Page 1

MVI69-DFCM

CompactLogix Platform

DF1 Interface Module

User Manual

Page 2

Please Read This Notice

Successful application of this module requires a reasonable working knowledge of the AllenBradley CompactLogix hardware and the application in which the combination is to be used.

For this reason, it is important that those responsible for implementation, satisfy themselves that

the combination will meet the needs of the application without exposing personnel or equipment

to unsafe or inappropriate working conditions.

This manual is provided to assist the user. Every attempt has been made to assure that the

information provided is accurate and a true reflection of the product’s installation requirements. In

order to assure a complete understanding of the operation of the product, the user should read all

applicable Allen-Bradley documentation on the operation of the A-B hardware.

Under no circumstances will ProSoft Technology, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of the product.

Reproduction of the contents of this manual, in whole or in part, without written permission from

ProSoft Technology, Inc. is prohibited.

Information in this manual is subject to change without notice and does not represent a

commitment on the part of ProSoft Technology, Inc. Improvements and/or changes in this

manual or the product may be made at any time. These changes will be made periodically to

correct technical inaccuracies or typographical errors.

ProSoft Technology, Inc.

1675 Chester Avenue, 4

Bakersfield, CA 93301

(661) 716-5100

(661) 716-5101 (Fax)

www.prosoft-technology.com

InRAx is a trademark of ProSoft Technology, Inc.

CompactLogix is a trademark of Allen-Bradley Company, Inc.

All other trademarks in the document are the properties of their respective owners/companies.

Copyright 2004 ProSoft Technology, Inc. All rights reserved.

MVI69-DFCM User Manual

June 24, 2004

th

Floor

ii

Page 3

Table of Contents

Table of Contents

1 PRODUCT SPECIFICATIONS.............................................................................. 1

1.1 G

ENERAL SPECIFICATIONS................................................................................... 1

1.1.1 Slave Functional Specifications.................................................................. 1

1.1.2 Master Functional Specifications ............................................................... 1

1.1.3 Physical....................................................................................................... 2

1.1.4 CompactLogix Interface.............................................................................. 2

1.2 H

ARDWARE SPECIFICATIONS ............................................................................... 2

2 FUNCTIONAL OVERVIEW .................................................................................. 3

2.1 GENERAL CONCEPTS............................................................................................ 3

2.1.1 Module Power Up....................................................................................... 3

2.1.2 Main Logic Loop......................................................................................... 3

2.1.3 Backplane Data Transfer............................................................................ 4

2.2 N

ORMAL DATA TRANSFER .................................................................................. 5

2.2.1 Read Block .................................................................................................. 6

2.2.2 Write Block.................................................................................................. 9

2.3 SPECIAL BLOCKS ................................................................................................. 9

2.3.1 Slave Status Blocks ..................................................................................... 9

2.4 COMMAND CONTROL BLOCKS........................................................................... 12

2.4.1 Event Command ........................................................................................ 12

2.4.2 Command Control..................................................................................... 13

2.4.3 Set Module Time Using Processor Time................................................... 14

2.4.4 Warm Boot ................................................................................................ 15

2.5 D

ATA FLOW BETWEEN MVI69-DFCM MODULE AND COMPACTLOGIX

PROCESSOR .................................................................................................................... 17

2.5.1 Slave Driver Mode .................................................................................... 17

2.5.2 Master Driver Mode ................................................................................. 20

3 MODULE CONFIGURATION............................................................................. 23

3.1 POWER UP.......................................................................................................... 23

3.2 C

ONFIGURATION FILE ........................................................................................ 23

3.3 SETTING UP THE MODULE ................................................................................. 27

3.3.1 Module Data Object (DFCMModuleDef)................................................. 32

3.4 S

3.5 U

TATUS OBJECT (DFCM_STATUS) ................................................................. 34

SER DATA OBJECTS......................................................................................... 34

3.6 SLAVE POLLING CONTROL AND STATUS ............................................................ 35

3.7 DFCM S

3.8 E

3.9 C

3.10 C

VENT COMMAND (DFCMEVENTCOMMAND) .................................................. 36

OMMAND CONTROL (DFCMCOMMANDCONTROL) ......................................... 37

LOCK (DFCMCLOCK) ..................................................................................... 37

LAVE POLLING CONTROL (DFCMSLAVEPOLLINGCONTROL) ............. 35

4 LADDER LOGIC ................................................................................................... 39

4.1 M

4.2 R

4.3 W

AINROUTINE ................................................................................................... 39

EADDATA ........................................................................................................ 40

RITEDATA ...................................................................................................... 43

iii

Page 4

Table of Contents

5 DIAGNOSTICS AND TROUBLESHOOTING .................................................. 51

5.1 READING STATUS DATA FROM THE MODULE ..................................................... 51

5.2 LED S

TATUS INDICATORS ................................................................................. 51

5.3 CLEARING A FAULT CONDITION ........................................................................ 52

5.4 T

5.5 U

ROUBLESHOOTING ........................................................................................... 52

SING THE CONFIGURATION/DEBUG PORT ........................................................ 54

5.5.1 Required Hardware .................................................................................. 54

5.6 REQUIRED SOFTWARE........................................................................................ 54

5.7 USING THE PORT .......................................................................................... 55

5.7.1 Menu Options............................................................................................ 55

5.7.1.1 A = Data Analyzer ................................................................................ 55

5.7.1.2 B = Block Transfer Statistics ................................................................ 58

5.7.1.3 C = Module Configuration.................................................................... 58

5.7.1.4 D = Database View ............................................................................... 59

5.7.1.5 E and F = Master Command Errors (Ports 1 and 2) ............................. 60

5.7.1.6 I and J = Master Command List (Ports 1 and 2)................................... 61

5.7.1.7 O and P = Slave Status List (Port 1 and 2) ........................................... 62

5.7.1.8 R = Receive Module Configuration...................................................... 62

5.7.1.9 S = Send Module Configuration ........................................................... 62

5.7.1.10 T or U = DF1 Override File Map List for Port 1 or Port 2 ............... 62

5.7.1.11 V = Version Information................................................................... 63

5.7.1.12 W = Warm Boot Module .................................................................. 63

5.7.1.13 1 and 2 = Communication Status (Ports 1 and 2) ............................. 63

5.7.1.14 6 and 7 = Port Configuration (Ports 1 and 2).................................... 64

5.7.1.15 Esc = Exit Program ........................................................................... 64

6 CABLE CONNECTIONS ...................................................................................... 65

6.1 DF1 C

OMMUNICATION PORTS ........................................................................... 65

6.1.1 Connecting the Cable to the Connector.................................................... 65

6.2 RS-232 CONFIGURATION/DEBUG PORT............................................................. 67

APPENDIX A – DFCM DATABASE DEFINITION .................................................. 69

APPENDIX B – STATUS DATA DEFINITION ......................................................... 71

APPENDIX C – CONFIGURATION DATA DEFINITION...................................... 73

APPENDIX D – DFCM COMMAND CONTROL...................................................... 83

APPENDIX E – COMMAND ERROR LIST VALUES ............................................. 85

APPENDIX F - UPLOADING AND DOWNLOADING THE CONFIGURATION

FILE ................................................................................................................................. 87

D

OWNLOAD A CONFIGURATION FILE TO YOUR PC........................................................ 87

U

PLOADING THE CONFIGURATION FILE TO THE MODULE .............................................. 92

APPENDIX G – COMMAND FUNCTION CODES .................................................. 97

iv

Page 5

Table of Contents

SUPPORT, SERVICE, AND WARRANTY .............................................................. 107

v

Page 6

Page 7

Product Specifications

1 Product Specifications

The MVI69-DFCM (“DF1 Communication Module”) product allows Allen-Bradley

CompactLogix I/O compatible processors to easily interface with other DF1 protocol

compatible devices. Compatible devices include not only Allen-Bradley PLC's (which all

support the DF1 protocol) but also a wide assortment of end devices.

1.1 General Specifications

The MVI69-DFCM module acts as a gateway between the DF1 network and the AllenBradley backplane. The data transfer from the CompactLogix processor is

asynchronous from the actions on the DF1 network. A 5000-word register space in the

module is used to exchange data between the processor and the DF1 network.

Some of the general specifications include:

• Support for the storage and transfer of up to 5000 registers to/from the

CompactLogix processor's controller tags

• Module memory usage that is completely user definable

• Two ports to emulate any combination of DF1 master or slave device

• Configurable parameters include:

Protocol : Full- or half-duplex

Termination Type BCC or CRC

Local Station ID 0 to 254

Baud Rate : 110 to 115,200

Parity : None, Odd and Even

Stop Bits : 1 or 2

RTS On and Off Timing : 0 to 65535 milliseconds

Minimum Response Delay : 0 to 65535 milliseconds

Use of CTS Modem Line : Yes or No

ENQ Delay 0 to 65535 milliseconds

Response Timeout 0 to 65535 milliseconds

Retry Count 0 to 10

• Address 255 is used for broadcast messages.

1.1.1 Slave Functional Specifications

The MVI69-DFCM module accepts DF1 commands from an attached DF1 master unit. A

port configured as a virtual DF1 slave permits a remote master to interact with all data

contained in the module. This data can be derived from other DF1 slave devices on the

network through a master port or from the CompactLogix processor.

1.1.2 Master Functional Specifications

A port configured as a virtual DF1 master device on the MVI69-DFCM module will

actively issue DF1 commands to other nodes on the DF1 network. One hundred

commands are supported on each port. Additionally, the master ports have an optimized

polling characteristic that will poll slaves with communication problems less frequently.

The CompactLogix processor can be programmed to control the activity on the port by

ProSoft Technology, Inc. 1

MVI69-DFCM User Manual

June 24, 2004

Page 8

Product Specifications

actively selecting commands from the command list to execute or issuing commands

directly from the ladder logic. The CompactLogix processor also has the ability to control

the scanning of slaves on the port.

1.1.3 Physical

This module is designed by ProSoft Technology and incorporates licensed technology

from Allen-Bradley (CompactLogix backplane technology).

• CompactLogix Form Factor - Single Slot

• Connections :

o RJ45 connectors for DF1 support of RS-232, RS-422 or RS-485

interfaces

o 1 – RJ45 RS-232 Configuration Tool Connector

1.1.4 CompactLogix Interface

• Operation via simple ladder logic

• Complete monitoring of module through RSLogix 5000 software

• CompactLogix backplane interface via I/O access

• All data related to the module is contained in a single controller tag with defined

objects to ease in the monitoring and interfacing with the module

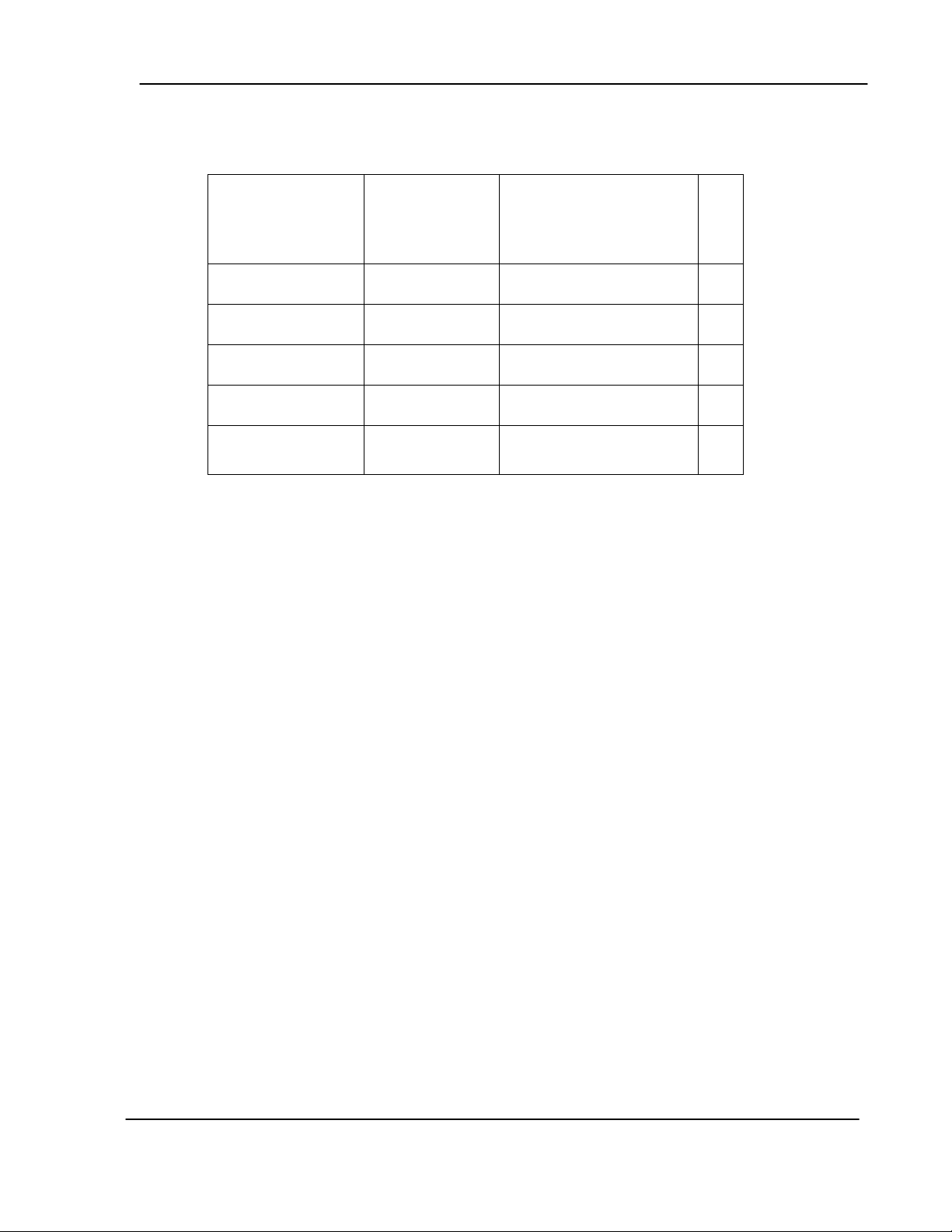

1.2 Hardware Specifications

The MVI69-DFCM module is designed by ProSoft Technology and incorporates licensed

technology from Allen-Bradley (CompactLogix backplane technology).

Current Loads 800 mA @ 5V (from backplane)

Operating Temperature

Storage Temperature

Relative Humidity 5 – 95% (w/o condensation)

DF1 Port Connector Two RJ45 connectors (RJ45 to DB9 cable

Configuration Connector RJ45 RS-232 Connector (RJ45 to DB9

0 to 60° C

32 to 140° F

-40 to 85°C

-40 to 185° F

shipped with unit (supporting RS-232, RS422 and RS-485 interfaces (RJ45 to DB9

cables shipped with unit.

cable shipped with unit.

2 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 9

Functional Overview

2 Functional Overview

This section provides a functional overview of the MVI69-DFCM module. A thorough

understanding of the information contained in this document is required for successful

implementation of the module in a user application. If you are not familiar with the data

transfer and DF1 protocol operations, read this document before setting up the module.

2.1 General Concepts

The following discussion covers several concepts that are key to understanding the

operation of the MVI69-DFCM module.

2.1.1 Module Power Up

• On power up the module begins performing the following logical functions:

• Initialize hardware components

o Initialize CompactLogix backplane driver

o Test and Clear all RAM

o Initialize the serial communication ports

• Read module configuration from the Compact Flash

• Initialize Module Register space

• Enable Slave Driver on selected ports

• Enable Master Driver on selected ports

Once this initialization procedure is complete, the module will begin communicating with

other nodes on the network, depending on the configuration.

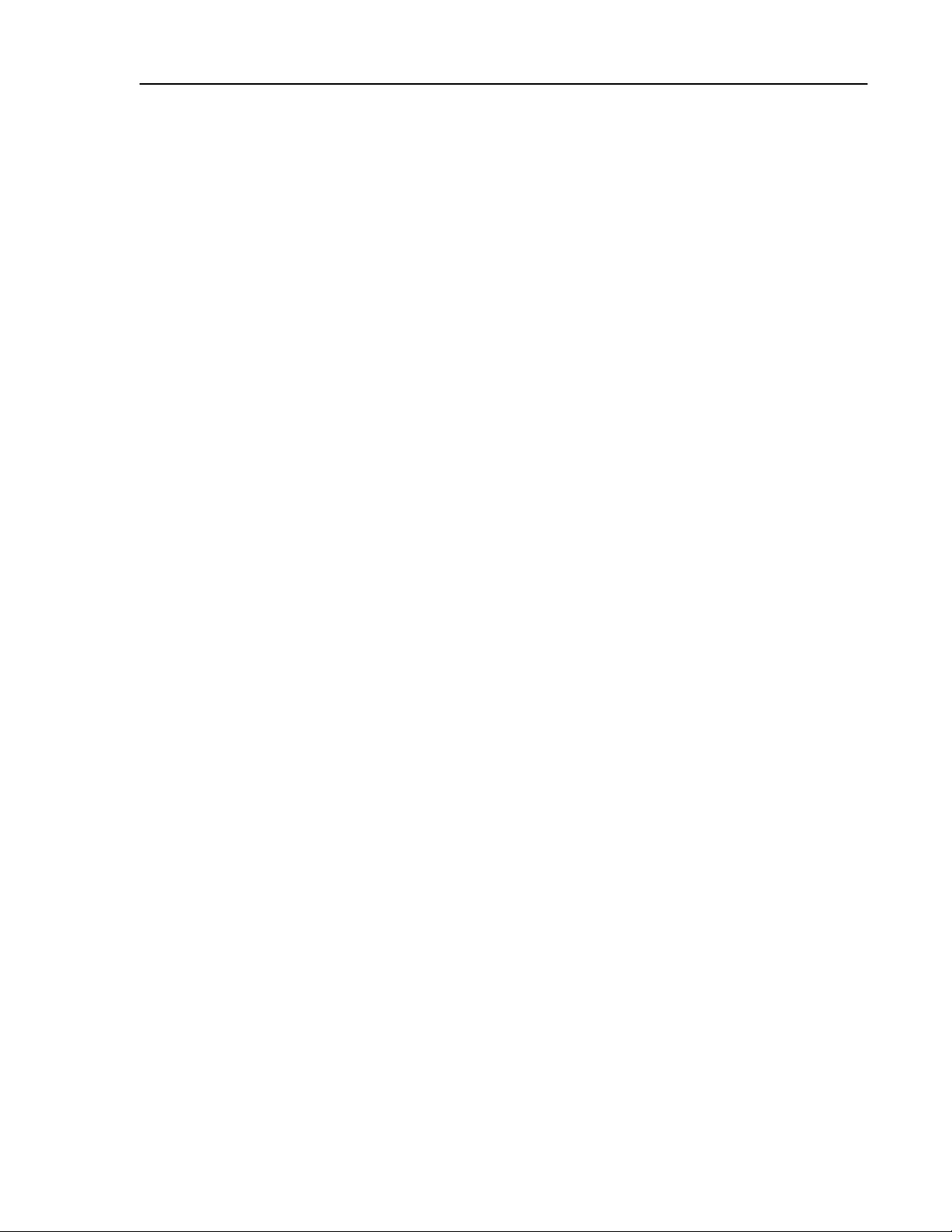

2.1.2 Main Logic Loop

Upon completing the power up configuration process, the module enters an infinite loop

that performs the following functions:

From P o wer Up Logic

From P o wer Up Logic

Call I/O Handler

Call I/O Handler

Call Cfg/ Dbg P o rt

Call Cfg/ Dbg P o rt

Call Cfg/ Dbg P o rt

Driver

Driver

Driver

Call DF 1

Call DF 1

Call DF 1

Driver

Driver

Driver

Call I/O Handler

Call I/O Handler

- Trans fers dat a betw een mo dule and p rocess or

- Trans fers dat a betw een mo dule and p rocess or

(user, status, configuratio n, et c. )

(user, status, configuratio n, et c. )

Call Serial Port Driver (Configuration/Debug Port)

Call Serial Port Driver (Configuration/Debug Port)

- Rx and Tx buffer rout ines are interr upt driven

- Rx and Tx buffer rout ines are interr upt driven

- Call to serial port routines chec ks to see if there is any data

- Call to serial port routines chec ks to see if there is any data

in the buffer, and de pen ding o n the value will ei th er servic e

in the buffer, and de pen ding o n the value will ei th er servic e

the buffer or wait for more c har act ers

the buffer or wait for more c har act ers

Cal l DF1 Dri ve r

Cal l DF1 Dri ve r

- If DF1 Mas ter P ort, poll s la ves using c omm and lis t

- If DF1 Mas ter P ort, poll s la ves using c omm and lis t

- If DF1 Slave P ort, respo nd to comman ds rec ei ved

- If DF1 Slave P ort, respo nd to comman ds rec ei ved

ProSoft Technology, Inc. 3

MVI69-DFCM User Manual

June 24, 2004

Page 10

Functional Overview

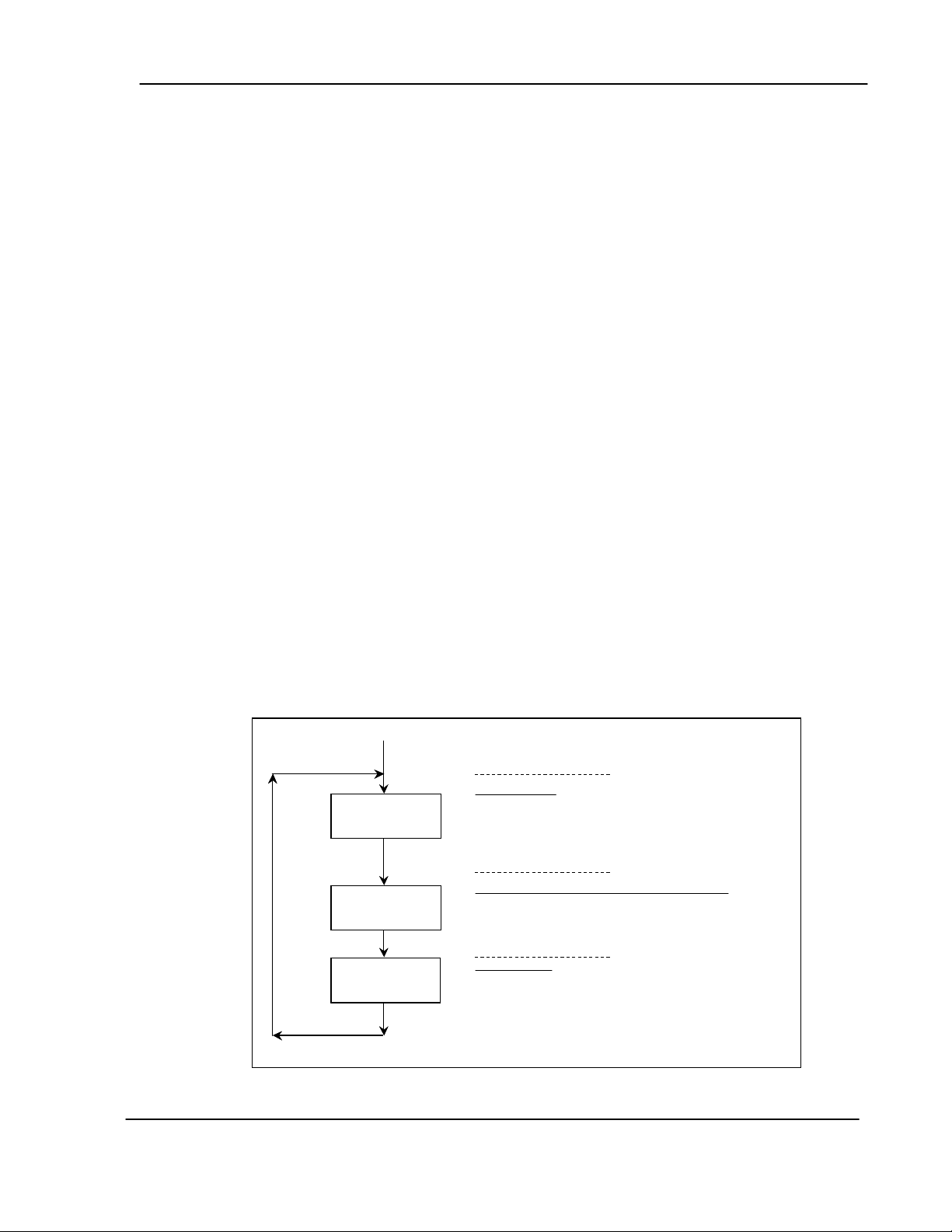

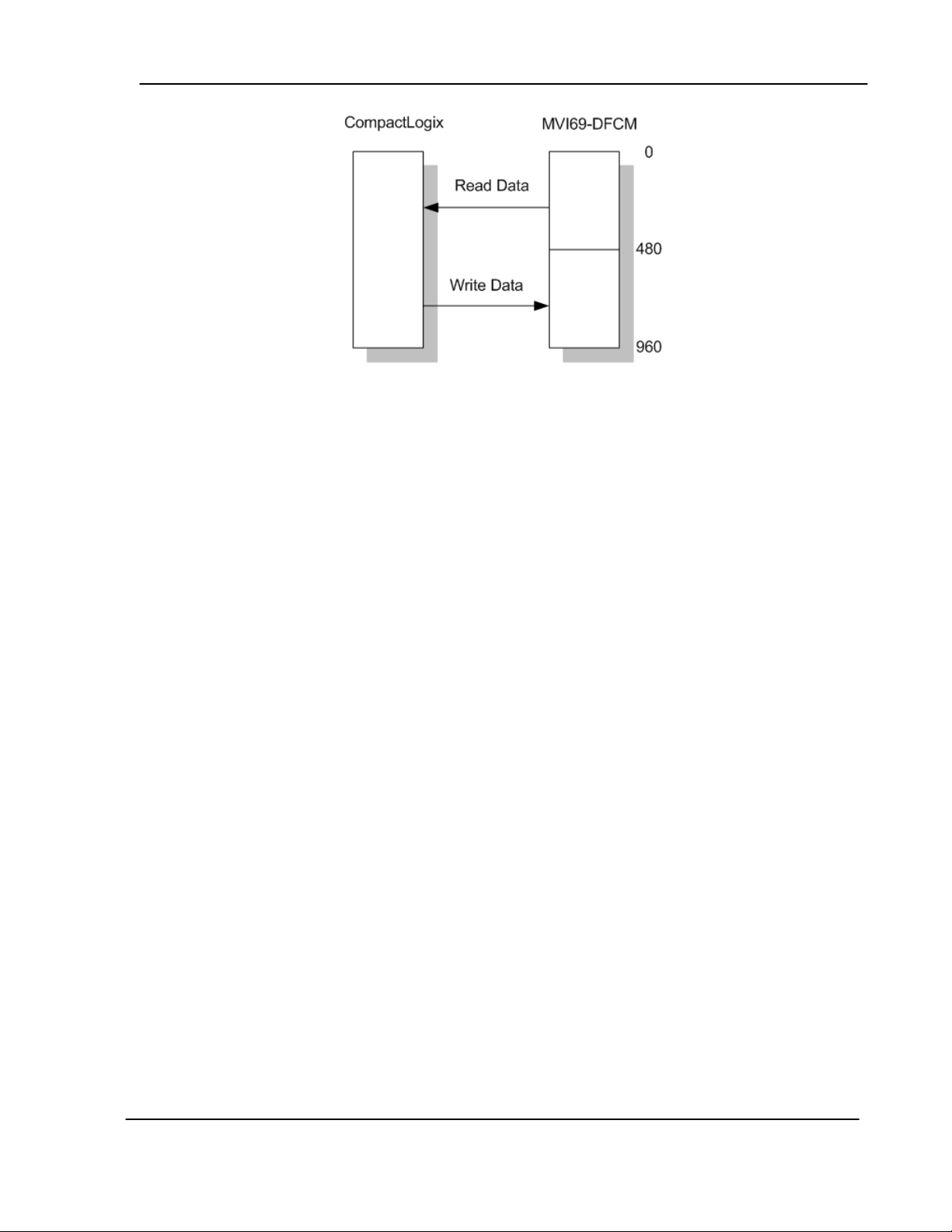

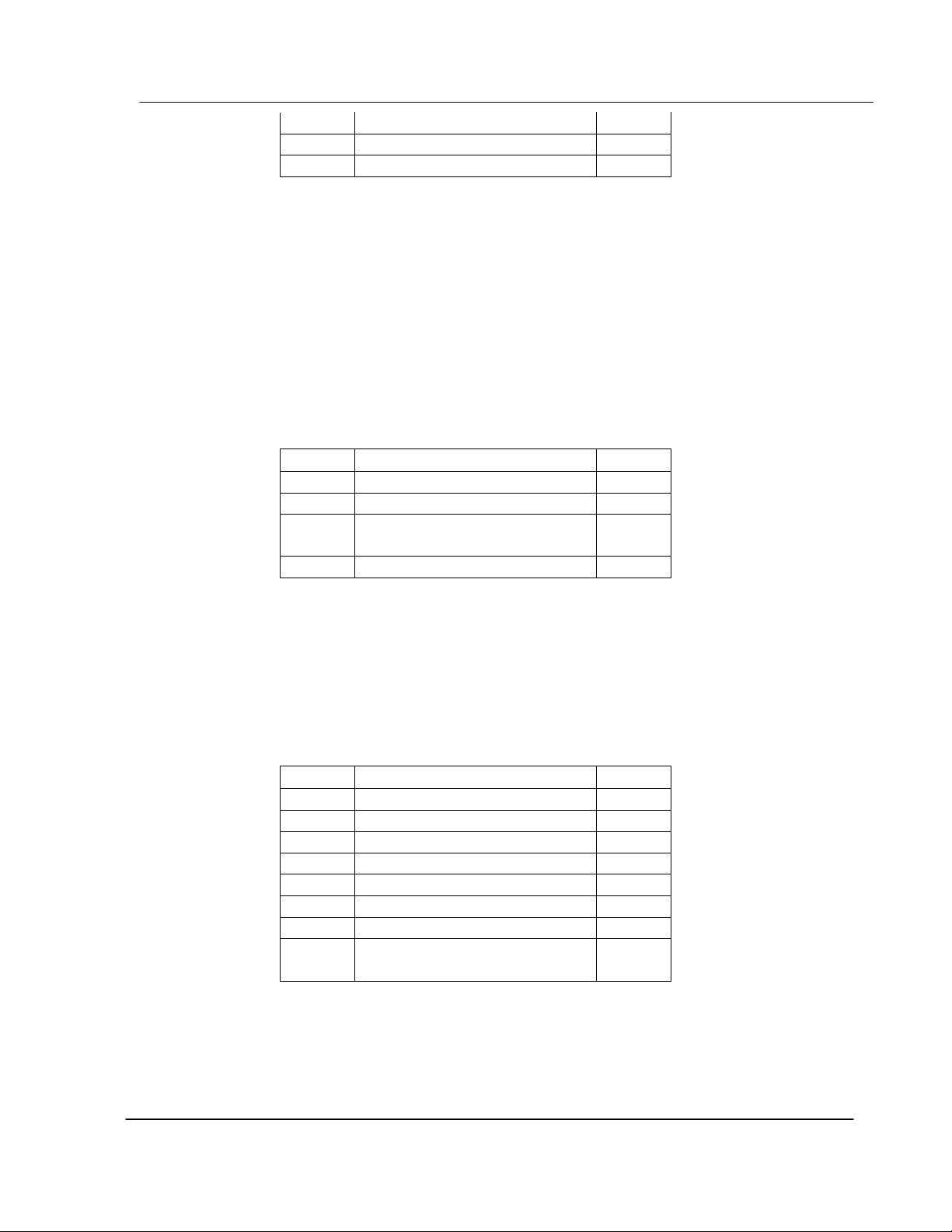

2.1.3 Backplane Data Transfer

The MVI69-DFCM module is unique in the way that the CompactLogix backplane is

utilized. Data is paged between the module and the CompactLogix processor across the

backplane using the module's input and output images. The update frequency of the

images is determined by the scheduled scan rate defined by the user for the module and

the communication load on the module. Typical updates are in the range of 2 to 10

milliseconds.

The data is paged between the processor and the module using input and output image

blocks. You can configure the size of the blocks using the Block Transfer Size parameter

in the configuration file. You can configure blocks of 60, 120, or 240 words of data

depending on the number of words allowed for your own application.

This bi-directional transference of data is accomplished by the module filling in data in the

module's input image to send to the processor. Data in the input image is placed in the

Controller Tags in the processor by the ladder logic. The input image for the module may

be set to 62, 122, or 242 words depending on the block transfer size parameter set in the

configuration file.

The processor inserts data to the module's output image to be transferred to the module.

The module's program extracts the data and places it in the module's internal database.

The output image for the module may be set to 61, 121, or 241 words depending on the

block transfer size parameter set in the configuration file.

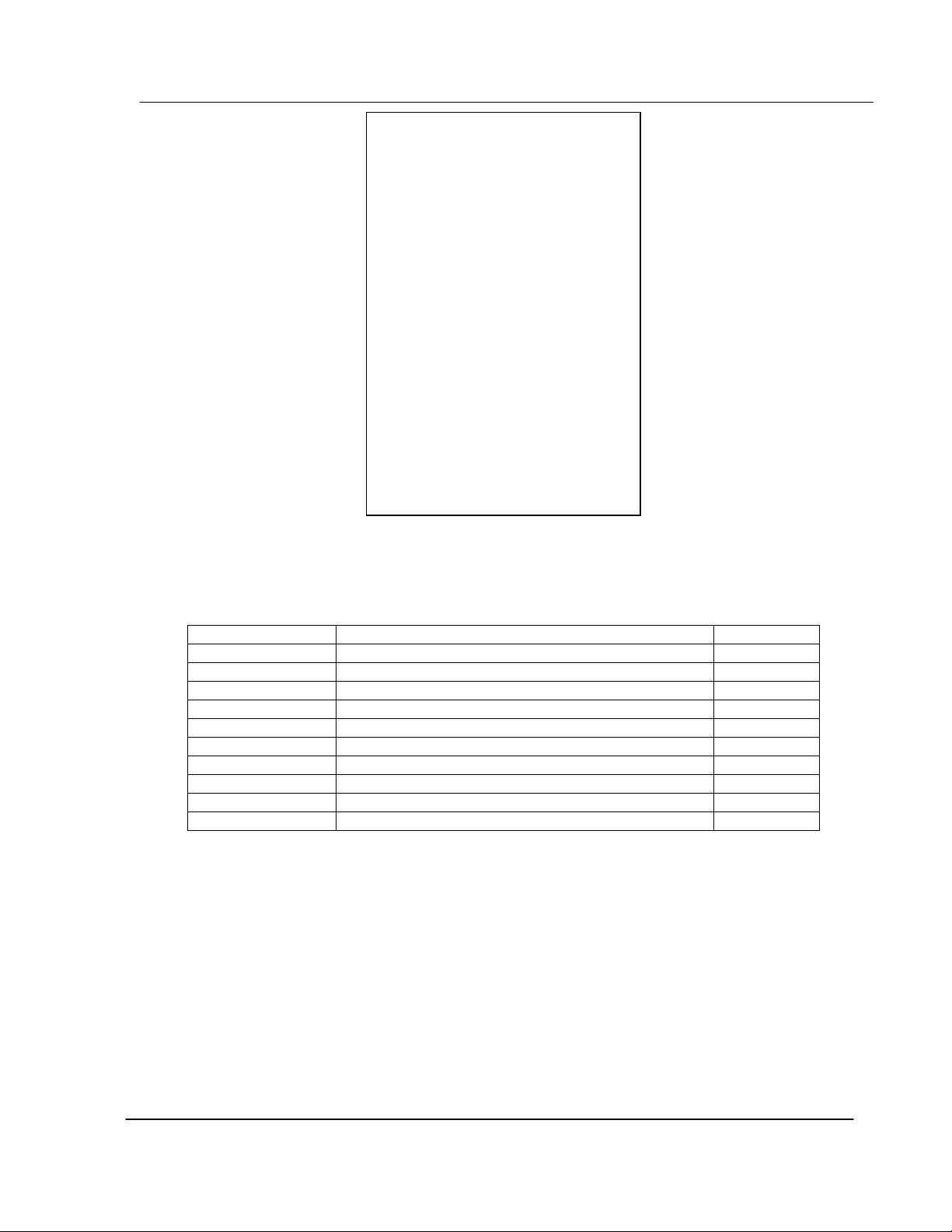

The following diagram displays the data transfer method used to move data between the

CompactLogix processor, the MVI69-DFCM module and the DF1 network.

Processor

Processor

MVI69-DFCM Module

MVI69-DFCM Module

Processor

Processor

Controller Tags

Controller Tags

Or User Files

Or User Files

Status

Status

Read Data

Read Data

Write Data

Write Data

Special Control

Special Control

Blocks

Blocks

Ladder

Ladder

Logic

Logic

Transfers

Transfers

Data from

Data from

module’s input

module’s input

image to data

image to data

areas in the

areas in the

processor

processor

Ladder

Ladder

Logic

Logic

Transfers

Transfers

Data from

Data from

Processor

Processor

data areas

data areas

to output image

to output image

Backplane Driver

Backplane Driver

Input Image

Input Image

Output Image

Output Image

Module’s

Module’s

Internal

Internal

Database

Database

Master

Master

Master

Driver

Driver

Driver

Logic

Logic

Logic

Slave

Slave

Slave

Driver

Driver

Driver

Logic

Logic

Logic

DF1

DF1

Port

Port

Drivers

Drivers

As shown in the diagram above, all data transferred between the module and the

processor over the backplane is through the input and output images. Ladder logic must

be written in the CompactLogix processor to interface the input and output image data

To DF1

To DF1

Network

Network

4 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 11

Functional Overview

with data defined in the Controller Tags. All data used by the module is stored in its

internal database. The diagram below displays the layout of the database:

Module’s Internal Database Structure

Data

Status

and

Config

0

4999

5000

7999

5000 registers for us e r data

3000 words of configu ration

and status data

Regist er

Data contained in this database is paged through the input and output images by

coordination of the CompactLogix ladder logic and the MVI69-DFCM module's program.

Up to 242 words of data can be transferred from the module to the processor at once.

Up to 241 words of data can be transferred from the processor to the module. The read

and write block identification codes in each data block determine the function to be

performed or the content of the data block. The block identification codes used by the

module are listed below:

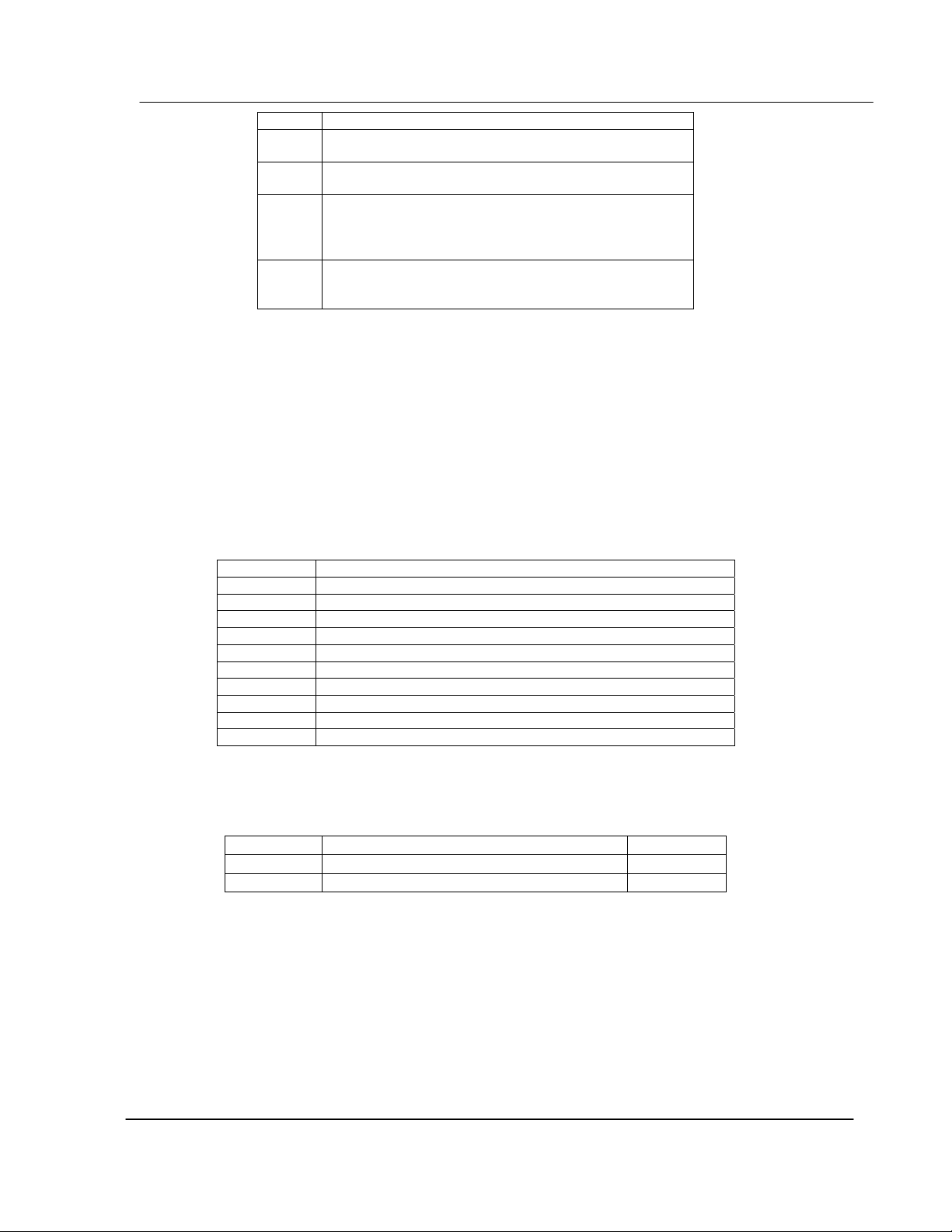

Block Range Descriptions

-1 Status Block

0 Status Block

1 to 999 Read or write data

1000 Event Port 1

2000 Event Port 2

3000 to 3001 Port 1 slave polling control

3002 to 3006 Port 1 slave status

3100 to 3101 Port 2 slave polling control

3102 to 3106 Port 2 slave status

5000 to 5006 Port 1 command control

5100 to 5106 Port 2 command control

9972 Set module time using received time

9973 Pass module time to processor

9998 Warm-boot control block

9999 Cold-boot control block

Each image has a defined structure depending on the data content and the function of

the data transfer as defined in the sections below:

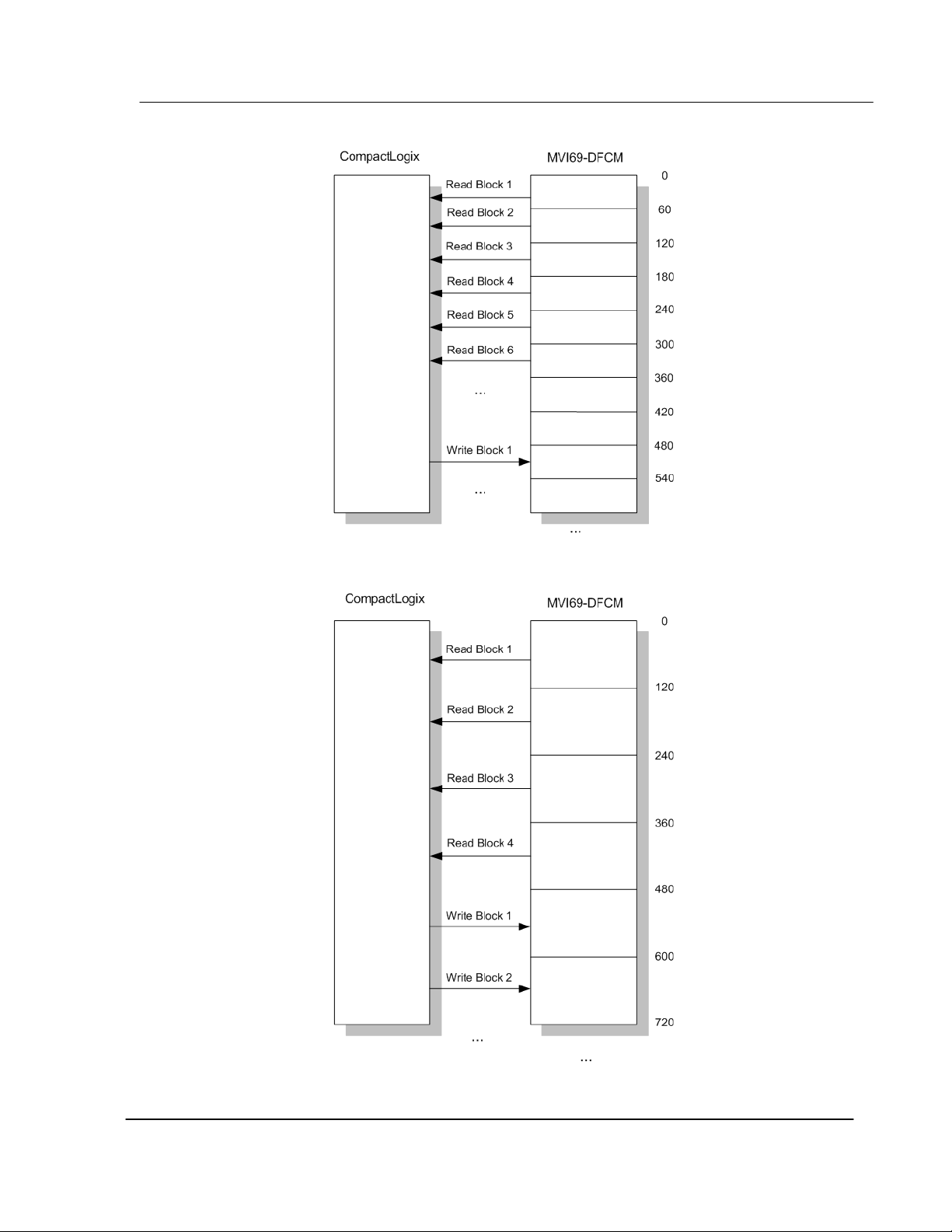

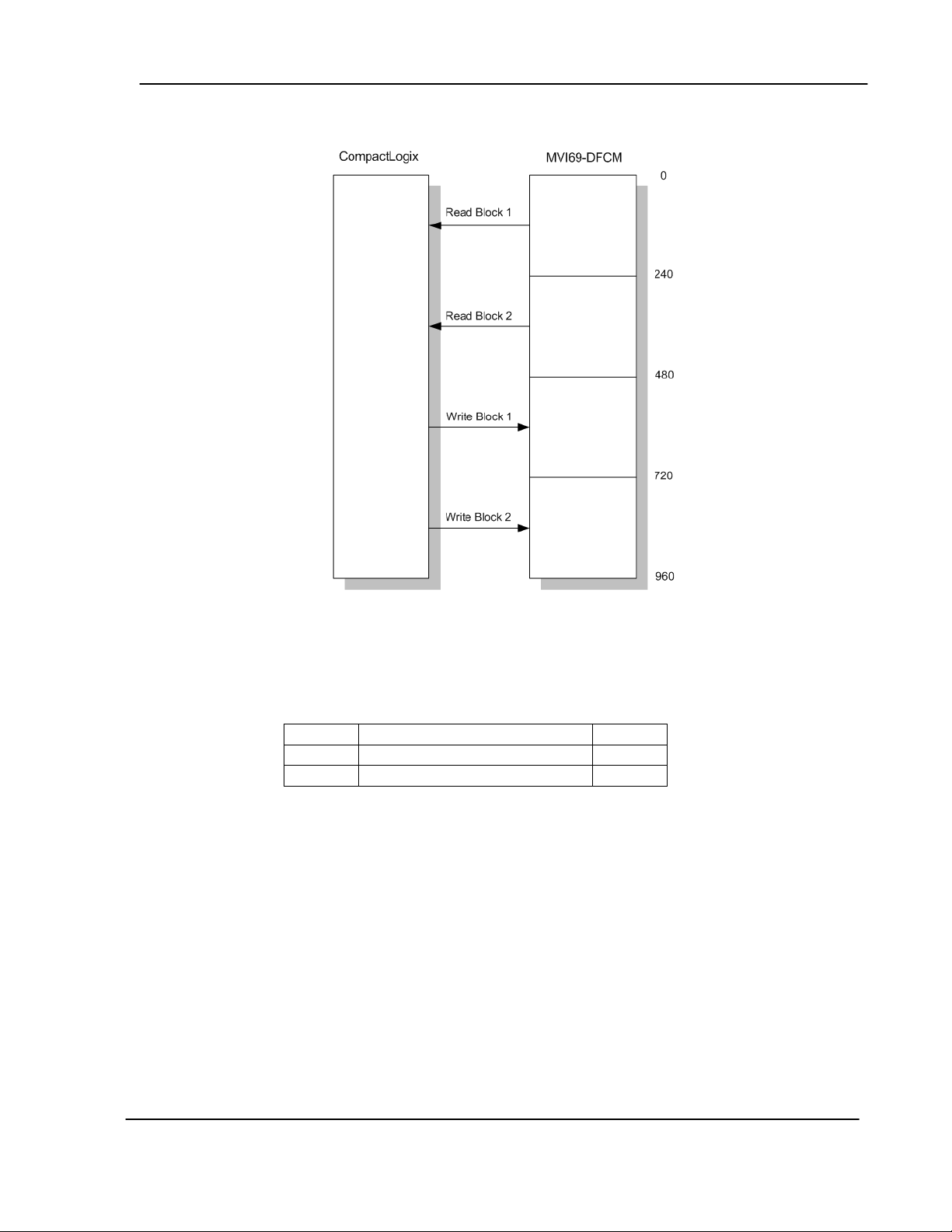

2.2 Normal Data Transfer

Normal data transfer includes the paging of the user data found in the module's internal

database in registers 0 to 4999 and the status data. These data are transferred through

read (input image) and write (output image) blocks. The structure and function of each

block is discussed in the following sections:

ProSoft Technology, Inc. 5

MVI69-DFCM User Manual

June 24, 2004

Page 12

Functional Overview

2.2.1 Read Block

These blocks of data are used to transfer information from the module to the

CompactLogix processor. The structure of the input image used to transfer this data is

shown below:

2 to (n+1) Read Data n

where

n = 60, 120, or 240 depending on the Block Transfer Size parameter (refer to the

configuration file).

The Read Block ID is an index value used to determine the location of where the data will

be placed in the CompactLogix processor controller tag array of module read data. The

number of data words per transfer depends on the configured Block Transfer Size

parameter in the configuration file (possible values are 60, 120, or 240).

The Write Block ID associated with the block is used to request data from the

CompactLogix processor. Under normal, program operation, the module sequentially

sends read blocks and requests write blocks. For example, if three read and two write

blocks are used with the application, the sequence will be as follows:

R1W1-->R2W2-->R3W1-->R1W2-->R2W1-->R3W2-->R1W1-->

This sequence will continue until interrupted by other write block numbers sent by the

controller or by a command request from a node on the DF1 network or operator control

through the module's Configuration/Debug port.

The following example shows a typical backplane communication application.

Assume that the backplane parameters are configured as follows:

Read Register Start: 0

Read Register Count: 480

Write Register Start: 480

Write Register Count: 480

The backplane communication would be configured as follows:

Offset Description Length

0 Read Block ID 1

1 Write Block ID 1

6 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 13

Functional Overview

Database address 0 to 479 will be continuously transferred from the module to the

processor. Database address 480 to 959 will continuously be transferred from the

processor to the module.

The Block Transfer Size parameter basically configures how the Read Data and Write

Data areas are broken down into data blocks (60, 120, or 240).

ProSoft Technology, Inc. 7

MVI69-DFCM User Manual

June 24, 2004

Page 14

Functional Overview

If Block Transfer Size = 60:

If Block Transfer Size = 120:

8 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 15

Functional Overview

If Block Transfer Size = 240:

2.2.2 Write Block

These blocks of data are used to transfer information from the CompactLogix processor

to the module. The structure of the output image used to transfer this data is shown

below:

Offset Description Length

0 Write Block ID 1

1 to n Write Data n

where n = 60, 120, or 240 depending on the Block Transfer Size parameter (refer to the

configuration file).

The Write Block ID is an index value used to determine the location in the module's

database where the data will be placed. Each transfer can move up to 200 words (block

offsets 1 to 200) of data.

2.3 Special Blocks

2.3.1 Slave Status Blocks

Slave status blocks are used to send status information of each slave device on a master

port. Slaves attached to the master port can have one of the following states:

ProSoft Technology, Inc. 9

MVI69-DFCM User Manual

June 24, 2004

Page 16

Functional Overview

State Description

0 The slave is inactive and not defined in the command list

1 The slave is actively being polled or controlled by the

2 The master port has failed to communicate with the slave

3 Communications with the slave has been disabled by the

Slaves are defined to the system when the module initializes the master command list.

Each slave defined will be set to a state of one in this initial step. If the master port fails

to communicate with a slave device (retry count expired on a command), the master will

set the state of the slave to a value of 2 in the status table. This suspends

communication with the slave device for a user specified scan count (Error Delay Count

parameter in the configuration file). Each time a command in the list is scanned that has

the address of a suspended slave, the delay counter value will be decremented. When

the value reaches zero, the slave state will be set to one.

In order to read the slave status table, you should refer to the sample ladder logic. The

ladder logic must send a special block to the module to request the data. Each port has

a specific set of blocks to request the data as follows:

BLOCK ID DESCRIPTION

3002 Request status for slaves 0 to 59 for Port 1

3003 Request status for slaves 60 to 119 for Port 1

3004 Request status for slaves 120 to 179 for Port 1

3005 Request status for slaves 180 to 239 for Port 1

3006 Request status for slaves 240 to 255 for Port 1

3102 Request status for slaves 0 to 59 for Port 2

3103 Request status for slaves 60 to 119 for Port 2

3104 Request status for slaves 120 to 179 for Port 2

3105 Request status for slaves 180 to 239 for Port 2

3106 Request status for slaves 240 to 255 for Port 2

The format of these blocks is as shown below:

Write Block – Request Slave Status

Offset Description Length

0 3002 – 3006 or 3102 – 3106 1

1 to n Spare n

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

for the master port.

master port and communications is successful.

device. Communications with the slave is suspended for

a user defined period based on the scanning of the

command list.

ladder logic. No communication will occur with the slave

until this state is cleared by the ladder logic.

10 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 17

Functional Overview

The module will recognize the request by receiving the special write block code and

respond with a read block with the following format:

Read Block – Read Slave Status

Offset Description Length

0 3002-3006 or 3102-3106 1

1 Write Block ID 1

2-61 Slave Poll Status Data 60

62 to n Spare (if present)

The sample ladder logic shows how to override the value in the slave status table to

disable slaves (state value of 3) by sending a special block of data from the processor to

the slave. Port 1 slaves are disabled using block 3000, and Port 2 slaves are disabled

using block 3100. Each block contains the slave node addresses to disable. The

structure of the block is displayed below:

Write Block – Disable Slaves

Offset Description Length

0 3000 or 3100 1

1 Number of slaves in block 1

2 to 61 Slave indexes 60

62 to (n+1) Spare

n=120, or 240 (if configured)

The module will respond with a block with the same identification code received and

indicate the number of slaves acted on with the block. The format of this response block

is displayed below:

Read Block – Disable Slaves

Offset Description Length

0 3000 or 3100 1

1 Write Block ID 1

2 Number of slaves processed 1

3 to (n+1) Spare

n=60, 120, or 240 (if configured)

The sample ladder logic explains how to override the value in the slave status table to

enable the slave (state value of 1) by sending a special block. Port 1 slaves are enabled

using block 3001, and Port 2 slaves are enabled using block 3101. Each block contains

the slave node addresses to enable. The format of the block is displayed below:

Write Block – Enable Slaves

Offset Description Length

0 3001 or 3101 1

1 Number of slaves in block 1

2 Slave indexes 1

ProSoft Technology, Inc. 11

MVI69-DFCM User Manual

June 24, 2004

Page 18

Functional Overview

3 to n Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

The module will respond with a block with the same identification code received and

indicate the number of slaves acted on with the block. The format of this response block

is displayed below:

Read Block – Enable Slaves

Offset Description Length

0 3001 or 3101 1

1 Write Block ID 1

2 Number of slaves processed 1

3-n Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

Important: The slaves are enabled by default. Therefore, this block should only be used

after Block 3000 or 3001 to re-enable the slaves.

2.4 Command Control Blocks

Command control blocks are special blocks used to control the module or request special

data from the module. The current version of the software supports five command

control blocks: event command control, command control, transfer time, warm boot and

cold boot.

2.4.1 Event Command

Event command control blocks are used to send DF1 commands directly from the ladder

logic to one of the master ports. The format for these blocks is displayed below:

Write Block – Event Command

Offset Description Length

0 1000 or 2000 1

1 Internal DB Address 1

2 Point Count 1

3 Swap Code 1

4 Node Address 1

5 Function Code 1

6 Parameter #1 1

7 Parameter #2 1

8 Parameter #3 1

9 Parameter #4 1

10 to n Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

12 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 19

Functional Overview

The block number defines the DF1 port to be considered. Block 1000 commands are

directed to Port 1, and block 2000 commands are directed to Port 2. The parameters

passed with the block are used to construct the command. The Internal DB Address

parameter specifies the module's database location to associate with the command. The

Point Count parameter defines the number of registers for the command. The Swap

Code is used to change the word or byte order. The Node Address parameter is used

to define the device on the DF1 network to consider. The Function Code parameter is

one of those defined in the ProSoft DF1 Command Set documentation. The parameter

fields in the block should be completed as required by the selected function code. Each

command has its own set of parameters. When the block is received, the module will

process it and place the command in the command queue. The module will respond to

each event command block with a read block with the following format:

Read Block – Event Command

Offset Description Length

0 1000 or 2000 1

1 Write Block ID 1

2 0=Fail, 1=Success 1

3 to n Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

Word two of the block can be used by the ladder logic to determine if the command was

added to the command queue of the module. The command will only fail if the command

queue for the port is full (100 commands for each queue) or the command requested is

invalid.

2.4.2 Command Control

Command control blocks are used to place commands in the command list into the

command queue. Each port has a command queue of up to 100 commands. The

module services commands in the queue before the master command list. This gives

high priority to commands in the queue. Commands placed in the queue through this

mechanism must be defined in the master command list. Under normal command list

execution, the module will only execute commands with the Enable parameter set to one

or two. If the value is set to zero, the command is skipped. Commands may be placed in

the command list with an Enable parameter set to zero. These commands can then be

executed using the command control blocks.

One to six commands can be placed in the command queue with a single request. The

format of the block is displayed in the following table:

Write Block – Command Control

Offset Description Length

0 5001-5006 or 5101-5106 1

1 Command index 1

2 Command index 1

3 Command index 1

4 Command index 1

ProSoft Technology, Inc. 13

MVI69-DFCM User Manual

June 24, 2004

Page 20

Functional Overview

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

Blocks in the range of 5001 to 5006 are used for Port 1, and blocks in the range of 5101

to 5106 are used for Port 2. The last digit in the block code defines the number of

commands to process in the block. For example, a block code of 5003 contains 3

command indexes that are to be used with Port 1. The Command index parameters in

the block have a range of 0 to 99 and correspond to the master command list entries.

The module responds to a command control block with a block containing the number of

commands added to the command queue for the port. The format of the block is

displayed below:

Read Block – Command Control

5 Command index 1

6 Command index 1

7 to n Spare

Offset Description Length

0 5000-5006 or 5100-5106 1

1 Write Block ID 1

2 Number of commands added to

command queue

1

3 to (n+1) Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

2.4.3 Set Module Time Using Processor Time

This block can be used to update the module’s internal clock (date and time).

Write Block – Set Module Time

Offset Description Length

0 9972 1

1 Year (0-9999) 1

2 Month (1-12) 1

3 Day (1-31) 1

4 Hour (0-23) 1

5 Minutes (0-59) 1

6 Seconds (0-59) 1

7 to n Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

14 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 21

Functional Overview

Set Module Time Response

Read Block – Set Module Time

Offset Description Length

0 9972 1

1 Write Block ID 1

2 to (n+1) Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

Get Module Time for Processor Time

Write Block – Get Module Time

Offset Description Length

0 9973 1

1 to n Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

Read Block – Write Module TIme

Offset Description Length

0 9973 1

1 Write Block ID 1

2 Year (0-9999) 1

3 Month (1-12) 1

4 Day (1-31) 1

5 Hour (0-23) 1

6 Minutes (0-59) 1

7 Seconds (0-59) 1

8 to n Spare

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

2.4.4 Warm Boot

This block is sent from the CompactLogix processor to the module (output image) when

the module is required to perform a warm-boot (software reset) operation. The structure

of the control block is shown below:

Offset Description Length

0 9998 1

1 to n Spare 247

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

ProSoft Technology, Inc. 15

MVI69-DFCM User Manual

June 24, 2004

Page 22

Functional Overview

Cold Boot

This block is sent from the CompactLogix processor to the module (output image) when

the module is required to perform the cold boot (hardware reset) operation. This block is

sent to the module when a hardware problem is detected by the ladder logic that requires

a hardware reset. The structure of the control block is shown below:

n=60, 120, or 240 depending on what is entered in the Block Transfer Size parameter

(see the configuration file).

Offset Description Length

0 9999 1

1 to n Spare 247

16 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 23

Functional Overview

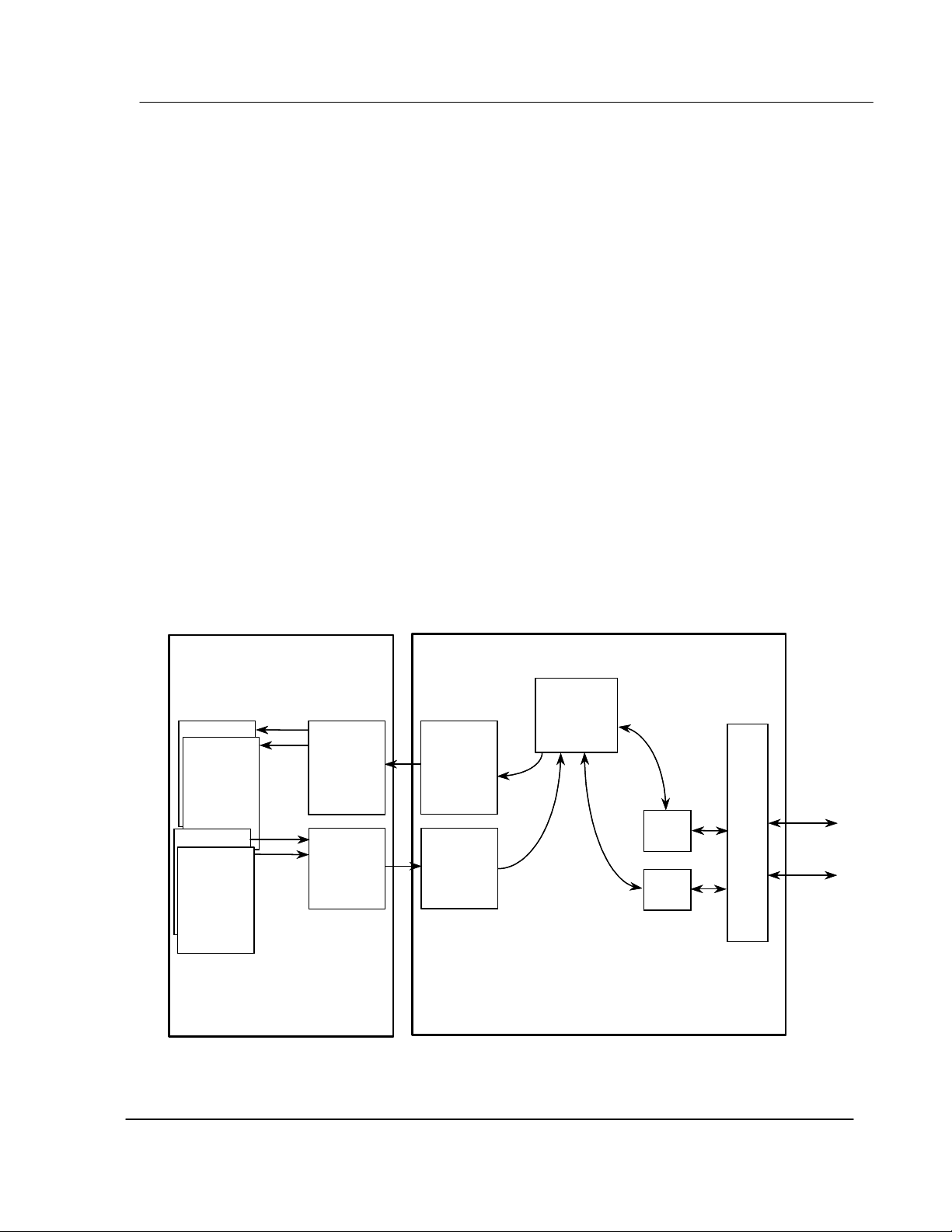

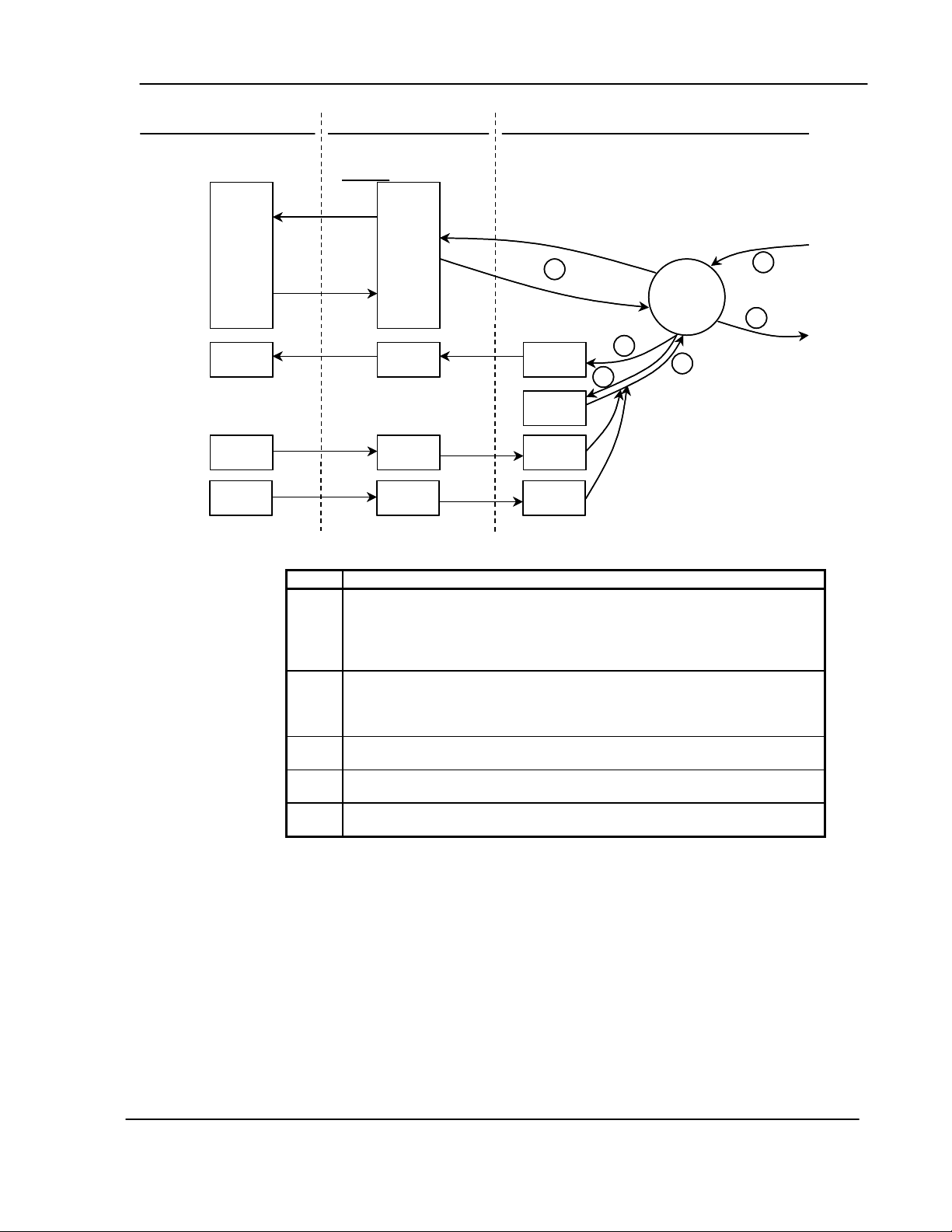

2.5 Data Flow between MVI69-DFCM Module and CompactLogix

Processor

The following discussion details the flow of data between the two pieces of hardware

(CompactLogix processor and MVI69-DFCM module) and other nodes on the DF1

network under the module’s different operating modes. Each port on the module is

configured to emulate a DF1 master device or a DF1 slave device. The operation of

each port is dependent on this configuration. The sections below discuss the operation

of each mode.

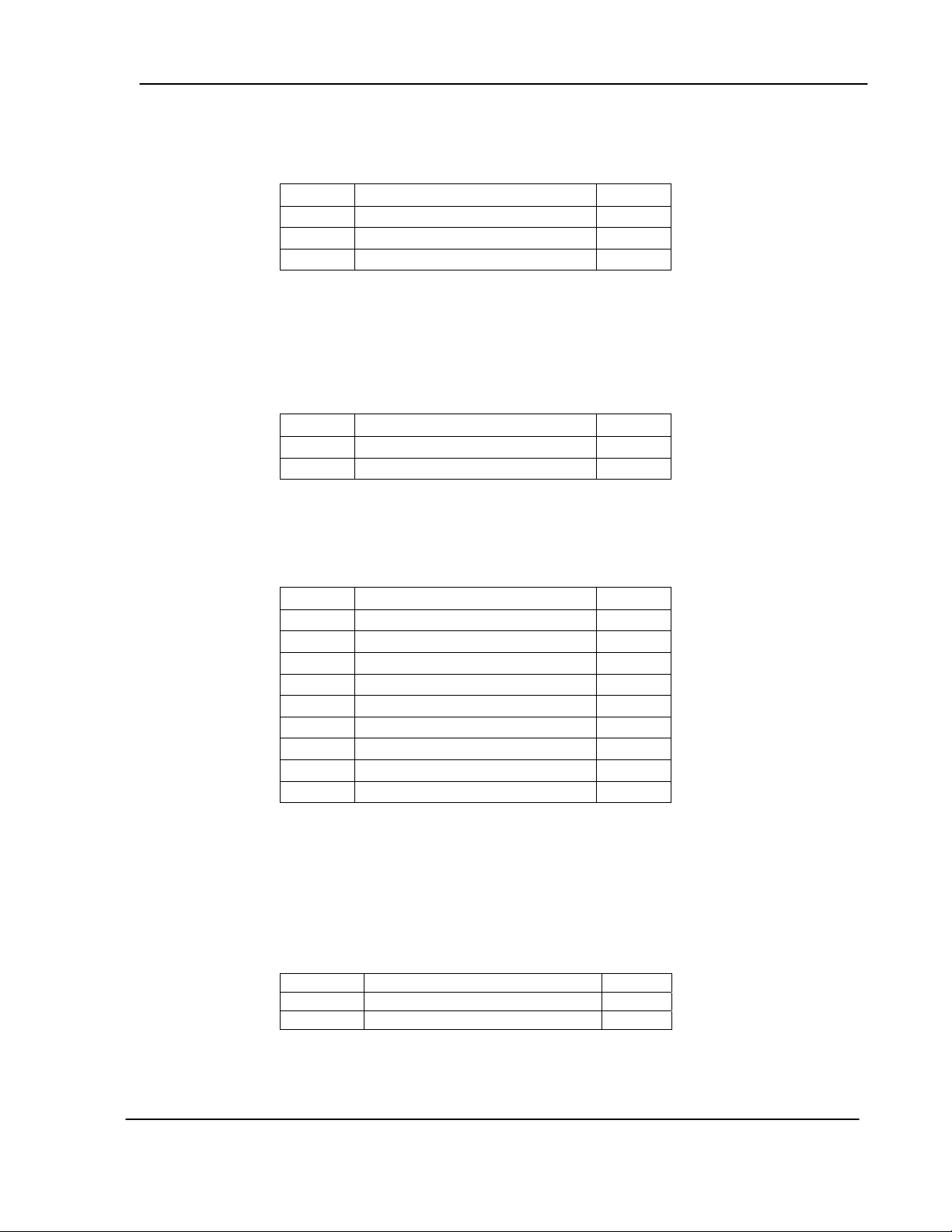

2.5.1 Slave Driver Mode

The Slave Driver Mode allows the MVI69-DFCM module to respond to data read and

write commands issued by a master on the DF1 network. The following flow chart and

associated table detail the flow of data into and out of the module.

Processor Memory DFCM ModuleBackplane Interface

Processor Memory DFCM ModuleBackplane Interface

User Files Or

User Files Or

Controller Tags

Controller Tags

Database

Database

Addresses

Addresses

0

0

from Module

from Module

Register

Register

Data

Data

storage

storage

Status

Status

2

2

Register

Register

Data

4999

4999

Data

Status

Status

Configuration

Configuration

Status

Status

3

3

5

5

3

3

Slave

Slave

Mode

Mode

Driver

Driver

1

1

4

4

Step Description

1 The DF1 slave port driver receives the configuration information from the

internal Compact Flash disk. This information is used to configure the

serial port and define the slave node characteristics. The module

simulates N-files to permit remote access of the database. Each file has a

configurable length of 60, 120, or 240-word registers.

2 A Host device, such as an Allen-Bradley PLC or an MMI package issues a

read or write command to the module’s node address. The port driver

qualifies the message before accepting it into the module.

3 Once the module accepts the command, the data is immediately

transferred to or from the internal database in the module. If the command

is a read command, the data is read out of the database and a response

message is built. If the command is a write command, the data is written

directly into the database and a response message is built.

4 Once the data processing has been completed in Step 3, the response is

issued to the originating master node.

5 Counters are available in the Status Block that permit the ladder logic

program to determine the level of activity of the Slave Driver.

ProSoft Technology, Inc. 17

MVI69-DFCM User Manual

June 24, 2004

Page 24

A

A

A

A

A

A

Functional Overview

Review the Module Set Up section for a complete list of the parameters that must be

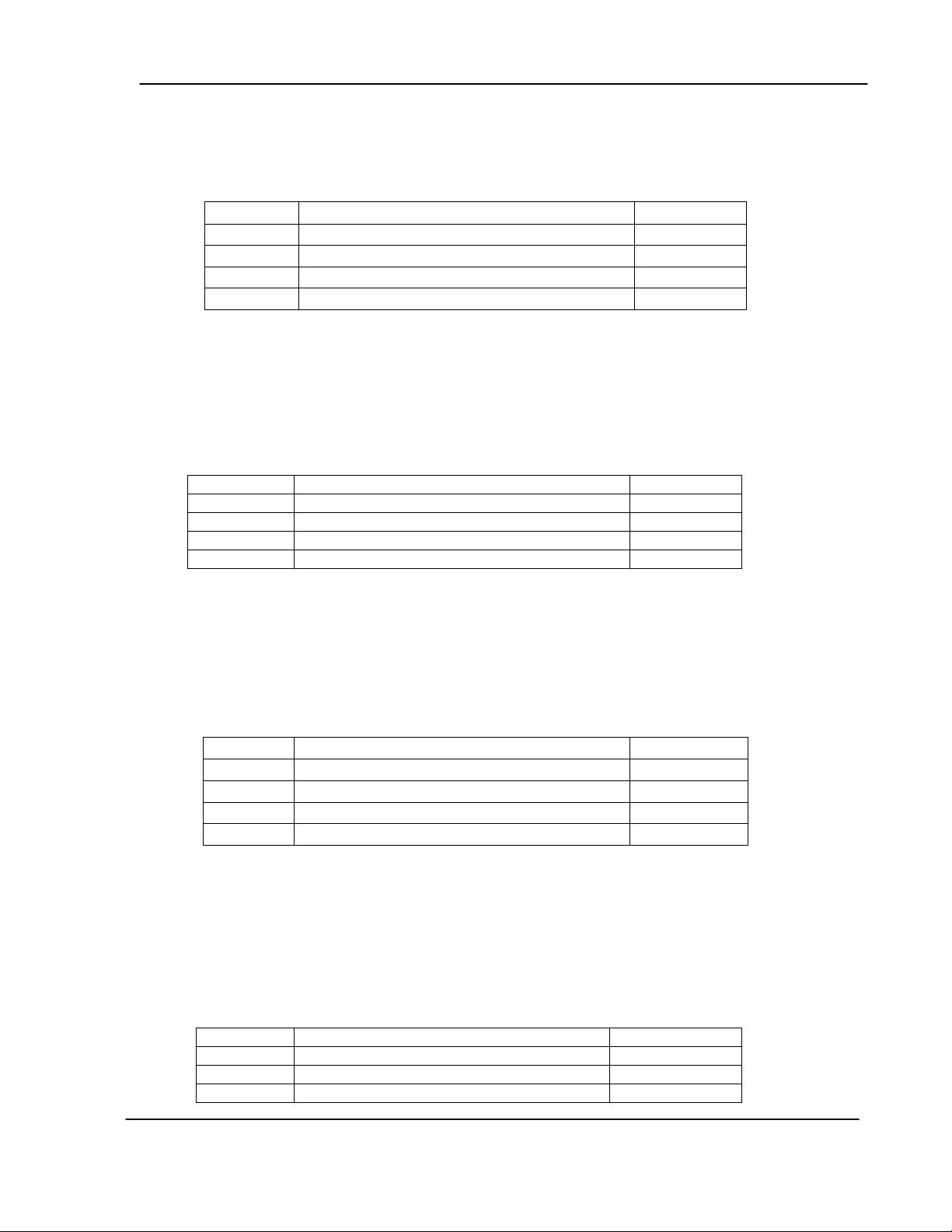

defined for a slave port. The slave driver supports the following DF1 command set:

Basic Command Set Functions

Command Function Definition

0x00 N/A Protected Write X

0x01 N/A Unprotected Read X

0x02 N/A Protected Bit Write X

0x05 N/A Unprotected Bit Write X

0x06 0x00 Echo Request X

0x06 0x03 Status Request X

0x08 N/A Unprotected Write X

PLC-5 Command Set Functions

Command Function Definition

Slave

Supported in

Slave

Supported in

0x0F 0x00 Word Range Write (Binary

ddress)

0x0F 0x01 Word Range Read (Binary

ddress)

0x0F 0x26 Read-Modify-Write (Binary

ddress)

0x0F 0x00 Word Range Write (ASCII

ddress)

0x0F 0x01 Word Range Read (ASCII

ddress)

0x0F 0x26 Read-Modify-Write (ASCII

ddress)

X

X

X

X

18 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 25

Functional Overview

SLC-500 Command Set Functions

Command Function Definition

0x0F 0xA1 Protected Typed Logical Read

With Two Address Fields

0x0F 0XA2 Protected Typed Logical Read

With Three Address Fields

0x0F 0XA9 Protected Typed Logical Write

With Two Address Fields

0x0F 0XAA Protected Typed Logical Write

With Three Address Fields

0x0F 0XAB Protected Typed Logical Write

With Mask (Three Address

Fields)

The PLC-5 and SLC-500 command set require the use of files. These files are emulated

in the module. The module defines these files depending on the following parameters in

the configuration file:

• First File

• File Size

• File Offset

For example, if these parameters are configured as:

First File: 7

File Size: 200

File Offset: 0

The database would be emulated as shown in the following table:

Slave

Supported in

X

X

X

X

X

ProSoft Technology, Inc. 19

MVI69-DFCM User Manual

June 24, 2004

Page 26

r

Functional Overview

In order to retrieve data from the modules database register 200, the remote master

would issue a command using the address N8:0. In order to interface with database

base register 405, the remote master would use the address N9:5. The following table

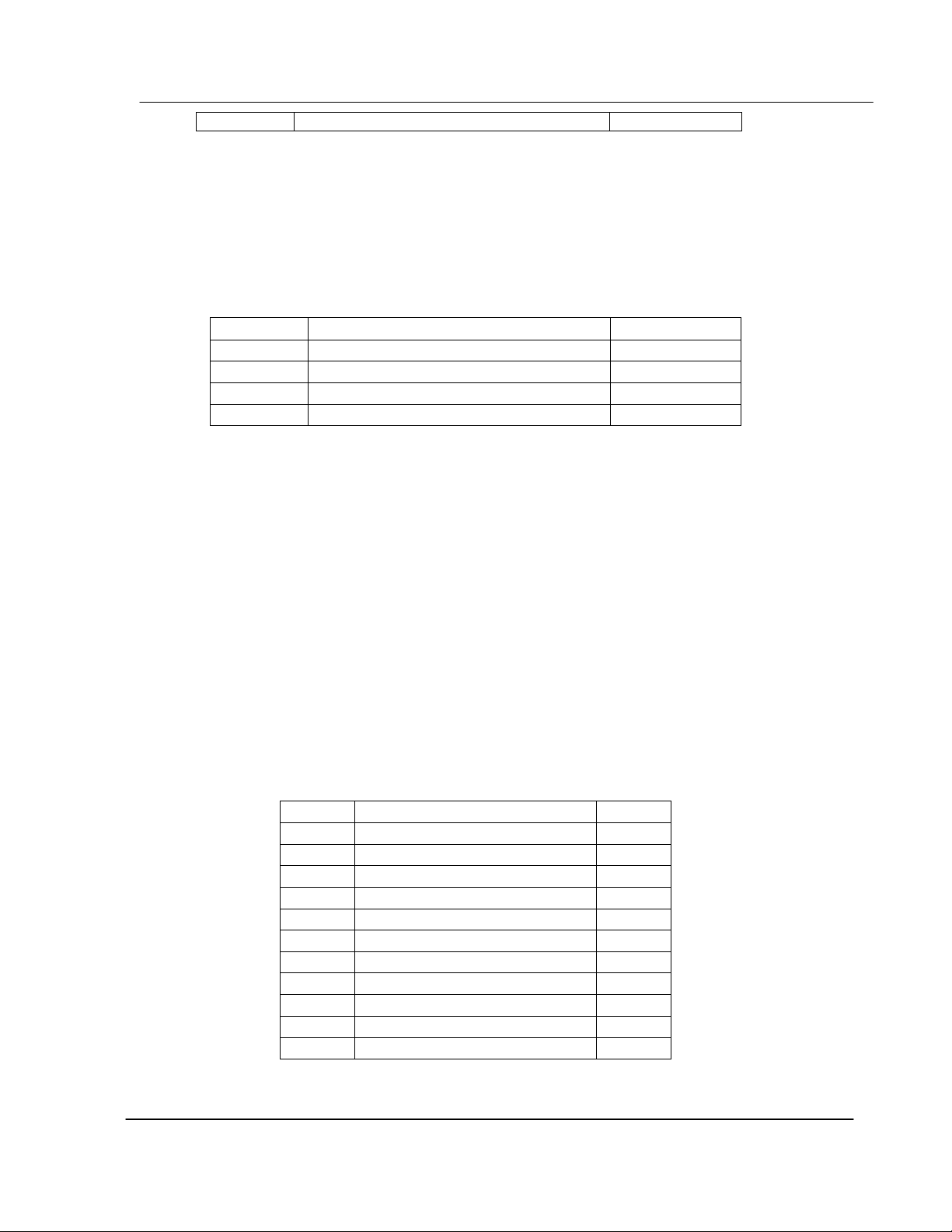

outlines the complete file emulation for the module:

Register Range Content Size

0 – 4999 User Data 5000

5000 – 5099 Backplane Configuration 10

5010 – 5039 Port 1 Setup 30

5040 – 5069 Port 2 Setup 30

5070 – 5199 Reserved 130

5200 – 6399 Port 1 Commands 1200

6400 – 7599 Port 2 Commands 1200

7600 – 7700 Misc. Status Data 200

7800 – 7999 Command Control 200

8000 – 9999 Reserved 2000

All the data in the module is available to a remote host. This permits the host device to

remotely configure the module and view the status data.

Database

Registe

N7:0 ------------> 0

N8:0 ------------> 200

N9:0 ------------> 400

N10:0 ------------> 600

N11:0 ------------> 800

N12:0 ------------> 1000

N13:0 ------------> 1200

N14:0 ------------> 1400

N15:0 ------------> 1600

N16:0 ------------> 1800

N17:0 ------------> 2000

N18:0 ------------> 2200

N19:0 ------------> 2400

N20:0 ------------> 2600

N21:0 ------------> 2800

N22:0 ------------> 3000

N23:0 ------------> 3200

N24:0 ------------> 3400

N25:0 ------------> 3600

N26:0 ------------> 3800

N27:0 ------------> 4000

N28:0 ------------> 4200

N29:0 ------------> 4400

N30:0 ------------> 4600

N31:0 ------------> 4800

N32:0 ------------> 5000

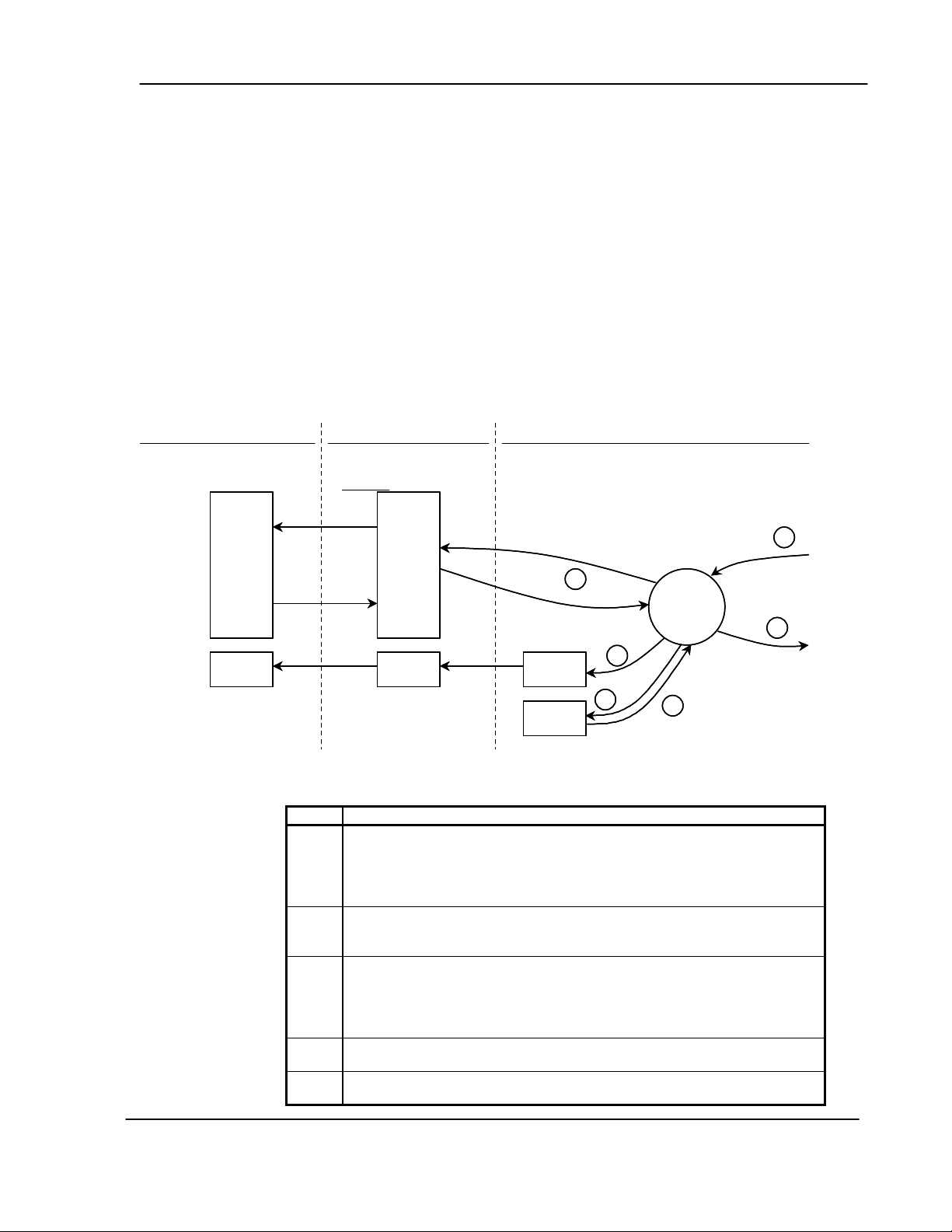

2.5.2 Master Driver Mode

In the Master Mode of operation, the MVI69-DFCM module is responsible for issuing read

or write commands to slave devices on the DF1 network. These commands are user

configured in the module via the Master Command List received from the CompactLogix

processor or issued directly from the CompactLogix processor (event command control).

Command status is returned to the processor for each individual command in the

command list status block. The location of this status block in the module's internal

database is user defined. The following flow chart and associated table detail the flow of

data into and out of the module.

20 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 27

Functional Overview

Processor Memory Backplane Interface

Processor Memory Backplane Interface

User Files Or

User Files Or

Controller Tags

Controller Tags

Register

Register

Data

Data

storage

storage

Status

Status

from Module

from Module

Event Cmd

Event Cmd

Data

Data

Command

Command

Control

Control

Database

Database

Addresses

Addresses

0

0

4999

4999

Register

Register

Data

Data

Status

Status

Event Cmd

Event Cmd

Data

Data

Command

Command

Control

Control

4

4

Status

Status

Configuration

Configuration

Event Cmd

Event Cmd

Data

Data

Command

Command

Control

Control

DFCM Memory

DFCM Memory

5

5

4

4

Master

Master

Command List

Command List

Master

Master

Mode

Mode

Driver

Driver

1

1

Step Description

1 The Master driver obtains configuration data from the internal Compact

Flash disk. The configuration data obtained includes the number of

commands and the Master Command List. These values are used by the

Master driver to determine the type of commands to be issued to the other

nodes on the DF1 network.

2 Once configured, the Master driver begins transmitting read and/or write

commands to the other nodes on the network. If writing data to another

node, the data for the write command is obtained from the module's

internal database to build the command.

3 Presuming successful processing by the node specified in the command, a

response message is received into the Master driver for processing.

4 Data received from the node on the network is passed into the module's

internal database, assuming a read command.

5 Status is returned to the CompactLogix processor for each command in the

Master Command List.

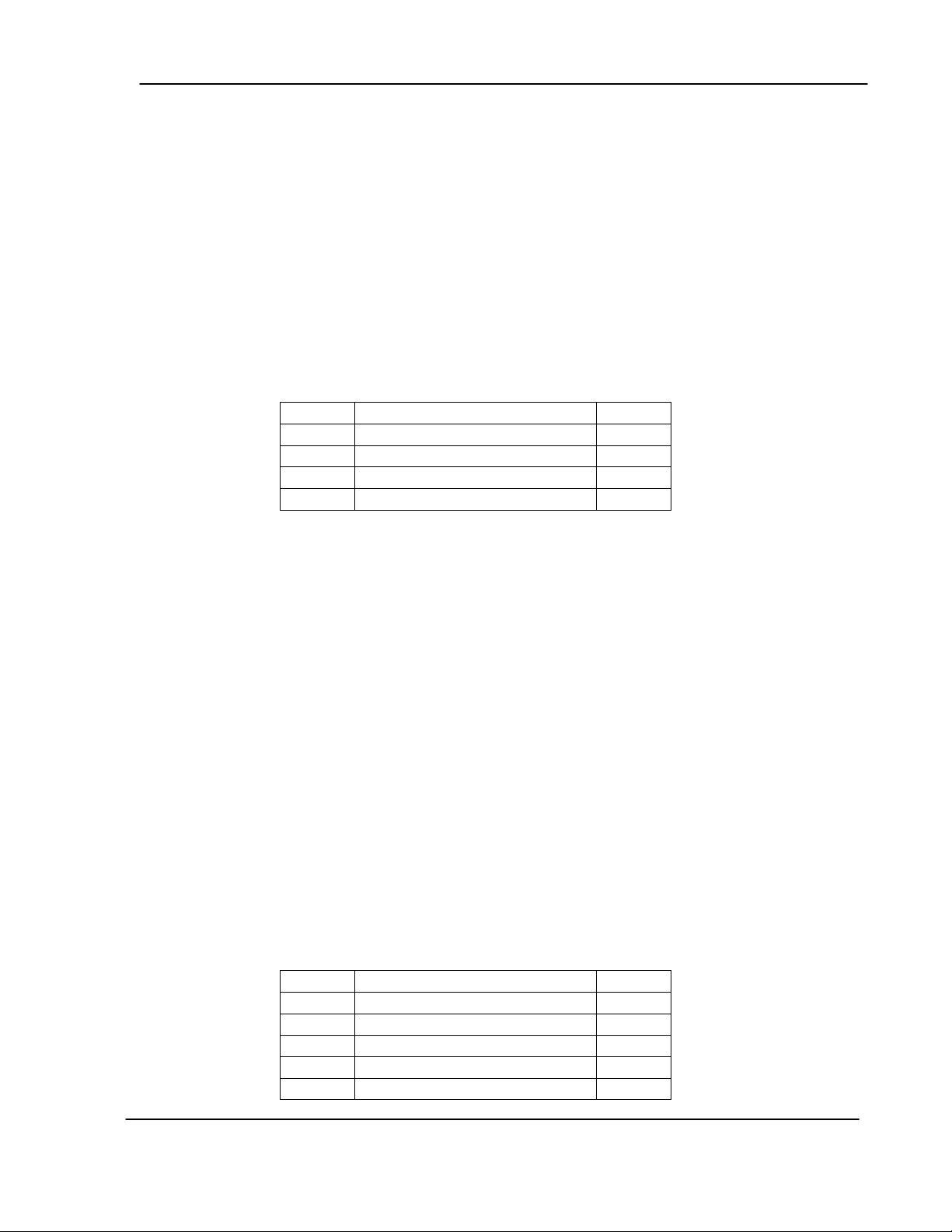

Refer to the appendix for a complete discussion of the structure and content of each

command. Care must be taken in constructing each command in the list for predictable

operation of the module. If two commands write to the same internal database address

of the module, the results will not be as desired. All commands containing invalid data

will be ignored by the module. The following table displays the functions supported by

the module and the format of each command:

3

3

2

2

ProSoft Technology, Inc. 21

MVI69-DFCM User Manual

June 24, 2004

Page 28

A

Functional Overview

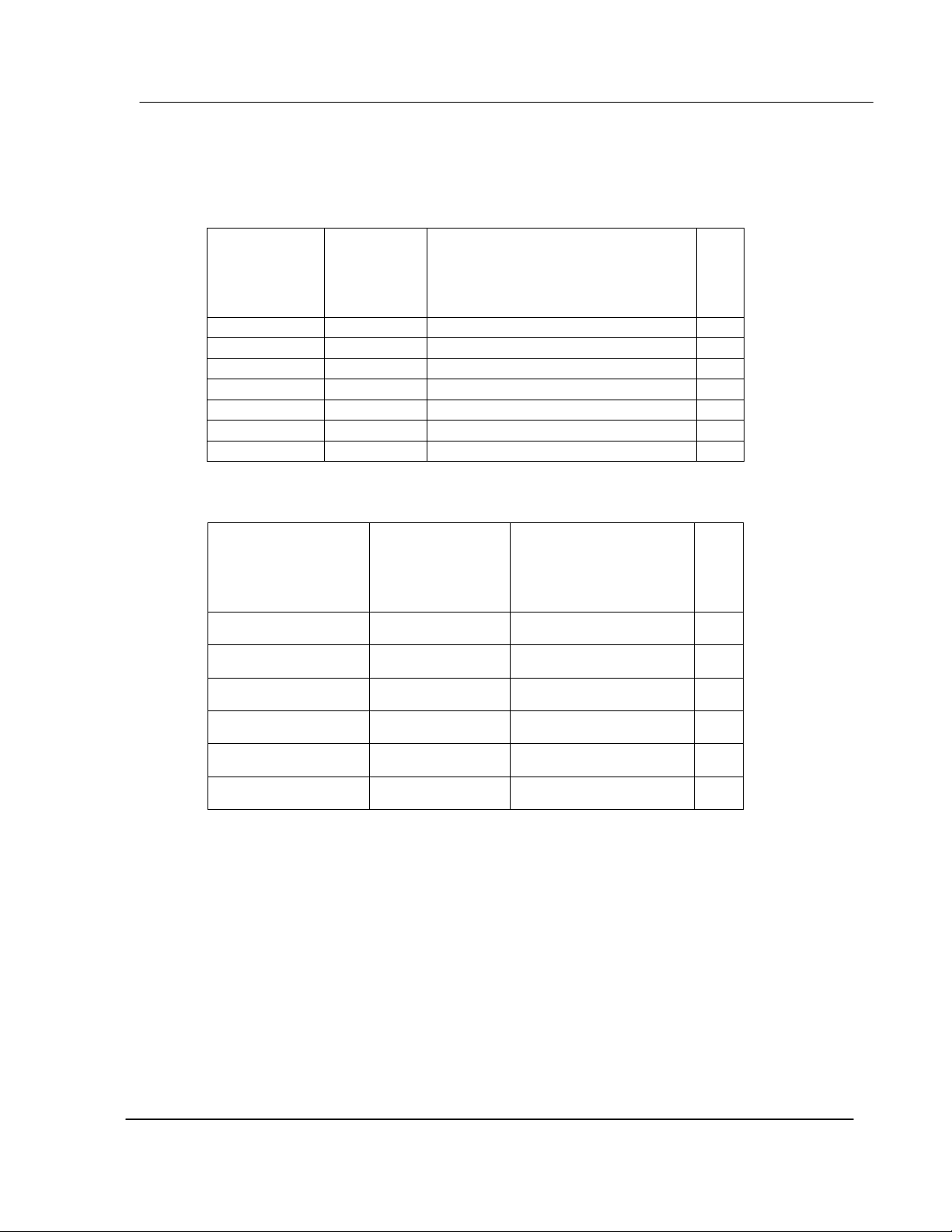

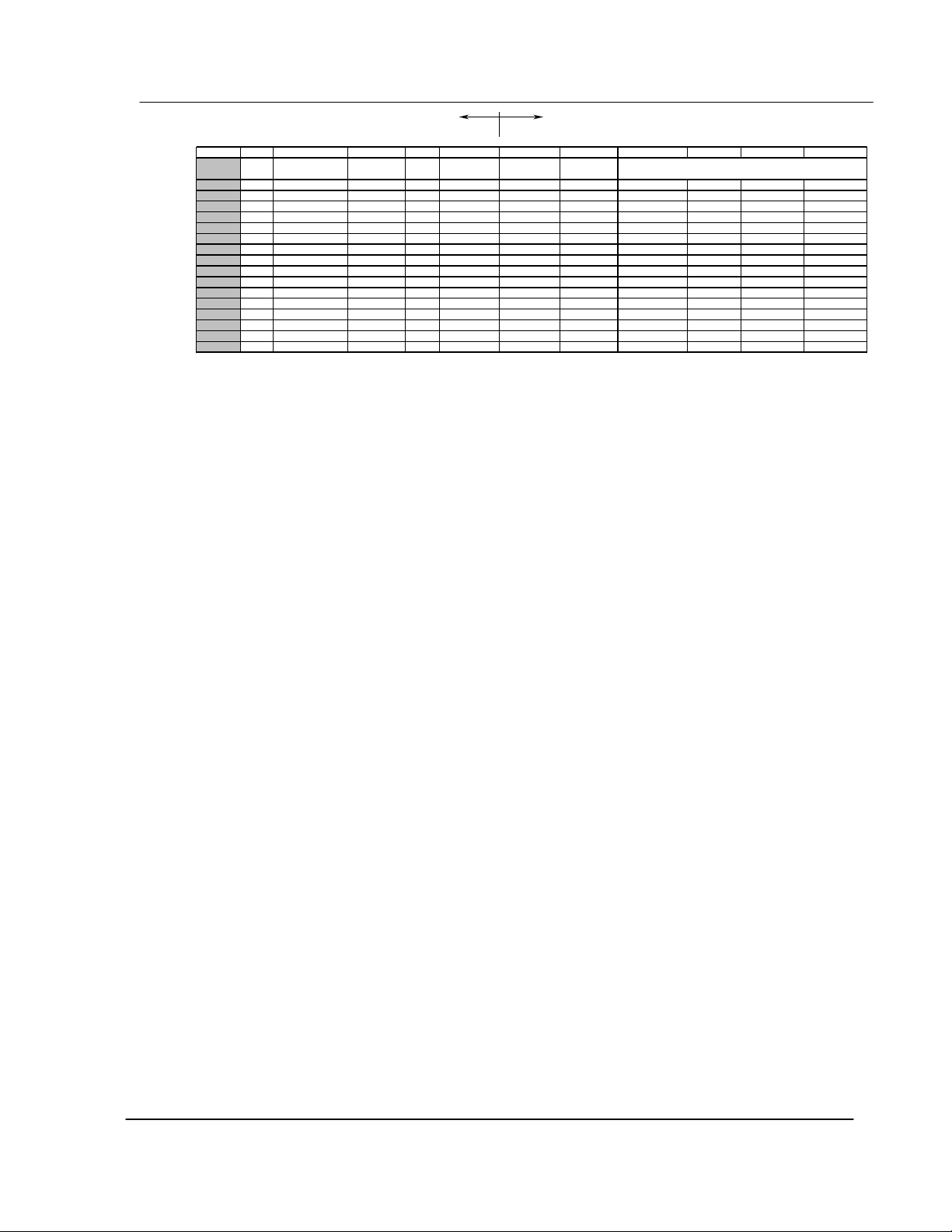

DF1 COMMAND STRUCTURE

Column # 1 2 3 4 5 6 7 8 9 10 11

Function Enable Internal Poll Interval Swap Node Function

Code Code Address Tim e Count Code

FC 1 Code Register Seconds Count Code Node 1 W ord Address

FC 2 Code Register Seconds Count Code Node 2 W ord Address

FC 3 Code Register Seconds Count 0 Node 3 W ord Address

FC 4 Code Register Seconds Count 0 Node 4 W ord Address

FC 5 Code Register Seconds Count Code Node 5 W ord Address

FC 100 Code Register Seconds Count Code Node 100 File Number Element Sub-Element

FC 101 Code Register Seconds Count Code Node 101 File Number Element Sub-Element

FC 102 Code Register Seconds Count 0 Node 102 File Number Element Sub-Element

FC 150 Code Register Seconds Count Code Node 150 File String

FC 151 Code Register Seconds Count Code Node 151 File String

FC 152 Code Register Seconds Count 0 Node 152 File String

FC 501 Code Register Seconds Count Code Node 501 File Type File Number Element

FC 502 Code Register Seconds Count Code Node 502 File Type File Number Element Sub-Element

FC 509 Code Register Seconds Count Code Node 509 File Type File Number Element

FC 510 Code Register Seconds Count Code Node 510 File Type File Number Element Sub-Element

FC 511 Code Register Seconds Count 0 Node 511 File Type File Number Element Sub-Element

Node Address = Destination Address for Message

Module Information Data Device Information Data

ddress Code Function Parameters

22 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 29

Module Configuration

3 Module Configuration

3.1 Power Up

On power up, the module enters into a logical loop waiting to receive configuration data

from the processor. Upon receipt, the module will begin execution of the command list if

it is present.

3.2 Configuration File

In order for the module to operate, a configuration file (DFCM.CFG) is required. This

configuration file contains information to set the data transfer characteristics between the

module and the processor, to configure the communication information, to establish the

DF1 protocol parameters, and to define the databases required to hold the protocol data

sets. Each parameter in the file must be set carefully in order for the application to be

implemented successfully.

The following provides an example of a DFCM configuration file. Please refer to

Appendix F for information on how to transfer the configuration file between the module

and the PC.

# DFCM69_120.CFG

#

# This file contains the configuration for the MVI69-DFCM communication

# module.

#

# LOCATION : Test Bench

# DATE : 02/19/2004

# CONFIGURED BY : RAR

# MODIFIED :

#

# This section is used to define the configuration for the Module level

# data.

#

[Module]

Module Name : Test Example of MVI69-DFCM Communication Module

Backplane Fail Count : 0 #

Error/Status Pointer : 2000 #Location for module status data (-1=ignore)

Block Transfer Size : 120 #Data size for BTR/BTW 60, 120 or 240

Read Register Start : 0 #Starting DB location where data read by processor

Read Register Count : 360 #Number of words transferred to processor (BT size * n)

Write Register Start : 1000 #Starting DB location where data placed by processor

Write Register Count : 240 #Number of words transferred from processor (BT size * n)

ProSoft Technology, Inc. 23

MVI69-DFCM User Manual

June 24, 2004

Page 30

Module Configuration

# This section is used to define the configuration for the DF1 master device

# simulated on Port 1.

#

[DF1 Port 1]

Enabled : Yes #Y=Use port, N=Do not use port

Type : Master #M=Master, S=Slave

Local Station ID : 0 #DF1 node address

Protocol : Full #F=Full-Duplex, H=Half-Duplex

Termination Type : CRC #B=BCC, C=CRC

Baud Rate : 19200 #Baud rate for port 110-115K

Parity : None #N=None,O=Odd,E=Even,M=Mark,S=Space

Data Bits : 8 #5, 6, 7 or 8

Stop Bits : 1 #1 or 2

Minimum Response Delay : 0 #0-65535 mSec before sending response msg

RTS On : 0 #0-65536 mSec before message

RTS Off : 1 #0-65536 mSec after message

Use CTS Line : No #Use CTS modem control line (Y/N)

Response Timeout : 15000 #Response messgage timeout (0-65535 mSec)

Retry Count : 2 #Response failure retry count

ENQ Delay : 0 #0-65535 mSec before DLE-ENQ sent

Minimum Command Delay : 10 #Minimum number of msec's between commands

Error Delay Count : 100 #0-65535 Command cycle count if error

Command Error Pointer : 3000 #Cmd Error list data (-1=ignore)

Slave List Pointer : 3100 #Slave status list data (-1=ignore)

First File : 7 #First file number for SLC simulation

File Size : 200 #Number of elements in each file

File Offset : 0 #Database offset for first file element

[DF1 Port 1 Commands]

# The file contains examples for a SLC 5/03 processor.

#

# LOCATION :

# DATE : 06/24/99

# CONFIGURED BY : RAR

# MODIFIED :

# 07/23/99 -- Set to read more data file types.

#

START

# 1 2 3 4 5 6 7 8 9 10 11

# Internal Poll Swap Node Func File File Elm Sub

# Enable Address Interval Count Code Address Code Type # # Elm

24 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 31

Module Configuration

1 10 0 10 0 1 501 N 7 0

1 1500 0 10 0 1 502 N 7 0 0

1 10 0 10 0 1 509 N 7 10

END

[DF1 Port 1 OVERRIDE DATA FILE MAPS]

# DB File First Word

# Address Number Element Length

START

END

# This section is used to define the configuration for the DF1 slave device

# simulated on Port 2.

#

[DF1 Port 2]

Enabled : Yes #Y=Use port, N=Do not use port

Type : Slave #M=Master, S=Slave

Local Station ID : 1 #DF1 node address

Protocol : FULL #F=Full-Duplex, H=Half-Duplex

Termination Type : CRC #B=BCC, C=CRC

Baud Rate : 19200 #Baud rate for port 110-115K

Parity : None #N=None,O=Odd,E=Even,M=Mark,S=Space

Data Bits : 8 #5, 6, 7 or 8

Stop Bits : 1 #1 or 2

Minimum Response Delay : 0 #0-65535 mSec before sending response msg

RTS On : 0 #0-65536 mSec before message

RTS Off : 1 #0-65536 mSec after message

Use CTS Line : No #Use CTS modem control line (Y/N)

Response Timeout : 1000 #Response messgage timeout (0-65535 mSec)

Retry Count : 2 #Response failure retry count

ENQ Delay : 0 #0-65535 mSec before DLE-ENQ sent

Minimum Command Delay : 0 #Minimum number of msec's between commands

Error Delay Count : 100 #0-65535 Command cycle count if error

Command Error Pointer : -1 #Cmd Error list data (-1=ignore)

Slave List Pointer : -1 #Slave status list data (-1=ignore)

First File : 7 #First file number for SLC simulation

File Size : 200 #Number of elements in each file

File Offset : 0 #Database offset for first file element

[DF1 Port 2 Commands]

# The file contains examples for a SLC 5/03 processor.

ProSoft Technology, Inc. 25

MVI69-DFCM User Manual

June 24, 2004

Page 32

Module Configuration

#

# LOCATION :

# DATE : 06/24/99

# CONFIGURED BY : RAR

# MODIFIED :

# 07/23/99 -- Set to read more data file types.

#

START

# 1 2 3 4 5 6 7 8 9 10 11

# Internal Poll Swap Node Func File File Elm Sub

# Enable Address Interval Count Code Address Code Type # # Elm

END

[DF1 Port 2 OVERRIDE DATA FILE MAPS]

# DB File First Word

# Address Number Element Length

START

3500 200 0 100

3600 230 0 200

END

The text file is separated into 5 sections with topic header names enclosed in the [ ]

characters. The sections present in the file are as follows:

[Section] Description

[Module] Used to define the configuration for module-level data

[DF1 Port x] Used to define the configuration for the DF1 master device

simulated on Port x.

DF1 Port x

Used to define the commands on the specified port

Commands

DF1 Port x Override

Data File Maps

Used to override the slave default mapping in specific database

ranges

After each section header, the file contains a set of parameters. Unique labels are used

under each section to specify a parameter. Each label in the file must be entered exactly

as shown in the file for the parameter to be identified by the program. If the module is not

considering a parameter, check the label for the data item. Each parameter's value is

separated from the label with the ':' character. This character is used by the program to

delimit the position in the data record where to start reading data. All data for a

parameter must be placed after the ':' character. For numeric parameter values, any text

located after the value will not be used. There must be at least one space character

between the end of the parameter value and the following text. The following example

shows a parameter entry:

RTS On : 6 #Set RTS On delay value from 0 to 65535 milliseconds

The parameter label is "RTS On" and the parameter value is 6. The characters after the

parameter value are ignored and are used for internal documentation of the configuration

file.

26 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 33

Module Configuration

Any record that begins with the '#' character is considered to be a comment record.

These records can be placed anywhere in the file as long as the '#' character is found in

the first column of the line. These lines are ignored in the file and can be used to provide

documentation within the configuration file. Liberal use of comments within the file can

ease the use and interpretation of the data in the file.

Sections of the configuration file that contain lists of data are formatted differently. Each

list begins with the label START and ends when the END label is reached. When

entering the list data, make certain that the first character in each line is left blank.

Refer to Appendix C for a description of configuration file parameters.

Changing parameters during operation

A copy of the module's configuration data is mapped in the module's database as

displayed in the following table. These values are initialized when the module first

receives its configuration from the configuration file.

Module

Register

Address

5000-5009 Data

5010-5039

and

5040-5069

5200-6399

and

6400-7599

Functional

Modes

Affected

General Module

Transfer

Master and

Slave

Master Master Command

Configuration

Port Configuration These sections are used to define the

List

Name

Description

This section of the configuration data contains

the module configuration data that defines the

data transfer between the module and the

CompactLogix processor.

characteristics of each of the DF1 serial

communication ports on the module. These

parameters must be set correctly for proper

module operation.

If the module’s Master Mode functionality is to

be supported on a port, the Master Command

List must be set up.

The configuration file is located in the module as well as on the CD and website. With a

new module, ProSoft recommends that you download the configuration file from the

module for editing. Refer to Appendix F for information on uploading and downloading

the configuration file.

3.3 Setting Up the Module

Set up of the MVI69-DFCM module only requires software configuration using the

RSLogix 5000 program. The easiest method to implement the module is to start with the

example provided with the module (MVI69DFCM.ACD). If you are installing this module

in an existing application, you can simply copy the elements required from the example

ladder logic to your application. NOTE: The module can only be added to a project using

the software in offline mode.

The first step in setting up the module is to define the module to the system. Right-click

the mouse button on the I/O Configuration option in the Controller Organization window

to display a pop-up menu. Select the New Module… option from the I/O Configuration

menu.

ProSoft Technology, Inc. 27

MVI69-DFCM User Manual

June 24, 2004

Page 34

Module Configuration

This will cause the program to display the following dialog box.

Select the 1756-Module (Generic 1756 Module) from the list and select the OK button.

You should configure the Connection Parameters according to the Block Transfer Size

parameter in the configuration file as follows:

28 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 35

Module Configuration

Block Transfer Size = 60

Block Transfer Size = 120

ProSoft Technology, Inc. 29

MVI69-DFCM User Manual

June 24, 2004

Page 36

Module Configuration

Block Transfer Size = 240

Fill in the dialog boxes as shown adjusting the Name, Description and Slot options for

your application. Be certain to select the Comm F

Failure to set the Assembly Instance and Size values correctly will result in a module

that will not communicate over the backplane of the CompactLogix rack. Select the Next

command button to display the next dialog box.

ormat as Data - INT in the dialog box.

Select the Request Packet Interval value for scanning the I/O on the module. This value

represents the minimum frequency the module will handle scheduled events. This value

should not be set to less than 1 millisecond. Values between 1 and 10 milliseconds

should work with most applications.

After completing the module setup, the Controller Organization window will display the

module’s presence. The data required for the module will be defined to the application,

and objects will be allocated in the Controller Tags data area. An example of the

Controller Organization window follows.

30 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 37

Module Configuration

The next step in the module’s setup is to define the User Defined Data Types to be used

with the module. Copy these data types from the example ladder logic if you are not

using the example. They will be defined if you are starting from the example ladder logic.

The Controller Organization window should display the User Defined Data Types shown

below:

The next step in module setup is to define the data to be used to interface with the

module and the ladder logic. Open the Controller Tags Edit Tags dialog box and enter

the values shown in the following example. The MVI69-DFCM module is defined in the

example as DFCM1. You can set the tag name to any valid tag name you desire. If you

are using the example ladder logic, this step has already been performed.

ProSoft Technology, Inc. 31

MVI69-DFCM User Manual

June 24, 2004

Page 38

Module Configuration

At this point, take the time to fill in the configuration values in the DFCM1 data table and

adjust array sizes. Refer to the Module Data Object section of this document for

information on configuring the module.

The last step in the module setup is to add the ladder logic. If you are using the example

ladder logic, adjust the ladder to fit your application. If you are not using the ladder

example, copy the ladder logic shown in the Controller Organization window below to

your application.

The module is now set up and ready to be used with your application. Insert the module

in the rack and attach the DF1 serial communication cables. Download the new

application to the controller and place the processor in run mode. If all the configuration

parameters are set correctly and the module is attached to a DF1 network, the module’s

Application LED (APP LED) should remain on and the backplane activity LED (BP ACT)

should blink very rapidly. Refer to the Diagnostics and Troubleshooting section of the

if you encounter errors. Attach a computer or terminal to Port 1 on the module and check

the status of the module using the resident debugger in the module. Refer to the

Diagnostics and Troubleshooting section for a complete discussion of the use of this

feature.

3.3.1 Module Data Object (DFCMModuleDef)

All data related to the MVI69-DFCM is stored in a user defined data type. An instance of

the data type is required before the module can be used. This is done by simply

declaring a variable of the data type in the Controller Tags Edit Tags dialog box. The

structure of the object is displayed in the figure below:

32 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 39

Module Configuration

This object contains objects that define the configuration, user data, status and command

control data related to the module. Each of these object types is discussed in the

following sections of the document.

ProSoft Technology, Inc. 33

MVI69-DFCM User Manual

June 24, 2004

Page 40

Module Configuration

3.4 Status Object (DFCM_STATUS)

This object is used to view the status of the module. The DFCM_STATUS object shown

below is updated each time a read block is received by the processor. This data can be

used to monitor the state of the module at a "real-time rate".

Refer to Appendix B for a complete listing of the data stored in this object.

3.5 User Data Objects

These objects are used to hold data to be transferred between the processor and the

MVI69-DFCM module. The user data is the read and write data transferred between the

processor and the module as "pages" of data up to 60, 120, or 240 words long depending

on the Block Transfer Size parameter.

The read data array should be dimensioned according to the Read Data Count parameter

in the configuration file. The ReadData task is responsible for placing the data received

into the proper position in the read data array. This data can be used for status and

control in the ladder logic of the processor.

The write data array should be dimensioned according to the Read Data Count

parameter in the configuration file. . The WriteData task is responsible for placing the

write data into the output image for transfer to the module.

34 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 41

Module Configuration

3.6 Slave Polling Control and Status

Two arrays are allocated in the processor to hold the polling status of each slave on the

master ports. This status data can be used to determine which slaves are currently

active on the port, are in communication error or have their polling suspended and

disabled. Ladder logic in the processor can be written to monitor and control the status of

each slave on a master port. The objects used are displayed below:

3.7 DFCM Slave Polling Control (DFCMSlavePollingControl)

This user-defined data type is used to send the Enable/Disable blocks to control the slave

polling with blocks 3000, 3001, 3100 or 3101.

ProSoft Technology, Inc. 35

MVI69-DFCM User Manual

June 24, 2004

Page 42

Module Configuration

3.8 Event Command (DFCMEventCommand)

This data type is used to issue event commands to the modules using blocks 1000 and

2000.

36 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 43

Module Configuration

3.9 Command Control (DFCMCommandControl)

This data type is used to issue command control commands to the module using blocks

5000 to 5006 or 5100 to 5106.

3.10 Clock (DFCMClock)

This data type is used to issue clock commands.

ProSoft Technology, Inc. 37

MVI69-DFCM User Manual

June 24, 2004

Page 44

Page 45

Ladder Logic

4 Ladder Logic

Ladder logic is required for application of the MVI69-DFCM module. Tasks that must be

handled by the ladder logic are module configuration, data transfer, special block

handling and status data receipt. This section discusses each aspect of the ladder logic

as required by the module. Additionally, a power-up handler should be written to handle

the initialization of the module's data and to clear any processor fault conditions.

The Controller Organization window for the example ladder logic for the MVI69-DFCM

module is shown below.

4.1 MainRoutine

The first rung copies the block transfer size value to be used in the ladder logic. This

value (60, 120, or 240) should match the “Block Transfer Size” parameter in the

configuration file.

The following routine is used to initialize the ladder logic after a boot request:

ProSoft Technology, Inc. 39

MVI69-DFCM User Manual

June 24, 2004

Page 46

Ladder Logic

The MainRoutine is used to recognize the presence of new read data from the module for

the processor. The module will cycle through its list of read blocks to transfer data from

the module to the processor. Whenever new data is available, the module will set the

value for the block in the module's input image (Local:1:I:Data[249]). The ladder logic

must constantly scan this input word for a new value. When a new value is present, the

ladder logic should perform the ReadData and WriteData tasks in that order.

4.2 ReadData

The ReadData task is responsible for handling all new data received from the module

and placing it in the proper location in the processor. Data is transferred from the module

to the processor using the module's input image (Local:1:I:Data[]). The first rung of the

task sets the last read block number (DFCM1.BP.LastRead) from the current block

number sent from the module (Local:1:I:Data[0]).

The module sends all the status data in blocks with identification codes of 0 and -1:

40 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 47

Ladder Logic

The next rung of the ladder logic determines if the new data received in the input image is

user data. If user data is present, the ladder logic will place the data in the correct

location in the processor's read data area (DFCM1.ReadData[]). Up to 60, 120, or 240

data words can be transferred in each block transfer depending on the Block Transfer

Size parameter.

The next two rungs of ladder logic are used to handle the receipt of the slave node status

data. These blocks are requested by the processor in the WriteData task and sent from

ProSoft Technology, Inc. 41

MVI69-DFCM User Manual

June 24, 2004

Page 48

Ladder Logic

the module to the processor. The two rungs below display the logic required to process

these blocks:

The following ladder rungs handle the command control block responses for Port 1 and

Port 2.

The following rung handles the block 9973 response from the module to the processor to

read the time and date information.

42 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 49

Ladder Logic

4.3 WriteData

The WriteData task is responsible for sending data from the processor to the MVI69DFCM module. Data is transferred from the processor to the module using the module's

output image (Local:1:O:Data[]). The first rung is used to store the currently requested

data set in the module's DFCM1.BP.LastWrite data object. This object is used in all

subsequent ladder logic in case the input word (Local:1:I:Data[1]) changes during

processing.

The next two rungs are used to handle processor control of the module using the warmand cold- boot control block numbers. When the processor requires the module to

perform one of these operations, it simply copies the block number into the output image

of the module and the module will perform the operation.

ProSoft Technology, Inc. 43

MVI69-DFCM User Manual

June 24, 2004

Page 50

Ladder Logic

The next 10 rungs are used to request the slave node status data associated with each

master port. Five requests are required for each port in order to obtain the data for the

potential 256-slave addresses on a port. The ladder logic below displays that required to

obtain the data for Port 1:

44 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 51

Ladder Logic

ProSoft Technology, Inc. 45

MVI69-DFCM User Manual

June 24, 2004

Page 52

Ladder Logic

The next five rungs display the logic for Port 2 slave status/control data:

46 ProSoft Technology, Inc.

MVI69-DFCM User Manual

June 24, 2004

Page 53

Ladder Logic

The next rung displays an example of command control. This block of data is passed

from the processor to the module to execute a command in the master port’s command

list.

Up to six commands can be transferred from the command list to the command queue

with one request.

The next rung is used to issue an event message (user constructed message) on Port 1.

ProSoft Technology, Inc. 47

MVI69-DFCM User Manual

June 24, 2004

Page 54

Ladder Logic

When the DFCM.BlockRequest.EventCommandP1 bit is set, the rung will execute. It will

place the command contained in the rung in the command queue for execution. This

technique can be used to issue commands on a port without constructing a master

command list or to execute commands that are to be issued under special conditions.

If the module is configured for no or only one block transfer, special processing is