ProSpot Fitness P-500 User Manual

PnoSP

olfitne,ss

rM

Moder P-5oo

Owners

1) Assembly lnstructions/Illustrations

2) Use and Operation of

Maintenance

3)

4) Warranty Information

5) Parts

List

of

your

Manual

PnoSrorf/zessrM

PnoSroty'lzessrM

Product

Product

Table

of

Contents

Assembly

Use and

Periodic

Warranty

Partslist....

Instructions.

Operation

Maintenance

Information.

of Your

your

of

PnoSroffrnessrM

pnoSror/aessrM

product.

. .

. . . . .

product.

. . ..

........1_10

. .......1

. .

.. . .

...........15

_12

|

.....

. I 3

.....14

lnstructions for Assembly

of the

PROSPOT/tnessrM

P-500

.

Before assembly, choose a safe location for

P-500 has a footprint

PROSPOTlrzessn P-500 away from any source

machine or spilled on any electrical

.

Approximate

.

A flat

area of 9' x 9' will be required to assemble and

.

You will need

.

5 mm Allen Wrench

.

14 mm Box End Wrench

.

17 mm Box End Wrench

.

19 mm Box End Wrench

.

Floor Padding,

.

good pair

A

them from the cartons.

r

HAND TIGHTEN

.

Before

easily

distinguished by

identified

assembly time is 1-1l2 hours.

the following tools and a helper to complete

assembly, separate

"1"

by

&

of approximately 8'x 8'. The barbell is

part.

Do not insert

as cardboard,

such

of scissors will be helpful in separating

all bolts. DO NOT fully

and identify the right-sided

manner

the

"R"

stickers.

to avoid scratching

tighten bolts until instructed

in whjch the

your

PROSPOTJitnessrM

water.

of

any object into the

properly

parts

pre-drilled

Do not allow

use the PROSPOT/itressrM

the assembly:

your

floor during assembly.

parts

the

from the left-sided

holes align with

P-500. The PROSPOTlrzessn

approximately 7' long.

liquid

any

electrical box.

from

one another while

to do so.

parts.

corresponding

Locate

to

be near the

P-500.

These

rals :- a.e

your

re-:, 19

.61s a-e

o

The PROSPOTfitnessrM

length

of bolt called for at each

o

WARNING:

Never

while the Power

P-500 uses several

step of assembly. Refer to

perform

Supply is

any maintenance

plugged

different lengths

the sizing charts

on the PROSPOffiressn

into

the watl

!!!

of bolts. Be careful to use

provided.

:^e ::..e.t

P-500

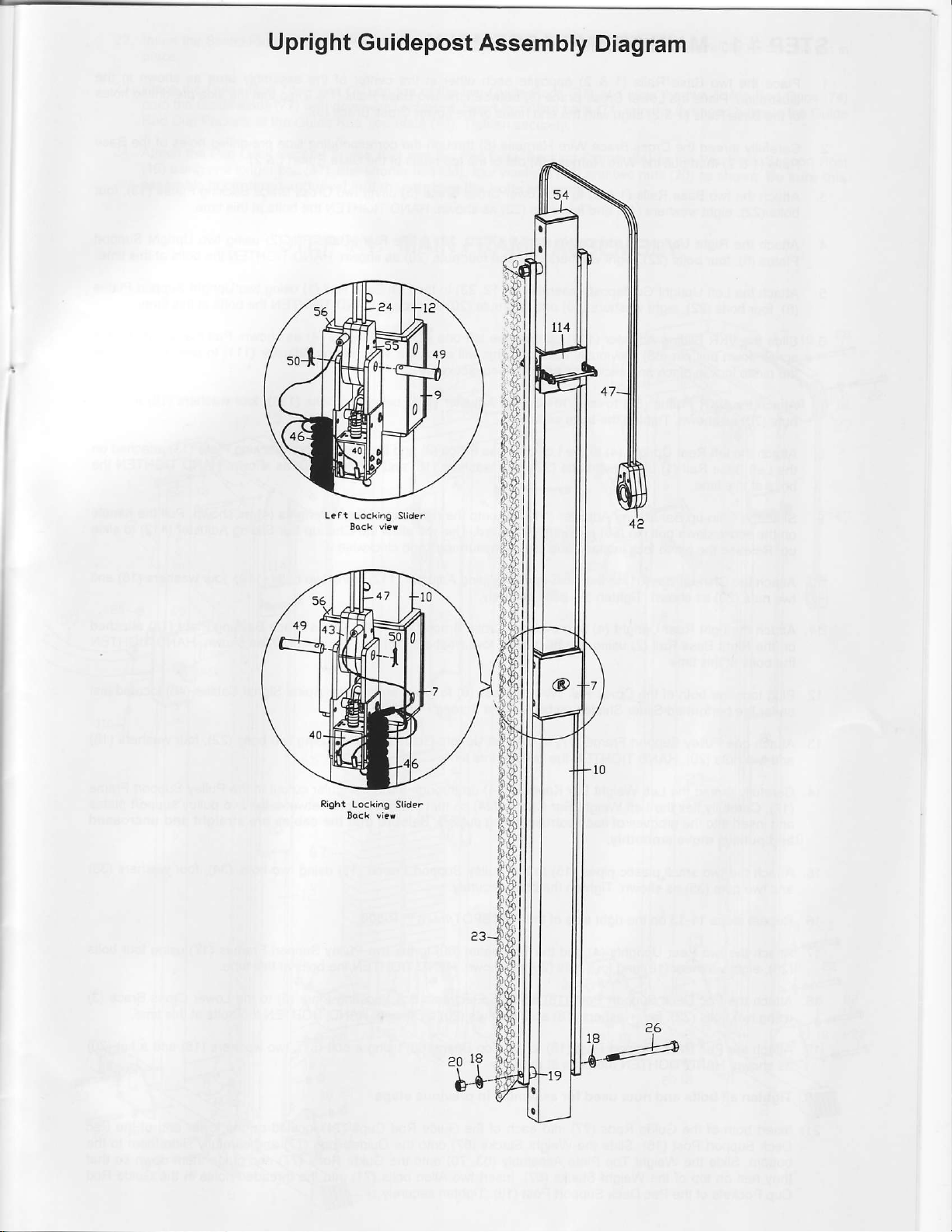

Upright

Guidepost

Assembly

Diagram

Leat Locki.g Slide.

Right

Lockihg Sli.te.

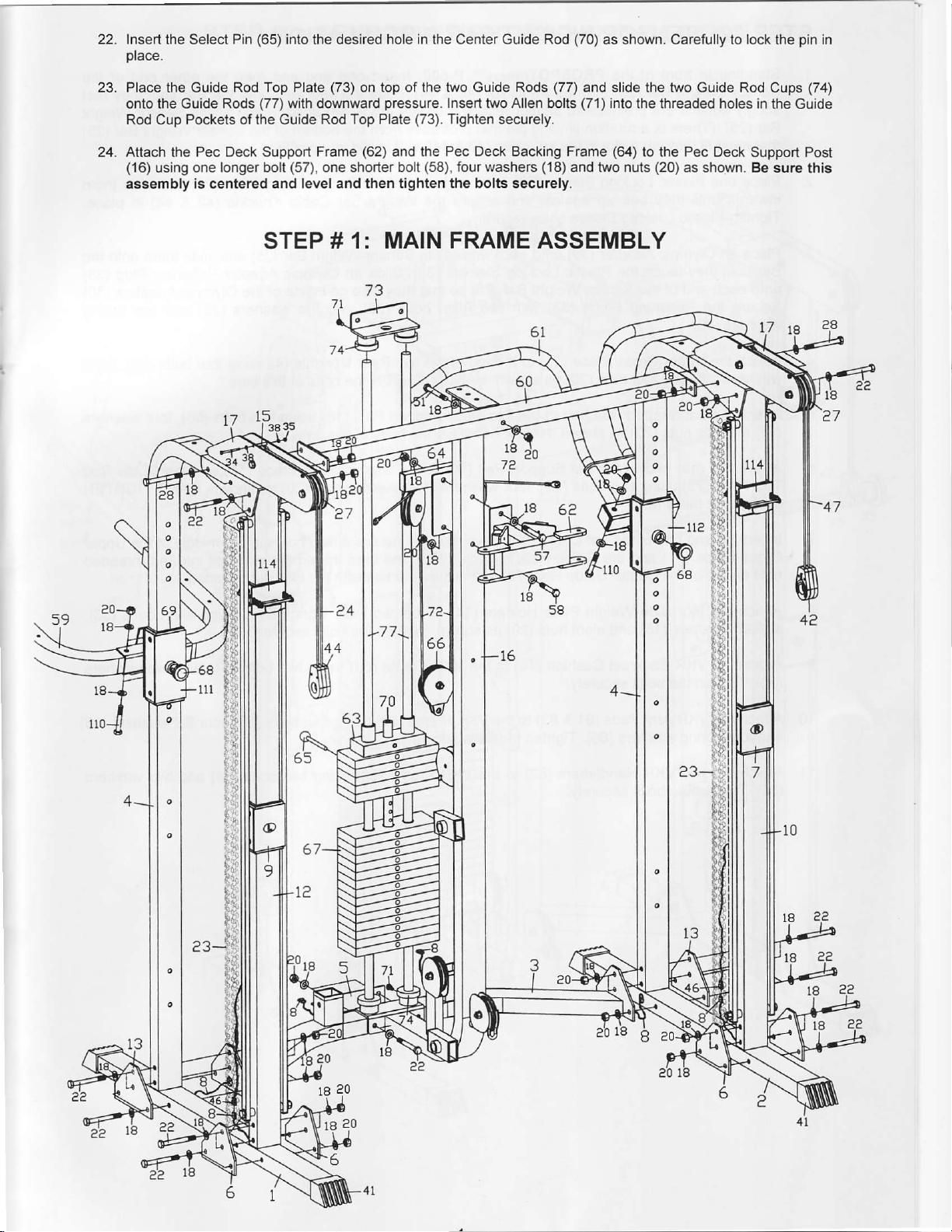

STEP # 1: MAIN FRAME ASSEMBLY

1. Place the two

lllustration. Place the Lower Cross Brace

Base Rails

of the

2. Carefully

3. Attach the

4. Attach the

5. Attach the

6. Slide the

7. Attach the VKR Frame

8. Attach the left Rear Upright

9. Slide the Chin-up Bar Sliding Adjuster

(1

Rails

(22),

bolts

(6),

Plates

(6),

four

screw down

pin

the

to

(20)

nuts

the Left Base Rail

bolts at this time.

on the screw

up. Release the

Base Rails

(1

thread the Cross

& 2) then

eight

bolts

VKR Sliding Adjuster

lock

as shown.

pull

two Base Rails

washers

Right Upright Guidepost

four bolts

Left Upright Guidepost Assembly

(22),

eight washers

pull pin

place

in

(1)

pull pin

down

pin

to lock in

(1

& 2) opposite each other

& 2) align with the end

Brace Wire Harness

Wire Harness

the

(1

2)

&

('18)

(22),

eight

previously

(68)

and secure

(59)

Tighten the bolts securely.

using two bolts

to the

and four nuts

Assembly

washers

(18)

('111)

up onto

installed. This will allow the

by turning knob clockwise.

VKR Sliding Adjuster

to the

(4)

to the Lower Cross

previously

(68)

place

and secure by turning

(3)

between the two

holes of the Lower Cross Brace

(8)

(8)

of the top holes of the Base

out

Lower Cross Brace

(20)

as shown.

(7,

(18)

and four

(9,

12, 23) to the Left Base Rail

four nuts

and

the left one of Rear Uprights

(22),

four washers

(1

12) up onto the right one

installed.

in the center of the assembly area as shown

Base Rails

through

10, 23\ to the Right Base

(20)

Brace

This will allow the Chin-up Baf S

the

corresponding

(3)

using two Cross

HAND TIGHTEN the bolts at this time.

(20)

nuts

as shown.

as shown. HAND TIGHTEN the bolts

(111)

using

(3)

and lhe Cross

(18)

and two nuts

knob

clockwise.

(1

HAND TIGHTEN

VKR

Sliding Adjuster

bolts

two

Rear Uprights

of

2) so

&

(3).

side

Rails

Rail

(1)

using

(4)

as shown. Pull the handle

(110)

Brace Backlng Plate (13)

(20)

the side

that

pre-drilled

(1

& 2).

Brace Backing Plates

(2)

using two Upright Support

two

(11'l)

four washers (18)

as shown.

(4)

as shown Pull the handle

id ng Adtuster (1

pre-drilled

holes of the Base

the bolts at this time.

Upright

Suppurt Plates

at this time.

to slide

HAND

TIGHTEN

in the

holes

(13),

four

on the

Release

up.

and

two

attached on

the

'12)

to slide

10. Attach the Chin-up Bar(61) tothe Chin-up BarSliding Adjuster

two nuts

1 1 . Attach the right Rear Upright

on the Right Base Rail

the bolts at this time.

12. Plug

under the

'13.

Attach one Pulley

and two

'14.

Carefully thread the Left Weight Bar Knuckle

(17).

and insert into the

and

15. Attach

and two nuts

16.

Repeat steps 11-13 on the right side of

'17.

Attach

(28),

18. Attach

using

(20)

as shown.

together

Carefully flex the Left Weight Bar Cables

pulleys

eight washers

two

both of

perforated

(20).

nuts

move smoothly.

two small

the

(35)

the two Rear Uprights

Pec Deck

the

bolts

(22),

Tighten

(2)

the

Slider Shields on back of the Screen

Support

HAND TIGHTEN

grooves

plastic pipes

as shown. Tighten

(18)

and four nuts

Support Post

four washers

the bolts securely.

(4)

to the Lower Cross Brace

using two bolts

Cross Rail Wire Harness

(17)

Frame

of each

corresponding

(15)

(4)

and the Top Beam

(18)

(22),

to the

the bolts at this time.

to the

the bolts

PROSPOTlirrressrM P-500.

the

(20)

as shown. HAND

(16)

and the Electronic Box Locating

and two nuts

four washers

(8)

to

Left

Upright

(44)

up through

(24)

so that the cables

pulleys.

Pulley

Support

securely.

(60)

(20)

(3)

(18)

lower

Panels

Guide Post

the

Be sure

Frame (17)

to the two Pulley

TIGHTEN

as shown.

(1

1 2) using two bolts ( 1 1

and the Cross Brace Backrng Plate

(20)

and two

ends of the Spiral Signal Cables

(23).

rectangular

that the cables are straight and

HAND TIGHTEN the bolts

nuts

(12)

using two bolts

cutout in the Pulley

are between the iwo

using

two bolts

Support Frames

the bolts

Plate

this

at

(5)

to the Lower

fourwashers

0)

as sholvn

(22).

puliey

(34).

(17)

time.

at this time.

HAND TIcHTEN

(46)

four

Support Frame

four

using four

Cross Brace

('18)

(13)

attached

located

washers

support

uncrossed

washers

and

just

(18)

plates

(38)

bolts

(3)

19. Attach the Pec Deck

as shown. HAND TIGHTEN

20. Tighten

21.

Insert both of the

Deck Support Post

bottom. Slide the Weight Top

they rest on top of the Weight

Cup Pockets of the Pec Deck

all bolts and nuts used for

Guide

(16).

Support Post

the bolts at this time.

Rods

Slide the Weight Stacks

(16)

to the Top Beam

assembly

(77)

into each of the Guide Rod Cups

Plate Assembly

Stacks

Support Post

(67).

(60)

using

previous

in

(67)

(63,

70) onto the Guide Rods

Insert two Allen bolts

(16).

Tighten securely.

onto

steps.

the

(51),

a bolt

(74)

located

Guide Rods

(71)

into

the threaded holes in the Guide Rod

two washers

on the lower end

(77)

and

(77)

carefully

and

guide

(18)

and a nut

of the

slide

them to the

them down

(20)

Pec

so that

Insert

place.

the Select

Pin

(65)

into the desired

hole in the

Center Guide

Rod

(70)

as shown. Carefully to lock the

pin

in

23.

Place

the Guide

the Guide Rods

onto

Rod Cup Pockets of the Guide

24.

Attach the

(16)

using one

assembly

Rod Top Plate

Pec Deck Support Frame

longer bolt

is centered and level and then tighten

(73)

on top of the two Guide Rods

(77)

with downward

Rod Top Plate

(57),

one shorter bolt

pressure.

(62)

and the

(73).

(58),

STEP # 1: MAIN

(77)

and slide the two Guide

lnsert two Allen bolts

Tighten securely.

Pec Deck Backing Frame

four washers

the bolts securely.

FRAME

(71)

(18)

and two nuts

ASSEMBLY

into

the threaded holes in

(64)

to the Pec Deck

(20)

as shown.

Rod Cups

the Guide

Support Post

Be sure

(74)

this

e0

18

69

a3-

Loading...

Loading...