EP-2126-SA3

SCSI TO SATA II

RAID SUBSYSTEM

Installation and User Manual

Revision 1.0

2

Preface

About this manual

This manual provides information regarding the quick installation and hardware features

of the EP-2126-SA3 RAID subsystem. This document also describes how to use the

storage management software. Information contained in the manual has been reviewed

for accuracy, but not for product warranty because of the various

environment/OS/settings. Information and specifications will be changed without further

notice.

This manual uses section numbering for every topics being discussed for easy and

convenient way of finding information in accordance with the user’s needs. The following

icons are being used for some details and information to be considered in going through

with this manual:

Copyright

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise, without the prior written consent.

Trademarks

All products and trade names used in this document are trademarks or registered

trademarks of their respective holders.

Changes

The material in this document is for information only and is subject to change without

notice.

IMPORTANT!

These are the important information that the user must remember.

WARNING!

These are the warnings that the user must follow to avoid

unnecessary errors and bodily injury during hardware and software

operation of the subsystem.

CAUTION:

These are the cautions that user must be aware to prevent damage

to the equipment and its components.

NOTES:

These are notes that contain useful information and tips that the

user must give attention to in going through with the subsystem

operation.

3

TABLE OF CONTENTS

Preface...................................................................................................................... 2

Before You Begin...................................................................................................... 5

Safety Guidelines ........................................................................................................5

Controller Configuration............................................................................................... 5

Packaging, Shipment and Delivery ................................................................................5

Unpacking the Subsystem ........................................................................................ 6

1 Product Introduction........................................................................................... 7

1.1 Identifying Parts of the EP-2126-SA3.....................................................................8

1.1.1 Front View....................................................................................................8

1.1.2 Rear View ....................................................................................................8

1.1.3 Top View......................................................................................................8

1.2 Enclosure Chassis................................................................................................9

1.3 Technical Specifications ...................................................................................9

1.3.1 RAID Features...............................................................................................9

1.3.2 Enclosure.................................................................................................... 10

1.3.3 Environmental............................................................................................. 10

2 Physical Components......................................................................................... 11

2.1 Controller Module .............................................................................................. 11

2.1.1 Controller Module Panel............................................................................... 11

2.1.2 Controller Module Installation.......................................................................12

2.1.3 Controller Board Replacement...................................................................... 13

2.2 Power Supply / Fan Module ................................................................................ 14

2.2.1 PSFM Panel ................................................................................................ 14

2.2.2 Power Supply Module LED ........................................................................... 15

2.2.3 Power Supply Installation ............................................................................15

2.2.4 Fan Replacement ........................................................................................ 17

2.3 Drive Carrier Module.......................................................................................... 18

2.3.1 Disk Drive Status Indicators ......................................................................... 18

2.3.2 Lock Indicator............................................................................................. 19

2.3.3 Disk Drive Installation .................................................................................19

2.4 LCD Display Panel.............................................................................................. 21

2.4.1 LCD Display Panel LEDs............................................................................... 21

2.4.2 LCD Front Panel Function Keys ..................................................................... 22

2.5 Rackmount Slide Rail Installation ........................................................................ 23

3 Getting Started with the Subsystem................................................................. 27

3.1 Connecting the RAID Subsystem to the Host.......................................................... 27

4 Introduction ...................................................................................................... 28

4.1 RAID Concepts.................................................................................................. 28

4.2 SCSI Concepts ..................................................................................................32

4.2.1 Multiple SCSI Format Support ...................................................................... 32

4.2.2 Host SCSI ID Selection ................................................................................ 33

4.2.3 Terminators................................................................................................ 33

4.3 Disk Drive Organization...................................................................................... 33

4.3.1 Physical Drive Groups.................................................................................. 33

4.3.2 Logical Unit Number (LUNs)......................................................................... 33

4.3.3 Hot-Swap Drive Replacement....................................................................... 34

4.3.4 Disk Failure Detection.................................................................................. 34

5 Configuration Utility Options............................................................................. 35

5.1 Configuring through a Terminal .......................................................................... 35

5.2 Configuring the Subsystem Using the LCD Panel ..................................................38

6 Accessing the proRAID Manager GUI................................................................ 40

6.1 Installation........................................................................................................ 40

6.1.1 Installing on Windows System....................................................................... 40

6.1.2 Installing on Linux ......................................................................................43

6.2 Starting ProRAID Manager..................................................................................44

4

6.3 Configuration Procedures ................................................................................... 46

6.3.1 Change Password .......................................................................................46

6.3.2 Mount RAID Subsystem............................................................................... 46

6.3.3 Detach RAID Subsystem..............................................................................47

6.3.4 View proRAIDMgr Log ................................................................................. 47

6.3.5 Event Manager ........................................................................................... 48

7 RAID Management ............................................................................................ 50

7.1 About RAID....................................................................................................... 50

7.1.1 RAID Considerations ...................................................................................50

7.2 Array Status......................................................................................................51

7.2.1 Array Properties.......................................................................................... 52

7.3 Creating a RAID ................................................................................................ 54

7.3.1 Configuring Array Options............................................................................ 54

7.3.2 Rebuilding an Array..................................................................................... 58

7.4 Parity Checking a RAID ...................................................................................... 59

7.5 Modifying RAID Settings..................................................................................... 59

7.5.1 Erase the RAID........................................................................................... 60

7.5.2 Change Settings..........................................................................................60

7.5.3 Delete Volume............................................................................................ 61

7.6 Selecting/Changing a Sparing disk ......................................................................61

8 Channel Management ........................................................................................ 62

8.1 Multiple SCSI Format Support............................................................................. 62

8.2 Host SCSI ID Selection....................................................................................... 62

8.3 Configuring Channel Options .............................................................................. 62

9 System Monitoring ............................................................................................ 64

9.1 System Information ........................................................................................... 64

9.2 Slot List (Disk View)........................................................................................... 64

9.3 LUN Mapping Information .................................................................................. 65

9.4 Controller Log ................................................................................................... 65

9.5 Hardware Monitor.............................................................................................. 66

10 Administration Menu....................................................................................... 67

10.1 System Setting ................................................................................................ 67

10.2 NTP setting ..................................................................................................... 69

10.3 Mail Notification............................................................................................... 70

10.4 SNMP Settings................................................................................................. 71

10.5 Restart ...........................................................................................................71

10.6 Set Faulty ....................................................................................................... 71

10.7 Updating Firmware .......................................................................................... 72

10.7.1 Upgrading Firmware through VT-100 Terminal Emulation ............................. 72

10.7.2 Upgrading Firmware through proRAID Management..................................... 74

APPENDIX............................................................................................................... 75

Menu Diagram .......................................................................................................... 75

5

Before You Begin

Before going through with this manual, you should read and focus to the following safety

guidelines. Notes about the subsystem’s controller configuration and the product

packaging and delivery are also included.

Safety Guidelines

To provide reasonable protection against any harm on the part of the user and to obtain

maximum performance, user is advised to be aware of the following safety guidelines

particularly in handling hardware components:

Upon receiving of the product:

Place the product in its proper location.

To avoid unnecessary dropping out, make sure that somebody is around for

immediate assistance.

It should be handled with care to avoid dropping that may cause damage to the

product. Always use the correct lifting procedures.

Upon installing of the product:

Ambient temperature is very important for the installation site. It must not exceed

30

◦

C. Due to seasonal climate changes; regulate the installation site temperature

making it not to exceed the allowed ambient temperature.

Before plugging-in any power cords, cables and connectors, make sure that the

power switches are turned off. Disconnect first any power connection if the power

supply module is being removed from the enclosure.

Outlets must be accessible to the equipment.

All external connections should be made using shielded cables and as much as

possible should not be performed by bare hand. Using anti-static hand gloves is

recommended.

In installing each component, secure all the mounting screws and locks. Make sure

that all screws are fully tightened. Follow correctly all the listed procedures in this

manual for reliable performance.

Controller Configuration

This RAID subsystem supports single controller configuration.

Packaging, Shipment and Delivery

Before removing the subsystem from the shipping carton, you should visually inspect

the physical condition of the shipping carton.

Unpack the subsystem and verify that the contents of the shipping carton are all

there and in good condition.

Exterior damage to the shipping carton may indicate that the contents of the carton

are damaged.

If any damage is found, do not remove the components; contact the dealer where

you purchased the subsystem for further instructions.

6

Unpacking the Subsystem

The package contains the following items:

• RAID subsystem unit

• Two power cords

• One external serial cable

• One external UPS cable

• One RJ-45 Ethernet cable

• Two external SCSI cables

• Two Active Terminators

• Installation Reference Guide

• Spare screws, etc.

If any of these items are missing or damaged, please contact your dealer or sales

representative for assistance.

7

1 Product Introduction

The EP-2126-SA3 RAID Subsystem

Features:

Intel 80331 64 bit I/O processor

Supports RAID levels 0, 1, 0+1, 3, 5, 6, 30, 50, NRAID and JBOD

Dual SCSI Ultra320 host channels support clustering technology

Instant availability and background initialization

Supports hot spare and automatic hot rebuild

Local audible event notification alarm

Real time drive activity and status indicators

Java based browser type GUI management utility

Supports password protection and UPS connection

Built-in Ethernet port interface for remote event notification

Transparent data protection for all popular operating systems

Supports multiple array enclosures per host connection

8

1.1 Identifying Parts of the EP-2126-SA3

The illustrations below identify the various parts of the subsystem. Each part will be

discussed in details in the following sections of this manual.

1.1.1 Front View

The front section consists of the Drive Carriers and the Smart LCD Panel.

1.1.2 Rear View

The rear view consists of the two Power Supply / Fan Modules and the Controller.

1.1.3 Top View

The illustration below shows the top view of the subsystem (without top cover)

indicating the controller and the two power supply fan module.

9

1.2 Enclosure Chassis

The EP-2126-SA3 is a redundant system with hot swappable disks, cooling fans and

power supplies. The chassis assembly contains 12 drive bays at the front. These drive

carriers are arranged in 3 rows of 4 drives. Each drive carrier is lockable and has a lock

indicator.

At the rear, the chassis assembly contains two power supply /fan modules and one

controller module. The power supply and cooling system is contained in one module for

efficient cooling.

NOTE: The modules of the enclosure are interchangeable with

other Epica products.

1.3 Technical Specifications

RAID Controller U320 SCSI-to-SATA II

Host Bus Interface Ultra 320 SCSI

Drive Bus Interface SATA II

Data Transfer Rate Up to 320MB/Sec

Cache Memory 256MB ~ 2GB ECC DDR SDRAM

RAID Processor Intel 80331 64 bit RISC

Remote Management R-Link Port

Monitor Port RS232

1.3.1 RAID Features

RAID Level

0, 1, 0+1, 3, 5, 6, 30, 50, NRAID and

JBOD

RAID Roaming Yes

Host Independent Yes

Continuous Rebuild Yes

Online Consistency Check Yes

Failed Drive Auto Rebuild Yes

Password Protection Yes

Bad Block Auto-remapping Yes

Hard Contact Relay Connection Yes

SMTP Manager and SNMP Agent Yes

10

1.3.2 Enclosure

Form Factor 2U 19-inch Rackmount Chassis

Failed Drive Indicators Yes

Backplane Board SATA II

Audible Alarm Yes

Hot-swap Drive Trays Twelve (12) 1-inch trays

Hot-swappable Power Supplies Two (2) 300W Power Supplies with PFC

Cooling Fans 2

UPS Connection Yes

Environment Monitor

Monitor Temperature, Fan, Power Supply

and Voltage

Power Requirements

AC 90V~264V Full Range

6A ~ 3A, 47Hz ~ 63Hz

1.3.3 Environmental

Relative Humidity 10% ~ 85% Non-condensing

Operating Temperature

10

◦

C ~ 40◦C (50◦F ~ 104◦F)

Weight 14 kg/30.8Lbs (without drives)

Physical Dimensions 482(W) x 460(D) x 88(H) mm

11

2 Physical Components

2.1 Controller Module

The EP-2126-SA3 includes a U320 SCSI-to-SATA II Controller Module.

2.1.1 Controller Module Panel

The Controller Module has 6 major parts: Host Channel, UPS Port, RS-232 Port,

Ethernet Port, Alarm Mute Button, and a Hard Contact Relay. These parts are described

as follows:

1. Host Channel

The subsystem is equipped with 2 host channels (Host channel A and Host channel

B), with two 68-pin SCSI connectors at the rear of the subsystem, for SCSI in and

out.

2. Uninterrupted Power Supply (UPS) Port

The subsystem may come with an optional UPS port allowing you to connect a UPS

device. Connect the cable from the UPS device to the UPS port located at the rear

of the subsystem. This will automatically allow the subsystem to use the functions

and features of the UPS.

3. RS-232 Port

The subsystem is equipped with a serial monitor port allowing you to connect to a

PC or terminal.

Below are the RS-232 settings.

Settings

Baud Rate 115200

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

12

4. R-Link Port : Remote Link through RJ-45 Ethernet for remote

management

The subsystem is equipped with one RJ-45 10/100 Ethernet port. You can use

Java-based browser to manage the RAID subsystem through Ethernet for remote

configuration and monitoring.

Link LED: Green LED indicates Ethernet is linking.

Access LED: The LED will blink orange when the 100Mbps Ethernet is being

accessed.

5. Alarm Mute Button

When the audible alarm is sounding, press this button to mute the audible alarm.

6. Hard Contact Relay

2.1.2 Controller Module Installation

In this section, you will be shown how to install the Controller Module.

a. Check for damage, especially to the connectors at the rear of the Controller Module.

CAUTION! Handle the module with care and avoid damaging the

connectors. Do not install the module if the connectors are

damaged.

b. With the Controller handle in the open position, carefully insert the module into the

enclosure.

c. Manually close the handle to complete the Controller Module installation.

13

d. Tighten the thumb screws on the handle to secure the Controller Module to the

enclosure.

2.1.3 Controller Board Replacement

NOTE: It is necessary to use ESD anti-static device when handling

sensitive parts of the controller module.

1. Loosen the thumb screws. Raise the controller handle and pull out the controller

module until it moves out of the slot.

2. Release the memory module lock and remove the memory module.

3. Remove four screws at the bottom of the controller module. Note that there are

four hex screws supporting the controller board to the module case.

4. Remove the eight (8) lock nut screws at the front panel.

14

5. Remove the controller board from the module case.

6. Remove the four hex nut screws.

7. Replace the controller board.

2.2 Power Supply / Fan Module

Every EP-2126-SA3 contains two 300W Power Supply / Fan Modules. All PSFMs

are inserted into the rear of the chassis.

2.2.1 PSFM Panel

15

On the back of the Power Supply/Fan Module, there are three distinct features: the

Power On/Off Switch, the AC Inlet Plug, and a Power On/Fail Indicator showing the

Power Status LED, indicating ready or fail.

Each fan within a PSFM is powered independently of the power supply within the same

PSFM. So if the power supply of a PSFM fails, the fan associated with that PSFM will

continue to operate and cool the enclosure.

2.2.2 Power Supply Module LED

When the power cord connected from main power source is inserted to the AC Power

Inlet, the power status LED becomes RED. When the switch of the PSFM is turned on,

the LED will turn GREEN. When the Power On/Fail LED is GREEN, the PSFM is

functioning normally.

2.2.3 Power Supply Installation

In this section, you will be shown how to install the Power Supply.

a. Check for damage, especially to the PCB Golden Fingers at the rear of the Power

Supply.

CAUTION! Handle the module with care and avoid damaging

the Golden Fingers. In addition, make sure there are no

fingerprints on the Golden Fingers. Do not install the module if

the Golden Fingers are damaged.

16

b. With the Power Supply handle in the open position, carefully insert the module into

the enclosure.

CAUTION! When inserting the PSFM, make sure the PSFM

position is correct (the handle is in the lower part when

closed).

c. Manually close the Power Supply handle.

IMPORTANT! To secure the Power Supply to the enclosure,

tighten the thumb screws.

d. Connect the Power Supply cord from the power source to the AC Power Inlet.

IMPORTANT! For safety reasons, make sure the power

switches are turned off when you plug-in the power

cords. When removing the power cords, ensure that the

switch on the back of each power supply fan module are

turned off and the power on/fail LED are red.

17

2.2.4 Fan Replacement

1. Remove the Power Supply Fan Module from the enclosure.

2. Unscrew 6 screws; 2 from left side, 2 from right side and 2 from top cover.

3. Pull up the top cover.

4. Disconnect the fan cable.

5. Unscrew the 4 screws of the power supply fan. Then remove the metal brace.

18

6. Remove the fan and replace.

2.3 Drive Carrier Module

The Drive Carrier Module houses a 3.5 inch hard disk drive. It is designed for maximum

airflow and incorporates a carrier locking mechanism to prevent unauthorized access to

the HDD.

2.3.1 Disk Drive Status Indicators

Every Drive Carrier has 2 status indicator lights. One indicator light is used for Power

On/Error. When this light is GREEN the power is on and everything is functioning

normally. When the Power On/Error light is ORANGE, then an error has occur that

requires the user’s attention.

The other status indicator light is the hard disk drive access light. When the hard disk

drive is being accessed, this light will flash BLUE.

In addition, both indicator lights are viewable within a 170° arc.

Disk Status

Indicator

Disk Activity

Indicator

Status Light

Indicator

19

2.3.2 Lock Indicator

Every Drive Carrier is lockable and is fitted with a lock indicator to indicate whether or

not the carrier is locked into the chassis or not. Each carrier is also fitted with an

ergonomic handle for easy carrier removal.

When the Lock Groove is vertical, then the Drive Carrier is unlocked.

When the Lock Groove is horizontal, this indicates that the Drive Carrier is locked.

2.3.3 Disk Drive Installation

This section describes the physical locations of the hard drives supported by the

subsystem and give instructions on installing a hard drive. The subsystem supports hotswapping allowing you to install or replace a hard drive while the subsystem is running.

a. Make sure the Lock Groove is in unlocked position. Press the carrier open button

and the Drive Carrier handle will flip open.

b. Pull out an empty disk tray. Pull the handle outwards to remove the carrier from

the enclosure.

c. Place the hard drive in the disk tray. Make sure the holes of the disk tray align with

the holes of the hard drive.

Carrier

Open

Button

Drive Carrier

is locked

Drive Carrier is

Unlocked

20

d. Install the mounting screws on the bottom part to secure the drive in the disk tray.

e. Slide the tray into a slot until it reaches a full stop. The HDD status LED will turn

green if subsystem is on.

f. Press the lever in until you hear the latch click into place.

21

2.4 LCD Display Panel

2.4.1 LCD Display Panel LEDs

Environmental Status

Parts Function

Power LED Green indicates power is ON.

Power Fail LED

If one of the redundant power supply unit fail,

this LED will turn to RED and alarm will sound.

Fan Fail LED

Turn RED when fan 1 & 2 speed is lower than

2000 RPM.

Over Temperature LED

If system temperature is over 70

o

C or disk

temperatures exceed 55

o

C the temperature

LED will turn RED and alarm will sound.

Voltage Warning LED

An alarm will sounds if detect voltage in the

controller is abnormal and voltage LED will

turn RED

Access LED

This LED will blink blue when the RAID

controller is busy / active.

22

2.4.2 LCD Front Panel Function Keys

PARTS FUNCTION

Up and Down

Arrow buttons

Use the Up or Down arrow keys to go through

the information on the LCD screen. This is also

used to move between each menu when you

configure the subsystem.

Select button

This is used to enter the option you have

selected.

Exit button EXIT

Press this button to return to the previous

menu.

23

2.5 Rackmount Slide Rail Installation

An optional Rail box can be purchased and included in the shipping package. Verify if

the content of the Rail Box is complete.

2 x Rack Rails

2 x Inner Brackets

4 x M5*P0.8 L=25mm Long

Screws

8 x M5*0.8 L=8.0mm Round Head

Screws

12 x M4*0.7 L=6.0mm Flat Head

Screws

NOTE: To lighten the weight of the RAID system, remove the disk

trays with disk drives from the chassis.

1. Remove one screw (lower part) from the RAID system ear.

24

2. Place one inner bracket to the side of the chassis. Align the holes on the front side

of the inner rail to the holes on the RAID system ear. Tighten the screw that was

removed in Step1.

3. Use four M4 flat head screws to attach the inner bracket to one of the side. Make

sure the holes of the inner bracket are aligned to the holes on the side of the RAID

system.

4. Repeat Steps 1 to 3 for the other inner bracket on the left side.

5. Loosen eight M4 screws on each of the rack rails. Make the necessary adjustment

on the length of the rack rails to conform to the depth of the rack. Then screw the

M4 screws back to the rack rails.

6. Place the right side rack rail on the rack cabinet. Use four M5 round head screws

to fix the rack rail to the rack post (Front Right and Rear Right).

NOTE: In the Front Right part of the rack rail, the M5 screws

must be placed in holes 1 and 3. In the Rear Right part, the M5

screws must be placed in holes 1 and 4.

25

7. Repeat Step 6 to fix the left side rack rail to the rack post (Front Left and Rear Left).

Take note of the positioning of the M5 screws in the holes.

8. Carefully insert the RAID system into the cabinet. Make sure the inner brackets

align with the center opening of the rack rails.

26

Front View

Rear View

9. Use two M5 long screws to fix the RAID system in the cabinet.

10. Insert the disk trays with disk drives, if they were removed prior to installation.

27

3 Getting Started with the Subsystem

3.1 Connecting the RAID Subsystem to the Host

This section describes how to connect the EP-2126-SA3 to your host system.

The subsystem supports Ultra 320 SCSI LVD interface which provides fast 320MB/s

data transfer rates using a 16-bit SCSI bus. Installation of the disk array is very similar

to the installation of a standard SCSI drive. The SCSI connector accepts the standard

68-pin LVD SCSI connector used on most LVD SCSI devices. Refer to your system

and/or SCSI host adapter manual for additional installation procedures that may apply

to your system or host adapter.

1. Connect the power cables to the AC Power inlets

2. Connect the remote management Ethernet cable to the controller Ethernet port.

3. Connect the external serial cable to the controller’s RS-232 Port (phone jack type)

4. Connect the other end of the external serial cable to the RS-232 Port (DB9 type) on

your host system.

5. The package comes with two external SCSI cables. For every pair of host channel

SCSI connector at the rear of the subsystem, attach one end of the external SCSI

cable to one of the SCSI connectors and the other end to the host adapter’s

external SCSI connector. (The host adapter is installed in your Host subsystem.)

6. Attach a SCSI terminator to the other SCSI Host Channel connector (Host Channel

Out port). Make sure to tighten the lock screws of the SCSI terminator.

7. Connect the other host system using the other external SCSI cable if you want to

configure subsystem into multi-host attachment.

NOTE: When one or more SCSI devices are connected, the total

length of all cables (internal or external) must not exceed 3 meters

(9.8 ft.) to ensure reliable operation.

IMPORTANT: For safety reasons, make sure the Disk Array and Host

Computer are turned off when you plug-in the SCSI cable.

28

4 Introduction

ProRAID Manager RAID Management Software is an OS-independent Java Application that

manages Epica systems via an Ethernet connection. This software is provided on a CD

shipped with your Epica system and should be installed on the host system that you will use

to manage the system.

The ProRAID Manager provides end users a friendly Java GUI that makes versatile RAID

functions available to general users. Users can easily plan and operation their RAID by using

ProRAID Manager, and they can simply configure different controller series at the same JAVA

Based Platform.

The ProRAID Manager supports Multi-Node Management. If you have several RAID

subsystems connected to the intranet, you can see all these systems when you login to the

ProRAID Manager. The IP Address section lists the RAID systems connected to the network.

4.1 RAID Concepts

RAID Fundamentals

The basic idea of RAID (Redundant Array of Independent Disks) is to combine multiple

inexpensive disk drives into an array of disk drives to obtain performance, capacity and

reliability that exceeds that of a single large drive. The array of drives appears to the host

computer as a single logical drive.

Five types of array architectures, RAID 1 through RAID 6, were originally defined; each

provides disk fault-tolerance with different compromises in features and performance. In

addition to these five redundant array architectures, it has become popular to refer to a nonredundant array of disk drives as a RAID 0 arrays.

Disk Striping

Fundamental to RAID technology is striping. This is a method of combining multiple drives

into one logical storage unit. Striping partitions the storage space of each drive into stripes,

which can be as small as one sector (512 bytes) or as large as several megabytes. These

stripes are then interleaved in a rotating sequence, so that the combined space is composed

alternately of stripes from each drive. The specific type of operating environment determines

whether large or small stripes should be used.

Most operating systems today support concurrent disk I/O operations across multiple drives.

However, in order to maximize throughput for the disk subsystem, the I/O load must be

balanced across all the drives so that each drive can be kept busy as much as possible. In a

multiple drive system without striping, the disk I/O load is never perfectly balanced. Some

drives will contain data files that are frequently accessed and some drives will rarely be

accessed.

29

By striping the drives in the array with stripes large enough so that each record falls entirely

within one stripe, most records can be evenly distributed across all drives. This keeps all

drives in the array busy during heavy load situations. This situation allows all drives to work

concurrently on different I/O operations, and thus maximize the number of simultaneous I/O

operations that can be performed by the array.

Definition of RAID Levels

RAID 0 is typically defined as a group of striped disk drives without parity or data

redundancy. RAID 0 arrays can be configured with large stripes for multi-user environments

or small stripes for single-user systems that access long sequential records. RAID 0 arrays

deliver the best data storage efficiency and performance of any array type. The disadvantage

is that if one drive in a RAID 0 array fails, the entire array fails.

RAID 1, also known as disk mirroring, is simply a pair of disk drives that store duplicate data

but appear to the computer as a single drive. Although striping is not used within a single

mirrored drive pair, multiple RAID 1 arrays can be striped together to create a single large

array consisting of pairs of mirrored drives. All writes must go to both drives of a mirrored

pair so that the information on the drives is kept identical. However, each individual drive can

perform simultaneous, independent read operations. Mirroring thus doubles the read

performance of a single non-mirrored drive and while the write performance is unchanged.

RAID 1 delivers the best performance of any redundant array type. In addition, there is less

performance degradation during drive failure than in RAID 5 arrays.

30

RAID 3 sector-stripes data across groups of drives, but one drive in the group is dedicated to

storing parity information. RAID 3 relies on the embedded ECC in each sector for error

detection. In the case of drive failure, data recovery is accomplished by calculating the

exclusive OR (XOR) of the information recorded on the remaining drives. Records typically

span all drives, which optimizes the disk transfer rate. Because each I/O request accesses

every drive in the array, RAID 3 arrays can satisfy only one I/O request at a time. RAID 3

delivers the best performance for single-user, single-tasking environments with long records.

Synchronized-spindle drives are required for RAID 3 arrays in order to avoid performance

degradation with short records. RAID 5 arrays with small stripes can yield similar performance

to RAID 3 arrays.

Under RAID 5 parity information is distributed across all the drives. Since there is no

dedicated parity drive, all drives contain data and read operations can be overlapped on

every drive in the array. Write operations will typically access one data drive and one parity

drive. However, because different records store their parity on different drives, write

operations can usually be overlapped.

Dual-level RAID achieves a balance between the increased data availability inherent in

RAID 1 and RAID 5 and the increased read performance inherent in disk striping (RAID 0).

These arrays are sometimes referred to as RAID 0+1 or RAID 10 and RAID 0+5 or RAID 50.

31

RAID 6 is similar to RAID 5 in that data protection is achieved by writing parity information

to the physical drives in the array. With RAID 6, however,

two

sets of parity data are used.

These two sets are different, and each set occupies a capacity equivalent to that of one of

the constituent drives. The main advantage of RAID 6 is High data availability – any two

drives can fail without loss of critical data.

In summary:

RAID 0 is the fastest and most efficient array type but offers no fault-tolerance. RAID 0

requires a minimum of two drives.

RAID 1 is the best choice for performance-critical, fault-tolerant environments. RAID 1 is

the only choice for fault-tolerance if no more than two drives are used.

RAID 3 can be used to speed up data transfer and provide fault-tolerance in single-user

environments that access long sequential records. However, RAID 3 does not allow

overlapping of multiple I/O operations and requires synchronized-spindle drives to avoid

performance degradation with short records. RAID 5 with a small stripe size offers similar

performance.

RAID 5 combines efficient, fault-tolerant data storage with good performance

characteristics. However, write performance and performance during drive failure is

slower than with RAID 1. Rebuild operations also require more time than with RAID 1

because parity information is also reconstructed. At least three drives are required for

RAID 5 arrays.

RAID 6 is essentially an extension of RAID level 5 which allows for additional fault

tolerance by using a second independent distributed parity scheme (two-dimensional

parity). Data is striped on a block level across a set of drives, just like in RAID 5, and a

second set of parity is calculated and written across all the drives; RAID 6 provides for an

extremely high data fault tolerance and can sustain multiple simultaneous drive failures.

It is a perfect solution for mission critical applications.

32

RAID Management

The subsystem can implement several different levels of RAID technology. RAID levels

supported by the subsystem are shown below.

RAID

Level

Description

Min

Drives

0

Block striping is provide, which yields higher performance than

with individual drives. There is no redundancy.

2

1

Drives are paired and mirrored. All data is 100% duplicated on

an equivalent drive. Fully redundant.

2

3

Data is striped across several physical drives. Parity protection is

used for data redundancy.

3

5

Data is striped across several physical drives. Parity protection is

used for data redundancy.

3

6

Data is striped across several physical drives. Parity protection is

used for data redundancy. Requires N+2 drives to implement

because of two-dimensional parity scheme

4

0 + 1

Combination of RAID levels 0 and 1. This level provides striping

and redundancy through mirroring.

4

30

Combination of RAID levels 0 and 3. This level is best

implemented on two RAID 3 disk arrays with data striped across

both disk arrays.

6

50

RAID 50 provides the features of both RAID 0 and RAID 5. RAID

50 includes both parity and disk striping across multiple drives.

RAID 50 is best implemented on two RAID 5 disk arrays with

data striped across both disk arrays.

6

4.2 SCSI Concepts

Before configuring the subsystem, you must first understand some basic SCSI concepts so

that the subsystem and SCSI devices will function properly.

4.2.1 Multiple SCSI Format Support

The subsystem support the SCSI interface standards listed below. Note that the data bit and

cable length restrictions must be followed.

SCSI Type Data Bit Data Rate Cable Length

SCSI-1 8 Bits 5 MB/Sec 6 m

Fast SCSI 8 Bits 10 MB/Sec 3 m

Fast Wide SCSI 16 Bits 20 MB/Sec 3 m

Ultra SCSI 8 Bits 20 MB/Sec 1.5 m

Ultra Wide SCSI 16 Bits 40 MB/Sec 1.5 m

Ultra 2 SCSI 8 Bits 40 MB/Sec 12 m

33

Ultra 2 Wide SCSI 16 Bits 80 MB/Sec 12 m

Ultra 160 Wide LVD 16 Bits 160MB/Sec 12 m

Ultra 320 LVD 16 Bits 320MB/Sec 12 m

4.2.2 Host SCSI ID Selection

A SCSI ID is an identifier assigned to SCSI devices which enables them to communicate with

a computer when they are attached to a host adapter via the SCSI bus. Each SCSI device,

and the host adapter itself, must have a SCSI ID number (Ultra 320 LVD SCSI = 0 to 15).

The ID defines each SCSI device on the SCSI bus. If there are more than one SCSI adapter in

the Host subsystem, each adapter forms a separate SCSI bus. SCSI IDs can be reused as

long as the ID is assigned to a device on a separate SCSI bus. Refer to the documentation

that came with your peripheral device to determine the ID and how to change it. The

subsystem must be assigned a unique SCSI ID ranging from 0 to 15 for the Ultra 320 LVD

SCSI host system. The default value is ID 0.

4.2.3 Terminators

Based on SCSI specifications, the SCSI bus must be terminated at both ends, meaning the

devices that are connected to the ends of the SCSI bus must have their bus terminators

enabled. Devices connected in the middle of the SCSI bus must have their terminators

disabled. Proper termination allows data and SCSI commands to be transmitted reliably on

the SCSI bus. The host adapter and the SCSI devices attached to it must be properly

terminated, or they will not work reliably. Termination means that terminators are installed in

the devices at each end of the bus.

NOTE: If your RAID subsystem is the last device on the SCSI bus,

attach the terminator included in the package to the Host Channel A

& B Out port before using the subsystem.

4.3 Disk Drive Organization

The subsystem arranges the SCSI drives connected to it as a physical drive group and logical

unit (LUN).

4.3.1 Physical Drive Groups

The subsystem has up to a maximum of twelve (12) individual disk drives which can be used

to form a physical drive group. To calculate the total size of a particular drive group,

(Smallest disk size) x (Number of disks) = Capacity for RAID 0

(Smallest disk size) x [(Number of disks) / 2] = Capacity for RAID 1

(Smallest disk size) x [(Number of disks) - 1] = Capacity for RAID 3 or 5

(Smallest disk size) x [(Number of disks) - 2] = Capacity for RAID 6

{(Smallest disk size) x [(Number of disks in each sub-array) - 1)]} x (Number of sub-arrays)

= Capacity for RAID 30 or 50

4.3.2 Logical Unit Number (LUNs)

A logical unit is a drive group read by the host system as a logical device. The subsystem

supports up to eight (8) LUNs for drive group.

34

4.3.3 Hot-Swap Drive Replacement

The subsystem supports hot-swapping of drives while the system is powered on. A disk may

be disconnected, removed or replaced with a different disk without turning off the system.

4.3.4 Disk Failure Detection

The subsystem can automatically detect disk failures. It monitors disk activities including the

elapsed time on all commands issued to the disks as well as parity errors and other potential

problems. A time-out will reset the disk and retry the command. If the command time-out

occurs again, the disk will fail. Any disk with too many errors will be shut down by subsystem.

35

5 Configuration Utility Options

The subsystem has a setup configuration utility built in containing important information

about the configuration as well as settings for various optional functions in the subsystem.

This chapter explains how to use and make changes to the setup utility.

Configuration Methods

There are three methods of configuring the subsystem. You may configure through the

following methods:

• VT100 terminal connected through the controller’s serial port

• Front panel touch-control keypad

• Java-based proRAID management

IMPORTANT: The subsystem allows you to access the utility using

only one method at a time. You cannot use both methods at the

same time.

5.1 Configuring through a Terminal

To start-up:

1. Connect a VT100 compatible terminal or a PC operating in an equivalent terminal

emulation mode to the monitor port located at the rear of the subsystem.

NOTE: You may connect a terminal while the subsystem’s power is

on.

2. Power-on the terminal.

3. Run the VT100 program or an equivalent terminal program.

36

4. The default setting of the monitor port is 115200 baud rate, 8 data bit, non-parity, 1 stop

bit and no flow control.

5. After connecting and powering on the terminal. Press “ l ” key to enter password screen.

The preset password is 8 zeroes. Type “00000000”.

37

6. Then press <Enter> to enter screen. The Main Menu will appear.

Keyboard Function Key Definitions

“ Enter ” key : to confirm a selected item

“ <Ctrl>+Q ” key : to exit a selection or Logout

“ ” Arrow keys : to move in / among fields or Traverse Menu

“ Tab ” key : to move to the next default value

VT100 terminal configuration Utility Main Menu Options

Select an option and the related information or submenu items display beneath it. The

submenus for each item are explained as below.

38

The configuration utility main menu options are:

Option Description

Quick setup Quickly establish a single RAID

RAID Management Set parameters for a single or multiple arrays

SCSI Configuration

Set SCSI parameters such as SCSI ID, speed and Tag

Queue.

System Management

Set System parameters such as Ethernet, Time, password,

Upgrade Firmware and Event Logs

Disk Management

Set disk utility such as view disk status, set spare, and, set

faulty.

5.2 Configuring the Subsystem Using the LCD Panel

All configurations can be performed through the LCD Display front panel function keys,

except for the “Firmware update”. The LCD provides a system of screens with areas for

information, status indication, or menus. The LCD screen displays menu items or other

information up to two lines at a time. The RAID subsystem password is set to 00000000 by

manufacture default.

Function Key Definitions

The four function keys at the top of the front panel perform the following functions:

Parts Function

Exit button Press this button to return to the previous menu.

Select button This is used to enter the option you have selected.

Up and Down arrow buttons

Use the Up or Down arrow keys to move between

each menu when you configure the subsystem.

39

The following tree diagram is a summary of the various configurations and setting functions

that can be accessed through the LCD panel menus.

40

6 Accessing the proRAID Manager GUI

ProRAID Manager RAID Management Software is an OS-independent Java Application that

manages Epica systems. This software is provided on a CD shipped with your Epica system

and should be installed on the host system that you will use to manage the system.

The ProRAID Manager provides end users a friendly Java GUI that makes versatile RAID

functions available to general users. Users can easily plan and operation their RAID by using

ProRAID Manager, and they can simply configure different controller series at the same JAVA

Based Platform.

The ProRAID Manager supports Multi-Node Management. If you have several RAID

subsystems connected to the intranet, you can see all these systems when you login to the

ProRAID Manager. The IP Address section lists the RAID systems connected to the network.

This section describes the steps that you need to take to get ProRAID Manager up and

running on your system.

6.1 Installation

6.1.1 Installing on Windows System

6.1.1.1 System Requirement

Server :

1. Windows NT/2K/XP/2003 or later version

2. IIS 4 or later version

3. JRE 1.4 or later version

Client :

1. Web Browser (ex. IE, Mozilla, FireFox, Opera ......)

2. JRE 1.4 or later version

3. Java Web Start 1.x or later version

6.1.1.2 Software Installation:

1. Setup IP Address of installation Server.

2. Install Apache Web server application or IIS.

3. Install JAVA 2 WebStart Software.

(Free download from: http://java.sun.com/j2se/index.jsp)

4. Install “ProRAIDMgr” to the Web server path.

Step 1: Insert the CD.

Step 2: Change to ‘Win32’ directory.

Step 3: Double click ‘Setup.exe’.

Step 4: Click ‘Next’ and follow screen.

41

Step 5: Select install path to your web sub directory.

5. Setup ProRAIDMgr Server IP Address then press ‘Next’.

Use Default IP Address: Use ProRAIDMgr Detecting IP Address.

Setup IP Address Manually: Type IP Address.

42

6. Press ‘Next’ to install ProRAIDMgr.

7. ProRAIDMgr has been successfully installed. Press ‘Finish’. Reboot the Windows.

8. Starting ProRAIDMgr :

a. Click Desktop ‘ProRAIDMgr Home’

short cut icon to start.

b. Open the browser with Java support, IE5.0 and NC6.0 or up are recommended.

Type ‘http:// <Host IP or Host Name >/proRAIDMgr/raidMgr.html’ in address bar.

43

6.1.2 Installing on Linux

6.1.2.1 System Requirement:

Server :

1. JRE 1.4 or later version

2. Bash shell

3. Apache web server

Client :

1. JRE 1.4 or later version

2. Java Web Start 1.x or later version

3. Web Browser (ex. Mozilla, Netscape, FireFox, Opera...)

6.1.2.2 Software Installation:

1. Setup IP Address of installation Server.

2. Install Web server application.

3. Install JRE or JDK.

4. Install JAVA 2 WebStart Software.

(Free download from: http://java.sun.com/j2se/index.jsp)

5. Install “ProRAIDMgr”.

Step 1: Login as ‘root’.

Step 2: Mount CD.

Step 3: Change directory to ‘UNIX’.

Step 4: Copy proraidmgr.tar.gz to the directory you want to install proRAIDMgr ($install_dir)

Step 5: cd $install_dir

Step 6: tar -xvzf proraidmgr.tar.gz

Step 7: cd $install_dir/proware

Step 8:./install.sh

Step 9: Create an alias named 'proRAIDMgr' in your web server config file

(ex. /etc/httpd/httpd.conf) and link it to $install_dir/proware/web

Sample:

Alias /proRAIDMgr/ "$install_dir/proware/web/"

<Directory "$install_dir/proware/web">

Options Indexes FollowSymlinks MultiViews

AllowOverride None

Order allow,deny

Allow from all

</Directory>

Step 10: Add the follow to mime.types file (ex. /etc/mime.types)

application/x-java-jnlp-file JNLP

6. Start proRAIDMgr:

Step 1: Restart your web server

Step 2: cd $install_dir/proware

Step 3: ./start

Step 4: Open your browser and navigate to http://your_ip/proRAIDMgr/raidMgr.html

Note:

1. You must login as root to install proRAIDMgr

2. If your IP address has been modified, please edit ./web/proRAIDMgr.jnlp manually

or exceute ./install.sh again.

44

6.2 Starting ProRAID Manager

1. Open the browser with Java support, IE5.0 and NC6.0 or up are recommended. Type

‘http:// <Host IP or Host Name >/proRAIDMgr/raidMgr.html’ in address bar.

2. In the page that opens, click START button to enter the proRAID Manager page.

3. Logon proRAID Manager in the first time. System will display a security warning. Before

clicking Start button, users may want to verify whether the downloaded applet is signed

by Proware Technology Inc. Normally, this won’t be a problem, unless your firmware is

hacked.

4. Logon. The default username will be ‘admin’ and password will be ‘proware’,

Administrator, admin account, can perform privilege functions. It is highly recommended

to change your password after the first logon.

45

5. Click Probe proFamily Server button. If you have several subsystems connected to the

intranet, you can see all these systems in left tree panel when you login to the ProRAID

Manager.

6. Double click the server name to enter server information page to view server Host Name,

OS version and IP Address.

46

6.3 Configuration Procedures

The proRAID Manager GUI provides the following configuration settings:

1. Change Password

2. Mount RAID Subsystem

3. Detach RAID Subsystem

4. proRAIDMgr Log

5. Event Manger

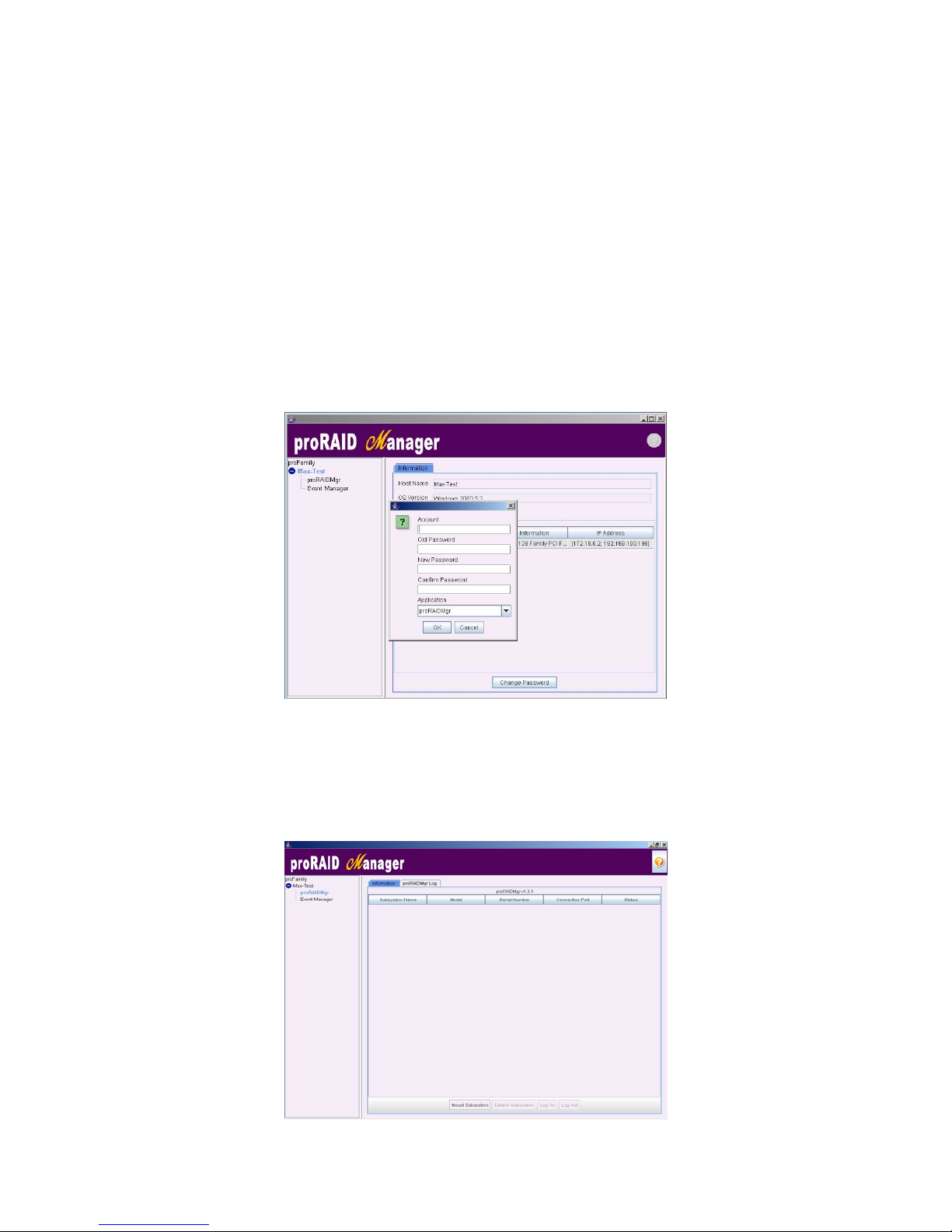

6.3.1 Change Password

To set or change the proRAIDMgr password, move the mouse cursor to Server Name

screen, and click on the Change Password button. The Modify Password screen appears.

The password option allows user to set the proRAIDMgr’s password protection feature. Click

on the OK button to finish the operation.

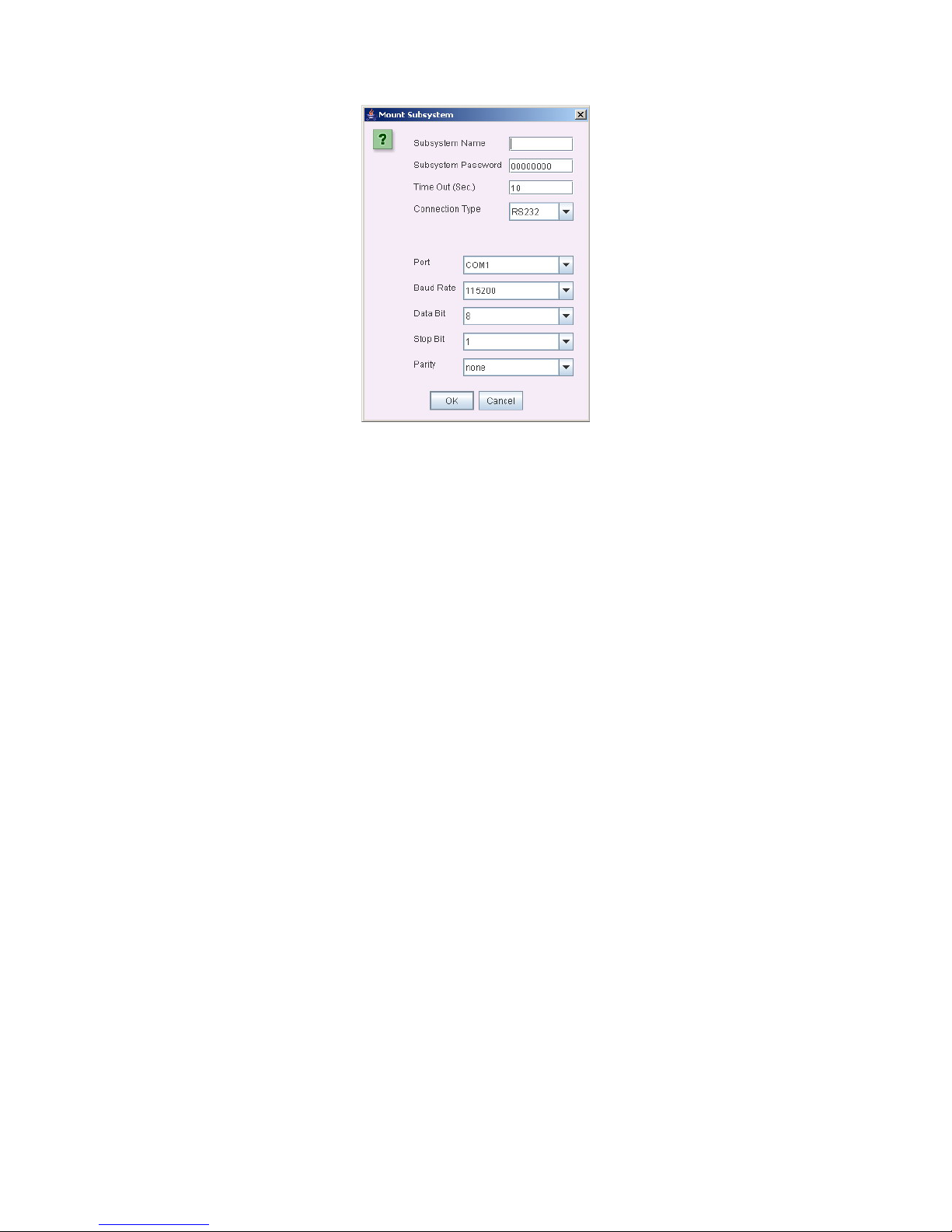

6.3.2 Mount RAID Subsystem

To Mount RAID Subsystem, move the mouse cursor to proRAIDMgr screen, and click on the

Information tab. Then click on the Mount Subsystem button and the System will display

the Mount Subsystem window.

47

Select the desired function.

Connection Type:

1. RS232: Connect the Monitor port of RAID Subsystem to Server system COM1 via

RS232 cross cable. The setting of port is ‘COM1’ or ‘/dev/ttyS0’. The speed of Baud

Rate is same as controller’s setting.

2. R-Link: R-Link is supporting management and configuration through web-based

graphic user interface and allows users to remotely manage their storage over their

network. Connect the R-Link port of RAID subsystem to your network hub or switch.

3. SCSI-Fibre: Connect the host channel SCSI / Fibre connector of the RAID

subsystem to SCSI / Fibre connector of Server system. This option is for viewing

only.

- Win32: [driver letter:] or [physicaldriveX]

- Linux: scsi generic device; sgX

- FreeBSD: daX

- Solaris-Sparc: /dev/rsdXc

Click on the OK button to finish the operation.

6.3.3 Detach RAID Subsystem

To Detach RAID Subsystem, move the mouse cursor to proRAIDMgr screen, and click on

the Information tab. Then Select the target RAID subsystem to detach by clicking the

Detach Subsystem button.

6.3.4 View proRAIDMgr Log

To view the proRAIDMgr Log, move the mouse cursor to proRAIDMgr screen, and click on

the proRAIDMgr Log tab. The proRAIDMgr Log Information screen appears. Use the

refresh Log and clear log button to refresh or clear logs manually.

48

6.3.5 Event Manager

6.3.5.1 E-Mail Setting

To set the E-mail function, move the mouse cursor to select ‘Event Manager’ in the left tree

node and choose E-Mail Setting tab. The proRAIDMgr E-Mail setting menu will show all

items. Then click on the ‘Edit’ button to edit.

In the email setting section, you need to enter the following information:

1. Sender E-mail address: Enter the sender e-mail address

2. SMTP server: Enter the IP address of the SMTP server

3. Port: Enter the port number. The default setting of port is 25.

4. Account: Enter the username

5. Password: Enter the password

After entering these fields enter the receivers e-mail address and click on Add command

button to add the receipts address. You can enter multiple e-mail addresses separated by

semi-colons.

This email setting defines the receivers which will get the warning message from proRAIDMgr

if there are events that happened.

After you complete the addition, tick on the ‘Save’ button.

49

6.3.5.2 Event Setting

To set the Event Notification function, move the mouse cursor to select ‘Event Manager’ in

the left tree node and choose ‘Event Setting’ tab. The proRAIDMgr Event Notification

function menu will show all items. Then click on the ‘Edit’ button and ‘Enable Event

Notification’ to select the desired function.

When an abnormal condition occurs: HD Bad Block, RAID Erase, Disk Fail, RAID Scrub,

proRAIDMgr Start Up, Disk Insert, RAID Initialize, RAID Check, RAID Rebuild, RAID

Damaged , RAID Expand, and Disk Remove, an error message will be email to administrator

that a problem has occurred.

Script Path: Select error conditions you want the Gateway to launch external program.

After you complete the addition, tick on the ‘Save’ button.

50

7 RAID Management

This section describes the available RAID Management tasks; these tasks may be selected

from the RAID subsystem menu in the left tree node of the ProRAID Manager screen.

7.1 About RAID

RAID stands for Redundant Array of Independent Disks. A RAID system consists of two or

more disks in parallel. This array of disks appears as one disk drive to the host computer

offering enhanced performance or data reliability or both.

There are different RAID levels with each level being suited to a particular application. For

example, RAID Level 1 uses mirroring to hold your data in 2 separate but identical locations.

If a disk fails the RAID controller will use either the data disk(s) or the mirror disk(s) for data

recovery giving you constant access to your data. This RAID Level is particularly suited to

mission critical applications such as accounting systems.

7.1.1 RAID Considerations

7.1.1.1 How Many Disks Are Available?

The number of physical disks that are available will influence your decision about which RAID

level you can choose and whether or not you can have a spare drive(s). The following table

shows the minimum number of disks that are required to implement each RAID level.

RAID Level

Minimum Number of

Disks

JBOD 1

Linear 1

0 2

1 2

3 3

5 3

6 4

0 + 1 4

30 6

50 6

If you wish to have a Spare Drive, you will need to have at least the minimum number of

disks, plus a disk for every Spare Drive you require.

7.1.1.2 Spare Drive Strategy

A Spare Drive is a disk drive that is set aside when creating your RAID system so that it can

be used to rebuild a RAID in the event of a disk drive in that RAID failing. This reduces the

risk to your data as the RAID can be rebuilt immediately without installing a new disk to

replace a failed disk in the RAID.

51

When creating your RAID you must consider which Sparing Strategy you want to implement.

There are 3 possible Sparing Strategies available in ProRAID Manager:

None

Local

Global

A Local Spare Drive is a spare disk that is only available to the RAID in which it was

created. If a disk fails in a RAID in the system, a Local Spare from another RAID cannot be

used to rebuild the degraded RAID.

A Global Spare Drive is a spare disk that is available to all RAIDs in the system. If a disk

fails in any RAID in the system, the Global Spare disk can be used to rebuild the degraded

RAID.

NOTE: A Spare Disk must have capacity equal to or greater than the

capacity of the disks in the RAID(s) to which it is assigned.

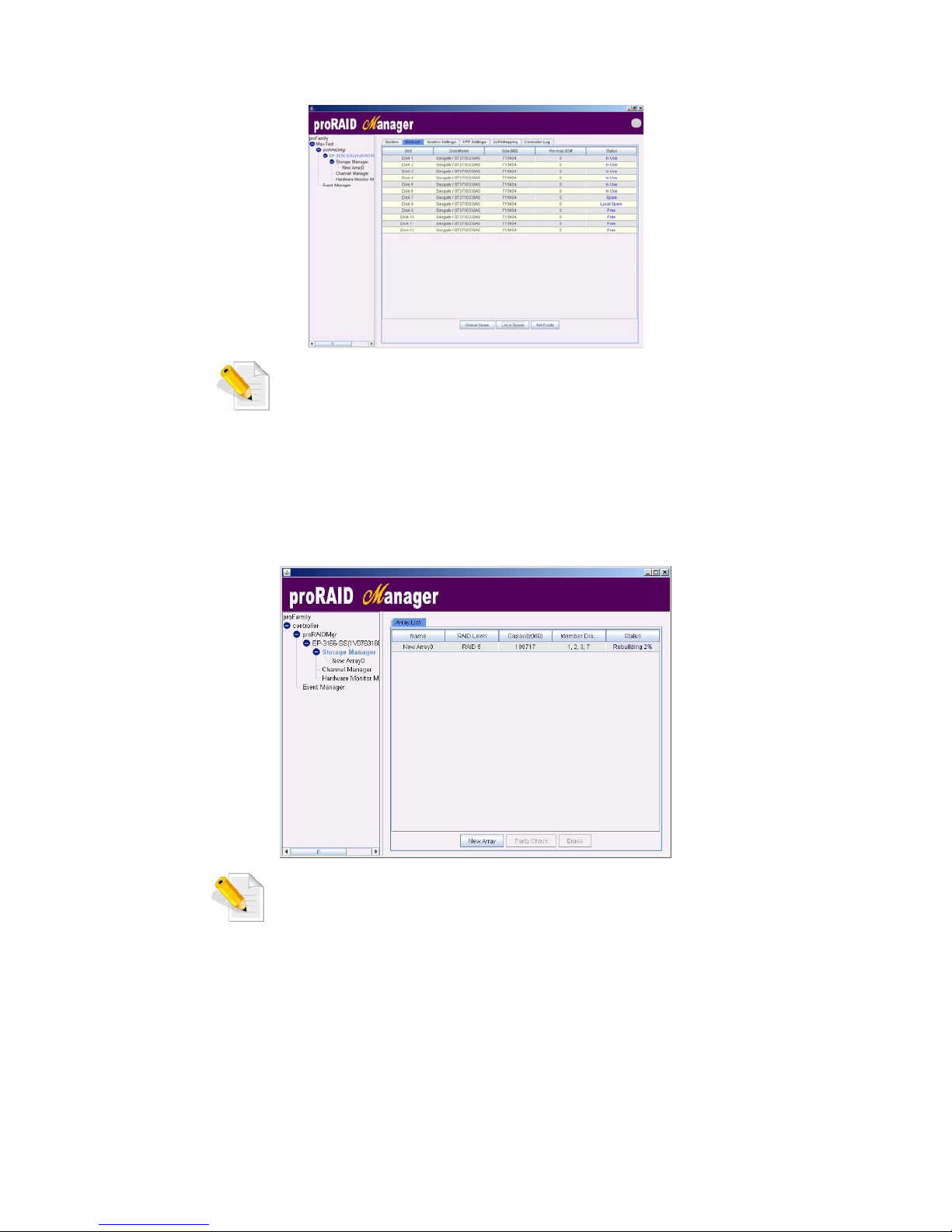

7.2 Array Status

The RAID Status screen displays a summary of all RAIDs currently created on the system.

This screen displays a summary of the RAID settings on the system, select ‘Storage

Manager’. This will display the information in table format. You can double-click on an entry

in the table to view more detailed information about the selected RAID. The tree view on the

left of the screen also lists the available RAIDs on the system.

52

The following table gives an explanation of each option/action available on this screen:

Field Description

RAID Name User-friendly name that helps you identify the RAID.

RAID Level

Configured when the RAID is created. The current options

are levels 0, 1, 0+1, 3, 5, 30, 50, linear and JBOD.

Capacity (MB) Capacity of the RAID in Megabytes.

Member Disks The disks include in the RAID.

State

The states available are:

Ready

Need to Rebuild

Initializing

Rebuilding

Expanding

Verifying

Cloning

Fail

If the RAID is rebuilding, initializing, expanding, checking

or cloning, the progress of the task will be displayed, e.g.

‘Initializing 75%’.

7.2.1 Array Properties

The Array Information screen displays details about the selected RAID. The Array Information

screen can be accessed in one of two ways:

Double clicking a highlighted RAID in the ' Array List ' screen.

Clicking a RAID in the tree view on the left of the screen.

The Array Information screen gives you details about the RAID such as the RAID level, Stripe

Size, Block Size, etc.

53

The following table gives an explanation of each option/action available on this screen:

Field Description

Array Name User-friendly name that helps you identify the Array.

RAID Level

Configured when the RAID is created. The current

options are levels 0, 1, 0+1, 3, 5, 30, 50, linear and

JBOD.

Capacity

(MB)

Capacity of the Array in Megabytes.

Stripe Size

This parameter sets the size of the stripe written to

each disk. You can set the stripe size to 8k, 16k, 32k,

64k, 128k, 256k or 512k.

Max Remapped BS#

The Maximum number of Bad Sector, which is 10,000.

Block Size

User can use this option to create the volume over 2TB.

For windows version: 1K, 2K and 4K.

For 64bit LBA mode: 512 bytes. Due to LSI chip

limitation, 16 Byte CDB option must run at U320 mode.

Joined Slots Select the disks that you want to join in the Array.

Volume Name User-friendly name that helps you identify the Volume.

Capacity

(MB)

Capacity of the Volume in Megabytes.

Read Ahead

The Maximum number of Read Ahead is 99. The

controller will read ahead to optimize performance on

sequential reads.

Mapping

Channel

Mapping LUN(s) to a host channel. LUN mapping is the

process to make a volume visible to a desired host

channels.

54

7.3 Creating a RAID

This Logical Volume allows you to easily verify that a Host system is able to connect to the

storage and map to this Logical Volume. You can create RAID configurations and Logical

Volumes that your storage architecture plan requires.

7.3.1 Configuring Array Options

To create a new Array, move the mouse cursor to Storage Manager link, and click on the

New Array button. On this screen you can configure your RAID using the drop down lists to

select the relevant parameters that define your RAID.

A “New Array Information”

screen is displayed showing the drive connected to the current

controller.

The create new Array allows user to select the Array name, RAID level, capacity, strip size,

Max Re-mapped BS#, Block Size, Background init, Ignore Bad Sectors, and Joined Slots.

Complete the following steps to configure the RAID options:

55

1. Array Name: The default Array name will always appear as New Array #. You can

rename the Array name providing it does not exceed the 20 characters limit.

2. Joined Slots: You can add disks to the Joined Slots list by selecting a disk in the

Free Slots List and clicking the >> button. To remove existing disks, select the disk in

the Joined Slots list and click the << button.

3. Raid Level: Set the RAID level for the Array. The available RAID levels for the current

Array are displayed.

4. Stripe Size: This parameter sets the size of the stripe written to each disk. You can set

the stripe size to 8k, 16k, 32k, 64k, 128k, 256k or 512k.

5. Max Re-mapped BS#: The Maximum number of Bad Sector is 10,000.

6. Block Size: User can use this option to create the volume over 2TB.

For windows version: 1K, 2K and 4K.

For 64bit LBA mode: 512 bytes. Due to LSI chip limitation, 16 Byte CDB option must

run at U320 mode.

7. Initialization Mode: Select this option to enable background initialization, otherwise

foreground initialization mode is in effect. Foreground mode allows for faster completion

and background mode is for instant available array.

NOTE: With foreground initialization, an array will be accessible

only after initialization is completed and volume can then be added.

With background initialization, an array will be accessible during

initialization and volume can be created immediately.

8. Ignore Bad Sectors: Use this option to Ignore Bad Sectors. This option is for rescuing

Array. It is recommended that you disable this option in normal situation.

9. Add Volume: Click on the New Array button to create a new volume. On this screen

you can configure the Volume name, capacity, Read Ahead, and Mapping Channel.

Volume Name: User-friendly name that helps you identify the Volume.

Capacity (MB): Capacity of the Volume in Megabytes.

Read Ahead: The Maximum number of Read Ahead is 99. The controller will read

ahead to optimize performance on sequential reads.

Mapping Channel: Mapping LUN(s) to a host channel. LUN mapping is the process

to make a volume visible to a desired host channels.

SCSI Channel: The RAID subsystem supports one SCSI Channel or Dual SCSI

Channel.

SCSI ID: Select 0 to 15 or Multiple ID. Each SCSI device attached to the SCSI card,

as well as the card itself, must be assigned a unique SCSI ID number. A Wide SCSI

channel can connect up to 15 devices. The RAID subsystem is as a large SCSI

device. We should assign an ID from a list of SCSI IDs.

SCSI LUN: Select a

Logical Unit Number

(LUN 0 to LUN 31). Most SCSI host

adapter treats each LUN like a SCSI disk.

56

Press ‘Save’ button and go back to Array List Screen. Note there will be indicated how

many percentage of the process has been done.

10. When creating your RAID you must consider which Sparing Strategy you want to

implement. To set the hot spare function, move the mouse cursor to select ‘RAID

Model’ in the left tree node and choose ‘Slot List’ tab. Then click on the ‘Global

Spare’ button or ‘Local Spare’ to select the desired function.

57

NOTE: A Spare Disk must have capacity equal to or greater than the

capacity of the disks in the RAID(s) to which it is assigned.

A Global Spare Drive is a spare disk that is available to all RAIDs in the system. If a

disk fails in any RAID in the system, the Global Spare disk can be used to rebuild the

degraded RAID.

A Local Spare Drive is a spare disk that is only available to the RAID in which it was

created. If a disk fails in a RAID in the system, a Local Spare from another RAID

cannot be used to rebuild the degraded RAID.

Press ‘OK’ button to go back to Slot List Screen. Disk status is displayed in the status area

of the Slot List screen.

58

NOTE: A Local Spare Drive has priority over a Global Spare Drive

when rebuilding an Array.

7.3.2 Rebuilding an Array

Rebuilding an Array means a Spare Drive has taken over a failed disk drive and parity is being

re-generated on the Spare Drive. An Array can also be rebuilt by replacing the failed disk

drive.

NOTE: The performance of the system will slow down during a

rebuild.

59

7.4 Parity Checking a RAID

To create a new Array, move the mouse cursor to Storage Manager link, and click on the

Parity Check button.

You can use this option to check the consistency of parity blocks, i.e. verify that parity

information matches the stored data on the redundant arrays. This is not possible to check

RAIDs created using RAID 0. During a RAID Verify the system reads each stripe and checks

for valid parity. The system will over write correct parity if any stripes were found with invalid

parity.

The verifying percentage can also be viewed in the status area.

NOTE: It is highly recommended to stop all I/O when you want to

perform the Parity Check function.

7.5 Modifying RAID Settings

To re-configure a RAID, move the mouse cursor to Storage Manager Link. The

modifications that can be carried out on the RAID are:

Erase the RAID

Change Settings

Delete Volume

60

7.5.1 Erase the RAID

You can delete any RAID from this screen, as follows:

1. Select the RAID you wish to delete from the Array List screen.

2. Click on the ‘Erase’ button to delete the selected RAID.

3. Confirm deletion of the RAID by selecting ‘OK’ to confirm in the ‘Erase Array’ dialog box.

7.5.2 Change Settings

You can change any of the settings for your RAID from this screen, as follows:

1. Double clicking a highlighted RAID in the ' Array List ' screen. Or select the RAID you

wish to modify from the tree view on the left of the screen. Click on the ‘Edit’ button to

enter the setting screen.

2. Select the field that you wish to change, and (where available) choose an option from the

drop down menu.

3. Click on the ‘Save’ button to save the settings.

NOTE: The RAID name has a maximum of 20 characters.

61

7.5.3 Delete Volume

You can delete the volume from this screen, as follows:

1. Double clicking a highlighted RAID in the ' Array List ' screen. Or select the RAID you

wish to modify from the tree view on the left of the screen. Click on the ‘Edit’ button to

enter the setting screen.

2. Select the volume that you wish to delete, and click on the ‘Delete Volume’ button to

delete the volume.

3. Click on the ‘Save’ button to save the settings.

7.6 Selecting/Changing a Sparing disk

To Select/change a sparing disk, move the mouse cursor to select ‘RAID Model’ in the left

tree node and choose ‘Slot List’ tab. Then click on the ‘Global Spare’ button or ‘Local

Spare’ to select the desired function.

NOTE: A Spare Disk must have capacity equal to or greater than the

capacity of the disks in the RAID(s) to which it is assigned.

NOTE: Once assigned, the disk cannot be used for assigning as

another spare or creating a RAID.

Press ‘OK’ button to go back to Slot List Screen. Disk status is displayed in the status area

of the Slot List screen.

62

8 Channel Management

This section describes the available Channel Management tasks; these tasks may be selected

from the RAID subsystem menu in the left tree node of the ProRAID Manager screen.

Before configuring the subsystem, you must first understand some basic SCSI concepts so

that the subsystem and SCSI devices will function properly.

8.1 Multiple SCSI Format Support

The subsystem support the SCSI interface standards listed below. Note that the data bit and

cable length restrictions must be followed.

SCSI Type Data Bit Data Rate Cable Length

Ultra Wide SCSI 16 Bits 40 MB/Sec 1.5 m

Ultra 2 Wide SCSI 16 Bits 80 MB/Sec 12 m

Ultra 160 Wide LVD 16 Bits 160MB/Sec 12 m

Ultra 320 LVD 16 Bits 320MB/Sec 12 m

8.2 Host SCSI ID Selection

A SCSI ID is an identifier assigned to SCSI devices which enables them to communicate with

a computer when they are attached to a host adapter via the SCSI bus. Each SCSI device,

and the host adapter itself, must have a SCSI ID number (Ultra 320 LVD SCSI = 0 to 15).

The ID defines each SCSI device on the SCSI bus. If there are more than one SCSI adapter in

the Host subsystem, each adapter forms a separate SCSI bus. SCSI IDs can be reused as

long as the ID is assigned to a device on a separate SCSI bus. Refer to the documentation

that came with your peripheral device to determine the ID and how to change it. The

subsystem must be assigned a unique SCSI ID ranging from 0 to 15 for the Ultra 320 LVD

SCSI host system. The default value is ID 0.

8.3 Configuring Channel Options

To configure channel options, move the mouse cursor to Channel Manager link, and click

on the Edit button. On this screen you can configure your channel using the drop down lists

to select the relevant parameters.

The Channel Information screen gives you details about the channel such as the SCSI ID,

Synchronized Speed, Max Transferred Speed, Wide, Tag Queue, etc.

63

1. SCSI ID: Select 0 to 15 or Multiple ID. The RAID subsystem is as a large SCSI device.

We should assign an ID from a list of SCSI IDs. If Multiple ID is selected, you can map ID

to a host channel.

2. Synchronized Speed: Select the Synchronized Speed. The current options are 40

MB/sec, 80MB/sec and 160MB/sec.

3. Max Transferred Speed: The RAID subsystem supports 320 MB/sec as the highest

data transfer rate.

4. Wide: If enabled

for a wide bus, throughput is double transfer rate, because each

transfer is of 16 bits--two bytes. (e.g. Select 160MB/sec as synchronized speed and

enable wide option, then max transferred speed should be 320MB/sec)

5. Tag Queue: The Enabled option is useful for enhancing overall system performance

under multi-tasking operating systems. The Command Tag (Drive Channel) function

controls the SCSI command tag queuing support for each drive channel. This function

should normally remain enabled. Disable this function only when using older SCSI drives

that do not support command tag queuing.

Press ‘Save’ button to save your settings.

64

9 System Monitoring

This section describes the steps that you need to take to get ProRAID Manager up and

running on your system.

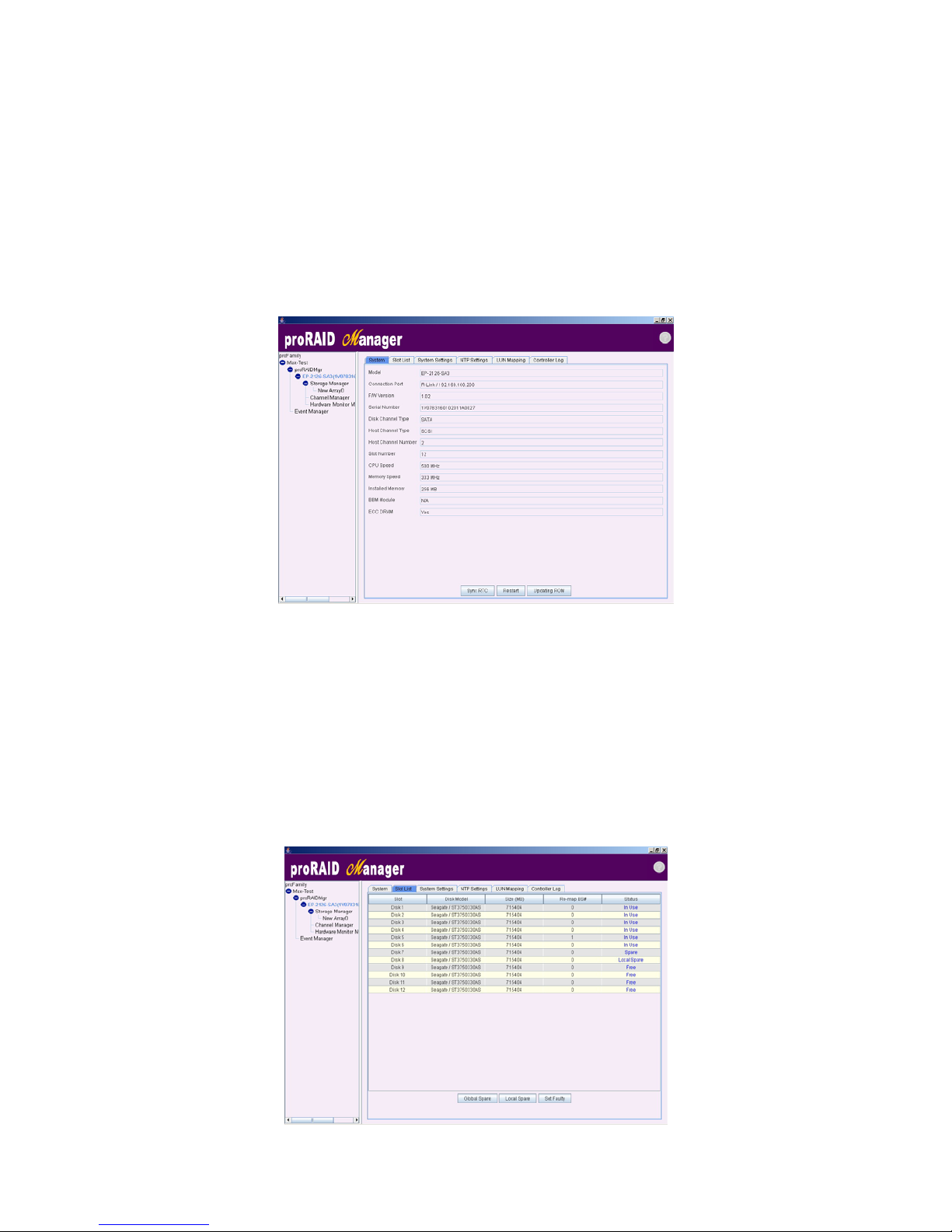

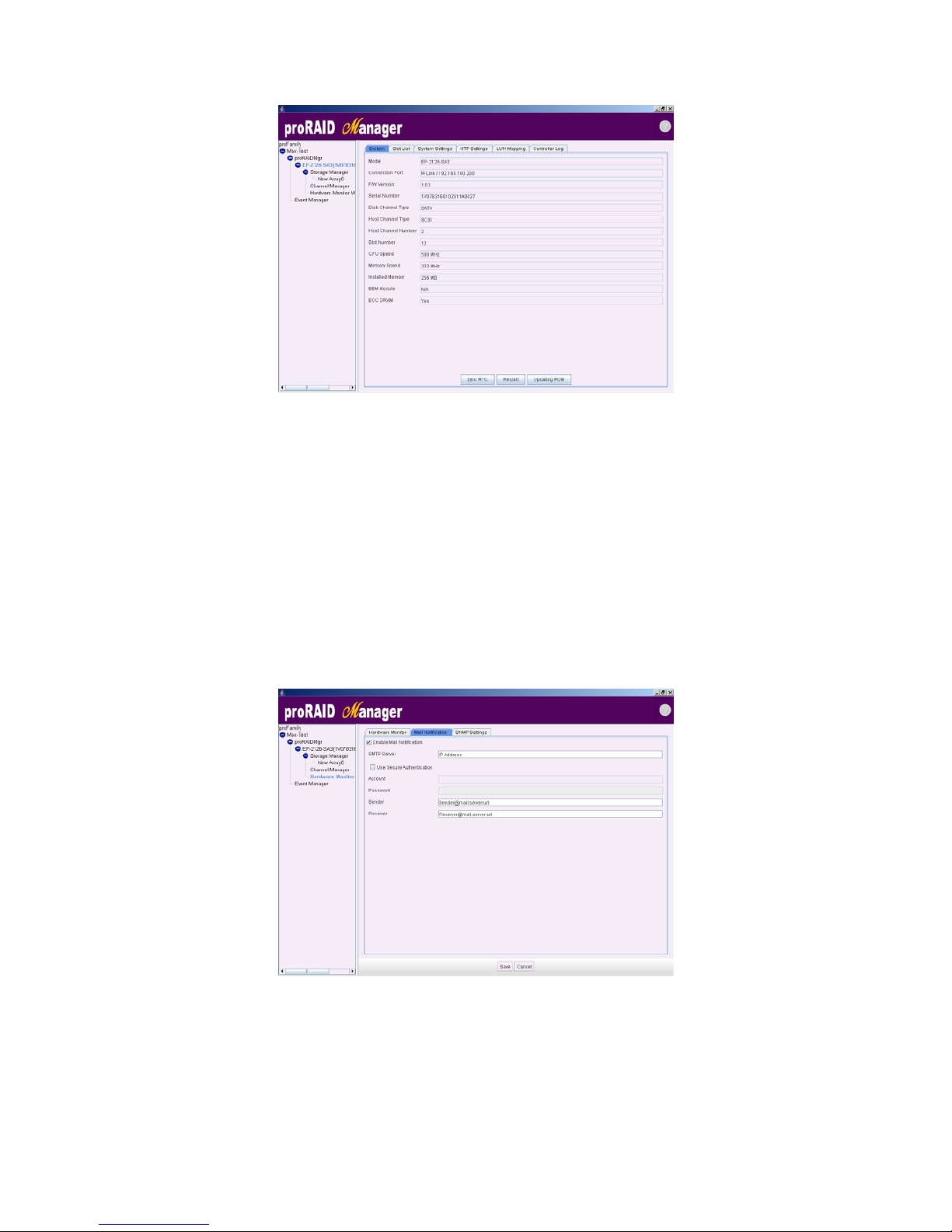

9.1 System Information

To view the system information, move the mouse cursor to select ‘RAID Model’ in the left

tree node and choose ‘System’ tab. The system information screen appears.

Use this feature to view the raid subsystem information. The model, connection port,

firmware version, serial number, disk channel type, host channel type, host channel number,

slot number, CPU speed, memory speed, installed memory, BBM module, and ECC DRAM

appear in this screen.

9.2 Slot List (Disk View)

The Disk View screen gives detailed information about the disks in the system. To view disk

information, move the mouse cursor to select ‘RAID Model’ in the left tree node and choose