Page 1

J138RSH and J150RSH

Operation and Maintenance Manual

3/8" J138RSH

1/2" J150RSH

WARNING

To reduce the risk of injury, read and understand these safety

warnings and instructions before using the tool. Keep these

instructions with the tool for future reference. If you have any

questions, contact your PROTO® representative or distributor.

3/8" Drive Sealed Head Ratchet

1/2" Drive Sealed Head Ratchet

Page 2

TABLE OF CONTENTS

Introduction 2

Safety Instructions 3

Specifications 4

Getting Started 5

Tool Components 6

Contact Information 8

INTRODUCTION

The PROTO® J138RSH and J150RSH are precision-built tools, designed for professionals, for torque assembly and disassembly of threaded

fasteners. These tools will deliver efficient, dependable service when used correctly and with care. As with any fine power tool, for best

performance the manufacturer’s instructions must be followed. Please study this manual before operating the tool and understand the

safety warnings and instructions. The instructions on installation, operation and maintenance should be read carefully, and the manuals

kept for reference. NOTE: Additional safety measures may be required because of your particular application of the tool. Contact your

PROTO® Distributor with any questions concerning the tool and its use.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Phone: +1 800-800-TOOL

Fax: +1 770-648-9108

www.protoindustrial.com

®

WARRANTY

We warrant that this tool shall be free from manufacturing defects for a period of ONE YEAR from the original purchase date. Our

obligation to the original purchaser shall be limited to repairing or replacing, at our expense (not including shipping charges) a defective

tool if returned by the original purchaser within two years from the date of purchase, all incoming shipping charges prepaid. THIS

WARRANTY DOES NOT COVER DEFECTS OR DAMAGES TO THE TOOL (i) after the warranty period expires; (ii) resulting from misuse or

abnormal operation; (iii) resulting from a failure to properly lubricate, maintain or operate the tool; or (iv) resulting from any repair or

maintenance services performed by any party other than PROTO® at all DeWALT Service Centers or a person authorized by PROTO® to

provide repair and maintenance services for this tool.

2

Page 3

WARNING

6.2 bars

(90 psig/620 kPa)

6.2 bars

(90 psig/620 kPa)

6.2 bars

(90 psig/620 kPa)

6.2 bars

(90 psig/620 kPa)

6.2 bars

(90 psig/620 kPa)

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING THE MACHINE.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

Do not use damaged, frayed or deteriorated air

hoses and fittings.

Always wear hearing protection when operating

this tool.

Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may

be harmful to your hands and arms. Stop using any

tool if discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming use.

Do not carry the tool by the hose.

Always turn off the air supply and disconnect

the air supply hose before installing, removing

or adjusting any accessory on this tool, or before

performing any maintenance on this tool.

Always wear eye protection when operating or

performing maintenance on this tool.

Keep body stance balanced and firm. Do not overreach when operating this tool.

6.2 bars

(90 psig/620 kPa)

Operate at 90 psig (6.2 bar / 620 kPa) Maximum

air pressure.

GENERAL SAFETY INSTRUCTIONS

WARNING

Always wear ANSI Z87.1 eye protection when operating or performing maintenance on this tool. Everyday

eye glasses are not safety glasses.

Always wear hearing protection when operating this tool.

Keep hands, loose clothing and long hair away from rotating end of tool.

Anticipate and be alert for sudden changes in motion during start up and operation of any power tool.

Keep body stance balanced and firm. Do not overreach when operating this tool.

Do not operate this tool for long periods of time. Vibration caused by tool action may be harmful to your

hands and arms. Stop using any tool if discomfort, tingling feeling or pain occurs. Seek medical advice

before resuming use.

Use rated accessories recommended by PROTO® only. Inspect accessories before use. Do not use cracked

or damaged accessories.

Do not operate this tool in the presence of flammable liquids, gasses, dust, or explosive atmospheres

This tool is not insulated against electric shock.

For safety, top performance, and maximum durability of parts, operate this tool at 90 psig.

(6.2 bar / 620 kPa) maximum air pressure at the inlet with 3/8’’ (10mm) inside diameter air supply hose.

Always turn off the air supply and disconnect the air supply hose before installing, removing or adjusting

any accessory on this tool, or before performing any maintenance on this tool.

Do not use damaged, frayed or deteriorated air hoses and fittings.

Do not lubricate tools with flammable or volatile liquids such as kerosene, diesel or jet fuel.

Do not remove any labels. Replace any damaged label.

3

Page 4

1/4” NPT

FULL FLOW

FITTING

AIR HOSE

3/8” (10 mm)

I.D. MIN.

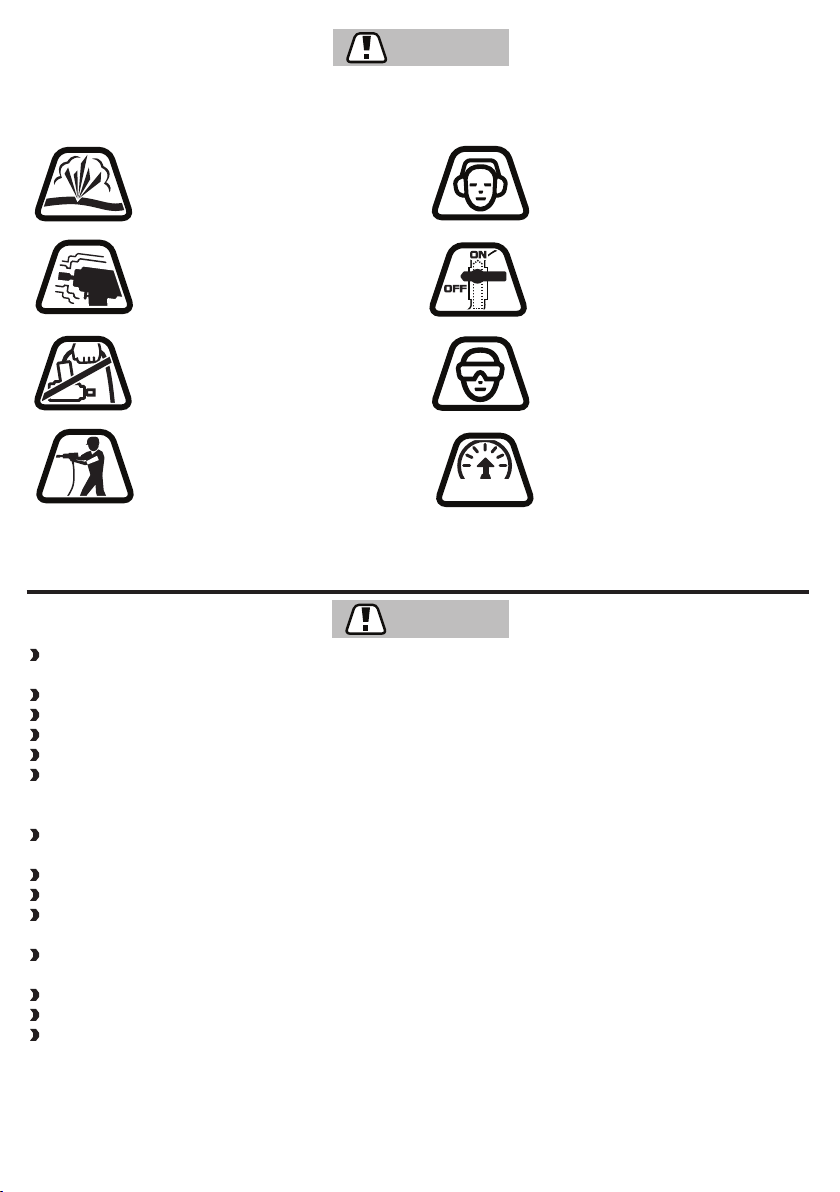

SPECIFICATIONS

Titanium Sealed Head

Quick Release Socket

Mechanism

Innovative

Forward/Reverse

Ring

Lightweight

Construction

Comfortable Non-Slip

Textured Rubber Grip

4

Use Hi-Flow air fittings and

couplers for maximum tool

performance

Page 5

GETTING STARTED

Always operate, inspect and maintain this tool in accordance with all regulations (local, state, federal

and country) that may apply to hand-held / hand-operated pneumatic tools.

Be sure all hoses and fittings are the correct size and are tightly secured.

Always use clean, dry air at 90 psig maximum air pressure. Dust, corrosive fumes and/or excessive mois-

ture can ruin the motor of an air tool.

The use of a hose whip is recommended. A coupler connected directly to the air inlet increases tool bulk

and decreases tool maneuverability.

For maximum performance, the coupler on the wall should be the next size larger than the coupler used

on the tool. The coupler closest to the tool should not be less than the proper air supply hose size.

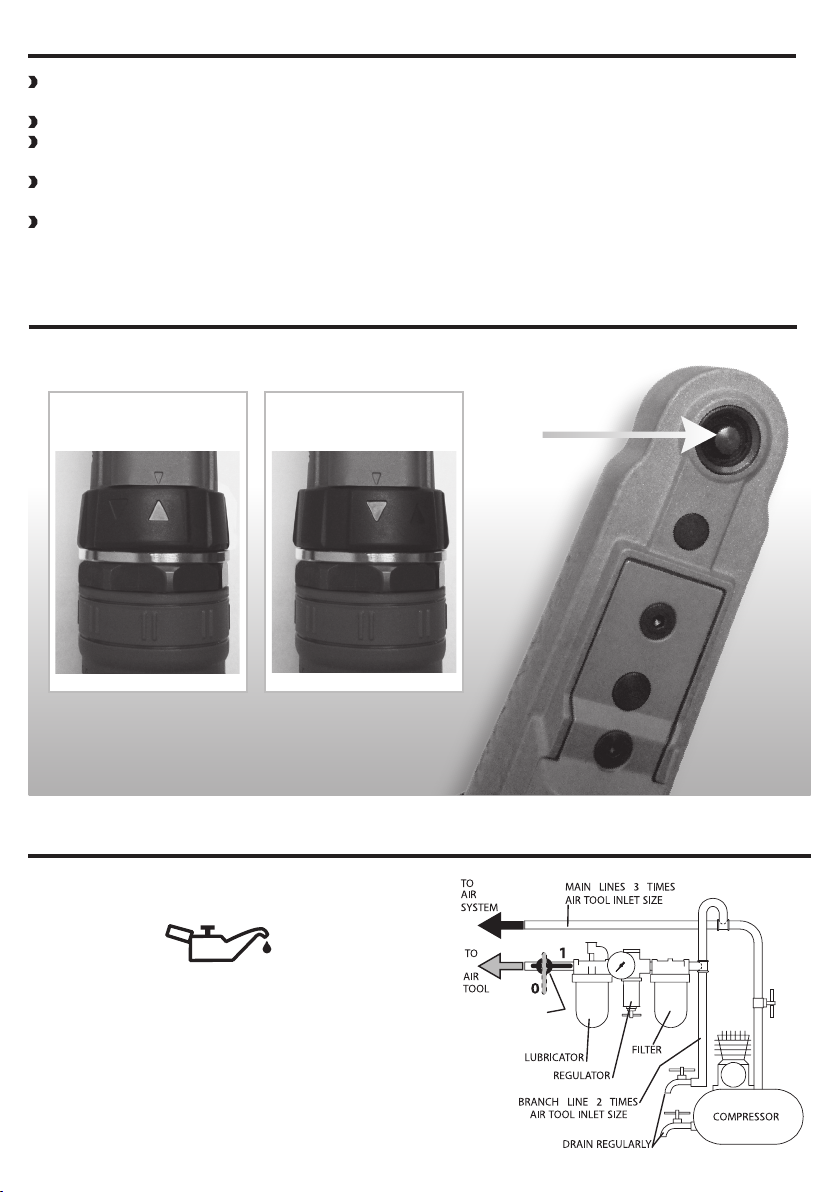

OPERATING FEATURES

Socket Release

Forward Position Reverse Position

Button

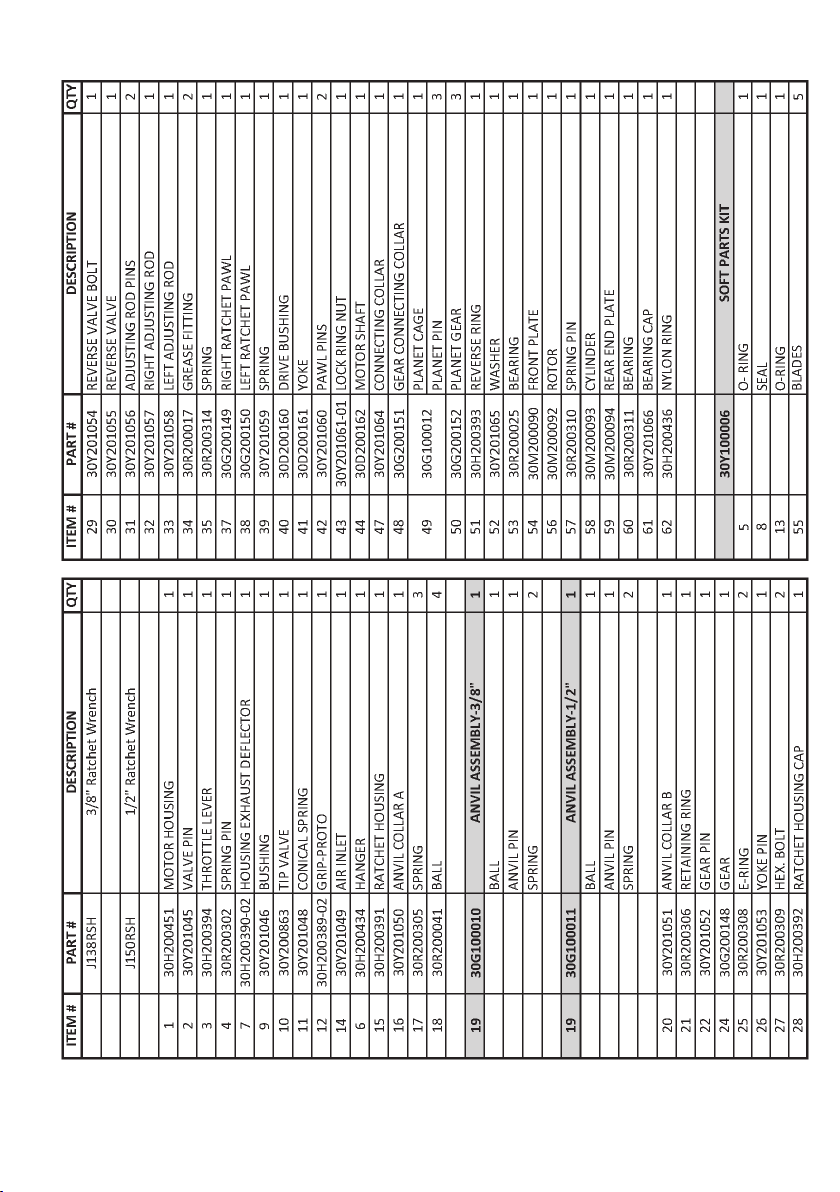

PLACING TOOL IN SERVICE

LUBRICATION

Always use an air line lubricator with this tool. After every eight

hours of operation, if a lubricator is not used on the compressed

air network, inject 1/2 to 1cm3 of approved air tool oil through the

machine’s inlet connection.

EMERGENCY

GATE VALVE

5

Page 6

48

61

60

14

6

12

59

57

40

29

41

30

31

47

37

33

44

38

62

42

58

39

43

35

56

18

54

34

53

55

52

24

50

11

49

10

9

25

8

7

4

1

2

3

27

28

26

32

15

34

16

18

17

19

20

21

5

13

22

51

6

Page 7

All parts available through www.servicenet.protoindustrial.com

7

Page 8

J138RSH and J150RSH

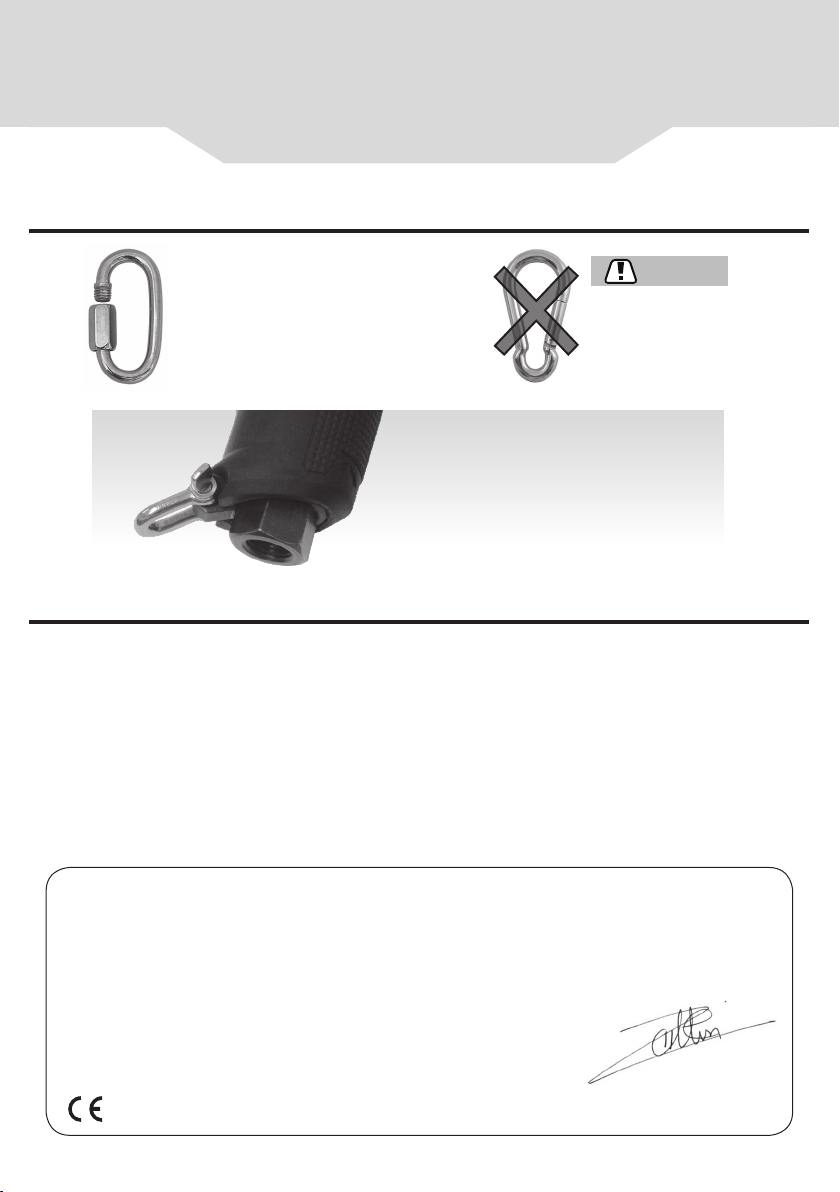

TETHERING THE TOOL

Operation and Maintenance Manual

Use ONLY the following load rated Connector for

tool suspension: Steel Wire, Stainless 316,

Max. Load Capacity 800 lb., Eye Inside Dia. 1/2 in.,

Overall Length 1 15/16 in., Opening 1/4 in.,

Stock Thickness 3/16 in. Type : Load Rated

Check threaded stud periodically.

Thread-locker recommended.

If tool is dropped, replace all tether parts.

WARNING

Do NOT use the following

type or any other type of

connector, serious injury

could occur.

CUSTOMER SERVICE

We at PROTO® are committed to our customers, please reference the following phone number for a direct contact to one of our

customer technicians. They will be more than happy to help with any service or warranty questions you may have about your power tool.

PROTO INDUSTRIAL TOOLS

2195 East View Parkway

Suite 103

Conyers, Georgia 30013

Phone: +1 800-800-TOOL

Fax: +1 770-648-9108

www.protoindustrial.com

®

CE DECLARATION OF CONFORMITY

WE, PROTO INDUSTRIAL TOOLS®, 2195 EAST VIEW PARKWAY, SUITE 103, CONYERS, GEORGIA 30013, DECLARE UNDER OUR SOLE

RESPONSIBILITY THAT THE PRODUCT J138RSH - PROTO 3/8” SEALED HEAD RATCHET WRENCH AND J150RSH - PROTO 1/2” SEALED

HEAD RATCHET WRENCH

- CONFORMS WITH THE DIRECTIVE AND STANDARDS «MACHINERY» DIRECTIVE 2006/42/CE

- AND IS IN CONFORMITY WITH THE PROVISIONS OF THE HARMONISED EUROPEAN STANDARD

EN ISO 12100:2010

EN ISO 11148-6:2012

EN ISO 15744:2008

EN ISO 28927-2:2009

8

Manual #30L200161.C

Eric Min

QUALITY MANAGER

05.10.2013

© 2013 PROTO

®

Loading...

Loading...