Datasheet P0406FC12C, P0406FC15C, P0406FC3.3C, P0406FC36C, P0406FC08C Datasheet (PROTEK)

...

05155

Only One Name Means ProTek’Tion™

APPLICATIONS

✔ Cellular Phones

✔ MCM Boards

✔ Wireless Communication Circuits

✔ IR LEDs

✔ SMART & PCMCIA Cards

IEC COMPATIBILITY (EN61000-4)

P0406FC3.3C*

thru

P0406FC36C*

FLIP CHIP ARRAY

✔ 61000-4-2 (ESD): Air - 15kV, Contact - 8kV

✔ 61000-4-4 (EFT): 40A - 5/50ns

FEATURES

✔ ESD Protection > 25 kilovolts

✔ Available in Multiple Voltage Types Ranging From 3.3V to 36V

✔ 250 Watts Peak Pulse Power per Line (tp = 8/20µs)

✔ Bidirectional Configuration & Monolithic Structure

✔ Protects 3 to 5 Lines

MECHANICAL CHARACTERISTICS

✔ Standard EIA Chip Size: 0406

✔ Weight 0.73 milligrams (Approximate)

✔ Flammability Rating UL 94V-0

✔ 8mm Plastic & Paper Tape and Reel Per EIA Standard 481

✔ Device Marking On Reel

✔ Top Contacts: Solder Bump 0.004” in Height (Nominal)

0406

(Single Chip Shown)

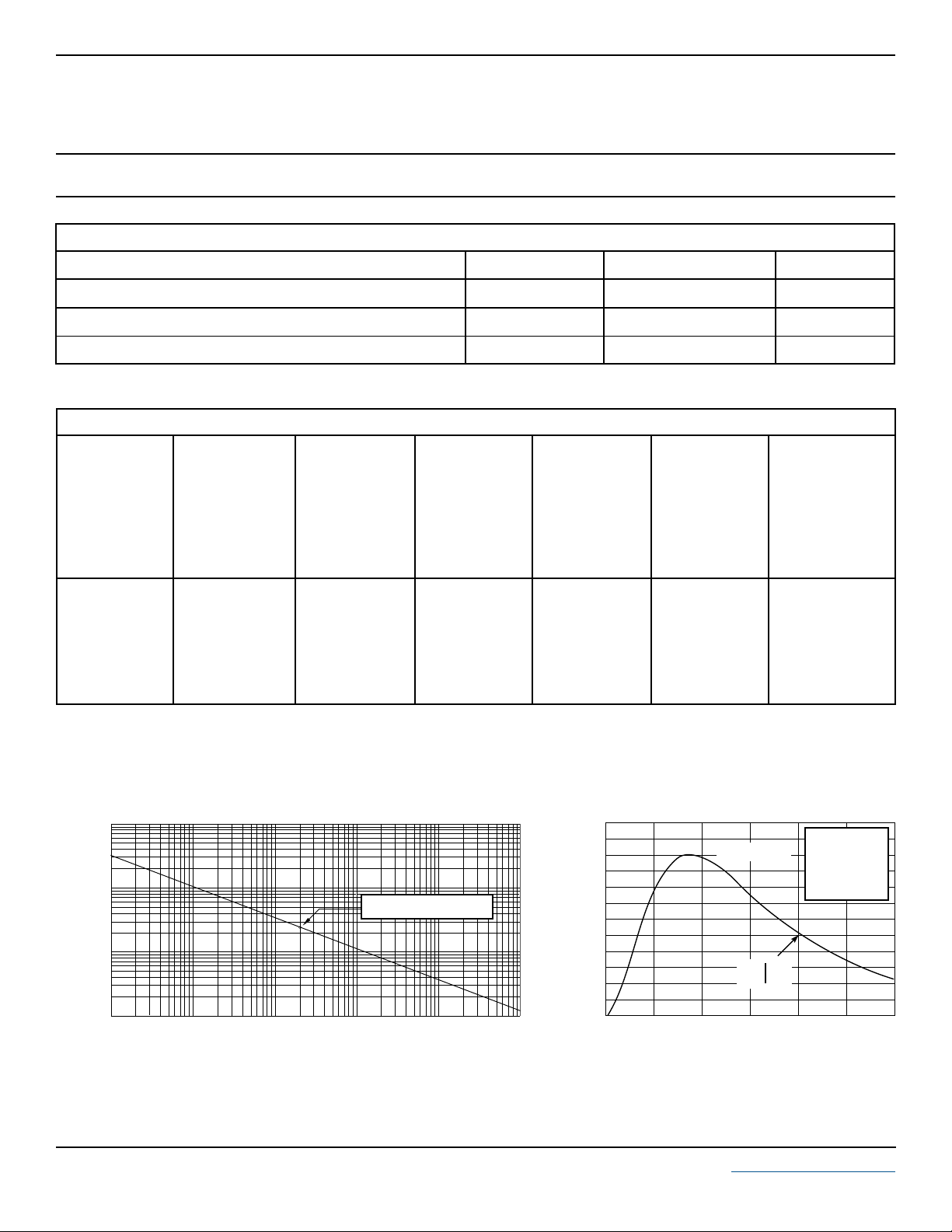

PIN CONFIGURATION

105155.R3 8/03 www.protekdevices.com

*U.S. Patent No. Des. “D456,367S”

DEVICE CHARACTERISTICS

MAXIMUM RATINGS @ 25°C Unless Otherwise Specified

P0406FC3.3C*

thru

P0406FC36C*

PARAMETER

Peak Pulse Power (tp = 8/20µs) - See Figure 1

Operating Temperature

Storage Temperature

SYMBOL VALUE

P

PP

T

J

T

STG

250 Watts

-55°C to 150°C

-55°C to 150°C°C

ELECTRICAL CHARACTERISTICS PER LINE @ 25°C Unless Otherwise Specified

PA RT

NUMBER

(See Note 1)

P0406FC3.3C

P0406FC05C

P0406FC08C

P0406FC12C

P0406FC15C

P0406FC24C

P0406FC36C

Note 1: All devices are bidirectional. Electrical characteristics apply in both directions.

Note 2: *Maximum leakage current < 5µA @ 2.8V. **Maximum leakage current <500nA @ 3.3V. ***Maximum leakage current <200nA @ 5V.

RATED

STAND-OFF

VOLTAGE

V

WM

VOLTS

3.3

5.0

8.0

12.0

15.0

24.0

36.0

MINIMUM

BREAKDOWN

VOLTAGE

@ 1mA

V

(BR)

VOLTS

4.0

6.0

8.5

13.3

16.7

26.7

40.0

MAXIMUM

CLAMPING

VOLTAGE

(See Fig. 2)

@ IP = 1A

V

C

VOLTS

7.0

9.8

13.4

19.0

24.0

43.0

64.0

MAXIMUM

CLAMPING

VOLTAGE

(See Fig. 2)

@8/20µs

VC @ I

PP

12.5V @ 20A

14.7V @ 17A

19.2V @ 13A

29.7V @ 9.0A

35.7V @ 7.0A

55.0V @ 5.0A

84.0V @ 3.0A

MAXIMUM

LEAKAGE

CURRENT

(See Note 2)

@V

WM

I

D

µA

75*

10**

10***

1

1

1

1

UNITS

°C

TYPICAL

CAPACITANCE

@0V, 1 MHz

C

pF

150

100

75

50

40

30

25

10,000

1,000

100

- Peak Pulse Current - Watts

PP

P

10

0.01 1 10 100 1,000 10,000

PEAK PULSE POWER VS PULSE TIME

FIGURE 1

t

- Pulse Duration - µs

d

250W, 8/20µs Waveform

FIGURE 2

120

PP

100

80

60

40

- Peak Pulse Current - % of I

20

PP

I

0

0 5 10 15 20 25 30

2 www.protekdevices.com05155.R3 8/03

PULSE WAVE FORM

t

f

Peak Value I

-t

e

td = t

t - Time - µs

*U.S. Patent No. Des. “D456,367S”

PP

IPP/2

TEST

WAVEFORM

PARAMETERS

tf = 8µs

td = 20µs

GRAPHS

P0406FC3.3C*

thru

P0406FC36C*

POWER DERATING CURVE

FIGURE 3

100

80

60

40

% Of Rated Power

20

0

0 25 50 75 100 125 150

TL - Lead Temperature - °C

Peak Pulse Power

8/20µs

Average Power

REFLOW SOLDER PROFILE

200°C

100°C

Note: This reflow profile does not take into account the printed circuit board (PCB) material

heating time. Additional time may be required for the preheat time and cool down time upon the

PCB or board material.

Instantaneous

to 200°C

1-2 Minutes

to 150°C

Pre-Heat

Time

FIGURE 5

OVERSHOOT & CLAMPING VOLTAGE FOR P0406FC05C

35

25

FIGURE 4

225°C

5-10 sec

1-2 Minutes to 25°C

Soldering

Time

Cool Down

Time

15

5 Volts per Division

5

-5

ESD Test Pulse - 25 kilovolt, 1/30ns (waveshape)

FIGURE 6

TYPICAL CLAMPING VOLTAGE VS PEAK PULSE CURRENT FOR P0406FC05C

14

12

10

8

6

4

- Clamping Voltage - Volts

C

V

2

0

0 5 10 15 20

- Peak Pulse Current - Amps

I

PP

3 www.protekdevices.com05155.R3 8/03

*U.S. Patent No. Des. “D456,367S”

PACKAGE OUTLINE & DIMENSIONS

P0406FC3.3C*

thru

P0406FC36C*

PACKAGE OUTLINE

TOP

F

END

E

MOUNTING PAD LAYOUT - Option 1

C

H

G

PACKAGE DIMENSIONS

MILLIMETERS

DIM

A

B

C

B

A

C

G

H

I

SIDE

E

F

G

H

I

NOTES:

1. Controlling dimensions in inches.

2. Decimal tolerances for mounting pad and

outline: .xxx ± 0.05mm (± 0.002”).

0.56 NOM

0.86 NOM

0.99 ± 0.0254

0.15 SQ

1.5 ± 0.0254

0.15 NOM

0.127 MAX

0.076 MIN

0.406 NOM

INCHES

0.022 NOM

0.034 NOM

0.039 ± 0.001

0.006 SQ

0.059 ± 0.001

0.006 NOM

0.005 MAX

0.003 MIN

0.016 NOM

PAD DIMENSIONS

MILLIMETERS

DIM

A

C

D

E

F

G

H

I

NOTE:

1.

Preferred:

0.51

0.30

0.46

0.20

0.15 SQ

0.71

0.99

0.51

Using 0.1mm (0.004”) stencil.

E

D

DIE

SOLDER

BUMPS

A

INCHES

0.020

0.012

0.018

0.008

0.006 SQ

0.028

0.039

0.020

SOLDER PRINT

0.010” - 0.012” DIA.

I

SOLDER PADS

F

SOLDER MASK

Outline & Dimensions: Rev 3 - 11/02, 06023

*U.S. Patent No. Des. “D456,367S”

4 www.protekdevices.com05155.R3 8/03

PACKAGE OUTLINE & DIMENSIONS

P0406FC3.3C*

thru

P0406FC36C*

MOUNTING PAD LAYOUT - Option 2

COPPER CONTACTS

0.009” [0.23] DIA.

H

G

SOLDER PRINT

0.014” [0.36] DIA.

PACKAGE DIMENSIONS

MILLIMETERS

DIM

A

A

DIE

SOLDER

BUMPS

I

F

SOLDER MASK

F

G

H

I

NOTES:

1. Controlling dimensions in inches.

2. Decimal tolerances for mounting pad and

outline: .xxx ± 0.05mm (± 0.002”).

3.

Preferred:

Outline & Dimensions: Rev 3 - 11/02, 06023

TAPE & REEL ORIENTATION

NOTE:

1. Top view of tape. Solder bumps are face

down in tape package.

0.51

0.15 SQ

0.71

0.99

0.51

Using 0.1mm (0.004”) stencil.

Triple Die - 0406

INCHES

0.020

0.006 SQ

0.028

0.039

0.020

COPYRIGHT © ProTek Devices 2003

SPECIFICATIONS: ProTek reserves the right to change the electrical and or mechanical

characteristics described herein without notice (except JEDEC).

DESIGN CHANGES: ProTek reserves the right to discontinue product lines without notice, and that

the final judgement concerning selection and specifications is the buyer’s and that in furnishing

engineering and technical assistance, ProTek assumes no responsibility with respect to the

selection or specifications of such products.

TAPE & REEL ORDERING NOMENCLATURE

1. Surface mount product is taped and

reeled in accordance with EIA 481.

2.

8mm Plastic Tape:

pieces per reel. Ordering Suffix: -T75-1

(i.e., P0406FC05C-T75-1).

3.

8mm Paper Tape:

pieces per reel. Ordering Suffix: -T75-2

(i.e., P0406FC05C-T75-2).

7 Inch Reels - 5,000

7 Inch Reels - 5,000

ProTek Devices

2929 South Fair Lane, Tempe, AZ 85282

Tel: 602-431-8101 Fax: 602-431-2288

E-Mail: sales@protekdevices.com

Web Site: www.protekdevices.com

5 www.protekdevices.com05155.R3 8/03

*U.S. Patent No. Des. “D456,367S”

Loading...

Loading...