EOM

Engineering

Operation &

Maintenance

XSD

Advanced™ Metal

Surge Dampener

Where Innovation Flows

www.wildenpump.com

REPLACES WIL-19011-E-0 6

WI L-19 011 - E - 07

TABLE OF CONTENTS

SECTION 1 CAUTIONS—READ FIRST! ..............................................1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM .................................2

SECTION 3 HOW IT WORKS—PUMP & AIR DISTRIBUTION SYSTEM ................3

SECTION 4 DIMENSIONAL DRAWINGS .............................................4

SECTION 5 PERFORMANCE

XSD1 ...................................................................6

XSD2 ...................................................................7

XSD3 ...................................................................8

SECTION 6 SUGGESTED INSTALLATION & TROUBLESHOOTING .....................9

SECTION 7 DISASSEMBLY / REASSEMBLY ........................................11

Reassembly Hints & Tips ..................................................14

SECTION 8 EXPLODED VIEW & PARTS LISTING

XSD1 Metal

PTFE/Rubber/SIPD/Ultra-Flex™-Fitted ...................................16

XSD2 Metal

PTFE/Rubber/SIPD/Ultra-Flex™-Fitted ...................................18

XSD2 Metal Advanced

PTFE/Rubber/SIPD/Ultra-Flex™-Fitted ...................................20

XSD3 Metal

PTFE/Rubber/Ultra-Flex™-Fitted ........................................22

SECTION 9 ELASTOMER OPTIONS .................................................24

Section 1

CAUTIONS—READ FIRST!

CAUTION: Do not over-lubricate air supply —

excess lubrication will reduce performance.

CAUTION: Do not exceed 8.6 bar (125 psig) air

supply pressure.

CAUTION: When choosing dampener materials,

be sure to check the temperature limits for

all wetted components. Example: Viton®

has a maximum limit of 177°C (350°F) but

polypropylene has a maximum limit of only 79°C

(175°F) .

CAUTION: Maximum temperature limits are

based upon mechanical stress only. Certain

chemicals will significantly reduce maximum

safe operating temperatures. Consult Chemical

Resistance Guide (E4) for chemical compatibility

and temperature limits.

TEMPERATURE LIMITS:

Polypropylene 0°C to 79°C 32°F to 175°F

PVDF –12°C to 107°C 10°F to 225°F

PFA 7°C to 107°C 20°F to 225°F

Neoprene –18°C to 93°C 0°F to 200°F

Buna-N –12°C to 82°C 10°F to 180°F

EPDM –51°C to 138°C –60°F to 280°F

Viton

®

FKM –40°C to 177°C –40°F to 350°F

Wil-Flex™ –40°C to 107°C –40°F to 225°F

Saniflex™ –29°C to 104°C –20°F to 220°F

Polyurethane –12°C to 66°C 10°F to 150°F

Polytetrafluoroethylene (PTFE)1 4°C to 104°C 40°F to 220°F

EPDM –51°C to 138°C –60°F to 280°F

Nylon –18°C to 93°C 0°F to 200°F

Acetal –29°C to 82°C –20°F to 180°F

SIPD PTFE

SIPD PTFE

with

Neoprene-backed

with

EPDM-backed –10°C to 137°C 14°F to 280°F

4°C to 104°C 40°F to 220°F

Polyethylene 0°C to 70°C 32°F to 158°F

Geolast

1

®

–40°C to 82°C –40°F to 180°F

4°C to 149°C (40°F to 300°F) - 13 mm (1/2”) and 25 mm (1”) models only.

NOTE: Not all materials are available for all

models. Refer to Section 2 for material options

for your pump.

CAUTION: The process fluid and cleaning fluids

must be chemically compatible with all wetted

dampener components. Consult Chemical

Resistance Guide (E4).

CAUTION: Dampener(s) should be thoroughly

flushed before installing into process lines.

FDA- and USDA- approved dampeners should be

cleaned and/ or sanitized before being used.

CAUTION: Always wear safety glasses when

operating dampener. If diaphragm rupture

occurs, process fluid may be forced out air

exhaust.

CAUTION: Before any maintenance or repair

is attempted, the compressed air line to the

dampener and pump should be disconnected

and all air pressure allowed to bleed from the

system. Disconnect all intake, discharge and air

lines. Drain the dampener by allowing any fluid

to flow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to dampener to make sure all

pipeline debris is clear. Use an in-line air filter.

A 5μ (micron) air filter is recommended.

CAUTION: Dampeners cannot be used in

submersible applications.

CAUTION: Tighten all hardware prior to

installation.

CAUTION: ATEX products have been assessed

for use in potentially explosive atmospheres in

accordance with the European Directive 94/9/

EC (ATEX 95). Users of ATEX products must be

familiar with ATEX requirements and follow

all safety guidelines. (Refer to Wilden Safety

Supplement WIL-18510-E).

WARNING: Prevent static sparking. If static

sparking occurs, fire or explosion could result.

Dampener, pump, valves and containers must

be grounded to a proper grounding point

when handling flammable fluids and whenever

discharge of static electricity is a hazard.

WIL-19 011- E - 0 7 1 WILDEN PUMP & ENGINEERING, LLC

Section 2

WILDEN DESIGNATION SYSTEM

XSD EQUALIZER

®

LEGEND

XSD X/ XXX X / XX X / XX / XXXX

MATERIAL CODES

REGULATOR BODY

AIR CHAMBER

WETTED PARTS/ OUTER PISTON

INLET SIZE

EQUALIZER® SURGE DAMPENER

DIAPHRAGM

O-RINGS

SPECIALTY CODE

(if applicable)

SPECIALTY CODES

MODEL

XSD = ATEX EQUALIZER®

INLET SIZE

1 = 25 mm (1”)

2 = 51 mm (2”)

3 = 76 mm (3”)

NOTE:

1

XSD1 and XSD2 Only

2

XSD3 Only

SURGE DAMPENER

WETTED PATH/

OUTER PISTON

AA = ALUMINUM/ALUMINUM

SS = STAINLESS STEEL/

STAINLESS STEEL

AIR CHAMBER

A = ALUMINUM

S = STAINLESS STEEL

REGULATOR BODY

A = ALUMINUM

S = STAINLESS STEEL

DIAPHRAGM

BNS = BUNA-N (Red Dot)

FSS = SANIFLEX™ (Cream)

EPS = EPDM (Blue Dot)

NES = NEOPRENE (Green Dot)

PUS = POLYURETHANE (Clear)

TNU = PTFE W/NEOPRENE

TEU = PTFE W/EPDM

VTS = VITON® (Silver or

WFS = WIL-FLEX™ (Orange Dot)

XBS = CONDUCTIVE BUNA-N

ULTRA-FLEX™ DIAPHRAGM

BNU = BUNA-N (Red Dot)

EPU = EPDM (Blue Dot)

NEU = NEOPRENE (Green Dot)

VTU = VITON® (Silver or

O-RINGS

BN = BUNA-N

TF = PTFE (White)

TV = PTFE Encapsulated Viton

White Dot)

(Two Red Dots)

White Dot)

1

2

0014 BSPT

00 40 ASNI Flange Connection (Advanced

NOTE: MOST EL ASTOMERIC MATERIALS USE COLORED DOTS FOR IDEN TIFICATION.

®

Viton

is a registered trademark of DuPont Elastomers.

Hytrel® is a registered trademark of DuPont Elastomers.

Santoprene® is a registered trademark of Exxon Mobil Corporation.

TM

)

WILDEN PUMP & ENGINEERING, LLC 2 WIL-19 011- E - 0 7

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

LIQUID SIDE LIQUID SIDE LIQUID SIDE

DIAPHRAGM DIAPHRAGM DIAPHRAGM

AIR

SIDE

AIR

SIDE

AIR

SIDE

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

AIR

SIDE

AIR

SIDE

AIR

REGULATOR

BODY

AIR

SIDE

Section 3

HOW IT WORKS—DAMPENER

All reciprocating pumps generate discharge pressure

fluctuation. The Equalizer

®

minimizes unwanted pressure

fluctuation by providing a supplementary pumping action.

This is accomplished by using a diaphragm as a separation

membrane within the Equalizer

®

to trap a given volume of

liquid on one side and pressurized air on the other.

When the fluid pressure falls in the system, the Equalizer

®

supplies additional pressure to the discharge line between

pump strokes by displacing fluid via diaphragm movement.

This movement provides the supplementary pumping

action needed to reduce pressure variation and pulsation.

PHASE 1 PHASE 3PHASE 2

The Equalizer

®

automatically sets and maintains the

correct air pressure matching the variations in liquid

flow or discharge pressure generated by the pump. A

shaft attached to the Equalizer

®

diaphragm triggers the

addition or removal of the air within the non-wetted side

of the Equalizer

to any pressure and/or flow setting of the pump with no

need for manual adjustment of the unit and/or system.

The Equalizer

®

. The Equalizer® automatically adjusts

®

has proven to be the cost effective choice

for protecting your liquid process system from unwanted

pulsation or pressure fluctuation. Contact your local Wilden

distributor for further information on the Equalizer

other pumping solutions.

®

and

A compressed air line attached to the air regulator body sets

and maintains pressure on the air side of the diaphragm. As

the reciprocating pump begins its stroke, liquid discharge

pressure increases which flexes the Equalizer

®

diaphragm

inward. This action accumulates fluid in the liquid chamber

(see Phase 2) and the air regulator allows compressed air

upon stroke completion, the liquid discharge pressure

decreases and compressed air in the air side forces the

Equalizer

into the discharge line (see Phase 3). This motion provides

the supplementary pumping action needed to minimize

pressure fluctuation.

to enter the air side. When the pump redirects its motion

®

diaphragm to flex outward displacing the fluid

WIL-19 011- E - 0 7 3 WILDEN PUMP & ENGINEERING, LLC

Section 4

XSD1

DIMENSIONAL DRAWINGS

DIMENSIONS — XSD1 METAL

DIMENSION METRIC (mm) STANDARD (inch)

A 295 11.6

B 244 9.6

C 147 5.8

D 295 11.6

E 297 11.7

XSD2

DIMENSIONS — XSD2 METAL

DIMENSION METRIC (mm) STANDARD (inch)

A 315 12.4

B 257 10.1

C 244 9.6

D 455 17.9

E 345 13.6

WILDEN PUMP & ENGINEERING, LLC 4 WIL-19 011- E - 0 7

DIMENSIONAL DRAWINGS

XSD2 Advanced

XSD3

TM

DIMENSIONS -

XSD2 ADVANCED METAL

ITEM METRIC (mm) STANDARD (inch)

A 345 13.6

B 257 10.1

C 279 11.0

D 513 20.2

E 325 12.8

DIN

F 125 DIA 4.9 DIA

G 165 DIA 6.5 DIA

H 18 DIA 0.7 DIA

ANSI

F 122 DIA 4.8 DIA

G 165 DIA 6.5 DIA

H 20 DIA 0.8 DIA

DIMENSIONS — XSD3 METAL

DIMENSION METRIC (mm) STANDARD (inch)

A 399 15.7

B 320 12.6

C 295 11.6

D 556 21.9

E 424 16.7

WIL-19 011- E - 0 7 5 WILDEN PUMP & ENGINEERING, LLC

Section 5

XSD1 TNU

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Time (sec)

0 0.5 1 1.5 2 2.5 3 3.5

Discharge Head

[bar (psig)]

1.4 (20)

2.8 (40)

4.1 (60)

5.5 (80)

6.9 (100)

8.3 (120)

0

0

1.4 (20)

2.8 (40)

4.1 (60)

5.5 (80)

6.9 (100)

8.3 (120)

1 1.5 2 2.5 3 3.5

XSD1 BNU

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Discharge Head

[bar (psig)]

Time (sec)

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

5.5 (80)

4.8 (70)

4.1 (60)

3.4 (50)

2.8 (40)

2.1 (30)

1.4 (20)

0.7 (10)

0

Discharge Head [bar (psig)]

1 2

XSD1 PERFORMANCE

XSD1 TNU

Time (sec)

XSD1 BNS

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

4.8 (70)

4.1 (60)

3.4 (50)

2.8 (40)

2.1 (30)

1.4 (20)

0.7 (10)

0

Discharge Head [bar (psig)]

1 1.5 2 2.5 3 3.5

Time (sec)

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

XSD1 BNS

8.3 (120)

6.9 (100)

5.5 (80)

4.1 (60)

2.8 (40)

1.4 (20)

0

Discharge Head [bar (psig)]

1 1.5 2 2.5 3 3.5

Time (sec)

These charts show discharge head fluctuations for a

diaphragm pump with and without a dampener. By

reviewing the variation in pressure, the level of dampening

can be estimated for an application. For example, the head

pressure generated by a 25 mm (1”) pump operating at

6.89 bar (100 psig) air inlet pressure and 6.2 bar (90 psig)

head pressure varies between 1.7 bar (25 psig) and 7.2

WILDEN PUMP & ENGINEERING, LLC 6 WIL-19 011- E - 0 7

bar (104 psig) resulting in a total pressure fluctuation of

5.5 bar (79 psig) for each stroke. When an XSD1/AAAA/

TNU/TF dampener is installed in the application, the

head pressure varies between 4.8 bar (69 psig) and 6.6

bar (96 psig) resulting in a pressure fluctuation of only

1.9 bar (27 psig). This results in a 67% reduction in head

pressure fluctuation.

XSD2 PERFORMANCE

XSD2 BNS

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

Discharge Head

[bar (psig)]

Time (sec)

0

0.7 (10)

1.4 (20)

2.1 (30)

2.8 (40)

3.4 (50)

4.1 (60)

4.8 (70)

0 1 2 3 4 5

0 1 2 3 4 5

XSD2 BNS

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Discharge Head

[bar (psig)]

Time

(sec)

1.4 (20)

0

2.8 (40)

4.1 (60)

5.5 (80)

6.9 (100)

8.3 (120)

1 2 3 4 5

XSD2 TNU

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

Discharge Head

[bar (psig)]

Time (sec)

0

1.4 (20)

2.8 (40)

4.1 (60)

5.5 (80)

0

20

40

60

80

100

120

0 1.5 2 2.5 3 3.5 4 4.5 5

XSD2 TNU

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Discharge Head

[bar (psig)]

Time

(sec)

0 1.5 2 2.5 3 3.5 4 4.5 5

XSD2 BNU

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Discharge Head

[bar (psig)]

Time

(sec)

0

1.4 (20)

2.8 (40)

4.1 (60)

5.5 (80)

6.9 (100)

8.3 (120)

1 2 3 4 5

XSD2 BNU

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

Discharge Head

[bar (psig)]

Time

(sec)

0

0.7 (10)

1.4 (20)

2.1 (30)

2.8 (40)

3.4 (50)

4.1 (60)

These charts show discharge head fluctuations for a

diaphragm pump with and without a dampener. By

reviewing the variation in pressure, the level of dampening

can be estimated for an application. For example

in reference to XSD2 BNS 100/90, the head pressure

generated by a 51 mm (2") pump operating at 6.89 bar (100

psig) air inlet pressure and 6.2 bar (90 psig) head pressure

WIL-19 011- E - 0 7 7 WILDEN PUMP & ENGINEERING, LLC

varies between 0.4 bar (6 psig) and 7 bar (102 psig)

resulting in a total pressure fluctuation of 6.6 bar (96 psig)

for each stroke. When an XSD2/AAAA/BNS/BN dampener

is installed in the application, the head pressure varies

between 4.7 bar (68 psig) and 6.8 bar (99 psig) resulting in

a pressure fluctuation of only 2.1 bar (31 psig). This results

in a 68% reduction in head pressure fluctuation.

XSD3 PERFORMANCE

1 2 3 4 5 6 7

XSD3 TNU

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Discharge Head

[bar (psig)]

Time

(sec)

0

1.4 (20)

2.8 (40)

4.1 (60)

5.5 (80)

6.9 (100)

8.3 (120)

1 2 3 4 5 6 7

XSD3 TNU

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

Discharge Head

[bar (psig)]

Time (sec)

0.7 (10)

0

1.4 (20)

2.1 (30)

2.8 (40)

3.4 (50)

4.1 (60)

1 2 3 4 5 6 7

XSD3 BNU

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Discharge Head

[bar (psig)]

Time

(sec)

0

1.4 (20)

2.8 (40)

4.1 (60)

5.5 (80)

6.9 (100)

8.3 (120)

1 2 3 4 5 6 7

XSD3 BNU

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

Discharge Head

[bar (psig)]

Time (sec)

0.7 (10)

0

1.4 (20)

2.1 (30)

2.8 (40)

3.4 (50)

4.1 (60)

1 2 3 4 5 6 7

XSD3 BNS

[6.89 bar (100 psig) inlet air / 6.2 bar (90 psig) discharge head]

Discharge Head

[bar (psig)]

Time

(sec)

0

1.4 (20)

2.8 (40)

4.1 (60)

5.5 (80)

6.9 (100)

8.3 (120)

1 2 3 4 5 6 7

XSD3 BNS

[4.1 bar (60 psig) inlet air / 3.4 bar (50 psig) discharge head]

Discharge Head

[bar (psig)]

Time (sec)

0.7 (10)

0

1.4 (20)

2.1 (30)

2.8 (40)

3.4 (50)

4.1 (60)

These charts show discharge head fluctuations for a

diaphragm pump with and without a dampener. By

reviewing the variation in pressure, the level of dampening

can be estimated for an application. For example

(XSD3 BNU 100/90), the head pressure generated by

a 76 mm (3”) pump operating at 6.89 bar (100 psig) air

inlet pressure and 6.2 bar (90 psig) head pressure varies

WILDEN PUMP & ENGINEERING, LLC 8 WIL-19 011- E - 0 7

between 2.1 bar (30 psig) and 6.5 bar (94 psig) resulting

in a total pressure fluctuation of 4.4 bar (64 psig) for

each stroke. When an XSD3/AAAA/BNU/BN dampener

is installed in the application, the head pressure varies

between 4.8 bar (69 psig) and 6.3 bar (91 psig) resulting of

a pressure fluctuation of only 1.5 bar (22 psig). This results

in a 66% reduction in head pressure fluctuation.

Section 6

SUGGESTED INSTALLATION

The model XSD1 has a 25 mm (1") inlet/discharge. The model

XSD2 has a 51 mm (2") inlet/discharge and the XSD3 has a

76 mm (3") inlet/discharge. The Equalizer® can be installed

in either horizontal or vertical orientations. A variety of

materials are available to satisfy temperature, chemical

compatibility, abrasion and flex concerns.

The Equalizer

®

installed on the discharge side of the pump

minimizes pulsation and protects in-line equipment. It can

also be connected on the suction side to prevent water

hammer associated with a positive inlet condition.

Install the Equalizer

®

as shown below. The use of flexible

connections and a Filter, Regulator, Lubricator (FRL) will

extend parts life. Shut-off valves on the suction side of

FLEXIBLE CONNECTION

PRESSURE GAUGE

SHUT-OFF VALVE

SHUT-OFF VALVE

SUCTION LINE

pump and the discharge side of Equalizer

®

will enable

maintenance personnel to safely service the equipment.

To maximize effectiveness, install the Equalizer® as close

as possible to the discharge of the pump.

It is important to support the pipe immediately

downstream from the Equalizer

®

. Use a tee connector

on the pump air supply line and connect the line to the

Equalizer® regulator body. This tee connector should be

installed after the FRL. The Equalizer® consumes very

little air, therefore, a 1/4” hose is more than adequate to

supply enough air volume. When the air supply to the

pump is shut down, the air to the Equalizer® will be shut

off as well.

PRESSURE GAUGE

AIR INLET

AIR SUPPLY

AIR SHUT-OFF VALVE

COMBINATION FILTER AND REGULATOR

NEEDLE VALVE

SHUT-OFF VALVE

SHUT-OFF VALVE

DISCHARGE LINE

FLEXIBLE CONNECTION

NOTE: In the event of a power failure, the shut-off

valve should be closed if the restarting of the pump is

not desirable once power is regained.

the shut-off valve (user supplied) installed in the air

supply line. A properly functioning valve will stop the

air supply to the pump, therefore stopping output. This

shut-of f valve should be located far enough away from

AIR-OPERATED PUMPS: To stop the pump from

operating in an emergency situation, simply close

WIL-19 011- E - 0 7 9 WILDEN PUMP & ENGINEERING, LLC

the pumping equipment such that it can be reached

safely in an emergency situation.

TROUBLESHOOTING

1) When there is a significant drop in the fluid discharge

pressure, there will be a noticeable release of air

through the small bleed hole in the air regulator

body. This is how the Equalizer

®

automatically adjusts

itself for optimal suppression. This is a good way

of verifying proper operation of the unit. If there is

a continuous discharge of air out of this hole during

®

steady fluid discharge pressure, the Equalizer

is not

functioning properly and should be inspected. The air

regulator body houses three (3) Glyd rings.

2) Fluid leakage around the clamp band area is normally

stopped by tightening the clamp band bolts. If

leakage continues, unit should be disassembled and

inspected.

3) Air leakage between the adapter plate and air chamber

requires tightening of four air chamber bolts on the

inside of the air chamber.

WILDEN PUMP & ENGINEERING, LLC 10 WIL-19 011- E - 0 7

Section 7

DAMPENER DISASSEMBLY

Tools Required:

• Deep well sockets and

ratchet (7/16”, 1/2” and

3/4”)

®

• Hex (Allen

(3/16” and 1/4”)

• Large adjustable wrench

or channel lock pliers

) wrenches

Tools Recommended:

• Large pipe wrench

• Vise equipped w/soft

jaws (such as aluminum,

plastic, plywood or other

suitable material)

CAUTION: Before any maintenance or repair is attempted, the compressed

air line to the Equalizer

pressure allowed to bleed from the system. Disconnect all intake, discharge,

and air lines. Be aware of any hazardous ef fects of contact with your process

fluid. PLEASE READ ALL DIRECTIONS BEFORE STARTING DISASSEMBLY.

NOTE: The model photographed for these instructions is a XSD1. Other

Equalizer

different components and fastener sizes.

®

models should be similar in design but may contain slightly

®

and the pump should be disconnected and all air

Step 1

Disassembly of the surge ends/

small clamp band is needed only

in the event of leakage. Leakage is

usually stopped by tightening the

small band bolts using a 7/16” deep

well socket.

WIL-19 011- E - 0 7 11 WILDEN PUMP & ENGINEERING, LLC

Step 2

If leakage persists, remove surge

ends and replace O-rings.

Step 3

Remove large clamp band using a

1/2” deep well socket.

DAMPENER DISASSEMBLY

Step 4

Set liquid chamber aside.

Step 5

Remove reducer bushing at top of

regulator.

Step 6

Loosen shaft assembly by using

adjustable wrench on outer piston

and 3/4” socket on shaft bolt inside

air regulator body. Turn counter

clockwise. One of two scenarios will

occur: outer piston will loosen from

shaft, or the shaft bolt will loosen

from shaft.

Step 7

In either case, this will allow the

removal of the inner and outer

pistons, diaphragm, shaft stop,

shaft, shaft stop washer and bolt.

WILDEN PUMP & ENGINEERING, LLC 12 WIL-19 011- E - 0 7

Step 8

Inspect shaft for nicks or abrasion.

Small nicks can usually be dressed

out. If shaft is chemically attacked or

nicks are hindering operation, shaft

should be replaced.

Step 9

Disassembly of the air chamber

from the regulator adaptor plate

is needed only in the event of air

leakage.

DAMPENER DISASSEMBLY

Step 10

In the event of an air leak, remove

the air chamber and replace the

gasket.

Step 11

Disassembly of the regulator body

from the regulator adaptor plate

is needed only in the event of air

leakage.

1

3

5

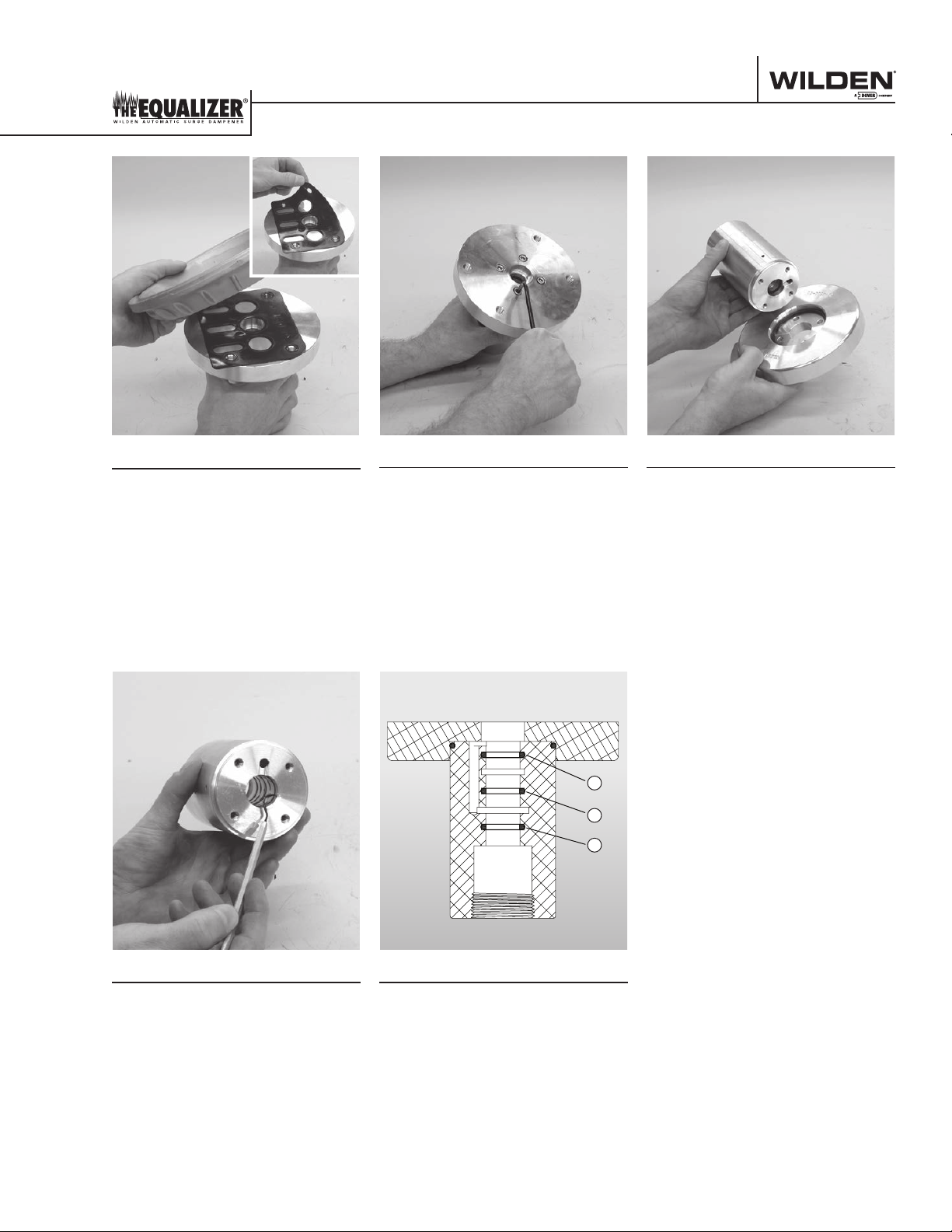

Step 12

In the event of an air leak, remove

the regulator adaptor plate and

replace the O-ring.

Step 13

Using an O-ring pick, remove the

Glyd rings from air regulator body.

Step 14

The air regulator body has five

(5) grooves cut into the inside

diameter. There are three Glyd rings

installed in the 1, 3 and 5 positions.

It is important that these Glyd rings

be installed in the correct grooves

®

so that the Equalizer

functions

properly. Please refer to the drawing

for the correct location of the Glyd

rings.

WIL-19 011- E - 0 7 13 WILDEN PUMP & ENGINEERING, LLC

REASSEMBLY HINTS & TIPS

AS SE MB LY:

Upon performing applicable maintenance to the

air distribution system, the Equalizer® can now

be reassembled. Please refer to the disassembly

instructions for photos and parts placement. To

reassemble the Equalizer®, follow the disassembly

instructions in reverse order. The air regulator body

needs to be assembled first, then the diaphragm and

finally the wetted path. Please find the applicable

torque specifications on this page. The following tips

will assist in the assembly process.

• Lubricate air regulator body , Glyd rings and shaft

bore center with NLGI grade 2 white EP bearing

grease or equivalent.

• Clean the inside of the air regulator body bore to

ensure no damage is done to new shaft seals.

• Stainless bolts should be lubed to reduce the

possibility of seizing during tightening.

MAXIMUM TORQUE SPECIFICATIONS

Model Description of Part Torque

Air chamber/adapter plate 24.4 N·m (18 ft-lb)

Air regulator body/adapter plate 7.9 N·m (70 in-lb)

XSD1

Outer piston/shaft bolt assembly

(all diaphragms)

Air chamber/adapter plate 24.4 N·m (18 ft-lb)

Air chamber/adapter plate 7.9 N·m (70 in-lb)

Outer piston/shaft bolt assembly

XSD2

(rubber & PTFE)

Outer piston/shaft bolt assembly

(Ultra-Flex™ & SIPD)

Air chamber/adapter plate 44.7 N·m (33 ft-lb)

Air regulator body/adapter plate 7.9 N·m (70 in-lb)

XSD3

Outer piston/shaft bolt assembly

(all diaphragms)

Figure A

SHA FT SE AL

54.2 N·m (40 ft-lb)

109 N·m (80 ft-lb)

74.6 N·m (55 ft-lb)

136 N·m (100 ft-lb)

SHAFT SEAL INSTALLATION:

PRE-INSTALLATION

• Once all of the old seals have been removed, the

inside of the air regulator body should be cleaned

to ensure no debris is left that may cause premature

damage to the new seals.

INSTALLATION

The following tools can be used to aid in the installation

of the new seals:

Needle Nose Pliers

Phillips Screwdriver

Electrical Tape

• Wrap electrical tape around each leg of the needle nose

pliers (heat shrink tubing may also be used). This is done

to prevent damaging the inside surface of the new seal.

• With a new seal in hand, place the two legs of the needle

nose pliers inside the seal ring. (See Figure A.)

• Open the pliers as wide as the seal diameter will allow,

then with two fingers pull down on the top portion of

the seal to form kidney bean shape. (See Figure B.)

• Lightly clamp the pliers together to hold the seal into

the kidney shape. Be sure to pull the seal into as tight

of a kidney shape as possible, this will allow the seal to

travel down the bushing bore easier.

• With the seal clamped in the pliers, insert the seal into

the bushing bore and position the bottom of the seal

into the correct groove. Once the bottom of the seal is

seated in the groove, release the clamp pressure on the

pliers. This will allow the seal to partially snap back to its

original shape.

• After the pliers are removed, you will notice a slight

bump in the seal shape. Before the seal can be properly

resized, the bump in the seal should be removed as

much as possible. This can be done with either the

Phillips screwdriver or your finger. With either the side

of the screwdriver or your finger, apply light pressure

to the peak of the bump. This pressure will cause the

bump to be almost completely eliminated.

• Lubricate the edge of the shaft with NLGI grade 2

white EP bearing

• Slowly insert the center shaft with a rotating motion.

This will complete the resizing of the seal.

• Perform these steps for the remaining seal.

Figure B

grease.

NEEDLE NOSE

PLIERS

TAPE

WILDEN PUMP & ENGINEERING, LLC 14 WIL-19 011- E - 0 7

SHA FT SE AL

TAPE

NOTES

Section 8

EXPLODED VIEW & PARTS LISTING

XSD1 ORIGINAL

7

TM

28

27

26

1

3

4

5

6

8

METAL

2

EXPLODED VIEW

27

26

19

20

21

22

24

23

25

PTFE FITTED

RUBBER FITTED

19

20

21

22

23

25

10

11

17

13

12

9

14

16

15

18

27

26

19

20

21

22

23

27

29

26

19

21

22

23

25

SIPD FITTED

ULTRA-FLEX FITTED

WILDEN PUMP & ENGINEERING, LLC 16 WIL-19 011- E- 07

EXPLODED VIEW & PARTS LISTING

XSD1 ORIGINAL

No. Part Description Qty.

1 Body, Regulator

2 Ring II, Glyd 3 08-3210-55-225 08-3210-55-225

3 O-Ring -230 (Ø2.484 x Ø.139) 1 76-1285-52 76-1285-52

4 Plate, Regulator Adapter 1 76-8510-01 76-8510-03

5 Screw, 1/4-20 x .75 Soc Hd Cap 4 76-6250-03 76-6250-03

6 Gasket, Center Block 1 04-3529-52 04-3529-52

7 Chamber, Air 1 04-3660-01 04-3660-03

8 Screw, 3/8-16 x 1.00 Soc Flt Csk Hd Cap 4 71-6250-08 71-6250-08

9 Chamber, Liquid 1 04-5000-01 04-5000-03

10 Clamp Band, Half 2 04-7330-08 04-7330-03

11 Bolt, 5/16-18 x 2.50 Rnd Hd Sq Neck 2 04-6070-03 04-6070-03

12 Washer, Plain 2 01-6732-03 01-6732-03

13 Nut, 5/16-18 Hex 2 04-6420-08 08-6400-03

14 O-Ring -229 (Ø2.359 x Ø.139) 2 * *

15 End, 1” NPT Surge 2 70-8600-01 70-8600-03

End, 1” BSPT Surge 2 70-8600-01-14 70-8600-03-14

16 Clamp Band Small 4 04-7100-08 04-7100-03

17 Bolt, 1/4-20 x 2.00 Rnd Hd Sq Neck 4 04-6050-08 01-6070-03

18 Nut, 1/4-20 Hex 4 04-6400-08 04-6400-03

19 Shaft, Straight 1 76-3800-03 76-3800-03

Shaft, Ultra-Flex™ 1 04-3830-03-07 04-3830-03-07

20 Stud, 1/2-20 x 1.50 Threaded 1 04-6150-08 04-6150-08

21 Stop, Shaft 1 76-8800-17 76-8800-17

22 Piston, Rubber & TPE Inner 1 04-3700-01-700 04-3700-01-700

Piston, Ultra-Flex™ Inner 1 04-3760-01-700 04-3760-01-700

Piston, PTFE Inner 1 04-3755-01 04-3755-01

Piston, SIPD Inner 1 04-3700-08 04-3700-08

23 Diaphragm, Primary 1 * *

Diaphragm, Ultra-Flex™ 1 * *

Diaphragm, PTFE 1 * *

Diaphragm, SIPD 1 * *

24 Diaphragm, Back-Up 1 * *

25 Piston, Rubber & TPE Outer 1 04-4552-01 04-4550-03

Piston, Ultra-Flex™ Outer 1 04-4560-01 02-4550-03

Piston, PTFE Outer 1 04-4600-01 04-4600-03

26 Washer, Stop 1 70-6790-08 70-6790-08

27 Screw, Hex Cap, 1/2-20 x 1.00 1 04-6090-08 04-6090-08

Screw, Hex Hd Cap, 3/8-16 x .88, Ultra-Flex™ 1 08-6140-08 08-6140-08

28 Reducer Bushing 1 70-6950-08 71-6950-03

29 Washer, (.406 ID x .812 OD x .065 THK) Ultra-Flex™ 1 15-6740-08-50 15-6740-08-50

1

Air Regulator Body includes qty. 3 Glyd Rings.

*Elastomer options listed on page 24.

All Bold face items are primary wear items.

TM

METAL

XSD1/AAAA/

P/N

1

1 76-8515-01 76-8515-03

XSD1/SSSS/

PARTS LISTING

P/N

WIL-19 011- E - 0 7 17 WILDEN PUMP & ENGINEERING, LLC

EXPLODED VIEW & PARTS LISTING

XSD2 ORIGINAL

7

TM

METAL

27

26

25

1

2

3

4

5

6

8

18

EXPLODED VIEW

26

25

18

20

19

21

23

22

24

26

25

18

20

19

21

22

24

PTFE FITTED

RUBBER FITTED

20

19

21

22

24

10

11

16

12

9

13

14

15

17

26

25

18

20

19

21

22

26

25

18

20

19

21

22

24

SIPD FITTED

ULTRA-FLEX FITTED

WILDEN PUMP & ENGINEERING, LLC 18 W IL-19 0 11- E-07

EXPLODED VIEW & PARTS LISTING

XSD2 ORIGINAL

No. Part Description Qty.

1 Body, Regulator

2 Ring II, Glyd 3 08-3210-55-225 08-3210-55-225

3 O-Ring -230 (Ø2.484 x Ø.139) 1 76-1285-52 76-1285-52

4 Plate, Regulator Adapter 1 76-8510-01 76-8510-03

5 Screw, 1/4-20 x .75 Soc Hd Cap 4 76-6250-03 76-6250-03

6 Gasket, Center Block 1 04-3529-52 04-3529-52

7 Chamber, Air 1 08-3660-01 08-3660-03

8 Screw, 3/8-16 x 1.00 Soc Flt Csk Hd Cap 4 71-6250-08 71-6250-08

9 Chamber, Liquid 1 08-5000-01 08-5000-03

10 Clamp Band, Half 2 08-7300-08 08-7300-03

11 Screw, 3/8-16 x 3.00 Hex Cap 2 08-6120-08 08-6120-03

12 Nut, 3/8-16 Heavy Hex 2 08-6450-08 08-6450-03

13 O-Ring -235 (Ø3.109 x Ø.139) 2 * 71-1280-55

14 End, 2” NPT Surge 2 71-8601-01 71-8601-03

End, 2” BSPT Surge 2 71-8601-01-14 71-8601-03-14

15 Band, Small Clamp 4 08-7100-08 08-7100-08

16 Bolt, 5/16-18 x 1.50 Rnd Hd Sq Neck 4 08-6050-08 08-6050-08

17 Nut, 5/16-18 Hex 4 04-6420-08 04-6420-03

18 Shaft, Straight 1 77-3800-03 77-3800-03

19 Stop, Shaft 1 71-8800-17 71-8800-17

20 Adapter, Shaft Stud Rubber Fitted 1 71-6153-08 71-6153-08

Stud, 1/2- 20 x 1.88 Threaded Ultra-Flex 1 08-6150-08 08-6150-08

Stud, 1/2- 20 x 2.13 Threaded PTFE 08-6152-08 08-6152-08

21 Piston, Rubber & TPE Inner 1 08-3700-01 08-3700-01

Piston, Ultra-Flex

Piston, PTFE Inner 1 08-3750-01 08-3750-01

Piston, SIPD Inner 1 04-3700-08 04-3700-08

22 Diaphragm, Primary 1 * *

Diaphragm, Ultra-Flex

Diaphragm, PTFE 1 * *

Diaphragm, SIPD 1 * *

23 Diaphragm, Backup 1 * *

24 Piston, Rubber & TPE Outer 1 08-4550-01 08-4550-03

Piston, Ultra-Flex

Piston, PTFE Outer 1 08-4600-01 08-4600-03

25 Washer, Stop 1 70-6790-08 70-6790-08

26 Screw, 1/2-20 x 1.00 Hex Cap 1 04-6090-08 04-6090-08

27 Reducer Bushing 1 70-6950-08 70-6950-08

TM

METAL

XSD2/AAAA

P/N

1

™

Inner 1 08-3761-01 08-3761-01

™

™

Outer 1 04-4552-01 04-4550-03

1 76-8515-01 76-8515-03

1 * *

PARTS LISTING

XSD2/SSSS

P/N

1

Air Regulator Body includes qty. 3 Glyd Rings.

*Elastomer options listed on page 24.

All Bold face items are primary wear items.

WIL-19 011- E - 0 7 19 WILDEN PUMP & ENGINEERING, LLC

EXPLODED VIEW & PARTS LISTING

XSD2 ADVANCEDTM METAL

EXPLODED VIEW

WILDEN PUMP & ENGINEERING, LLC 20 WIL-19 0 11- E-07

EXPLODED VIEW & PARTS LISTING

XSD2 ADVANCEDTM METAL

XSD2/AAAA/040

No. Part Description Qty.

1 Body, Regulator

2 Ring II, Glyd 3 08-3210-55-225

3 O-Ring -230 (Ø2.484 x Ø.139) 1 76-1285-52

4 Plate, Regulator Adapter 1 76-8510-01

5 Screw, 1/4-20 x .75 Soc Hd Cap 4 76-6250-03

6 Gasket, Center Block 1 04-3529-52

7 Chamber, Air 1 08-3690-01

8 Screw, 3/8-16 x 1.00 Soc Flt Csk Hd Cap 4 71-6250-08

9 Chamber, Liquid 1 71-5000-03-42

10 Washer (Type A), Plain 14 02-6730-03

11 Screw, 3/8-16 x 1.75 Hex Cap 14 04-6181-03

12 Spring (Belleville Type), Disk 14 08-6820-03-42

13 Nut, 3/8-16 Hex 14 02-6430-03

14 Shaft, Straight 1 77-3800-03

15 Adapter, Shaft Stud Rubber Fitted 1 71-6153-08

Stud, 1/2-20 x 1.88 Threaded Ultra-Flex

Stud, 1/2-20 x 2.13 Threaded PTFE 1 08-6152-08

16 Stop, Shaft 1 71-8800-17

17 Piston, Rubber & TPE Inner 1 08-3700-01

Piston, Ultra-Flex™ Inner 1 08-3761-01

Piston, PTFE Inner 1 08-3750-01

Piston, SIPD Inner 1 04-3700-08

18 Diaphragm, Primary 1 *

Diaphargm Ultra-Flex

Diaphargm, PTFE 1 *

Diaphragm, SIP 1 *

19 Diaphragm, Backup 1 *

20 Piston, Rubber & TPEOuter 1 08-4550-03

Piston, Ultra-Flex

Piston, PTFE Outer 1 08-4600-03

21 Washer, Stop 1 70-6790-08

22 Screw, 1/2-20 x 1.00 Hex Cap 1 04-6090-08

23 Reducer Bushing 1 70-6950-08

1

Air Regulator Body includes qty. 3 Glyd Rings.

*Elastomer options listed on page 24.

All Bold face items are primary wear items.

1

™

™

™

Outer 1 04-4550-03

1 76-8515-01

1 08-6150-08

1 *

PARTS LISTING

P/N

WIL-19 011- E - 0 7 21 WILDEN PUMP & ENGINEERING, LLC

EXPLODED VIEW & PARTS LISTING

XSD3 ORIGINAL

6

7

TM

28

27

26

1

2

3

4

5

8

9

19

METAL

EXPLODED VIEW

27

26

19

20

21

22

24

23

25

27

26

19

20

21

9

8

PTFE FITTED

RUBBER FITTED

20

21

22

23

25

12

13

10

11

14

17

16

15

18

22

23

25

ULTRA-FLEX FITTED

27

29

26

19

21

22

23

25

WILDEN PUMP & ENGINEERING, LLC 22 WIL-19 0 11- E-07

EXPLODED VIEW & PARTS LISTING

XSD3 ORIGINAL

No. Part Description Qty.

1 Body, Regulator

2 Ring II, Glyd 3 15-3210-55-225 15-3210-55-225

3 O-Ring -230 (Ø2.484 x Ø.139) 1 76-1285-52 76-1285-52

4 Plate, Regulator Adapter 1 76-8510-01 76-8510-03

5 Screw, 1/4-20 x .75 Soc Hd Cap 4 76-6250-03 76-6250-03

6 Gasket, Center Block 1 04-3529-52 04-3529-52

7 Chamber, Air 1 15-3660-01 15-3660-03

8 Washer, Plain 10 15-6740-08-50 15-6740-08-50

9 Screw, 3/8-16 x 1.13 Hex Cap 10 15-6130-08 15-6130-08

10 Chamber, Liquid 1 15-5000-01 15-5000-03

11 Clamp Band, Half 2 15-7300-08 15-7300-03

12 Screw, 1/2-13 x 3.50 Hex Cap 2 15-6120-08 15-6120-03

13 Nut, 1/2-13 Heavy Hex 2 15-6420-08 15-6420-03

14 O-Ring -348 (Ø4.350 x Ø.210) 2 08-1371-52 08-1371-52

15 End, 3” NPT Surge 2 78-8600-01 78-8600-03

End, 3” BSPT Surge 2 78-8600-01-14 78-8600-03-14

16 Band, Small Clamp 4 15-7100-08 15-7100-03

17 Bolt, 5/16-18 x 2.25 Rnd Hd Sq Neck 4 15-6050-08 15-6050-08

18 Nut, 3/8-16 Heavy Hex 4 08-6450-08 08-6450-03

19 Shaft, Straight 1 78-3800-03 78-3800-03

20 Stop, Shaft 1 78-8800-17 78-8800-17

21 Washer, Shoulder 1 15-6850-08 15-6850-08

22 Piston, Rubber & TPE Inner 1 15-3700-01 15-3700-01

Piston, Ultra-Flex

Piston, PTFE Inner 1 15-3750-01 15-3750-01

23 Diaphragm, Primary 1 * *

Diaphragm, Ultra-Flex

Diaphragm, PTFE 1 * *

24 Diaphragm, Backup 1 * *

25 Piston, Rubber & TPE Outer 1 15-4550-01 15-4550-03

Piston, Ultra-Flex

Piston, PTFE Outer 1 15-4600-03 15-4600-03

26 Stop, Washer 1 78-6790-08 78-6790-08

27 Nut, 3/4-16 Hex 1 78-6450-08 78-6450-08

28 Reducer Bushing 1 70-6950-08 70-6950-03

1

Air Regulator Body includes qty. 3 Glyd Rings.

*Elastomer options listed on page 24.

All Bold face items are primary wear items.

TM

METAL

XSD3/AAAA/

P/N

1

™

Inner 1 15-3760-08 15-3760-08

™

™

Outer 1 15-4560-01 15-4560-03

1 78-8515-01 78-8515-03

1 * *

PARTS LISTING

XSD3/SSSS/

P/N

WIL-19 011- E - 0 7 23 WILDEN PUMP & ENGINEERING, LLC

Section 9

ELASTOMER OPTIONS

METAL XSD1

EQUALIZER

METAL XSD2

EQUALIZER

METAL XSD2

ADVANCED

EQUALIZER

METAL XSD3

EQUALIZER

ELASTOMER DIAPHRAGM

BACK-UP

DIAPHRAGM

ULTRA-FLEX™

DIAPHRAGM

SIP DIAPHRAGM O-RINGS

NEOPRENE 04-1010-51 04-1060-51 04-1020-51 04-1030-72 N/A

NITRILE 04-1010-52 04-1060-52 04-1020-52 N/A 70-1280-52

®

VITON

04-1010-53 N/A 04-1020-53 N/A N/A

EPDM 04-1010-54 04-1060-54 04-1020-54 N/A N/A

®

PTFE 04-1010-55 N/A N/A N/A 70-1280-55

SANIFLEX™ 04-1010-56 04-1060-56 N/A N/A N/A

WIL-FLEX™ 04-1010-58 N/A N/A N/A N/A

ESD NITRILE 04-1010-86 04-1020-86 N/A N/A N/A

NEOPRENE 08-1010-51 08-1060-51 08-1020-51 08-1030-72 N/A

NITRILE 08-1010-52 08-1060-52 08-1020-52 N/A 71-1281-52

®

VITON

08-1010-53 N/A 08-1020-53 N/A N/A

EPDM 08-1010-54 08-1060-54 08-1020-54 N/A N/A

®

PTFE 08-1010-55 N/A N/A N/A 71-1281-55

SANIFLEX™ 08-1010-56 08-1060-56 N/A N/A N/A

WIL-FLEX™ 08-1010-58 N/A N/A N/A N/A

ESD NITRILE 08-1010-86 08-1060-86 N/A N/A N/A

NEOPRENE 08-1010-51 08-1060-51 08-1020-51 08-1030-72 N/A

NITRILE 08-1010-52 08-1060-52 08-1020-52 N/A N/A

®

VITON

08-1010-53 N/A 08-1020-53 N/A N/A

EPDM 08-1010-54 08-1060-54 08-1020-54 N/A N/A

®

PTFE 08-1010-55-42 N/A N/A N/A N/A

SANIFLEX™ 08-1010-56 08-1060-56 N/A N/A N/A

WIL-FLEX™ 08-1010-58 N/A N/A N/A N/A

ESD NITRILE 08-1010-86 08-1060-86 N/A N/A N/A

NEOPRENE 15-1010-51 15-1060-51 15-1020-51 N/A N/A

NITRILE 15-1010-52 15-1060-52 15-1020-52 N/A 08-1371-52

®

VITON

®

EPDM 15-1010-54 15-1060-54 15-1020-54 N/A N/A

15-1010-53 N/A 15-1020-53 N/A 08-1371-60

PTFE 15-1010-55 N/A N/A N/A N/A

SANIFLEX™ 15-1010-56 15-1060-56 N/A N/A N/A

WIL-FLEX™ 15-1010-58 N/A N/A N/A N/A

WILDEN PUMP & ENGINEERING, LLC 24 WI L-1 9 011 - E- 07

Warranty

Each and every product manufactured by Wilden Pump and Engineering, LLC is built to meet the highest

standards of quality. Every pump is functionally tested to insure integrity of operation.

Wilden Pump and Engineering, LLC warrants that pumps, accessories and parts manufactured or supplied by

it to be free from defects in material and workmanship for a period of five (5) years from date of installation or

six (6) years from date of manufacture, whichever comes first. Failure due to normal wear, misapplication, or

abuse is, of course, excluded from this warranty.

Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump

or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential

damage or expense arising from the use or misuse of its products on any application. Responsibility is limited

solely to replacement or repair of defective Wilden pumps and parts.

All decisions as to the cause of failure are the sole determination of Wilden Pump and Engineering, LLC.

Prior approval must be obtained from Wilden for return of any items for warranty consideration and must be

accompanied by the appropriate MSDS for the product(s) involved. A Return Goods Tag, obtained from an

authorized Wilden distributor, must be included with the items which must be shipped freight prepaid.

The foregoing warranty is exclusive and in lieu of all other warranties expressed or implied (whether written or oral)

including all implied warranties of merchantability and fitness for any particular purpose. No distributor or other

person is authorized to assume any liability or obligation for Wilden Pump and Engineering, LLC other than expressly

provided herein.

PLEaSE PrInt or tYPE anD faX to WILDEn

PumP InformatI on

Item # Serial #

Company Where Purc hase d

Your InformatIon

Company Name

Industry

Name Title

Street Address

City State Postal Code Country

Telephone Fax E-mail Web Address

Number of pumps in facility? Number of Wilden pumps?

Types of pumps in facility (check all that apply): Diaphragm

Media being pumped?

Other

Centrifugal

Gear

Submersible

Lobe

How did you hear of Wilden Pump?

Other

NOTE: WARRANTY VOID IF PAGE IS NOT FA XED TO WILDEN

Trade Journal

Trade Show

onCE ComPLEtE, faX to (909) 783-3440

WILDEN PUMP & ENGINEERING, LLC

Internet/E-mail

Distributor

PSG® Brands

ABAQUE®

PERISTALTIC PUMPS

mouvex.com

ALMATEC®

DOUBLEDIAPHRAGM PUMPS

VANE PUMPS & COMPRESSORS

FLUID DYNAMICS™

POLYMER BLENDING SYSTEMS

AIROPERATED

almatec.de

AUTOMATIK

PELLETIZING SYSTEMS

maag.com

BLACKMER®

blackmer.com

uiddynamics1.com

GRISWOLD™

CENTRIFUGAL PUMPS

griswoldpump.com

MAAG

PLASTIC MANUFACTURING &

FILTRATION

PROCESSING FILTRATION

maag.com

MAAG

INDUSTRIAL PUMPS

GEAR & SCREW PUMPS

maag.com

MAAG

PUMP SYSTEMS

EXTRUSION PUMPS & SYSTEMS

maag.com

MOUVEX®

ECCENTRIC DISC PUMPS,

VANE PUMPS &

COMPRESSORS

mouvex.com

NEPTUNE™

DIAPHRAGM METERING PUMPS,

POLYMER SYSTEMS & MIXERS

neptune1.com

QUATTROFLOW™

QUATERNARY DIAPHRAGM

PUMP TECHNOLOGY

quattroow.com

REDSCREW™

SCREW PUMPS

redscrewpump.com

SYSTEM ONE®

CENTRIFUGAL PUMPS

blackmer.com

WILDEN®

AIROPERATED

DOUBLEDIAPHRAGM PUMPS

wildenpump.com

22069 Van Buren St.

Grand Terrace, CA 92313-5651

T: +1 (909) 422-1731

F: +1 (909) 783-3440

Where Innovation Flows

PSG reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. 11-2014

Authorized PSG Representative:

Copyrigh t ©2014, Pump Solutions Gr oup (PSG), A Dover Compa ny

Loading...

Loading...