Page 1

Page 2

INTRODUCTION ................................................................................ 6

FIRMWARE VERSIONS ....................................................................... 6

SAFETY INSTRUCTIONS ..................................................................... 7

CERTIFICATE .................................................................................. 11

1 GENERAL OVERVIEW ............................................................... 12

1.1 Description ....................................................................... 13

1.2 Specifications ................................................................... 13

1.2.1 Basic Specifications .................................................... 13

1.2.2 Key Measurements ..................................................... 15

1.2.3 Key Features .............................................................. 15

1.3 The Layout of A434L ......................................................... 16

1.4 Ordering Information ........................................................ 17

1.4.1 Standard Accessories .................................................. 17

1.4.2 Options ..................................................................... 19

2 PREPARATION FOR USE ........................................................... 21

2.1 General Information .......................................................... 21

2.2 Power Adaptor ................................................................. 21

2.3 Battery ............................................................................. 22

2.3.1 Caution ..................................................................... 23

2.3.2 Installing a Battery...................................................... 24

2.3.3 Charging a Battery ..................................................... 25

2.3.4 Battery Low ............................................................... 25

2.3.5 Battery Power Off ...................................................... 26

2

Page 3

2.4 Front Panel ....................................................................... 27

2.4.1 Key Layout ................................................................ 27

2.4.2 ① Function Hard ........................................................ 28

2.4.3 ② Soft Keys ............................................................... 28

2.4.4 ③ Power Switch Key .................................................. 28

2.4.5 ④ Multi Keys ............................................................. 29

2.4.6 ⑤ ESC, Back, Arrow Keys ............................................ 33

2.4.7 ⑥ Enter Keys ............................................................. 34

2.4.8 ⑦ Knob Keys ............................................................. 35

2.4.9 Display ...................................................................... 35

2.5 Upper Panel ..................................................................... 36

2.5.1 DC Power Connector.................................................. 37

2.5.2 RF OUT/Reflection ...................................................... 37

2.5.3 Ethernet Port ............................................................. 37

2.5.4 USB Port ................................................................... 38

2.6 FAN ................................................................................. 38

2.6.1 FAN Operation .......................................................... 38

2.6.2 FAN alarm ................................................................. 38

3 GETTING STARTED .................................................................. 40

3.1 Power Up ......................................................................... 41

3.1.1 Initialization ............................................................... 41

3.1.2 System Information .................................................... 42

3.2 Layout of the Display Screen .............................................. 43

3.3 Function Hard Keys Structure ............................................. 45

3.3.1 System Screen Menu .................................................. 46

3.3.2 Common Menu ......................................................... 47

3.3.3 VSWR Menu .............................................................. 52

3.3.4 DTF Menu ................................................................. 54

3.3.5 Cable Loss Menu........................................................ 55

3.3.6 Power Meter Menu .................................................... 57

3.4 System Key ....................................................................... 58

3

Page 4

3.5 Multi Keys ........................................................................ 60

3.5.1 Numeric Data Entry .................................................... 61

3.5.2 Specific Function Keys ................................................ 61

4 MEASUREMENT DATA ANALYSIS.............................................. 70

4.1 VSWR .............................................................................. 71

4.1.1 VSWR Display Description ........................................... 71

4.1.2 Setting Frequency ...................................................... 74

4.1.3 Calibration ................................................................ 75

4.1.4 VSWR Measurement .................................................. 77

4.1.4.1 Setting Trace Point .............................................. 79

4.1.4.2 Scale Adjustment ................................................ 79

4.1.4.3 Using Markers .................................................... 79

4.1.4.4 Limit Line ........................................................... 80

4.2 DTF ................................................................................. 81

4.2.1 DTF Display Description .............................................. 81

4.2.2 DTF Setup ................................................................. 83

4.2.3 Calibration ................................................................ 85

4.2.4 DTF Measurement...................................................... 87

4.2.4.1 Scale Adjustment ................................................ 88

4.2.4.2 Using Markers .................................................... 89

4.2.4.3 Windowing ........................................................ 89

4.3 Cable Loss ........................................................................ 91

4.3.1 Cable Loss Display Description ..................................... 91

4.3.2 Setting Frequency ...................................................... 92

4.3.3 Calibration ................................................................ 93

4.3.4 Cable Loss Measurement ............................................ 95

4.3.4.1 Scale Adjustment ................................................ 96

4.3.4.2 Using Markers .................................................... 96

4.4 Power Meter .................................................................... 97

4.4.1 Connecting Sensors.................................................... 97

4.4.2 Setting Power Meter .................................................. 99

4.4.3 Power Measurement ................................................ 100

4

Page 5

4.5 Save & Load ................................................................... 101

4.5.1 Save ....................................................................... 101

4.5.1.1 Save Trace ........................................................ 102

4.5.1.2 Save Screen ...................................................... 103

4.5.1.3 Save State ........................................................ 104

4.5.2 Load ....................................................................... 105

4.5.2.1 Load Trace ....................................................... 105

4.5.2.2 Load Screen ...................................................... 107

4.5.2.3 Load State ........................................................ 107

4.5.2.4 Memory Type ................................................... 107

5 SOFTWARE UPGRADE............................................................ 108

5.1 Upgrade Method ............................................................ 109

6 WARRANTY INFORMATION .................................................... 113

Appendix 1 — Band List ................................................................. 117

Appendix 2 — Cable List ................................................................ 125

5

Page 6

This Operating Manual represents design, specifications, overview of

functions, and detailed operation procedure of A434L RF master, to ensure

effective and safe use of the technical capabilities of the instrument by the

user.

RF Master operation and maintenance should be performed by qualified

engineers with initial experience in operating of microwave circuits and PC.

The following abbreviations are used in this Manual:

PC – Personal Computer

DUT – Device Under Test

IF – Intermediate Frequency

CW – Continuous Wave

SWR – Standing Wave Ratio

The first edition of this Operating Manual applies directly to instruments that

have the firmware version 1.xx.

6

Page 7

Carefully read through the following safety instructions before putting the

Analyzer into operation. Observe all the precautions and warnings provided

in this Manual for all the phases of operation, service, and repair of the

Analyzer.

The Analyzer must be used only by skilled and specialized staff or thoroughly

trained personnel with the required skills and knowledge of safety

precautions.

A434L complies with INSTALLATION CATEGORY II as well as POLLUTION

DEGREE 2 in IEC61010–1.

A434L is MEASUREMENT CATEGORY I (CAT I). Do not use for CAT II, III, or

IV.

A434L is for INDOOR USE only.

A434L is tested in stand-alone condition or in combination with the

accessories supplied by GS INSTRUMENTS CO., LTD. against the

requirement of the standards described in the Declaration of Conformity. If

it is used as a system component, compliance of related regulations and

safety requirements are to be confirmed by the builder of the system.

N

Never operate the Analyzer in the environment containing inflammable

gasses or fumes.

Operators must not remove the cover or part of the housing. The Analyzer

must not be repaired by the operator. Component replacement or internal

adjustment must be performed by qualified maintenance personnel only.

Never operate the Analyzer if the power cable is damaged.

Never connect the test terminals to mains.

7

Page 8

Electrostatic discharge can damage your Analyzer when connected or

disconnected from the DUT. Static charge can build up on your body and

damage the sensitive circuits of internal components of both the Analyzer

and the DUT. To avoid damage from electric discharge, observe the

following:

- Always use a desktop anti-static mat under the DUT.

- Always wear a grounding wrist strap connected to the desktop

anti-static mat via daisy-chained 1 MΩ resistor.

- Connect clamp on the body of the Analyzer to the body of

the DUT before you start operation.

Observe all the general safety precautions related to operation of equipment

powered by mains.

The protection provided by the equipment may be impaired if the

equipment is used in a manner not specified by the manufacturer.The

definitions of safety symbols used on the instrument or in the Manual are

listed below.

Storage

Before first use store your equipment in the factory package at

environment temperature from 0 to +50 ºС and relative humidity up to

95% (at 25ºС).

After you have removed the factory package store the equipment at

environment temperature from +10 to +35 ºС and relative humidity up

to 80% (at 25ºС).

Ensure to keep the storage facilities free from dust, fumes of acids and

alkalies, aggressive gases, and other chemicals, which can cause corrosion.

8

Page 9

Moderate Ventilation

Environment

Ambient temperature 2ºС to 50ºС

Maximum 80% RH between 2ºС and 31ºС,

decreasing to 50% RH at 50ºС

Maximum altitude 2,000m

MAINS supply voltage fluctuations up to 10% of the

nominal voltage

Transient over-voltages according to installation

category II

Pollution degree 2

IPX0

Refers to the Manual if the instrument is

marked with this symbol.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

Maintain moderate ventilation condition to prevent overheating of the

product.

Warning

Never perform cleaning of the instrument if the power cable is connected

to the power outlet.Never clean the internal components of the instrument.

N

Do not position the equipment so that it is difficult to operate the power

cord.

9

Page 10

A chassis terminal; a connection to the

instrument’s chassis, which includes all exposed

metal structure.

CAUTION

This sign denotes a hazard. It calls attention to a

procedure, practice, or condition that, if not

correctly performed or adhered to, could result

in injury or death to personnel.

CAUTION

This sign denotes a hazard. It calls attention to a

procedure, practice, or condition that, if not

correctly performed or adhered to, could result

in damage to or destruction of part or the entire

instrument.

Note

This sign denotes important information. It calls

attention to a procedure, practice, or condition

that is essential for the user to understand.

10

Page 11

CERTIFICATE

11

Page 12

1

GENERAL

OVERVIEW

OPERATING

MANUAL

Page 13

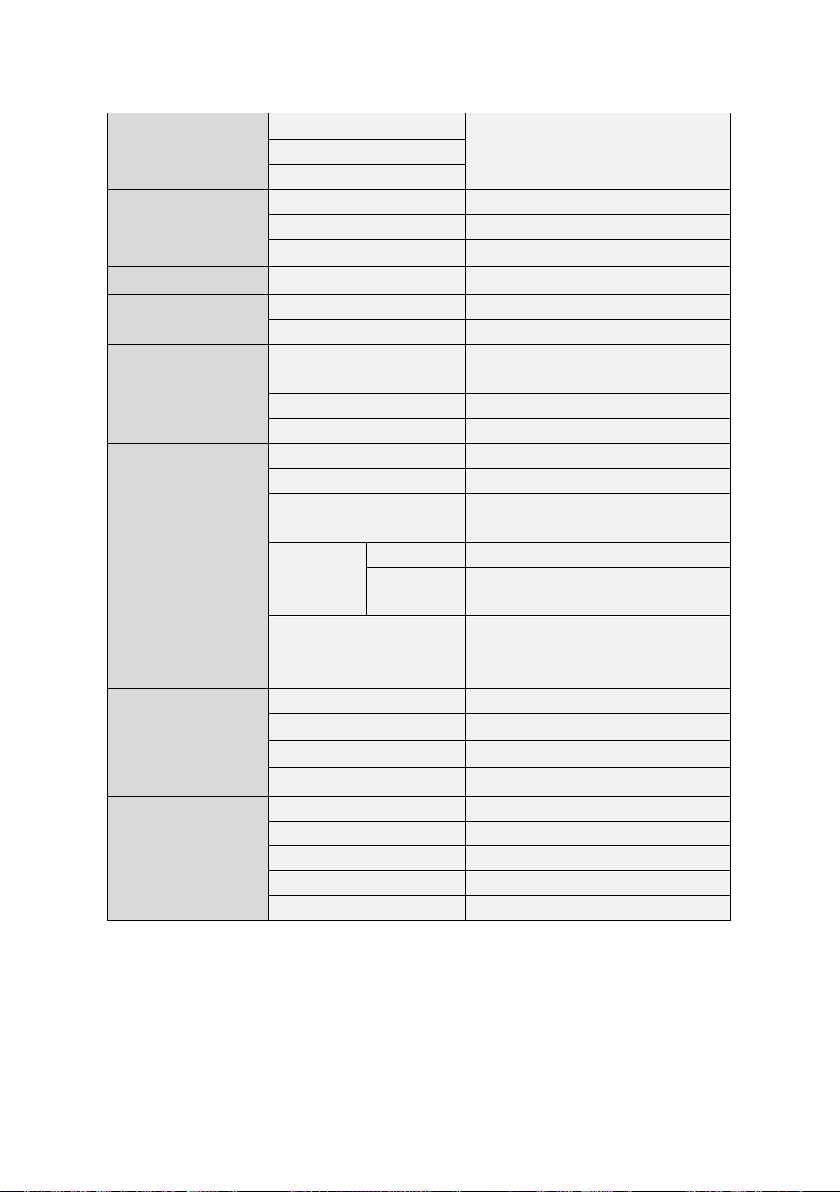

Item

Sub Item

Specification

General

Max Input Power

+25dBm Damage level

Frequency Range

5MHz to 4GHz

Frequency Accuracy

< ±3ppm

Frequency Resolution

10kHz

Impedance

50Ω

Scan Speed

< 1msec /data point

Display

Single & Dual mode

Test port

N Female

1.

1.1 Description

A large number of cell site problems are caused by the antenna system,

cable, or connectors. It is important to have the right instrument available

when either servicing or certifying cell sites for operation.

The Protek A434L RF master is a lightweight portable diagnostic tool for an

accurate detection of operational problems. The Protek A434L has all the

measurement functions necessary to accurately verify the antenna system

from VSWR to power measurements. In addition, the Protek A434L makes

distance-to-fault measurements to accurately pinpoint the fault's location.

The Protek A434L user interface is with a front keypad and a TFT color, 7inch display providing ease of use and control. The application specific

software allows the user to easily compare and analyze measurements and

generate comprehensive reports. The Protek A434L is equipped with a

rechargeable and infield installable lithium-ion battery providing over four

hours of operation.

1.2 Specifications

1.2.1 Basic Specifications

13

Page 14

Test curve storage

Internal : Minimum 512MB

External : Limited by size of USB

(32G)

Screen storage

Setup storage

VSWR

Number of data points

126, 251, 501, 1001, 2001

Return loss Range

0 to -60dB

VSWR Range

1 to 65

Cable Loss

Cable loss range

0 to -30dB, 0.01dB Resolution

Interference

Immunity

On-Frequency

+10dBm

On-Channel

+20dBm

DTF

Return Loss Display

Range

0 to 60dB

Distance Range

0 to 1250m (4125ft)

VSWR Display Range

0 to 65

Miscellaneous

Dimension

260X193X67mm

Weight

<2.45Kg include battery

A434L Voltage and

Current

12Vd.c., 3.5A

Adaptor

AC Input

100 to 250Vd.c., 1.5A

DC

Output

12Vd.c., 5A

Battery

Li-lon (4hr operating time after

full charging), 12Vd.c.,

7600mAh

Environmental

Operating Temperature

0°C ~ +50°C

Storage Temperature

-40°C ~ +80°C (-40°F ~ +176°F)

Humidity

95%R.H. NO Condensation

Degree of protection

IPX0

Power

Meter(Option)

Frequency Range

20MHz to 3.8GHz

Sensor Type

Average

Peak Power Sensor

-40dBm to +10dBm

Accuracy

±7%

Test Port

Precision N Female

14

Table 1.1 Basic Specifications

Page 15

1.2.2 Key Measurements

High resolution VSWR Measurements

Distance to Fault (DTF) Measurements

Cable Loss Measurements

RMS Power Measurements (optional)

1.2.3 Key Features

Rechargeable and infield replaceable lithium-ion battery

Built-in world-wide signal standards and frequency

channels

7 Inch TFT color display viewable in daylight

Dual display to view multiple measurements

simultaneously to reduce test time

Easy front keypad operation

Superior immunity to RF interference

Up to 2001 data points to locate long range problems

Built-in cable menus containing >90 cables’

characteristics

User friendly menu structure

Saves up to Memory (user setups, traces, screens)

Alphanumeric labeling of saved data

Automatic Time/Date stamp of saved data

USB Port (USB 2.0)

Remote firmware upgrade capability

15

Page 16

Fast one-touch selection of menu item or positioning

Smart Battery management can be check Battery

Rechargeable and field replaceable Lithium Ion battery

Backlight keypad for easier use in dark environments

Sun-Light Readable LCD for readability

1.3 The Layout of A434L

marker

capability

with more than 4 hours operation time

16

Figure 1.1 A434L Front Panel

Page 17

Figure 1.2 A434L Rear Panel

Figure 1.3 A434L Upper Panel

1.4 Ordering Information

1.4.1 Standard Accessories

The standard accessories supplied with the A434L RF Master are as

follows:

17

Page 18

Description

Picture

Specification

Soft Carrying Case

AC-DC Adapter

Input: 100 ~ 240Va.c.,

1.5A

Output: 12Vd.c., 5A

Neck Strap

Hand Strap

Li-ion Battery

Output: 8.4Vd.c. MAX,

7800mAh

User’s Manual

Hard Copy

18

Page 19

Description

Picture

Specification

Power Sensor

(Part No: S134)

Frequency Range

: 20MHz to 3.8GHz

Sensor Type : Average

Peak Power Sensor

: -40dBm to +10dBm

Accuracy : ±7%

Test Port : Precision N

Female

Battery Charger

(Part No: C122R5)

Input: 100 ~ 240Va.c.,

1.5A

Output: 12Vd.c., 5A

1.4.2 Options

The options supplied with the A434L RF Master are as follows:

19

Page 20

2

PREPARATION FOR

USE

OPERATING

MANUAL

Page 21

2.

2.1 General Information

Unpack the Analyzer and other accessories. Check the contents of the

package against the list specified in section 1.4.1. Connect your A434L to

the AD-DC Adaptor(12Vd.c., 5A) or Li-ion Battery(8.4Vd.c. MAX, 7800mAh)

power source by means of the Power Cable supplied with the instrument.

Warm-up the Analyzer for 20 minutes after turning the power on.

Assemble the test setup using cables, connectors, fixtures, etc, which allow

DUT connection to the Analyzer.

Perform calibration of the Analyzer. Calibration procedure is described in

section 4.1.3.

2.2 Power Adaptor

The equipment uses following power supply.

Product: Switching Power Supply Adaptor

Model no. FSP060-DBAE1

AC INPUT: 100-240Va.c.~, 1.5A, 50-60Hz

DC OUTPUT: 12.0Vd.c. 5.0A MAX

Manufactured by: Zhonghan Electronics (Shenzhen)

Trade mark: FSP GROUPINCUC

21

Page 22

2.3 Battery

A434L use CE, UL Certificated PBP-7800 Battery.

Figure 2.1 A434L Battery

CAUTION

RISK OF EXPLOSIOM IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE MANUFACTURER’S

INSTRUCTIONS.

22

Page 23

① If the “push” button on the battery is pressed, the remained

battery volume will be displayed in the battery icon next to the

“push” button.

② Each level of the battery indicator takes 20% of the battery

portion. If the battery level is three, it means the battery is

charged 40% - 60%.

③ As illustrated below, please insert the battery pack while the

printed label is on the upside.

④ Non rechargeable Li-Ion battery was in analyzer.

⑤ This non rechargeable Li-Ion battery is CR02032.(made by Hitachi

Maxwell Ltd)

2.3.1

Caution

① Avoid placing the battery pack near heating sources of on the

place near windows.

② Do not store the battery pack in the high humidity.

③ If the battery is unused for a long time, separate it from the unit.

④ Keep this battery pack away from children

⑤ If electrolyte from the battery pack is leaking or the battery pack

smells strangely, keep the battery pack away from fire.

⑥ In case that electrolyte from the battery pack is touched by any

part of the human body, wash it immediately and go to hospital

to prevent potential damage.

⑦ Use the authorized charger only.

⑧ Do not abandon the battery pack in the car in the summer.

⑨ Avoid any shock to the battery pack.

⑩ Do not replace non rechargeable Li-Ion battery except for

certified person.

⑪ This battery has about ten-month warranty.

23

Page 24

1

Open the battery cover.

2

Insert the battery (Observe correct battery polarity orientation

when installing).

3

Close the battery cover.

2.3.2

Installing a Battery

Caution: Full charge the battery before first using the analyzer.

Figure 2.2 A434L Right Side View

24

Page 25

1

Insert the battery in the analyzer.

2

Plug in the AC- DC adapter and switch on the external power.

3

The charge indicator icon on the screen, indicating that the

battery is charging and is fully charged.

2.3.3

Charging a Battery

You may charge the battery both in the analyzer and in the external battery

charger.

During charging and discharging, the battery voltage, current, and

temperature are monitored. If any of the monitored conditions exceed their

safety limits, the battery will terminate any further charging or discharging

until the error condition is corrected.

2.3.4

Battery Low

If A434L runs out of battery, the following message will appear on the

display.

25

Page 26

Figure 2.3 Battery 10% or Battery 5% Screen Display

2.3.5

Battery Power Off

If the battery power is lower than 1%, the following message will appear

on the display, and the Power will be Off.

26

Figure 2.4 Battery Power Off Screen Display

Page 27

2.4 Front Panel

The front view of A434L is represented in figure 1.1. The front panel is

equipped with the following parts:

2.4.1

Key Layout

Figure 2.5 A434L Key Layout

27

Page 28

«VSWR» Activates the VSWR

measurement mode.

«DTF» Activates the DTF measurement mode.

«Cable Loss» Activates the Cable Loss

measurement mode.

«Power Meter» Activates the RF Power

measurement mode. An optional power sensor

must be connected to the instrument before

using this function

«System» Opens the system screen menu.

«CAL» Opens the calibration screen menu.

2.4.2 ① Function Hard keys

The six hard keys are located at the left of the display. The function of each

key is indicated on each key. Depending on the selection of Hard Keys, the

functions shown in the screen menu may vary.

2.4.3 ② Soft Keys

The six keys at the right of the display are the Soft Keys.

28

Page 29

Each Soft Key has a function which varies

depending on the operation mode. The

function of each key is displayed at the right

side of the display as a screen menu. As the

LCD is touch-screen, the function can be

selected by touching the screen menu.

«Power Switch» toggles between On and

Off states of the Analyzer.

Note

Holding the key for more than 3 seconds

on an operating Analyzer will turn off the

power supply

CAUTION

Do not disconnect the power cable from

the mains when the Analyzer is operating.

This can damage the Analyzer software.

2.4.4 ③ Power Switch Key

2.4.5 ④ Multi Keys

Enter values printed on the keys when a value input pop-up window is

prompted on the screen. Open a menu linked with the functions in blue or

directly perform the specified function.

29

Page 30

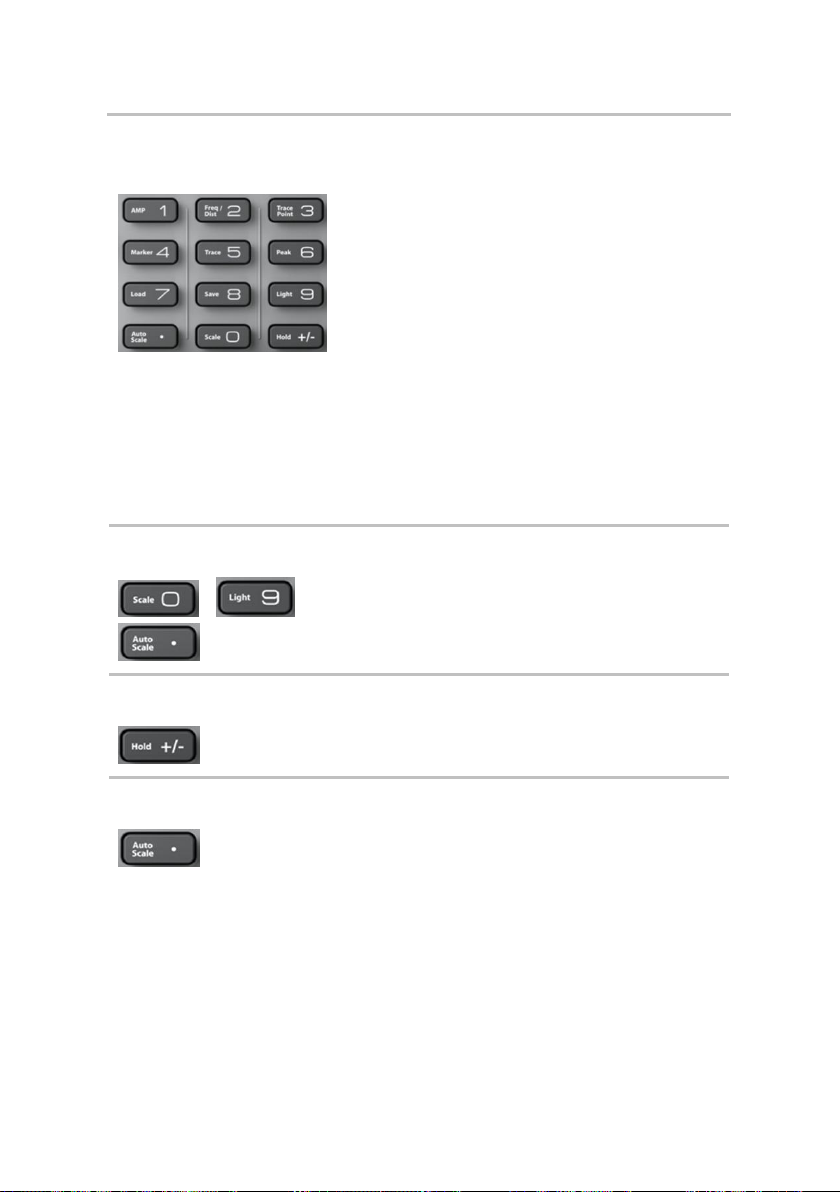

«Numeric & specific

function» key

Multi keys operate as follows when a user

is prompted to input values by pop-up

window.

Numeric keys from 0 to 9 are used

to input user setting numbers.

The plus/minus (+/-) key is used to

assign positive or negative

numbers in the user settings.

The period key (.) is used to input

numbers with decimal points.

Multi keys are used in VSWR, DTF, and

Cable Loss measurement mode. Unless

otherwise specified, multi keys do not

support Power Meter mode.

«0»…«9», «.» keys

...

«0»…«9», numeric keys and decimal

point used for entry of decimal numbers at

the cursor location.

«±» key

«±» key is used to change the sign of a

decimal number.

«Auto Scale» key

«Auto Scale» The instrument can

automatically set the scale to the

minimum and maximum values of a

measurement on the Y-axis of the

graph for optimum display of the

traces. Every time AUTO SCALE key is

pressed, the top and bottom scales

are set to the minimum and maximum

values with margin on the Y-axis of

the screen display.

30

Page 31

«AMP» key

«AMP» AMP (amplitude) defines a

manual setting for the scale on the Yaxis of the graph. It can be selected in

VSWR, DTF, and Cable Loss

measurement mode.

«Freq/Dist» key

«Freq/Dist» key causes different

screen menu to be displayed

depending on a measurement mode.

In VSWR or Cable Loss measurement

modes it opens a frequency screen

menu and in DTF measurement mode

it opens a distance screen menu.

«Trace Point» key

«Trace Point» Trace point is used to

select the number of data points to

take during a VSWR and Cable Loss

measurement mode. There are four

data points available: 126, 251, 501,

1001 and 2001. The default number

of trace points is 1001.

«Marker» key

«Marker» A marker is used to get

the data on the specific point of a

trace. A total of six markers can be

displayed on the screen and each

marker can be assigned

independently. Placing a marker on

the trace displays the marker’s Y

coordinates next to the marker’s

position. If the marker table is turned

on, both X and Y coordinates of all

activated markers are displayed.

31

Page 32

«Trace» key

«Trace» key enables for selection of

active channel and trace. Active

channel is a channel, which accepts

the channel parameter setting

commands. Active trace is similarly a

trace, which accepts the trace

parameter setting commands. Before

sending commands to change a

channel or a trace settings, activate

the channel or trace,

«Peak» key

«Peak» This key is used to find the

peak value of a trace. Pressing this key

leads to the activation of Marker CH1

and places the marker to the peak

point of the trace.

«Load» key

«Load» key enables for recalling of

the Trace, Screen, and State.

«Save» key

«Save» key enables for saving of the

Trace, Screen, and State.

«Light» key

«Light» This key is used to adjust the

brightness of the LCD display.

Adjustment can be made from 0 to

100% and the default setting is 50%.

32

Page 33

«Scale» key

«Scale» This key is used to select a

unit of Y axis of the graph in VSWR

and DTF measurement modes. Either

VSWR or Return Loss can be selected.

In Cable Loss measurement mode,

Return Loss only can be selected.

«Hold» key

«Hold» This key is used to pause a

sweep in all measurement modes.

«ESC» key

«ESC» key is used for the following:

If there is an active data entry

field, this key cancels all

the data entered in the

field and restores the value

of the field as it was before

any new numbers or

characters were entered.

If there is no active data entry

field, this key brings the

user back to an upper level

of the soft key menu.

2.4.6 ⑤ ESC, Back, Arrow Keys

33

Page 34

«Back» key

«Back»

Delete a character or number.

«Arrow» key

«Arrow» key is used for the

following:

Moves a marker position or

highlighted selection bar

one point at a time.

«ENTER» key

«ENTER» key is used for the

following:

If there is an active data

entry field, this key

completes the entry

process and assigns the

new value to the field.

If there is no active data

entry field, this key

enables the function of

a highlighted soft key.

2.4.7 ⑥ Enter Keys

34

Page 35

«Knob» key

«Knob» The rotary knob is used for

the following:

Move an active marker or a

highlighted selection bar in

the list.

The Analyzer is equipped with 7” color LCD. The display can come

complete with a touch screen (TS option). The touch screen LCD allows

manipulating the Analyzer by touching the LCD screen directly with a

finger.

CAUTION

Do not press the touch screen with a

pen, screwdriver or any other sharp-

pointed object. This can damage the

touch screen.

2.4.8 ⑦ Knob Keys

2.4.9 Display

35

Page 36

The display consists of the control elements and area for measurement result

indication.

The main control element of the display is a vertical soft key menu bar in the right-

hand part of the screen.

The soft key menu bar consists of program soft key panels, which appear one

instead of the other on the screen. Each panel represents one of the submenus of

the soft key menu. All the panels are integrated into multilevel menu system and

allow access to all the functions of the Analyzer.

Note

The top line of the screen represents

the menu bar, which enables you direct

access to the submenus of the soft key

menu. This menu is an auxiliary one and

can be hidden.

2.5 Upper Panel

All Input/Output ports of the Protek A434L are located on the upside of

the instrument as shown in Figure 2.6

36

Figure 2.6 A434L Upper Panel

Page 37

Provides input for the DC power

source via an AC-DC adapter.

In case of emergency, to avoid danger

of electric shock or the like, pull the

power cable out of the power outlet

or the DC power connector of the

instrument.

Output(Accepts) an internal(external)

output(input) with a frequency range from

5MHz to 4GHz.

50ohm N-type RF Connector, maximum

allowable input is +25dBm.

Ethernet port allows the user to connect the

Analyzer to a LAN (Local Area Network).

This connection enables the user to control

the instrument using an external PC. Used

for upgrading the instrument’s firmware.

10BASE-T & 100BASE-TX support

CAT5e UTP Cable uses

2.5.1 DC Power Connector

2.5.2 RF OUT/Reflection

2.5.3 Ethernet Port

37

Page 38

USB ports allow connection of various

external USB compatible devices, such as

flash memory stick and Power Sensor. Used

for either saving measurement data or an

optional external power sensor.

5Vd.c. , 500mA

Type A

2.5.4 USB Port

2.6 FAN

2.6.1 FAN Operation

FAN operates if the internal temperature of the system rises.

The FAN is ON when the temperature is higher than 70.0℃

The FAN is OFF when the temperature is lower than 65.0℃

2.6.2 FAN Alarm

The message of “Fan check required!!!” will be indicated in the bottom left

corner of the displaye if the FAN does not properly operates.

38

Page 39

Figure 2.7 FAN Alarm Screen Display

39

Page 40

3

GETTING STARTED

OPERATING

MANUAL

Page 41

3.

3.1 Power Up

3.1.1

Initialization

The initialization screen (Figure 3.1) appears when the instrument is started

with the indication “System Initialization”. After a successful initialization,

data loading and self-test, the VSWR measurement screen appears.

41

Page 42

Figure 3.1 Boot Logo / Initialization Screen

3.1.2

System Information

Before using the instrument, verify the firmware’s version and status of the

instrument.

Firmware version: For the instrument’s best performance, make

sure the latest version of firmware has been installed. Information

about the latest firmware can be located at www.gsi-protek.com

Verify the system temperature is within the instrument operating

range. Depending on the storage condition, the temperature of the

instrument at power up may be out of normal operating range in

winter or summer season. Measurements over the operating

temperature range may be out of resolution.

42

Page 43

Figure 3.2 System Screen

3.2 Layout of the Display Screen

Figure 3.3 Display Screen

43

Page 44

Indicates the instrument is using an external power supply.

The internal battery is charged when an external power

supply is connected.

Indicates the instrument is using the internal battery and

shows the remaining battery capacity.

Battery Off Icon: This icon appears when a battery is not

installed in the instrument.

Battery Gauge: Indicates the status of the internal battery

Measurement Mode: Indicates a current measurement mode. The

selected mode is displayed in dark blue.

Date and Time: Indicates the system clock information.

Screen Menu set: Indicates the set of screen menu selections.

Screen Menu: Indicates the selectable screen menu. Selection of

the menu can be made by pressing the soft key or touching the

screen menu directly.

Trace Information

Calibration On/Off Status

Calibration Information: Calibrated frequency band and timing

Trace Points

Y Scale Unit

Trace Average (applicable to VSWR and Cable Loss

measurement mode only) before using the instrument, verify

the firmware’s version and status of the instrument.

44

Page 45

Span

Band Name

Cable Name (applicable to DTF measurement mode only)

Max D: Maximum measurement distance limited by user

frequency setting

VT (Relative Propagation Velocity), CL (Cable Loss) – applicable

to DTF measurement mode only

Message window: Displays the result of performed functions or

error messages.

3.3 Function Hard Keys Structure

Function hard keys on the front panel of the instrument are used to select

measurement modes or perform specified functions. Refer to the following

sections for the key structure to be used in each measurement modes.

Figure 3.4 Function Hard Key

45

Page 46

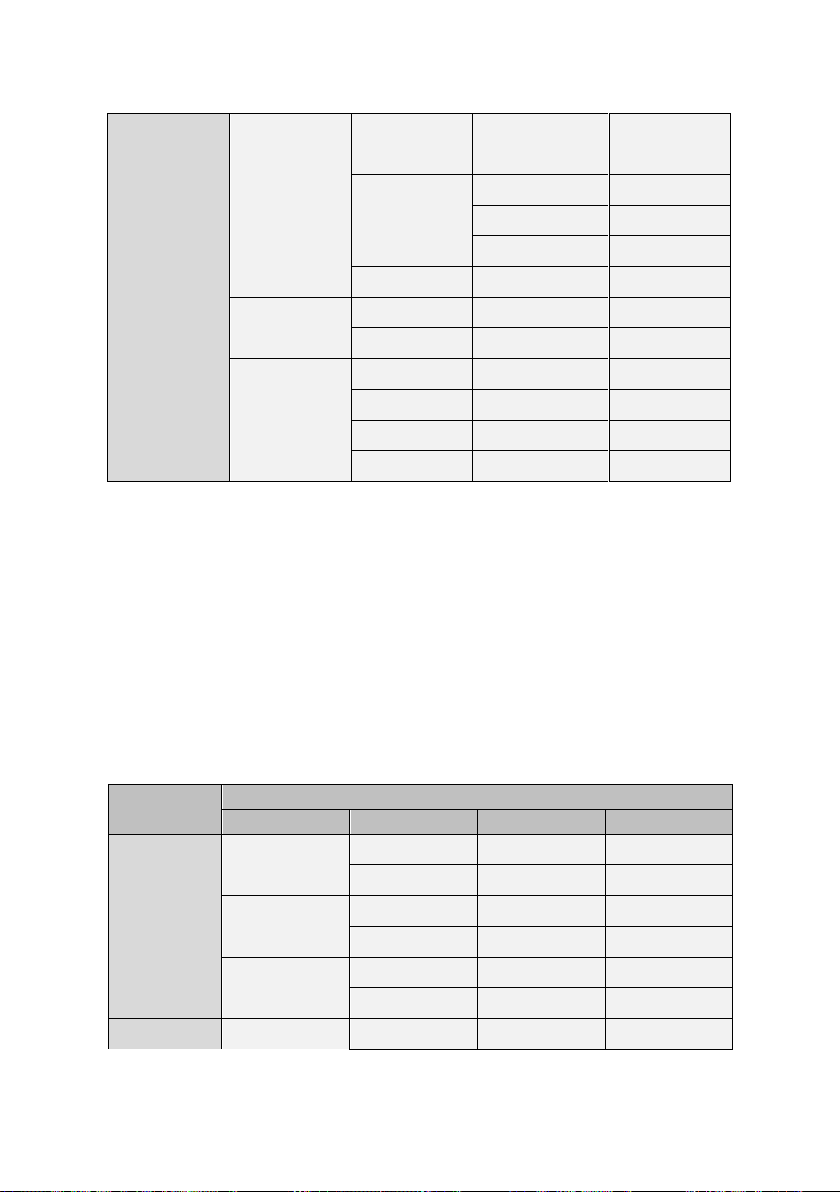

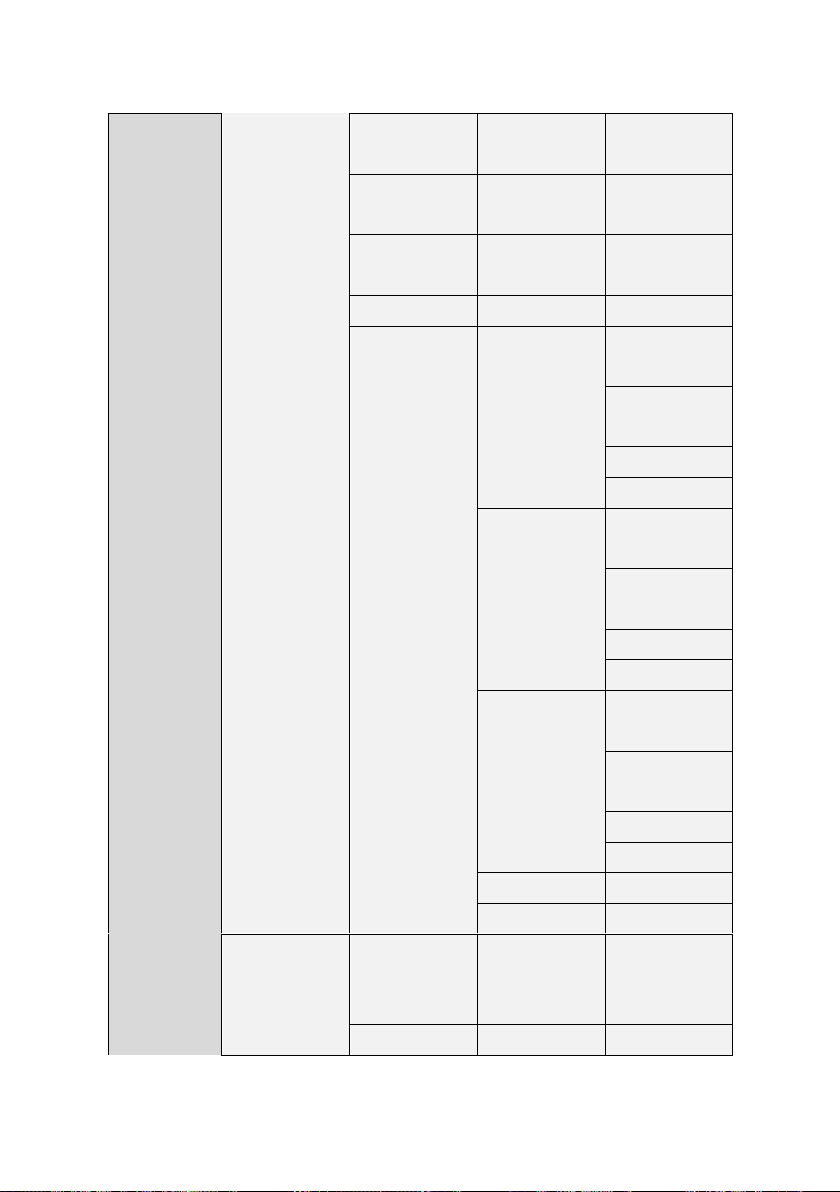

Function Key

Screen Menu

1st Layer

2nd Layer

3rd Layer

4th Layer

SYSTEM

Upgrade

Confirm

No

Beep

OFF ON

Sweep Mode

Conti

Sing

Instrument

Setting >>

Language >>

English

Return

Date/Time >>

Date Format

YMD MDY

DMY

Set Date

Set Time

Return

LAN >>

Apply

IP Addr

10.10.10.73

Net Mask

255.255.255.0

Gateway

10.10.10.1

Return

Alignment

3.3.1

System Screen Menu

System screen menu is used to change the basic settings of the instrument

and consists of sub-menus as shown in Table 3.1.

46

Page 47

Touch Screen

>>

Return

Sleep Time

Enter

Back Space

Cancel

Return

Preset

Yes

No

LED >>

10 Sec

OFF

10 Sec

20 Sec

Return

Function Key

Screen Menu

1st Layer

2nd Layer

3rd Layer

4th Layer

CAL

Open

Start

Back

Short

Start

Back

Load

Start

Back

VSWR

AMP

Max(Top)

Table 3.1 Menu Structure in system mode

3.3.2

Common Menu

The menu structure is common to all the measurement modes except to the

Power Meter mode, shown in Table 3.2. Refer to section 3.3.6 for screen

menus applicable to the Power Meter mode.

47

Page 48

DTF

Cable Loss

2.00

Min(Bottom)

1.00

Limit

OFF ON

Limit Level

3.00

Dual Mode

Freq/

Dist

Start Freq

5.00 MHz

Stop Freq

4000.00 MHz

Center Freq

2002.50 MHz

Span Freq

3995.00MHz

Band List >>

Standard Band

>>

Select

Add to Custom

Return

Custom Band

>>

Select

Delete

Delete All

Return

Return

Trace Point

126

251

501

1001

2001

Marker

Marker

1 2 3 4 5 6

48

Page 49

Marker View

OFF ON

Marker Type

Normal Delta

Marker

Clear All

Marker Edit

Marker Band >>

Marker Band 1

>>

Band View

OFF ON

Band Slect

Start Stop

Band Edit

Return

Marker Band 2

>>

Band View

OFF ON

Band Slect

Start Stop

Band Edit

Return

Marker Band 3

>>

Band View

OFF ON

Band Slect

Start Stop

Band Edit

Return

Clear All

Return

Trace

Trace

T1 T2 T3

T4

Trace Capture

49

Page 50

Trace View

OFF ON

Clear Write

Trace Clear

Trace

Clear All

Peak

Peak Right

Peak Left

Max Search

Min Search

Load

Load Trace

(*.tra)

Select

File Manager >>

Rename

Delete

Delete All

Copy to USB

Copy All

to USB

Return

Destination >>

Trace 1

Trace 1

Trace 2

Trace 3

Trace 4

Return

Return

Load Screen

(*.jpg)

Select

File Manager >>

Rename

Delete

Delete All

Copy to USB

Copy All

to USB

50

Page 51

Return

Return

Load Setup

(*.sta)

Select

File Manager >>

Rename

Delete

Delete All

Copy to USB

Copy All

to USB

Return

Return

Load From

Internal USB

Save

Save Trace

(*.tra)

Trace 1

Trace 2

Trace 3

Trace 4

Return

Save Screen

(*.png)

Save State

(*.sta)

Save to

Internal

USB

Light

Auto Scale

Scale

Hold

3.2 Menu Structure Common to all measurement mode

51

Page 52

Function

Key

Screen Menu

1st Layer

2nd Layer

3rd Layer

4th Layer

VSWR

Freq/

Dist

Start Freq

(453.0 MHz)

Stop Freq

(464.0 MHz)

Center Freq

(458.5 MHz)

Span

(11.0 MHz)

Band List >>

(C450 P Up)

Startdard Band

Custom Band

Return

AMP

Max (Top)

0.00 dB

Min (Bottom)

40.00 dB

Limit

OFF ON

Limit Level

10.00 dB

Marker

Marker

1 2 3 4 5

6

Marker View

3.3.3

VSWR Menu

The menu structure of the VSWR hard function key and multi keys in VSWR

measurement mode is shown in Table 3.3.

52

Page 53

OFF ON

Marker Type

Normal

Delta

Marker Clear

All

Marker Edit

Marker Band >>

Marker Band 1

>>

Band View

OFF ON

Band Select

Start Stop

Band Edit

Return

Marker Band 2

>>

Band View

OFF ON

Band Select

Start Stop

Band Edit

Return

Marker Band 3

>>

Band View

OFF ON

Band Select

Start Stop

Band Edit

Return

Clear All

Return

3.3 Menu Structure Used for VSWR Measurement mode

53

Page 54

Function Key

Screen Menu

1st Layer

2nd Layer

3rd Layer

4th Layer

DTF

Freq/

Dist

Start Freq

(453.0 MHz)

Stop Freq

(464.0 MHz)

Distance

(25.0 Meter)

Band List >

(C450 P Up)

Startdard Band

Custom Band

Return

Cable List >

(FSJ 250)

Startdard Band

Custom Band

Return

DTF Setting >

Apply

Velocity

Cable Loss

Unit

Meter

Feet

Windowing

>>

(Rectangular)

Rectangular

Blackman

Hamming

Hann

Return

3.3.4

DTF Menu

The menu structure of the DTF hard function key and multi keys in DTF

measurement mode is shown in Table 3.4.

54

Page 55

Return

AMP

Max (Top)

4

Min (Bottom)

1

Limit

OFF ON

Limit Level

1.01

Marker

Marker

1 2 3 4 5

6

Marker View

OFF ON

Marker Type

Normal

Delta

Marker Clear

All

Marker Edit

Function Key

Screen Menu

1st Layer

2nd Layer

3rd Layer

4th Layer

The menu structure of the Cable Loss hard function key and multi keys

in Cable Loss measurement mode are shown in Table 3.5

3.4 Menu Structure Used for DTF Measurement Mode

3.3.5

Cable Loss Menu

55

Page 56

Calbe Loss

Freq/

Dist

Start Freq

(453.0 MHz)

Stop Freq

(464.0 MHz)

Center Freq

(458.5 MHz)

Span

(11.0 MHz)

Band List >

(C450 P Up)

Startdard Band

Custom Band

Return

AMP

Max (Top)

0.00 dB

Min (Bottom)

40.00 dB

Limit

OFF ON

Limit Level

10.00 dB

Marker

Marker

1 2 3 4 5

6

Marker View

OFF ON

Marker Type

Normal

Delta

Marker Clear

All

Marker Edit

Marker Band >>

Band View

56

Page 57

Marker Band 1

>>

OFF ON

Band Select

Start Stop

Band Edit

Return

Marker Band 2

>>

Band View

OFF ON

Band Select

Start Stop

Band Edit

Return

Marker Band 3

>>

Band View

OFF ON

Band Select

Start Stop

Band Edit

Return

Clear All

Return

Function Key

Screen Menu

1st Layer

2nd Layer

3rd Layer

4th Layer

Power Meter

Initialize/Preset

The menu structure of the Power Meter hard function key and multi keys

in Power Meter is shown in Table 3.6.

Table 3.5 Menu Structure Used for Cable Loss Measurement Mode

3.3.6

Power Meter Menu

57

Page 58

Frequency

Display Setup

>>

Unit

dBm Watts

External Offset

0.00 dB

Return

Mode >>

(Average)

AVG

Return

Table 3.6 Menu Structure Used in Power Meter Measurement Mode

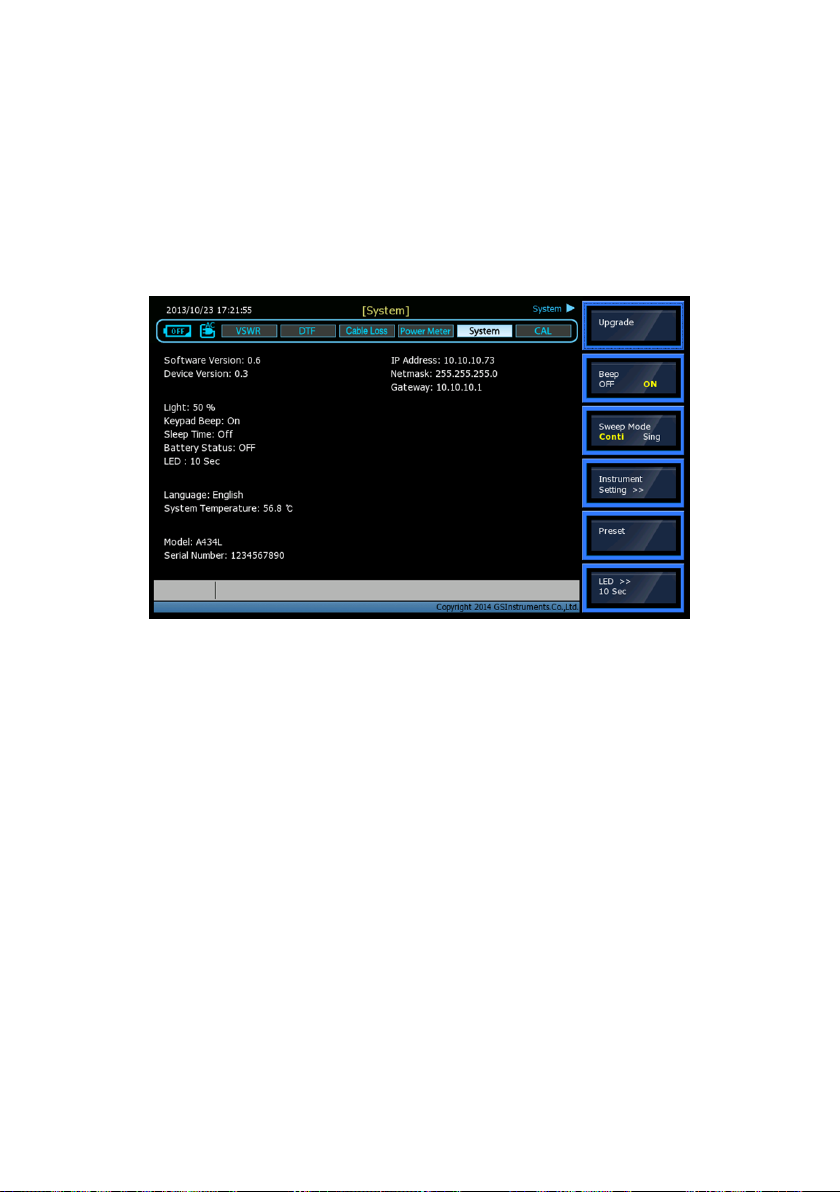

3.4 System Key

The System key enables users to verify the system information or change the

instrument settings.

Selecting the System key opens the following information:

58

Software Version

Device Version

Brightness of the display

Keypad beep On/Off setting

Sleep Mode setting: time to sleep mode

Battery remaining charge capacity

Keypad Backlight On time

Selected language

Page 59

System temperature

Model / Serial Number

IP Address Info

Figure 3.5 System Status Screen

The System key opens the following screen menu:

Upgrade: Upgrades the firmware of the instrument. For detailed

upgrade procedure, refer to the section “5.Software Upgrade”.

Beep: Activates or deactivates the beep sound when keys are

pressed.

Sweep Mode: Sets the sweep mode either single or continuous in

VSWR, DTF, or Cable Loss measurements. If Sweep Mode is set

Single, the message “Hold On” is displayed at the completion of a

current sweep and the sweep stops. Every time the Hold key is

pressed, the sweep is done once.

59

Page 60

Instrument Setting

Language: Changes the language used to display the menu,

messages and information on the screen display. Currently only

available in English.

Time/Date: Sets the time of the system clock.

LAN

Touch Screen

Sleep Time: Sets the time to enter into power saving mode.

Power saving mode is automatically activated when no key

entry occurs during the Sleep Time.

Preset : Set Default Configuration Data

LED: Keypad Backlight On time. If no Keypad input is LED Off after

a set time.

3.5 Multi Keys

Twelve multi keys are located under the LCD display. The Multi keys serve

multiple functions depending on the operation mode. The dual purpose

keys are indicated in black color and the specific functions in blue color. The

key is used to enter a numeric data when a user is prompted to input values.

In all the other cases, the keys are used to perform the specific function.

The function and operating procedure for each multi keys are described in

the following sections

60

Page 61

Figure 3.6 Multi Keys Layout

3.5.1

Numeric Data Entry

Multi keys operate as follows when a user is prompted to input values by

pop-up window.

Numeric keys from 0 to 9 are used to input user setting numbers.

The plus/minus (+/-) key is used to assign positive or negative

numbers in the user settings.

The period key (.) is used to input numbers with decimal points.

3.5.2

Specific Function Keys

Multi keys are used in VSWR, DTF, and Cable Loss measurement mode.

Unless otherwise specified, multi keys do not support Power Meter mode.

1. AMP

AMP (amplitude) defines a manual setting for the scale on the Y-axis of the

graph. It can be selected in VSWR, DTF, and Cable Loss measurement mode.

61

Page 62

Depending on the choice of an amplitude unit, allowable input value is

limited to the following:

In case Y scale is VSWR:

Max(Top): Setting value can be from 1.01 to 65.00 and it

cannot be equal to or smaller than the Min(Bottom) setting

value. Adjustment can be made by steps of 0.01.

Min(Bottom): Setting value can be from 1.0 to 64.99 and it

cannot be equal to or larger than the Max(Top) setting value.

Adjustment can be made by steps of 0.01.

In case Y Scale is Return Loss:

Max(Top): Setting value can be from 0.0 to 59.99dB and it

cannot be equal to or smaller than the Min(Bottom) setting

value. Adjustment can be made by steps of 0.01.

Min(Bottom): Setting value can be from 0.01 to 60.00dB and

it cannot be equal to or larger than the Max(Top) setting

value. Adjustment can be made by steps of 0.01.

Limit line: Turns On and Off the display of the limit line on the

screen.

If a measurement exceeds the limit line, the trace above the

limit line is displayed in red color.

An audible beep sound is generated.

Limit level: Sets the position of a limit line. Depending on the Y-

scale of a graph, the input value is set automatically as none for

VSWR or dB for Return Loss. The value of limit level is displayed on

the limit line.

The instrument takes the negative value of the Return Loss

internally. Users don’t need to add minus (-) sign before typing

in a value. Y-axis of a graph also doesn’t show minus sign.

62

Page 63

2. Freq/Dist

Freq/Dist key causes different screen menu to be displayed depending on a

measurement mode. In VSWR or Cable Loss measurement modes it opens

a frequency screen menu and in DTF measurement mode it opens a distance

screen menu.

VSWR/ Cable Loss Measurement Mode

Center: Sets a center frequency of the measurement to be

made.

Start: Sets a start frequency of the measurement to be made.

Stop: Sets a stop frequency of the measurement to be made.

Span: Sets a user-defined frequency span.

Band: Opens standard or custom frequency band registered

in the instrument.

Standard: Opens the world-wide standard Band List

registered in the instrument.

- Top of List: Moves to the first page of the Band

List.

- Page Up: Moves to the previous page.

- Page Down: Moves to the next page.

- Bottom of List: Moves to the last page of the

Band List.

- Add to Custom: Copies a frequency band

registered in the Standard Band List to the

Custom Band.

Custom: Opens the customized Band List registered in

the instrument.

- Top of List: Moves to the first page of the Band

List.

- Page Up: Moves to the previous page.

- Page Down: Moves to the next page.

- Bottom of List: Moves to the last page of the

Band List.

63

Page 64

- Delete Custom: Deletes a frequency band from

DTF Measurement Mode

Start Frequency: Sets a starting frequency to measure DTF

Stop Frequency: Sets a stop frequency to measure DTF

Distance: Sets a distance to measure. The maximum

measurable distance is 1250m (4125ft).

Cable List: Opens a list of coaxial cables registered in the

instrument. About forty kinds of cables are registered in the

standard cable list. The user can register additional cables to

the instrument by using the application software program

provided with the instrument.

Standard: Opens the Cable List registered in the

instrument.

- Top of List: Moves to the first page of the Cable

- Page Up: Moves to the previous page.

- Page Down: Moves to the next page.

- Bottom of List: Moves to the last page of the

- Add to Custom: Copies a cable registered in the

Custom: Opens a Custom Cable List registered in the

instrument.

- Top of List: Moves to the first page of the Cable

- Page Up: Moves to the previous page.

- Page Down: Moves to the next page.

- Bottom of List: Moves to the last page of the

- Delete Custom: Deletes a cable registered in the

Window: Applies video filtering to the display of the trace. If

the video filter is activated by turning the Window On, traces

the Custom Band.

List.

Cable List.

Standard Cable List to the Custom Cable List.

List.

Cable List.

Custom Cable List.

64

Page 65

are reduced by smoothing out the sharp transitions, thereby

enabling users easy to discriminate noises and peaks.

Setup

Velocity: Opens the Relative Propagation Velocity

parameter for data entry. Enter the propagation

velocity for the type of transmission line being tested.

Cable Loss: Opens the Cable Loss parameter for data

entry. Enter the loss per meter for the type of

transmission line being tested.

Unit: Selects the unit of X-axis scale to display the

measurement results in Meter or Feet.

3. Trace Point

Trace point is used to select the number of data points to take during a

VSWR and Cable Loss measurement mode. There are four data points

available: 126, 251, 501 and 1001. The default number of trace points is

1001.

4. Marker

A marker is used to get the data on the specific point of a trace. A total of

six markers can be displayed on the screen and each marker can be assigned

independently. Placing a marker on the trace displays the marker’s Y

coordinates next to the marker’s position. If the marker table is turned on,

both X and Y coordinates of all activated markers are displayed.

Marker

Select: Selects an Active Marker whose position is moved by

the dial knob or Up and Down arrow keys. The assigned

number of an active marker is displayed in red color on the

Select screen menu and the marker’s number is also displayed

next to the marker on the trace.

Marker View: Hides or displays the selected marker on the

screen. In the same measurement mode markers appear at

65

Page 66

the previous positions when the Marker View is turned off

and on. If a measurement mode has been changed, markers

are not restored to previous positions but move to the left

end of the trace.

All Off: Turns all markers off the screen. Markers are

redisplayed on the previous position if markers are turned

back on. If a measurement mode is changed, current settings

are not restored.

Draw Type: Selects the maximum number of markers to be

used simultaneously. Available options are either 4CH or 6CH.

If 4CH mode is selected, markers number 5 and number 6

cannot be activated. Settings changed in Draw Type are

reflected in Marker CH and Marker table.

Marker Table: Displays a table on the left side of the screen

when Marker Table is activated. All X and Y coordinates of

the activated markers are displayed on the table. Depending

on the selection in Draw Type, the number of markers on the

table is either 4 or 6.

Marker Edit: Sets the marker position manually. A pop-up

window appears for users to set the frequency and the

marker position is moved to the setting frequency

Moving Markers

Knob – Turning the knob clockwise moves a marker to the

right and counter clockwise moves it to the left. The knob is

used to move the marker position fast.

Up/Down Arrow Keys – Pressing the up arrow key (↑)

moves a marker’s position one point to the right and

pressing the down arrow key (↓) moves a marker’s position

one point to the left. Up/Down Arrow keys are used to

move a marker’s position precisely.

As the instrument is equipped with a touch panel operation,

a marker can be placed to the desired position by simply

66

Page 67

touching the screen. Quickly moves an activated marker to the desired

position and makes a fine adjustment using a dial knob or up/down arrow

keys.

5. Trace

Captures a trace for comparison with other traces or saves traces.

Figure 3.7 Trace Screen Display

Select: Selects an active trace. Every time Select screen menu is

pressed, the active trace changes. Channel numbers are assigned

to each captured traces or loaded traces. Refer to Save & Load” for

procedures to load traces.

Capture: Captures a current trace on the screen and assigns a

Trace CH. Refer to “Save & Load” for procedures to save traces.

View: Hides or displays the Trace CH on the screen. Press Select

screen menu key to choose the Trace CH. Traces with View set OFF

are hidden from the screen. The information about the hidden

traces is also cleared from the information window shown on the

upper right of the screen. Setting View On restores hidden traces

and information on the window.

67

Page 68

Info: Hides or displays the trace information window on the upper

right corner of the screen. This is used to view traces overlaid with

the trace information window.

Clear CH: Deletes an active trace channel from the screen. The

cleared channel is not restored. It is used to select and delete a

trace channel one by one when multiple channels are displayed on

the screen. Verify the channels to delete with View ON/OFF

function in advance settings as cleared channels cannot be

restored.

Clear All: Deletes all channels from the instrument and initialize

the trace settings.

6. Peak

This key is used to find the peak value of a trace. Pressing this key leads to

the activation of

Marker CH1 and places the marker to the peak point of the trace.

Peak Right: Moves a marker to the nearest peak on the right.

Peak Left: Moves a marker to the nearest peak on the left.

Max Search: Moves a marker to the highest point of the trace.

Min Search: Moves a marker to the lowest point of the trace.

7. Load

Load key enables for recalling of the Trace, Screen, and State

8. Save

Save key enables for saving of the Trace, Screen, and State.

9. Light

This key is used to adjust the brightness of the LCD display. Adjustment can

be made from 0 to 100% and the default setting is 50%.

68

Page 69

10. Scale

This key is used to select a unit of Y axis of the graph in VSWR and DTF

measurement modes.

Either VSWR or Return Loss can be selected. In Cable Loss measurement

mode, Return Loss only can be selected.

11. Auto Scale

The instrument can automatically set the scale to the minimum and

maximum values of a measurement on the Y-axis of the graph for optimum

display of the traces. Every time AUTO SCALE key is pressed, the top and

bottom scales are set to the minimum and maximum values with margin on

the Y-axis of the screen display.

12. Hold

This key is used to pause a sweep in all measurement modes. The

Hold state is activated by pressing the Hold key, and it is

maintained even if users change the measurement mode. The

sweep resumes when the Hold key is pressed again.

When Sweep Mode is set Single in the System screen menu, a Hold

message is displayed on the screen in red color and the

measurement stops at the completion of a single sweep. Pressing

the Hold key it triggers another single sweep.

69

Page 70

4

MEASUREMENT

DATA ANALYSIS

OPERATING

MANUAL

Page 71

4.

4.1 VSWR

To get maximum power into a load it is required that the load impedance

match the generator impedance. Any impedance difference, or

mismatching would not produce maximum power transfer. A mismatch at

the antenna system produces a reflective 'traveling wave' which goes in the

opposite direction from the incident wave. As the two traveling waves cross

each other in opposite direction, it produces an interference pattern called

a "standing wave". VSWR is the ratio between the power that is sent

forward to the antenna and the amount of the power that is reflected back

toward the transmitter.

Some of the consequences of having a high VSWR condition in cellular

services are: dropped calls, poor reception, and an overall unacceptable

performance in the cell (or section of cell) covered by the base station

antenna. Therefore, the VSWR of the antenna system including the feed line

is one of the most critical factors in the service and maintenance of the RF

transmitter systems.

4.1.1

VSWR Display Description

The screen shown in Figure 4.1 is displayed when VSWR measurement

mode is selected. Various kinds of information related to the VSWR

measurement are shown on the screen.

71

Page 72

Figure 4.1 VSWR Measurement Screen Display

Calibration Info: Displays a calibration state on the measurement frequency

band that a user has selected. When the instrument is first turned on, the

state is “Cal Off”. The symbol “Cal On” is displayed along with the execution

time and frequency band after the calibration is successfully completed.

Trace Point: Sets the number of data points to take during a measurement

mode. Selection is made from one of five choices.

126, 251, 5001, 1001, 2001

Selecting 501 data points provides twice as many measurement points as

251, but it takes approximately twice as long for the trace to sweep and

display.

Selecting the trace points larger than needed for

the measurement will result in a longer sweep

time. This may hinder the user from

observing the fast changing traces.

72

Page 73

It is recommended to select high resolution trace

points only when measuring the wide frequency

band or a precise measurement is required.

The previously executed calibration is effective

even after the trace points change.

Trace Average: Indicates the average value of a single sweep over the user

setting frequency band.

Freq. Span: It is a user-defined frequency band. Changing the frequency

band doesn’t affect the sweep time, but affects the calibration. Recalibration

is required if the frequency setting is changed.

Freq Band Info: The band name is displayed if the band is selected from the

band list stored in the instrument. If the user sets the start, stop, center or

span frequency manually, the band name will show “Custom”

Limit Line: Sets the upper limit value of the trace. The portion of the trace

that exceeds the limit line is displayed in red color. The captured trace by

using the Trace function does not display the exceeded portion of the trace

in different color.

Y scale unit: It is the measurement unit of the Y axis displayed for the trace.

Return Loss (dB)

VSWR

73

Page 74

Action

Note

Setting Center Freq and Span.

1. Press the Freq/Dist key.

Multi key.

2. Select the

Center Freq

screen menu.

The current setting is displayed

on the Window.

3. Enter a center frequency value.

4. Press the Enter key.

5. Select the

Span

screen menu.

6. Enter a span value.

7. Press the Enter key.

Setting Start/ Stop Frequency.

1. Press the Freq/Dist key.

The current setting is cleared

when a new value is entered.

Press the ESC key to delete one

by one the numbers displayed

on the pop-up window.

Pressing the ESC key repeatedly

will cancel the input mode.

The frequency input unit is in

MHz and the minimum input

steps is 0.01MHz

2. Select the

Start

screen menu.

3. Enter a start frequency value.

4. Press the Enter key.

5. Select the

Stop

screen menu.

6. Enter a stop frequency value.

7. Press the Enter key.

Selection from the band list stored in the instrument.

1. Press the Freq/Dist key.

Press the Up(↑) / Down(↓) arrow

keys or rotate the dial knob to

select a band from the list.

Select the

Page Up/Page Down

screen menu for searching

bands not shown in the screen.

2. Select the

Band

screen menu.

3. Select the band from the list and

press the Enter key.

4.1.2

Setting Frequency

Frequencies can be set manually or selected from a band list stored in the

instrument. It is desirable to set the frequency to a value that covers the

normal range of the measurement with enough margin.

74

Table 4.1 Frequency Setting Procedure

Page 75

Changing the frequency settings will automatically turn

calibration off with the symbol “CAL OFF” displayed on the

screen. Always set the frequency before calibrating the

instrument. Changing the trace points during the

measurement doesn’t affect the calibration.

4.1.3

Calibration

The instrument must be calibrated to get a reliable measurement

result. For best results, set the frequency and calibrate the

instrument immediately before taking a measurement.

Calibration accessories (optional)

Calibration Kit which contains one 50ohm load, one Open

standard and one Short standard

Test cable: Use a phase stable cable for reliable and

consistent measurement results

To minimize the measurement error, connect the port

extension cable to the RF In port on the instrument and

then connect the Cal Kit to the end of the extension

cable.

75

Page 76

Figure 4.2 VSWR Calibration Connection

Bending or moving the phase unstable cable while making

a measurement may cause errors in the measurement. The

test cable used for port extension must be phase stable in

the measurement frequencies.

At the successful completion of each calibration step, the

message is displayed with a beep sound.

Figure 4.2 illustrates the connection method when a port extension cable is

used for calibration.

76

Page 77

Action

Note

Performs Calibration after the frequency setting and test cable connections.

1. Press the CAL

key.

Hard function key.

2. Connect an

Open standard.

Connect CAL Kit “Open” connector to the RF out port.

3. Select the

Open/Start

screen menu.

When the

Open/Start

screen menu is selected, a

progress bar is displayed to show the progress.

When a progress bar is disappeared, Open calibration

is finished.

4. Connect a

Short standard.

Connect CAL Kit “Short” connector to the RF out port.

5. Select the

Short/Start

screen menu.

When the

Short/Start

screen menu is selected, a

progress bar is displayed to show the progress.

When a progress bar is disappeared, Short calibration

is finished.

6. Connect the

Load standard.

Connect CAL Kit “Load” connector to the RF out port.

7. Select the

Load/Start

screen

menu.

When the

Load/Start

screen menu is selected, a

progress bar is displayed to show the progress.

When a progress bar is disappeared, Load calibration is

finished.

Calibration state is changed to “Cal On” after the Open-Short-Load calibration.

To compensate errors caused by a port extension cable or adapters, perform

Open-Short-Load calibration including the port extension cable.

Table 4.2 Calibration Procedure

4.1.4

VSWR Measurement

The instrument is ready to take VSWR measurement after completing the

Open-Short-Load calibration using a port extension cable.

77

Page 78

After calibration, do not change the connection of

the port extension cable or the frequency setting. It

can cause produce an error in the measurement.

When the frequency setting is changed, a warning

alarm will sound and the calibration state is

changed to “Cal Off”. After changing the frequency

setting, recalibrate the instrument using the OpenShort-Load standard.

The end of the port extension cable must be connected to the device

(antenna or feed line) for VSWR measurement as shown in Figure 4.3. The

result of the VSWR measurement is displayed on the screen in real time.

Figure 4.3 Connection for VSWR Measurement

78

Page 79

The maximum allowable input level of the

instrument is +25dBm. Do not connect the RF In

port of the instrument directly to the output port of

the system. An over power input degrades the

performance of the instrument and may cause a

malfunction of the instrument.

Do not connect the instrument to the antenna when

there is a risk of lightning. Electric shock may cause

a malfunction or damage the instrument.

4.1.4.1 Setting Trace Point

Adjust a trace point to change the resolution of the VSWR measurement.

Changing the Trace Point doesn’t affect the calibration state.

4.1.4.2 Scale Adjustment

Press Auto Scale key to optimize the Y scale and display the entire trace.

Press AMP key to set the maximum and minimum values on the Y scale

manually.

Press Scale key to select the display unit of the Y scale.

Scale adjustment doesn’t affect the calibration state.

4.1.4.3 Using Markers

Depending on the draw type setting, four or six markers can be used

simultaneously. The Y axis value on a current trace is displayed next to each

marker on the screen, but the frequency information is not provided.

Activate the marker table to see both, the level and frequency information

when moving a marker to the specific frequency using the Marker Edit

function.

79

Page 80

Figure 4.4 Using Markers in VSWR Measurement Mode

4.1.4.4 Limit Line

By setting a limit line, users can easily check if a measurement exceeds the

specified limit. It appears as a horizontal line at the value set. An alarm

sounds when a trace exceeds the limit line and the exceeded portion is

displayed in red color.

80

Page 81

Figure 4.5 Limit Line Application

4.2 DTF

While VSWR is an indicator to express the efficiency of the antenna’s energy

transmission, DTF is a measurement to identify the fault locations in the

antenna line system. Most of the antenna line system consists of the various

types of coaxial cables, connectors and devices such as dividers and surge

arrestors. Since VSWR is a measurement to verify the impedance

discontinuity of the total feed line system, it is necessary to perform DTF

measurement to identify the exact component that is contributing to the

performance of the line system. The DTF measurement makes it easy to

identify the fault location by displaying the relative distance of the signal

reflections or discontinuities from various points of the line system

4.2.1

DTF Display Description

The screen shown in Figure 4.6 is displayed when DTF measurement mode

is selected. The distance from the instrument is shown on the X-axis, while

81

Page 82

the relative magnitude of the discontinuity is shown on the Y-axis. The

information related to the DTF measurement is shown on the screen.

Figure 4.6 DTF Measurement Screen

Limit Line & Limit Level Info: Sets the upper limit value of a trace.

The portion of the trace that exceeds the limit line is displayed in

red color. However, the captured trace by using TRACE function

doesn’t discriminate the color even if the trace exceeds the limit

line.

Calibration Info: Displays a calibration state on the measurement

frequency band that a user has selected. When the instrument is

first turned on, the state is “Cal Off”. The symbol “Cal On” is

displayed along with the execution time and frequency band after

the calibration is successfully completed.

Maximum Distance: Displays the maximum measurable distance

within the user setting frequency band. Setting the frequency

band narrow will increase the measurable distance while setting

the frequency band wide will decrease the distance.

Y Scale Unit: Is the measurement unit of the Y-axis that the trace

is displayed.

Return Loss (dB)

VSWR

Freq. Span: Is the user-defined frequency band. Changing the

82

Page 83

frequency band doesn’t affect the sweep time, but affects the

calibration. Recalibration is required if the frequency setting is

changed.

Freq. Band Info: The band name is displayed if the band is selected

from the band list stored in the instrument. If the user sets the start,

stop, center or span frequency manually, the band name will show

“Custom”.

Cable Info: The name of user selected cable is displayed on the

screen. A cable name is displayed if the cable is selected from a

Cable List stored in the instrument. If the user sets the Velocity and

Cable Loss manually, the band name will show “Custom”. The

following information is also displayed.

Rel. Propa. Vel.: The relative propagation velocity for the

cable type selected by the user selected from the Cable List or

manually set by selecting the Velocity key.

Nominal Atten.: The loss per unit distance for the cable type

that the user selected from the Cable List or set manually by

selecting the Cable Loss key

By using the application program supplied with the

instrument, users can store user’s cable to the instrument. For

details, refer to the Application Program.

4.2.2

DTF Setup

Set the conditions for DTF measurements. The user setting parameters for

DTF measurements are the following:

Frequency Setting: Sets the start and stop frequency to make a

measurement. If a specific frequency band has been set in VSWR

measurement mode, it can be applied to DTF measurement. To

change the maximum measurement distance or increase the

83

Page 84

Action

Note

Frequency Setting.

Press the Freq/Dist key.

Select the

Start Freq

screen menu.

{Enter start frequency value}

Press the Enter key.

Additional calibration is

not necessary if a Freq

Band has been set and a

calibration has been

measurement resolution, is necessary to change the frequency

setting.

Distance Setting: The maximum measurable distance is displayed

on the left side of the screen depending on the frequency setting.

Any value within the maximum measurable distance can be set.

Optimum resolution is achieved when the user setting distance is

the same as the maximum measurable distance.

Cable Setting: Selects a cable type of the feed line. By using this

key, users can select the cable stored in the instrument without

setting the detailed parameters of the cable.

Setup: Used to change the setting of the cable parameters or

change the distance unit. It consists of the following sub menus:

Velocity: Sets the relative propagation delay of a cable. It

affects the calculation of the distance in the DTF

measurement.

Cable Loss: Sets the loss per distance unit of a cable. It affects

the peak level of the discontinuity in the DTF measurement.

After calibration, do not change the connection of the port extension

cable or the frequency setting. It can cause a

frequency setting, recalibrate

A detailed procedure for DTF setup is as follows:

84

measurement error. When the frequency setting is

changed, a warning alarm will sound and the calibration

state is changed to “Cal Off”. After changing the

the instrument using the Open-Short-Load standard.

Page 85

Select the

Stop Freq

screen menu.

{Enter stop frequency value}

Press the Enter key.

performed for the band

in VSWR measurement,

and the same Freq. band

is used in the DTF

measurement.

Distance Setting.

Select the

Distance

screen menu.

{Enter measuring distance}

Press the Enter key.

The ending point can

only be set in distance

setting.

The maximum

measurable distance is

1,250m (4,125ft).

Cable Setting.

Select the

Cable List

screen menu.

[Standard]/[Custom]

{Select a cable by using Knob or

arrow key}