Proton HD P1-E-7020, HD P1-F-7015, HD P1-E-7015, HD P1-T-7015, HD P1-T-7020 Operation Manual

...Page 1

OPERATIONS MANUAL

FOR INDUSTRIAL CURTAINS

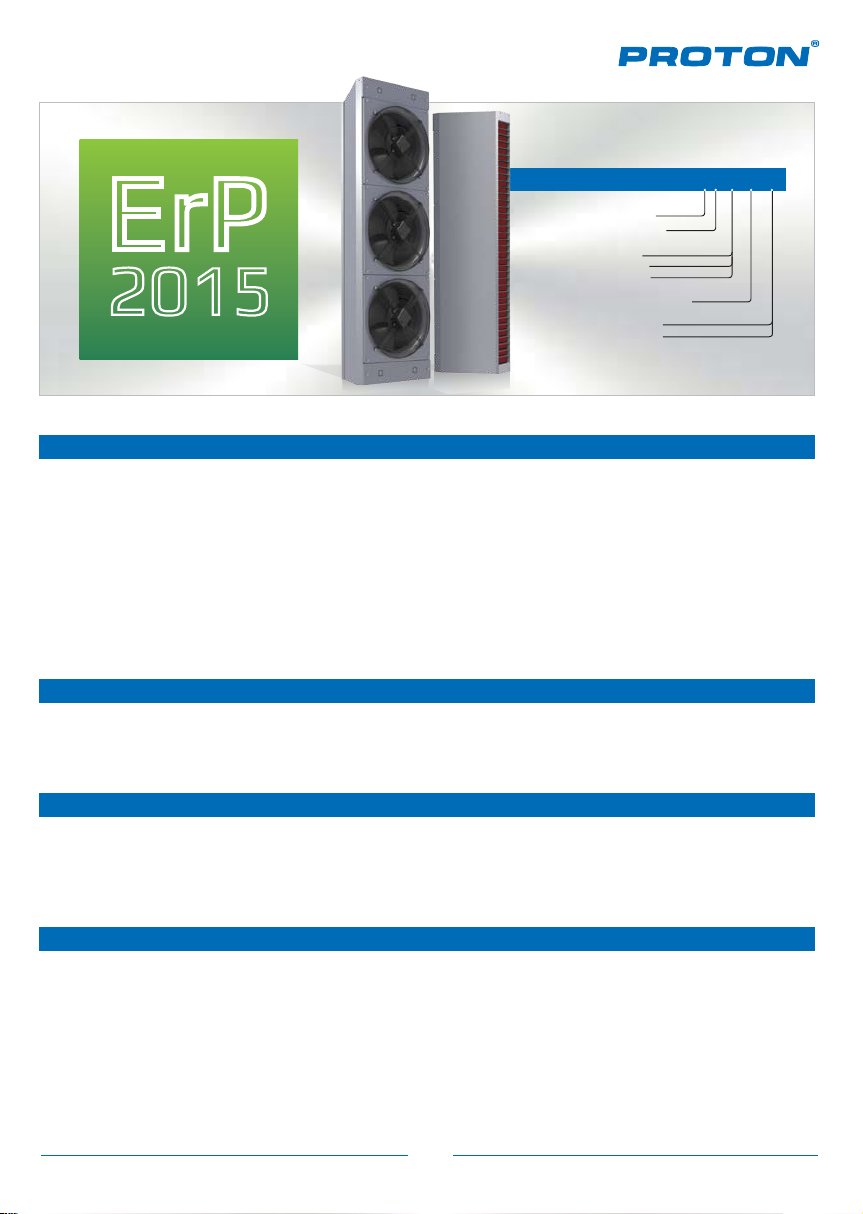

PROTON HEAT DOOR P1

ErP

2015

05010416

Water heating

Electric heating

Without heating

www.protongroup.org

Safety precautions

Construction and dimensions

Technical parameters

Installation

EN

RU

Page 2

CONTENTS

Maintenance guide for industrial curtains PROTON HEAT DOOR P1:

1. Introduction ...........................................................................................................................................................

2. Safety precautions .............................................................................................................................................

3. General information ...........................................................................................................................................

4. Dimensions ............................................................................................................................................................

5. Construction .........................................................................................................................................................

6. Technical characteristics .................................................................................................................................

7. Installation ............................................................................................................................................................

8. Connection of heat medium ...........................................................................................................................

9. Control elements ................................................................................................................................................

10. Wiring control elements ..................................................................................................................................

11. Reference information ....................................................................................................................................

3

4

5

6

7

8

10

11

12

13

15

2

Page 3

1. INTRODUCTION

The company PROTON GROUP LLC thanks you for choosing

industrial curtains PROTON HEAT DOOR P1.

This manual is an integral part of the product and must

always accompany it, and should be transferred to the user.

To provide proper wiring and application of the industrial

curtain, please, study this manual thoroughly before

installation.

We recommend keeping the manual safe in order to address

it during operation and maintenance.

The user should strictly follow safety instructions while

installing, using and servicing the unit.

The access to the unit must be restricted for unauthorized

and unqualified personnel. The appropriate training of the

maintenance sta should be provided.

The manufacturer disclaims any responsibility for damage

caused by wrong installation and misuse of the unit.

The manufacturer disclaims any responsibility for damage

done by people who didn’t study the manual.

The manufacturer preserves the right to introduce any

amendments to the manual without prior notification.

The manufacturer preserves the right to alter the

construction which doesn’t impact its functioning and basic

technical parameters.

The industrial curtain is intended only and exclusively to be

installed and used for purposes which it has been designed.

Any misuse or noncompliance with the manufacturer’s

instructions may lead to property damages, personnel injuries

or death. The user has to take measures to eliminate

possibilities of wrong operation of the curtain.

3

Page 4

2. SAFETY PRECAUTIONS

Before any actions connected with the air curtains, please, study

this manual to provide safety.

Installation and connection of the equipment to pipelines and

networks must be performed by qualified personnel only,

having appropriate access.

During installation, start-up, repair and maintenance of the

industrial curtain follow the safety rules.

Install the industrial curtain on a firm base or surface, which

can stand its weight filled with water.

Use screws appropriate for the material which the base is

made of.

Check correctness of wiring of the system, accordance of the

heat medium parameters with the parameters indicated on

the rating plate as well as leak proof of joints before filling in

the heat medium.

Avoid substances and impurities in the heat medium causing

copper corrosion.

Check compliance of parameters of the electrical supply

network indicated on the industrial curtain’s rating plate

before connecting to the power supply.

Check grounding. Prohibit the use of the equipment without

grounding as it may cause property damages, personnel

injuries and death.

Current network which feeds the curtain’s motor and controls

must be additionally protected by a fuse to prevent

consequences of shunt fault.

Thermal protection of fan motor is built-in and works in a

standalone mode.

While unit operating under low temperatures, the user must

-t

provide protection of the water heat exchanger or use heat

medium with special additives preventing copper corrosion.

To prevent defrosting of the industrial curtain’s heat

exchanger when circulation of the heat medium is stopped

during a heating period under outdoor temperatures lower

than 0°C, you need to drain the heat medium from the heat

exchanger and blow it o by compressed air.

4

Page 5

3. GENERAL INFORMATION

PROTON HD P1-T-7015

P – industrial curtainP – industrial curtain

ErP

2015

PROTON HEAT DOOR P1

This is an industrial curtain of high eciency. The products of this series are used to create a barrier in

form of a powerful air stream, which covers door and gateways in buildings where maintenance of

constant climatic conditions is required. The air curtains PROTON HEAT DOOR P1 successfully solve the

problem of heat losses in buildings by cutting o cold or hot outdoor air, and prevent access of dust,

insects, gases, etc. The air curtains are a reliable and valuable solution for energy saving and

separation of climate.

Construction of the air curtains allows to mount them as modules choosing appropriate angle of

curtains installation, and revolving louvers direct the air into the needed area. Wide range of heating

options makes decision-making easier in any buildings.

1– single-phase motor1– single-phase motor

T – water heating

T – water heating

E – electric heating

E – electric heating

F – without heating

F – without heating

70 – distance of air stream70 – distance of air stream

15 – length 1500 mm

15 – length 1500 mm

20 – length 2000 mm

20 – length 2000 mm

Heating curtains with water heating

Heating curtains apply hot water as a heat medium. They are very ecient and powerful, save money

and require low overhead and operating costs.

Electric heating

These air curtains apply electric heating elements as a heat medium. The advantage of this equipment

is that it is easy and simple to install. Electric curtains are optimal solution for buildings where there is

no hot water supply and its use is unreasonable.

Without heating

Curtains without heating are designed for cutting o outdoor air in doorways of the conditioned

buildings, refrigerators, where ingress of outdoor air is undesirable. This type of curtains is very

eective for preventing access of dust, insects, gases, etc.

5

Page 6

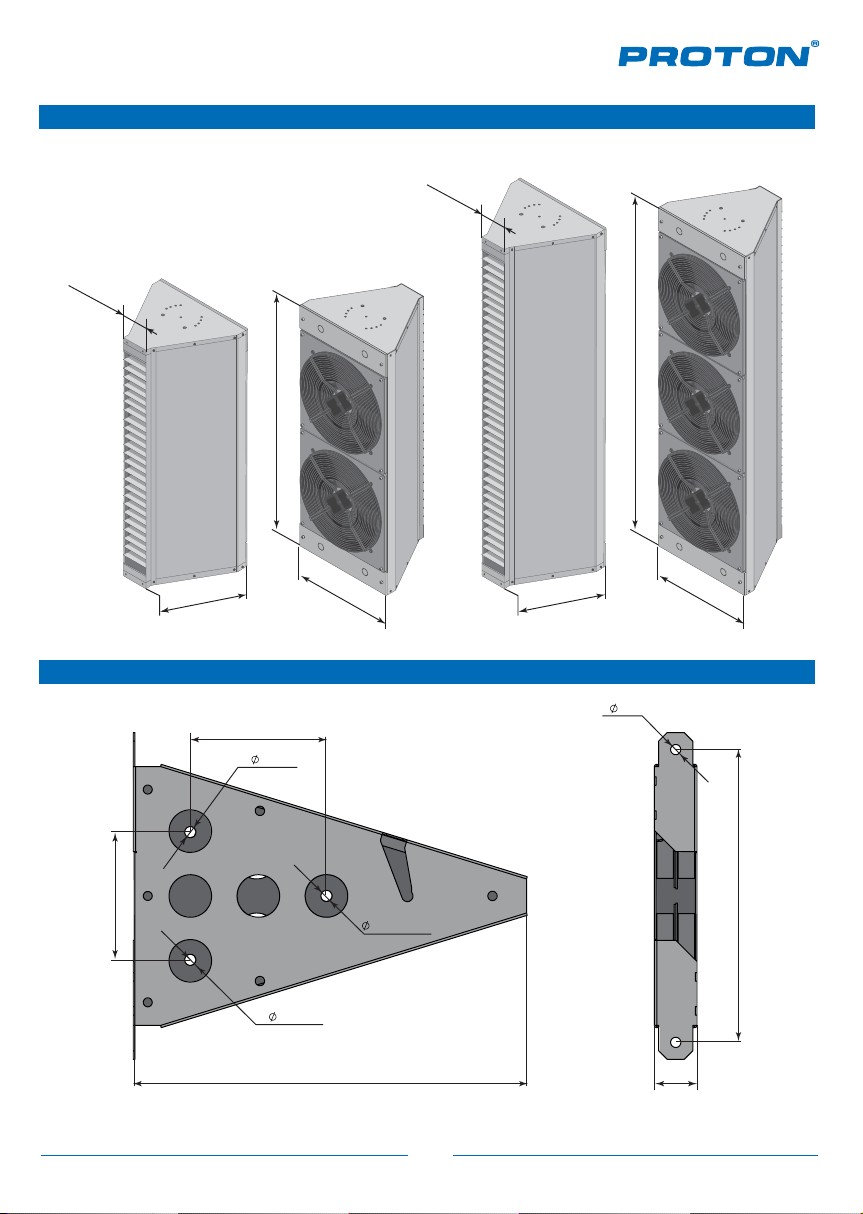

4. DIMENSIONS

Dimensions of industrial curtain PROTON HEAT DOOR P1

100

1500

100

2000

560

590

Dimensions of a mounting console СM HD

160

13.2

150

13.2

462

560

590

12

344

13.2

50

6

Page 7

5. CONSTRUCTION

PROTON HEAT DOOR P1

1

3

4

1. Casing.

2. Side panel.

3. Diusor.

4. Axial fan.

5. Heat exchanger or Finned tubular

electric heating elements.

5

Major components of the industrial curtain

PROTON HEAT DOOR P1:

Casing

The casing consists of galvanized or dyed

2

metal.

Single-phase AC-fan

Rated power supply is 230 V/50 Hz. Motor

protection grade is IP54, F-isolation class.

Operating temperature is up to +60°C.

Directing louvers

They are made of steel and dyed with special

paint and provide minimal air resistance at

the outlet from the curtain. Modern look and

high protection from corrosion guarantee long

life and safety.

Heat exchanger

The heat exchanger consists of copper tubes and aluminum lamellas pressed on them. It is equipped

with copper pipes with threading connection (external thread 3/4”). The copper-aluminum heat

exchanger is distinguished by high eciency, is not exposed to corrosion if a prepared heat medium

with no additives causing copper corrosion is used. Maximal parameters of heat medium supply

are 105 °C/1,6 MPa.

Finned tubular electric heaters

The heating elements, installed into the curtains, are made of high-alloy stainless steel. For better

heat extraction, toroid-like coils with width of 10 mm with additional corrugation are added to these

heating elements. The frame for mounting is made of galvanized steel. Joint boxes are equipped with

clamping cables. Thermal sensors of overheat protection of the finned tubular electric heaters are

fastened on their top and bottom sides.

7

Page 8

6. TECHNICAL PARAMETERS

6.1 Industrial curtains with water heating PROTON HD P1-T-70

General parameters

Air curtain’s standard size

Airflow

Heat power

Max. warm air throw

Air temperature increase

Volume of water in heat exchanger

Noise level

Max. temperature of heat medium

Max. working pressure

Diameter of connection pipes

Weight

Supply voltage of the curtain

Rated current of the curtain

Power of motors

Motor protection rating

Dimensions (WxHxL) Габариты (Ш х В х Г)

mm

m³/h

kW

m

°С

dm³

dB

°С

MPa

inch

kg

V/Hz

А

W

IP

mm 1500 х560 х590 2000 х560 х590

Parameters according to the heat medium

(°С)

Qp

(m³/h)

T /zT

p

P

p1

(°С)

0

5

10

15

790010900

20

25

Water 90/70 Water 80/60 Water 70/50 Water 60/40Parameters

P

g

54.8

51.4 29.124.3 2.3

47.9 25.6

44.5 22.3

41.0 19.135.3 1.8

37.5

Q

P

w

p2 p

(m³/h) (kW) (kPa)

(°С)

28.0 2.1

31.6 2.0

32.720.6 2.4

HD P1-T-7015 HD P1-T-7020

1500

7900

54.8 75.0

7.0

20.6

3.28

68

105

1.6

3/4

62.6 71.5

230/50

4.0

840

54

HD P1-T-7015

47.3

43.8

40.4

36.9

33.3

29.8

P

g

Q

P

w

p2 p

(m³/h) (kW) (kPa)

(°С)

17.8

2.1

21.5

1.9

25.1

1.8

28.8

1.6

32.4

1.5

36.016.238.9 1.7

1.3

25.4

22.1

19.0

16.1

13.4

10.9

39.8

36.3

32.7

29.2

25.6

22.0

P

g

Q

P

w

p2 p

(m³/h) (kW) (kPa)

(°С)

15.0

1.7

18.6

1.6

22.3

1.4

25.9

1.3

29.5

1.1

33.2

1.0

18.9

16.0

13.3

10.8

8.5

6.2

32.2

28.6

25.1

21.5

17.8

14.1

P

g

230/50

2000

10900

7.0

20.5

4.42

70

105

1.6

3/4

6.0

1260

54

P

p2 p

(°С)

12.1

15.8

19.4

23.0

26.6

30.2

Q

w

(m³/h) (kW) (kPa)

13.2

1.4

10.7

1.3

1.1

8.4

0.9

6.3

0.8

4.5

0.6

3.0

Parameters according to the heat medium

(°С)

T /zT

p

Qp

(m³/h)

(°С)

P

p1

0

5

10

15

20

25

– water temperature at the inlet of the industrial curtain

P

z

P

– water temperature at the outlet of the industrial curtain

p

Q

– water consumption

w

Q

– air consumption

p

Data on operat ing characteris tics of indust rial curtains PROTON HEAT DOOR P1 when using hea t medium with diering tempe ratures is to b e provided on

demand.

There is danger of heat exchanger defrosting (breakage) if room temperature falls lower than 0 °C.

As maximal pressure of heat medium is 1,6 MPa, water circuit system must have protectio n from pressure rise h igher than accepted va lue.

P

75.0

70.3

65.5

6.7

55.9

51.1

g

Water 90/70 Water 80/60 Water 70/50 Water 60/40Parameters

Q

P

w

p2 p

(m³/h) (kW) (kPa)

(°С)

20.5

3.3

24.1

3.1

27.8

2.9

31.4

2.7

35.1

2.5

38.7

2.3

26.5

23.4

20.5

17.8

15.3

12.9

64.6

59.8

55.0

50.2

45.3

40.4

P

g

P

p1

P

p2

P

g

p

HD P1-T-7020

Q

P

w

p2 p

(m³/h) (kW) (kPa)

(°С)

17.6

2.8

21.3

2.6

24.9

2.4

28.6

2.2

32.2

2.0

35.8

1.8

– air temperature at the inlet of the industrial curtain

– air temperature at the outlet of the industrial curtain

– heat power of the industrial curtain

– water pressure drop in heat exchanger

20.3

17.6

15.1

12.7

10.5

8.5

54.1

49.3

44.5

39.6

34.6

29.6

P

g

Q

P

w

p2 p

(m³/h) (kW) (kPa)

(°С)

14.8

2.4

18.4

2.2

22.1

1.9

25.7

1.7

29.3

1.5

33.0

1.3

14.9

12.5

10.3

8.3

6.5

4.9

P

43.6

38.7

33.8

28.8

23.8

18.6

g

Q

P

w

p2 p

(m³/h) (kW) (kPa)

(°С)

11.9

1.9

15.5

1.7

19.2

1.5

22.8

1.3

26.4

1.0

30.0

0.8

10.2

8.2

6.4

4.8

3.4

2.2

8

Page 9

6. TECHNICAL PARAMETERS

6.2 Industrial curtains with electric heating PROTON HD P1-E-70

General parameters

Air curtain’s standard size

Airflow

Heat power

Max. warm air stream throw

Air temperature increase

Noise level

Weight

Supply voltage of the curtain

Rated current of the curtain

Power of motors

Motor protection rating

Dimensions (WxHxL)

mm

m³/h

kW

m

°С

dB

kg

V/Hz

А

W

IP

mm

HD P1-E-7015 HD P1-E-7020

1500 2000

8000

18.0

7.0

7.0

68

68.8

400/50

28.0

840

54

1500 х560 х590 2000 х560 х590

6.3 Industrial curtains without heating PROTON HD P1-F-70

General parameters

Air curtain’s standard size

Airflow

Max. air stream throw

Noise level

Weight

Supply voltage of the curtain

Rated current of the curtain

Power of motors

Motor protection rating

Dimensions (WxHxL)

mm

m³/h

m

dB

kg

V/Hz

А

W

IP

mm

HD P1-F-7015 HD P1-F-7020

1500 2000

8500

7.0

68

51.1

230/50

4.0

840

54

1500 х560 х590 2000 х560 х590

11000

24.0

7.0

6.5

70

73.2

400/50

37.0

1260

54

11500

7.0

70

56.4

230/50

6.0

1260

54

9

Page 10

7. INSTALLATION

min 450 mm

min 450 mm

up to 7 m

up to 14 m

up to 7 m

up to 9 m

PROTON HEAT DOOR P1

Picture 1. Vertical installation on the

left (right) side of a doorway.

Picture 3. Horizontal installation on the top

Minimal distances from walls and ceiling Installation

of a doorway.

min 450 mm

Picture 2. Vertical installation on both sides

of a doorway.

Picture 4. Vertical and horizontal installation

when a doorway is large.

Owing to the module construction,

the curtains PROTON HEAT DOOR P1

are to be installed on the top or

one/both sides of doorways by

combining several modules of 1,5

and 2 m, that allows to cover the

length of doorway.

The curtains are to be fixed on

mounting consoles.

Horizontal installationVertical installation

10

Page 11

8. CONNECTION OF HEAT MEDIUM

Piping industrial curtains PROTON HEAT DOOR P1

Air outtake

Ball cock

PROTON HEAT DOOR P1

Two-way valve with actuator

0,003

Ball cock

Outlet pipeline

Inlet pipeline

Control board

Drain

Coarse filter

Industrial curtains can be installed in closed heating systems with forced circulation with maximal

temperature of the heat medium 105 °C and maximal pressure 1,6 MPa.

When connecting to the heating main pipes it is necessary to provide the following conditions:

1.

The air curtain has to be completed with intercepting cocks on the inlet and outlet pipes.

2.

It is recommended to install a coarse filter on the inlet pipe and air outtake on the outlet pipe.

3.

Provide at least one cock for heat medium drainage on the bottom point on the piping scheme of the

curtain.

4.

Provide at least one air outtake on the upper point on the piping scheme of the curtain.

5.

The diameter of pipes should be selected in accordance with hydraulic calculations of the heat supply

system.

6.

Heating tubes from the heating system pipe to the curtain must be installed with the pitch of 3° to

the pipes the heat supply system.

7.

All cable trays for wiring a fan and two-way valve should be installed higher than pipes of the heating

system.

8.

Installation must be done by technician/company who has appropriate permissions for performing

such a type of work.

Manifold of a heat medium

When connecting the heat medium pay your attention that

manifolds of the heaters must be fixed. For this use two keys:

one – for fixing heat exchanger manifolds, the second – for

connecting it to the system.

11

Page 12

9. CONTROL ELEMENTS

ECOMATIC PRO

ECOMATIC PRO are control elements with help of which

advantages of heating and ventilation systems become

more noticeable and perceivable as its use provide

comfortable inside temperature and significant energy

of climatic conditions in a room. Using PROTON PRO you increase equipment lifetime protecting it from

functioning under alarm conditions.

RDE Control board

Protection equipment and control elements need to be used for correct

use of a device, fed by the electrical network. The control board RDE has

been developed for proper application of electric industrial curtains

PROTON HEAT DOOR P1. This board considers all peculiarities of use of

equipment where finned tubular electric heaters, motors, alarm

protection are installed.

The control board RDE is placed in plastic casing with IP65 protection

and has a transparent door with additional gasket for manual control.

You can see signals of operating/alarm statuses through the door that

increases ease of use.

RDU Control board

savings due to fast response of the system to changes

It is a simplified version of the control board RDE as there is no

elements to control over finned tubular electric heaters.

DC 230 Door contactor

A door contactor is a device designed for automatic turn on of the

mechanism (a curtain) when a moving part (door) reaches a certain

place.

The door contactor has two pairs of contacts, normally opened and

normally closed. Closed pair allows to control a connection position of a

limit switch: if a signal is transferred by this pair doesn’t return, you can

conclude that a cable to the switch has been damaged. Opened pair can

be used to transfer a signal after the contactor had responded.

More information about ECOMATIC PRO you can receive on demand.

12

Page 13

10. WIRING CONTROL ELEMENTS

10.1

Wiring of industrial curtain with water heating or curtain without

heating to control board RDU

1

Tz

M

2

Indicators to the scheme

1

—joint box of the curtain

—control board RDU

2

1

2

X1

Contacts of groups of

the overheat sensors

*

2х1.5

Contactors of a group

3

N

X1

of electric motors

*

3х2.5

PE

Notes

*

The section is indicated for cables with cooper cores and length less than 20 m.

13

Page 14

X1; K3M (К5М)

4х6

Contacts of a group

of electric heaters

*

10. WIRING CONTROL ELEMENTS

ЭК2

7PE8 9

10.2

Wiring of industrial curtain with electric heating to control board

RDE

1

Tz

ЭК1

2

3 4

1

2

X2

Contacts of groups of

the overheat sensors

2х1.5

Indicators to the scheme

1

—joint box of the curtain

—control board RDE

2

*

Contacts of a group

5 6

X1; K2M (К4М)

of electric heaters

* *

4х6

10M1112

PEPE

X2

Contactors of a group

of electric motors

3х2.5

Notes

*

The section is indicated for cables with cooper cores and length less than 20 m.

14

Page 15

11.1 Table of pressure calculation on a wire depending on its section

Material of the conductor – copper:

Material of the conductor – copper

Section of current

conducting core, mm

1.5

2.5

4.0

6.0

10.0

16.0

25.0

35.0

50.0

70.0

95.0

120.0

Material of the conductor – aluminum:

Section of current

conducting core, mm

2.5

4.0

6.0

10.0

16.0

25.0

35.0

50.0

70.0

95.0

120.0

2

Current, A

19.0

27.0

38.0

46.0

70.0

85.0

115.0

135.0

175.0

215.0

260.0

300.0

2

Current, A

20.0

28.0

36.0

50.0

60.0

85.0

100.0

135.0

165.0

200.0

230.0

Voltage, 220 V

Power, kW

4.1

5.9

8.3

10.1

15.4

18.7

25.3

29.7

38.5

47.3

57.2

66.0

Material of the conductor – aluminum

Voltage, 220 V

Power, kW

4.4

6.1

7.9

11.0

13.2

18.7

22.0

29.7

36.3

44.0

50.6

Voltage, 380 V

Current, A

16.0

25.0

30.0

40.0

50.0

75.0

90.0

115.0

145.0

180.0

220.0

260.0

Voltage, 380 V

Current, A

19.0

23.0

30.0

39.0

55.0

70.0

85.0

110.0

140.0

170.0

200.0

Power, kW

10.5

16.5

19.8

26.4

33.0

49.5

59.4

75.9

95.7

118.8

145.2

171.6

Power, kW

11.6

15.1

19.8

25.7

36.3

46.2

56.1

72.6

92.4

112.2

132.0

Data is presented as a reference. For calculations for actual projects address to specialists.

15

Page 16

11.2 Recommended diameters of pipes depending on power of equipment’s

heat output

kW Water consumption Inside diameter Type

15 kW

23 kW

39 kW

61 kW

96 kW

180 kW

0.6 m³/h

1.0 m³/h

1.6 m³/h

2.5 m³/h

4.0 m³/h

8.0 m³/h

20 mm

25 mm

32 mm

40 mm

50 mm

70 mm

3/4

1

1

1

1

1

2

1

2

4

2

2

Data is presented as a reference. For calculations for actual projects address to specialists.

16

Page 17

171819

Page 18

Page 19

Page 20

Service department

In case of any failures in operation of equipment address the authorized

support centers of the Manufacturer.

For information about support centers and procedure of claim submission

contact Manufacturer’s service department:

PROTON GROUP LLC

03680, Ukraine, Kyiv,

3, Nesterova str.

Tel.: +380 (44) 537 0930

Fax: +380 (44) 537 0903

E-mail: service@proton.kiev.ua

www.protongroup.org

www.protongroup.org

Loading...

Loading...