www.pro-pen.com

TECHNICAL AND OPERATING MANUAL

M3000/d

PNEUMATIC VERSION

Reference : 90703-MDIS-4314/0810C1

Distributor stamp

P R O - P E N

Propen reserved all rights on improvement of its products.

This document is not contractual.

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap014314.fm.doc)

- 2

(Ref.90703-MDIS4314/0601C0-chap014314.fm.doc) PRO-PEN

Foreword

Before reading this manual, it is recommended, unless you have already done so, that you view the start-up video

included on the CD-ROM and execute the provided marking exercise .

It is nevertheless also highly recommended that you read the entire manual.

This machine is designed for marking applications. The manufacturer is not responsible for the quality of the work, or

for any damage resulting from improper use of the M3000, should it be used for any purpose other than marking.

This manual is designed to help you find the information you need as quickly and efficiently as possible.

It is made up of five main sections :

• Introduction - Start up,

• Using the marking program with a PC keyboard in the "program" mode,

• Using the marking program with a mini-keyboard in the "marking" mode,

• Using the machine,

• Technical data about the machine.

An index of key words will help you find information.

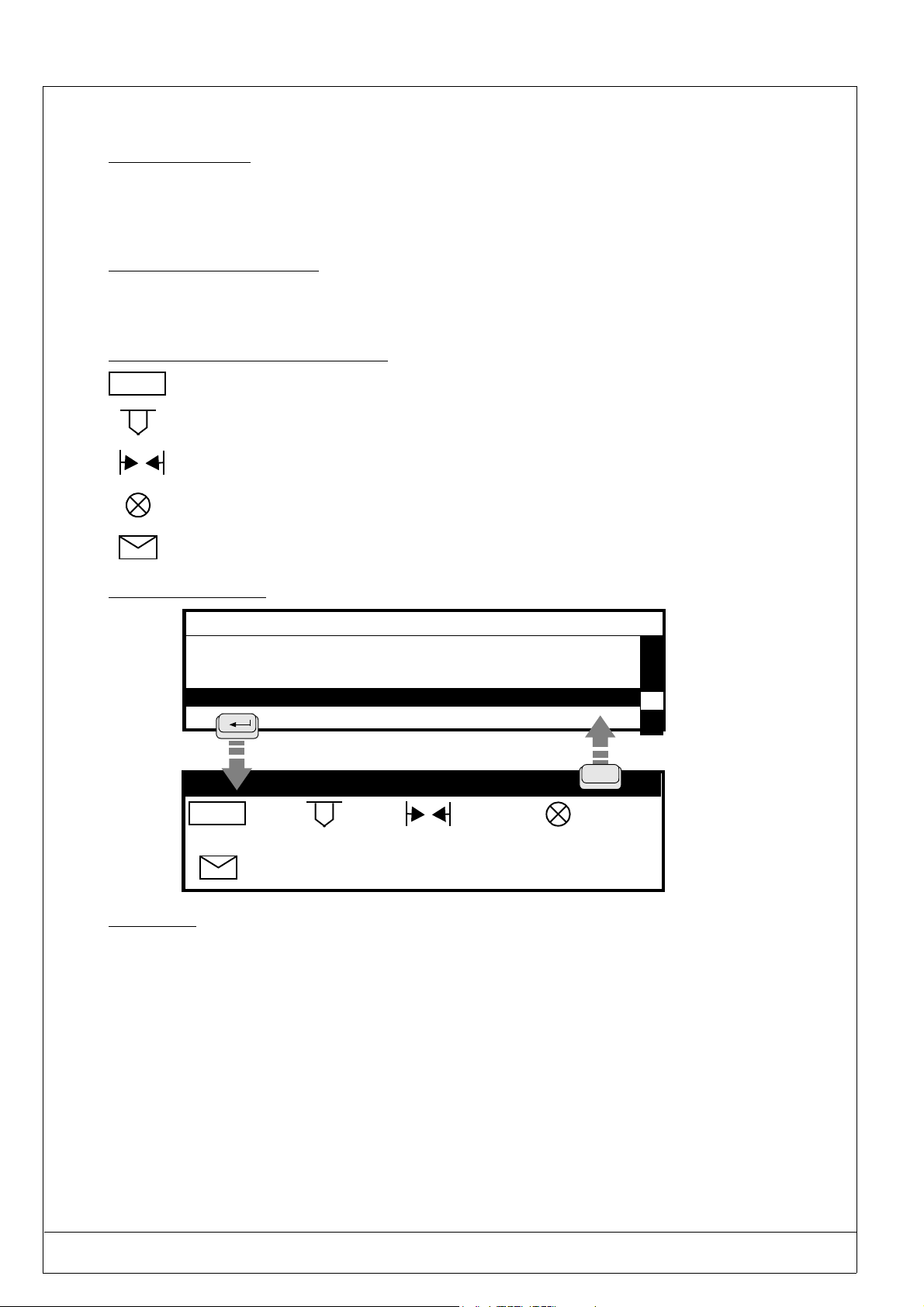

Furthermore, the four icons displayed below will help you to pinpoint the important points in the manual :

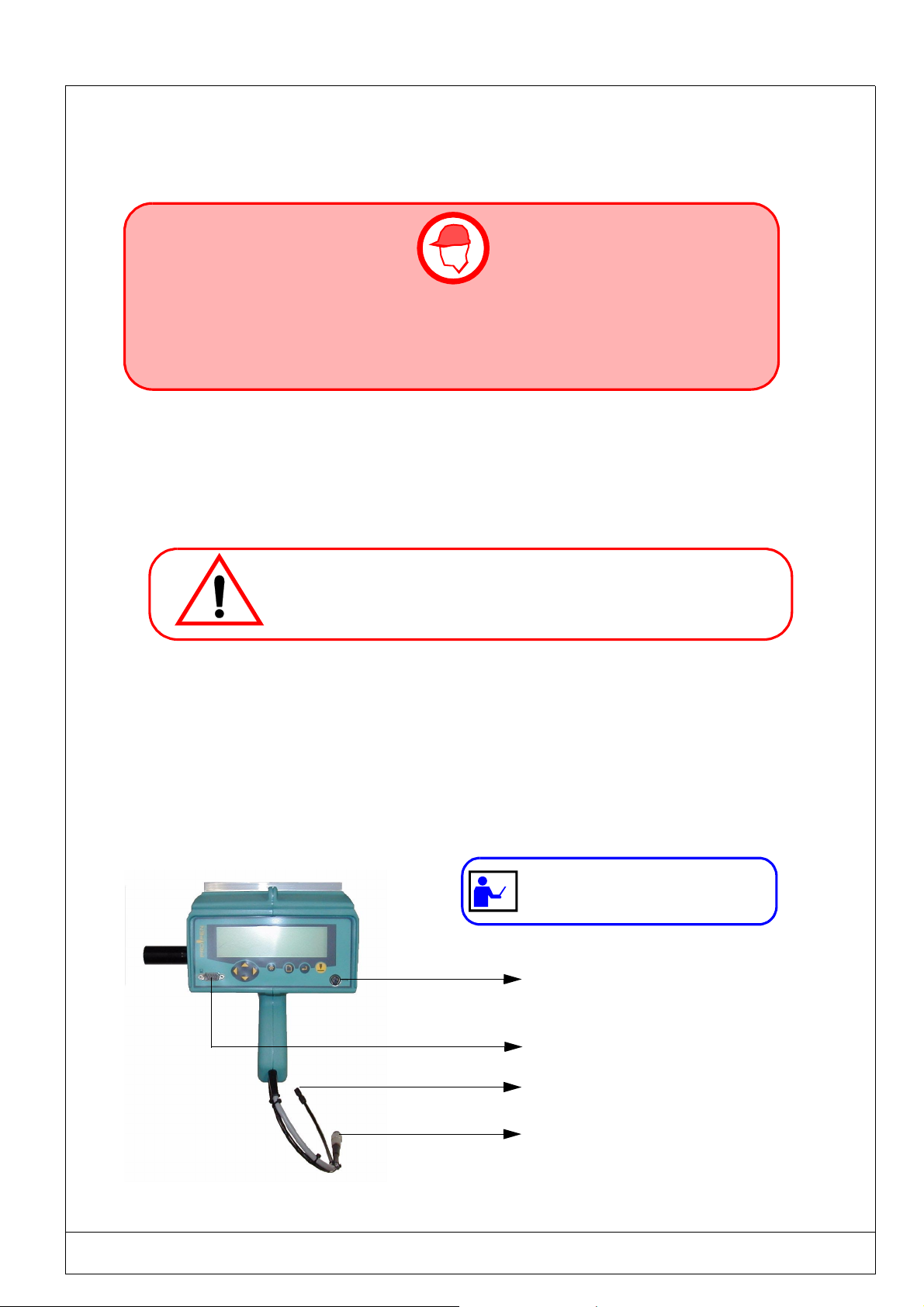

SAFETY AT THE WORKSTATION

Indicates the various precautions to be taken before installing and using

the M3000 safely.

RECOMMENDATIONS AND LIMITS OF WARRANTY

Indicates the various procedures to be followed to conform to the conditions of

the warranty.

ADVICE ON USE

Further advice on optimizing the performance of your M3000.

WHAT TO DO IF........

This icon refers to a chart in the last chapter giving instructions on what to do in

case of problems or a malfunction of your marking equipment.

- 3

PRO-PEN (Ref.90703-MDIS4314/0810C1-chap014314.fm.doc)

Technical Manual Updates

This chart will help you to keep track of the various updates to the manual since the first edition.

Date of

Revision

November 2003 0311A0 First edition

November 2003 0311B0 - Development of program P03 : version V6.00

January 2006 0601C0 . Change in certifying organization,

October 2008

Revised

name

0810C1

Modified pages

- Assembly with C clips

. Update of conformity certificate:

- Directive 98/37/CE,

- Directive 2002/96/CE.

Update of Regulation observance

- 4

(Ref.90703-MDIS4314/0601C0-chap014314.fm.doc) PRO-PEN

1

INTRODUCTION

AND START-UP

INTRODUCTION AND START-UP 1 - 5

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap014314.fm.doc)

1 - 6 INTRODUCTION AND START-UP

(Ref.90703-MDIS4314/0601C0-chap014314.fm.doc) PRO-PEN

1.1) Unpacking Instructions

When opened, the package will appear as shown below:

power block

battery pack

lateral handle

accessories

documentation

battery cable

PC keyboard

INTRODUCTION AND START-UP 1 - 7

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap014314.fm.doc)

1.2) Description of the M3000

1.2.1. Generalities

The M3000 is a numerically-controlled micro-percussion marking M3000. The mechanical part is based on a X/Y table

guided by step by step motors that move a marking tool.

The electronic command is incorporated within the machine. It is made up of electronic boards and a cooling system.

The man/M3000 interface is also incorporated and made up of :

1 LCD screen

1 Mini keyboard

1 switch on the handle to trigger marking.

All of the elements making up this equipment are run by a simple user-friendly marking program.

The external PC keyboard (105 keys) is also included with the M3000 for easy programming of the files.

As a further option, the M3000 may be driven by a Windows® based program when connecting the Control Unit to a PC

using an RS232 cable.

Its light weight and its specially conceived ergonomics will permit the operator to carry it to the parts to be marked no

matter where they are located, on a working site, in a hangar, etc...

The electric power needed to run the M3000 may come directly from the mains supply or from the portable battery attached to the operator’s belt.

The connection to the pneumatic supply is situated at the end of the handle.

1 - 8 INTRODUCTION AND START-UP

(Ref.90703-MDIS4314/0601C0-chap014314.fm.doc) PRO-PEN

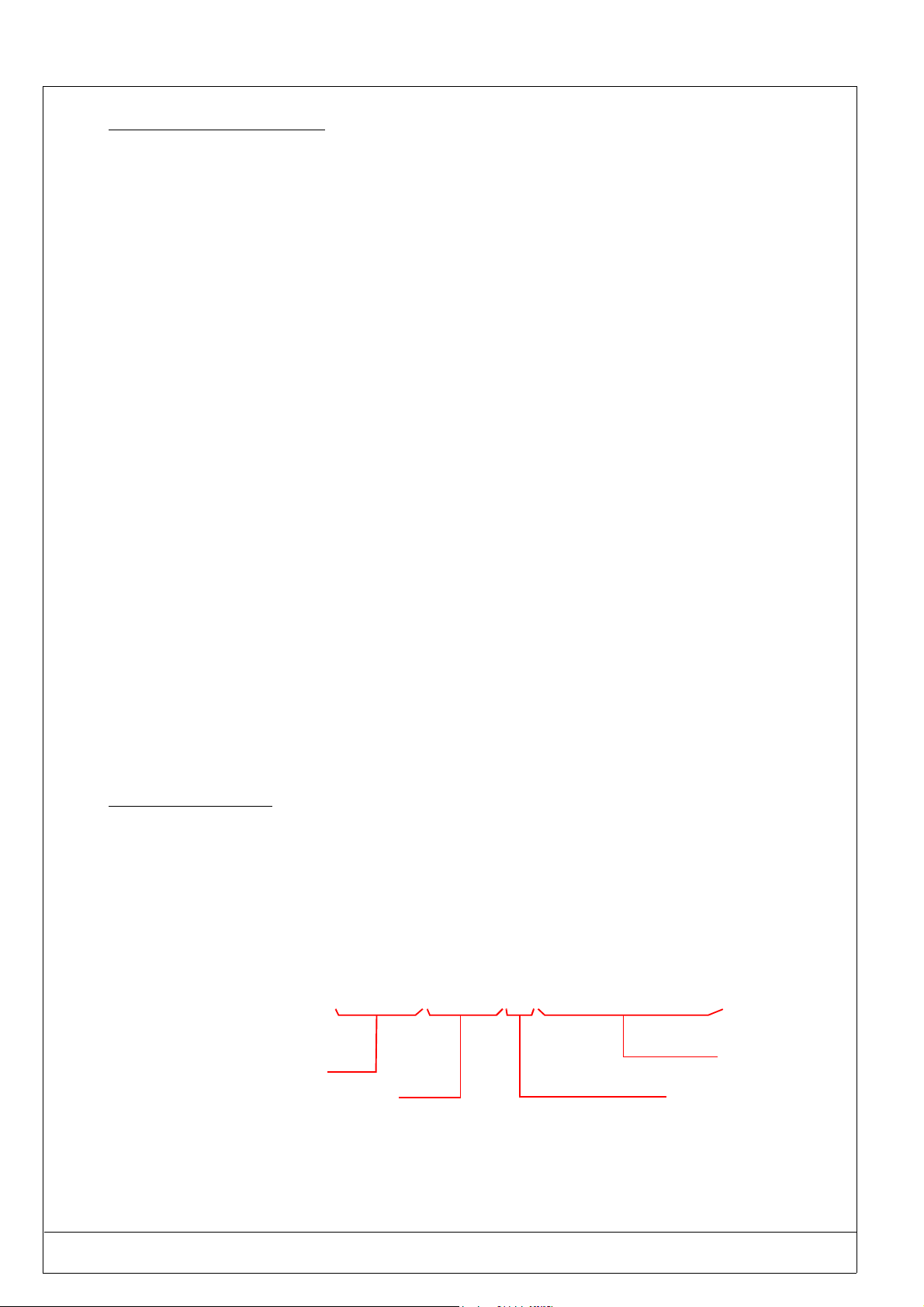

1.3) Physical Characteristics

• Weight : 4.8 Kg. - side handle excluded

• Layout of overall dimensions

DIMENSIONS

Unit

INTRODUCTION AND START-UP 1 - 9

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap014314.fm.doc)

1.4) Functional description

Hole for lifting ring

front side

RS232 plug for connection

with a PC

Lateral support handle:

It can be attached on the right

or on the left of the M3000.

Power Outlet towards:

- the mains supply

or

- the battery

mini-keyboard

keyboard plug outlet

of PC type

1 - 10 INTRODUCTION AND START-UP

(Ref.90703-MDIS4314/0810C1-chap014314.fm.doc) PRO-PEN

1.5) Identification plate of the marking equipment

Your marking equipment may be identified by its descriptive plate glued on the M3000.

Please note down the type and the serial number of the element for all correspondence with Pro-Pen.

INTRODUCTION AND START-UP

1 - 11

Regulation observance

Manufacturer, GravoTech Marking SAS - 56 avenue Jean Jaurès BP 80015 - 10604 LA CHAPELLE SAINT LUC France (head office) declares:

! Declaration of compliance

CE marking on the equipment attests the observance of the following European directives:

• Directive 98/37/EC of the European Parliament and of the Council of 22 June 1998, concerning the consolidation of the laws of member states relating to the machines.

• Directive 2006/95/EC of the European Parliament and of the Council of 12 December 2006 on the harmonisation of the laws of the Member States relating to electrical equipment designed for use within certain voltage

limits.

• Directive 2004/108/EC of the European Parliament and of the Council of 15 December 2004 on the harmonisation of the laws of the Member States relating to electromagnetic compatibility.

! Declaration of compliance to other directives

Equipment is compliant with the following European directives:

• amended Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on waste

electrical and electronic equipment (WEEE).

Waste Electronic and Electrical Equipment

This symbol indicates that once this equipment has reached the end of its useful life, it must not be

disposed of with non-sorted municipal waste, in accordance with European Directive 2002/96/EC.

The equipment must be disposed of at an appropriate collection point for processing, sorting, and

recycling of Waste Electronic and Electrical Equipment (WEEE).

The elements which compose Waste Electronic and Electrical Equipment (WEEE) may contain substances which

have harmful effects on the environment or on human health.

By following these instructions, you are helping the environment, contributing to the preservation of our natural

resources, and protecting human health.

! Declaration of compliance to norms

The equipment is compliant with the following norms:

• Standard NF EN 61000-6-2 of January 2006 concerning electromagnetic compatibility (EMC) - Part 6-2: generic

standards- Immunity for industrial environments.

• Standard NF EN 61000-6-4 of March 2007 concerning electromagnetic compatibility (EMC) - Part 6-4: generic

standards- Standard on emissions for industrial environments.

The modification or transformation of this equipment, adaptation and accessor y

installation unrecommended by Pro-Pen modify this equipment’ s characteristics and

therefore void the compliance with the applicable EU directives. These modifications

void Pro-Pen’s liability. In this case, the machine and equipment installer is

responsible for the final work station’s compliance.

PRO-PEN (Ref.90703-MDIS4314/0810C1-chap014314.fm.doc)

1.7) Limits of use and recommendations

To ensure your safety and extend the life of your M3000, please read this manual before using the

equipment.

• This equipment has been designed to function between :

• 5°C and 40°C with mains power,

• 5°C and 30°C with battery supplied power.

• Do not use this marking equipment in an explosive environment.

• The ground connection of the M3000 must conform to current legislation. The M3000 should be

connected to the electric monophased power supply using a standard 3 pin plug including one

ground connection.

• During marking operations, the operator should keep fingers and all other objects away from the

area where the marking tool will evolve.

Should this advice be disregarded, possible injuries could result in pinching and light scratching.

1.8) Conditions of warranty and limits of use

This equipment is designed to be used with PRO-PEN marking tools. Any other use, or the use of a non

PRO-PEN marking tool is the sole responsibility of the operator.

• Never lubricate any part of the marking tool or the guiding bars of

the carriages with any product whatsoever.

• Never use more than 6 Bar of air pressure.

• The compressed air has to be brought in by a suitable installation.

• The air has to be clean and dry and not greasy.

PRO-PEN is not responsible for any injuries resulting from disregard of the above rules of operation,

or other general safety rules applicable for the use of this equipment. Furthermore, disregard of this

advice may suspend the warranty.

For more information, please refer to the warranty note delivered with the M3000.

• The batteries are not included in the warranty of your M3000. In order to lengthen their

lifespan, consult the recommendations found in chapter 4.3) Battery and Charger

• Never use any battery or power supply not delivered by PRO-PEN

• Never recharge the battery with a charger other than the one delivered by PRO-PEN.

1 - 12

INTRODUCTION AND START-UP

(Ref.90703-MDIS4314/0601C0-chap014314.fm.doc) PRO-PEN

1.9) Start - up

MAKE SURE THAT THE M3000 IS SWITCHED OFF BEFORE MAKING ANY ELECTRICAL

CONNECTIONS OR CONNECTING COMPONENTS.

THE POWER SUPPLY SHOULD BE CONNECTED LAST.

1.9.1. Installation

After unpacking the equipment, it should be installed on a workbench.

• Never place the M3000 on the floor.

Liquid or solid impurities could seep into the M3000 and block its running.

1.9.2. View of the connections

To start the M3000, connect it to 24V power, then, depending on the case, connect it to either:

• the PC keyboard

or

• the RS232 connection

The RS232 connection is not obligatory for operating

keyboard connection

RS232 connection

Connection for pipe Ø4 x 6

Power 24V connection

INTRODUCTION AND START-UP 1 - 13

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap014314.fm.doc)

1.9.3. Connecting the keyboard

Plug the connecting plug to the socket shown in the picture on page 12.

The connector of the M3000 is a Mini Din female type.

1.9.4. Connecting the compressed air

A rapid connector for flexible tubing (.Ø 4 x 6) is fitted at the end of the tubing. If your installation uses tubing of a

different diameter, this connector can be replaced by one of an appropriate diameter

The air pressure at the connector should always be between 5.5 and 6 Bar.

The usage of tubing that is too long will cause a drop in pressure. In this case, the pressure at the end where the air enters

should be above 6 Bar in order to ensure a range of 5.5 to 6 Bar at the gun entrance.

Use a pressure reducer valve/ pressure release valve with a simple filter (Ref.: 2501).

1.9.5. Connecting the power supply

1.9.5.1 - Connecting the power supply

• Check that the input voltage of your power supply is correct: 115 or 230V

The power supply must be connected in this order:

1. M3000 : Attach and lock the metallic male connector to the female connector.

2. Supply : Reconnect the male plug to your low voltage power supply.

1.9.5.2 - Connecting the battery (optional)

• Put on the battery belt. The battery should be on your back.

• From the M3000 side :

- Push and screw the metallic male connector to the 1 m. cable (female part)

- Push and screw the circular plug (Jack type, 6.35mm) to the rear of the battery case

1.9.6. Connection to a ground connection in both cases:

The marking equipment must be properly grounded to provide:

- A safe environment for the operators,

- A permanent electric potential to be used as a reference,

- A protection against electromagnetic interference.

The ground connection in the factory must be of good quality. If such were not the

case, a specific ground connection should be installed for the marking equipment.

1 - 14 INTRODUCTION AND START-UP

(Ref.90703-MDIS4314/0601C0-chap014314.fm.doc) PRO-PEN

INTRODUCTION AND START-UP 1 - 15

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap014314.fm.doc)

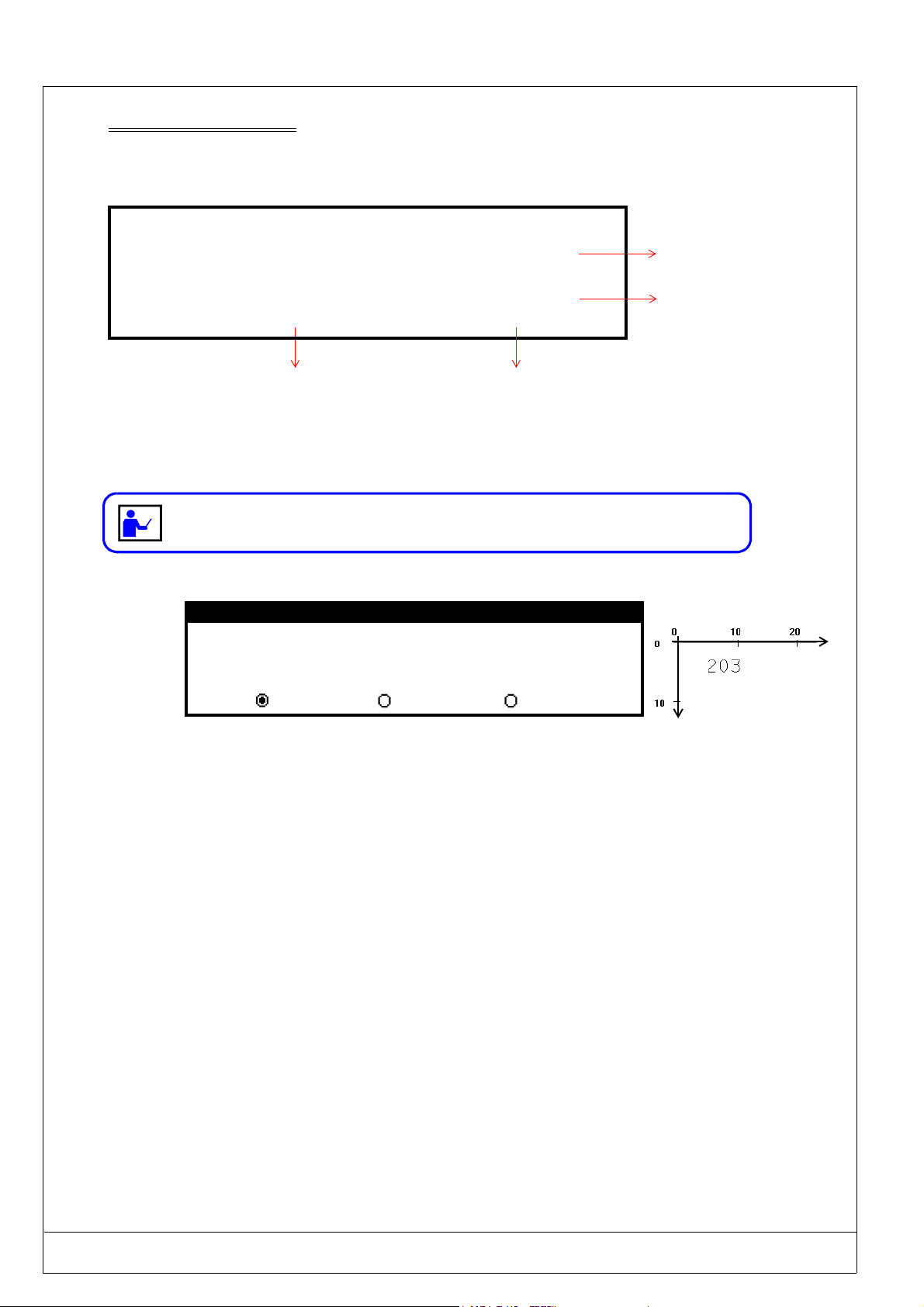

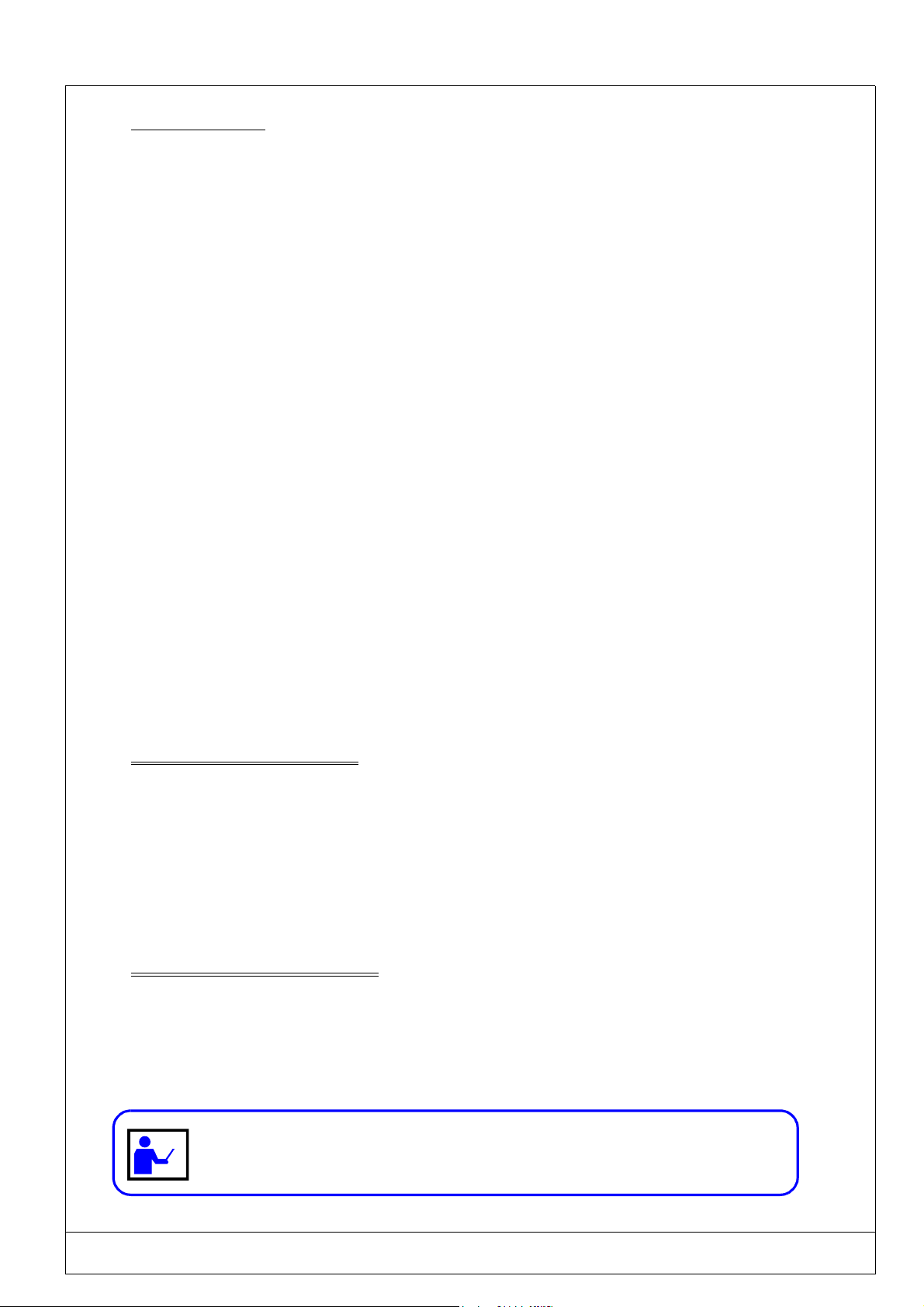

1.10) Coordinate system

The coordinate system used by your M3000 is as shown in this diagram.

The origin position in relation to the foot is given with a ± 1.5mm. tolerance. This

position is defined by the 3 and 5mm values.

.

Y axis - 40mm path

Origin

Foot

X axis - 60mm path

COORDINATES

Unit

When you hold the M3000 :

• The coordinates will be given in absolute values in relation to the origin.

• The X axis is a horizontal axis going from left to right.

• The Y axis is a downward vertical axis.

The two axes are run by the marking program.

At the beginning of a cycle, the marking tool will always begin at the 0 origin and will return to this origin point at the

end of the cycle.

1 - 16 INTRODUCTION AND START-UP

(Ref.90703-MDIS4314/0601C0-chap014314.fm.doc) PRO-PEN

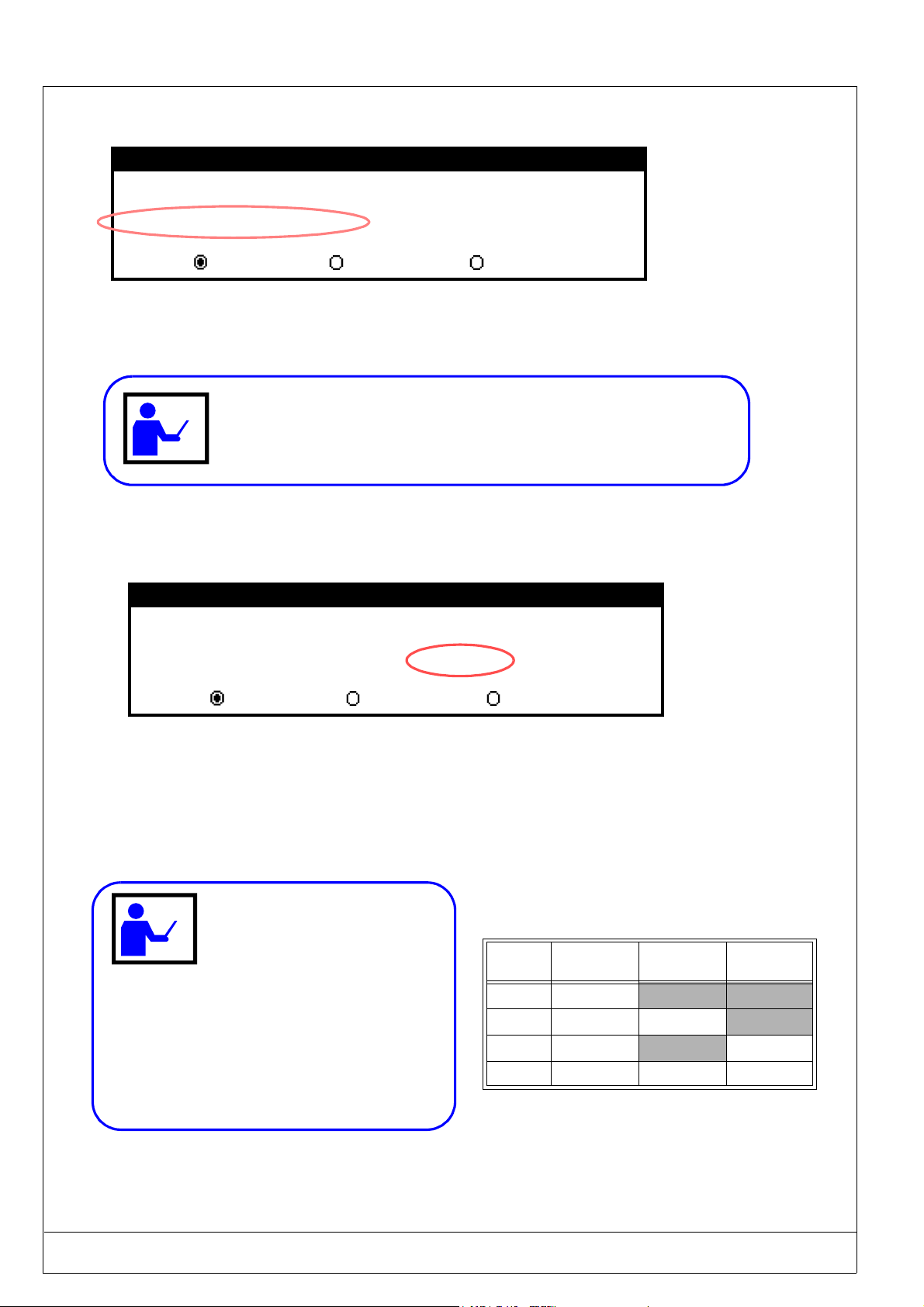

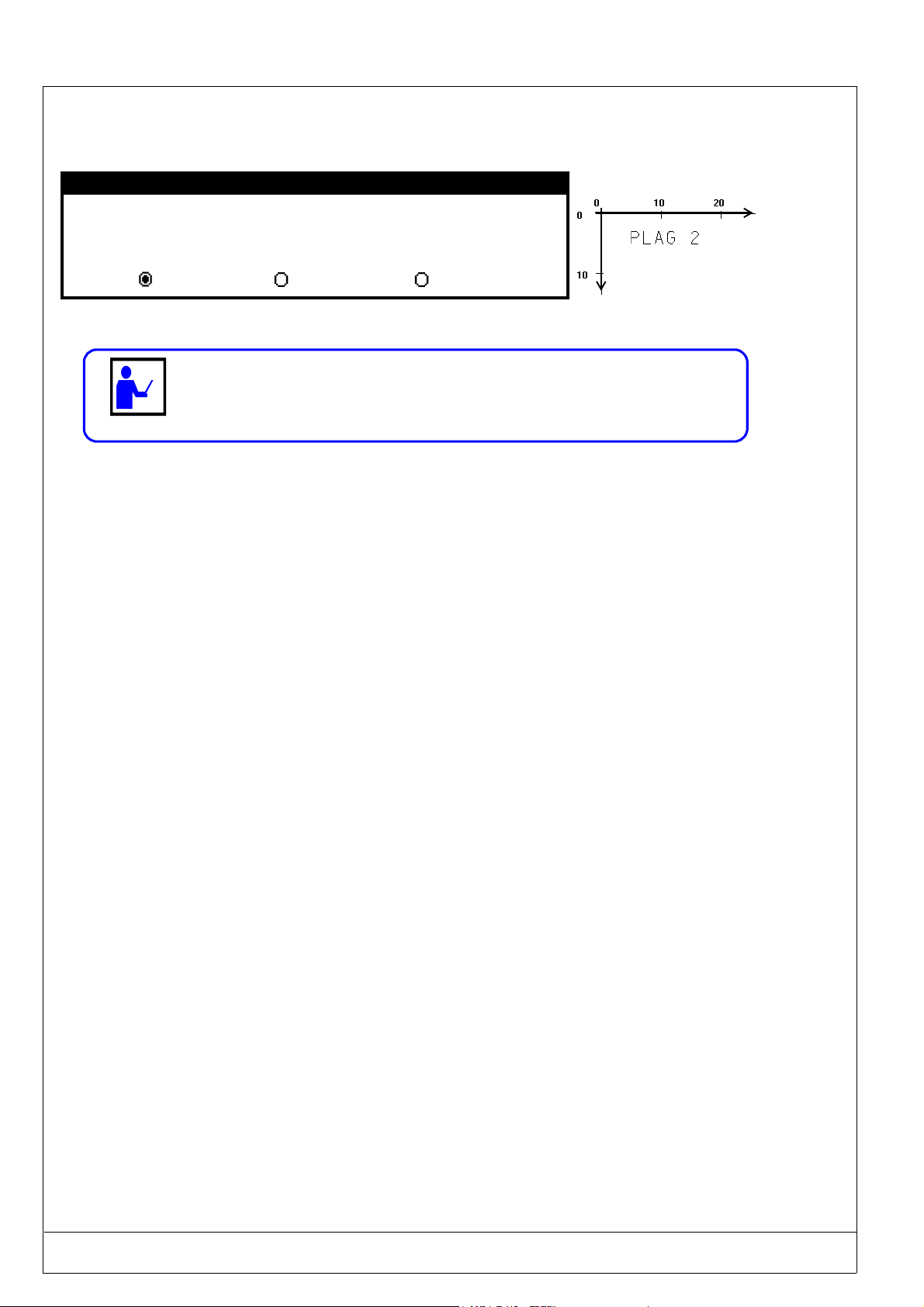

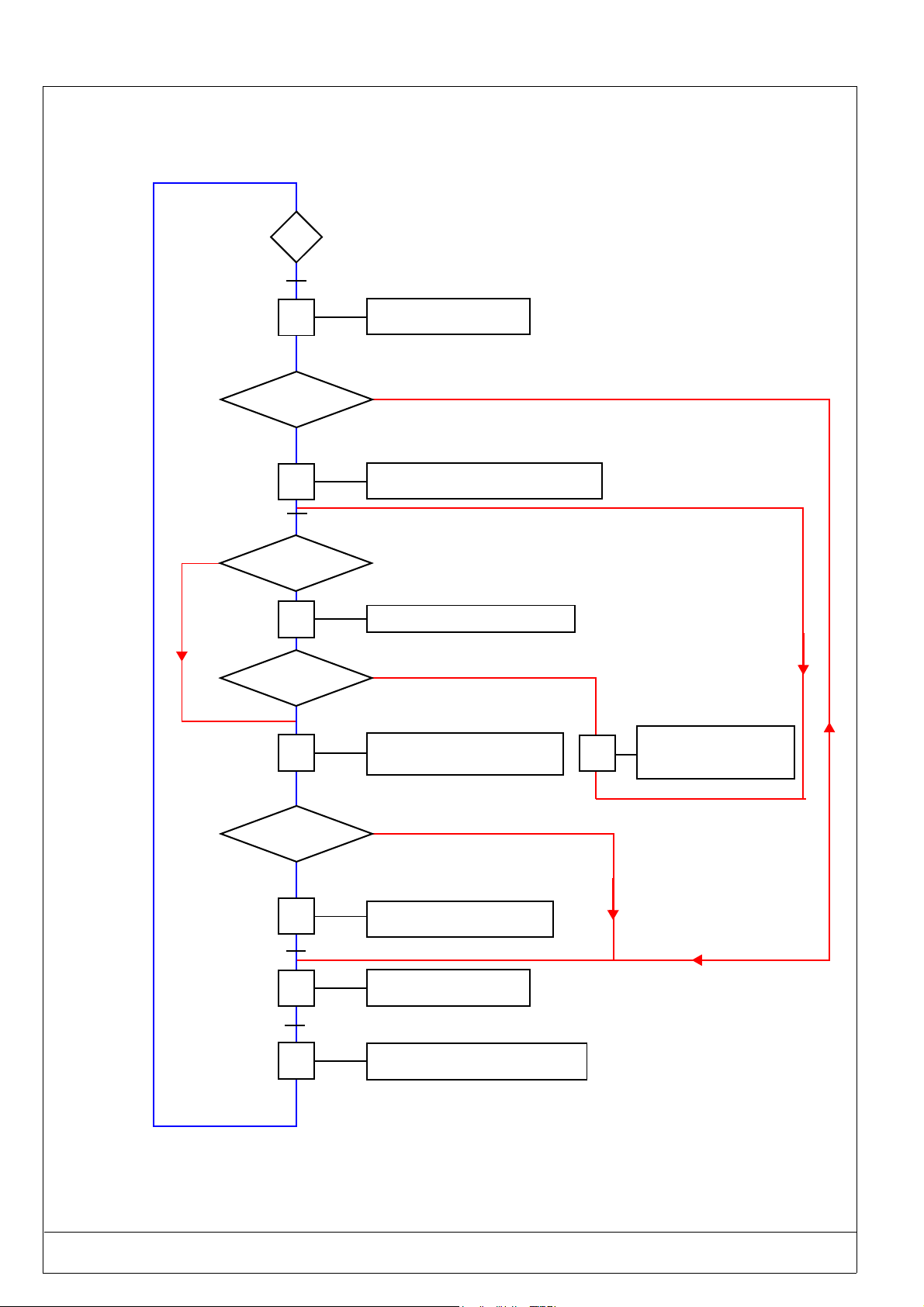

1.11) Starting up the program

The marking program will automatically start when the M3000 is switched on:

An introduction screen will appear after a few seconds:

Name

PRO PEN

and then will be replaced by the main menu screen shown in the following chapter.

Version XXXX (XX/XX/XXXX)

M 3000

program

version

(Nº + date)

Should you have any problems or questions regarding your equipment,

please contact your distributor, giving the information shown on the

introduction screen.

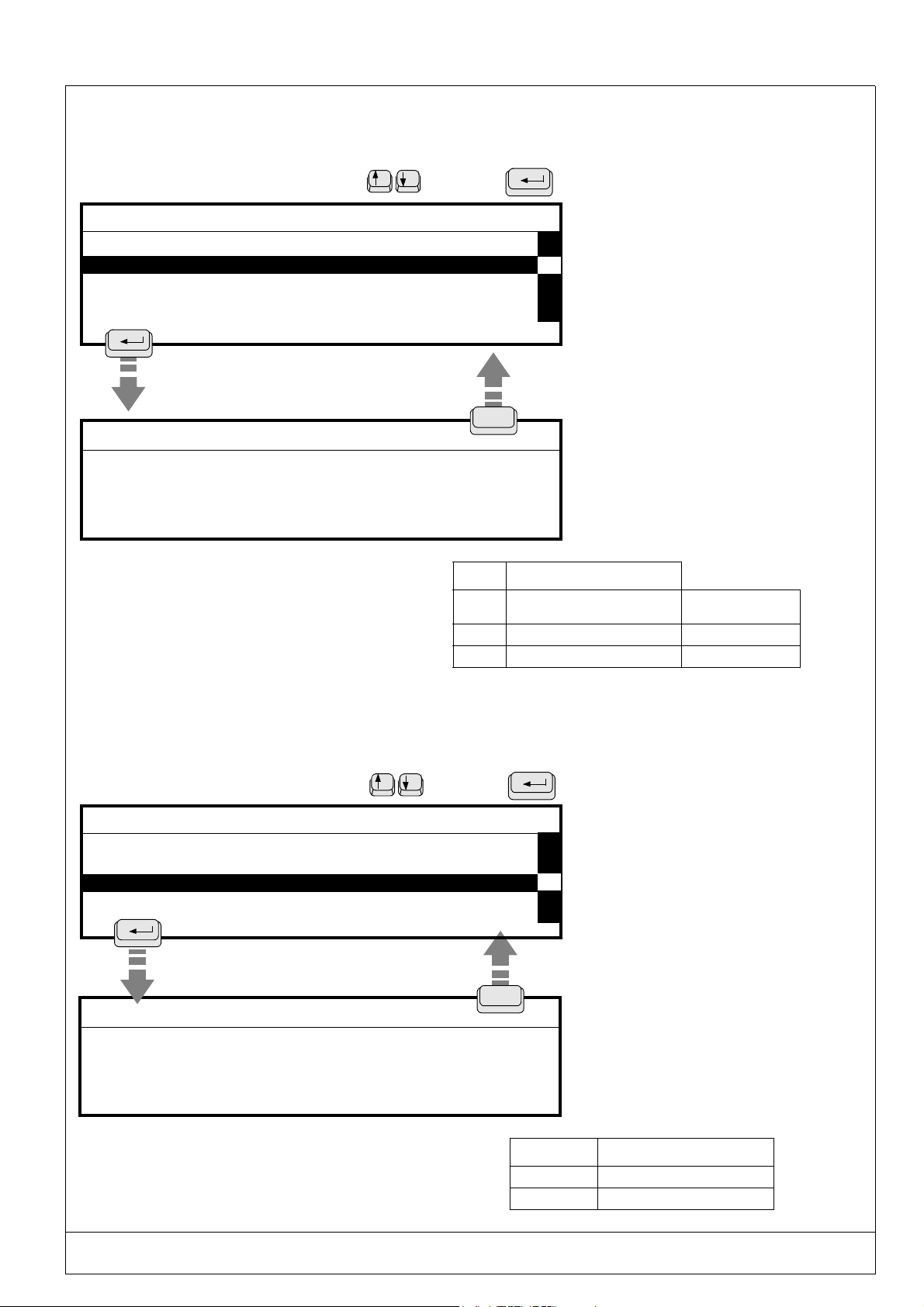

After turning the power on, two cases shown below could possibly occur:

Power on

PC keyboard

connected

NO

See chapter 3 - operating

with the mini keyboard

See chapter 2 - operating

with an external keyboard

YES

INTRODUCTION AND START-UP 1 - 17

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap014314.fm.doc)

1 - 18 INTRODUCTION AND START-UP

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2

USING THE MARKING

PROGRAM WITH

EXTERNAL KEYBOARD

IN "PROGRAMMING"

MODE

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 1

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2 - 2 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.1) General information

The following chart shows the the marking program’s many possibilities..

Marking Possibilities: Texts

Logos

CE logo in separated dots

Lines - circle - arcs of circle - ovals - rectangles

Fonts: Continuous stroke

Highly legible separated dots

5x7 standard

Marking Type: Linear, horizontal or vertical marking

Angular and radial marking

Marking date and hour

Marking variables (serial numbers, batch numbers ,

shifts...)

Marking effects: Normal

Inverted

Mirrored

Reflected

Character format: Height of characters from 1 to 80 mm (0.1mm steps)

Automatic centering of text

Compression of characters between 0.1 and 9.99

Inclination of characters between -180° and +180°

Variable spacing between characters

Software functions: Creation of marking files

Marking one time, n times, infinite and repeat last

Short cut funtion keys

Simulation of marking file or block

Pause after the blocks

Parameters Choice of user language

Conversion and management of units : millimeters or

inches

Two user levels : operator or supervisor

Downloading of logos

Definition of marking priorities (marking quality, intermediate, cycle running time)

Indication of "Julian" date and daylight saving time

Historical file

Dialogue configuration with machine

Data reception by RS232

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 3

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.2) The program menus

2.2.1. Main menu

The main menu has five sub-menus, each represented by an icon :

Marking Menu

(see chapter 2.6)

File Menu

Create/Display/Modify

marking files

(see chapter 2.6)

File Manager Menu

(see chapter 2.7)

Downloading Menu

Communication with PC

Configuration Menu

(see chapter 2.9)

H

Function Mode

(see chapter 2.9.1.)

(optional)

(see chapter 2.8)

2 - 4 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.3) Access to different menus

The external keyboard gives access to the various menus and functions of the marking program, and will permit you to

enter information needed for marking. The main keys used are the following :

ENTER

ESC

ARROW KEYS

UP - DOWN

LEFT

RIGHT

FUNCTION

KEYS

F2 TO F12

PAG E U P

PAGE DOWN

SPACE

TAB

F2

Esc

Access to different menus or to different entry zones in a marking file.

Validate data.

Return to the previous screen.

Move the cursor within the entry zones.

Access to different program functions.

F12

Move between blocks in a marking file.

Moving the cursor between the various entry zones.

ESC : Return to previous screen F2 to F12 : Access to different

program functions

Esc

~

!

1

Tab

Ctrl

SPACE : Activation / Deactivation

of ticked boxes

2

F1

F3

F2

2

“

£

2

3

F4

$%

5

4

F5 F6

&

6

F7

(

‘

7

)

8

9

F8

#

0

F9 F10

=

-

QWER TYU I OP

AS D F GHJ K L

MZXCVBN

Alt

+

;

^

<

>

.

,

Alt Gr

ENTER : Validation

of entered data

?

/

105 Keys AT Keyboard (QWERTY)

Access a menu using the TAB

or arrow keys.

The selected icon will be backlighted

Press

PAGE UP- PAGE DOWN :

Moving between blocks

Scroll

lock

End

Pause

Attn

num

/

lock

*

789

456

123

End

0

Inser Delete

.

_

+

Enter

Screen

F11 F12

print

Syst

_

_

{

@

[

}

]

Inser

Delete

Enter

Ctrl

ARROW KEYS UP-DOWN-LEFT-RIGHT :

Moving the cursor within

the entry zones

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 5

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.4) Definition of a marking file

A marking file contains all the data to be marked on a part. It may be made up of one or several lines.

In the language of PRO-PEN, a marking file is made up of marking blocks.

The block to be marked may be made up of alphanumeric text or a logo,...

A marking file contains between 1 and 25 marking blocks.

The marking file for the plate shown opposite is made up of

5 marking blocks.

The following pages will explain the preparation of these

marking blocks.

All the necessary details for the personalization of the marking blocks will be included. (creation or

modification of a file, etc.)

2.5) Creation of a marking file

2.5.1. New marking file:

A new marking file may be created at all times using

the SHIFT + F5 keys

F5

+= NEW FILE

2 - 6 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

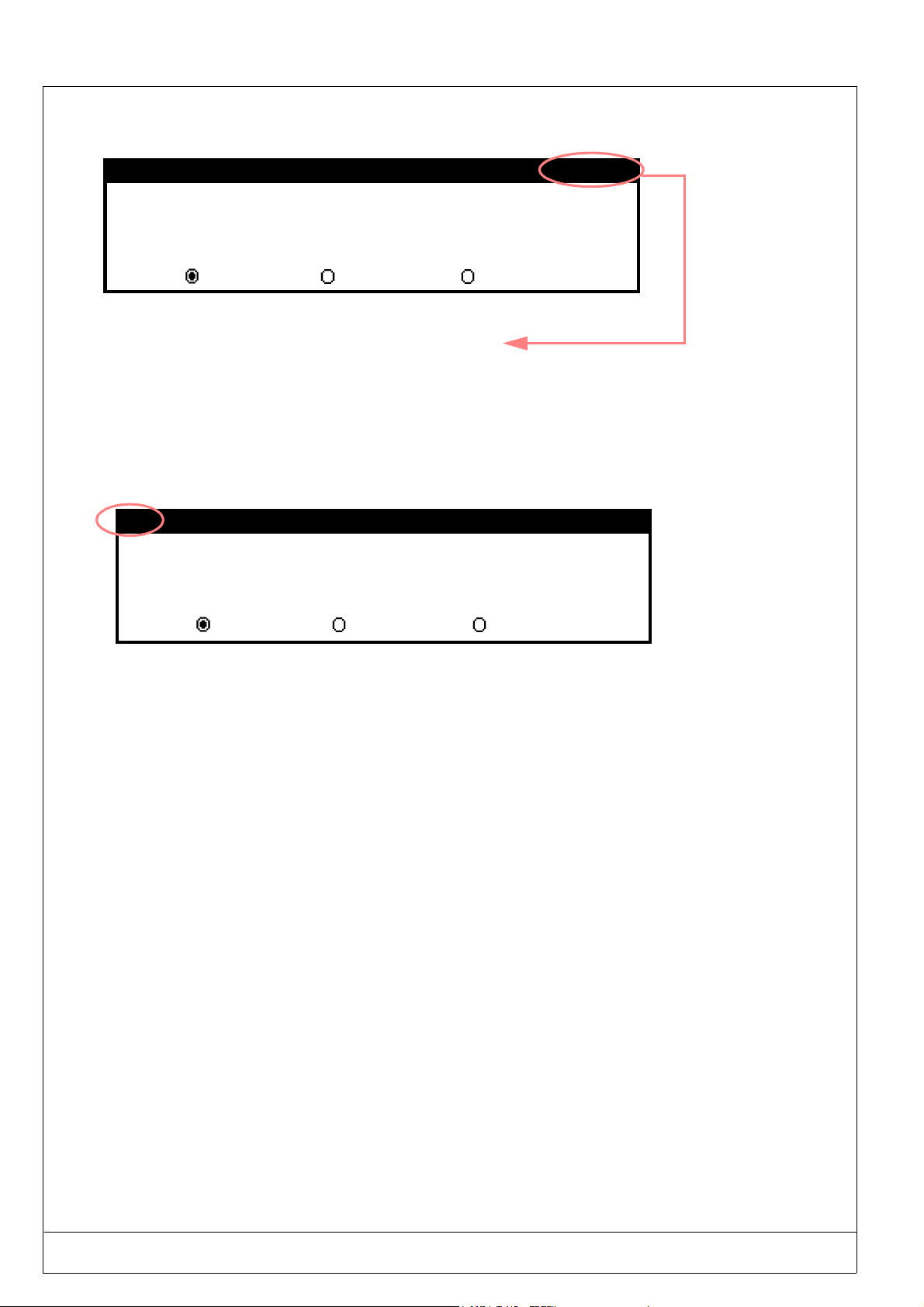

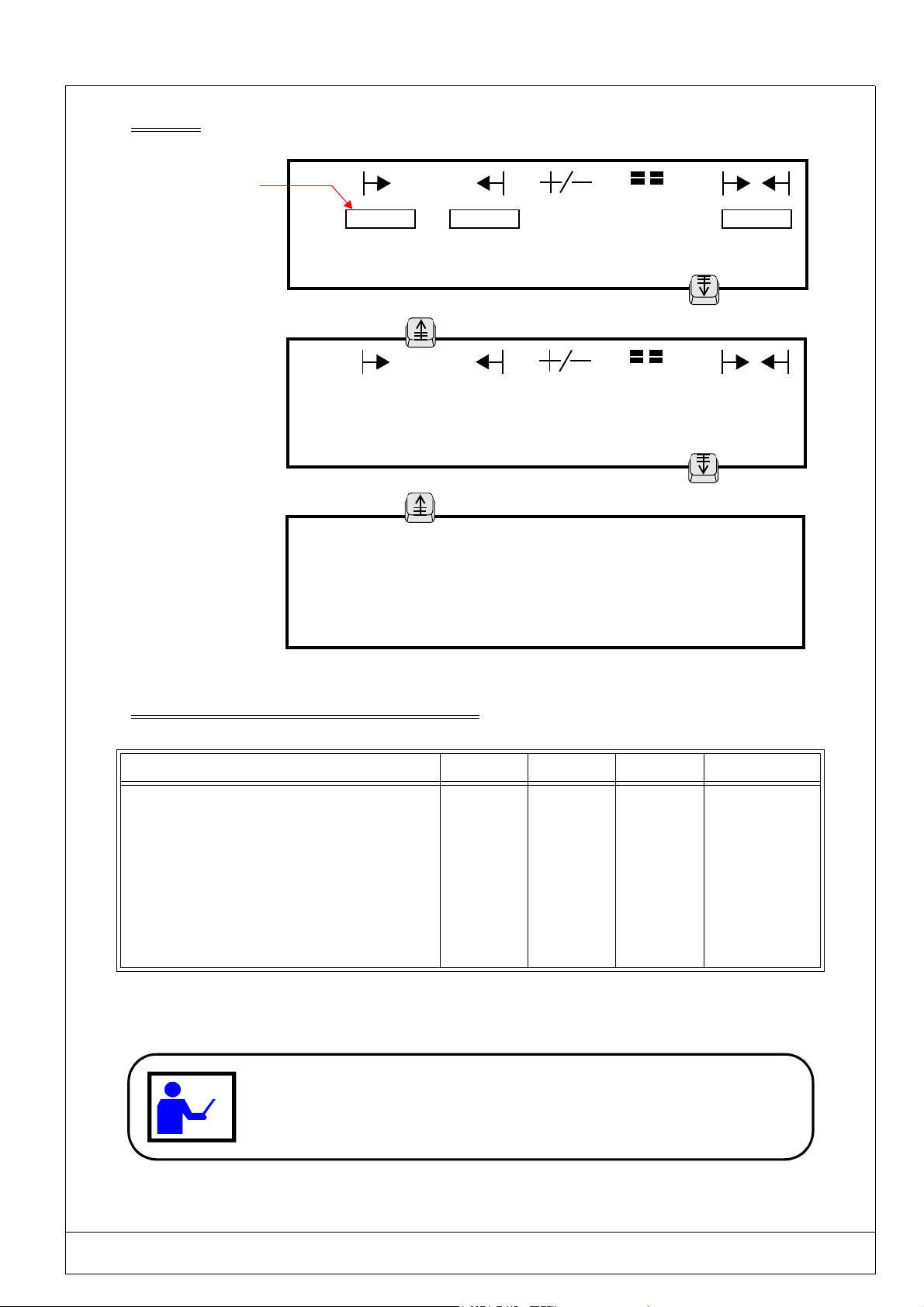

2.5.2. Marking data entry screen

The following procedures must be carried out when creating the first marking file.

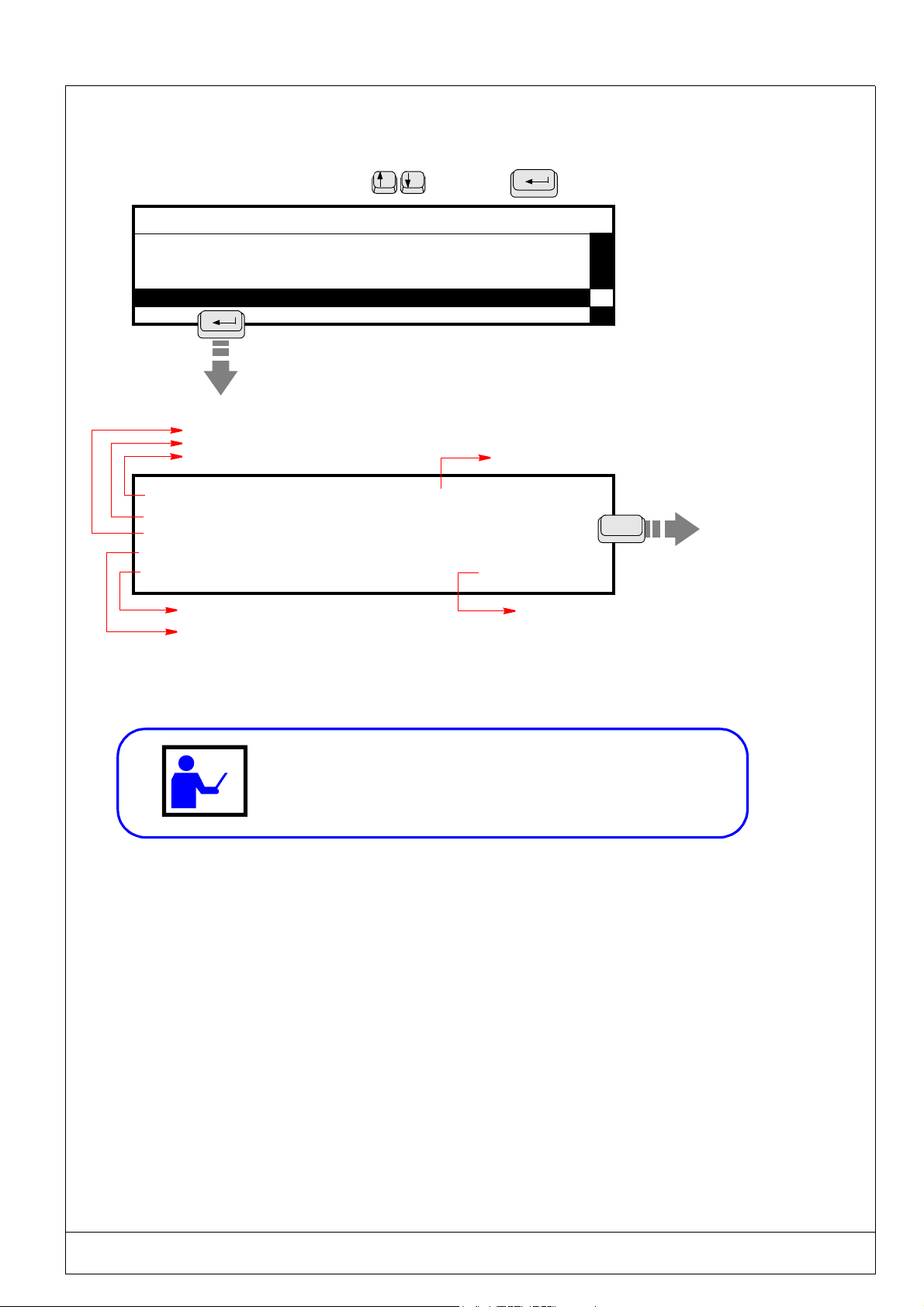

Select the “File” Menu using the arrow keys. Press or TAB

No files in memory. Press F5 to create a file.

F5

to validate.

H

Block :

Esc

*

X : 0.00 Y : 0.00 [mm]

Text :

Size : 0.50 [mm] Stroke : 2

Linear Angular Radial

F2

Block : 1

8 / 81

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Pause Font N° : 0

Spacing : 1.00

Inclination : 0.00

To move between blocks in a marking file, use the "Page UP" and

"Page DOWN" keys located above the 4 arrow keys (see § 2.3)

:

4/4

:

Block : 1/1

“Empty” marking

block with

entry zones for entering

characteristics.

Esc

Special

marking

effects

Access to previous block in the marking file

Access to following block in the marking file

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 7

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.5.3. Preparing a marking block

2.5.3.1 - Marking characteristics

7

1

*

2

3

1 - X-Y Coordinates............................................................... 2.5.4. 2-9

2 - Text to be marked ............................................................. 2.5.5. 2-10

3 - Character size....................................................................2.5.6. 2-12

4 - Stroke................................................................................2.5.7. 2-12

5 - Type of marking................................................................ 2.5.8. 2-13

6 - Block N° ...........................................................................2.5.9. 2-18

7 - Number of current file ....................................................2.5.10. 2-18

2.5.3.2 - Marking parameters

X : 0.00 Y : 0.00 [mm]

Text :

Size : 0.50 [mm] Stroke : 2

Linear Angular Radial

55 5

Chapter Page

88 8

1

Block : 1/1

6

4

8

Block : 1

Normal Mirrored Inverted Reflected

2

3

Centering

Compression : 1.00

Inclination : 0.00

14

8 - Marking effect ......................................................................................2.5.11. 2-19

9 - Automatic centering ............................................................................... 2.5.12. 2-21

10 - Pause ...................................................................................... 2.5.13. 2-22

11 - Font N° ..................................................................................... 2.5.14. 2-23

12 - Compression ..................................................................................... 2.5.15. 2-23

13 - Spacing ..................................................................................... 2.5.16. 2-23

14 - Inclination ...................................................................................... 2.5.17. 2-24

8 / 81

Pause Font N° : 0

Spacing : 1.00

10

13

:

4/4

:

11

Chapter Page

2 - 8 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

MARKING CHARACTERISTICS

2.5.4. X and Y Coordinates

*

X : 2.50 Y : 10.00 [mm]

Text :

Size : 0.50 [mm] Stroke : 2

Linear Angular Radial

The X - Y coordinates position the text in the marking zone.

They are given :

- In millimeters or in inches, depending on the chosen units,

- With a precision of 0.1 mm (5/100"),

- In absolute values related to the M3000 origin.

These coordinates may be entered :

- Using the keyboard directly,

- Using the F3 function key (see chapter 2.10.2.)

- Using the F9 function key (see chapter 2.10.8.)

Y = 10 mm

X = 2.5 mm

0

10

Y

Block : 1/1

100

20

X

2.5.4.1 - Linear and angular marking

For these two modes, the coordinates correspond to the point at the bottom left of the first character

marked.

X

0

0

Y

10

Y

10

Linear marking

20

X

X

0

0

10

Y

Y

10

Angular marking

20

X

2.5.4.1 - Radial marking

The coordinates correspond to the center of a base circle.

0

10

0

10

Y

X

20

X

20

Y

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 9

Radial marking

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.5.5. Text to be marked

*

X : 0.00 Y : 0.00 [mm]

Text : Marking machine

Size : 0.50 [mm] Stroke : 2

Linear Angular Radial

Enter the text to be marked in the designated block

The text may be made up of :

and/or

upper and lower case characters,

and/or

numbers,

and/or

lines,

and/or

“keywords”

The maximum number of characters per block is 30.

The letters and numbers to be marked depend on the font selected.

(see chapter 2.9.7.).

Block : 1/1

2.5.5.1 - Definition of "keywords"

The keywords correspond to codes interpreted by the marking program.

These are not marked literally, but “converted” before marking. The keywords are framed between the character @.

2.5.5.2 - Using "keywords"

Keywords must be framed by the character "@" in the text entry zone.

Example of a marking file :

*

X : 5.00 Y : 5.00 [mm]

Text : @"Miribel, "DD/MM/YY@

Size : 3.00 [mm] Stroke : 2

Linear Angular Radial

Marking obtained

Block : 2/2

X

Miribel, 07/02/01

Y

2 - 10 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

List of "Keywords"

KEYWORDS DEFINITION CORRESPONDING MARKING

@DD@ day of the month - 01 to 31 09 - for the 9th day of the month

@MM@ month of the year - 01 to 12 05 - for the month of May

@YYYY@ year in 4 figures 2002

@YY @ year in 2 figures 02

@Y@ year in 1 figure 2

@hh@ hour - 00 to 23 12 - for 12 hr

@m@ tenths of minute (first figure) - 1 to 5 2 - for 12 hr 28 mins 35 secs

@mm@ minute - 00 to 59 28 - for 28 mins

@ss@ seconds - 00 to 59 35 - for 35 secs

@WW@ week number- 01 to 53 19 - for the week beginning

May 7, 2001

@CCC @ day of the year- 001 to 366 028 - for January 28th, 2002

@DS@ day interpretation code

@MS@ month interpretation code

@YS@ year interpretation code

For instructions on how to use

these "keywords" see "System

variables"

(chapter 2.9.4.)

@Kx@ counter interpretation code (K0 to K3)

@Q@ shift interpretation code

@Vx@ variable interpretation code

@LOGOx@ to mark logo N° x (stored in the memory) see page 2-55

@CI(...)@ marking of : circles - ellipses - arcs of circles

@RE(...)@ marking of rectangles

@LI(...)@ marking of lines

@DELAY(...)@ time delay between 2 blocks

@CB(...)@ data reception from RS232

@VS(...)@ saving a text in a variable

To mark texts corresponding to keywords, it is important to respect the above

syntax (for capital and small letters).

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 11

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.5.6. Character size

*

Block : 1/1

X : 0.00 Y : 0.00 [mm]

Text :

Size : 2.00 [mm] Stroke : 2

Linear Angular Radial

The size will determine the height of the capital letters that are marked, in either inches or millimeters.

The value is between 0.5 (0.020 in.) and 30.8 mm.(1.215 in.)

The resolution is 0.1 mm (5/100").

The first time that a file is marked, you are advised to activate the “Off-limit control” (see chapter 2.9.3.2 -). In this way, the program will inform you if the text

to be marked is too long for the M3000’s marking zone.

2.5.7. Stroke code

*

X : 0.00 Y : 0.00 [mm]

Text :

Size : 2.00 [mm] Stroke : 2

Block : 1/1

Linear Angle Radial

The stroke code will induce the variation of the power with which the marking tool will hit the part.

Four stroke codes are available : 0, 2, 4 and 6.

The higher the stroke code, the deeper the marking.

The stroke code 0 cannot be selected

when the standard foot is in use.

STROKE

CODE

EV M5

N°1

EV M5

N°2

Selecting the force code :

• For marking of thin parts (< 5mm.) : 2,

• For marking of hard parts : 6,

• For marking very thick parts : between 4 or

6,

0ACTIVATED

2 ACTIVATED ACTIVATED

4ACTIVATED ACTIVATED

6 A CT IVATED AC TI VATED ACT IVAT ED

• For a deep marking on hard materials : 6.

EV M5

N°3

2 - 12 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.5.8. Type of marking

*

Block : 1/1

X : 0.00 Y : 0.00 [mm]

Text :

Size : 0.00 [mm] Stroke : 2

Linear Angular Radial

This zone will determine the type of marking to be made on the block under preparation.

Certain types of marking will require new entry zones or a new screen.

To validate the type of marking selected, press on the space bar.

The new entry zones will appear automatically.

2.5.8.1 - “Linear” marking

Use the linear marking block to mark straight lines of text parallel to the X axis.

*

X : 5.00 Y : 25.00 [mm]

Text : ABCDE 12345

Size : 2.00 [mm] Stroke : 2

Block: 1/1

Linear Angular Radial

10

0

0

10

20

30

Y

20

30

X

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 13

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.5.8.2 - “Angular” marking

*

Block : 1/1

X : 5.00 Y : 25.00 [mm]

Text :

Size : 2.00 [mm] Stroke : 2

Linear Angular Radial

Use the angular marking blocks to mark lines of text at an angle.

A new entry zone will appear on the screen when the angular marking mode is selected.

*

Block : 1/1

X : 5.00 Y : 25.00 [mm]

Text : ABCDE 12345

Size : 0.00 [mm] Stroke : 2

Angle : 45.00

Linear Angular Radial

Angle value in degrees (between 0 and 360°)

10

0

0

10

20

Y

20

45°

30

X

0

0

10

10

90°

20

X

Specific case : use a 90°

angle to mark on

the Y axis direction

(vertically).

Y

REMARK : This type of marking is only available in “Supervisor” mode

(see paragraph 2.9.1.)

2 - 14 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

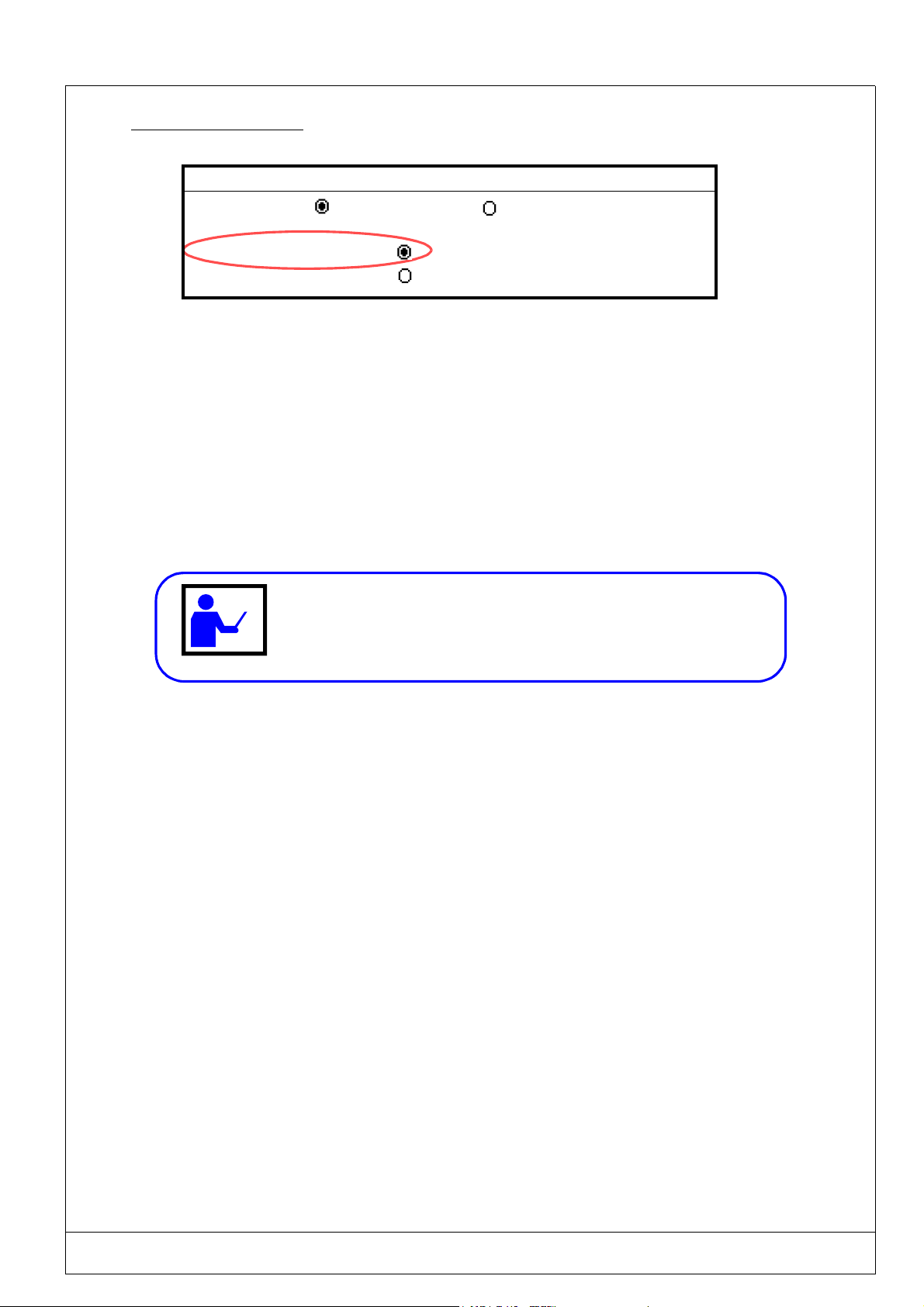

2.5.8.3 - “Radial” marking.

*

Block : 1/1

X : 0.00 Y : 0.00 [mm]

Text :

Size : 0.00 [mm] Stroke : 2

Linear Angular Radial

Use the radial text marking block to mark text along the circumference of a circle.

Two new entry zones will be created when using this option ; angle value and circle radius. You must

also refer to a second entry screen (pressing F2) to determine the marking direction.

Marking in a clockwise direction

*

Bloc : 1/1

X : 20.00 Y : 20.00 [mm]

Text : CLOCKWISE

Size : 3.00 [mm] Stroke : 2

Angle : 45.00

Radius : 12

Linear Angular Radial

Value of the start

angle in degrees

F2

Radius value in mm

Block : 1

8 / 81

:

:

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

Y = 20 mm

X = 20 mm

A

R

Pause Font N°: 0

Spacing : 1.00

Clockwise direction:

Activated = marking in a clockwise direction

45°

A : center of the base circle

R : radius of the base circle

Esc

4/4

REMARK : This type of marking is only available when in “Supervisor” mode.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 15

(see paragraph 2.9.1.)

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

Marking in a counter-clockwise direction

*

Block : 1/1

X : 20.00 Y : 20.00 [mm]

Text : ANTI-CLOCKWISE

Size : 3.00 [mm] Stroke : 2

Angle : 45.00

Radius : 12

Linear Angular Radial

F2

Value of the start

angle in degrees

Block : 1

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

Y = 20 mm

8 / 81

X = 20 mm

45°

Radius value in mm

:

4/4

:

Pause Font N° : 0

Spacing : 1.00

Clockwise direction:

Deactivated : = counter-clockwise marking direction

REMARK : This type of marking is only available

when in the “Supervisor” mode (see paragraph

2.9.1.).

Esc

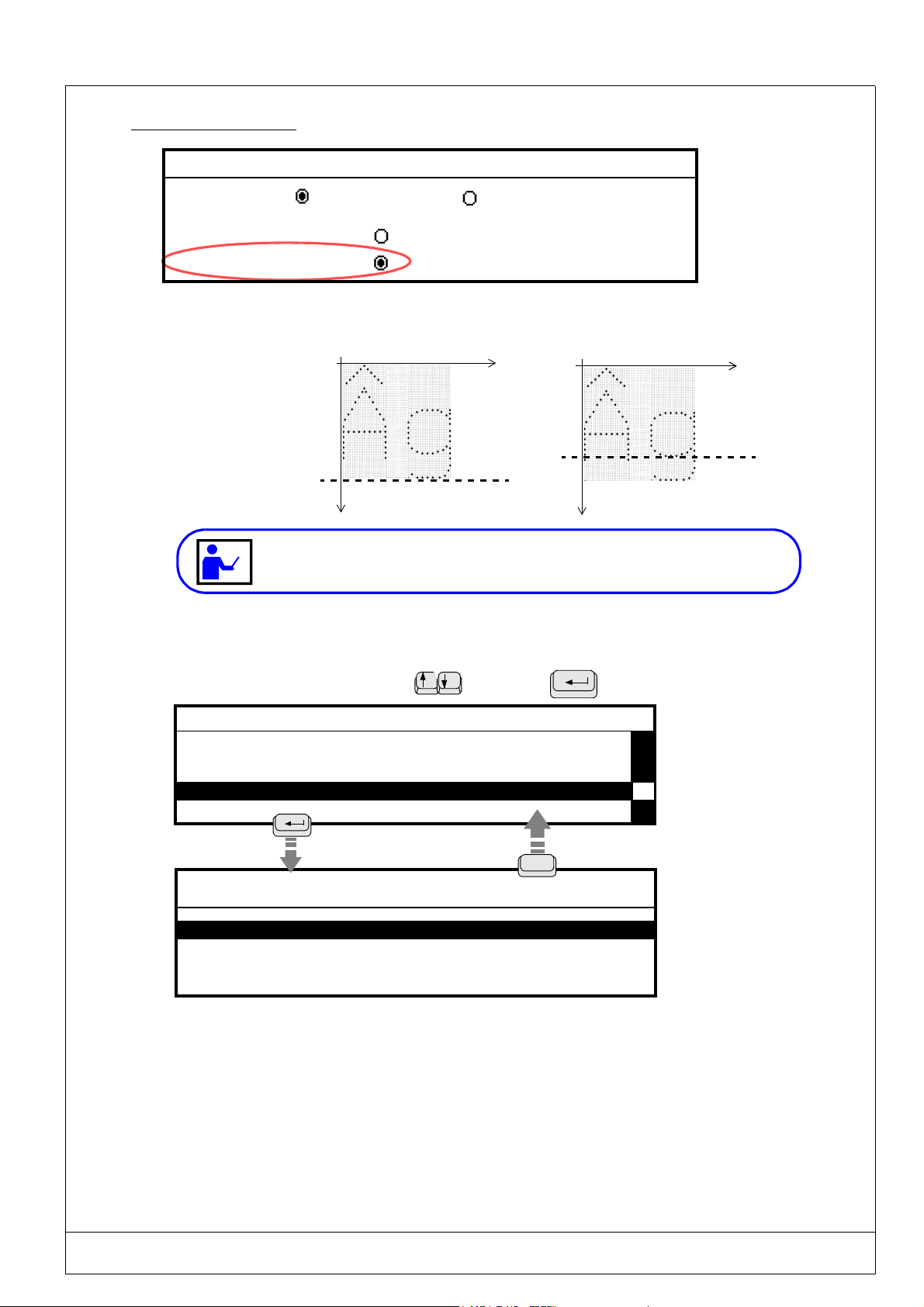

Marking obtained in the“radial” mode

Marking in CLOCKWISE direction Marking in COUNTER-CLOCKWISE direction

X

Y

X

Y

Y

Y

X

X

The ...... indicates

the starting point

of the marking

(X-Y coordinates).

2 - 16 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

Marking of a part with a radius higher than 40mm

In this case, the center of the circle is placed on the outside of the marking window.

Marking area 60 x 40 mm

Angle = 160°

Radius = 50 mm

*

X : 70 Y : 40.00 [mm]

Text : 123456789

Size : 3.00 [mm] Stroke : 2

Angle : 160

Linear Angular Radial

F2

Block : 1

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

For this type of marking make sure to

always run a simulation before marking.

Radius : 50

8 / 81

Pause Font N° : 0

Spacing : 1.00

Clockwise direction:

:

:

4/4

Block : 1/1

Esc

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 17

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.5.9. Block number

*

X : 20.00 Y : 20.00 [mm]

Text : ABCDE 12345

Size : 3.00 [mm] Stroke : 2

Angle : 45.00

Linear Angular Radial

The first figure (3) indicates the number of the current block.

The second figure (5) indicates the number of blocks contained in the file.

Radius : 12

2.5.10. Number of current file

*

X : 0.00 Y : 0.00 [mm]

Text :

Size : 0.50 [mm] Stroke : 2

Block: 3/5

Block : 1/1

Linear Angular Radial

The number of the current file is displayed in this zone in one of three ways :

-

* : you have created a new file but have not saved it yet,

- 112 : the file has been saved as 112,

- 112

* : the 112 file has been modified but the modifications have not been saved yet.

2 - 18 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

MARKING PARAMETERS

H

Esc

*

X : 0.00 Y : 0.00 [mm]

Text :

Size : 0.50 [mm] Stroke : 2

Linear Angular Radial

F2

Block: 1/1

Marking parameters screen

Block : 1

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

8 / 81

Pause Font N° : 0

2.5.11. Special marking effects

*

*

X : 0.00 Y : 0.00 [mm]

Text :

Size : 0.50 [mm] Stroke: 2

Linear Angular Radial

F2

Block : 1

8 / 81

Spacing : 1.00

:

4/4

:

Esc

All these parameters

apply to each block

individually

Block: 1/1

Block : 1/1

:

4/4

:

Esc

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

Pause Font N° : 0

Spacing : 1.00

REMARK

The marking effects will be applied to each block, one by one.

Several marking effects are available so that the marking corresponds to the particularities of the parts. These marking effects are available from the "Marking characteristics" screen, pressing on the F2 function key.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 19

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

Marking obtained in “linear” and “angular” mode

The .. indicates the starting point for the marking (X -Y coordinates)

Result

Marking impression

“Linear“ marking ”Angular“ marking Angle = 35°

10

Normal

0

0

10

Y

20

X

010

0

10

20

X

Y

Mirrored : symmetry

along the Y axis

Inverted : symmetry

along the X and

Y axes

Reflected : symmetry

along the X axis

10

0

0

10

20

X

10

Y

10

0

0

10

20

X

10

Y

0

0

10

20

10

X

10

Y

10

0

0

20

X

Y

0

X

20

10

0

Y

0

X

20

10

0

Y

These marking effects are acessible only in the linear or angular marking mode.

They are not available in the radial mode.

2 - 20 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.5.12. Centering

Block : 1

8 / 81

:

4/4

:

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Pause Font N° : 0

Spacing : 1.00

Inclination : 0.00

This option will permit you to automatically center the texts on a part.

The X value should correspond to the center of the text to be marked. It is possible for you to center texts using different

X values.

Depending on the marking blocks of a same file, the centering may appear as shown below :

Centered text of the "Linear" marking

type

0

0

10

20

Y

10

Centered text in

X

20

relation to

X = 20 mm

30

40

X

Centered text of the "Radial" marking

clockwise direction

type -

Centered text of the "Radial" marking

type - anti-clockwise direction

REMARK

The centering option will apply to each

block individually

X

90°

Y

Centered text

using a

90° angle

X

270°

Y

Centered text using a

270° angle

The text to be marked may exceed the limits of the M3000 if the X or Y values

are too high, or if the characters are too large. Should this occur, reduce one of

these values.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 21

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

REMARK

In the case of marking a centered angular text, the program will begin by calcualting the centering values in relation to X,

then make the rotation along the given angle.

To mark at 90°, the text to be marked will be centered according to the value entered for Y

Center positioning along X then

rotation according to the angle required

Angle at 45°

Angle at 90°

2.5.13. Pause

If this option is activated, marking will be interrupted after the marking of the given block.

Press ENTER to resume marking

An example of an application this option offers you is the possibility to make several markings on a same part in

different spots.

Block : 1

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

2 - 22 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

8 / 81

Pause Font N° :0

Spacing : 1.00

:

4/4

:

This option is available for

each block individually.

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.5.14. Font numbers

Block : 1

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

The fonts in the memory are represented by a number. (see chapter 2.9.7.)

Use the font zone to enter the number of the font to be used in the current marking block.

The program will use the standard font N°1 ( separated dots) by default.

8 / 81

Pause Font N° : 0

Spacing : 1.00

:

4/4

:

2.5.15. Compression

Block : 1

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination: 0.00

This option will permit you to alter the width of the characters without changing their height.

8 / 81

Pause Font N° : 0

Spacing : 1.00

:

4/4

:

The compression value is the proportional factor between height and width of the characters, ( width/height ratio). Values

should be between 0.1 and 9.9 in graduations of 0.1. The origin value is 1.

Example:

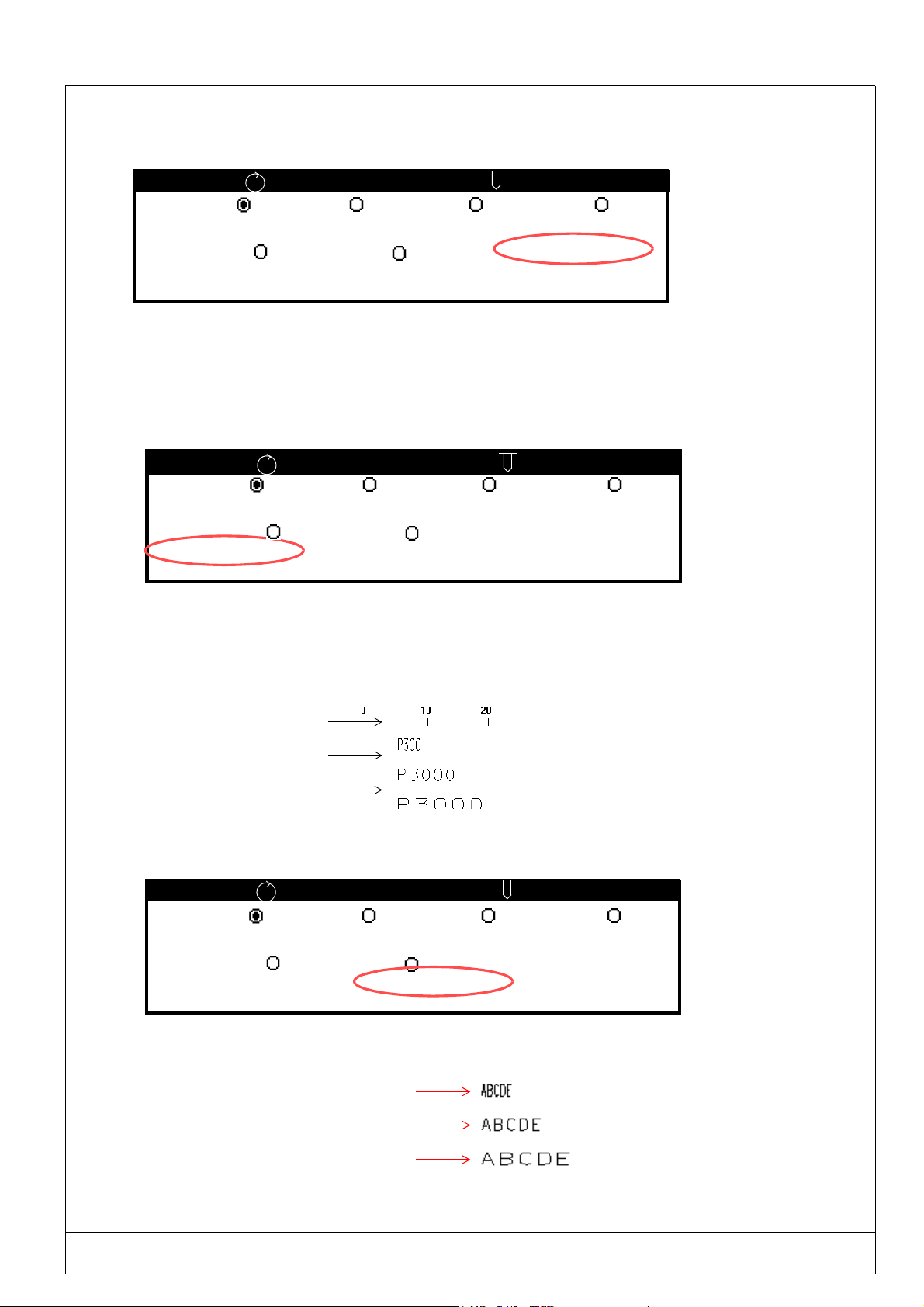

Compression 0.50 :

Compression 1.00 :

Compression1.50 :

H

2.5.16. Spacing

Block : 1

Normal Mirrored Inverted Reflected

Centering

Compression : 1.00

Inclination : 0.00

This function will enable you to modify the distance between characters without altering their dimensions.

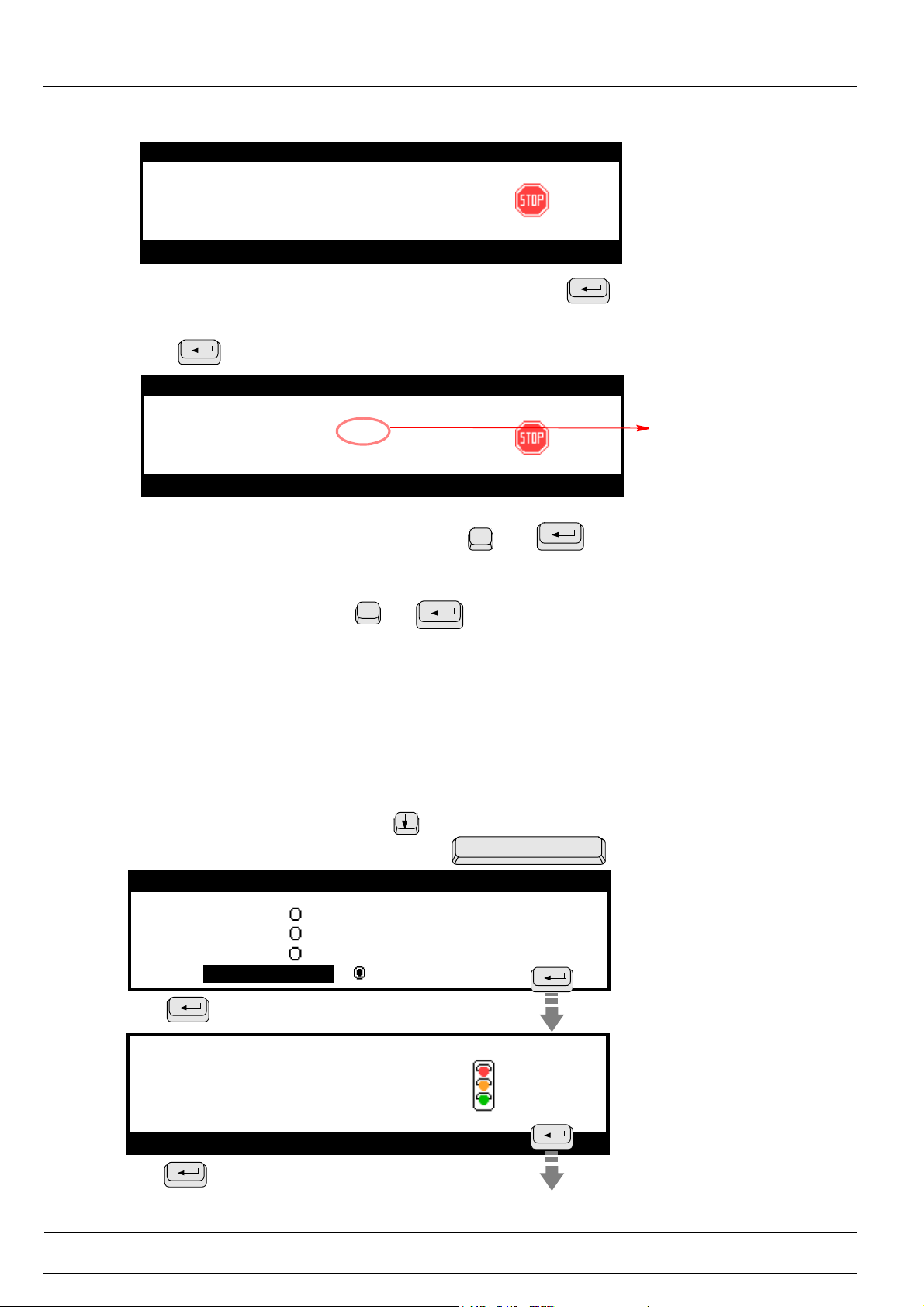

The space value may vary between 0.1 and 9.9, in graduations of 0.1. The origin value is 1.

Example:

8 / 81

Pause Font N° : 0

Spacing : 1.00

Compression 0.50 :

:

4/4

:

Compression 1.00 :

Compression1.50 :

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 23

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.5.17. Inclination

Block : 1

Normal Mirrored Inverted Reflected

8 / 81

:

4/4

:

Block : 1

Centering

Compression : 1.00

Inclination : 0.00

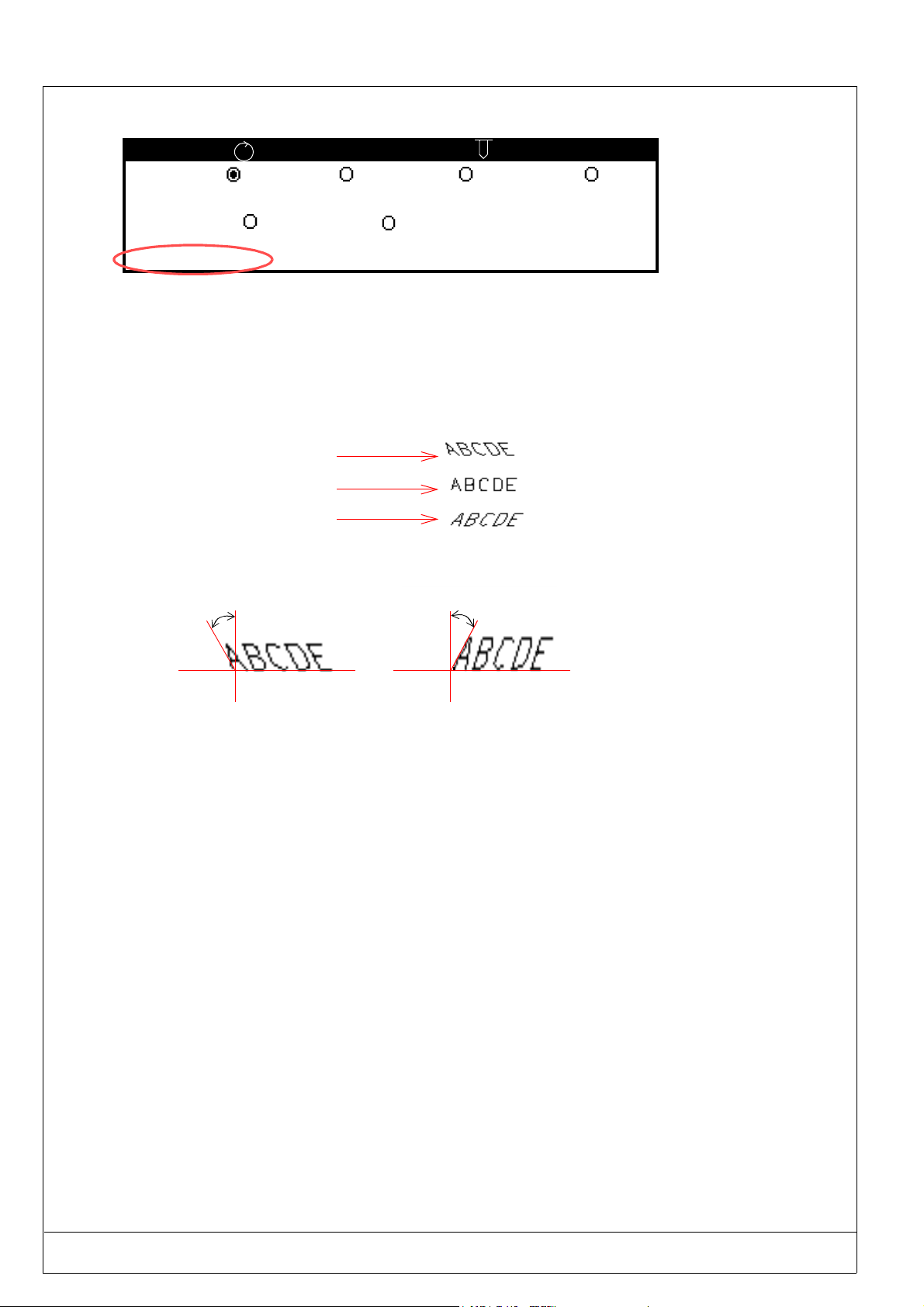

This parameter will determine the value, in degrees of the angle of inclination of the characters in relation to the vertical

axis, between -180° and +180°.

If the value is positive, the character will slant towards the right. If the value is negative, the character

will slant to the left.

Example:

Inclination - 30 :

Inclination 0.00 :

Inclination + 30 :

- 30°

Pause Font N° : 0

Spacing : 1.00

+ 30°

.

.

2 - 24 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.6) The "Marking" menu

Select this menu using the arrows keys. Press ENTER or TAB

Esc

MARKING : TEST

1 time

n times

infinite

File simulation

The marking principle is the following :

• Marking the file,

• Return to the axis origin,

• Management of the number of cycles with the command board,

• Return to the first step.

:

[ 1

:

:

]times

to validate.

H

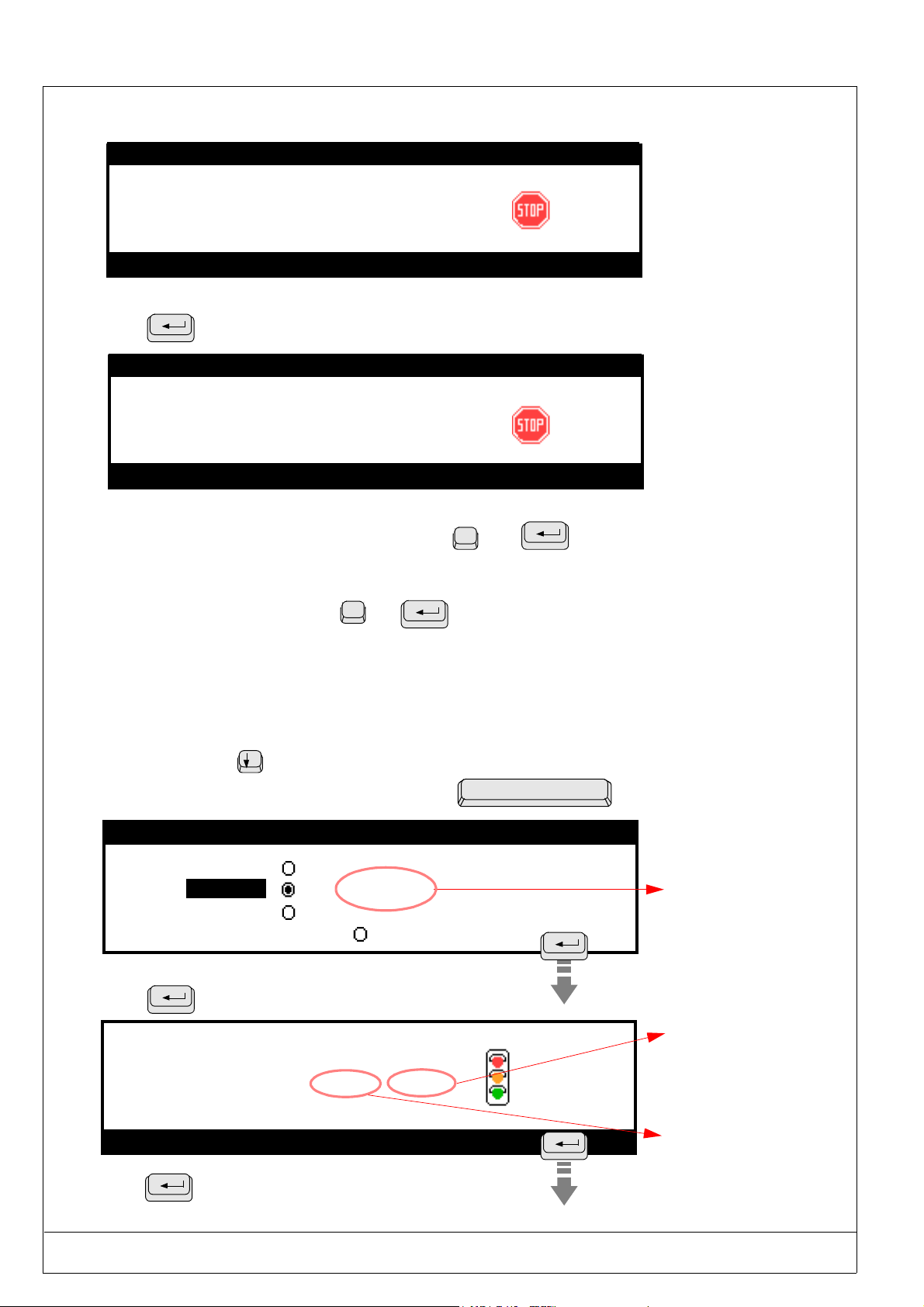

2.6.1. Marking one time

This option will permit you to execute a single marking of the current file.

MARKING : TEST

1 time

n times

infinite

File simulation

Press to access the marking screen

MARKING :

Enter > Start marking

Press to launch the marking cycle.

:

[ 1

:

:

] times

000 001

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 25

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

The following screen will be displayed during marking :

Marking in progress....

MARKING :

Enter >Suspend marking

Press

Marking in progress....

to interrupt the marking cycle, if necessary.

MARKING:

Abandon the current marking? :_

Enter > Suspend marking

Resume marking

Machine return to origins

Return to marking menu screen

Interruption of marking: press on

000 001

000 001

press on

}

then

O

N

then

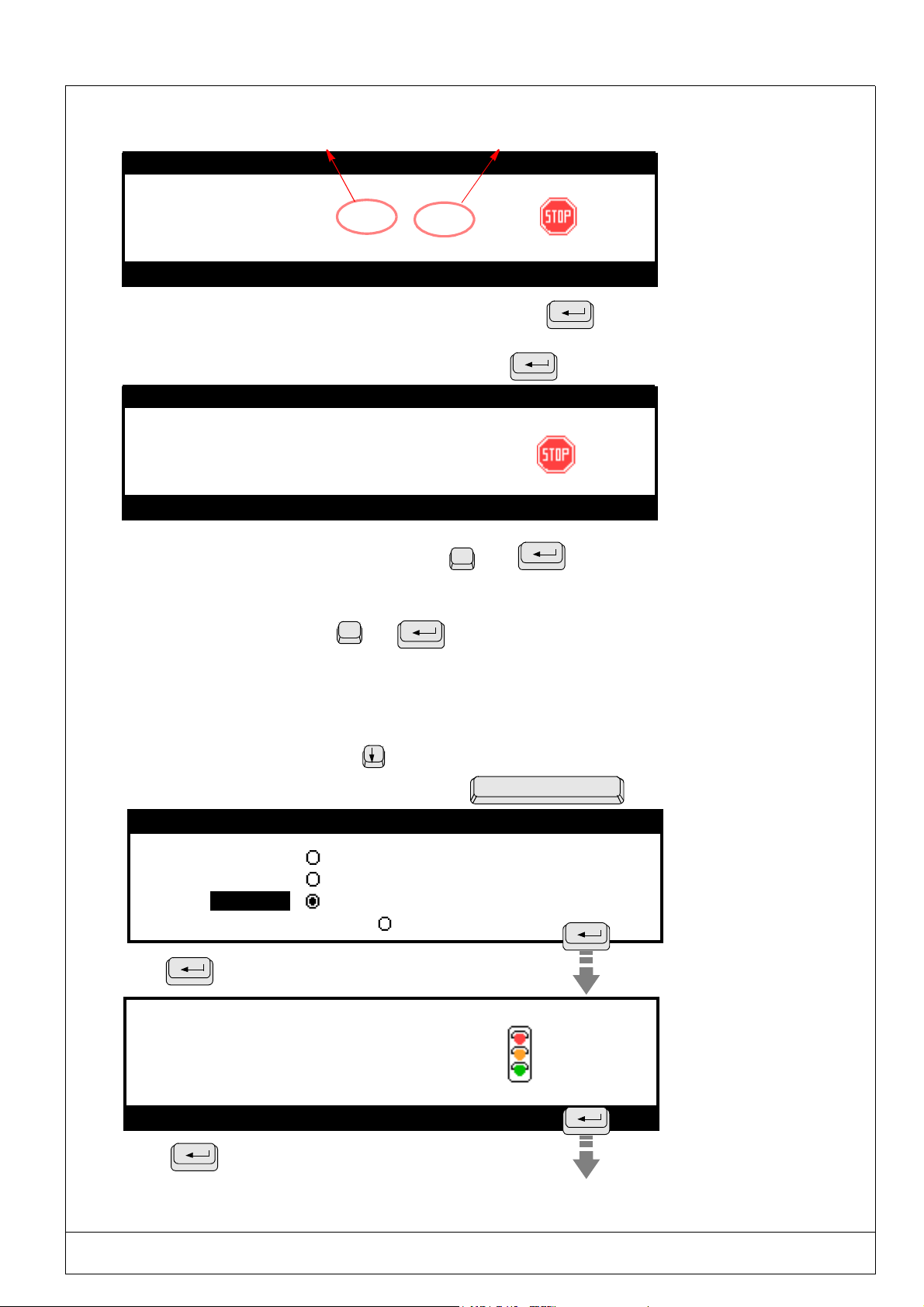

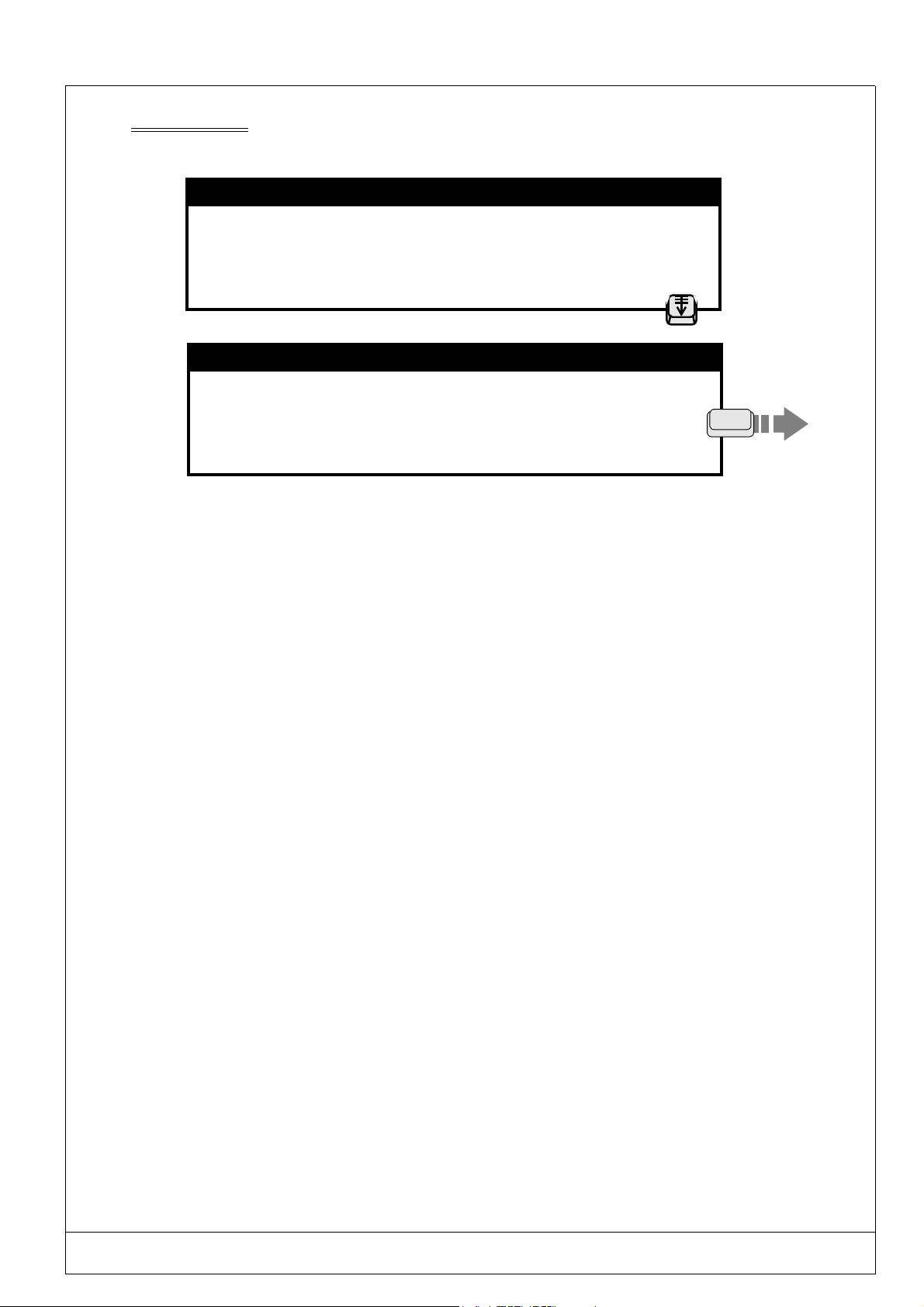

2.6.2. Marking “n” times

This option will permit you to mark a specified number of times the same marking file.

Press the arrow key

Validate this option by pressing once on the space bar

MARKING : TEST

1 time

n times

infinite

File simulation

Press to access the marking screen

MARKING :

Enter > Start marking

Press to launch the marking cycle

to access this option

:

:

:

[ 20

000 020

] times

Enter the

number of

markings

required in this

entry zone

The number

of parts to

be marked

will appear in

this zone

The number of

parts already

marked will

appear in this

zone

2 - 26 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

The following screen will be displayed during marking :

Number of parts marked Number of parts to be marked

Marking in progress....

MARKING :

001 020

Enter > Suspend marking

When the marking head returns to the M3000 origin, simply press to mark

the next part or press on the trigger of the M3000.

If you wish to interrupt the marking cycle in progress, press

Marking in progress....

MARKING :

015 020

Abandon the current marking? :_

Enter > Suspend marking

Resume marking

Machine return to origins

press on

N

then

Return to marking menu screen

Interruption of marking: press on

then

O

2.6.3. Infinite standard marking

This option is similar to the “n” times mode, except that the marking will be repeated infinitely.

To access the “infinite” mode, press

Validate this option by pressing once on the space bar

MARKING: TEST

1 time

n times

infinite

File simulation

Press to access the marking screen

MARKING :

Enter > Start marking

:

[

:

]times

:

0

Press to launch the marking cycle

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 27

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

The following screen will be displayed during marking

Marking in progress....

MARKING :

Enter > Suspend marking

0

When the marking head returns to the M3000 origin, simply press to mark the next part

or press on the trigger of the M3000.

Press

Marking in progress....

Abandon the current marking ? :_

Enter > Suspend marking

if you wish to interrupt the marking cycle underway.

MARKING :

143

Number

of parts

marked

Resume marking

N

Machine return to origins

press on

then

Return to marking menu screen

Interruption of marking: press on

then

O

2.6.4. File simulation

This option will permit you to execute a simulation of the marking file. Simulation consists of viewing the rectangles containing the marking blocks (start and end of block).

The marking tool will move without marking the part

To access the “File simulation” option, press

Validate this option by pressing once on the space bar

MARKING: TEST

1 time

n times

infinite

File simulation

Press

To access the marking simulation screen

S I M U L A T I O N

Enter > Start marking

:

[ 1

:

:

] times

:

Press

To access the marking simulation screen

2 - 28 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

Follow the instructions that will appear on the subsequent screens.

The screens shown below will appear one after the other.

Marking in progress....

S I M U LA T I O N

:

Block 1 start position

Pause...

< Space> to continue

Enter > Suspend marking

- The marking tool will move to the start position in the lower left corner of the first character of the first

marking block to be marked.

- Press on the space bar to continue.

Marking in progress....

S I M U LA T I O N

:

Block 1 end position

Pause...

< Space> to continue

Enter > Suspend marking

- The marking tool will move to the start position in the lower right corner of the last character in the

first marking block to be marked.

- Press on the space bar to continue.

Beginning of

the simulation

Beginning of

the simulation

End of the

simulation

End of the

simulation

This procedure will be carried out for each marking block.

When the simulation of the last block is complete, the marking tool will return to the M3000

origin.

The main menu screen will be displayed.

To execute a simulated marking of only one block and not of the whole marking

file, go on this block and press on F4. This key will permit you to rapidly execute

adjustments on a block without systematically simulating the whole marking file.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 29

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

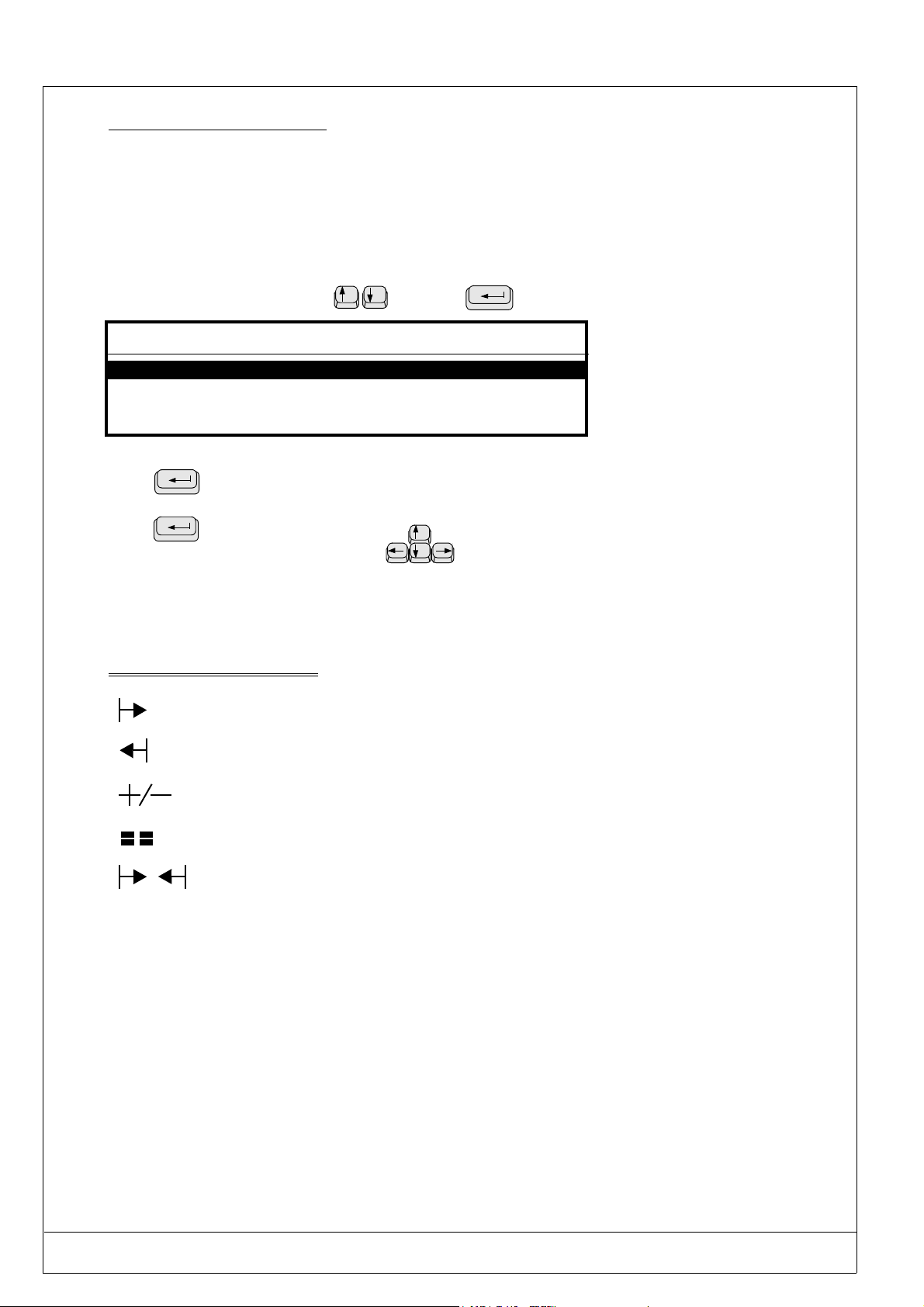

2.7) “File manager” Menu

This menu will permit you to make modifications on the existing files :

• Opening a file for marking,

• Opening a file for modification,

• Deleting a file.

Select this menu using the arrows

Open

a file

Select the open / delete option using the arrow

Press

to validate.

or TAB

keys. Press

or TAB .

Esc

keys.

to validate.

H

Delete

a file

The screen shown below contains the list of all files in the command board’s memory.

- Open a file- 99. 0 % Free

- Open a file- 99. 0 % Free

001 TEST

002 TEST2

010 TEST3

050 TEST4

250 TEST5

This figure indicates the percentage

of remaining memory space, in

relation to the amount available at

the beginning (50Kb).

The files are arranged by an ascending number order.

If you have saved more than 5 files, a pull-down bar will appear on the right of the screen. It will indicate that

you may access the other files using the

Select the file to be opened or deleted using the arrow keys. Press

arrows.

to validate.

2 - 30 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

.

2.7.1. Opening a file for marking

Select the file to be opened using the arrows keys. Press et valid to validate.

- Opening a file- 99. 0 % Free

001 TEST

002 TEST2

010 TEST3

050 TEST4

250 TEST5

When the file is open, press to return to the main menu.

Continue as directed in the “Marking” chapter

(see page 2-28).

2.7.2. Opening a file to make and save modifications

Select the file to be opened using the arrow keys. Press et valid to validate.

-Opening a file- 99. 0 % Free

-Opening a file- 99. 0 % Free

001TEST

002 TEST2

010 TEST3

050 TEST4

250 TEST5

When the file is open, proceed to make the necessary modifications.

The file name will then be followed by a star : *

Case one

Press

Esc

to exit. The following message will appear .

Save modifications ?

Confirm Esc/y/n : _

Esc : Return to the file without

saving the modifications.

n : Return to the main menu

without saving the modifications

y : Save

The following screen will appear :

Number of the file

010*

Enter file number [0 999] :

File comments

in 3 characters

Comments on the

file using 32

characters.

Enter the new file name : this will replace the existing file name.

Enter file comments (optional), for example, the description of the part or the type of marking.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 31

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

If an existing file name is entered, the following message will appear :

y : Save the file with the modifications

made to the old file version

010

Replace file

Existing file !

(y/n) : _

n : Return to main menu

If the response is "y", the following screen will appear if the file is to be over written or a new number

given:

010

Enter file number [0 999 ] : 010

194 Bytes

File comments

MARKING TEST

File saved

Exit: [ ESC ]

Press ESC to return to the main menu.

Case two

Press F11 to save the modifications.

Follow the two procedures below :

- Enter the new file number, this will replace the existing file name. Press "ENTER" to validate.

- Enter the file comments (optional).

010*

Enter file number [0 999] : 010

File comments

MARKING TEST

If the file name already exists in the memory, the following message will appear :

y : Save the file with the modifications

made to the old file version

010

Replace file

Existing file !

(y/n) : _

n : Return to main menu

If the response is "y", the following screen will appear if the file is to be over written or a new number

given:

010

Enter file number [0 999 ] : 010

194 Bytes

File comments

MARKING TEST

File saved

Exit : [ ESC ]

Press ESC to return to the main menu.

2 - 32 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.7.3. Deleting a file

Select the file to be deleted using the arrow keys. Press validez

-Deleting a file- 99. 0 % Free

-Deleting a file- 99. 0 % Free

TTTTTtttEttSTTTST

001TEST

TTTESTTESTEST

002TEST2

010TEST3

050TEST4

250TEST5

to validate.

The program will ask for confirmation as a safety measure :

DELETE FILE 001

Confirmation

Esc/ y / n : _

Esc : Return to main menu without deleting the file.

y : Delete the file and return to the main menu.

n : Return to the main menu without deleting the file

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 33

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.8) Communication with the PC” menu (optional)

This menu is optional and only functions with the PW03 marking program, or the back-up program for PW02

files.

Use this menu to transfer information :

• From a PC to the internal program of the M3000 command board,

• From the command board to the M3000.

Access this menu using the arrow or TAB

PC COMMUNICATION

Command :

Data transmission indicator (direction: PC/Machine or Machine/PC).

The indicator will flash when data is being transmitted.

keys. Press to validate.

H

If you are using this option, please refer to the operating manual included with the"PW03 Program" .

2 - 34 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.9) “Configuration” Menu

This menu will permit you to access the various parameters for marking configuration

Select this menu using the arrow keys . Press or TAB

The configuration parameters will appear on three subsequent screens.

Use the arrow

keys to move from one screen to the other.

- CONFIGURATION -

Function mode

H

Machine temporization

File parameters

System variables

Setting the date/time

to validate.

H

Esc

- CONFIGURATION -

Language

List of available fonts

List of available logos

Wear and tear counter configuration

Machine characteristics

- CONFIGURATION -

Dialogue configuration

Select a parameter using the arrow

Esc

Esc

keys. Press to validate.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 35

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.9.1. Function mode

Select this parameter using the arrow

keys. Press to validate.

- CONFIGURATION -

Function mode

Machine temporization

File parameters

System variables

Setting the date/time

Function mode OPERATOR (L)

Function mode SUPERVISOR (H)

Select the function mode using the arrow keys. Press

There are two function modes available :

• operator - represented by the letter : L : Access limited to certain program functions,

• supervisor - represented by the letter : H : Access to all program functions.

H

Esc

to validate.

The operator mode will allow restricted operating of the program for creation of simple files. The following menus are

not available in this mode:

• Radial marking • Language

• Angular marking • List of available fonts

• File parameters, • List of available logos,

• System variables, • Machine characteristics.

• Setting the date/time,

2 - 36 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.9.2. Machine temporization

Select this parameter using the keys and validate with

- CONFIGURATION -

Function mode

Temporisation machine

Machine temporization

File parameters

System variables

Setting the date/time

Esc

Pneumatic marking tool

Raising time:

Lowering time:

Marking speed:

Movement speed:

20.0 ms

20.0 ms

33 mm/s

110 mm/s

Delays

It is possible to adjust the values of the delays to adapt the machine to the particularities of some applications.

It is nevertheless strongly recommended to use the values defined by default.

The modification of the delays will affect the files contained in the machine’s

memory.

•

Speeds

The marking and movement speeds displayed on the screen are the reference speeds programmed by default

(intermediate speeds).

Position the cursor using the "up" and "down’ arrows on the keyboard to modify and enter the new value.

These speeds can be personalized. In this case, select the marking in the "intermediate speed’ mode.

Value of the speeds programmed by default:

Speed: Marking quality Intermediate Cycle time

Marking - 20% of the reference

value

Moving - 40% of the reference

value

Reference value + 20% of the reference

value

Reference value + 40% of the reference

value

• The speed modifications will affect all the files contained in the machine’s

memory.

• The modification of a reference speed will bring about the automatic modification of the

speed related to the cycle time as well as that related to the quality of the marking.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 37

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.9.3. File parameters

This menu can only be accessed in the "supervisor" mode.

Select this parameter using the arrow

- CONFIGURATION -

Function mode

Machine temporization

File parameters

File parameters

System variables

Setting the date/time

File parameters

Units

Off-limit control

Character case

Move between the various options using the arrow

Press the space bar to activate or deactivate a parameter.

mm

keys. Press to validate.

H

Esc

inches

keys.

Press

to validate the activation/deactivation of a parameter.

These parameters apply to ALL of the marking files.

The choice of the "inch" unit will bring about the conversion in ALL of the files.

2.9.3.1 - Units

File parameters

Unit

Off-limit control

Character case

The marking program may be set to use either inches or millimeters as the unit of measurement. All the values giving

measurements of length as well as the size of the characters willbe given in the selected unit of measurement.

mm

inches

When the unit of measurement changes, all the values contained within the marking files

will automatically be converted.

2 - 38 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.9.3.2 - Off-limit control

File parameters

Units

mm

inches

Off-limit control

Character case

This parameter will always be activated by default.

• if the marking goes off limits, the program will send an error message,

• the calculation time (and therefore the cycle running time) will be extended.

It is recommended that you use this option only when updating the marking files.

When the off-limit control is deactivated :

• the marking tool can hit the mechanical stops if the text is too long, or if the coordinates are incorrect,

• The calculation and cycle running times will be shorter.

It is recommended that the file be prepared with the "Off-limits control"

option activated and then be deactivated when the preparation has been

finished.

The examples on the following pages show texts that are off-limits

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 39

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

• Example: Off-limits on the X axis

Marking file

*

X : 50.00 Y : 20.00 [mm]

Text : ABCDE 12345

Size : 8.00 [mm] Stroke : 2

Linear Angular Radial

• Machine movements:

X = 60 mm

Y = 40 mm

• Coordinates of text to be marked:

X = 50 mm

Y = 20 mm

• Character size = 8 mm

• Text length = 48.40 mm

In the given example it is necessary top modify the

value of X, the size of the characters, or reduce the

text to be marked.

Press on any key to return to the main menu.

0

0

10

20

Y

Possible error message

Press any key ....

Bloc : 1/1

10 20 30 40 50X60

Bloc k 1 text off-limits..

along X

• Example: off-limit on the Y axis

Marking file

TEST5 Block : 1/1

X : 35.00 Y : 30.00 [mm]

Text : ABCDE 12345

Size : 8.00 [mm] Stroke : 2

Angle : 90° Radius : 30

Linear Angular Radial

• Machine movments:

X = 60 mm

Y = 40 mm

• Coordinates of text to be marked:

X = 35 mm

Y = 30 mm

Radius = 30 mm

• Character size = 8 mm

• Text height = 42.17 mm

possible error message

10 20 30 40 50

10

20

30

Y

In this example it is necessary to modify the value of Y and the size of th characters to be marked.

Press on any key to return to the main menu.

Press any key....

Block 1 text off-limits.

along Y

X

2 - 40 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.9.3.3 - Character case

File parameters

Units

mm

inches

Off-limit control

Character case

For lower case letters, the extra space necessary for downstoke characters (such as p,g...) will be taken into consideration

by the program.

X

X

Y

difference when

marking capital

letters

Y

Activated character case

Deactivated character case

When the character case mode is activated and a capital letter text is to be marked,

this text will be shifted on the Y axis according to the required Y coordinate .

2.9.4. System variables

Select this parameter using the arrow

- CONFIGURATION -

Function mode

Machine temporization

File parameters

System variables

System variables

Setting the date / time

keys. Press to validate.

The system variables

apply to all marking

Esc

System variables

Counter Configuration

Shift Configuration

Days/Months/Years Format Configuration

Variable Configuration

These parameters will permit you to personalize marking using the following functions :

- Counters : these counters are used for the increment / decrement function of a serial number.

- Shift : this parameter will permit you to determine the texts to be marked according to the current hour.

- Day/Month/Year option : this parameter will permit you to define personalized formats for marking the months, years,

and days.

- Variables : this parameter will permit you to mark repetitive texts common to several marking files.

files.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 41

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

2.9.4.1 - Counter Configuration

These counters are used for the increment / decrement function. Data may be marked using

either the numeric or alphanumeric mode. Eight independent counters are available for a marking file.

Each counter has a code made up of 8 digits.

The “keywords” for identification are K0 to K7.

The counters are parametered in the sub-menu “Counter configuration”, found in the “System variables” menu.

Select this parameter using the arrow

System variables

Counter Configuration

Shift Configuration

Days/Months/Years Format Configuration

Variable Configuration

To enter data :

Press

Enter the data,

Press

Move between entry zones using the arrow

Description of the symbols used

to validate an entry zone,

to validate.

Gives the value of the counter at the beginning.

keys. Press to validate.

keys.

Gives the value of the counter at the end.

Gives the value of the increment.

Gives the value of the batch or the number of the entry.

Gives the value of the counter during marking.

2 - 42 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

Utilization

Typing area:

8 characters max

K0 :

K1 :

01

01

K2 : 001 999 1 1 356

K3 : 000 400 2 1 098

Page Down

Page Up

K4 :

K5

K6:

50 00

- 1 1

01

01

45

K7: 1A 9Z 1 2 5B

Page Down

Page Up

K0 :

K1 :

K2 :

K3 :

MM DD hh mm

# # # # # # # #

# # # # # # # #

# # # # # # # #

# # # # # # # #

K4 :

K5 :

K6 :

K7 :

MM DD hh mm

# # # # # # # #

# # # # # # # #

# # # # # # # #

# # # # # # # #

Explanatory description of the 3 screen shown above

N°of the counter K2 K3 K4 K7

The values given are: Numeric Numeric Numeric Alphanumeric

The next number to be marked is : 356 098 45 5B

The start marking value was : 001 000 50 1A

The end value will be : 999 400 00 9Z

The increment / decrement will be : 1 2 - 1 1

Number of parts to be marked with the same number : 1 1 1 2

DECREMENT FUNCTION

The decrement function may be obtained by entering an end value lower than the start

value. For exam

ple, for the K4 counter below, there will be a decrementing of the

number because the start value is higher than the end value.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 43

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

Initialization of the counters

The screen shown below will permit you to determine an hour or date when the counters will return to their start

.

values.

MM DD hh mm

K0 :

K1 :

K2 :

K3 :

# # # # # # # #

# # # # # # # #

# # # # # # # #

# # # # # # 0 0

RAZ every hour

The reset of a counter to 0 (RAZ) will be common to all the marking files.

Example of a marking file

X : 10 Y : 10 [mm]

Text : @K2@

Size : 3 [mm] Stroke : 2

MM DD hh mm

K4 :

K5 :

K6 :

K7 :

# # # # 0 0 0 0

# # # # # # # #

# # 0 1 0 0 0 0

0 1 0 1 0 0 0 0

RAZ on January 1st at 00:00

(i.e. once a year)

RAZ everyday at 00:00

RAZ on the 1st of each month

Marking obtained

X

Linear Angular Radial

Y

2 - 44 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.9.4.2 - Shift configuration

This parameter is used to determine the texts to be marked, in order to identify the working shifts according to the current

hour.

Shift configuration is possible each day of the week within 5 time slots.

The “keyword” for identification is Q.

The time used is that of the M3000.

Select this parameter using the arrow keys. Press

System variables

Counter Configuration

Shift Configuration

Days/Months/Years Format Configuration

Variable Configuration

to validate.

START END SUNDAY

1 :

00 : 00 00 : 00

2 :

00 : 00 00 : 00

CODE

3 : 00 : 00 00 : 00

4 : 00 : 00 00 : 00

5 : 00 : 00 00 : 00

Page Up

START END MONDAY

1 :

00 : 00 05 : 59

2 :

06 : 00 13 : 59

3 : 14 : 00 20 : 00

4 : 20 : 01 23 : 59

CODE

Night shift

Morning

Shift 3

Evening shift

5 : 00 : 00 00 : 00

To enter data :

Press

to validate an entry zone,

Enter data,

Press

to validate.

Move between entry zones using the arrow

Typing area:

20 characters max.

Page Down

keys.

In the example shown above, the marking carried out on Monday will be :

• "Night shift" from 00:00 mn 00 s. to 05:59 mn 59 s.

• "Morning" from 06:00 mn 00 s. to 13:59 mn 59 s.

• "Shift 3" from 14:00 mn 00 s. to 20:00 mn 59 s.

• "Evening shift" from 20:01 mn 00 s. to 23:59 mn 59 s.

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 45

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

.

Marking file executed at 5:00 pm:

Marking obtained

X

*

X : 5.00 Y : 5.00 [mm]

Text : @Q@

Size : 2.00 [mm] Stroke : 2

Block : 1/1

Linear Angular Radial

When choosing the shifts schedule make sure that there is no overlapping of hours.

This means that the end of one is not the beginning of the next one.

Y

2 - 46 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.9.4.3 - Days/Months/Years Format Configuration

These parameters will permit you to define a code for identifying the days of the week, the months as well as the 5 next

year, so that the marking is personalized.

Select this parameter using the arrow keys. Press

System variables

Counter Configuration

Shift Configuration

Days/Months/Years Format Configuration

Variable Configuration

Use these arrow keys to access / exit from

•

the three days/months/years data entry screens

To enter data :

•

Press

to validate an entry zone,

Enter data,

Press

Move between entry zones using the arrow

to validate.

keys.

DAYS / CORRESPONDING CODES

Sunday

Monday

Tuesday : Saturday :

Wednesday :

: Thursday :

SUN

: Friday :

Mon

02

04

05

SAT

Wednesday

to validate.

Esc

Code entry zone

(Maximum : 8 characters)

MONTHS / CORRESPONDING CODES

01

02

03

04

-AFEB

03

April

050605-May

JUNE

J-07

07

AUG

08

Code entry zone

(Maximum : 10 characters)

YEARS / CORRESPONDING CODES

2000

2001

00

01

2002 C21-Y1

2003 C21-Y2

2004

Code entry zone

(Maximum : 9 characters)

09

10

11

12

S-09

OCT

NOV

12

Esc

Esc

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 47

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

The “keywords” are :

- DS for days,

- MS for months,

- YS for years.

Example using codes on the previous page :

Marking file

(marking carried

out on Wednesday,

February 7, 2001)

Marking obtained

*

X : 5.00 Y : 5.00 [mm]

Text : @"Lyon "DS DD-MS/YS@

Size : 2.00 [mm] Stroke : 2

Linear Angular Radial

X

Y

Block : 1/1

2 - 48 USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE

(Ref.90703-MDIS4314/0601C0-chap024314.fm.doc) PRO-PEN

2.9.4.4 - Variable Configuration

It is possible to save and load repetitive texts that are common to several marking files by entering the number given to

each variable.

The variables are in memory spaces (10 in total) that can contain texts made up of 32 characters max.

These are common to all the marking files.

They may be identified by their key words V0 to V9.

System Variables

Counter Configuration

Shift Configuration

Days/Months/Years Format Configuration

Variable Configuration

Variable Configuration

V0 :

Variable Configuration

V1 : ABCDE0123

V9 : XYZ789

Enter a text in the

selected variable

Each press on the

ENTER key will access

the next variable.

Variable Configuration

Always validate the contents of a

variable so that it is saved.

ESC

System Variables

Counter Configuration

Shift Configuration

Days/Months/Years Format Configuration

Variable Configuration

USING THE MARKING PROGRAM WITH EXTERNAL KEYBOARD IN "PROGRAMMING" MODE 2 - 49

PRO-PEN (Ref.90703-MDIS4314/0601C0-chap024314.fm.doc)

Programming in a marking file

*

X : 10.00 Y : 10.00 [mm]

Text : @V1@

Size : 3.00 [mm] Stroke : 2

Linear Angular Radial

The marking obtained with the coordinates X=10mm and Y=10mm will be contained in the V1 variable : ABCDE0123

Concatenation of variables

It is possible to program several variables in a same syntax .

*

X : 10.00 Y : 10.00 [mm]

Text : @V0 V2 V5 V8@