 4050XP Parallel and Ethernet Interface

At the rear side of the printer you will find two interface connectors:

S Parallel IEEE 1284 (1)

S Ethernet 10 Base T (2)

S Connect the interface cable coming from the computer or from the network

to the printer´s parallel (1) or 10 Base T port (2).

S Check in the CONFIG. MENU the HOST CHANNEL.

S For the parallel connection the setting PARALLEL ONLY is necessary.

S To activate the 10 Base T interface the setting must be I/O EXTENSION.

Note: For detail information about the Ethernet interface see the included

Ethernet Reference Manual.

Page 19

Installing the Printer and the intelligent Paper Stacker

1-19

1.7 Power ON/OFF Switch

S Connect the printer to the mains using the power cord (14).

S The power ON/OFF switch (15), can be found in the housing under the lower

tractor cassette to the rear of the printer, switches the printer's power supply

ON or OFF.

When switched ON the printer performs an internal self test which checks the

electronics, fans, and the motors for the paper transport mechanism.

The display (17) presents the message:

MEMORY TEST!

PLEASE WAIT ...

After successful completion two messages pop up shortly after each other:

OFFLINE (1)

..................

..................

PCL

Then all fields of the display will show black squares and a short beep sounds;

power ON is indicated by a green LED (16).

Installing the Printer and the intelligent Paper Stacker

1-20

The following message appears:

ONLINE (1)

..................

..................

02 WARMING UP

After a short delay the message WARMING UP in line 4 will disappear.

Note: If an arror message is displayed please refer to section 6.2 Error

Messages.

1.8 Handling the Tractor Cassettes

The printer has two tractor cassettes for fanfold paper, the LOWER

TRACTOR cassette and the UPPER TRACTOR cassette. The tractor cassettes

are in the Starter Kit Package 1 and 2

If the printer is used without the intelligent Paper Stacker, align the printer with

the front edge of the table. Ensure that the cables at the paper exit do not block

the paper path.

Simply slide the tractor cassettes forward into the respective guides (see

illustration). Remove the tractor cassettes by lifting and pulling them toward you.

Take out the UPPER TRACTOR before inserting paper into the LOWER

TRACTOR. If more than two different fanfold papers are to be processed, it is

useful to work with additional tractor cassettes. Such an additional tractor

cassette can be preloaded with paper and quickly mounted into the printer as

required.

Page 20

Installing the Printer and the intelligent Paper Stacker

1-21

1.9 Inserting Fanfold Paper

Insert the paper as shown in the illustration; the top edge of the paper must be

close to the paper guide. (About three transport punches behind the last

transport pin of the tractor.)

Check that the fold points outwards behind the first page (default setting for

SELECT FOLD = POSITIVE). If not tear off one page or change the setting for

SELECT FOLD to NEGATIVE (see chapter 4 Explanation of Individual Menu

Items).

Fold = POSITIVE

Fold = NEGATIVE

Note: Paper must only be inserted while the printer is powered on!

Installing the Printer and the intelligent Paper Stacker

1-22

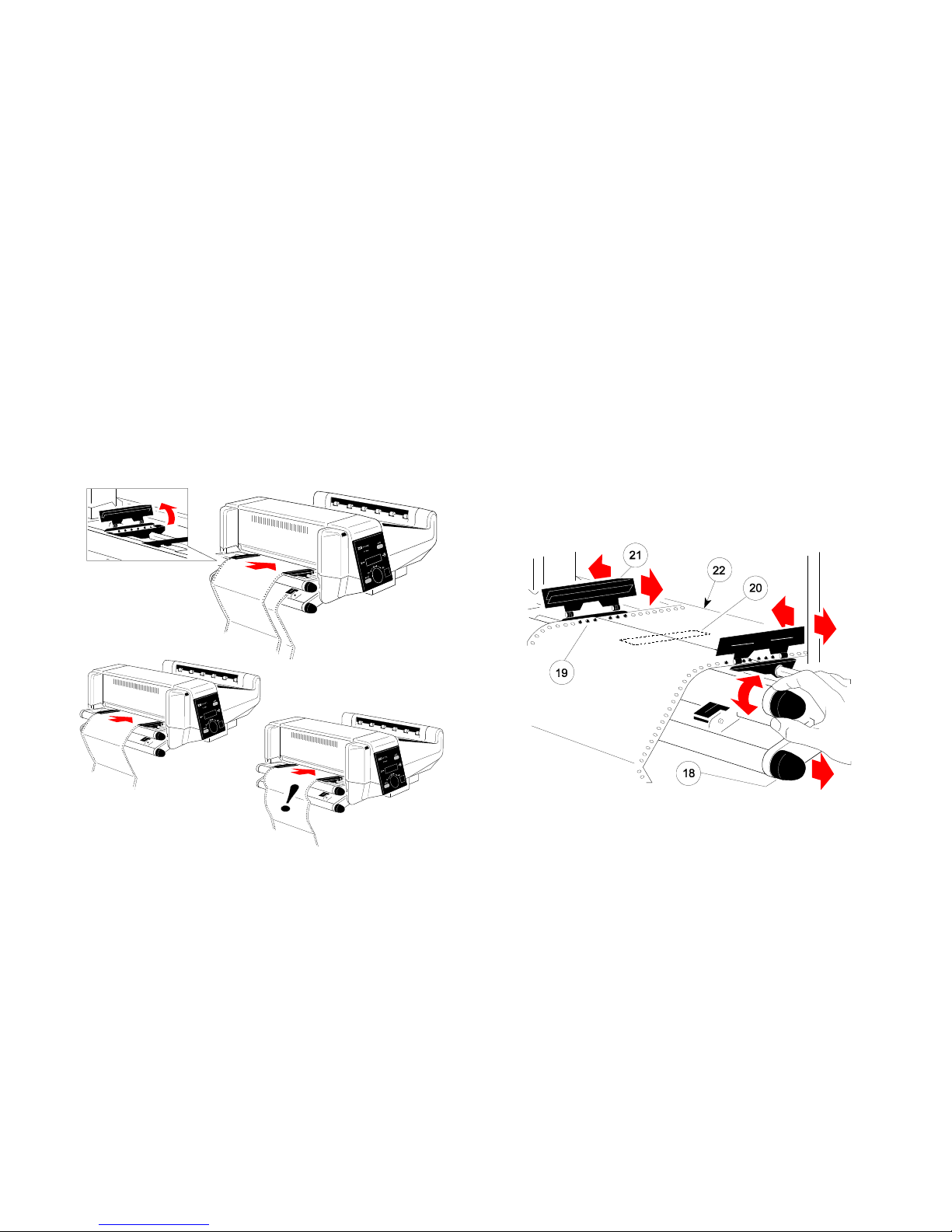

Inserting paper for the first time or changing to another paper width:

1. Pull out and turn the knob (18) to the right (small paper) or left (wide paper)

to adjust the tractors to the paper width, and center the paper support (20)

between the tractors.

2. Open the tractor covers (21), insert the paper, and close one tractor cover

again.

3. Turn the knob (18) for final adjustment of the paper. The pins (19) of the

tractor must be centered in the transport punches of the paper. Close the

other tractor cover.

4 Turn the tractor until the top edge of the paper digs into the paper

guide (22). (or put the paper already into the paper guide (22) during

inserting).

Note: The top edge of the paper must be close to the paper guide (22). (About

three transport punches behind the last transport pin of the tractor.)

The pins (19) of the tractor must be centered in the transport punches of

the paper.

Page 21

Installing the Printer and the intelligent Paper Stacker

1-23

1.10 Operating the intelligent Paper Stacker

Correct operation of the stacker is only ensured if the fold behind the first page

is positive i.e. the fold points towards the operator. If the fold is negative (it

points to the printer) the first page must be torn off.

Note: The before mentioned procedure is only necessary for inserting new

paper (e.g. a new pile of paper or newly inserting the paper after paper

jam). See also chapter 1.9 Inserting Fanfold Paper on the previous

page.

1.10.1 Adjusting the Paper Exit Tray

To stack the paper precisely the intelligent Paper Stacker needs to be adjusted

to the paper length. This is done by means of the metal frame at the rear. To set

the paper length perform the following steps:

S Loosen the two adjustment screws (1)

S Move the bar (2) until the required length is visible on the ruler (3).

S Tighten the adjustment screws (1).

Note: The adjustment range for the paper length is from 7 inch up to 17 inch.

Installing the Printer and the intelligent Paper Stacker

1-24

1.10.2 Remove Paper

There is a switch (25) at the front of the table (below the operator panel) which

causes the paper exit tray (26) to move up and down.

Move the paper exit tray down and remove the paper. After 30 seconds or when

a next print job is processed the paper exit tray is lifted automatically into the

operating position.

Page 22

2-1

2 Printer Operation

2.1 Control Panel

The control panel

S gives information about the printer status

S controls various parameter settings

S allows manual control of the paper handling

2.1.1 Description of the two Indicators

S The 4-line Liquid Crystal Display (LCD) (93) indicates the current status of

the printer. If any error occurs (e.g. COVER OPEN) the resulting error

message will be displayed. W hile configuring the printer menu settings and

parameters appear on the display.

S The green indicator lamp (94) is lit if the printer is supplied with power by

setting the power ON/OFF switch to ON.

Printer Operation

2-2

2.1.2 Description of the LCD Indicator

The LCD Indicator gives information about the status of the printer.

In general it can be distinguished between:

S ONLINE messages

S OFFLINE messages

When the printer is in the ONLINE mode the display shows:

O N L I N E ( 1 )

1 6 . 0 0 x 1 2 I N C H

L O W E R - - > B O T T O M

In line two the selected paper format is shown and in line three the selected

paper input and paper output.

Note: The value after ONLINE is the indication of the actual PROFILE.

When the printer is in the OFFLINE mode status information, error messages,

or menu messages are displayed.

Example: The display content after paper jam.

Note: The printer status gets OFFLINE when a failure occurs.

O F F L I N E ( 1 )

1 6 . 0 0 x 1 2 I N C H

L O W E R - - > B O T T O M

Page 23

Printer Operation

2-3

1 3 J A M L O W E R I N P U T

The error message in line four is flashing and the printer is sending a short

acoustic signal.

Note: The value behind OFFLINE indicates the last selected PROFILE.

Example: The printer is warming up.

O N L I N E ( 1 )

1 6 . 0 0 x 1 2 I N C H

L O W E R - - > B O T T O M

0 2 W A R M I N G U P

Example: The printer receives data for a print job.

O N L I N E ( 1 )

1 6 . 0 0 x 1 2 I N C H

L O W E R - - > B O T T O M

D A T A

Example: Display content after pressing (90).

O F F L I N E ( 1 )

S E L E C T P R O F I L E

C U T F O R M

F O R M F E E D

Printer Operation

2-4

In this state it is possible to turn (91) to shift next following lines onto the

display.

S SELECT FOLD LOWER

S SELECT FOLD UPPER

S CHANGE PROFILE

S BASIC SETTINGS

S TEST MODE

S RESET PRINTER

Example: Select Profile

O F F L I N E ( 1 )

S E L E C T P R O F I L E

C U T F O R M

F O R M F E E D

Example: By turning (91) the desired menu point is showing in line two.

After selecting the menu point Select Profile by pressing (91) you get the

following information:

S E L E C T P R O F I L E

1 r

2

3

By turning (91) the display contents change to the values available 1 up to

10 (PP4050) resp. 1 up to 50 (PP 4050XP/PP 4650) (only three of them are

displayed at a time).

Example: After selecting the desired Profile Number (for example 10, because

this number stands in line two) press the key (95) and the following

information is getting:

Page 24

Printer Operation

2-5

S E L E C T P R O F I L E

1 0 r

1 1

1 2

After pressing (90) the printer use Profile number 10.

Printer Operation

2-6

2.1.3 Function Keys

The function of the four keys (90) to (92) and (95) depends on the printer

operation state.

Short Description of Keys in the ONLINE mode

Number Key Function

90 OFFLINE

- changing to OFFLINE mode

- stops data transfer

- stops printing

Note: In the ONLINE mode all other keys have no function.

Short Description of Keys in the OFFLINE mode

Number Key and Symbol Function

90 ONLINE

- changing to ONLINE mode (after an

error message)

- starts data transfer

- leaving the Menu Mode

91 - Quick set up wheel to activate a cut

function after a print job is terminated

without automatic cut.

- navigation through the menu (turn)

- selection of parameters (press)

92 - return to the higher menu level

95 - confirm and save the selection

Note: All newly selected values must be confirmed and saved

immediately by pressing the key (95)!

Page 25

Printer Operation

2-7

2.2 Menu Mode

All operator selected features are accessible via the control panel and

combined in the printer MENU.

This feature provides:

S easy handling of configuration (language, etc.)

S quick parameter changes

S activation of test functions

There are four entry points:

S SELECT PROFILE - for profile selection (1 up to 50)

S CHANGE PROFILE - to change the profile settings

S BASIC SETTINGS - to control the printer (power save, menu access)

S TEST MODE - to make test prints and get information about the

printer

The menu has three levels:

S Level 1 the Main Function

allows the selection of a group of subfunctions

S Level 2 Subfunctions

can be activated as a function or allow to choose a group of

values

S Level 3 Parameters and values

can be selected/activated in this level

Printer Operation

2-8

2.2.1 To Activate the Menu

To activate the menu, please follow the next steps:

S Press

The printer enters from the ONLINE mode into the OFFLINE mode and the

display shows

OFFLINE (1) The number in brackets indicates the actual profile!

SELECT PROFILE

CUT FORM

FORM FEED

The next, but not visible items are:

FEED MULTIPLE PAGES

SELECT FOLD LOWER

SELECT FOLD UPPER

CHANGE PROFILE

BASIC SETTINGS

TEST MODE

RESET PRINTER

Selection of functions and parameters at a certain menu level:

S Turn the quick set up wheel with the symbol to the left or

right; the button has a wrap around function, i.e. after the last item the first

item is repeated.

After selecting CHANGE PROFILE by pressing the quick set up wheel you

have entered the main function level of the Menu Mode:

CHANGE PROFILE (1)

PAPER MENU

PCL MENU

GENERAL MENU

To switch to the next level first scroll the requested menu item into line two

(below the head line). Then press the quick set up wheel .

Page 26

Printer Operation

2-9

Now you are at the Subfunction level. Movement in both directions is possible

by:

S pressing the quick set up wheel to enter the next lower level

S pressing the key to enter a higher level.

If the selection is e.g. PCL MENU the display will indicate:

PCL MENU

FONT NUMBER

PITCH

SYMBOL SET

The next, but not visible items are:

LINE SPACING

TOP MARGIN

LEFT MARGIN

RIGHT MARGIN

TEXT LENGTH

PERF. SKIP

$$ COMMANDS

Now select the requested menu item of this menu (for example PERF. SKIP) by

turning the with the quick set up wheel and press the same buttom to enter

the lowest level.

At the last level to select/confirm values, the asterisk (*) at the right indicates the

actual selection.

PERF. SKIP

OFF *

ON

By turning the quick set up wheel to the left or right you are able to change

from OFF to ON.

2.2.2 To Confirm and Save Selection

S press ; the confirmed value is displayed with an asterisk (*) in the last

position.

Note: All newly selected values must be confirmed and saved immediately

by pressing this key!

The Menu Mode is left by pressing the key.

Note: All actual parameter settings can be printed with the function

SELF TEST in the TEST MODE.

Printer Operation

2-10

2.2.3 Example to Start a Self Test

Panel keys are now used and associated display messages are shown for the

next steps. The following example demonstrates how to do so:

Key Display

1. Switch the printer on. ONLINE (1)

16.00 x 12 INCH

LOWER --> BOTTOM

2. Press (90) OFFLINE (1)

SELECT PROFILE

CUT FORM

FORM FEED

Note: The number in brackets behind ONLINE or OFFLINE indicates

the selected Profile.

3. Turn (91) until OFFLINE (1)

TEST MODE

RESET PRINTER

SELECT PROFILE

4. Press (91) TEST MODE

select the TEST MODE TEST MENU

INFO MENU

5. Press (91) TEST MENU

select TEST MENU PANELTEST

SELF TEST

CONT SELF TEST

6. Turn (91) TEST MENU

SELF TEST

CONT SELF TEST

CONFIG. PRINT

Page 27

Printer Operation

2-11

Key Display

7. Press (91) TEST MENU

activate SELF TEST SELF TEST *

CONT SELF TEST

CONFIG. PRINT

The printer starts to print using paper from the defined paper source.

8. Press (90) ONLINE (1)

16.00 x 12 INCH

LOWER --> BOTTOM

Note: The Self Test informs about all settings of the actual Profile (see

Paragraph 3.2 Printout off Standard Configuration).

To cut the SELF TEST-Page, please execute following steps:

9. Press (90) OFFLINE (1)

SELECT PROFILE

CUT FORM

FORM FEED

10. Turn (91) OFFLINE (1)

CUT FORM

FORM FEED

SELECT FOLD LOWER

11. Press (91) OFFLINE (1)

CUT FORM *

FORM FEED

SELECT FOLD LOWER

Page 28

3-1

3 Configuring the Printer

3.1 What is Configuring ?

This chapter describes how to use the control panel and menu to set up or

configure your printer so that the printer and your computer system can

communicate correctly with each other.

The important menus are:

S SELECT PROFILE

S CHANGE PROFILE

S PAPER MENU

S PCL MENU or HEXDUMP MENU

S GENERAL MENU

S BASIC SETTINGS

S CONFIG. MENU

S TEST MODE

S TEST MENU

S INFO MENU

3.1.1 Profiles

All parameters which characterise a print job and its corresponding form (e.g.

SOURCE, PAPER LENGTH, DESTINATION, FUSER TEMP.) are contained in

one profile. In total 10 PROFILEs ( for PP4050) and 50 PROFILES (for

PP4050XP/4650 are available and can be either programmed via the operator

panel or by means of the utility called Profiler. The profiler provides an utmost

comfortable way of creating profiles. More about the Profiler 4050 on next page.

There are two items in the OFFLINE MENU which deal with profiles, SELECT

PROFILE to activate a profile and CHANGE PROFILE to define its contens. All

parameter settings via the operator panel, via the Profiler 4050 or via PJL

commands are effecting the actually selected profile. The number of the actually

selected profile is shown in the first line of the operator panel. After switching on

the printer the last selected profile will be active.

The function RECALL FACTORY in the CONFIG. MENU is setting

allparameters of all profiles to the factory default values.

Configuring the Printer

3-2

Different applications use also different settings. All these settings for an

application are collected in a PROFILE. For example: Application A needs

fanfold paper cut into single sheets with a top margin of one, application B

processes fanfold paper in a batch with a top margin of six. Simply by pressing

SELECT PROFILE the Profile containing the information for the specific

application requirements can be activated.

S Profiler 4050 and Profiler 4050/4060/4650

The Profiler 4050 represents a utility which can be used for printer configuration.

It provides the capability to program up to 10 profiles (for PP 4050 and 50

profiles (for PP 4050XP/4650 whose contents can be defined and archived on a

PC and downloaded into the printer. All relevant configuration parameters are

presented on the screen in a similar way as they are shown on the printer’s

operator panel display. The utility runs under Windows 95 / 98, W indows NT,

Windows ME, Windows 2000 and Windows XP.

Attention: The printer must be in the ONLINE state when profiles are

downloaded from the PC.

Note: For detailled description of the Programm see Paragraph 3.6

Configuration Tools.

3.1.2 Basic Printer Settings

All parameters which characterise general printer features and functions can be

defined in the menu mode BASIC SETTINGS and the submenu CONFIG.

MENU.

3.1.3 Test Mode

S The TEST MENU allows running of various self tests and configuration print

outs.

S The INFO MENU allows the print out of all release informations of the

printer.

Page 29

Configuring the Printer

3-3

3.2 Printout of Standard Configuration

The factory default configuration can be printed within the TEST MENU and is

shown on the following page.

The upper part of the SELFTEST printout shows the actual selections and

parameter values.

Main functions appear in the first line of each menu block.

Second and following lines show the selection at subfunction level and the

selected parameters behind the "=" sign.

Below the menu section on the test page information is given about the

hardware and software configuration of the printer and stacker is given:

S FLASH memory size for printer firmware and fonts

S memory size (DRAM)

S Printer and Stacker firmware version

S Panel version

S available emulations

The rest of the page is filled up with a diagonal test pattern. The black frame

around the test page reflects the actual paper format. The default format is 12

inch for paper length and 16 inch for image width.

Configuring the Printer

3-4

3.2.1 How to Start the SELF TEST

Key Display

1. Switch the printer ON ONLINE (1) (after initialisation)

16.00 x 12 INCH

LOWER --> BOTTOM

2. OFFLINE (1)

SELECT PROFILE

...

3. turn until OFFLINE (1)

TEST MODE

...

4. press the button TEST MODE

TEST MENU

INFO MENU

5. press the button TEST MENU

PANEL TEST

SELF TEST

CONT SELF TEST

6. turn to the right TEST MENU

SELF TEST

CONT SELF TEST

CONFIG. PRINT

7. press the button TEST MENU

SELF TEST *

...

The printer starts to print the self test.

The printer returns to the operating mode after pressing .

Note: If the printer is in the ONLINE mode press , select CUT FORM, and

press to cut the page!

Page 30

Configuring the Printer

3-5

Sample of the SELF TEST

*) Depending on setting of EMULATION in the GENERAL MENU either

PCL MENU or HEXDUMP MENU is indicated.

**) This value is depending on the selected FONT NUMBER;

for FONT NUMBER 0, 39 - 44 = PITCH and

for FONT NUMBER 1 - 38 = POINT SIZE

See Paragraph 3.4 Menu Structure for the different entry points and Chapter

4 Explanation of individual Menu Items !

Configuring the Printer

3-6

3.3 Printout of the Profiles

To printout the contents of all 10 Profiles use the same sequence as described

in paragraph 3.2.1 How to Start the SELF TEST up to point 6.

After selecting CONFIG. PRINT, the printer starts to print all 10 resp. 50

Profiles.

Sample of PROFILE 1

*) Depending on setting of EMULATION in the GENERAL MENU (see

TEST PRINT) either PCL MENU or HEXDUMP MENU is indicated.

**) This value is depending on selected FONT NUMBER;

for FONT NUMBER 0, 39 - 44 = PITCH and

for FONT NUMBER 1 - 38 = POINT SIZE

See Paragraph 3.4 Menu Structure for the different entry points and Chapter

4 Explanation of individual Menu Items !

Page 31

3-7

3-8

3.4 Menu Structure

n = 1 up to 10 (PP 4050); 1 up to 50 (PP4050XP) PAPER MENU

PAPER

OFFLINE (n) PAPER LENGTH 2)

SELECT PROFILE SELECT PROFILE LENGTH FACTOR 2)

CUT FORM 1 IMAGE WIDTH 2)

FORM FEED 2 SOURCE

SELECT FOLD LOWER .. DESTINATION

SELECT FOLD UPPER 50 ORIENTATION

CHANGE PROFILE LANDSCAPE MODE

BASIC SETTINGS ORIENT. MODE

TEST MODE PAPER EXTENDED

RESET PRINTER PAPER SELECTION

PAPER PATH SELECT.

FUSER TEMP.

CHANGE PROFILE (n) TONER DENSITY

PAPER MENU VER SHIFT

PCL MENU or 1) HOR SHIFT

HEXDUMP MENU CUT SHIFT

GENERAL MENU INIT. LINE REGISTR.

n = 1 up to 50 PCL MENU

or 1) FONT NUMBER

PITCH or POINT SIZE 3)

SYMBOL SET

1) Depending on setting of LINE SPACING

EMULATION TOP MARGIN 2)

in GENERAL MENU LEFT MARGIN 2)

= PCL or HEXDUMP RIGHT MARGIN 2)

TEXT LENGTH 2)

PERF. SKIP 2)

$$ COMMANDS

2) Only displayed if PAPER HEXDUMP MENU

in PAPER MENU UEL COMMAND

= CUSTOM

GENERAL MENU

EMULATION 1)

3) Depending on selected FONT AUTO FORM FEED

AUTOMATIC CUT

JOB SEPARATION

TRACTOR CHANGE CUT

REPRINT LAST PAGE

BASIC SETTINGS

CONFIG. MENU CONFIG. MENU

CLOCK MENU POWER SAVE

KEEP TEMP. HIGH

4) only with panel version 0.26 or higher ALARM BELL 4)

LANGUAGE

MENU ACCESS

HOST CHANNEL

TRACTOR POOL

CMC7 Bar Width 5)

RECALL FACTORY

RESET DEVELOP. INFO

RESET OPC INFO

5) only for printer PP4050MICR RESET FUSER INFO

6) only for printer PP 4050XP/4650 CLOCK MENU 6)

WEEKDAY

DAY

MONTH

YEAR

HOUR

MINUTE

SECOND

TEST MODE

TEST MENU TEST MENU

INFO MENU PANEL TEST

SELF TEST

CONT SELF TEST

CONFIG. PRINT

PCL TYPE LIST

Note:

For detail setting of the possible parameters see next pages!

INFO MENU

PRINTER TYPE

ENGINE ID

FIRMWARE VERSION

STACKER VERSION

PANEL VERSION

DEVELOPER INFO

OPC INFO

FUSER INFO

Page 32

Configuring the Printer

3-9

3.5 Menu Item Description

OFFLINE

PARAMETER VALUE

SELECT PROFILE see below

CUT FORM

FORM FEED

FEED MULTIPLE PAGES 1......16

SELECT FOLD LOWER POSITIVE *,

*,*,

*, *

NEGATIVE *+

*+*+

*+

SELECT FOLD UPPER POSITIVE *,

*,*,

*, *

NEGATIVE *+

*+*+

*+

CHANGE PROFILE see below

BASIC SETTINGS see below

TEST MODE see below

RESET PRINTER NO *

YES

The following table show menu modes, submenus and parameters.

Precondition is: Access to all menu items is alloved. (MENU ACCESS = ALL) Otherwise

restrictions are to observed.

SELECT PROFILE

Entry Point = SELECT PROFILE

PARAMETER VALUE

SELECT PROFILE 1 *

2

..

..

10 (PP4050 max. 10; PP4050XP/4650

max. 50)

Note: A asterisk (*) after the value indicates the actual setting!

Configuring the Printer

3-10

PAPER MENU

Entry Point = CHANGE PROFILE (n = 1 - 10) ---> PAPER MENU

Paper Menu Value / Parameter

PAPER CUSTOM *

LETTER

A4

PAPER LENGTH

(Only for

CUSTOM)

12 INCH *

( Range: 3...20 inch; in steps of

1

/4 or 1/6 inch)

LENGTH FACTOR

(Only for

CUSTOM)

1 *

( Range: 1 - 20 logical pages)

IMAGE WIDTH

(Only for

CUSTOM)

16 INCH *

( Range: 0,5...16 inch; in steps of 0.05 inch)

SOURCE LOWER *

UPPER

DESTINATION BOTTOM *

TOP ( Always with cutting )

BOTTOM CUT

ORIENTATION PORTRAIT *

LANDSCAPE

LANDSCAPE MODE REVERSE *

PCL COMPATIBLE

ORIENT. MODE FIXED *

AUTOMATIC

PAPER EXTENDED NO *

YES

PAPER SELECTION ONLY PJL *

RECOGNIZE

IGNORE

PAPER PATH

SELECT.

RECOGNIZE *

IGNORE

FUSER TEMP. MIDDLE *

HIGH

LOW

Page 33

Configuring the Printer

Paper Menu Value / Parameter

3-11

TONER DENSITY LOW

MIDDLE *

HIGH

ECO-TOP

MICR LOW

MICR MIDDLE

MICR HIGH

Note:

MICR is only available in PP 4050 MICR

printer.

VER SHIFT 0/100 INCH *

( Range: -50/100 up to +50/100 inch )

HOR SHIFT 0/100 INCH *

( Range: -50/100 up to +50/100 inch )

CUT SHIFT 0/100 INCH *

( Range: -50/100 up to +50/100 inch )

INIT LINE REGISTR. 1 *

( Choice: 1 up to 6 patterns)

1 = No correction

2 = Displacement on the first 2 pages by 0,5 mm

3 = Displacement on the first 2 pages by 1,0 mm

4 = Displacement on the first 2 pages by 1,5 mm

5 = Displacement on the first 5 pages up to 0,5 mm

6 = Displacement on the first 5 pages up to 1,0 mm

Configuring the Printer

3-12

PCL MENU

Entry Point = CHANGE PROFILE ---> PCL MENU

Note: The PCL MENU will be displayed if the EMULATION in the

GENERAL MENU is set to PCL

PCL Menu Value / Parameter

FONT NUMBER 0 *

( Range: Font No. 0 up to 54 )

PITCH 10.00 *

(For Font No. 0, 39...44 are values

0.44...99.99 CPI possible)

POINT SIZE 12.00 *

(For Font No. 1...38 are values

4.00...999.75 in

steps of 0.25 PT)

( Font No. 45...54 are not scalable )

SYMBOL SET ROMAN-8 *

ISO L1

....

( 31 symbol sets are selectable )

LINE SPACING 6 LINES/ INCH *

( Range: 1,2,3...48 LPI )

TOP MARGIN 0 LINES *

( Range: 0 - 999 lines )

LEFT MARGIN 0 COLUMNS *

( Range: 0 - 999 columns )

RIGHT MARGIN MAXIMUM *

( Range: 0 - 999 columns and Maximum )

TEXT LENGTH 72 LINES *

( Range: 0 - 999 lines )

PERF. SKIP OFF *

ON

$$ COMMANDS OFF

ON

Page 34

Configuring the Printer

3-13

HEXDUMP MENU

Entry Point = CHANGE PROFILE ---> HEXDUMP MENU

Note: The HEXDUMP MENU will be displayed if the EMULATION in the

GENERAL MENU is set to HEXDUMP

Hexdump Menu Value / Parameter

UEL COMMAND RECOGNIZE *

IGNORE

Configuring the Printer

3-14

GENERAL MENU

Entry Point = CHANGE PROFILE ---> GENERAL MENU

General Menu Value / Parameter

EMULATION PCL *

HEXDUMP

AUTO FORM FEED OFF *

(Range: OFF or 1 - 120 sec.)

AUTOMATIC CUT OFF *

(Range: OFF or 1 - 120 sec.)

JOB SEPARATION OFF *

ON

TRACTOR CHANGE CUT ON *

OFF

REPRINT LAST PAGE OFF *

ON

Page 35