Page 1

PXM

PROFIBUS DPV0/DPV1 Master

User Manual

PMEPXM0100

PMEPXM0100H

11/2020

Revision 1.06

Page 2

Preface

DANGER

indicates a hazardous situation which, if not avoided,

will result in

death

or

WARNING

ind

icates a hazardous situation which, if not avoided,

could result in

, death

Note: Before installing, configuring, operating, or maintaining the PMEPXM0100(H)

products, please review this information and the information located on:

https://www.schneider-electric.com/en/product/PMEPXM0100 or

https://www.schneider-electric.com/en/product/PMEPXM0100H

for the latest software, documentation, and installation files specific to the

PMEPXM0100(H) products.

For additional support, please contact Schneider Electric at

https://www.schneider-electric.com/en/work/support/

Installation and maintenance of the PMEPXM0100(H) products should be carried out by

suitably trained personnel in accordance with applicable codes of practice. In case of

malfunction or damage, no attempts of repair should be made. Your PMEPXM0100(H)

product(s) should be returned for repair. Do not dismantle the product.

Notice

Read these instructions carefully and look at the equipment to become familiar with the

device before trying to install, operate, service, or maintain it. The following special messages

may appear throughout this documentation or on the equipment to warn of potential hazards

or to call attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a “Danger” or “Warning” safety label indicates

that an electrical hazard exists which will result in personal injury if the

instructions are not followed.

This is a safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

DANGER

serious injury.

or serious injury.

Revision 1.06 Page 2 of 238

WARNING

Page 3

Preface

CAUTION

indicates a hazardous situation which, if not avoided,

could result in

minor

NOTICE

is used to address practices not related to physical injury.

UNGUARDED EQUIPMENT

CAUTION

or moderate injury.

NOTICE

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising

out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction and

operation of electrical equipment and its installation and has received safety training to

recognize and avoid the hazards involved.

BEFORE YOU BEGIN

Do not use this product on machinery lacking effective point-of-operation guarding. Lack of

effective point-of-operation guarding on a machine can result in serious injury to the operator

of that machine

WARNING

Do not use this software and related automation equipment on equipment

which does not have point-of-operation protection.

Do not reach into machinery during operation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

This automation equipment and related software is used to control a variety of industrial

processes. The type or model of automation equipment suitable for each application will vary

depending on factors such as the control function required, degree of protection required,

production methods, unusual conditions, government regulations, etc. In some applications,

more than one processor may be required, as when backup redundancy is needed.

Only you, the user, machine builder or system integrator can be aware of all the conditions

and factors present during setup, operation, and maintenance of the machine and, therefore,

can determine the automation equipment and the related safeties and interlocks which can

be properly used. When selecting automation and control equipment and related software

for a particular application, you should refer to the applicable local and national standards

and regulations. The National Safety Council's Accident Prevention Manual (nationally

recognized in the United States of America) also provides much useful information.

Revision 1.06 Page 3 of 238

Page 4

Preface

EQU

IPMENT OPERATION HA

Z

ARD

In some applications, such as packaging machinery, additional operator protection such as

point- of-operation guarding must be provided. This is necessary if the operator's hands and

other parts of the body are free to enter the pinch points or other hazardous areas and serious

injury can occur. Software products alone cannot protect an operator from injury. For this

reason, the software cannot be substituted for or take the place of point-of-operation

protection.

Ensure that appropriate safeties and mechanical/electrical interlocks related to point-ofoperation protection have been installed and are operational before placing the equipment

into service. All interlocks and safeties related to point-of-operation protection must be

coordinated with the related automation equipment and software programming.

NOTE: Coordination of safeties and mechanical/electrical interlocks for point-of-operation

protection is outside the scope of the Function Block Library, System User Guide, or other

implementation referenced in this documentation.

START-UP AND TEST

Before using electrical control and automation equipment for regular operation after

installation, the system should be given a start-up test by qualified personnel to verify correct

operation of the equipment. It is important that arrangements for such a check be made and

that enough time is allowed to perform complete and satisfactory testing

WARNING

Verify that all installation and set-up procedures have been completed.

Before operational tests are performed, remove all blocks or other temporary

holding means used for shipment from all component devices.

Remove tools, meters, and debris from equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Follow all start-up tests recommended in the equipment documentation. Store all equipment

documentation for future references.

Software testing must be done in both simulated and real environments.

Verify that the completed system is free from all short circuits and temporary grounds that

are not installed according to local regulations (according to the National Electrical Code in

the U.S.A, for instance). If high-potential voltage testing is necessary, follow

recommendations in equipment documentation to prevent accidental equipment damage.

Before energizing equipment:

Remove tools, meters, and debris from equipment.

Revision 1.06 Page 4 of 238

Page 5

Preface

Close the equipment enclosure door.

Remove all temporary grounds from incoming power lines.

Perform all start-up tests recommended by the manufacturer.

OPERATION AND ADJUSTMENTS

The following precautions are from the NEMA Standards Publication ICS 7.1-1995 (English

version prevails):

Regardless of the care exercised in the design and manufacture of equipment or in the

selection and ratings of components, there are hazards that can be encountered if

such equipment is improperly operated.

It is sometimes possible to misadjust the equipment and thus produce unsatisfactory

or unsafe operation. Always use the manufacturer’s instructions as a guide for

functional adjustments. Personnel who have access to these adjustments should be

familiar with the equipment manufacturer’s instructions and the machinery used with

the electrical equipment.

Only those operational adjustments actually required by the operator should be

accessible to the operator. Access to other controls should be restricted to prevent

unauthorized changes in operating characteristics.

For professional users in the European Union

If you wish to discard electrical and electronic equipment (EEE), please contact your

dealer or supplier for further information.

Revision 1.06 Page 5 of 238

Page 6

Preface

POSSIBLE HOT SURFACE

North American Hazardous Location Approval

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D HAZARDOUS LOCATIONS, OR

NONHAZARDOUS LOCATIONS ONLY.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT WHILE THE CIRCUIT IS LIVE

OR UNLESS THE AREA IS KNOW TO BE FREE OF IGNITABLE CONCENTRATIONS.

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF ANY COMPONENT MAY IMPAIR SUITABILITY

FOR CLASS I, DIVISION 2.

ADAPTÉ POUR UNE UTILISATION EN CLASSE 1, DIVISION 2, GROUPES A, B, C ET D LIEUX

DANGEREUX OU EXCLUSIVEMENT EMPLACEMENT NON DANGEREUX

AVERTISSEMENT - RISQUE D'EXPLOSION - NE PAS DECONNECTER L'EQUIPEMENT LORSQUE LE

CIRCUIT EST ALIMENTE, A MOINS QUE LA ZONE SOIT CONTROLEE ABSENTE DE CONCENTRATION

INFLAMMABLES.

AVERTISSEMENT - RISQUE D'EXPLOSION - REMPLACEMENT DE TOUT COMPOSANT PEUT NUIRE A

LA CONFORMITÉ DE CLASS I, DIVISION 2.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having

jurisdiction.Warning - Explosion Hazard - When in hazardous locations, turn off power before

replacing or wiring modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off

or the area is known to be non-hazardous.

These products are intended to be mounted in an IP54 enclosure. The devices shall provide

external means to prevent the rated voltage being exceeded by transient disturbances of more

than 40%. This device must be used only with ATEX certified backplanes.

DO NOT OPEN WHEN ENERGIZED.

CAUTION

Certain surfaces may be hot.

Failure to follow these instructions can result in injury or equipment damage.

Revision 1.06 Page 6 of 238

Page 7

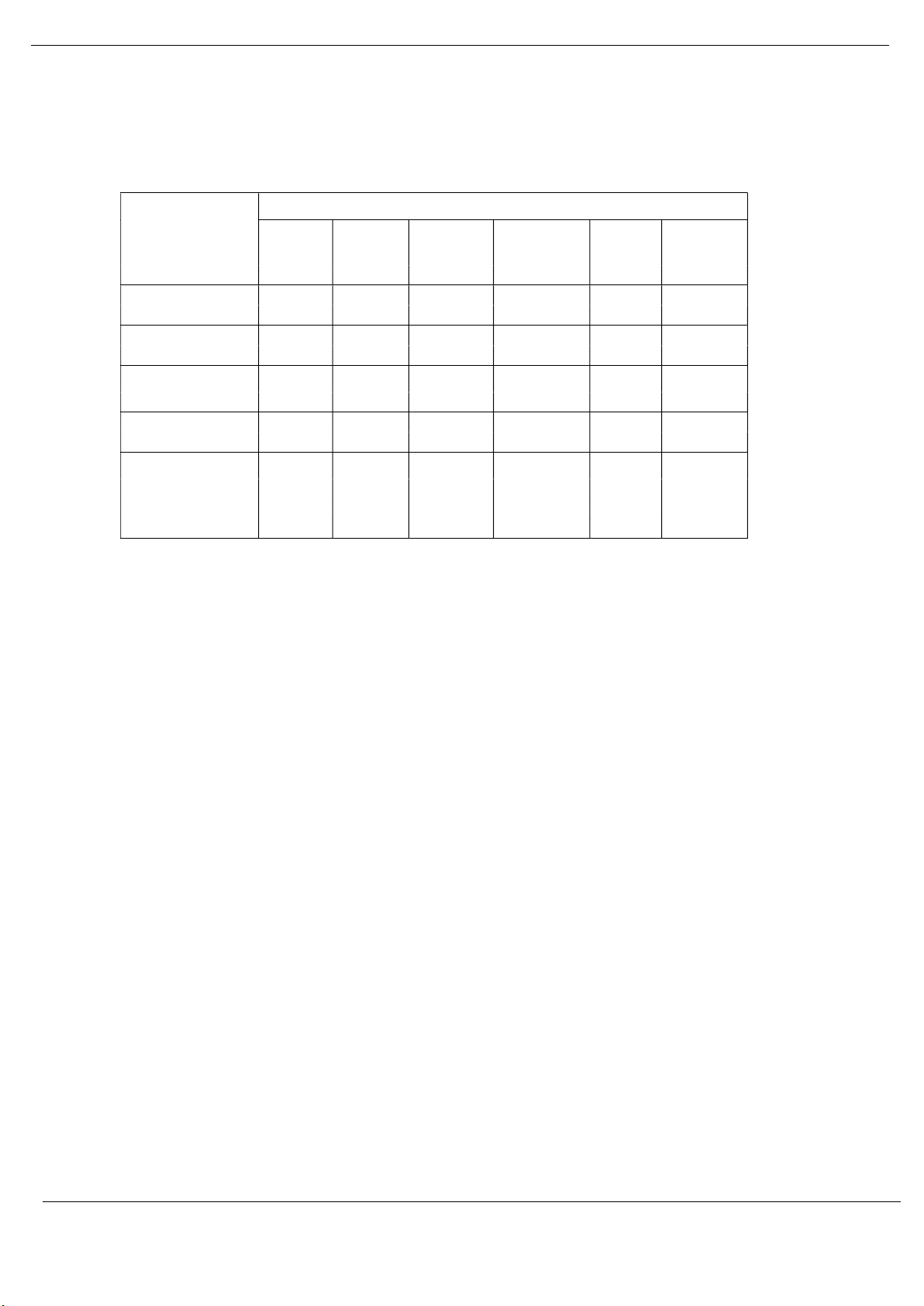

China RoHS Declaration Table

部件名称

Part Name (Pb) (Hg) (Cd) (Cr (VI)) (PBB) (PBDE)

金属部件

Metal parts

塑料部件

Plastic parts

电子件

Electronic

触点

Contacts

线缆和线缆附件

Cables &

cabling

accessories

铅

X O O O O O

O O O O O O

O O O O O O

O O X O O O

X O O O O O

Preface

有害物质 - Hazardous Substances

汞

镉 六价铬

多溴联

苯

多溴二苯

醚

本表格依据 SJ/T11364 的规定编制。

O: 表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X: 表示该有害物质至少在该部件的某㇐均质材料中的含量超出 GB/T 26572 规定的限量要求。

This table is made according to SJ/T 11364.

O: Indicates that the concentration of hazardous substance in all of the homogeneous materials

for this part is below the limit as stipulated in GB/T 26572.

X: Indicates that concentration of hazardous substance in at least one of the homogeneous

materials used for this part is above the limit as stipulated in GB/T 26572.

Revision 1.06 Page 7 of 238

Page 8

Preface

CONTENTS

1. Preface ............................................................................................................................. 15

1.1. Introduction to the PXM ........................................................................................ 15

1.2. Prerequisites .......................................................................................................... 15

1.3. Features ................................................................................................................. 15

1.4. Architecture ........................................................................................................... 16

1.5. Additional Information .......................................................................................... 18

1.6. Support .................................................................................................................. 19

2. Installation ....................................................................................................................... 20

2.1. Module Layout ....................................................................................................... 20

2.2. Module Mounting .................................................................................................. 21

2.3. Backplane Connector ............................................................................................. 23

2.4. PROFIBUS DP Port (RS485) .................................................................................... 23

3. Setup ................................................................................................................................ 24

3.1. Setup Introduction ................................................................................................. 24

3.2. Install Configuration Software ............................................................................... 24

3.3. Network Parameters ............................................................................................. 25

3.4. GSD File Management ........................................................................................... 25

3.5. PXM Type Library ................................................................................................... 28

3.5.1. Compatibility ...................................................................................................... 28

3.5.2. Installation ......................................................................................................... 28

3.5.3. Updating Project ................................................................................................ 30

3.5.4. Mandatory Settings in Control Expert ............................................................... 31

3.5.5. Library Content .................................................................................................. 31

3.6. Creating a New Project .......................................................................................... 32

3.7. PXM Parameters .................................................................................................... 35

Revision 1.06 Page 8 of 238

Page 9

Preface

3.7.1. General ............................................................................................................... 35

3.7.2. PROFIBUS ........................................................................................................... 40

3.7.3. HSBY ................................................................................................................... 43

3.7.4. Security .............................................................................................................. 45

3.7.5. SNMP .................................................................................................................. 48

3.7.6. Time ................................................................................................................... 48

3.8. Verify Configuration .............................................................................................. 49

3.9. Module Download ................................................................................................. 51

3.10. Device Discovery (Online) ...................................................................................... 52

3.10.1. Discovery ........................................................................................................ 52

3.10.2. Device Station Address Change...................................................................... 55

3.11. Adding PROFIBUS DP Devices ................................................................................ 56

3.11.1. General ........................................................................................................... 57

3.11.2. PROFIBUS Configuration ................................................................................ 58

3.11.3. DPV1 ............................................................................................................... 61

3.11.4. User Parameters ............................................................................................. 62

3.11.5. Slot Configuration .......................................................................................... 63

3.11.6. Start-up Parameters ....................................................................................... 66

3.11.7. Mapping Report ............................................................................................. 67

3.12. PROFIBUS Device Bulk Instantiation ...................................................................... 68

3.12.1. Copy, Paste and Paste Special ........................................................................ 68

3.12.2. Import / Export Device Lists ........................................................................... 70

3.13. Control Expert Configuration................................................................................. 71

3.13.1. Configure Project Settings .............................................................................. 71

3.13.2. Instantiate PXM (Placeholder) ....................................................................... 72

3.13.3. Instantiate PXM DTM (Generic EDS) .............................................................. 73

3.13.4. Modifying PXM IP address ............................................................................. 75

3.13.5. Modifying PXM Connection Settings.............................................................. 77

3.13.6. PXM RPI Recommendations ........................................................................... 79

3.13.7. PXM Mapping Export/Import for Control Expert ........................................... 79

3.13.8. Download to M580 Controller ....................................................................... 83

Revision 1.06 Page 9 of 238

Page 10

Preface

3.13.9. Control Expert Project Clean-up .................................................................... 84

4. Operation ......................................................................................................................... 87

4.1. PROFIBUS DP ......................................................................................................... 87

4.2. Control Expert Connection .................................................................................... 87

4.3. Control Expert Mapping ........................................................................................ 88

4.3.1. PXM Master DDT (T_PXM_Master) ................................................................... 88

4.3.2. Device DDT ......................................................................................................... 93

4.3.3. Master Mapping DFB ......................................................................................... 97

4.3.4. Device Mapping DFB .......................................................................................... 99

4.4. Change Configuration on the Fly (CCOTF) ........................................................... 100

4.5. Explicit Messaging Function Blocks ..................................................................... 102

4.5.1. ID DFB ............................................................................................................... 103

4.5.2. RDRec DFB ........................................................................................................ 109

4.5.3. WRRec DFB ....................................................................................................... 111

4.5.4. RDDiag DFB ...................................................................................................... 114

4.5.5. RDAlarm DFB .................................................................................................... 116

4.5.6. GlobalControl DFB ............................................................................................ 119

4.6. Explicit Messaging Utility ..................................................................................... 123

4.7. Global Control Utility ........................................................................................... 126

4.8. DPV1 Communication .......................................................................................... 127

4.8.1. Class 1 Messaging (MS1) .................................................................................. 127

4.8.2. Class 2 Messaging (MS2) .................................................................................. 129

4.9. Diagnostics ........................................................................................................... 134

4.9.1. Notification ...................................................................................................... 135

4.9.2. Extraction ......................................................................................................... 137

4.10. Global Control ...................................................................................................... 139

4.11. Alarming ............................................................................................................... 140

4.11.1. Notification ................................................................................................... 140

4.11.2. Extraction ..................................................................................................... 143

Revision 1.06 Page 10 of 238

Page 11

Preface

4.12. Fast Device Replacement (FDR) ........................................................................... 144

4.13. Firmware upgrading ............................................................................................ 145

5. HSBY ............................................................................................................................... 148

5.1. Introduction ......................................................................................................... 148

5.2. PXM in HSBY ........................................................................................................ 148

5.2.1. Controlled SWAP .............................................................................................. 151

5.2.2. Uncontrolled SWAP ......................................................................................... 152

5.3. Configuration ....................................................................................................... 153

5.3.1. HSBY Holdover ................................................................................................. 155

5.3.1. HSBY DP Deadtime ........................................................................................... 156

5.3.2. HSBY Switch Over Command Rate ................................................................... 156

5.3.3. HSBY Switch Over Retry Limit .......................................................................... 156

5.4. Download Configuration ..................................................................................... 157

5.5. Control Expert Setup ........................................................................................... 158

5.6. Operation ............................................................................................................. 159

5.6.1. Control Expert Operation ................................................................................. 159

5.6.2. Manual SWAP on PXM Unrecoverable Hardware Error .................................. 159

5.7. Diagnostics ........................................................................................................... 159

5.7.1. ProSoft Configurator for Modicon Diagnostics ................................................ 159

6. Migrating PTQ-PDPMV1 Projects ................................................................................... 161

7. Device Type Manager (DTM) ......................................................................................... 165

7.1. Installation ........................................................................................................... 165

7.2. Configuration ....................................................................................................... 165

7.1. Operation ............................................................................................................. 168

8. Diagnostics ..................................................................................................................... 172

8.1. LEDs...................................................................................................................... 172

8.2. Module Status Monitoring .................................................................................. 174

8.2.1. PXM DP Master ................................................................................................ 174

8.2.2. Device Status .................................................................................................... 189

Revision 1.06 Page 11 of 238

Page 12

Preface

8.3. PROFIBUS Packet Capture ................................................................................... 196

8.4. Target Browser .................................................................................................... 200

8.5. Module Event Log ................................................................................................ 203

8.6. Web Server .......................................................................................................... 203

9. Troubleshooting Guide .................................................................................................. 205

10. Technical Specifications .............................................................................................. 207

10.1. Dimensions .......................................................................................................... 207

10.2. Electrical .............................................................................................................. 207

10.3. PROFIBUS DP ....................................................................................................... 208

10.4. Certifications ........................................................................................................ 208

11. PROFIBUS DP ............................................................................................................... 209

11.1. Introduction ......................................................................................................... 209

11.2. PROFIBUS master and slave ................................................................................ 210

11.3. PROFIBUS master class 1 (DPM1) or class 2 (DPM2) ........................................... 210

11.4. Cyclic communication .......................................................................................... 211

11.5. Acyclic communication ........................................................................................ 211

11.6. Topology of PROFIBUS DP ................................................................................... 212

11.7. PROFIBUS DP cable description ........................................................................... 212

11.8. PROFIBUS DP connector description ................................................................... 213

12. Appendix ..................................................................................................................... 214

12.1. DPV1 Response Status ......................................................................................... 214

12.2. DPV1 Extended Status Codes .............................................................................. 214

12.3. SysLog Events ....................................................................................................... 216

12.4. Verification Notifications ..................................................................................... 219

12.5. Additional CIP Objects ......................................................................................... 220

12.5.1. PXM General Status...................................................................................... 220

12.5.2. PXM Master Statistics .................................................................................. 223

Revision 1.06 Page 12 of 238

Page 13

Preface

12.5.3. Profibus End-Point Diagnostic Admin ......................................................... 225

12.5.4. Profibus End-Point Diagnostic ...................................................................... 226

12.5.5. Profibus End-Point Statistics Admin ............................................................. 227

12.5.6. Profibus End-Point Statistics ........................................................................ 227

12.5.7. Profibus Data Exchange Admin .................................................................... 229

12.5.8. Profibus Data Exchange ................................................................................ 229

12.5.9. EtherNet/IP Connection Diagnostics ............................................................ 230

12.5.10. EtherNet/IP IO Message Diagnostics ........................................................... 231

12.5.11. EtherNet/IP Explicit Message Diagnostics ................................................... 231

12.5.12. EtherNet/IP Communication Capacity ......................................................... 232

12.5.13. EtherNet/IP Bandwidth Diagnostics ............................................................. 233

12.5.14. IO Connection Diagnostic ............................................................................. 233

12.5.15. IO Connection Information .......................................................................... 234

12.5.16. IO Connection Diagnostics ........................................................................... 235

12.5.17. Explicit Connection Diagnostic ..................................................................... 236

13. Index ............................................................................................................................ 237

Revision 1.06 Page 13 of 238

Page 14

Preface

Revision History

Revision Date Comment

1.03 17 April 2019 Initial release

1.04 28 August 2019 Added PCM Enhanced IO Scan Option in EcoStruxure Control Expert Export.

1.05 9 January 2020 Added timing diagram detail for Freeze and Sync Global Controls.

Added note on manual HSY SWAP on PXM disconnection / unrecoverable

hardware error.

Added Control Expert Project Clean-Up recommendations (3.13.9)

Added Set Watchdog All option (3.11.2)

Added HSBY Master Mapping Timing Diagram (Figure 4.4)

Updated non-interfering Safety description (1.3)

1.06 17 November 2020 Added Project Properties (3.6)

Additional Slot configuration information (3.11.5)

Updated LiveList definition in Control Expert DDT (4.3.1.1)

Added PROFIBUS Capture functionality (8.3)

Added Auto Recommend description (Table 3.4)

Updated Default Watchdog description (Table 3.4 and Table 3.11)

Updated FDR Config Retrieval Status (Table 8.4)

Revision 1.06 Page 14 of 238

Page 15

Preface

1. PREFACE

1.1. INTRODUCTION TO THE PXM

This manual describes the installation, operation, and diagnostics of the ProSoft PXM

PROFIBUS DPV0/DPV1 Master – PMEPXM0100 or PMEPXM0100H. The PXM allows the user

to integrate PROFIBUS DP slave devices into Schneider Electric’s M580 Control System. This

will allow the M580 Control System to exchange process, alarming, and diagnostic data with

PROFIBUS DP devices as well as provide parameterization and asset management of slave

devices using Device Type Managers (DTMs).

1.2. PREREQUISITES

The PXM module operates in the M580 System with following requirements:

EcoStruxure Control Expert: V14 or greater

(+ ControlExpert_V140_HF_PMEPXM0100 hotfix)

M580 CPU Firmware: 2.80 or greater

1.3. FEATURES

The PXM can exchange process data (DPV0) with up to 125 PROFIBUS DP slave devices which

will be formatted into the engineering units in the M580 Control System by using the

automatically generated Control Expert mapping imports.

The ProSoft Configurator for Modicon will allow the user to configure each PXM as well as

each PROFIBUS DP slave device connected to the PXM for DPV0 communication. The utility

will also automatically generate the mapping routines and structures (in either Function Block

or Structured Text) which can be imported into Control Expert.

The PXM also provides DPV1 communication allowing the user to exchange DPV1 Class 1 and

Class 2 data with each slave device. The PXM Gateway DTM can be used to configure and

parameterize each slave device using Device Type Manager (DTM) technology.

The PXM will allow the user to monitor and extract DPV1 alarms from each slave device on

the connected PROFIBUS DP fieldbus from the M580 controller.

The PXM provides a range of statistics and tools to provide a detailed diagnostic overview of

each PXM which speeds-up system commissioning. The Configuration Utility allows the user

to do a PROFIBUS DP packet capture of the running fieldbus which can be used to analyse the

Revision 1.06 Page 15 of 238

Page 16

Preface

bus behaviour and packets received. The PXM also provides global and device specific

statistics.

Each PXM connection to the M580 controller can be customized to the required data size.

This provides the user with a range of EtherNet/IP connection sizes and counts to limit the

amount of memory used by each PXM.

The PXM also allows the user to customize the required security level for an application by

enabling or disabling certain protocols as well as having a configurable Access Control List. In

addition to this the PXM can log up to 2048 events into non-volatile memory (NV) which can

later be offloaded to a SysLog Server.

The PXM can be used in one of two modes; Standalone or HSBY.

Standalone

In this mode a single PXM is connected a single M580 controller. The PXM can be run in the

local rack or a remote rack (using either the controller connection or NOC).

HSBY

In this mode the PXM can be used in a redundant M580 Control Architecture. Each PXM will

be located in the local rack of each redundant M580 controller. This will allow the PXM to

switch with the M580 controllers in an HSBY system when needed. The PXM will provide a

bumpless transfer when switching from Primary PXM to Standby PXM when a switch over

event occurs.

Safety

The module can be installed in the same rack as safety modules, as it is a non-interfering type

1 device.

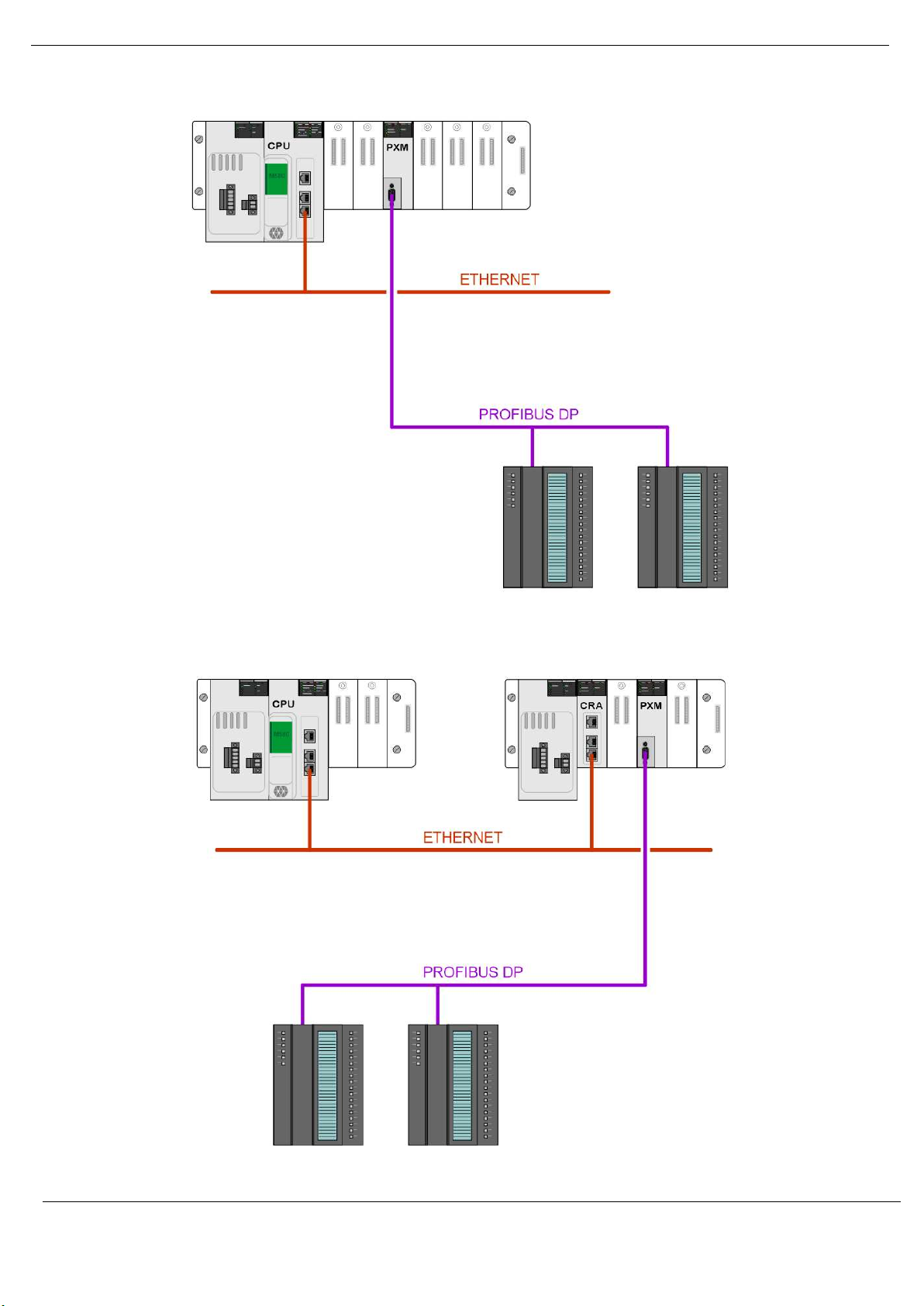

1.4. ARCHITECTURE

The PXM can be configured to operate in one of three architectures; Standalone, HSBY, or

Remote.

The figure below provides an example of the typical network setup in a Standalone

architecture.

Revision 1.06 Page 16 of 238

Page 17

Preface

Figure 1.1 - PXM Standalone architecture

Alternatively, the PXM can be configured to operate in a Remote Rack of the M580 system.

Figure 1.2 - PXM Standalone architecture in a Remote Rack

Revision 1.06 Page 17 of 238

Page 18

Preface

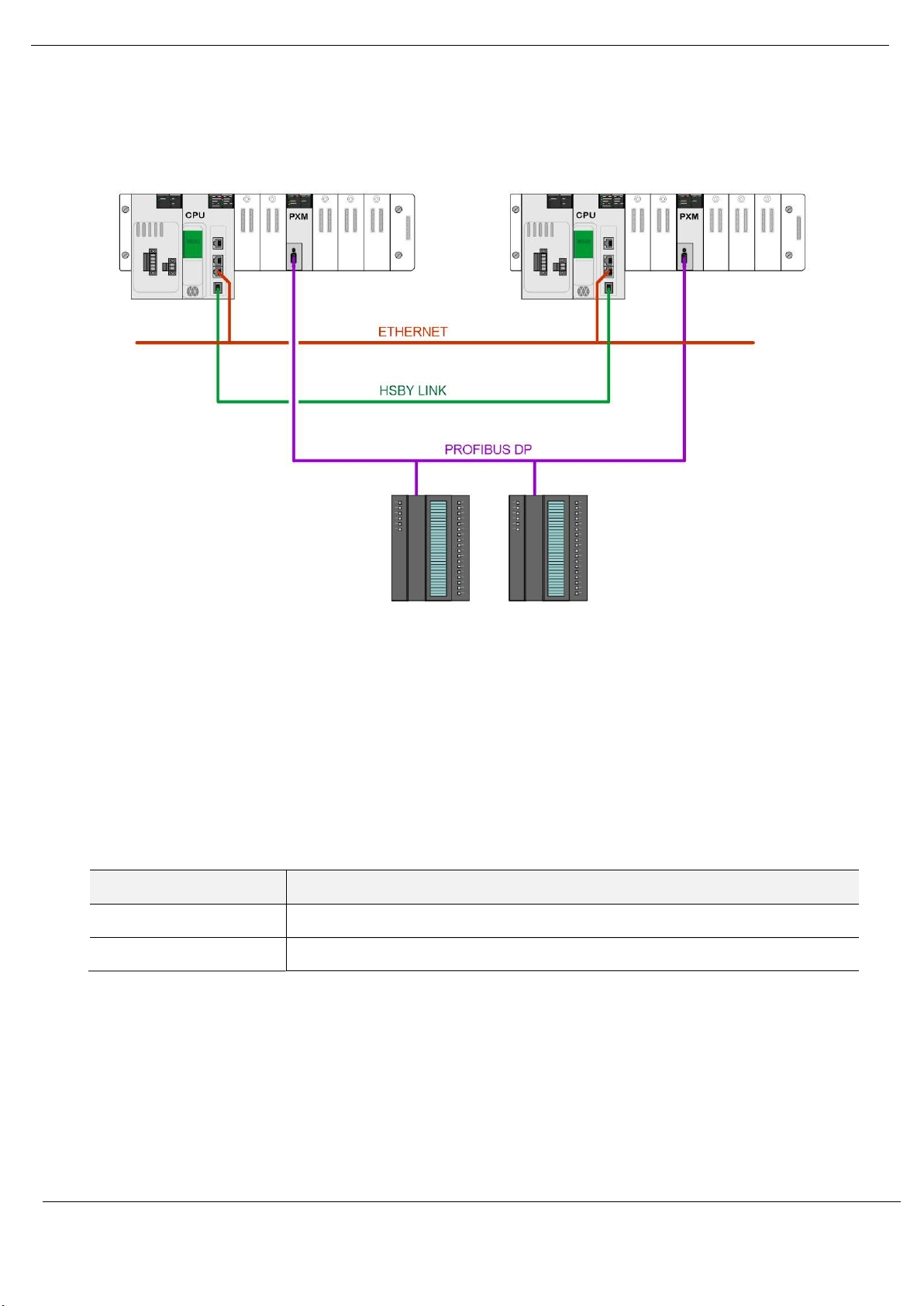

When the M580 control system is operating in a redundant HSBY architecture, each PXM will

operate in the local rack as shown below:

Figure 1.3 - PXM HSBY architecture

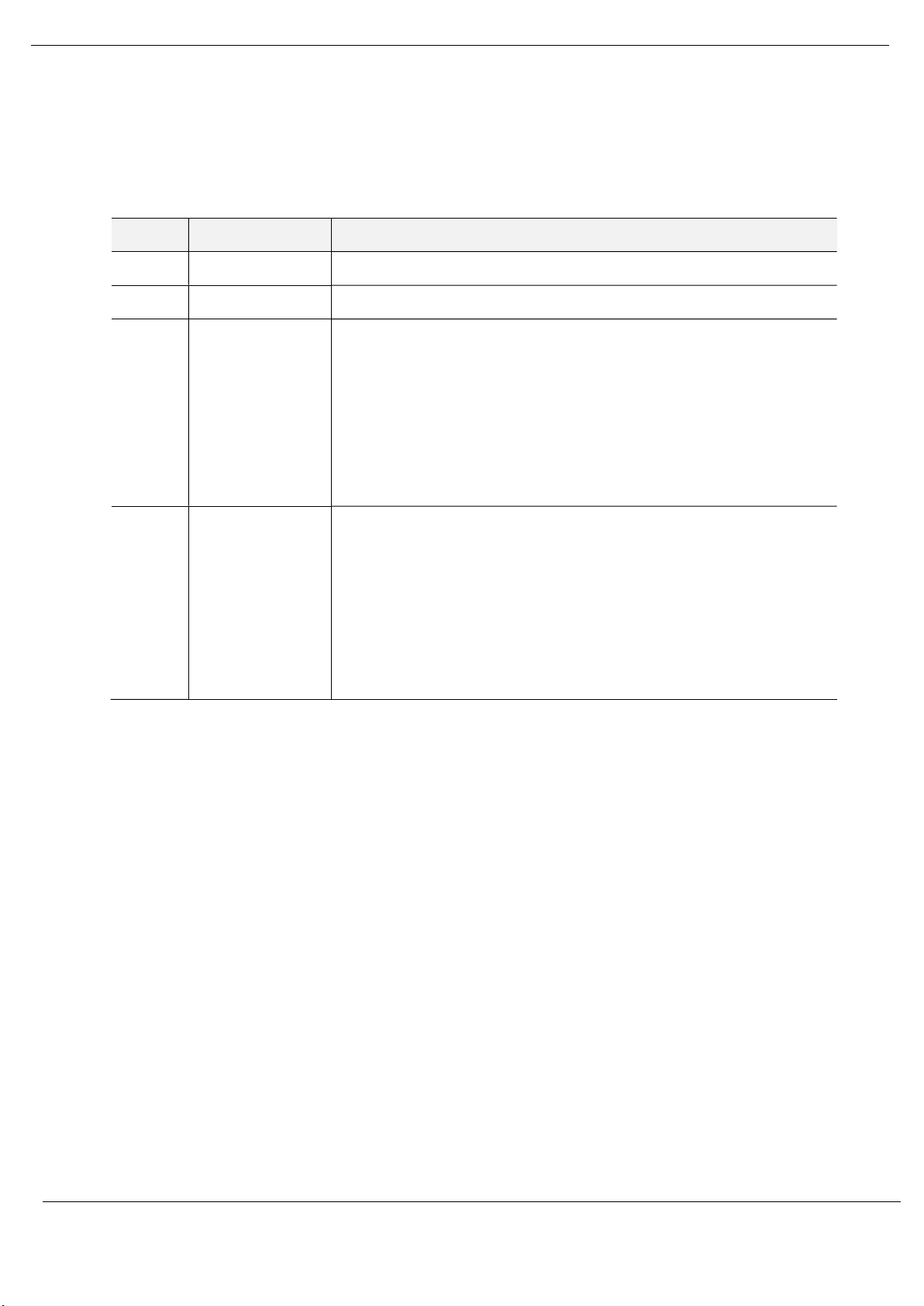

1.5. ADDITIONAL INFORMATION

The following web sites contain additional information that can assist the user with the

module installation and operation, including the required ProSoft Configurator for Modicon

configuration software.

Resource Link

PMEPXM0100

PMEPXM0100H

https://www.schneider-electric.com/en/product/PMEPXM0100

https://www.schneider-electric.com/en/product/PMEPXM0100H

Table 1.1 - Additional Information

Revision 1.06 Page 18 of 238

Page 19

Preface

1.6. SUPPORT

Technical support is provided via the Web (in the form of user manuals, FAQ, datasheets etc.)

to assist with installation, operation, and diagnostics.

For additional support the user can use either of the following:

Resource Link

Contact Us web link https://www.schneider-electric.com/en/work/support/

Table 1.2 – Support Details

Revision 1.06 Page 19 of 238

Page 20

Installation

2. INSTALLATION

2.1. MODULE LAYOUT

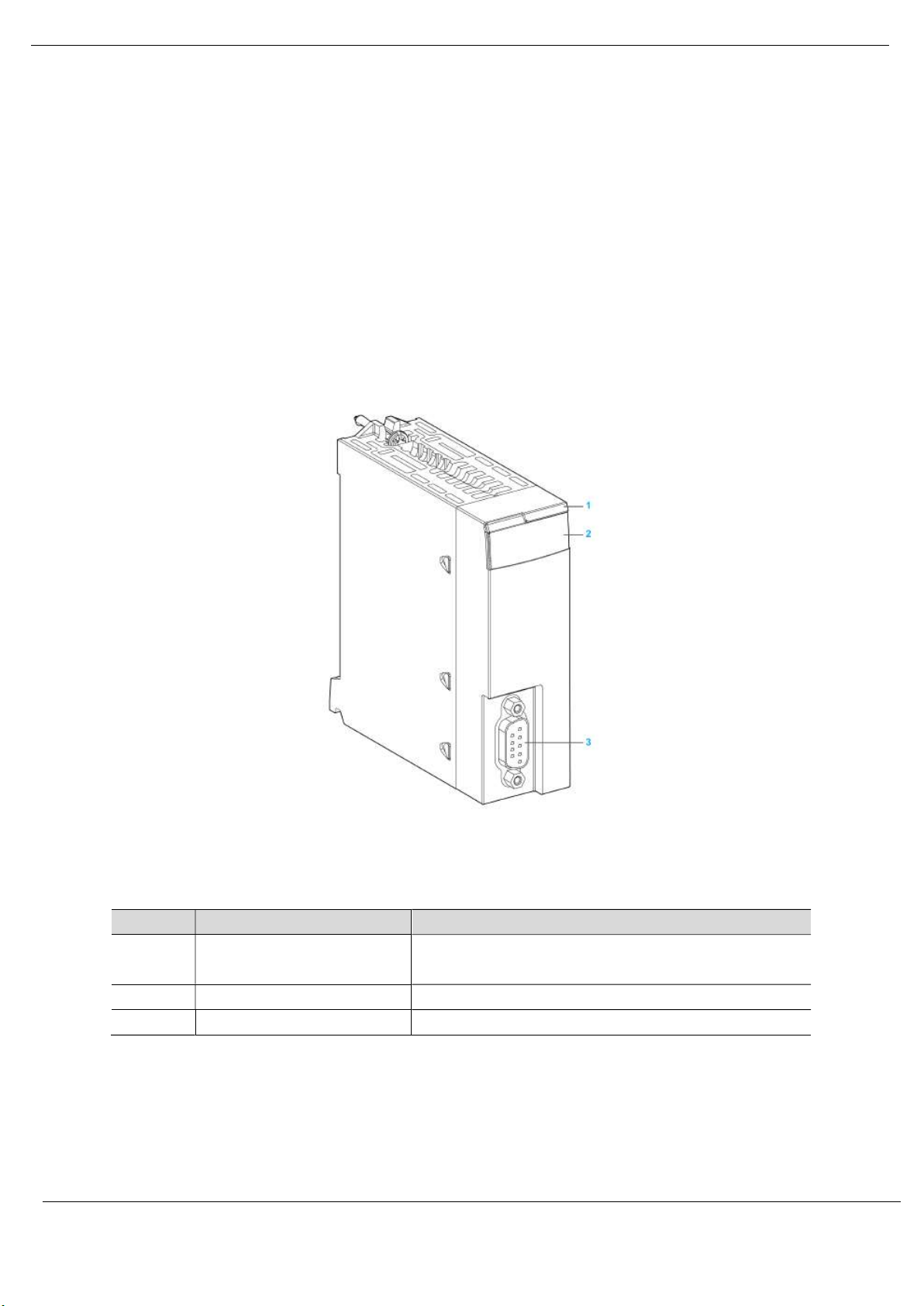

The PXM has one RS485 PROFIBUS DP port at the front of the module and one M580

backplane port at the back of the module, as shown in the figure below. The front port is used

to connect to the PROFIBUS DP fieldbus and the backplane port is used to connect to the

M580 backplane. All the required power is derived from the M580 backplane.

Figure 2.1 - PXM Front and Side view

Number Element Function

1 Module name

2 LED array LED indication to diagnose the module

3 SUB-D 9 female connector PROFIBUS DP Port

Table 2.1 – Module layout

The module provides seven diagnostic LEDs as shown in the front view figure below. These

LEDs are used to provide information regarding the module system operation, the Backplane

Revision 1.06 Page 20 of 238

ePXM0100 (Standard)

ePXM0100H (Harsh)

Page 21

Installation

interface, and the PROFIBUS DP fieldbus interface. See the Diagnostics section for details on

each LED state.

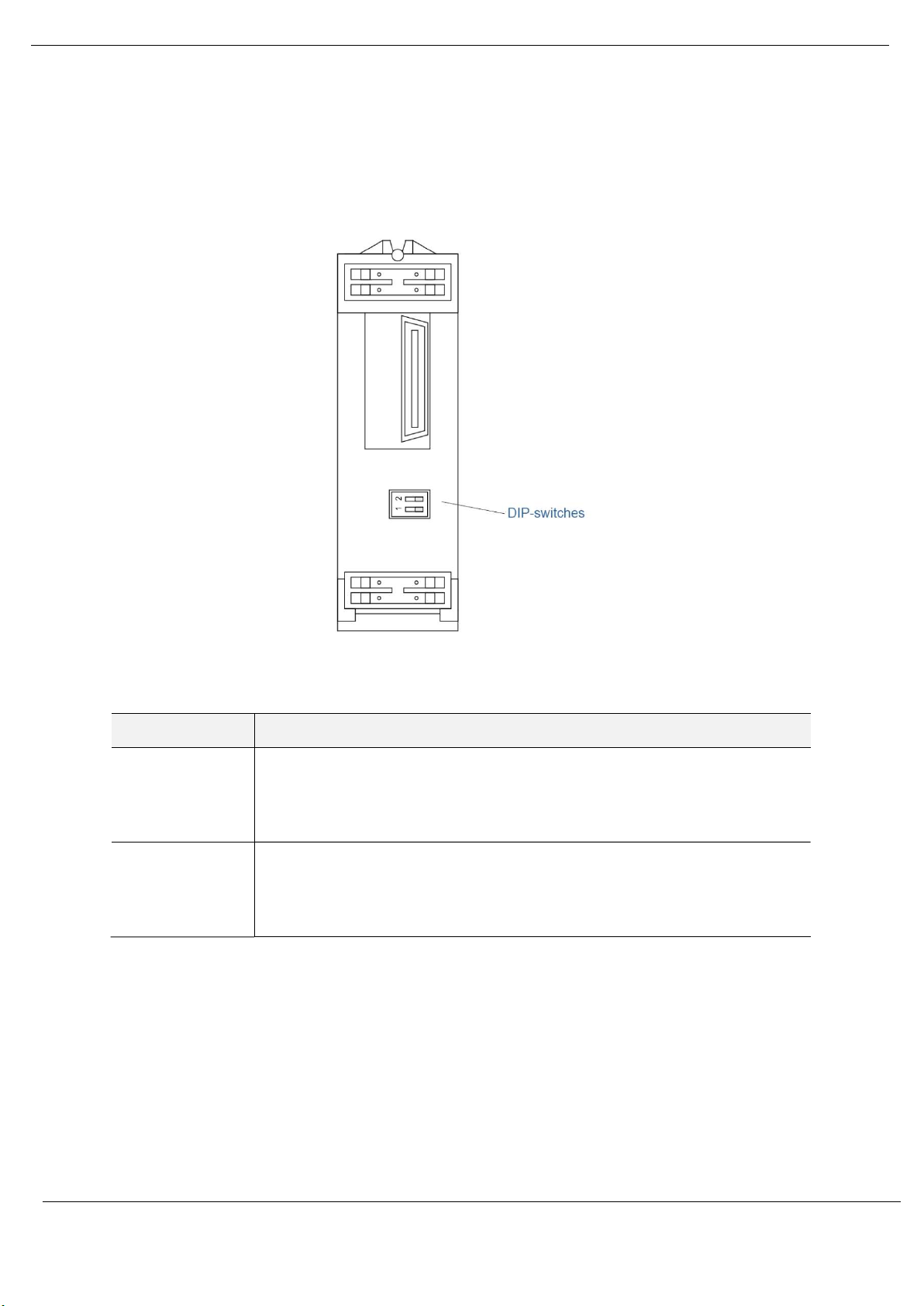

The module provides two DIP-switches at the back of the enclosure as shown in the figure

below.

Figure 2.2 - PXM Back view

DIP Switch Description

DIP Switch 1 This DIP switch is used to reject the configuration in NV memory as well as the

configuration received from the Head module (using TFTP). This action resets the

module to Factory Defaults. The module will then wait for new configuration to be

downloaded to it.

DIP Switch 2 Used to force the module into “Safe Mode”. When in “Safe Mode” the module will not

load the application firmware and will wait for new firmware to be downloaded. This

should only be used in the rare occasion when a firmware update was interrupted at

a critical stage.

Table 2.2 - DIP Switch Settings

2.2. MODULE MOUNTING

The PXM module will connect directly to the M580 backplane. Note that it does not use the

X80 backplane connector and will only power up on an Ethernet backplane. In an M580

architecture, you can mount the PXM module on a local rack or a remote drop.

Revision 1.06 Page 21 of 238

Page 22

Installation

EQUIPMENT DAMAGE

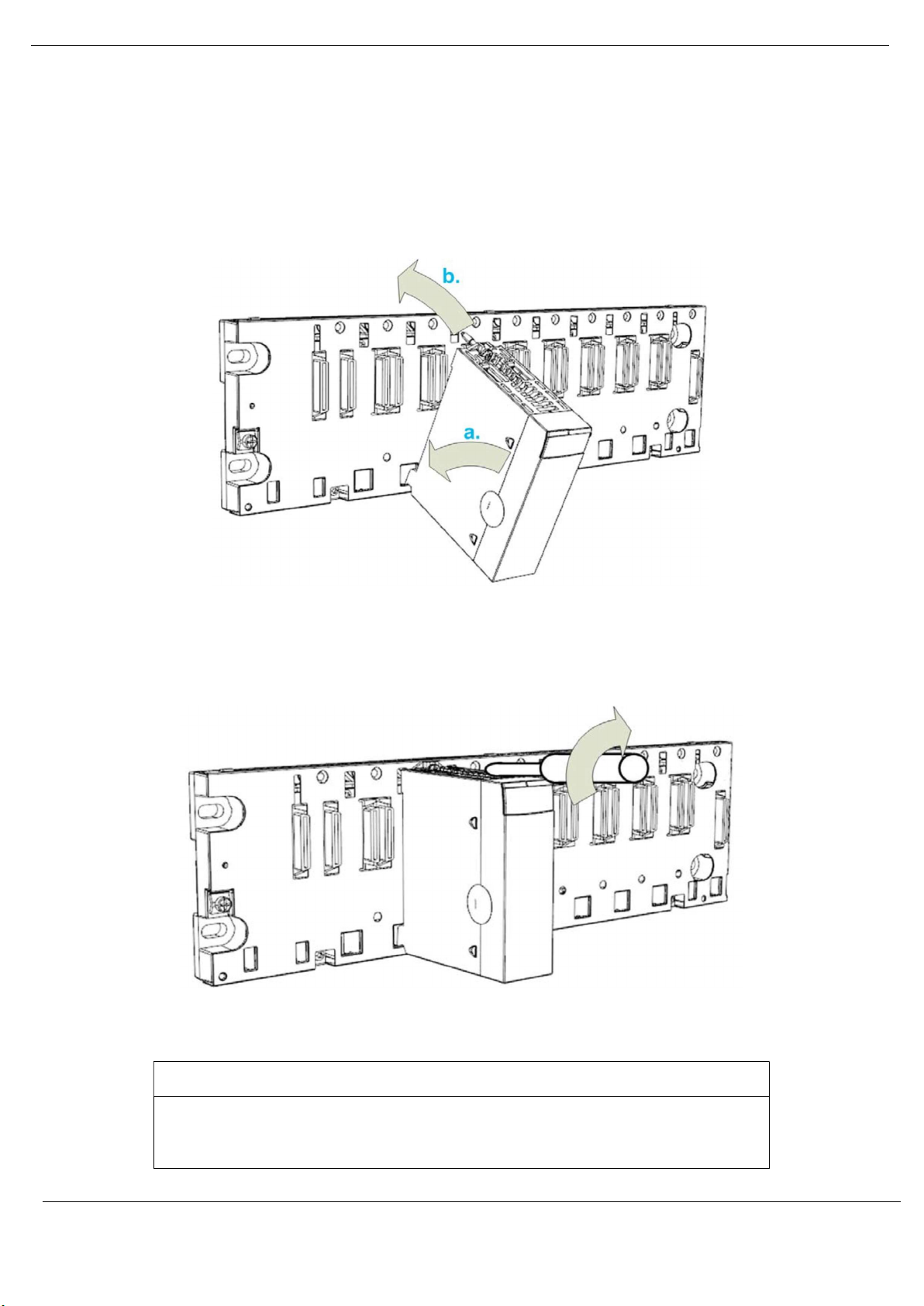

Follow the step below to mount the module on the backplane:

a. Insert the locating pins on the bottom of the module into the corresponding slots in

the rack.

b. Use the locating pins as a hinge and pivot the module until it is flush with the rack.

(The twin connector on the back of the module inserts the connectors on the rack).

Figure 2.3 – Mounting the PXM to the backplane

Tighten the retaining screw to hold the module in place on the rack:

Figure 2.4 – Tightening the PXM to the backplane

Revision 1.06 Page 22 of 238

NOTICE

The maximum tightening torque is 1.5 Nm (1.11 lb-ft).

Failure to follow these instructions may result in equipment damage.

Page 23

Installation

2.3. BACKPLANE CONNECTOR

The Ethernet bus interface at the back of the PXM module connects to the Ethernet backplane

connector when you mount the module in the rack (see Module Mounting section). The

module is powered by the backplane. It is hot swappable, that is, it may be installed and

uninstalled without turning off the power supply to the rack.

The X Bus connector of the backplane is not present nor required. The module uses the

Ethernet bus on the Ethernet backplane to manage the connectivity to the Ethernet I/O

scanner.

The module communicates with a PC that is connected to the Ethernet network using an asset

management, a network manager, or a web browser.

2.4. PROFIBUS DP PORT (RS485)

The PROFIBUS DP port uses a female DB9 connector. This provides connection for the

communication conductors, cable shielding and +5Vdc output power.

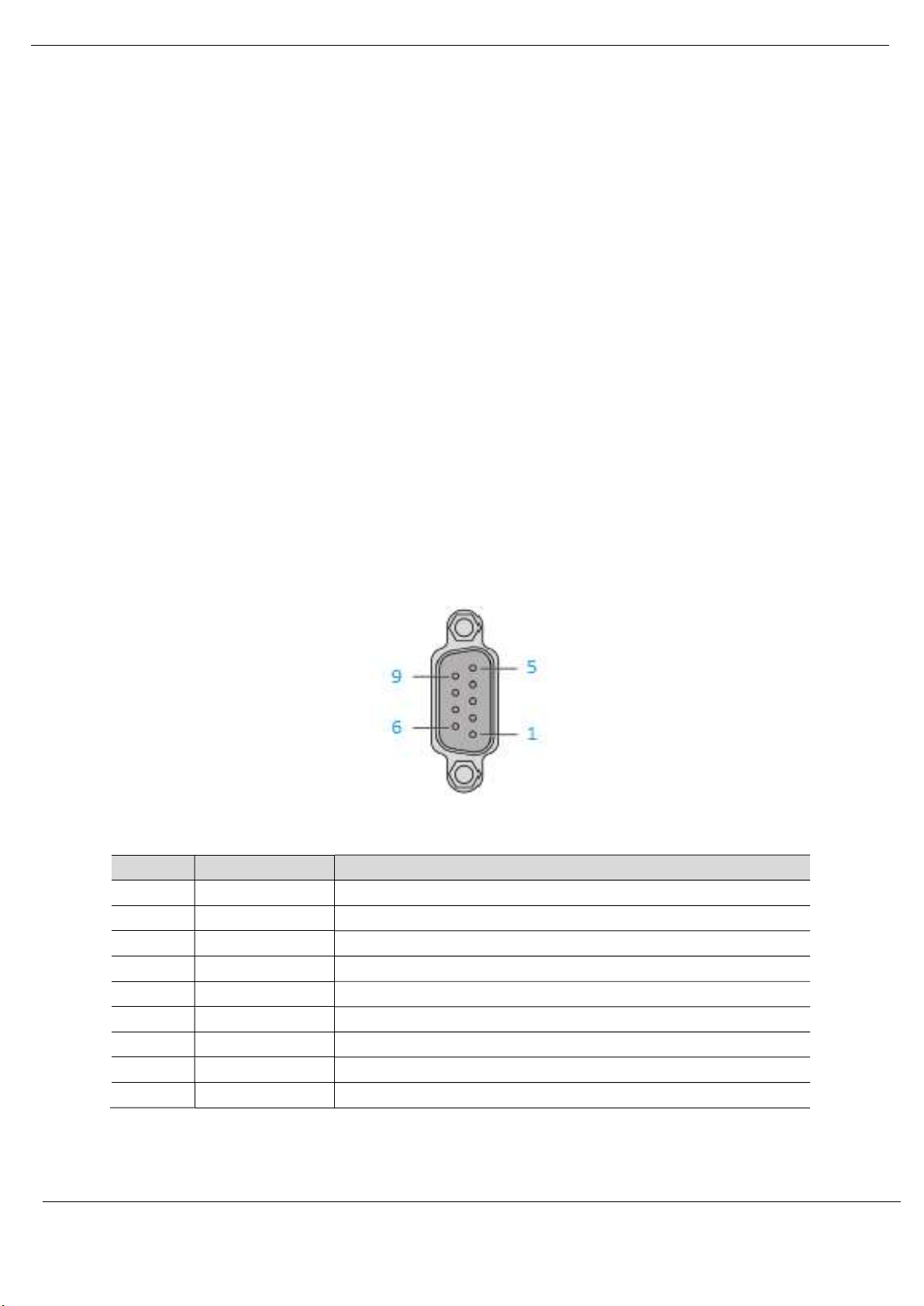

Figure 2.5 - PXM PROFIBUS DP (RS485) DB9 connector

Pin Signal Description

1 - Not connected

2 - Not connected

3 RxD/TxD-P Data received and transmit (+)

4 CNTR-P Control signal to repeater (+)

5 DGND Reference potential for +5Vdc

6 VP +5Vdc for terminating resistors (active termination)

7 - Not connected

8 RxD/TxD-N Data received and transmit (-)

9 - Not connected

Table 2.3 – DB 9 Connector layout

Revision 1.06 Page 23 of 238

Page 24

Setup

3. SETUP

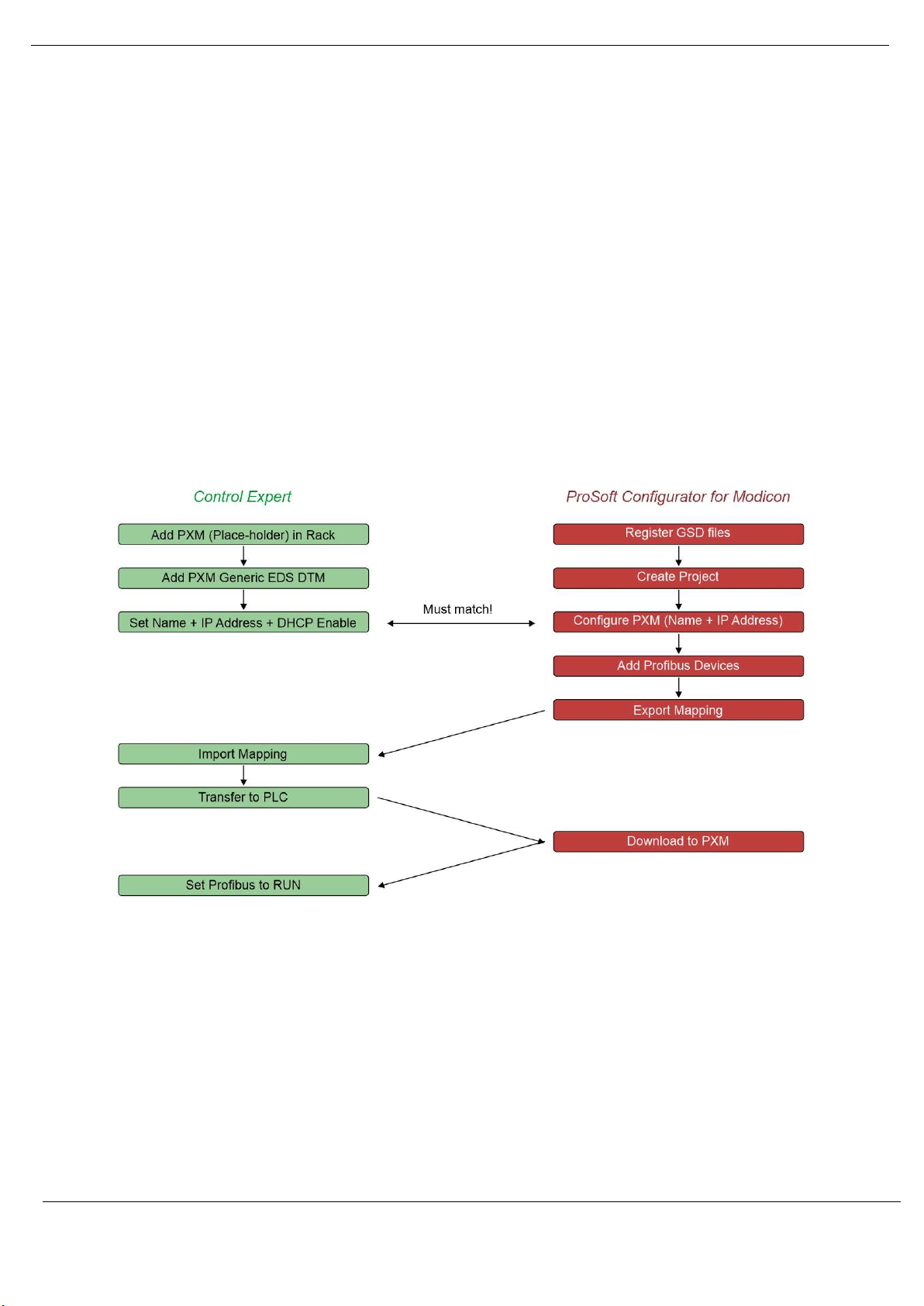

3.1. SETUP INTRODUCTION

The setup of the PXM requires configuration in both Control Expert and the ProSoft

Configurator for Modicon (PCM).

The figure below provides an overview of the required steps to configure a new PXM module.

Although it is not important whether the user starts with the Control Expert configuration or

the PCM configuration, it is important that the Control Expert configuration is transferred to

the M580 controller, before the PXM can be downloaded.

Figure 3.1 – PXM Configuration Overview

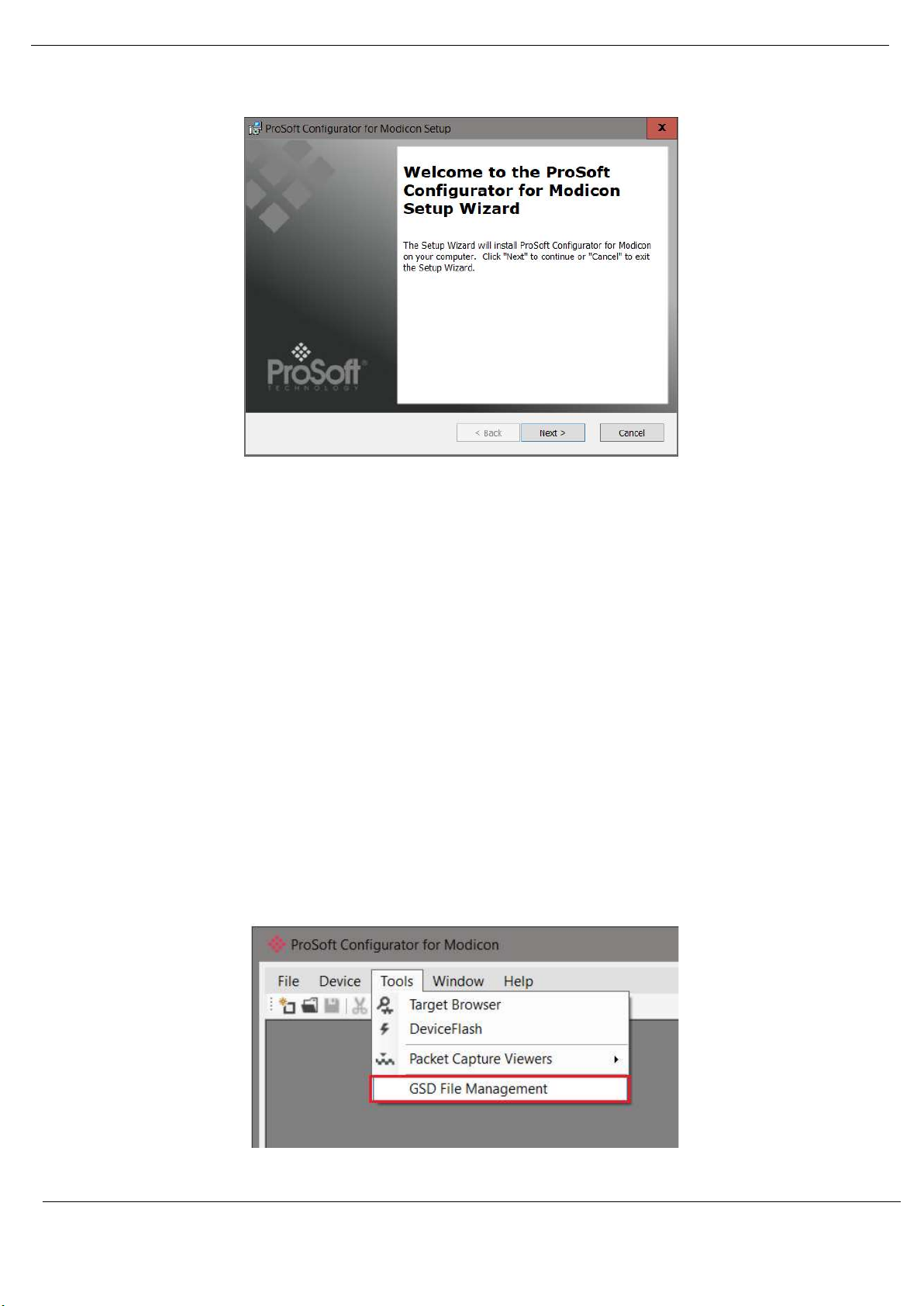

3.2. INSTALL CONFIGURATION SOFTWARE

All the PROFIBUS network setup and configuration of the PXM module is achieved by means

of the ProSoft Configurator for Modicon.

Revision 1.06 Page 24 of 238

Page 25

Setup

Figure 3.2 - ProSoft Configurator for Modicon Installation

3.3. NETWORK PARAMETERS

The module Ethernet network parameters (e.g. IP address) will be managed by the Head

module in the local M580 rack. See the Control Expert Configuration section.

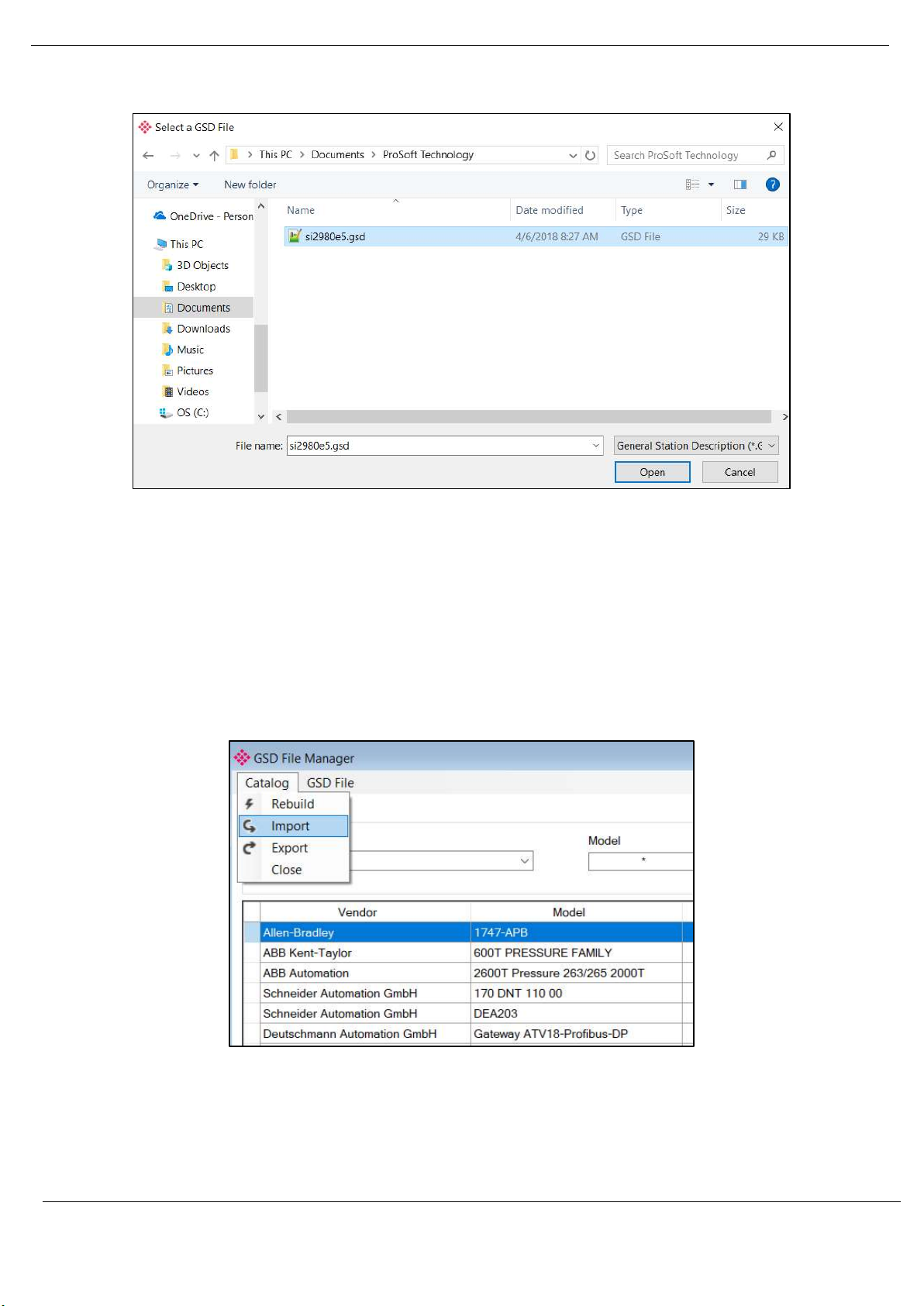

3.4. GSD FILE MANAGEMENT

Each PROFIBUS device has a GSD file that is required to provide information needed to

configure the device for data exchange. The ProSoft Configurator for Modicon manages the

GSD library which is used for adding devices to the PXM.

The GSD File Management Tool is opened by selecting GSD File Management under the Tool

menu in the configuration utility.

Figure 3.3 – Launching the GSD File Management Tool

Revision 1.06 Page 25 of 238

Page 26

Setup

Once the tool has been opened a list of slave devices already registered using their GSD files.

Figure 3.4 – GSD File Management Tool

To add a GSD file the user will need to select the Add option under the GSD File menu.

Figure 3.5 – GSD File Adding

The required GSD file will need to be selected as shown below:

Revision 1.06 Page 26 of 238

Page 27

Setup

Figure 3.6 – GSD File Adding

Once the file has been selected the GSD File Management tool will add the slave device to the

device list and recompile the GSD catalog.

A GSD catalog can be reused by another ProSoft Configurator for Modicon by exporting the

GSD catalog on one ProSoft Configurator for Modicon and importing it in another. This is done

by selecting either Import or Export under the Catalog menu as shown below:

Figure 3.7 – GSD Catalog importing

Revision 1.06 Page 27 of 238

Page 28

Setup

3.5. PXM TYPE LIBRARY

The PXM requires the use of a number of system DFBs and DDTs. These are contained

within the PXM Type Library which must be registered before using a PXM in a Control

Expert application.

3.5.1. COMPATIBILITY

The PXM Type Library has the following minimum requirements:

• EcoStruxure Control Expert: V14 or greater

• M580 CPU Firmware: 2.80 or greater

3.5.2. INSTALLATION

Download the PXM Type Library and unzip it to a suitable folder.

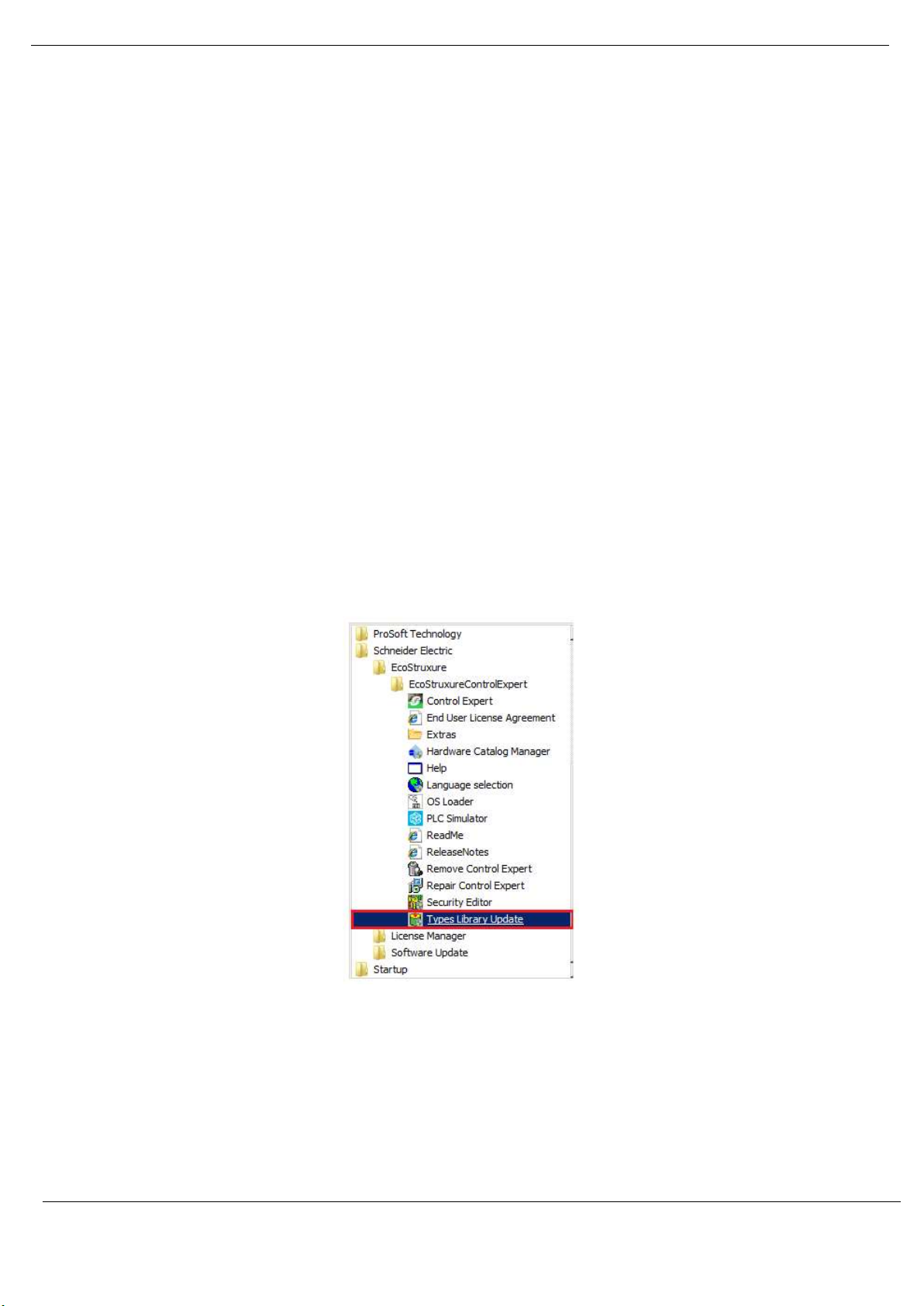

In the Windows Start menu, under the Schneider Electric … EcoStruxure, select the Types

Library Update item.

Figure 3.8 – Launch Type Library Update utility

Revision 1.06 Page 28 of 238

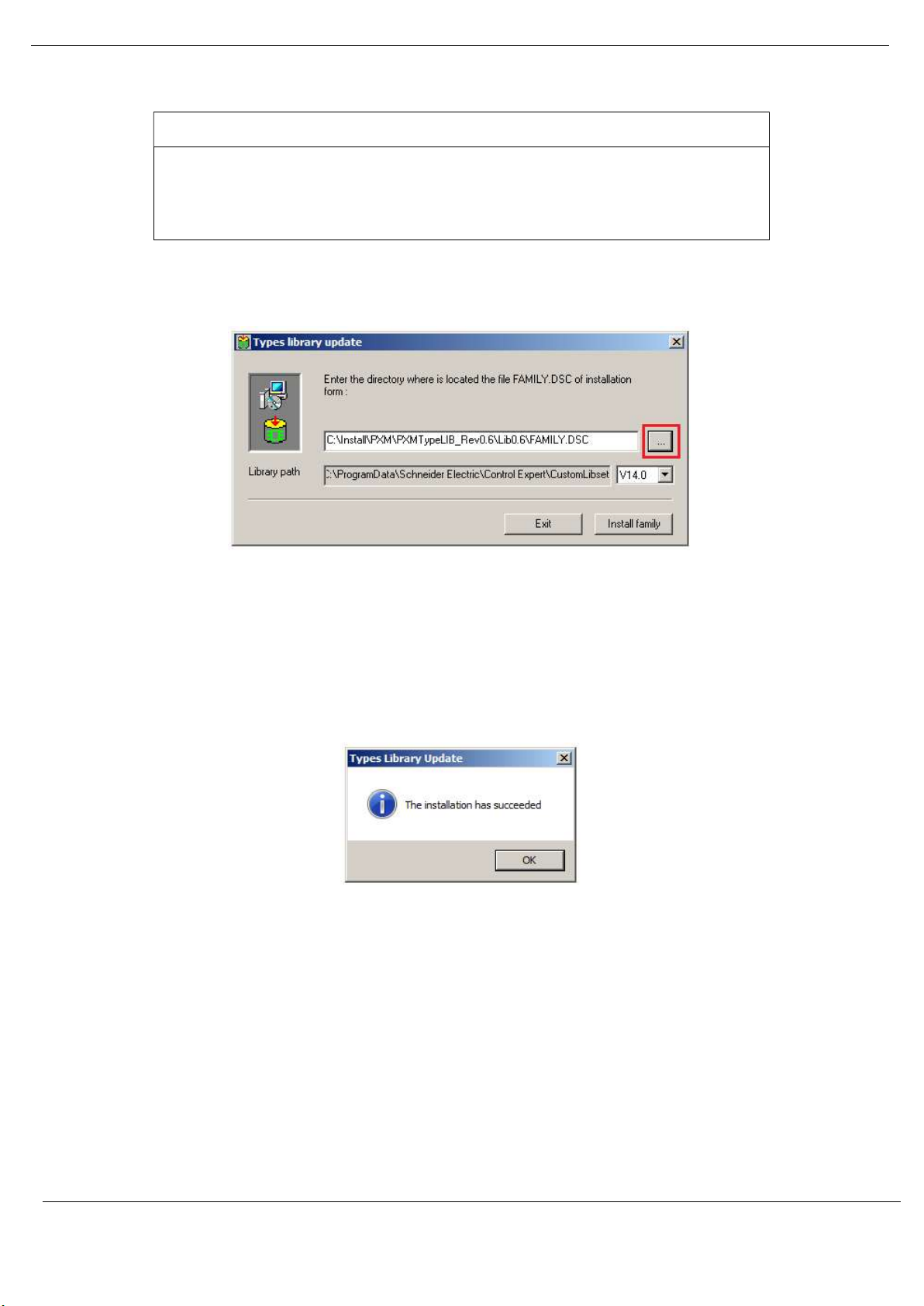

Page 29

UNEXPECTED BEHAVIOUR

NOTICE

A Type Library cannot be registered if Control Expert is running. Be sure to close

Control Expert before starting this process.

Failure to follow these instructions may result in an unexpected behaviour.

The Types Library Update utility will open.

Setup

Figure 3.9 – Type Library Update utility

Use the Browse button (“…”) to navigate to the Family.dsc file in the PXM Type Library

folder. Then click Ok.

The successfully registration will then be indicated by the following prompt:

Figure 3.10 – PXM Type Library Installation Succesful

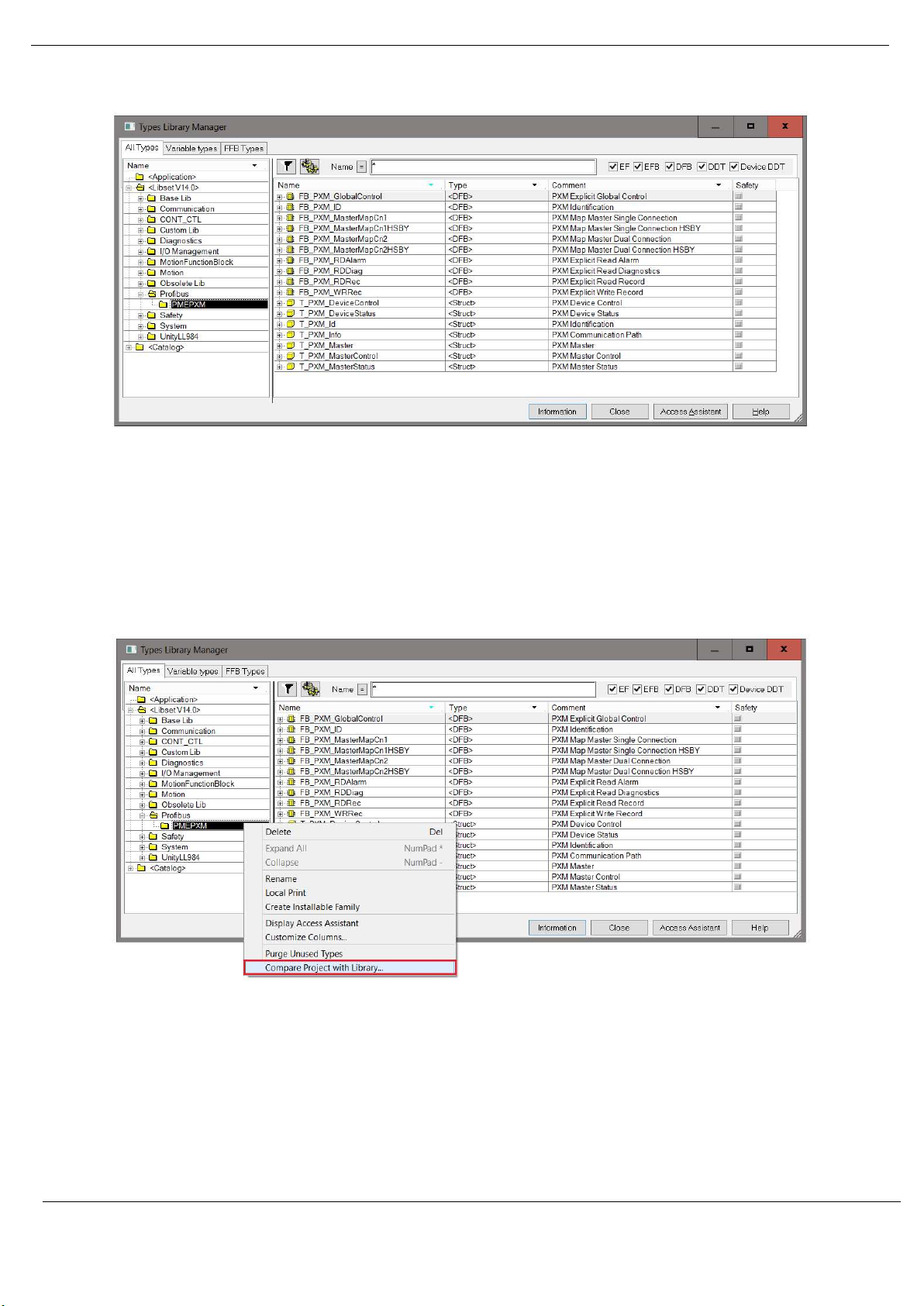

The imported library can be viewed in Control Expert by selecting the Types Library Manager

item under the Tools menu. In the Type Library Manager, select the PMEPXM folder which

can be found in the following folder:

<LibsetV14.0>\Profibus

Revision 1.06 Page 29 of 238

Page 30

Setup

Figure 3.11 – Type Library Manager – PXM

3.5.3. UPDATING PROJECT

If a newer revision of the PXM Type Library is installed, then the existing project will need to

be updated. To update the project, open the Types Library Manager item under the Tools

menu. Right-click on the PMEPXM folder and select the Compare Project with Library option.

Figure 3.12 – Type Library Manager – Compare with project

The Library Version Management window will open showing any differences between the

project and the updated PXM Type Library. To update, select the Update All button.

Revision 1.06 Page 30 of 238

Page 31

Setup

Figure 3.13 – Type Library Manager – Update Project

3.5.4. MANDATORY SETTINGS IN CONTROL EXPERT

Any project making use of the PXM Type Library must have the Allow Dynamic Arrays option

enabled.

This can be enabled by selecting the Project Settings option under the Control Expert Tools

menu. In the Project Settings window, select the Variables left menu item and then check the

Allow Dynamic Arrays (ANY_ARRAY_XXX) option.

Figure 3.14 – Project Settings

3.5.5. LIBRARY CONTENT

The PXM Type Library contains the following:

Type DFB Description

DFB FB_PXM_MasterMapCn1 Master Mapping for Standalone Single Connection

FB_PXM_MasterMapCn2

FB_PXM_MasterMapCn1HSBY Master Mapping for HSBY Single Connection

Revision 1.06 Page 31 of 238

Master Mapping for Standalone Dual Connection

Page 32

Setup

DDT

FB_PXM_MasterMapCn2HSBY

FB_PXM_ID Identification for Explicit messaging

FB_PXM_RDDiag

FB_PXM_RDRec Explicit Read Record

FB_PXM_WRRec Explicit Write Record

FB_PXM_RDAlarm

FB_PXM_GlobalControl Explicit Global Control

T_PXM_Master

T_PXM_MasterControl

T_PXM_MasterStatus Master Status

T_PXM_DeviceControl

T_PXM_DeviceStatus PROFIBUS Slave Device Status

T_PXM_Id Explicit Identification

T_PXM_Info

Master Mapping for HSBY Dual Connection

Explicit Read Diagnostics

Explicit Read Alarm

Master mapping structure (Status, Control and

Input/Output Data)

Master Control

PROFIBUS Slave Device Control

Explicit connection path

Table 3.1 – PXM Type Library Content

For more details on the Mapping DFBs and DDTs see section 4.3.3.

For more details on the Explicit Messaging DFBs and DDTs see section 4.5.

3.6. CREATING A NEW PROJECT

Before the user can configure the module, a new ProSoft Configurator for Modicon project

must be created. Under the File menu, select New.

Figure 3.15 - Creating a new project

Revision 1.06 Page 32 of 238

Page 33

Setup

A ProSoft Configurator for Modicon project will be created, showing the Project Explorer tree

view. To save the project use the Save option under the File menu.

The properties associated with each project can be configured by right-clicking on the project

and selecting the Project Properties option.

Figure 3.16 – Selecting Project Properties

The Project Properties window will open.

Figure 3.17 – Project Properties window

The Project Properties are as follow:

Parameter Description

Default Folder The default folder to be used for:

Importing (PCB-PTQ) files and,

Exporting Control Expert files.

If blank, then the import and export will default to the path:

[UserProfile]\Documents\Prosoft Technology

Auto FDR after Download When this option is selected, an FDR Upload command will be automatically sent

immediately after a Download (including after CCOTF).

Revision 1.06 Page 33 of 238

Page 34

Setup

Use Raw Slot Format When adding a new slave device with this option enabled, instead of the

module data being decorated into multiple data points, only a single data point

of type byte array will be added. The Slot description will default to “Slot” and

the slot number, e.g. “Slot 1”.

This behaviour will apply to PTQ imports and adding manually adding slave

devices.

Using this option generates Control Expert slave device configuration that is

similar to that of legacy (PTQ) data types.

Note: Changing the option after a slave has been instantiated will have no

effect.

Table 3.2 – Project Properties

A new device can now be added by selecting Add under the Device menu.

Figure 3.18 - Adding a new device

In the Add New Device window select the PXM PROFIBUS Master and click the Ok button.

Revision 1.06 Page 34 of 238

Page 35

Setup

Figure 3.19 – PXM PROFIBUS Master

The PXM will appear in the Project Explorer tree as shown below, and its configuration

window opened.

The PXM configuration window can be reopened by either double clicking the module in the

Project Explorer tree or right-clicking the module and selecting Configuration.

Figure 3.20 – PXM configuration

Refer to the additional information section in this document for the ProSoft Configurator for

Modicon Utility’s installation and operation documentation.

3.7. PXM PARAMETERS

The PXM parameters will be configured by the ProSoft Configurator for Modicon . Refer to

the additional information section for documentation and installation links for ProSoft’s

Configurator for Modicon.

3.7.1. GENERAL

Revision 1.06 Page 35 of 238

Page 36

Setup

The General configuration is shown in the figure below. The PXM General configuration

window is opened by either double clicking on the module in the tree or right-clicking the

module and selecting Configuration.

Figure 3.21 – PXM General configuration

The General configuration consists of the following parameters:

Parameter Description

Instance Name This instance name is used to identify the specific PXM module, and must conform to

the specific naming convention.

Description This parameter is used to provide a more detail description of the application for the

module.

Master Mode The PXM can operate in one of three modes:

Quiet

This mode allows the user to connect the PXM to an active bus and run a DP packet

capture. In this mode the PXM will not communicate on the DP Bus but rather only

listen.

Standalone

In this mode the PXM is the DP Master on the bus and connected to a non-HSBY M580

controller. This mode will not support any form of redundancy.

Revision 1.06 Page 36 of 238

Page 37

Setup

HSBY

In this mode the PXM will operate in conjunction with the HSBY M580 controllers

providing DP Master redundancy. When the HSBY M580 swaps from the active to

standby controller the PXM will provide similar functionality and the Standby PXM

module in HSBY will take over the DP network,

A - IP Address The IP address of the target module. The user can use the target browse button to

launch the target browser to the select the PXM on the network.

B - IP Address When the PXM is operating in HSBY mode this is the IP address of the other partner

PXM module.

Class 2 – IP Address This a second IP address that is assigned to the module and can be used for DPV1 Class

2 messaging (e.g. DTM). When operating in HSBY mode only the active DP Master will

have this IP address enabled. When a HSBY swap occurs, the new active DP Master will

enable this IP address and the new standby DP Master will disable this IP address.

The Class 2 IP address is only available when one of the PXM modules is in a Primary

role. When both PXM are in a Standby role (e.g. disconnected from the PLC, or PLCs

in STOP) then the Class 2 IP address will not be available.

IO Connection The PXM can connect to the M580 controller using a range of IO Connection Sizes and

Counts. Note that when the connection size is greater than 1024 bytes the PXM will

consume two Class 1 EtherNet/IP connections.

256 bytes

512 bytes

1024 bytes

1536 bytes

2048 bytes

2560 bytes

Table 3.3 - General configuration parameters

Revision 1.06 Page 37 of 238

Page 38

Setup

THE PXM WILL NOT BE ABLE TO COMMUNICATE WITH THE M580 CONTROLLER

UNINTENDED EQUIPMENT OPERATION

NOTICE

The configured Instance Name will need to match the name given in Control Expert

for the PXM DTM or the PXM will not communicate with the M580 controller.

See the Instantiate PXM DTM section.

Failure to follow these instructions may result in an unexpected behaviour.

The configured Master Mode must match the system configuration in Control Expert.

WARNING

Do not apply a Standalone configuration in a HSBY system.

Do not apply a HSBY configuration in a Standalone system.

Applying a Standalone configuration in an HSBY system, or vice versa, can have

unexpected consequences.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The PXM Instance Name parameter can either be entered manually or built using the Instance

Name utility. To select the latter option, click on the Build button adjacent to the Instance

Name.

Figure 3.22 – Instance Name Build

The Instance Name builder can be used to build the correct Instance Name for the following

arhitectures:

Standalone – Local Rack

Standalone – Remote Rack

HSBY – Local Rack

An example of each is shown below.

Revision 1.06 Page 38 of 238

Page 39

Setup

Figure 3.23 – Instance Name Builder – Standalone - Local Rack

Figure 3.24 – Instance Name Builder – Standalone - Remote Rack

Figure 3.25 – Instance Name Builder – HSBY (Local Rack)

Revision 1.06 Page 39 of 238

Page 40

Setup

3.7.2. PROFIBUS

The PROFIBUS configuration is shown in the figure below. The PXM PROFIBUS configuration

window is opened by either double clicking on the module in the tree or right-clicking the

module and selecting Configuration.

Figure 3.26 – PXM PROFIBUS configuration

The PROFIBUS configuration consists of the following parameters:

Parameter Description

Basic Settings

Station Address (TS)

Highest Address (HSA)

BAUD Rate

PROFIBUS Station Address for the PXM module. TS should be different than any

other slaves address on the PROFIBUS network, it should also be less-than or equal

to the HSA below:

Min: 0

Max: 126

Default: 1

Highest Station Address. This is the highest station address of the active stations

(masters). Passive stations (slaves) can have a higher address than the HSA.

A low HSA is better for PROFIBUS performance.

Min: 1

Max: 126

Default: 126

Baud Rate (in Kbps) of the PROFIBUS network: 9.6, 19.2, 45.45,

93.75, 187.5, 500, 1500, 3000, 6000 or 12000 Kbps. The baud rate selected

Revision 1.06 Page 40 of 238

Page 41

Extra DPV1 Poll / Cycle

Token Retry Limit

Message Retry Limit

TTR

Slot Time (TSL)

Gap Update Factor

Quiet Time (TQUI)

Setup

should be supported by all slaves in the configuration. The baud rate should be

selected depending on the cable length, see chapter “PROFIBUS DP”

Advanced Settings

The number of additional DPV1 Polls (Class 2) per PROFIBUS Cycle.

This parameter should be equal or greater to the maximum number of simultaneous

explicit DPV1 messages that may be sent.

Increasing this parameter results in faster Asset Management DTM updates.

Error Management

Token Retry Limit is the number of times that a PROFIBUS Master tries to pass the

token before deciding that a station is not there. Value must be in the following

range:

Min: 0

Max: 15

Default: 3

Message Retry Limit is the number of telegram repetitions if the address doesn’t

react. Value must be in the following range:

Min: 0

Max: 15

Default: 1

Timing

Target Rotation Time indicates the maximum time available for a token circulation

(time for PROFIBUS token to be passed to another master and be back). It takes in

account the number of slaves with their IO size (data exchanges telegram), different

telegrams needed and their duration times (FDL status, global control, pass token),

all mandatory timing with respect to the PROFIBUS standard (time slot, min and

max Tsdr, Tqui, Tset, …) and a safety margin which allows bandwidth for acyclic

messages (DPV1, …).

Min: 0

Max: 16777215

Slot Time (in tbits) is the maximum time the PXM will wait, after the transmission

of a request, for the reception of the first byte (Tchar) of an answer. (It allows

detecting a timeout.) It can be increased when repeaters are used in the PROFIBUS

network topology. The value must respect the rule:

Min: 37

Max: 16383

Gap Update Factor: The range of addresses between 2 consecutive active stations

is called GAP. This GAP is submitted to a cyclic check during which the system

identifies the station condition (not ready, ready or passive).

Min: 1

Max: 100

Quiet time (in tbits) is the time that a station may need to switch from sending to

receiving. It must respect the rule:

TQUI < MIN_TSDR

Min: 0

Max: 255

Revision 1.06 Page 41 of 238

Page 42

Setup

Setup Time (TSET)

PROFIBUS Cycle

Default Watchdog

Min TSDR

Max TSDR

Idle Time 1 (Tid1)

Idle Time 2 (Tid2)

Auto Recommend

Setup Time (in tbits) is the reaction time on an event. Calculation of TSET must

respect the rule:

Min: 1

Max: 494

PROFIBUS Cycle (in ms) (read/Write) field defines the cyclic time the master will

respect between two IO Data Exchange sequences. This parameter can be increased

by the user when the PROFIBUS network load does not allow the processing of

acyclic requests.

Default Devices Watchdog (in ms) value defines the watchdog value assigned by

default to any new devices added to the configuration.

This value will also overwrite any existing device’s watchdog value, if it is less than

the new Default Watchdog value.

Note: The watchdog value is represented by 2 factors (viz. WD1 and WD2) in the

expression: Watchdog = WD1 x WD2 x 10ms.

When a new value is entered it will be rounded-up to comply with the Profibus

representation.

Note: The Set Watchdog (ALL) function can be used to modify all existing devices’

watchdog value.

Smallest Station (in tbits) is the minimum time that a PROFIBUS DP slave must wait

before it may answer. It must respect the rule:

TQUI < MIN_TSDR

Min: 11

Max: 1023

Largest Station (in tbits) is the maximum time that a PROFIBUS DP slave may take

in order to answer. Calculation of MAX_TSDR must respect the rule:

Min: 37

Max: 65525

Time Idle1 (in tbits) is the time between the acknowledgement frame or token

frame reception and the transmission of the next frame.

Tid1 = Max(Tsyn+Tsm, MIN_TSDR)

with

Tsyn= 33

Tsm= 2 + 2* TSET + TQUI

Time Idel2 (in tbits) is the time between the transmission of an unconfirmed packet

and the transmission of the next packet.

Tid2 = Max (Tsyn+Tsm, MAX_TSDR)

with

Tsyn= 33

Tsm= 2 + 2* TSET + TQUI

The Auto Recommend option is used to automatically calculate the following

aforementioned parameters:

Target Rotation Time (TTR)

Slot Time (TSL)

Gap Update Factor

Revision 1.06 Page 42 of 238

Page 43

Setup

UNEXPECTED

BEHAVIOUR

Quiet Time (TQUI)

Setup Time (TSET)

PROFIBUS Cycle

Default Watchdog

When the Auto Recommend option is checked, the above values are disabled, and

the recommended values for these parameters are calculated when the Apply or

Ok buttons are pressed.

When the Auto Recommend option is unchecked, the user may modify these

values.

Note that if any of the entered parameters are below the acceptable minimums,

then they will be corrected even though the Auto Recommend option is unchecked.

Table 3.4 - PROFIBUS configuration parameters

When the user changes the BAUD rate all the PROFIBUS timing parameters and HSBY

parameters will change to the default values for that specific BAUD Rate.

NOTICE

Ensure that all timing parameters are correct after making any BAUD rate changes.

Failure to follow these instructions may result in an unexpected behaviour.

3.7.3. HSBY

The HSBY configuration is shown in the figure below. The HSBY mechanism is described in

chapter 5.

The PXM HSBY configuration window is opened by either double clicking on the module in

the tree or right-clicking the module and selecting Configuration.

Revision 1.06 Page 43 of 238

Page 44

Setup

Figure 3.27 – PXM HSBY configuration

The HSBY configuration consists of the following parameters:

Parameter Description

PXM RPI (ms) The PXM’s RPI (Requested Packet Interval) as configured in the Control

Expert project.

Valid values are 5-1000 milliseconds.

This parameter is not used directly in the PXM’s configuration, but is

used to calculate HSBY parameters when the Recommend button is

used.

MAST Task Period (ms) The period of the MAST Task as configured in the Control Expert project.

Valid values are 1-255 milliseconds.

This parameter is not used directly in the PXM’s configuration, but is

used to calculate HSBY parameters when the Recommend button is

used.

HSBY Holdover (ms) This is the amount of time the active PXM will keep running the

PROFIBUS DP network without an EtherNet/IP Class 1 connection from

a running Primary M580 PLC located in the local rack.

The above state can occur when the PXM switches from the active M580

controller to the standby M580 controller. During this switch over there

is a period where the PXM will operate the DP network without a

connection to a Primary M580 controller where the last received data

(from a M580 controller) is being used for the Holdover time before the

PXM sets the DP network to OFFLINE.

Revision 1.06 Page 44 of 238

Page 45

Setup

INCORRECT BEHAVIOR OF HSBY SYSTEM : SWAP MAY FAIL AND PXM MAY

See chapter 5 for configuration guidelines.

HSBY DP Deadtime (ms) The DP Deadtime is the amount of time the standby PXM will wait when

the DP network is quiet before taking over as the DP Master.

HSBY Switch Over Cmd Rate (ms) This is the rate at which the Standby PXM sends a switch over request to

the active PXM. This value will depend on the BAUD rate selected, but

generally the faster (i.e. lower) this parameter is set the faster the switch

over will be.

HSBY Switch Over Retry Limit This is the retry limit before the standby PXM takes over the DP network

if it has not received confirmation from the active PXM to take over the

DP network.

Table 3.5 - HSBY configuration parameters

WARNING

INTERMITTENTLY RUN

In an HSBY system the HSBY parameters must be configured correctly and must match

the configuration inside Control Expert.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

3.7.4. SECURITY

The Security configuration is shown in the figure below. The PXM Security configuration

window is opened by either double clicking on the module in the tree or right-clicking the

module and selecting Configuration.

Revision 1.06 Page 45 of 238

Page 46

Setup

Figure 3.28 – PXM Security configuration

The Security configuration consists of the following parameters:

Parameter Description

HTTP Enable Enabling this will allow the PXM to respond to HTTP requests when a

user wants to view the Webserver. If this has been disabled, the user will

not be able to view the Webserver.

SNMP Enable Enabling this will allow the PXM to respond to SNMP requests. If this has

been disabled, a SNMP server will not be able to see the PXM.

Access Control List (ACL) The ACL will allow the user to allow certain IP address ranges to only

access certain protocols. This can be enabled by selecting the Access

Control Enable option. NOTE: The Global Security Services above will

override any ACL rule.

Range Start

This is the starting IP address of the range specific to the rules in the line

item (e.g. allowing HTTP).

Range End

This is the end IP address of the range specific to the rules in the line

item.

Revision 1.06 Page 46 of 238

Page 47

Setup

PXM WILL NOT OPERATE CORRECTLY

INCORRECT BEHAVIOUR OF A HSBY SYSTEM: SWAP MAY FAIL

Subnet

The subnet mask that will be applied to the received IP address to check

if it is in the range.

SNMP, EIP, HTTP

These are the protocols that will be allowed for a specific IP range.

Enable SysLog Events The PXM can log up to 2048 events internally in NV memory. When

enabling SysLog Events the PXM will unload these events to a SysLog

Server.

SysLog Server IP Address This is the IP address of the SysLog Server.

The PXM will connect to the SysLog server using TCP Port 601.

Table 3.6 - Security configuration parameters

NOTICE

Do not exclude the PLC’s IP address when configuring the Access Control List. If

the PLC is excluded, it will not establish a connection with the PXM.

Do not exclude the PLC’s “IP Address A” when configuring the Access Control

List. This address is used for the PXM’s explicit messaging.

Adjust the SysLog server settings to allow the connection of PXM to the SysLog

server with TCP Port 601.

Failure to follow these instructions may result in an unexpected behaviour.

WARNING

In an HSBY system, do not exclude the two partner PXM’s IP addresses when

configuring the Access Control List.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

In case the PXM module is no longer contactable due to an invalid ACL configuration being

downloaded to it, the following steps should be followed:

1. Remove the module and set DIP Switch 1 to the ON position

2. Reinsert the module.

3. Download corrected configuration to the module (PCM)

4. Using PCM, Upload the corrected configuration to the FDR server.

5. Remove the module and set DIP Switch 1 to the OFF position

6. Reinsert the module.

Revision 1.06 Page 47 of 238

Page 48

Setup

3.7.5. SNMP

The SNMP configuration is shown in the figure below. The PXM SNMP configuration window

is opened by either double clicking on the module in the tree or right-clicking the module and

selecting Configuration.

Figure 3.29 – PXM SNMP configuration

The SNMP configuration consists of the following parameters:

Parameter Description

Agent SysLocation Physical location of the module.

Agent SysContact Contact name of the person responsible for maintaining the module.

Community Name - Get Community name for the read commands

Table 3.7 - SNMP Configuration parameters

3.7.6. TIME

The PXM can synchronize its local clock with an NTP (Network Time Protocol) server. This

allows the SysLog events to be logged with an accurate timestamp. The Time configuration is

shown in the figure below. The PXM Time configuration window is opened by either double

clicking on the module in the tree or right-clicking the module and selecting Configuration.

Revision 1.06 Page 48 of 238

Page 49

Setup

Figure 3.30 – PXM Time configuration

The Time configuration consists of the following parameters:

Parameter Description

Time Source The can select one to two options for the time source:

None

No Time synchronization will occur when this mode is set.

NTP

The PXM will attempt to synchronize to an NTP time server.

Primary Server IP Address The IP address of the primary NTP server. If the primary is not available

and there is a secondary NTP server at the Secondary IP address, then

the PXM will attempt to synchronize to the Secondary NTP Server.

Secondary Server IP Address The IP address of the secondary NTP server.

Update Interval This is how often the PXM will synchronize its internal clock with the NTP

time server.

Table 3.8 - Time configuration parameters

3.8. VERIFY CONFIGURATION

The PXM’s configuration can be verified at any time by right-clicking on the PXM in the project

tree and selecting the Verify Configuration option.

Revision 1.06 Page 49 of 238

Page 50

Setup

Figure 3.31 - Selecting Verify Configuration

Once the project configuration has been checked, the verification results are displayed. Each

verification item is categorized as one of the following:

Info – Information Only

Warning – User to take note.

Error – Invalid configuration that will be prevent configuration download.

The total count of errors and warnings are displayed at the bottom of the window.

Figure 3.32 – Verification Results

Each time a module download is selected, the configuration will first be verified. Should any

warnings or errors be generated then the verification result window will be displayed. Should

any errors be generated, the download process will be aborted. All the possible Verification

Notifications are listed in section 12.4.

Revision 1.06 Page 50 of 238

Page 51

Setup

3.9. MODULE DOWNLOAD

Once the PXM configuration has been completed, it must be downloaded to the module. The

configured IP address of the module will be used to connect to the module.

To initiate the download, right-click on the module and select the Download option.

Figure 3.33 - Selecting Download

Once complete, the user will be notified that the download was successful.

Figure 3.34 - Successful download

If the Auto FDR after Download option is enabled in the Project Properties, the notification

will indicate this as follows:

Figure 3.35 - Successful download with automatic FDR Upload

Revision 1.06 Page 51 of 238

Page 52

Setup

UNEXPECTED BEHAVIOUR

Within the ProSoft Configurator for Modicon environment the module will be in the Online

state, indicated by the green circle around the module. The module is now configured and

will start operating immediately.

Figure 3.36 - Module online

3.10. DEVICE DISCOVERY (ONLINE)

Once the online with the PXM in the ProSoft Configurator for Modicon the user will be able

to scan the PROFIBUS network for slave devices.

NOTICE

Check that all PROFIBUS parameters have been configured correctly.

Incorrect parameters (e.g. BAUD rate) will result in the PXM not communicating with

slave devices on the PROFIBUS network.

Failure to follow these instructions may result in an unexpected behaviour.

3.10.1. DISCOVERY

The slave device discovery can be found by selecting the Discovered Nodes tab in the PXM

status window.

Revision 1.06 Page 52 of 238

Figure 3.37 –Device Discovery

Page 53

Setup

UNEXPECTED

BEHAVIOUR

To start a new device discovery the Start Discovery button must be pressed. Once the

discovery is done the slave devices found will be listed below. The time to scan the bus will

depend on the BAUD Rate selected. The higher the BAUD rate the faster the bus discovery

scan time will be.

Figure 3.38 –Devices Found

The status of the discovered slave devices will be one of the following:

Status Description

Data Exch The device is configured and is exchanging data.

No Data Exch The device is configured but not exchanging data.

Ident Mismatch The device type configured at that station address is different from the

device discovered.

Unconfigured The device is not configured.

Table 3.9 – Discovered Device Status

If a device has been found that is not currently in the PXM configured device list the user will

be able to add the device from this window by right-clicking on the device and selecting Add

Device.

NOTICE

The appropriate GSD file will need to be already registered before a device can be

added to the PXM configuration.

Failure to follow these instructions may result in an unexpected behaviour.

Revision 1.06 Page 53 of 238

Page 54

Setup

Figure 3.39 – Adding the Field Devices Found

The user will need to select the GSD file add the device to the PXM configured device list.

Figure 3.40 – Selecting the GSD for the slave device

Once the devices have been correctly set up (as well as the correct mapping is in Control

Expert) the devices will show up as exchanging data.

Figure 3.41 – Discovering running devices

The Discovered Nodes list will be cached and display the same information until the Start

Discovery is again selected.

Revision 1.06 Page 54 of 238

Page 55

Setup

3.10.2. DEVICE STATION ADDRESS CHANGE

Certain devices can be set up to allow remotely changing of the station address. Devices with

this option set generally defaults to station address 126. The user can change the station

address of a device (if the device is correctly setup) by right-clicking on the device in the

Discovery Lost and selecting Change Station Address.

Figure 3.42 – Changing Station Address

Next the user will need to select the new station address for the device. Once selected press

the Set button.

Figure 3.43 – Selecting new Station Address.

Once the request has been sent the user can either start a new network discovery to confirm

the address has changed or monitor the LiveList (see the Diagnostics section).

The amount of time for the device to appear at the new station address is device dependent.

In the LiveList there will be a period where both node addresses show up while the original

station address is timing out.

Check that the new station address is correct.

Revision 1.06 Page 55 of 238

Page 56

Setup

CAUTION

COMMUNICATION FAILURE

UNEXPECTED BEHAVIOUR

WARNING

Do not set the station address to an address that is already present on the PROFIBUS

network.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The slave device will need to be in the correct state before it will accept a command to change

its station address (e.g. Not be in data exchange state).

NOTICE

Check that slave device is in the correct state before proceeding.

Failure to follow these instructions may result in an unexpected behaviour.

3.11. ADDING PROFIBUS DP DEVICES

The user will need to add each PROFIBUS device to the PXM which can then be configured.

This is done by right-clicking on the PROFIBUS Devices item in the tree and selecting Add