Page 1

Industrial Nozzle

Style #366-BC

Corrosion resistant cast brass construction. Ideal for marine, offshore, industrial or other corrosive environments

Constant flow selectable gallonage nozzle with multi flow settings

Select flow remains constant regardless of pattern change

Multi pattern detents for positive positioning of pattern

Combination of fog and straight stream

Flush without shutting down

Standard optimum operating pressure 100 PSI(7 bar)

Conforms to all aspects of NFPA 1964 (Spray nozzles, shutoff and tips) 2003 edition

STYLE INLET LENGTH WEIGHT FLOW

LBS GPM LPM

366-BC 1-1/2” 8.5” 8.8 30-60-95-125 115-230-360-475

www. protekfire.com sales @protekf ire.com

PR OT EK

NFPA1964

COMPLIANT

Page 2

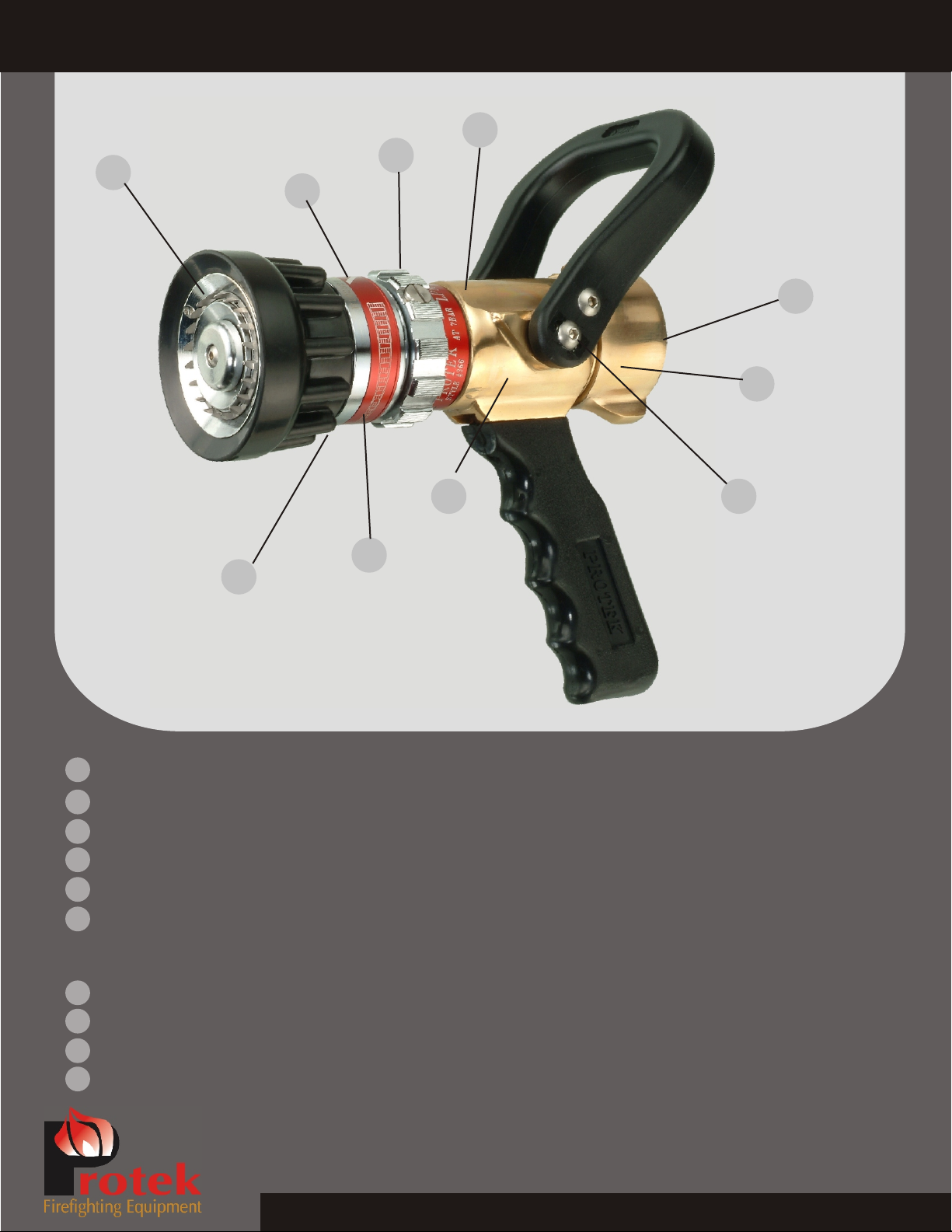

UNIQUE FEATURES ON PROTEK INDUSTRIAL NOZZLES

4

3

1

2

5

6

8

7

9

10

1

2

3

4

5

6

316 stainless steel spinning teeth ensure corrosion resistance and durability

Laser etched anodized indicating bands for long life and easy use (No stick labels to fade and come loose)

Large metal flow select ring (Easy to change flow setting even with a wet glove)

Major component made from brass (UNS C83600, ASTM B62/B584) for a long in serving life

Choice of inlet thread or connection

Stainless steel inlet screen catches solid before they enter nozzle (only things that gets through can be flushed

10

without shutting down)

7

8

9

New improved handle with two reinforced metal pieces on each side to ensure breakage free

Heavy duty chrome plated metal balls ensures a smooth action and long dependable service life

Each nozzle etched with a unique series number. Aids identification, tracks manufacturing date and warranty

Flow pattern detents gives positive positioning

www. protekfire.com sales @protekf ire.com

Loading...

Loading...