Page 1

J138WP-M and J150WP-M

Operation and Maintenance Manual

To reduce the risk of injury, read and understand these safety

warnings and instructions before using the tool. Keep these

instructions with the tool for future reference. If you have any

questions, contact your PROTO® representative or distributor.

WARNING

3/8" Mini Air Impact Wrench

1/2" Mini Air Impact Wrench

1/2" J150WP-M

3/8" J138WP-M

© 2015 PROTO

Page 2

2

INTRODUCTION

The PROTO® J138WP-M and J150WP-M are precision-built tools, designed for professionals for high torque assembly

and disassembly of threaded fasteners. These tools will deliver efficient, dependable service when used correctly and

with care. As with any fine power tool, for best performance the manufacturer’s instructions must be followed. Please

study this manual before operating the tool and understand the safety warnings and instructions. The instructions on

installation, operation and maintenance should be read carefully, and the manuals kept for reference. NOTE: Additional

safety measures may be required because of your particular application of the tool. Contact your PROTO® Distributor with

any questions concerning the tool and its use.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Phone: +1 800-800-TOOL

Fax: +1 770-648-9108

www.protoindustrial.com

TABLE OF CONTENTS

Introduction 2

Safety Instructions 3

Specifications 4

Getting Started 5

Tool Components 6, 7

Contact Information 8

WARNING

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING THE MACHINE.

SAVE FOR FUTURE REFERENCE

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

Do not use damaged, frayed or deteriorated air hoses

and fittings.

Air powered tools can vibrate in use. Vibration, repetitive

motions or uncomfortable positions may be harmful to

your hands and arms. Stop using any tool if discomfort,

tingling feeling or pain occurs. Seek medical advice before

resuming use.

Do not carry the tool by the hose.

Keep body stance balanced and firm. Do not overreach

when operating this tool.

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting any

accessory on this tool, or before performing any maintenance on this tool.

Always wear hearing protection when operating

this tool.

Always wear eye protection when operating or

performing maintenance on this tool.

Always wear respiratory protection when operating

this tool.

Operate at 90 psig (6.2 bar / 620 kPa) Maximum

air pressure.

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

Page 3

3

GENERAL SAFETY INSTRUCTIONS

Keep away from children

Always wear ANSI Z87.1 eye protection when operating or performing maintenance on this tool. Everyday eye glasses

are not safety glasses

Always wear hearing protection when operating this tool

Keep hands, loose clothing and long hair away from rotating end of tool

Anticipate and be alert for sudden changes in motion during start up and operation of any power tool

Keep body stance balanced and firm. Do not overreach when operating this tool

Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the work by

hand or against the body is unstable and can lead to loss of control

Do not operate this tool for long periods of time. Vibration caused by tool action may be harmful to your hands and

arms. Stop using any tool if discomfort, tingling feeling or pain occurs. Seek medical advice before resuming use

Stay alert. Do not use the tool while tired or under the influence of drugs, alcohol, or medication

Use only impact accessories. Non-impact accessories may break and cause a hazardous condition. Inspect accesso-

ries prior to use to ensure that it con tains no cracks.

Do not operate this tool in the presence of flammable liquids, gasses, dust, or explosive atmospheres

This tool is not insulated against electric shock, contact with a live wire will make exposed metal parts live

Always turn off the air supply and disconnect the air supply hose before installing, removing or adjusting any acces-

sory on this tool, or before performing any maintenance on this tool

Avoid unintentional starting. Be sure trigger is off before connecting to the air supply

For safety, top performance, and maximum durability of parts, operate this tool at 90 psig (6.2 bar / 620 kPa)

maximum air pressure at the inlet with 3/8’’ (10mm) inside diameter air supply hose. Adequate air supply volume

is required for full power. Restrictions in the supply and volume will cause a drop in air pressure when the trigger is

pulled resulting in lower power

Do not use damaged, frayed or deteriorated air hoses and fittings

Do not lubricate tools with flammable or volatile liquids such as kerosene, diesel or jet fuel

Do not remove any labels. Replace any damaged label

Tool service must be performed by qualified repair personnel. When servicing, use only PROTO® authorized, identical

replacement parts. Use only lubricants recommended by PROTO

®

Do not use this tool at heights exceeding 6 feet (2m)

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

- lead from lead-based paints

- crystalline silica from bricks and cement and other masonry products

- arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles

Do not use the tool if the trigger does not turn the tool on or off

Accessories and tools get hot during operation. Wear gloves when touching them

Inspect anvils and hog rings prior to use. Missing or damaged items should be replaced before use

Page 4

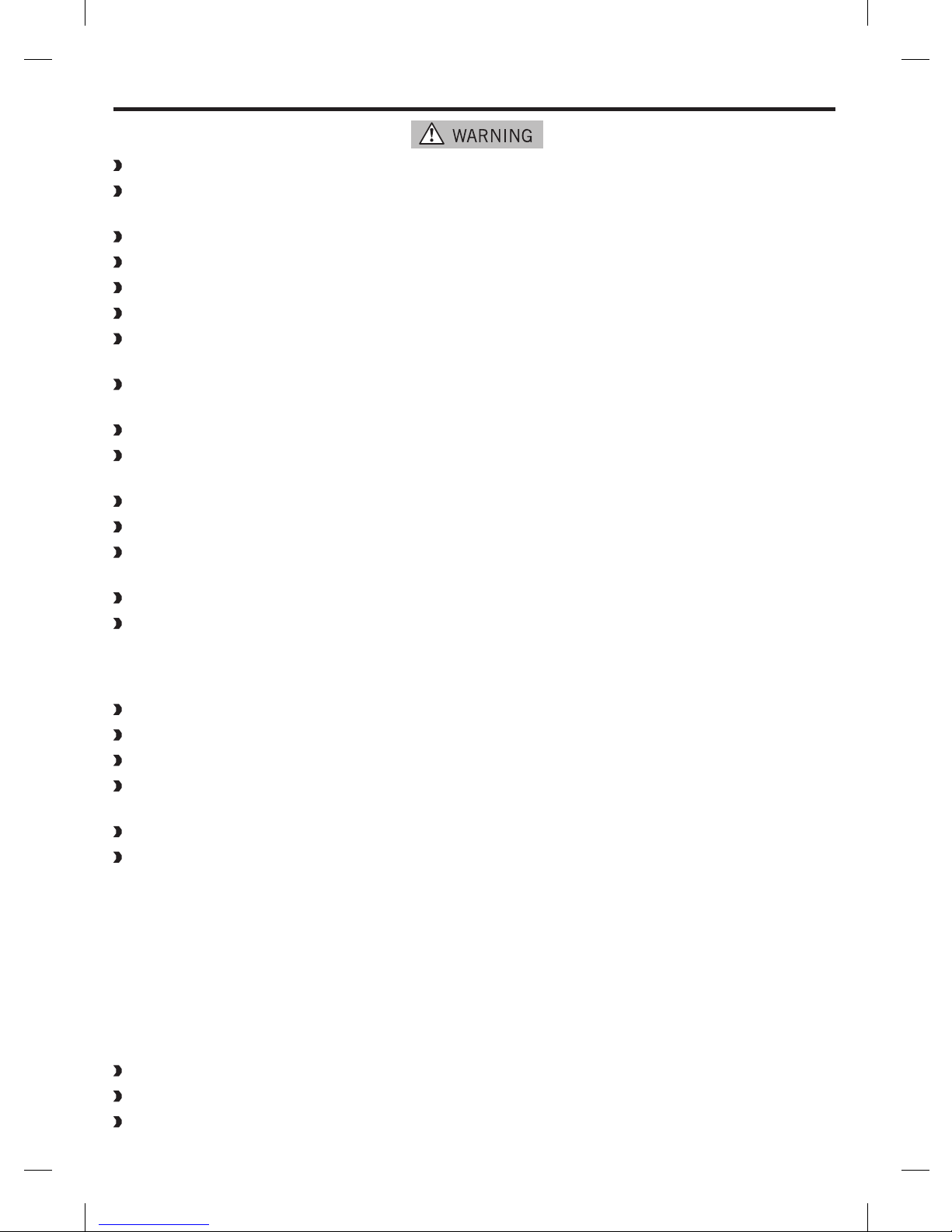

4

1/4” NPT

HIGH FLOW

FITTING

AIR HOSE

3/8” (10 mm)

I.D. MIN.

COMPACT

Refer to chart below

for size

SPECIFICATIONS

HIGH TORQUE

Refer to chart below for

breakaway torque specs

SPECIFICATIONS

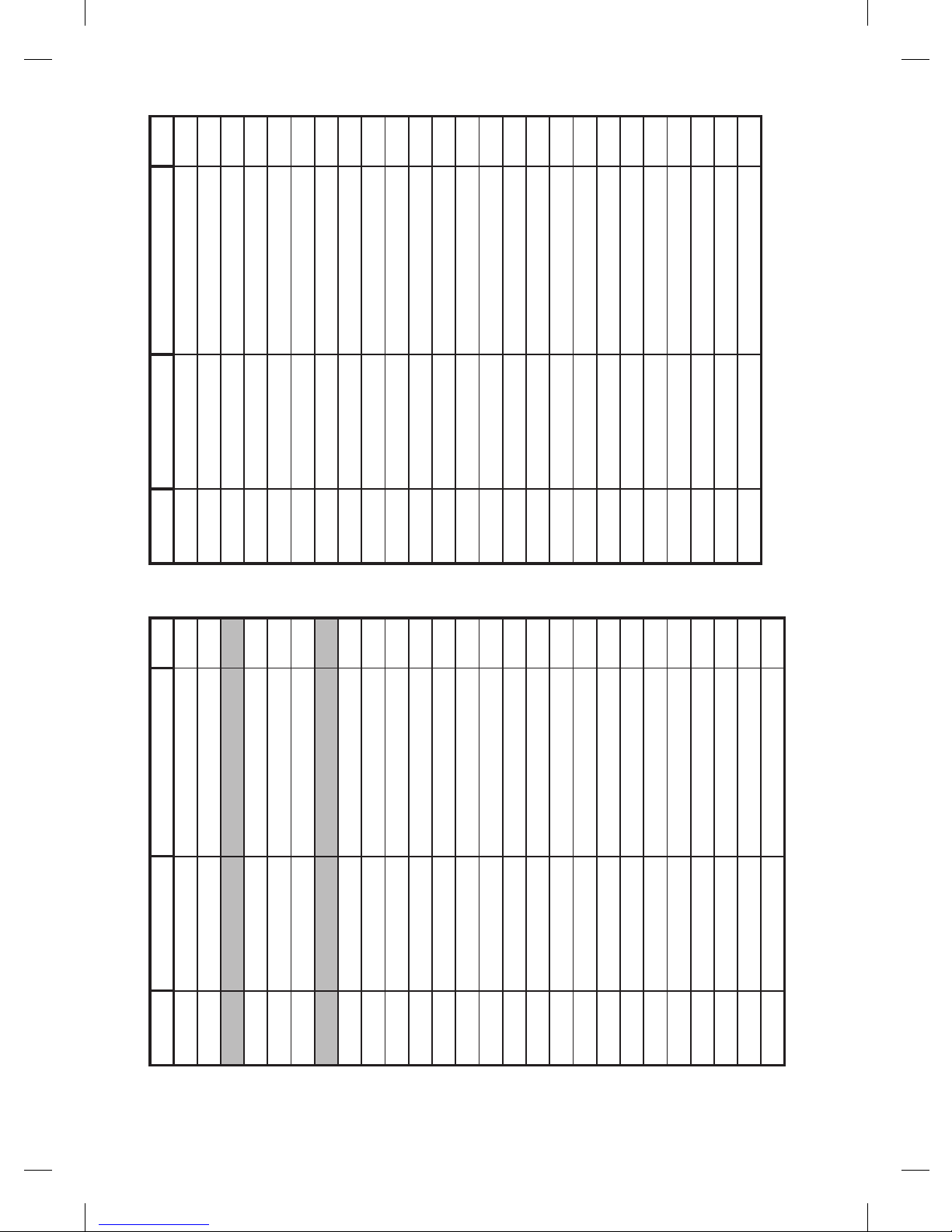

Model #

Square

Drive

Blow

Rate

Breakaway

Torque

Noise Level Vibration Level

in bpm ft-lbs / Nm Pressure dB(A) Power dB(A) Pressure dB(C) m/s

2

J138WP-M 3/8 1260 445 / 603 93.2 3 104.2 3 <130 3 7.78 1.27

J150WP-M 1/2 1650 635 / 861 97.1 3 108.1 3 <130 3 9.57 1.44

Model #

Free

Speed

Average Air

Consumption

Working

Pressure

Weight Dimensions

rpm cfm / l/min psi / bar lbs / kg in / mm

J138WP-M 6,000 3 / 85 90 / 6.2 2.8 / 1.3 4.4 x 2.4 x 6.8 / 111 x 61.5 x 173

J150WP-M 10,000 4.5 / 127 90 / 6.2 2.8 / 1.3 4.4 x 2.4 x 6.8 / 111 x 61.5 x 173

* = measurement uncertainty in dB(A) ** = measurement uncertainty in m/s²

VARIABLE SPEED TRIGGER

For maximum speed control

ONE-HAND FORWARD/REVERSE

SWITCH

Integrated 3-position

regulator for power control and

ease of use

RUBBER BUMPERS

Protect the tool

from damage

COMFORT GRIP

Rubber injected overlay,

resistant to oils and acids

Page 5

5

GETTING STARTED

Always operate, inspect and maintain this tool in accordance with all regulations (local, state, federal and country) that may apply to

hand-held / hand-operated pneumatic tools

For maximum performance, the air coupler on the wall should be the next size larger than the air coupler used on the tool. The coupler

closest to the tool should not be smaller than the proper air supply hose size

Be sure all hoses and fittings are the correct size and are tightly secured

Always use clean, dry air at 90 psig maximum air pressure. Dust, corrosive fumes and/or excessive moisture can ruin the motor of an

air tool

Inject the tool every 100-200 cycles with 1-3 grams of grease. Applications vary and grease may need to be applied more in colder

climates/conditions and less in hotter climates/conditions. The grease that should be used should be Petroleum or Synthetic, NLGI

Grade 2, -4/2300 F(-20/1100 C). The tool has a 1/8” Flush type grease fitting. If lower performance is observed immediately after

adding grease, service is needed to remove the build-up within the clutch housing

The use of a hose whip is recommended. A coupler connected directly to the air inlet increases tool bulk and decreases tool

maneuverability

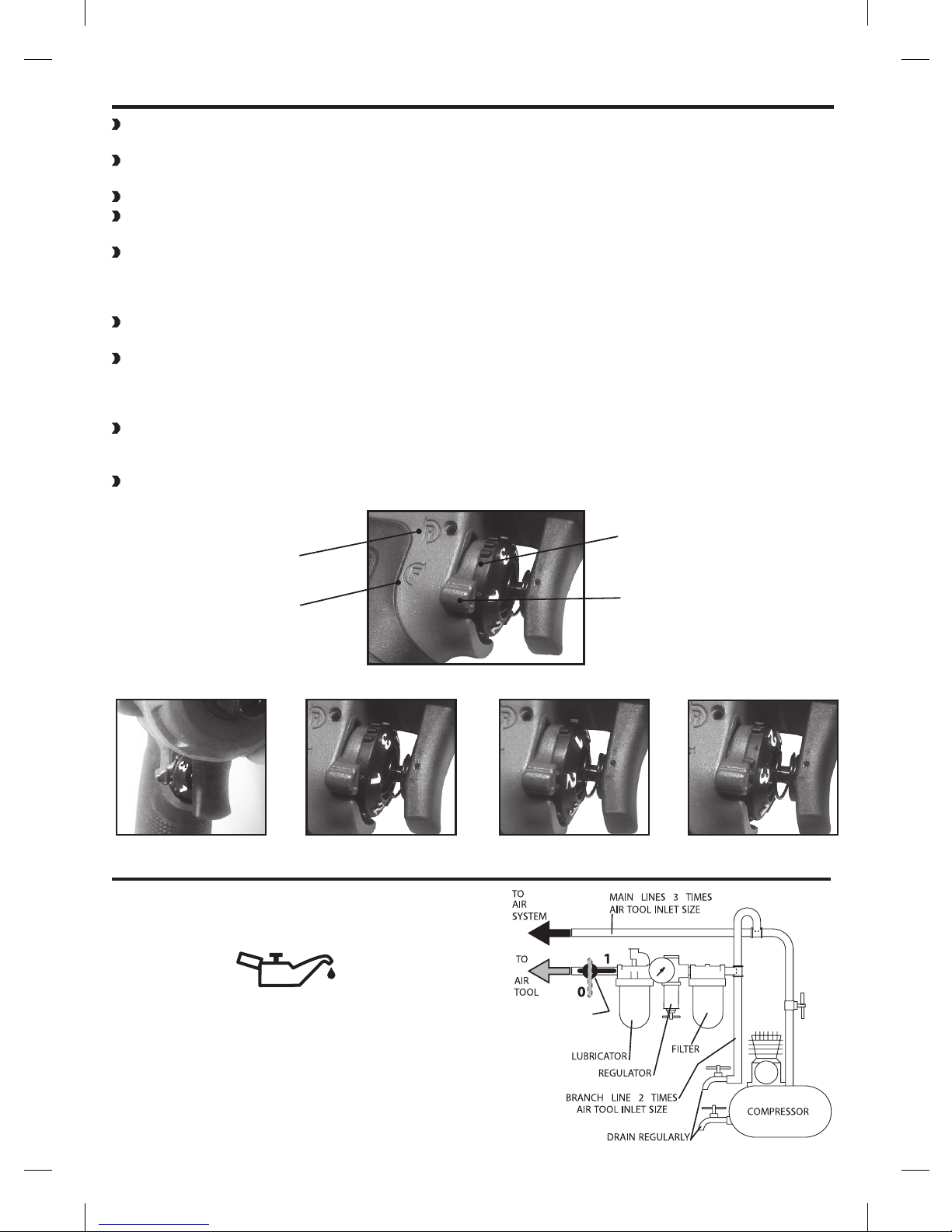

The regulator has 3 power positions, position 1 is the lowest and 3 is full power. To set the tool power with the regulator, turn the

dial until the power setting represented by 1, 2 or 3 is under the lever in the forward position as shown in Figure A. When the reverse

setting is selected the tool will operate, in reverse, at full power regardless of the power setting that is chosen. The F on the handle

represents forward and the R represents reverse

The Forward / Reverse Lever must be fully engaged in either the forward or reverse position to ensure the tool works with maximum

performance. If the Forward / Reverse Lever is positioned in the middle (see example below, bottom left picture) between forward and

reverse, the tool will not be as efficient and powerful

Use Hi-Flow air fittings and couplers for maximum tool performance

Figure A

Not Engaged - No Power

Power Setting 3 (Max)

Power Setting 2Power Setting - 1 (Low)

FORWARD/REVERSE LEVER

REVERSE POSITION

FORWARD POSITION

POWER SETTING

EMERGENCY

GATE VALVE

PLACING TOOL IN SERVICE

LUBRICATION

Always use an air line lubricator with this tool. After every eight

hours of operation, if a lubricator is not used on the compressed

air network, inject 1/2 to 1cm3 of approved air tool oil through the

machine’s inlet connection.

Page 6

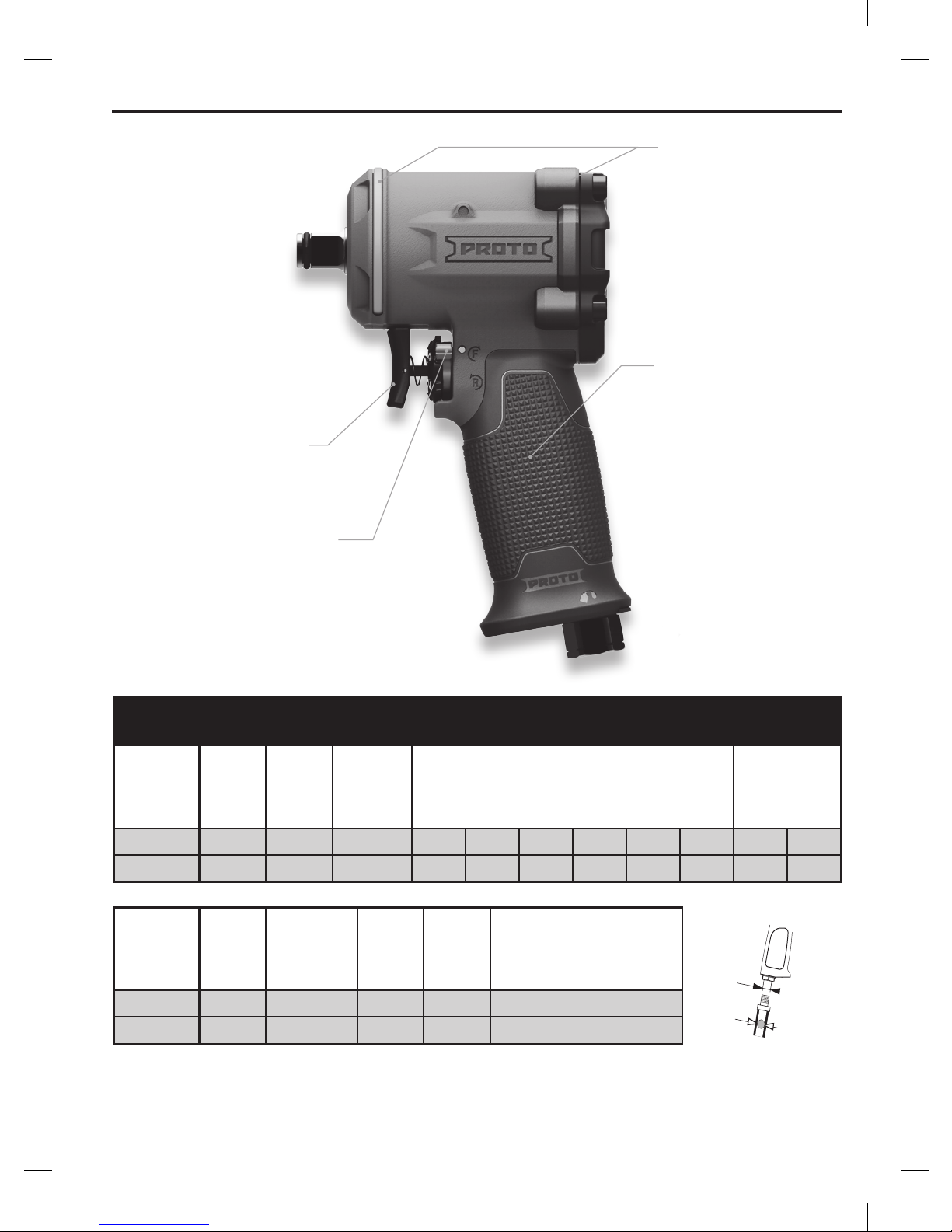

6

410

411

L

401

413

202

104A*

L __

104*

417*

420

I

105*

418

*

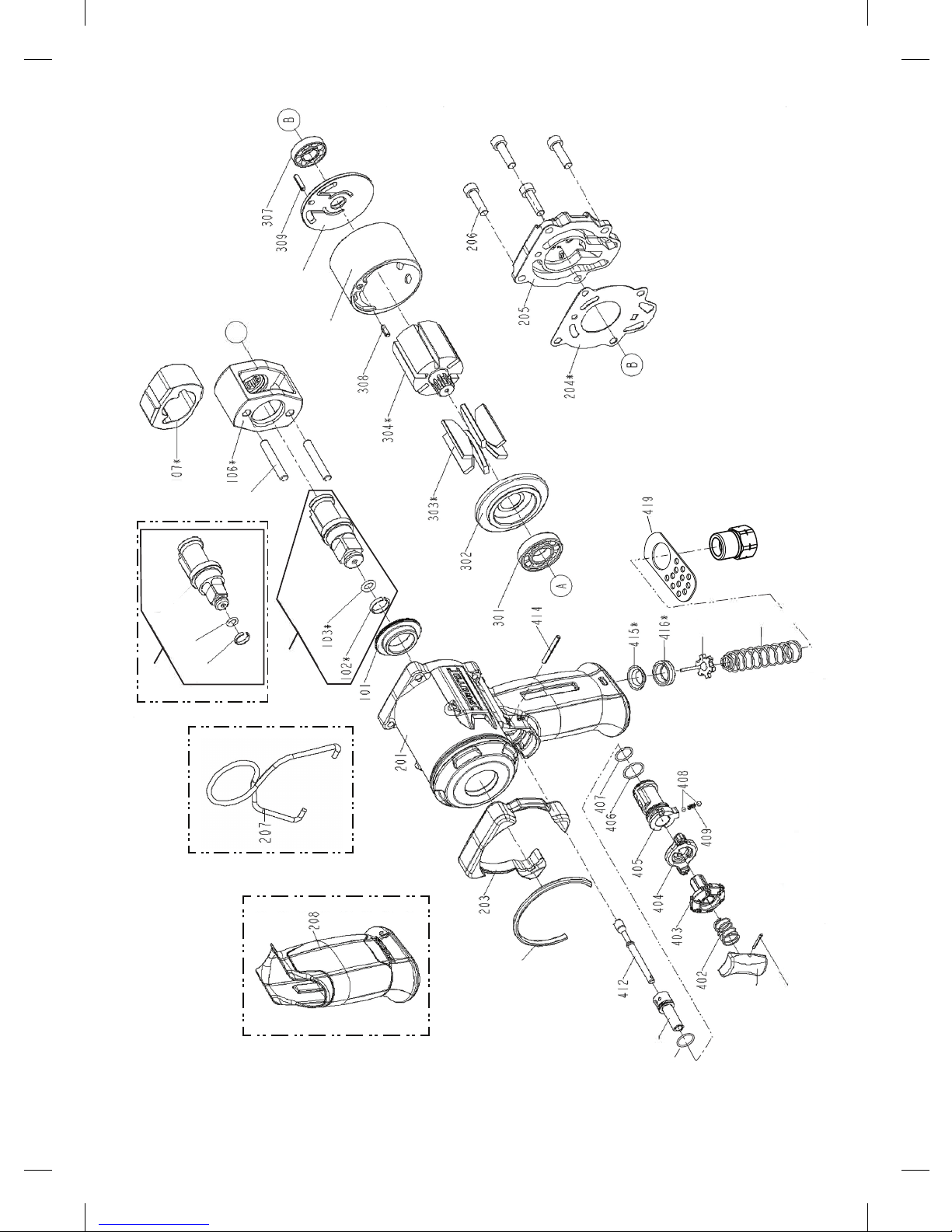

(*) Wearing Parts

A

306

305

I Jl38-KI

102A*

103A*

Page 7

7

All parts available through www.servicenet.protoindustrial.com

ITEM # PART # DESCRIPTION QTY

101 N449222 HAMMER CASE BUSHING 1

104 N449227 1/2" ANVIL ASSEMBLY 1

102 N449223 1/2" SOCKET RETAINER RING 1

103 N449225 1/2" O-RING 1

104A N449228 3/8" ANVIL ASSEMBLY 1

102 N449224 3/8" SOCKET RETAINER RING 1

103 N449226 3/8" O-RING 1

105 N449229 HAMMER PIN 2

106 N449230 HAMMER FRAME 1

107 N449231 HAMMER 1

201 N449269 3/8" HOUSING 1

201 N449270 1/2" HOUSING 1

202 N449283 FRONT BUMPER 1

203 N449285 REAR BUMPER 1

204 N449286 GASKET (PACKING)-MOTOR 1

205 N449287 REAR COVER PLATE 1

206 N449288 HEX.SOC.HD.BOLT 4

207 N449289 HANGER 1

208 N449292 GRIP 1

301 N449293 BEARING 1

302 N449298 FRONT BEARING PLATE 1

303 N449299 ROTOR BLADES 6

304 N449300 ROTOR 1

ITEM # PART # DESCRIPTION QTY

305 N449301 CYLINDER 1

306 N449302 REAR END PLATE 1

307 N449303 BEARING 1

308 N449304 SPRING PIN 1

309 N449305 SPRING PIN 1

401 N449296 TRIGGER 1

402 N449297 SPRING 1

403 N449306 REGULATOR A 1

404 N449307 LEVER 1

405 N449315 REVERSE VALVE 1

406 N449316 O-RING 1

407 N449317 O-RING 1

408 N449318 BALL-DETENT 2

409 N449319 POSITIONING SPRING 1

410 N449320 O-RING 1

411 N449321 REGULATOR B 1

412 N449322 TRIGGER PIN-TIP VALVE 1

413 N449323 SPRING PIN 1

414 N449324 SPRING PIN 1

415 N449325 BUSHING-TIP VALVE 1

416 N449326 SEAL-TIP VALVE 1

417 N449327 TIP VALVE 1

418 N449328 SPRING 1

419 N449330 EXHAUST DEFLECTOR 1

420 N449332 AIR INLET 1

Page 8

8

CUSTOMER SERVICE

We at PROTO are committed to our customers, please reference the following phone number for a direct contact to one of our

customer technicians. They will be more than happy to help with any service or warranty questions you may have about your power tool.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Phone: +1 800-800-TOOL

Fax: +1 770-648-9108

www.protoindustrial.com

CE DECLARATION OF CONFORMITY

WE, PROTO INDUSTRIAL TOOLS, 2195 EAST VIEW PARKWAY, SUITE 103, CONYERS, GEORGIA 30013, DECLARE UNDER OUR SOLE

RESPONSIBILITY THAT THE PRODUCTS J138WP-M 3/8” MINI AIR IMPACT WRENCH AND J150WP-M 1/2” MINI AIR IMPACT WRENCH

- CONFORM WITH THE DIRECTIVE AND STANDARDS "MACHINERY" DIRECTIVE 2006/42/CE

- AND ARE IN CONFORMITY WITH THE PROVISIONS OF THE HARMONISED EUROPEAN STANDARD

EN ISO 12100:2010

EN ISO 11148-6:2012

EN ISO 15744:2008

EN ISO 28927-2:2009

KEVIN LIN

QUALITY MANAGER

09.23.2015

Manual #N455497

J138WP-M and J150WP-M

Operation and Maintenance Manual

WARRANTY

We warrant that this tool shall be free from manufacturing defects for a period of TWO YEARS from the original purchase date. Our

obligation to the original purchaser shall be limited to repairing or replacing, at our expense (not including shipping charges) a defective

tool if returned by the original purchaser within two years from the date of purchase, all incoming shipping charges prepaid. THIS

WARRANTY DOES NOT COVER DEFECTS OR DAMAGES TO THE TOOL (i) after the warranty period expires; (ii) resulting from misuse or

abnormal operation; (iii) resulting from a failure to properly lubricate, maintain or operate the tool; or (iv) resulting from any repair or

maintenance services performed by any party other than PROTO® at all PROTO® Service Centers or a person authorized by PROTO® to

provide repair and maintenance services for this tool.

Page 9

Petite clé à chocs 3/8 po

Petite clé à chocs 1/2 po

J138WP-M et J150WP-M

Guide d’utilisation et de maintenance

Pour réduire tout risque de dommages corporels, lire et comprendre

ces consignes de sécurité et directives avant toute utilisation de

l’outil. Conserver ces instructions avec l’outil pour toute future

référence. Si vous avez des questions, veuillez contacter un

représentant PROTOMD ou l’un de ses distributeurs.

AVERTISSEMENT

1/2" J150WP-M

3/8" J138WP-M

© 2015 PROTO

Page 10

10

INTRODUCTION

Les modèles J138WP-M et J150WP-M PROTOMD sont des outils conçus pour les professionnels pour le montage ou le démontage à fort

couple de fixations filetés. Ces outils resteront fiables et efficaces dans la mesure où ils seront utilisés correctement et respectés. Comme

pour tout outil électrique de précision, pour des performances optimales, suivez les instructions du fabricant. Veuillez étudier ce guide

d’utilisation avant toute utilisation de l’outil et en comprendre les consignes de sécurité et les directives. Les instructions d’installation,

d’utilisation et de maintenance doivent être lues attentivement, et les guides d’utilisation conservés pour référence. REMARQUE : des

mesures de sécurité additionnelles pourront être requises pour une utilisation particulière de l’outil. Pour toute question relative à cet

outil et à son utilisation, veuillez contacter votre distributeur PROTOMD.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Téléphone : +1 800-800-TOOL

Télécopie : +1 770-648-9108

www.protoindustrial.com

TABLE DES MATIÈRES

Introduction 10

Consignes de sécurité 11

Caractéristiques techniques 12

Instructions de démarrage 13

Description de l’outil 14, 15

Coordonnées 16

AVERTISSEMENT

CONSIGNES DE SÉCURITÉ IMPORTANTES CI-INCLUSES. LIRE CE GUIDE

D’UTILISATION AVANT TOUTE UTILISATION DE L’OUTIL.

CONSERVEZ POUR RÉFÉRENCE FUTURE

RISQUES DE DOMMAGES CORPORELS EN CAS DE NON-RESPECT DE CES DIRECTIVES.

Ne pas utiliser de tuyaux ou raccords endommagés, détériorés

ou fissurés.

Les outils à air comprimé peuvent vibrer pendant leur

utilisation. Les vibrations, actions répétitives ou positions

inconfortables peuvent être nocives pour les bras et les mains.

Discontinuer l’utilisation de l’outil en cas d’inconfort, de

picotements ou de douleurs. Consulter un médecin avant d’en

reprendre l’utilisation.

Ne pas transporter l’outil par son tuyau à air.

Maintenir une posture équilibrée et ferme. Ne pas effectuer de

travaux hors de portée avec cet outil.

Arrêter l’arrivée d’air et déconnecter le tuyau d’air comprimé

avant d’installer,de retirer ou d'ajuster tout accessoire sur cet

outil, ou avant d’effectuer toute maintenance sur l’outil.

Porter systématiquement une protection auditive

pendant l’utilisation de cet outil.

Arrêter l’arrivée d’air et déconnecter le tuyau d’air

comprimé avant d’installer,de retirer ou d'ajuster

tout accessoire sur cet outil, ou avant d’effectuer

toute maintenance sur l’outil.

Porter systématiquement une protection oculaire

pendant l’utilisation de cet outil ou sa maintenance.

Utiliser à une pression d’air maximum de 6,2

bars/620 kPa (90 psi).

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

Page 11

11

CONSIGNES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT

Ne pas laisser à la portée des enfants

Porter systématiquement une protection oculaire ANSI Z87.1 pendant l’utilisation de cet outil ou sa maintenance. Les

lunettes courantes ne sont pas des lunettes de protection

Porter systématiquement une protection auditive pendant l’utilisation de cet outil

Protéger les mains, les vêtements amples et les cheveux longs de toute extrémité rotative de l’outil

Anticiper et être prêt à tout changement soudain de course lors du démarrage et du fonctionnement de tous les outils

électriques

Maintenir une posture équilibrée et ferme. Ne pas effectuer de travaux hors de portée avec cet outil

Sécurisez et fixez la pièce à travailler sur une surface stable à l'aide d'un serre-joint ou de tout autre outil. Il est dé-

conseillé de tenir la pièce à la main ou contre le corps pour des raisons d'instabilité, pouvant aller jusqu'à une perte

de contrôle

Ne pas utiliser cet outil de façon prolongée. Les vibrations causées par l’outil peuvent être nocives pour les mains ou

les bras. Discontinuer l’utilisation de l’outil en cas d’inconfort, de picotements ou de douleurs. Consulter un médecin

avant d’en reprendre l’utilisation

Restez vigilant. N'utilisez pas l'outil lorsque vous êtes épuisé ou que vous avez consommé de la drogue, de l'alcool ou

des médicaments

Utiliser exclusivement des accessoires à percussion. Tout autre type d’accessoires pourrait se briser et poser des

risques sérieux. Avant toute utilisation, vérifier qu’ils ne comportent aucune fissure

Ne pas utiliser cet outil en présence de poussières, gaz ou liquides inflammables ou en milieu déflagrant

Cet outil n’est pas isolé contre les décharges électriques

, le contact avec un fil sous tension engendre également la

mise sous tension des surfaces métalliques

Arrêter l’arrivée d’air et déconnecter le tuyau d’air comprimé avant d’installer, de retirer ou d'ajuster tout accessoire

sur cet outil, ou avant d’effectuer toute maintenance sur l’outil

Évitez une mise en marche non intentionnelle. Assurez-vous que la détente est en position d'arrêt avant de le

brancher à l'alimentation d'air

Pour votre sécurité, des performances optimales et une durée de vie maximale des pièces, utiliser cet outil à une

pression d’air maximum de 6,2 bars/620 kPa (90 psi) à l’arrivée d’un tuyau à air de 19 mm (3/4 po) de diamètre

interne. Pour garantir une puissance maximale, une alimentation d'air suffisante est requise. Une alimentation et

un volume insuffisants vont provoquer une chute de la pression d'air, et donc une puissance réduite, au moment

d'enfoncer la gâchette

Ne pas utiliser de tuyaux ou raccords endommagés, détériorés ou fissurés

Ne pas lubrifier les outils avec des liquides inflammables ou volatils tels que kérosène, diesel ou carburéacteur

Ne retirer aucune étiquette. Remplacer toute étiquette endommagée

La maintenance de l'outil doit être effectuée par un technicien d'entretien qualifié. Durant la maintenance, n'utilisez

que des pièces de rechange identiques autorisées par

Proto

MD

. N'utilisez que des lubrifiants recommandés par Proto

MD

N'utilisez pas cet outil à plus de 2 m (6 pi)

La poussière engendrée par les travaux de ponçage, sciage, meulage, fraisage et autres activités liées à la

construction contient des substances chimiques reconnues par l’état de Californie comme pouvant causer le

cancer, des malformations congénitales ou autres dommages aux organes reproducteurs. Exemples de substances

chimiques :

- plomb provenant de peintures à base de plomb

- silice cristallisée issue des briques, du ciment et autres produits de maçonnerie

- arsenic et chrome provenant de bois traité chimiquement

Le risque d'exposition dépend de votre fréquence de travail sur ce type d'activité.

Pour minimiser vos risques d'exposition, il est conseillé de : travailler dans une zone bien ventilée, et de travailler

avec du matériel de sécurité approuvé, tels que des masques anti-poussière, conçus spécialement pour filtrer les

particules microscopiques

N'utilisez pas l'outil si sa gâchette ne permet pas de le mettre en marche et de l'arrêter

Les mèches, les douilles et les outils peuvent devenir brûlants au toucher pendant l’utilisation. Porter des gants avant

tout contact

Vérifier enclumes, chevilles d’arrêt et anneaux ouverts avant toute utilisation. Tout élément manquant ou endommagé

devrait être remplacé avant toute utilisation

Page 12

12

RACCORD À

HAUT DÉBIT

NPT ¼ PO

TUYAU À

AIR, D. INT.

de 10 mm

(3/8 PO) MIN.

COMPACT

Reportez-vous au tableau

ci-dessous pour les

spécifications

CARACTÉRISTIQUES TECHNIQUES

UN COUPLE ÉLEVÉ

Reportez-vous au tableau

ci-dessous pour les spécifications

CARACTÉRISTIQUES TECHNIQUES

Modèle nº

Conducteur

taux

d'impact

Couple de

démarrage

Niveau de bruit

Niveau

de vibrations

po bpm pi-lb/nm Pressure dB(A) Power dB(A) Pressure dB(C) m/s

2

J138WP-M 3/8 1260 445 / 603 93.2 3 104.2 3 <130 3 7.78 1.27

J150WP-M 1/2 1650 635 / 861 97.1 3 108.1 3 <130 3 9.57 1.44

Modèle nº

Vitesse

à vide

Consommation

moyenne d'air

Pression de

service

Poids Dimensions

R/MIN cfm / l/min psi / bar lbs / kg in / mm

J138WP-M 6,000 3 / 85 90 / 6.2 2.8 / 1.3 4.4 x 2.4 x 6.8 / 111 x 61.5 x 173

J150WP-M 10,000 4.5 / 127 90 / 6.2 2.8 / 1.3 4.4 x 2.4 x 6.8 / 111 x 61.5 x 173

* = Incertitude d'evaluation en dB(A) ** = Incertitude d'evaluation en m/s²

GÂCHETTE À VITESSE

VARIABLE

Pour le contrôle de la vitesse

LEVIER AVANT/ARRIÈRE À UNE MAIN

Avec régulateur à 3 positions intégré

pour le contrôle de la puissance et une

utilisation facile

TAMPONS EN CAOUTCHOUC

Protection contre

les chocs

POIGNÉE CONFORTABLE

Revêtement injecté de caoutchouc, résistant aux huiles

et aux acides

Page 13

13

Pas engagé – Aucune

puissance

Réglage de puissance 3

(max)

Réglage de

puissance 2

Réglage de puissance – 1

(bas)

Figure A

LEVIER DE MARCHE

AVANT/ARRIÈRER

POSITION MARCHE

ARRIÈRE

POSITION AVANT

RÉGLAGE DE PUISSANCE

INSTRUCTIONS DE DÉMARRAGE

Utiliser, inspecter et maintenir systématiquement cet outil conformément aux réglementations en vigueur (locales, fédérales,

régionales ou nationales) régissant les outils pneumatiques portables/commandés manuellement

S’assurer que tout tuyau ou raccord est de la taille correcte et soigneusement arrimé

Utiliser systématiquement de l’air sec et net à une pression maximum de 6,2 bars/620 kPa (90 psi). Les poussières, les

émanations corrosives et/ou l’humidité excessive pourraient endommager gravement le moteur d’un outil pneumatique

L’utilisation d’un tuyau flexible est recommandée. Un coupleur directement connecté à une embouchure d’air

augmentera la masse de l’outil et diminuera sa maniabilité

Pour optimiser les performances, le coupleur à air mural devrait être de la taille tout de suite supérieure au coupleur à

air utilisé avec l’outil. Le coupleur le plus proche de l’outil ne devrait pas être inférieur à la taille correcte du tuyau à air

comprimé

Le régulateur dispose de 3 positions, la position 1 étant la puissance minimale et la position 3 la puissance maximale

de l’appareil. Pour sélectionner le niveau de puissance avec le régulateur, tournez le cadran jusqu’à ce que le paramètre

de puissance désiré (1, 2 ou 3) soit sous le levier en position avant, comme montré sur la figure A. Si le réglage arrière

est sélectionné, l’outil fonctionnera dans le sens inverse et à puissance maximale sans tenir compte du niveau de

puissance sélectionné. Le F sur la poignée représente la position avant et le R représente la position arrière

Le levier de marche Avant/Arrière doit être pleinement enfoncé sur la position avant ou arrière pour optimiser les

performances de l’outil. Si le levier de marche Avant/Arrière est positionné au milieu (voir l’exemple

ci-dessous, photo inférieure gauche) entre l’avant et l’arrière, l’outil ne sera pas aussi efficace et puissant

SOUPAPE DE

SÉCURITÉ

LUBRIFICATEUR

RÉGULATEUR

VERS LE

SYSTÈME D’AIR

PURGER RÉGULIÈREMENT

COMPRESSEUR

BRANCHER UNE LIGNE 2 FOIS LA

TAILLE DE L’EMBOUCHURE DE

L’OUTIL PNEUMATIQUE

FILTRE

VERS L’OUTIL

PNEUMATIQUE

LIGNES PRINCIPALES 3 FOIS LA

TAILLE DE L’EMBOUCHURE DE

L’OUTIL PNEUMATIQUE

MISE EN SERVICE DE L’OUTIL

LUBRIFICATION

Utiliser systématiquement un lubrificateur pour ligne d’air avec

cet outil. Toutes les huit heures d’utilisation, si un lubrificateur

n’est pas utilisé sur le réseau à air comprimé, injecter 1/2 à

1 cm3 d’huile homologuée pour les outils pneumatiques dans

l’embouchure de l’outil.

Page 14

14

410

411

L

401

413

202

104A*

L __

104*

417*

420

I

105*

418

*

(*) Wearing Parts

A

306

305

I Jl38-KI

102A*

103A*

Page 15

15

Toutes les pièces sont disponibles auprès de www.servicenet.protoindustrial.com

PRODUIT Nº PIÈCE Nº DESCRIPTION QTÉ

101 N449222

DOUILLE - BOÎTIER POUR MARTEAU

1

104 N449227 ENSEMBLE D’ENCLUME-1/2 PO 1

102 N449223 BAGUE DE RETENUE - 1/2 PO 1

103 N449225 JOINT TORIQUE - 1/2 PO 1

104A N449228 ENSEMBLE D’ENCLUME-1/2 PO 1

102A N449224 BAGUE DE RETENUE - 3/8 PO 1

103A N449226 JOINT TORIQUE - 3/8 PO 1

105 N449229 PLOT DE MARTEAU 2

106 N449230 BÂTI DE MARTEAU 1

107 N449231 MARTEAU 1

201 N449269 BOÎTIER 3/8" 1

201 N449270 BOÎTIER 1/2" 1

202 N449283 PARE-CHOCS AVANT 1

203 N449285 PARE-CHOCS ARRIÈRE 1

204 N449286

GARNITURE (ÉTANCHÉITÉ) -

MOTEUR

1

205 N449287 PLAQUE DE CAPOT ARRIÈRE 1

206 N449288 HEX.SOC.HD.BOULON 4

207 N449289 CROCHET 1

208 N449292 POIGNEE 1

301 N449293 ROULEMENT 1

302 N449298 PLAQUE ROULEMENTS AVANT 1

303 N449299 PALE DU ROTOR 6

304 N449300 ROTOR 1

PRODUIT Nº PIÈCE Nº DESCRIPTION QTÉ

305 N449301 CYLINDRE 1

306 N449302 PLAQUE D'EXTRÉMITÉ ARRIÈRE 1

307 N449303 ROULEMENT 1

308 N449304 GOUPILLE DE RESSORT 1

309 N449305 GOUPILLE DE RESSORT 1

401 N449296 GÂCHETTE 1

402 N449297 RESSORT 1

403 N449306 RÉGULATEUR A 1

404 N449307 LEVIER 1

405 N449315 VALVE D'INVERSION 1

406 N449316 JOINT TORIQUE 1

407 N449317 JOINT TORIQUE 1

408 N449318 BALL-DETENT 2

409 N449319 RESSORT 1

410 N449320 JOINT TORIQUE 1

411 N449321 RÉGULATEUR B 1

412 N449322

GOUPILLE DE DÉTENTE –

EMBOUT VALVE

1

413 N449323 GOUPILLE DE RESSORT 1

414 N449324 GOUPILLE DE RESSORT 1

415 N449325 BAGUE – EMBOUT VALVE 1

416 N449326 JOINT – EMBOUT DE VALVE 1

417 N449327 EMBOUT VALVE 1

418 N449328 RESSORT 1

419 N449330 DEFLECTEUR D'ÉCHAPPEMENT 1

420 N449332 ENTRÉ D'AIR 1

Page 16

16

SERVICE CLIENTÈLE

Nous, chez PROTO, sommes au service de notre clientèle, veuillez noter le numéro de téléphone suivant pour contacter directement l’un

de nos techniciens-clients. Ils seront ravis de vous aider et répondre à vos questions relatives à l’entretien ou à la garantie de votre outil

électrique.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Téléphone : +1 800-800-TOOL

Télécopie : +1 770-648-9108

www.protoindustrial.com

CERTIFICAT DE CONFORMITÉ CE

NOUS, PROTO INDUSTRIAL TOOLS, 2195 EAST VIEW PARKWAY, SUITE 103, CONYERS, GEORGIA 30013, DÉCLARONS, SOUS NOTRE

SEULE RESPONSABILITÉ, QUE LES PRODUITS J138WP-M PETITE CLÉ À CHOCS PNEUMATIQUE 3/8 PO ET J150WP-M PETITE CLÉ À

CHOCS PNEUMATIQUE 1/2 PO

- SONT CONFORMES AUX DIRECTIVES ET DIRECTIVES STANDARDS "MACHINERIE" 2006/42/CE

- ET SONT EN CONFORMITÉ AVEC LES PROVISIONS DU STANDARD EUROPÉEN HARMONISÉ :

EN ISO 12100:2010

EN ISO 11148-6:2012

EN ISO 15744:2008

EN ISO 28927-2:2009

Guide d’utilisation nº N455497

Kevin Lin

DIRECTEUR DU SERVICE

DE LA FIABILITÉ

09.23.2015

J138WP-M et J150WP-M

Guide d’utilisation et de maintenance

GARANTIE

Nous garantissons cet outil contre tout vice de fabrication pour une période de DEUX ANS à compter de sa date originelle d’achat. Notre obligation vis-à-vis de l’acheteur originel se limite à la réparation ou au remplacement, à nos frais (frais de port exclus) de l’outil défectueux,

s’il nous est retourné par son acheteur originel dans les deux ans à compter de la date d’achat, frais de port prépayés. CETTE GARANTIE

NE COUVRE PAS TOUT DÉFAUT OU DOMMAGE À L’OUTIL (i) encouru une fois la garantie expirée ; (ii) résultant d’un usage abusif ou d’une

utilisation anormale ; (iii) résultant d’une lubrification, d’un entretien ou d’une utilisation, inadéquat de l’outil ; ou (iv) résultant d’une

réparation ou de services d’entretien effectués par toute partie autre que PROTOMD auprès de tous les centres de réparation

PROTOMD ou d’une personne agrée par PROTOMD pour effectuer toute réparation ou tout service de maintenance sur cet outil.

Page 17

Para reducir el riesgo de lesión, lea y comprenda estas advertencias

e instrucciones de seguridad antes de utilizar la herramienta.

Conserve estas instrucciones con herramienta para referencia futura.

Si tiene alguna pregunta, póngase en contacto con su representante

o distribuidor de PROTO

®

.

ADVERTENCIA

Impacto Mini de Air de Transmisión de 3/8"

Impacto Mini de Air de Transmisión de 1/2"

J138WP-M y J150WP-M

Manual de operación y mantenimiento

1/2" J150WP-M

3/8" J138WP-M

© 2015 PROTO

Page 18

18

INTRODUCCIÓN

El J138WP-M y el J150WP-M de PROTO® son unas herramientas construida con precisión, diseñadas con miras a los profesionales para

el montaje y desmontaje con alto par de torsión de sujetadores roscados. Estas herramientas entregarán un servicio eficiente y confiable

cuando se utilizan correctamente y con cuidado. Como con cualquier herramienta eléctrica de calidad, para lograr el mejor desempeño se

deben seguir las instrucciones del fabricante. Por favor estudie este manual antes de usar la herramienta y comprenda las advertencias

e instrucciones de seguridad. Se deben leer con cuidado las instrucciones de instalación, operación y mantenimiento, y los manuales

deben conservarse como referencia. NOTA: Pueden ser necesarias medidas adicionales de seguridad debido a su aplicación particular

para la herramienta. Comuníquese con su distribuidor PROTO® para cualquier pregunta acerca de la herramienta y su uso.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Teléfono: +1 800-800-TOOL

Fax: +1 770-648-9108

www.protoindustrial.com

TABLA DE CONTENIDOS

Introducción 18

Instrucciones de seguridad 19

Especificaciones 20

Primeros Pasos 21

Componentes de la Herramienta 22, 23

Información de Contacto 24

No utilice mangueras de aire y accesorios

dañados, desgastados o deteriorados.

Las herramientas neumáticas pueden vibrar durante

el uso. La vibración, los movimientos repetitivos o

las posiciones incómodas pueden ser peligrosos para

las manos y los brazos. Deje de usar cualquier herramienta si siente incomodidad, tiene una sensación

de hormigueo o siente dolor. Busque asesoramiento

médico antes de continuar el uso.

No transporte la herramienta por la manguera.

Mantenga una postura equilibrada y firme. No ponga

en peligro su estabilidad al operar esta herramienta.

Use siempre protección auditiva al operar esta

herramienta.

Use siempre protección para los ojos al operar esta

herramienta o al realizar tareas de

mantenimiento.

Siempre use protección ocular al operar o

realizar el mantenimiento de esta herramienta.

Apague siempre el suministro de aire y

desconecte la manguera de suministro de aire antes

de instalar, retirar o ajustar cualquier accesorio o

antes de realizar cualquier tarea de mantenimiento

en esta herramienta.

Operar a una presión máxima de aire

de 90 psig (6,2 bares)

SE ADJUNTA INFORMACIÓN IMPORTANTE SOBRE SEGURIDAD.

LEA ESTE MANUAL ANTES DE UTILIZAR LA MÁQUINA.

CONSERVE PARA REFERENCIA FUTURA

EL NO OBSERVAR LAS SIGUIENTES ADVERTENCIAS PODRÍA OCASIONAR LESIONES.

ADVERTENCIA

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

6.2 bars

(90 psig/

620 kPa)

Page 19

19

INSTRUCCIONES GENERALES DE SEGURIDAD

ADVERTENCIA

Mantenga alejado de los niños

Siempre use protección ocular ANSI Z87.1 al operar o realizar el mantenimiento de esta herramienta. Los anteojos de uso diario

no son lentes de seguridad.

Siempre use protección auditiva cuando utilice esta herramienta.

Mantenga las manos, la ropa suelta y el cabello largo lejos del extremo giratorio de la herramienta.

Anticípese y esté atento a los cambios repentinos en el movimiento durante el arranque y la operación de cualquier herramienta

eléctrica.

Mantenga una postura corporal equilibrada y firme. No ponga en peligro su estabilidad al operar esta herramienta.

Use abrazaderas u otra forma práctica de sujetar y sustentar la pieza de trabajo a una plataforma estable. Sostener el

trabajo con la mano o contra el cuerpo es inestable y puede ocasionar la pérdida de control

No opere esta herramienta durante períodos prolongados. La vibración provocada por la acción de la herramienta puede ser

peligrosa para sus manos y brazos. Deje de utilizar cualquier herramienta si se produce malestar, sensación de hormigueo o

dolor. Consulte con un médico antes de volver a utilizarla.

Manténgase alerta. No use la herramienta cuando esté cansado o bajo la influencia de drogas, alcohol o

medicamentos

Utilice solamente accesorios para llaves de impacto. Los accesorios comunes pueden romperse y causar una situación de

peligro. Inspeccione el accesorios antes de usarlo para asegurarse de que no tenga fisuras

No utilice esta herramienta en presencia de líquidos inflamables, gases, polvo o atmósferas explosivas

Esta herramienta no está aislada contra descargas eléctricas

, el contacto con un cable vivo transmitirá la corriente a las

piezas expuestas de metal

Siempre apague el suministro de aire y desconecte la manguera de suministro de aire antes de instalar, retirar o ajustar

cualquier accesorio de esta herramienta, o antes de realizar cualquier tarea de mantenimiento sobre esta herramienta

Evite el encendido accidental. Asegúrese de que el interruptor esté en apagado antes de conectar al suministro de

aire

Con miras a la seguridad, desempeño óptimo y máxima durabilidad de las partes, haga funcionar esta herramienta a 90 psig

( 6,2 bar/620 kPa) de presión máxima de aire en la admisión, con manguera de suministro de aire de 3/4’ (19mm) de diámetro

interior. Se requiere un volumen adecuado de suministro de aire para una potencia completa. Las restricciones en el suministro

y volumen causarán una caída en la presión de aire cuando el gatillo se presiona, lo que resultará en una menor potencia

No utilice mangueras de aire y accesorios dañados, desgastados o deteriorados.

No lubrique las herramientas con líquidos inflamables o volátiles tales como queroseno, diésel o combustible para aviones

No retire las etiquetas. Sustituya cualquier etiqueta dañada.

A manutenção da ferramenta deve ser executada apenas pelo técnico de reparo qualificado. Quando for feita a

manutenção utilize apenas a peças de reposição idênticas autorizadas da

Proto

MD

. Use apenas os lubrificantes

recomendados pela

Proto

MD

Não use esta ferramenta em alturas maiores que 6 pés (2m)

El polvo creado por el lijado, el corte, el pulido, la perforación y otras actividades de construcción contiene

productos químicos que el Estado de California ha determinado que causan cáncer, defectos de nacimiento o daños

reproductivos. Algunos ejemplos de estos productos químicos son:

- plomo de pinturas con base de plomo

- silicio cristalino de ladrillos, cemento y otros productos de albañilería

- arsénico y cromo de la leña con tratamiento químico

Su riesgo ante estas exposiciones varía de acuerdo con la frecuencia en que realice este tipo de trabajo.

Para reducir su exposición a estos productos químicos: trabaje en un área bien ventilada, y trabaje con equipos de

seguridad aprobados, como máscaras para polvo especialmente diseñadas para filtrar las partículas microscópicas

No use la herramienta si el gatillo no enciende ni apaga la herramienta

Las brocas, los casquillos y las herramientas se calientan durante el funcionamiento. Use guantes cuando los

toque

Inspeccione los yunques y los anillos abiertos antes de utilizarlos. Deben cambiarse los artículos que faltan o están

dañados antes de utilizarse

Page 20

20

ESPECIFICACIONES

ACCESORIO

DE FLUJO ALTO

DE ¼" NPT

MANGUERA

DE AIRE

DE 3/8"

(10 MM)

D.I. MIN.

COMPACTO

Consulte la tabla siguiente

para especificaciones

ALTA TORSIÓN

Consulte la tabla siguiente para

especificaciones

ESPECIFICACIONES

No. de

modelo

Eje

Tasa de

Soplado

Par de

Arranque

Nivel de ruido

Nivel de

Vibración

pulg bpm lb-pie / Nm Presión dB(A) Potencia dB(A) Presión dB(C) m/s

2

J138WP-M 3/8 1260 445 / 603 93.2 3 104.2 3 <130 3 7.78 1.27

J150WP-M 1/2 1650 635 / 861 97.1 3 108.1 3 <130 3 9.57 1.44

No. de

modelo

Velocidad

Libre

Consumo

Promedio de

Aire

Presión de

Trabajo

Peso Dimensiones

rpm cfm / l/min psi / bar lbs / kg in / mm

J138WP-M 6,000 3 / 85 90 / 6.2 2.8 / 1.3 4.4 x 2.4 x 6.8 / 111 x 61.5 x 173

J150WP-M 10,000 4.5 / 127 90 / 6.2 2.8 / 1.3 4.4 x 2.4 x 6.8 / 111 x 61.5 x 173

* = incertidumbre de medición en dB(A) ** = incertidumbre de medición en m/seg2

GATILLO DE VELOCIDAD

VARIABLE

Para control de la velocidad

INTERRUPTOR DE AVANCE/

RETROCESO DE UNA MANO

Con un regulador integrado

de 3 posiciones para el

control de potencia y

facilidad de uso

TOPES DE GOMA

Proteja la herramienta

contra daños

MANGOS CONFORTABLES

Superposición de inyección de caucho, resistente

al aceite y el ácido

Page 21

21

Figure A

PALANCA DE

AVANZAR / RETROCEDER

POSICIÓN INVERSA

POSICIÓN DE AVANCE

CONFIGURACIÓN

DE POTENCIA

PRIMEROS PASOS

Siempre haga funcionar, verifique y mantenga esta herramienta de acuerdo con todas las regulaciones (locales, estatales,

federales y nacionales) que pueden aplicarse a las herramientas neumáticas portátiles/manuales

Asegúrese de que todas las mangueras y accesorios sean del tamaño correcto y estén bien apretados

Use siempre aire limpio y seco a presión de aire máxima de 90 psig. El polvo, los vapores corrosivos y/o la humedad

excesiva pueden estropear el motor de una herramienta neumática

Se recomienda el uso de un látigo de manguera. Un acoplador conectado directamente a la admisión de aire aumenta el

volumen de la herramienta y disminuye su maniobrabilidad

Para un rendimiento máximo, el acoplador de aire en la pared debe ser del siguiente tamaño más grande que el

acoplador de aire utilizado en la herramienta. El acoplador más cercano a la herramienta no debe ser menor que el

tamaño apropiado de la manguera de suministro de aire

El regulador tiene 3 posiciones de potencia, la posición 1 es la potencia más baja y la 3 es la potencia máxima. Para

configurar la potencia de la herramienta con el regulador, gire el indicador hasta que el ajuste de potencia representado

por 1, 2 o 3 se encuentre debajo de la palanca en la posición hacia adelante como se muestra en la Figura A. Cuando

se selecciona la configuración de reversa, la herramienta funciona a máxima potencia, independientemente de la

configuración de potencia elegida. La F en el mango representa avance y la R representa reversa

La Palanca de Avanzar / Retroceder debe estar completamente engranada en la posición de avanzar o retroceder para

asegurarse que la herramienta trabaje a su máximo rendimiento. Si la Palanca de Avanzar / Retroceder está en la mitad

(vea el ejemplo de abajo, en la figura inferior izquierda) entre la posición de avanzar y la de retroceder, la herramienta

no será tan eficiente y poderosa

No está Engranado - No

hay Potencia

Configuración

de Potencia 3 (Máx.)

Configuración

de Potencia 2

Configuración

de Potencia - 1 (Baja)

VÁLVULA DE PUERTA

DE EMERGENCIA

LUBRICADOR

REGULADOR

AL SISTEMA

DE AIRE

DRENAR REGULARMENTE

COMPRESOR

RAMAL DOS VECES EL TAMAÑO DE

ENTRADA DE LA HERRAMIENTA

NEUMÁTICA

FILTRO

A LA HERRAMIENTA

NEUMÁTICA

LÍNEAS PRINCIPALES TRES VECES

EL TAMAÑO DE ENTRADA DE LA

HERRAMIENTA NEUMÁTICA

PARA PONER LA HERRAMIENTA EN SERVICIO

LUBRICACIÓN

Utilice siempre un lubricante de línea de aire con esta herramienta.

Después de cada ocho horas de funcionamiento, si no se utiliza un

lubricante en la red de aire comprimido, inyecte de 1/2 a 1 cm3 de

aceite aprobado para herramientas de aire a través de la conexión

de admisión de la máquina.

Page 22

22

410

411

L

401

413

202

104A*

L __

104*

417*

420

I

105*

418

*

(*) Wearing Parts

A

306

305

I Jl38-KI

102A*

103A*

Page 23

23

Todas las piezas están disponibles a través de www.servicenet.protoindustrial.com

No. DE

ARTÍCULO

No. DE PIEZA DESCRIPCIÓN CTD

101 N449222

CASQUILLO - CAJA DEL MARTILLO

1

104 N449227 ENSAMBLAJE DEL YUNQUE-1/2" 1

102 N449223 ANILLO DE RETENCIÓN - 1/2" 1

103 N449225 JUNTA TÓRICA - 1/2" 1

104A N449228 ENSAMBLAJE DEL YUNQUE-3/8" 1

102A N449224 ANILLO DE RETENCIÓN - 3/8" 1

103A N449226 JUNTA TÓRICA - 3/8" 1

105 N449229 CLAVIJA DE MARTILLO 2

106 N449230 MARCO DEL MARTILLO 1

107 N449231 MARTILLO 1

201 N449269 CARCASA 3/8" 1

201 N449270 CARCASA 1/2" 1

202 N449283 PARACHOQUES FRONTAL 1

203 N449285 PARACHOQUES POSTERIOR 1

204 N449286 JUNTA (EMPAQUE) DEL MOTOR 1

205 N449287 PLACA CUBIERTA TRASERA 1

206 N449288 HEX.SOC.HD.BOLT 4

207 N449289 GANCHO 1

208 N449292 MANGO 1

301 N449293 RODAMIENTO 1

302 N449298

PLACA DE SOPORTE FRONTAL

DEL MOTOR

1

303 N449299 HOJA DEL ROTOR 6

304 N449300 ROTOR 1

No. DE

ARTÍCULO

No. DE PIEZA DESCRIPCIÓN CTD

305 N449301 CILINDRO 1

306 N449302 PLACA DEL EXTREMO TRASERO 1

307 N449303 BEARING 1

308 N449304 CLAVIJA DE RESORTE 1

309 N449305 CLAVIJA DE RESORTE 1

401 N449296 GATILLO 1

402 N449297 RESORTE 1

403 N449306 REGULADOR A 1

404 N449307 PALANCA 1

405 N449315 VÁLVULA DE REVERSA 1

406 N449316 JUNTA TÓRICA 1

407 N449317 JUNTA TÓRICA 1

408 N449318 RODAMIENTO DE BOLA 2

409 N449319 RESORTE 1

410 N449320 JUNTA TÓRICA 1

411 N449321 REGULADOR B 1

412 N449322

CLAVIJA DEL GATILLO-VÁLVULA

DE PUNTA

1

413 N449323 CLAVIJA DE RESORTE 1

414 N449324 CLAVIJA DE RESORTE 1

415 N449325 CASQUILLO-VÁLVULA DE PUNTA 1

416 N449326 SELLO-VÁLVULA DE PUNTA 1

417 N449327 VÁLVULA DE PUNTA 1

418 N449328 RESORTE 1

419 N449330 DEFLECTOR DEL ESCAPE 1

420 N449332 ENTRADA DE AIRE 1

Page 24

24

SERVICIO A CLIENTES

Nosotros en PROTO estamos comprometidos con nuestros clientes, por favor diríjase al siguiente número de teléfono para ponerse en

contacto con un de nuestros técnicos para clientes. Ellos estarán más que contentos en ayudarlo con cualquier otra pregunta del servicio y

la garantía que pueda tener acerca su herramienta eléctrica.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Teléfono: +1 800-800-TOOL

Fax: +1 770-648-9108

www.protoindustrial.com

DECLARACIÓN DE CONFORMIDAD DE LA CE

NOSOTROS, PROTO INDUSTRIAL TOOLS, 2195 EAST VIEW PARKWAY, SUITE 103, CONYERS, GEORGIA 30013, DECLARAMOS BAJO NUESTRA

EXCLUSIVA RESPONSABILIDAD QUE EL PRODUCTO J138WP-M IMPACTO MINI DE AIRE DE TRANSMISIÓN DE 3/8” y J150WP-M IMPACTO

MINI DE AIRE DE TRANSMISIÓN DE 1/2”

- CUMPLE CON LA DIRECTIVA Y NORMAS DE «MAQUINARIA» DIRECTIVA 2006/42/CE

- Y ESTÁ EN CONFORMIDAD CON LAS DISPOSICIONES DE LA NORMA EUROPEA ARMONIZADA

EN ISO 12100:2010

EN ISO 11148-6:2012

EN ISO 15744:2008

EN ISO 28927-2:2009

J138WP-M y J150WP-M

Manual de operación y mantenimiento

Kevin Lin

GERENTE DE CALIDAD

09.23.2015

Pieza No. N455497

GARANTÍA

Garantizamos que esta herramienta estará libre de defectos de fabricación por un período de DOS AÑOS desde la fecha de compra original.

Nuestra obligación para con el comprador original se limita a reparar o reemplazar, a nuestra costa (sin incluir gastos de envío) una

herramienta defectuosa si es devuelta por el comprador original dentro del plazo de dos años a partir de la fecha de compra, prepagados

todos los gastos de envío entrantes. ESTA GARANTÍA NO CUBRE DEFECTOS O DAÑOS A LA HERRAMIENTA (i) después de que expire el periodo

de garantía, (ii) como resultado de uso inadecuado u operación anormal, (iii) como resultado de fallar en lubricar, mantener y operar la

herramienta adecuadamente, o (iv) como resultado de cualquiera de los servicios de reparación o mantenimiento realizados por cualquier

persona o entidad que no sea PROTO® en todos los Centros de Servicio de PROTO® o una persona autorizada por PROTO® para ofrecer

servicios de reparación y mantenimiento de esta herramienta.

Loading...

Loading...