Page 1

INSTRUCTION MANUAL

Type [I

Miter Saw

For Your Own Safety, Read Instruction Manual

Before Starting Operations.

Record the Model No, and Serial No. and date

ot purchase in your manuat for future reference.

Model No.

Serial No.

Date of Purchase

y2 o8Z --/ _-O

Page 2

Uontents i'"

GENERAL SAFETY RULES ........................ ..i'_,..iii_"'i'i.2 _i_li Arm and Clamp ............ 13

SPECIALSAFETY o Jn, !!i.OMeBlade...................iiii....14

MOTOR _ ____RSAWOPERATION ........... i"" 15

Body:land Hand Position ..................................... 15

... 6

,7

.,=_8

I,,,...L. ...................... :.........g

Mounting the saw ......... i............................................... 9

Assembling the Lower Blade Guard ........................... 9

Blade Square to Table ............................................... 10

Checking and Adjusting Blade Square ...................... 11

Travel Pivot Adjustment ............................................. 12

Bevel Pivot Adjustment .............................................. 12

Fence Positions ........................................................... 12

Miter/Bevel Cut ..................................... 16

Compound Cut ............................................................ 17

Cutting Bowed Mater al ............................................ 17

Workpiece Support ..................................................... 18

Auxiliary Fence ........................................................... 18

Filler Blocks for Cutting Crown Moldings .................. 19

Vertical Bevel Cutting ................................................. 19

MAINTAINING YOUR MITER SAW ............................. 21

CONTENT PARTS,,_ ..................................................... 22

TROUBLE SHOOTING ................................................. 27

General Safety Rules

1,Know Your Power Tool

Read and understand the owner's manual and

labels affixed to the tool. Learn its application

and limitations as well as the specific potential

hazards peculiar to this tool.

2.Ground all Tools

This tool is DOUBLE INSULATED to give you

added protection. Double insulation does not

take the place of normal safety precautions

when operating this tool. When servicing this

double insulated tool, use only identical parts,

3.Keep Guards in Place

In working order, and in proper adjustment and

alignment.

4.Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

5,Keep Work Area Clean

Cluttered areas and benches invite accidents.

Floor must not be slippery due to wax or

sawdust.

6.Avoid Dangerous Environment

Don't use power tools in damp or wet locations

or expose them to rain. Keep work area well

lighted. Provide adequate surrounding work

space.

7,Keep Children Away

All visitors should be kept a safe distance from

work area.

8.Make Workshop Child Proof

With padlocks, master switches, or by removing

starter keys.

9.Don't Force Tool

It will do the job better and safer at the rate for

which it was designed.

10.Use Right Tool

Don't force tools or attachment to do a job it

was not designed for.

11,Wear Proper Apparel

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wrist watches) which may get

caught in moving parts. NONSLIP footwear is

recommended, Wear protective hair covering to

contain long hair. Roll long sleeves above the

elbow.

2

12.Use Safety Goggles

Wear safety goggles (must comply with ANStZ

87.1) at all times. Everyday eyeglasses only

have impact resistant lenses, they are NOT

safety glasses, Also, use face or dust mask if

cutting operation is dusty, and ear protectors

(plugs or muffs) during extended periods or

operation.

13,Secure Work

Use clamps or a vise to hold work when

practical. It's safer than using your hands and

frees both hands to operate tool.

14.Don't Overreach

Keep proper footing and balance at all times,

15.Maintain Tools with Care

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing blades, bits, cutters, etc.

16.Disconnect Tools

Before servicing, when changing accessories

such as blades, bits, cutters, etc,

17.Avotd Accidental Starting

Make sure switch is in "OFF" position before

plugging in,

18.Use Recommended Accessories

Consult the owner's manual for recommended

accessories. Follow the instructions that accom-

pany the accessories. The use of improper

accessories may cause hazards.

19.Never Stand on Tool

Serious injury could occur if the tool is tipped or

if the cutting tool is accidentally contacted.

Do not store materials above or near the tool

such that it is necessary to stand on the tool to

reach them,

2O.Check Damaged Parts

Before further use of the tool, a guard or other

part that is damaged should be carefully

checked to ensure that it will operate properly

and perform its intended function, Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A

guar_ or other part that is damaged should be

properly repaired or replaced.

21,Never Leave Tool Running Unattended

Turn power off, Don't leave tool until it comes to

a complete stop.

Page 3

Special

BEFORE USING THE SAW:

1. Assembly and alignment.

2. Learn the function and proper use of:

A. The on-off switch.

B. The upper and lower blade guards.

C, The arbor lock and handle latch.

D. The bevel clamp, fence clamps, and miter

lock handle.

3. Read and understand all safety instructions and'

operating procedures throughout the manual.

4. Read the warning label on the miter saw,

WHEN INSTALLING OR MOVING

THE SAW:

1, To avoid injury from unexpected saw movement'.

A. Place the saw on a firm level surface where

there is plenty of room for handling and

properly supporting the workplace.

B. Support the saw so the table is level and the

saw does not rock.

C. Bolt or clamp the saw to its support,

2, Before moving the saw, lock the miter, bevel

and power-head positions. Unplug electric cord.

3, To avoid back injury, get help when you need to

lift the saw more than 10 inches. Hold the tool

close to your body. Bend your knees so you can

lift with your legs, not your back. Lilt by using

the hand-hold areas at the bottom of the base.

Never carry the tool by the cord or power head

handle. Damage to insulation could cause an

electric shock. Damage to wire connections

could cause a fire.

BEFORE EACH USE:

1. Inspect your saw. If any part of this miter saw is

missing, or bent, or has failed in any way, or

any electrical parts don't work properly, turn the

saw off and unplug the saw. Replace damaged,

missing, or failed parts before using the saw

again.

2. Plan Your Work to protect your eyes, hands,

face, and ears.

A. Wear safety goggles (not glasses) that

comply with ANStZ87,1(shown on package).

Using any power tool can result in foreign

objects being thrown into the eyes, which

can result in permanent eye damage. Safety

goggles are available at stores. Use of

glasses or use of goggles not in compliance

with ANSiZ87.1 could result in severe injury

from breakage of the eye protection.

WEAR YOUR

B. For dusty operations, wear a face shield

along with safety goggles.

C. To avoid injury from jams, slips or thrown

pieces:

@Choose the right 10-inch diameter blade for

the material and the type of cutting you

ptan to do. Use this miter saw to cut only

wood, wood-like products or soft metals

like aluminum. Other materials may sha-

tter, grab at the blade, or create other

dangers.

e Make sure the direction of rotation arrow

on the blade matches the direction arrow

on the saw. The blade teeth should always

point downward at the front of the saw.

eMake sure the blade is sharp, undamaged

and properly aligned. With the saw un-

plugged, push the power-head all the way

down, Hand spin the blade and check for

clearance. Tilt the power-head to 45 degree

bevel and repeat the check, if the blade hits

anything, make the adjustments shown in

the Maintaining Maximum Cutting Capacity

section,

eMake sure the blade and arbor collars are

clean.

• Make sure the collars' recessed sides are

facing toward the blade.

eMake sure the recessed side of the blade

washer (just under the arbor screw head)

faces the collar.

eUsing 1/2-inch box end wrench, make sure

the arbor cap screw retaining the blade

collars is firmly hand tightened.

eMake sure all clamps and locks are tight

and there is no excessive play in any parts.

• Never cut FREEHAND:

a. Brace your workplace solidly against the

fence and table top so it will not rock or

twist during the cut. Make sure no

debris is caught beneath_the workpiece.

b. Make sure no gaps between the work-

piece, fence and table will let the

workpiece shift after it is cut in two.

co Use jigs, fixtures or a different tool for

unstable workpieces.

3

Page 4

• Never cut more than one workplace at a time.

• Make sure the cut off piece C_n move

sideways after it's cut off. Otherwise, it could

get wedged against the blade and thrown

violently. .............._ ,_;_

blocks, etc,)for any workpieces large enou-

gh to tip when not held down to the tabte

top.

b. Do not use this saw to cut pieces too small

to let you easily hold the work while you

keep the thumb side of your index (poi-

nter) finger against the outside edge of the

fence.

c. When cutting irregularly shaped work*

pieces, plan your work so it will not slip

and pinch the blade. A piece of motding,

for example, must lie flat or be held by a

fixture or jig that will not let it twist, rock

or slip while being cut.

d. Properly support round material such as

dowel rods, or tubing. They have a

tendency to roll while being cut, causing

the blade to _bite. _ To avoid this, always

use a fixture designed to properly hold

your work piece.

• Make sure there are no nails or foreign

objects in the part of the workpiece to be cut.

• Make sure bystanders are clear of the tool and

workpiece. Keep them clear of the area behind

the saw where debris will be thrown.

• Never turn your miter saw _ON_ before

clearing everything except the workpiece and

related support devices off the table.

D. To avoid risk of hearing damage, wear ear

plugs or muffs during extended periods of

operation.

E, To avoid being suddenly pufled into the blade:

1. Do not wear gloves.

2. Remove all jewelry and loose clothing.

3. Tie back long hair.

4. Rol! long sleeves above the elbow.

G, To avoid an electrical shock, make sure your

fingers do not touch the metal prongs on the

plug when inserting or removing the plug to

or from a live outlet.

H. Never put lubricants on the blade while it's

spinning,

1.To avoid burns or other fire damage, never

use the saw near flammable liquids, vapors or

gases.

J. To avoid injury from unsafe accessories, use

only accessories shown on the recommended

accessories list in this manual.

WHENEVER SAW IS RUNNING:

ii = ii i i =========lllll

I WARNING: Don't allow familiarity (gained trom

Irequent use of your miter saw) to cause a careless

mistake. Always remember that a careless fraction

....#fa second is enough,, t,o cause a severe injury.

1. Before actually cutting with the saw, let it run

for a while. If your saw makes an unfamiliar

noise or if it vibrates excessively, stop immedi-

ately. Turn the saw off. Unplug the saw. Do not

restart until finding and correcting the problem,

2. Never confine the piece being cut off. Never

hold it, clamp it, touch it, or use length stops

against it. It must be free to move sideways. If

confined, it could get wedged against the blade

and thrown violently.

3. Avoid awkward hand positions where a sudden

slip could cause a hand to move into the blade.

4, Let the blade reach ful! speed before cutting.

5. Feed the saw into the workpiece only fast

enough to let the blade cut without bogging

down or binding,

6. Before freeing jammed material, release switch

and unplug the saw. Wait for all moving parts to

stop.

7. After finishing a cut, keep holding the power-

head down, release the switch, and wait for all

moving parts to stop before moving your hands,

f

4

Page 5

Motor

POWER SUPPLY

Motor Specifications

:The AC motor, u_ed _!n this saw is a universal,

nonreversible type having the following specifica-

tions:

Maximum Developed H.P .............................. 3

Voltage ............................................................ 120

Amperes ...................................................... 15

Hertz (Cycles) ................................................ 60

Phase .................................... :.:_...................... Single

RPM ................................................................... 4500

Rotation of Shaft ....................................... Clock wise

Brake ........................................................... Automatic

-- i JJL

WARNING: To avoid electrical hazards, fire

hazards, or damage to the tool, use proper circuit

protection. Your saw is wired at the factory for 120v

operation, Connect to a 120v, 15-amp, branch

circuit and use a 15-amp time delay fuse or circuit

breaker. To avoid shock or fire, if power cord is

worn or cut, or damaged in any way, have it

:replaced immediately.

I ,i ii ii ,,,i, ,11

DOUBLE INSULATED

The miter saw is double insulated to provide a

double thickness of insulation between you and the

tool's electrical system. All exposed metal parts

are isolated from the internal metal motor compo-

i nents with protective insulation,

Your unit has a plug that looks like the one shown

below

This power tool is equipped with a 2-conductor

cord listed by Underwriters Laboratories (UL). The

plug permits you to use any conventional 120-volt

electrical outlet without necessity for maintaining a

ground connection.

CAUTION: Double insulation does not take the

place of normal safety precautions when operating

this tool.

DANGER: To avoid electrocution:

1. Use only identical replacement parts when

servicing a tool with double insulation. Servicing

should be performed by a qualified service

technician,

2. Do not use in rain or where floor is wet,

This toot is intended for indoor residential use

only.

MOTOR SAFETY PROTECTION

CAUTION: Toavoid motor damage, this motor

should be blown out or vacuumed frequently to

keep sawdust from interfering with normal motor

ventilation.

1, Connect this tool to a 120V, 15-amp branch

circuit with a 15-amp time delay fuse or circuit

breaker.Using the wrong size fuse can damage

the motor.

2. If the motor won't start, release the trigger

switch immediately. UNPLUG THE TOOL, Check

the saw blade to make sure it turns freely. If the

blade is free, try to start the motor again. If the

motor still does not start, refer to the "MotOr

Trouble-Shooting Chart."

3, It the motor suddenly stalls while cutting wood,

release the trigger switch, unplug the tool, and

free the blade from the wood, Then you may

restart the motor and finish the cut.

4 Fuses may "blow"or circuit breakers may trip

frequently if:

a, MOTOR IS OVERLOADED-Overloading can

occur if you feed too rapidly or make too

many start/stops in a short time,

b. Voltages not more than 10_ above or below

the nameplate voltage can handle normal

loads. For heavy loads, however, the voltage

at motor terminals must equal the voltage

specified on nameplate

5 Most motor troubles may be traced to loose or

incorrect connections, overload, tow voltage

(such as small size wire in the supply circuit) or

to overly long supply circuit wire, Always check

the connections, the load and the supply circuit

whenever motor doesn't work well. Check wire

sizes and length with the Wire Size Chart below,

WIRE SIZES

The use of any extension coro ¢ilt cause some

toss of power. To keep this to a minimum and to

prevent overheating and motor burn-out, use the

table below to determine the minimum wire size

(A.W.G.) extension cord.

For circuits that are farther than 100 feet away

from electrical service box, the wire size must be

increased proportionately in order to deliver ample

voltage to the saw motor.

Length of the Wire Sizes Required For 120V

Conductor (American Wire Gage Number)

0-25Ft No, 16

26-50Ft No,14

51-100Ft No. 12

Page 6

Getting To Know Your

1. Warning label

3. Fence

Lock Screws

Handle Latch

Bevel

LoCk Halndle

Power Cord

Upper

Blade

Guard

Lock Off Button

/

7. Miter

Saw Handle

Sawdust

Ejection

Port

\

ger Switch

Changing Blade

Wrench

Bevel Scale

6. Lower

Blade Guard

Fence o

Warning Line

Miter Scale

Index Spring

Miter

Lock Handle

6

Page 7

Getting To Know

1. Warning label

2. Handle Latch

The miter saw can be locked in the lowered

position for compact storage

3. Fence Lock Screws

The fence has two positions for increased

crosscut capacity. The lock screws secure the

fence to the base. The saw is shipped with the

fence in the rear position.

4. Miter Lock Handle

The miter lock handle securely locks the miter

saw at a desired miter angle, Index points have

been provided at 0°,15°R/L, 22.5°R/L,30°RiL,and

45°RiL.

.

=

The bevel lock handle locks the miter saw at a

desired bevel angle.

Lower Blade Guard

The blade guard helps protect your hands from

the blade in the raised position. To avoid

binding on the workpiece, it retracts as the

blade is lowered.

Miter Saw Handle

The saw handte contains the trigger switch with

a lock-off button, The blade is lowered into the

workpiece by pushing down on the handle. The

saw will return to it's upright position when the

handle is released.

iiiiiiiiiiiiiiii IIIIHIII I HIHIII II I Hill

Glossary of

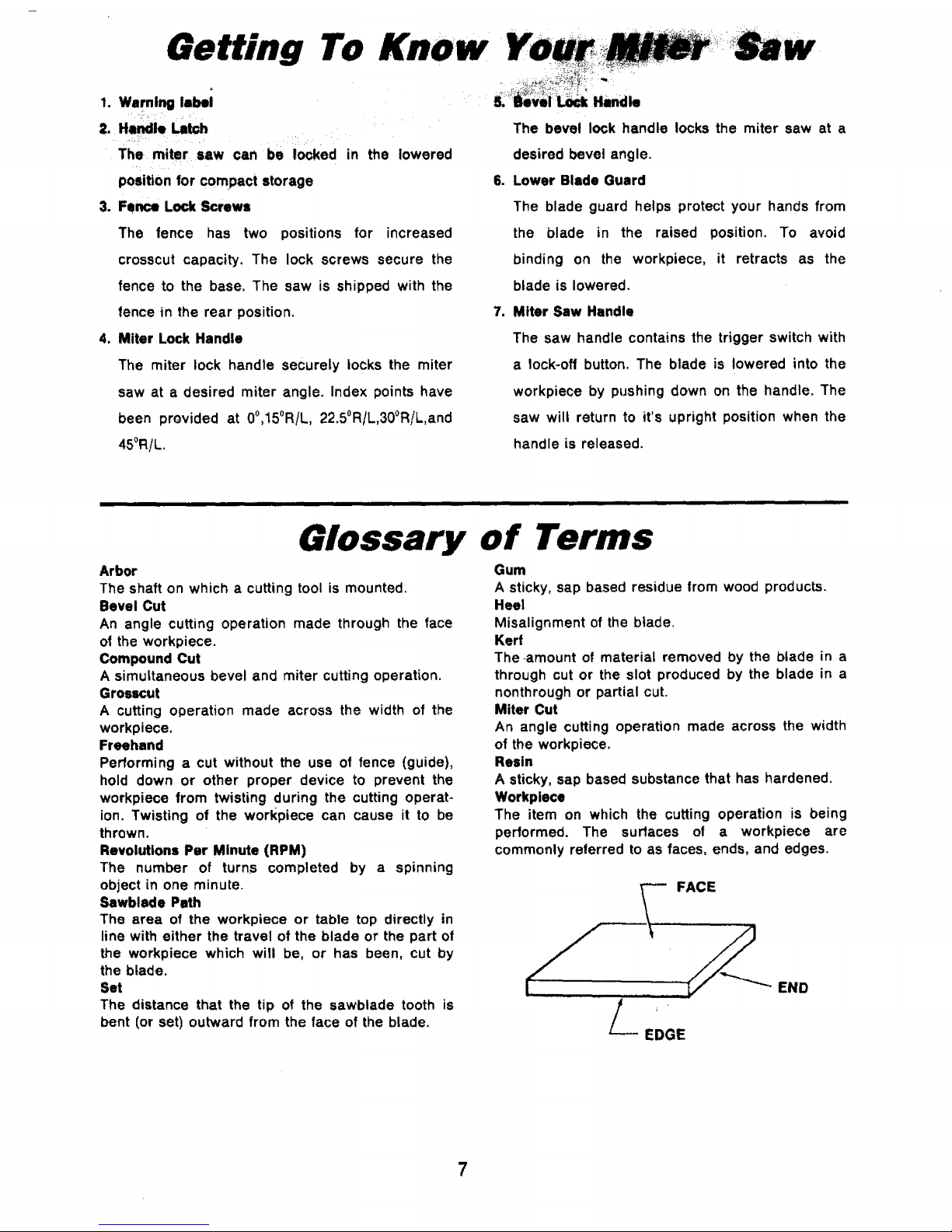

Arbor

The shaft on which a cutting tool is mounted,

Bevel Cut

An angle cutting operation made through the face

of the workpiece.

Compound Cut

A simultaneous bevel and miter cutting operation.

Grosscut

A cutting operation made across the width of the

workpiece.

Freehand

Performing a cut without the use of fence (guide),

hold down or other proper device to prevent the

workpiece from twisting during the cutting operat-

ion. Twisting of the worl<piece can cause it to be

thrown.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning

object in one minute.

Sawblade Path

The area of the workpiece or table top directly in

line with either the travel of the blade or the part of

the workpiece which will be, or has been, cut by

the blade.

Set

The distance that the tip of the sawblade tooth is

bent (or set) outward from the face of the blade.

Gum

A sticky, sap based residue from wood products.

Heel

Misalignment of the btade.

Kerr

The.amount of material removed by the blade in a

through cut or the slot produced by the blade in a

nonthrough or partial cut.

Miter Cut

An angle cutting operation made across the width

of the workpiece.

Resin

A sticky, sap based substance that has hardened.

Workplece

The item on which the cutting operation is being

performed. The surfaces of a workpiece are

commonly referred to as faces, ends, and edges.

EDGE

FACE

END

7

Page 8

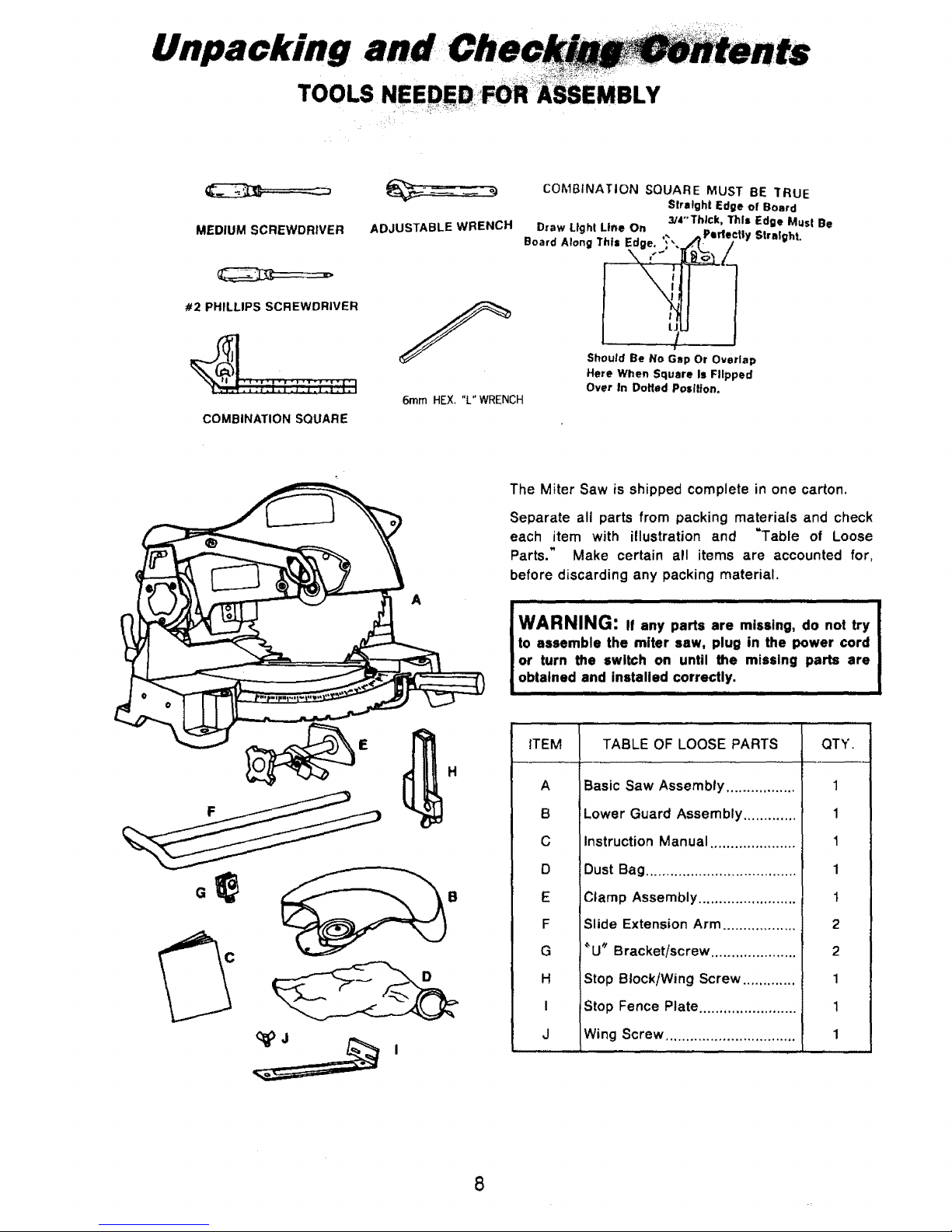

n al

U packing

TOOLS

IBLY

MEDIUM SCREWDRIVER

#2 PHILLIPS SCREWDRIVER

COMBINATION SQUARE

ADJUSTABLE WRENCH

6ramHEX,"L"WRENCH

COMBINATION SQUARE MUST GE TRUE

Stratgh! Edge of Board

3/4"'Thtck, This Edge Must Be

Draw Light Line On

°o.,,.,oo0,,,.V0. :i

t.

ShOuld Be No Gap Or Overlap

Here When Square Is Flipped

Over In Doffed Position,

_ Perlectly Straight.

A

The Miter Saw is shipped complete in one carton.

Separate all parts from packing materials and check

each item with illustration and =Table of Loose

Parts." Make certain all items are accounted for,

before discarding any packing material.

,,,ll i iiiiiiiiiii i ,,,,,l_lul,iii ii i

l WARNING: If any parts are missing, do not try

I to assemble the miter saw, plug in the power cord

I or turn the switch on until the missing parts are

obtained and installed correctly.

ITEM QTY.

A

B

C

D

E

F

G

H

I

J

TABLE OF LOOSE PARTS

Basic Saw Assembly .................

Lower Guard Assembly .............

Instruction Manual .....................

Dust Bag .....................................

Clamp Assembly

Slide Extension Arm ..................

_U_ Bracket/screw .....................

Stop Block/Wing Screw .............

Stop Fence Plate ........................

Wing Screw ................................

1

1

1

1

I

2

2

1

1

1

8

Page 9

,q s e rn u Ey et

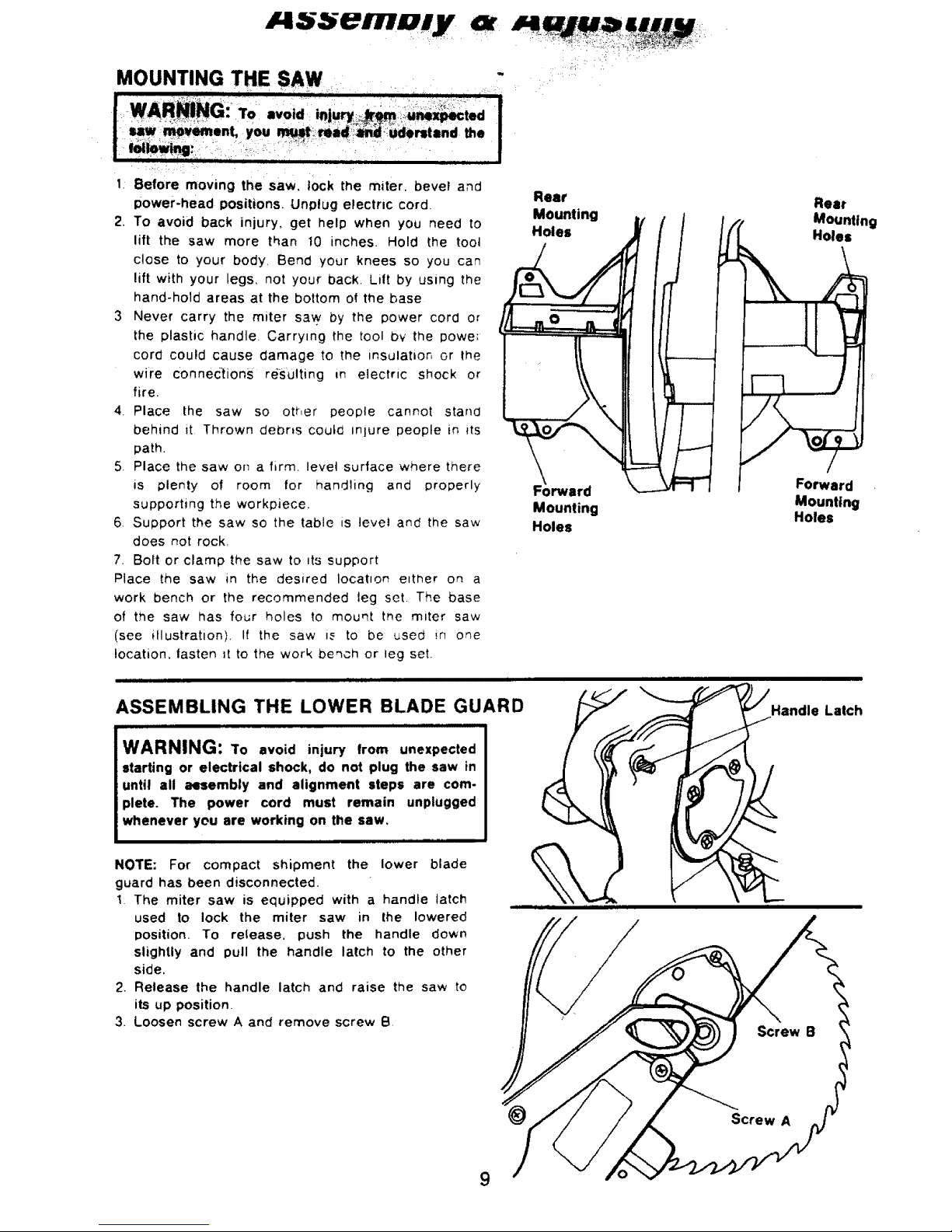

MOUNTING THE SAW

1: Before moving the saw, lock the miter, bevel and

Rear

power-head positions. Unplug electric cord.

Mounting

2. To avoid back injury, get help when you need to

Holes

lift the saw more than 10 inches. Hold the toot

close to your body. Bend your knees so you can

lift with your legs, not your back. Lilt by using the

hand-hold areas at the bottom of the base

3 Never carry the miter s3w by the power cord or

the plastic handle. Carrying the tool bv the powe;

cord could cause damage to the insWatior, or the

wire Connec-tions re-suiting in electric shock or

fire.

4. Place the saw so other people cannot stand

behind it Thrown debris coutcl miure people in its

path.

5_ Place the saw or_ a firm. level surface where there

is plenty of room for handling and properly

supporting the workpiece.

6 Support the saw so the table is levet and the saw

does not rock,

7. Bolt or clamp the saw to _ts support

Place the saw in the desired Iocat=on e_ther on a

work bench or the recommended leg set The base

of the saw has four holes to mount the miter saw

(see illustration) I! the saw is to be used _,n one

location, lasten tt to the work beqch or leg set.

Forward

Mounting

Holes

ASSEMBLING THE LOWER BLADE GUARD

WARNING: To avoid injury from unexpected

starting or electrical shock, do not plug the saw in

until all aGsembly and alignment steps are com-

plete. The power cord must remain unplugged

whenever you are working on the saw,

NOTE: For compact shipment the lower blade

guard has been disconnected.

1 The miter saw is equipped with a handle latch

used to lock the miter saw in the lowered

position. To release, push the handle down

slightly and pull the handle latch to the other

side.

2. Release the handle latch and raise the saw to

its up position.

3. Loosen screw A and remove screw 8

Rear

Mounting

Holes

Forward

Mounting

Holes

Handle Latch

9

Page 10

4.Remove the screw C and spacer in the lower

guard.

5,Slide slotted end of lower guard mounting

bracket under screw head and rotate lower

guard mounting bracket until hole in bracket

lines up with threaded hole ;n upper guard.

Threaded Hole

Mounting Bracket

Slotted

& Spacer

6.Replace' screw B, that was removed in step 3.

Tighten screw A and screw B.

7. Replace screw C and spacer, that were

removed in step 4. Tighten the screw C and

spacer through the slot.

NOTE: With the blade guard attached, the guard

should raise as the blade is lowered towards

the work table and drop to cover the blade as

the power head is raised.

\

Screw B

IIIIIIIIIIIIH II III IIIIIII -

BLADE SQUARE TO TABLE

NOTE: The miter saw was assembled aligned and

inspected before shipment. Alignment should be

checked and any adjustments made to insure

accurate cuts,

!. Check miter lock handle setting. The miter lock

handle should be at the 0° position, To reset the

miter angle, turn the miter lock-handle counter

clockwise and press down the index spring.

2 Lower the blade and lock the handle latch, Use

the combination square to check blade square-

ness to table, If the blade does not contact the

full length of the square, follow the alignment

procedure.

a, Loosen the bevel lock handle.

b. Grasp the metal upper guard and move the

cutting head to the left as far as it will go,

10

Page 11

A;

c, Loosen the right side bevel stop lock nut.

:, ,.: : : . ....

Lower the bevel stop bolt: .down as faras it

will go, i ....... :i:_il j

d. Grasp the metal upper,,i_:g_rd !:Im_in and

:position the i_i_:_i:_:h_i'iUhtilthe blade

co,tactw th lengtho, the

square,

e. Tighten the bevel lock handle.

f, Use 10ram wrench end to hold the bevel stop

tock nut in place.

g. Use another wrench to turn the bevel stoD

bolt until it hits the bottom of the bevel stop.

h, Lock the bevel stop nut.

3, Check the bevel indicator. If indicator needs

adjustment use a phillips screwdriver and slide

the indicator to the 00on the scale.

Bevel Sto

Bevel

Lock Nut

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, ,,,,,,,,,,,, , illlllll L Jill1

CHECKING AND ADJUSTING BLADE SQUARE

I, To check blade squareness to tence_ use a

combination square, Place the square against

the fence and next to the blade as illustrated,

Place the square so the set in the teeth won't

hold it from the blade. The blade should contact

the full length of the square=

2 If blade is not square to the fence, follow the

alignment procedure,

a, Loosen miter tock handle a half turn. ]-he

latch handle should still be secured witt7

blade in lowered position.

NOTE: Take the saw oft its stand, bench or

plywood base if readjustment is necessary.

CAUTION: To keep from losing control of the

unit, steady the base with one hand while

loosening the two bolts with the other hand,

b, With tt_e unit securely resting on a large

stable surface, tilt the unit by lifting up on

one side or the other of the base. Loosen the

two miter arm bolts on the underside of the

turn table with a 6rnm hex. "L" wrench. Tilt

the unit by lifting up on one side or the other

side of the base.

c, Return the saw to its normal resting position.

Make sure the miter lock handle is loose but

do not release the index spring.

d. Use the miter saw handle to turn the turn

table and saw so that the blade contacts the

full length of the square. Watch out for tooth

set. Turn the miter lock handle clockwise to

lock saw square to fence,

e. Tilt saw as in Step b and tighten bolts,

f. Recheck blade squareness to fence and

readjust it necessary.

Adjustment of Miter Scale Indicator

1 Loosen the phillips screws that hold the indi-

cator in place, Reposition the indicator and

retighten screw,

11

Page 12

Ass,

TRAVEL PIVOT ADJU : T

.OTE:These at the

factory _:_andn_rmlt_ild_ i _ot_i'_u|i'e r"djustment.

1. T_imiter_';a_ Shouidrise completely to the up

pos!_On by itself, If the _saw will not raise by

itself or if there is play in the pivot joints the

following adjustments are necessary.

a. Loosen the hex lock nut with an adjustable or

24turn wrench.

b. Recheck the saw travel. Saw should rise

freely to its up travel stop. Check to see that

the saw will raise from all positions and

there is no looseness in the pivot. If saw still

won't fully rise, have service check and

repair it.

Adjustable

Wrench

Lock Nut

BEVEL PIVOT ADJUSTMENT

1. The miter saw should bevel easily by loosening

the bevel lock handle and tilting the power head

to the left. If movement is tight or if there is

looseness in the pivot follow the adjustment

procedure.

a. Loosen the bevel lock handle.

b. Turn the hex lock nut with an adjustable or

3/4" wrench.

c. Recheck bevel movement of the miter

Readjust if necessary.

Bevel Lock

Handle

FENCE POSITIONS

The miter saw has two fence positions.The front

fence position is used for workpieces up to

standard 2 × 4 for cut off and bevel operation, floor

and ceiling moldings, and door casings. The rear

fence position is used for cut off and bevel

operation for a standard 2 × 6 workpiece.

Standard 2×4 measures 1 1/2 _ x3 1/2 _

Standard 2;<6 measures 1 I/2" x5 1/2"

The base on either side of the work table has two

sets of holes for locating the fence. To change the

fence position, remove the two fence lock screws.

Put the fence in the other fence position and install

the fence lock screws.

REAR FENCE POSITION

On/Off Trigger Switch

To prevent the trigger from being accidentally

engaged, a lock-off button is provided. To start the

tool, press in the lock-off button and squeeze the

trigger. Release the trigger to stop the miter saw.

Adjustable

Wrench

12 FRONT FENCE POSITION

Page 13

Assembly

ASSEMBLINGEXTENSIONARM

AND CLAMP o :

2. Lock the m!_r_W_:i_ei_emd _tion.

NOTE: T_ :_te_ion arm Withl attached stop block

can be mounted on the left or right side of saw to

suit your operation.

3. Tilt saw back on its rear legs to expose

underneath of base.

4. Slide adjustable stop block over back rail of side

extension arm,

5. Stide extension arm through first, pair of 1/2"

diameter holes on outside of miter saw base,

6, Find the second pair of holes underneath miter

saw base, Put _U_ bracket over hole nearest to

the front edge of the miter saw.

7. Slide extension arm through both the second

pair of holes and _U" bracket, Make sure the

extension arm passes completely through the

second pair of holes,

8. Tighten Screw on _U" bracket with screwdriver

to hold extension arm in place.

9. Repeat steps 1-8 for other side of miter saw

Omitting step 4-installation of stop block.

Stop Block

Extenslon Arm

Stop Block

\

Wing Screw

Wing _;crew

Extension Arm

Front Edge

Miter Saw

Pan Head

Screw

_U_ Bracket

t0.

11.

12.

13.

1/2_ Dia. Hole

Set the saw back down,

Find the two 3/8" diameter forward mounting

holes. Find the two 5/8 _ diameter holes next to

them. Use the 5/8" holes for mounting the

clamp assembly.

Put the clamp assembly 5/8 _ diameter rod into

the hole on the same side of the blade as the

stop block. Make sure clamp guide is on the

outside of the saw base,

Put the stop fence plate on the stop block and

tighten wing screw to set it in place.

Stop

Fence

Stop Fence Plate

Wing Screw

Clamp Assembly

13

Page 14

&A

REMOVING

NUll:: To avoid Injury from unexpected starting,

unplug the saw whenever you are removing or

installing the blade.

1. Unplug the saw from the outlet.

2. Loosen the screw A and 'remove the screw B

holding the lower guard mounting plate to

the upper guard with phillips screwdriver.

3. Lift the lower guard up and tilt the lower guard

assembly back so the arbor screw is exposed.

4. Find the arbor lock between the upper guard

and the miter saw handle. Place changing

blade wrench over arbor screw.

5. Press the arbor lock and hold it in firmly while

turning the wrench clockwise. The arbor lock

will engage after some turning of the wrench.

6. Remove the arbor screw, arbor washer, outer

blade collar, and the blade.

NOTE: Pay attention to pieces removed, noting

their position and direction they face (see illustra-

tion). Wipe the blade collars clean of any saw dust

before installing the new blades.

7. install the new 10" blade. Make sure the

rotation arrow on the btade matches the

clockwise rotation arrow on the upper guard.

8. Instal! the outer blade collar, arbor washer and

arbor screw. Press the arbor lock and turn the

1/2" wrench counter clockwise to secure the

blade. Tighten arbor screw securely.

9. Lower the lower blade guard. Tighten the

screw A and B with a phillips screwdriver.

DANGER: Never use saw without mounting

plate securely in place. It keeps the arbor

screw from falling out if it accidentally loosens,

and prevents the spinning blade from coming

off the machine.

10. Be sure the arbor lock is reteased so the blade

turns freely.

NOTE: The arbor lock can be damaged by impro-

per use. If the arbor lock will not hold, lower the

blade down on to a scrap piece of wood positioned

against the fence. This will serve as an alternate

locking means.

11. If blade contacts turn table, refer to assembly

and alignment, for adjustment.

Screw A

Miter

Handle

U

Blade

Guard

Arbor Washer

10 _ Blade

/

Arbor Screw \

Ouler Inner Blade Collar

Blade Collar (Do Not Remove)

,, ,, ,,

WARNING: Alter installing a new blade, make

sure the blade clears the table slot at the0°and45 _

bevel positions. Lower the blade into the lower

table and check Ior any contact with the base or

turn table stru_ure.

B

14

Page 15

Miter

1. Inspect your saw. Replace dama_ missing or

failed paris before using th9 llw,:_ _::

2. Wear safety __IU_)that

comply

3. For: dusty operations, wear a face shield along

with safety goggles.

4. To avoid injury from jams, slips or thrown

pieces:

a. Choose the right lO-inch diameter blade for

the material and the type of cutting you plan

to do. Use this miter saw to cut only wood,

woodlike products or soft metals like alumi-

num. Other materials may shatter, grab at

the blade or create other dangers.

b. Make surethe direction of rotation arrow on

the blade matches the d_rection arrow on the

saw_ The teeth of the blade should always

point downward at the front of the saw.

c. Make sure the blade is sharp, undamaged

and properly aligned.

d. Make sure the blade and arbor collars are

clean.

e. Make sure the collars' recessed sides are

facing toward the blade.

f. Make sure the recessed side of the blade

washer (just under the arbor screw head)

faces the collar.

g Using a 1/2" box end wrench, make sure the

arbor screw retaining the blade collars is

firmly hand tightened.

h. Make sure alt clamps and locks are tight and

there is no excessive play in any parts.

5. Never cut more than one workpiece at a time.

6. Make sure the cut off piece can move sideways

Saw

after it's cut off. Otherwise, it could get

wedged against the blade and thrown violent-

ly.

7. Never cut FREEHAND:

a. Brace your workpiece solidly against the

fence and table top so it will not rock or

twist during the cut. Make sure there is no

debris caught beneath the workpiece.

b. Make sure no gaps between the workpiece,

fence and table will cause shifting after the

workpiece is cut in two.

e. Use jigs, fixtures or a different tool for

unstable workpieces.

8. Use extra caution with large, very small or

awkward workpieces:

a. Use extra supports (tables, saw horses,

blocks, etc.) for any workpieces large

enough to tip when not held down to the

table top.

b. Do not use this saw to cut pieces too small

to let you easily hold the work while you

keep the thumb side of your index (pointer)

finger against the cutside edge of the fence.

c, When cutting irregularly shaped workpieces,

plan your work so it will not slip and pinch

the blade. A piece of molding, for example,

must lie flat or be held by a fixture or jig

that will not let it twist, rock or slip while

being cut.

d. Properly support round material such as

dowel rods, or tubing. They have a tende-

ncy to roll while being cut, causing the

blade to _bite." To avoid this, use a fixture

designed to properly hold your workpiece,

BODY AND HAND POSITION

Proper positioning of your body and hands when

operating the miter saw will make cutting easier

and safer. Never place hands near cutting area.

Place hand at least 4" from path of blade. Hold

workpiece firmly to the fence to prevent movement

toward the blade. Keep hands in position until

trigger has been released and the blade has

completely stopped. Before making a cut, make a

_dry run _with the power off so you can see the

path of the blade.

WARNING: Do not try to cut short pieces. You I

cannot properly support the workplace and keepl

your hold down hand the required distance from_

the blade.

I

, ....... I

15

Page 16

MITER CUT

When a miter cut is required, move the saw to the

cJesired angle. Do not stand in front of the saw

table. Move with the handle to the miter angle to

make the cut.

BEVEL CUT

When a bevel cut is required, tilt the blade to the

desired bevel angle. Stand to the left side of the

handle to make the cut.

16

Page 17

COMPOUND CUT

When a compound cut is required, select the

correct bevel and miter position. Move with the

handle to the miter angle to make the cut:

CUTTING BOWED MATERIAL

Before cutting a workpiece, check to make sure it

is not bowed. If it is bowed the workpiece must be

positioned and cut as illustrated. Do not position

workpiece incorrectly or try to cut the workpiece

without the support of the fence. This will cause

pinching of the workpiece on the blade. The

workpiece could suddenly jump or move and your

hand could hit the blade.

CORRECT

INCORRECT

17

Page 18

WORKPIECE SUPPORT

Long pieces need extra supports. The supports

should be placed along the workpiece so the

workpiece does not sag and your hand holding the

workp=ece is positioned 4 or mor_ _mit_ blade

path.i The support should I_thewo_iece _lay flat

on the base and work t&bie durin_g the cutting

operation;

Workpiece

Workpiece

Support

AUXILIARY FENCE

Certain types of molding need a fence face

extension due to the size and position of the

workpiece. Holes are provided in the fence to

attach an auxiliary fence made of straight wood

typically 1/2 inch thick by 3 inches high by 20

inches long. The auxitary fence is used with the

saw in the 0° bevel position. If a bevel cut is

desired, the auxiliary fence will have to be

removed.

o

O

18

Page 19

FILLER BLOCKS FOR CUTTING CROWN MOLDINGS

The majority of crown moldings have contact

surfaces of 52o and 38o to the rear surface of the

molding. When•joining the face of :_i!il_r i_

these angles must be mai_ined,:_Thei_ilowing

illustrations show two _m_:that can be used

when cuffing: cr0wn moldings depending on how

the flflerblock is attached to the fence.

When the filler blocks are attached with the face of

the filler blocks pointing upwards, the molding

must be placed on the table upside down.

When the flilar blocks are attached to the fence

wtth_the face of the filler blocks pointing down-

wards, the molding must be placed on the table

right side up, This is the same position as it would

be when nailed between the ceiling and wail.

Make 2 filler blocks 10 inches long. Fasten blocks

securely to fence, For block lace pointing down-

ward, you may need to drill new fastener holes in

the fence.

Filler 8lock Face

Pointing Upward

Molding

Table

/

i

L

Fence Filler

S Block

Face

Pointing

_jDownward

.,..38__ M°ld|ng

1

i iii i i i iiiiiiiiiiiiiiiiiiiiiiiiii iiiiii

VERTICAL BEVEL CUTTING

To make a miter cut in a 2x4 workpiece (actual 1

5/8"x3 1/2") in the verticat position (on edge) a

spacer, such as the auxiliary fence described on

the previous page is required. Fence is located in

the front fence position.

Space Block

Fence

3-_-"(89 mm)

!

l i

j Workpiece

t

/ -- --_ 1"_L4'(41ram)

I

f

19

Page 20

opposite end. Compound mi_rs:_;_re:_i_ky" to

make because the: m_i_S_etti_:_and 'bevel setting

are dir_ly_reiated t0 :each other, Every time the

miter Setting is changed the bevel setting must

also be adjusted, likewise every adjustment to

bevel requires a corresponding adjustment to

miter. Because it may take severat tries to obtain

the desired angle it is advisable to make test cuts

in a scrap piece of material.

TIPS FOR CUTTING COMPOUND MITERS

A compound miter is a cut requiring botha miter Miter i

setting and bevel setting. A compound miter is

used for making frames or boxes that hive sloping .............

sides and are wide at One end lnd. nari_Ow_ the Bevel

Setting

33,8 °

33.80

31.6°

RIGHT

31.6°

LEFT

TIPS FOR CUTTING CROWN MOLDING

Miter

Setting

Type of Cut

.33.8 ° 31.6_

LEFT

LEFT SIDE, INSIDE CORNER:

1.Position top of molding

against fence.

2.Left side is finished piece.

33.8o 31.6_

RIGHT

RIGHT SIDE, INSIDE CORNER:

1.Position bottom of molding

against fence,

2.Left side is finished piece.

LEFT SIDE, OUTSIDE CORNER:

1.Position bottom of molding

against fence.

2.Right side is finished piece.

RIGHT SIDE, OUTSIDE CORNER:

1.Position top of molding against

fence.

2.Right side is finished piece.

A compound miter saw !s excellent for cutting

crown molding. Crown molding is difficult to cut

because in order to fit correctly it must be

precisely mitered.

All Standard (U.S.) crown molding has a top rear

angle (fits next to ceiling) of 52° and a bottom rear

angle (fits against wall) of 380.

NOTE:On all above cuts lay molding with broad

back surface flat on table.

Pre-testing Compound Settings on Scrap Material

Is Extremely Important !

i,cornr

2O

Page 21

Maintaining Your

MAINTENANCE

Atways unplug the power cord before imymatnten,

ance check on this SaW.i_.... :_.... i::......

DANGEI=h Never put I_bricants on the blade while

.o""...,°,;; ,m

mrUng or electrical shock, unplug the

power, cord I

| bef_ wo,_ing on the saw.

iiiiii iiii i ii

I WARNING: For your safety, this saw Is double

I Insulated. To avoid electrical shock, fire or injury,

I use only parts Identical to those Identified in the

I parts list. Reassemble exactly as original assembly

| to avoid electrical hazards.

i iiiiiiii i iiiiiiiiiiiii i iiiii iiii lllliHii

OUST

Periodically, sawdust will accumulate under the

work table and base. This could cause difficulty in

the movement of the work table when setting up a

miter cut. Frequently blow out or vacuum up the

sawdust

i iiiiiiiii ] i iii i

WARNING: If blowing sawdust, wear proper

eye protection to keep debris from blowing into /

eyes.

iiiiii iiii

BASIC BLADE REQUIREMENTS

10_ Diameter

Blades marked for 5,500 RPM or higher.

5/8 '1Arbor Hole

REPLACING CARBON BRUSHES

The carbon brushes furnished will fast approxi-

mately 50 hours of running time or 10,000 on/off

cycles, Replace both carbon brushes when either

has less than 1/4 _ length of carbon remaining. To

inspect or replace, first unplug the saw, then

remove the black plastic cap on the side of the

motor (caution, this cap is spring loaded by the

brush assembly). Then pull out the brush. Repeat

for the other side. To reassemble reverse the

procedure. The ears on the metal end of the brush

assembly go in the same hole the carbon part fits

into. Tighten the cap snugly but do not overtighten.

NOTE: To reinstall the same brushes, first make

sure the brushes go back in the way they came

out. This will avoid a break in period that reduced

performance and increases wear.

LOWER BLADE GUARD

Do not use the saw without the lower guard. The

lower blade guard is attached to the saw for

protection. Should the lower guard become dama-

ged, do not use the saw until damaged guard has

been replaced. Devetop a regular check to make

sure the lower guard is working properly. Clean

the lower guard of any dust or build up with a

damp cloth,

LUBRICATION

All the motor bearings in this tool are lubricated

with a sufficient amount of high grade lubricant for

the life of the unit under normal operating

conditions, therefore, no further lubrication is

required. (See below.)

Infrequent Lubrication As Required:

t. Lubrication of arm pivot for free movement.

a. By loosening nut and applying oil to washer

and to contact face (minor).

b, Disassembly means required to grease pivot

bolt and contact faces (major).

NOTE: Disassembly should be done by an

authorized service technician. Removal of the

upper guard and the bolt stop is necessary

before pivot can be disassembled. Pay close

attention to the spring-end positions in the

castings. Mark with chalk to avoid later confu-

sion.

2. Lubrication of-mechanism which pivots lower

guard. Use light household oil (sewing machine

oi!) on metal-to-metal or metal-to-plastic guard

contact areas as required for smooth, quiet

operation. Avoid excess oil, to which sawdust

will cling,

CAUTION: Do not use solvents on the guard.

They could make the plastic 'cloudy" and brittle.

i ii ii ii i

WARNING: When cleaning lower guard unplug

the saw from the outlet to avoid unexpected start-

up.

i ===ll i = 11

(WHITE

Wiring Diagram

cl

(RED)

FIELD LEAD _ _ .. FIELD LEAD _'_

.... v, ,----_ , v , .........w "' _.UJ .J=

(GRAY) I I _v

BRAKE LEAD _ / m_

I SWITCH

I'= X N.C. ARMATURE

,, n -,_x---,I \. )

; _ _ BRUSH

2_ ' _-

N---_-_-! (WHITE) I -"

[ BRUSH LEAD J

21

Page 22

1

!4

Page 23

Content Parts

,, ........ .,,. ,,

I 9o02 ;ooi

2 021203-001

3 021109-001

4 022300-001

5 021611-000

6 021117-001

7 900430-000

8 020314-005

9 021120-003

10 224037-000

11 020804-0()0

12 303188-000

13 028304-003

14 900475-000

,,,,, H ........

....... ":: "I ...............

:Part No,

• ,,,,.......... , , ,

Fief. No.

Bevel Lock Knob

Spring Washer

Flat Washer

Nut

Wave Washer (2)

Flat Washer

Blade Guard Asm.

Screw 12)

Washer /2)

Fence

Screw (3)

Table Insert

Bolt. Shoulder

Table Assembly

15 221013-000

16 270305-000

19 303229-000

20 303018-004

21 021117-001

23 022300-001

24 224050-000

25 021120-003

26 021204-003

27 020314-009

28 020701-009

29 270316-000

,i

Description

Base

Spring Index

Grip Miter Index

Handle-Miter

Washer -.

Nut

Arm-Miter

Washer (2)

Spring Washer (2)

Hex HD. Screw (2)

ScrewlWasher

Plate-Clamp

30

38

37

Part No.

30

31

32

33

34

35

36

37

38

Ref. No,

028302-003

020301-009

022111-001

!026105-007

270246-000

!020716-001

1224038-000

_303198-000

1303243-000

Description

Shaft, Bevel

Hex HD. Screw (2)

Nut (2)

Pin

Pointer-Bevel

Screw/Washer (2)

Table

Pointer-Miter

Shoe

23

Page 24

\

\

\

0

onto

\

\

\

\

/

24

Page 25

t l" •

IE

,,,,,,

rio

v e"

i,) el)

_,NN _.am_m o m m ,," m ,.,

8_888_8_8888

• _88_8=8=88 888_ °

°999999999_999 99999999.'9_

v I_ 0 .£:

= _o_ a.7 _ Z-_-_ _'

: _ rd_ r,,_ _l:l Z €.,D _:l.

._ _ _ _ _ _ _

___=

25

Page 26

Content

131

129

125

124

123

122

Part No,

122

123

124

125

126

127

128

129

130

131

132

Ref. No,

022306-000

021101-004

270226-000

029301-003

225067-000

303266-000

028912-003

020906-000

302037-000

024101-000

021108-000

Delcriptlon

Nut

Washer

Plate -

Spring-Guard

Lower Guard Plate

Spacer

Bolt

Bolt

Lower Guard

Pull Nail (3)

Flat Washer (3)

, k

MEMO:

26

Page 27

Trouble Shooting

TROUBLE

Brake does not stop

blade within

2-5 seconds.

Motor does not start.

PROBLEM

1. Brushes not seated

or lightly sticking,

,

Angle of cut

not accurate.

Can't move

miter adjustment.

Motor brake winding-

overheated from use of not

recommended accessory

or rapid on/off cycling.

3. Arbor screw loose.

4. Other.

!, Fuse.

2. Brushes worn.

3. Other.

Brush sparking when !. Normal--automatic brake

switch released, working properly.

Blade hits table. 1, Misalignment, -See Assembly and Alignment.

2. Damaged depth stop. -Get authorized Service.

1. Misalignment. -See Assembly and Alignment.

1. Sawdust under table, --Vacuum or blow out dust,

WEAR EYE PROTECTION

Power-head

wobbles.

Power-head

won't fully rise.

Blade binds, jams,

burns wood.

Tool vibrates or

shakes.

1. Loose pivot points,

1. Pivot misadjustment,

2. Part tailure.

3. Pivot spring not replaced

..... properly alter service,

1. Improper operation.

2. Dull blade.

3. Improper blade.

4. Warped blade.

1. Saw blade not round.

2. Saw blade damaged.

3. Saw blade loose.

4. Other.

REMEDY

.... insp'_'"t!c'_'_nlrepla'_e_.,_= _. brushes ........

(see maintenance section).

-Use a recommended blade.

-- Let cool down.

- Retighten

-Authorized service. Check motor brake winding,

switch, condition of commutator,

- 15-Amp time delay luse, or CKT. breaker.

-- See =M ainten ance."

- Authorized service.

-See Assembly and Alignment,

- See Assembly and" Alignment,

-Get authorized Service.

- Get authorized Service.

-See Basic Saw Operation,

-Replace or sharpen blade.

--Replace with 10" diameter blade designed

for the material being cut.

- Replace blade.

- Replace blade.

-- Replace blade.

-Tighten arbor screw.

:_ ; --Get authorized Service.

27

Page 28

PRO-TECH POWER, INC.

13750 Van Ness Avenue

Gardena, CA 90249

Printed in Taiwan 3/96

Loading...

Loading...