Instructions for the following series products:

LADDER CLIMBING CABLE SLEEVE

Model Numbers: See Figure 1

User Instruction Manual Cabloc Detachable Cable Sleeve

This manual is intended to be used as part of an employee training program as recommended by OSHA.

WARNING: These instructions must be provided to the user and

this

equipment must read and understand these instructions before

installer of this equipment. The user and installer of

use or installation. Follow the manufacturer’s

instructions for other safety equipment used with this system. Follow these instructions for proper use,

inspection, and

maintenance of this equipment. This product is intended to be

used as a part of a complete Cabloc

ladder safety system. Alterations, substitutions, or misuse of this equipment, or failure to follow instructions,

may result in serious injury or death.

IMPORTANT: If you have questions on the installation, use, maintenance, or suitability of this equipment for

your application, contact PROTECTA.

IMPORTANT: Before using this equipment, record the product

identifi cation information from the installation and

service label in the “Inspection and Maintenance Log” at the back of this manual.

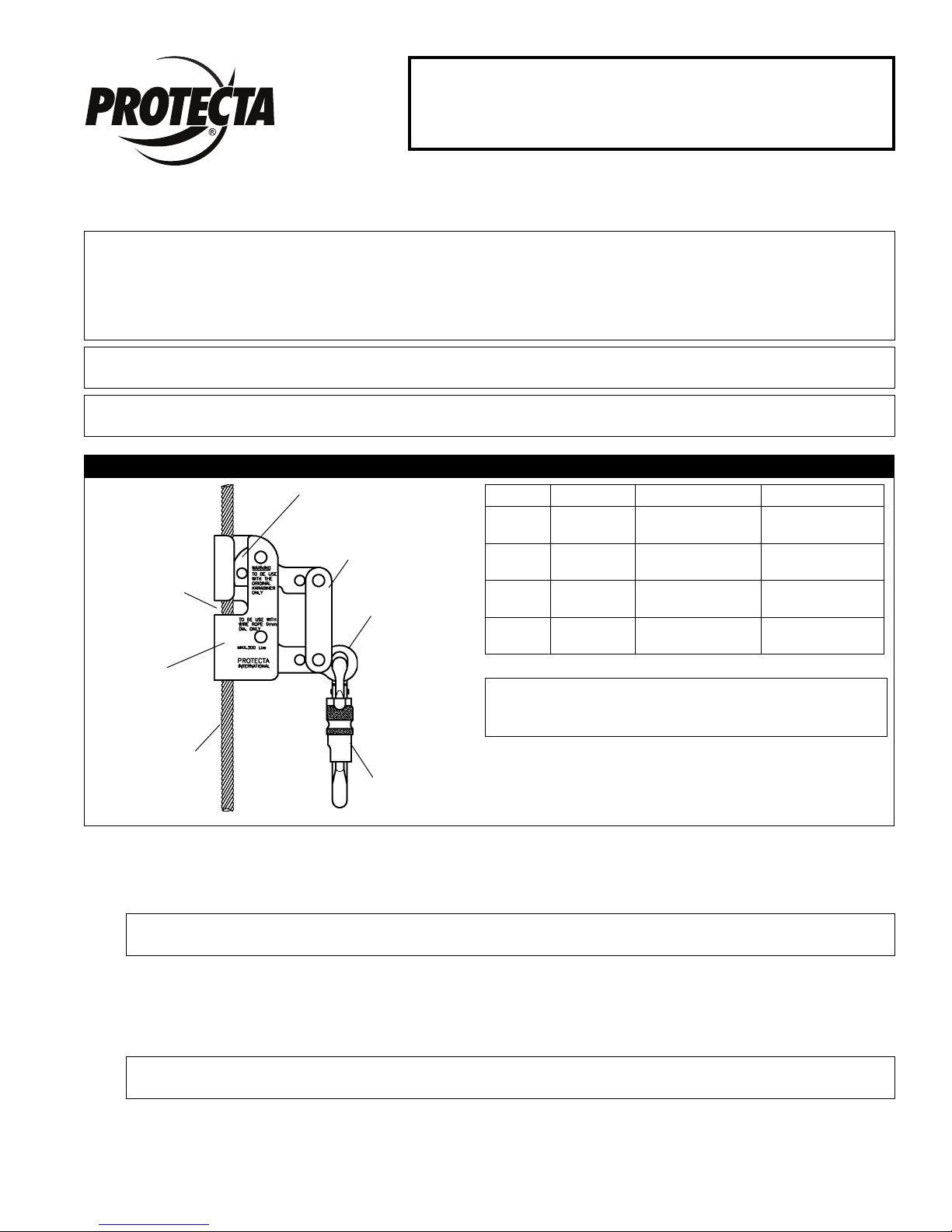

Figure 1 - Cabloc Detachable Cable Sleeves

Cable

Installation

Slot

Sleeve

Body

Cable Shoe

Brake Lever

Attachment

Point

Model Cable Dia. Safety Standard Anti-Inversion

AC350A

AC351A

AC350C

AC351C

5/16”

(8 mm)

3/8 “

(9.5 mm)

5/16”

(8 mm)

3/8 “

(9.5 mm)

ANSI A14.3

ANSI A14.3

CSA Z259.2.1

CSA Z259.2.1

√

√

7 X 19 CABLE ONLY: Cabloc Cable Sleeves shall only

be used on 7 x 19 constructed cable of the diameters

specifi ed above.

7 x 19 Constructed

Steel Cable

(Carrier Cable)

Carabiner

1.0 APPLICATIONS

1.1 PURPOSE: The Cabloc detachable cable sleeve is designed to arrest the fall of personnel while climbing a

fi xed ladder. The detachable cable sleeve is not intended to be used for material handling.

NOTE: The installer and user must ensure the ladder meets all applicable local, state, and federal

standards, including ANSI A14.3.

1.2 LIMITATIONS: Cabloc detachable cable sleeves must be used with a PROTECTA approved ladder safety

system. Use only the Cabloc Sleeve model specifi ed in Figure 1 for you applicable cable diameter and safety

standard(s). The Cabloc cable sleeve must be directly connected to an approved full body harness with the

carabiner supplied with the sleeve (see Figure 1). Do not use connection devices other than the supplied

carabiner. Do not add additional connectors or lanyards between the user and the cable sleeve.

NOTE: ANSI A14.3 and OSHA 1926.1053 states that the length of connection between the carrier cable

and

attachment point on the full body harness must not exceed 9 in. (0.2 m) in Canada per CSA Z 259.2.1-98.

1.3 Refer to applicable local, state, and federal (OSHA) requirements governing this

information on ladder safety systems and associated components, including OSHA 1910.27.

equipment for more

© Copyright 2012, Capital SafetyForm No: 5902216 Rev: F

2.0 SYSTEM REQUIREMENTS

2.1 COMPATIBILITY OF COMPONENTS AND SUBSYSTEMS: This equipment is designed for use with

PROTECTA approved components and subsystems. The use of non-approved components and subsystems

may jeopardize compatibility of equipment, and could affect the safety and reliability of the complete

system. Contact Capital Safety if you have questions about compatibility of equipment.

WARNING: Before using a Cabloc Ladder System in combination with a climb assist system, consult

the climb assist system manufacturer’s instructions for any restrictions or limitations concerning

simultaneous use of these systems. Capital Safety has found that some connection combinations may

interfere with proper operation of the Cabloc Detachable Sleeve and may result in failure to arrest a fall.

Avoid connecting the sleeve used on the Cabloc Ladder System into the same harness connection D-ring

as is occupied by the climb assist system. Ensure that movement of the arm of the Cabloc sleeve is not

restricted or interfered with by the climb assist system or its connectors. Failure to heed this warning may

result in serious injury or death.

2.2 COMPATIBILITY OF CONNECTORS: Connectors used with this system (hooks, carabiners, D-rings) must

be capable of supporting a minimum of 5,000 lbs. Use caution to assure compatibility of hooks and the

connection point. Non-compatible connectors may unintentionally disengage (roll-out). Connectors must be

compatible in size, shape, and strength. All connectors used must be self closing/self locking connectors.

3.0 OPERATION AND USE

3.1 BEFORE EACH USE: Inspect the ladder climbing system according to the manufacturer’s instructions. Do

not climb a structure that is not in good condition. Verify from the label markings that the system has been

formally inspected within the last year. Do not use a defective or improperly maintained Cabloc system.

Inspect the detachable cable sleeve according to section 5.0. Inspect your full body harness according to the

manufacturer’s instructions.

3.2 CONNECTING THE CABLOC CABLE SLEEVE TO THE CARRIER CABLE:

WARNING: The Cabloc sleeve must only be used on a vertical cable system. Do not use the cable on

angled or horizontal cable systems as the sleeve may no lock properly on the cable. In situations where a

fall hazard exists, use a back-up fall arrest system, such as a lanyard, to protect against a fall.

Step 1. Ensure the sleeve is correctly positioned relative to the carrier cable. The “up” arrow on the sleeve

must be pointing to the ascending direction. See Figure 2.

IMPORTANT: Never install the sleeve upside down on the cable.

Step 2. Remove the carabiner and pivot the handle to its full upright position. This will draw back the

cable shoe to allow insertion of the carrier cable into the sleeve housing. The sleeve design does

not allow the sleeve to be installed or removed while the carabiner is attached to the handle.

Step 3. Rotate the top of the sleeve to the right until the sleeve body is horizontal. Position the sleeve

so that the cable slides all the way into the cable installation slot. Rotate the sleeve back into a

vertical position so that the cable is captive in the cable slot.

Step 4. Allow the handle to return to its operating position. This will allow the cable shoe to contact the

cable and lock the cable in the sleeve body. Reattach the supplied Carabiner to the attachment

point of the Cabloc sleeve.

Figure 2 - Installation

Step 1 Step 2 Step 3 Step 4

2

3.3 CONNECTING THE CABLOC SLEEVE TO THE HARNESS: Use only the supplied carabiner to connect the

Cabloc to the harness. Do not substitute with other connectors. Do not use other connecting devices, such

as; lanyards, chain, links, or clevis. These types of connectors do not meet PROTECTA requirements. OSHA

and ANSI A14.3 prohibits connections between the carrier cable and the harness that exceed nine inches in

length. When connecting ensure the gate on the carabiner is closed and locked. CSA Z259.2.1-98 prohibits

the use of connectors longer than 0.2m in length.

3.4 CLIMBING ON THE SYSTEM:

Step 1. Don the appropriate full body harness according to the manufacturer’s instructions.

Step 2. Attach the Cabloc cable sleeve to the carrier cable (see section 3.2).

Step 3. Connect the Cabloc cable sleeve to the attachment point on the full body harness.

Step 4. To ascend, climb up the ladder normally. The detachable cable sleeve will follow the climber.

The carrier cable will snap out of the cable guides as the climber passes the guides. Reconnect

the carrier cable to the cable guide after passing each guide. Do not remove detachable cable

sleeve from carrier cable to pass cable guides. Use caution when climbing. Avoid carrying tools or

equipment that do not allow your hands to be free for climbing. Ensure items carried are secure

to avoid dropping on climbers below. Climb within your ability. Long climbs may require several

rest stops during ascent or descent to avoid exhaustion. Avoid climbing in high winds or severe

weather whenever possible.

Step 5. To descend, climb down smoothly in a normal position. Allow the detachable cable sleeve to

lead the climber down. Climbing down out of position (leaning back excessively) will cause the

detachable cable sleeve to lock on the carrier cable. If the detachable cable sleeve locks, move

upward slightly to release, then continue down the ladder.

4.0 TRAINING

4.1 TRAINING: It is the responsibility of the user and purchaser of this equipment to assure they are familiar

with these instructions, operating characteristics, application limits, and the consequences of improper use

of this equipment. Users and purchasers of this equipment must be trained in the correct care and use of

this equipment.

IMPORTANT: Training must be conducted without exposing the user to a fall hazard. Training should be

repeated on a periodic basis.

5.0 INSPECTION

5.1 FREQUENCY:

• Before Each Use: Visually inspect the detachable cable sleeve with the Cabloc installation according to

section 5.2 and 5.3. Inspect other system components according to manufacturer’s instructions.

• Formal Inspection: A formal inspection of the detachable cable sleeve must be performed at least

annually by a competent person1 other than the user.

• After a Fall: If a fall occurs with the detachable cable sleeve or on the Cabloc system a formal

inspection of the entire system must be performed by a competent person other than the user. See

sections 5.2 and 5.3. Record the inspection results in the “Inspection and Maintenance Log”.

5.2 INSPECTION GUIDELINES FOR CABLOC LADDER SAFETY SLEEVE:

• Inspect: the brake lever and cable shoe for bends, cracks, and deformation. Inspect the connection

point for wear or distortion. Check all surfaces for corrosion. All fasteners and rivets must be securely

attached. Operation of the brake lever and cable shoe must be free and smooth. Springs must be secure

and of suffi cient strength to pull the brake lever down. See Figure 1.

• Inspect: the sleeve body for wear on the inside where the cable passes through.

• Inspect Markings: All markings must be present and completely legible. See Figure 3.

• In Canada: ensure that the anti-inversion device is operational by turning the cable sleeve upside

down and trying to operate the brake lever. If the lever operates up and down in the inverted position,

the anti-inversion device is defective and the sleeve must be removed from service and destroyed or

returned to Protecta for repair.

5.3 IF INSPECTION REVEALS AN UNSAFE OR DEFECTIVE CONDITION: Remove the ladder safety system

or detachable cable sleeve from service and destroy or contact an authorized service center for repair.

1 Competent Person: An individual designated by the employer to be responsible for the immediate supervision, implementation, and monitoring of the

employer’s managed fall protection program who, through training and knowledge, is capable of identifying, evaluating, and addressing existing and potential fall

hazards, and who has the employer’s authority to take prompt corrective action with regard to such hazards.

3

Figure 3 - Markings

B

A

C

AC350A

A B C

AC351A

A B

AC350C

A B C

AC351C

A B C

4

6.0 MAINTENANCE, SERVICE, AND STORAGE

6.1 The Cabloc sleeve may be cleaned using commercial parts cleaning solvents and rinsed with warm, soapy

water. Light machine oil may be applied to moving parts if required. Do not use excessive oil, or allow oil to

contact cable clamping surfaces. Store the detachable cable sleeve in a cool, dry, clean environment, out of

direct sunlight. Avoid areas where chemical vapors exits. Thoroughly inspect sleeve after extended storage.

6.2 ADDITIONAL MAINTENANCE and servicing procedures must be completed by an authorized service

center. Authorization must be in writing.

7.0 SPECIFICATIONS

DETACHABLE SLEEVE:

• Material: Stainless Steel

• Breaking Strength: 5,500 lbs (24.5 kN)

• Net Weight (with Carabiner): 1.54 lbs (.70 kg)

• Cable: Galvanized Steel or Stainless Steel 7 x 19 Constructed Cable (See Figure 1 for required

diameter)

CARABINER:

• Material: High strength steel

• Breaking Strength: 5,500 lbs (24.5 kN)

5

Warranty to End User: D B Industries, Inc., dba CAPITAL SAFETY USA (“CAPITAL SAFETY”)

LIMITED LIFETIME WARRANTY

warrants to the original end user (“End User”) that its products are free from defects in materials and

workmanship under normal use and service. This warranty extends for the lifetime of the product

from the date the product is purchased by the End User, in new and unused condition, from a CAPITAL

SAFETY authorized distributor. CAPITAL SAFETY’S entire liability to End User and End User’s exclusive

remedy under this warranty is limited to the repair or replacement in kind of any defective product

within its lifetime (as CAPITAL SAFETY in its sole discretion determines and deems appropriate). No oral

or written information or advice given by CAPITAL SAFETY, its distributors, directors, offi cers, agents

or employees shall create any different or additional warranties or in any way increase the scope of

this warranty. CAPITAL SAFETY will not accept liability for defects that are the result of product abuse,

misuse, alteration or modifi cation, or for defects that are due to a failure to install, maintain, or use the

product in accordance with the manufacturer’s instructions.

CAPITAL SAFETY’S WARRANTY APPLIES ONLY TO THE END USER. THIS WARRANTY IS THE ONLY

WARRANTY APPLICABLE TO OUR PRODUCTS AND IS IN LIEU OF ALL OTHER WARRANTIES AND

LIABILITIES, EXPRESSED OR IMPLIED. CAPITAL SAFETY EXPRESSLY EXCLUDES AND DISCLAIMS

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND

SHALL NOT BE LIABLE FOR INCIDENTAL, PUNITIVE OR CONSEQUENTIAL DAMAGES OF ANY NATURE,

INCLUDING WITHOUT LIMITATION, LOST PROFITS, REVENUES, OR PRODUCTIVITY, OR FOR BODILY

INJURY OR DEATH OR LOSS OR DAMAGE TO PROPERTY, UNDER ANY THEORY OF LIABILITY, INCLUDING

WITHOUT LIMITATION, CONTRACT, WARRANTY, STRICT LIABILITY, TORT (INCLUDING NEGLIGENCE) OR

OTHER LEGAL OR EQUITABLE THEORY.

Garantie offerte à l’utilisateur fi nal : D B Industries, Inc., dba CAPITAL SAFETY USA (« CAPITAL SAFETY »)

GARANTIE LIMITÉE SUR LA DURÉE DE VIE

garantit à l’utilisateur fi nal d’origine (« Utilisateur fi nal ») que les produits sont libres de tout défaut matériel et de

fabrication dans des conditions normales d’utilisation et de service. Cette garantie couvre toute la durée de vie du

produit, de sa date d’achat à l’état neuf et inutilisé par l’utilisateur auprès d’un distributeur agréé CAPITAL SAFETY.

La responsabilité intégrale de Capital Safety et le seul recours du Client dans le cadre de cette garantie se limitent

à la réparation ou le remplacement en nature des produits défectueux pendant leur durée de vie (à la seule

discrétion de Capital Safety et selon ce qu’elle juge approprié). Aucun renseignement ou avis oral ou écrit fourni par

CAPITAL SAFETY, ses détaillants, administrateurs, cadres, distributeurs, mandataires ou employés ne représentera

une garantie ou n’augmentera de quelque manière la portée de la présente garantie limitée. CAPITAL SAFETY

n’accepte aucune responsabilité pour les défauts causés par un abus, une utilisation abusive, une altération ou une

modifi cation, ou pour les défauts causés par le non-respect des instructions du fabricant relatives à l’installation,

à l’entretien ou à l’utilisation du produit.

CETTE GARANTIE CAPITAL SAFETY S’APPLIQUE UNIQUEMENT À L’UTILISATEUR FINAL. ELLE EST LA SEULE

GARANTIE APPLICABLE À NOS PRODUITS. ELLE EXCLUT TOUTE AUTRE GARANTIE EXPRESSE OU IMPLICITE.

CAPITAL SAFETY EXCLUT EXPLICITEMENT ET DÉCLINE TOUTE GARANTIE IMPLICITE DE MISE EN MARCHÉ ET

D’ADAPTATION À DES FINS PARTICULIÈRES, ET NE SERA RESPONSABLE POUR AUCUN DOMMAGE-INTÉRÊT

DIRECT OU INDIRECT, CORRÉLATIF OU ACCESSOIRE DE TOUTE NATURE Y COMPRIS ET DE MANIÈRE NON

LIMITATIVE, LES PERTES DE PROFITS, LES REVENUS OU LA PRODUCTIVITÉ, LES BLESSURES CORPORELLES,

VOIRE LA MORT OU DOMMAGES À LA PROPRIÉTÉ, DANS LE CADRE DE TOUTE THÉORIE DE RESPONSABILITÉ, Y

COMPRIS ET DE MANIÈRE NON LIMITATIVE UN CONTRAT, UNE GARANTIE, UNE RESPONSABILITÉ (Y COMPRIS LA

NÉGLIGENCE) OU TOUTE AUTRE THÉORIE LÉGALE OU ÉQUITABLE.

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

A Capital Safety Company

CSG USA & Latin America

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

solutions@capitalsafety.com

CSG EMEA

(Europe, Middle East, Africa)

Le Broc Center

Z.I. 1ère Avenue

5600 M B.P. 15 06511

Carros

Le Broc Cedex

France

Phone: + 33 4 97 10 00 10

Fax: + 33 4 93 08 79 70

information@capitalsafety.com

CSG Canada

260 Export Boulevard

Mississauga, ON L5S 1Y9

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

info.ca@capitalsafety.com

CSG Australia & New Zealand

95 Derby Street

Silverwater

Sydney NSW 2128

AUSTRALIA

Phone: +(61) 2 8753 7600

Toll-Free : 1 800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

Fax: +(61) 2 87853 7603

sales@capitalsafety.com.au

www.capitalsafety.com

ISO

9001

Certificate No. FM 39709

CSG Northern Europe

5a Merse Road

North Moons, Moat

Reditch, Worcestershire, UK

B98 9HL

Phone: + 44 (0)1527 548 000

Fax: + 44 (0)1527 591 000

csgne@capitalsafety.com

CSG Asia

Singapore:

16S, Enterprise Road

Singapore 627666

Phone: +65 - 65587758

Fax: +65 - 65587058

inquiry@capitalsafety.com

Shanghai:

Rm 1406, China Venturetech Plaza

819 Nan Jing Xi Rd,

Shanghai 200041, P R China

Phone: +86 21 62539050

Fax: +86 21 62539060

Loading...

Loading...