Page 1

™

Page 2

TABLE OF CONTENTS

QUICK REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PAGE 02

IMPORTANT SAFETY INSTRUCTIONS AND GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PAGE 03

BOARD SETTINGS AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 04

FUSE BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 08

LOW PRESSURE REGULATOR (LPR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 10

HYPER2™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 12

ANTI CHOP EYES/ BALL DETENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 13

TRIGGER ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 14

ON/OFF AIRPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PAGE 14

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 15

TROUBLE SHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 16

WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE 17

WWW.PROTOPAINTBALL.COM

WWW.PROTOPAINTBALL.COM

MATRIX OWNER’S MANUAL

INCLUDED WITH YOUR MATRIX

- MATRIX Marker

- Allen tool set including 1/16”, 5/64”, 3/32”, 1/8”, 5/32”, 3/16” and 1/4”

- 1 oz. Dye Slick Lube™

- Parts Kit

- Barrel Sock

- Owner’s Manual

- Warrant Card

ADDITIONAL RECOMMENDED TOOLS

- 3/8’ Allen wrench

- 5/16” Allen wrench

- Canned Air

Page 3

W ARNING

IMPORTANT SAFETY INSTRUCTIONS AND GUIDELINES

• The MATRIX marker is not a toy. Misuse may cause serious injury or death.

• Please read, understand and follow the directions in the MATRIX owner’s manual.

• Eye protection that is designed specifically for paintball and meets ASTM/CE standards must be

worn by user and persons within range.

• Recommend 18 years or older to purchase. Person under 18 must have adult supervision.

• Always treat the MATRIX marker as if it were loaded and able to fire.

• Only use compressed air or nitrogen gas in the MATRIX marker. DO NOT USE CO

2

.

• Do not exceed 850 psi input pressure.

• Ensure all air lines and fittings are tightened and secured before gassing up the MATRIX.

• Always chronograph the MATRIX marker before playing paintball.

• Never shoot the MATRIX marker at velocities in excess of 300 feet per second,

or at velocities greater than local or national laws allow.

• Never look into the barrel or breech area of the MATRIX when the marker is switched on and able to fire.

• Always fit a barrel blocking device to your MATRIX when not in use on the field of play.

• The owner’s manual should always accompany the product for reference or in the event of

resale and new ownership.

• Do not point the MATRIX marker at anything that you do not intend to shoot.

• Do not shoot at people, animals, houses, cars or anything not related to the sport of paintball.

• Do not fire the MATRIX without the Fuse bolt screwed in completely.

• If you read these instructions and do not fully understand them or are unsure of your ability to make

necessary adjustments properly, call DYE or your local pro shop for help.

Air Supply - The MATRIX should be operated using air/nitrogen gas only. This air needs to be supplied to the Hyper2™ in-line

regulator at a regulated pressure of no more than 850 psi. The Hyper2™ in-line regulator comes factory preset at 185psi.

Gassing Up Your MATRIX - Screw in your air system to the on/off airport and turn the knob of the airport clockwise, all the way in.

Turning On Your MATRIX - The MATRIX’s power is controlled by two buttons. The top button turns the marker on and off, while the

bottom button turns the eye on and off. Hold the power button for 3 seconds to turn the marker on. The LED in the grip will

illuminate during the boot sequence.

NOTE: If the eye is not working properly, try replacing the battery.

Orange - Boot sequence

Red - Breech is clear, no ball (eye on)

Green - Ball in breech, ready to fire (eye on)

Blinking Orange - Indicates a low battery, battery should be changed as soon as possible

Blinking Red - Eye is off

Blinking Green - Eye failure (see MATRIX Board, page 4)

LPR - The LPR is pre-set from the factory at approximately 75-80 psi and should need no

adjustment out of the box. If fine tuning adjustment is desired or needed, you must be sure that

you are adjusting the LPR correctly. See page 10 for detailed instructions. If the LPR is

improperly adjusted, you could dramatically hinder the MATRIX’s performance or prevent the

marker from functioning at all.

NOTE: Turning the adjustment screw clockwise, or in, will lower

the LPR’s output pressure. Turning the adjustment screw

counterclockwise, or out, will raise the LPR’s output pressure.

Hopper

- To get the best performance out of your MATRIX, it is

recommended that you use a motorized loader. Preferably one

that force feeds the paint really, really fast!

Adjusting Velocity - The velocity is adjusted through the Hyper2™ in-line

regulator. The Hyper2™ in-line is preset from the factory at approximately 230

psi. This pressure setting should have the marker shooting at about 285fps.

Your paint-to-barrel fit will also have a noticeable affect on your velocity. Make

sure that the paintball fits into the barrel loosely but does not drop through.

NOTE: For the Hyper2™, turning the adjustment screw clockwise, or in, will lower the

output pressure, decreasing the velocity. Turning the adjustment screw counterclockwise,

or out, will raise the output pressure, increasing the velocity.

NOTE: If the battery is too low, it may not be able to power the solenoid correctly. This

will affect your MATRIX’s velocity, causing it to become inconsistent and/or low.

QUICK REFERENCE - USING YOUR MARKER

2

Page 4

MATRIX BOARD - SETTINGS AND FUNCTIONS MATRIX BOARD - SETTINGS AND FUNCTIONS (CONTINUED)

When servicing your marker:

• Make sure a barrel sock is fitted

to the MATRIX.

• Make sure your hopper is removed

from the MATRIX.

• Make sure there are no paintballs in the

breech of the MATRIX.

• Always remove the first stage regulator

and relieve all residual gas pressure from

the MATRIX before disassembly.

• The MATRIX can hold a small residual

charge of gas, typically 1 shot, with the

first stage regulator removed. Always

discharge the marker in a safe direction to

relieve this residual gas pressure.

WARNING

• The MATRIX is not water resistant.

Excess moisture can cause damage

to electronic parts.

• Keep the board and all electrical

components clean of dirt, paint

and moisture.

• To clean the board, use canned air. If a

more aggressive cleaning method is

needed, lightly scrub the components

with a soft, dry brush. Heavy scrubbing

will damage the board.

WARNING

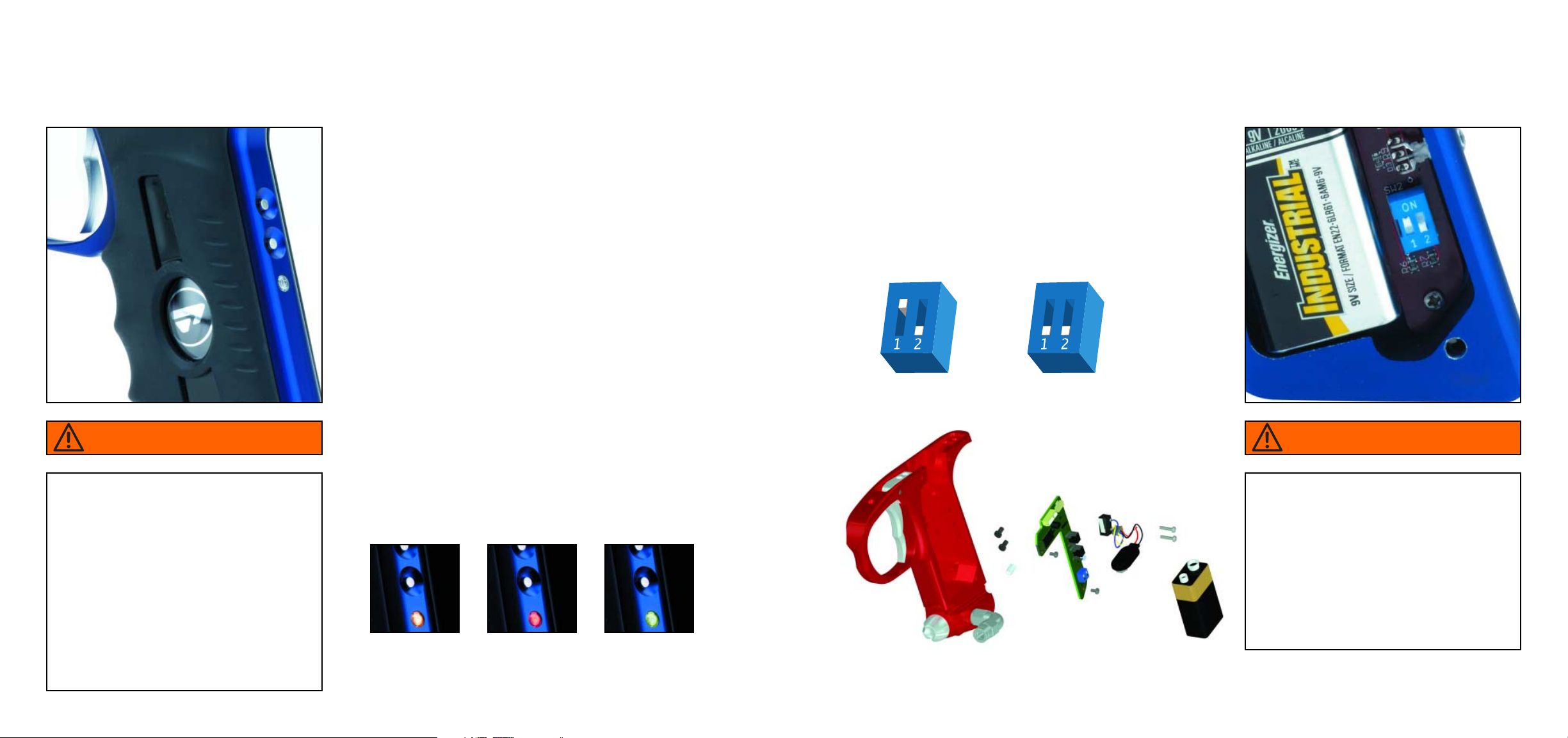

TURNING THE MATRIX ON AND OFF

To turn on the MATRIX, press and hold the upper button (see figure 1) until the LED light

turns orange. The orange light indicates board bootup. After the bootup sequence, the

LED will turn either RED (no ball) or GREEN (ball ready to fire). To turn the MATRIX off,

press and hold the power button until the LED turns off.

NOTE: The MATRIX automatically switches off after 10 minutes of non-use.

FIRING THE MATRIX

As soon as the marker is turned on and the LED turns from orange to either red or green,

the MATRIX is ready to fire. If there is no ball and the LED is RED, you need to hold the

trigger for 1 second to force the MATRIX to fire once. If there is a paintball inside the

breech and the LED is green, just press the trigger to fire the marker.

LED LIGHT INDICATOR

There is a LED light mounted on the back strap of the frame, under the two buttons. This

light provides information to the user by the MATRIX. There are three colors on the LED

light: red, green and orange.

When you turn on the marker in normal operation mode with the power button, the light

colors mean the following:

Orange Bootup sequence.

Red No ball detected inside the MATRIX (eye on).

Green Ball detected inside the MATRIX (eye on).

Blinking Red Eye function turned off. The MATRIX will fire even though there is

no ball inside the breech.

Blinking Green Eye blocked. This means that your eyes are either dirty or

there is a bad connection. The ROF (rate of fire) is automatically

reduced to prevent chopping. If this happens during game play,

you can turn the eye off to increase your ROF.

Blinking Orange Indicates a low battery. Battery should be changed as

soon as possible.

NOTE: The eye is always activated when you turn the marker on.

ORANGE GREENRED

BOARD SETTINGS AND CONFIGURATION MODE

There are four settings you can alter on the MATRIX board with the DIP switches inside

the grip frame

(see figure 2):

ABS Anti Bolt Stick.

Trigger Sensitivity This setting adjusts the delay between two trigger pulls.

Dwell This is the time the solenoid is activated for.

ROF Rate Of Fire when the eye is deactivated.

Anti Bolt Stick - When ABS is activated, the dwell is increased after 15 seconds of nonuse for the next shot fired. This helps to prevent bolt-stick, but may result in higher

velocity for the first shot.

ABS on ABS off

(default)

Figure 1

Figure 2

5

W WW.PROTOPAINTBALL.COMWWW.PROTOPAINTBALL.COM

Page 5

CHECKING CONFIGURATIONS

You can check your DIP switch configuration by pulling and holding the trigger when

you turn the marker on. Hold the trigger until the LED starts flashing. Orange indicates

the anti bolt stick (ABS) setting (1 flash = off and 2 flashes = on). For example, if your

ABS is ON then the LED will flash orange twice.

BATTERY

The 9V battery will last for about 40,000 shots. Please be aware that there are

substantial differences in performance between different brands of batteries. Use of

high quality alkaline or lithium ion batteries is recommended for maximum battery life.

If you plan not to use your marker for a long period of time (a month), it is

recommended that you remove the battery from the marker. When the battery voltage

starts to go too low, you will notice your velocity starts to decrease and the board can

turn off. For tournament use, it is recommended to change the battery for each

tournament. When changing your battery, take special care to ensure the wiring harness

is not pinched under the battery

(see figure 1).

CHANGING THE BATTERY

The battery is housed on the left side of the grip frame. To access the battery, remove

the three screws holding the left side grip panel down. Use a 3/32” Allen wrench.

Carefully lift the battery out of the frame, taking care not to damage the battery lead

wires.

When inserting a new battery, make sure the solenoid and eye wires are pushed into the

wire passage at the rear of the frame. This will ensure that the wires are not pinched or

cut.

NOTE: IF THE MARKER WILL NOT FUNCTION WITH

THE EYE ON, THERE IS A GOOD CHANCE THE

BATTERY NEEDS TO BE CHANGED.

Configuration Mode - The following settings can only be modified in configuration mode. To

activate the configuration mode, turn your marker off and set DIP switch 2

to the on position. Next, turn your marker on. The 3-color LED cycles

through all colors for one second to indicate that you have entered the

configuration mode. To cycle through different settings, pull and release the

trigger. Configuration mode has 3 settings that can be changed.

Green - Trigger Sensitivity Values 1 - 20 (factory default 5)

Trigger sensitivity is the amount of time that the trigger has to be released before the

next trigger pull is allowed. In some situations with too low of a value, the marker may

begin to shoot full-auto.

Red - Dwell Values 5 - 30 (factory default 18)

Dwell is the amount of time that the solenoid will be activated. Follow these steps for

the best way to set your dwell:

• Remove loader and any paintballs from the MATRIX marker.

• With the dwell set at 12, start increasing the value until the marker begins to fire.

• When you reach the setting where the marker begins to fire, get some paint and a

loader and go to a chronograph.

• Increase the dwell until you see no increase in the velocity. This is the optimal dwell

setting to be used.

Orange - Rate Of Fire (ROF) Values 5 - 24 (factory default 24bps)

[When Anti Chop Eye (ACE) is deactivated] The ROF is unlimited by software when the eye is on. The only limiting factor is the

loader feed rate. The marker pneumatic cycle rate is far faster than any loader on the

market. You should set this setting to the constant feed rate of your loader. Setting this

higher than your loader is capable of feeding risks chopping a ball.

TO CHANGE THE VALUE OF A SETTING:

While in configuration mode, pull the trigger and hold it for more than one second. The LED will flash to indicate the previous setting.

After that, you can set the new value with the trigger.

For example, if you want to change the trigger sensitivity to 7 units:

1 Cycle through menus by pulling and releasing the trigger until the LED light is GREEN (trigger sensitivity).

2 Pull and hold the trigger until the LED starts to flash (factory default for trigger sensitivity setting is 5 units, so the LED will flash 5 times).

3 When the LED stops flashing, pull and release the trigger seven times in a fast pace. The new value is set after you haven't touched the

trigger for one second. The LED will cycle through all colors to indicate that the new value is saved. All other configurations are changed

the same way. Just as in part 2 above, change the mode to RED for "dwell" or ORANGE for "ROF when ACE is deactivated" to change the

desired configurations.

4 To exit configuration mode, set DIP 2 to the off position.

NOTE: You cannot turn your marker off with the power button when the marker is in configuration mode.

You must first set DIP switch 2 to the off position.

NOTE: When you set the values, remember that only trigger sensitivity starts from 1. The "dwell" and "rate of fire" start from 5.

Therefore, to set the dwell at 20, you need to pull the trigger fifteen times, because the first trigger pull will start at 5.

MATRIX BOARD - SETTINGS AND FUNCTIONS (CONTINUED)

Normal Mode Configuration Mode

MATRIX BOARD - SETTINGS AND FUNCTIONS (CONTINUED)

• A low battery will not be able to power

both the ACE eye and the trigger switch,

causing ACE eye failure.

• If the battery is low, it may not be able to

power the solenoid correctly. This will

affect the MATRIX’s velocity, causing it to

become inconsistent and/or low.

• An intermittent blinking orange light

indicates a low battery. A low battery can

cause malfunctions to the marker. In this

case the battery should be changed as

soon as possible.

WARNING

Figure 1

6 7

Page 6

FUSE™ BOLT - ASSEMBLY AND MAINTENANCE (CONTINUED)FUSE™ BOLT - ASSEMBLY AND MAINTENANCE

BOLT MAINTENANCE

Regular MATRIX Fuse™ bolt maintenance is vital to the performance of the MATRIX.

If the Fuse™ bolt is not kept well-greased and the o-rings in good shape, the performance of the MATRIX will be greatly hindered.

To remove the bolt, you will need a 1/4“ Allen wrench. Unscrew the bolt from the rear of the marker. It only takes one and one half revolutions

to unscrew the bolt so that it can be pulled out. After the bolt has been cleaned and greased and is ready to be inserted into the body, be

sure all bolt sleeve components are screwed together snugly. Slowly push the bolt into the body. Take care not to cut or nick the o-rings as

they pass the threads.

GREASE THE MATRIX FUSE™ BOLT EVERY 10-15 THOUSAND SHOTS.

BEFORE INSTALLING THE BOLT INTO THE MARKER, BE SURE ALL BOLT SLEEVE COMPONENTS ARE

SCREWED TOGETHER SNUGLY.

If you do not grease the bolt, you will run the risk of damaging o-rings. This will create excessive friction and drag on the bolt, ultimately

resulting in breaking the bolt. When greasing the MATRIX Fuse™ bolt, pay special attention to all o-rings that are on the bolt and that ride on a

surface of the bolt. The first seven o-rings listed below should be generously greased during maintenance.

FUSE™ BOLT O-RING LIST

1 Bolt tip (014 BN70) 6 Top hat (017 UR70)

2 Bolt sail (015 BN70) 7 Top hat (013)

3 Inside bolt stem (009 BN70) 8 Outer sleeve (020 BN70)

4 Rear bolt stem (009 BN70) 9 Front bumper (015 BN70)

5 Front wall internal (017 UR70) 10 Rear bumper (111 BN70)

NOTE: All remaining o-rings should have a thin coating of grease as well.

FUSE™ BOLT OPERATION

To achieve top performance from your MATRIX, it is important to understand the basic

operation of the MATRIX’s patented FUSE™ bolt system.

This design consists of three sleeves threaded together to capture the only moving part

of the system, the bolt.

The FUSE™ Bolt has four

components

1 Cylinder

2 Bolt

3 Top Hat

4 Rear Cap

Air is supplied to the bolt at two

points. A high-pressure supply of

air is routed to the back of the bolt

into the supply chamber. This air

source is responsible for propelling

the ball. Low-pressure air is supplied from the LPR to

the solenoid. From the solenoid, the air is routed

through two small holes to the section of the bolt

referred to as the cylinder.

When the MATRIX is aired up, air is transferred by the solenoid to the front of the

cylinder. This air pushes against the bolt sail and the bolt is held in the back position.

When the bolt is held back, the 013 o-ring in the top hat seals around the bolt and

contains the air in the supply chamber.

When the marker is fired, the microswitch is pressed, telling the solenoid to switch the

flow of air from the front of the cylinder to the rear of the cylinder. Air that enters the

rear of the cylinder will push on the bolt sail, moving the bolt forward. The air in the

front of the cylinder is vented.

As the bolt moves forward, the tapered stem passes through the top hat. Once the bolt

stem can no longer seal against the 013 o-ring, the air contained in the supply chamber

is released. The air passes through the venturi ports in the bolt and out the front of the

bolt to propel the ball. When the bolt is in the forward position, the inside bolt stem oring prevents the flow of air from continuously flowing through the marker when the bolt

is forward. This helps the marker shoot much more efficiently.

NOTE: LOW OR ERRATIC VELOCITY MAY BE DUE TO A LOW

BATTERY NOT SUPPLYING AMPLE ELECTRICAL CURRENT TO THE

SOLENOID. IN THIS CASE, CHANGE THE BATTERY.

When servicing your marker:

• Make sure your hopper is removed

from the MATRIX.

• Make sure there are no paintballs in the

breech of the MATRIX.

• Always remove the air supply and

relieve all gas pressure in the MATRIX

before disassembly.

• When using the MATRIX in temperatures

below 50º it may be necessary to lube the

FUSE bolt more frequently.

WARNING

1

2

9

10

3 4

5

7

6

88 8 8 8

1

2

3

4

89

W WW.PROTOPAINTBALL.COM

BACK POSITION

FORWARD POSITION

Page 7

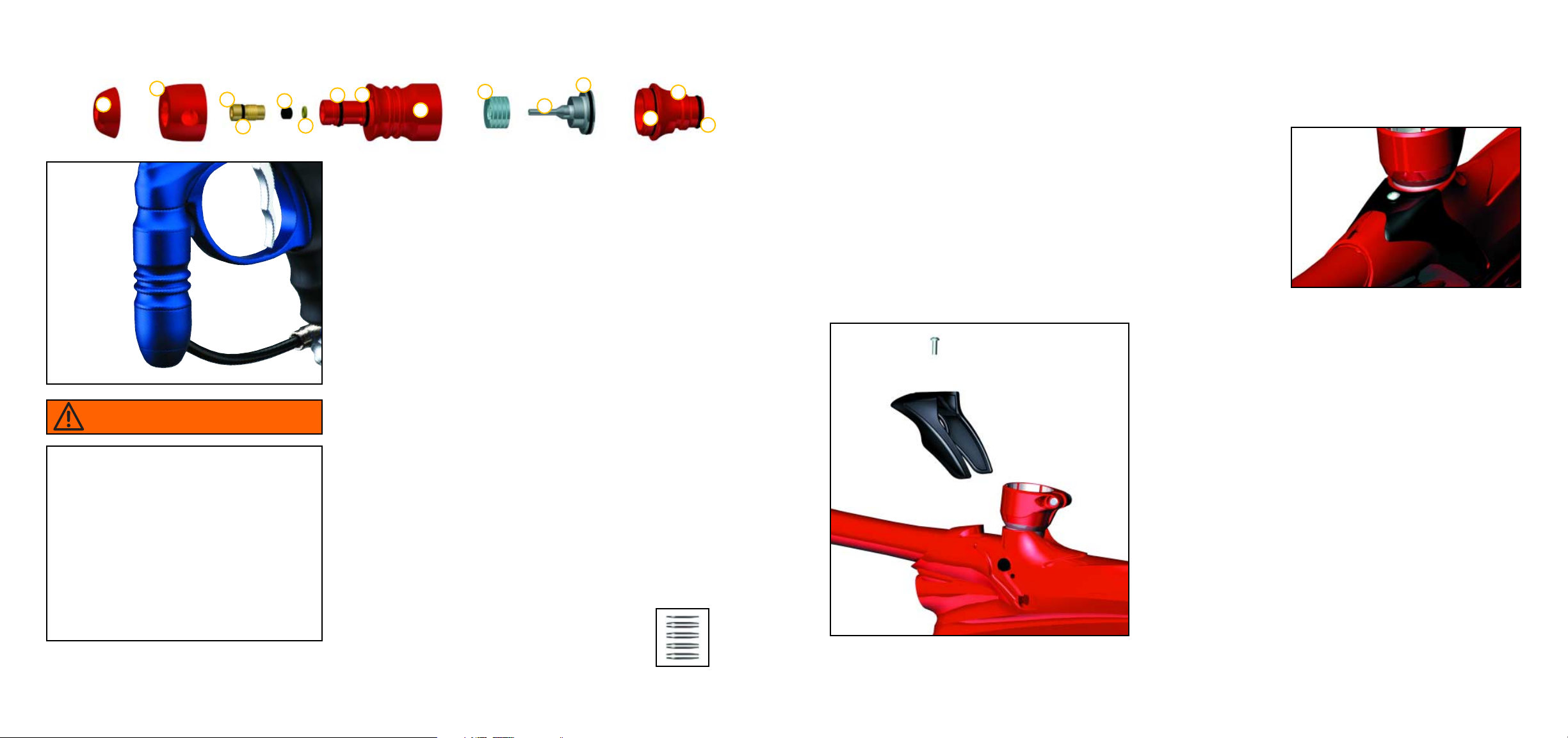

LPR (LOW PRESSURE REGULATOR) - ADJUSTMENTS AND MAINTENANCE

When servicing your marker:

• Make sure your hopper is removed

from the MATRIX.

• Make sure there are no paintballs in the

breech of the MATRIX.

• Always remove the air supply and

relieve all gas pressure in the MATRIX

before disassembly.

• It is not recommended for the user to

remove the LPR from the body and

disassemble it.

LPR ASSEMBLY, CLEANING, TESTING AND CHANGING SEALS

The Low-Pressure Regulator (LPR) is located in the lower front of the MATRIX (see figure 1).

The function of the LPR is to lower the air pressure supplied to the marker by the in-line,

before it reaches the solenoid. This pressure is used to move the bolt forward and back.

The factory setting is 75 PSI. You can fine tune your MATRIX to its minimum cycle pressure.

This will reduce the amount of force of the bolt hitting the ball (reducing ball breaks) and

help with efficiency. Too low of pressure will cause the bolt to not cycle, move sluggishly or

not at all. If you experience dramatic shoot down during rapid fire, the LPR may be adjusted

too low. Too high of pressure will cause the marker not to shoot as smoothly, potentially

increase ball breakage and cause undue wear and fatigue on the bolt components.

It is important to keep the seat and piston face clean of all dirt and debris. Clean the seat

and piston face and grease the retainer o-ring every six months or 60,000 shots.

The LPR has five components and six seals

1 Piston large o-ring (012 BN70) 6 Piston small o-ring (006 UR90)

2 Piston 7 Main seal (mounted in the seal retainer)

3 Piston spring 8 Seal retainer o-ring (010 BN70)

4 Body 9 Seal retainer (functions as an adjustment screw also)

5 Body o-rings (3pcs, 012 BN70)

The only user-serviceable part in the LPR is the seal retainer. This seal needs to be changed

in the unlikely case the LPR is creeping up.

LPR (LOW PRESSURE REGULATOR) - ADJUSTMENTS AND MAINTENANCE

CHANGING THE SEAL RETAINER

1 Screw out LPR cap in front of the marker using a 1/4” Allen wrench.

2 Screw out LPR seal assembly (brass) using a 3/16” Allen wrench.

3 Screw in new LPR seal assembly.

4 Screw LPR cap in place securely.

If the user needs to replace the whole LPR assembly, follow these instructions (refer to

figure 2):

1 Take frame off the marker.

2 Screw out LPR set screw using a 5/64” Allen wrench.

3 Screw out LPR cap using a 1/4” Allen wrench.

4 Pull out the LPR by screwing a rod with a 10/32 thread into the seal retainer

(brass piece) inside the LPR and pulling it out.

5 Put everything back in reverse order. Be sure to grease the #012 o-rings, so as to

prevent cutting them upon installation.

6 Tighten LPR cap securely.

The LPR pressure can be set quite accurately even without an LPR test tool. Screwing the

adjustment screw (seal retainer) all the way in will set the LPR pressure to approximately

25 psi. Now turning out the adjusting screw 180 degrees will increase the pressure by

approximately 5 psi. For example, turning the screw 5 complete turns out will set the

pressure to approximately 75 psi. Use a 3/16” Allen wrench to make all adjustments to the

LPR. Turning the adjustment screw clockwise, or in, will lower the LPR’s output pressure.

Turning the adjustment screw counterclockwise, or out, will raise the LPR’s output

pressure.

Figure 1

WARNING

1

2

3

4

5

5

5

6

7

8

9

10

When servicing your marker:

• Make sure your hopper is removed

from the MATRIX.

• Make sure there are no paintballs in the

breech of the MATRIX.

• Always remove the air supply and

relieve all gas pressure in the MATRIX

before disassembly.

• It is not recommended for the user to

remove the LPR from the body and

disassemble it.

WARNING

11

W WW.PROTOPAINTBALL.COM

Figure 2

Page 8

HYPER2™ IN-LINE REGULATOR - ADJUSTMENTS AND MAINTENANCE ANTI CHOP EYES/ BALL DETENTS - MAINTENANCE AND CHANGING

• The Hyper2™ can hold a small residual

charge of gas, typically 1 shot. Always

discharge the marker in a safe direction to

relieve this residual gas pressure.

• Always remove the regulator from the

MATRIX before servicing.

• Improper stacking of shims will cause

failure of the regulator and possible

damage to the MATRIX.

• Excessive dirt and debris can affect

the Hyper2™’s performance and increase

the need for servicing.

WARNING

USAGE

Carefully connect your air hose from your bottle or air system to the Hyper2™ In-Line. The

Hyper2™ In-Line is set by the factory to approximately 185psi. This pressure should give

you a velocity of approximately 285fps.

ADJUSTMENTS

The output pressure of the Hyper2™ In-Line is adjusted by turning the brass seat housing.

The seat housing screw is located up inside the bottom of the reg. A 3/16” Allen wrench

will be needed for this operation. By turning the housing counterclockwise, you will

increase the output pressure of the regulator to the marker. By turning the housing

clockwise, you will decrease the output pressure of the regulator.

After each adjustment of the output pressure of the Hyper2™ In-Line, you will need to cycle

your marker a few times. This will allow your marker and air system to stabilize at their new

operating pressure. The Hyper2™ will need a break-in period of about 2,500 shots to let its

seat form to the piston and reach its optimum performance.

The Hyper2™ has eight components and six o-rings

1 Retaining cap 6Piston small o-ring (007 UR90)11 Piston large o-ring (018 BN70)

2 Swivel 7 Swivel o-rings (013 BN70) 12 Reg cap o-ring (020 BN70)

3 Seat housing 8Reg body 13 Reg cap

4Retainer o-ring (010 BN70) 9 Shim stack 14 ASA o-ring (015 BN70)

5 Reg seat 10 Piston

Disassembly of the Hyper2™ In-Line is easily done with 3/8”

and 5/16” Allen wrenches.

MAINTENANCE

To ensure top performance from the Hyper2™, maintenance should be performed every six

months or sooner, depending on the severity of playing conditions. Cold, wet weather will

shorten the effective life of the grease. Heavy dust or fine sand can infiltrate the Hyper2™

and prevent the piston from moving smoothly and/or cut the o-rings.

1 Make sure the inlet and outlet ports and connecting fittings are free of all dirt and paint.

2 Examine all o-rings for nicks or cuts.

3 Carefully inspect the seat for excessive wear that might cause spiking and over-pressurizing.

4 Clean any accumulated dirt out of the air chambers and passages.

5 Keep the piston o-rings and spring pack generously greased to allow

smooth velocity adjustment and prevent erratic velocity

spikes and drop off.

6 Clean off all old grease that may be contaminated with dirt;

reapply fresh grease to the piston and other necessary areas.

7 Be sure to reassemble the internal components and

shim stack

(see figure 2) in the proper order and direction.

8 See diagram for assistance.

ANTI CHOP EYES

The Anti Chop Eye (ACE) system will prevent the MATRIX from chopping paint by not allowing

the marker to fire until a ball is fully seated in front of the bolt. The eyes use a beam across the

breech. On one side there is a transmitter, and on the opposite side a receiver. In order for the

marker to fire with the eyes turned on, the signal between the two eyes must be broken. After

every shot, before the next ball drops in the breech, the eye transmitter and receiver must see

each other. If the eyes are dirty and cannot see each other between shots, the LED on the board

will start blinking green. This means that the eyes are dirty. This is an extremely reliable system

as long as the eyes are kept clean. The most common reason for dirty eyes is broken paint. If

the eyes become dirty the marker will default to a reduced rate of fire to prevent chopping. If

this happens during game play, you can bypass this by turning the eyes off. Clean the eyes as

soon as possible.

NOTE: IF THE BATTERY IS LOW, THE MARKER MAY ACT AS IF THE EYES

ARE DIRTY OR NOT FIRE AT ALL. IN THIS CASE, REPLACE THE BATTERY.

13

W WW.PROTOPAINTBALL.COMWWW.PROTOPAINTBALL.COM

1

2

3

4

5

6

7

7

8

9

10

11

13

14

12

Figure 3

Figure 2

Figure 1

CLEANING THE ANTI CHOP EYES

Quite often, just cleaning the breech out with a swab will clean the eyes well

enough for them to read one another. For a thorough cleaning, the best method is

to use air. Using an air hose or canned air (typically used for dusting keyboards)

works best.

Blow the eyes clean from inside the breech. If you feel the eyes still need a more

detailed cleaning, remove the eye cover to gain full access to the eyes.

To remove the eye cover, you will need a 1/16” Allen wrench.

NOTE: Regular eye cleaning is recommended even if no paint is broken. Clean the

eyes every two months or 10,000 shots to eliminate any built up dirt. Excess grease

from the front bolt o-ring can build up in front of the eyes. Remember to check for

this after greasing the bolt and cycling the marker a few times.

CHANGING BALL DETENTS

The ball detents are also located under the eye cover. If you are experiencing

double feeding or chopping, check the condition of the ball detents. They should

come to a soft point. If they are flat or heavily rounded, they should be replaced.

Ball detents should be replaced about every 40,000 shots.

NOTE: TAKE CARE WHEN REPLACING THE EYE COVER. OVERTIGHTENING THE RETAINING SCREW COULD RESULT IN

STRIPPING THE THREADS.

Figure 2

Shim Stack

Page 9

TRIGGER ADJUSTMENT AND ON/OFF AIRPORT

Figure 1

MATRIX EXPLODED VIEW

• Be sure the trigger is not adjusted to the

point where it is too sensitive and may

cause accidental discharge of the marker.

• Removing the trigger spring will cause

premature wear on the microswitch,

resulting in failure.

•

Be sure you do not pinch the wires

between the frame and body when

reattaching the frame to the body.

W ARNING

15

1 Clamping Feed Neck

2 Ball Detent

3Eye Cover

4 Hyper2™

5 “ACE” Eye

6 Solenoid

7 Front Frame Screw

8 45 Frame

9 Rear Frame Screw

10 LPR Retaining Screw

11 LPR

12 LPR Cap

13 Fuse Bolt

14 MATRIX Body

15 Eye Cover Screw

16 On/Off Airport

PARTS LIST

1

3

4

5

6

7

12

11

13

8

10

15

16

9

2

14

14

ADJUSTING YOUR TRIGGER

The trigger’s forward travel and over travel are fully adjustable so that the user can finetune the trigger to his or her exact liking.

• Remove the grip frame from the body of the MATRIX.

• As you pull the frame away from the body, take care so as not to damage the wires

running between the two parts. Be careful not to lose the trigger spring.

• The two adjustment screws are located at the top of the trigger in the grip frame

(see figure 1).

• Use a 5/64” Allen wrench to make the desired adjustments.

• The screw toward the front of the trigger controls the forward travel. Screwing it in

will shorten the trigger’s length of pull.

Note: If this screw is adjusted too far, the switch will be held down at all times and the marker

will not fire.

• The screw toward the rear of the trigger controls the over travel. By turning this

screw you can adjust how far the trigger will travel after it reaches the firing point.

Note: If this screw is adjusted too far, the trigger will not be allowed to travel far enough to

depress the switch and fire the marker.

• When the desired trigger pull has been achieved, reattach the frame to the body.

• Take care that the spring is seated properly. Using the trigger without a spring is

not recommended and will cause the microswitch to fail much sooner than when a

spring is used.

• Be sure that all wires are laid properly in their appropriate cavities.

NOTE: Be sure that the frame and trigger assembly are kept clean. If there is excess

dirt or paint build up around the trigger, the trigger will no longer move freely. In

addition, paint and dirt can cause the microswitch to not function properly or fail.

ON/OFF AIRPORT

The MATRIX comes equipped with an On/Off Airport attached to the bottom of the

frame. To turn on the gas supply, twist the on/off knob clockwise, all the way in. To turn

off the gas supply, twist the on/off knob counterclockwise, all the way out. As you turn

the knob out, the residual gas between the Hyper2™ and the on/off airport is vented.

REMOVING THE ON/OFF AIRPORT

1 Follow the instructions on page 7 to remove the battery from the frame.

2 Using a 3/32 allen key, turn the airport locking screw counterclockwise until

the on/off airport is loosened.

3 Slide the on/off airport off of the frame.

4 To re-install the on/off airport, follow steps 1-3 in reverse order.

WWW.PROTOPAINTBALL.COM

Page 10

TROUBLE SHOOTING GUIDE MATRIX WARRANTY INFORMATION

17

W WW.PROTOPAINTBALL.COM WWW.PROTOPAINTBALL.COM

WARRANTY

DYE Precision, Inc.

Warrants for one year to the initial retail purchaser, from the initial date of purchase, that the paintball marker and regulator are free from defects in

materials and workmanship, subject to the requirements, disclaimers and limitations of this warranty. Disposable parts, normal maintenance and standard

wear and tear parts such as batteries, o-rings and seals are not warrantied. The solenoid and electronic components on the marker are warrantied for six

months. This warranty does not cover scratches, nicks, improper disassembly, improper re-assembly, misuse, neglect or improper storage. Modification to

the product will void the warranty. The only authorized lubricant for the marker is Slick Lube™. Use of any other lubricant will void your warranty. This

warranty is limited to repair or replacement of defective parts with the customer to pay shipping costs. Warranty card and proof of purchase must be

submitted to Dye Precision for warranty to be in effect. This warranty is not transferable. This warranty does not cover performance. Paintball markers are

non-refundable.

TECHNICAL SUPPORT

Our Technical Support Department is open Monday through Friday, from 9am to 5pm, PST, and can be reached at 858-536-5183. Additional support is

available through our web site, www.protopaintball.com.

DISCLAIMER

The specifications & photographs in this material are for information and general guidance purposes only.

Our products are continually updated and changes may be made to specification, design or appearance from time to time. These are subject to change

without notice. Contents of box may therefore vary from owner’s manual. For details of changes in design, specification or appearance consult your local

distributor or dealer.

The FUSE™ bolt and Slick Lube™ are registered trademarks. Design rights, copyrights and all other rights reserved. All patterns, drawings, photographs,

instructions or manuals remain the intellectual property of the manufacturer.

Covered by U.S. Patent 5,613,483. Additional patents pending.

All rights will be strictly enforced.

DYE Precision, Inc.

USA 10637 Scripps Summit Ct. San Diego, CA 92131

P 858-536-5183 F 858-536-5191

EUROPE Unit 1, ZK Park, 23 Commerce Way

Croydon, Surrey CRO 4ZS United Kingdom

P +44 (0) 20-8649-6330 F +44 (0) 20-8649-6339

ASIA 3F-2, No. 287, Jung Jeng Rd., Luju Hsiang

Taoyuan 338, Taiwan (R.O.C.)

P +886-3-312-6540 F +886-3-311-8723

MATRIX TROUBLE SHOOTING

KEY : O-RING SIZE O-RING HARDNESS PART NUMBER CORRESPONDING TO THE DIAGRAM

#000 UR70 (#)

AIR LEAK BETWEEN THE FRAME AND BODY

- First remove the frame and try to pinpoint the source of the leak:

- If it comes from the small hole under the LPR, you need to remove your LPR. The cause of

the leak is one of the three #012 BN70 (5) o-rings on the outside of the LPR or the

#006 UR90 (6) o-ring found inside the LPR (see page 10).

- If it comes from somewhere around the solenoid, there are three likely causes:

1. #015 BN70 (5) on the bolt sail (page 9)

2. #020 BN70 (8) on the cylinder [the one on the middle of the cylinder] (page 9)

3. Seat under the solenoid

4. If it leaks from any of the set screws under the body, re-loctite the screws with red loctite.

AIR LEAK FROM THE LPR CAP (REFER TO PAGE 10)

- Remove the LPR and change the forward-most #012 BN70 (5) o-ring on the LPR body.

If that does not help, change the seal retainer (7) inside the LPR body. Refer to page 10 of the

manual for disassembly instructions.

INCONSISTENT VELOCITY OVER THE CHRONO

- In-line regulator not giving consistent pressure: refer to the Hyper2™ section below, or if using

an after-market regulator, refer to its manufacturer.

- Low battery: change the battery.

- Bad seals in the bolt: take out the bolt, clean it, lube it with Dye Slick Lube™. Replace any orings that seem damaged, swollen or in otherwise bad shape. Most likely the o-ring at fault is

the #017 UR70 (5) front wall o-ring. Also check that the #014 BN70 (1) o-ring on the

bolt tip is in place (see page 9).

- LPR pressure set incorrectly or LPR pressure fluctuating: if pressure is too low, the bolt will

not cycle correctly. Try turning the LPR pressure a bit higher. If the pressure seems

inconsistent, you can have an authorized Matrix center check the LPR pressure.

List of tech centers can be found at www.protopaintball.com.

- Dwell set too low: if you set the dwell too low, the dump chamber will not empty completely

and will cause erratic velocities. Refer to board settings on page 6 for information on

setting the dwell.

TRIGGER BOUNCE

- Raise the trigger sensitivity value (see page 6).

- If you are having excessive trigger bounce when firing the gun, make sure you have an uncut

spring behind the trigger. Adjust the trigger so that the firing point of the trigger pull is

located about halfway through the travel of the pull.

AIR LEAK BETWEEN THE BODY AND REAR CAP

- Replace the #020 BN70 (8) o-ring on the bolt rear cap (see page 9).

MARKER WILL NOT FIRE

- A low battery may cause malfunctions to the marker. In this case, the battery should be

changed as soon as possible.

- If the LED light is red, the marker will not fire because there is no ball in the breech. Hold the

trigger for 1 second and the marker should fire. If it does not fire after holding the trigger, or if

the LED light is green and it will not fire:

- Make sure dwell setting is at the stock value of 18 (see page 6).

- Make sure the trigger is adjusted properly and is actuating the microswitch (see page 14).

- Make sure there are no broken solenoid wires.

- Sticking bolt: pull out the bolt, check for swollen o-rings and re-grease o-rings.

MARKER SHOOTING SLOW WHEN EYE IS ON AND BLINKING GREEN

- The eyes are not working correctly. Clean the eyes with rubbing alcohol and a cotton swab.

You'll know that they are clean if the LED turns red when there is nothing

inside the breech of the MATRIX.

- Make sure the eye wires are not broken or pinched.

- The battery may be low. In this case, the battery should be changed as soon as possible.

- Make sure the eye ribbon cable is plugged in correctly with the metal tab facing up.

MARKER ISN'T WORKING THOUGH EYES ARE CLEAN AND ALL WIRES ARE CONNECTED;

MARKER DOES WORK IF EYES ARE TURNED OFF

- Change the battery. The voltage in the battery is too low for the eye to function correctly.

AIR LEAK THROUGH THE BARREL (REFER TO PAGE 9)

- There are three possible o-rings that cause this leak:

- If the leak comes through the inside of the bolt, replace the #013 BN70 (7) on the bolt top hat.

If the cause is the #013 BN70 (7) o-ring, the input pressure to the gun is likely too high.

- If you hear a loud pop while firing the marker and air is rushing out from the front of the gun, it means:

- The Hyper2™ is set too high causing the #013 BN70 (7) top hat o-ring to blow off, replace the o-ring.

- The #017 UR70 (5) inside the bolt cylinder or #020 BN70 (8) outside the bolt cylinder is leaking,

replace the o-ring.

AIR LEAK FROM THE BACK HOLE OF THE BOLT

- Take out the bolt, unscrew the back part of the bolt and change the #009 BN70 (3,4) o-ring on the back

of the bolt shaft.

HYPER2™ TROUBLE SHOOTING (REFER TO PAGE 12)

NOTE: TO TAKE APART THE REGULATOR, USE A 5/16” ALLEN WRENCH ON THE BOTTOM AND A 3/8” ALLEN

WRENCH ON THE TOP. TWIST COUNTERCLOCKWISE TO OPEN. DO NOT USE ANY OTHER METHOD.

NO OR POOR AIR FLOW

- Check for blocked air passage in hose line or regulator. Adjustment screw (3) may be screwed in too far.

- Seat (5) may have excessively deep piston groove cut into it. Replace if needed.

ERRATIC VELOCITY OR SHOOT DOWN

- Piston (10) or shim stack (9) may be binding due to excessive dirt or lack of lubricant.

- Seat (5) may be dirty or damaged. Clean and grease regulator. Inspect and replace

damaged parts as needed.

- Make sure shim stack (9) is stacked properly (see page 12, figure 2).

OUTPUT PRESSURE CREEPS UP

- Dirty seat (5) or damaged piston face. Clean and inspect; if either is damaged, replace.

- Piston o-ring #007 UR90 (6) may be damaged.

AIR LEAK FROM SIDE VENT HOLE

- Piston o-rings #007 UR90 (6) and #018 BN70 (11) may be damaged. Inspect o-rings. Replace if any

visible nicks or cuts are found.

AIR LEAK FROM BOTTOM OF ADJUSTMENT SCREW

- This is a safety bleed-off to help prevent over-pressurizing. De-gas the Hyper2™; be sure all

air is vented out of the regulator. Supply air back to the regulator. The leak should stop. If the leak

persists, replace the regulator seat (5). Make sure there are no nicks or scratches on the raised ring at

the bottom of the seat-retaining cavity.

16

Page 11

Proto Paintball

USA

10637 Scripps Summit Ct. San Diego, CA 92131

P 858-536-5183 F 858-536-5191

EUROPE Unit 1, ZK Park, 23 Commerce Way

Croydon, Surrey CRO 4ZS United Kingdom

P +44 (0) 20-8649-6330 F +44 (0) 20-8649-6339

ASIA 3F-2, No. 287, Jung Jeng Rd., Luju Hsiang

Taoyuan 338, Taiwan (R.O.C.)

P +886-3-312-6540 F +886-3-311-8723

www.protopaintball.com

www.dyematrix.com

Copyright ©2006 DYE Precision, Inc. The stylized “proto” logo and the “P” logo are either registered

trademarks, trademarks, or design trademarks of DYE Precision, Inc.

Dye Precision, Inc. U.S. Patent # 5,613,483 and additional patents pending.

™

™

Loading...

Loading...