Page 1

Metering pumps

Vario C, VAMC

Operating instructions

EN

Original operating instructions (2006/42/EC)Part no. 987096 BA VA 022 08/18 EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Page 2

Read the following supplementary information in its entirety! Should you

already know this information, you will benefit more from referring to the

operating instructions.

The following are highlighted separately in the document:

n Enumerated lists

Operating guidelines

ð

Outcome of the operating guidelines

- see (reference)

Information

This provides important information relating to the cor‐

rect operation of the unit or is intended to make your

work easier.

Safety notes

Safety notes are identified by pictograms - see Safety Chapter.

These operating instructions conform to current EU regulations applicable

at the time of publication.

Please state identity code and serial number, which you can find on the

nameplate when you contact us or order spare parts. This enables the

device type and material versions to be clearly identified.

Supplementary information

Fig. 1: Please read!

Validity

State the identity code and serial number

Supplemental directives

2

Page 3

Table of contents

1

Identity code.................................................................................... 4

2 Safety Chapter................................................................................. 5

3 Carrying out repairs......................................................................... 9

4 Information on disposal................................................................. 12

5 Technical Data............................................................................... 13

5.1 Performance data.................................................................. 13

5.2 Precision............................................................................... 13

5.3 Shipping weight..................................................................... 13

5.4 Wetted materials................................................................... 14

5.5 Ambient conditions................................................................ 14

5.5.1 Ambient temperatures........................................................ 14

5.5.2 Media temperatures........................................................... 14

5.5.3 Air humidity........................................................................ 14

5.6 Motor data............................................................................. 14

5.7 Stroke sensor "Sigma".......................................................... 15

5.8 Sound pressure level............................................................ 15

5.9 Supplementary information for modified versions................. 15

6 Dimensional Drawings................................................................... 16

7

Diagrams for Setting the Capacity................................................. 17

8 Wear parts Vario C, VAMC............................................................ 18

8.1 Spare parts kits..................................................................... 18

8.2 Diaphragms........................................................................... 18

9 Declaration of Conformity for Machinery....................................... 19

Table of contents

3

Page 4

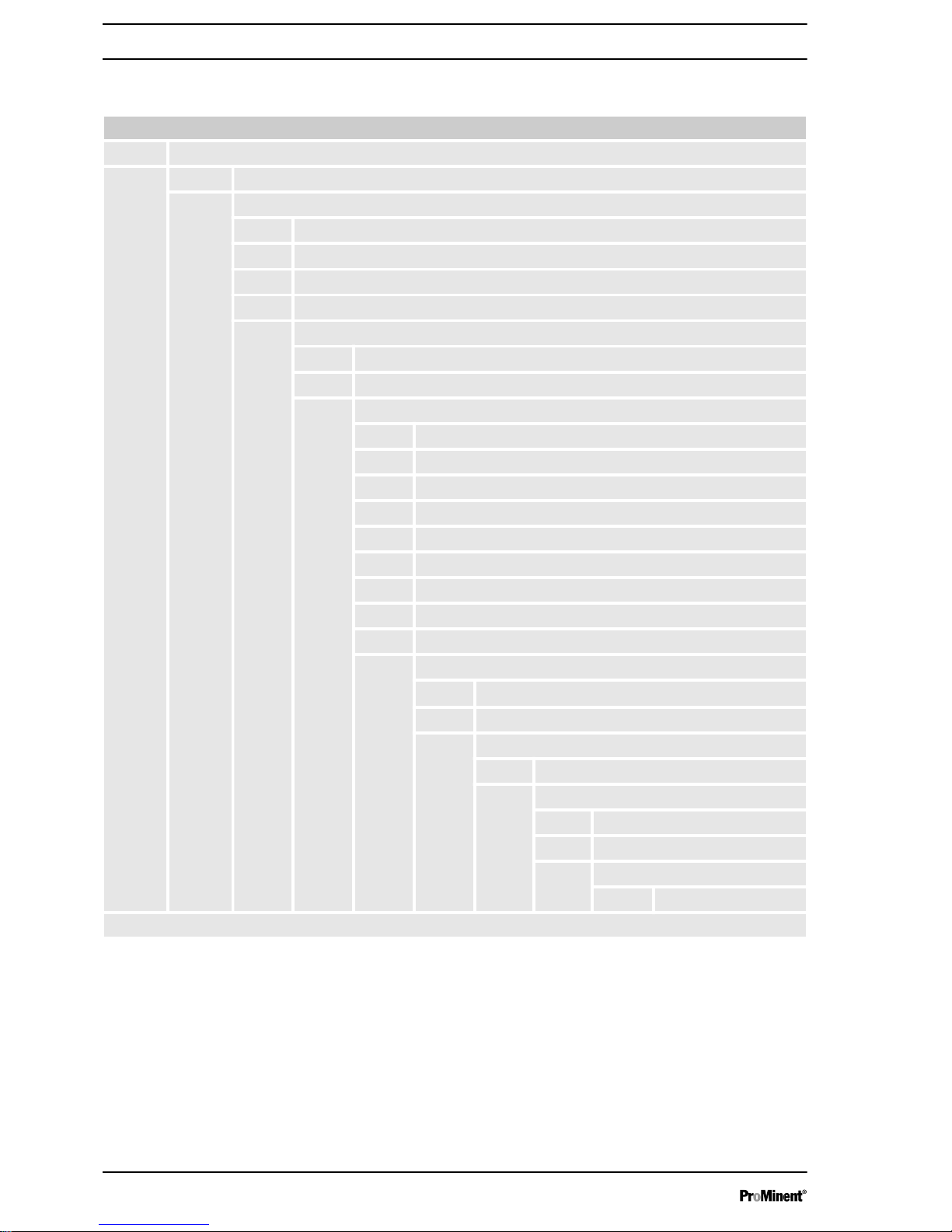

1 Identity code

Product range Vario, Version c

VAMC Capacity

_ _ _ _ _ Performance data at maximum back pressure and type: refer to nameplate on the pump housing

Material of dosing head/valves

PPE Polypropylene with EPDM seal

PCB PVC with EPDM seal

PVT PVDF with PTFE seal

SST Stainless steel with PTFE seal

Dosing head design

0 no valve spring (standard)

1 with 2 valve springs, Hastelloy C4

Hydraulic connector

0 Standard connection - Union nut with hose connection

1 Union nut and PVC insert

2 Union nut and PP insert

3 Union nut and PVDF insert

4 Union nut and stainless steel insert

5 Union nut and PVC tube nozzle

6 Union nut and PP tube nozzle

7 Union nut and PVDF tube nozzle

8 Union nut and stainless steel tube nozzle

Design

0

with ProMinent® logo (standard)

M Modified

Motor connector

_ refer to nameplate on motor

Stroke sensor

0 No stroke sensor

3 with stroke sensor (Namur)

Setting the stroke length

0 Manual (standard)

Identity code

4

Page 5

2 Safety Chapter

WARNING!

We should like to remind the operator of the pump that

he has a duty to use the advice on safety and operation

of the pump for operating instructions for his staff.

The following signal words are used in these operating instructions to

denote different severities of danger:

Signal word Meaning

WARNING Denotes a possibly dangerous sit‐

uation. If this is disregarded, you

are in a life-threatening situation

and this can result in serious inju‐

ries.

CAUTION Denotes a possibly dangerous sit‐

uation. If this is disregarded, it

could result in slight or minor inju‐

ries or material damage.

The following warning signs are used in these operating instructions to

denote different types of danger:

Warning signs Type of danger

Warning – high-voltage.

Warning – danger zone.

n Only use the pump to meter liquid feed chemicals.

n Only use the pump after it has been correctly installed and started up

in accordance with the technical data and specifications contained in

the operating instructions.

n Observe the general limitations with regard to viscosity limits, chem‐

ical resistance and density - see also ProMinent® resistance list (In the

product equipment catalogue or at

www.prominent.com

!

n All other uses or modifications are prohibited.

n The pump is not intended for the metering of gaseous media and

solids.

n The pump is not intended to meter extremely hazardous media or

media harmful to life.

n The pump is not intended to meter flammable media.

n The pump is not intended to meter oxidants without the use of suitable

protective equipment.

n The pump is not intended for the metering of explosive media.

n The pump is not intended for operation in areas at risk from explosion.

n The pump is not intended for unprotected outside use.

n The pump is only intended for industrial use.

n The pump should only be operated by trained and authorised per‐

sonnel.

n You have a responsibility to adhere to the information contained in the

operating instructions at the different phases of the unit's service life.

General

Identification of safety notes

Warning signs denoting different types of

danger

Intended use

Safety Chapter

5

Page 6

Action Qualification

Storage, transport, unpacking Instructed person

Assembly Technical personnel, service

Planning hydraulic installation Qualified personnel who have a

thorough knowledge of metering

pumps.

Hydraulic installation Technical personnel, service

Installation, electrical Electrical technician

Operation Instructed person

Maintenance, repair Technical personnel, service

Decommissioning, disposal Technical personnel, service

Troubleshooting Technical personnel, electrical

technician, instructed person,

service

Explanation of the terms:

Technical personnel

A qualified employee is deemed to be a person who is able to assess the

tasks assigned to him and recognise possible dangers based on his/her

technical training, knowledge and experience, as well as knowledge of

pertinent regulations.

Note:

A qualification of equal validity to a technical qualification can also be

gained by several years employment in the relevant work area.

Electrical technician

Electrical technicians are deemed to be people, who are able to complete

work on electrical systems and recognise and avoid possible dangers

independently based on their technical training and experience, as well as

knowledge of pertinent standards and regulations.

Electrical technicians should be specifically trained for the working envi‐

ronment in which they are employed and know the relevant standards and

regulations.

Electrical technicians must comply with the provisions of the applicable

statutory directives on accident prevention.

Instructed person

An instructed person is deemed to be a person who has been instructed

and, if required, trained in the tasks assigned to him/her and possible dan‐

gers that could result from improper behaviour, as well as having been

instructed in the required protective equipment and protective measures.

Service

Customer Service department refers to service technicians, who have

received proven training and have been authorised by ProMinent or Pro‐

Maqua to work on the system.

Qualification of personnel

Safety Chapter

6

Page 7

WARNING!

Warning of hazardous feed chemical

Should a dangerous feed chemical be used: it may

escape from the hydraulic components when working on

the pump, material failure or incorrect handling of the

pump.

– Take appropriate protective measures before

working on the pump (e.g. safety glasses, safety

gloves, ...). Adhere to the material safety data sheet

for the feed chemical.

–

Drain and flush the liquid end before working on the

pump.

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets provided

by the manufacture of the hazardous substance. The

actions required are described in the safety data sheet.

Check the safety data sheet regularly and replace, if

necessary, as the hazard potential of a substance can

be re-evaluated at any time based on new findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they are

kept up to date, as well as for producing an associated

hazard assessment for the workstations affected.

WARNING!

Danger of electric shock

A mains voltage may exist inside the pump housing.

– If the pump housing has been damaged, you must

disconnect it from the mains immediately. It may

only be returned to service after an authorised

repair.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

–

Depressurise the system before commencing any

work on hydraulic parts.

CAUTION!

Warning of feed chemical spraying around

An unsuitable feed chemical can damage the parts of

the pump that come into contact with the chemical.

– Take into account the resistance of the wetted mate‐

rials and the ProMinent Resistance List when

selecting the feed chemical - see the ProMinent

Product Catalogue or visit ProMinent.

Safety information

Safety Chapter

7

Page 8

CAUTION!

Danger of personnel injury and material damage

The use of untested third party parts can result in per‐

sonnel injuries and material damage.

– Only fit parts to metering pumps, which have been

tested and recommended by ProMinent.

CAUTION!

Danger from incorrectly operated or inadequately main‐

tained pumps

Danger can arise from a poorly accessible pump due to

incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

– Adhere to the maintenance intervals.

All isolating protective equipment must be installed for operation:

n Drive front cover

n Motor fan cowling

n Motor terminal box cover

n Plug (Pos. 9 in Fig. 6 in Chap. "Repair")

In the event of an electrical accident, disconnect the mains cable from the

mains or press the emergency cut-off switch fitted on the side of the

system!

If feed chemical escapes, also depressurise the hydraulic system around

the pump as necessary. Adhere to the safety data sheet for the feed

chemical.

Sound pressure level LpA < 70 dB according to EN ISO 20361

at maximum stroke length, maximum stroke rate, maximum back pressure

(water)

Isolating protective equipment

Information in the event of an emergency

Sound pressure level

Safety Chapter

8

Page 9

3 Carrying out repairs

WARNING!

Only return the metering pump for repair in a cleaned

state and with a flushed liquid end - refer to the chapter

"Decommissioning"!

Only return metering pumps with a completed Decon‐

tamination Declaration form. The Decontamination Dec‐

laration constitutes an integral part of an inspection /

repair order. A unit can only be inspected or repaired

when a Declaration of Decontamination Form is sub‐

mitted that has been completed correctly and in full by

an authorised and qualified person on behalf of the

pump operator.

The "Decontamination Declaration Form" can be found

at www.prominent.de.

WARNING!

Warning of hazardous feed chemical

Should a dangerous feed chemical be used: it may

escape from the hydraulic components when working on

the pump, material failure or incorrect handling of the

pump.

– Take appropriate protective measures before

working on the pump (e.g. safety glasses, safety

gloves, ...). Adhere to the material safety data sheet

for the feed chemical.

– Drain and flush the liquid end before working on the

pump.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

–

Depressurise the system before commencing any

work on hydraulic parts.

CAUTION!

Warning of feed chemical spraying around

An unsuitable feed chemical can damage the parts of

the pump that come into contact with the chemical.

– Take into account the resistance of the wetted mate‐

rials and the ProMinent Resistance List when

selecting the feed chemical - see the ProMinent

Product Catalogue or visit ProMinent.

Safety information

Carrying out repairs

9

Page 10

CAUTION!

Warning of feed chemical spraying around

PTFE seals, which have already been used / com‐

pressed, can no longer reliably seal a hydraulic connec‐

tion.

– New, unused PTFE seals must always be used.

CAUTION!

Danger of personnel injury and material damage

The use of untested third party parts can result in per‐

sonnel injuries and material damage.

– Only fit parts to metering pumps, which have been

tested and recommended by ProMinent.

P_VA_0005_SW

1

2

3

9

4

6

5

Fig. 2: Liquid end parts

1 Suction connector

2 Dosing head

3 Pressure connector

4 Diaphragm

5 Backplate

6 Slide rod

9 Plug

n If necessary take protective measures.

n Adhere to the material safety data sheet for the feed chemical.

n Ensure that the system is at atmospheric pressure.

1. Empty the liquid end (turn the liquid end upside down and allow the

feed chemical to run out; flush out with a suitable medium; flush the

liquid end thoroughly when using hazardous feed chemicals!)

2. Turn the stroke adjustment dial as far as 0% stroke length when the

pump is running (the drive axle is then difficult to turn).

3. Switch off the pump and secure it to prevent it being switched on

again.

4. Unscrew the hydraulic connectors on the discharge and suction

side.

5. Remove the screws.

Carrying out repairs

10

Page 11

6. Loosen the dosing head (2) and the backplate (5) from the pump

housing - but only loosen!

7. Hold the pump housing with one hand and clamp the diaphragm (4)

with the other hand between the dosing head (2) and the backplate

(5).

8. Loosen the diaphragm (4) from the drive axle with a gentle back‐

wards turn of the dosing head (2), diaphragm (4) and backplate (5)

in an anticlockwise direction. (Possibly hold the slide rod (6) using

an appropriate wrench through the opening for the plug (9).)

9. Unscrew the diaphragm (4) completely from the drive axle.

10. Clean the sealing surfaces.

11. Place the diaphragm (4) into the backplate (4).

12. Position the dosing head (2) so that the suction connector (1) lies

above the leakage hole of the backplate (5).

13. Insert the screws and manually tighten the diaphragm in a clockwise

direction up to the slide rod (6).

14. Switch the pump on.

15. Set the stroke length to 100%.

16. Place the dosing head (2) with the screws onto the diaphragm (4)

and the backplate (5) - the suction connector must be pointing

downwards in the pump's subsequent fitting position.

17. When the pump is running, rotate the liquid end as far to the right

until the suction connection (1) is pointing vertically downwards.

18. Now disconnect the pump from the power supply so that the slide

rod (6) comes to a standstill approximately at the rear end position.

19. Gently tighten the screws (1) and then tighten them diagonally. See

below for the tightening torque.

20. With PP types with bleed valve: Allow the cover of the liquid end to

rest in the dosing head, then press the grip on the bleed valve into

the dosing head.

CAUTION!

Leakage possible

– Check the tightening torque of the screws

after 24 hours of operation!

–

With PP dosing heads, recheck the tightening

torque again after three months!

Data Value Unit

Tightening torque for screws: 4.5 ... 5.0 Nm

Tightening torque

Carrying out repairs

11

Page 12

4 Information on disposal

In accordance with the European Directive 2012/19/EU on waste electrical

and electronic equipment, this device features the symbol showing a

waste bin with a line through it. The device must not be disposed of along

with domestic waste. To return the device, use the return and collection

systems available and observe the local legal requirements.

Sign indicating EU collection system

Information on disposal

12

Page 13

5 Technical Data

WARNING!

Risk of personal injuries

Please observe the ”Supplement for modified version“ at

the end of the chapter!

It replaces and supplements the technical data!

5.1 Performance data

The capacity at maximum back pressure can be found on the nameplate

on the housing.

VAMC Type Suction lift Permissible priming pressure, suction

side

m WS bar

10008, 10016, 07026, 07042 7 2.8

07012, 07024, 04039, 04063 6 1.7

All figures refer to water at 20 °C.

The suction lift applies to filled suction line and filled liquid end - when

installed correctly.

5.2

Precision

Data Value Unit

Reproducibility ±2 % *

* - when installed correctly, under constant conditions, at least 30%

stroke length and water at 20 °C

5.3 Shipping weight

Material version Shipping weight

kg

PVT 6.0

SST 7.2

Only for "M - modified" design:

Precision

Technical Data

13

Page 14

5.4 Wetted materials

Material version Liquid end Suction/pressure

connector

Seals Balls Valve seat

PPE PP PP EPDM Glass PP

PCB PVC PVC FPM-B Glass PVC

PVT PVDF PVDF PTFE Ceramic PTFE

SST Stainless steel

1.4404

/1.4571

Stainless steel

1.4581/1.4571

PTFE Stainless steel

1.4404

PTFE

Diaphragm is PTFE coated.

5.5

Ambient conditions

5.5.1 Ambient temperatures

Data Value Unit

Storage and transport temperature -10 ... +50 °C

Ambient temperature in operation (drive +

motor):

-10 ... +45 °C

5.5.2 Media temperatures

Material version PPE PCB PVT SST

Long-term temperature*

[°C]

-10 ... +50 -10 ... +45 -10 ... +50 -10 ... +50

Max. temperature for 15

min** [°C]

100 60 100 120

* at max. operating pressure

** at max. 2 bar

5.5.3

Air humidity

Maximum air humidity*: 95% rel. humidity

*non-condensing

5.6

Motor data

The key electrical data for the motor can be found on the nameplate on

the motor.

Motor data sheets, special motors, special motor flanges

–

Further information on motors can be found on our

homepage under motor data sheet.

Pump, compl.

Air humidity

Electrical data

Technical Data

14

Page 15

5.7 Stroke sensor "Sigma"

Install the sensor according to the chapter "Installation,

electrical".

5–25 V DC, in accordance with Namur or DIN 60947-5-6, potential-free

design.

Data Value Unit

Nominal voltage * 8 VDC

Power consumption - active surface

uncovered

> 3 mA

Power consumption - active surface cov‐

ered

< 1 mA

Rated switching distance 1.5 mm

* Ri ~ 1 kΩ

Cable colour Polarity

blue -

brown +

5.8 Sound pressure level

Sound pressure level LpA < 70 dB according to EN ISO 20361

at maximum stroke length, maximum stroke rate, maximum back pressure

(water)

5.9

Supplementary information for modified versions

(With identity code specification "Version": "M" - "modified")

Technical data of pumps in the modified version can deviate from those of

the standard pumps. They can be queried by stating the details of the

serial number.

During operation with an automatic stroke length adjustment control

together with a variable speed motor, the stroke rate must not fall below

30 strokes / min. Otherwise technical problems occur, because the

mechanical resistance of the stroke adjustment spindle becomes too high.

The motor data sheets for the modified version are valid. They may

deviate from the standard motor data sheets.

With a modified version, it is absolutely necessary to specify the details of

the serial number requesting and ordering the spare and replacement

parts.

Namur sensor (identity code characteristic

"stroke sensor": 3)

Sound pressure level

Technical data

motor

Spare parts

Technical Data

15

Page 16

6 Dimensional Drawings

–

Compare the dimensions on the dimension sheet

and pump.

–

All dimensions are in mm.

61_01_101_00_53_72_05

P_VA_0003_SW

Fig. 3: Dimensional drawing of Vario C

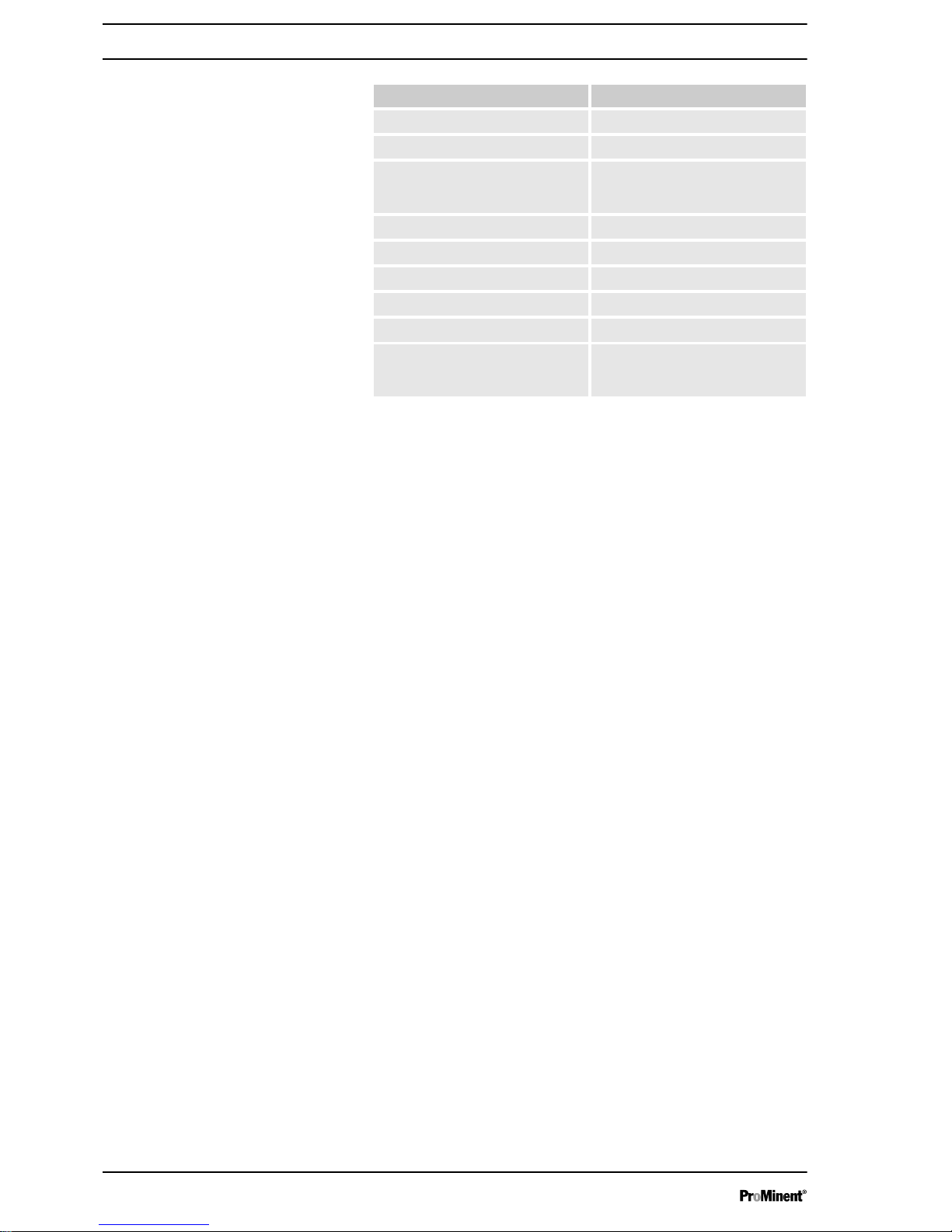

Material ver‐

sion

A B C D E * F ** Connector

PCB 191 142 92 243 226 176 DN10

PPE 191 142 92 243 226 178 DN10

PVT 191 142 95 246 228 180 DN10

SST 190 140 90 241 226 180 DN10

* with hose nozzle

** with insert

Dimensional drawing of Vario C

Dimensional Drawings

16

Page 17

7 Diagrams for Setting the Capacity

Vario (FM 042)

0

5

0 20 40 60 80 100 120

S [%]

Q (l/h)

VAMc 07042

VAMc 07026

VAMc 10008

VAMc 10016

0

5

10

15

20

25

30

35

40

45

0 2 4 6 8 10 12

p [bar]

Q (l/h)

VAMc 07042

VAMc 07026

VAMc 10008

VAMc 10016

Vario (FM 063)

0

5

10

15

20

25

30

35

40

45

50

Q (l/h)

0 20 40 60 80 100 120

s (%)

55

60

65

VAMc 04063

VAMc 04039

VAMc 07012

VAMc 07024

0

5

10

15

20

25

30

35

40

45

50

Q [l/h]

0 2 4 6 8 10 12

s [bar]

55

60

65

VAMc 04063

VAMc 04039

VAMc 07012

VAMc 07024

Fig. 4: Capacity Q at minimum back pressure dependent on the stroke length s and capacity Q dependent on the back

pressure p.

Diagrams for Setting the Capacity

17

Page 18

8 Wear parts Vario C, VAMC

The spare parts kit generally includes the wear parts for the liquid ends.

8.1

Spare parts kits

Scope of delivery PPE, PCB, PVT:

1 diaphragm

1 suction valve, complete

1 discharge valve, complete

2 valve balls

1 sealing sets complete (cover rings, ball seat housings)

Scope of delivery SST:

1 diaphragm

2 valve balls

1 complete sealing set (cover rings, gaskets, ball seat)

Tab. 1: Types 10008, 10016, 07026, 07042

Liquid end Material version Order no.

FM 042 - DN 10 PPE 910753

FM 042 - DN 10 PCB 910754

FM 042 - DN 10 PVT 1003641

FM 042 - DN 10 SST 910751

Tab. 2: Types 07012, 07024, 04039, 04063

Liquid end Material version Order no.

FM 063 - DN 10 PPE 910758

FM 063 - DN 10 PCB 910759

FM 063 - DN 10 PVT 1003642

FM 063 - DN 10 SST 910756

8.2 Diaphragms

Tab. 3: Diaphragms for ...

Liquid end Order no.

FM 042, Types 10008, 10016, 07026, 07042 811458

FM 063, Types 07012, 07024, 04039, 04063 811459

Wear parts Vario C, VAMC

18

Page 19

9 Declaration of Conformity for Machinery

In accordance with DIRECTIVE 2006/42/EC OF THE EUROPEAN PAR‐

LIAMENT AND OF THE COUNCIL, Appendix I, BASIC HEALTH AND

SAFETY REQUIREMENTS, section 1.7.4.2. C.

We,

n ProMinent GmbH

n Im Schuhmachergewann 5 - 11

n DE - 69123 Heidelberg,

hereby declare that the product specified in the following, complies with

the relevant basic health and safety requirements of the EC Directive, on

the basis of its functional concept and design and in the version distributed

by us.

Any modification to the product not approved by us will invalidate this dec‐

laration.

Tab. 4: Extract from the Declaration of Conformity

Designation of the product: Metering pump, Vario C product range

Product type: VAMc...

Serial number: see nameplate on the device

Relevant EC directives: EC Machinery Directive (2006/42/EC)

Compliance with the protection targets of the Low Voltage Directive 2014/35/EU

according to Appendix I, No. 1.5.1 of the Machinery Directive 2006/42/EC

EC EMC Directive (2014/30/EU)

Harmonised standards applied, in

particular:

EN ISO 12100:2010

EN 809:1998 + A1:2009 + AC:2010

EN 6100-6-2:2005 + AC:2005

EN 6100-6-3:2007 + A1:2011 + AC:2012

Date: 20.04.2016

You will find the EC Declaration of Conformity to download on our home‐

page.

Declaration of Conformity for Machinery

19

Page 20

987096, 3, en_GB

© 2012

ProMinent GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: ++49 6221 842-0

Fax: ++49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

Loading...

Loading...