PR-111, PR-112 & PR-113

Inverter

Plasma Cutter

Punktschweißgerät

Series

Resistance

Spot Welder

Kurzanleitung

Instruction Manual

Version 1.0

All Info Copyright © Pro Spot International Inc.

About Pro Spot

Pro Spot International, Inc., based in Carlsbad, California, manufactures resistance spot welding equipment

specializing in applications for the collision repair industry. The company began in 1986. The company owns and manages

an on site machine shop, research & development department, a fabrication facility and production lines for the various

welders.

Pro Spot International exports its products worldwide, export sales are managed through our headquarter offi ce.

The company owns numerous patents for our ingenious application tools, machines, and procedures.

Pro Spot training and services

Pro Spot Distributors and Sub-Distributors are carefully selected and are well trained in the collision repair industry. We offer

technical and service education at our world wide training facilities at

regular intervals so your local distributor will always be up to date and

able to pass on the latest in spot welding technology to our customers.

Customer service is an important part of any investment and

our distributors and sub-distributors will be there to support your

technical and service needs. We have a great customer service record, we intend to keep it that way.

Pro Spot is certified by CASE and a member of the ICAR Industry Training Alliance

Contact Information

Pro Spot International, Inc. U.S.A.

www.prospot.com

5932 Sea Otter Place

Carlsbad, CA 92010

2

Phone: +1 760-407-1414

Toll free (US only): 877- PRO SPOT

Fax: 760-407-1421

E-Mail: info@prospot.com

CAUTION!

BEFORE INSTALLING, OPERATING OR CARRYING OUT MAINTENANCE ON THE

PLASMA CUTTER, READ THE CONTENTS OF THIS MANUAL CAREFULLY, PAYING PAR-

TICULAR ATTENTION TO THE SAFETY RULES.

In the event of these instructions not being clear, please contact your supplier.

CONGRATULATIONS ON YOUR NEW PURCHASE!

YOU ARE NOW IN THE POSSESSION OF ONE OF THE SAFEST AND MOST TECHNOLOGI-

CALLY ADVANCED PLASMA CUTTERS ON THE MARKET.

FOLLOW OUR SUGGESTIONS AND YOU WILL BE GUARANTEED SAFE AND PROBLEM-

FREE OPERATION.

SAFETY RULES AND GENERAL WARNINGS

INTRODUCTION

Your plasma cutting unit is ¿ tted with sophisticated safeguards which block

functioning and therefore the cutting operations until all the safety conditions

are present. The plasma cutting technique requires dangerously high voltage

for pilot arc starting and during cutting, therefore the following safety rules

must be observed with great care.

ELECTRICITY

1-Make sure that the unit is earthed and that the supply line has an adequate

earth connection.

2-Make sure that the work bench has a satisfactory earth connection.

void contact between the metal bars being cut and bare skin or damp

3-A

clothes.

4-Do not lean on the piece being cut or hold it in your hands.

5-Do not carry out cutting operations in damp environments or on wet surfaces.

6-Do not use the unit if the torch or cables appear damaged.

7-Always turn the unit off before replacing the electrode, the nozzle or the spreader tip of the torch.

8-Always switch the unit off and remove the power cable from the mains socket before carrying out

any maintenance inside the unit.

CAUTION!

Repairs, maintenance and operation of the unit should be carried out by trained personnel

who are aware of the risks caused by the high voltage needed to operate the plasma cutting

unit. The operator should work in compliance with current standards and abide by all safety

regulations.

CAUTION!

If during the cutting operation a slight electric shock is felt, stop work immediately and do not

use the unit until the fault has been discovered and resolved.

EYE AND BODY PROTECTION

One of the hazards during the cutting process is the emission of electromagnetic waves due to the

electric arc. The length of these waves ranges from infrared to ultraviolet. If these rays hit the eyes,

they can cause various complaints such as conjunctivitis, burns to the retina, deterioration of sight,

etc. Moreover a high concentration of ultraviolet rays can burn the skin. It is, therefore, extremely

important that the operator uses adequate safety equipment and clothing, such as:

14

1-Split or leather gloves

2-Split or leather aprons

3-Shin-guards

4-Safety shoes

5-Safety mask (or even better helmet) large enough to cover the whole

of the face, equipped with safety lenses able to ¿ lter all the radiation and

reduce the intensity of the light absorbed by the eye.

CAUTION!

Never, under any circumstances, look at an electric arc without eye protection.

CAUTION!

A further hazard for eyes is the risk of splinters or particles which may be deta-

ched during the cutting operations or during grinding,

brushing or hammering away of the scale.

Always wear goggles or protective shields with transparent lenses during

these operations to prevent splinters or other foreign bodies from entering the eye.

IMPORTANT: safety screens should be installed around the cutting area to protect other people, who

may be working in adjacent areas, from the radiation given out by the arc.

CUTTING FUMES AND GASES

Harmful fumes and metallic powders are produced during the cutting operation. Metals which are

painted or coated or which contain mercury , cadmium, zinc, lead and graphite may produce harmful

concentrations of toxic fumes during cutting.

To protect the operator or other persons from exposure to possible toxic fumes, fume respirators

should be worn and work areas should be adequately ventilated.

When working in enclosed environments, suction units should be ¿ tted below the cutting area.

CAUTION!

When halogenated solvents or degreasing agents are present, the material to be cut should

be cleaned properly to prevent the formation of toxic gases. Some chlorinated solvents may

decompose in the presence of the radiation given out by the arc and may generate phosge-

ne gas.

FIRE HAZARDS

1-Prevent sparks or hot scale from producing À ames

2-Remove inÀ ammable or combustible materials from the cutting area.

3-Make sure that ¿ re-¿ ghting equipment is located near the work area.

4-Situate the unit in an area where the air can be sucked in and exhausted from the grilles on the panel

Do not cut fuel or lubricant containers even if these are empty.

Do not cut containers or casings which contain inÀ ammable material.

Never cut in environments which are polluted by inÀ ammable gas or combustible liquid va-

CAUTION!

pours (such as petrol).

15

NOISE

Noise is generated during the cutting process. The noise level depends on the cutting parameters used.

CAUTION!

Noise can damage hearing

Wear adequate hearing protection.

BURNS

The operator should be adequately protected during cutting operations. This should be routine practice.

CAUTION!

Do not point the torch jet at people or foreign bodies.

EMC

Before installing the plasma cutting unit, carry out an inspection of the surrounding area, observing

the following guidelines:

1-Make sure that there are no other power supply cables, control lines, telephone leads or other

equipment near the unit.

2-Make sure that there are no radio receivers or television appliances.

3-Make sure there are no computers or other control systems.

4-Make sure that there is no-one with a pacemaker or hearing aid in the area around the unit.

5-Check the immunity of any other equipment operating in the same environment. In certain cases

additional protective measures may be required.

Interference can be reduced in the following ways:

1-If there is interference in the power supply line, an E.M.C. ¿ lter should be inserted between the

mains and the unit.

2-The output cables of the unit should be shortened; these should be kept close together and stretched

along the ground.

3-All the panels of the unit should be correctly closed after carrying out maintenance.

GENERAL INFORMATION

PLASMA ARC AND BASIC PRINCIPLES FOR THE PERFORMANCE OF PLASMA CUTTING

¥ Plasma is a gas that is heated to an extremely high temperature and ionised so that it becomes

a conductor of electricity

.

¥ This cutting procedure utilises the plasma to transfer the electric arc to the metal workpiece,

which is melted by the heatand then separated.

¥ The torch uses compressed air from a single source, for both the plasma and cooling and pro-

tective gas.

¥ The start of the cycle is determided by an arc, called the pilot arc, which is struck between the

mobile electode(negative polarity) ab dthe torch nozzle (positive polarity) due to the short circuit

between these two elements.

¥ When the torch is brought into direct contact with the workpiece to be cut (connetcted to the

positive polarity of the power source) the pilot arc is transfered between the electrode and the

workpiece itself thus striking a plasma arc, also called cutting arc.

¥ The duration of the pilot arc is set in the fatcory at 3 seconds; if the transfer has not been made

within this time, the cycle is automatically stopped except for the cooling air which is kept on.

16

POWER SUPPLY CONNECTION

The machine must be connected to a Line-Neutral system with a “PE” protected grounding wire. Check

that the relevant socket terminal is actually connected to the distribution system grounding.

CONNECTION TO GROUND CABLE

Connect the dinse plug to the socket and the work cable clamp to the piece to be cut or to the metallic

workbench.

Take following precautions:

¥ Verify that there is a good electrical contact particularly if insulated or oxidated coated sheets

are cut.

¥ Make ground connections as close as possible to the cutting area. The use of the metallic struc-

tures which are not part of the workpiece, such as the return cable of the cutting current, may

endanger the safety system and give poor cutting results.

¥ Do not make a ground connection on the piece which has to be removed.

TORCH CONNECTION

WARNING!: Before starting the cutting operations verify that the parts are properly assembled

by inspecting the head of the torch as shown on paragraph “Torch Maintenance”

LOCATION AND HANDLING OF THE POWER SOURCE

¥ Choose location verifying that there is a good air À

ow and no dust, smoke or gas is present.

¥ Make sure that obstacles do not prevent the cooling air À ow out of front and rear openings of

the machine.

¥ Arrange an open space of at least 5m around the machine.

¥ In the case the machine has to be moved, always disconnect the plug from the outlet and gather

the cables and pipes so as not to damage them.

COMPRESSED AIR

A source of clean, dry air or nitrogen must be supplied to your plasma cutting unit. The supply pressure must be between 72.5 and 150 psi (5 and10.3 bar). The À ow rate is approximately 3.5 cu.ft./

min. (100L/min.). Failure to observe these precautions could result in excessive operating temperatures or damage to the torch.

An air regulator is included with the unit with optimum pressure setting set to 65 PSI, 4.5 Bar.

Note: the regulator should never be set above 6 bar.

MANUAL PURGE

Oil in the air is a severe problem and must be avoided.

The unit is also equipped with an air ¿ lter which captures

water and oil vapor.

Model 30A - 40A: The vapor collected can be drained

PR-111:

out turning the drain knob located on the air ¿ lter. Three

Position Drain knob, select the desired position:

1. Open

2. Open when no air pressure, closed when air pressure. The drain knob should not be left in this position

during cutting operations.

3. Closed

Model 45A: water contained in the ¿ lter glass can be drained by pushing upward the drain connector.

PR-112/113:

water contained in the ¿ lter glass can be drained by pushing

upward the drain connector.

Note: The unit will not operate if the input air pressure is below 55 PSI, 3.8 Bar.

17

FUNCTIONS

30A - 40A MODEL

PR-111

1.ON/FF Switch – In the ON position the machine is ready for normal operation. All system

control circuits are activated. OFF position deactivates control circuits.

2.Output Current Knob - Adjusts the cutting current supplied by the machine according to the

thickness of material/speed.

3.Green LED– Turns ON when input voltage is applied within normal range – blinks slowly

when input voltage goes above 260Vac, or below 180Vac.

4.Red LED–Turns ON when torch is triggered. Blinks quickly during 3 second safety pre-À ow

prior to pilot arc ignition. Blinks slowly if cutting arcs not initiated after 3 second pilot arc

ignition.

5.Yellow LED– Turns ON when the thermal protection is activated. Blinks slowly when the

under pressure protection is working (the pressure is under 3,8 Bar).

6. Air regulator - Adjusts the input air pressure - pull upward to unlock - nominal air pressure

setting is 4,5 Bar. Note: the regulator should never be set above 6 Bar.

7.Compressed air connection

8. Input cord

9. Work cable with clamp

10. Torch (with a trigger security cap)

18

45A MODEL

PR-112/113

1.ON/FF Switch – In the ON position the machine is ready for normal operation. All system

control circuits are activated. OFF position deactivates control circuits.

2.Output Current Knob - Adjusts the cutting current supplied by the machine according to the

thickness of material/speed.

3.Digital Ammeter - when unit is on views the set cutting current when unit is on, during pilot

arc time views the pilot arc current and during cutting views the cutting current.

4.Green LED – Turns ON when input voltage is applied to the machine.

5.Red LED –Turns ON when pilot or cutting arcs are initiated.

6.Yellow LED – Turns ON when the thermal protection is activated or when voltage exceeds

with compressed air

7.Yellow LED – Turns on when the under pressure protection is working (the pressure is under

3,8 Bar) or when voltage exceeds without compressed air.

8.Torch Gas Purge Button – Allows to remove any condensation that may have accumulated

in the torch and leads while the system was shut down.

9. Air Pressure Gauge – shows the input air pressure

10.Air regulator - Adjusts the input air pressure - pull upward to unlock - nominal air pressure

setting is 4,5 Bar. Note: the regulator should never be set above 6 Bar.

11.Input cord

12.Work cable with clamp

13.Torch (with a trigger security cap)

19

CUTTING OPERATION

PRELIMINARIES

ARNING: unplug the unit from the power supply before assemble or disassemble piled parts,

W

single parts, parts of the torch, torch assemblies or cables.

¥ Check and follow instructions as foreseen in the paragraphs “Safety and Installation” of the

present instructions manual.

PARTS OF THE TORCH

¥ Check the torch for proper assembly. Install proper torch parts for the desired application (refer

to Section called Torch Consumable Parts Selection). NOTE: The power supply will not operate unless the torch shield cup is fully seated against the PIP (Parts in Place) pins in the torch

head.

INPUT POWER

¥ Check the power source for proper input voltage.

¥ Make sure the power source meets circuit protection and wiring requirements.

¥ Plug unit in and close main disconnect switch to supply primary power to the system.

GROUND CABLE

¥ Check for a solid ground cable connection to the workpiece.

AUTOMATIC PURGE SYSTEM

30A - 40A model

¥ Place the ON/OFF switch to the ON position. The ON light will À icker momentarily as the system

powers up and then stays on. Activate the torch button to initiate gas purge (pre-À ow) to remove

any condensation that may have accumulated in the torch and leads while the system was shut

down. When the gas purge is complete, pilot arc will be initiated.

45A model

¥ Place the ON/OFF switch to the ON position. Activate the torch button to initiate gas purge (pre-

À ow) to remove any condensation that may have accumulated in the torch and leads while the

system was shut down. When the gas purge is complete, pilot arc will be initiated. To cool torch

handle or to further remove condensation in the torch and leads push the torch gas purge button

on the front panel of the unit.

WARNING

Do not initiate pilot arc during adjustment.

CHECKING AIR QUALITY

¥ To check air quality, deactivate the torch (post-À ow) and place ¿ lter lens in front of the torch. Any

oil or moisture in the air will be visible on the lens. DO NOT initiate pilot arc while checking air

quality.

20

CUTTING

A. Cutting with a Hand Torch

¥ The torch can be comfortably held in one hand or steadied with two hands. Choose the technique

that feels most comfortable and allows good control and movement. Position the index ¿ nger or

thumb to press the control switch on the torch handle.

¥ For edge starts, hold the torch perpendicular to the workpiece with the front of the tip on the

edge of the workpiece at the point where the cut is to start. - Fig. A. For piercing, angle the torch

slightly to direct sparks away from the torch until the pierce is complete. Fig. B

Fig. A Fig. B

¥ For drag cuts keep the torch in contact with the workpiece. For standoff cutting, hold the torch

2-3 mm from the work.

¥ With the torch in starting position, press the control switch. After an initial gas purge (pre-air),

the pilot arc will come on and remain on for 3 seconds until the cutting arc starts.

¥ Once on, the main arc remains on as long as

the control switch is held down, unless the torch

is withdrawn from the work or torch motion is

too slow. Keep moving while cutting. Cut at a

steady speed without pausing. Maintain the

cutting speed so that the arc lag is about 30°

behind the travel direction. Fig. C

If the cutting arc is interrupted, and the torch

Fig. C

trigger is still pressed, the pilot arc comes back

on automatically for 3 seconds.

¥ To shut off the torch simply release the control switch. When the switch is released a post-À ow

will occur. If the torch trigger is pressed during the post-À ow, the pilot arc will restart.

B. Piercing with a Hand Torch

Note: Recommended maximum piercing capacity is 2mm. If necessary to make a cut on a

metal sheet with a tickness more than 2mm without an edge start, make a hole ø 6mm at

least using an electric drill to start cutting.

¥ When piercing with a hand torch, tip the torch

slightly so that blowback particles blow away

from the torch tip (and operator) rather than

directly back into it. Fig. B

¥ Complete the pierce off the cutting line and then

continue the cut onto the line. Hold the torch

perpendicular to the workpiece after the cut is

complete. Fig. D

¥ Clean spatter and scale from the shield cup and the tip as soon as possible. Spraying or dipping

the shieldcup in anti-spatter compound will minimize the amount of scale which adheres to it.

C. Grates Cutting

To cut grates it is suggestable to set cutting current between 20 - 34A.

Fig. B

Fig. D

21

WARNING

Disconnect primary power at the source and wait that the torch has cooled before disassembling the

torch or torch leads. Frequently review the Important Safety Precautions at the front of this Manual.

Be sure the operator is equipped with proper gloves, clothing, eye and ear protection. Make sure no

part of the operator’s body comes into contact with the work piece while the torch is activated.

CAUTION

Sparks from the cutting process can cause damage to coated, painted, and other surfaces such as

glass, plastic and metal.

NOTE Handle torch leads with care and protect them from damage.

TORCH CONSUMABLE PARTS SELECTION

To change the torch consumable parts use the following procedure: Position the torch with the shield

cup facing upward to prevent these parts from falling out when the cup is removed.

Torch for models 30A / 40A

PR-111

Use:

- 0,90 mm ø nozzle to cut pieces more than

5 mm thick (output current 30-40

Amp)

- 0,80 mm ø nozzle to cut pieces more than

5 mm thick (output current 20-30 Amp)

- 0,65 mm ø nozzle to cut pieces less than

5 mm thick (output current 10-20 Amp)

SHIELD CUP

NOZZLE

GAS DIFFUSER

ELECTRODE

TORCH HEAD

ASSEMBLY

Torch for model 45A

PR-112/113

Use:

1,00 mm ø nozzle to cut with output current

40-45 Amp

- 0,90 mm ø nozzle to cut with output current

30-40 Amp)

SPACER

SHIELD CUP

NOZZLE

GAS DIFFUSER

ELECTRODE

TORCH HEAD ASSEMBLY

WARNING: Wait the torch has suffi ciently cooled before replacing torch parts.

1. Unscrew and remove the shield cup from the Torch Head Assembly.

2. Remove the tip, gas distributor, and electrode.

3. Install the electrode, gas distributor, and tip.

4. Hand tighten the shield cup until it is seated on the torch head. If resistance is felt when installing

the cup, check the threads before proceeding.

22

WORK

TABLE

OPERATING FAULTS

During cutting operations performance faults may arise which are not caused by plant malfunctioning

but by other operational faults such as:

Insuf¿

cient penetration :

Interruption of the cutting arc:

Excessive scoria settlement:

Tilted cutting (not perpendicular):

too high cutting speed;

torch is too tilted;

piece is too thick;

cutting current too low;

torch parts are worn out;

non-genuine Manufacturer’s parts;

cutting speed too slow;

excessive distance between torch and workpiece;

AC line too low - reduce output current;

torch parts are worn out;

non-genuine Manufacturer’s parts;

work cable is disconnected;

too low cutting speed (bottom dross);

too high cutting speed (top dross);

excessive distance between torch and workpiece;

cutting current too low;

torch parts are worn out;

non-genuine Manufacturer’s parts;

torch position not correct;

asymmetric wear of nozzle hole and/or wrong; assemblage of the torch parts;

Excessive wear of nozzle and

electrodes:

air pressure too low;

exceeding system capability (material too thick);

contaminated air (humidity-oil);

excessive pilot arc arc ignitions in the air;

Improperly assembled torch;

torch tip contacting workpiece;

damaged or loose torch head components;

non-genuine Manufacturer’s parts.

MAINTENANCE

Maintenance can only be carried out on the unit if the person in charge of this operation has the necessary

technical knowledge and the correct tools. If this is not the case, contact your nearest service centre.

CAUTION!

Never access inside the machine (panel removal) or touch the torch (disassemblage)

without having disconnected power plug.

Any inspection performed under voltage inside the machine or inside the torch may cause

severe electric shocks caused by direct contact with parts under voltage.

23

UNIT

Keep the cutting or gouging area and the area around the machine clean and free of combustible

materials. No debris should be allowed to collect , this could obstruct air À ow to the machine.

Inspect the unit every 3-4 months (depending on how often the unit is used) and use compressed air

to remove any dust deposits.

CAUTION!

Only use dry compressed air for cleaning. Do not point the jet of air at the electronic circuits.

TORCH

Periodically , according to its use or to cutting faults verify wear of the parts connected to plasma arc:

Shield Cup:

Unscrew manually from head of the torch. Clean throughly abd replace if damaged (burns, distortions or

cracks). Verify integrity of superior metal sector (actuator torch safety).

Tip:

Check wear of plasma arc hole and of inner and outer surfaces. If the hole is widened compared to its

original width or if it is damaged, replace tip. If surfaces are particularly oxidated clean them with extra

¿ ne abrasive paper.

Air Distribution Ring:

Verify the are no burns or cracks or that airÀ ow holes are not obstructed. If damaged, replace immediately .

Electrode:

Replace electrode when crater settling on emitting surface is about 2mm.

WARNING!

¥ Before making any operation to the torch let it cool at least all along the “postgas” period.

¥ Except for particular cases it is advisable to replace electrode and tip AT THE SAME TIME.

¥ Respect assembly order of torch parts (reserved compared to disassemblage).

¥ Be carefull that distributing is assembled properly.

¥ Reassemble shield cup screwing tightly and manually.

¥ Never assemble shield cup without having assembled electrode distributing ring and tip befo-

rehand.

¥ Timely and appropriate control procedures on torch parts are essential for safety and functionality of

the cutting system.

TORCH BODY, HANDLE AND CABLE

¥ These parts usually need no particular maintenance with the exception of a periodic inspection and

an accurate cleaning to be made WITHOUT THE USE OF SOLVENTS.

In case of damages to the insulation such as breaks, cracks and burns or even a loosening of electric

coonductors, the torch CANNOT BE USED FURTHER SINCE SAFETY CONDITIONS HAVE NOT

BEEN RESPECTED.

IN THIS CASE, REPAIRING (EXTRAORDINARY MAINTENANCE) CANNOT BE MADE ON SITE

BUT NEEDS TO BE DELEGATED TO A SERVICE CENTER TO MAKE SPECIAL REST TRIALS

AFTER REP AIRING HAS BEEN EXECUTED.

In order to keep the torch and the cable ef¿ cient it is necessary to follow these precautions:

¥ DO NOT touch torch and cable with warm or hot parts.

¥ DO NOT strain the cable.

¥ DO NOT move the cable on sharp edges or abrasive surfaces.

¥ gather the cable in regular coils if it is too long.

¥ DO NOT step on the cable.

COMPRESSED AIR FILTER

The unit is equipped with a ¿ lter for the compressed air. This ¿ lter is ¿ tted with a knob for the ma-

nual drain of the condensation. Purge periodically to remove the water/oil in the ¿ lter by following

the instructions of paragraph “Compressed air”.

24

TROBLESHOOTING

SYMPTOM

GREEN LED OFF, Fan not operat-ing. No Input

Power.

GREEN LED ON, YELLOW Overtemperature

LED ON. Unit is overheated.

GREEN LED ON,

Model 30A - 40A - YELLOW Overtemperature /

under pressure LED blinks.

Model 45A - YELLOW under pressure LED ON.

No air À ow in purge or pre-À ow.

POSSIBLE CAUSE AND REMEDY

1. Plug unit into 230V outlet.

2. Reset Breaker.

1. Make sure the unit has not been operated

beyond duty cycle limits.

2. Air Flow obstructed.

1. Air not connected or pressure too low. Check

source for at least 5 Bar (72.5 PSI) during purge or pre-À ow, adjust air pressure to 4,5 Bar (65

PSI).

2. Air ¿ lter or air line blocked, torch blocked. Re-

place ¿ lter cartridge. Check that air line and torch

leads are free of twists and kinks.

GREEN LED ON, YELLOW Overtemperature /

under pressure LED OFF, no air À ow when torch

switch pressed.

GREEN LED ON, YELLOW Overtemperature

/ under pressure LED OFF. Air À ows, Pilot arc

does not start.

Torch has pilot arc but does not cut.

1. Shield cup not properly installedon torch. Check that shield cup isfully seated against torch.

2. Faulty Torch Switch or Parts Assembly in torch

holder. Refer to Maintenance paragraph.

3. Faulty Main PC Board Repair / Replace Power

Supply.

1. Faulty torch parts. Inspect torch parts and replace if necessary.

2. Gas pressure too high. Set pressure to 65 psi

(4.5 BAR).

3. Faulty main PC Board. Repair /replace.

1. Work lead not connected. Make sure work lead

is connected securely to bare metal.

2. AC input power too low. Use shortest distance

to breaker panel possible.

3. Faulty Main PC Board.Repair/Replace.

25

LISTA RICAMBI TORCIA / TORCH PARTS LIST / LISTA DE REPUESTOS DE LA ANTORCHA /

LISTE PIÈCES DE RECHANGE DE LA TORCHE PT40-60

01 CORPO TORCIA TORCH HEAD 1

02 ELETTRODO ELECTRODE 1

03 DIFFUSORE AIR DIFFUSER 1

04 CAPPA 1,0 (40-45A) TIP D.1,0 (40-45A) 1

04 CAPPA 0,9 (30-40A) TIP D.0,8 (30-40A) 1

04 CAPPA 0,8 (20-30A) TIP D.0,8 (20-30A) 1

04 CAPPA 0,65 (10-20A) TIP D. 0,65 (10-20A) 1

05 UGELLO SHIELD CUP 1

06 CHIAVE ELECTRODE WRENCH 1

07 IMPUGNATURA+MICRO HANDLE+MICRO 1

08 MICRO MICRO 1

09 FASCIO CAVI CABLE ASSEMBLY 1

MODELLO / MODEL 45A

10 DISTANZIALE SPACER 1

Da usare solo con correnti di taglio superiori a 35A - to be used only with cutting current over 35A

01 CUERPO ANTORCHA TÈTE DE LA TORCHE 1

02 ELECTRODO ELECTRODE 1

03 DIFUSOR AIRE ANNEAU DE DIFUSION 1

04 TOBERA 1,0 (40-45A) BEC D.1,0 (40-45A) 1

04 TOBERA 0,9 (30-40A) BEC D.0,8 (30-40A) 1

04 TOBERA D.0,8 (20-30A) BEC D.0,8 (20-30A) 1

04 TOBERA D. 0,65 (10-20A) BEC D. 0,65 (10-20A) 1

05 BOQUILLA PROTEC. EXT. COUPELLE BLINDÉE 1

06 LLAVE PARA ELECTRODO CLÈ POUR ELECTRODE 1

07 EMPUÑADURA + MICRO POIGNÈE + MICRO 1

08 MICRO MICRO 1

09 HAZ DE CABLES FAISCEAU DE CÂBLES 1

MODELO / MODÈLE 45A

10 DISTANCIADOR ENTRETOISE 1

para utilizar solo con corriente de corte superior a los 35A - à utiliser suelement avec courant de coupe superieur à 35A

50

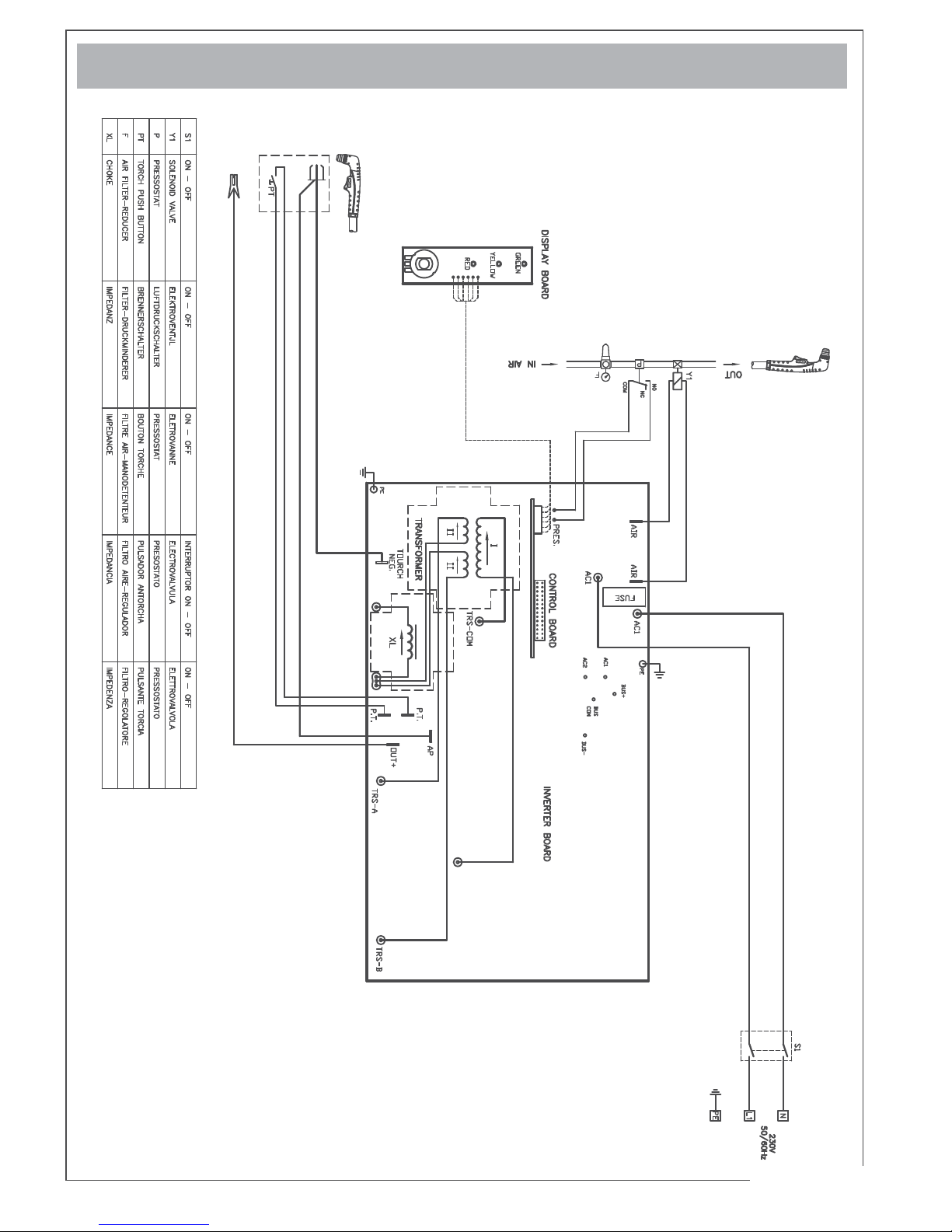

SCHEMA ELETTRICO / WIRING DIAGRAM / ESQUEMA ELECTRICO / SCHÉMA ÉLECTRIQUE

- MOD.30A

51

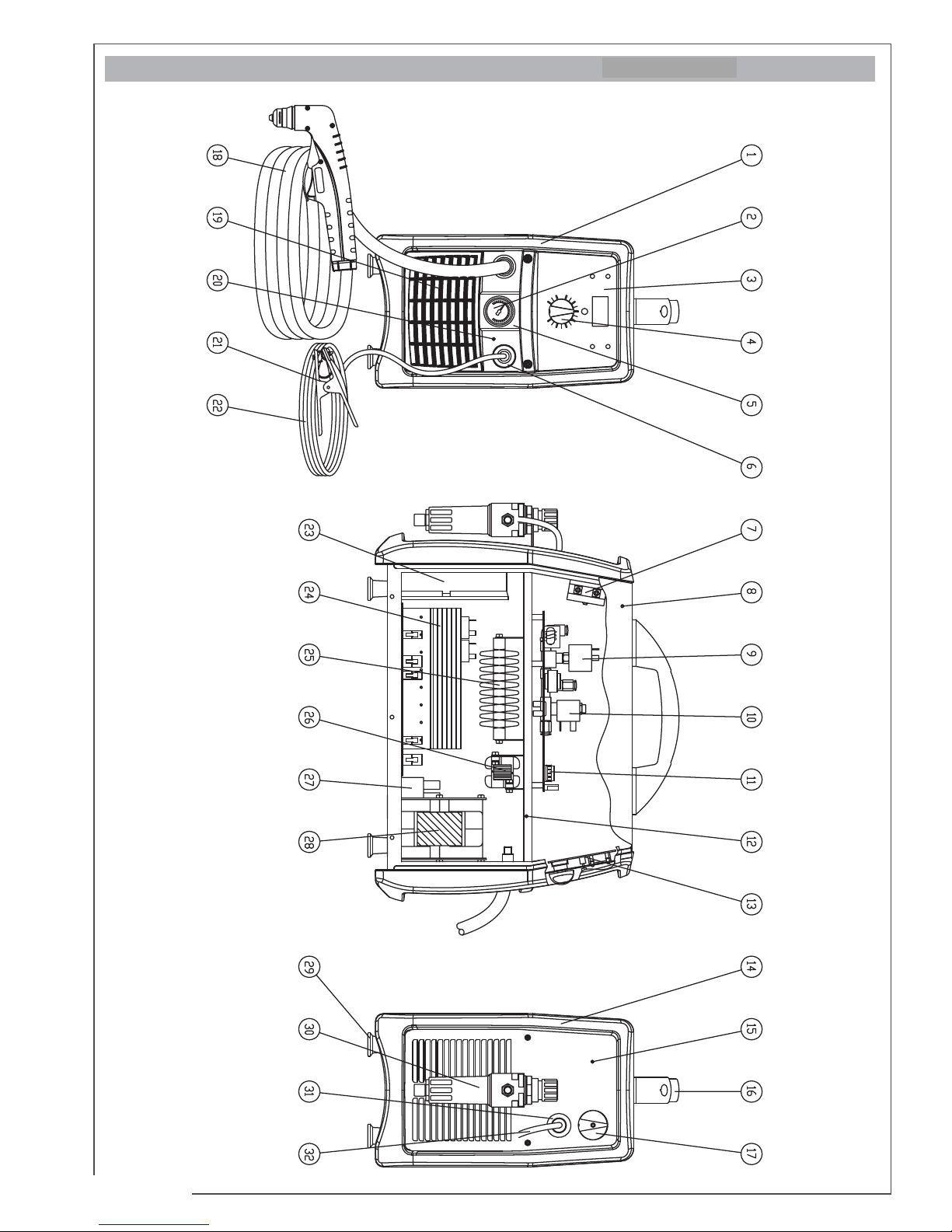

ESPLOSO / PARTS DRAWING / DESPIECE / VUE ÉCLATÉE - MOD.30A

LIST A RICAMBI / P ARTS LIST / LIST A DE REPUEST OS / LISTE PIÈCES DE RECHANGE - MOD.30A

PR-111

PR-111

01 PRESSACAVO CABLE CLAMP 1

01 DADO PER PRESSACAVO NUT FOR CABLE CLAMP 1

02 TARGA ADESIVA REGULATION PLATE 1

02 ETICHETTA FRONTALE FRONT LABEL 1

03 MANOPOLA POTENZ. POTENTIOMETER KNOB 1

04 GUSCIO FRONTALE FRONT FRAME 1

05 DIVISORIO DIVIDING PANEL 1

06 ELETTROVALVOLA SOLENOID VALVE 1

07 PRESSOSTATO PRESSURE SWITCH 1

08 MANIGLIA PLASTIC HANDLE 1

09 COPERCHIO COVER PANEL 1

10 PRESSACAVO CABLE CLAMP 1

11 CAVO DI ALIMENTAZIONE INPUT CABLE 1

12 TORCIA PLASMA PT-40 PLASMA TORCH PT-40 1

13 PRESSACAVO + GHIERA CABLE CLAMP + NUT 1

14 CAVO DI MASSA EARTH CABLE 1

15 PINZA DI MASSA EARTH CLAMP 1

16 SCHEDA PANNELLO FRON. FRONT PANEL P.C. BOARD 1

17 SCHEDA CONTROLLO CONTROL P.C. BOARD 1

18 MODULO COMPLETE P.C. BOARD 1

19 FONDO LOWER PANEL 1

20 PIEDINO LITTLE FEET 1

21 INTERRUTTORE ON/OFF ON/OFF SWITCH 1

22 FILTRO FILTER 1

23 MANOMETRO PER FILTRO FILTER GAUGE 1

01 PASA CABLE PASSE-CÂBLE 1

01 TUERCA PASA CABLE ECROU POUR PASSE-CABLE 1

02 ETIQUETA REG. FRONTAL ETIQUETTE DE RÉG. FRONT. 1

02 ETIQUETA FRONTAL ETIQUETTE FRONTAL 1

03 POMO PARA POTENC. POIGNÉE DU POTENTIOMÈTRE 1

04 MARCO FRONTAL CADRE FRONTAL 1

05 PANEL INTERNO PANNEAU INTÉRIEUR 1

06 VALVULA SOLENOIDE ELECTROVANNE 1

07 PRESOSTATO PRESSOSTAT 1

08 MANILLA DE PLASTICO POIGNÉE 1

09 PANEL DE COBERTURA COUVERCLE 1

10 PASA CABLE PASSE-CÂBLE 1

11 CABLE DE ALIMENTACION CÂBLE DE ALIMENTATION 1

12 ANTORCHA PLASMA PT-40 TORCHE PLASMA PT-40 1

13 PASA CABLE + TUERCA PASSE-CÂBLE + ECROU 1

14 CABLE DE MASA CÂBLE DE MASSE 1

15 PINZA DE MASA BORNE DE MASSE 1

16 CIRCUITO PANEL FRONTAL CIRCUIT PANNEAU FRONTAL 1

17 CIRCUITO DE CONTROL CIRCUIT IMPRIMÉ DE CONTROL 1

18 CIRCUITO COMPLETO CIRCUIT IMPRIMÉ COMPLET 1

19 FONDO PANNEAU DU FOND 1

20 PIE CHICO PETIT PIED 1

21 INTERRUPTOR ON/OFF INTERRUPTEUR MARCHE/ARRÊT 1

22 FILTRO FILTRE 1

23 FILTRO DEL MANOMETRO FILTRE DU MANOMÈTRE 1

52

SCHEMA ELETTRICO / WIRING DIAGRAM / ESQUEMA ELECTRICO / SCHÉMA ÉLECTRIQUE

- MOD.40A

PR-111

53

ESPLOSO / PARTS DRAWING / DESPIECE / VUE ÉCLATÉE - MOD.40A

PR-111

54

LIST A RICAMBI / P ARTS LIST / LISTA DE REPUESTOS / LISTE DES PIÈCES DE RECHANGE - MOD.40A

01 PRESSACAVO CABLE CLAMP 1

01 DADO PER PRESSACAVO NUT FOR CABLE CLAMP 1

02 TARGA ADESIVA REGULATION PLATE 1

02 ETICHETTA FRONTALE FRONT LABEL 1

03 MANOPOLA POTENZ. POTENTIOMETER KNOB 1

04 GUSCIO FRONTALE FRONT FRAME 1

05 SCHEDA PANNELLO FRON. FRONT PANEL P.C. BOARD 1

06 DIVISORIO DIVIDING PANEL 1

07 ELETTROVALVOLA SOLENOID VALVE 1

08 ELETTROVALVOLA SOLENOID VALVE 1

09 PRESSOSTATO PRESSURE SWITCH 1

10 COPERCHIO COVER PANEL 1

11 PRESSACAVO CABLE CLAMP 1

12 CAVO DI ALIMENTAZIONE INPUT CABLE 1

13 MANIGLIA PLASTIC HANDLE 1

14 TORCIA PLASMA PT-40 PLASMA TORCH PT-40 1

15 PRESSACAVO + GHIERA CABLE CLAMP + NUT 1

16 CAVO DI MASSA EARTH CABLE 1

17 PINZA DI MASSA EARTH CLAMP 1

18 ETICHETTA LABEL 1

19 TRASFORMATORE TRANSFORMER 1

20 SCHEDA CONTROLLO CONTROL P.C. BOARD 1

21 MODULO COMPLETE P.C. BOARD 1

22 FONDO LOWER PANEL 1

23 PIEDINO LITTLE FEET 1

24 INTERRUTTORE SWITCH 1

25 FILTRO REGOLATORE FILTER 1

26 MANOMETRO PER FILTRO FILTER GAUGE 1

01 PASA CABLE PASSE-CÂBLE 1

01 TUERCA PASA CABLE ECROU POUR PASSE-CABLE 1

02 ETIQUETA REG. FRONTAL ETIQUETTE DE RÉG. FRONT. 1

03 POMO PARA POTENC. POIGNÉE DU POTENTIOMÈTRE 1

04 MARCO FRONTAL CADRE FRONTAL 1

05 CIRCUITO PANEL FRONTAL CIRCUIT PANNEAU FRONTAL 1

06 PANEL INTERNO PANNEAU INTÉRIEUR 1

07 VALVULA SOLENOIDE ELECTROVANNE 1

08 VALVULA SOLENOIDE ELECTROVANNE 1

09 PRESOSTATO PRESSOSTAT 1

10 PANEL DE COBERTURA COUVERCLE 1

11 PASA CABLE PASSE-CÂBLE 1

12 CABLE DE ALIMENTACION CÂBLE DE ALIMENTATION 1

13 MANILLA DE PLASTICO POIGNÉE 1

14 ANTORCHA PLASMA PT-40 TORCHE PLASMA PT-40 1

15 PASA CABLE + TUERCA PASSE-CÂBLE + ECROU 1

16 CABLE DE MASA CÂBLE DE MASSE 1

17 PINZA DE MASA BORNE DE MASSE 1

18 ETIQUETA ETIQUETTE 1

19 TRANSFORMADOR TRANSFORMATEUR 1

20 CIRCUITO DE CONTROLO CIRCUIT IMPRIMÉ DE CONTROL 1

21 CIRCUITO COMPLETO CIRCUIT IMPRIMÉ COMPLET 1

22 FONDO PANNEAU DU FOND 1

23 PIE CHICO PETIT PIED 1

24 INTERRUPTOR ON/OFF INTERRUPTEUR MARCHE/ARRÊT 1

25 FILTRO FILTRE 1

26 FILTRO DEL MANOMETRO FILTRE DU MANOMÈTRE 1

PR-111

55

LISTA RICAMBI TORCIA / TORCH PARTS LIST / LISTA DE REPUESTOS DE LA ANTORCHA /

LISTE PIÈCES DE RECHANGE DE LA TORCHE PT-80

PR-112/113

01 CORPO TORCIA TORCH HEAD 1

02 ELETTRODO ELECTRODE 1

03 DIFFUSORE AIR DIFFUSER 1

04 CAPPA 1,0 (40-50A) TIP D.1,0 (40-50A) 1

04 CAPPA 0,9 (30-40A) TIP D.0,9 (30-40A) 1

05 UGELLO SHIELD CUP 1

06 DISTANZIALE SPACER 1 *

07 CHIAVE ELECTRODE WRENCH 1

08 FASCIO CAVI CABLE ASSEMBLY 1

09 IMPUGNATURA+MICRO HANDLE+MICRO 1

* Da usare solo con correnti di taglio superiori a 40A - to be used only with cutting current over 40A

01 CUERPO ANTORCHA TÈTE DE LA TORCHE 1

02 ELECTRODO ELECTRODE 1

03 DIFUSOR AIRE ANNEAU DE DIFUSION 1

04 TOBERA 1,0 (40-50A) BEC D.1,0 (40-50A) 1

04 TOBERA 0,9 (30-40A) BEC D.0,8 (30-40A) 1

05 BOQUILLA PROTEC. EXT. COUPELLE BLINDÉE 1

06 DISTANCIADOR ENTRETOISE 1 *

07 LLAVE PARA ELECTRODO CLÈ POUR ELECTRODE 1

08 HAZ DE CABLES FAISCEAU DE CÂBLES 1

09 EMPUÑADURA + MICRO POIGNÈE + MICRO 1

* para utilizar solo con corriente de corte superior a los 40A - à utiliser suelement avec courant de coupe superieur à 40A

56

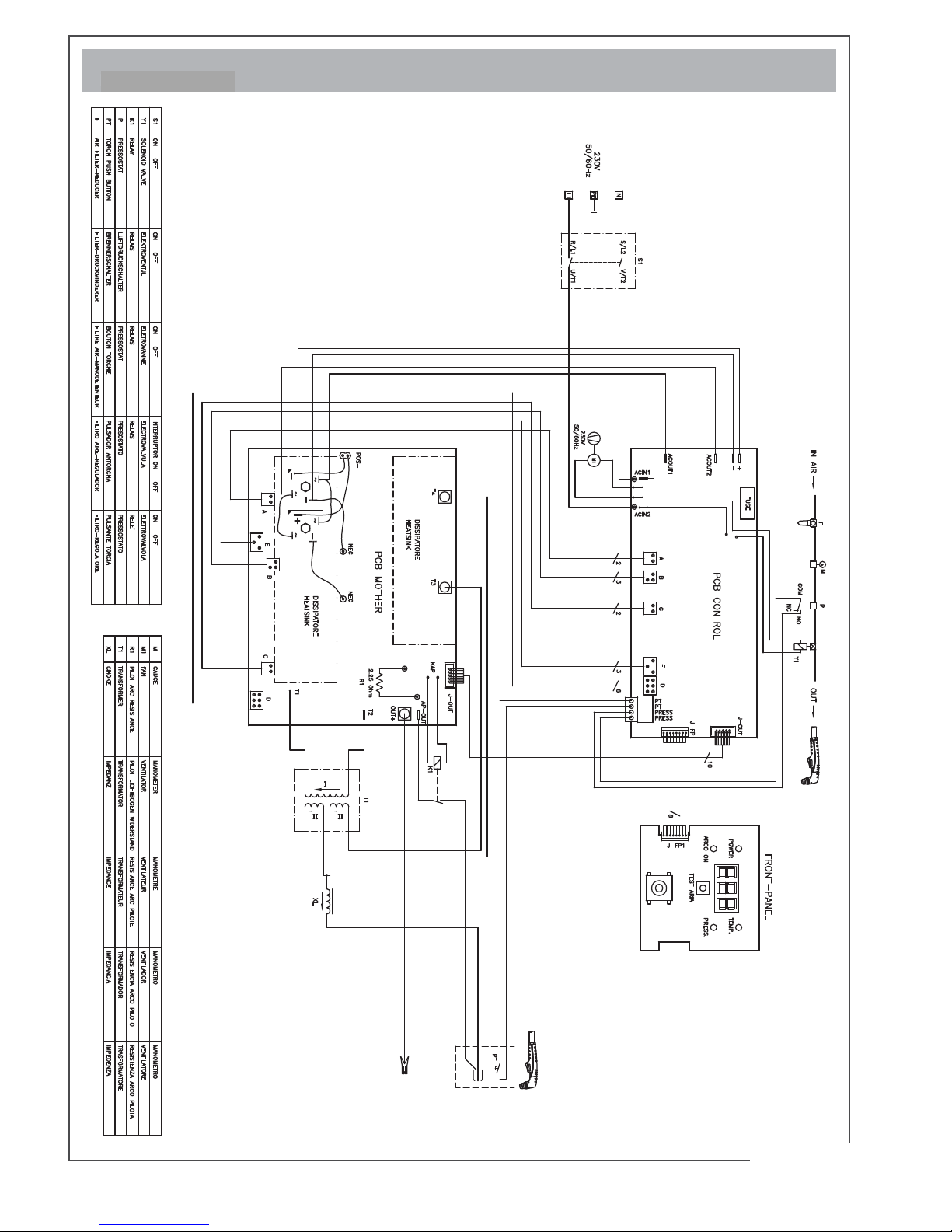

SCHEMA ELETTRICO / WIRING DIAGRAM / ESQUEMA ELECTRICO / SCHÉMA ÉLECTRIQUE

- MOD.45A

PR-112/113

57

ESPLOSO / PARTS DRAWING / DESPIECE / VUE ÉCLATÉE - MOD.45A

PR-112/113

58

LIST A RICAMBI / P ARTS LIST / LISTA DE REPUESTOS / LISTE DES PIÈCES DE RECHANGE - MOD.45A

PR-112/113

01 GUSCIO FRONTALE FRONT FRAME 1

02 MANOMETRO GAUGE D.40 1

03 ETICHETTA FRONTALE FRONT LABEL 1

04 MANOPOLA POTENZIOM. POTENTIOMETER KNOB 1

05 INSER T O PER MANOM. GAUGE GROMMET 1

06. PRESSACAVO CABLE CLAMP 1

07 INTERRUTTORE 20A SWITCH 20 A 1

08 COPERCHIO COVER PANEL 1

09 PRESSOSTATO 3,6BAR PRESSOSTAT 3,6 BAR 1

10 ELETTROVALVOLA 230V SOLENOIDE VALVE 230V 1

11 SCHEDA CONTROLLO CONTROL P.C.BOARD 1

12 DIVISORIO DIVIDING PANEL 1

13 SCHEDA PANNELO FRONT.FRONT PANEL P.C.BOARD 1

14 GUSCIO POSTERIORE BACK FRAME 1

15 FONDO/RETRO BACK/LOWER PANEL 1

16 MANIGLIA HANDLE 1

17 MANOPOLA POTENZ. SWITCH KNOB 1

18 TORCIA PT-80 M4 TORCH PT80 MT4 1

19 FERRITOIA PLASTIC AIR-VENT 1

20 PANNELLO FRONTALE FRONT PANEL 1

21 PINZA DI MASSA EARTH CLAMP 1

22 CAVO DI MASSA EARTH CABLE 1

23 VENTILATORE FAN 230V 50/60HZ 1

24 SCHEDA MADRE MOTHER P.C.BOARD 1

25 RESITENZA 4,5OHM RESISTANCE 4,5 OHM 1

26 IMPEDENZA 23X19CU CHOKE 23X19 CU 1

27 RELE’ 30A 24VDC RELAY 30A 24VDC 1

28 TRASFORMATORE TRANSFORMER 1

29 PIEDINO LITTLE FEET 1

30 RIDUTTORE M140 REDUCER M140 1

31 PRESSACAVO+GHIERA CABLE CLAMP+RING NUT 1

32 CAVO DI ALIMENTAZIONE INPUT CABLE 1

01 MARCO FRONTAL CADRE FRONT AL 1

02 MANOMETRO D.40 MANOMETRE D.40 1

03 ETIQUETA FRONTAL ETIQUETTE FRONTAL 1

04 POMO PARA POTENC. POIGNÉE DU POTENTIOM. 1

05 ABRAZADERA PARA MAN. BAGUE POUR MANOMETRE 1

06. PRENSACABLE PRESSE FIL 1

07 CONMUTADOR 20 A COMMUTATEUR 20 A 1

08 PANEL DE COBERTURA COUVERCLE 1

09 PRESOSTATO 3,6 BAR PRESSOSTAT 3,6 BAR 1

10 ELECTROVALVULA 230V ELECTROVANNE 230V 1

11 CIRCUITO DE CONTROL CIRCUIT DE CONTROLE 1

12 PANEL INTERNO PANNEAU INTÉRIEUR 1

13 CIRCUITO PANEL FRONTAL CIRCUIT P ANNEAU FRONTAL 1

14 MARCO POSTERIOR CADRE ARRIÈRE 1

15 FONDO/PANEL POSTERIOR PANNEAU ARRIÈRE/DU FOND 1

16 MANILLA POIGNÉE 1

17 POMO PARA CONMUTADOR BOUTON DE COMMUT. 1

18 ANTORCHA PT-80 MT.4 TORCHE PT-80 MT.4 1

19 ASPILLERA GRILLE DE VENTIALTION 1

20 PANEL FRONTAL PANNEAU FRONTAL 1

21 PINZA DE MASA BORNE DE MASSE 1

22 CABLE DE MASA CÂBLE DE MASSE 1

23 VENTILADOR 230V 50/60HZ VENTILATEUR 230V 50/60HZ 1

24 CIRCUITO PRINCIPAL CIRCUIT PRINCIPAL 1

25 RESISTENCIA4,5 OHM RESISTANCE 4,5 OHM 1

26 IMPEDANCIA 23X19 CU IMPEDANCE 23X19 CU 1

27 RELÉ 30A 24VDC RELAIS 30A 24VDC 1

28 TRANSFORMADOR TRANSFORMATEUR 1

29 PIE CHICO PETIT PIED 1

30 REGULADOR M140 MANODETENTEUR M140 1

31 PASA CABLE + VIROLA PASSE-CÂBLE + BAGUE 1

32 CABLE DE ALIMENTACION CÂBLE DE ALIMENTATION 1

59

NOTES

25

90

NOTES

91

26

NOTES

91

27

Pro Spot international, Inc.

5932 Sea Otter Place

Carlsbad, CA 92010

Toll Free (US Only): (877) PRO SPOT

Phone: (760) 407-1414

Fax: (760) 407-1421

E-mail: info@prospot.com

Web: www.prospot.com

All Info Copyright © Pro Spot International Inc.

Loading...

Loading...