Page 1

USER’S

MANUAL

PA-6222

12” Waterproof True Flat

Touch POS Terminal

Powered by Intel® Celeron®

J1900 Quad-Core

PA-6222 M2

Page 2

PA-6222

12” Waterproof True Flat

Touch POS Terminal

Powered by Intel® Celeron®

J1900 Quad-Core

COPYRIGHT NOTICE & TRADEMARK

All trademarks and registered trademarks mentioned herein are the property of their

respective owners.

This manual is copyrighted in Feb. 2017. You may not reproduce or transmit in any

form or by any means, electronic, or mechanical, including photocopying and

recording.

DISCLAIMER

This user’s manual is meant to assist users in installing and setting up the system. The

information contained in this document is subject to change without any notice.

CE NOTICE

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Page 3

FCC NOTICE

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

You are cautioned that any change or modifications to the equipment not expressly

approve by the party responsible for compliance could void your authority to operate

such equipment.

CAUTION! Danger of explosion if battery is incorrectly replaced. Replace only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

WARNING! Some internal parts of the system may have high electrical voltage. And

therefore we strongly recommend that qualified engineers can open and disassemble the

system. The LCD and Touchscreen are easily breakable, please handle them with extra

care.

Page 4

Contents

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

1-1 About This Manual…...................................................................

2

1-2 POS System Illustration…............................................................

3

1-3 System Specifications...................................................................

5

1-4 Safety Precautions…....................................................................

9

CHAPTER 2 SYSTEM CONFIGURATION

2-1 System External I/O Port & Pin Assignment……………………

11

2-2 Main Board Component Locations & Jumper Settings………….

16

2-3 VFD Board Component Locations & Pin Assignment.................

31

2-4 MSR Board Component Locations & Pin Assignment.................

33

2-5 Secondary Cash Drawer...............................................................

35

CHAPTER 3 SOFTWARE

3-1 Driver……..…..............................................................................

38

3-2 Embedded Peripheral Devices………..........................................

44

3-3 API………………………………................................................

70

3-4 BIOS Operation….……...............................................................

78

3-5 Watchdog Timer Configuration…………………………………

114

3-6 BIOS Update Instructions……………………………………….

117

3-7 System Resource Map…………………………………………...

121

CHAPTER 4 SYSTEM DIAGRAMS

Exploded Diagram for Cable cover..……………………………………

138

Exploded Diagram for Storage….………………………........................

139

Exploded Diagram for Back Cover………………………......................

140

Exploded Diagram for LCD & Touch Panel…………………..………..

143

Exploded Diagram for Inside Case……………………….......................

145

Exploded Diagram for MSR……...………………………......................

147

Exploded Diagram for 2nd Display…...……………………....................

149

Exploded Diagram for Stand………………............................................

150

Exploded Diagram for PPC Packing……………....................................

152

Exploded Diagram for POS Packing……………....................................

154

Exploded Diagram for Stand Packing……...……...................................

155

Page 5

PA-6222 SERIES USERS MANUAL

Page: 1

INTRODUCTION

This chapter gives you the information for the PA-6222. It also outlines

the system specifications.

Sections included:

About This Manual

POS System Illustration

System Specifications

Safety precautions

Experienced users can jump to chapter 2 on page 2-1

for a quick start.

CHAPTER

1

Page 6

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 2

1-1. ABOUT THIS MANUAL

Thank you for purchasing our PA-6222 Series System. The PA-6222 is an updated

system designed to be comparable with the highest performance of IBM AT personal

computers. The PA-6222 provides faster processing speed, greater expandability and

can handle more tasks than before. This manual is designed to assist you how to install

and set up the whole system. It contains four chapters. Users can configure the system

according to their own needs.

Chapter 1 Introduction

This chapter introduces you to the background of this manual. It also includes

illustrations and specifications for the whole system. The final section of this chapter

indicates some safety reminders on how to take care of your system.

Chapter 2 System Configuration

This chapter outlines the location of motherboard, printer, VFD, MSR components

and their function. You will learn how to set the jumpers and configure the system to

meet your own needs.

Chapter 3 Software

This chapter contains detailed information for driver installations of the Intel® Utility,

VGA, LAN, Sound, Touch Screen, embedded peripheral devices, BIOS setup &

update, Watchdog timer and resource map.

Chapter 4 System Diagrams

This chapter shows the exploded diagrams and part numbers of PA-6222 components.

Page 7

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 3

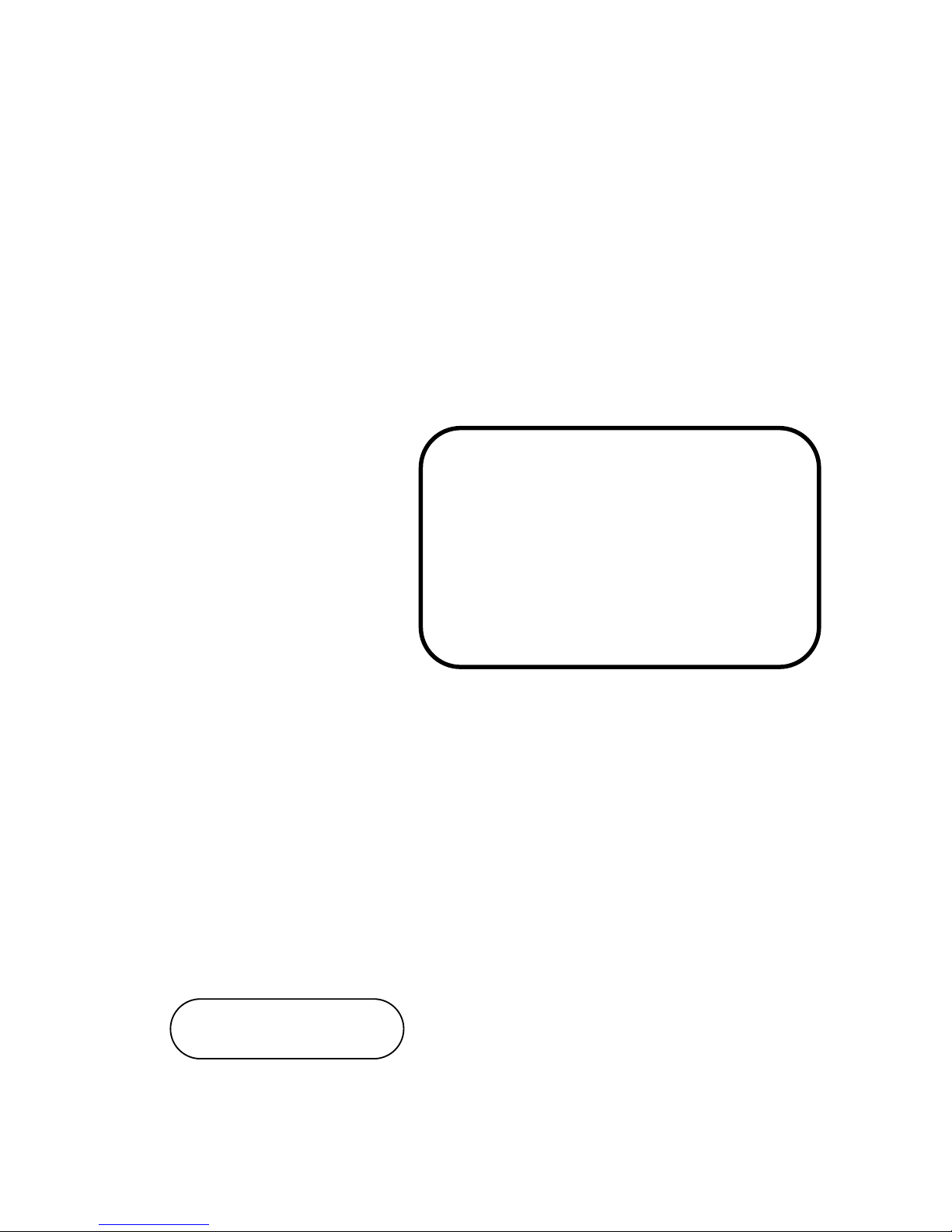

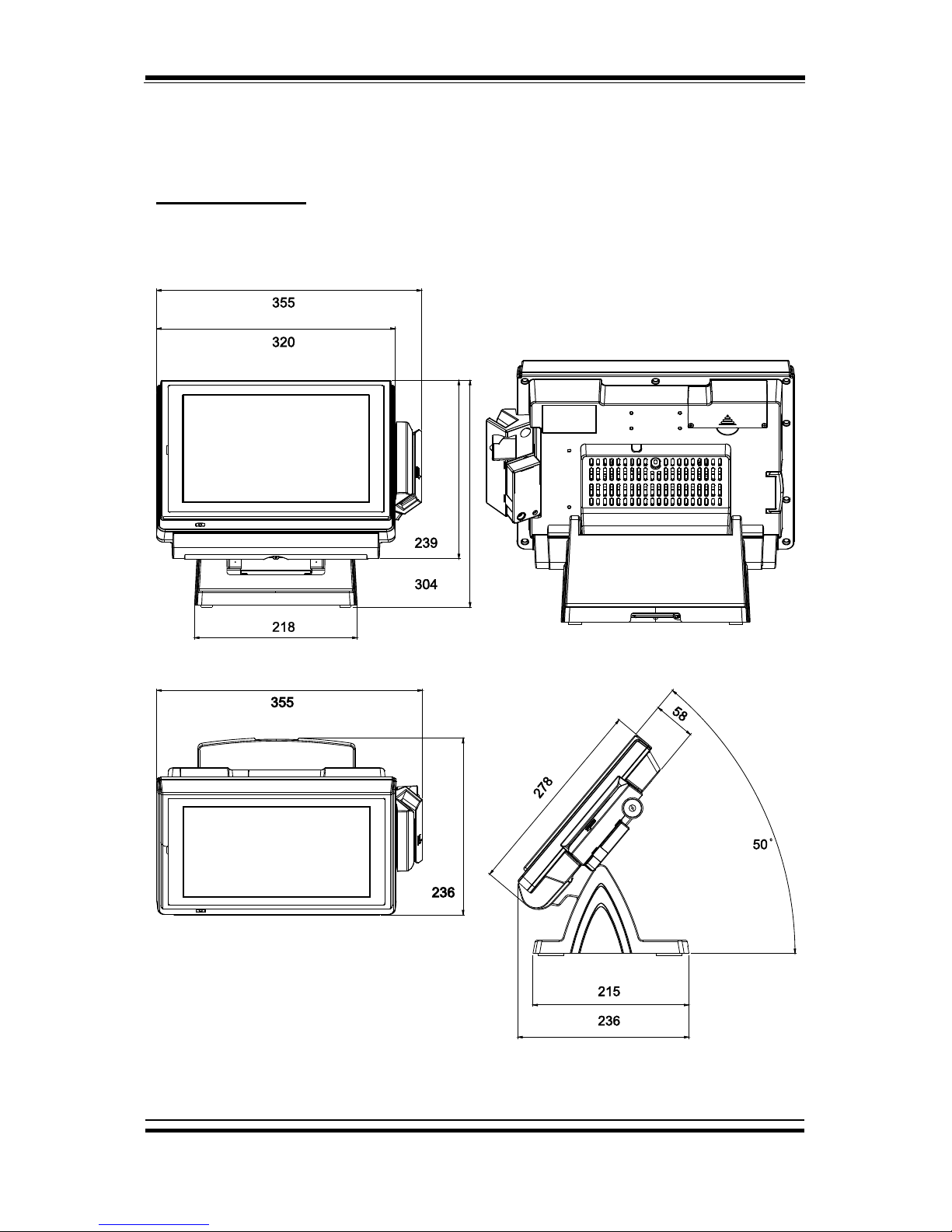

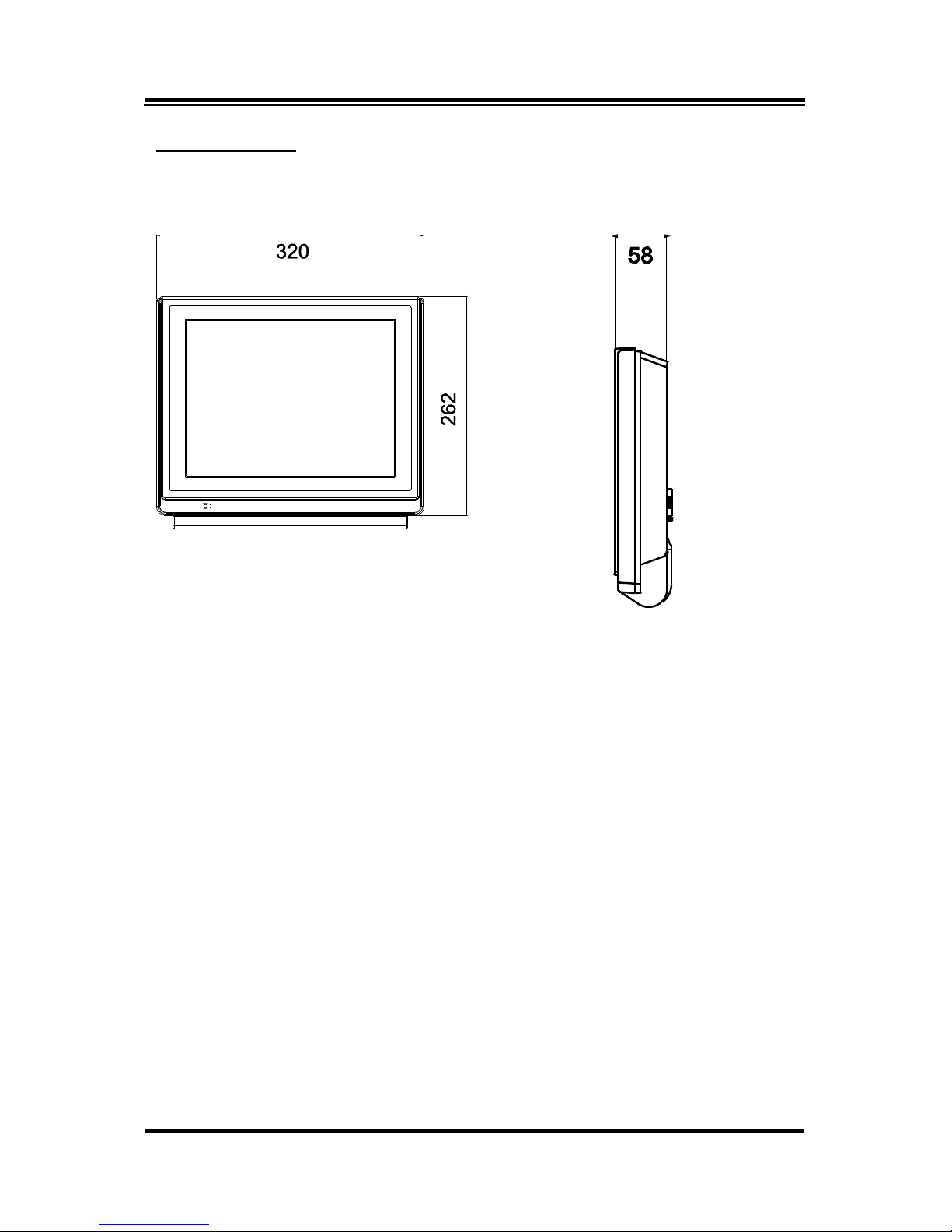

1-2. POS SYSTEM ILLUSTRATION

Small stand type

Front View

Rear View

Top View

Side View

Unit: mm

Page 8

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 4

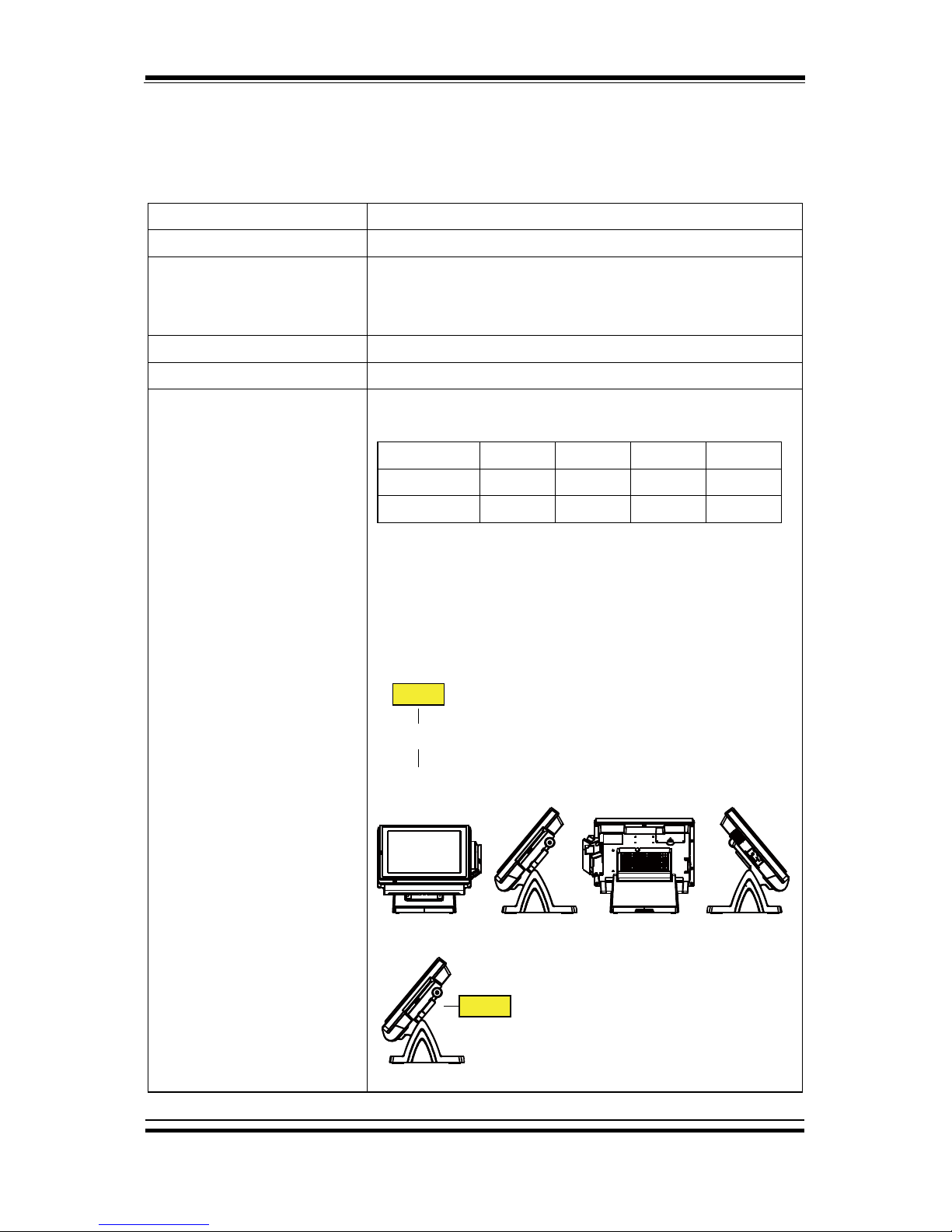

Stand-less type

Front View

Side View

Unit: mm

Page 9

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 5

1-3. SYSTEM SPECIFICATIONS

System

CPU

Intel® Celeron® J1900

Memory

DDR3L SO-DIMM(up to 8GB)

OS Support

Windows POSReady7

Windows 8.1

Windows 10 IoT Enterprise LTSB 2016

LAN

1 x RJ45

VGA

1 x DB-15

Wireless LAN (Optional)

802.11 b/g/n

AP distance

0˚

90˚

180˚

270˚

5M

-48 dB

-45 dB

-49 dB

-43 dB

10M

-46 dB

-50 dB

-52 dB

-50 dB

Note:

1. Test tolerance: ± 5dB

2. AP: ASUS RT-N56U (2 x internal antenna with 3.8

dBi gain)

Angle: 0° Angle: 270°Angle: 180°Angle: 90°

AP

(Distance)

AP

Page 10

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 6

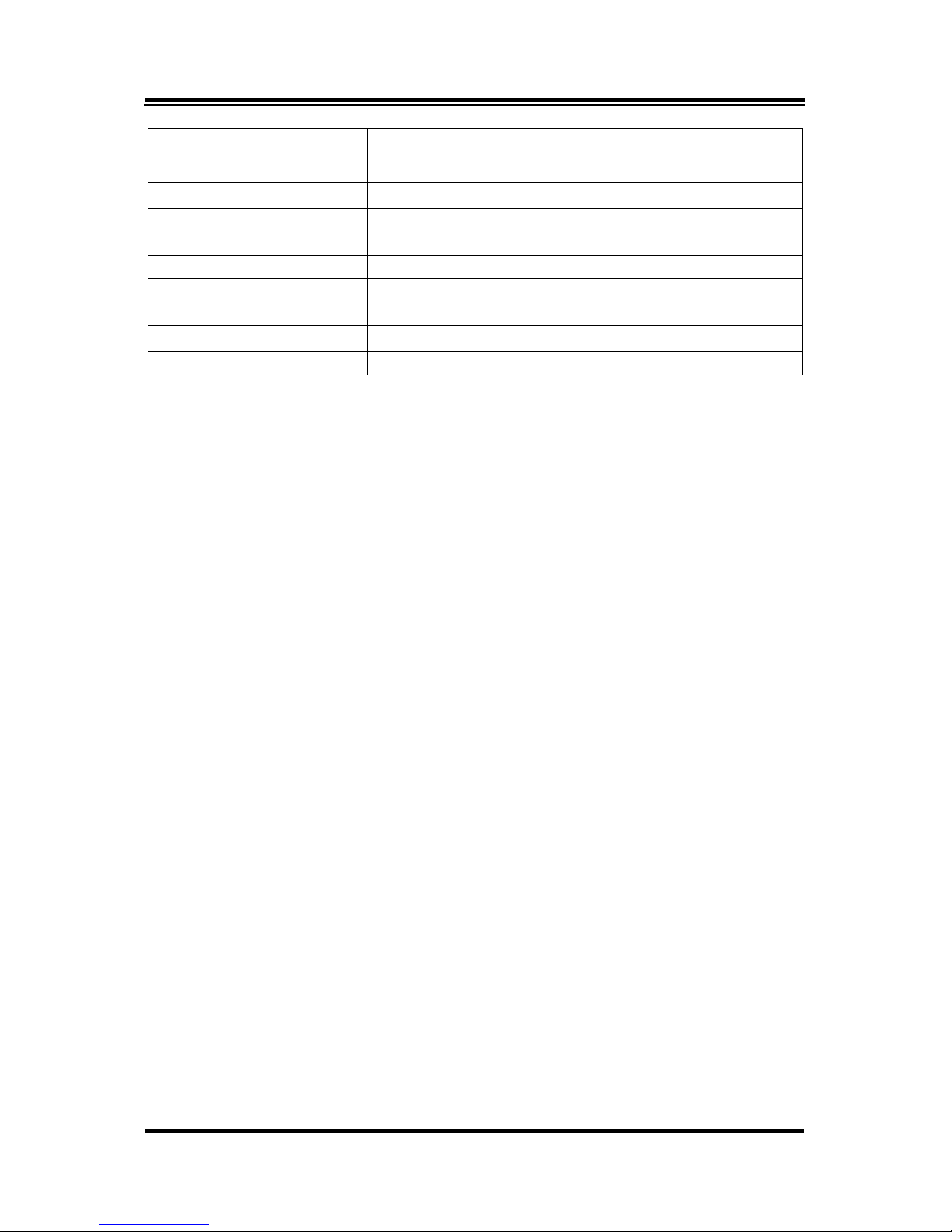

Audio

2W speaker

System Weight

5kg, PPC only:3.2kg

Dimension (W x H x D)

320 x 303 x 236 mm

Network

10/100/1000M

Mounting Type

Support VESA 75/100

Line Out

1 x phone jack

Cash Drawer

1 x RJ11(+12/24V selectable)

DC-in

1 x 4pin DC Power Jack

Viewing Angel

24~30˚

Serial Ports

3 x RJ45, 1 x RJ45 optional(+5V/12V selectable)

Page 11

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 7

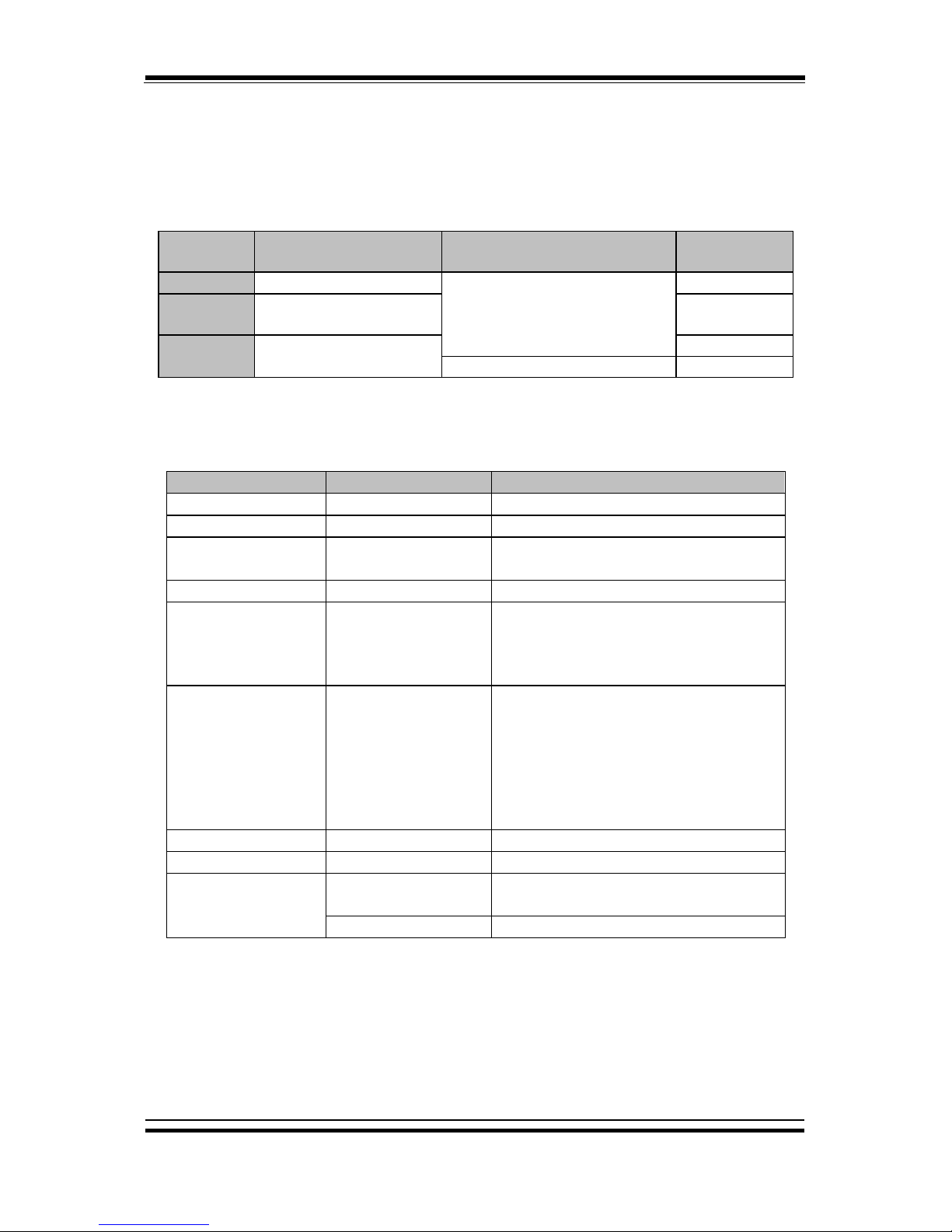

Power Supply: 72 Watt power adapter

Power Consumption

(AC):

System

Status

CPU/

HDD/ Memory

COM & USB Ports to supply

power of Rear I/O

Consumption

OFF

Off

Without

1.6W

IDLE

Turns on, but not to

execute extra AP

14.7W

Full

Loading

100% loading of burn-

in test

18.7W

USB dummy load 500mA x4

29.5W

Certificate: CE/ FCC

Type

Standard

Description

EMI

EN 55022 Class A

-

EMS

EN 55024

-

IEC 61000-4-2

ESD

8kV air discharge

4kV contact discharge

IEC 61000-4-3

RS

80~1000MHz, 3V/m, 80% AM(1kHz)

IEC 61000-4-4

EFT

AC Power Port: 1kV

DC Power Port: 0.5kV

Signal Ports & Telecommunication

Ports: 0.5kV

IEC 61000-4-5

Surge

AC Power Port:

Line to line: 1kV

Line to earth(GND): 2kV

DC Power Port:

Line to earth(GND): 0.5kV

Signal and Telecommunication Port:

Line to GND: 1kV

IEC 61000-4-6

CS

0.15~80MHz, 3Vrms, 80% AM, 1kHz

IEC 61000-4-8

PFMF

50Hz, 1A/m

IEC 61000-4-11

Voltage Dips

> 95% reduction for 0.5 periods

30% reduction for 25 periods

Voltage Interruptions

> 95% reduction for 250 periods

Page 12

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 8

Display

Customer Display

12” TFT LCD

Resolution: 1024 x 768

Touchscreen

Bezel-Free 5-wire resistive touch

Brightness

500 cd/m2 LED Backlight

Environment

Temperature

Operating: 0~35°C (32 ~ 95°F)

Storage: -5~60°C (-4 ~ 140°F)

Humidity

20~90%

Optional accessories

MSR & i-Button

JIS-I or II, ISO Track1+2+3

Fingerprint

8-bit grayscale reader

2nd Display

8” LCD or 10.4” LCD

Customer Display

VFD, 20 columns and 2 lines, each column is 5 x 7 dots

Page 13

Chapter 1 Introduction

PA-6222 SERIES USERS MANUAL

Page: 9

1-4. SAFETY PRECAUTIONS

The following messages are safety reminders on how to protect your systems from

damages, and extending the life cycle of the system.

1. Check the Line Voltage

a. The operating voltage for the power supply should be within the range of

100V to 240V AC; otherwise the system may be damaged.

2. Environmental Conditions

a. Place your PA-6222 on a sturdy, level surface. Be sure to allow enough

space around the system to have easy access needs.

b. Avoid installing your PA-6222 Series POS system in extremely hot or cold

places.

c. Avoid exposure to sunlight for a long period of time (for example, in a

closed car in summer time. Also avoid the system from any heating device.).

Or do not use the PA-6222 when it has been left outdoors in a cold winter

day.

d. Bear in mind that the operating ambient temperature is between 0C and

35C (32F and 95F).

e. Avoid moving the system rapidly from a hot place to a cold place, and vice

versa, because condensation may occur inside the system.

f. Protect your PA-6222 against strong vibrations, which may cause hard disk

failure.

g. Do not place the system too close to any radio-active device. Radio-active

device may cause signal interference.

h. Always shutdown the operation system before turning off the power.

3. Handling

a. Avoid placing heavy objects on the top of the system.

b. Do not turn the system upside down. This may cause the hard drive to

malfunction.

c. Do not allow any objects to fall into this product.

d. If water or other liquid spills into the product, unplug the power cord

immediately.

Page 14

PA-6222 SERIES USER’S MANUAL

Page: 10

SYSTEM

CONFIGURATION

Helpful information that describes the jumper and connector settings,

component locations, and pin assignment.

Sections included:

External I/O Port Pin Assignment

How to Set Jumpers

Component Locations & Jumper Settings

- Mainboard

- VFD Board (peripheral device)

- MSR Board (peripheral device)

Secondary Cash Drawer Port

CHAPTER

2

Page 15

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 11

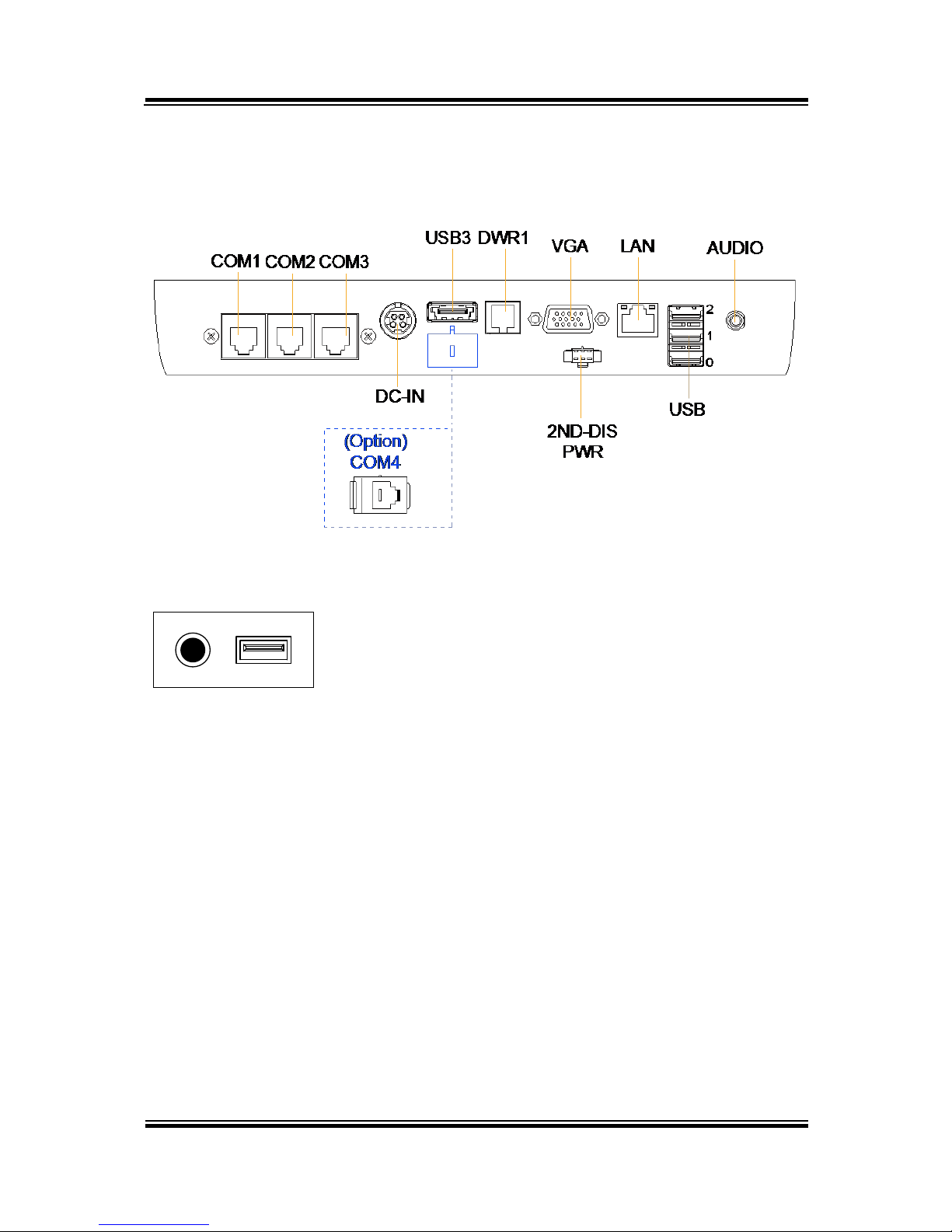

2-1. SYSTEM EXTERNAL I/O PORT & PIN ASSIGNMENT

Rear I/O

Side I/O

Power USB4

button

Page 16

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:12

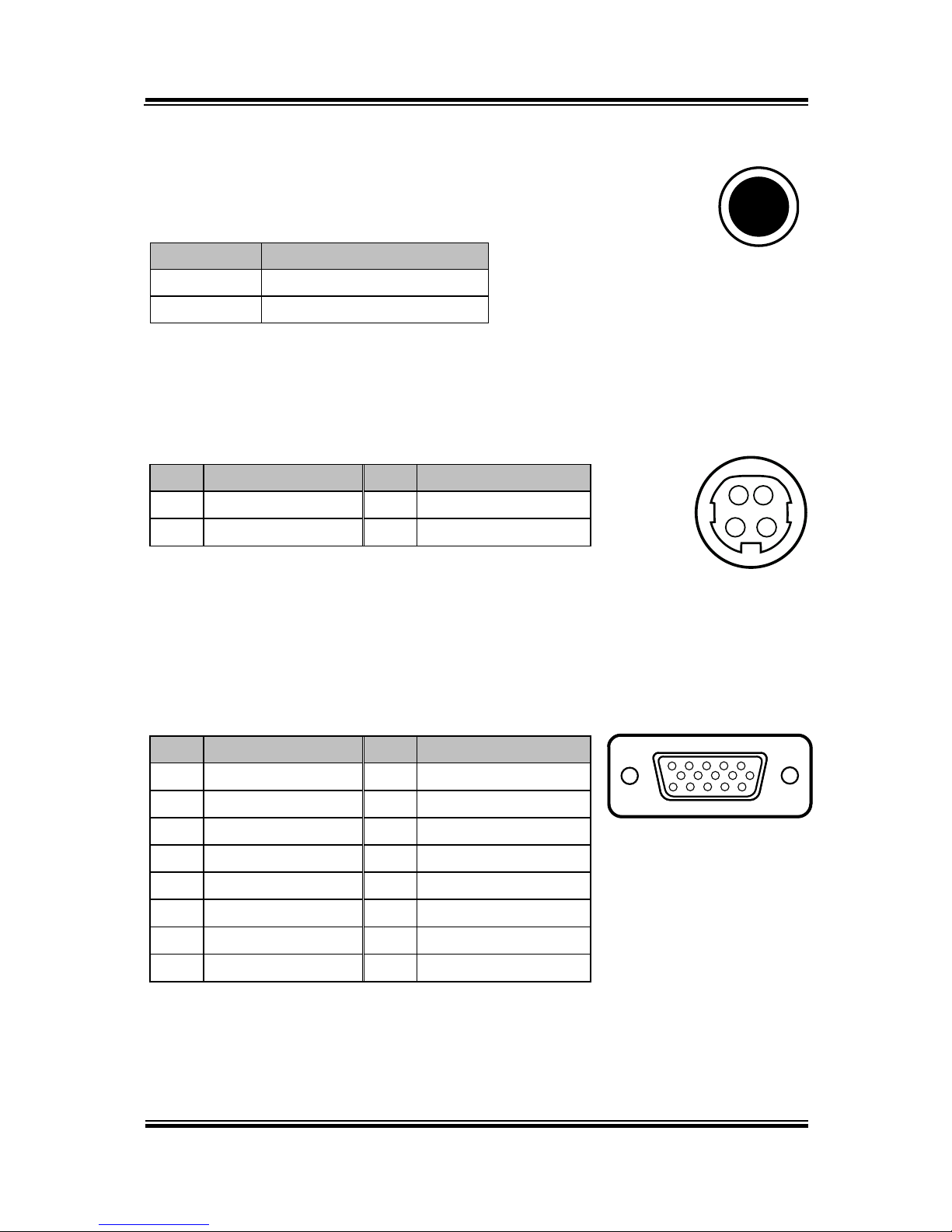

Power Button

To turn on the system, press the power button on the side

of the system briefly.

ACTION

ASSIGNMENT

Click

0V

Release

+3.3V

DC-IN Port

DC-IN: DC Power-In Port (rear IO)

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

GND

3

+24V

2

GND

4

+24V

VGA Port

VGA: VGA Port, D-Sub 15-pin (rear IO)

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

RED

9

+5V

2

GREEN

10

GND

3

BLUE

11

NC 4 NC

12

DDCA DATA

5

GND

13

HSYNC

6

GND

14

VSYNC

7

GND

15

DDCA CLK

8

GND

3 4

1 2

DC-IN

Power

Button

15

610

1115

VGA

Page 17

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 13

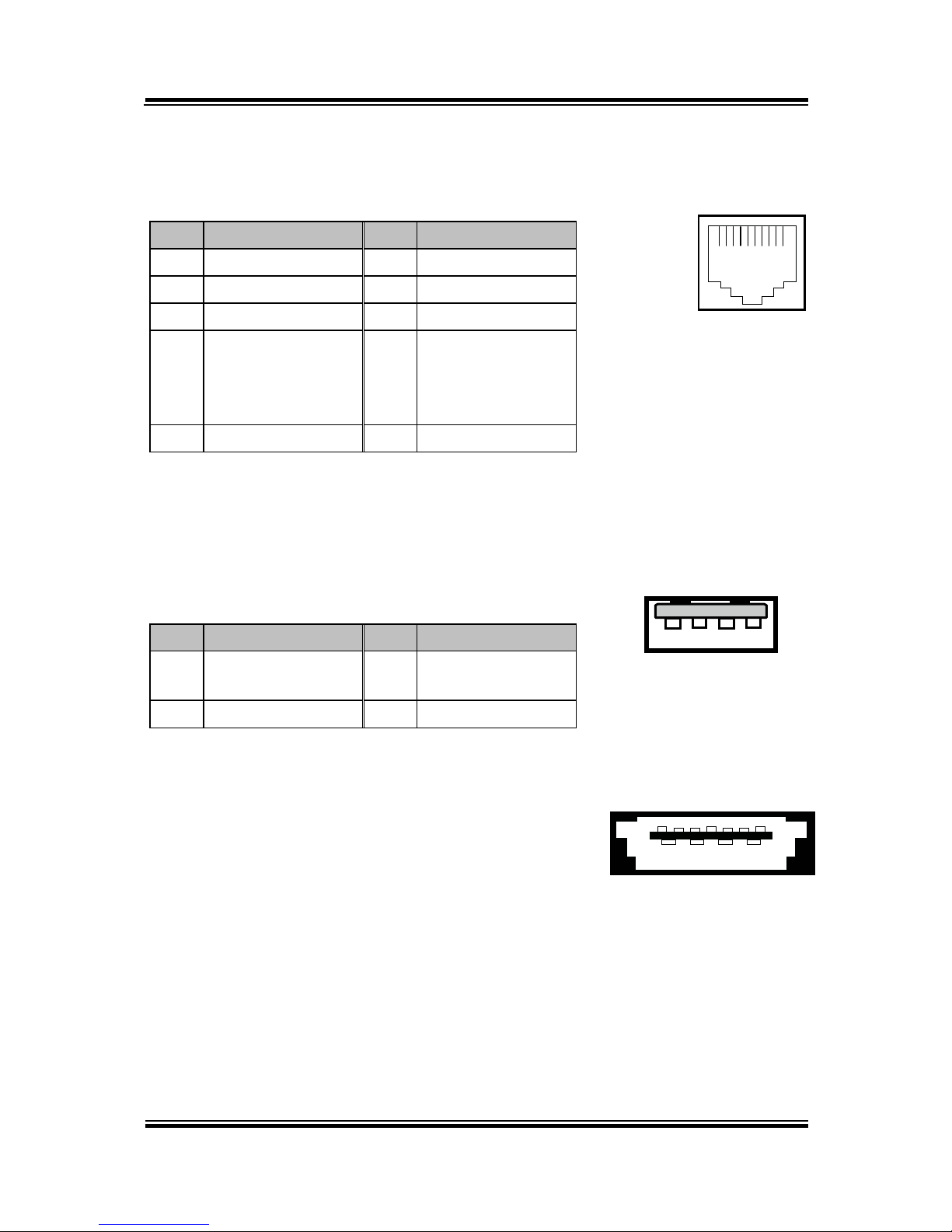

COM Port

COM1, COM2, COM3: COM Ports (rear IO)

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

DCD1/2/3

6

DSR1/2/3

2

RXD1/2/3

7

RTS1/2/3

3

TXD1/2/3

8

CTS1/2/3

4

DTR1/2/3

9

RI/+5V/+12V

selectable

(Maximum

current: 1A)

5

GND

10

NC

USB Port

USB0, USB1, USB2, USB3, USB4: USB Port Type A Ports

USB0~3: Real I/O

USB4: Side IO

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

+5V(Maximum

current: 0.5A)

3

D+

2

D- 4 GND

101

COM1/

COM2/

COM3

1 4

USB0/

USB1/

USB2/

USB4/

1 4

USB3

Page 18

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:14

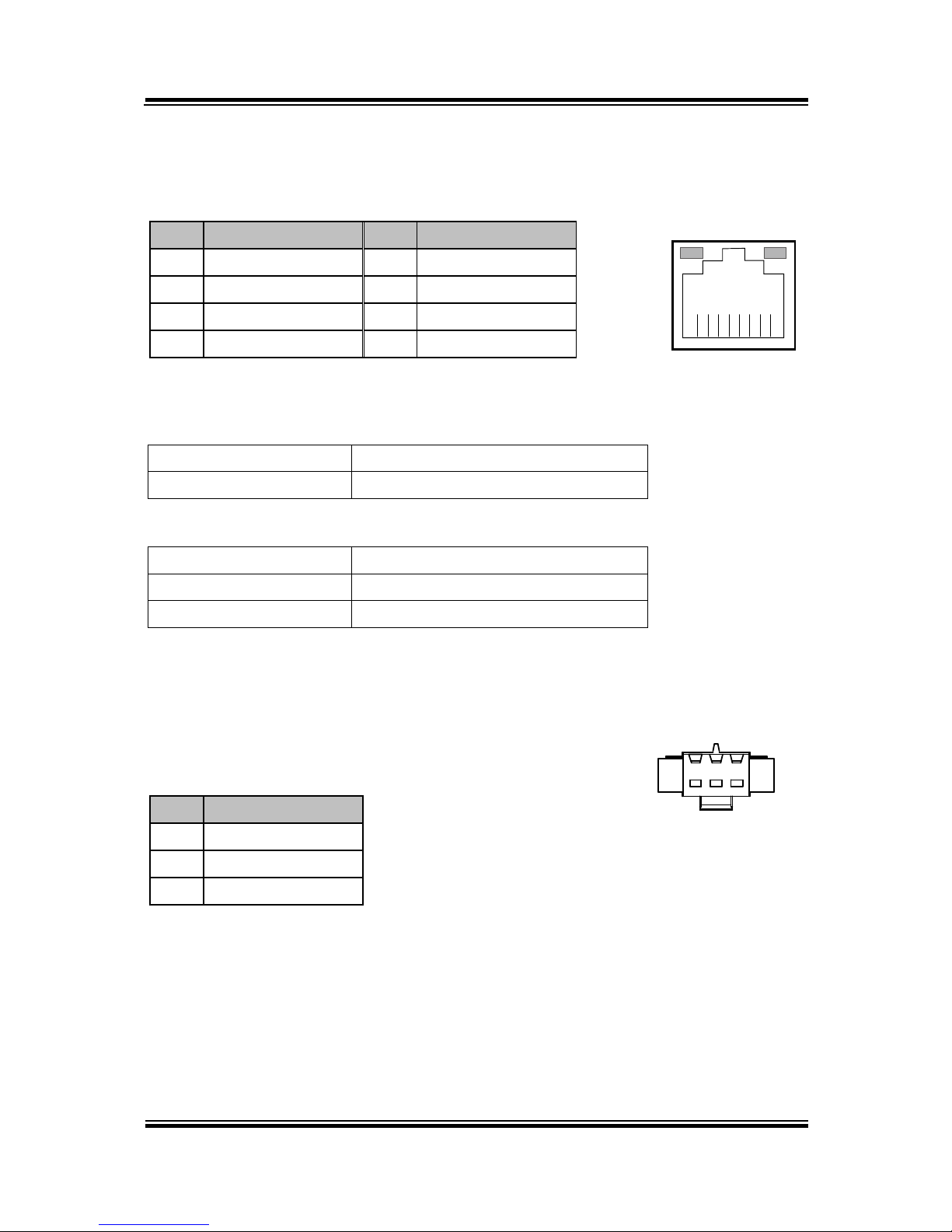

LAN Port

LAN: LAN RJ45 Port (rear IO)

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

MDI_0P

5

MDI_2N

2

MDI_0N

6

MDI_1N

3

MDI_1P

7

MDI_3P

4

MDI_2P

8

MDI_3N

LAN LED Indicator:

Left Side LED

Yellow Color Blinking

LAN Message Active

Off

No LAN Message Active

Right Side LED

Green Color On

10/100Mbps LAN Speed Indicator

Orange Color on

Giga LAN Speed Indicator

Off

No LAN switch/ hub connected.

2nd Display Power Port (Optional)

2nd DIS PWR: DV12 Power Supply of 2nd Display

PIN

ASSIGNMENT

1

VCC12

2

GND

3

VCC12

Yellow Green

8 1

LAN

1 3

2ND DIS PWR

Page 19

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 15

DC 24V Port (Optional)

DC 24V Port: DC24V power supply for the stand-printer

PIN

ASSIGNMENT

P1

GNDV

P2

+24V

P3

NA

Cash Drawer Port

DRW1, DRW1-1, DRW1-2: Signal from M/B GPIO (rear I/O)

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

GND

4

+12V/+24V (Max. current: 1A)

2

Drawer Open

5

NC 3 Drawer Sense

6

GND

DRW1

Open

Close

PB-6822RA, RB

Write

To

Write

To

700h

588h

000h

588h

PB-6822RC

Write

To

Write

To

02h

SIO LDN

06h’s 90h

00h

SIO LDN

06h’s 90h

16

DRW1

DC 24V Port

Page 20

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:16

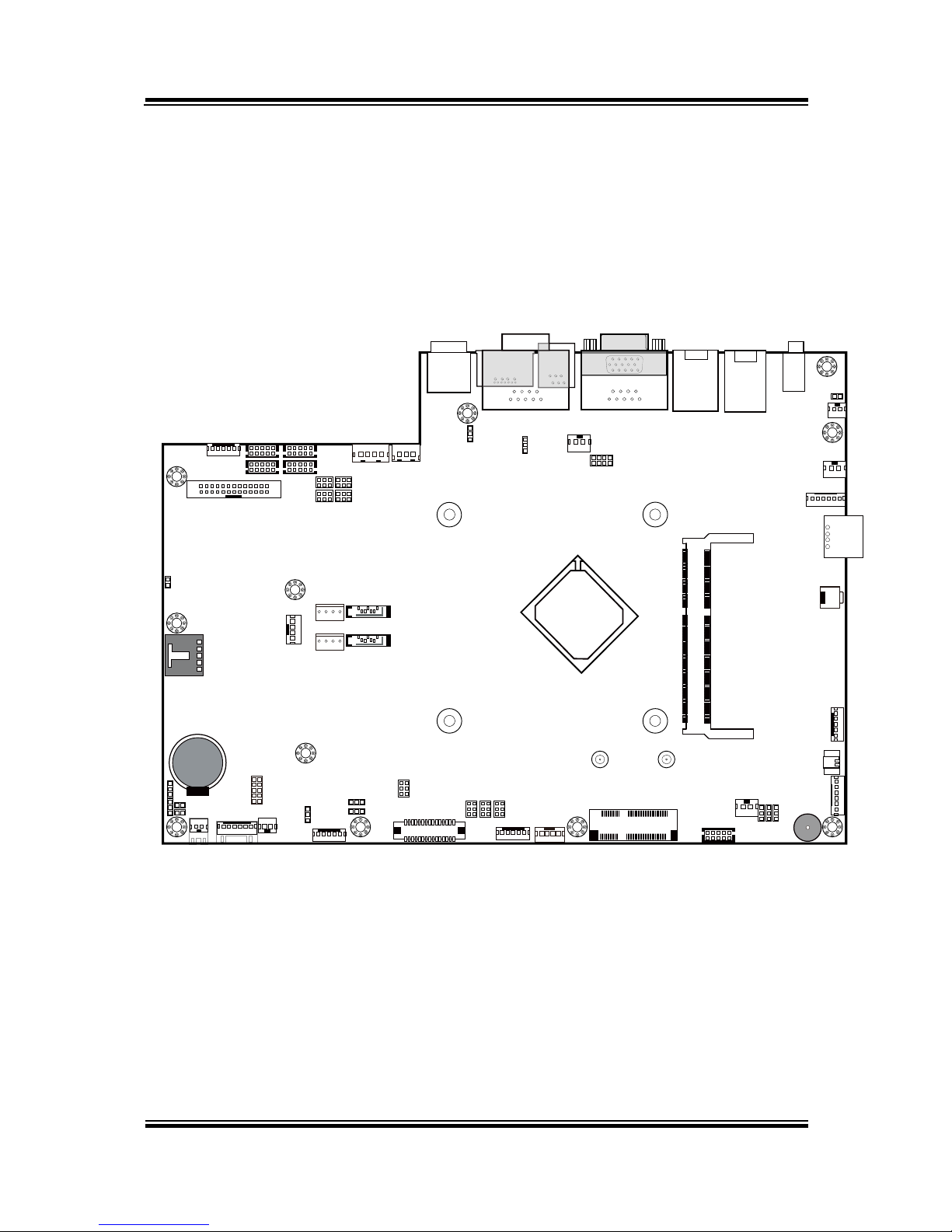

2-2. MAINBOARD COMPONENT LOCATIONS & JUMPER

SETTINGS

M/B: PB-6822

SW1_2

SPK2

PS/2_1

1

5

TOUCH1

LED1_1

LED1_3

1

LVDS1

USB7

J3

JP_VDD1

JP_12

JP_8

JP_9

USB1

JP32

SW1_3

JP19

JP30

USB2

COM1_1

COM4_1

COM2_1

COM3_1

JP_COM4

JP_COM3

JP_COM2

JP_COM1

PRT_PWR1

PWR_IN1

VGA1

USB8LAN1

LINE-OUT1

JP31

USB4

SW1

USB6

JI_BUTTON1

PS/2_2

SP1

SPK1

SLOT1

COM4_2

JP20

JP21

JP22

COM2

COM3

DC5V_PWR1

JP37

JP29

JP5

DC12V_PWR1

LPT1

J2

SATA2

SATA1

JPWR_4P2

JPWR_4P1

JP14

JP15

JINV4

JINV1

JP4

JP3

JP38JP39

30

291

2

Battery

1

1

1

1

1 31 4

1

6

5

10

14

1

1

1

1

1 21 21 2

5 65 65 6

526

1

1

1

1

1

12

910

6

1

1

6

1

1

15

15

1

5

11517 51

21618

52

1

4

1

127

8

1

10

5

6

1

6

1

1

1

2

255

6

5

6

6

1

1

4

1

2

6

10

5

10

5

26

13

14

1

1 4

1 4

1 7

1 7

Intel

®

Celeron® J1900

Quad-Core

DIMM1

1

2

71

72

73

74

203

204

ESATA1

DRW1

15

1

61

1

PB-6822 Mainboard Component Locations

Page 21

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 17

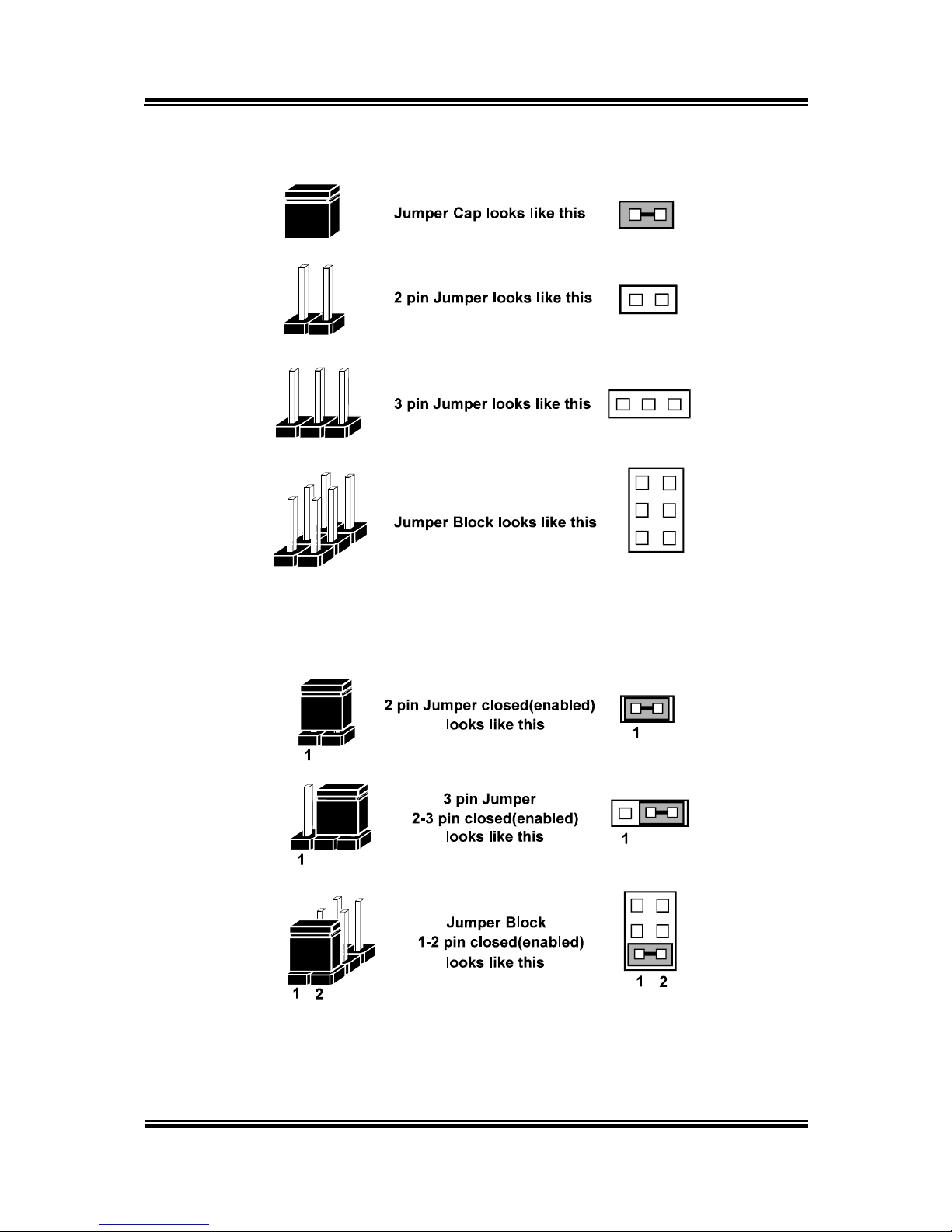

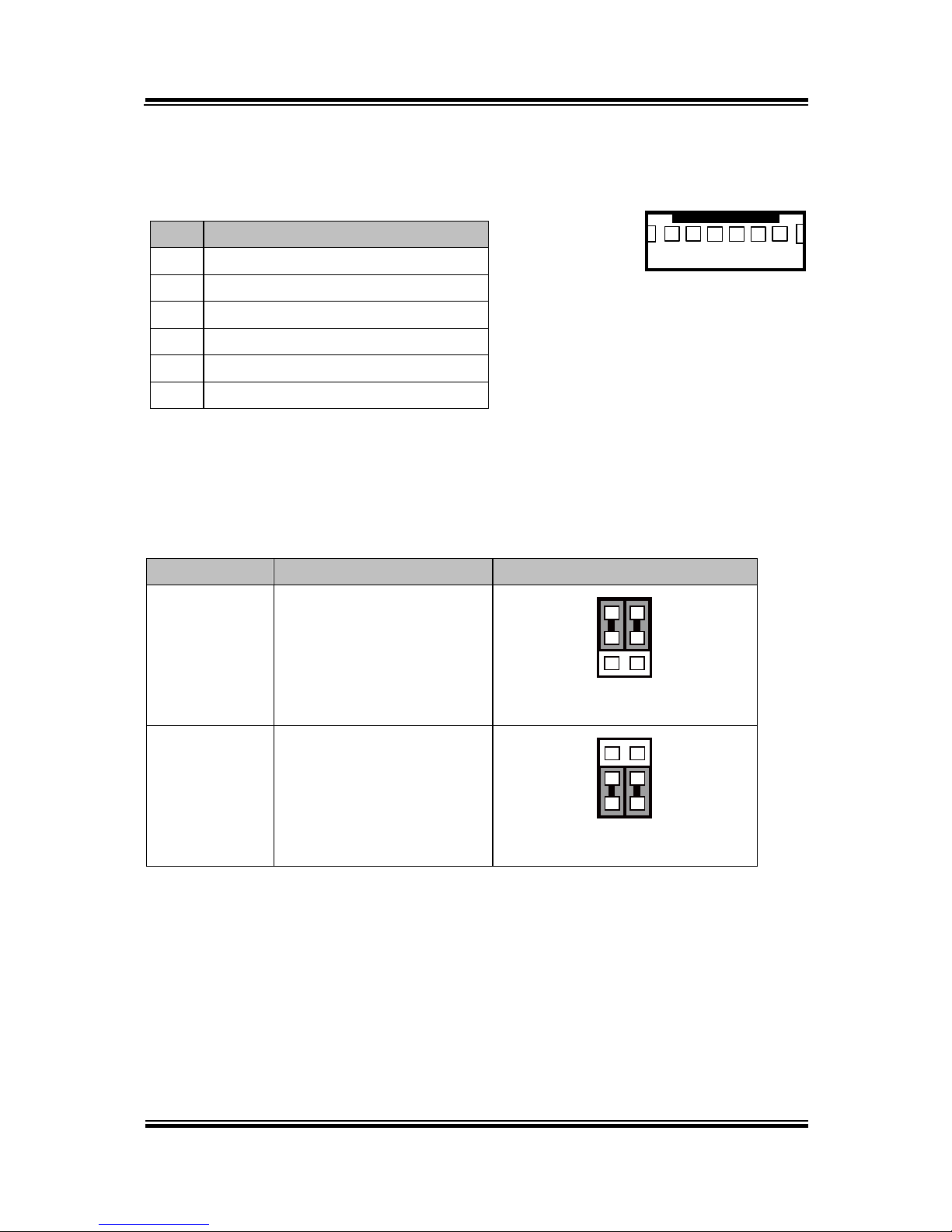

2-2-1. How to Set Jumpers

You can configure your board by setting the jumpers. A jumper consists of two or three

metal pins with a plastic base mounted on the card, and by using a small plastic "cap",

also known as the jumper cap (with a metal contact inside), you are able to connect the

pins. So you can set-up your hardware configuration by "opening" or "closing" pins.

Jumpers can be combined into sets that called jumper blocks. When jumpers are all in

the block, you have to put them together to set up the hardware configuration. The

figure below shows what this looks like.

Jumpers & caps

If a jumper has three pins for example, labelled PIN1, PIN2, and PIN3. You can

connect PIN1 & PIN2 to create one setting and shorting. You can either connect PIN2

& PIN3 to create another setting. The same jumper diagrams are applied all through

this manual. The figure below shows what the manual diagrams look and what they

represent.

Page 22

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:18

Jumper diagrams

Jumper settings

Page 23

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 19

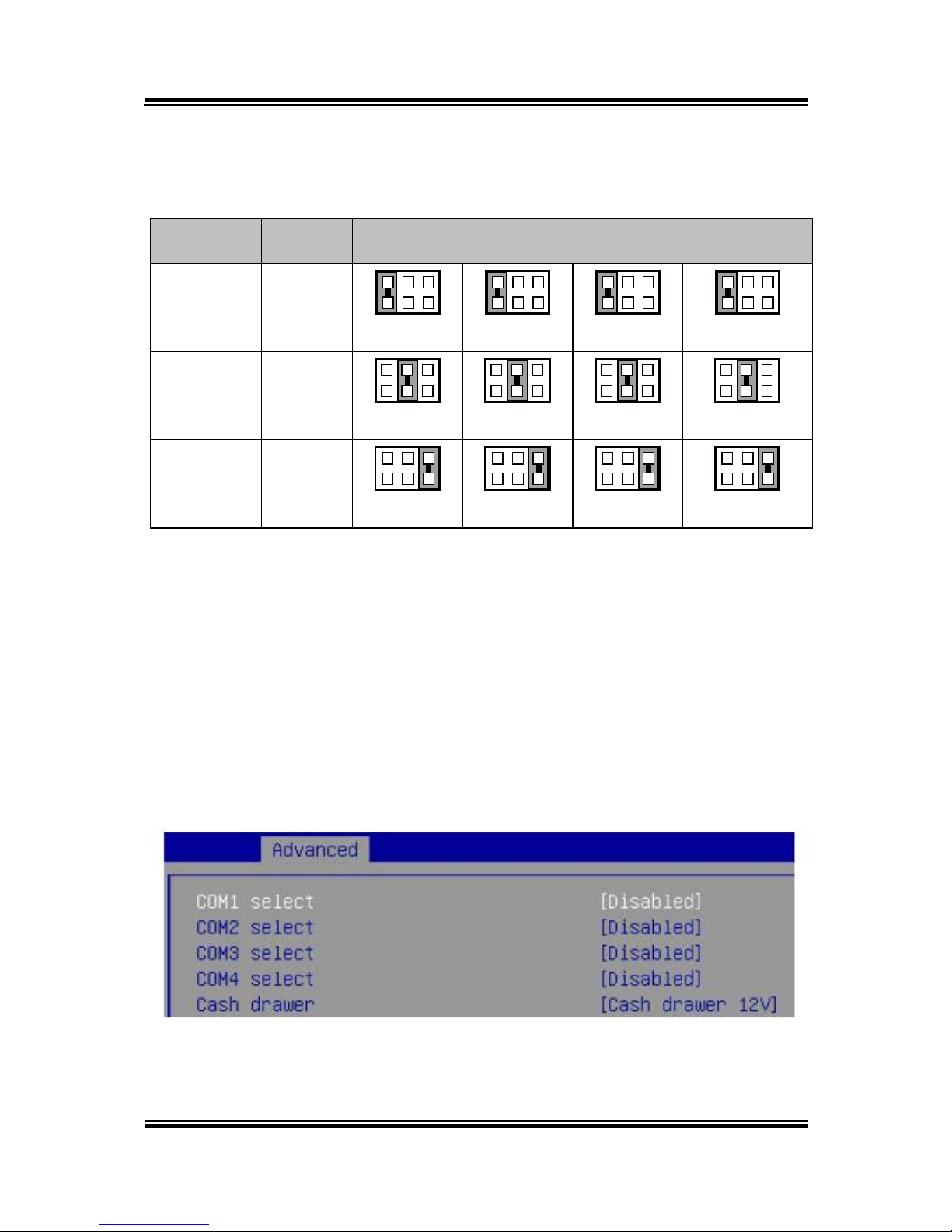

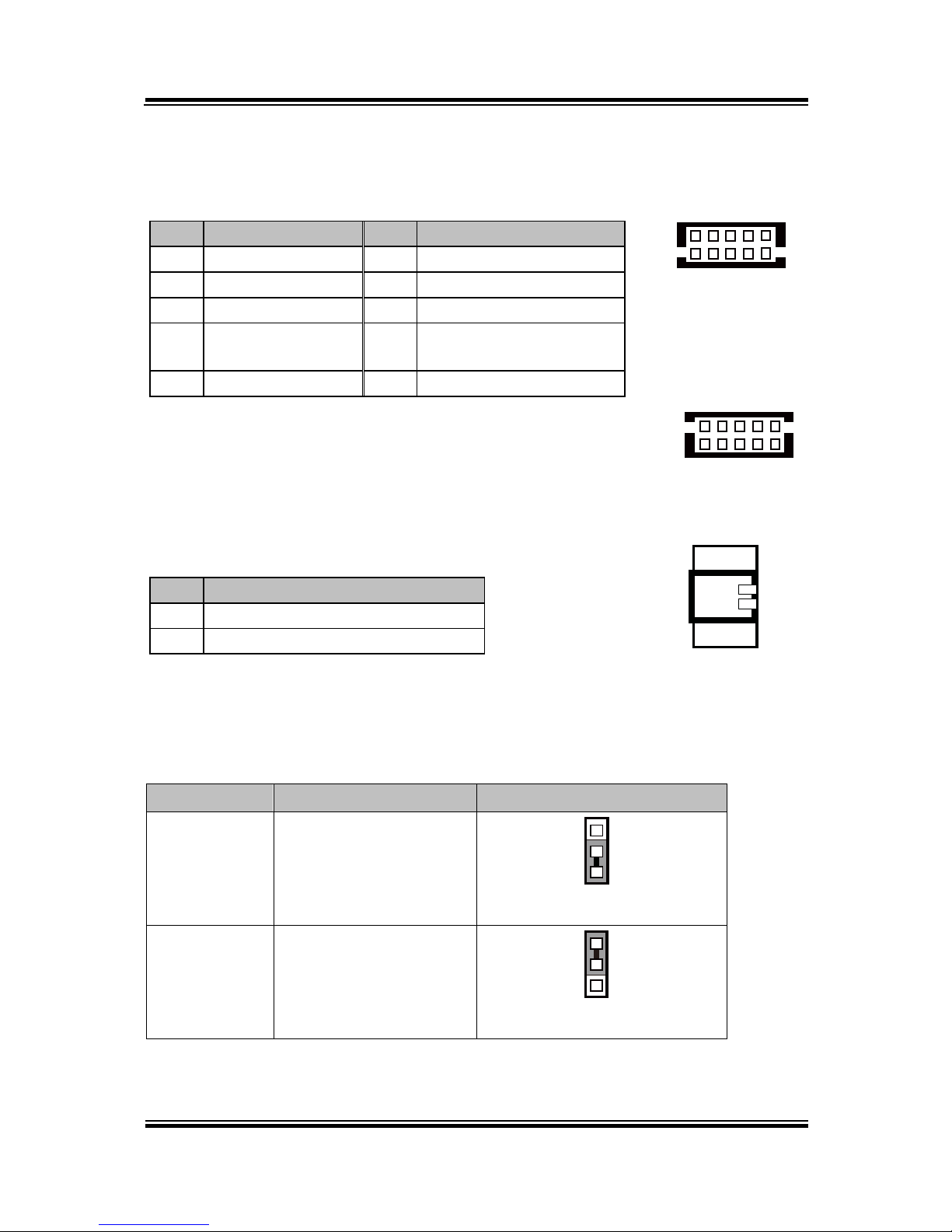

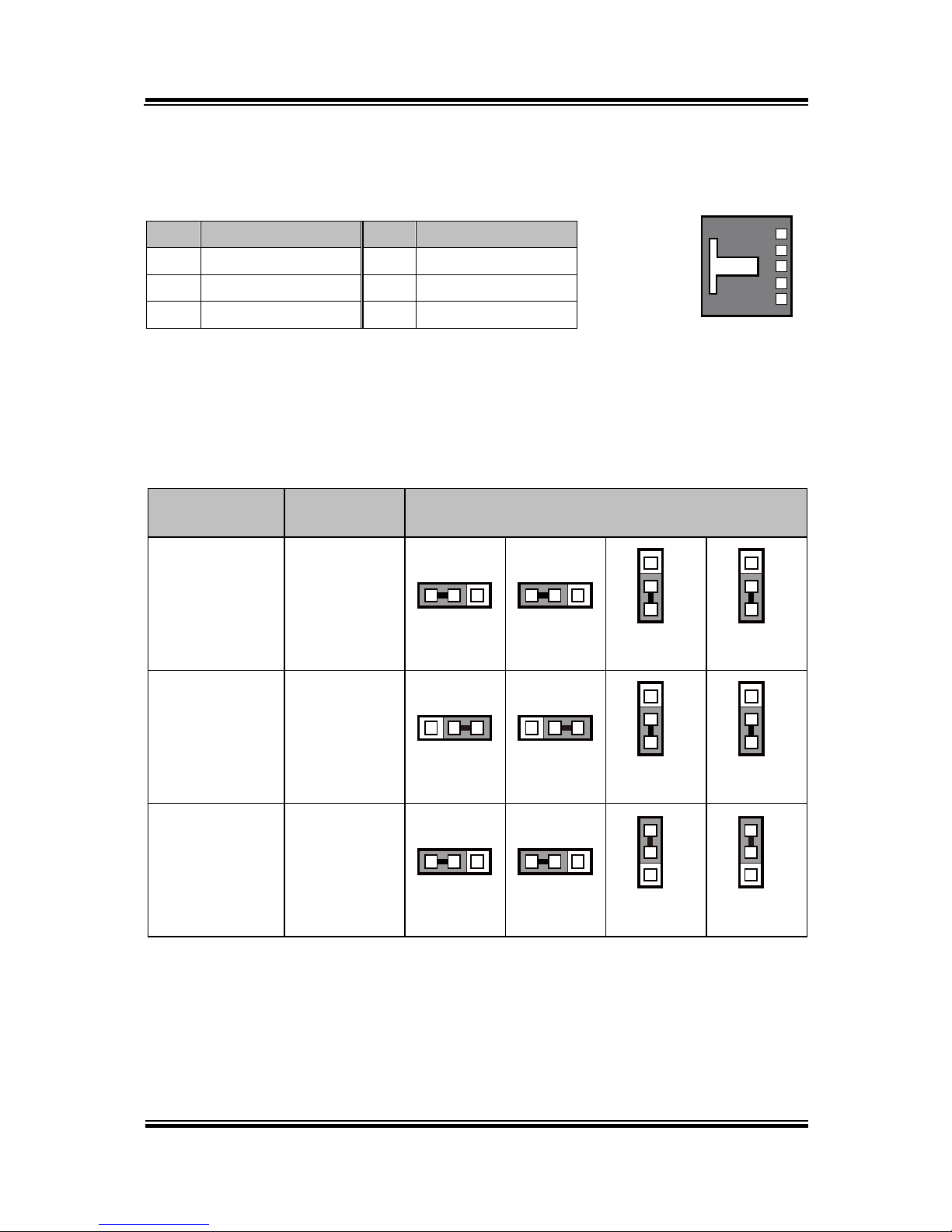

COM Port RI & Voltage Selection

JP_COM1, JP_COM2, JP_COM3, JP_COM4: Pin-headers on board

SELECTION

JUMPER

SETTING

JUMPER ILLUSTRATION

RI

1-2

5

6

1

2

JP_COM1

5

6

1

2

JP_COM2

5

6

1

2

JP_COM3

5

6

1

2

JP_COM4

+12V

3-4

5

6

1

2

JP_COM1

5

6

1

2

JP_COM2

5

6

1

2

JP_COM3

5

6

1

2

JP_ COM4

+5V

5-6

5

6

1

2

JP_COM1

5

6

1

2

JP_COM2

5

6

1

2

JP_COM3

5

6

1

2

JP_ COM4

Note: Manufacturing Default is no connection for JP_COM1, JP_COM2, JP_COM3 and

JP_COM4.

Caution:

1. Voltage of external COM 1~ COM4 ports are made to control on BIOS for your convenience.

The corresponding jumpers JP_COM1~ JP_COM4 are set open (no connection) by default;

refer to Voltage Adjust Configuration for detailed jumper setting (BIOS default at RI).

2. JP_COM1~ JP_COM4 are enabled when COM1~ COM4 voltage adjustment is disabled on

BIOS

3. Voltage of COM port is adjustable by BIOS or jumpers. Either way cannot be applied

simultaneously in case of system error, component damage or serious boot failure.

PS: COM4 is optional

Page 24

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:20

COM Connector

COM1-1, COM2-1, COM3-1, COM4-1, COM4-2: COM Connectors

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

DCD

6

DSR

2

RXD

7

RTS

3

TXD

8

CTS

4

DTR

9

RI/+5V/+12V selectable

(Max. current: 1A)

5

GND

10

NC

For details, refer to COM Port RI & Voltage Selection.

I-Button Connector

JI_BUTTON1: i-Button Connector

PIN

ASSIGNMENT

1

COM3_DTR_R_I

2

COM3_RXD_R_I

I-Button Function Selection

JP20, JP21, JP22: i-Button Function Connectors

SELECTION

JUMPER SETTING

JUMPER ILLUSTRATION

COM 3

1-2

1

3

JP20/JP21/JP22/

i-Button*

2-3

1

3

JP20/JP21/JP22/

Note: Manufacturing Default is COM3.

*COM3 & COM3-1 will not function when jumpers JP20, JP21 & JP22 are set as “i-Button.”

1

2

JI_BUTTON1

51

10

6

COM1-1/

COM2-1/

COM3-1/

COM4-1/

610

1

5

COM4-2/

Page 25

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 21

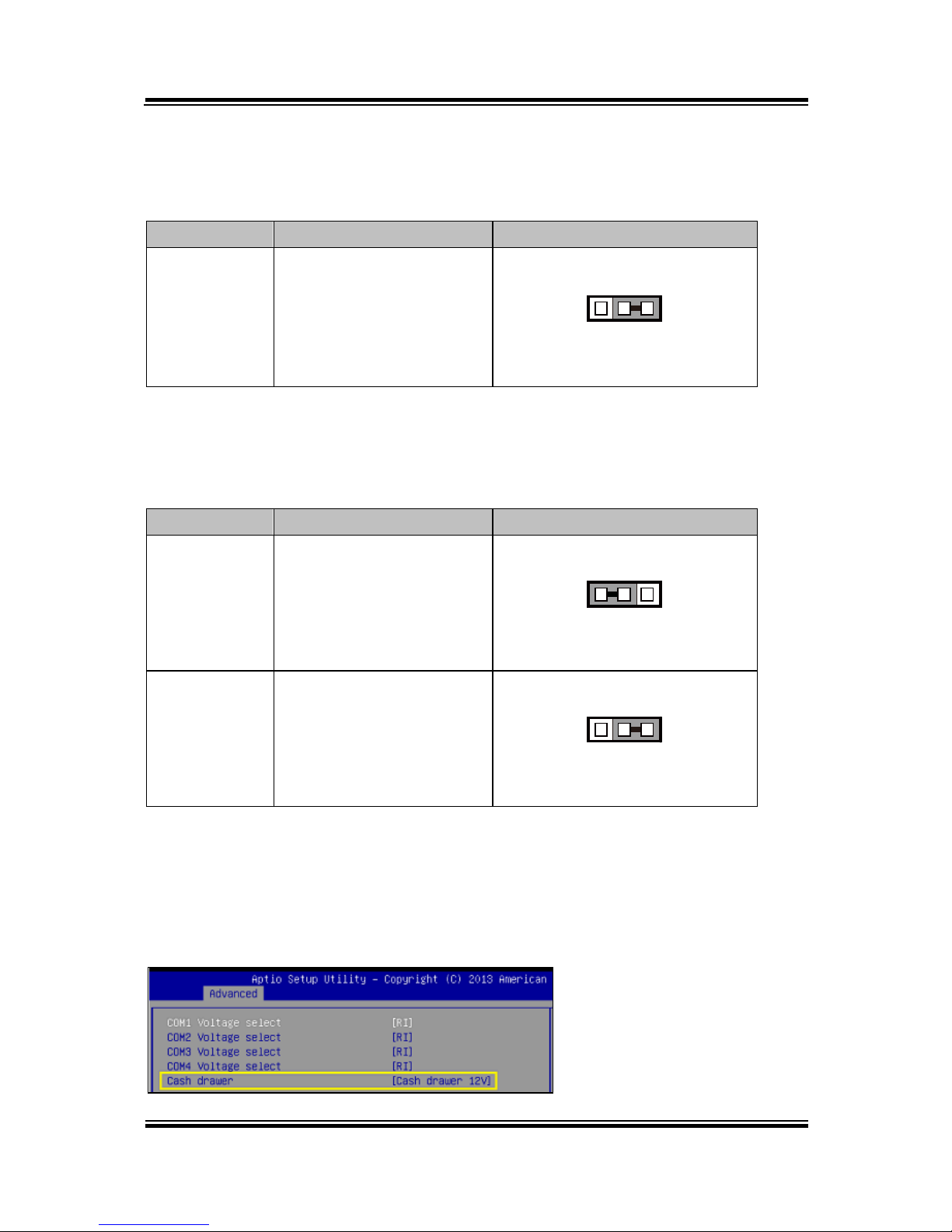

Cash Drawer Control Selection

JP37: DRW1 control connector

SELECTION

JUMPER SETTING

JUMPER ILLUSTRATION

DRW1

2-3

1 3

JP37

Cash Drawer Power Selection

JP29: DRW1 power selection

SELECTION

JUMPER SETTING

JUMPER ILLUSTRATION

+24V

1-2

1 3

JP29

+12V

2-3

1 3

JP29

Caution:

1. Voltage of external DRW1 port is made to control on BIOS for your convenience. The

corresponding jumper JP29 is set open (no connection) by default.

2. JP29 is enabled when Cash drawer is disabled on BIOS.

3. Voltage of cash drawer port is adjustable by BIOS or jumpers. Either way cannot be applied

simultaneously in case of system error, component damage or serious boot failure.

Page 26

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:22

USB Connector

USB1, USB2, USB6, USB7: USB 2.0 connector

PIN

ASSIGNMENT

1

5V (Maximum current: 0.5A)

2

D- 3 D+ 4 GND

5

GND

Note: USB1 would be used when jumpers

JP14 & JP15 are set as 1-2 (short)

connected.

LED Connector

LED1_1, LED1_3: Power indication LED connector

PIN

ASSIGNMENT

1

GND

2

PWR_LED

2 1

LED1_1/

LED1_3/

1

5

USB1/

USB2/

USB7/

1

5

USB6

Page 27

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 23

Power Connector

DC12V_PWR1: DC 12Voltage Provider Connector

PIN

ASSIGNMENT

1

VCC12

2

GND

3

VCC12

DC5V_PWR1: DC 5Voltage Provider Connector

PIN

ASSIGNMENT

1

5V 2 GND

Power for Thermal Printer Connector

PRT_PWR1: Power for Thermal Printer Connector

PIN

ASSIGNMENT

1

VCC24SB

2

VCC24SB

3

GND

4

GND

External Speaker Connector

SPK1, SPK2: External speaker connector

PIN

ASSIGNMENT

1

SPK_GND

2

SPK_OUT

1 3

DC12V_PWR1

1 4

PRT_PWR1

12

SPK1/

SPK2/

12

DC5V_PWR1

Page 28

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:24

Inverter Connector

JINV1, JINV4: Inverter connectors

PIN

ASSIGNMENT

1

+12V

2

+12V

3

GND

4

BRCTR

5

GND

6

LVDS_BKLTEN

LED Backlight Power Control Selection

JP12: LED backlight power control connectors

SELECTION

JUMPER SETTING

JUMPER ILLUSTRATION

Control by

driver on M/B

1-3, 2-3

It applied to the panel

without driver built-in

21

65

JP12

Control by

PWM

3-5, 4-6

It applied to the panel

with built-in driver inside

21

65

JP12

Note: Manufacturing Default is Control by PWM.

1

6

JINV1/

JINV4/

Page 29

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 25

Panel Resolution Selection

JP8, JP9: Panel resolution control connectors

SELECTION

JUMPER

SETTING

JUMPER ILLUSTRATION

1024 x 768

(24 bit)

JP8: 1-3, 4-6

JP9: 3-5, 4-6

21

65

JP8

21

65

JP9

Note: Manufacturing Default is 1024 x 768 (24bit).

LVDS Connector

LVDS1: LVDS Connector

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

LVDS_VCC

16

LVDS_CLKA_D+

2

GND

17

VDS_CLKA_D-

3

NC

18

GND

4

NC

19

LVDS_A2_D+

5

GND

20

LVDS_A2_D-

6

LVDS_B2_D-

21

GND

7

LVDS_B2_D+

22

LVDS_A1_D+

8

GND

23

LVDS_A1_D-

9

LVDS_B1_D-

24

GND

10

LVDS_B1_D+

25

LVDS_A0_D+

11

LVDS_B3_D+

26

LVDS_A0_D-

12

LVDS_B3_D-

27

LVDS_A3_D+

13

LVDS_B0_D+

28

LVDS_A3_D-

14

LVDS_B0_D-

29

LVDS_VCC

15

GND

30

LVDS_VCC

2

1 29

30

LVDS1

Page 30

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:26

Touch Panel Connector

TOUCH1: Touch panel connectors

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

LR (Low Right)

4

UR (Up Right)

2

LL (Low Left)

5

UL (Up Left)

3

Probe

Touch Panel Signal Interface Selection

JP14, JP15, JP38, JP39: Control connectors for touch panel signal interface

SELECTION

JUMPER

SETTING

JUMPER ILLUSTRATION

USB1

Connector

JP14: 1-2

JP15: 1-2

JP38: 2-3

JP39: 2-3

1 3

JP14

1 3

JP15

3

1

JP38

3

1

JP39

USB

Interface

JP14: 2-3

JP15: 2-3

JP38: 2-3

JP39: 2-3

1 3

JP14

1 3

JP15

3

1

JP38

3

1

JP39

RS-232

Interface

JP14: 1-2

JP15: 1-2

JP38: 1-2

JP39: 1-2

1 3

JP14

1 3

JP15

3

1

JP38

3

1

JP39

Note: 1. Manufacturing Default is USB Interface.

2. The COM2 & COM2-1 connector will not function when JP38 & JP39 are set

as 1-2 connected.

3. USB1 connector when JP14 & JP15 are set as 1-2 connected.

1

5

TOUCH1

Page 31

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 27

Clear CMOS Data Selection

JP3: Clear CMOS data selection

SELECTION

JUMPER SETTING

JUMPER ILLUSTRATION

Normal

Open

1

JP3

Clear CMOS*

1-2

1

JP3

Note: Manufacturing Default is Normal.

*To clear CMOS data, you must power-off the computer and set the jumper to “Clear CMOS” as

illustrated above. After five to six seconds, set the jumper back to “Normal” and power-on the

computer.

MSR/Card Reader Connector

PS/2_1, PS/2_2: MSR/Card reader connectors

PIN

ASSIGNMENT

1

KB_CLK (Output)

2

KB_CLK_C (Input)

3

KB_DATA_C (Input)

4

KB_DATA (Output)

5

+5V

6

GND

6

1

PS/2_1

6

1

PS/2_2

Page 32

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:28

SATA & SATA Power Connector

SATA1, SATA2: Serial ATA connectors

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

G1 5 RX-

2

TX+

6

RX+

3

TX-

7

G3 4 G2

Note: SATA1 only supports the optional RAID

function on board.

JPWR_4P1, JPWR_4P2: Serial ATA power connectors

PIN

ASSIGNMENT

1

VCC

2

GND

3

GND

4

VCC12

Note: JPWR_4P1 only supports the

optional RAID function on board.

1 7

SATA1/

SATA2/

1 4

JPWR_4P1/

JPWR_4P2/

Page 33

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 29

Printer Connector

LPT1: Printer connector

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

STBJ

14

ALFJ

2

PDR0

15

ERRJ

3

PDR1

16

PAR_INITJ

4

PDR2

17

SLCTINJ

5

PDR3

18

GND

6

PDR4

19

GND

7

PDR5

20

GND

8

PDR6

21

GND

9

PDR7

22

GND

10

ACKJ

23

GND

11

BUSY

24

GND

12

PE

25

GND

13

SLCTJ

26

NC

26

13

14

1

LPT1

Page 34

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:30

Mini-PCIe / mSATA Connector

SLOT1: Mini-PCIe connector, not support USB function

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

WAKE#

27

GND

2

+3.3V

28

+1.5V

3

Reserved

29

GND

4

GND

30

SMB_CLK

5

Reserved

31

PETn2

6

+1.5V

32

SMB_DATA

7

CLKREQ#

33

PETp2

8

Reserved

34

GND

9

GND

35

GND

10

Reserved

36

NC

11

REFCLK1-

37

GND

12

Reserved

38

NC

13

REFCLK1+

39

+3.3V

14

Reserved

40

GND

15

GND

41

+3.3V

16

Reserved

42

Reserved

17

Reserved

43

GND

18

GND

44

Reserved

19

Reserved

45

NC

20

Reserved

46

Reserved

21

GND

47

NC

22

PERST#

48

+1.5V

23

PERn2

49

NC

24

+3.3SB

50

GND

25

PERp2

51

Reserved

26

GND

52

+3.3V

12151617

18

51

52

SLOT1

Page 35

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 31

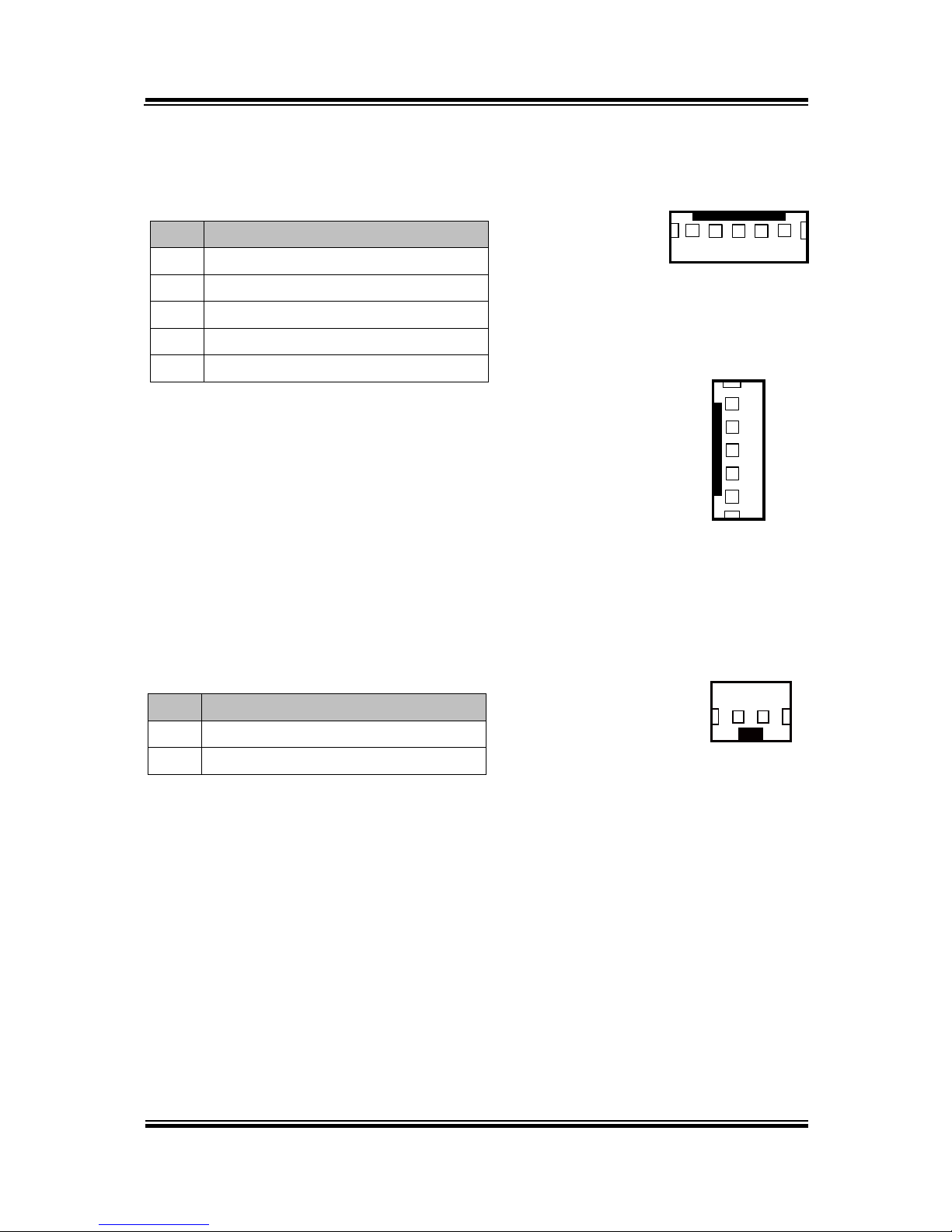

2-3. VFD BOARD COMPONENT LOCATIONS & PIN

ASSIGNMENT

VFD Board: MB-4103, LD720

JP12V

CN1

1

1

16

MB-4103 & LD720 VFD Board Component Locations

Page 36

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:32

Power Switch Selection

JP12V: Power Switch Selection

SELECTION

JUMPER SETTING

JUMPER ILLUSTRATION

OFF

1-2

3

1

JP12V

ON

2-3

3

1

JP12V

Note: Manufacturing Default is ON.

RS-232 Serial Interface Connector

CN1: RS-232 serial interface wafer

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

GND

9

NC 2 TXD

10

NC 3 RXD

11

NC 4 DTR

12

NC 5 DSR

13

NC 6 RTS

14

NC 7 CTS

15

NC 8 +12V/+5V

16

NC

1

16

CN1

Page 37

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 33

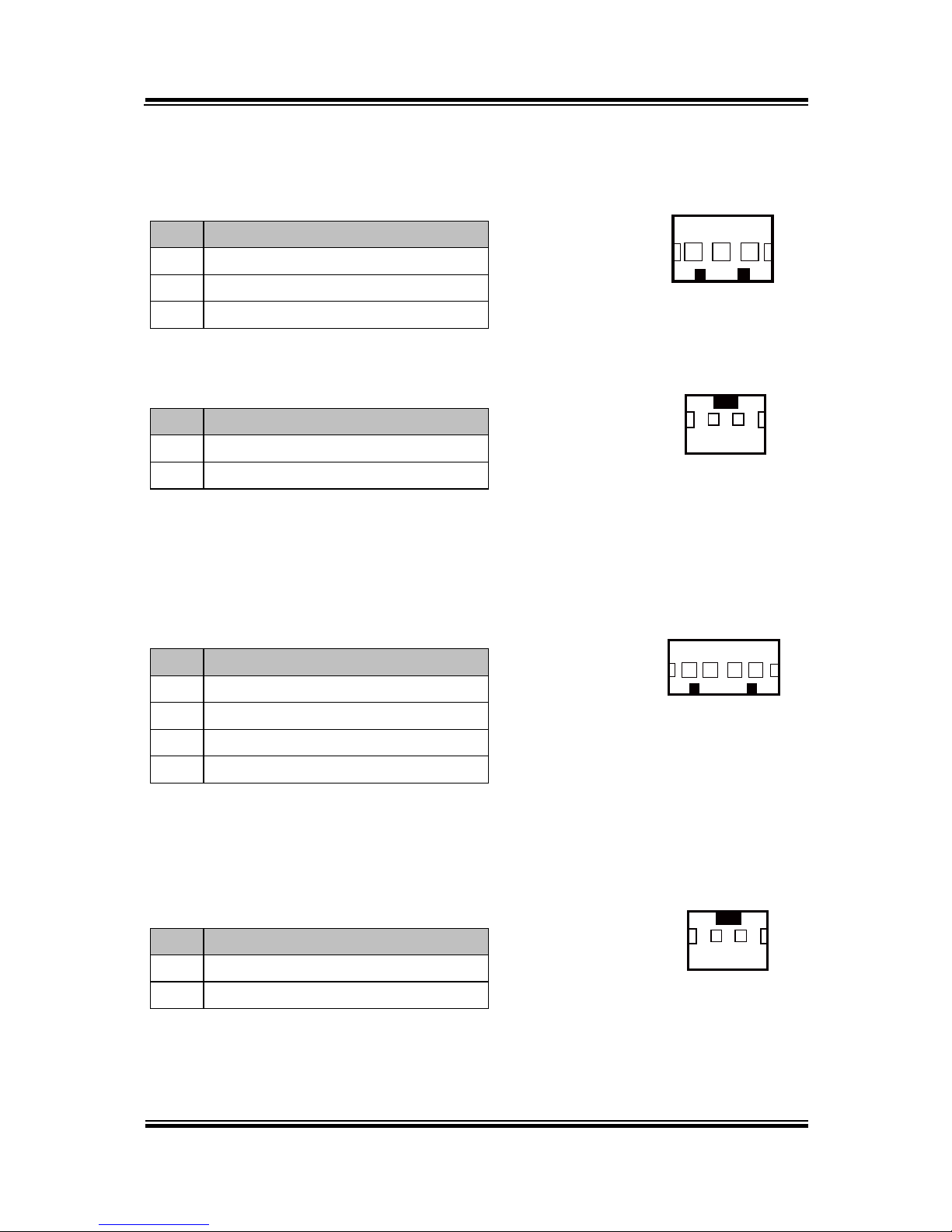

2-4. MSR BOARD COMPONENT LOCATIONS & PIN

ASSIGNMENT

ID TECH

1

7

CN

ID-TECH MSR Board Component Locations

Main Connector

CN:

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

Chassis Ground

5

K-CLK

(Computer connections)

2

P-CLK

(Keyboard connections)

6

K-DATA

(Computer connections)

3

P-DATA

(Keyboard connections)

7

GND

4

+5V Vcc

1

7

CN

Page 38

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:34

MB-3012

IO1

I_BUTTON1

1 12

1

2

MB-3012 MSR Board Component Locations

Information Button Reader

I_BUTTON1: Information button reader

PIN

ASSIGNMENT

1

I_B1

2

GND

Output Connector

IO1: Output wafer

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

CLK_KB

7

RX_MSR

2

CLK_PC

8

TX_MSR

3

DATA_KB

9

GND

4

DATA_PC

10

USB_D+_R

5

+5V

11

USB_D-_R

6

CHASSIS GND

12

GND

1

2

I_BUTTON1

1 12

IO1

Page 39

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page: 35

2-5. Secondary Cash Drawer

2-5-1. DRW1-2 Port (Only for PA-6222RC)

DRW1 is used by default. If you need a second port, adopt either way below.

Step.1

DRW1 includes two groups of

GPIO pins. The second group

is normally unused but can be

enabled by the jumper.

Set the pin-header jumper

JP37 as 1-2 connected if

necessary.

JP37: DRW1-2 control

connector

Note: Manufacturing Default is GND.

SELECTIO

N

JUMPER SETTING

JUMPER ILLUSTRATION

DRW1-2

Open

1-2

GND

2-3

Page 40

Chapter 2 System Configuration

PA-6222 SERIES USER’S MANUAL

Page:36

Step.2

You can split DRW1 into two channels of DRW1-1 & DRW1-2 with the Y-Cable

(optional unit).

Step.3

DRW1, DRW1-1, DRW1-2 shares the same power source

(refer to Cash Drawer Power Selection for adjustment, default at 12V).

DRW1, DRW1-1, DRW1-2: Signal from M/B GPIO (rear I/O)

DRW1-1

Open

Close

PB-6822RA, RB

Write

To

Write

To

700h

588h

000h

588h

PB-6822RC

Write

To

Write

To

02h

SIO LDN06h’s 90h

00h

SIO LDN 06h’s 90h

DRW1-2

OPEN

CLOSE

PB-6822RA, RB

Write

To

Write

To

N/A

N/A

N/A

N/A

PB-6822RC

Write

To

Write

To

04h

SIO LDN 06h’s 90h

00h

SIO LDN 06h’s 90h

PIN

ASSIGNMENT

PIN

ASSIGNMENT

1

GND

4

+12V/+24V (Max. Current: 1A)

2

Drawer Open

5

NC

3

Drawer Sense

6

GND

Page 41

PA-6222 SERIES USERS MANUAL

Page:37

SOFTWARE

This chapter provides the detailed information of driver utilities and

BIOS settings for the system.

Sections included:

Driver

- Intel

®

Chipset Device Software Installation Utility

- VGA Driver Utility

- LAN Driver Utility

- Sound Driver Utility

- Touchsreen Driver Utility

- For Intel Trusted Execution Engine Interface

Embedded Peripheral Device

- VFD

- MSR

API

BIOS Operation

- Setup

- Watchdog Timer Configuration

- Update Procedure

- System Resource Map

CHAPTER

3

Page 42

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:38

3-1. DRIVER

3-1-1. Introduction

Enclosed with the PA-6222 Series package is our driver utilities, which comes in a

DVD-ROM format.

3-1-1-1 . API Package Folder

Refer to the "3-3 API" for the details.

+--->\DEMO PROJECT\

+--->\ProxAPI standard\

+--->\Document\

3-1-1-2 . Driver Folder

1. The sequence of setup is "Main Chip -> VGA -> LAN -> SOUND -> TXE ->

TOUCH[Device folder]"

2. You will be prompted to reboot when installation is complete.

+--->\Flash BIOS\AFUa.bat

+--->\Plaform\

+--->\Device\

3-1-1-3 . User Manual Folder

\AdbeRdr930_en_US.exe (PDF File reader)

3-1-1-4 . README

The DRIVER DISC introduction

Page 43

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:39

3-1-2. Intel

®

Chipset Device Software Installation Utility

3-1-2-1. Introduction

The Intel® Chipset Software Installation Utility installs Windows *.INF files to the

target system. These files outline to the operating system how to configure the Intel

chipset components in order to ensure the following features function properly:

SATA Storage Support (SATA & SATA II)

USB Support (1.1 & 2.0)

Identification of Intel

®

Chipset Components in Device Manager

3-1-2-2. Installation of Intel® Chipset Driver

The utility pack is to be installed only for POSReady 7, Windows 8.1 and Windows

10 series, and it should be installed right after the OS installation. Please follow the

steps below:

1. Connect the USB CD-ROM device to PA-6222 and insert the driver disk.

2. Enter the “Main Chip” folder where the Chipset driver is located (depending

on your OS platform).

3. Click Setup.exe file for driver installation.

4. Follow the on-screen instructions to complete the installation.

5. Once the installation is completed, shut down the system and restart PA-6222

for the changes to take effect.

Page 44

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:40

3-1-3. VGA Driver Utility

The VGA interface embedded with PA-6222 can support a wide range of display

types. You can have dual displays via CRT & LVDS interfaces work

simultaneously.

3-1-3-1. Installation of VGA Driver

To install the Graphics driver, follow the steps below:

1. Connect the USB-CD ROM device to PA-6222 and insert the driver disk.

2. Enter the “Graphics” folder where the VGA driver is located (depending on

your OS platform).

3. Click Setup.exe file for driver installation.

4. Follow the on-screen instructions to complete the installation.

5. Once the installation is completed, shut down the system and restart PA-6222

for the changes to take effect.

3-1-4. LAN Driver Utility

PA-6222 is enhanced with LAN function that can support various network adapters.

Installation platform for the LAN driver is listed as follows:

3-1-4-1. Installation of LAN Driver

To install the LAN Driver, follow the steps below:

1. Connect the USB DVD-ROM device to PA-6222 and insert the driver disk.

2. Enter the “LAN Chip” folder where the LAN driver is located (depending on

your OS platform).

3. Click Setup.exe file for driver installation.

4. Follow the on-screen instructions to complete the installation.

5. Once the installation is completed, shut down the system and restart PA-6222 for

the changes to take effect.

For more details on the Installation procedure, please refer to the Readme.txt

file found on LAN Driver Utility.

Page 45

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:41

3-1-5. Sound Driver Utility

The sound function enhanced in this system is fully compatible with Windows

POSReady 7 & Windows 8 & Windows 10 series. Below, you will find the content of

the Sound driver.

3-1-5-1. Installation of Sound Driver

To install the Sound Driver, follow the steps below:

1. Connect the USB DVD-ROM device to PA-6222 and insert the driver disk.

2. Enter the “Sound Codec” folder where the sound driver is located (depending on

your OS platform).

3. Click Setup.exe file for driver installation.

4. Follow the on-screen instructions to complete the installation.

5. Once the installation is completed, shut down the system and restart PA-6222 for

the changes to take effect.

3-1-6. Touchscreen Driver Utility

The touchscreen driver utility can only be installed on Windows POSReady 7 &

Windows 8 & Windows 10 series, and it should be installed right after the OS

installation.

3-1-6-1. Installation of Touchscreen Driver

To install the touchscreen driver, follow the steps below:

1. Connect the USB DVD-ROM device to PA-6222 and insert the driver disk.

2. Enter the “Device\Touch Controller” folder where the touchscreen driver is

located.

3. Click Setup.exe file for driver installation.

4. Follow the on-screen instructions to complete the installation.

5. Once the installation is completed, shut down the system and restart PA-6222 for

the changes to take effect.

Page 46

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:42

3-1-7. Fingerprint Driver Utility (Optional)

The fingerprint driver utility can only be installed on a Windows platform, and it

should be installed right after the OS installation.

3-1-7-1. Installation of Fingerprint Driver

To install the fingerprint driver, follow the steps below:

1. Connect the USB DVD-ROM device to PA-6222 and insert the driver disk.

2. Enter the “Device\Embedded Fingerprint” folder where the fingerprint driver is

located.

3. Click Setup.exe file for driver installation.

4. Follow the on-screen instructions to complete the installation.

5. Once the installation is completed, shut down the system and restart PA-6222 for

the changes to take effect.

3-1-8. RFID Module Driver Utility (Optional)

The RFID driver utility can only be installed on Windows POSReady7 & Windows

8 & Windows 10 series, and it should be installed right after the OS installation.

3-1-8-1. Installation of RFID Module Driver

To install the RFID driver, follow the steps below:

1. Connect the USB DVD-ROM device to PA-6222 and insert the driver disk.

2. Enter the “Device\RFID” folder where the RFID Module driver is located.

3. Click Autorun.exe file for driver installation.

4. Select Mifare Demo Software V1.5R8.

5. Follow the on-screen instructions to complete the installation.

6. Once the installation is completed, shut down the system and restart PA-6222 for

the changes to take effect.

Page 47

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:43

3-1-9. Wireless Module Driver Utility (Optional)

The wireless driver utility can only be installed on Windows POSReady7 &

Windows 8 & Windows 10 series, and it should be installed right after the OS

installation.

3-1-9-1. Installation of Wireless Driver

To install the wireless driver, follow the steps below:

1. Connect the USB DVD-ROM device to PA-6222 and insert the driver disk.

2. Enter the “Device\WIFI module” folder where the wireless driver is located.

3. Click exe file for driver installation.

4. Follow the on-screen instructions to complete the installation.

5. Once the installation is completed, shut down the system and restart PA-6222 for

the changes to take effect.

3-1-10. For Intel Trusted Execution Engine Interface

3-1-10-1. Introduction

For POSReady 7 only. Pre-install Microsoft's Kernel-Mode Driver Framework

(KMDF) version 1.11 before you install the Intel(R) Trusted Execution Engine (TXE)

driver in order to avoid errors in Device Manager.

3-1-10-2. Installation Instructions for Kernel-Mode Driver Framework (KMDF)

To install the Kernel-Mode Driver Framework (KMDF), follow the steps below:

1. Insert the driver disk into a CD ROM device.

2. (For POSReady 7 only) Enter the “Windows 7 KMDF” folder where the Chipset

driver is located (depending on your OS platform).

3. (For POSReady 7 only) Click Setup kmdf-1.11 exe file for driver installation.

4. Enter the “Intel(R) TXE Package” folder where the Chipset driver is located

(depending on your OS platform).

5. Click Setup TXE.exe file for driver installation.

Page 48

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:44

3-2. EMBEDDED PERIPHERAL DEVICES

Command lists and driver installation guide for peripheral devices of the system VFD and MSR – are explicitly included in this section.

3-2-1. VFD: MB-4103 (RS-232)

3-2-1-1. Command List

1. VFD Registry Operation

Registry Path: [HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\

LineDisplay\Prox-PMP4000]

Registry Name

Default Data

Notes

Default Value

LineDisplay.PMP4000.1

-

BaudRate

9600

-

BitLength

8 - Parity

0 - Port

COM1

-

Stop

1

-

1. OPOS VFD Service Object and Method Relations

Method

Status of support

Notes

Open

○ - Close

○ - ClaimDevice

○ - ReleaseDevice

○ - Enable

○ - Disable

○ - DisplayText

○ - DisplayTextAt

○ - ClearText

○

-

Page 49

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:45

3-2-1-2. OPOS Driver

The MB4000_OposSetup.exe program sets up the registry information and example

program of VFD for OPOS program uses.

1. Installation

Below steps guide you to install the MB4000_OposSetup program.

Run the MB4000_OposSetup setup file

This setup also installs the Prox-PMP4000 program.

Follow the wizard instructions to complete the installation.

2. Launching Program

Below steps guide you to load the Prox-PMP4000 program.

Click LineDisplay folder from the path Start/Programs/Protech OPOS.

Click Prox-PMP4000 to launch the program.

Page 50

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:46

3. OPOS Control Object of Prox-PMP4000 program

Main screen buttons:

Button/Item

Description

Text

Display text at the current cursor position.

TextAt

Display the string of characters at the specified “y ” and

“x ”.

Clear

Clear the current window by displaying

Attribute

Normal, blink, reverse, blink, reverse

4. MB4103 type

Key Name

Type

Default Value

Note

BaudRate

String

9600

UART Baud Rate (default)

BitLength

String

8

UART Data Bit (default)

Parity

String

0

UART Parity Bit (default)

Port

String

COM1

UART Port (default)

Stop

String

1

UART Stop Bit (default)

Page 51

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:47

5. OPOS APIs Support List

Category

Type

Name

Mutability

OPOS

APG

Version

VFD .SO

Properties

common bool

AutoDisable

R/W

1.2

Not Applicable

Properties

common long

BinaryConversion

R/W

1.2

Not Applicable

Properties

common long

CapPowerReporting

Read only

1.3

Not Applicable

Properties

common

string

CheckHealthText

Read only

1.0

Supported

Properties

common bool

Claimed

Read only

1.0

Supported

Properties

common long

DataCount

Read only

1.2

Not Applicable

Properties

common bool

DataEventEnabled

Read only

1.0

Not Applicable

Properties

common bool

DeviceEnabled

R/W

1.0

Not Applicable

Properties

common bool

FreezeEvents

R/W

1.0

Not Applicable

Properties

common long

OpenResult

Read only

1.5

Not Applicable

Properties

common bool

OutputID

Read only

1.0

Not Applicable

Properties

common bool

PowerNotify

R/W

1.3

Not Applicable

Properties

common bool

PowerState

Read only

1.3

Not Applicable

Properties

common long

ResultCode

Read only

1.0

Supported

Properties

common long

ResultCodeExtended

Read only

1.0

Not Applicable

Properties

common long

State

Read only

1.0

Supported

Properties

common

string

ControlObject

Description

Read only

1.0

Not Applicable

Properties

common long

ControlObject Version

Read only

1.0

Not Applicable

Properties

common

string

ServiceObject

Description

Read only

1.0

Supported

Properties

common long

ServiceObject Version

Read only

1.0

Supported

Properties

common

string

DeviceDescription

Read only

1.0

Supported

Properties

common

string

ControlObject

Description

Read only

1.0

Not Applicable

Properties

specific long

CapBlink

Read only

1.0

Not Applicable

Properties

specific bool

CapBlinkRate

Read only

1.6

Not Applicable

Properties

specific bool

CapBrightness

Read only

1.0

Not Applicable

Properties

specific long

CapCharacterSet

Read only

1.0

Not Applicable

Properties

specific long

CapCursorType

Read only

1.6

Not Applicable

Properties

specific bool

CapCustomGlyph

Read only

1.6

Not Applicable

Properties

specific bool

CapDescriptors

Read only

1.0

Not Applicable

Properties

specific bool

CapHMarquee

Read only

1.0

Not Applicable

Properties

specific bool

CapICharWait

Read only

1.0

Not Applicable

Properties

specific long

CapReadBack

Read only

1.6

Not Applicable

Properties

specific long

CapReverse

Read only

1.6

Not Applicable

Properties

specific bool

CapVMarquee

Read only

1.0

Not Applicable

Properties

specific long

BlinkRate

R/W

1.6

Not Applicable

Properties

specific long

DeviceWindows

Read only

1.0

Not Applicable

Page 52

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:48

Category

Type

Name

Mutability

OPOS

APG

Version

VFD .SO

Properties

specific long

DeviceRows

Read only

1.0

Not Applicable

Properties

specific long

DeviceColumns

Read only

1.0

Not Applicable

Properties

specific long

DeviceDescriptors

Read only

1.0

Not Applicable

Properties

specific long

DeviceBrightness

R/W

1.0

Not Applicable

Properties

specific long

CharacterSet

R/W

1.0

Not Applicable

Properties

specific string

CharacterSetList

Read only

1.0

Not Applicable

Properties

specific long

CurrentWindow

R/W

1.0

Not Applicable

Properties

specific long

Rows

Read only

1.0

Not Applicable

Properties

specific long

Columns

Read only

1.0

Not Applicable

Properties

specific long

CursorRow

R/W

1.0

Not Applicable

Properties

specific long

CursorColumn

R/W

1.0

Not Applicable

Properties

specific long

CursorType

R/W

1.6

Not Applicable

Properties

specific bool

CursorUpdate

R/W

1.0

Not Applicable

Properties

specific long

MarqueeType

R/W

1.0

Not Applicable

Properties

specific long

MarqueeFormat

R/W

1.0

Not Applicable

Properties

specific long

MarqueeUnitWait

R/W

1.0

Not Applicable

Properties

specific long

MarqueeRepeatWait

R/W

1.0

Not Applicable

Properties

specific long

InterCharacterWait

R/W

1.0

Not Applicable

Properties

specific string

CustomGlyphList

Read only

1.6

Not Applicable

Properties

specific long

GlyphHeight

Read only

1.6

Not Applicable

Properties

specific long

GlyphWidth

Read only

1.6

Not Applicable

Methods

common

Open

-

1.0

Supported

Methods

common

Close

-

1.0

Supported

Methods

common

Claim

-

1.0

Supported

Methods

common

ClaimDevice

-

1.0

Supported

Methods

common

Release

-

1.0

Supported

Methods

common

ReleaseDevice

-

1.0

Supported

Methods

common

CheckHealth

-

1.0

Not Applicable

Methods

common

ClearInput

-

1.0

Not Applicable

Methods

common

ClearOutput

-

1.0

Not Applicable

Methods

common

DirectIO

-

1.0

Not Applicable

Methods

specific

DisplayText

-

1.0

Supported

Methods

specific

DisplayTextAt

-

1.0

Supported

Methods

specific

ClearText

-

1.0

Supported

Methods

specific

ScrollText

-

1.0

Not Applicable

Methods

specific

SetDescriptor

-

1.0

Not Applicable

Methods

specific

ClearDescriptors

-

1.0

Not Applicable

Methods

specific

CreateWindow

-

1.0

Not Applicable

Methods

specific

DestroyWindow

-

1.0

Not Applicable

Methods

specific

RefreshWindow

-

1.0

Not Applicable)

Methods

specific

ReadCharacterAtCursor

-

1.6

Not Applicable

Methods

specific

DefineGlyph

-

1.6

Not Applicable

Page 53

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:49

Category

Type

Name

Mutability

OPOS

APG

Version

VFD .SO

Events

common

DataEvent

-

1.0

Not Applicable

Events

common

DirectIOEvent

-

1.0

Not Applicable

Events

common

ErrorEvent

-

1.0

Not Applicable

Events

common

OutputComplete

Event

-

1.0

Not Applicable

Events

common

StatusUpdate

Event

-

1.3

Not Applicable

Page 54

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:50

3-2-2. MSR: MB-3102 (PS/2)

3-2-2-1. OPOS Driver

The MB301X_OposSetup.exe program sets up the registry information of MSR

reader for OPOS program uses.

1. Installation

Below steps guide you to install the MB301X_OposSetup program.

Run the OPOSMSR_Setup.exe setup file.

This setup also installs the Prox-PMP3000 program.

Follow the wizard instructions to complete the installation.

2. Launching Program

Below steps guide you load the Prox-PMP3000 program.

Click MSR folder from the path Start/Programs/Protech OPOS.

Click Prox-PMP3000 to launch the program.

Page 55

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:51

3. Configuration of Prox-PMP3000 program

a.) Main screen & Control tab items:

Button/Item

Description

COM

(dropdown list) To set COM port number (only for

USRT/USB interface).

AutoDisable

(check box) Set auto-disable

FreeseEvents

(check box) Set freeze events

Page 56

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:52

b.) Description tab: S.O and C.O information

c.) Track Control tab items

Button/Item

Description

DecodeData

Set decode data properties applicable).

ParseDecodeData

Set parse decode data properties

TransmitSentinels

Set transmit-sentinels properties

ErrorReporting Type

Card, track

TracksToRead

Track1, track2, track3, tracks12, tracks13, tracks14,

tracks23, tracks24, tracks34, tracks123, tracks124,

tracks134, tracks234, tracks1234 (Tracks4 is not

applicable).

Page 57

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:53

d.) Track Data tab items

Button/Item

Description

TracksData

(Row) Display data of all tracks (Track4 is not applicable).

e.) Parsed Data tab items

Button/Item

Description

Parsed Data

Display special properties.

4. MB301X type (RS232/PS2)

Key Name

Type

Default Value

Note

default

string

PMP3000

OPOS S.O Link

Page 58

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:54

5. OPOS APIs support List

Category

Type

Name

Mutability

OPOS

APG

Version

VFD .SO

Properties

common bool

AutoDisable

R/W

1.2

Supported

Properties

common long

BinaryConversion

R/W

1.2

Not Applicable

Properties

common long

CapPowerReporting

Read only

1.3

Supported

Properties

common

string

CheckHealthText

Read only

1.0

Supported

Properties

common bool

Claimed

Read only

1.0

Supported

Properties

common long

DataCount

Read only

1.2

Supported

Properties

common bool

DataEventEnabled

R/W

1.0

Supported

Properties

common bool

DeviceEnabled

R/W

1.0

Supported

Properties

common bool

FreezeEvents

R/W

1.0

Supported

Properties

common long

OpenResult

Read only

1.5

Supported

Properties

common long

OutputID

Read only

1.0

Not Applicable

Properties

common long

PowerNotify

R/W

1.3

Not Applicable

Properties

common long

PowerState

Read only

1.3

Not Applicable

Properties

common long

ResultCode

Read only

1.0

Supported

Properties

common long

ResultCodeExtended

Read only

1.0

Supported

Properties

common long

State

Read only

1.0

Not Applicable

Properties

common

string

ControlObject

Description

Read only

1.0

Not Applicable

Properties

common long

ControlObjectVersion

Read only

1.0

Not Applicable

Properties

common

string

ServiceObject

Description

Read only

1.0

Supported

Properties

common long

ServiceObjectVersion

Read only

1.0

Not Applicable

Properties

common

string

DeviceDescription

Read only

1.0

Supported

Properties

common string

DeviceName

Read only

1.0

Supported

Properties

specific bool

CapISO

Read only

1.0

Supported

Properties

specific bool

CapJISOne

Read only

1.0

Supported

Properties

specific bool

CapJISTwo

Read only

1.0

Supported

Properties

specific bool

CapTransmitSentinels

Read only

1.5

Supported

Properties

specific long

TracksToRead

R/W

1.0

Supported

Properties

specific bool

DecodeData

R/W

1.0

Not Applicable

Properties

specific bool

ParseDecodeData

R/W

1.0

Supported

Properties

specific long

ErrorReportType

R/W

1.2

Not Applicable

Properties

specific string

Track1Data

Read only

1.0

Supported

Properties

specific string

Track2Data

Read only

1.0

Supported

Properties

specific string

Track3Data

Read only

1.0

Supported

Properties

specific string

Track4Data

Read only

1.5

Not Applicable

Properties

specific string

AccountNumber

Read only

1.0

Supported

Properties

specific string

ExpirationDate

Read only

1.0

Supported

Properties

specific string

Title

Read only

1.0

Supported

Page 59

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:55

Category

Type

Name

Mutability

OPOS

APG

Version

VFD .SO

Properties

specific string

FirstName

Read only

1.0

Supported

Properties

specific string

MiddleInitial

Read only

1.0

Supported

Properties

specific string

Surname

Read only

1.0

Supported

Properties

specific string

Suffix

Read only

1.0

Supported

Properties

specific string

ServiceCode

Read only

1.0

Supported

Properties

specific

binary

Track1

DiscretionaryData

Read only

1.0

Supported

Properties

specific

binary

Track2

DiscretionaryData

Read only

1.0

Supported

Properties

specific bool

TransmitSentinels

R/W

1.5

Supported

Methods

common

Open

-

1.0

Supported

Methods

common

Close

-

1.0

Supported

Methods

common

Claim

-

1.0

Supported

Methods

common

ClaimDevice

-

1.5

Supported

Methods

common

Release

-

1.0

Supported

Methods

common

ReleaseDevice

-

1.5

Supported

Methods

common

CheckHealth

-

1.0

Not Applicable

Methods

common

ClearInput

-

1.0

Supported

Methods

common

ClearOutput

-

1.0

Not Applicable

Methods

common

DirectIO

-

1.0

Not Applicable

Events

common

DataEvent

-

1.0

Supported

Events

common

DirectIOEvent

-

1.0

Not Applicable

Events

common

ErrorEvent

-

1.0

Not Applicable

Events

common

OutputCompleteEvent

-

1.0

Not Applicable

Events

common

StatusUpdateEvent

-

1.0

Not Applicable

Page 60

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:56

3-2-3. MSR: GIGA-TMS MJR243R (RS-232)

3-2-3-1. Command List

1. MSR Registry Operation

Registry Path:

[HKEY_LOCAL_MACHINE\SOFTWARE\OLEforRetail\ServiceOPOS\

MSR\MJR243]

Registry Name

Default Data

Notes

CapISO

1

Capability for reading

ISO track data

CapJISOne

1

(reserved)

CapJISTwo

1

(reserved)

CapTransmitSentinels

1

Capability for reading

Transmit Sentinels

Debug

0

Enable the tracing,

and create a log file

Description

GIGATMS

MSR POS

Description for SO driver

DeviceName

MJR243

Devive Name for CO open

FileName

(NULL)

(reserved)

HardwareProvider

0

(reserved)

Model

MJR243

Device model name

Parity

None

Parity for the communication

port

Port

COM4

Comport

Protocol

Hardware

Communication Control

Baudrate

19200

RS232 baudrate

Page 61

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:57

2. OPOS MSR Service Object and Method Relations

Method

Status of support by

the driver

Notes

Open

○ - Close

○ - Claim

○ - ClaimDevice

○ - Release

○ - ReleaseDevice

○

-

ClearInput

○

-

ClearInputProperties

○ - DataEvent

○

-

Claimed

○

Read only

DataCount

○

Read only

DataEventEnabled

○

R/W

DeviceEnabled

○

R/W

FreezeEvents

○

R/W

OpenResult

○

Read only

ResultCode

○

Read only

ResultCodeExtended

○

Read only

State

○

Read only

ControlObjectDescription

○

Read only

ControlObjectVersion

○

Read only

ServiceObjectDescription

○

Read only

ServiceObjectVersion

○

Read only

DeviceDescription

○

Read only

DeviceName

○

Read only

CapISO

○

Read only

CapTransmitSentinels

○

Read only

AccountNumber

○

Read only

DecodeData

○

R/W

ExpirationDate

○

Read only

FirstName

○

Read only

MiddleInitial

○

Read Only

ParseDecodeData

○

R/W

ServiceCode

○

Read Only

Suffix

○

Read Only

Surname

○

Read Only

Title

○

Read Only

Track1Data

○

Read Only

Track1DiscretionaryData

○

Read Only

Page 62

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:58

Method

Status of support by

the driver

Notes

Track2Data

○

Read Only

Track2DiscretionaryData

○

Read Only

Track3Data

○

Read Only

TracksToRead

○

R/W

TransmitSentinels

○

R/W

Page 63

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:59

3-2-3-2. OPOS MSR Register

The OPOS MSR Register program sets up the registry information of MSRHK

reader for OPOS program uses.

1. Installation

Below steps guide you to install the OPOS MSR Register program.

Insert the setup CD

Run the setup file OPOSMSR_Setup.exe located in the Software folder of CD.

This setup also installs the OPOS MSR Tester program.

Follow the wizard instructions to complete the installation.

2. Launching Program

Below steps guide you to load the OPOS MSR Register program.

Click OPOS folder from the path Start/Programs/GIGA‐TMS.

Click OPOS MSR Register to launch the program.

Page 64

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:60

3. Configuration of OPOS MSR Register program

a.) Main screen buttons/items:

Button/Item

Description

Control Object

(Check box) Register the OPOSMSR.ocx common

control object driver. This needs to be checked to run the

OPOS MSR Tester program.

Service Object

(Left pane) The Service Object driver types. So far only

four types are supported. Each type support specific MSR

readers. For more details, please refer to the section

OPOS MSR Service Object and Method Relations.

Service Object

(Right pane) The registered MSR with specified device

name.

Reg

Create a new device name for selected MSR.

Unreg

Remove selected device name from registry.

Exit

End the program.

b.) Follow the steps below to register the MSRHK OPOS information.

Step 1: Select an item in Service Object List box (left pane). Make sure the

correct item is selected.

Step 2: Click Reg button

Step 3: In the OPOS MSR Setting screen, enter the device name and click OK.

Page 65

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:61

c.) Example 1. MAGTEK USB HID

d.) Example 2. PROMAG MSR/MJR PART‐ NO, Keyboard mode.

Page 66

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:62

e.) Example 3. PROGRAM MSR PART‐ NO, HID mode.

If your system doesn’t have any other common control driver, then click Control

Object check box.

Note: To run the OPOPS MSR Tester program, the Control Object must be checked.

4. MJR243 type

Key Name

Type

Default Value

Note

CapISO

string

1

Capability for reading ISO

track data

CapJISOne

string

1

(reserved)

CapJISTwo

string

1

(reserved)

CapTransmitSentinels

string

1

Capability for reading

Transmit Sentinels

Debug

string

0

Enable the tracing, and create a

log file

Description

string

GIGATMS

MSR POS

Description for SO driver

DeviceName

string

MJR243

Devive Name for CO open

FileName

string

(NULL)

(reserved)

HardwareProvider

string

0

(reserved)

Model

string

MJR243

Device model name

Parity

string

None

Parity for the communication

port

Port

string

COM4

Comport Number

Protocol

string

Hardware

Communication Control

Page 67

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:63

Key Name

Type

Default Value

Note

Baudrate

string

19200

RS232 baudrate

5. OPOS APIs support list

Category

Type

Name

Mutability

OPOS

APG

Version

MSR .SO

Properties

common bool

AutoDisable

R/W

1.2

Not Applicable

Properties

common long

BinaryConversion

R/W

1.2

Not Applicable

Properties

common bool

CapCompare

FirmwareVersion

Read only

1.9

Not Applicable

Properties

common long

CapPowerReporting

Read only

1.3

Not Applicable

Properties

common bool

CapStatisticsReporting

Read only

1.8

Not Applicable

Properties

common bool

CapUpdateFirmware

Read only

1.9

Not Applicable

Properties

common bool

CapUpdateStatistics

Read only

1.8

Not Applicable

Properties

common

string

CheckHealthText

Read only

1.0

Not Applicable

Properties

common bool

Claimed

Read only

1.0

Supported

Properties

common long

DataCount

Read only

1.2

Supported

Properties

common bool

DataEventEnabled

R/W

1.0

Supported

Properties

common bool

DeviceEnabled

R/W

1.0

Supported

Properties

common bool

FreezeEvents

R/W

1.0

Supported

Properties

common long

OpenResult

Read only

1.5

Supported

Properties

common long

OutputID

Read only

1.0

Not Applicable

Properties

common long

PowerNotify

R/W

1.3

Not Applicable

Properties

common long

PowerState

Read only

1.3

Not Applicable

Properties

common long

ResultCode

Read only

1.0

Supported

Properties

common long

ResultCodeExtended

Read only

1.0

Supported

Properties

common long

State

Read only

1.0

Supported

Properties

common

string

ControlObject

Description

Read only

1.0

Supported

Properties

common long

ControlObjectVersion

Read only

1.0

Supported

Properties

common

string

ServiceObject

Description

Read only

1.0

Supported

Properties

common long

ServiceObjectVersion

Read only

1.0

Supported

Properties

common

string

DeviceDescription

Read only

1.0

Supported

Properties

common

string

DeviceName

Read only

1.0

Supported

Properties

specific bool

CapISO

Read only

1.0

Supported

Properties

specific bool

CapJISOne

Read only

1.0

Not Applicable

Properties

specific bool

CapJISTwo

Read only

1.0

Not Applicable

Properties

specific bool

CapTransmit

Sentinels

Read only

1.5

Supported

Properties

specific long

CapWriteTracks

Read only

1.1

Not Applicable

Page 68

Chapter 3 Software

PA-6222 SERIES USERS MANUAL

Page:64

Category

Type

Name

Mutability

OPOS

APG

Version

MSR .SO

Properties

specific string

AccountNumber

Read only

1.0

Supported

Properties

specific bool

DecodeData

R/W

1.0

Supported

Properties

specific long

EncodingMaxLength

Read only

1.1

Not Applicable

Properties

specific long

ErrorReportType

R/W

1.2

Not Applicable

Properties

specific string

ExpirationDate

Read only

1.0

Supported

Properties

specific string

FirstName

Read only

1.0

Supported

Properties

specific string

MiddleInitial

Read only

1.0

Supported

Properties

specific bool

ParseDecodeData

R/W

1.0

Supported

Properties

specific string

ServiceCode

Read only

1.0

Supported

Properties