Page 1

VessJBOD

1730, 1740, 1830, 1840

Product Manual

Ve rsion 1.2

Page 2

VessJBOD 1000 Series Product Manual

ii

Copyright

© 2009 Promise Technology, Inc. All Rights Reserved.

Copyright by Promise Technology, Inc. (Promise Technology). No part of this

manual may be reproduced or transmitted in any form without the expressed,

written permission of Promise Technology.

Trademarks

Promise, and the Promise logo are registered in U.S. Patent and Trademark

Office. All other product names mentioned herein may be trademarks or

registered trademarks of their respective companies.

Important data protection information

You should back up all data before installing any drive controller or storage

peripheral. Promise Technology is not responsible for any loss of data resulting

from the use, disuse or misuse of this or any other Promise Technology product.

Notice

Although Promise Technology has attempted to ensure the accuracy of the

content of this manual, it is possible that this document may contain technical

inaccuracies, typographical, or other errors. Promise Technology assumes no

liability for any e rror in thi s p ubl ic ati on, an d fo r damages, whether direct, in dire ct,

incidenta l, c ons eq uen tia l or othe rw is e, t hat m ay res ul t fro m suc h error, including ,

but not limited to loss of data or profits.

Promise Technology provides th is publicat ion “as is ” without w arranty of any kind,

either express or implied, including, but not limited to implied warranties of

merchantability or fitness for a particular purpose.

The published information in the manual is subject to change without notice.

Promise Technology reserves the right to make changes in the product design,

layout, and driver revisions without notification to its users.

This version of the Product Manual supersedes all previous versions.

Recommendations

In this Product Manua l , the appearance of products made by other companies,

including bu t not lim ited to sof tware, serve rs, and d isk driv es, is f or the purp ose of

illustration and explanation only. Promise Technology does not recommend,

endorse, prefer, or support any product made by another manufacturer.

Page 3

iii

Contents

Chapter 1: Introduction to VessJBOD . . . . . . . . . . . . . . . . . . . . . . . . .1

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

VessJBOD Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Architectural Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Current (maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Relative Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Dimensions (H x W x D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Net Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Carton Dimensions (H x W x D) . . . . . . . . . . . . . . . . . . . . . . . . .5

Carton Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Warranty and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CE Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FCC Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

KCC Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Chapter 2: VessJBOD Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Unpacking the VessJBOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mounting VessJBOD in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installing Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Drive Slot Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Installing Your Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Making Data and Management Connections . . . . . . . . . . . . . . . . .13

JBOD Expansion to a VessRAID Subsystem . . . . . . . . . . . . . .13

Drive Enclosures for a SuperTrak RAID Controller . . . . . . . . . .15

Setting Up Serial Cable Connections . . . . . . . . . . . . . . . . . . . . . . .17

Connecting the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Disk Drive LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

I/O Module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Setting up the Serial Connection . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Page 4

VessJBOD 1000 Series Product Manual

iv

Chapter 3: Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Disk Drive LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

I/O Module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

CLI Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Cable Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Enclosure Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Factory Default Command . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Help Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Link Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Route Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Uptime Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

VPDR Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

? Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Chapter 4: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Updating the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Downloading the Firmware Image File . . . . . . . . . . . . . . . . . . .37

Updating Firmware in WebPAM PROe . . . . . . . . . . . . . . . . . . .37

Updating Firmware with the JBOD Flash Utility . . . . . . . . . . . .39

Replacing a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

VessJBOD 1730 and 1740 . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

VessJBOD 1830 and 1840 . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Replacing an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Removing the old I/O module . . . . . . . . . . . . . . . . . . . . . . . . . .41

Installing the new I/O module . . . . . . . . . . . . . . . . . . . . . . . . . .42

Replacing a Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Chapter 5: Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Contacting Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Returning the Product For Repair . . . . . . . . . . . . . . . . . . . . . . . . . .51

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Page 5

1

Chapter 1: Introduction to VessJBOD

This chapter covers the following topics:

• About This Manual (below)

• VessJBOD Overview (page 2)

• Architectural Description (page 3)

• Features (page 3)

• Specifications (page 3)

About This Manual

This Product Manual describes how to setup, use, and maintain the VessJBOD

1730, 1740, 1830, and 1840 external disk array subsystems. It also describes

how to use the built-in command-line interface (CLI).

This manual includes a full table of contents, index, chapter task lists, and

numerous cross-references to help you find the specific information you are

looking for.

Also included are four levels of notices:

Note

A Note provides helpful information such as hints or alternative

ways of doing a task.

Important

An Important calls attention to an essential step or point required

to complete a task. Important items include things often missed.

Caution

A Caution informs you of possible equipment damage or loss of

data and how to avoid them.

Warning

A Warning notifies you of probable equipment damage or loss of

data, or the possibility of physical injury, and how to avoid them.

Page 6

VessJBOD 1000 Series Product Manual

2

VessJBOD Overview

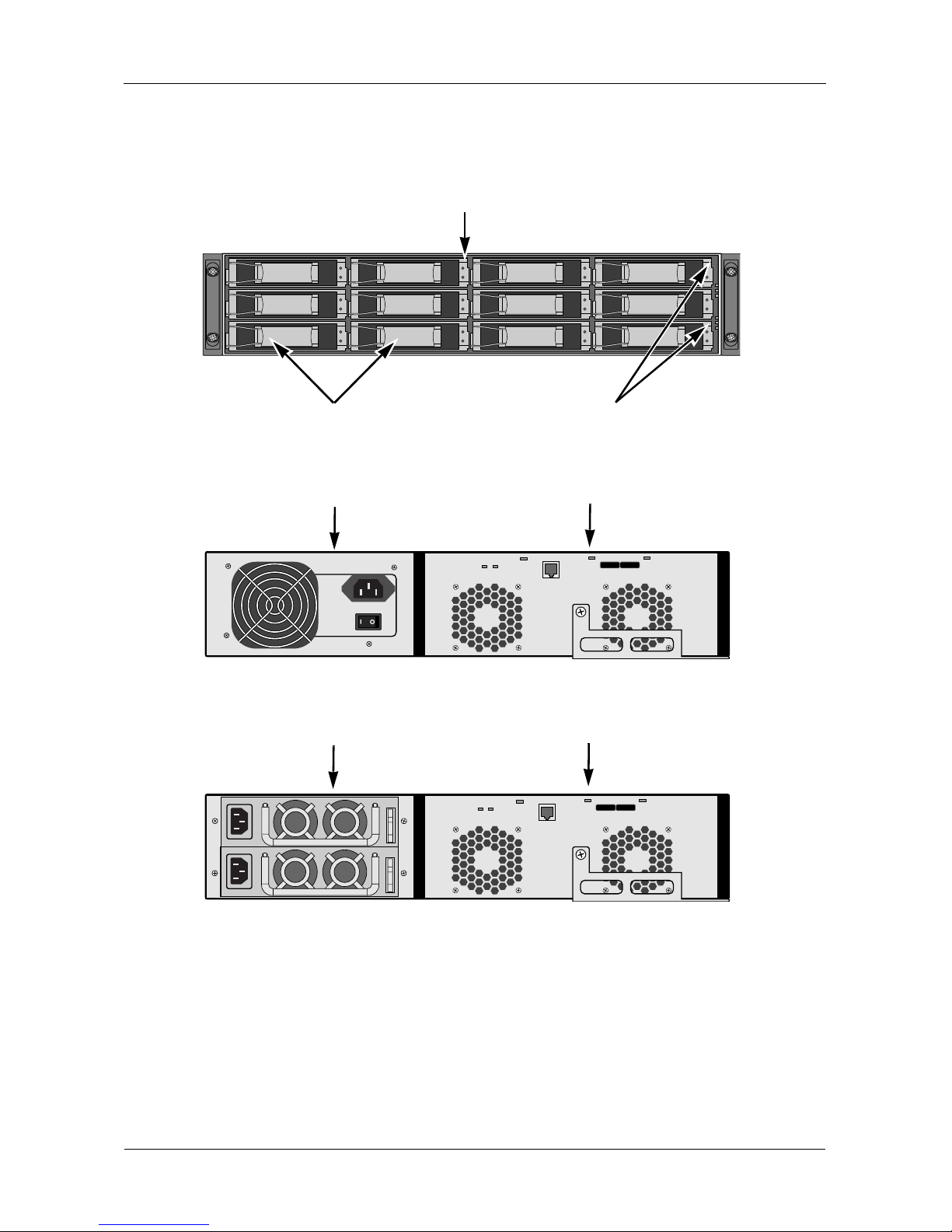

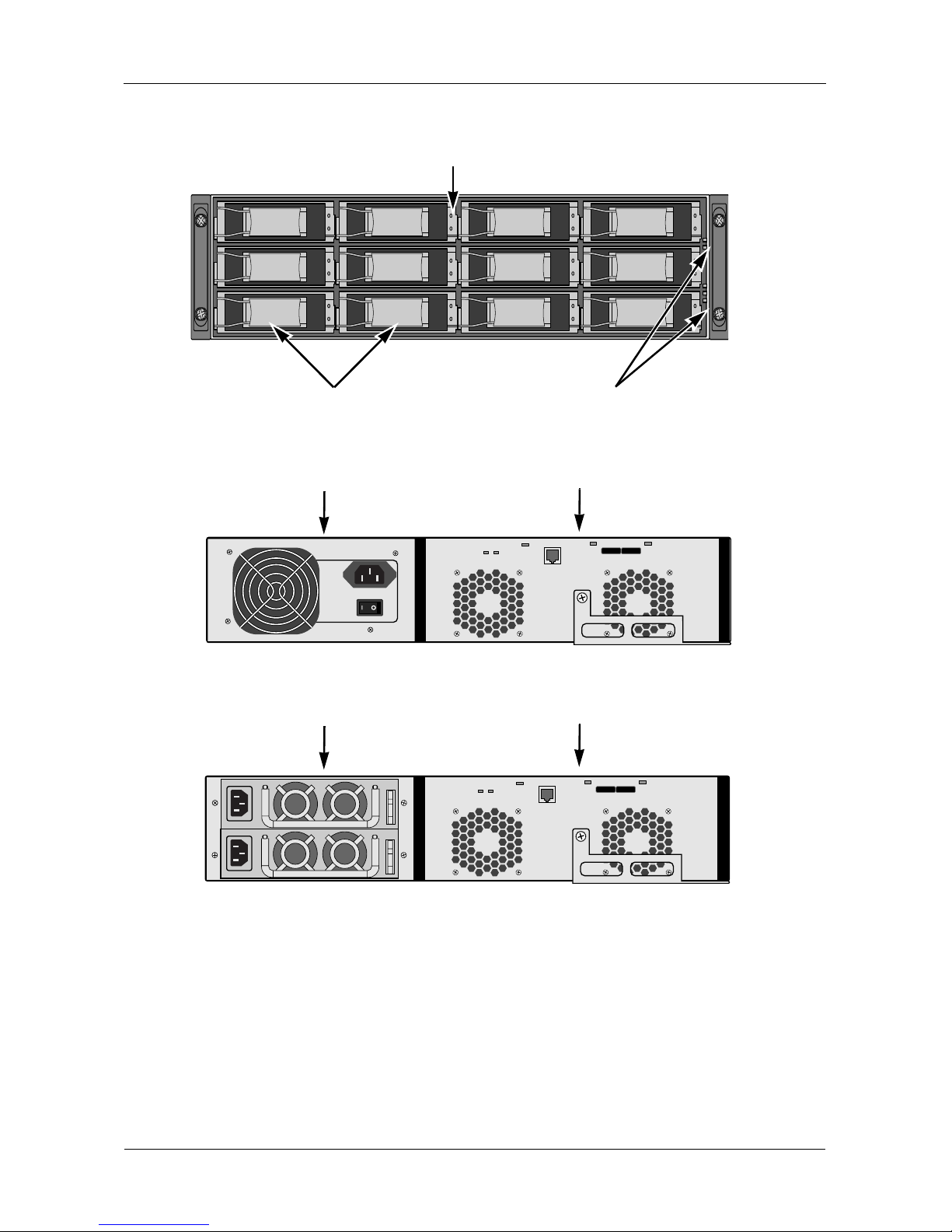

Figure 1. VessJBOD front view

Figure 2. VessJBOD 1730 rear view

Figure 3. VessJBOD 1830 rear view

Drive Carrier LEDs

Drive Carriers Power and Status LEDs

I/O Module

Power Supply

I/O Module

Power Supplies

Page 7

Chapter 1: Introduction to VessJBOD

3

Architectural Description

The VessJBOD 1730, 1740, 1830, and 1840 are Serial Attached SCSI (SAS)

subsystems designed for JBOD expansion to a SAS-capable host system.

The VessJBOD subsystems support:

• 3.0 Gb/s SATA disk drives

• 3.0 Gb/s SAS disk drives

All VessJBOD enclosures include a mid-plane, power supply unit, and enclosure

processor all in one cable-less chassis design. Multiple fans and optional power

supplies provide redundancy to ensure continued usage during component

failure.

Features

• RJ11 serial port supports RS232 protocol via adapter cable.

• 12 hot-swappable drive bays in a robust 2U rackmount chassis.

• 16 hot-swappable drive bays in a robust 3U rackmount chassis.

• Redundant, hot-swappable power supplies on 1830 and 1840 models.

• Drive Support: Up to 16 3.5" x 1" SAS or SATA 3 Gb/s hard disk drives.

• Supports any combination of SAS and SATA drives in the system.

• Staggered phys ical drive spin-up.

• Command Line Interface via RJ-11 Serial Port.

• Three years complete system limited warranty includes 24 x 7 email and

phone support w ith hig hl y ex pe rien ce d tec hn ic al s upp ort technicians and an

advanced replac em ents program.

• Compatible with leading SAS hard drives, host bus adapters, and RAID

controllers.

Specifications

Power Supply

1840: 450W, Dual hot-swappable and redundant, 100-240 VAC auto-ranging, 5060 Hz, with PFC

1830: 350W, Dual hot-swappable and redundant, 100-240 VAC auto-ranging, 5060 Hz, with PFC

1740: 450W, Single, 100-240 VAC auto-ranging, 50-60 Hz, with PFC and

80PLUS certification

Page 8

VessJBOD 1000 Series Product Manual

4

1730: 350W, Single, 100-240 VAC auto-ranging, 50-60 Hz, with PFC and

80PLUS certification

Current (maximum)

1840: 8 A @ 100 VAC or 4 A @ 240 VAC current rating with two power cords

1830: 6A @ 100 VAC or 3 A @ 240 VAC Current rating with two power cords

1740: 7A @ 100 VAC or 3.5 A @ 240 VAC Current rating with one power cord

1730: 6A @ 100 VAC or 3 A @ 240 VAC Current rating with one power cord

Power Consumption

1740, 1840: without disk drives, 72.2 W; with disk drives, 242.3 W

1730, 1830: without disk drives, 80.3 W; with disk drives, 233.4 W

Temperature

Normal conditions:

5° to 40°C operational (-40° to 60°C non-operational)

Conditions of running SAS disk drives with one failed cooling fan:

5° to 35°C operational (-40° to 60°C non-operational)

Relative Humidity

95 percen t maximum

Vibration

Random, 0.21 grms, 5-500 Hz, 30 Mins, X, Y, Z axis.

Dimensions (H x W x D)

1840, 1740: 13 x 45 x 46 cm (5.1 x 17.7 x 18.1 in)

1830, 1730: 8.8 x 45 x 46 cm (3.5 x 17.7 x 18.1 in)

Net Weight

1840: 15.8 kg (34.8 lb) without drives, 23.8 kg (52.5 lb) with 16 drives*

1830: 12.6 kg (27.8 lb) without drives, 18.6 kg (41.0 lb) with 12 drives*

1740: 13.8 kg (30.4 lb) without drives, 21.8 kg (48.1 lb) with 16 drives*

1730: 10.8 kg (23.5 lb) without drives, 16.8 kg (37.1 lb) with 12 drives*

* Assuming 0.5 kg (1.1 lb) per drive.

Page 9

Chapter 1: Introduction to VessJBOD

5

Carton Dimensions (H x W x D)

All models: 28.5 x 57.2 x 75.2 cm (11.2 x 22.5 x 29.6 in)

Carton Weight

1840: 20.8 kg (45.9 lb)

1830: 18.0 kg (38.8 lb)

1740: 19.2 kg (42.3 lb)

1730: 16.2 kg (35.7 lb)

Safety

BSMI, CB, CCC, CE, FCC Class B, MIC, VCCI, UL, cUL, TUV.

Environmental

RoHS, China RoHS.

Wa rranty and Support

Warranty: Three year limited warranty on all components except the optional

battery backup unit, which has a one-yea r warranty.

Support: 24x7 email and phone support (English only). 24x7 access to Promise

support site for drivers, firmware, and compatibility.

CE Statement

Warning: This is a class B product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

FCC Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Page 10

VessJBOD 1000 Series Product Manual

6

KCC Statement

Page 11

7

Chapter 2: VessJBOD Installation

This chapter covers the following topics:

• Unpacking the Vess JBOD (below)

• Mounting VessJBOD in a Rack (page 9)

• Installing Disk Drives (page 11)

• Making Data and Management Connections (page 13)

• Setti ng Up Serial Cabl e Connections (page 17)

• Connecting the Power (p ag e 18)

• Setting up the Serial Connection (page 20)

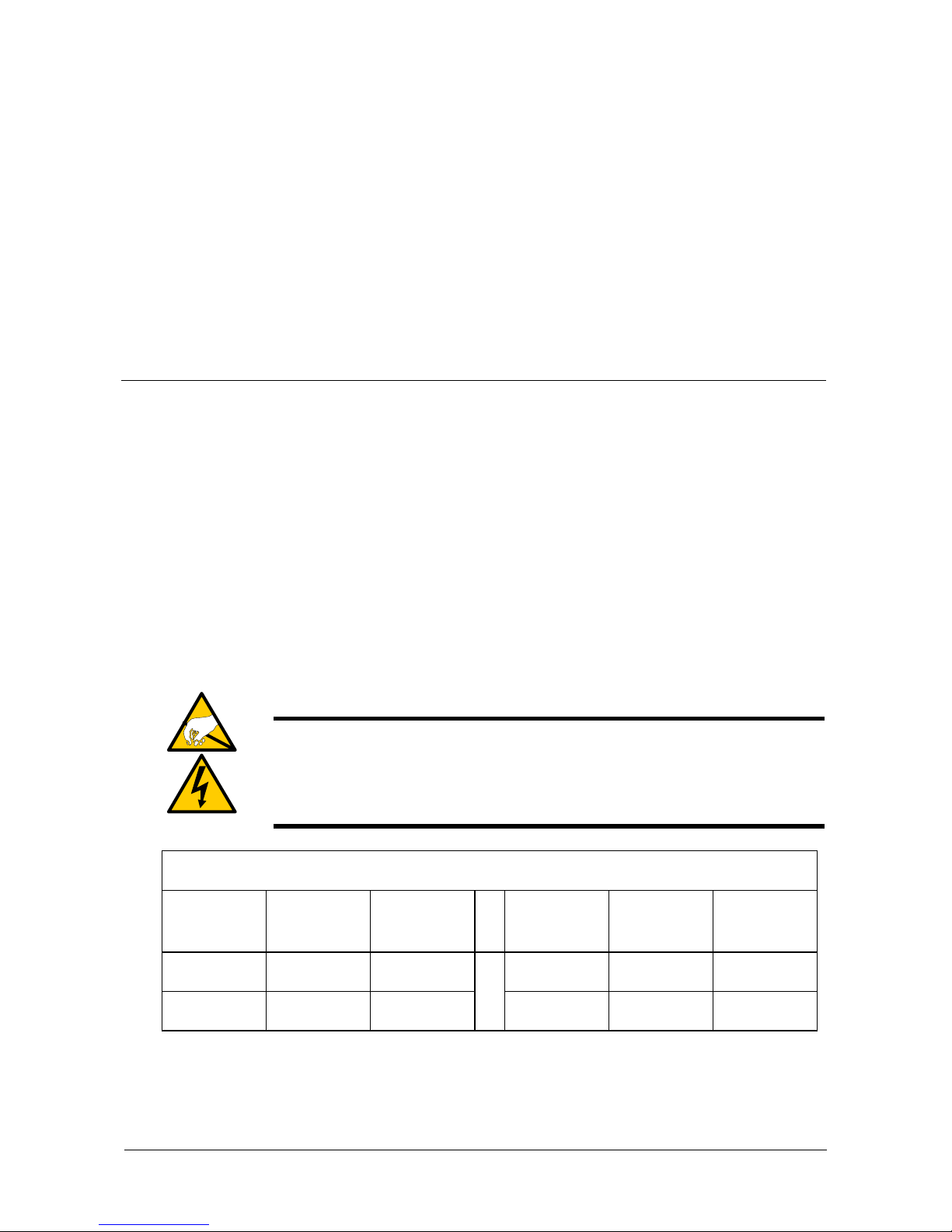

Unpacking the VessJBOD

The VessJBOD box contains the following items:

•VessJBOD Unit

• Quick Start Guide printed

• RJ11-to-DB9 serial data cable

• Screws for disk drives

(70 pieces for 16-bay, 50 pieces

for 12-bay)

• 1.5m (4.9 ft) Power cords

(1700 models, 1; 1800 models, 2)

•CD with Product Manual and Quick

Start Guide in PDF format

Warning

The electronic components within the VessJBOD enclosure are

sensitive to damage from Electro-Static Discharge (ESD).

Observe appropriate precautions at all times when handling the

VessJBOD or its subassemblies.

VessJBOD Models and Descriptions

1800

Model

Drive

Slots

Power

Supplies

1700

Model

Drive

Slots

Power

Supplies

1840 16 2 1740 16 1

1830 12 2 1730 12 1

Page 12

VessJBOD 1000 Series Product Manual

8

Figure 1. VessJBOD front view

Figure 2. VessJBOD 1730 rear view

Figure 3. VessJBOD 1830 rear view

For a description of the LEDs, see pages 18 and 19.

Drive Carrier LEDs

Drive Carriers Power and Status LEDs

I/O Module

Power Supply

I/O Module

Power Supplies

Page 13

Chapter 2: VessJBOD Installation

9

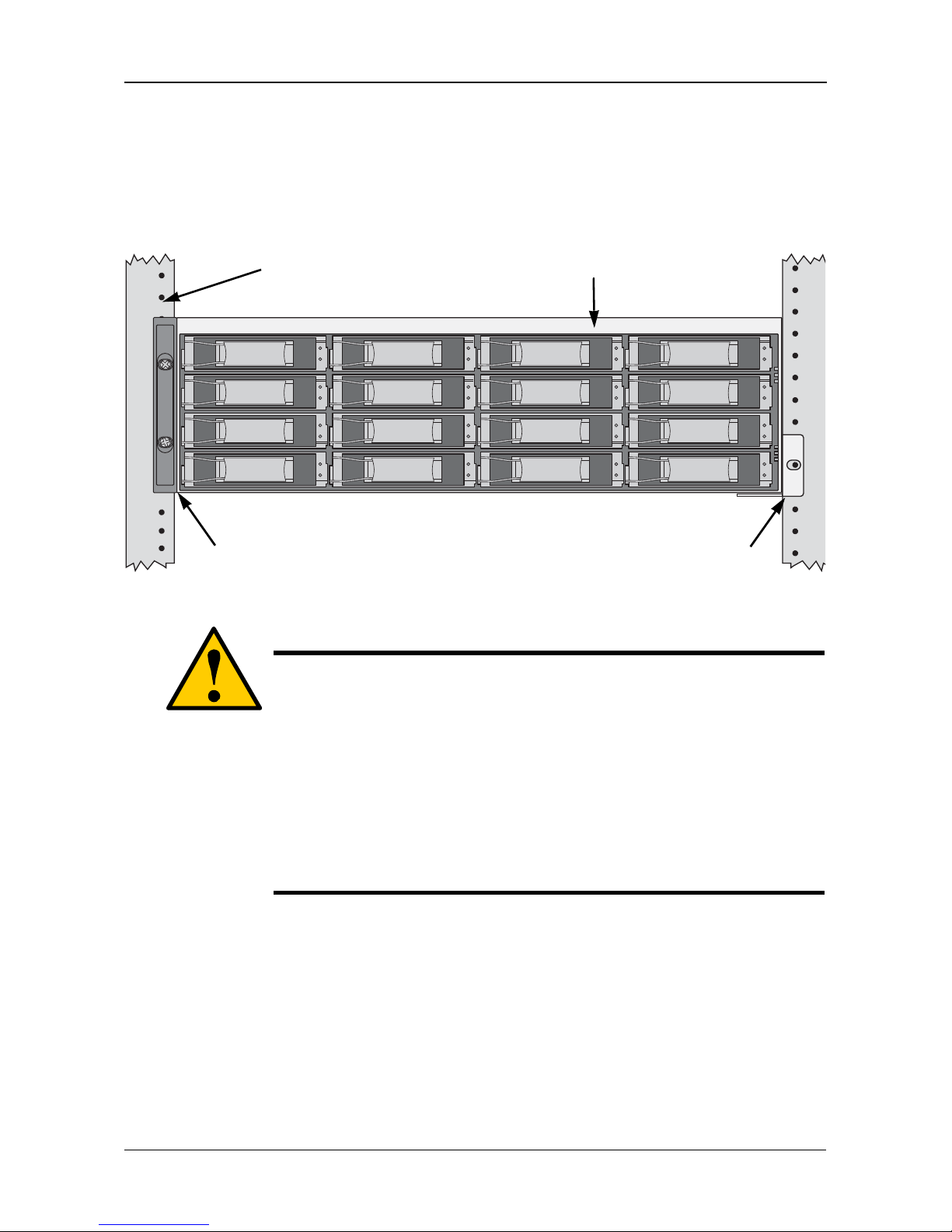

Mounting VessJBOD in a Rack

The VessJBOD subsystem installs to the rack using the available m oun tin g rail s.

You can also use your existing rails.

Figure 4. VessJBOD mounted in a rack with the available rails

To install the VessJBOD subsystem into a rack with the available mounting rails:

1. Check the fit of the mounting rails in your rack system.

2. Adjust the length of the mounting rails as needed.

3. Attach the mounting rail assemblies to the outside of the rack posts, using

the attaching screws from your rack system.

Be sure the support is on the bottom facing inward.

4. Square the rail assemblies in the rack.

5. Tighten the adjustment screws and the attaching screws.

Cautions

• At least two persons are required to safely lift, place, and

attach the VessJBOD subsystem into a rack system.

• Do not lift or mov e the VessJBOD subsys te m by the handles,

power supply or the I/O module. Hold the subsystem itself.

• Only a qualified electrician who is familiar with the installation

procedure should mount and install the VessJBOD

subsystem.

• Be sure all switches are OFF before installing the VessJBOD

subsystem or ex changing components.

V e r tic al Ra ck Post VessJBOD subsystem

Mounting rails mount

outside the rack post

Handles mount

outside the rack post

Page 14

VessJBOD 1000 Series Product Manual

10

6. Place the VessJBOD subsystem onto the rails.

7. Secure the VessJBOD subsy stem to the rack through each h andle, us ing the

attaching screws from your rack system.

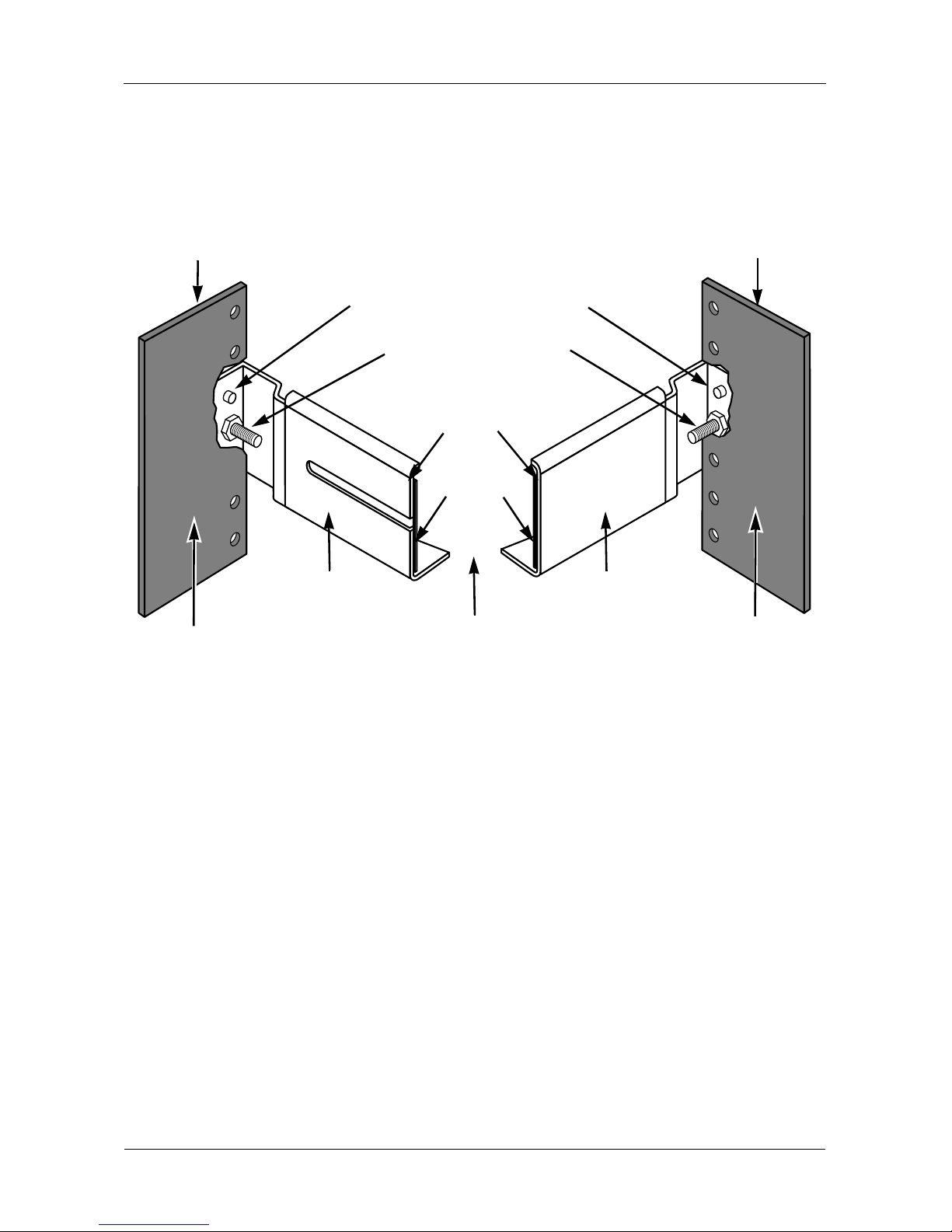

Figure 5. Rack mount assembly diagram

This completes rack mounting. Go to “Installing Disk Drives” on page 11.

Inside of post

Rack front post

Rail attach ing screws

(not included)

Rail adjustment screw

(center, outside of rail)

Flange

Inside of post

Rack back post

Front rail

Rear rail

Support

Locating pins (2 on each end)

Page 15

Chapter 2: VessJBOD Installation

11

Installing Disk Drives

You can populate the VessJBOD with SAS or SATA ha rd di sk dri ves. Fo r opti ma l

performance, install physical drives of the same model and capacity.

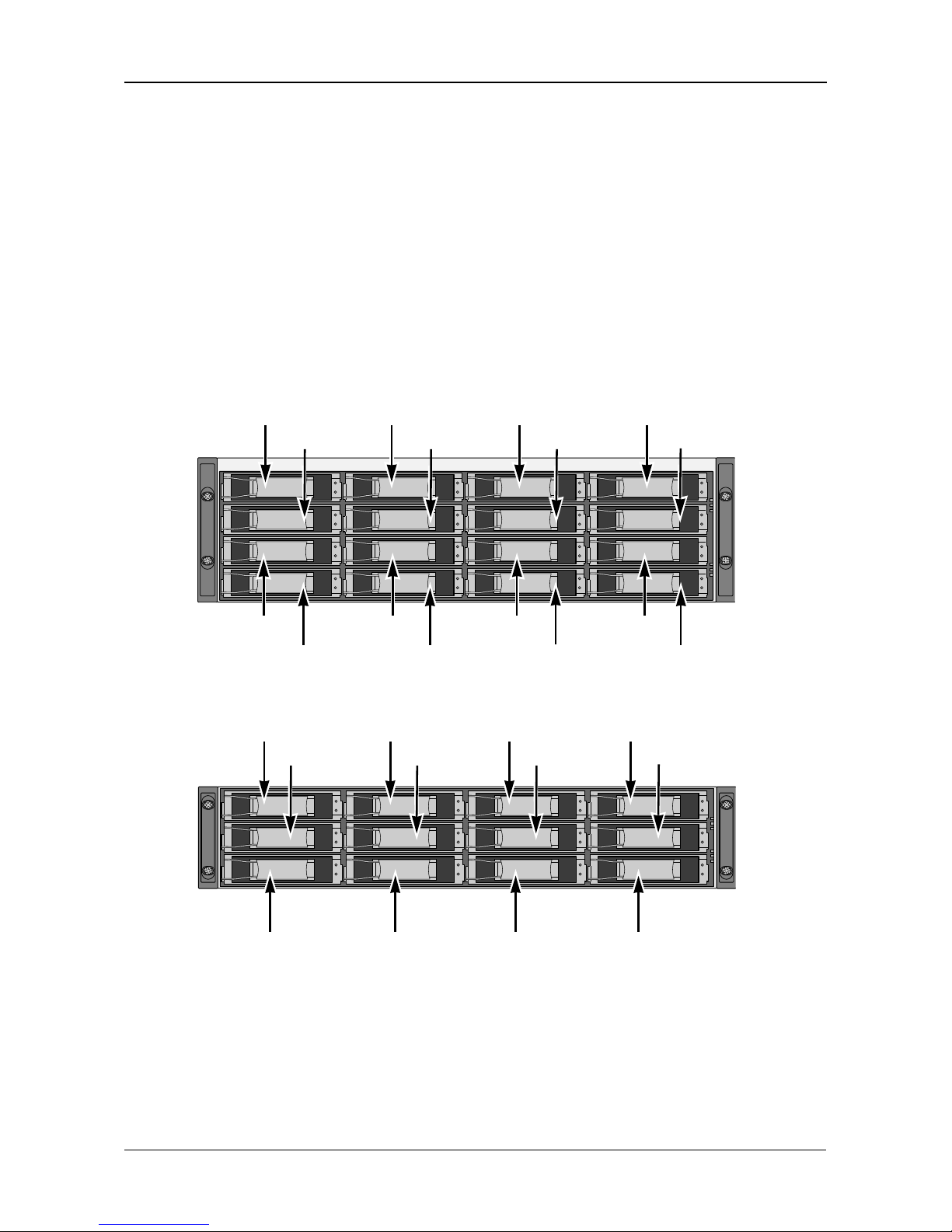

Drive Slot Numbering

You can install any suitable disk drive into any slot in the enclosure. The

diagrams below show how VessJBOD’s drive slots are numbered.

Slot numbering is reflect ed in the W eb PAM PROe and CLU user i nterfac es when

used with a VessRAID subsystem.

Figure 6. VessJBOD drive slot numbering

Figure 7. VessRAID 1730 and 1830 drive slot numbering

Install all of the drive carriers into the VessJBOD enclosure to ensure proper

airflow, even if you do not populate all the carriers with disk drives.

8

65

1234

7

13

14

15

16

9101112

8

65

1234

7

9101112

Page 16

VessJBOD 1000 Series Product Manual

12

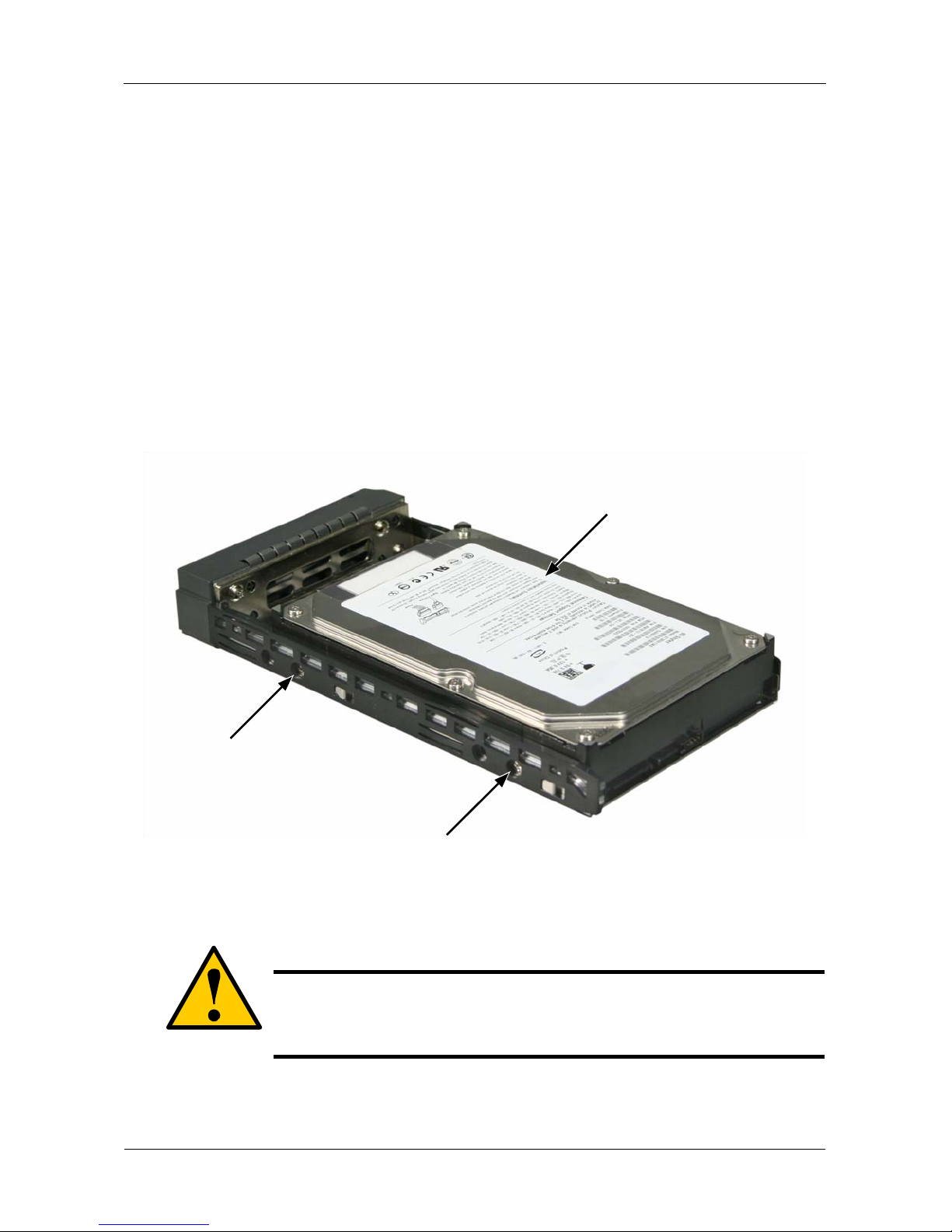

Installing Your Disk Drives

1. Remove a disk drive carrier.

2. Carefully lay the disk drive into the drive carrier at the front, so that the screw

holes on the sides line up.

3. Insert the screws through the holes in the drive carrier and into the sides of

the disk drive.

• Install only the counter-sink screws supplied with the VessJBOD.

• Install four screws per drive.

• Snug each screw. Be careful not to over-tighten.

4. Reinstall the drive carrier into the VessJBOD chassis.

Repeat steps 1 through 3 until all of your disk drives are installed.

Figure 8. Disk drive mounted in a drive carrier

This completes disk drive installation. Go to “Making Data and Management

Connections” on page 13.

Caution

V es sJB OD sup ports disk drive hot-swapping. To avoid hand

contact with an electrical hazard, do not remove more than one

drive carrier a time.

Disk drive

mounting screw

mounting screw

Page 17

Chapter 2: VessJBOD Installation

13

Making Data a nd Management Connections

You can configure your VessJBOD as:

• JBOD Expansion to a VessRAID subsystem

• Drive enclosures for a SuperTrak RAID controller

JBOD Expansion to a VessRAID Subsystem

Configuring a Data Path

To establish the data path:

1. Connect the SAS or iSCSI HBA card in the Host PC to the SAS IN ports or

the iSCSI ports on the VessRAID controller. See page 14, Figure 9.

2. Connect the SAS Expansion port (with a diamond icon) of the VessRAID

controller to the SAS IN p ort (with a circle icon) on the I/O module of the firs t

VessJBOD.

3. Connect the SAS OUT port (with a diamond icon) of the VessJBOD I/O

module of the first VessJBOD to the SAS IN port (with a circle icon) on the

I/O module of the second VessJBOD.

4. Connect the remaining VessJBOD units in the same manner.

Be sure to connect circle icon to diamond icon and vice versa.

All SAS ports have SFF-8088 connectors.

Configuring a Management Path

V e ss RA ID su bs ys tem s ha ve one RAID controller. The c ontr oller has an Ethernet

(RJ45) Management Port connector that enables you to monitor the VessJBOD

subsystems over your network using the WebPAM PROe software.

To establish the management path:

1. Connect the Mana gemen t port on each VessRAID contro ller to y our netwo rk

switch. See Figure 9.

2. Connect the Host PC’s or Server’s NIC to your network switch.

Direct Management of VessJBOD

A management connection directly to the VessJBOD uses a serial connection to

the Host PC. See pages 17 and 20 for more information.

Page 18

VessJBOD 1000 Series Product Manual

14

Figure 9. Data and management connections with VessRAID

This completes data and management connections. Go to “Setting Up Serial

Cable Connections” on page 17.

Caution

Make data conn ections carefully. If you accidently switch a SAS IN

connection with a SAS OUT, the RAID system cannot function.

Host PCs or

Servers

SAS HBA

cards

Network

Switch

VessRAID

VessJBOD

SAS Expansion por

t

diamond icon

VessJBOD

SAS OUT port

diamond icon

SAS IN port

s

circle icon

SAS IN port

circle icon

SAS IN port

circle icon

Management Port

Page 19

Chapter 2: VessJBOD Installation

15

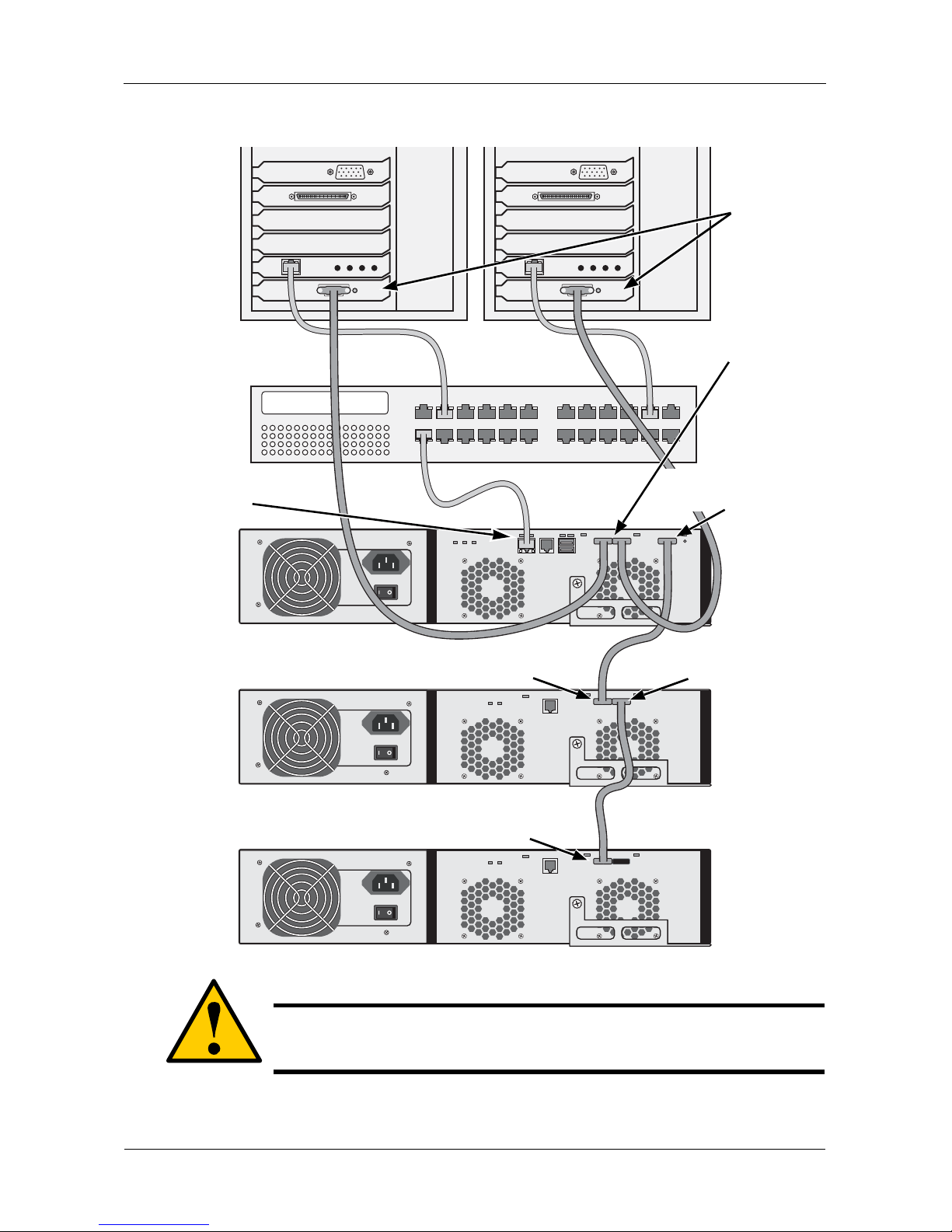

Drive Enclosures for a SuperTrak RAID Controller

Configuring a Data Path

To establish the data path:

1. Connect the SuperTrak RAID Controller in the Host PC to the SAS IN port

(with a circle icon) on the I/O module of the first VessJBOD. See page 16,

Figure 10.

2. Connect the SAS OUT port (with a diamond icon) of the I/O module of the

first VessJBOD to the SAS IN port (with a circle icon) on the I/O module of

the second VessJBOD.

3. Connect the remaining VessJBOD units in the same manner.

Be sure to connect circle icon to diamond icon and vice versa.

All SAS ports have SFF-8088 connectors.

Configuring a Management Path

The SuperTrak RAID Controller installs in the Host PC, therefore it does not

require a separate network management connection.

You can monitor the VessJBOD subsystems using the WebPAM PRO software

installed on the Host PC.

Direct Management of VessJBOD

A management connection directly to the VessJBOD uses a serial connection to

the Host PC. See pages 17 and 20 for more information.

Page 20

VessJBOD 1000 Series Product Manual

16

Figure 10.Data connections with SuperTrak

This completes data and management connections. Go to “Setting Up Serial

Cable Connections” on page 17.

Caution

Make data conn ections carefully. If you accidently switch a SAS IN

connection with a SAS OUT, the RAID system cannot function.

VessJBOD

VessJBOD

VessJBOD

Host PC or Server

SuperTrak RAID

Controller card

SAS OUT port

diamond icon

SAS OUT port

diamond icon

SAS IN port

circle icon

SAS IN port

circle icon

SAS port on

RAID controller

SAS IN port

circle icon

Page 21

Chapter 2: VessJBOD Installation

17

Setting Up Serial Cable Connections

Serial communication enables the Command Line Interface (CLI) on your PC to

monitor and control the VessJBOD. The VessJBOD package includes a RJ11-toDB9 serial data cable.

The CLI is explained in “Chapter 3: Management” on page 21.

Figure 11. The serial connector on the back of the VessJBOD

To set up a serial cable connection:

1. Attach the RJ11 end of the serial data cable to the RJ11 serial connector on

the controller.

2. Attach the DB9 end of the serial dat a cable to a seria l port on the Host PC or

Server.

This completes the serial cable connection. Go to “Connecting the Power” on

page 18.

RJ11 Serial Connector

Page 22

VessJBOD 1000 Series Product Manual

18

Connecting the Power

Plug-in the power cord on the power supply on the back of the VessJBOD

enclosure and switch on the power supply. If you have a VessJBOD 1830 or

1840, plug-in and turn on both power supplies.

When the power is switched on, the LEDs light up.

Front Panel LEDs

When boot-up is finished and the VessJBOD subsystem is functioning normally:

• Power and Global Enclosure Status LEDs display green continuously.

• Controller Activity LED flashes green when there is controller activity.

• System Heartbeat LED blinks green once per second.

Figure 12.VessJBOD front panel LED display

Disk Drive LEDs

There are two LEDs on each drive carrier. They report the presence of a disk

drive, activity of the drive, and the drive’s current condition.

Caution

After you turn the power supply swit ches of f, you must wait at least

10 seconds before you turn the power switches on again.

Power

Controller Activity

Global Enclosure Status

Reserved

Reserved

System Heartbeat

Page 23

Chapter 2: VessJBOD Installation

19

Figure 13.VessJBOD disk drive carrier LEDs

If there is a disk drive in the carrier, the Power/Activity LED disp lays green . If not,

the Power/Activity LED remains dark. The Power/Activity LED flashes during

drive activity.

The RAID subsystem controls the Disk Status LED behavior. With a VessRAID,

the LED displays green when a drive is configured.

I/O Module LEDs

When boot-up is finished and the VessJBOD subsystem is functioning normally:

• Fan LEDs display green continuously.

• The I/O Module LED displays green, and flashes green for activity.

• SAS port LEDs flash green when there is activity.

Figure 14.VessJBOD I/O Module LEDs

Disk Status

Power/Activity

Fan 2

Fan 1

Fan 1 Fan 2

SAS OUT port

Status

SAS IN port

Status

I/O Module

Status

Page 24

VessJBOD 1000 Series Product Manual

20

Setting up the Serial Connection

V ess JBOD h as a Com mand Line In terface (CLI) t o mana ge all of it s func tions via

your PC’s terminal emulation program, such as Microsoft HyperTerminal. This

procedure uses the serial cable connection you made on page 17.

You must use the serial connection to run the CLI for direct management of the

VessJBOD unit. See “Chapter 3: Management” on page 21.

To set up a se rial connection:

1. Change your terminal emulation program settings to match the following

specifications:

• Bits per secon d: 115200

• Data bits: 8

• Parity: None

• Stop bits: 1

• Flow control: none

2. Start your PC’s terminal VT100 or ANSI emulation program.

3. Press Enter once to launch the CLI.

When connected and ready, the CLI screen displays:

***********************************************

Promise SAS Expander v2.00.0000.xx

***********************************************

cli>

The cli> prompt on your screen indicates that you have a conne ction and the

CLI is ready to accept commands.

Page 25

21

Chapter 3: Management

This chapter covers the following topics:

• Front Panel LEDs (below)

• Disk Drive LEDs (page 22)

• I/O Module LEDs (page 23)

• CLI Command Set (page 24)

Front Panel LEDs

Even though the Command Line Interface (CLI) offers monitoring of VessJBOD,

the LED indicators on the front of the VessJBOD unit provide important status

information.

When boot-up is finished and the VessJBOD subsystem is functioning normally:

• Power and Global Enclosure Status LEDs display green continuously.

• Controller Activity LED flashes green when there is controller activity.

• System Heartbeat LED blinks green once per second.

Figure 1. VessJBOD front panel LED display

See the table below.

Power

Controller Activity

Global Enclosure Status

Reserved

Reserved

System Heartbeat

Page 26

VessJBOD 1000 Series Product Manual

22

When the Global Enclosure LED on VessJBOD’s front panel shows Amber or

Red, check the LEDs on the back of VessJBOD. These LEDs give the status of

individual components.

Disk Drive LEDs

There are two LEDs on each drive carrier. They report the presence of a disk

drive, activity of the drive, and the drive’s current condition.

Figure 2. VessJBOD disk drive carrier LEDs

If there is a disk drive in the carrier, the Power/Activity LED disp lays green . If not,

the Power/Activity LED remains dark.

The Power/Activity LED flashes during drive activity.

LEDs

State

Dark

Steady

Green

Flashing

Green

Amber Red

Power System Off Normal — — —

Global

Enclosure

Status

System Off Normal

Locating the

Enclosure

Fan, pow er supply,

temperature, or voltage

problem*

Controller

Activity

System Off

or no SAS

ports

connected

One or more

SAS ports

connected

Activity — —

Controller

Heartbeat

System Off — Normal** — —

* Check the LEDs on the back of the enclosure for more information.

** Blinks green once per second.

Disk Status

Power/Activity

Page 27

Chapter 3: Management

23

The RAID subsystem controls the Disk Status LED behavior. With a VessRAID,

the Disk Status LED displays green when a drive is configured.

I/O Module LEDs

When boot-up is finished and the VessJBOD subsystem is functioning normally:

• Fan LEDs display green continuously.

• The I/O Module LED displays green, and flashes green for activity.

• SAS port LEDs flash green when there is activity.

Figure 3. VessJBOD I/O Module LEDs

See the table below.

LEDs

State

Dark

Steady

Green

Flashing

Green

Amber Red

Power/

Activity

No Drive

Drive

Present

Activity — —

Status*

No Drive or

Unconfigured

Drive OK

Locating the

Drive

Drive

Rebuilding

Array Drive

Offline

* The RAID subsystem controls Disk Status LED behavior. The pattern

described here is from a VessRAID.

Fan 2

Fan 1

Fan 1 Fan 2

SAS OUT port

Status

SAS IN port

Status

I/O Module

Status

Page 28

VessJBOD 1000 Series Product Manual

24

CLI Command Set

The CLI uses the following set of commands:

cable – Specifies the length of cable for optimal signal quality. See page 24.

enclosure – Displays full information on the VessJBOD enclosure and its

component s. See page 25.

factorydefault – Restores factory default settings. See page 28.

help – Use alone to see the list of commands. Use with a command to see a list

of options. Examples: enclosure -help or enclosure -h. See page 29.

link – Display s the c urrent st atus o f the PHYs (links), error counter, expander and

attached SAS addresses. See page 29.

route – Displays addresses of components through a downstream (expansion)

connection. See page 33.

uptime – Displays the number of days, hours, minutes and seconds since the

firmware was loaded (since the VessJBOD was started or restarted). See

page 34.

vpdr – Displays vital product data on field replaceable units. See page 35.

? – Use alone to see the list of commands. Use with a command to see a list of

options. Example: enclosure -? See page 35.

Cable Command

The Cable command displays the current cable length settings for the two SAS

ports. The I/O module supports cables from 1 to 8 meters in length.

LEDs

State

Dark Green Amber Red Blinking

Fan

Not

detected

OK

One fan

turning too

slowly

Multiple

fans turning

too slowly

—

I/O Module No power OK Error — —

SAS IN/

OUT Port s

No

connection

Port

connected

——

Green:

Activity

Note

Command options are NOT case-sensitive.

Page 29

Chapter 3: Management

25

CN#1 is the SAS IN port, circle icon. CN#2 is the SAS OUT port, diamond icon.

See page 23, Figure 3.

To view the current settings:

At the cli> prompt, type cable and press Enter.

The system returns:

CN#1 Cable Length = 1 meter

CN#2 Cable Length = 1 meter

To set Expansion connector CN2 for a 3-meter cable:

At the cli> prompt, type cable -a mod -s “cn2=3” and press Enter.

The system returns:

Cable length of connector 2 is set to 3 meter

Enclosure Command

The Enclosure command:

• Enables you to reboot the VessJBOD enclosure (below)

• Displays information about the VessJBOD enclosure (page 26)

• Enables you to make enclosure settings (page 27)

Reboot the Controller

You can reboot just the controller (I/O module). This action might be needed to

help with setting changes on the VessJBOD.

To reboot the controller:

1. Verify that no data I/O activity is in progress.

2. At the cli> prompt, type enclosure -a mod -s “reboot=1” and press Enter.

Caution

A controller reboot does NOT meet the system restart

requirements for a firmware upgrade.

Page 30

VessJBOD 1000 Series Product Manual

26

When the cli> prompt reappears, the controller has rebooted.

Viewing Information

To view enclosure information:

At the cli> prompt, type enclosure and press Enter.

The system returns:

---------------------------------------------------------------Time since system powerup: 1 day 9 hours 46 minutes 36 seconds

Enclosure : SAS JBOD 3U-16 Bay

Serial Nu mbe r : Cx20j-1 234 5

I/O Module ID : 1 Max I/O Module Cnt : 1

Firmware Version : 02.00.0000.xx I/O Module Role : Primary

Max HDD Slots : 16 Max Connectors : 2

Max PSU Cnt : 2 Max Fan Cnt : 2

Max Temp Sensor Cnt : 8 Max Voltage Sensor Cnt : 2

=================================================================

CU Status Fan1Speed Fan2Speed

=================================================================

1 Operational 4735 rpm 4037 rpm

===============================================================

ID Location Temp Reading

===============================================================

1 I/O Modul e 27C/80F

-----------------------------------------------------------------

Thermal Management : Enabled

Allows to shut do wn the syst em whe n

critical temperature is reached : Yes

Current minimum fan speed (1-4) : Level 1

Note

To reboot the VessJBOD enclosure:

1. V erif y that no dat a I/O acti vi ty is in prog res s.

2. Turn the power supply switch (switches) OFF.

3. Wait 10 seconds. Turn the power supply swit ch

(switches) ON.

Page 31

Chapter 3: Management

27

Controller temperature threshold : 71C/159F (critical)

61C/141F (warning)

===============================================================

ID Location Voltage

===============================================================

1 I/O Module 4.825V

2 I/O Module 12.360V

---------------------------------------------------------------

Enclosure Settings List

The Enclosure command enables you to make settings for the enclosure.

• Enclosure W arning Temperature – Measured a t the backp lane. Fan s peed

increases until temperature falls below the threshold.

• Enclosure Critical Temperature – Measured at the backplane.

Temperature value for automatic shutdown.

• Controller Warning Temperature – Measured inside the I/O module. Fan

speed increases until temperature falls below the threshold.

• Controller Critical Temperature – Measured inside the I/O module.

Temperature value for automatic shutdown.

• Thermal Management – Monitors enclosure temperature, adjusts fan

speeds, displays red LED on cooling unit when a fan fails

• Automatic Shutdown – Shuts down the VessJBOD 30 seconds after the

enclosure or controller reaches critical temperature.

• Minimum Fan Speed – Specifies the minimum fan speed when the

VessJBOD reaches enclosure or controller warning temperature.

Making Enclosure Settings

To set the enclosure warning temperature to 51°C (141°F):

At the cli> prompt, type enclosur e -a mo d -s “en c_warn ing=5 1” and pre ss

Enter.

Warning temperature range is 10° to 51°C (50° to 123°F)

To set the enclosure critical temperature to 61°C (141°F):

At the cli> prompt, type enclosure -a mod -s “enc_critical=61” and press

Enter.

Critical temperature range is 51° to 61°C (123° to 141°F)

To set the controller warning temperature to 51°C (141°F):

At the cli> prompt, type enclosure -a mod -s “ ctrl_wa rn ing= 75” an d pr ess

Enter.

Page 32

VessJBOD 1000 Series Product Manual

28

Warning temperature range is 10° to 75°C (50° to 172°F)

To set the controller critical temperature to 61°C (141°F):

At the cli> prompt, type enclosure -a mod -s “ctrl_cri tical=90” and press

Enter.

Critical temperature range is 75° to 90°C (172° to 194°F)

To enable Thermal Management:

At the cli> prompt, type enclosure -a mod -s “thermalmanager=1” and

press Enter.

For this command, a 1 enables and a 0 disables .

To enable Automatic Shutdown:

At the cli> prompt, type enclosure -a mod -s “allowshutdown=1” and

press Enter.

For this command, a 1 enables and a 0 disables .

To set the minimum fan speed to medium high:

At the cli> prompt, type enclosure -a mod -s “minfanspeed=3” and press

Enter.

For this command:

• 1 means low

• 2 means medium-low

• 3 means medium-high

• 4 means high

The actual speed depends on the fan manufacturer.

Factory Default Command

The factory default command enables you to restore factory default settings in

the VessJBOD enclosure.

To restore the enclosure to the default settings:

At the cli> prompt, type factorydefault -a mod -s “default=1” and press

Enter.

Or, at the cli> prompt, type factorydefaults and press Enter.

When the cli> prompt appears again, all settings have been restored to the

default values.

Caution

Promise recommen ds that you keep Automa tic Shutdow n enabled

at all times.

Page 33

Chapter 3: Management

29

Help Command

The VessJBOD CLI uses the standard Unix online help system.

To access general help:

At the cli> prompt, type help and press Enter.

To access help with a specific function:

At the cli> prompt, ty pe help followed by the nam e of the function and press

Enter.

Or , at the cli> prom pt, type the name of th e function fol lowed by -h and pres s

Enter.

See “CLI Command Set” on page 24 for a list of supported functions.

Link Command

The Link command displays information about VessJBOD links, including:

• Link Status (page 29)

• Link Statistics (page 30)

• Clearing Statistics (page 3 2)

• Expander SAS Addresses (page 32)

• Attached SAS Addresses (page 32)

Viewing Link Status

To view link status:

At the cli> prompt, type link and press Enter.

The system returns:

Link Status:

======================================================================

Phy Port Type Rate Init Dev Link PRdy

====================================================================

0 DSK01 SAS 3.0G OK End ---- Rdy

1 DSK02 SAS 3.0G OK End ---- Rdy

2 DSK03 SAS 3.0G OK End ---- Rdy

3 DSK04 SAS 3.0G OK End ---- Rdy

4 DSK05 SAS 3.0G OK End ---- Rdy

5 DSK06 SAS 3.0G OK End ---- Rdy

6 DSK07 SAS 3.0G OK End ---- Rdy

7 DSK08 SAS 3.0G OK End ---- Rdy

Page 34

VessJBOD 1000 Series Product Manual

30

8 DSK09 SAS 3.0G OK End ---- Rdy

9 DSK10 SAS 3.0G OK End ---- Rdy

10 DSK11 SAS 3.0G OK End ---- Rdy

11 DSK12 SAS 3.0G OK End ---- Rdy

12 DSK13 SAS 3.0G OK End ---- Rdy

13 DSK14 SAS 3.0G OK End ---- Rdy

14 DSK15 SAS 3.0G OK End ---- Rdy

15 DSK16 SAS 3.0G OK End ---- Rdy

16 CN#1 ---- ---- ---- ---- ---- ---17 CN#1 ---- ---- ---- ---- ---- ---18 CN#1 ---- ---- ---- ---- ---- ---19 CN#1 ---- ---- ---- ---- ---- ---20 CN#2 SAS 3.0G OK End ---- Rdy

21 CN#2 SAS 3.0G OK End ---- Rdy

22 CN#2 SAS 3.0G OK End ---- Rdy

23 CN#2 SAS 3.0G OK End ---- Rdy

Phy : PHY ID Port: Port Id Type: SAS or SATA

Rate: Rate 3G/6G Init: Init Passed Dev : Device Type

Link: Link Connected PRdy: Phy Ready

----------------------------------------------------------------------

The following items are reported in the table above:

• Phy – Each link is a PHY, numbered 0 through 23

• Port – DSK01 through DSK16 represe nt drive slot s. Eac h slot has one PHY.

See “Drive Slot Numbering” on page 11.

CN#1 is the SAS IN port, circle icon. CN#2 is the SAS OUT port, diamond

icon. See page 23, Figure 3. Each port has four PHYs.

• Type – Physical drive type, SAS or SATA

• Rate – Physical drive data rate, 3.0 Gb/s

• Dev – Device type. End means an end device. Exp means an expansion

device

• Link – Normally, ---- is displayed. If there is a connection at the moment the

link command runs, it displays CONN

• PRdy – PHY Ready Status. If the port is ready, it displays Rdy

Viewing Link Statistics

To view link status:

1. At the cli> prompt, type link and press Enter.

2. Scroll down to Link Statistics.

Page 35

Chapter 3: Management

31

The screen displays:

Link Statistics:

======================================================================

Phy Type InDW DsEr DwLo PhRe CoVi PhCh

======================================================================

0 DSK01 ------- ------- ------- ------ - ----- -- 0x11

1 DSK01 ------- ------- ------- ------ - ----- -- 0x61

2 DSK01 ------- ------- ------- ------ - ----- -- 0x0D

3 DSK01 ------- ------- ------- ------ - ----- -- 0x0D

4 DSK01 ------- ------- ------- ------ - ----- -- 0x01

5 DSK01 ------- ------- ------- ------ - ----- -- 0x61

6 DSK01 ------- ------- ------- ------ - ----- -- 0x11

7 DSK01 ------- ------- ------- ------ - ----- -- 0x0D

8 DSK01 ------- ------- ------- ------ - ----- -- 0x0D

9 DSK01 ------- ------- ------- ------ - ----- -- 0x01

10 DSK01 ------- ------- ------- ------- ------- 0x0D

11 DSK01 ------- ------- ------- ------- ------- 0x0D

12 DSK01 ------- ------- ------- ------- ------- 0x01

13 DSK01 ------- ------- ------- ------- ------- 0x5D

14 DSK01 ------- ------- ------- ------- ------- 0x0D

15 DSK01 ------- ------- ------- ------- ------- 0x09

16 CN#1 ------- ------- ------- ------- ------- ---17 CN#1 ------- ------- ------- ------- ------- ---18 CN#1 ------- ------- ------- ------- ------- ---19 CN#1 ------- ------- ------- ------- ------- --20 CN#2 ------- ------- ------- ------- ------- 0x8F

21 CN#2 ------- ------- ------- ------- ------- 0x8F

22 CN#2 ------- ------- ------- ------- ------- 0x8F

23 CN#2 ------- ------- ------- ------- ------- 0x8F

----------------------------------------------------------------------

The following items are reported in the table above. All counts are hexadecimal:

• Phy – Each link is a PHY, numbered 0 through 23

• Port – DSK01 through DSK16 represe nt drive slot s. Eac h slot has one PHY.

See “Drive Slot Numbering” on page 11.

CN#1 is the SAS IN port, circle icon. CN#2 is the SAS OUT port, diamond

icon. See page 23, Figure 3. Each port has four PHYs.

Page 36

VessJBOD 1000 Series Product Manual

32

• InDW – Invalid D-word Count

• DsER – Disparity Error Count

• DwLo – Dword Sync Loss Count

• PhRe – PHY Reset Problem Count

• CoVi – Code Violation Count

• PhCh – PHY Change Count

If the count is zero, the counter shows dashes (------).

The fact that errors occur does not necessarily indicate a problem or that the

VessJBOD unit is malfunctioning.

An individual error count that increments regularly indicates a possible problem

and requires further investigation.

Clearing Statistics

To clear the link error statistics:

At the cli> prompt, type link -a clear -c "stats" and press Enter.

Viewing SAS Addresses

To view SAS addresses:

1. At the cli> prompt, type link and press Enter.

2. Scroll down to Expander SAS Addresses or Attached SAS Addresses.

The screen displays:

Expande r SAS Addr ess es:

==============================================================

Type SAS Address

==============================================================

Base 50 00 15 5D 21 12 22 00

SSP 50 00 15 5D 21 12 22 3E

SMP 50 00 15 5D 21 12 22 3F

Attache d SAS Addr ess es:

================================================================

Port SAS Address

================================================================

DSK01 50 00 15 E0 11 4E 5E B2

DSK02 50 00 15 E0 11 4E 80 C2

DSK03 50 00 15 E0 11 4C 22 02

Page 37

Chapter 3: Management

33

DSK04 50 00 15 E0 11 4D E2 22

DSK05 50 00 15 E0 11 4D 8F B2

DSK06 50 00 15 E0 11 4D D0 62

DSK07 50 00 15 E0 11 4D DE E2

DSK08 50 00 15 E0 11 4D 8E F2

DSK09 50 00 15 E0 11 4C 97 62

DSK10 50 00 15 E0 11 4C 36 62

DSK11 50 00 00 E0 11 4F 18 E2

DSK12 50 00 00 E0 11 4F 18 D2

DSK13 50 00 00 E0 11 4D 8E 52

DSK14 50 00 00 E0 11 4D E2 22

DSK15 50 00 00 E0 11 4E 49 C2

DSK16 50 00 00 E0 11 4D DC F2

CN#1 No Device Attached

CN#2 50 00 15 5F FF C0 22 3F

----------------------------------------------------------------

The following items are reported in the table above:

• Port – DSK01 through DSK16 represe nt drive slot s. Eac h slot has one PHY.

See “Drive Slot Numbering” on page 11.

CN#1 is the SAS IN port, circle icon. CN#2 is the SAS OUT port, diamond

icon. See page 23, Figure 3. Each port has four PHYs.

Route Command

To view the SAS addresses of the devices in your domain:

At the cli> prompt, type route -a list and press Enter.

The system returns:

Routing Table Mapping:

Entry# SAS Address CnID

--------------------------------------------------0159 500000E0114D8FB2 CN#2

0163 500000E0114C2252 CN#2

0202 500000E0120B3562 CN#2

0238 500000E01212F582 CN#2

0287 500000E0120B26B2 CN#2

0365 5000155FFFC0223E CN#2

0462 500000E0114F18F2 CN#2

Page 38

VessJBOD 1000 Series Product Manual

34

0468 500000E01205B472 CN#2

0542 500000E01122C5B2 CN#2

0624 500000E0114E4A32 CN#2

0639 500000E0114D8E32 CN#2

0700 500000E0120B2A62 CN#2

0721 500000E0114DE7A2 CN#2

0751 500000E0114E5EA2 CN#2

0764 500000E0120B28F2 CN2

0765 500000E0114C2342 CN#2

0977 500000E0120A2472 CN#2

1023 5000155FFFC02408 CN#2

--------------------------------------------------------------------

The route command displays SAS addresses that are attached to the SAS ports

of the VessJBOD unit. Three items are reported:

• Entry# – Arbitrary numbers, listed in sequence

• SAS Address – Of the disk drive or other component

• CnID – External SAS port connector

CN#1 is the SAS IN port, circle icon. CN#2 is the SAS OUT port, diamond

icon. See page 23, Figure 3.

Route Troubleshooting

If your system returns:

No SAS Routi ng En try Exist s

...it indicates that no downstream devices are found.

Uptime Command

The uptime command informs you of the elapsed period of time since the

VessJBOD unit was powered on.

To display uptime:

The I/O module supports cables from 1 to 8 meters in length.The system

returns:

System has been running 1 day 9 hours 46 minutes 36 seconds

Page 39

Chapter 3: Management

35

VPDR Command

The vpdr command displays vital product data on the major components of the

VessJBOD enclosure.

To display vital product data:

At the cli> prompt, ty pe vp dr -i and the num ber of t he compo nen t, and p ress

Enter.

For this command:

• 1 – Controller (I/O module)

• 6 – Backplane

For example, vpdr -i 1 returns:

Board ID :0

OEM Name :PROMISE

OEM Model :Cx20s-Jbo d

Mfg Part :IOC-C620s-01

Mfg SN :B17D 07 138 400 004

Mfg Rev :A1R1.0

Mfg Date :2009:02:15

WWN :20 00 01 01 55 FF FC 0D

? Command

The VTrak CLI uses the standard Unix online help system.

To access help with a specific function:

At the cli> prompt, type ? followed by the name of the function and press

Enter.

Or , at the cli> prom pt, type the name of th e function fol lowed by -? and pres s

Enter.

See “CLI Command Set” on page 24 for a list of supported functions.

Page 40

VessJBOD 1000 Series Product Manual

36

Page 41

37

Chapter 4: Maintenance

This chapter covers the following topics:

• Updating the Firmware (below)

• Replacing a Power Supply (page 40)

• Replacing an I/O Module (page 41)

• Replacing a Cooling Fan (page 42)

Updating the Firmware

There are two ways to update the VessJBOD’s firmware.

• Through a VessRAID subsystem using WebPAM PROe

• With the JBOD Flash Utilit y

Downloading the Firmware Image File

Go to the Promise website at http://www.promise.com/support/support_eng.asp

and download the latest firmware image (.img) file to your TFTP server or your

Host PC. The firmware image file includes all of the files to update the

VessJBOD.

Updating Firmware in WebPAM PROe

This procedure updates the firmware on all VessJBOD subsystems that appear

in the WebPAM PRO interface on the Host PC.

To update the firmware:

1. Click the Subsystem icon.

2. Click the Software Management icon.

3. Clic k the Firmware Update tab.

4. Do one of the following actions:

• Click the Download Flash File from TFTP Server option, then click the

Next button.

• Click the Dow nload Flash File from Local File through HTTP option,

then click the Next button.

Warning

Do not restart the VessJBOD during a firmware upgrade

procedure. Wait until you see the Flash image completed

message.

Page 42

VessJBOD 1000 Series Product Manual

38

5. For the TFTP Server option:

• Enter the hostname or IP address of your TFTP server in the field

provided.

• Enter the port number of your TFTP server in the field provided (69 is

the default).

• Enter the fil ena me of th e Firmware Update file in th e f iel d p r ovided. The

filename is similar to exp.fw.2.03.0000.00.bin.

• Click the Submit button.

For the Local File option:

• Click the Browse button.

• Navigate to the Firmware Update file. The filename is similar to

exp.fw.2.03.0000.00.bin.

• Click the file, then click the Open button.

• Click the Submit button.

6. When the download is completed, click the Nex t button.

A popup message appears warning you not to reboot the VessRAID during

the firmware update procedure.

7. In the popup message, click the OK button.

The update pr ogress di splay s. Then a popu p mess age ap pears t o tell y ou to

reboot the VessRAID.

8. In the popup message, click the OK button.

9. Restart the VessRAIDs and VessJBODs:

• Shut down the VessRAID subsystems. See “Shutting Down the

Subsystem” in the VessRAID Product Manua l.

• On the VessJBOD subsystems, turn OFF the power supply switches.

• Wait 30 seconds, then turn ON the VessJBOD power supply switches.

• Wait 30 additional seconds, then turn ON the VessRAID power supply

switches.

To verify the firmware update, run the enclosure command in the CLI. See

page 25.

Note

After you click the Submit button, if WebPAM PROe displays this

message: error transferring image, you entered an incorrect file

name or an incorrect location. Check the information and try

again.

Page 43

Chapter 4: Maintenance

39

Updating Firmware with the JBOD Flash Utility

The download firmware image (.img) file package includes a Windows-based

utility to update the firmware on the VessJBOD. The JBOD utility:

• Updates firmware on VessJBOD subsystems only

• Updates one VessJBOD at a time

• Runs on Windows PCs over a RS232 serial connection

• Works with any RAID system configuration

Preparing the Utility

To prepare the utility:

1. Verify that your serial connection from your PC to the VessJBOD is online.

See “Setting up the Serial Connection” on page 20.

2. Unzip the firmware download, locate and open the expfwdlutil folder.

The utility file is expfwdlutil_<version number>.exe.

By default, the utility connects to the VessJBOD through the Host PC’s

COM1 port.

If you are using a different COM port, you must change the port setting in the

configuration file.

To access the configuration file and change the COM port setting:

1. Double click the expfwdlutil_<version number>.exe file to start the utility.

2. In the Flash Utility dialog box, click the Quit butt on. In the Warning bo x, click

the Yes button.

When the utility opened, it created a fwdl.ini file in the same directory.

3. Open t he fwdl.ini configuration file in a text editor and change the comport

number as required.

[settings]

file=

comport=1

The file value fills in automatically when you run the utility.

Save and close the fwdl.ini file.

Warning

Do not restart the VessJBOD during a firmware upgrade

procedure. Wait until you see the Firmware download finished

successfully message.

Page 44

VessJBOD 1000 Series Product Manual

40

Updating the Firmware

To update the firmware:

1. Double click the expfwdlutil_<version number>.exe file.

The Flash Utility dialog box appears.

2. Clic k the Browse button and navigate to the Firmware Update file in the

firmware folder.

The firmware file is exp.fw.<version number>.bin.

3. Click the file, then click the Open button.

4. Clic k the Start button.

The update begins. You can monitor progress on the Progress bar. The

operation takes about four minutes.

5. When you see the message:

Firmware download finished successfully.

Please power cycle the system for the new firmware to take effect.

Click the Quit button. In the Warning box, click the Yes button.

6. Restart the VessJBOD:

• Tu rn OFF the powe r suppl y switch (switches).

• Wait 30 seconds, then turn ON the power supply switch (switches).

To verify the firmware update, run the enclosure command in the CLI. See

page 25.

Replacing a Power Supply

VessJBOD 1730 and 1740

The power supply on the VessJBOD 1730 and 17 40 was no t designed for onsite

replacement. If you need to replace the power supply, contact Technical Support

and make arrangements to return the subsystem to Promise for service. See

page 46.

VessJBOD 1830 and 1840

The redunda nt power supplie s on the V es sJBOD 183 0 and 1840 are designed as

field-replaceable units. You can replace a power supply without removing the

VessJBOD from the rack.

Removing the old power supply

To remove the power supply:

1. Verify that the power supply LED is amber or red.

2. Switch off the power to the power supply you plan to replace.

Page 45

Chapter 4: Maintenance

41

3. Unpl ug the power cord.

4. Loosen and remove the retaining screw on the left side of the power supply.

5. Pull the power supply out of the VessRAID enclosure .

Installing the new power supply

To install the power supply:

1. Carefully slide the power supply into the enclosure.

2. Install and tighten the retaining screw on the left side of the power supply.

3. Plug in the power cord.

4. Switch on the power supply.

5. Verify that the new power supply LED is green.

This completes the power supply replacement procedure.

Replacing an I/O Module

The I/O module monitors and manages the logical drives. When the I/O module

is replaced, all of y our l ogical d rive dat a and config urations remain i ntact because

this logical drive information is stored on the disk drives.

I/O module failure is rare. But you might have to remove and reinstall the same

I/O module in order to replace a cooling fan as described in this chapter.

Removing the old I/O module

To replace the I/O module:

1. Shut do wn the VessJBOD. Tur n OFF the power supply switch (switches).

2. Disconnect the SAS, s erial, and power cables.

3. On the I/O module, loosen the thumbscrew, swing the latch to the right and

pull the I/O module out of the enclosure. See Figure 1.

Caution

• Do not replace the I/O module based on LED colors alone.

Only replace the I/O module when directed to do so by

Promise Technical Support. See page 46.

• Only a qualified technician should perform this procedure.

• You must shut down the VessJBOD subsystem before you

can perform this procedure.

Page 46

VessJBOD 1000 Series Product Manual

42

Figure 1. Removing the I/O module

Installing the new I/O module

1. Carefully slide the new I/O module into the enclosure.

2. Swing the latch to the left and secure it with the thumbscrew.

3. Reconnect the SAS, serial, and power cables.

4. Switch on the power. Turn ON the power supply switch (switches).

The VessJBOD restarts. For more information about VessJBOD’s start-up

behavior, see “Connecting the Power” on page 18.

This completes the I/O module replacement procedure.

Replacing a Cooling Fan

To replace a fan:

1. Verify that the Fan LED on the cooling unit is amber or red. See Figure 2.

Figure 2. Fan LEDs

2. Shut down the VessJBOD and remove the I/O module.

See “Replacing an I/O Module” on page 41.

Cautions

• Only a qualified technician should perform this procedure.

• You must shut down the VessJBOD subsystem before you

can perform this procedure.

Thumbscrew

Latch

Fan 2 LED

Fan 1 LED

Page 47

Chapter 4: Maintenance

43

3. Lay the I/O module on a non-static surface and remove the cover attaching

screws, one on each side, then remove the cover.

Figure 3. I/O module cover and attaching screw. 3U model shown

4. Remove the four attaching screws. See Figure 4.

5. Detach the fan’s power connector and lift the old fan out of the I/O module.

Figure 4. I/O module cooling fan. 3U model shown

6. Place a new fan in the I/O module, attach the power connector, and install

the four attaching screws.

7. Attach the I/O module cover and install the two attaching screws.

Attaching screw

(one each side)

Cover

Attaching

screws (4)

Power

connectors

Page 48

VessJBOD 1000 Series Product Manual

44

See page 43, Figure 3.

8. Reinstall the I/O module.

See “Replacing an I/O Module” on page 41.

This completes the fan replacement procedure.

Page 49

45

Chapter 5: Support

This chapter covers the following topics:

• Frequently Asked Questions (below)

• Contacting Technical Support (page 46)

• Limited Warranty (page 49)

• Returning the Product For Repair (page 51)

Frequently Asked Questions

What kind of disk drives can I use with VessJBOD?

The VessJBOD supports 3.0 GB/s Serial ATA disk drives and 3.0 Gb/s SAS

drives.

VessJBOD does not support Parallel ATA (PATA) disk drives.

Can I take the disk drives from my Promise VTrak, put them into the

VessJBOD, and keep my disk array or logical drive intact?

Yes. Like VessJBOD, the newer VTrak subsystems use the industrystandard DDF method of disk metadata, stored in the reserve sector of each

physical driv e. Us e the Transport function to prepare your disk drives bef ore

moving them. See “Preparing the Disk Array for Transport” in the VessRAID

Product Manual.

Early VTrak subsystems used a proprietary method of disk metadata.

VessRAID subsystems have a metadata-to-DDF conversion feature that

converts disk drives in attached VessJBOD enclosures. To use the

conversion feature, you must restart the VessRAID and VessJBOD after

installing disk drives from an older VTrak subsystem.

Note that if you m ove your d isk drives from the VessJBOD to a n e arly V T rak,

the older subsystem will not recognize your disk array or logical drive.

How can I tell when the VessJBOD has fully booted?

When the VessJBOD unit is fully booted up, the Power and FRU LEDs will

light up green. The heartbeat LED blinks green once a second.

What happens if a disk drive fails?

Depending on the nature of the failure, the failed drive the drive might not

appear in the CLI—or the fail ed dri ve mig ht ap pea r with s om e erro rs—wh en

you run the link command. See page 29.

Can I hot-swap a failed drive with a new one?

Yes. Disk drives are hot-swappable on the VessJBOD.

Page 50

VessJBOD 1000 Series Product Manual

46

Can a VessJBOD 1840 run using just one power supply?

Yes, it is possible to run the VessJBOD 1840 on a single power supply.

There are two power su pp lies so that the 18 40 wi ll conti nue runn ing if on e of

the power suppl y fails. But de liberately leaving one po wer suppl y off ne gates

this advantage.

In addition, leaving one power supply off reduces air flow through the

VessRAID enclosure and can contribute to overheating. Always switch on

both power supplies.

Contacting Technical Support

Promise Technical Support provide s several supp ort options fo r Promise use rs to

access information and updates. We encourage you to use one of our electronic

services, whi ch provid e pr oduct inform ation u pdates for the most ef ficien t serv ice

and support.

If you decide to contact us, please have the following info rmation available:

• Product model and serial number

• BIOS, firmware, and driver version numbers

• A description of the problem / situation

• System configuration information, including: motherboard and CPU type,

hard drive model(s), SAS/SATA/ATA/ATAPI drives & devices, and other

controllers.

Technical Support Services

United States

Promise Online™ Web Site http://www.promise.com/support/

support_eng.as p

(technical documents, drivers, utilities, etc.)

E-mail Support e-Support On-Line

Fax Support +1 408 228 1100 Attn: Technical Support

Phone Support +1 408 228 1400 option 4

If you wish to write us for

support:

Promise Technology, Inc.

580 Cottonwood Drive

Milpitas, CA 95035, USA

Page 51

Chapter 5: Support

47

The Netherlands

Germany

Italy

E-mail Support e-Support On-Line

Fax Support +31 0 40 256 9463 Attn: Technical Support

Phone Support +31 0 40 235 2600

If you wish to write us for

support:

Promise Technology Europe B.V.

Science Park Eindhoven 5542

5692 EL Son, The Netherlands

E-mail Support e-Support On-Line

Fax Technical Support +49 0 2 31 56 76 48 29

Attn: Technical Support

Phone Technical Support +49 0 2 31 56 76 48 10

If you wish to write us for

support:

Promise Technology Germany

Europaplatz 9

44269 Dortmund, Germany

E-mail Support e-Support On-Line

Fax Support +39 0 6 367 124 00 Attn: Technical Support

Phone Support +39 0 6 367 126 26

If you wish to write us for

support:

Promise Technology Italy

Piazza del Popolo 18

00187 Roma, Italia

Page 52

VessJBOD 1000 Series Product Manual

48

Taiwan

China

E-mail Support e-Support On-Line

Fax Support +886 3 578 2390 Attn: Technical Support

Phone Support +886 3 578 2395 ext. 8822 or 8823

If you wish to write us for

support:

Promise Technology, Inc.

2F, No. 30, Industry E. Rd. IX

Science-based Industrial Park

Hsin-Chu 30075, Taiwan (R.O.C.)

E-mail Support e-Support On-Line

Fax Support

+86 10 8857 8015

Attn: Technical Support

Phone Support +86 10 8857 8085 or 8095

If you wish to write us for

support:

Promise Technology China – Beijing

Room 1205, Tower C

Webok Time Center, No.17

South Zhong Guan Cun Street

Hai Dian District, Beijing 100081, China

E-mail Support e-Support On-Line

Fax Support +86 21 6249 4627 Attn: Technical Support

Phone Support +86 21 6249 4192, 4193, or 4199

If you wish to write us for

support:

Promise Technology China – Shanghai

Room 508, Leader Tower

1 189 West Wu Ding Road

Jing An District, Shanghai 200042, China

Page 53

Chapter 5: Support

49

Limited Warranty

Promise Technology, Inc. (“Promise”) warrants that this product, from the time of

the delivery of the product to the original end user:

a) all components for a period of three (3) years;

b) will conform to Promise’s specifications;

c) will be free fro m defe cts in material and workma ns hip u nder normal use

and service.

This warranty:

a) applies only to products which are new and in cartons on the date of

purchase;

b) is not transferable;

c) is valid only when accompanied by a copy of the original purchase

invoice.

d) Is not valid on spare parts.

This warranty shall not apply to defects resulting from:

a) improper or inadequate maintenance, or unauthorized modification(s),

performed by the end user;

b) operation outside the environmental specifications for the product;

c) accident, misuse, negligence, misapplication, abuse, natural or

personal disaster, or maintenance by anyone other than a Promise or a

Promise-authoriz ed service center.

Disclaimer of other warranties

This warranty covers only parts and labor, and excludes coverage on software

items as expressly set above.

Except as expressly set forth above, Promise DISCLAIMS any warranties,

expressed or implied, by statute or otherwise, regarding the product, including,

without limitation, any warranties for fitness for any purpose, quality,

merchantability, non-infringement, or otherwise. Promise makes no warranty or

representation concerning the suitability of any product for use with any other

item. You assume full responsibility for selecting products and for ensuring that

the products selected are compatible and appropriate for use with other goods

with which they will be used.

Promise DOES NOT W A RRA NT th at any p r od uct is f ree from e rrors o r that it will

interface without problems with your computer system. It is your responsibility to

Page 54

VessJBOD 1000 Series Product Manual

50

back up o r otherwise save important data before installing any p roduct and

continue to back up your important data regularly.

No other document, statement or representation may be relied on to vary the

terms of this limited warranty.

Promise’s sole responsibility with respect to any product is to do one of the

following:

a) replace the product with a conforming unit of the same or superior

product;

b) repair the product.

Promise shall not be liable for the cost of procuring substitute goods, services,

lost profits, unrealized savings, equipment damage, costs of recovering,

reprogramming, or reproducing of programs or data stored in or used with the

products, or for any other general, special, consequential, indirect, incidental, or

punitive damages, whether in contract, tort, or otherwise, notwithstanding the

failure of the essential purpose of the foregoing remedy and regardless of

whether Promise has been advised of the possibility of such damages. Promise

is not an insurer. If you desire insurance against such damage, you must obtain

insurance from another party.

Some stat es d o not a llow the excl usion or limit at ion of in ciden tal o r con seque ntial

damages for consumer products, so the above limitation may not apply to you.

This warranty gives specific legal rights, and you may also have other rights that

vary from state to state. This limited warranty is governed by the State of

California.

Your Responsibilities

You are responsible for determining whether the product is appropriate for your

use and will interface with your equipment without malfunction or damage. You

are also responsible for backing up your data before installing any product and

for regularly b acking up your dat a a fter in stall ing the p roduct. Pro mise is not liable

for any damage to equipment or data loss resulting from the use of any product.

Page 55

Chapter 5: Support

51

Returning the Product For Repa ir

If you suspect a product is not working properly, or if you have any questions

about your product, contact our Technical Support Staff through one of our

Technical Services, making sure to provide the following information:

• Product model and serial number (required)

• Return shipping addres s

• Daytime phone number

• Description of the problem

• Copy of the original purchase invoice

The technician will as si st you in dete rmi nin g w het her th e prod uc t requ ires repair.

If the product needs repair, the Technical Support Department will issue an RMA

(Return Merchandise Authorization) number.

Return ONLY the specific product covered by the warranty (do not ship cables,

manuals, disk ettes, etc.), with a copy of your proof of purchase to:

You must follow the packaging guidelines for returning products:

• Use the original shipping carton and packaging

• Include a summary of the product’s problem(s)

• Write an attention line on the box with the RMA number

• Include a copy of proof of purchase

Important

Obtain an RMA number from Technical Support before you return

the product and write the RMA number on the label. The RMA

number is essential for tracking your product and providing the

proper service.

USA and Canada: Promise Technology, Inc.

Customer Service Dept.

Attn.: RMA # ______

47654 Kato Road

Fremont, CA 94538

Other Countries: Return the product to your dealer

or retailer.

Contact t hem for instructions

before shipping the product.

Page 56

VessJBOD 1000 Series Product Manual

52

You are responsible for the cost of insurance and shipment of the product to

Promise. Note that damage incurred due to improper transport or packaging is

not covered under the Limited Warranty.

When repairing returned product(s), Promise may replace defective parts with

new or recondition ed parts, or replace the entire unit wi th a n ew or rec on diti on ed

unit. In the event of a replacement, the replacement unit will be under warranty

for the remainder of the original warranty term from purchase date, or 30 days,

whichever is longer.

Promise will p ay for st andard retur n shippin g charges o nly. You will be required to

pay for any addition al shi pp ing options (such as express shipping).

Page 57

53

Index

Symbols

? command 35

A

about this manual 1

automatic shutdown 28

C

cable

command

24

RJ11-to-DB9 17

CE statement 5

clear statistics 32

Command

?

35

cable 24

CLI 24

enclosure 25

factory default 28

help 29

link 29, 45

route 33

set 24

uptime 34

vpdr 35

component data 35

connection

power

18

serial 17

controller

activity LED

18, 21

critical temp 28

reboot 25

warning temp 27

D

disk drives

from VTrak subsystem

45

hot-swappable 45

install 11

LEDs 19, 22

supported 45

download firmware image file 37

downstream devices 33

E

enclosure

automatic shutdown

28

command 25

critical temp 27

fan speed 28

global status LED 18, 21

information 26

settings 27

thermal management 28

warning temp 27

error counts 32

F

factory default command 28

fan

LED

19, 23

replace 42

speed 28

FCC statement 5

firmware update 37

H

help command 29

Page 58

VessRAID 1000 Series Product Manual

54

I

I/O module

LED

19, 23

reboot 25

replace 41

information, view 26

K

KCC statement 5

L

LED

controller activity

18, 21

disk drive activity 19, 22

disk drive power 19, 22

disk drive status 19, 22

enclosure global status 18, 21

fan 19, 23

front panel 18, 21

I/O module 19, 23

power 18, 21

SAS port 19, 23

system heartbeat 18, 21

link

command

29, 45

statistics 30

status 29

M

mapping, routing table 33

P

PHY 29–33

port

circle icon

13–16, 25, 30–34

CN#1 25, 30–34

CN#2 25, 30–34

diamond icon 13–16, 30–34

SAS expansion 13, 14

port, cont.

SAS IN

13–16, 25, 30–34

SAS OUT 13–16, 25, 30–34

power

connection

18

LED 18, 21

power supply, replace 40

R

reboot

controller

25

I/O module 25

regulatory statements 5

replace

blower

42

fan 42

I/O module 41

power supply 40

returning product for repair 51

RJ11-to-DB9 cable 17

route command 33

routing table mapping 33

S

SAS

address

32, 33

expander 32

expansion port 13, 14

port LED 19, 23

screws, counter-sink 12

settings

default

28

enclosure 27

specifications, VessJBOD 3

statistics

clear

32

link 30

status, link 29

Page 59