Operating Instructions

PS-AMS1x with

Fieldbus-Interface Profibus-DP

Version 2019/01/09 ©2019 PS Automation GmbH

Subject to changes!

2

3

Table of contents

1. Description .................................................................................................................................................................... 4

2. Connecting the Fieldbus ................................................................................................................................................ 4

2.1 Wiring to terminal block ......................................................................................................................................... 4

2.1.1. Termination ..................................................................................................................................................... 5

2.1.2. Fieldbus status LED ......................................................................................................................................... 5

2.2 Connection with Plug & Socket ............................................................................................................................... 5

2.2.1. Termination ..................................................................................................................................................... 5

2.2.2. Fieldbus status LED ......................................................................................................................................... 5

2.3. Slide switch for selecting the communication interface ........................................................................................ 6

3. Fieldbus address ............................................................................................................................................................ 6

4. Process Image ............................................................................................................................................................... 7

4.1. Process Image OUTPUT .......................................................................................................................................... 7

4.1.1. Byte 1 - Set Value High-Byte ........................................................................................................................... 7

4.1.2. Byte 2 - Set Value Low-Byte ............................................................................................................................ 7

4.1.3. Byte 3 - Process Sensor High-Byte .................................................................................................................. 8

4.1.4. Byte 4 - Process Sensor Low-Byte ................................................................................................................... 8

4.1.5. Byte 5 - Command ........................................................................................................................................... 8

4.1.6. Byte 6 - Address .............................................................................................................................................. 8

4.1.7. Byte 7 - Data-High ........................................................................................................................................... 8

4.1.8. Byte 8 - Data-Low ............................................................................................................................................ 8

4.2. Process Image INPUT ............................................................................................................................................. 8

4.2.1. Byte 1 - Actual Value High-Byte ...................................................................................................................... 8

4.2.2. Byte 2 - Actual Value Low-Byte ....................................................................................................................... 8

4.2.3. Byte 3 - Working Condition / Error Code of the Actuator .............................................................................. 8

4.2.4. Byte 4 - Address .............................................................................................................................................. 9

4.2.5. Byte 5 - Data-High ........................................................................................................................................... 9

4.2.6. Byte 6 - Data-Low ............................................................................................................................................ 9

5. Diagnosis ..................................................................................................................................................................... 10

6. Technical Data ............................................................................................................................................................. 10

7. GSD-File ....................................................................................................................................................................... 11

8. Parameter Storage Addresses ..................................................................................................................................... 11

9. Simulation of Profibus-environment........................................................................................................................... 11

10. Hints for Programming .............................................................................................................................................. 11

Annex: Process Image Profibus-DP in PS-AMS ................................................................................................................ 13

4

1. Description

The optional fieldbus-interface Profibus-DP (DPV0, DPV1 and Publisher Support of DPV2) allows operation of the

actuator via Profibus-DP. This interface communicates to the actuator via the standard serial port. The actuator does

then not use analogue set values. Feedback from a process sensor to the optionally available process controller PSIC

integrated in the actuator is digitally transmitted as well. Command level allows on request to read out all

parameters and diagnostics data.

Adjustment of parameterisation of the actuator is not possible via fieldbus.

Note: The actuator has a single communication port. This is used when the optional fieldbus interface is installed.

For parameterisation of the actuator with the communication software PSCS or handheld unit PSC, the position of a

switch on the main board of the actuator PS-AMS1x has to be changed, see chapter 2.3. After that, communication

with PC is possible via the date cable. After parameterisation, the switch has to be placed to position “Fieldbus”

again, to allow communication of the fieldbus module to the actuator.

-> See also Instruction Manual AMS-PSCS

Note: „Digital Set Value“ (in the communication software AMS-PSCS under Operate - Configuration - Set Value &

Feedback) must be activated to control the actuator via the fieldbus interface!

Note: During PC communication there may unreasonable data appear in the (Profibus-based) process image.

2. Connecting the Fieldbus

Caution: When working at or on the actuator’s processor board, proper earthing of the worker has to be ensured. As

a makeshift it will help to firmly touch the actuator housing with bare hands before working on the actuator, to

create an equalisation of potential.

Wiring of the Fieldbus-Line is depending on the version of the PS-AMS-actuator, either to an internal terminal block

on the main board, or to a socket at the outside of the actuator.

2.1 Wiring to terminal block

There are two specific metal cable glands for insertion of the Profibus cables. These allow connection of the shielding

as shown in picture 1.

Figure 1 EMC cable gland with earthing cones

Wiring of the two Profibus cable is made to terminal blocks on the AMS main board. The two wires coming from the

previous device go to terminals A1 and B1. Wiring to a subsequent device can be done from terminals A2 and B2.

5

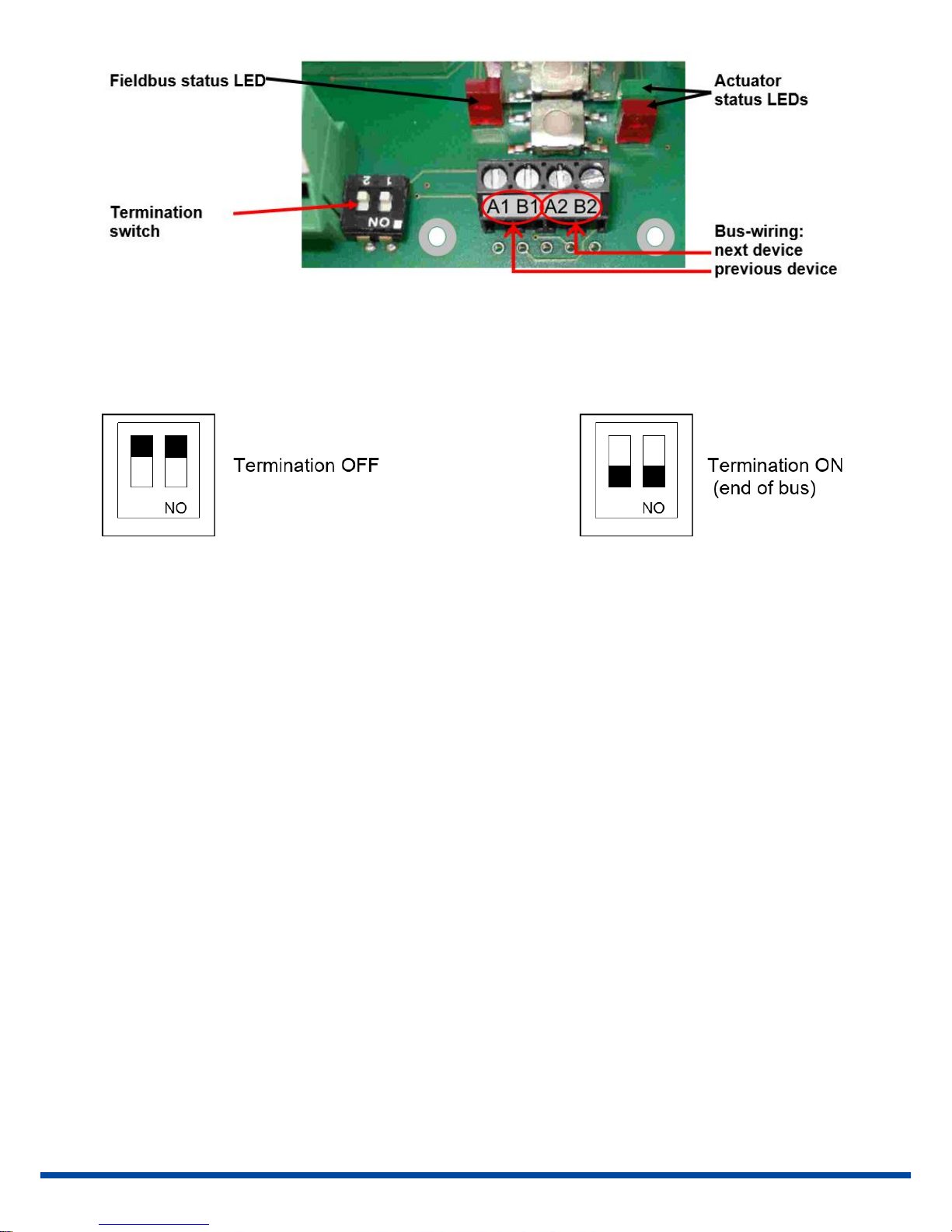

Figure 2 Terminal block on the main board of an actuator for Profibus DP

2.1.1. Termination

Termination of the bus is possible with the termination switch next to the terminal block, see picture 2. Both

switches have to be put to the same position mandatorily.

2.1.2. Fieldbus status LED

There is one single red LED next to the terminal block for signalling the status of the fieldbus, see picture 2.

LED Off = Mode „data exchange“

LED On = No connection to the fieldbus

2.2 Connection with Plug & Socket

At the outside of the actuator housing a socket is fitted to accept a standard Profibus plug of maker Phoenix Contact.

Appropriate type is VS-09-PROFIBUS-SC, Order No. 16 54 54 9. The two Profibus wires coming from the previous

device go to terminals A1 and B1. Wiring to the following device is made to terminals A2 and B2.

2.2.1. Termination

Termination is made inside the plug, if required.

2.2.2. Fieldbus status LED

There is one single red LED next to the terminal block for signalling the status of the fieldbus, see picture 2.

LED Off = Mode „data exchange“

LED blinking = No connection to the fieldbus

6

2.3. Slide switch for selecting the communication interface

On the main board inside the actuator there is a slide switch for selecting the

interface, see picture 3.

For normal operation, i.e. when the actuator is controlled via the fieldbus, put the

switch to lower position (red arrow).

For adjustment work, parameterisation, etc. the interface has to be put in upper

position to allow PC-communication (yellow arrow).

Caution: After finishing adjustment work, make sure that the switch is in lower

(red) position. In upper (yellow) position the interface does communicate to the

bus, but not to the actuator’s electronic!

yellow = PC-communication

red = fieldbus-communication

3. Fieldbus address

The actuator is supplied with address 0 adjusted. At commissioning the user can modify the address using the two

turn-coding switches, see picture 4. After this modification switch the actuator off for a short period and on again to

adopt the change.

Figure 4 Turn coding switches for adjusting the fieldbus address

Figure 3 Slide switch for selecting the interface

7

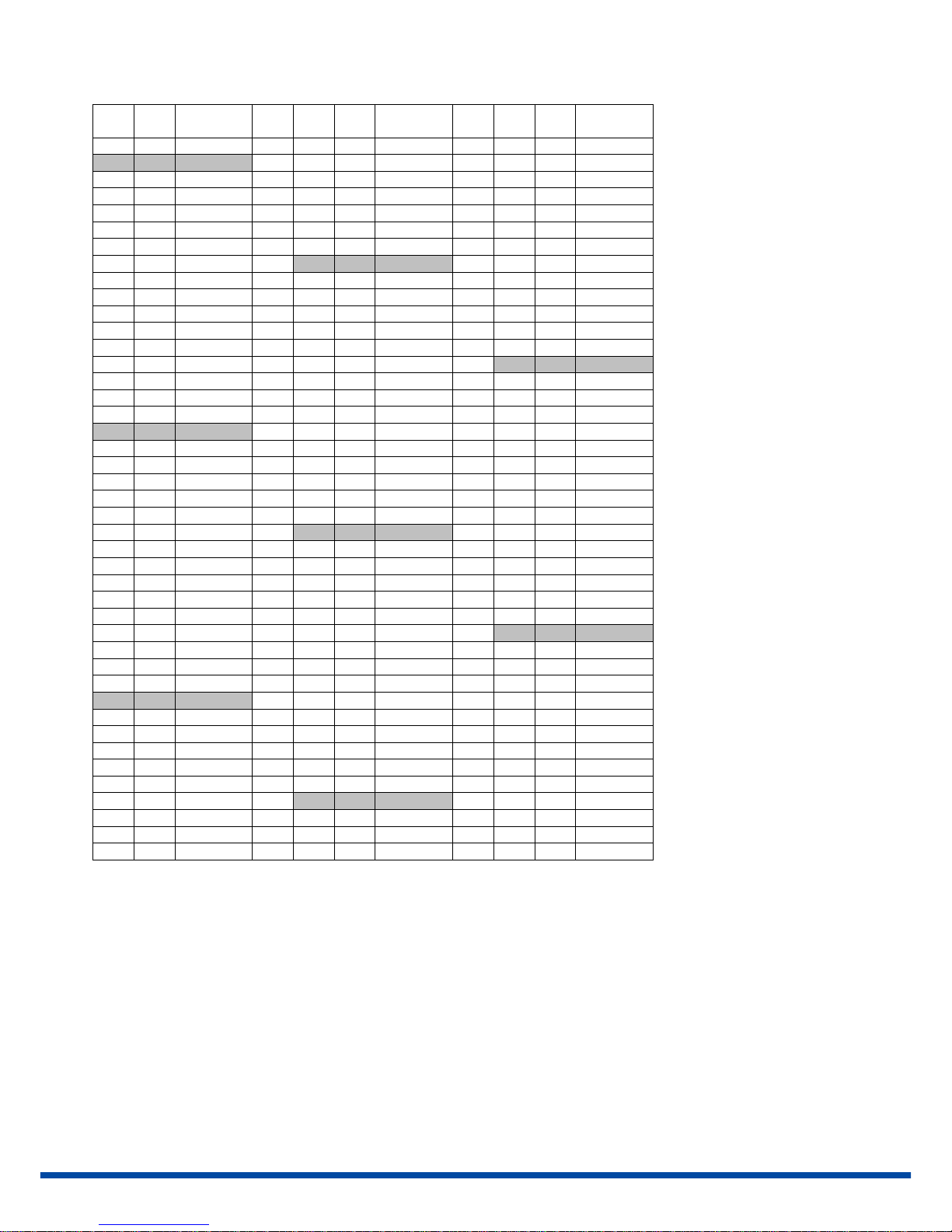

Adjustment of addresses 0 to 125 is possible as per the table below.

S302

S301

Profibus-

address

S302

S301

Profibus-

address

S302

S301

Profibus-

address

0 0 0 2 A

42 5 4 84

0 1 1 2 B 43 5 5 85 0 2 2 2 C

44 5 6 86

0 3 3 2 D 45

5 7

87

0 4 4 2 E 46

5 8

88

0 5 5 2 F 47

5 9

89

0 6 6 3 0 48

5 A

90

0 7 7 3 1 49

5 B

91

0 8 8 3 2 50

5 C

92

0 9 9 3 3 51

5 D

93

0 A 10

3 4

52

5 E

94

0 B 11

3 5

53

5 F

95

0 C 12

3 6

54

6 0

96

0 D 13

3 7

55

6 1

97

0 E 14

3 8

56

6 2

98 0 F

15

3 9

57

6 3

99

1 0 16

3 A

58

6 4

100

1 1 17

3 B

59

6 5

101

1 2 18

3 C

60

6 6

102

1 3 19

3 D

61

6 7

103

1 4 20

3 E

62

6 8

104

1 5 21

3 F

63

6 9

105

1 6 22

4 0

64

6 A

106

1 7 23

4 1

65

6 B

107

1 8 24

4 2

66

6 C

108

1 9 25

4 3

67

6 D

109

1 A 26

4 4

68

6 E

110

1 B 27

4 5

69

6 F

111

1 C 28

4 6

70

7 0

112

1 D 29

4 7

71

7 1

113

1 E 30

4 8

72

7 2

114

1 F 31

4 9

73

7 3

115

2 0 32

4 A

74

7 4

116

2 1 33

4 B

75

7 5

117

2 2 34

4 C

76

7 6

118

2 3 35

4 D

77

7 7

119

2 4 36

4 E

78

7 8

120

2 5 37

4 F

79

7 9

121

2 6 38

5 0

80

7 A

122

2 7 39

5 1

81

7 B

123

2 8 40

5 2

82

7 C

124

2 9 41

5 3

83

7 D

125

4. Process Image

See table „Process Image AMS Profibus-DP“ in the annex

4.1. Process Image OUTPUT

The process image OUTPUT shows the details how control of the actuator (as slave) is done.

4.1.1. Byte 1 - Set Value High-Byte

Bit 7 of Byte 1 (MSB) defines the input to be in percent (MSB = 0) or in tenth of percent (MSB = 1).

4.1.2. Byte 2 - Set Value Low-Byte

Input has to be made as per MSB of Byte 1.

8

4.1.3. Byte 3 - Process Sensor High-Byte

Bit 7 of Byte 3 (MSB) defines the input to be in percent (MSB = 0) or in tenth of percent (MSB = 1).

Caution: When using an analogue process sensor, Byte 3 and Byte 4 have to be set to „0xFF“!

4.1.4. Byte 4 - Process Sensor Low-Byte

Input has to be made as per MSB of Byte 3.

Caution: When using an analogue process sensor, Byte 3 and Byte 4 have to be set to „0xFF“!

4.1.5. Byte 5 - Command

Use the command byte to read / write data from / to the memory of the actuator.

0x00 = no action

0x20 = send data for RAM

0x21 = read data from RAM

0x1D = send data for E²PROM

0x1E = read data from E²PROM

Caution: To ensure that a command is sent to the correct address with the correct data, follow this procedure when

writing to the process image:

Write 0x00 to command Byte 5

Write address (Byte 6), Data-High (Byte 7) and Data-Low (Byte 8)

Write the actual command, e.g. 0x1E

As result the command will be sent to the actuator for one time. To send another command, the command byte

0x00 has to be sent again.

Note: At reading of data, these will be available at Byte 5 and Byte 6 of the process image INPUT after 250 msec.

4.1.6. Byte 6 - Address

Address for memory access

4.1.7. Byte 7 - Data-High

High-Byte of data to be written

4.1.8. Byte 8 - Data-Low

Low-Byte of data to be written

4.2. Process Image INPUT

The process image INPUT shows the details of the feedback of the actuator (as slave).

4.2.1. Byte 1 - Actual Value High-Byte

Feedback is scaled in line with the set value, as adjusted under 4.1.1.

4.2.2. Byte 2 - Actual Value Low-Byte

Feedback is scaled in line with the set value, as adjusted under 4.1.1.

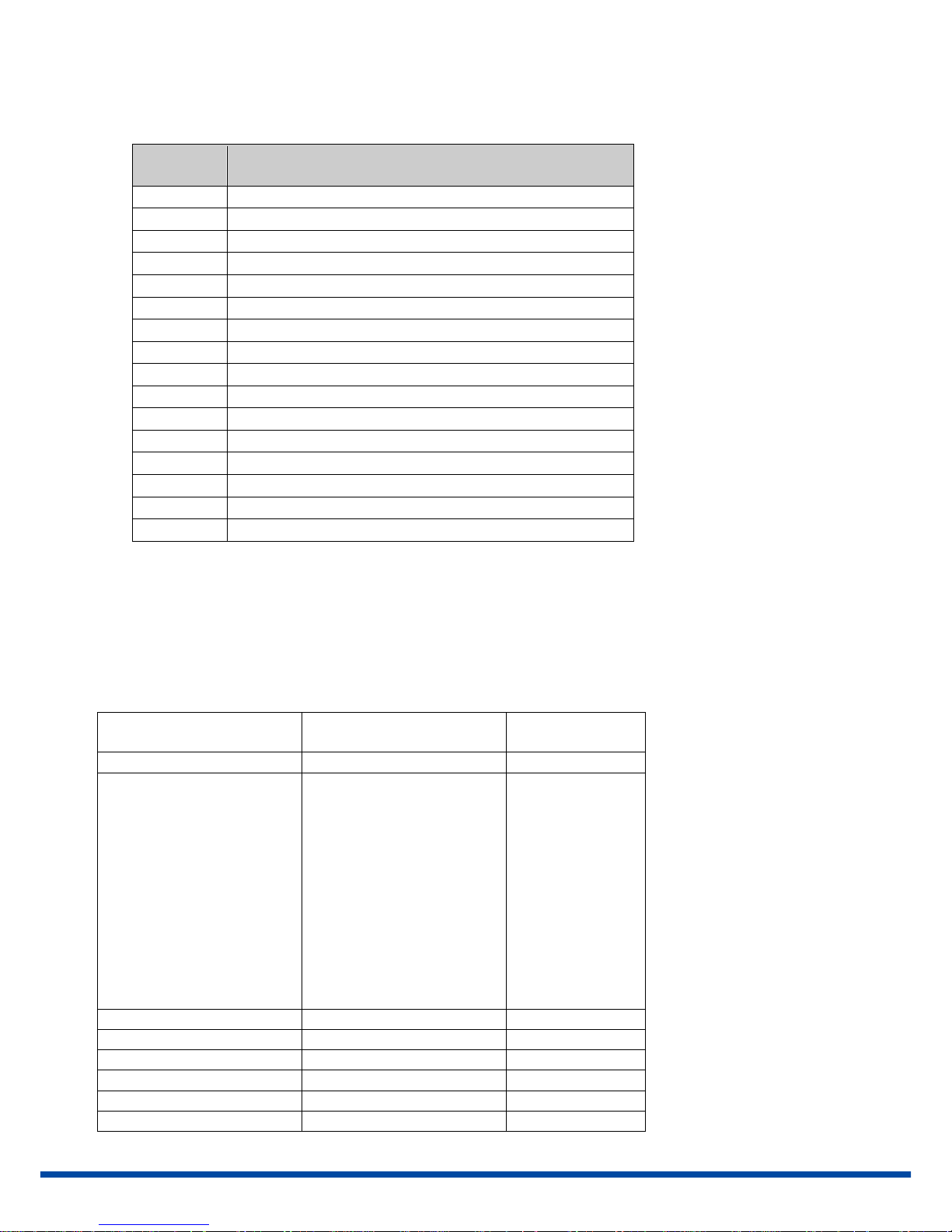

4.2.3. Byte 3 - Working Condition / Error Code of the Actuator

The below table lists the messages that can appear during operation. Messages referring to the fieldbus interface

will be covered under „5. Diagnosis“.

9

Error Nr. [dec]

Description of Status

Working condition

0 Normal operation

1

Actuator doing auto-commissioning

2

Actuator not commissioned to the valve

14

Actuator not in AUTO mode

(in conjunction with local control unit

PSC.2)

Peripheral errors

3 Set value error

4

Torque error

5

Fail Safe-action is started

6

Set value error of the process sensor

12

Position passed over

13

Position nor reached

11

Undervoltage at supply

Errors in actuator

7

Mechanical / positioning error

8

Critical / maximum temperature reached

9

Electronics error / CRC

10

Limit of wear reached

Communication

error 32

No communication to actuator possible

Note: Error Nr. 32 may be displayed twice during commissioning of the actuator to the valve: when either end

position is reached and the measured values are stored inside the actuator. During normal operation, this error

signals a malfunction if it is displayed longer than 10 sec.

4.2.4. Byte 4 - Address

Address for memory access

4.2.5. Byte 5 - Data-High

High-Byte of data to be read

4.2.6. Byte 6 - Data-Low

Low-Byte of data to be read

10

5. Diagnosis

In the case of errors, the fieldbus interface of this actuator provides specific diagnosis data. These diagnosis data

refer to the fieldbus interface only.

Error Nr.

[dec]

Description of Error

0

Reserved

1

Error at initialising RS485/232 interface

2

Error at E²PROM

3

Stack error

4

Hardware error of Fieldbus-ASIC

5

Configuration error of gateway (unknown protocol)

6

Reserved

7

RS485/RS232 transmit-buffer overflow

8

RS485/RS232 receive-buffer overflow

9

Time-out while receiving at RS485/RS232 interface

10

Transmission error of RS485/RS232 interface

11

Receiving error of RS485/RS232 interface

12

Address error of RS485/RS232 interface

13

Configuration error by Profibus-master

14

General error of RS485/RS232 interface

15

Internal error

Note: Information about operating condition and error codes are available at Byte 3 of the process image INPUT

only.

6. Technical Data

In the case of errors, the fieldbus interface of this actuator provides specific diagnosis data. These diagnosis data

refer to the fieldbus interface only.

Communication protocol

Profibus DP (DPV0, DPV1,

Publisher Support of DPV2)

Fieldbus baud rate

up to 12 MBaud (Autodetect)

Baud rate / Wire length

kbit/s

Segment length

[m]

9,6

1200 19,2

1200 45,45

1200 93,75

1200 187,5

1000 500

400 1500

200

3000

100

6000

100

12000

100

Cycle time for data refresh

250 ms

Cycle time for data transfer

250 ms

Process image OUTPUT

8 Byte

Process image INPUT

6 Byte

11

7. GSD-File

The GSD-file is the device data sheet describing the Profibus DP slave in detail. Use the file “Configuration File

ProfibusDP V1.3” as provided on our homepage www.ps-automation.com in the section „Downloads“ under „ More

Downloads“.

8. Parameter Storage Addresses

RAM-Parameter

Address

Data high

Data low

Range

Unit

Description

000

x x 0...1000

% / ‰

present digital set value

001

x x 0...1023

digit

present set value

002

x x 0...1023

digit

present feedback

005

x x 0...1000

% / ‰

present digital feedback

Diagnosis data

185

x x 0...65536

starts x 50

Number of motor starts

186

x x 0...65536

starts

Number of motor starts at

excess temperature

187

x x 0...65536

h x 2

Operation time of actuator

188

x x 0...65536

min x 6

Operation time of motor

189

x x 0...65536

min

Operation time of motor at

excess temperature

Basically all data are accessible that are displayed in the communication software PSCS. The required addresses are

available on request.

Note: The current layout does not allow writing parameters to the actuator via the fieldbus.

9. Simulation of Profibus-environment

PS Automation provides a simulation software PSAMS1xProfibusSim_V2_0 for the Profibus-DP-master simulator

BW1131 made by Bihl & Widemann.

1.) Start PSAMS1xProfibusSim_V2_0.exe on the PC

2.) Adjust communication port and Profibus address

3.) Push the button "Open Profibus-DP" in the software

4.) Enter a set value in the range of 0...100%; pushing the button "Write Profibus-DP" will drive the actuator

5.) After testing press the button "Close Profibus-DP"

6.) Disconnect power from the actuator

10. Hints for Programming

To transmit consistent date of a length of 3 or more than 4 bytes in S7 / CPU 315-2, the SFC-calls (SFC14/15) have to

be applied. The maximum number of consistent data is depending on the CPU used. Please refer to the respective

manuals for CPU-data.

12

PS Automation GmbH

Gesellschaft für Antriebstechnik

Philipp-Krämer-Ring 13

D-67098 Bad Dürkheim

Tel.: +49 (0) 6322 94980-0

E-Mail: info@ps-automation.com

www.ps-automation.com

Hong Kong

MaxAuto Company Ltd.

Room 2008, 20/F., CCT Telecom Building

11 Wo Shing Street

Fotan, Shatin, Hong Kong

Phone: <+852> 26 87-50 00

Fax: <+852> 81 01-37 43

E-mail: info@maxonic.com.hk

www.maxonicauto.com

China

Shenzhen Maxonic Automation

Control Co., Ltd.

Maxonic Automation Control Mansion

No. 3 Lang Shan Road, Hi-Tech Industrial Park,

Shenzhen, Guangdong, PRC.

518057

Phone: <+86> 755 86 25 03 88

Fax: <+86> 755 86 25 03 74

E-mail: cg@maxonic.com.cn

www.maxonicauto.com

India

PS Automation India Pvt Ltd.

Srv. No. 25/1, Narhe Industrial Area,

A.P. Narhegaon, Tal. Haveli, Dist.

IND-411041 Pune

Phone: <+ 91> 20 25 47 39 66

Fax : <+ 91> 20 25 47 39 66

E-mail: sales@ps-automation.in

www.ps-automation.in

Great Britain

IMTEX Controls Ltd.

Unit 5A, Valley Industries,

Hadlow Road

GB-Tonbridge, Kent TN11 0AH

Phone: <+44> (0) 17 32-85 03 60

Fax: <+44> (0) 17 32-85 21 33

E-mail: sales@imtex-controls.com

www.imtex-controls.com

Italy

PS Automazione S.r.l.

Via Pennella, 94

I-38057 Pergine Valsugana (TN)

Phone: <+39> 04 61-53 43 67

Fax: <+39> 04 61-50 48 62

E-mail: info@ps-automazione.it

Spain

Sertemo, S.L.

Pol. Ind. Alba - Avda. Generalitat 15

Apartado de Correos, 142

E-43480 Vila-Seca (Tarragona)

Phone: <+34> 9 77 39 11 09

Fax : <+34> 9 77 39 44 80

E-mail: hans@sertemo.com

www.sertemo.com

Annex: Process Image Profibus-DP in PS-AMS

Loading...

Loading...