Pro-Weld CD-312 User Manual

OPERATION/MAINTENANCE

MANUAL

PRO WELD

CD-312

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

TABLE OF CONTENTS

INTRODUCTION

WARRANTY

UNPACKING YOUR UNIT

SUGGESTED SAFETY PRECAUTIONS

GENERA

THE CD WELDING PROCESS

POWER REQUIREMENTS

SYSTEM SPECIFICATIONS

WELDING SYSTEM HOOK-UP

9.1

9.2

9.3

L DESCRIPTION

Straight Polarity

Reverse Polarity

Cuphead Pin

1

1

1

1

2

2

3

3

4

4

5

6

10.0

11.0

11.5

12.0

13.0

14.0

15.0

16.0

17.0

SYSTEM OPERATION

GUN SET-UP

11.1

11.2

11.3

11.4

11.6

WELDABLE MATERIAL COMBINATIONS 15

CAUSES OF

TROUBLE SHOOTING POOR WELDS 16

ROUTINE WELDER MAINTENANCE 17

ASSEMBLY –CD-312 CONTROLLER

16.1

TROUBLE SHOOTING – ELECTRICAL 22

9

Standard

Installing or Changing Collets or Chucks 10

For Weld Pins with Collet Protector 10

Template Adapter

Collet Protector with Blunt Leg 11

Parts List LD CD Handgun 14

PC Board Assembly Drawing

POOR OR ERRATIC WELDS 16

11

21

7

9

18,19,20

18.0

19.0

CHECK LIST CD-312 SYSTEM P.N. 100-0108 24

CHECK LIST CD-312 SYSTEM P.N. 100-0109 24

PRO WELD

CD-312

LIST OF FIGURES

1

2 STRAIGHT POLARITY HOOK-UP 4

3

4

5

6 STANDARD GUN SETUP 9

7

8 TEMPLATE ADAPTER GUN SETUP 11

9 COLLET PROTECTOR/

10

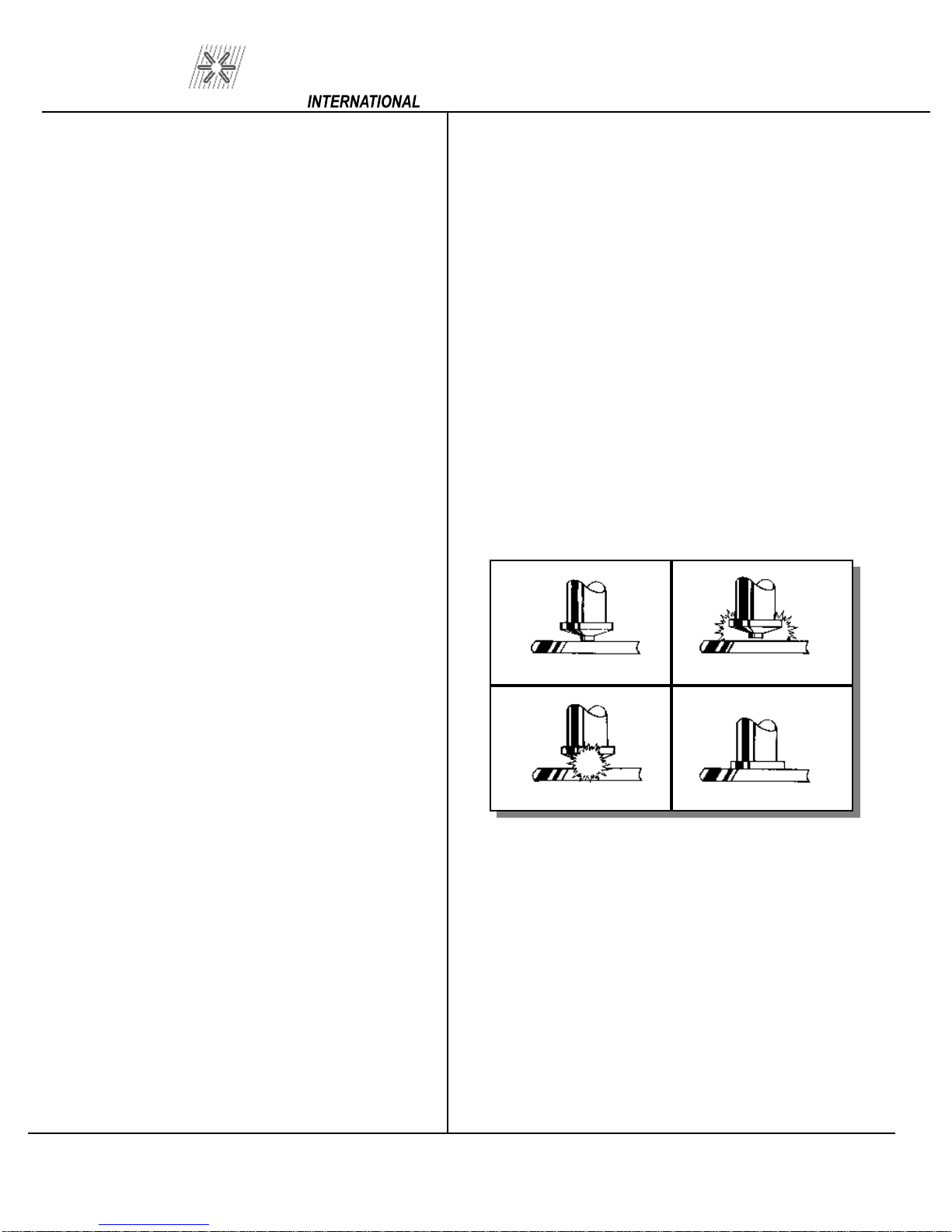

CD CONTACT PROCESS

REVERSE POLARITY HOOK-UP

CUPHEAD PIN HOOK-UP

FRONT PANEL LAYOUT

COLLET PROTECTOR SETUP

LIGHT DUTY CD GUN

2

6

7

10

BLUNT LEG SETUP

13

5

11

11

12

13

14

15 G

16

17

18

19

HOT WELD

COLD WELD

ARC BLOW

WELD WITHOUT FOOTPIECE

PARTS LIST

PARTS LIST

PARTS LIST

PC BOARD

16

17

OOD WELD

21

16

17

17

18

(continued)

(continued)

19

20

PRO WELD

CD-312

PRO WELD

CD-312

PRO WELD

CD-312

PRO WELD

CD-312

PRO WELD

1

.0 INTRODUCTION

Your new stud welding equipment is carefully

constructed of the finest components and materials

available. Used

you years of profitable, efficient service.

The system incorporates the latest in enginee

ing advances, for completely reliable end welding of

mild steel, stainless steel, aluminum and lead free

copper and brass fasten

A careful study of this manual will enable you

to understand how the welder operates to insure

proper performance under al

properly, this equipment will give

2.0 WARRANTY

The electrical and mechanical components of

the stud welder are thoroughly performance i

spected prior to assembly in the welder. The asse

bled welder is completely performance checked. The

welder is delivered to you in functional electro

mechanical condition.

All p

arts used in the assembly of the welder

and its accessories are fully warranted for a period of

1 YEAR from the date of delivery

welding capacitors are warranted for a period of 1

YEAR from the date of delivery. The printed circuit

boards

for a period of 3 years.

the right to repair or replace, at their option, defe

tive parts which fail during the guarantee period.

No

ment

purchaser within ten (10) days after the defect is first

discovered. The manufacturer does not assume any

liability for paying shipping cost or any labor or m

terials furnished where such cost are not expressly

authorized in writing.

acces

abuse, improper installation, maladjustment, or use

not in accordance with the operating instructions fu

nished by the manufacturer. The warranty is valid

only when studs are purchased from sources a

proved by the manufacturer or are of identical spec

fi

used in all proweld equipment are warranted

Under the warranty, the manufacturer reserves

tice of any claim for warranty repair or replac

must be furnished to the manufacturer by the

The manufacturer does not warrant any parts or

sories against failures resulting from misuse,

cations to the manufacturer’s

ers.

l operating conditions.

. In addition, the

n-

m-

-

c-

e-

a-

p-

CD-312

3

.0 UNPACKING YOUR UNIT

possible to the point of installation before unpacking

it. Do not operate the unit from an extension power

r-

cord if possible. Once the unit is unpacked it is reco

mended that you inspect it for any physical damage.

inspected at the factory. Upon

hooked up to the recommended incoming power b

fore welding. We recommend that you check that you

have received all the items listed on the shipping

check list. (see SECTION 1

adequate ventilation. Do not restrict the air flow

through the side l

the control housing.

Upon receipt of your unit, place it as close as

Your unit has been completely assembled and

receipt, the unit must be

8 or 19)

Place the unit in a large enough area to provide

ouvers. Do not allow water to enter

4.0 SUGGESTED SAFETY PRECA

TIONS

ity of the welder to observe certain safety rules to i

sure his personal safety and to protect those working

near him.

Reference is directed, without endorsement or

recommendation, t

and Cutting, and to AWG Publication A6,1-66, Re

om

ing.

r-

i-

while welding or weld in the rain. Avoid wear-

In any welding operation, it is the responsibi

o ANSI Z49.1, Safety in Welding

mended Safety Practices for Gas-Shield Arc Wel

1. Always treat electricity with respect. Under

open circuit conditions, the welding machine

output voltage may be dang

2. Don’t work on live circuits or conductors.

Disconnect the main power line before check

ing the machine or perform

nance operations.

3. Be sure the welding machine cabinet is

properly grounded to a good electrical ground.

4. Don’t stand in water or on a damp floor

ing wet sweaty cloths when welding.

U-

erous.

ing any mainte

m-

e-

l-

n-

c-

d-

-

-

PAGE 1

PRO WELD

5. Don’t operate with worn or poorly con

nected cables. Don’t operate weld gun with

loose cable connections. Inspect all cable

quently for insulation failures, exposed wires,

loose connections, and repair as needed.

6. Don’t overload welding cab

to operate with hot cables.

7. Don’t weld near flammable materials or liq

uids, in or near atmospheres, or o

ing explosive gases.

8. Don’t weld on containers which have held

combustible or flammable materials, or on ma

terials which give off flammable or toxic va

pors when heated, without proper cleaning,

purging, or inerting.

les or continue

n ducts carry

-

s fre

CD-312

1

10 volt AC line voltage. The system comes complete

with power cord, weld cables and gun. Just add the

-

-

-

-

-

accessories required for t

This manual should provide all the information r

quired for you to be able to set up, weld, and maintain

the CD-312 welding system.

6.0 THE CD WELDING PROCESS

common method of CD stud welding. Practically

foolproof, it produces no reverse side marking in

most cases and is suitable for most commercial and

industrial applications.

accessories for the length and diameter stud you are

going to weld. Refer to the CD Acc

and CD Stud Welding Gun Section for information

on accessories and gun set

Contact welding

First

, the gun must be set

he stud size to be welded.

e-

is the simplest and most

-up with the proper

essories Guide

-up.

9. Be sure t

when welding in confined spaces.

10. Never look at the electric arc without wear

ing protec

11. Always use the proper protective clothing,

gloves, ect.

12. Never strike an arc when near a bystander

who is unaware of the dangers of ultraviolet

light on their eyes.

5.0 GENERAL DESCRIPTION

CD-

tained heavy duty capacitor discharge power supply

capable of welding up to 5/16” flanged studs in mild

steel or stainless steel

It can weld up to 1/4 flanged studs (5/16” weld base

diameter) in aluminum or brass.

for longer life and has been designed for easy mai

te

nance and field service. This welder uses standard

312 HEAVY DUTY PORTABLE

CD ST

The CD-312 portable CD welder is a self co

The CD

o provide for proper ventilation

tive eye shields.

UD/PIN WELDER

(3/8” in weld base diameter).

-312

utilizes a solid state control board

n-

n-

1 2

-

Initial Contact

3 4

Forced Into Molten Pool

(FIGURE 1 CONTACT CD WELD)

base material (SEE FIGURE 1). Verify that the gun is

held perpendicular to the work

di

porizes the tip. The proper tip design is critical. This

is what determines the length of time of the weld. An

arc is briefly sustained which melts the stud base su

face and the work surface directly underneath the

stud. The spring pressure in the gun then forces the

stud into the molten pool, completing the weld in a

proximately six milliseconds.

The stud is first placed in contact with the

scharges the capacitors through the stud which v

During Weld

After Weld

. Pulling the trigger

a-

r-

p-

PAGE 2

PRO WELD

T

his technique, when equipment is set up properly,

is simple and easily mastered. The same power su

ply is capable of welding many different sizes and

materials of fasteners. If you require assistance in

se

lecting the proper accessories, contact our cu

tomer service department or your field represent

tive.

7.0 POWER REQUIREMENTS

110 VOLT OPERATION

110 volt AC 60 H:

Internal :

circuit breaker

Integral 9 foot power cord

25 amp service

20 amp;

(P/N: 104-0021)

s-

a-

p-

CD-312

Capacitance:

88,000 uF nominal

Weld Mode:

Polarity:

Power Required:

Int

STANDARD GUN & CABLE SPECIFICATIONS

Contact

Straight or Reverse

110 Volt AC 60 Hz 25 Amp

ernal Fusing:

20 Amp Circuit Breaker

3AG 1 Amp 250 volt (2 on PC board)

IF EXTENSION REQUIRED

Cable Length

50

12’

25’

30’

110 Volt

#16/3

#16/3

#14/3

#12/3

8.0 SYSTEM SPECIFICATIONS

Weight:

48 Lbs.

Size:

Ch

Panel Controls:

Weldable Materials:

Brass, Zinc coated, Galvanized

Weldable Stud Diameter:

Weld Rate:

Weld Voltage:

45-

8 1/2” W x 10” D x 16 1/2” H

21.6 cm W x 25.4 cm D x 42 cm H

assis:

16 Ga. Steel (Painted International Orange)

Power

Voltage Control

Steel, Stainles

12 Ga. Through 3/8” Weld Base

(Max W.B. Dia.

24 per minute 5/16”

185 VDC

s steel, Aluminum, Copper,

For AL=5/16” {1/4” thread})

WELD GUN-LIGHT DUTY PRECISION

CD CONTACT

Part Number:

300 300-

Weight:

2 lbs. (not including cable)

(

Size:

Weldable Stud Diameter:

14 Ga. Thr

Material:

Integral Gun Cable Length:

Connectors:

Cables

Ground Cable:

lbs. (including 25 ft. #4 weld cable & 16

SOW control cable)

6 1/2” x 5 3/4” x 2”

High strength, impact resistant, glass fiber re

inforced polycarbonate

25 feet – #4 AWG

Male Camlok / 2 Pin Hubbell Male

(1) #4 x 15’

0100 B Collet Gun

0101 Taper Tip Gun

ough 1/4” Flanged

(P/N: 125-0100)

-4

-

PAGE 3

Loading...

Loading...