Page 1

MVI56E-AFC

Enhanced Liquid and Gas Flow

Computer for ControlLogix®

v4.04

October 2, 2018

SETUP AND CONFIGURATION GUIDE

Page 2

For professional users in the European Union

If you wish to discard electrical and electronic equipment (EEE), please contact your dealer or supplier

for further information.

Warning – Cancer and Reproductive Harm – www.P65Warnings.ca.gov

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology, Inc.

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

© 2018 ProSoft Technology, Inc. All rights reserved.

October 2, 2018

ProSoft Technology®, is a registered copyright of ProSoft Technology, Inc. All other brand or product names are or

may be trademarks of, and are used to identify products and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are available at:

www.prosoft-technology.com

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501 to 4

(b) of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the

Canadian Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The

following warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

I, DIV. 2.

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

Class 2

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Page 3

Warnings

North America Warnings

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501 to 4

(b) of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the

Canadian Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The

following warnings must be heeded:

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

C Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

Avertissement - Risque d'explosion - Avant de déconnecter l'équipement, couper le courant ou s'assurer que

l'emplacement est désigné non dangereux.

D Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

back up the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Electrical Ratings

Backplane Current Load: 800 mA @ 5.1 Vdc; 3 mA @ 24 Vdc

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Shock: 30 g, operational; 50 g, non-operational; Vibration: 5 g from 10 Hz to 150 Hz

Relative Humidity: 5% to 95% with no condensation

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Agency Approvals and Certifications

Please visit our website: www.prosoft-technology.com

Page 4

Contents MVI56E-AFC ♦ Version 4.04

Contents

Your Feedback Please ........................................................................................................ 2

Important Installation Instructions ........................................................................................ 2

MVI (Multi Vendor Interface) Modules ................................................................................. 2

Warnings .............................................................................................................................. 3

Battery Life Advisory ............................................................................................................ 3

1 Before You Begin ..................................................................................... 9

Pre-Configuration Processes ..................................................................................... 9

Pre-Configuration Requirements ............................................................................. 10

Downloading EAFC Manager ............................................................................. 10

Downloading AOIs to your system ..................................................................... 11

Locating information for your meter type ................................................................. 12

Configuration Aids.................................................................................................... 14

Using the Modbus Dictionary ................................................................................... 16

Procedure ........................................................................................................... 18

2 Creating an EAFC Manager Project ...................................................... 21

Starting EAFC Manager ........................................................................................... 21

3 Configuring Site Parameters ................................ ................................. 23

Accessing Site Configuration Parameters ............................................................... 23

Configuring Site Options ..................................................................................... 26

Configuring Pass-thru Options ........................................................................... 27

Viewing Site Configuration Status ........................................................................... 27

UDT Tag Prefix ........................................................................................................ 28

Exporting UDT Files ............................................................................................ 29

Setting Communication Parameters ........................................................................ 31

Configuring Modbus TCP/IP ............................................................................... 33

Setting Whitelist Options .......................................................................................... 37

Advanced Tab ..................................................................................................... 38

Configuring Serial 1 and Serial 2 ........................................................................ 40

Poll Button ................................................................................................................ 44

Local Port Settings Dialog Box ................................................................................ 44

Read Button ............................................................................................................. 45

Write Button ............................................................................................................. 45

Special Wnd Button ................................................................................................. 45

Done Button ............................................................................................................. 46

Remapping Button ................................................................................................... 46

Accessing the Data .................................................................................................. 46

Site Status ................................................................................................................ 46

4 Configuring Meter Parameters .............................................................. 47

Prerequisites ............................................................................................................ 47

Page 4 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 5

MVI56E-AFC ♦ Version 4.04 Contents

What Parameters Do I Have to Configure? ............................................................. 47

Configuring Meter and Stream Identification Parameters ....................................... 48

Setting End of Period Parameters ...................................................................... 49

Setting a Stream Name ...................................................................................... 51

Configuring Meter Type, Product Group, Units, and Primary Input ......................... 52

Selecting and Configuring Meter Type, Product Group, Units and Primary Input

Parameters .............................................................................................................. 53

Product Group .................................................................................................... 55

System of Units ................................................................................................... 55

5 Configuring Common Parameters ......................................................... 57

Selecting the Physical Device .................................................................................. 58

Specifying Reference Temperature and Pressure (Reference Conditions) ............ 60

Setting Accumulators and Flow Rates ..................................................................... 61

Flow Rate Period Unit ......................................................................................... 61

Flow Rate Unit .................................................................................................... 61

Accumulation Unit ............................................................................................... 62

Accumulator Rollover.......................................................................................... 62

Configuring Process Input Scaling........................................................................... 63

Zero Scale .......................................................................................................... 63

Full Scale ............................................................................................................ 63

Enabling/Disabling the Meter (Control Opts) ........................................................... 64

Backplane Return .................................................................................................... 64

Process Inputs .................................................................................................... 64

Component Analysis Function Block .................................................................. 64

Configuring Calculation Options .............................................................................. 66

Configuring Resettable Accumulators ..................................................................... 67

Non-Resettable Accumulators ............................................................................ 68

Resettable Accumulators .................................................................................... 69

Net Accumulator Calculation .............................................................................. 74

Accumulator Totalizer and Residue .................................................................... 75

Meter Factors ........................................................................................................... 75

Meter Alarm Control Options ................................................................................... 76

Setting Stream Options and Enabling/Disabling Meters ......................................... 78

ProSoft Technology, Inc. Page 5 of 149

October 2, 2018

Page 6

Contents MVI56E-AFC ♦ Version 4.04

6 Configuring Differential Meter Parameters ........................................... 81

7 Configuring Linear Meter Pulse Count Options ................................... 85

8 Configuring Linear Meter Pulse Frequency Options ........................... 87

9 Configuring Gas Parameters ................................................................. 88

10 Configuring Liquid Parameters ............................................................. 91

11 Configuring Density Units ..................................................................... 95

12 Configuring Primary Input Characteristics .......................................... 96

13 Configuring K-factor Characteristics .................................................... 97

14 Configuring Meter Factors................................................................... 101

15 Installing the Module in the Rack ........................................................ 105

Module Initialization ............................................................................................... 105

16 Connecting the MVI56E-AFC to the EAFC Manager .......................... 107

17 Downloading the Project to the MVI56E-AFC ..................................... 111

18 Creating a RSLogix Project and Importing an AOI ............................ 113

Create an RSLogix Project .................................................................................... 113

Importing the AOI Rungs ....................................................................................... 116

Configuring the AOIs ............................................................................................. 121

19 Using the MVI56E-AFC Web Page ....................................................... 123

Firmware Upgrade Link ......................................................................................... 124

Component Integrity Link ....................................................................................... 125

Software Component Detail Information ........................................................... 126

Component Integrity Page Operation ............................................................... 127

Verification ........................................................................................................ 128

Monitor ................................................................................................................... 128

Site Configuration ............................................................................................. 130

Page 6 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 7

MVI56E-AFC ♦ Version 4.04 Contents

Meter Configuration .......................................................................................... 133

Stream Configuration ........................................................................................ 135

Meter Calculations ............................................................................................ 136

Meter Accumulators .......................................................................................... 138

Meter Status ..................................................................................................... 139

Data Displays .................................................................................................... 141

20 What’s Next? ......................................................................................... 143

21 Support, Service and Warranty ............................................................ 145

Contacting Technical Support ................................................................................ 145

Warranty Information ............................................................................................. 147

22 Index ................................................................ ...................................... 149

ProSoft Technology, Inc. Page 7 of 149

October 2, 2018

Page 8

Contents MVI56E-AFC ♦ Version 4.04

Page 8 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 9

MVI56E-AFC ♦ Version 4.04 Before you Begin

1 Before You Begin

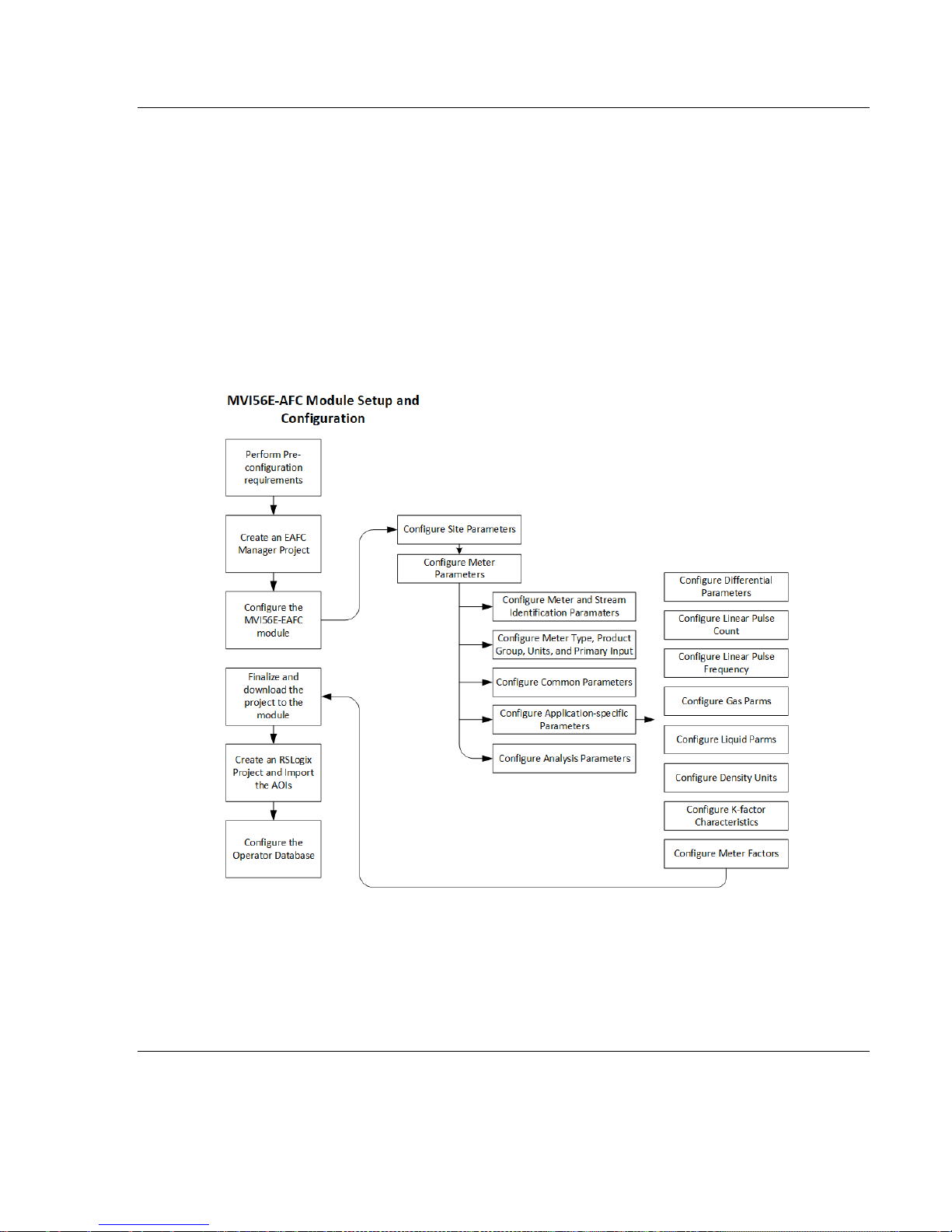

Pre-Configuration Processes

This section describes the pre-configuration process. There are a small number

of tasks to complete before configuring your MVI56E-AFC project.

The following flow illustrates the full configuration process.

ProSoft Technology, Inc. Page 9 of 149

October 2, 2018

Page 10

Before you Begin MVI56E-AFC ♦ Version 4.04

Pre-Configuration Requirements

Before you start to configure the MVI56E-AFC, you must:

Download EAFC Manager software

Download the MVI56E-AFC Add-On Instructions (AOIs)

Downloading EAFC Manager

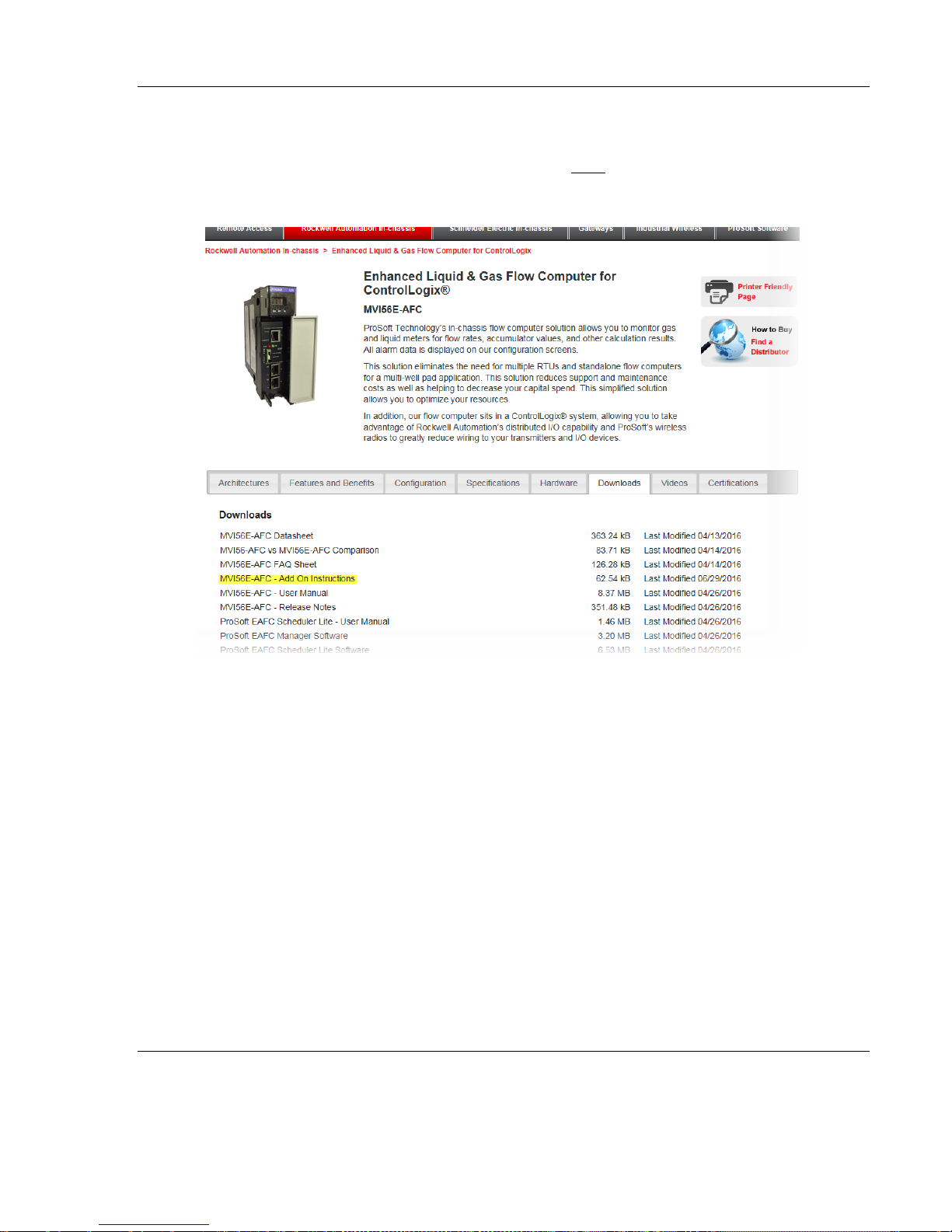

The EAFC Manager can be downloaded from the ProSoft Technology website.

1 Navigate to the MVI56E-AFC webpage found here.

2 Click on the DOWNLOADS tab.

3 Click on the PROSOFT EAFC MANAGER link and follow the prompts to

download and install the application.

Note: Leave this page open. You will also be downloading AOIs from this page as described in the

next section.

Page 10 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 11

MVI56E-AFC ♦ Version 4.04 Before you Begin

Downloading AOIs to your system

1 Navigate to the MVI56E-AFC webpage found here.

2 Click on the DOWNLOADS tab.

3 Select MVI56E-AFC ADD ON INSTRUCTIONS.

The AOIs are downloaded as a zip file.

The zip file contains the Main AOI as well as four additional AOIs that pertain to

your meter application. The four additional AOIs include:

Linear Gas

(MVI56E-AFC_AddOn_Rung_MeterLinearGas_vx_x.L5X)

Linear Liquid

(MVI56E-AFC_AddOn_Rung_MeterLinearLiquid_vx_x.L5X)

Differential Liquid

(MVI56E-(AFC_AddOn_Rung_MeterDifferentialLiquid_vx_x.L5X)

Differential Gas

(MVI56E-AFC_AddOn_Rung_MeterDifferentialGas)vx_x.L5X)

ProSoft Technology, Inc. Page 11 of 149

October 2, 2018

Page 12

Before you Begin MVI56E-AFC ♦ Version 4.04

Meter Type

Configured As (Differential or Linear)

Turbine

Linear

Positive

Displacement

Linear

Magnetic

Linear

Orifice

Differential

V-Cone

Differential. You must configure the meter as V-Cone type in the MVI56E-AFC

Manager (Meter Configuration / Calculation Options)

Wedge

Differential. Refer to Wedge Meter Applications for information about using the

wedge meters.

Vortex

Linear or Differential

Ultrasonic

Linear or Differential

Coriolis

Linear or Differential

Download the Main AOI and the AOI file that pertains to your meter type. For

instance, if the MVI56E-AFC is going to be used for Differential Gas meter runs,

you only need the MVI56E-AFC_MeterDifferentialGas_Vx_x.L5X file.

You will use these files when you set up your RSLogix project later in this guide.

Locating information for your meter type

MVI56E-AFC supports the following meters:

Note: Due to the broad range of meters in the market today, refer to the manufacturer specification

to evaluate the use of the module (even if listed here).

Note: For Vortex, Ultrasonic, or Coriolis meters, the selection depends on the output generated by

the meter.

If the meter provides a pulse train representing the volume increment, the

MVI56E-AFC should be configured as linear with the primary input set to Pulse

Count.

If the meter provides instantaneous flow rate, the MVI56-AFC should be

configured as differential with the primary input set to Flow Rate.

Page 12 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 13

MVI56E-AFC ♦ Version 4.04 Before you Begin

What type of meter

are you

configuring?

What is the primary

output from your flow

meter and associated

instrumentation?

Configure your

meter type as…

Configure your

primary input as…

Orifice Meter

Differential Pressure

Differential

Differential Pres

V-Cone Meter

Differential Pressure

Differential

Differential Pres

Wedge Meter

Differential Pressure

Differential

Differential Pres

Coriolis Meter

Flow Rate

Differential

Flow Rate

Pulse Count and Pulse

Frequency

Linear

Pulse Count

Pulse Frequency Only

Linear

Pulse Frequency

Vortex Meter

Flow Rate

Differential

Flow Rate

Pulse Count and Pulse

Frequency

Linear

Pulse Count

Pulse Frequency Only

Linear

Pulse Frequency

Ultrasonic Meter

Flow Rate

Differential

Flow Rate

Pulse Count and Pulse

Frequency

Linear

Pulse Count

Pulse Frequency Only

Linear

Pulse Frequency

Turbine Meter

Pulse Count and Pulse

Frequency

Linear

Pulse Count

Pulse Frequency

Linear

Pulse Frequency

Pulse Count

Linear

Pulse Count

Positive

Displacement

Same as Turbine

Magnetic

Same as Turbine

To locate configuration information about your meter, refer to the following table:

The following sections provide configuration steps based on:

Meter Type

Primary Meter Output

What’s being measured

Locate the configuration steps for your application and then use the links

provided to jump to the sections of this manual that only apply to you.

ProSoft Technology, Inc. Page 13 of 149

October 2, 2018

Page 14

Before you Begin MVI56E-AFC ♦ Version 4.04

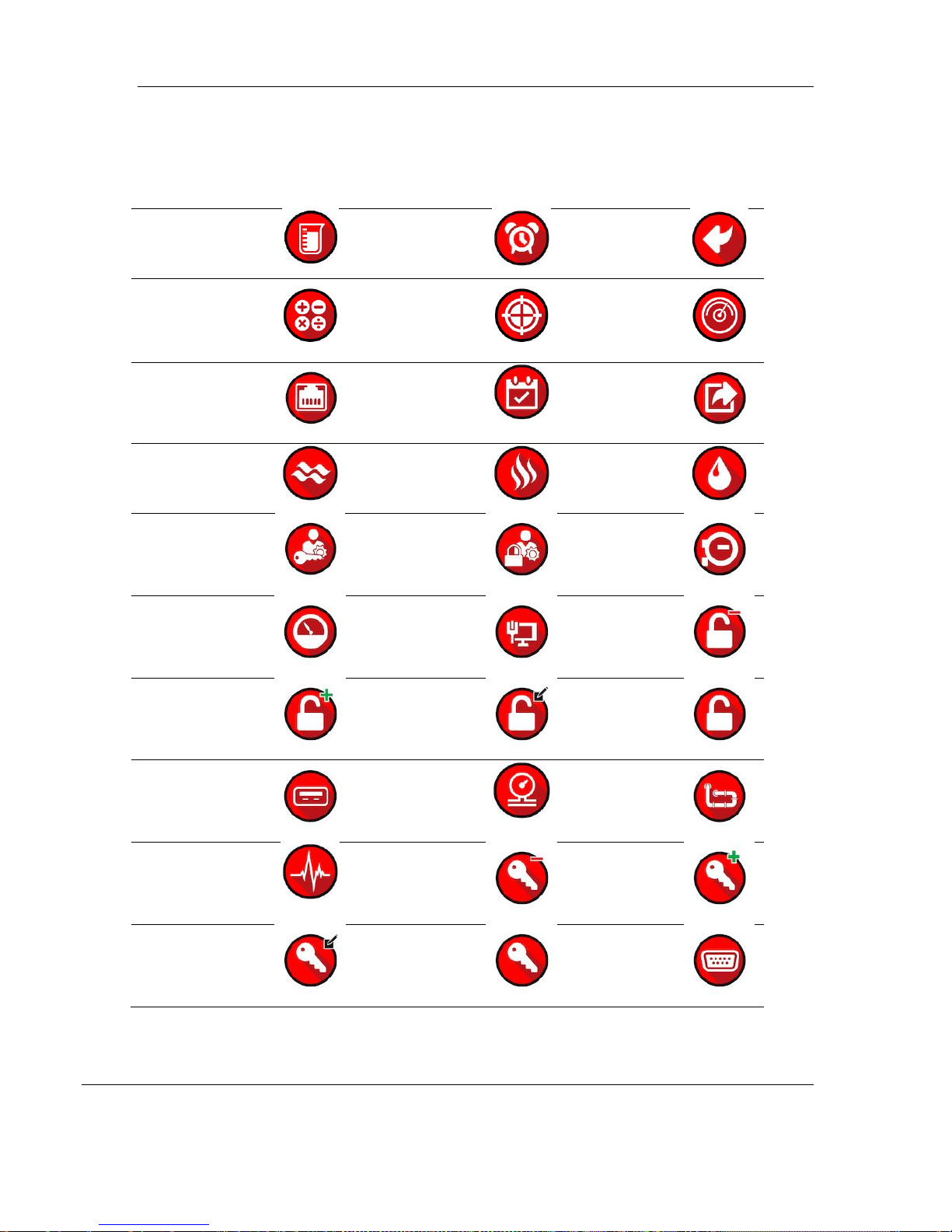

Accumulator

Alarm

Back

Calculate

Calibrate

Calibrate 2

Ethernet

Event

Export

Flow

Gas

Liquid

Login

Logout

Meter

Meter

Network

Delete

Permission

Add

Permission

Edit

Permission

Generic

Permission

Port

Pressure

Prover

Pulse

Delete Role

Add Role

Edit Role

Generic

Role

Serial

Connection

Configuration Aids

This manual contains icons within each section. Each icon represents a

relationship to the topic.

Page 14 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 15

MVI56E-AFC ♦ Version 4.04 Before you Begin

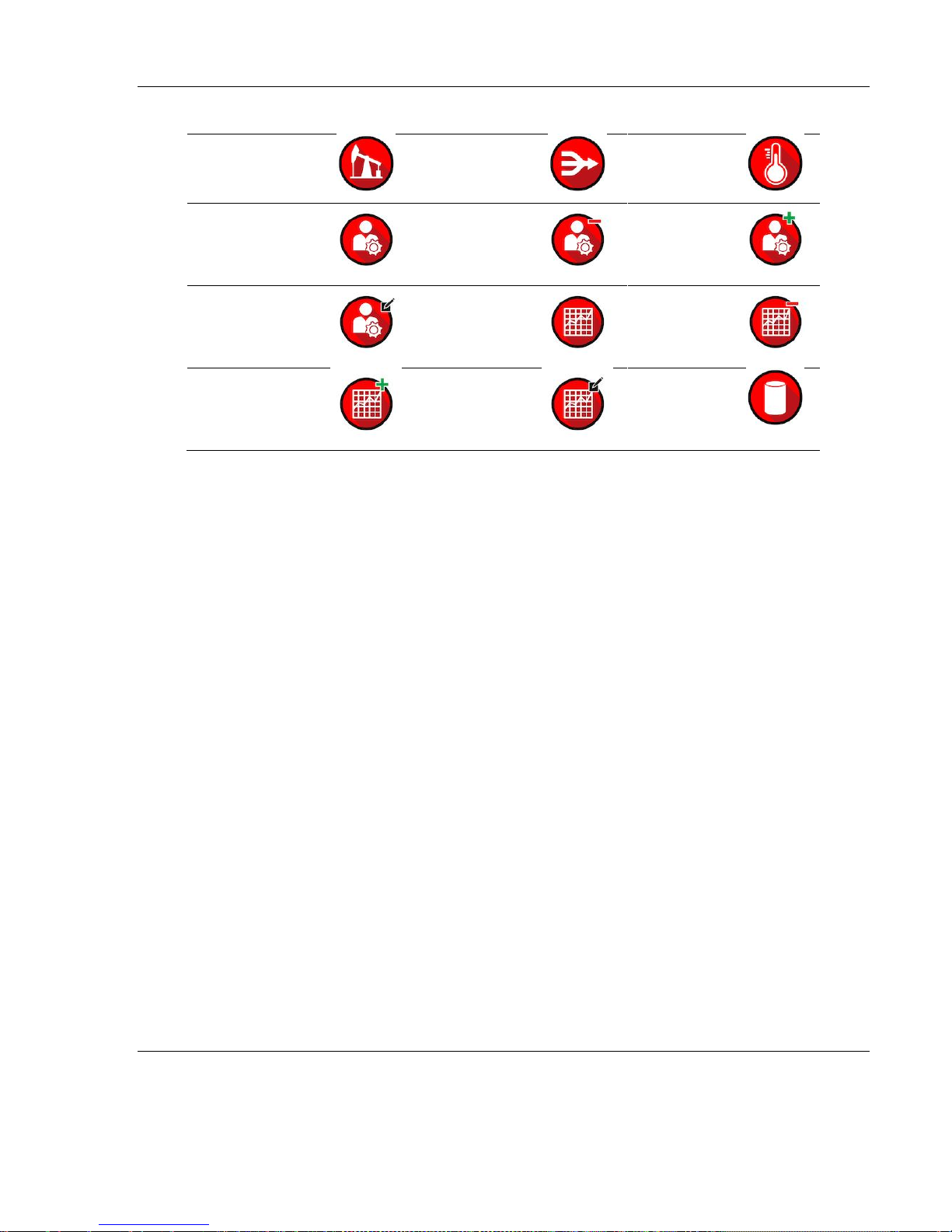

Site

Stream

Temp

User

Delete User

Add User

Edit User

View

Delete

View

Add View

Edit View

Volume

The icons are used as visual cues to provide a hint of the type of information

contained within a section.

ProSoft Technology, Inc. Page 15 of 149

October 2, 2018

Page 16

Before you Begin MVI56E-AFC ♦ Version 4.04

Using the Modbus Dictionary

Important: Although this manual is continuously maintained to bring you the latest information, the

Modbus Dictionary contains the latest information on registers and dictionary sections. It is

recommended that you use the Modbus Dictionary to locate bank and register values to ensure

that you are looking at the latest information.

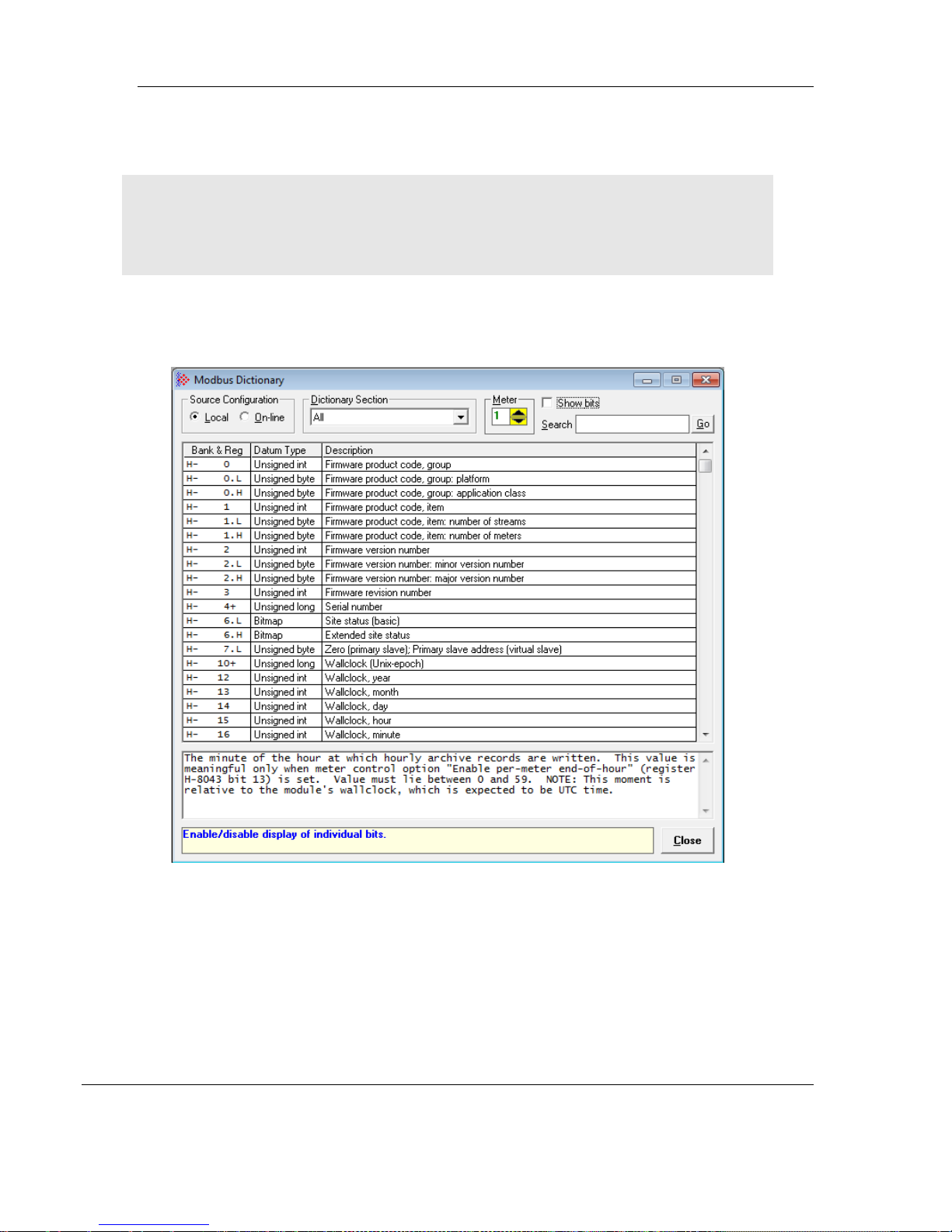

The Modbus dictionary provides a means to locate data anywhere in the module.

The dictionary allows you to select various data types from database regions. It

then displays Modbus bank and register values.

Page 16 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 17

MVI56E-AFC ♦ Version 4.04 Before you Begin

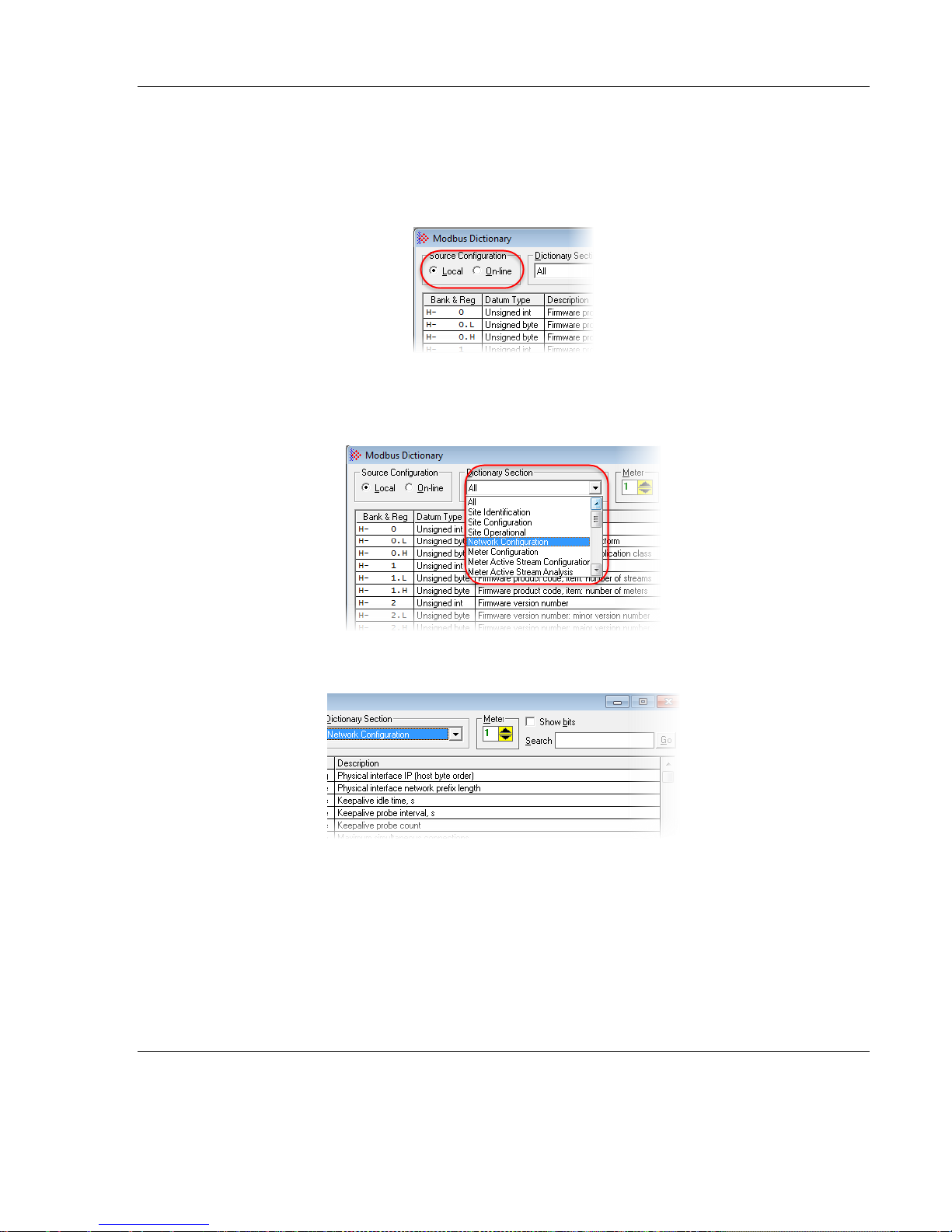

You can use the Modbus Dictionary locally or while EAFC manager is directly

connected to the MVI56E-AFC. From the Source Configuration section, select

LOCAL if you are just running Modbus Dictionary locally or select ON-LINE if

connected to a module.

The Dictionary Section drop-down list allows you to select different types of data

from different sections of the module.

The Meter selection allows you to specify a specific meter in order to view only

information pertaining to the selected meter.

If selected, the SHOW BITS checkbox allows the bits to be displayed in the Bank &

Reg column.

The Search box allows you to search for specific data. The search is applied to

entries in the Description column and is case insensitive.

ProSoft Technology, Inc. Page 17 of 149

October 2, 2018

Page 18

Before you Begin MVI56E-AFC ♦ Version 4.04

Procedure

Ensure that you have a suitable project loaded, especially its version. This

ensures that dictionary items present for your module are available for display.

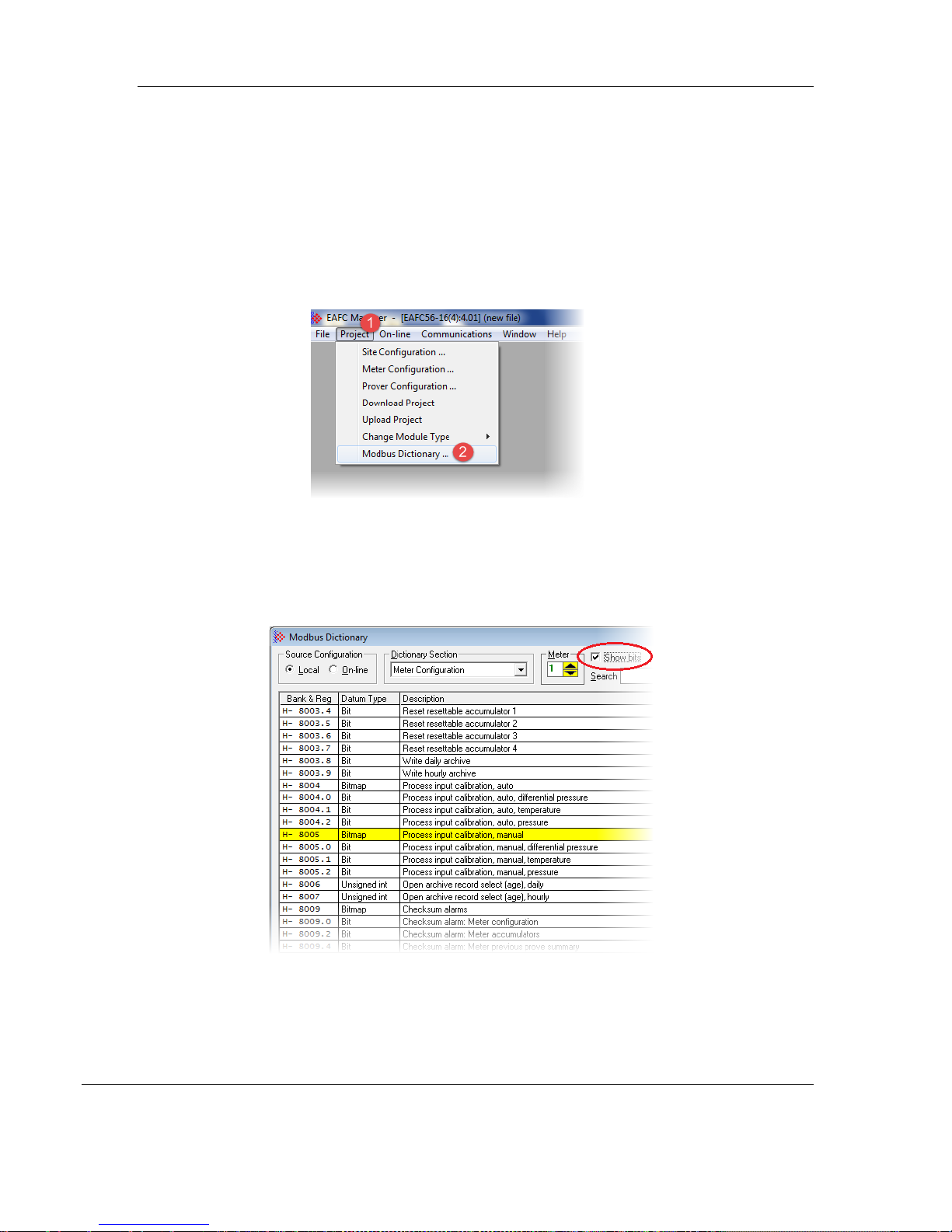

1 In EAFC Manager, select the PROJECT tab.

2 Select Modbus Dictionary, See Starting EAFC Manager for information on

setting your module type.

3 Select the SOURCE CONFIGURATION (Local or On-line).

4 Select the DICTIONARY SECTION from the drop-down list.

5 Select the METER stream.

6 Check the SHOW BITS checkbox to enable the display of individual bits.

Page 18 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 19

MVI56E-AFC ♦ Version 4.04 Before you Begin

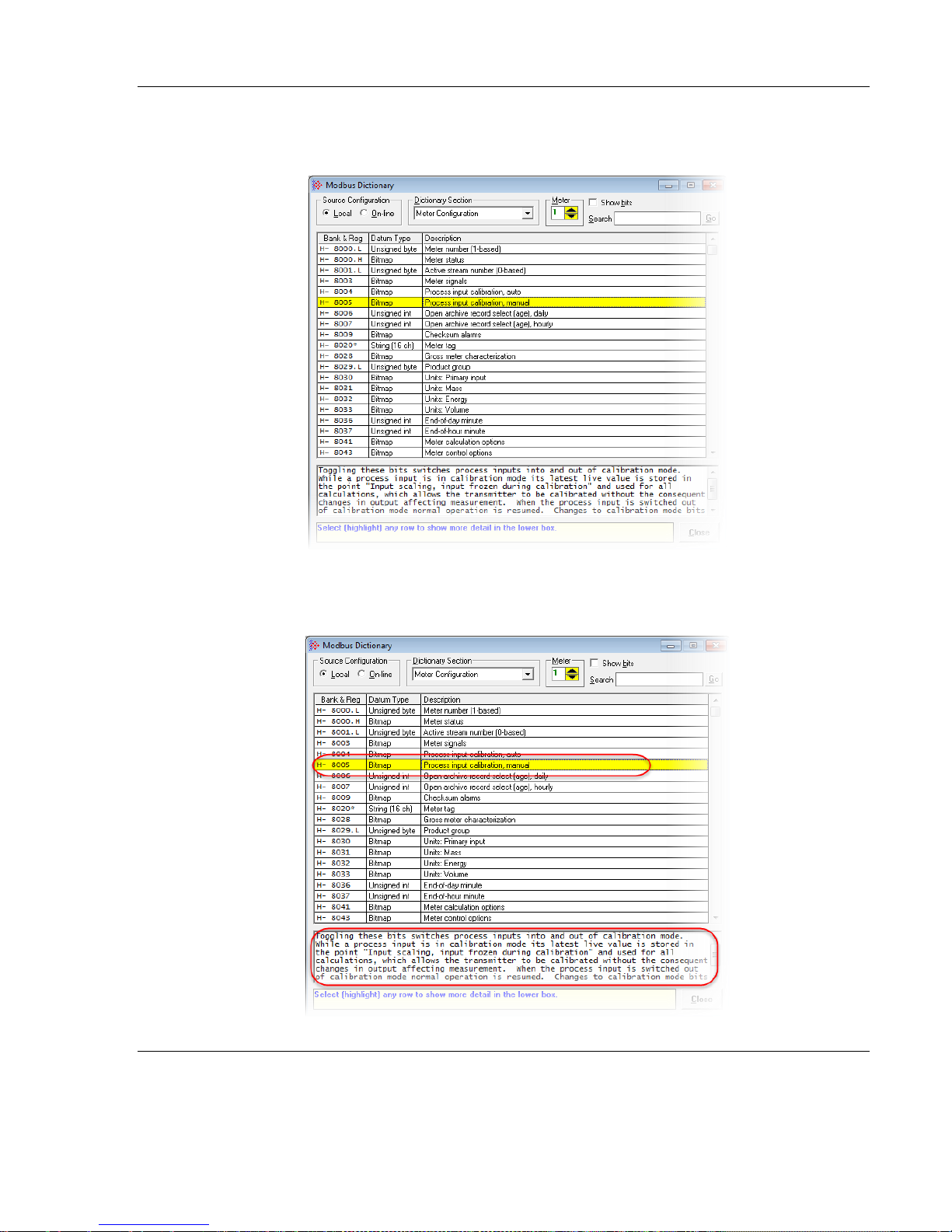

7 Click on the appropriate row.

8 Once a row is selected, additional information is displayed at the bottom of

the window.

ProSoft Technology, Inc. Page 19 of 149

October 2, 2018

Page 20

Before you Begin MVI56E-AFC ♦ Version 4.04

9 Observe the Bank and Reg information in the first column. This column may

contain a number of items with different representations.

In the first row, the first position indicates whether the register is a Holding

Register (H-) or an Input Register (I-), the second position represents the

register (8000). The third position indicates high order bytes (H), low order

bytes (L), multiple registers (*), and a plus sign (+) indicates that there are

two registers (used for 32-bit quantities, i.e., long integer and floating point

elements).

If SHOW BITS is checked, a number in the third position is the bit number. For

Datum Type “String”, each register holds two characters.

Page 20 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 21

MVI56E-AFC ♦ Version 4.04 Creating an EAFC Manager Project

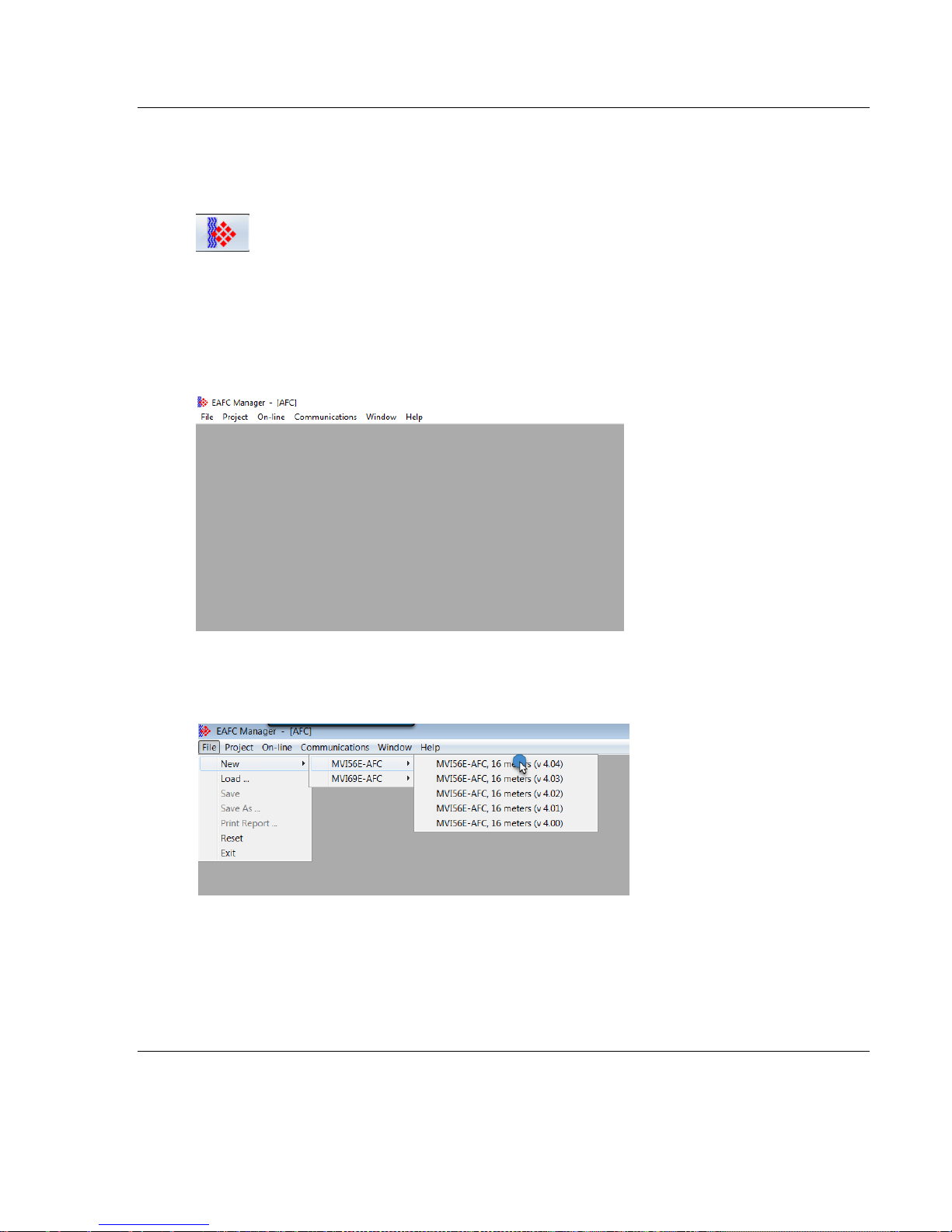

2 Creating an EAFC Manager Project

Starting EAFC Manager

1 Click START > PROGRAMS.

2 From the Programs menu, choose PROSOFT TECHNOLOGY.

3 From the ProSoft Technology folder, choose EAFC MANAGER.

The EAFC Manager opens.

4 Select FILE > NEW > MVI56E-AFC > MVI56E-AFC, 16 METERS (VX.XX). The

EAFC Manager project must match the firmware running on the EAFC.

ProSoft Technology, Inc. Page 21 of 149

October 2, 2018

Page 22

Creating an EAFC Manager Project MVI56E-AFC ♦ Version 4.04

Communications between the EAFC Manager and the MVI56E-AFC is not

required during the configuration stage. However, you can establish

communications at this point if you wish. Simply follow the instructions Chapter

19 “Installing the Module in the Rack” and Chapter 20 “Connecting the MVI56E-

AFC Module to the EAFC Manager”.

When you are ready to download the EAFC Manager project to the module, see

Chapter 21 ”Downloading the Project to the Module “. For information on creating

an RSLogix project and importing and using the AOIs, see Chapter 22 “Create

your RSLogix Project and Import the AOIs”.

Page 22 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 23

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

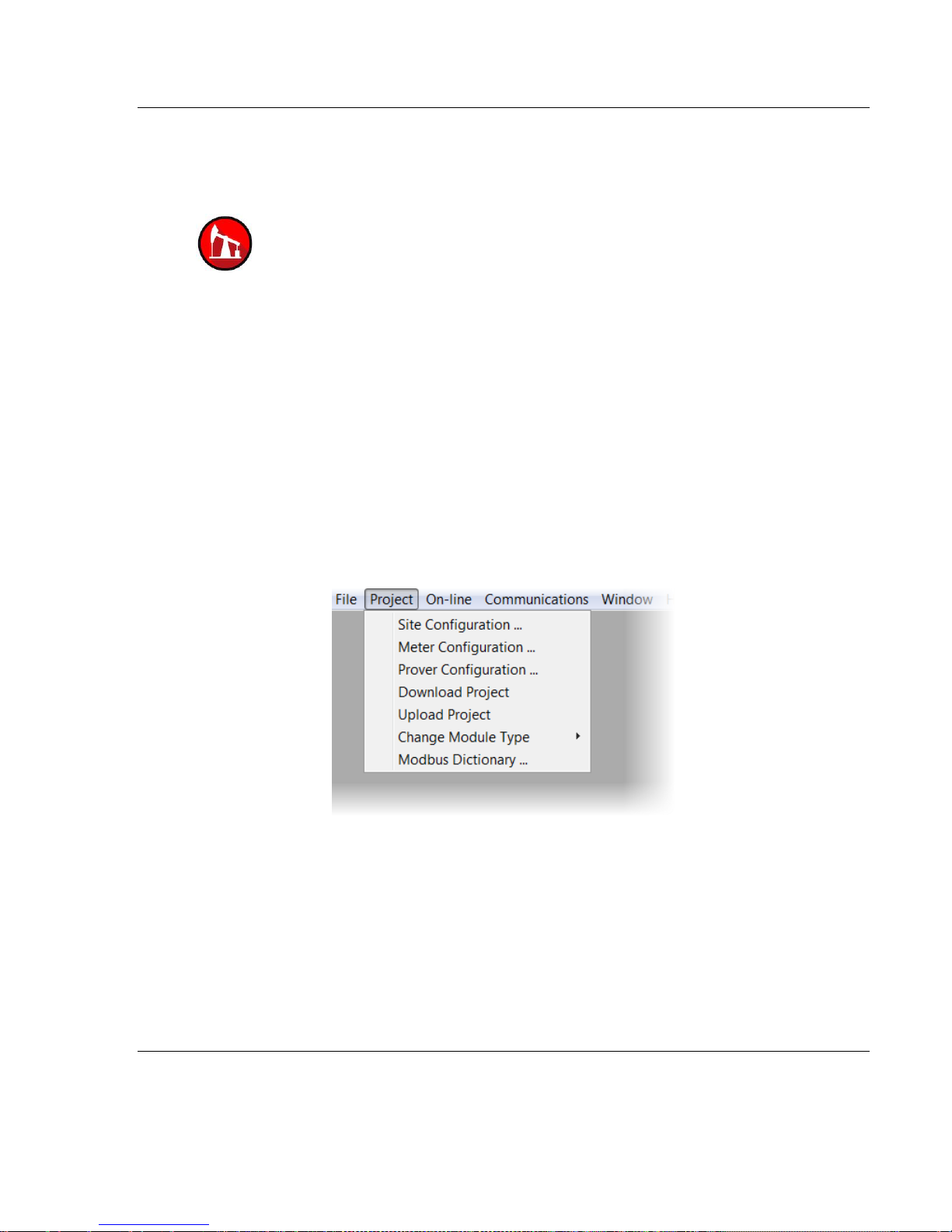

3 Configuring Site Parameters

Configure the overall settings for the site. The Site Configuration dialog box is

where you assign the settings that apply to the entire project.

Project name

Modbus slave addresses

Memory allocation

Port configuration and mapping

Site options and status

You can also obtain the MVI56E-AFC firmware version from this window.

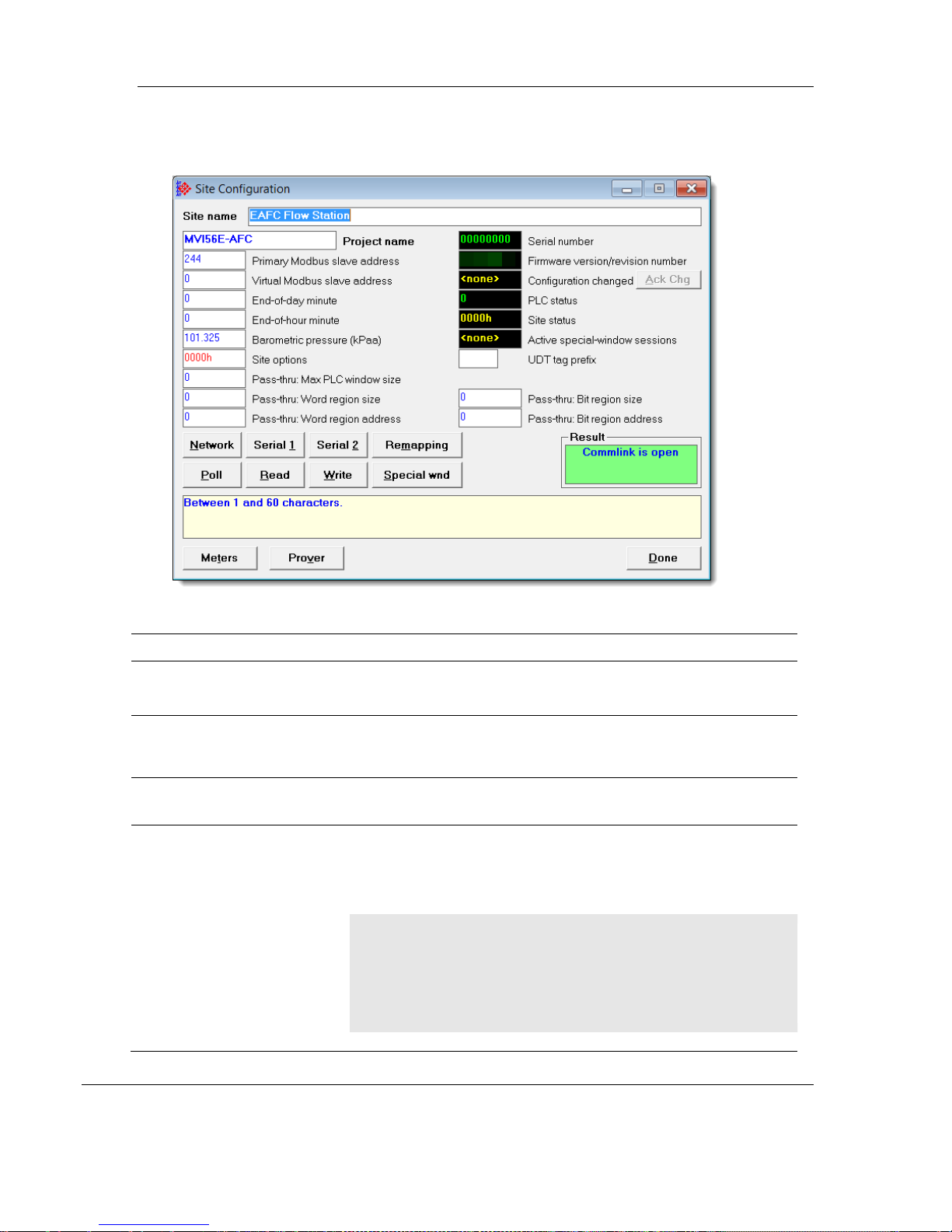

Accessing Site Configuration Parameters

From the Project menu, choose SITE CONFIGURATION.

ProSoft Technology, Inc. Page 23 of 149

October 2, 2018

Page 24

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Parameter

Description

Site Name

Enter a site name. This parameter identifies the site (1 to 64

characters). The default is “AFC Flow Station”. Edit this if needed.

Project Name

This parameter allows an external application such as EAFC

Manager to synchronize its database with the database resident in

the module. Default is "MVI56E-AFC".

Primary and Virtual Modbus

Slave Address

If you plan on setting these parameters, please refer to the MVI56E-

AFC Reference Guide for additional details.

End of Day Minute

This parameter sets the minute of the day when the daily archives

are created. The default value of 0 (zero) creates the daily archive at

midnight. Valid values are between 0 and 1439. This moment is

relative to the module’s wallclock, which is expected to be UTC time.

Important: The End of Period (End-of-day minute and End-of-hour

minute) settings are global settings, unless these settings are set by

meter on the Meter Configuration page. If these parameters are set

per meter, and enabled under control options, the options specified

per meter take precedence over the same settings on the Site

Configuration page.

This action opens the Site Configuration dialog box.

Page 24 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 25

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Parameter

Description

End of Hour Minute

This parameter sets the minute of the hour when the hourly archives

are created. The default value of 0 (zero) creates hourly archives at

the top of each hour. Valid values are between 0 and 59. This

moment is relative to the module’s wallclock, which is expected to be

UTC time.

Important: The End of Period (End-of-day minute and End-of-hour

minute) settings are global settings, unless these settings are set by

meter on the Meter Configuration page. If these parameters are set

per meter, and enabled under control options, the options specified

per meter take precedence over the same settings on the Site

Configuration page.

Barometric Pressure

This parameter sets the barometric pressure used on the module

calculations. The module expects each meter's pressure input to be

in gauge units. Because the AGA8, AGA3, and some API2540

calculations require the pressure of the fluid to be in absolute units,

the module adds barometric pressure to the gauge pressure in order

to obtain the absolute pressure.

The calculation assumes that all meters measured by a single

MVI56E-AFC are located at the same site and have the same

barometric pressure.

ProSoft Technology, Inc. Page 25 of 149

October 2, 2018

Page 26

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Parameter

Description

Event log lockable

If clear, the event log behaves as a FIFO buffer; a new record

overwrites the old one even if the overwritten event has never

been downloaded, in which case, the event is permanently

lost. If set, and the log is full with never downloaded events,

then the log is locked. Controllable events (changes to most

datum points) are not allowed to occur. Non-critical, noncontrollable events (e.g. checksum alarms) are discarded and

are permanently lost, and critical non-controllable events (e.g.

PLC mode change) are written as usual and the overwritten,

never downloaded events are permanently lost. A locked log

must be downloaded to unlock it for normal behavior.

Barometric pressure in psia

If set, the barometric pressure will be expressed in psia units,

otherwise it will use kPaa.

Configuring Site Options

The Site Options dialog box opens when you click the SITE OPTIONS field in the

Site Configuration dialog box. Not all options are available unless other

parameters and options are selected during the configuration process.

Page 26 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 27

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Configuring Pass-thru Options

The Pass-Thru feature can be used for delivering data written by Modbus

packets directly to the PLC logic, bypassing the MVI56E-AFC’s Modbus

database. For details on configuring this option, please refer to the MVI56E-AFC

Reference Guide.

The module supports the Modbus Pass-Thru feature for write commands. When

the pass-thru region in the virtual slave is properly configured, all Modbus write

commands pointing inside that area will be handled by ladder logic using the

Modbus Pass-Thru function block.

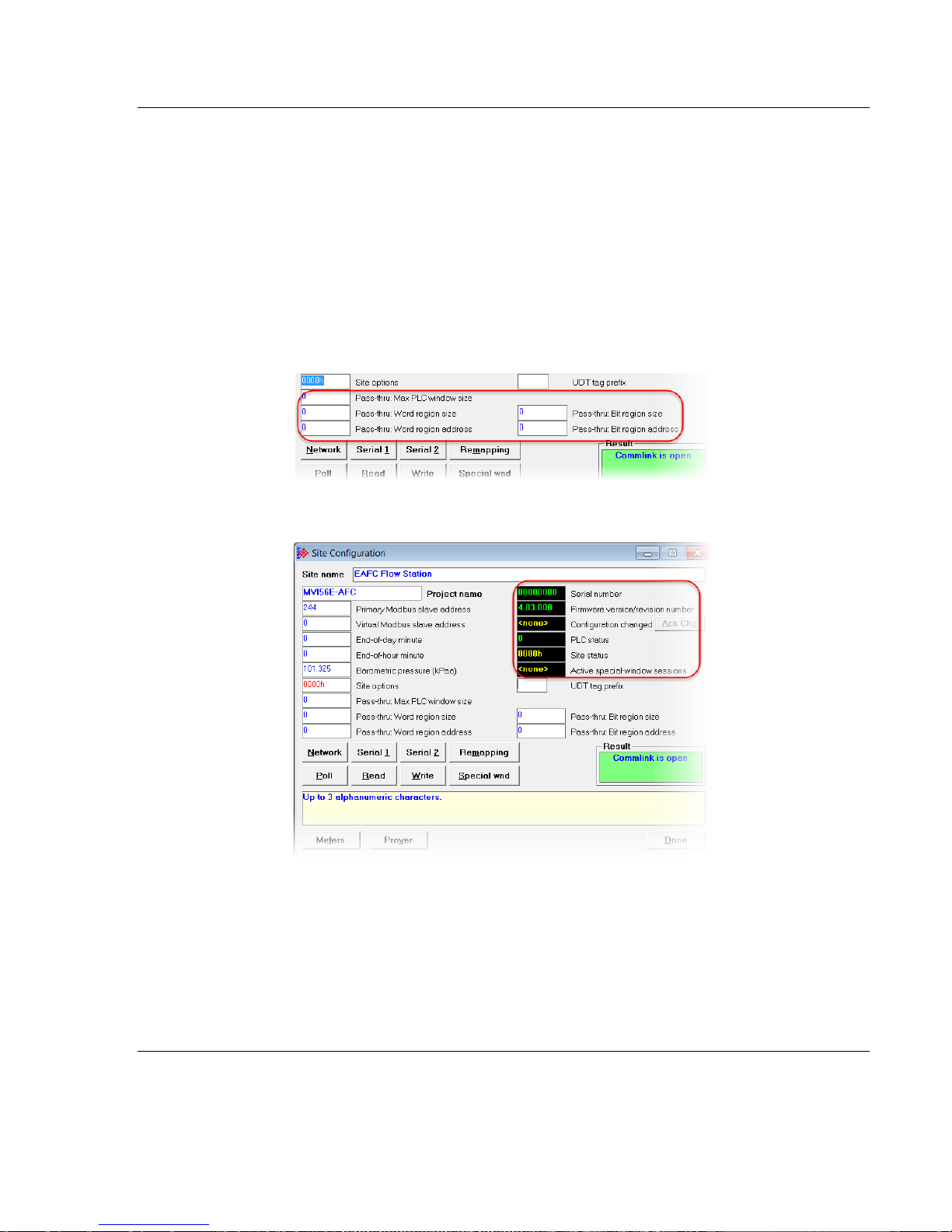

Viewing Site Configuration Status

This section of the Site Configuration screen is used to provide Site status

information. Site status features are discussed in the MVI56E-AFC Reference

Guide.

ProSoft Technology, Inc. Page 27 of 149

October 2, 2018

Page 28

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

UDT Tag Prefix

Prefix for generated UDT names. UDT definition files generated for the AFC

project, including those for backplane-return layouts and archive record layouts,

may be imported into the RSLogix project. To avoid conflict with names of other

types, tags, and files, especially those generated for other EAFC modules in the

same rack, this optional prefix may be prepended to each generated name (after

the leading “EAFC_”).

If not specified, generated names are not prefixed. If specified, the prefix must be

an alphanumeric string of not more than 3 characters, and it is prepended to

each generated name with an underscore (“_”) separator.

Page 28 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 29

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Exporting UDT Files

You can export UDT files through the Backplane Return window.

Note: The backplane return window exports Backplane Return UDTs. Archive record layout UDTs

are exported from the Archive Configuration Window (after saving the project).

From the Meter Configuration window:

1 Select the meter number.

2 Click on the BACKPLANE RETURN button.

This opens the Backplane-Return Configuration window.

ProSoft Technology, Inc. Page 29 of 149

October 2, 2018

Page 30

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

3 From the Dictionary section, select the UDT file files. This activates the

INSERT ITEM button.

4 Click the INSERT ITEM button to add the file to the Process Input side of

the page. When UDT files are inserted, the EXPORT UDT button is

activated.

5 Do the same from the Component Analysis tab.

6 When you’ve finished adding the UDT files, click the EXPORT UDT button.

The files are placed in a sub-directory of the directory that contains the

project. The directory is named using the name of the project and

extension .PLC.

Page 30 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 31

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Setting Communication Parameters

ProSoft Technology, Inc. Page 31 of 149

October 2, 2018

Page 32

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

TCP

Communication

Use to configure Modbus TCP/IP communication

settings.

Serial 1 or Serial 2

Use Serial 1 or Serial 2 buttons to configure serial

communication settings. Use Serial 2 to set up a Modbus

Master.

Page 32 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 33

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Configuring Modbus TCP/IP

You must configure the communication parameters for the Ethernet port using

the EAFC Manager software (Site Configuration):

ProSoft Technology, Inc. Page 33 of 149

October 2, 2018

Page 34

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Server Configuration

The Server tabs allow you set different configurations for up to four servers.

Page 34 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 35

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Step

Task

Description/Example

1

Click on the tab

of the server

that you want to

configure.

Enable the

server by

clicking the

Enabled

checkbox.

2

Configure the

network

Interface.

This field indicates the IP address of the physical interface in dotted

decimal format.

The Mask bits indicate the network prefix length of the physical

interface. This is a number between 1 and 31.

TCP port is the Modbus TCP/IP port for the selected server. This the

MBAP listener port, typically 502 (default). You can use a range

between 1024 and 65535.

3

Set up Mode

and AFC Slave

settings

Set the module as an End Device or a Gateway.

The following process applies to each server:

ProSoft Technology, Inc. Page 35 of 149

October 2, 2018

Page 36

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Step

Task

Description/Example

If set to an End Device (has its own Modbus database), the unit code

is ignored and is echoed verbatim in the response regardless of its

value.

If set to Gateway (protocol converter between the TCP network on

one end, and a traditional serial Modbus network on the other end),

the serial Modbus network is virtual consisting of the MVI56E-AFC’s

primary and virtual slaves (only), and the unit code must be the

configured slave address of the targeted MVI56E-AFC slave.

4

AFC Slave

The effect of the AFC Slave option depends on Mode setting.

If the device is set as End Device, then this option selects which of

the two MVI56E-AFC slaves is to be the addressed end device.

If the device is set to Gateway, then this option changes to a

checkbox that hides the primary slave. If not selected, both slaves

are addressable, but if set, only the virtual slave is addressable.

In either case, if a command addresses the virtual slave but the

virtual slave does not exist, no response is issued.

AFC slave indicates whether this is a primary or virtual slave.

5

Swap Words

If checked, swaps the Modbus words transferred through this port.

This parameter is only accessible to those data points that hold 32-bit

quantities (long integers, floats, totalizers).

6

Disable passthru

The Modbus Pass-thru feature allows you to configure a Modbus

Pass-Thru region in the Virtual Slave (Project > Site Configuration).

See the MVI56E-AFC Reference Guide for detailed information.

7

Maximum

simultaneous

connections

Set the maximum number of connections for this server. Eight (8)

total connections are available and can be configured as required.

For example, each server might represent a different network. Server

1 might have a single connection while server 2 may have 3, server 3

with 2, and server 4 with 2 for a total of 8.

8

Reserved

connections

A “reserved connection” is one whose resources are always available

for use by this server, whether or not such a connection is currently in

use, so that regardless of activity on other servers, this number of

Page 36 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 37

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Step

Task

Description/Example

connections to this server can always simultaneously exist. This

setting must not exceed the maximum number of connections

permitted for this server if that maximum is non-zero. The total

number of reserved connections over all servers must not exceed the

maximum number of connections permitted overall. Server #1 always

has at least one reserved connection. Range 1 to 8, default 1 with

corresponding for others as 0 to 8..

9

Idle connection

timeout, min.

Specify the number of minutes that a connection may be idle before

being disconnected. A timeout of 0 means no timeout (the connection

may remain idle indefinitely).

Setting Whitelist Options

Whitelist configuration is an ordered sequence of eight entries, each of which

comprises:

An IP range (network IP and mask length)

A boolean "color" flag; white = allow, black = deny.

An entry whose components are all zero (IP 0.0.0.0, prefix length is 0, color is

"white") is empty. It is ignored during application of the whitelist and its position in

the sequence is irrelevant. The relative positioning of non-empty entries is

relevant however, as a later entry can override the effect of an earlier entry.

See the MVI56E-AFC Reference Guide for detailed information.

ProSoft Technology, Inc. Page 37 of 149

October 2, 2018

Page 38

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Parameter

Description

Keepalive idle time

This setting enables a network server to free up resources allocated to

broken connections. The three settings are:

Idle time

Probe interval

Probe count

When a connection becomes idle (no requests to the server), it could be

merely because the client has nothing to say or it could be due to a broken

connection. “Keepalive” enables the server to reasonably determine which

and act accordingly.

When a connection has been idle for the “idle time”, the server sends up to

“probe count” probes at the rate of the “probe interval” delay between each.

Advanced Tab

Overall Settings

Page 38 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 39

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Parameter

Description

A “probe” is a TCP/IP packet that asks the client “Are you still there?”. If the

client answers any probe with “Yes, I’m still here”, then the connection is

good. The client is merely silent and the server resets “keepalive” logic for

another cycle.

If the client does not answer any probe, then the server deems the

connection to be broken and closes it to free up its resources for allocation.

Keepalive probe interval

See above.

Keepalive probe count

See above.

Maximum simultaneous

connections

The maximum concurrently active connections over all servers. This should

be a number between 1 and 8. The default is 8.

Complete packet timeout

The timeout for receiving a complete packet. The timeout becomes

effective upon receipt of the first octet of a packet's MBAP header and

imposes a limit on the time that may elapse before receiving the last octet

of that packet. If the timeout expires, the connection is shut down. Valid

range is 1 through 60 with a default of 5 seconds.

Orphaned connection

timeout

This timeout (in minutes) becomes active when a connection is orphaned

by a sufficiently significant change to its parent server’s configuration. This

setting provides a window of time during which the connection remains

alive so that the client can gracefully close it before establishing a

replacement connection according to the network’s updated requirements.

Server changes causing orphanization include (but not limited to):

Disabling the server

Change of IP address

Change to whitelist the disallows the client’s IP

Reduction or removal of access permitted, e.g. primary vs virtual

slave.

Change of protocol; e.g., gateway vs end-device mode, swap

options.

Orphanization of a connection breaks the association between the

connection and its parent server so that the connection no longer belongs

to any server. Server settings in effect prior to orphanization become

frozen for that orphan for the remainder of its limited life. A subsequent

reconfiguration of this or any other server that reestablishes the frozen

settings does not re-associate the connection with the server; the

connection remains orphaned and its timeout remains active.

Upon timeout expiry, the connection is shut down. A timeout of 0 causes

an immediate shutdown. Changing this setting does not adjust timeouts in

effect for already existing orphans.

Valid values: 0 to 60, Default is 0.

ProSoft Technology, Inc. Page 39 of 149

October 2, 2018

Page 40

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Parameter

Values

Baud Rate

9600, 19200, 28800, 38400, 57600, 115200, 230400

Data Bits

7 or 8

Stop Bits

1 or 2 Bits

Mode

RTU or ASCII

Parity

None, Even or Odd

Web Interface/Gateway

This IP address and Mask bits pertain to the address of the module itself. This is

not a Modbus TCP/IP address used by the MVI56E-AFC application. The default

web interface address is 192.168.0.250.

Once configured, click READ from the Site page to save changes.

Configuring Serial 1 and Serial 2

The MVI56E-AFC contains two serial port connections. Serial 2 may be used as

a Modbus Master.

Serial Only

The module supports the following communication parameters for each

communication port:

Note: Do not configure a port for both RTU mode and 7 data bits as this combination is not

supported by the Modbus protocol.

Page 40 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 41

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

You must configure the communication parameters for each communication port

using the MVI56E-AFC Manager software (Site Configuration):

ProSoft Technology, Inc. Page 41 of 149

October 2, 2018

Page 42

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Option

Description

Modbus Master

Enables the Modbus Master for the port (Serial 2). The Modbus Master

command is generated from the processor using ladder logic (Modbus

master block). After the Modbus Master transaction is completed the

module is ready to receive another Modbus Master request from the

ladder logic:

Modbus Slave

MVI-AFC

Processor

Modbus

Master

Block

Modbus

Command

The following Modbus functions are support for Modbus Master operation:

Modbus Function Code

Description

1

Read Coil Status

2

Read Input Status

3

Read Holding Registers

4

Read Input Registers

15

Force (Write) Multiple Coils

16

Preset (Write) Multiple

Registers

The module offers flexibility for Modbus Master operation, allowing ladder

logic to select one of the following data types:

Bit (packed 16 to a word)

Word (16-bit register)

Long (32-bit items as register pairs)

Long Remote (32-bit items as single registers)

Note: Long data type implements each data unit as one pair of 16-bit

registers (words). Each register contains two bytes. Long remote data

type implements each data unit as one 32-bit register. Each register

contains four bytes. The proper choice depends on the remote slave’s

Modbus implementation.

Hide Primary Slave

When checked, protects the Primary Modbus Slave from any read or write

command from a Modbus master device. In this case, you could also

remap the register from the Primary Slave to the Virtual Slave protecting

each register from write commands (refer to the Primary & Virtual Modbus

Port Options

Page 42 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 43

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Option

Description

Slaves Configuration section).

Swap Modbus Words

If checked, the words transferred by a Modbus master device will be

swapped. This setting only applies to double-register data items (floating

point and long integer).

Disable Pass-thru

The Modbus pass-through feature allows you to configure a Modbus

Pass-through region in the virtual slave (Project > Site Configuration).

After the module receives a holding register write command (Modbus

functions 6 or 16) or a bit write command (Modbus functions 5 or 15), it

generates a pass-through block to be sent to the processor containing the

Modbus command data. You can define a word pass-through region for

words or bits.

Note: You must enable the Virtual Slave by configuring a Modbus

address greater than 0 (Project > Site Configuration).

You can control which communication parts will support the pass-through

(Project > Site Configuration > Port X button).

This feature requires ladder logic to read the pass-through block from the

module to the processor. Refer to the Ladder Logic section in the

MVI56E-AFC Reference Guide for more information about the passthrough feature.

ProSoft Technology, Inc. Page 43 of 149

October 2, 2018

Page 44

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

Poll Button

The function of the POLL button is to update the display of site status (the blackbackground boxes in the upper right quadrant of Site Configuration).

Local Port Settings Dialog Box

This dialog is displayed whenever menu item Communications/Local Port

Settings is clicked, or any other action that requires a connection to the module is

invoked while such a connection is not yet present. Such “other actions” include

the READ, WRITE, and POLL buttons of the Site Configuration pane, but also

numerous other actions such a Read and Write of Meter Configuration, menu

item Project/Download Project, and menu item Communications/Login Module.

If a connection is already present, this dialog is not automatically displayed upon

any “other action” but only upon the Local Port Settings menu item. Similarly, if

the connection exists but the operator has not logged in, while the “other action”

requires login, the Login Module window is automatically displayed.

Both conditions are cascaded. For example, a Read when not connected

displays first the Local Port Settings window to connect and then the Login

Module window to log in.

Adjust the communication settings if necessary. Click CONNECT to save the

settings and OK to connect.

Page 44 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 45

MVI56E-AFC ♦ Version 4.04 Configuring Site Parameters

Read Button

The READ button reads the current site configuration from the module to the local

PC. Look at the result area (green rectangle) on the Site Configuration dialog box

for the status of the read operation. When a "Success" indication shows in the

result area, it indicates that the site configuration has been successfully read to

the local PC.

Write Button

After you have completed the site configuration on the local PC EAFC Manager

software, click the WRITE button to transfer the configuration to the module.

When the Result area shows "Success", the site configuration has been

successfully written to the module.

Click the READ button to read the current module site configuration. The

configuration should match the last write operation data.

If the result area shows "Time out", verify the network connections.

Special Wnd Button

This button displays the Special Windows dialog.

This dialog allows you to set times in minutes or seconds. The times represent

times of no activity. For example, if you set Event log download to 60 seconds,

and no download activity has occurred within that time period, the Event Log

activity is abandoned and no data is logged or committed. The same holds true

for the alarm log, transmitter calibration, and Enron access. You must enter the

ProSoft Technology, Inc. Page 45 of 149

October 2, 2018

Page 46

Configuring Site Parameters MVI56E-AFC ♦ Version 4.04

time interval and optionally the Virtual Slave location of the data. When you are

satisfied with your settings, click DONE. You can come back at any time and

change your settings.

If you want to access these special windows via the virtual slave, assign an

address in the virtual slave to the special window in the Virtual slave location

column. If the Virtual slave location is set to “0”, the special window is unavailable

in the virtual slave.

Done Button

This button stores your settings temporarily and closes the Site Configuration

dialog box. Note that you must also save your project before closing EAFC

Manager, otherwise your configuration will be discarded.

Remapping Button

Refer to the MVI56E-AFC Reference Guide.

Accessing the Data

Information on accessing data is discussed in the MVI56E-AFC Reference

Guide.

Site Status

Site status information is discussed in the MVI56E-AFC Reference Guide.

Page 46 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 47

MVI56E-AFC ♦ Version 4.04 Configuring Meter Parameters

4 Configuring Meter Parameters

Prerequisites

Ensure that all site information is configured as described in the previous

chapters.

What Parameters Do I Have to Configure?

The Meter Configuration page allows you to configure your meter based on your

application. Parameters on this page are based on information that you initially

provide to EAFC Manager.

Configuring a Meter consists of the following steps:

1. Configure Meter Type, Product Group, Units, and Primary Input

2. Configure Meter Identification and Stream Identification Parameters

3. Configure Common Parameters

4. Configure Application-specific Parameters

5. Configure Analysis Parameters

ProSoft Technology, Inc. Page 47 of 149

October 2, 2018

Page 48

Configuring Meter Parameters MVI56E-AFC ♦ Version 4.04

Configuring Meter and Stream Identification Parameters

Identification Parameters identify the meter.

1 Select the Meter number.

2 Click the IDENTIFICATION button to display the Meter Identification window.

Page 48 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 49

MVI56E-AFC ♦ Version 4.04 Configuring Meter Parameters

3 Add the following identifying parameters:

General Type

Manufacturer

Model

Serial Number

Size

Nominal K Factor

4 Click OK when you are done. Repeat this for every configured meter.

Setting End of Period Parameters

These parameters set the End-of-day minute and End-of-hour minute.

End-of-Day Minute

This parameter sets the minute of the day when the daily archives are created.

The default value of 0 (zero) creates the daily archive at midnight. Valid values

are between 0 and 1439.

End-of-hour minute

This parameter sets the minute of the hour when the hourly archives are created.

The default value of 0 (zero) creates hourly archives at the top of each hour.

Valid values are between 0 and 59.

ProSoft Technology, Inc. Page 49 of 149

October 2, 2018

Page 50

Configuring Meter Parameters MVI56E-AFC ♦ Version 4.04

Setting Precedence

You can set the End-of-day minute and End-of-hour minute on the Site page as

well. The parameters set on the site page represent a global setting and End of

Period parameters set on the Meter Configuration are ignored. However, you can

give the Meter setting precedence using the Meter Control Options dialog.

1 Click on the CONTROL OPTS button.

2 Click on the Enable per meter end-of-day and Enable per meter end-of-

hour check boxes.

3 Click DONE.

The settings in the End of Period section for the meter now take precedence over

those set on the Site page.

Page 50 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 51

MVI56E-AFC ♦ Version 4.04 Configuring Meter Parameters

Sample rate alarming – This is the longest period that can elapse between

successive fresh samples of process input values without raising the “sample

rate too low” alarm. This value is specified in seconds with a range of 0 through

30. Zero “0” means that the sample rate test is not performed and alarms are not

raised. The complete implementation requires supporting logic in the PLC. The

default for gas product is 1 second and for any liquid product is 5 seconds.

Setting a Stream Name

To set a Stream Name, click on the IDENTIFICATION button under the Stream

Enabled indicator.

Enter a product description and click OK.

ProSoft Technology, Inc. Page 51 of 149

October 2, 2018

Page 52

Configuring Meter Parameters MVI56E-AFC ♦ Version 4.04

Configuring Meter Type, Product Group, Units, and Primary Input

These parameters must be configured before you configure any common or

application detail parameters. What you select here affects the available

parameters that must be configured for your application.

EAFC Manager needs these parameters in order to hide or show parameters that

pertain specifically to your meter and its primary output based on your meter and

associated instrumentation.

For example, a meter that measures the flow of Crude oils requires that specific

parameters be provided that may not be required of a meter that measures the

flow of gas.

Parameters available to you are determined by these selections.

Based on the previous examples, you essentially have to answer 3 questions

before you begin meter configuration:

1. What kind of meter are you configuring?

2. What is the primary output from your flow meter and associated

instrumentation?

3. What are you measuring (Gas or Liquid)?

Page 52 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 53

MVI56E-AFC ♦ Version 4.04 Configuring Meter Parameters

Column 1

Column 2

Column 3

Column 4

What kind of meter

are you configuring?

What is the primary

output from your flow

meter and associated

instrumentation?

Configure your meter

type as…

Configure your

primary input as…

Orifice Meter

Differential Pressure

Differential

Differential Pres

V-Cone Meter

Differential Pressure

Differential

Differential Pres

Wedge Meter

Differential Pressure

Differential

Differential Pres

Coriolis Meter

Flow Rate

Differential

Flow Rate

Pulse Count and

Pulse Frequency

Linear

Pulse Count

Pulse Frequency Only

Linear

Pulse Frequency

Vortex Meter

Flow Rate

Differential

Flow Rate

Pulse Count and

Pulse Frequency

Linear

Pulse Count

Pulse Frequency Only

Linear

Pulse Frequency

Ultrasonic Meter

Flow Rate

Differential

Flow Rate

Pulse Count and

Pulse Frequency

Linear

Pulse Count

Pulse Frequency Only

Linear

Pulse Frequency

Selecting and Configuring Meter Type, Product Group, Units and Primary

Input Parameters

The following table helps you determine what Meter Type and Primary Input

parameters must be entered in EAFC Manager based on the kind of meter you

are configuring and the primary output of the meter and associated

instrumentation.

To use the following table:

1. Locate the type of meter you are using from Column 1.

2. Determine the primary output of your meter and associated

instrumentation from Column 2.

3. Note your Meter Type from Column 3.

4. Note your Primary Input from Column 4.

You will use the information from Columns 3 and 4 to select your first two

parameters in EAFC Manager.

ProSoft Technology, Inc. Page 53 of 149

October 2, 2018

Page 54

Configuring Meter Parameters MVI56E-AFC ♦ Version 4.04

Column 1

Column 2

Column 3

Column 4

Turbine Meter

Pulse Count and

Pulse Frequency

Linear

Pulse Count

Pulse Frequency

Linear

Pulse Frequency

Pulse Count

Linear

Pulse Count

Positive Displacement

Same as Turbine

Magnetic

Same as Turbine

Columns 3 and 4 of this table have a direct relationship with the Meter

Configuration page of EAFC Manager.

For example, if you are configuring a Coriolis Meter with a primary output of

Pulse Count and Pulse Frequency, your settings in EAFC Manager for Meter

Type and Primary Input would be Linear and Pulse Count as shown in the

following example.

It is important to note that the settings selected within the Meter Type, Product

Group and Units section of the page, determine what configuration parameters

are viewable on the EAFC Manager Meter Configuration page.

Once you’ve selected the correct Meter Type and Primary Input settings based

on the table, you can select the Product Group, and System of Units.

Page 54 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 55

MVI56E-AFC ♦ Version 4.04 Configuring Meter Parameters

Product Group

The Product Group represents what you are measuring (i.e., gas or liquid). The

Product Group drop-down list allows you to select the appropriate Product Group

for your application. Refer to the MVI56E-AFC Reference Guide for detailed

information.

Note: The Product Injected Meter Type feature produces an Accumulation Overflow error. The

associated flow calculations will be invalid.

System of Units

System of Units pertains to how measurements are displayed and are used for

calculations.

US – Temperature in °F, Pressure in psi, Differential Pressure in

hw@60°F.

SI – Temperature in °C, Pressure and Differential Pressure in kPa.

Once these parameters are configured, the parameters that you see on EAFC

Manager are those that apply to your application. That is, what you see on the

MVI56E-AFC Manager page is dependent on these parameter configuration

settings.

Troubleshooting Tip: If the EAFC Manager displays an "Illegal Data Value" message, it typically

indicates an invalid meter type or product group configuration. The module does not accept a

configuration file that attempts to change a meter type or product group for a meter that is currently

enabled. Disable all meters, change the meter types and product groups, and then enable the

meters again.

ProSoft Technology, Inc. Page 55 of 149

October 2, 2018

Page 56

Page 57

MVI56E-AFC ♦ v4.04 Common Parameters

5 Configuring Common Parameters

Common parameters are common to all applications. These parameters are

always visible and should be configured.

ProSoft Technology, Inc. Page 57 of 149

October 2, 2018

Page 58

Common Parameters MVI56E-AFC ♦ Version 4.04

Common parameters include:

Physical Device

Reference Conditions

Accumulators and Flow Rates

Process Input

Control Options

Backplane Return

Calculation Options

Resettable Accumulators

Meter Factors

Stream Options

Selecting the Physical Device

Select your device from the drop-down list. Selects here change calculation

methods based on the meter.

Page 58 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 59

MVI56E-AFC ♦ Version 4.04 Common Parameters

If you are using a differential gas type meter, measuring differential pressure, you

have the option of selecting from the following standards:

Orifice plate (AGA 3 [2012])

Orifice plate (AGA 3 [1992])

Orifice plate (ISO 5167-2)

Nozzle, ISA 1932 (ISO 5167-3 type 1)

Nozzle, long radius (ISO 5167-3 type 2)

Nozzle, Venturi (ISO 5167-3 type 3)

Venturi tube, cast (ISO 5167-4 type 1)

Venturi tube, machined (ISO 5167-4 type 2)

Venturi tube, rough (ISO 5167-4 type 3)

V-cone [Rev 3.2]

V-cone [Rev 2.5]

Wafer-cone

Wedge

The options in the drop-down list change depending on your selections to meter

types. For example, if you select a Linear device type, the following physical

device types are available:

ProSoft Technology, Inc. Page 59 of 149

October 2, 2018

Page 60

Common Parameters MVI56E-AFC ♦ Version 4.04

Specifying Reference Temperature and Pressure (Reference

Conditions)

Measurements of gas and liquids are calculated based on their characteristics at

a specific temperature and atmospheric pressure. Specify the reference

conditions in this area. The default values are 15°C/101.325 kPaa (SI) and

60°F/14.696psia (US), which are the standard API base conditions. If configured

reference conditions are different from API base, the API calculations are done

twice as necessary to correct from flowing conditions to API base and then decorrect from API base to your selected reference.

Page 60 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 61

MVI56E-AFC ♦ Version 4.04 Common Parameters

Setting Accumulators and Flow Rates

Flow Rate Period Unit

Click on the FLOW RATE PERIOD UNIT box to change the flow rate period.

Flow Rate Unit

Click on the FLOW RATE UNIT box to change the flow rate unit.

ProSoft Technology, Inc. Page 61 of 149

October 2, 2018

Page 62

Common Parameters MVI56E-AFC ♦ Version 4.04

Accumulation Unit

Click on the ACCUMULATOR UNIT box to change volume accumulator units.

Accumulator Rollover

This is the value when mass accumulators are reset to zero and it 1 greater than

the highest value that the accumulator may hold.

A value of 1000000 specifies a 6-digit accumulator that rolls over to 0 from

999999. Any unsigned 32-bit value may be entered. A value of 0 indicates a freerunning accumulator, which rolls over to 0 from 4294967295. The default value is

100000000 (8 zeros).

Page 62 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 63

MVI56E-AFC ♦ Version 4.04 Common Parameters

Product Group

Input Variables

Gas

Temperature, Pressure, Flow Rate, Differential Pressure, Pulse Frequency

Liquid

Temperature, Pressure, Flow Rate, Differential Pressure, Pulse Frequency,

Density, Water Content

Configuring Process Input Scaling

Click the PROCESS INPUT button to configure the valid input ranges. If input data

is not within the configured range, the MVI56E-AFC will flag an alarm on the

Meter Monitor dialog box (refer to Meter Monitor section) and the alarm bit for the

meter is set.

The entries available on this dialog box depend on the selected product group,

device, and primary input:

Zero Scale

This value is the minimum valid value for the input variable.

Full Scale

This value is the maximum valid value for the input variable.

ProSoft Technology, Inc. Page 63 of 149

October 2, 2018

Page 64

Common Parameters MVI56E-AFC ♦ Version 4.04

Enabling/Disabling the Meter (Control Opts)

When this option is selected, the meter will begin processing calculations. You

must disable the meter by unchecking this box before you can change the meter

type or product group. You should also disable any meter that is not being used

to allow for best possible module performance. After enabling or disabling the

meter, click DONE, and then click the WRITE button in the Meter Configuration

area. To retrieve the status of a meter, click the READ button in the Meter

Configuration area.

Note: The meter can also be enabled or disabled from ladder logic (refer to the MVI56E-AFC

Setup and Configuration Guide).

Backplane Return

There is at least one backplane function block that is repeatedly and frequently

delivered from the processor (PLC) to the module. This is the block delivers

process inputs used for measurement.

Process Inputs

The backplane transfer protocol specifies that each function block output by the

PLC to the module must elicit a corresponding input function block at the same

location in the overblock with the same size. This returned block contains no data

(contents are all zero).

In order to make use of the empty function block, functionality was developed to

increase efficiency. The normally empty function block from the module to the

PLC now contains selected values that would likely be required by the PLC

program on a regular basis. This is done by mapping slots in the input function

block to points in the Modbus address space. This process is known as

Backplane Return.

Component Analysis Function Block

Another function block that delivers a new component analysis for a gas stream

is similar. When required, it is delivered regularly and although output contents

are relevant, there are no matching input contents that are meaningful for such

an analysis.

The default configuration in the GUI shows the database points that were preselected from the process input return and the empty mapping for the analysis

return.

Page 64 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 65

MVI56E-AFC ♦ Version 4.04 Common Parameters

This provides the user with full functionality for the configuration of both

backplane return blocks.

The user is allowed to select desired values from the Modbus database which

the module delivers to the PLC automatically and on a regular basis without

having to create and issue a separate backplane transaction such as Modbus

Gateway in order to retrieve those values.

The user has the responsibility to re-trigger the analysis function block when the

previous one has completed. This makes the behavior semi-automatic (in

contrast to Process Input behavior which is fully automatic.

Using the Window

Move files from the Dictionary side of the page to the Process Input or

Component Analysis tabs.

1 Select the file.

2 Click on the Process Input or Component Analysis tabs.

3 Click the INSERT ITEM button.

4 Use the MOVE UP or MOVE DOWN buttons to move the file up or down in

the list.

5 Click OK.

If you are moving UDT files, move them from the Dictionary to the Process Input

tab as described for any files.

Click the UDT EXPORT button to export the UDT files.

ProSoft Technology, Inc. Page 65 of 149

October 2, 2018

Page 66

Common Parameters MVI56E-AFC ♦ Version 4.04

Configuring Calculation Options

Click on the CALCULATION OPTS button to access the Meter Calculations Options

dialog. Details on each option can be found in the Modbus Dictionary.

Options that to not apply to the current application are grayed out. See

Calculations Options in the MVI56E-AFC Reference Guide for detailed

information.

Page 66 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 67

MVI56E-AFC ♦ Version 4.04 Common Parameters

Configuring Resettable Accumulators

The MVI56E-AFC supports a total of 12 accumulators per meter channel, divided

into the following categories:

Non-Resettable Accumulators (6)

Resettable Accumulators (4)

Archive Accumulators (2)

Click the RESETTABLE ACCUM button.

The accumulator types are independent. For example, resetting a resettable

accumulator does not affect the other accumulators.

For multiple-stream firmware, each stream also has a set of ten accumulators

(six non-resettable, and four resettable). Increments are applied both to the

meter accumulators and to the accumulators for the active stream.

ProSoft Technology, Inc. Page 67 of 149

October 2, 2018

Page 68

Common Parameters MVI56E-AFC ♦ Version 4.04

Non-Resettable Accumulators

The non-resettable accumulators are only reset when the accumulator rollover

value is reached. The accumulator rollover value, and the accumulator unit must

be configured using the EAFC Manager.

The module supports six non-resettable accumulators in order to show the

measure quantity to be totalized.

Non-resettable accumulator mass

Non-resettable accumulator energy (Gas applications)

Non-resettable accumulator net

Non-resettable accumulator gross

Non-resettable accumulator gross standard (Liquid apps only). For Oil-

water emulsion, this is a non-resettable accumulator for gross clean oil.

Non-resettable accumulator water (Liquid apps only)

Refer to the Modbus Dictionary in EAFC Manager for more information about the

Modbus addresses for these registers.

Page 68 of 149 ProSoft Technology, Inc.

October 2, 2018

Page 69

MVI56E-AFC ♦ Version 4.04 Common Parameters

Resettable Accumulators

From the Resettable Accumulator Select window, click OPTIONS.

The resettable accumulators are referred to as:

Resettable Accumulator 1

Resettable Accumulator 2

Resettable Accumulator 3

Resettable Accumulator 4

Resettable Accumulators are configured from the Resettable Accumulator Select

dialog box. To open this dialog box, click the RESETTABLE ACCUM button on the

Meter Configuration dialog box.

ProSoft Technology, Inc. Page 69 of 149

October 2, 2018

Page 70

Common Parameters MVI56E-AFC ♦ Version 4.04

Accumulator

Modbus address for accumulator

select (Meter-relative)

Default Value

Resettable accumulator 1

126

Net (code 3)

Resettable accumulator 2

127

Gross (code 4)

Resettable accumulator 3

128

Gross Standard (code 5)

Resettable accumulator 4

129

Mass (code 1)

Code

Quantity

0

None

1

Mass

2

Energy (Gas Only)

3

Net

4

Gross

5

Gross Standard (Liquid Only)

6

Water (Liquid Applications Only)