Page 1

HMP-200 BENDER

INSTRUCTION SET

PRO-TOOLS

7616 INDUSTRIAL LANE TAMPA, FLORIDA 33637-6715

813-986-9000 PHONE 813-985-6588 FAX

www.pro-tools.com

Page 2

HMP-200 BENDER

ASSEMBLY INSTRUCTIONS

STEP 1 STEP 2

BOLT LEFT SIDE PLATE

TO BASE AS SHOWN WITH

1/2”x20 HEX BOLT & FLAT

WASHER

WELD BASE TO PLATE

ON EACH SIDE

STEP 3 STEP 4

NOTE:

OFFSET HOLE PATTERN

BOLT RIGHT SIDE OF PLATE

TO BASE AS SHOWN WITH

1/2-20 HEX BOLTS * WASHERS

INSTALL SPACER SLEEVES

AS SHOWN BELOW

PLACE JACK ASSEMBLY

ON BLOCK, POSITION AS

SHOWN

813-986-9000 Pro-Tools

PAGE 2

1/2 -20 x 7 HEX BOLTS,

NUTS, & FLAT WASHER

SPACER SLEEVE

Page 3

HMP-200 BENDER

ASEMBLY INSTRUCTIONS

STEP 5

STEP 7

1” BOLT, NUT,

& WASHERS

A. SCREW THREADED

ROD (IN TOP OF JACK)

UP APPROXIMATELY 2 1/4”

B. PLACE ROLLER

BLOCK ON TOP OF ROD.

C. INSERT 1” SHAFT

THROUGH SIDE PLATES,

ROLLER, & BLOCK.

D. INSTALL DIE WRIST

PIN SLEEVE, 1” BOLT, NUT,

& WASHERS.

1” SHAFT

STEP 6

STEP 8

ALL METAL TO METAL

SURFACES MUST BE

GREASED

IT WILL BE NECESSARY

TO WORK JACK UP

& DOWN TO MAKE

SURE THE ALIGNMENT

ON THE SIDE PLATES

IS CORRECT. IF

NECESSARY, LOOSEN

BOLTS & ADJUST UNTIL

JACK MOVES UP & DOWN

FREELY.

INSTALL BOTH

RETURN SPRINGS

AS SHOWN

3/8-16 BOLTS

IMPORTANT:

TIGHTEN SIDE PLATE

BOLTS TIGHT. ALL

OF THE PRESSURE IS

ON THESE BOLTS.

INSTALL DIE AS SHOWN

BOLT FOLLOW BAR

SUPPORT BRACKET

TO ROLLER BLOCK

AS SHOWN

ADJUST HEIGHT TO

MATCH HEIGHT OF

ROLLER BLOCK

813-986-9000 Pro-Tools

PAGE 3

Page 4

HMP-200 BENDER

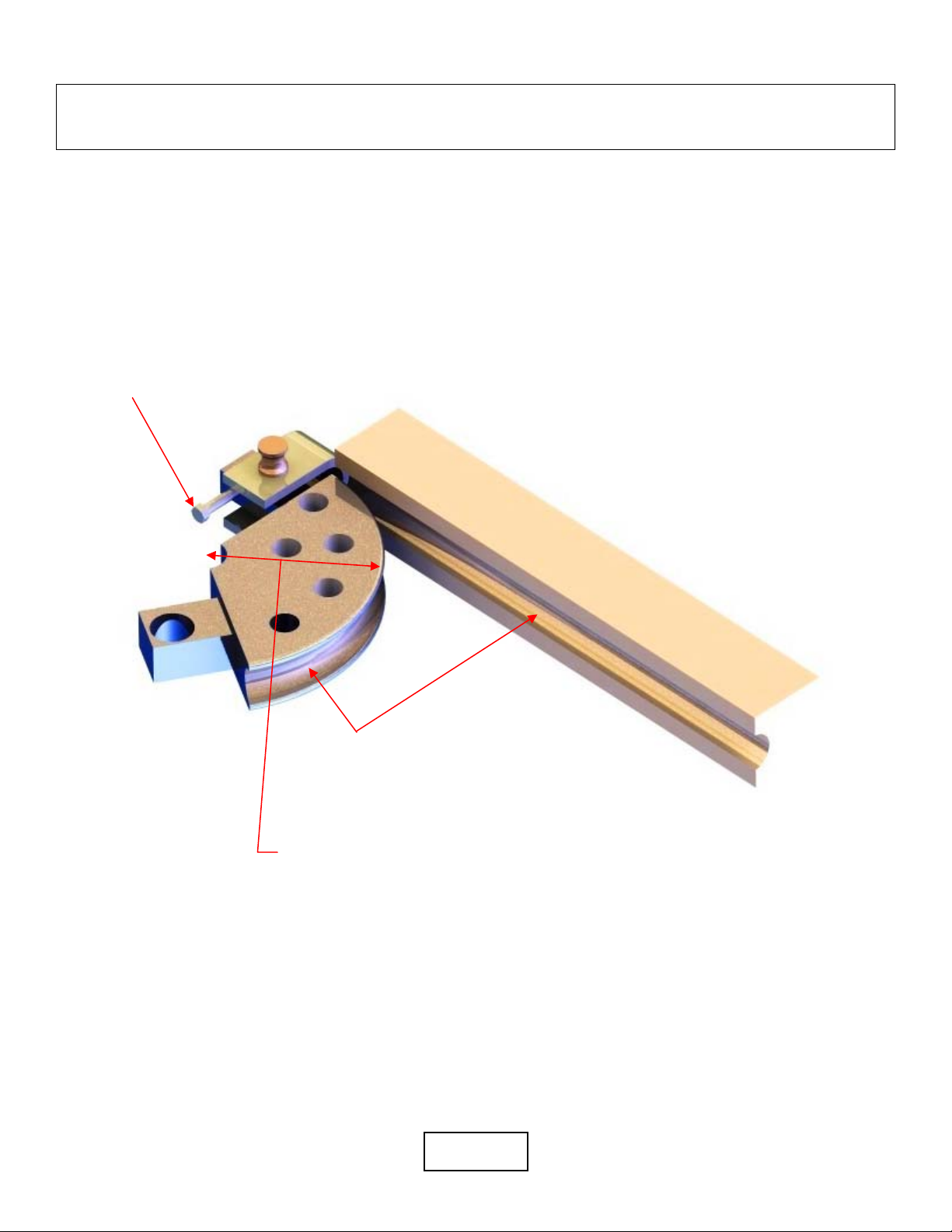

DIE INSTALL

REMEMBER TO GREASE PIVOT

WHEN USING THE DEGREE INDICATOR

IT WILL BE NECESSARY TO JACK THE HYDRAULIC

JACK UNTIL ALL SLACK IS TAKEN OUT OF THE DIE SET.

AT THIS POINT, SET THE INDICATOR AT ZERO. YOU

CAN NOW BEND THE TUBE ACCURATELY TO ANY

DEGREE.

REMEMBER THERE IS ALWAYS “SPRING BACK” ON

TUBING SO IT IS NECESSARY TO BEND PAST THE

POINT THAT YOU ACTUALLY DESIRE TO ALLOW FOR

THIS. WE SUGGEST USING A TEST PIECE OF TUBING

TO DETERMINE THE AMOUNT OF “SPRING BACK” FOR

EACH TUBING SIZE, BEFORE STARTING THE JOB.

PIVOT

SNUG BOLT SO

TUBING DOES NOT

MOVE.

DEGREE

INDICATOR

STEEL DIE

ALUMINUM BAR

LINE BAR & DIE UP

EDGE TO EDGE.

813-986-9000 Pro-Tools

PAGE 4

Page 5

BENDING INSTRUCTIONS

IN THE NEXT FEW PAGES, WE ARE GOING TO TRY TO EXPLAIN A FEW THINGS ABOUT BENDERS & GIVE

SOME EXAMPLES & EXPLANATIONS ON MAKING BENDS.

WE ARE GOING TO TAKE YOU THROUGH A STEP BY STEP PROCEDURE SHOWING YOU HOW TO

DETERMINE THE STARTING POINT OF YOUR BEND, HOW TO CALCULATE THE LENGTH OF TUBING YOU

NEED TO START WITH, AND AS MANY WAYS AS POSSIBLE FOR YOU TO BE ABLE TO PRODUCE

PROFESSIONAL, ACCURATE BENDS.

THE GENERAL RULE, AS FAR AS THE QUALITY OF THE BEND IS AS FOLLOW:

THE THCIKER THE WALL SIZE AND THE SMALLER THE DIAMETER OF THE TUBING BECOMES, THE

BETTER THE BEND.THIN WALL TUBING WILL FLATTEN SOMEWHAT ON ITS OUTER DIAMETER. THIS IS

COMPLETELY NORMAL FOR ANY BENDER OTHER THAN A TRUE MANDREL BENDER. A MANDREL

BENDER USES A STEEL BALL OR SIMILAR SHAPED DEVICE WITH AN OUTSIDE DIAMETER SLI GHTLY

SMALLER THAN THE INSIDE DIAMETER OF THE TUBING BEING BENT. THIS HAS THE EFFECT OF

THINNING THE WALL THICKNESS ON THE OUTSIDE OF THE TUBING, HOWEVER THE ROUNDNESS OF

THE TUBING IS PRESERVED ALMOST PERFECTLY. EXHAUST HEADERS ARE BENT WITH MANDREL

BENDERS. IF A COMPANY TELLS YOU TH EIR BENDER IS A MANDREL BENDE R A ND IT DOES NOT USE

INSIDE MANDRELS, BEWARE!!! TRUE MANDREL BENDERS ARE EXTREMELY EXPENSIVE.

BEFORE WE START WITH BENDING CALCULATIONS WE ARE GOING TO LIST A FEW ITEMS OF

IMPORTANCE.

PIVOT POINT MUST BE LUBRICATED.

(ALL PURPOSE WHEEL BEARING GREASE

WORKS VERY WELL.)

SMALL DIE INSTALLATION

ALWAYS INSTALL DIE IN

LOWEST HOLE POSSIBLE.

BENDER FRAME SHOWN

CUT OFF FOR ILLUSTRATION

PURPOSES ONLY.

DANGER!

WHEN BENDING, DO NOT LET THE END OF THE

FOLLOW BAR GET ANY CLOSER THAN 2” FROM

THE EDGE OF THE ROLLER. IF NECESSARY,

RELEASE THE TENSION ON JACK & SLIDE BAR

BACK.

2” MIN.

THREADED ROD

AFTER INSTALLING DIE & FOLLOW BAR,

REMOVE “PLAY” BY UNSCREWING

THREADED ROD IN JACK UNTIL TIGHT,

NOT BY PUMPING THE JACK.

ROLLER

813-986-9000 Pro-Tools

PAGE 5

Page 6

BENDING INSTRUCTIONS

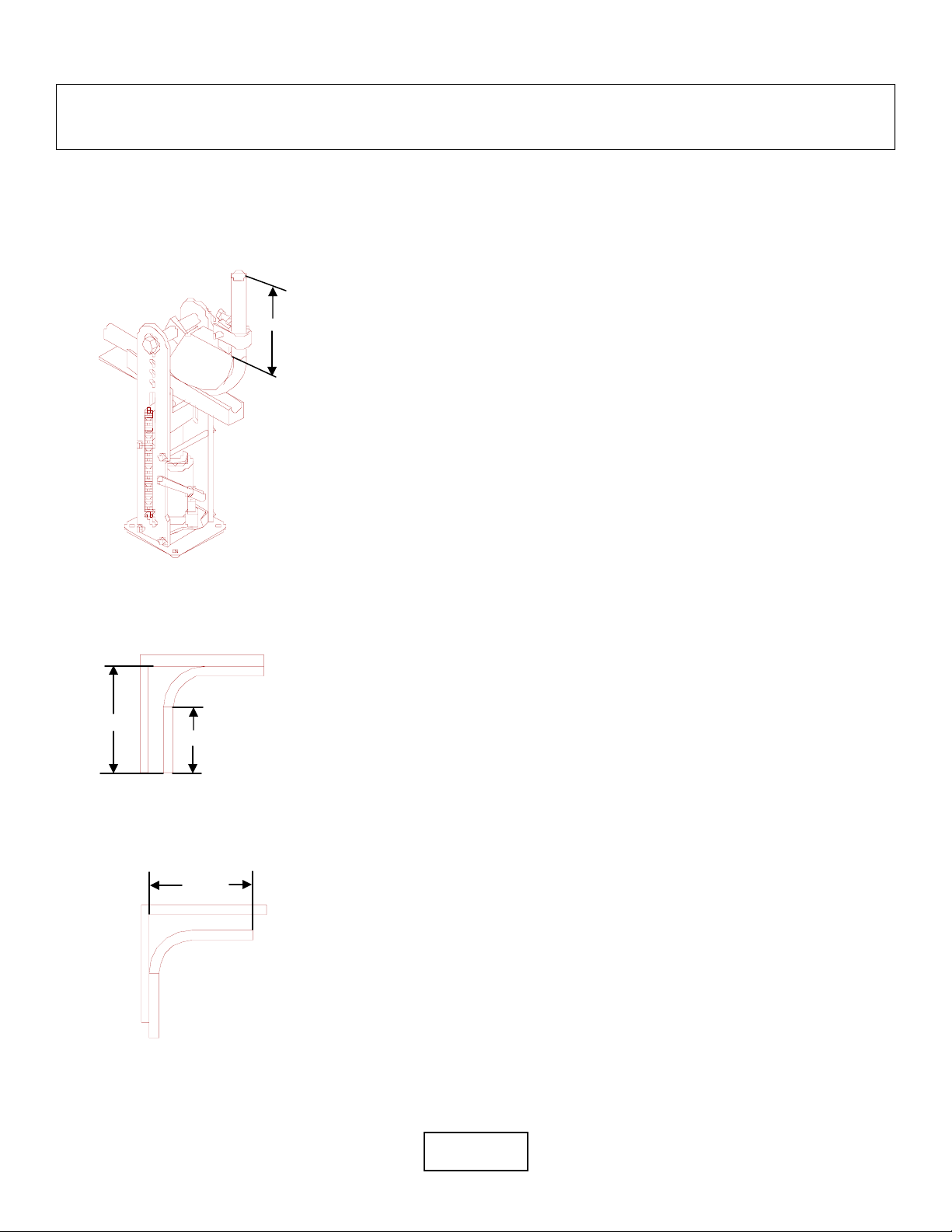

NOTE:

TO CALCULATE LENGTH OF TUBING USED IN A BEND,

MULTIPLY RADIUS OF BEND X 6.28 X DEGREE OF BEND,

THEN DIVIDE BY 360.

TIGHTEN BOLT SO TUBE

WILL NOT SLIP

EXAMPLE:

8 INCH RADIUS, 90 DEGREE BEND WOULD BE;

8 x 6.28 x 90/360 = 12.56

ABSOLUTELY NO GREASE IN RADIUS.

AT ALL TIMES TUBING, DIE RADIUS, AND

BAR RADIUS MUST BE CLEAN AND GREASE FREE.

TO MEASURE RADIUS:

START AT IMAGINARY CENTER OF CUTOUT, MEASURE TO EDGE OF DIE.

NOTE: ALL ROUND TUBE RADIUS MEASUREMENTS ARE “CENTER LINE RADIUS”

813-986-9000 Pro-Tools

PAGE 6

Page 7

BENDING INSTRUCTIONS

THE NEXT FEW PAGES WILL SHOW YOU HOW TO DO A TES T BEND AND HOW TO INTERPRET THE

INFORMATION SO YOU WILL BE ABLE TO MAKE ACCURATE BE NDS.

NOTE: FOR SAFETY’S SAKE WE STRONGLY RECOMMEND THAT YOU BOLT THE BENDER TO THE FLOOR

OR WORKBENCH BEFORE STARTING ANY BENDS.

STEP 1

STEP 2

STEP 3

THE TUBING FOR OUR TEST IS 1 3/4” x 36” LONG. ONLY ONE PIECE IS NECESSARY TO GIVE YOU ALL

THE TUBING FOR OUR TEST IS 1 3/4” x 36” LONG. ONLY ONE PIECE IS NECESSARY TO GIVE YOU ALL

THE INFORMATION YOU WILL NEED TO MAKE ACCURATE BENDS. IT IS A GOOD IDEA TO KEEP A

THE INFORMATION YOU WILL NEED TO MAKE ACCURATE BENDS. IT IS A GOOD IDEA TO KEEP A

NOTEBOOK TO LOG YOUR INFORMATION ON THE TEST BEND. IT WILL BE NECESSARY TO RUN THE

NOTEBOOK TO LOG YOUR INFORMATION ON THE TEST BEND. IT WILL BE NECESSARY TO RUN THE

SAME TEST FOR EACH SIZE TUBING YOU PLAN TO BEND.

SAME TEST FOR EACH SIZE TUBING YOU PLAN TO BEND.

NOTE: EACH SIZE OF TUBING BENDS AND STRETCHE S AN D USES A DIFFERENT AMOUNT

NOTE: EACH SIZE OF TUBING BENDS AND STRETCHE S AN D USES A DIFFERENT AMOUNT

OF TUBING IN THE BEND, SO IT WILL BE IMPORTANT TO LOG THE RESULTS FROM EACH

OF TUBING IN THE BEND, SO IT WILL BE IMPORTANT TO LOG THE RESULTS FROM EACH

TEST.

TEST.

TAKE THE 36” PIECE OF TUBING & MEASURE FROM YOUR RIGHT BACK TO YOUR LEFT EXACTLY

12” & 24” AS SHOWN SO THERE WILL BE NO MISTAKING WHICH END IS WHICH AFTER YOU MAKE

THE BEND.

24”

12”

INSTALL THE TUBING IN THE BENDER AND POSTION THE EDGE

OF THE DIE EXACTLY IN THE CENTER OF THE MARK AS SHOWN,

THEN MAKE A 90 DEGREE BEND. IN THIS EXAMPLE, WE ARE USING

A 1 3/4” x 7” TUBING DIE.

813-986-9000 Pro-Tools

PAGE 7

Page 8

BENDING INSTRUCTIONS

STEP 4

(IMPORTANT) WITH YOUR TUBE BENT TO 90 DEGREES, BUT STILL IN THE

BENDER, CHECK TO SEE IF THE EDGE OF YOUR DIE IS STILL LINED UP

12”

WITH YOUR MARK. IF IT IS, YOU’RE OK. IF NOT, IT WILL BE NECESSARY TO

CUT ANOTHER PIECE OF TUBING AND REPEAT THE TEST. THE MARK MUST

BE LINED UP WITH THE DIE IN ORDER TO GET ACCURATE INFORMATION.

IT WILL BE MECESSARY TO CHECK YOUR BEND WITH A CARPENTER’S

SQUARE TO VERIFY THAT YOUR 90 DEGREE BEND IS ACCURATE.

IF YOU OVER BEND, SIMPLY INSTALL THE TUBE IN A VISE AND YOU WILL BE

ABLE TO PULL IT BACK VERY EASILY. IF IT IS NOT BENT ENOUGH, IT WILL

BE NECESSARY TO RE-INSTALL THE TUBE IN THE BENDER TO FINISH THE BEND

21”

12”

20 1/8”

STEP 5

WE NOW HAVE A COMPLETED 90 DEGREE BEND. USE YOUR CARPENTER’S

SQUARE AS SHOWN IN STEP 5 TO TAKE YOUR FIRST MEASURMENT. IN THIS

TEST OUR 12 INCH SIDE IS NOW 21 INCHES.

STEP 6

OUR SECOND MEASUREMENT AS SHOWN IN STEP 6 SHOWS THAT OUR

24 INCH SIDE IS NOW 20 1/8.

WHAT THIS TEST HAS SHOWN US IS THAT WHEN INSTALLED IN THE

BENDER USING 1 3/4 x 7” R. DIE SET, IT HAS SHORTENED UP THE 24” SIDE

BY 3 7/8” AND ADDED 9” TO THE 12” SIDE.

813-986-9000 Pro-Tools

PAGE 8

Page 9

HOLE SAW NOTCHER

WARRANTY POLICY

ALL PRODUCTS THT PRO-TOOLS MANUFACTURES CARRY A ONE YEAR

GUARANTEE AGAINST DEFECTS IN MATERIAL OR WORKMANSHIP. (PRODUCTS

THAT WE SELL BUT DO NOT MAKE ARE COVERED UNDER THAT MANUFACTURING

WARRANTY PLAN). ANY TOOLS OR PARTS THAT FAIL ARE 100% COVERED

UNDER THE WARRANTY AND WILL BE REPAIRED FREE OF CHARGE (EXCLUDING

FRIEGHT CHARGES). MISUSE OR ABUSE IS NOT COVERED. SIMPLY CALL AND

GET A WARRANTY AUTHORIZATION NUMBER AND IT WILL BE PROMPTLY

AND CHEERFULLY TAKEN CARE OF.

SAFETY WARNINGS

•ALWAYS READ AND UNDERSTAND DIRECTIONS THAT ARE INCLUDED WITH ALL

PRO-TOOLS EQUIPMENT BEFORE OPERATING. IF DIRECTIONS ARE NOT INCLUDED,

CALL PRO-TOOLS IMMEDIATELY.

•USE OF FABRICATION EQUIPMENT MAY PRESENT A PINCH OR CRUSH HAZZARD.

•ALWAYS OPERATE PRO-TOOLS EQUIPMENT WEARING SAFETY EQUIPMENT.

•ALWAYS USE THE CORRECT EQUIPMENT FOR THE PROJECT.

•NEVER USE PIPE BENDING DIES ON A TUBE OR TUBE DIES ON A PIPE.

•KNOW THE MATERIALS YOU ARE USING BEFORE BEGINNING FABRICATION.

•ALWAYS INSPECT EQUIPMENT PRIOR TO USE TO MAKE SURE IT IS IN GOOD

WORKING ORDER. IF YOU ARE IN DOUBT, DO NOT USE AND CONTACT PRO-TOOLS.

•NEVER SUBSTITUTE COMPONENTS FROM OTHER EQUIPMENT. MAKE SURE

COMPONENTS MATCH.

•NEVER EXCEED THE MANUFACTURER’S SPECIFICATIONS SET BY PRO-TOOLS.

•ALWAYS LUBRICATE METAL ON METAL PARTS!!!!

813-986-9000 Pro-Tools

PAGE 9

Page 10

FAQ’s

Q: HOW MUCH CAN THE HMP-200 BEND A TUBE.

A: THE HMP-200 CAN ONLY GO TO 90 DEGREES.

Q: IS THE BENDER PORTABLE.

A: YES IT CAN BE MOUNTED ON OUR STANDS OR ON ANY ROLLING TABLE.

Q: WHAT IS THE MAXIMUM DIAMETER THIS BENDER WILL DO?

A: THIS BENDER WILL BEND UP TO 2” O.D. ROUND TUBE OR 1.5” SQ.

Q: HOW MANY DEGREES CAN I BEND?

A: YOU CAN BEND UP TO 110 DEGREES MAX. AFTER SPRING BACK.

Q: WHAT TYPE OF MATERIAL CAN I BEND?

A: YOU CAN BEND ALUMINUM, STAINLESS STEEL, DOM, 4130 CHROME MOLY TO

NAME A FEW. CONTACT OUR SALES DEPARTMENT FOR SPECIFICS.

Q: CAN THIS BENDER USE OTHER PRO-TOOLS DIES?

A: NO IT CAN NOT. EACH BENDER IS DESIGNED TO USE ITS OWN DIES TO ENSURE

THE POSSIBLE BEND.

QUALITY PRODUCTS MADE BY PEOPLE WHO CARE

PAGE 10

PRO-TOOLS (813) 986-9000

Loading...

Loading...