Page 1

Page 2

PROTEK 9216A

Digital LCR Meter

User’s Manual

Volume 1: Basic Operation Rev. 3.0

Page 3

Table of contents

Introduction ........................................................................................................................................................... 4

Warranty......................................................................................................................................................... 4

General Safety Summary .............................................................................................................................. 5

Preventing Injury ..................................................................................................................................... 5

Preventing Instrument Damage .............................................................................................................. 5

Maintenance, Repair, and Storage ................................................................................................... 5

Product Damage Prevention ............................................................................................................ 6

Line Voltage Requirements .............................................................................................................. 6

Fuse Requirements .......................................................................................................................... 6

Conventions Used in This Manual ................................................................................................................. 7

Safety Terms ........................................................................................................................................... 7

Product Familiarization ......................................................................................................................................... 8

Front Panel Components ............................................................................................................................... 8

Fixture Inputs ........................................................................................................................................... 8

Measurement Modes and the Mode Selection Keys ............................................................................... 9

Alphanumeric Displays and Parameter Indicators .................................................................................. 9

Programming and Operator Interface Keys .......................................................................................... 10

Rear Panel Components .............................................................................................................................. 12

Specifications ............................................................................................................................................... 13

Display ................................................................................................................................................... 13

Test Conditions ...................................................................................................................................... 13

Accuracy ................................................................................................................................................ 13

Features and Options ................................................................................................................................... 14

General Features................................................................................................................................... 14

Options .................................................................................................................................................. 15

Basic Operations ................................................................................................................................................. 16

Operation of the LCR Meter For the First Time ........................................................................................... 16

Unpacking and Inspection ..................................................................................................................... 16

Installation ............................................................................................................................................. 16

Startup Procedures ...................................................................................................................................... 17

Before Applying Power .......................................................................................................................... 17

Before Using the Test Fixture................................................................................................................ 17

Fixture Options ............................................................................................................................... 17

Null Calibration Procedure .............................................................................................................. 18

Changing Test Setup Parameter Settings.................................................................................................... 18

2

Page 4

.

.

.

.

.

.

Default Setup ......................................................................................................................................... 19

Changing, Storing, and Recalling Custom Setups ................................................................................ 20

Measurement Mode........................................................................................................................ 20

Frequency ....................................................................................................................................... 20

Drive Voltage .................................................................................................................................. 21

Bias ................................................................................................................................................. 22

Measurement Rate ......................................................................................................................... 24

Settling Time .................................................................................................................................. 25

Triggering........................................................................................................................................ 25

Store and Recall ............................................................................................................................. 26

Range ............................................................................................................................................. 26

Series and Parallel Equivalent Circuits .......................................................................................... 29

Display Types ................................................................................................................................. 29

3

Page 5

Chapter

Introduction

Important Background Information

The PROTEK 9216A DIGITAL LCR Meter is a high quality instrument that gives you

many years of good service. Please read the information in this chapter before using or

applying power to the meter. Information on operating and using the meter is given in

the following chapters.

Warranty

PROTEK warrants that this product will be free from defects in materials and

workmanship for a period of one year from the date of purchase. If any such product

proves defective during this warranty period, PROTEK, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, the customer must notify PROTEK of

the defect before the expiration of the warranty period and make suitable arrangements

for the performance of service. The customer shall be responsible for packaging and

shipping the defective product to the service center designated by PROTEK, with

shipping charges prepaid. PROTEK shall pay for the return of the product to customer if

the shipment is to a location within the country in which the PROTEK service center is

located. The customer shall be responsible or paying all shipping charges, duties, taxes,

and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper

use or improper or inadequate maintenance and care. PROTEK shall not be obligated

to furnish service under this warranty:

To repair damage resulting from attempts by personnel other than PROTEK repre-

sentatives to install, repair or service the product;

To repair damage resulting from improper use or connection to incompatible

equipment; or

To service a product that has been modified or integrated with other products when

the effect of such modification or integration increases the time or difficulty of

servicing the product.

This warranty is given by PROTEK with respect to this product in lieu of any other

warranties, expressed or implied. PROTEK and its vendors disclaim any implied

warranties of merchantability or fitness for a particular purpose.

4

Page 6

.

.

.

.

.

.

PROTEK’s responsibility to repair or replace defective products is the sole and

exclusive remedy provided to the customer for breach of this warranty. PROTEK

and its vendors will not be liable for any indirect, special, incidental, or

consequential damages irrespective of whether PROTEK or the vendor has

advance notice of the possibility of such damages.

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any products connected to it.

NOTE: Only qualified personnel should perform service procedures.

Preventing Injury

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified for this

product.

Avoid Electrical Overload. To avoid electric shock or fire hazard, do not apply a voltage

to a terminal this is outside the range specified for that terminal.

Ground the Product. This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must be connected to

earth ground. Before making connections to the input or output terminal of the product,

ensure that the product is properly grounded.

Do Not Operate Without Cover. To avoid electric shock or fire hazard, do not operate

this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified for

this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate this

product in damp or wet conditions.

Do Not Operate in an explosive atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Keep Probe Surface clean. To avoid electric shock and erroneous readings, keep the

probe surface clean.

Preventing Instrument Damage

Maintenance, Repair, and Storage

This equipment is composed of many high-precision components and components

which require high internal pressure. Care is required when handling or storing this

equipment.

Occasionally, if the surface of the panel is dirty, rub the affected area lightly with a

soft cloth soaked in a light neutral detergent or alcohol. Never use highly volatile

material such as benzene or paint thinner.

The ideal ambient temperature range for storing this equipment is 10C to 60C

(14F to 140F).

5

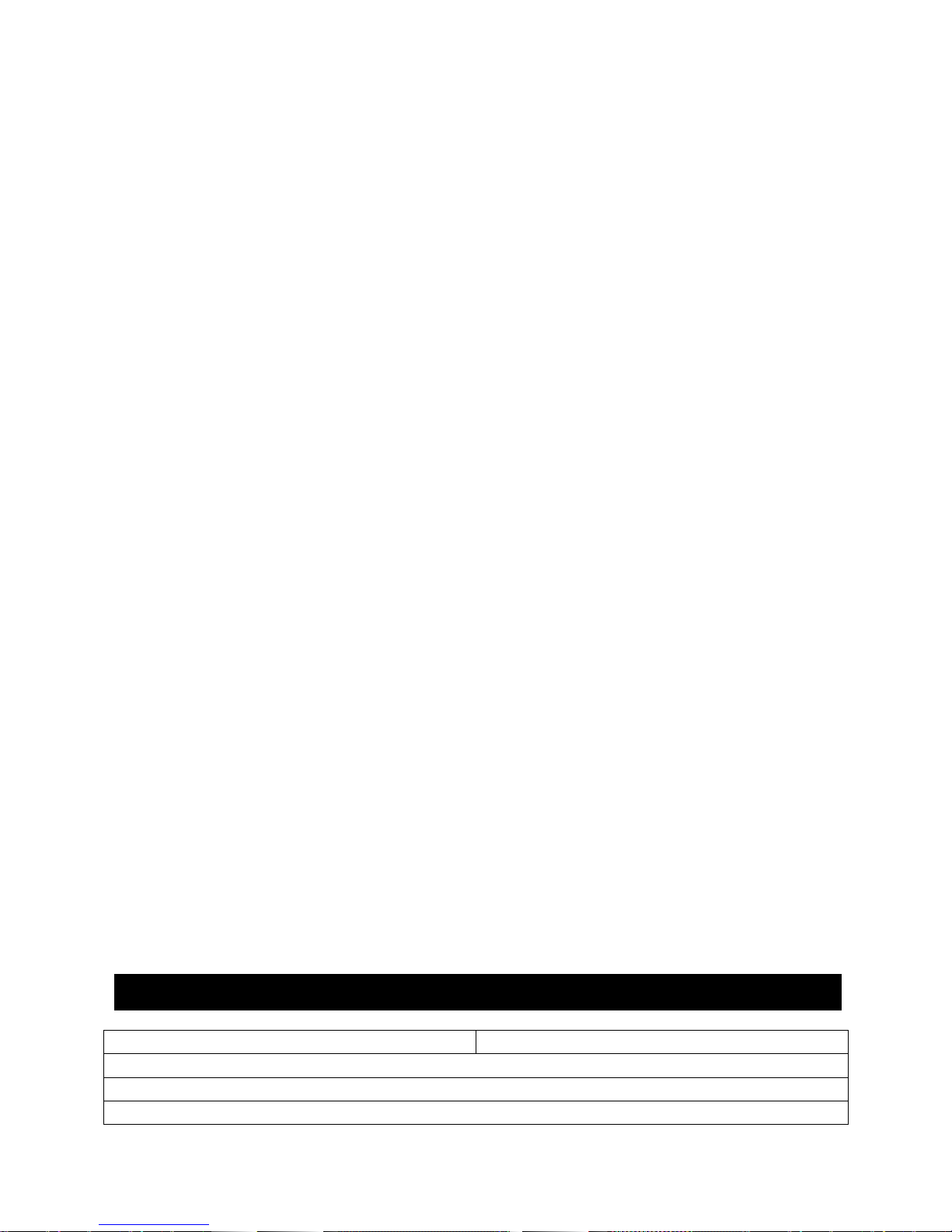

Page 7

To avoid personal injury, do not remove the product covers. Do not operate the

Rating

Operating Voltage Range

AC 115 V

AC 98 V–132 V

AC 230 V

AC 196–253 V

product without the covers properly installed.

Two spare fuses are shipped with this equipment.

In order to maintain this equipment in a stable and efficient operating condition,

calibrate the equipment after every 1,000 hours operating time or every 6 months,

whichever is shorter.

Product Damage Prevention

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

Provide Proper Ventilation. To prevent product overheating, provide proper ventilation.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it Suspected Failures inspected by qualified service personnel.

Do not immerse in Liquids Clean the probe using only a damp cloth. Refer to the

cleaning instructions.

Line Voltage Requirements

Refer to the following table for the correct operating voltage ranges for this LCR meter.

Check the line voltage prior to connecting to the power source, and verify that it is within

a voltage range listed below.

If the LCR meter is to be used at a voltage other than 230V AC, the operating voltage

may be changed by the following procedure ·

Remove the power cable from AC input.

Insert a flat-bladed screwdriver into the slot located on right side of the fuse holder

cap; remove the cap by pressing and then pulling up the screwdriver.

Rotate the cap on the fuse holder to set the voltage to the desired level.

Connect power cable to the AC input.

If a voltage below AC 115 V is required, the power cable and fuse may need to be

changed. In such case, contract your nearest dealer for appropriate service.

After use, disconnect the equipment from the AC outlet.

Fuse Requirements

In order to prevent circuit damage resulting from over current, use the correct fuse value.

The fuse ratings are as follows.

6

Page 8

.

.

.

.

.

.

Circuit No.

Shape (diameter length) mm

Rating

Remarks

F1101

5.2 20

250 V T500 mA

For AC l15V

250 V T250 mA

For AC 230 V

F601

5.2 20

250 V F250 mA

Circuit No.

Shape (diameter length) mm

Rating

Remarks

F602

5.2 20

250 V F250 mA

The internal fuse rating is as follows:

Note: Refer to the section on troubleshooting in the Reference Manual for instructions

on replacement of the internal fuse.

Conventions Used in This Manual

In this manual, you will find various procedures, which contain steps of instructions

for you to perform. To keep these instructions clear and consistent, this manual

uses the following conventions:

Operating procedures and names of front panel controls are in uppercase and

The case of each name used in the manual is the same (Initial Capitals or

Instruction steps are numbered (1, 2, 3, ), unless there is only one step.

When steps require that you make a sequence of selections using front panel

Safety Terms

The following terms are also used in this manual:

WARNING identifies conditions or practices that could result in injury.

CAUTION identifies conditions or practices that could result in damage to this

NOTICE identifies conditions or practices that could result in incorrect test

boldface print.

UPPERCASE) as that used on the instrument itself.

controls and keys, an arrow () is used in the text to indicate an LED result when a

front panel entry is made. Also, whether a name is a key or LED display reading is

clearly indicated:

Example: Press DISP (Entry) ENTER

product or other property.

data.

7

Page 9

Product Familiarization

Test Frequency

Measurement Rate

Bias

Test Voltage

Display option

Back space

Measurement modeFixture inputs

Trigger

Setup Key pad Enter

Chapter

2

Description of the LCR Meter and Its Features

In this chapter, the controls and connections of the LCR Meter are described, and its

basic operation is summarized in terms of the meter’s specifications, features and options,

and operating modes.

Front Panel Components

The front panel and its displays, controls, and connections are shown in the following

illustration:

First, the displays, controls, and connections on the left side of the front panel are explained, and then the many buttons and keys on the right side are described.

Fixture Inputs

The input terminals labeled IL, PL, PH, and IH connect the test fixture or adapter to the

instrument, as discussed in the section in Chapter 3 on “Connecting a Component.” Two

of the terminals provide a current source to the component under test, and the other two

terminals provide a high impedance connection to measure the voltage across the device.

This four-wire or “Kelvin” type of measurement setup is designed to increase accuracy by

reducing the amount of current in the voltage-sensing wires. Warning: Do not connect

any active voltage source to these terminals, especially high voltages.

Measurement Modes and the Mode Selection Keys

These keys select the measurement to make on the component under test. One of five

measurement modes may be selected: Auto, R+Q, L+Q, C+D or C+R. The selected

8

Page 10

mode is indicated by LEDs above the alphanumeric displays. The operation of each

1

mode can be explained as follows:

AUTO In this mode, the meter automatically selects the most appropriate

measurement on the device. The selection is made according to the following

criteria:

If |Q| < 0.125, the meter selects the R+Q measurement mode.

If Q > +0.125, the meter selects the L+Q measurement mode.

If Q < 0.125 and the meter is in the series equivalent circuit mode, the C+R

measurement mode is selected.

If Q < 0.125 and the meter is in the parallel equivalent circuit mode, the C+D

measurement mode is selected.

R+Q In this mode, resistance is displayed on the main parameter display

and the Q (quality factor) is displayed on the secondary parameter display. The R-

value is either the series or parallel equivalent resistance of the component under test.

The unit for R is , k, or M. The Q value is the dimensionless ratio of the

imaginary part of the component’s impedance to its real part. If Q has a positive (+)

value, the reactive component of the device under test is inductive. If Q has a

negative () value, it is capacitive.

L+Q In this mode, the series or parallel equivalent inductance value of a

component under test is displayed on the main parameter display units in units of µH,

mH, or H, and its dimensionless Q value is displayed on the secondary parameter

display.

C+D In this mode, the series or parallel equivalent capacitance value of a

component under test is displayed on the main parameter display in units of pF, nF,

or µF. On the secondary parameter display, the dimensionless ratio D 1/Q is given.

D is normally a small value for a good capacitor.

C+R In this mode, the capacitance is displayed on the main parameter

display and the equivalent resistance is displayed on the secondary parameter

display. The unit for resistance is unless the k indicator LED is lit.

Alphanumeric Displays and Parameter Indicators

The two 5-digit (plus sign) LED1-segmented alphanumeric displays provide measurement

results, entered parameter values, and status messages. The left display gives the value

of the main parameter of the component under test (L, R, C) and the right display gives

the value of its secondary parameter (Q,D, R, %). Above and next to these two

alphanumeric displays are various LEDs that, when lit, indicate something about the

measurement:

LED = light-emitting diode

9

Page 11

AUTO, R L, C, % LEDs that indicate the measurement type for the main parameter

2

2

Q, D, R, % LEDs that indicate the measurement type for the secondary

parameter

, k, M LEDs indicating the units of the value being displayed on the left

µH, mH, H

pF, nF, F

k The right-side display is dimensionless or has units of ohms

unless this LED is on.

REM, ACT, ERR These LEDs give information on the status of the remote control

(computer) interface operations.

REM: Indicates that the display is being controlled remotely via the interface

connector on the rear panel.

ACT: Indicates that the remote control interface is active.

ERR: Indicates that a remote command contained an error.

NOM, LIM, LIM Indicates which Binning

Programming and Operator Interface Keys

On the right side of the front panel of the LCR meter, there are many buttons and keys for

programming test conditions and for general operator interface. These keys are grouped

according to function, and some groups have LED indicators associated with them show

which option has been selected.

parameter is being entered

Frequency The 9216A has five selectable fixed frequencies with an accuracy to

100ppm (0.01%). 100Hz, 120Hz, 1kHz, 10kHz or 100 kHz may be selected by

pressing the up/down keys on the front panel keypad until its corresponding LED is

illuminated.

Drive Voltage

VOLT Pressing the VOLT key, the output voltage will cycle through three

fixed output drive voltages (0.1V, 0.25V, 1.0V). An LED indicates the selected

drive voltage. If NO LED is lit, then the output drive voltage is in the vernier

mode.

CONS This key sets the meter to the constant voltage mode.

BIAS The bias mode is used only for capacitance measurements. Pressing

these keys for any other measurement will generate the “bias for c” error message.

INT Selects a 2.0 VDC internal bias.

EXT Selects a voltage from an external source to be applied to the

capacitor under test.

Binning is explained later.

10

Page 12

MEAS RATE Selects the measuring rate. At frequencies of 1 kHz or greater, slow

(2 measurements per second), medium (10 measurements per second, and fast

measurements (20 measurements per seconds) may be selected.

DISPLAY

Average The average of 2 to 20 measurement readings will be displayed.

The number of measurements in the average is selected from the keypad.

HOLD This key holds the meter in its current measurement range. Pressing

the hold key a second time returns the meter to the Auto-Range mode. A

specific range may also be entered from the numeric keys on the keypad.

EQU This key toggles the equivalent circuit for the component under test

between a series or parallel circuit.

DISP The DISP key cycles through the display parameters that may be

selected. The display parameters that may be selected are:

VALUE The measured value of the device under test is displayed.

DEV The deviation from a value previously entered is displayed.

% DEV The percent deviation from a previously entered value is

displayed.

ENTRY Used for entering parameter values.

BINS Selects the bin number when Binning is enabled.

Note: Certain displays are not available unless data has been entered. For example,

DEV and % DEV are not available unless a nominal value has already been entered.

Also, BINS is not available unless binning data has previously been entered.

Backspace key used for correcting mistakes when entering

numeric data. This key also serves as the “Local” function.

[0]...[9] These keys are used to enter parameters and are only active

when the meter is in the ENTRY mode.

ENTER [, µH, pF], [k, mH, n F], [M, H, µF]. These three keys are

used for entering numeric parameters in the entry mode (e.g. R, L, C

values). The bottom-most key (M, H, µF) may be used as a general

entry key for entering parameters not listed on the keypad, such as

percent %.

SETUP

STO, RCL The 9216A can store up to nine setups in the memory. To

store the present configuration in memory location #n, press STO [n]

ENTER. To recall a setup, press RCL [n] CAL ENTER.

CAL Enables a series of internal calibration routines, including

open/short and settling time calibration, output amplitude drive, and

internal self-tests.

BIN#, NOM, LIM These keys are used to enter Binning parameters.

The BINNING LED is on when Binning is enabled and the optional

handler is active.

11

Page 13

TRIGGER

MODE This key toggles between continuous (CONT) or TRIGGERED

measurements .

TRIG When TRIGGER mode is selected, measurements are initiated when this

key is pressed or by the handler or computer interfaces. The TRIG LED will flash

when this mode is enabled.

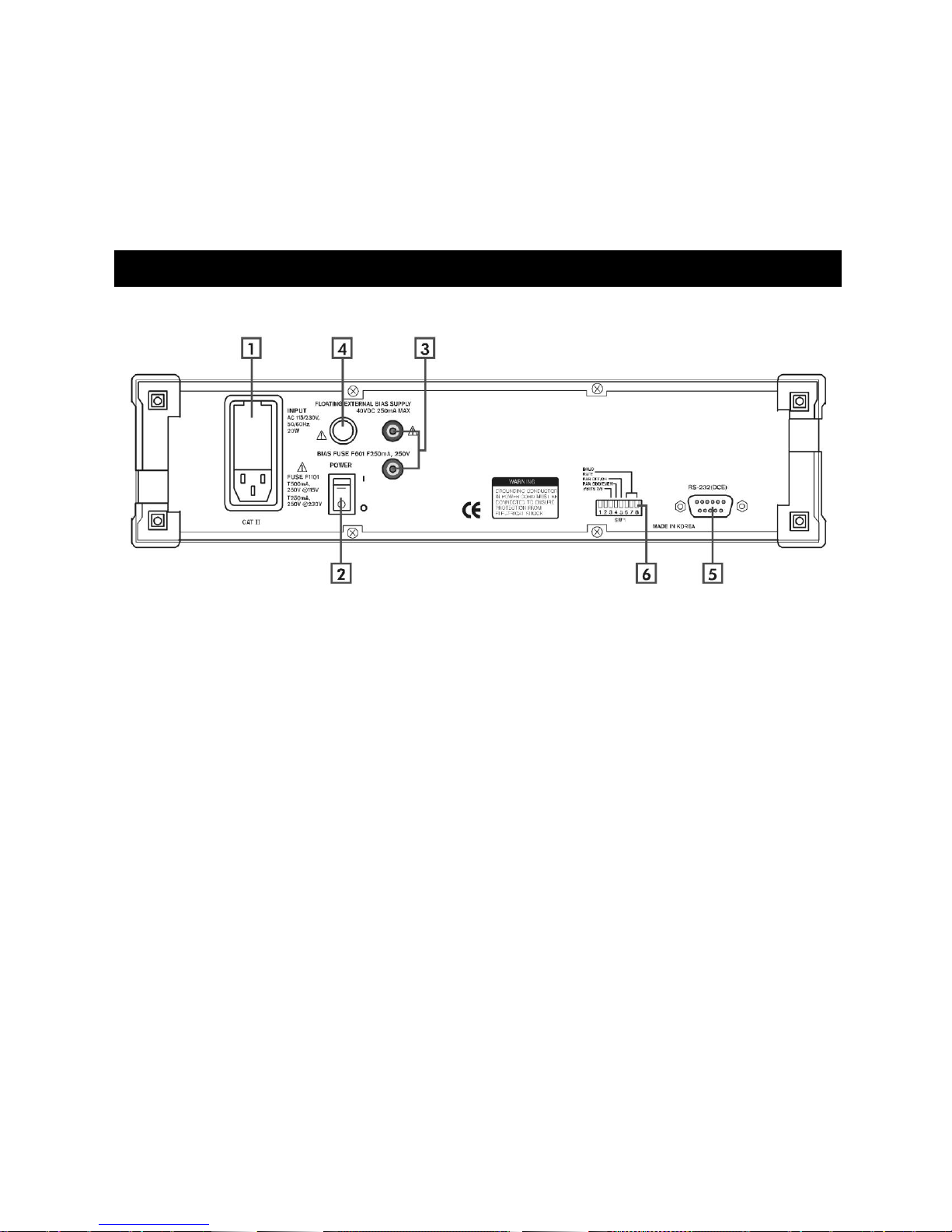

Rear Panel Components

The rear panel and its controls and connections are shown in the following illustration:

[1] AC POWER CONNECTOR The AC power cord is inserted into this connector. The

fuse and line voltage selector are located in the connector housing.

[2] POWER SWITCH Turns the meter on and off.

[3] EXTERNAL BIAS INPUT Two banana plugs are used to input an external bias

voltage. The bias supply voltage must be floating and well filtered. Neither input

connector can be referenced to ground.

[4] EXTERNAL BIAS FUSE Protects external bias circuit from currents greater than 250

mA.

[5] RS232 DB25 This connector allows the meter to communicate as a DCE (data

communications equipment, e. g. a modem) to a DTE (data terminal equipment, e.g.,

a computer) using the RS-232C protocol. For further information, refer to the

material on remote programming in the Reference Manual.

[6] SW1 The switches set the RS232C protocol parameters. The Baud rate, word

length and parity may be set.

12

Page 14

Specifications

Display

Measurement Modes: Auto, R+Q, L+Q, C+D, C+R

Equivalent Circuit: Series or Parallel

Parameters Displayed: Value, Deviation, % Deviation or Bin Number. Deviation

and % deviation are calculated from a stored relative value

Averaging: 2–10 Measurements

Measurement Range: R+Q: R: 0.0001–2000 M

Q: 0.00001–50

L+Q: L: 0.0001 µH–99999 H

Q: 0.00001–50

C+D: C: 0.0001 pF–99999 µF

D: 0.00001–10

C+R: C: 0.0001 pF–99999 µF

R: 0.00001–99999 k

Test Conditions

Accuracy

Test Frequency: 100 Hz, 120 Hz, 1 kHz, 10 kHz, 100 kHz

Frequency accuracy: ±100ppm.

Drive Voltage: Preset Levels: 0.10, 0.25, and 1.0 Vrms.

Vernier: 0.1 to 1.0 Vrms with 50 mV resolution.

Drive level accuracy: ±2%.

Measurement Rates: (a) Slow (2 meas./sec.), Medium (10 meas./sec.), or Fast

(20 meas./sec.) for test frequencies of 1 kHz and above.

(b) Approx. 0.6, 2.4, or 6 measurements per second at

100 Hz and 120 Hz.

Ranging Auto or Manual

Triggering Continuous, Manual, or Remote over RS232 or

Handler Interface

Bias Voltage Internal: 2.0 VDC ±2%

External: 0 to +40 VDC (fused @ 0.25 A)

Conditions: Allow 30 minutes of warmup before measurements; all accuracies are at

23° C (73F) ±5°C

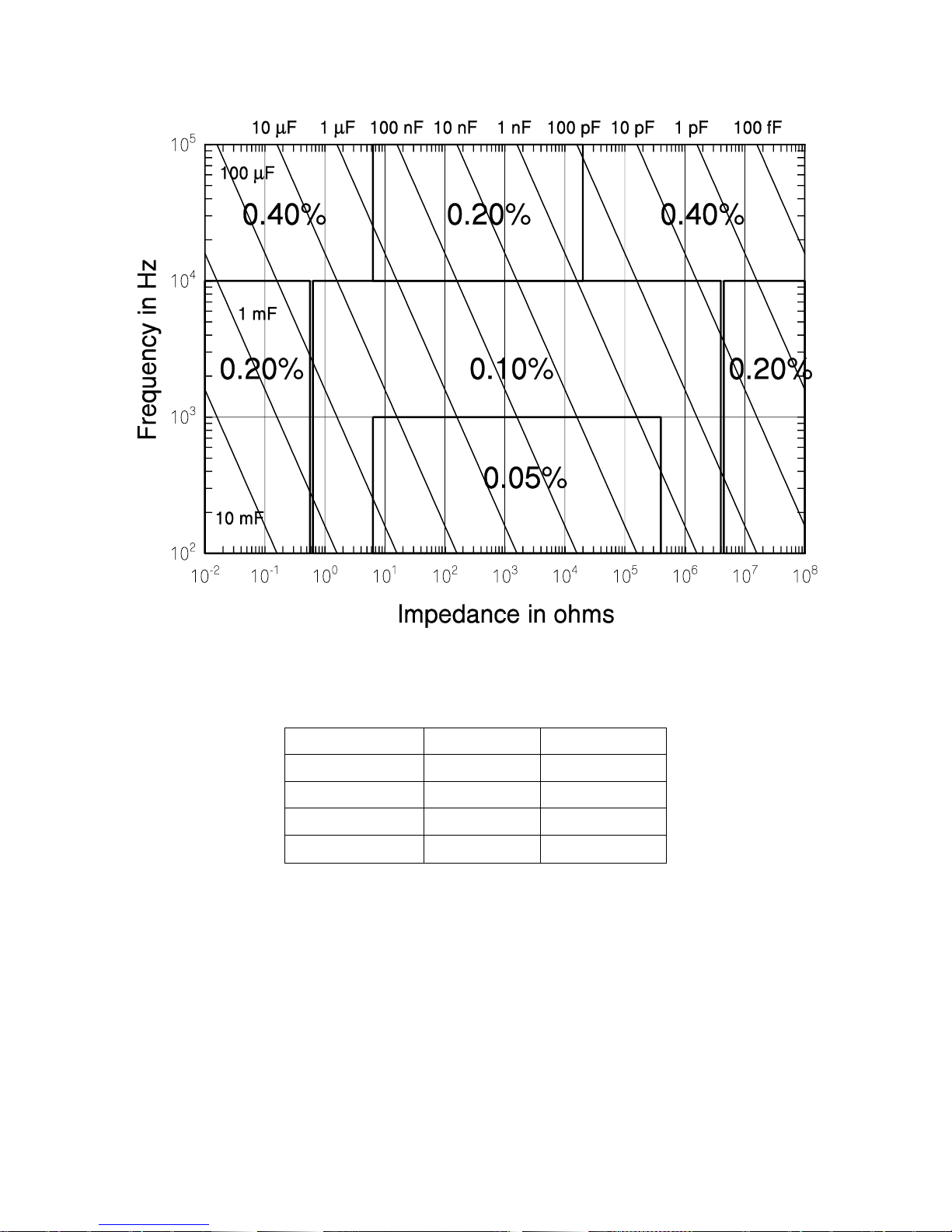

Basic accuracy 0.05%. Refer to the accuracy section in the Reference Manual for

detailed specifications.

The following summarizes typical accuracy specifications:

13

Page 15

Feature

Specification

Fixture

4-wire Kelvin fixture for parts with radial and axial leads

Protection

Protected up to 1 Joule of stored energy, 200 V DC for charged capacitors;

fused at 0.25 A output current for biased measurement

Zeroing

Open and short circuit compensation. Compensation Limits: short circuit:

R<20, Z<50, open circuit: Z>10k

Binning

Up to 8 Pass Bins, QDR and General Fail Bins, all defined by the front panel or

computer interface. Binning setups may be stored in nonvolatile memory

Self Test

Tests the ROM, CPU, nonvolatile RAM, clock generator, A/D converter,

internal bias, multiplier, output drive circuitry, gain circuitry, and source

resistances.

Store and Recall

memory

Stores and recalls nine complete instrument setups. Recall 0 recalls the default

setup.

RS232 Interface

All instrument functions can be controlled or read over the interface.

Operating Conditions

0 to 50°C at a relative humidity of 0 to 80%

Power

20 Watts, 110/220 VA, 50/60 Hz

Dimensions

4 ¼ " H 14 ¼ " W 15" D

Weight:

12 ¾ lbs

Warranty

Two year parts and labor on materials and workmanship

Accuracy Value

better than 1% for R > 0.125 and R < 16 M

L > 2.5 H and L < 25 kH

C > 1.25 pF and C < 12.8 mF

better than 5 % for R > 21 m and R < 96 M

L > 420 nH and L < l50 kH

C > 0.21 pF and C < 77 mF

at the following conditions:

1.0V, 0.5V, or 0.25V output voltage

Slow or medium measurement speed

Q and D < 0.1 for R and C

Q > 10 for L

100Hz, 120Hz or 1 KHz test frequency for R

100 Hz test frequency for L

10 KHz test frequency for L

Features and Options

General Features

max

min

and C

and C

max

min

14

Page 16

Feature

Specification

IEE-488 interface

Instrument functions can be controlled and read over this interface

Handler/sorter interface

DB male connector provides the signal lines for binning, instrument

status and input trigger.

Note: option consists of both interfaces

Kelvin clips

Provides connection to devices that are not easily accommodated by the

test fixture. Polarity is indicated for biased measurements.

SMD Tweezers

Provides connection to surface mount components

BNC fixture adapter

Connects remote fixtures or devices to the 9216A

Options

15

Page 17

Basic Operations

Chapter

3

How the 9216A Operates and What It Can Do

The 9216A LCR meter is very versatile in that the user can customize the

measurement and operating modes to obtain the best results in a particular

situation. In this chapter, the basics of the meter’s operation are summarized.

Operation of the LCR Meter For the First Time

Before using 9216A LCR Meter, ensure that it is properly installed, and powered

on.

To get the maximum accuracy for your most critical measurements you

should know how to select the various options and to set up the test conditions

and the proper use of the test fixture you have chosen to use with your meter.

Unpacking and Inspection

After unpacking the 9216A LCR Meter, verify that all parts are included and have

not been damaged during transportation. Retain the packing materials.

Packing Contents:

9216A LCR Meter

Radial Fixture

Power Cord

User Manuals

Installation

To properly install and power on the meter, perform the following steps:

Be sure you have the appropriate operating environment.

Leave a space of at least 5.1 cm (2 in) on each side of the meter for proper

ventilation.

Check the fuse for proper type and rating.

Check for proper electrical connections.

Connect the proper power cord to the power connector on the rear panel.

16

Page 18

Startup Procedures

When turned on, the meter will first enter the self-test mode and perform the

following procedure: first, it will display the program version “0X” and the model

number “HC9216” for about three seconds. Next, the meter will display “test” and

“…..” while it performs the self-test. If all tests are successful, “test pass” will be

displayed as a result. In order for the self-test to operate correctly, it is important

to follow certain startup procedures.

Before Applying Power

Prior to turning the unit on, be sure there are no components in the input fixture.

Components in the fixture will cause the self-test to fail and display an error code.

Before Using the Test Fixture

When the self-test is completed, “over range” will be displayed, and the user can

proceed to set up the test conditions and to make measurements. For maximum

accuracy, however, a “null calibration” of the test fixtures needs to be performed

before taking any measurements.

Fixture Options

On the front panel of the instrument there are four BNC connectors designated IL,

PL, PH, IH. In what is known as a “4-wire Kelvin connection,” two of these

terminals provide current to and from the device under test, and two of the

terminals sense the potential (voltage) across the device. Separate wires are

used for sensing the voltage so to minimize the effect of the current in the sensing

wires inside the meter and to minimize stray impedance that can cause

measurement errors.

There are several fixtures available for special measurements: Radial fixture

(standard), Kelvin clips, SMD tweezers, and BNC adapter. The optional fixtures

may be purchased through our distributors.

The standard 9216A test fixture attaches to the four input terminals on the front

panel of the meter and provides two polarized, spring-loaded connection slots to

secure radial-leaded components under test while they are being measured. The

fixture also accommodates axial-leaded components whose leads are bent to

enable insertion into the fixture. Most components will plug into this test fixture,

thereby eliminating the need for special fixtures.

17

Page 19

Null Calibration Procedure

Whenever the test configuration is changed, including a change of the fixture,

open and short circuit “null” calibrations should be made prior to taking

measurements to compensate for stray impedances, such as component lead

impedance, and fixture, cable and other stray capacitance. Null calibration should

be performed after any change in fixture configuration or for changes in the drive

amplitude. This calibration corrects for all frequencies and all ranges-it is not

necessary to re-calibrate for changes in frequency. For critical measurements,

null calibration should be performed frequently at some interval during the course

of measurements.

The LCR meter store open and short circuit calibration data in nonvolatile

memory. These data values are stored with the STO key and recalled using the

RCL key, allowing null calibration data to be saved for different fixtures.

The null calibration procedure is on the menu that is invoked by pressing the

CAL (Calibrate) key in the SETUP group of keys on the front panel of the meter.

To perform a null calibration, press the CAL key until the message “nuLL cAL”

appears on the alphanumeric display. Pressing the ENTER key while this

message is being displayed causes the message to change to “Short cAL.”

The short-circuit null calibration is done by placing a wire in the fixture

(thereby shorting the fixture’s terminals) that is between 26 to 16 AWG (0.02" to

0.05" or 0.51 to 1.30 mm dia.). The calibration proceeds automatically after the

user presses the ENTER key and moves hands and any miscellaneous objects

away from the fixture. When the short circuit calibration is finished, the meter

prompts the user for the next operation by displaying the message “oPEn cAL.”

To perform the open-circuit null calibration, remove the shorting wire, press

ENTER and again move hands away from the fixture. When the unit has finished,

it displays the message “cAL donE.” To dismiss this message and return to a

normal display mode, press the DISP (Display) key.

Changing Test Setup Parameter Settings

When powered on, the 9216A LCR Meter initially uses the default test setup

parameters, which include selection of the automatic (AUTO) measurement

mode, and the result of the measurement is displayed on the alphanumeric

readout. For most measurements, the test conditions in the automatic mode are

sufficient. However, by pressing the parameter keys on the front panel, the user

may enter customized test setup parameter selections, and by pressing the

keypad keys, enter the desired values of test parameters. Test parameters that

are not associated with dedicated keys on the front panel or keypad, such as the

number of measurements being averaged, deviation measurements, etc., may be

entered by pressing the DISP key to enter the ENTRY mode. Table 3-1 below

shows appropriate settings for typical component values.

18

Page 20

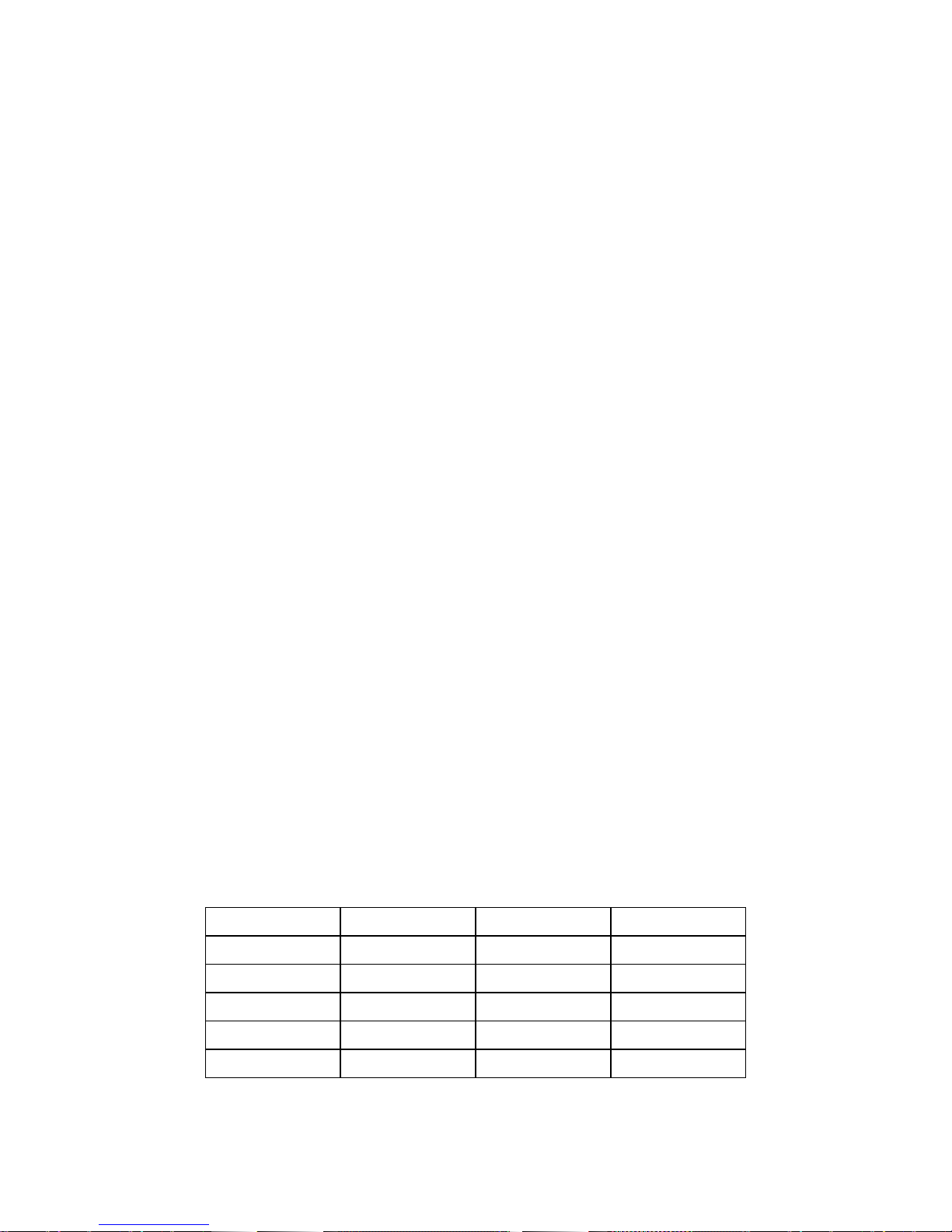

Table 3-1 Test Setup Parameter Settings for Typical Component Values.

Component

Value

Meas. Mode

Equiv. Circuit

Frequency

Unknown

Any

AUTO

Series

1 kHz

Resistor

< 1 k

> 1 k

R+Q

Series

1 kHz

100 or 120 Hz

Inductor

< 10 H

10 H–1 mH

1 mH–1H

> 1H

L+Q

Series

100 kHz

10 kHz

1 kHz

100 or 120 Hz

Capacitor

< 10 pF

10 pF–400 pF

400 pF–1 F

> 1 F

C+D

C+D

C+D

C+R or C+D

Parallel

Series or parallel

Series

Series

10 kHz

10 kHz

1 kHz

100 or 120 Hz

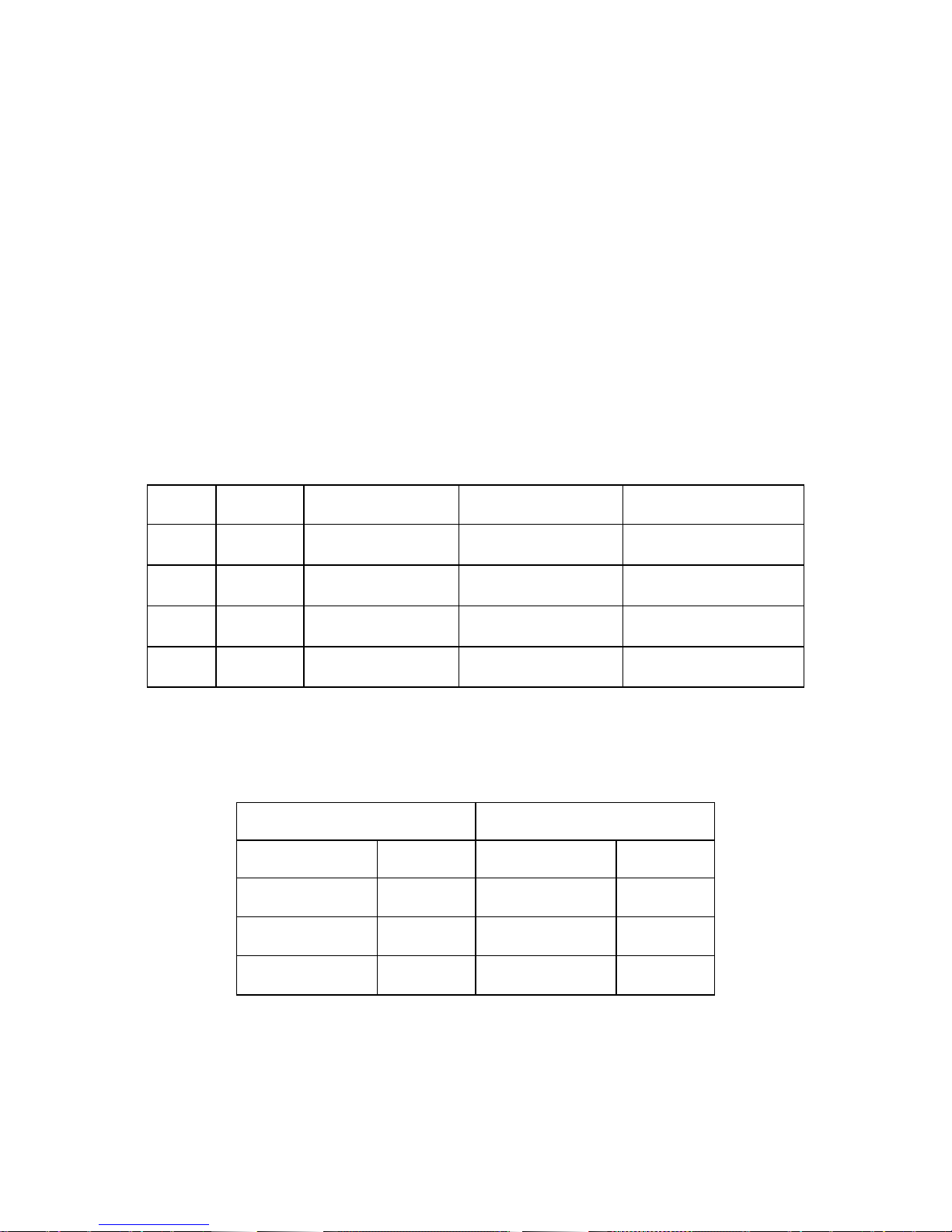

Setting

Value

Parameter

AUTO

Frequency

1KHz

Drive Voltage

1.0Vrms.

Bias

OFF

Measurement Rate

SLOW

Averaging

OFF

Range Hold

OFF

Equivalent Circuit

SERIES

Display

VALUE

Trigger Mode

CONT

Binning

OFF

Default Setup

Holding down the backspace key () key while turning on the power to the meter

causes the meter to have the default setup values as listed in the table below.

Note: All user calibration settings and values will be lost.

To prevent the user calibration settings from being destroyed, after turning on

the meter without pressing the backspace key, press RCL [0] ENTER. This

key sequence will reset the meter to the default settings listed in the table below

without affecting user-entered calibration values. See the sections that follow for

more details on the settings listed in the table below.

Table 1-1: 9216A default settings

19

Page 21

Changing, Storing, and Recalling Custom Setups

Measurement Mode

The measurement mode is selected by pressing one of the four keys in the

PARAMETER group of keys on the front panel.

AUTO In this mode, the meter automatically selects the most appropriate

measurement on the device. The selection is made according to the following

criteria:

If |Q| < 0.125, the meter selects the R+Q measurement mode.

If Q > +0.125, the meter selects the L+Q measurement mode.

If Q < 0.125 and the meter is in the series equivalent circuit mode, the

C+R measurement mode is selected.

If Q < 0.125 and the meter is in the parallel equivalent circuit mode, the

C+D measurement mode is selected.

R+Q In this mode, resistance is displayed on the main parameter display and the

Q (quality factor) is displayed on the secondary parameter display. The R-value

is either the series or parallel equivalent resistance of the component under test.

The unit for R is , k, or M. The Q value is the dimensionless ratio of the

imaginary part of the component’s impedance to its real part. If Q has a positive

(+) value, the reactive component of the device under test is inductive. If Q has a

negative () value, it is capacitive.

L+Q In this mode, the series or parallel equivalent inductance value of a

component under test is displayed on the main parameter display units in units of

µH, mH, or H, and its dimensionless Q value is displayed on the secondary

parameter display.

C+D In this mode, the series or parallel equivalent capacitance value of a

component under test is displayed on the main parameter display in units of pF,

nF, or µF. On the secondary parameter display, the dimensionless ratio D 1/Q

is given. D is normally a small value for a good capacitor.

C+R In this mode, the capacitance is displayed on the main parameter

display and the equivalent resistance is displayed on the secondary parameter

display. The unit for resistance is unless the k indicator LED is lit.

Frequency

The output frequency is accurate to 100ppm (0.01%). Frequencies are set by

pressing the up/down keys () on the front panel keypad until the LED

corresponding to the desired frequency is illuminated. If the meter is on range

hold on Range 0, the 100 kHz frequency selection is disabled. If 100 kHz is

selected while in Range 0, the meter will beep and “r-f error” (range frequency

error) will be appear on the alphanumeric display. For more details, see the

section on Range.

20

Page 22

Drive Voltage

The 9216A meter has three fixed output rms voltages, 0.1 V, 0.25 V and 1.0 V.

These voltages are selectable from the front panel. A variable rms voltage is also

available, which is adjustable from 0.1 V to 1.0 V with 50 mV resolution. The

accuracy of the voltage levels is 2% or greater. To select a fixed voltage, press

and release the VOLT key located in the DRIVE VOLT section on front panel

keypad until the LED indicates the desired voltage.

To set the variable output voltage:

1. Press the CAL keypad button. The DISP LED will indicate the ENTRY

mode. On the alphanumeric display, “vtest” and the current voltage will be

shown.

2. Enter the desired output voltage from the numeric keypad (0.1 to 0.9 may

be entered) and press ENTER (M H µF key).

3. The output voltage may be set in 50mV steps. NOTE: If the drive voltage

is a value other than one of the three fixed voltages the CONS LED will light .

The output voltage is applied to the device under test through a source

impedance. Thus, the voltage across the device is always less than or equal to

the output drive voltage. The available source impedances for the four auto

ranging selections made by the meter are 25 (Range 3), 400 (Range2), 6.4

k (Range 1) and 100 k (Range 0), all of which are accurate to 2%. The

source impedance is automatically selected as a function of the measurement

range, unless the unit is in the constant voltage mode. In the constant voltage

mode, the source impedance is always 25 . See the section on Range for

determining which measurement range the meter is using.

Figure 3-1 shows the voltage across the Device Under Test (DUT) vs. the

DUT impedance for the different measurement ranges. The values are

normalized to a 1.0-V output drive setting for different applied voltages; that is, the

Figure plots the normalized voltage across the DUT, given by

(V

DUT/Vsource

) = R

DUT

/(R

source

+ R

DUT

)

Note that the voltage applied to the DUT is nearly equal to the output voltage at

the upper end of each range and decreases due to lower impedance toward the

lower end of the range. This is because of the impedance of the voltage source.

If the meter is in the constant voltage (CV) mode, the source impedance is always

set to 25 . For any DUT with impedance significantly larger than 25, the

voltage across the part is essentially equal to the output drive voltage.

For most devices, including resistors and capacitors, and for many inductors,

the 1.0 Vrms setting is the most appropriate setting. For some inductors and for

semiconductor or active devices, such as diodes and transistors, the 0.25 or 0.1

Vrms setting should be used. Certain devices require a specific test voltage, such

as Z5U ceramic disk capacitors (test voltage = 0.5 Vrms). In these cases, use a

variable voltage setting to obtain the exact voltage required. In general, use the

largest voltage possible for the best signal-to-noise ratio and accuracy.

21

Page 23

Figure 3-1. Normalized Voltage Across DUT vs. DUT Impedance

Bias

Internal or external DC bias voltages can be applied to capacitors. Electrolytic

and tantalum capacitors need a positive bias for accurate measurements,

although the meter bipolar test voltage will not typically be enough to damage

them. The 2 VDC internal or up to 40 VDC external bias voltage allows

measurements to be made while approximating actual operating conditions. The

external bias capability also allows C-V measurements to be made on

semiconductor devices.

Notice: Always be certain that the capacitor being tested is inserted with the

correct polarity. The bias voltage is always positive to the right and is marked on

the meter. Failing to observe the correct polarity can result in the destruction of

the component under test and possibility injury. Beware that capacitors can hold

their charge for a long time if removed from the fixture without discharging the DC

bias voltage.

Warning: Care must be taken to discharge the capacitor after making

measurements, especially when using a high external bias voltage. Failing to

discharge the device can result in damage to the device, damage to the meter, or

possible injury. The meter is protected internally against discharging capacitors

with up to 1 joule of stored energy (C*V/2).

The internal and external bias circuitry will work only if the unit is in the C+D or

C+R mode. Bias voltage cannot be applied if the meter is in the R+Q, L+Q or

AUTO mode.

The error message “bias for c” will appear if the bias button is pressed in an

inappropriate mode. Whenever the bias circuitry is active, the meter is in the

constant voltage mode, so that the voltage across the capacitor under test will

22

Page 24

stabilize in a reasonable amount of time. See the section on the constant voltage

mode for effects on ranges and accuracy.

It will take a short while for the internal circuitry and the DUT to stabilize after

applying the bias voltage. The time is primarily determined by the RC time

constant of the source resistance and the capacitor under test, plus the internal

AC coupling capacitor of 0.47 F. During this time, the reading on the meter may

change if it is continuously triggered. In this case, the initial readings should be

disregarded. If this is a problem, use the triggered mode (simply wait a short time

before triggering) or increase the settling time. See the section on measurement

rate for information on how to set the settling time. In addition, the capacitance of

some capacitors will slowly drift after a change in DC voltage.

Internal Bias

To apply the 2.0V DC internal bias voltage to the capacitor under test, first verify

that the capacitor is connected to the test fixture with correct polarity (positive to

the right). Press the INT key to apply the bias voltage. After a second or two, the

reading should be stable. Before removing it from the fixture, press the INT key a

second time to switch off the bias in order to discharge the capacitor.

External Bias

The meter has rear panel connectors to allow an external bias voltage of up to

+40 VDC to be applied across the capacitor under test. This supply must be

floating (neither side connected to ground) and must be current limited to less

than 250mA. A linear supply is recommended (instead of a switching supply).

The supply should be well filtered, to remove ripple from the bias voltage.

Connections to the bias supply are made on the rear panel with two banana jacks.

The red jack is the positive side of the supply and the black, the negative. There

is an internal diode within the unit to prevent a negative voltage from being

applied. The bias supply lines are fused with a 250mA fuse on the rear panel,

next to the banana jacks. If the meter does not yield stable readings when the

external bias switched is on, check this fuse. If the bias supply is connected

backwards, there is a good chance that the bias supply fuse will blow. Provisions

are needed to discharge the bias voltage from the capacitor under test before

removing it from the fixture. In general, external switches or discharging resistors

should be provided along with the bias supply to ensure safe operation.

To apply an external bias voltage, ensure that the bias supply is connected

correctly. Verify that the capacitor is installed with the correct polarity in the test

fixture (positive to the right). Next press EXT button to apply the bias voltage.

After a second or two, the reading should be stable. After the measurement is

complete, discharge the capacitor under test before removing it from the fixture.

For occasional nonproduction use with small capacitors (<500 µF) and low

bias voltages (<20 VDC), the meter can discharge the capacitor internally. Press

the EXT button to switch off the bias. The capacitor will then discharge through

the meter in the same manner as the internal bias.

23

Page 25

Another solution for somewhat larger bias voltages and/or capacitors is to

Frequency

Slow

Medium

Fast

100KHz

2.8

14

28

10KHz

2.8

14

27

1KHz

0.7

13

24

120Hz

0.7

2.8

7

100Hz

0.6

2.4

6

connect a resistor across the terminals of the bias supply. Switch off the bias

supply and allow the capacitor to discharge through the resistor before removing

it from the fixture. Make certain the discharge resistor is rated to handle the

steady state current that the bias voltage will generate through it and that the

supply can provide this additional current. For larger capacitors or higher supply

voltages it will be necessary to provide external switches to remove the bias

voltage and discharge the capacitor.

Measurement Rate

The 9216A has three measurement rates, which are selected by pressing the

Rate button. Slow, medium or fast rate may be selected. Table 3-2 lists the

maximum measurement rates attainable when the meter is not in the auto-range

mode, binning is disabled, and the RS232 interface is active. The measurement

affects the accuracy with slow and medium being the most accurate and fast

being the least accurate.

The actual measurement time can be calculated from the following equation:

T

= Ts + (Ni /f + Tdi + Trs + Td) Nm+ T

meas

calc

where Ts = settling time, Ni = number of test frequency cycles used in the

measurement, f = test frequency, Tdi = deintegration time, T

delay time, Nm = number of submeasurements per measurement, and T

calculation time. Tdi, Td and T

are constants, while Trs and f are set by the

calc

= resync time, Td =

rs

calc

=

measurement frequency. Ni and Nm are determined by the measurement rate

and Ts can be set by the user. See Table 3-3 for the appropriate values.

In addition to these factors, the measurement time is increased when using

auto ranging, binning RS232 interface. Binning adds about 2.5 ms to the total

measurement time. Autoranging adds n*(T

range changes required and T

is calculated according the equation given

meas

1 ms) where n = number of

meas

above.

It is difficult to determine the exact amount of time added when using RS-232

interfaces, since it is dependent on baud rate, the speed of the computer, and the

software. It takes about 5 ms for the meter to respond to send back over the

interface. In general, simple commands and responses like

Table 3-2 Measurement Rates (Number of Measurements/Sec)

24

Page 26

Table 3-3: Table for appropriate values

Variables

Appropriate Values for Variables

Nm

Slow

8

Medium

8

Fast

5

Ni

100/120Hz

1KHz

10KHz

100KHz

Slow

20

40

400

4000

Medium

4

4

40

400

Fast

2

2

20

200

Txx

Trs

Tdi

Td

T

calc

Ts 1/f

2 ms

2 ms

3 ms

2–99 ms

setting the frequency or checking what range the meter is on, can be returned in

about l0 ms. Longer responses, like XALL?, can take as long as 2 seconds over

the RS-232. If communications speed is critical, the binary data format, which

reduces the number of bytes transferred, can be used.

Settling Time

Occasionally it is advantageous to delay making a measurement after the meter

is triggered. This allows bias voltages on capacitors to stabilize or contacts on a

handler to debounce. The settling time is set in 1ms intervals from 2 to 99 ms.

To set the settling time,

1. Press the CAL key until the “settle” message appears in the left

alphanumeric display and the present settling time, in the right display.

2. Enter the new settling time value, from 2 to 99.

3. Press the ENTER key.

If an illegal value is entered, the meter will beep and display “range error.”

Triggering

The 9216A can make measurements continuously or in response to a trigger. To

change the trigger mode:

1. Press the MODE key in the TRIGGER group of front panel keys until the

desired mode LED is on; either CONT or TRIGGERED may be selected.

2. In the continuous mode, the meter will trigger itself at its maximum

measurement rate. In the trigger mode, the trigger can be from the TRIG

button or from the RS232 or Handler interface.

The TRIG LED will flash whenever the TRIG key is depressed and the meter will

make a single measurement.

25

Page 27

Note: When making a measurement, the meter will ignore any triggers it

receives until the current measurement is complete.

Store and Recall

The STO and RCL buttons allow nine complete instrument setups to be saved in

nonvolatile memory. All the test conditions, including binning, configuration and

open short circuit compensation, are saved.

To store a setup,

1. Press the STO button, which will display the “store” message.

2. Press the number where the setting is to be stored ([1]–[9]), then press the

ENTER button.

To recall a stored setting,

1. Press the RCL button, which will display “rcl”.

2. Press the number where the setting is stored ([1]–[9]), and then press the

ENTER button

Notes: 1. STO 0 ENTER will give an error since the factory default setting is

stored in location 0.

2. RCL 0 ENTER returns the default setup, including null calibration

values.

3. If a “cal error 4” appears during the self-test, or a “rcl error” message

appears when recalling a setup, the stored setup was lost and must be re-

entered.

Range

The meter has four measurement ranges, designated by the numbers 0 to 3. The

range may be selected manually or the meter cans auto range. Table 3-4

specifies the impedance ranges for each of the measurement ranges. Each of

the four ranges has a source impedance of approximately the mid-scale

impedance. Note that the measurement ranges determine an impedance range

(not a parameter value range), so the ranges of inductance and capacitance

depend upon the test frequency. The parameter f is the test frequency. In

addition, the impedance of a capacitor is inversely proportional to its capacitance,

so larger capacitors are measured in the lower impedance ranges.

Table 3-4: Measurement Range and Impedance Range

Range Source R Resistance Inductance Capacitance

3 25.0 10 –100.0 0.0001 H–(15.9/f) H 99999 F–(1.59/f) mF

2 400 100.0 –1.6 k (15.9/f) H–(255/f) H (1.59/f) mF–(99.5/f) F

1 6.4 1.6 k–25.6 k (255/f) H–(4074/f) H (99.5/f) F–(6.22/f) F

0 100 k 25.6 k–2000 M (4074/f) H–99999H (6.22/f) F–0.0001pF

* f is test frequency

26

Page 28

Autoranging Mode

During normal operations, the meter automatically changes to the most accurate

range for the device under test. When the meter measures an impedance that is

out of its current range, it goes up or down one range, and makes another

measurement. If this measurement is within the current range, it displays it. If not,

it changes ranges (if available), and repeats this process. There is built-in

hysteresis to avoid repeated range changes when a component is on a range

boundary. Up-range changes occur when the impedance measured exceeds

450% of the mid-scale impedance (i.e, the source impedance), or 12.5% over the

nominal range limit. Down-range changes occur when the measured impedance

drops below 22% of the mid-scale impedance, or 12.5% below the nominal range.

See Table 3-5 for the actual values where the range changes occur.

Table 3-5 Range Change Points When Autoranging

Ranging To Lower Impedances Ranging To Higher Impedances

Range Change Impedance Range Change Impedance

2 to 3 Z < 88 3 to 2 Z > 115

1 to 2 Z < 1.4 k 2 to 1 Z > 1.8 k

0 to 1 Z < 22.4 k 1 to 0 Z > 29.9 k

RANGE HOLD Mode

It is sometimes desirable to disable auto ranging since it takes nearly a complete

measurement cycle each time a range changes occurs. This can be annoying if

there are no parts in the fixture and the meter is continuously triggering, since an

empty fixture appears as a very large (nearly infinite) impedance. The meter will

auto range to range 0 (range 1 for 100 kHz) and then auto range back to the

appropriate range when a part is inserted in the fixture. Range holding is helpful if

measurement speed is a concern or if a number of parts with similar values are

being measured.

There are two ways to implement a RANGE HOLD mode:

1. The present measurement range can be held simply by pressing the

HOLD key. The LED above the HOLD key indicates that the meter is in the

RANGE HOLD mode.

2. A measurement range can also be directly entered from the ENTRY

display. Select the ENTRY display using the DISP key, then press HOLD.

The message “range” will appear in the left display, and the present range, 0–

3, will appear in the right display. Enter the desired range and press the

ENTER button.

Use the DISP key to return to the desired display. The RANGE HOLD LED will

be on. If an invalid range is entered, the meter will beep and display the message

“range error” and not accept the range entry. Range 0 cannot be entered when

the frequency is set to 100kHz. If this is attempted, the meter will beep and

display an “r-f error” (range-frequency error). To return the meter to the auto

ranging mode, simply press the HOLD button.

27

Page 29

Constant Voltage (CONS) Mode

Range

Source R

Resistance

Inductance

Capacitance

3

25.0

10 µ–360

.0001 µH–(57/f) H

99999 µF–(442/f) mF

2

25.0

360 –5.76 k

(57/f) H–(917/f) H

(442f) mF–(27.7/f) µF

1

25.0

5.76 k–90.0 2k

(917f) H–(1432/f) H

(27.7/f) µF–(1.77/f) µF

0

25.0

90.0 k–2000 M

(1432/f) H–99999 H

(1.77/f) µF–0.0001 pF

Ranging to a Lower Impedance

Ranging to a Higher Impedance

Range to Change

Impedance

Range to Change

Impedance

2 to 3

Z< 315

3 to 2

Z< 400

1 to 2

Z< 5.04K

2 to 1

Z< 6.4K

0 to 1

Z<78,.8K

1 to 0

Z<100K

Occasionally, a test will require using a specific drive voltage that is not possible

using the normal source resistance for that measurement range. In these cases,

press the CONS key and thereby set the source impedance to a fixed 25 . The

voltage across the component under test will be almost constant for all devices

with impedance substantially larger than 25. When the meter is in constant

voltage mode, the measurement range changes to avoid overloading the meter.

However, it also reduces the accuracy of the measurement by a factor of 2. See

the accuracy section in the Reference Manual for more detail. Tables 3-6 and 3-7

list the impedance ranges when using the constant voltage mode.

Under certain conditions, the “over load” message will be displayed. This

normally occurs when the unit is in the constant voltage mode with the range hold

on. To correct this, simply change to a higher impedance range, or use auto

ranging.

Table 3-6 Measurement and Impedance Ranges for Constant Voltage Mode

Table 3-7: Range change Points when Auto-Ranging in Constant Voltage Mode

28

Page 30

Series and Parallel Equivalent Circuits

1

Component

Equivalent Circuit

Q

Inductor

Series

L/R

Parallel

Rp/Lp

Capacitor

Series

1/CR

Parallel

CpR

p

1

Generally, as illustrated in Figure 3-2, any non-ideal component has a different

value for a series or parallel equivalent circuit due to the characteristics of the

component. The “quality” of an inductor is expressed by Q, the ratio of the

reactive (inductive) part of its impedance to its resistive part. The quality of a

capacitor is similarly defined, as summarized in Table 3-8. Often it is more useful

to calculate a capacitor’s “dissipative factor,” which is the inverse of its Q

. As Q

for inductors decreases towards 10 and Q for resistors or D for capacitors

increase towards 0. 1, the series and parallel circuit values begin to diverge. Most

components have an approximate value for the series equivalent circuit.

Manufacturers often specify which representation should be used when testing

their devices.

Figure 3-2 Series and Parallel Equivalent Circuits.

Table 3-8 Quality Factors for Equivalent Circuits.

Display Types

The DISP key can select one of five different types of displays. A display is

selected by repeatedly pressing the DISP key until till the LED indicates the

desired display option. These options are described as follows:

VALUE: This is the default display mode when the meter is turned on.

DEV: In the Deviation display mode, the difference between the currently

measured component value and a previously entered value is displayed. The

Deviation display is selected by repeatedly pressing the DISP key until the DEV

W. L. Everett and G. E. Anner, Communication Engineering (3rd edition), McGraw-Hill, 1956.

29

Page 31

LED is lit. The Deviation display is not available in the AUTO mode and if no

nominal value has been previously entered.

To Enter a Nominal Value,

1. Press and release the DISP key until the ENTRY LED is lit.

2. Select the measurement mode by pressing one of the keys in the

PARAMETER group of keys on the front panel.

3. The left alphanumeric display shows the currently stored nominal value.

4. Enter a new nominal value using the numeric keypad.

5. Press the appropriate enter key (Q, µH, pF, ), (k, mH, nF) or (M, H,

µF).

% DEV In this mode, the meter displays the difference between the currently

measured component value and a previously entered value as a percentage. It is

also not available in the AUTO mode or if no nominal value has been previously

been entered.

ENTRY In the ENTRY display mode, the user is permitted to enter nominal

values, measurement conditions and calibration data. If an out of range or

incorrect value is entered, the meter will beep and display a “range error”

message.

30

Page 32

1

PROTEK 9216A

Digital LCR Meter

User’s Manual

Volume 2: Reference

Table of Contents

Background on Components and Measurements ................................................................................................ 4

Definitions of Resistive and Reactive Parameters .......................................................................................... 4

Component Categories............................................................................................................................ 4

Units ........................................................................................................................................................ 5

Series and Parallel Equivalent Circuits ........................................................................................................... 5

Quality Factors ......................................................................................................................................... 6

Accuracy and Calibration ...................................................................................................................................... 8

Accuracy Specifications .................................................................................................................................. 8

General Accuracy Equation ..................................................................................................................... 8

Accuracy Equations for Specific Measurement Modes ......................................................................... 10

R + Q Accuracy............................................................................................................................... 10

Page 33

2

L+Q Accuracy ................................................................................................................................. 10

C+D Accuracy ................................................................................................................................. 10

C+R Accuracy ................................................................................................................................. 12

Accuracy When Holding a Nonoptimal Range ...................................................................................... 13

Verification of Meter Performance ................................................................................................................ 14

Functional Tests .................................................................................................................................... 14

Necessary Equipment: .................................................................................................................... 15

Front Panel Test ............................................................................................................................. 15

Self Tests ........................................................................................................................................ 15

Output Voltage ................................................................................................................................ 15

Resistance Measurement ............................................................................................................... 16

Capacitance Measurement ............................................................................................................. 16

Performance Tests ................................................................................................................................ 17

Necessary Equipment..................................................................................................................... 17

Frequency Accuracy ....................................................................................................................... 17

Amplitude Accuracy ........................................................................................................................ 17

Impedance Accuracy ...................................................................................................................... 18

Calibration Procedures ................................................................................................................................. 20

Introduction ............................................................................................................................................ 20

Calibration Enable........................................................................................................................... 20

Calbytes .......................................................................................................................................... 21

Necessary Equipment and Conditions ............................................................................................ 22

Amplitude Calibration ............................................................................................................................. 22

Frequency Calibration............................................................................................................................ 23

Standard Resistor Calibration ................................................................................................................ 24

Remote Control of the LCR Meter ...................................................................................................................... 26

Using the Interfaces ...................................................................................................................................... 26

RS232 Interface ..................................................................................................................................... 26

The RS232 Interface Standard ....................................................................................................... 26

Setting Up to Use the RS-232 Interface .......................................................................................... 27

List of Commands .................................................................................................................................. 29

Status Displays and Error Messages ........................................................................................................... 30

Definitions of Status Bytes ..................................................................................................................... 32

Serial Polling ................................................................................................................................... 31

Standard Event ............................................................................................................................... 31

Measurement .................................................................................................................................. 32

Page 34

3

Binning ................................................................................................................................................................ 33

Binning Options ............................................................................................................................................ 33

Binning Examples .................................................................................................................................. 33

Nested Bins .................................................................................................................................... 33

Sequential Bins With Different Nominal Values .............................................................................. 34

Sequential Bins With a Single Nominal Value................................................................................. 34

General Procedures .............................................................................................................................. 35

Setting Up the Bins ....................................................................................................................................... 36

Procedures ............................................................................................................................................ 36

Initial Setup ..................................................................................................................................... 36

Nominal Values for Pass Bins 0 to 7 ............................................................................................... 36

Limits for Pass Bins 0 to 7 ............................................................................................................... 36

Values for Fail Bins 8 and 9 ............................................................................................................ 36

Enable Binning ................................................................................................................................ 37

Using a Worksheet and Reusing Setups ........................................................................................ 37

Summary of Binning Setups .................................................................................................................. 38

Pass/Fail Setup ............................................................................................................................... 38

Nested or Overlapping Bins ............................................................................................................ 38

Sequential Bins ............................................................................................................................... 38

Troubleshooting .................................................................................................................................................. 39

General Problems ........................................................................................................................................ 39

Nothing Happens at Turn-on ................................................................................................................. 39

Reset Procedure ............................................................................................................................. 39

Internal Fuse Check ........................................................................................................................ 39

External Bias Fuse Check............................................................................................................... 39

Error Messages ............................................................................................................................................ 40

Operational Errors ................................................................................................................................. 40

Self-test Errors ....................................................................................................................................... 40

Calibration Errors ................................................................................................................................... 42

RS-232 Problems .................................................................................................................................. 42

9216A TEST PERFORMANCE RECORD................................................................................................... 44

Page 35

4

v

tVtV

cos||)(

tj

jtj

eeVeV

vv

||||

i

tItI

cos||)(

tj

jtj

eeIeI

ii

||||

1j

v

i

iv

i

v

j

tj

tj

e

I

V

eI

eV

tI

tV

ZZ

||

||

||

||)()(

||

||

||

||

0

I

V

e

I

V

Z

j

||

||

||

||

2/

I

V

je

I

V

Z

j

Chapter

1

Background on Components and Measurements

Properties of Resistors, Inductors, and Capacitors