ProMinent DULCO turb C Series, TUC 1, TUC 2, TUC 4, TUC 3 Assembly And Operating Instructions Manual

Page 1

Assembly and operating instructions

DULCO® turb C

Turbidity sensor

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Technical changes reserved.

Part no. 986062 BA DT 034 01/11 EN

Page 2

ProMinent Dosiertechnik Heidelberg GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

email: info@prominent.de

Internet: www.prominent.com

986062, 1, en_GB

© 2011

2

Page 3

Supplemental instructions

General non-discriminatory approach

In order to make it easier to read, this

document uses the male form in

grammatical structures but with an

implied neutral sense. It is aimed

equally at both men and women. We

kindly ask female readers for their

understanding in this simplification of

the text.

Supplementary information

Read the following supplementary

information in its entirety!

The following are highlighted sepa‐

rately in the document:

n Enumerated lists

Instructions

Results of the instructions

ð

Information

Safety information are provided with

detailed descriptions of the endan‐

gering situation, see

Ä Chapter 1.1

„Explanation of the safety informa‐

tion“ on page 6

This provides important informa‐

tion relating to the correct opera‐

tion of the system or is intended to

make your work easier.

Safety information

3

Page 4

Table of contents

Table of contents

Introduction................................................................................................ 6

1

1.1 Explanation of the safety information................................................. 6

1.2 Users' qualifications........................................................................... 8

2 Safety and responsibility.......................................................................... 10

2.1 General safety information .............................................................. 10

2.2 Correct and proper use.................................................................... 11

3 Functional description / product identification.......................................... 12

3.1 Scope of delivery............................................................................. 16

4 Mounting and Installation......................................................................... 17

4.1 Wall mounting.................................................................................. 18

4.2 Installation (hydraulic)...................................................................... 21

4.3 Installation (electrical)...................................................................... 23

5 Operating diagram................................................................................... 26

5.1 Overview of device /Control elements............................................. 26

5.2 Overview of operating structure....................................................... 27

6 Commissioning........................................................................................ 30

6.1 Load drying agent............................................................................ 30

6.2 Routine measurement..................................................................... 33

6.3 Access code.................................................................................... 34

6.4 Device configuration........................................................................ 35

6.4.1 Selecting the output...................................................................... 35

6.4.2 Configuration of fault current (ERLV)............................................ 37

6.4.3 Configure alarm ........................................................................... 38

6.4.4 OFFSET configuration.................................................................. 41

6.4.5 Extended settings......................................................................... 43

7 Operation................................................................................................. 55

7.1 Calibrate sensor............................................................................... 55

7.1.1 Standard solutions for calibration................................................. 55

4

Page 5

Table of contents

7.1.2 Perform calibration........................................................................ 59

8 Maintenance, troubleshooting and repair................................................ 66

8.1 Information about fault maintenance............................................... 66

8.1.1 System error messages................................................................ 67

8.1.2 Faults in the process..................................................................... 67

9 Spare parts and accessories................................................................... 69

Standards complied with.......................................................................... 70

10

11 Disposal of used parts............................................................................. 71

12 Declaration of Conformity........................................................................ 72

13 Index........................................................................................................ 73

5

Page 6

Introduction

1 Introduction

Data and functions

This operating manual provides infor‐

mation on the technical data and

functions of the DULCO®

bidity sensor.

turb C tur‐

DANGER!

Nature and source of the danger

Consequence: Fatal or very

serious injuries.

1.1 Explanation of the safety information

Introduction

These operating instructions provide

information on the technical data and

functions of the product. These oper‐

ating instructions provide detailed

safety information and are provided

as clear step-by-step instructions.

The safety information and notes are

categorised according to the following

scheme. A number of different sym‐

bols are used to denote different sit‐

uations. The symbols shown here

serve only as examples.

Measure to be taken to avoid this

danger

Danger!

Denotes an immediate threat‐

–

ening danger. If this is disre‐

garded, it will result in fatal or

very serious injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or

very serious injuries.

Measure to be taken to avoid this

danger

Warning!

Denotes a possibly hazardous

–

situation. If this is disregarded,

it could result in fatal or very

serious injuries.

6

Page 7

Introduction

CAUTION!

Nature and source of the danger

Possible consequence: Slight or

minor injuries, material damage.

Measure to be taken to avoid this

danger

Caution!

Denotes a possibly hazardous

–

situation. If this is disregarded,

it could result in slight or minor

injuries. May also be used as

a warning about material

damage.

NOTICE!

Nature and source of the danger

Damage to the product or its sur‐

roundings

Measure to be taken to avoid this

danger

Type of information

Hints on use and additional infor‐

mation

Source of the information, addi‐

tional measures

Information!

–

Denotes hints on use and

other useful information. It

does not indicate a hazardous

or damaging situation.

Note!

Denotes a possibly damaging

–

situation. If this is disregarded,

the product or an object in its

vicinity could be damaged.

7

Page 8

Introduction

1.2 Users' qualifications

WARNING!

Danger of injury with inadequately qualified personnel!

The operator of the plant / device is responsible for ensuring that the qualifi‐

cations are fulfilled.

If inadequately qualified personnel work on the unit or loiter in the hazard

zone of the unit, this could result in dangers that could cause serious injuries

and material damage.

– All work on the unit should therefore only be conducted by qualified per‐

sonnel.

Unqualified personnel should be kept away from the hazard zone

–

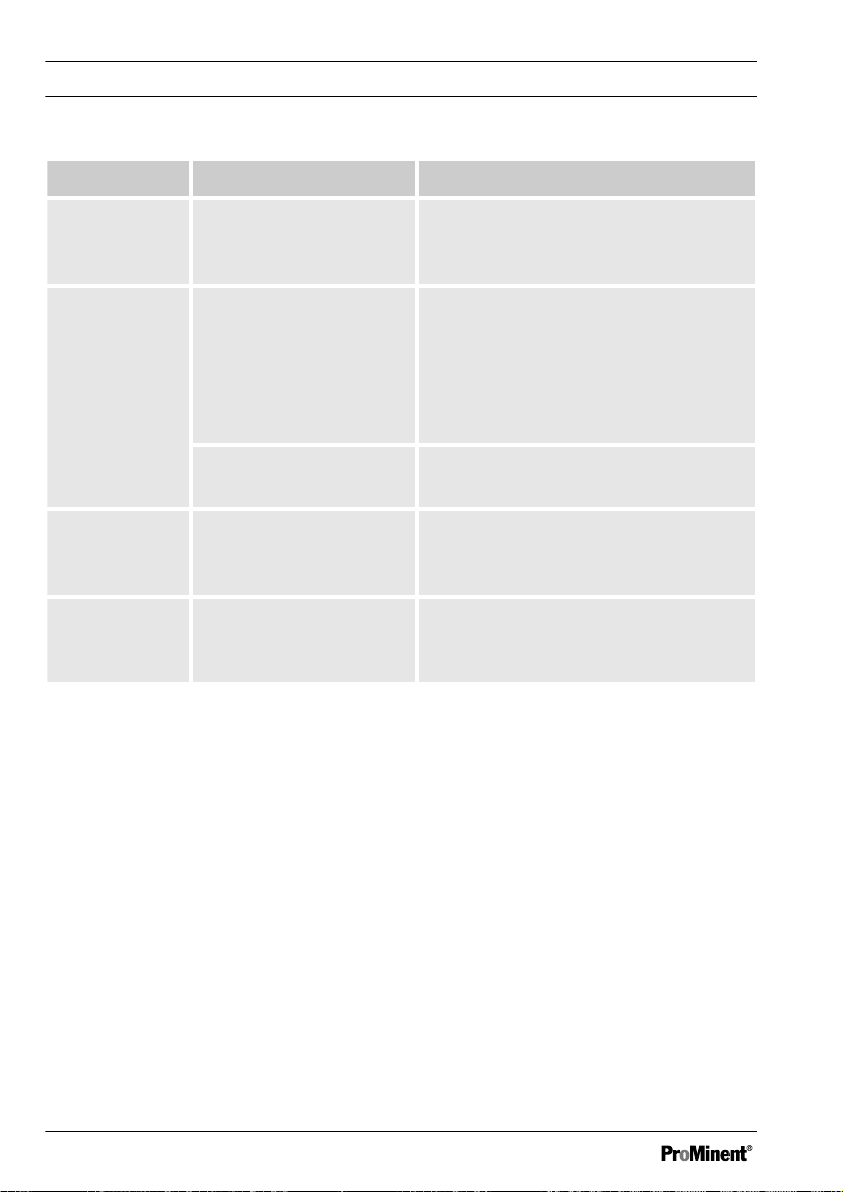

Training Definition

Instructed per‐

sonnel

An instructed person is deemed to be a person who has

been instructed and, if required, trained in the tasks

assigned to him/her and possible dangers that could

result from improper behaviour, as well as having been

instructed in the required protective equipment and pro‐

tective measures.

Trained user A trained user is a person who fulfils the requirements

made of an instructed person and who has also received

additional training specific to the system from ProMinent

or another authorised distribution partner.

Trained qualified

personnel

A qualified employee is deemed to be a person who is

able to assess the tasks assigned to him and recognize

possible hazards based on his/her training, knowledge

and experience, as well as knowledge of pertinent regu‐

lations. The assessment of a person's technical training

can also be based on several years of work in the rele‐

vant field.

8

Page 9

Introduction

Training Definition

Electrician Electricians are deemed to be people, who are able to

complete work on electrical systems and recognize and

avoid possible hazards independently based on his/her

technical training and experience, as well as knowledge

of pertinent standards and regulations.

Electricians should be specifically trained for the working

environment in which the are employed and know the

relevant standards and regulations.

Electricians must comply with the provisions of the appli‐

cable statutory directives on accident prevention.

Customer Service

department

Customer Service department refers to service techni‐

cians, who have received proven training and have been

authorised by ProMinent to work on the system.

Note for the system operator

The pertinent accident prevention regulations, as well as all other generally

acknowledged safety regulations, must be adhered to!

9

Page 10

Safety and responsibility

2 Safety and responsibility

2.1 General safety information

WARNING!

WARNING!

Live parts!

Possible consequence: Fatal or

very serious injuries

– Measure: Disconnect the

mains power supply prior to

opening the housing

Disconnect damaged, defec‐

–

tive or manipulated devices

from the power supply

WARNING!

Unauthorised access!

Possible consequence: Fatal or

very serious injuries.

– Measure: Ensure that there

can be no unauthorised

access to the unit

Operating errors!

Possible consequence: Fatal or

very serious injuries.

– The unit should only be oper‐

ated by adequately qualified

and technically expert per‐

sonnel

Please also observe the oper‐

–

ating instructions for control‐

lers and fittings and any other

component groups, such as

sensors, sample water

pumps ...

– The operator is responsible

for ensuring that personnel

are qualified

CAUTION!

Electronic malfunctions

Possible consequence: Material

damage right through to destruc‐

tion of the unit

10

– The mains connection cable

and data cable should not be

laid together with cables that

are prone to interference

Measure: Take appropriate

–

interference suppression

measures

Page 11

NOTICE!

Safety and responsibility

2.2 Correct and proper use

Correct and proper use

Damage to the product or its sur‐

roundings

– The unit is not intended to

measure or regulate gaseous

or solid media

The unit may only be used in

–

accordance with the technical

details and specifications pro‐

vided in these operating

instructions and in the oper‐

ating instructions for the indi‐

vidual components

NOTICE!

Correct sensor operation

Damage to the product or its sur‐

roundings

– Correct measuring and control

is only possible if the sensor is

working perfectly

Check and calibrate the

–

sensor regularly

NOTICE!

Correct and proper use

The device is designed to

measure the turbidity of water.

The unit may only be used in

accordance with the technical

details and specifications provided

in this operating manual and in

the operating manuals for the indi‐

vidual components (such as, for

example, controllers, sensors, fit‐

tings, calibration devices,

metering pumps, etc.).

Any other uses or modifications

are prohibited.

11

Page 12

Functional description / product identification

3 Functional description / product identification

Brief functional description

The DULCO® turb C is designed for the online measuring of turbidity in

untreated water, process water and treated process water in drinking water pro‐

cessing plants.

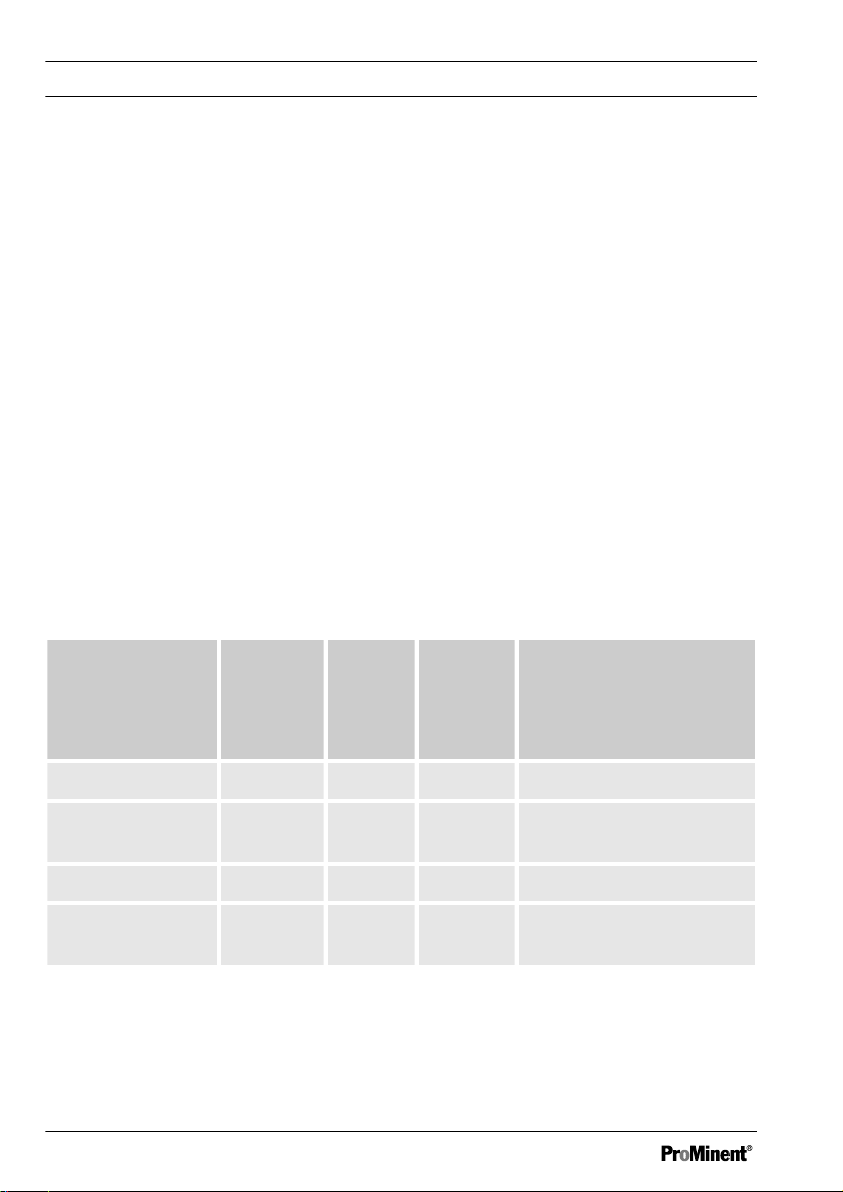

The DULCO® turb C product range is comprised of four device types:

Types TUC 1 and TUC 3 work with infrared light and fulfil the requirements of

the international standards ISO 7027 and DIN EN 27027.

Types TUC 2 and TUC 4 work with white light and fulfil USA standard US EPA

180.1.

Both device types can be equipped with ultrasonic cleaning (TUC 3 / TUC 4) or

without ultrasonic cleaning (TUC 1 / TUC 2). The sample cell ultrasonic cleaning

system extends the calibration and maintenance intervals in media where

coating formation is common.

DULCO® turb C

Part

number

IOS

7027

US EPA

180.1

Ultrasonic cleaning

DIN EN

27027

TUC 1 1037696 Infrared No

TUC 2 1037695 White

No

light

TUC 3 1037698 Infrared Yes

TUC 4 1037697 White

Yes

light

12

Page 13

Functional description / product identification

An inlet side pressure regulating valve is standard. The DULCO turb C pressure

regulating valve reduces the pressure from up to 13.8 bar (200 PSI) to 1.0 bar

(15 PSI).

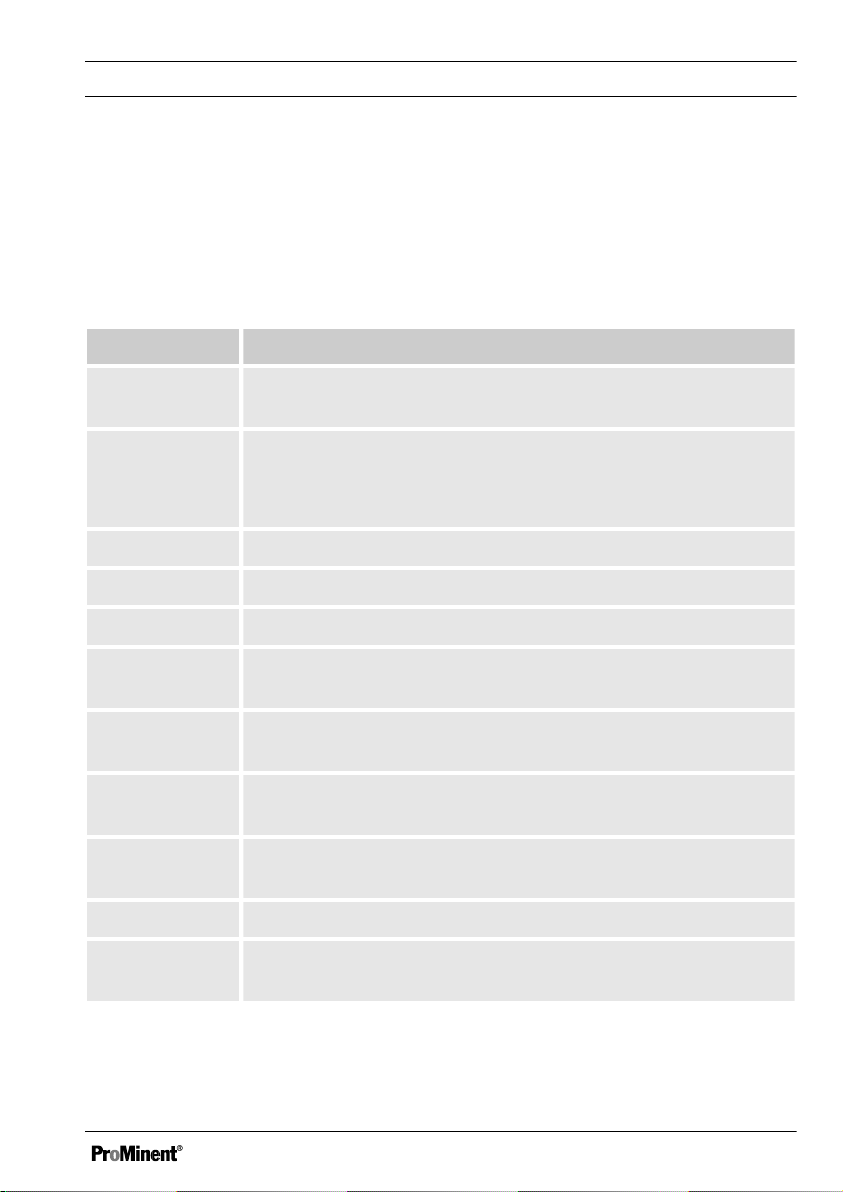

Specifications

Measuring

0 – 1000.0 NTU

range

Accuracy limit ± 2 % of the displayed value or ± 0.02 NTU under 40 NTU,

depending on which value is the greater.

± 5 % of the displayed value above 40 NTU

Resolution 0.0001 NTU below 10 NTU

Response time configurable

Display Multiple row LCD display with backlighting

Alarm Two programmable alarms, 120 - 240 VAC, 2 A Form C

relay

Analogue

4 ... 20 mA, 600 Ω

output

Communication

Bi-directional RS-485, Modbus

interface

Maximum

water pressure

Integrated pressure regulating valve regulates 1380 kPa

(200 PSI). in relation to the flow rate

Flow rate 6 l/h ... 60 l/h

Operating tem‐

1 °C ... 50 °C

perature

13

Page 14

Functional description / product identification

Materials that

come into con‐

Polyimide (PA), silicone, polypropylene (PP), stainless steel,

borosilicate glass

tact with the

media

Voltage supply 100 – 240 VAC, 47 – 63 Hz, 80VA

Galvanic Isola‐

tion

Ambient condi‐

tions

dual insulation, degree of interference overvoltage category

II

Not suitable for operation outdoors.

Operation altitude maximum 2000 m (above sea level).

maximum 95 % relative air humidity (non-condensing).

Enclosure

IP 66

rating

Standards

compliant with

Shipping

USEPA 180.1 for type

27027 for type

„White light“

approx. 2.5 kg

„Infrared“

weight

Option: ultrasonic cleaning (TUC 3 /

TUC 4)

The

„Ultrasonic cleaning“

option is

used in order to continuously clean

the sample chamber. It serves neither

to clean previously soiled sample

chambers, nor can it replace manual

operate the system. The system emits

an ultrasonic frequency via a spring to

a piezoelectric transducer, which is

connected to the base of the flowthrough cuvette. The cuvette's detec‐

tion system only works in

[AUTO mode]

cleaning. However, the cleaning inter‐

vals for manual cleaning can be sig‐

nificantly extended by the use of this

system. The use of a sample

chamber with an

transducer“

„ultrasound

is necessary in order to

; ISO 7027 and DIN EN

.

14

Page 15

Functional description / product identification

The system can detect the following

fault states:

n Incorrect cuvette installed

n Error occurred in transducer

n Transducer has no contact to the

spring

If an error occurs, the message

[CLN]

appears in the lower part of the LCD

display. An alarm is triggered and 2

mA is applied to the current output.

The alarm relay is triggered if the

alarm funktion in

to

[ERROR]

[ALM1/ALM2]

is set

The 4 ... 20 mA output is set to 0, 2, 4

mA if the funktion

[error level] [ERLV]

was set to the corresponding mAlevel.

Interface RS-485

The DULCO® turb C

offers basic com‐

munications functions in combination

with straightforward applications, such

as

[Hilgraeve HyperTerminal]

(included with most

[Microsoft Windows software]

pack‐

ages). In addition, you can also use

[Visual Basic]

as well as other pro‐

grams.

15

Page 16

Functional description / product identification

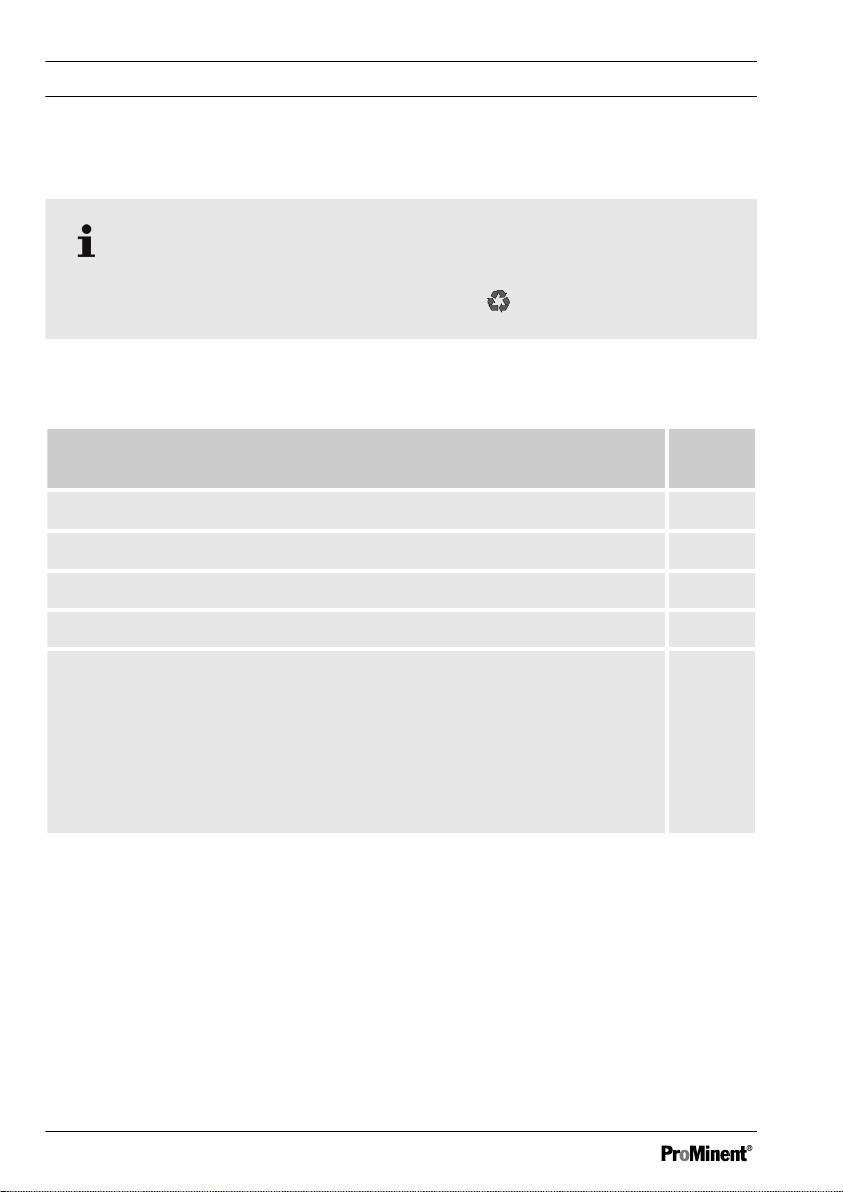

3.1 Scope of delivery

Packaging material

Dispose of packaging material environmentally. All packaging components

are provided with their corresponding recycling

code.

The following components are included as standard with a DULCO® turb C:

Description Quan‐

tity

DULCO® turb C with terminal boxes and integrated und flow fittings

1

Operating Manual 1

Packet drying agent 1

Cuvette 1

Hose kit

1

n Shut-off clamp (1 piece)

n Back-pressure valve (1 piece)

n Connection hoses with connection pieces for pressure regu‐

lating valves (2 pieces)

n Bleed screw (used in pressurised systems) (1 piece)

Remove the DULCO® turb C from the packaging. Carefully check the compo‐

nents. Ensure that no visible damage has been caused during shipping. If the

components supplied fail to comply with the order, please contact your local dis‐

tributor or the ProMinent customer services department immediately.

16

Page 17

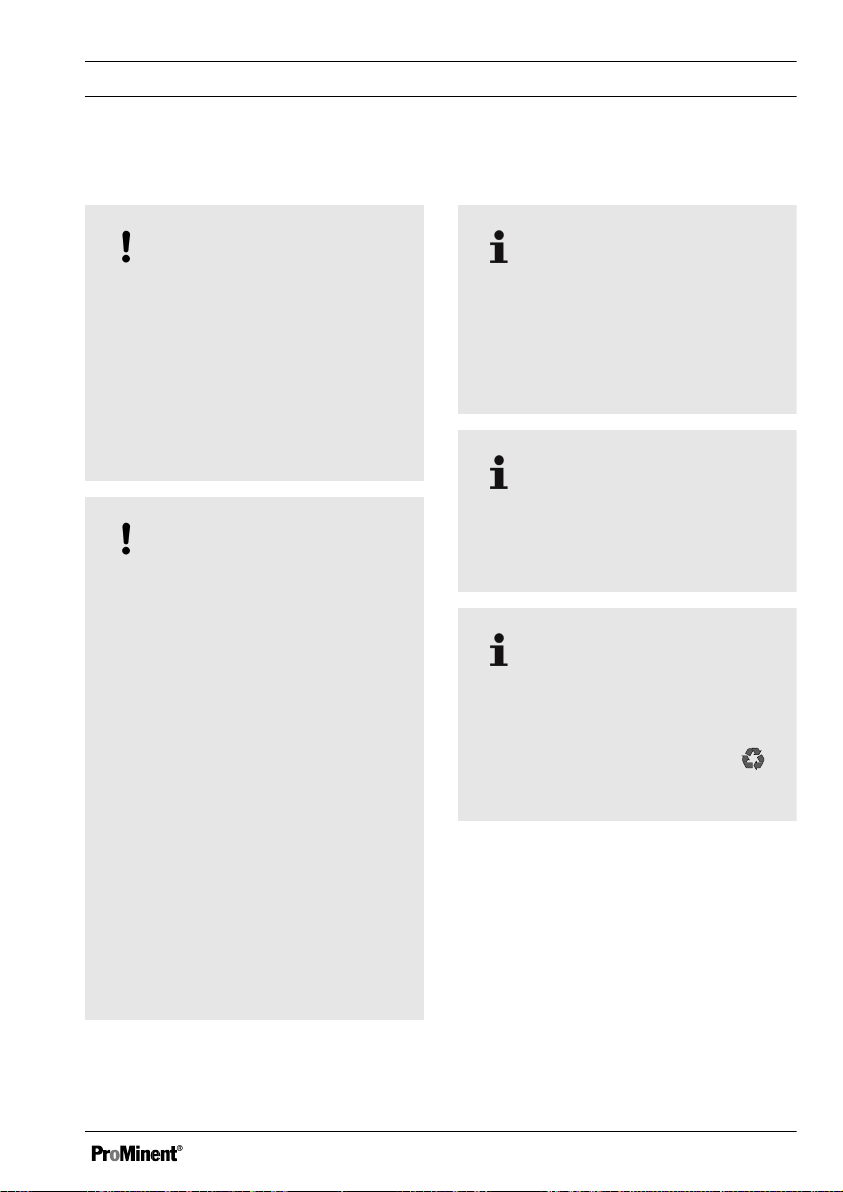

4 Mounting and Installation

Mounting and Installation

NOTICE!

Drying agent

Possible device malfunctions due

to moisture in the device.

Install the drying agent bag before

initial commissioning, see

Ä Chapter 6.1 „Load drying

agent“ on page 30

NOTICE!

Mounting position and conditions

– The installation (electrical)

may only take place after

mounting (mechanical)

Ensure that there is unim‐

–

peded access for operation

– Ensure for secure and vibra‐

tion-free fastening.

– Avoid direct sunlight

– Permissible ambient tempera‐

ture for the sensor at fitting

position: 1 ... 50℃ at max.

95% relative air humidity (non-

condensing)

– Consider the permissible

ambient temperature and the

connected components

Reading and operating posi‐

tion

–

Install the device in a favour‐

able position for reading and

operating (preferably at eye

level)

Mounting position

–

Leave sufficient free space for

the cables and necessary

work

Packaging material

Dispose of packaging material

environmentally. All packaging

components are provided with

their corresponding recycling

code.

17

Page 18

Mounting and Installation

4.1 Wall mounting

Installation (mechanical)

NOTICE!

Distance to the sampling site

Install the sensor no further than maximum 3 meters from the sampling site.

This is the only way to ensure a quick response time from the system.

Free space above the sensor

Allow for at least 200mm free space above the sensor for all required work

on the sensor.

Fasten the sensor with four M6 screws and the terminal box with two M4

screws.

18

Page 19

Mounting and Installation

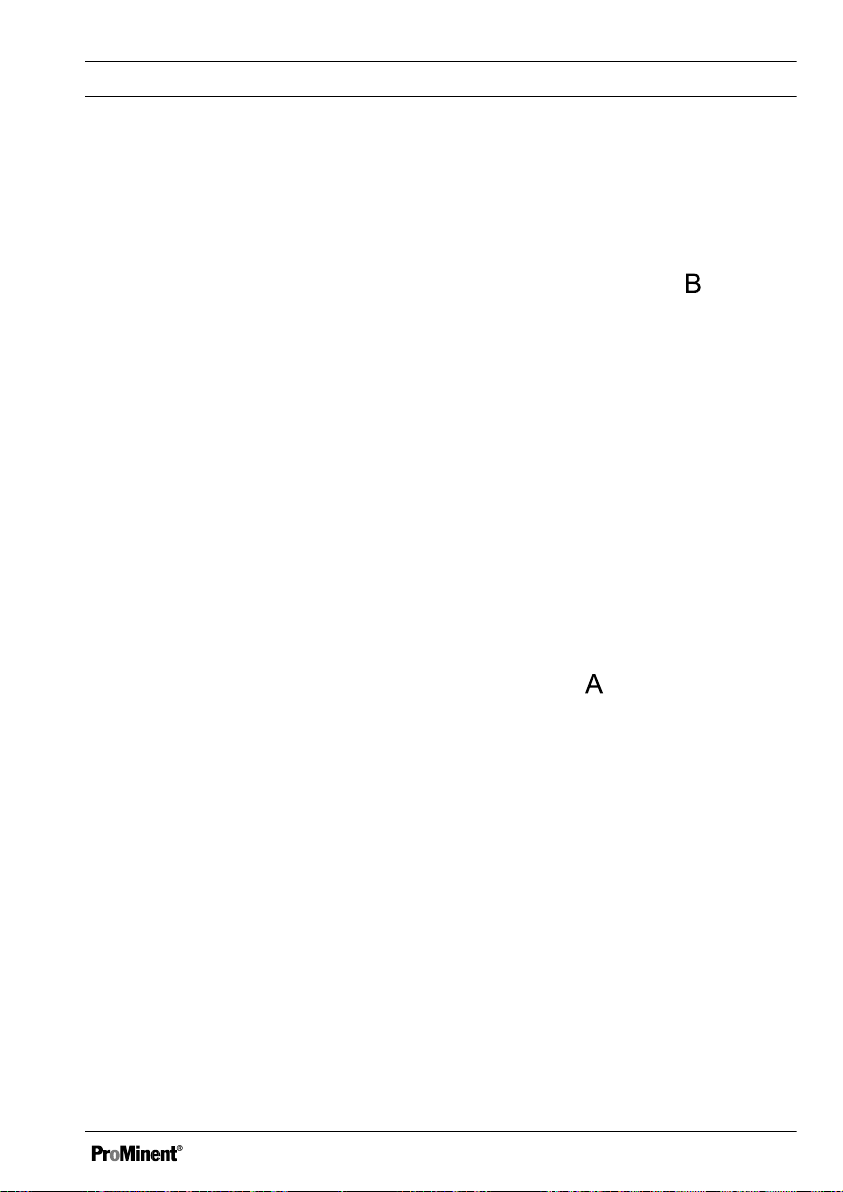

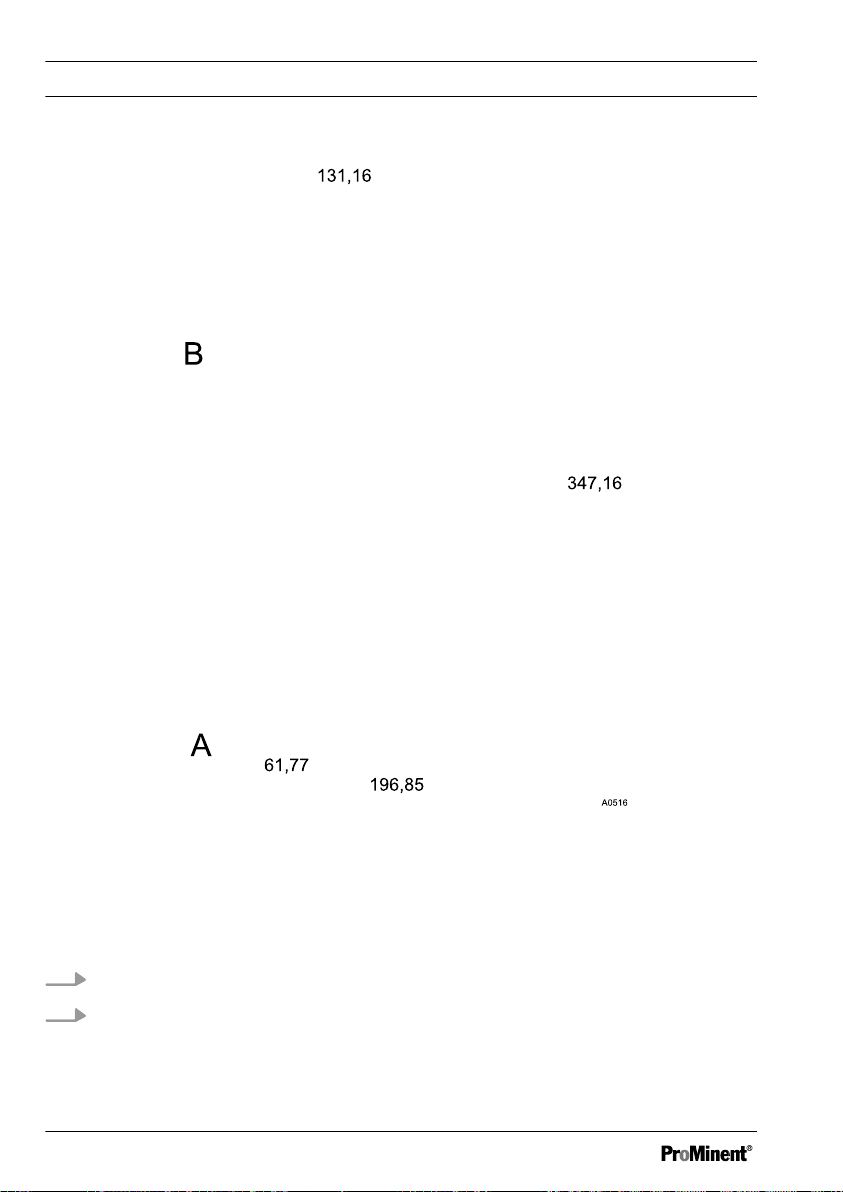

Fig. 1: The diagram is not to scale. It is for information only. All values given in

millimetres.

A Terminal box

B

DULCO® turb C housing

19

Page 20

Mounting and Installation

Fig. 2: The diagram is not to scale. It is for information only. All values given in

millimetres.

A Terminal box

B

DULCO® turb C housing

1. Fasten the terminal box (A) to the wall with two M4 screws

2.

Fasten the DULCO® turb C housing (B) above the terminal box to the wall

with four M6 screws

20

Page 21

4.2 Installation (hydraulic)

Mounting and Installation

Leakage on the bleed screw

CAUTION!

Free outlet at sensor outlet

Feed the sample water which has

flowed through the sensor to a

free drain. The sampled water

may not be fed back into the

process.

CAUTION!

Algae growth under the influence

of light

Possible algae growth if unsuit‐

able hoses are used.

Do not use transparent hoses if

the installation is subjected to

powerful sources of light. This

prevents the formation of algae in

the installation.

Slight leakage may occur at the

bore hole for the bleed screw

during the installation process.

This will cease as soon as normal

flow is established.

In the event that the installation

continues to leak permanently at

this point due to the high pressure

in this area, we recommend

sealing off the bore hole with the

sealing plug supplied. In order to

ensure free drainage, a bleed

option must be installed at

another area of the outlet in order

to avoid overpressure or under‐

pressure in the system.

Permissible operating param‐

eters

–

Maximum liquid temperature

50 °C

–

Maximum pressure 13.8 bar

–

Flow rate 6 ... 60 l/h

21

Page 22

Mounting and Installation

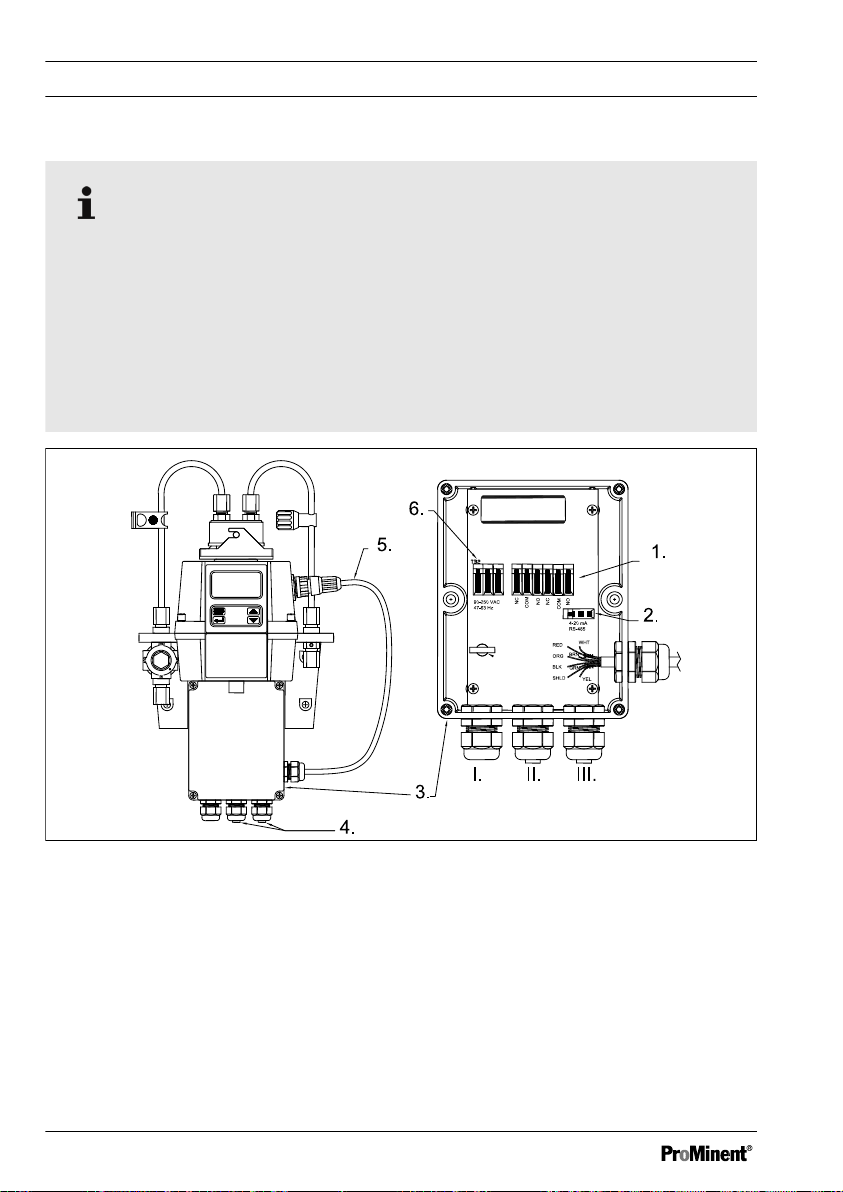

Fig. 3: Recommended pipes for the sensor

I. Flow unit

4. Hose connector. 4.75 mm interior

II. Sensor unit with operating unit

III. Terminal box

1. Backpressure valve. To regulate

the flow and in order to remove

small air bubbles

22

5. Detail: Hose

6. Detail: Union nut hose connection

diameter, 8 mm external diam‐

eter. Hose connection to the sam‐

pling site

Page 23

Mounting and Installation

2. Vent screw. For use on pressur‐

ised systems. Not used for pres‐

sureless systems

3. Hose connector. 4.75 mm interior

diameter, 8 mm external diam‐

eter. Hose connection for free

sample water outlet

4.3 Installation (electrical)

WARNING!

Live parts!

Possible consequence: Fatal or

very serious injuries

– Measure: Disconnect the

power supply before opening

the housing

Disconnect damaged, defec‐

–

tive or manipulated devices

from the power supply

– The provision of a suitable

isolating device (emergencyoff switch, etc.) is the respon‐

sibility of the plant operator

7. Detail: Replacement hose con‐

nection

8. Shut-off clamp. To shut-off the

inlet in an emergency or for nec‐

essary work

The signal leads of the

DULCO® turb C may not be

routed alongside faulty cabling.

Faults could lead to malfunctions

in the DULCO® turb C.

NOTICE!

Do not route any RS-485 cables

in the same cable duct as the

power supply cable. This may

result in major anomalies.

23

Page 24

A0518

Mounting and Installation

RS-485

The RS-485 digital interface (2 leads / half duplex) is characterised by a very

high tolerance to electromagnetic interference due to the symmetrical signal

transmission. This means that cable lengths of up to 900m can be used. The

final device on a bus must be equipped with a 120 ohm resistor, in order to

avoid signal overlapping.

In order to avoid damage, only separate and connect the RS-485 cable if the

DULCO® turb C is switched off.

Fig. 4: Cable assignment of the sensor

I. Power cable threaded connection

(supplied without power cable)

II. Alarm cable threaded connection

III. Sensor cable threaded connec‐

tion

1. Terminal Alarm 1 and Alarm 2

(0.25 - 1.5 mm2) maximum 2

ampere

24

3. Terminal box

4. Liquid-tight threaded connection

5. Sensor cable

6. Terminal power cable (0.25 - 1.5

mm2)

Page 25

Mounting and Installation

2. Terminal 4-20 mA / RS 485 (0.25

- 1.5 mm2)

All terminals in the terminal box are labelled and are self-explanatory.

All cable bushings are equipped with blanks on shipping. These must be

removed as required.

Strip the Insulation on all cables to a length of 6 mm.

Equip all cables with strain relief.

Supply voltage: 100 - 240 VAC at 47 - 63 Hz

1. Release the four housing screws from the corners of the terminal box.

2. Lift off the terminal box cover.

3. Remove the blanks from the required bore holes

4. Guide the cables into the threaded connections

5. Connect the cables with the designated terminals.

6. Tighten the clamping nuts of the threaded connections so that they are

properly sealed

7. Place the terminal box cover back onto the terminal box

8. Manually tighten the housing screws

9. Once again check the seating of the seals and threaded connections. Pro‐

tection class IP 66 is only achieved if the control panel mounting is correct

25

Page 26

Operating diagram

5 Operating diagram

Overview of device /Control elements

5.1

n Users' qualification: Instructed person, see

tions“ on page 8

Fig. 5: Overview of device /Control elements

1. LCD display

2. UP key

4. ENTER button

5. MODE/EXIT button

3. DOWN key

Ä Chapter 1.2 „Users' qualifica‐

Function Description

LCD display The parameters of the respective mode are shown on the

LCD display.

UP key To increase a displayed number

26

Page 27

Operating diagram

Function Description

DOWN key To decrease a displayed number

ENTER button To apply, confirm or save a displayed value or status or

MODE/EXIT

button

In order to call-up and select the three optional modes

[CAL], [CONFIG]

5.2 Overview of operating struc‐

ture

The sensor is equipped with three

modes, which can be selected by

means of the MODE/EXIT button:

n

[AUTO mode]

display of the current measured

values

n

[CAL]

: Calibration mode for exe‐

cuting the calibration process

n

[CONFIG]

configuring customer-specific set‐

tings. Automatic switchover into

the mode

undertaken within 15 minutes

: Standard mode,

: Configuration mode for

[AUTO mode]

if no entry

and

[AUTO]

(measurement)

27

Page 28

Operating diagram

Fig. 6: Overview of operating structure

28

Page 29

Configuration menu

The configuration menu is subdivided

into several submenus, in order to

facilitate configuration.

The following submenus are avail‐

able:

Operating diagram

n Select the output

[O/P]

n Configuration of 4 ... 20 mA inter‐

face

[ERLV]

n Configuration of the alarm

[ALM1 / ALM2]

n Configuration of the offset

[OFST]

n Configuration of access protection

[CODE]

n Extended settings

[EXTD]

The procedure for configuring the

menu settings is described here

Ä Chapter 6.4 „Device configura‐

tion“ on page 35

.

The extended settings are grouped

together in order to prevent accidental

alteration.

n Speed of response

n Screen resolution

n LCD illumination brightness

n Displayed units

n Ultrasonic cleaning

n RS-485 parameters

n Drying agent alarm

[RESP]

[RES]

[BRT]

[UNIT]

[CLN]

[BITS]

[DESC]

The procedure for configuring the

extended settings is described here

Ä Chapter 6.4.5 „Extended set‐

tings“ on page 43

.

29

Page 30

Commissioning

6 Commissioning

Unit NTU (optionally FNU)

NTU (Nephelometric Turbidity Unit) is a unit of measurement for measuring the

turbidity of liquids. Alternatively, the measurement can be expressed as FNU

(Formazine Nephelometric Unit), see

undertaken 1:1.

Measured values over 1000 NTU are outside of the sensor's measurement

range. Measured values over 1100 NTU cause the display to flash and a mes‐

sage to be displayed warning of excessive measured values.

Ä „Units“ on page 48

. The calculation is

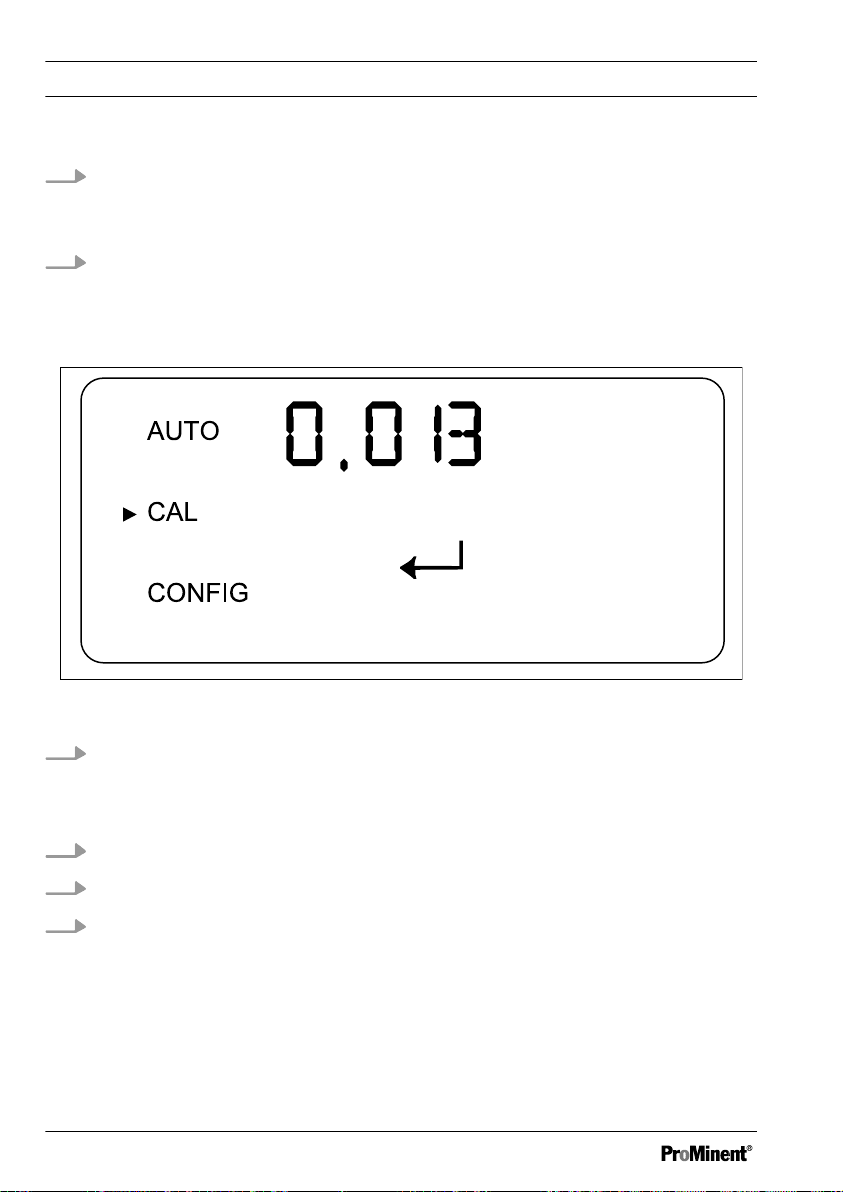

During normal operation of the sensor, an arrow is positioned next to

[AUTO]

.

In this state, the lower row indicates the unit of measurement and the upper row

shows the current measured value.

Fig. 7: Display in automatic mode

6.1 Load drying agent

Remove transport mounting

The transport mounting must be removed before initial insertion of the drying

agent bag. This pipe can be subsequently disposed of.

30

Page 31

Commissioning

The DULCO® turb C is equipped with an dehumidifying device. A drying agent

bag in the sensor serves to dry the air. The thermal discharge from the sensor is

used to heat the air. A fan mounted in the inner part of the sensor serves to cir‐

culate the warm air around the optical sleeve and cuvette. The DULCO® turb C

continuously monitors the state of the drying agent bag. As soon as the drying

agent needs to be exchanged, this is indicated in the lower row of the LCD dis‐

play; Warning

[DESC]

(for desiccant). Replacement drying agent bags can be

obtained from Prominent or from your local representative.

Saturated drying agent can cause an alarm to be triggered, in order to indicate

the requirement for exchange. Refer to

Ä „Drying agent alarm“ on page 51

31

Page 32

Commissioning

NOTICE!

Seal sensor housing

Possibility of premature drying agent saturation.

A damaged seal can lead to premature saturation of the drying agent.

Check the seal every time the drying agent is exchanged. Correct the seal

seating or exchange it if necessary.

1. Release the four screws from the corners of the housing and remove the

upper part of the sensor

Fig. 8: Load drying agent

2.

Insert the drying agent immediately after opening the packaging, in

order to avoid premature saturation.

Remove the new drying agent bag (2) from the packaging and place it

together with the humidity indicator card (3) in the lower part of the sensor

(1). In doing so, place the humidity indicator card (3) on the new drying

agent bag (2).

32

Page 33

Commissioning

3. Place the upper part back on the lower part and tighten the four screws

hand-tight.

The sensor must be reset in order to enable detection of the new

ð

drying agent. In order to do so, remove the sensor connection cable

for 2 seconds and then re-connect it. Otherwise the

[DESC]

warning

may be shown on the LCD display.

6.2 Routine measurement

Routine measurement: The turbidity

can be correctly measured approx. 45

- 60 minutes after beginning measure‐

ment / commissioning (warm-up

phase).

If a continuous process water flow

passes through the sensor, then the

sensor shows you the measured tur‐

bidity level of the sample on the LCD

display. In addition, a 4-20 mA signal

or a digital signal is given, depending

on the selected option.

33

Page 34

A0519

Commissioning

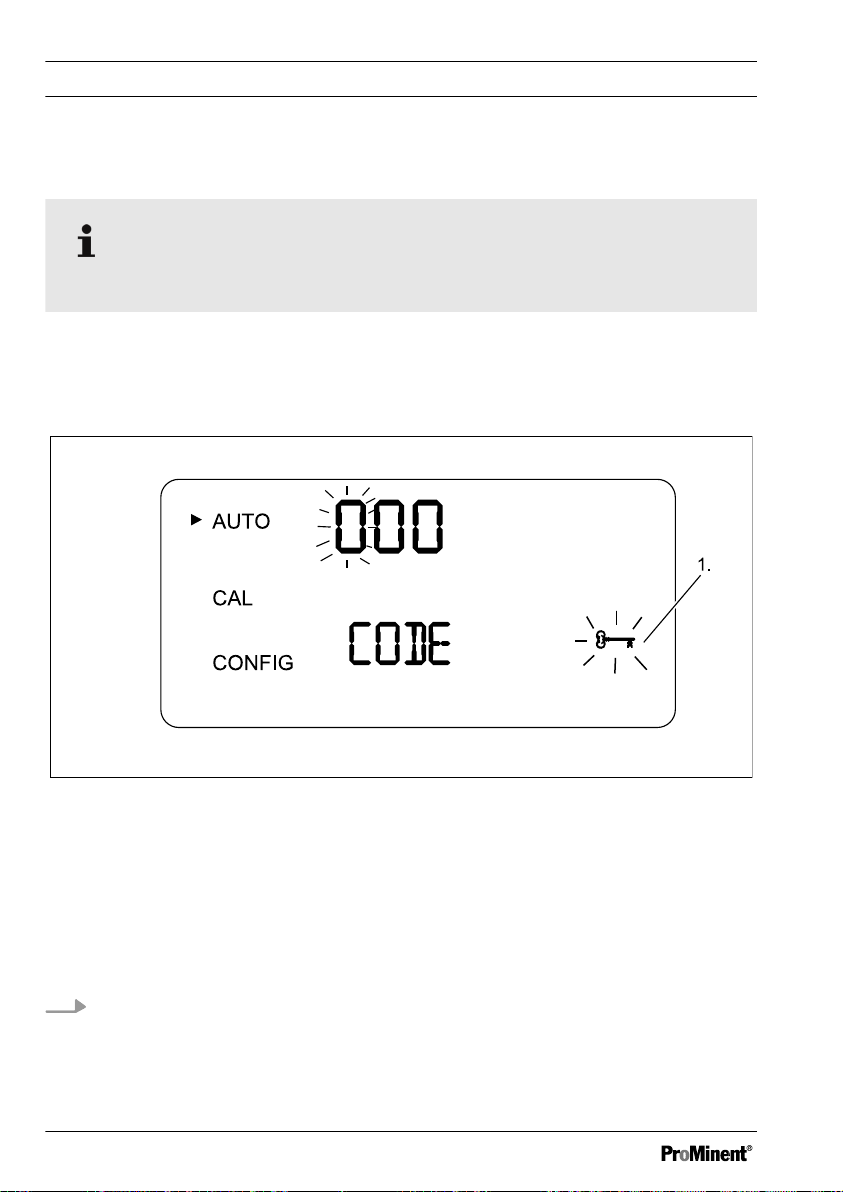

6.3 Access code

The access code cannot be changed.

You can activate the access code for the sensor in the configuration menu. If

the access code is activated, then this is indicated in the lower right-hand sec‐

tion of the LCD display.

[MODE/EXIT button]

„Security“

.

-Symbol (1) displays, if you press the

Fig. 9: Access code

When one of the access code numbers if flashing, you can change the number

with the UP or DOWN button and confirm with the ENTER button.

Entering the access code

The access code (333) has to be entered in order to access the

„CONFIG“

menus.

„CAL“

or

1. The first number of the access code flashes. Select the correct number

with the UP or DOWN button and then press ENTER

The second number of the access code flashes.

ð

34

Page 35

A0530

Commissioning

2. Select the correct number with the UP or DOWN button and then press

ENTER

The third number of the access code flashes.

ð

3. Select the correct number with the UP or DOWN button and then press

ENTER

If you have selected the valid access code, then you will now have

ð

access to the sensor's calibration mode. In the event that the access

code is incorrect, the sensor returns to AUTO mode.

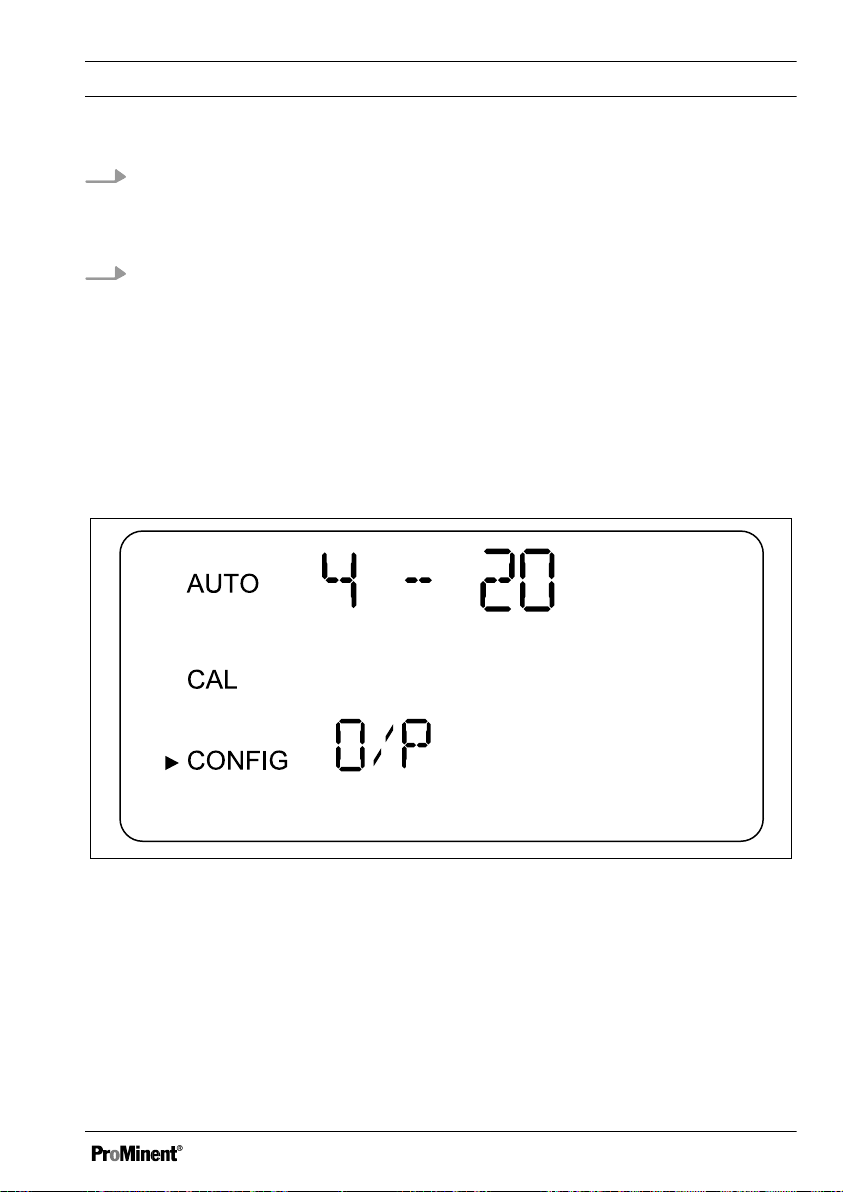

Device configuration

6.4

6.4.1 Selecting the output

Fig. 10: Selecting the output

35

Page 36

Commissioning

Function Options Info

Output (O/P)

n 4 - 20 mA

n 485

n off

4 - 20 mA

Value 4 mA 0 ... 1000 NTU Selection of the lower

turbidity limit value

(LOLM)✱, which corre‐

sponds to the output

value 4 mA.

Value 20 mA 0 ... 1000 NTU Selection of the upper

turbidity limit value

(UPLM)✱✱

, which corre‐

sponds to the output

value 20 mA.

✱ = a higher NTU value can be entered than for

„value 20 mA“

, in order to

reverse the sign of the output current

✱✱ = a lower NTU value can be entered than for

„value 4 mA“

, in order to

reverse the sign of the output current

485

Baud Value baud

n 1200

Selection of the baud

rate for the I/O interface

n 2400

n 4800

n 9600

n 19200

36

Page 37

A0625

Commissioning

Function Options Info

Addr 1 ... 255 Selection of the device

address

MBUS ASCII

Selection ASCII or RTU

RTU

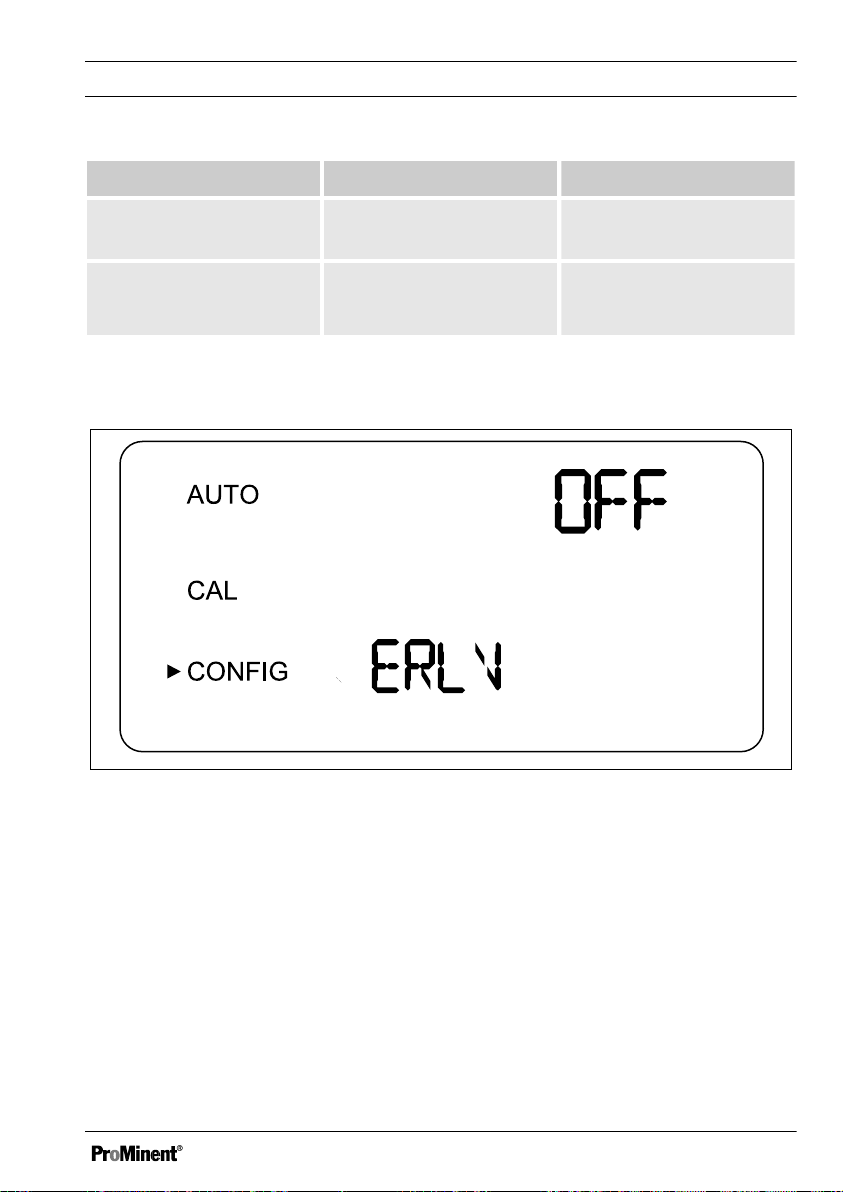

6.4.2 Configuration of fault current (ERLV)

Fig. 11: Configuration of fault current (ERLV)

The 4-20 mA signal output can be utilized in the event of a system error on the

DULCO® turb C in order to indicate the problem by activating the

[ERLV ON]

function. In doing so, fault currents of 4.00 mA, 2.00 mA or 0 mA can be

selected. In the event of an error, the configured current value is output to the

controller, regardless of which measured value is pending. If the function is

switched off by setting

[OFF]

then the 4-20 mA signal output remains unaffected

by fault conditions.

37

Page 38

Commissioning

Select the desired fault current by pressing the buttons ▲

the ↲, in order to store the selected setting.

Function Options Info

Error Level (ERLV) OFF

0 mA

2 mA

4 mA

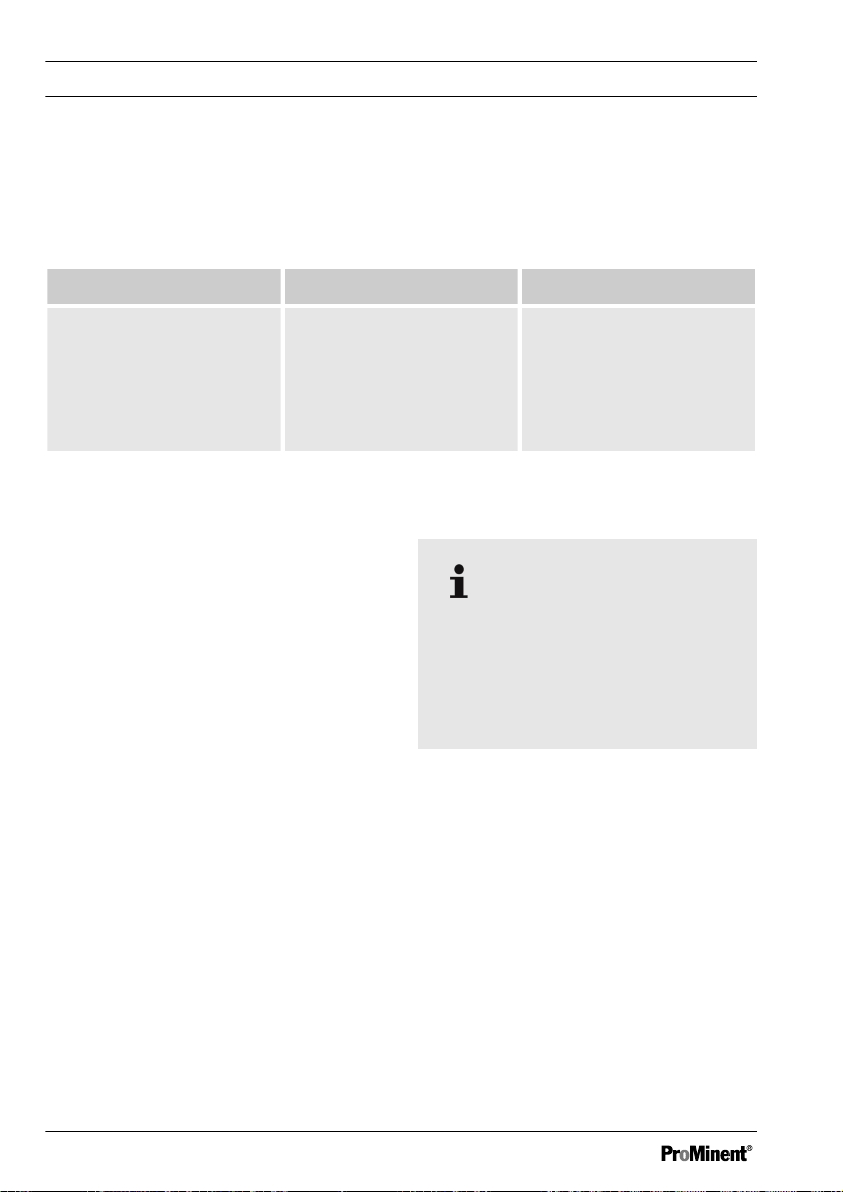

6.4.3 Configure alarm

Alarm function

The sensor is equipped with two inde‐

pendently programmable alarm

relays. Three items of information

have to be entered in order to fully

configure the alarms:

Alarm triggering in the event

of an internal system error

The relay produces an alarm in

the event of an internal system

n Alarm function: HI, LO, OFF or

ERROR

error, regardless of the configured

turbidity values.

n Alarm limit value (limit value at

which the alarm becomes active)

n Alarm delay time (how long the

limit value must be exceeded

before the alarm is activated and

the period of time before the

alarm is reset)

and ▼ and then press

38

Page 39

Commissioning

You can either deactivate the alarm

(OFF) or program it so that it works in

accordance with one of the following

modes:

n Alarm HI: The relay triggers the

alarm in the event that the tur‐

bidity value exceeds the pro‐

grammed alarm value for at least

the specified period of time

n Alarm LO: The relay triggers the

alarm in the event that the tur‐

bidity value drops below the pro‐

grammed alarm value for at least

the specified period of time

n Alarm ERROR: The relay triggers

the alarm when an internal system

error occurs

Limit value alarm

The turbidity threshold at which the

alarm is triggered is referred to as the

„Limit value alarm“

. You can con‐

figure the limit value across the entire

display range of the device in steps of

0.01 NTU.

Delay period alarm

The alarm delay times prevent the

alarm from being triggered in the

event that the turbidity briefly exceeds

or drops below the threshold value.

The delay function works as follows:

n Delay time

bidity must exceed the

value alarm“

„Alarm on“

: The tur‐

„Limit

for a period of at

least the time configured here,

before the alarm will be triggered.

If the time for

„Delay alarm on“

is

set to 5 seconds and the turbidity

only exceeds

„Limit value alarm“

for 4 seconds, then the alarm will

not be triggered. However, if the

turbidity exceeds the

alarm“

for 5 seconds or longer,

„Limit value

then the sensor triggers an alarm.

n Delay time

bidity must drop below

value alarm“

„Alarm off“

: The tur‐

„Limit

for a period of at

least the number of seconds con‐

figured here, before the alarm will

be triggered. If the time for

alarm off“

is set to 5 seconds and

the turbidity only exceeds

value alarm“

for 4 seconds, then

„Delay

„Limit

the alarm will not be deactivated.

As soon as the turbidity remains

below

„Limit value alarm“

for at

least 5 seconds, the sensor deac‐

tivates the alarm.

39

Page 40

A0531

Commissioning

Menu Alarm

Fig. 12: Menu Alarm

Function Options Info

Alarm 1 (ALM1)

or

Alarm 2 (ALM2)

n HI

n LO

n OFF

n ERROR

Select the alarm function

Limit value (S/P) 0 ... 1000 NTU Set the

alarm“

delay time alarm on

(DLY▲)

1 ... 30 s For the function

alarm on“

number of seconds.

Delay time alarm off

(DLY▼)

1 ... 30 s For the function

alarm off“

number of seconds.

40

„Limit value

on

„Delay

set the

„Delay

set the

Page 41

A0624

Commissioning

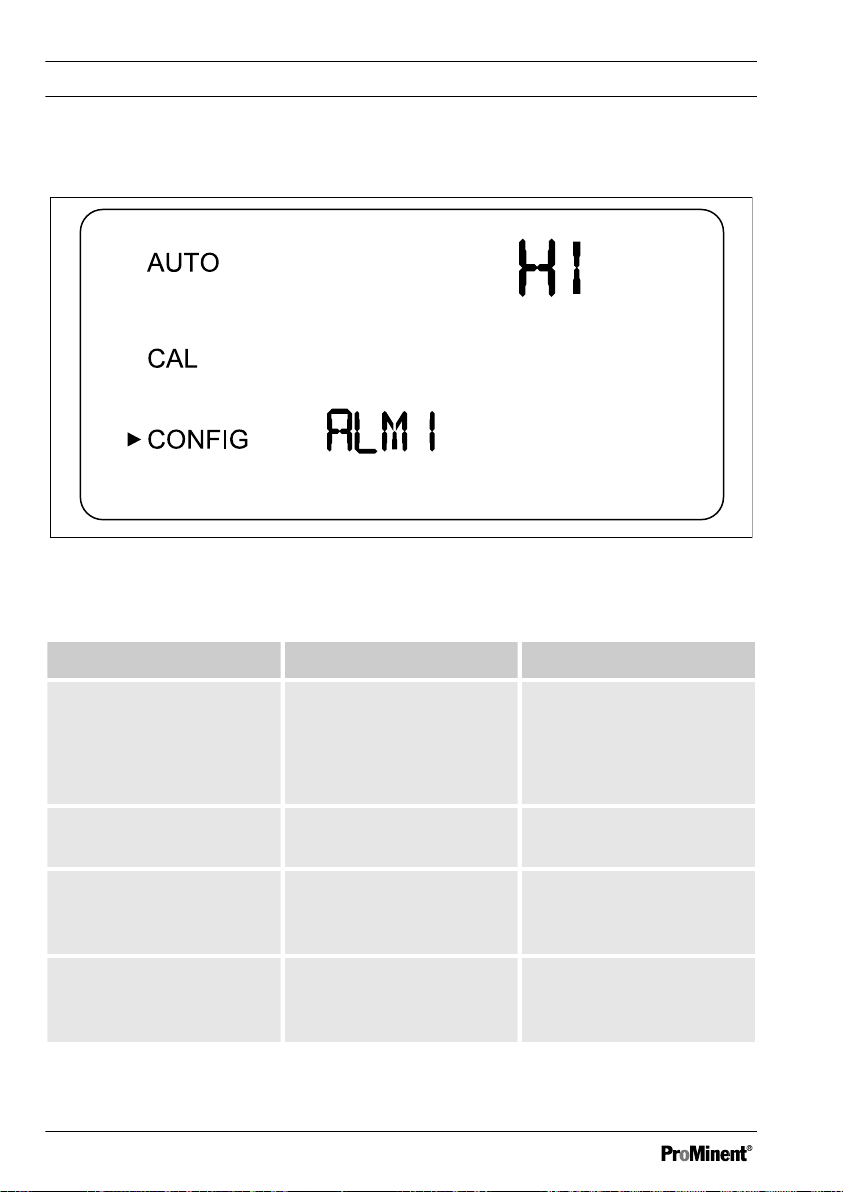

6.4.4 OFFSET configuration

The OFFSET symbol is shows as soon as an offset is being used. The max‐

imum offset amounts to 1.00 NTU. If the device deviation is greater than 1

NTU, then it is recommended to carry out a complete calibration.

Fig. 13: OFFSET configuration

41

Page 42

Commissioning

In certain circumstances it may be desirable to use an offset function in order to

balance the device, instead of performing a complete calibration (as described

under

Ä Chapter 7.1 „Calibrate sensor“ on page 55

). This procedure is not rec‐

ommended as a replacement for regular calibration, however, it can be used in

order to compensate for known minor deviations where measuring operations

cannot be interrupted. This balancing method means that the device only dis‐

plays precise turbidity values in the immediate vicinity of the sample value and

not across the entire measured range.

Proceed as follows in order to configure the offset:

1. Take a sample of the process water being monitored by the device and

make a note of the turbidity as indicated by the device.

2. Measure the turbidity value of the sample with the help of a calibrated

manual laboratory measuring device (reference device)

3. Compare the turbidity value indicated by the device with the value meas‐

ured by the reference device. If the values are extremely close to each

other (depending on the accuracy of the reference device), then no offset

configuration or calibration is required and the procedure can be aborted

at this point.

However, if the values differ significantly (however, less than 1 NTU),

ð

then proceed as follows in order to improve the turbidity value for the

device, so that the device matches the laboratory value.

4. Select the offset function by pressing

is positioned next to

5. Press the key ↲, until

At this point, the upper row of the display indicates the operating con‐

ð

[CONFIG]

[OFST]

is shown in the lower row

[MODE/EXIT button]

dition of the offset function.

6. If the function is switched off, then switch it

7. Select the desired offset value with ▼ or ▲

Press the key ↲, to accept the value.

ð

42

until the arrow

[ON]

, by pressing ▼ or ▲ .

Page 43

A0532

Commissioning

The difference between the value measured by the DULCO® turb

C NTU-value and the value measured by the reference device is

the offset value.

For example, if the DULCO® turb C measures a value of 0.016

NTU for the process water, and the reference device measures a

value of 0.012 NTU for the sample, then entering an offset value of

-0.04 will cause the DULCO® turb C to display the value 0.012

NTU

8. At this point, the offset configuration is completed. At this stage, the device

remains in configuration mode

[MODE/EXIT button]

in order to return to

[CONFIG]

. Press the key

[AUTO]

6.4.5 Extended settings

Extended settings

Fig. 14: Extended settings

43

Page 44

A0533

Commissioning

Function Options Info

[ON]

[OFF]

(On)

(Off)

Select the function

"Extended settings" in

order to access configu‐

Extended settings

ration for the following

options:

n Speed of response

n Screen resolution

n LCD illumination

n Units

n Ultrasonic cleaning

n RS-485 parameters

n Alarm drying agent

brightness

Response time

Fig. 15: Response time

44

Page 45

Function Options Info

Commissioning

Reaction time

(RESP)

1 ... 100 %

Factory setting: 10

%

Select a reaction time for the dis‐

played and output NTU values.

Select the highest reaction time (i.e.

the highest number) in order to avoid

anomalies caused by air or other influ‐

ences.

Select the lowest reaction time (i.e.

the lowest number) if rapid changes

are to be expected, which are to be

monitored.

The displayed number is a relative

reaction time. The approximate reac‐

tion time (in seconds) can be calcu‐

lated by the displayed number multi‐

plied by 5.

45

Page 46

A0534

Commissioning

Screen resolution

Fig. 16: Screen resolution

Function Options Info

Screen resolution (RES) 1 ... 0.001

Factory setting: 0,01

For displayed values

under 10 NTU the

DULCO® turb C is able

to display a value with

up to four digits after the

decimal point

46

Page 47

LCD illumination brightness

A0535

Fig. 17: LCD illumination brightness

Commissioning

Function Options Info

LCD illumination bright‐

ness (BRT)

1 ... 10

Factory setting: 8

Adjust the backlighting

for the LCD display as

required

47

Page 48

A0536

Commissioning

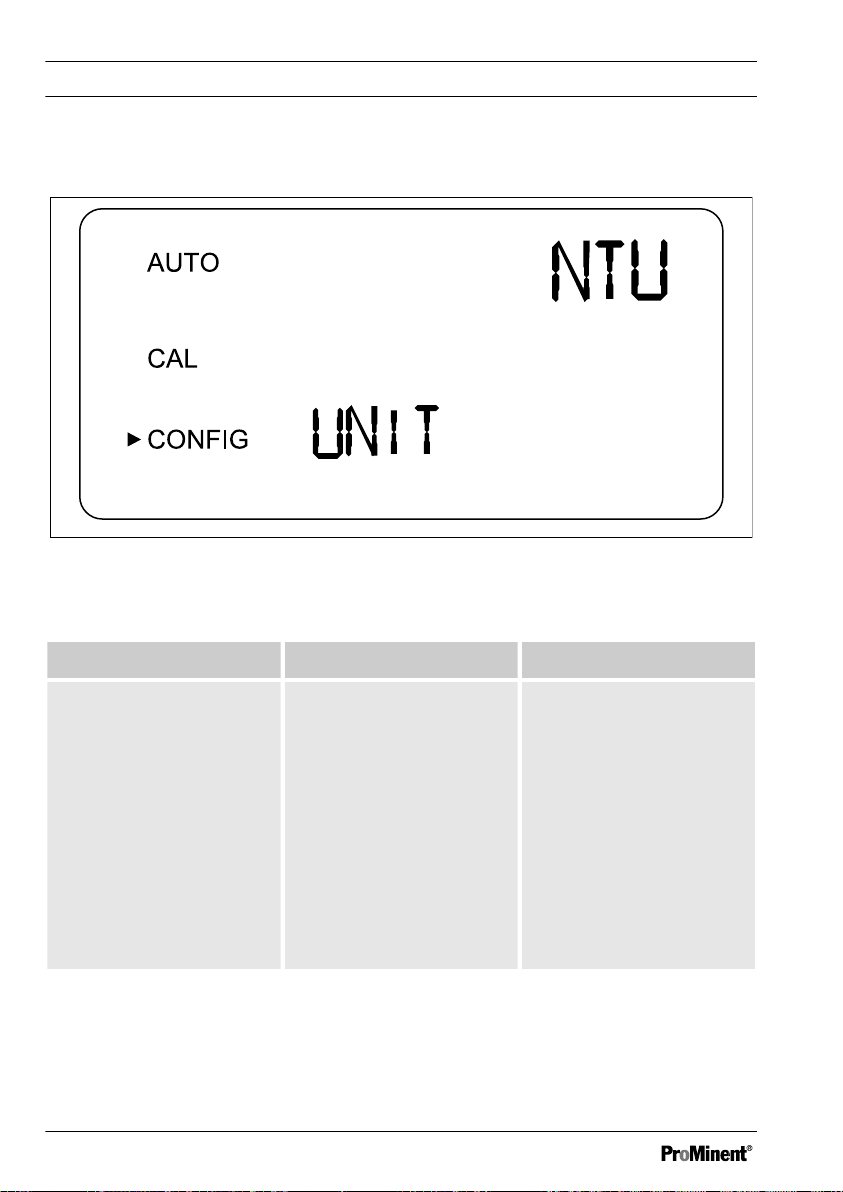

Units

Fig. 18: Units

Function Options Info

Units (UNIT)

n NTU

n FNU

Select a unit for dis‐

playing the turbidity

measurement:

Factory setting: NTU

NTU

[Nephelometric Turbidity

Units]

or

FNU

[Formazin Nephelo‐

metric Units]

48

Page 49

A0537

Commissioning

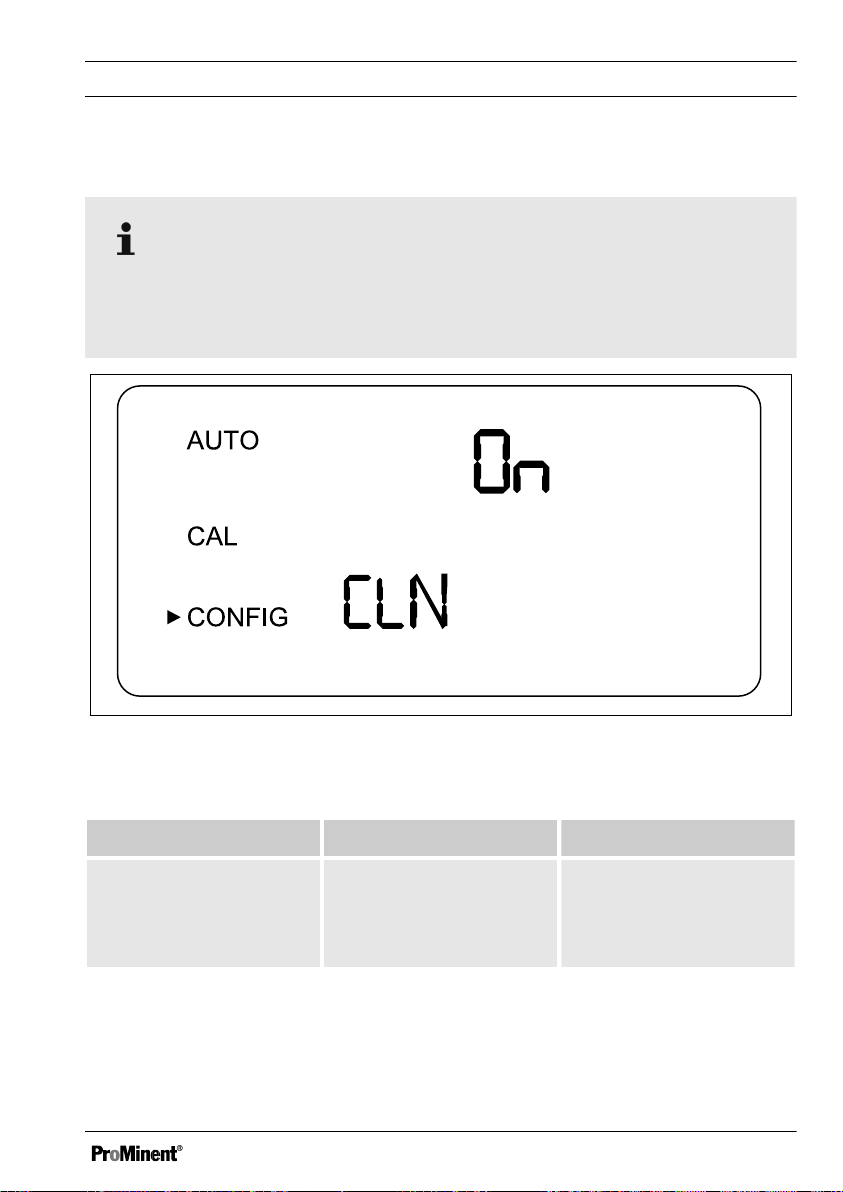

Ultrasonic cleaning (models TUC 3 and TUC 4)

Error message in the event of incorrect cuvette

Only active if a corresponding cuvette with ultrasound transducer is used. If

you use a cuvette without an ultrasound transducer, then an error message

will be shown on the LCD display.

Fig. 19: Ultrasonic cleaning

Function Options Info

Ultrasonic cleaning

(CLN)

[ON]

(On)

[OFF]

(Off)

Factory setting:

[ON]

If the ultrasonic cleaning function is working normally

Switching the ultrasonic

cleaning function on and

off

„AUTO“

matic measuring mode (AUTO)

flashes in auto‐

49

Page 50

A0538

Commissioning

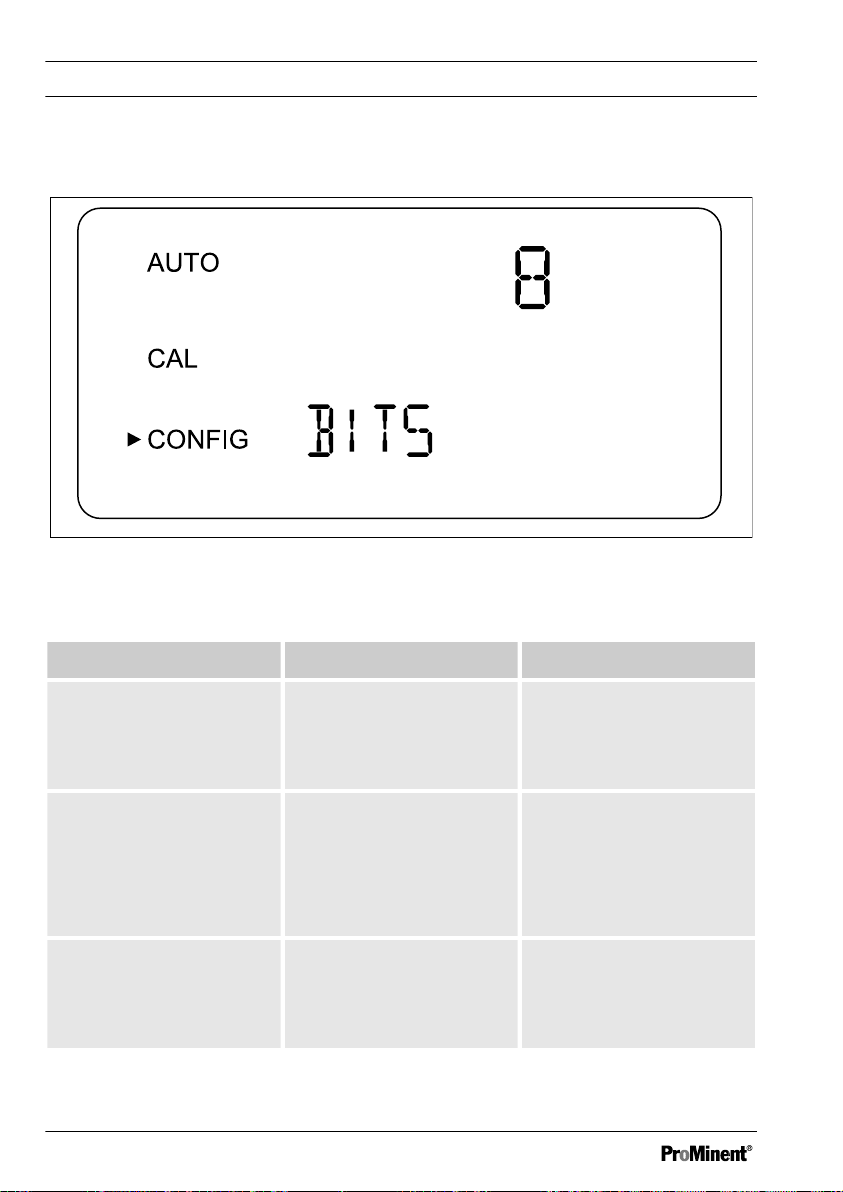

RS-485 parameters

Fig. 20: RS-485 parameters

Function Options Info

Bits (BITS) 7

8

Factory setting: 8

Parity (PRTY) nOnE

ODD

The required number of

data bits for the commu‐

nications software

deployed

The parity bit required

for the communications

software.

E

Factory setting: nOnE

Stop 1

2

The stop bit required for

the communications

software.

Factory setting: 1

50

Page 51

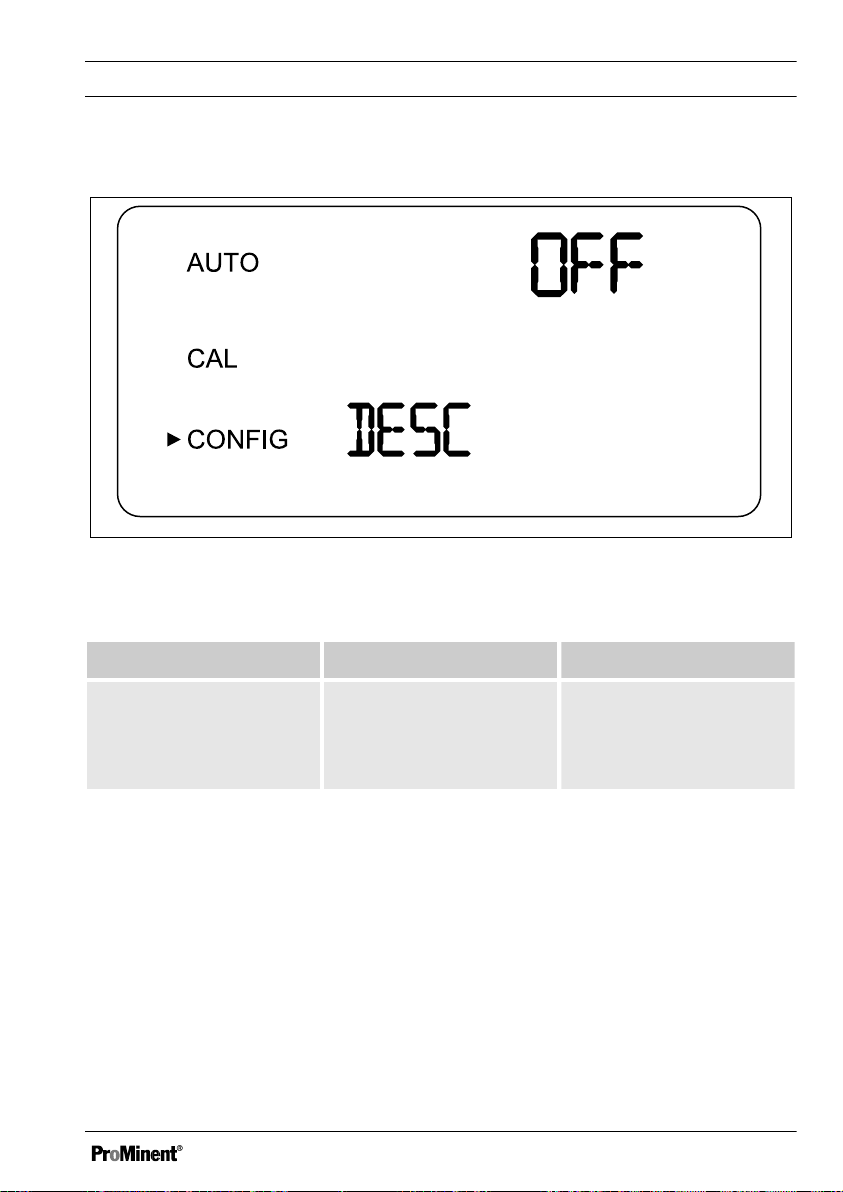

Drying agent alarm

A0539

Fig. 21: Drying agent alarm

Commissioning

Function Options Info

Drying agent alarm

(DESC)

[ON]

(On)

[OFF]

(Off)

Factory setting:

[OFF]

In order to activate one or both alarms, then you must configure

Ä Chapter 6.4.3 „Configure alarm “ on page 38

.

In order to indicate an error via the 4-20 mA signal,

must be selected in alarm current, see

“ on page 38

.

Ä Chapter 6.4.3 „Configure alarm

Select

[ON,]

in order to

trigger an alarm when

the drying agent is satu‐

rated

„ERROR“

, see

„ERROR ALARM (ERLV)“

Configuration of 4 mA output

Allow a constant output of 4 mA and will allow you to calibrate or adjust the 4

mA signal.

51

Page 52

A0607

Commissioning

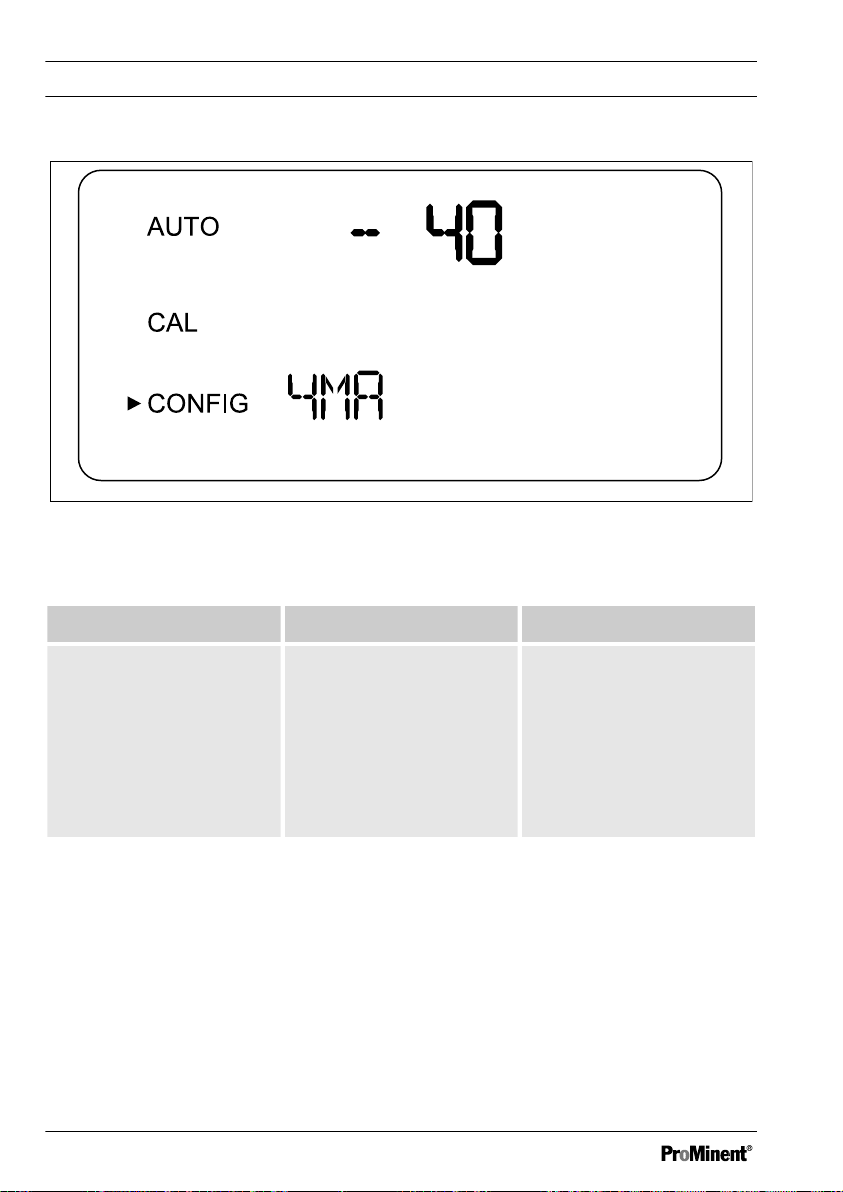

Fig. 22: Configuration of 4 mA output

Function Options Info

Configuration of 4 mA

output

- 40 ... + 40 Configure the mA value

in order to adapt to the

superordinated control

system (e.g. SPC or

SCADA)

One count number cor‐

responds to 0.01 mA

Configuration of 20 mA output

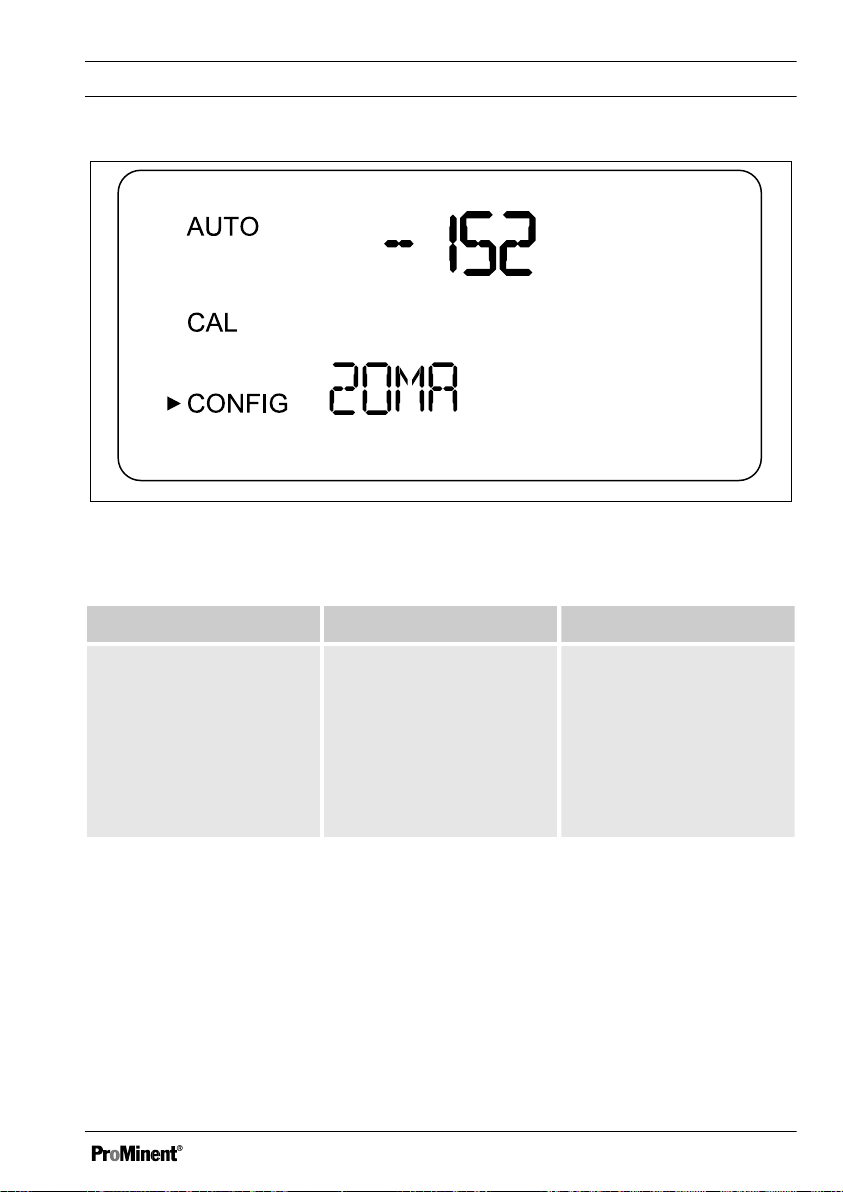

Allow a constant output of 20 mA and will allow you to calibrate or adjust the 20

mA signal.

52

Page 53

A0608

Fig. 23: Configuration of 20 mA output

Function Options Info

Commissioning

Configuration of 20 mA

- 1000 ... + 1000 Configure the mA value

output

Save configuration settings

If you have set the extended settings

(EXTD) to

the

[↲]

„OFF“

then you can use

-button to save the settings and

return to the permanent display in

„AUTO“

mode, see figure Fig. 6

in order to adapt to the

superordinated control

system (e.g. SPC or

SCADA)

One count number cor‐

responds to 0.01 mA

53

Page 54

Commissioning

If you have set the extended settings

„ON“

(EXTD) to

[↲]

-button after the final menu in the

then you can use the

extended settings to save your set‐

tings and return to the permanent dis‐

play in

„AUTO“

mode, see figure

Fig. 6. All changes previously under‐

taken in the configuration menu can

be stored in this manner.

You can access the configuration

menu at any time in order to reset or

modify some or all of the parameters.

You can exit the configuration menu

at any time by pressing the

[MODE/EXIT button]

. In doing so,

any changes to the parameters that

you have modified will be stored.

Flow controller

The flow controller (part number

1037880) limits high-pressure sys‐

tems to a flow of less than 1 l/min.

54

Page 55

7 Operation

Operation

7.1 Calibrate sensor

The sensor was tested and cali‐

brated before leaving the factory.

For this reason, you can use the

sensor right away. Under normal

conditions, it is recommended to

carry out calibration at least once

every three months.

The alarm relay switches over to

alarm state if the sensor is in

[CAL] or [CONFIG] mode. If no

entry is made in [CAL] mode

within a period of 15 minutes, the

sensor automatically toggles back

over to [AUTO] mode.

7.1.1 Standard solutions for cali‐

bration

If you operate the sensor across

its entire measurement range

from 0.02 NTU to 1000 NTU, then

you must perform calibration with

all three standard solutions (0.02

NTU, 10.0 NTU and 1000 NTU). If

the sensor is only operated in

measurement ranges under 10

NTU, then you may perform a

simplified calibration with standard

solutions 0.02 NTU and 10.0

NTU.

55

Page 56

Operation

CAUTION!

Use of diluted formazine

Possible consequences: Inaccu‐

rate calibration. Malfunctions in

dependent processes.

Diluted formazine is instable.

Ensure that freshly prepared for‐

mazine solution is used when per‐

forming calibration.

If possible, use a standard solu‐

tion from Prominent for calibra‐

tion. These standard solutions are

more stable than formazine and

have a minimum shelf-life of 12

months. In doing so, observe the

use-by-date on the standard solu‐

tion packaging.

Indexing the standard solution with

your cuvette

CAUTION!

Malfunction of the control circuit

Possible consequence: Poor endproduct quality

Ensure that your controller or

other measuring equipment is

configured so that the indexing

process does not lead to uninten‐

tional control functions in the

measurement and control system.

The controller connected to the

sensor may not process the sig‐

nals and use them for control pur‐

poses during indexing of the sig‐

nals.

Calibration set order number:

1037699

56

NOTICE!

Screen resolution

We recommend indexing the

DULCO® turb C in the "Commis‐

sioning / Display resolution"

menu, so that the following resolu‐

tion is achieved

1000 NTU: No digits after the

–

decimal point on the display

– 10 NTU: Two digits after the

decimal point on the display

– 0.02 NTU: Four digits after the

decimal point on the display

Page 57

Operation

Handling the standard solu‐

tion

The standard solution 1000 NTU

must be lightly shaken before use

for calibration.

Standard solution 10 NTU must

be transferred to the cuvette from

the supply bottle before it is used

for the first time. The filling for the

10 NTU cuvette is then usable for

3 months.

Do not use the standard solution

once the use-by-date has expired.

Purpose of indexing

The standard solution cuvettes

have minimal manufacturing toler‐

ances. This results from the man‐

ufacturing process and is unavoid‐

able.

In order to minimise the effects of

these manufacturing tolerances

on the calibration process, you

must index and mark the position

on the cuvette with the lowest tur‐

bidity value (lowest NTU value).

You can mark the index points

with the help of the marking rings

supplied. These marking rings are

included with the calibration set

packaging. The marking ring must

first be placed around the plastic

cover of the respective cuvette.

57

Page 58

Operation

Prerequisites: The sensor is opera‐

tional and is switched to

[AUTO]

mode.

1. Open the flow unit by screwing

it clockwise and remove the inline flow fitting from the cuvette.

2. Place the

[1000 NTU]

calibra‐

tion cuvette in the DULCO® turb

C

3. Rotate the

[1000 NTU]

calibra‐

tion cuvette one full turn in 20°

steps. On each step, wait until

the displayed measured value

has stabilised.

Mark the point on the cuv‐

ð

ette with the lowest NTU

value with the help of the

marking ring supplied, so

that the marker points

towards yourself.

4. Remove the

[1000 NTU]

calibra‐

tion cuvette and place the

[10 NTU]

calibration cuvette in

the DULCO® turb C

6. Remove the

[10 NTU]

calibra‐

tion cuvette and place the

[0.02 NTU]

calibration cuvette in

the DULCO® turb C

7. Rotate the

[0.02 NTU]

calibra‐

tion cuvette one full turn in 20°

steps. On each step, wait until

the displayed measured value

has stabilised.

Mark the point on the cuv‐

ð

ette with the lowest NTU

value with the help of the

marking ring supplied, so

that the marker points

towards yourself.

8. Place the cuvette sample with

the cuvette into the DULCO

®

turb C

9. Close the in-line flow fitting by

screwing it in an anticlockwise

direction.

ð

The DULCO® turb C is in

[AUTO]

mode.

5. Rotate the

[10 NTU]

cuvette one full turn in 20°

steps. On each step, wait until

the displayed measured value

has stabilised.

Mark the point on the cuv‐

ð

ette with the lowest NTU

value with the help of the

marking ring supplied, so

that the marker points

towards yourself.

58

calibration

For subsequent calibra‐

tion, place the calibra‐

tion cuvette into the

DULCO® turb C so that

the marking ring marker

points towards yourself.

Page 59

Operation

7.1.2 Perform calibration

CAUTION!

Malfunction of the control circuit

Possible consequence: Poor end-product quality

Ensure that your controller or other measuring equipment is configured so

that the calibration process does not lead to unintentional control functions

in the measurement and control system. The controller connected to the

sensor may not process the signals and use them for control purposes

during calibration of the signals.

NOTICE!

Fan standstill

The sensor fan is switched off during the calibration process, in order to

extend the service life of the drying agent.

The fan is switched on:

during the calibration countdown

–

– after returning to

[AUTO]

mode.

– After 5 minutes without input from the operator

– Whichever occurs first.

Keep the measurement chamber covered if no cuvette is inserted and only

place a cuvette into the measurement chamber if it is completely dry, in

order to avoid premature saturation of the drying agent.

59

Page 60

Operation

NOTICE!

Cleaning the cuvette

Possibility measurement value distortion

Before inserting the respective cuvette, it must be thoroughly cleaned with

the cleaning cloth provided with the calibration set. Even minimal traces of

foreign bodies on the surface of the cuvette can cause the measured result

to be falsified.

Prerequisites: The sensor is operational and is switched to

[AUTO]

mode.

Fig. 24: Display [Calibration 1000 NTU]

1. Use the

ð

[MODE/EXIT button]

key to select

[CAL]

mode.

The LCD display (see Fig. 24) shows an arrow next to

[CAL]

. The

lower display value (1000) is the selected calibration point. The upper

displayed value is the currently measured NTU value.

2. Open the flow unit by screwing it in a clockwise direction and remove the

cuvette sample together with the cuvette.

60

Page 61

A0523

Operation

3.

Place the

[1000 NTU]

calibration cuvette in the DULCO® turb C so that the

marking ring marker points towards yourself, see

Ä „Indexing the standard solution with your cuvette“ on page 56

4. Slowly rotate the calibration cuvette 20° from the centre point to the left

and then 20° from the centre point to the right

Leave the calibration cuvette in the position with the lowest measured

ð

value.

Fig. 25: Display [Start calibration ]

5. Press the ↲-key in order to start calibration to

ð

A 30 second countdown begins, after which the DULCO® turb C is

calibrated to

[1000 NTU]

.

[1000 NTU]

61

Page 62

A0525

Operation

Fig. 26: Display [Calibration 10 NTU]

6. Remove the

7.

Place the

[1000 NTU]

[10 NTU]

Calibration cuvette

calibration cuvette in the DULCO® turb C so that the

marking ring marker points towards yourself, see

Ä „Indexing the standard solution with your cuvette“ on page 56

8. Slowly rotate the calibration cuvette 20° from the centre point to the left

and then 20° from the centre point to the right

Leave the calibration cuvette in the position with the lowest measured

ð

value.

62

Page 63

A0524

Fig. 27: Display [Start calibration ]

A0526

Operation

9. Press the ↲-key in order to start calibration to

ð

A 60 second countdown begins, after which the DULCO® turb C is

calibrated to

[10 NTU]

.

Fig. 28: Display [Calibration 0.02 NTU]

10. Remove the

[10 NTU]

Calibration cuvette

[10 NTU]

63

Page 64

A0527

Operation

11.

Place the

[0.02 NTU]

calibration cuvette in the DULCO® turb C so that the

marking ring marker points towards yourself, see

Ä „Indexing the standard solution with your cuvette“ on page 56

12. Slowly rotate the calibration cuvette 20° from the centre point to the left

and then 20 ° from the centre point to the right

Leave the calibration cuvette in the position with the lowest measured

ð

value.

Fig. 29: Display [Start calibration ]

13. Press the ↲-key in order to start calibration to

[0.02 NTU]

ð

A 30 second countdown begins, after which the DULCO® turb C is

calibrated to

14.

Remove the

15.

Place the cuvette sample with the cuvette into the

[0.02 NTU]

[0.02 NTU]

.

calibration cuvette from the DULCO® turb C

DULCO® turb C.

16. Close the in-line flow fitting by screwing it in an anticlockwise direction

ð

The DULCO®

turb C is now calibrated and is returned to

[AUTO]

mode.

64

Page 65

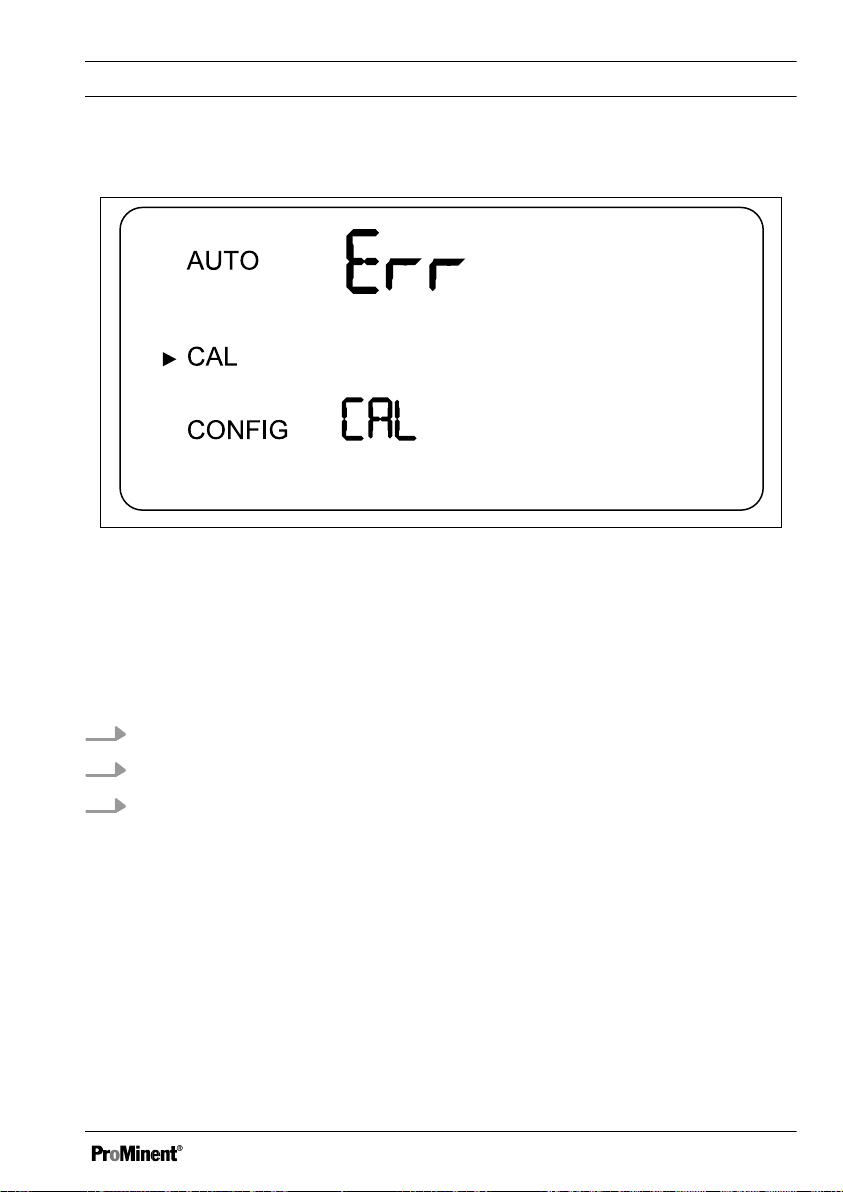

Incorrect calibration

A0528

Fig. 30: Display [Incorrect calibration]

If the

[Err CAL]

message is shown, then the DULCO® turb C internal diagnostics

system has determined that an error has occurred during calibration.

Operation

Press the

[MODE/EXIT button]

in order to repeat the calibration process.

Restoring the factory calibration settings

1. In order to restore the factory calibration, press and hold the ▲-key

2. Now press the ↲-key and release it again

3. Now release the ▲-key.

The sensor will now work with the factory calibration values.

ð

65

Page 66

Maintenance, troubleshooting and repair

8 Maintenance, troubleshooting and repair

8.1 Information about fault main‐

tenance

The sensor continuously carries out

self-diagnostic checks. Any errors are

displayed in the bottom row of the dis‐

play.

The sensor has a three-stage fault

detection system:

n Warning

A warning is merely a mes‐

–

sage on the display which

serves to indicate a pending

problem. No alarms are

issued. For example, if the

drying agent alarm is deacti‐

vated and the drying agent is

saturated, the LCD display

shows the following warning:

[DESC]

n Fault

– An error indicates a malfunc‐

tion or problem which can

generally be rectified by the

operator. This includes, for

example, a lamp failure

[LAMP]

[CAL]

or incorrect calibration

. If an error occurs, the

sensor continues to indicate

values, however, the accuracy

of these measured values is

uncertain, meaning that you

cannot rely on the values

given.

n Malfunction

A malfunction is a system

–

error. This problem cannot be

rectified by the operator. The

sensor must be sent back to

the factory for repair. These

faults relate to malfunctions in

the

[CPU], [A/D], [EEPROM]

or other units, which are inte‐

grated into the sensor. In the

case of malfunction, the

device will no longer work cor‐

rectly and the message

will be shown on the LCD dis‐

play. Both alarm relays are

activated and the current

output is set to 2 mA.

[FAIL]

66

Page 67

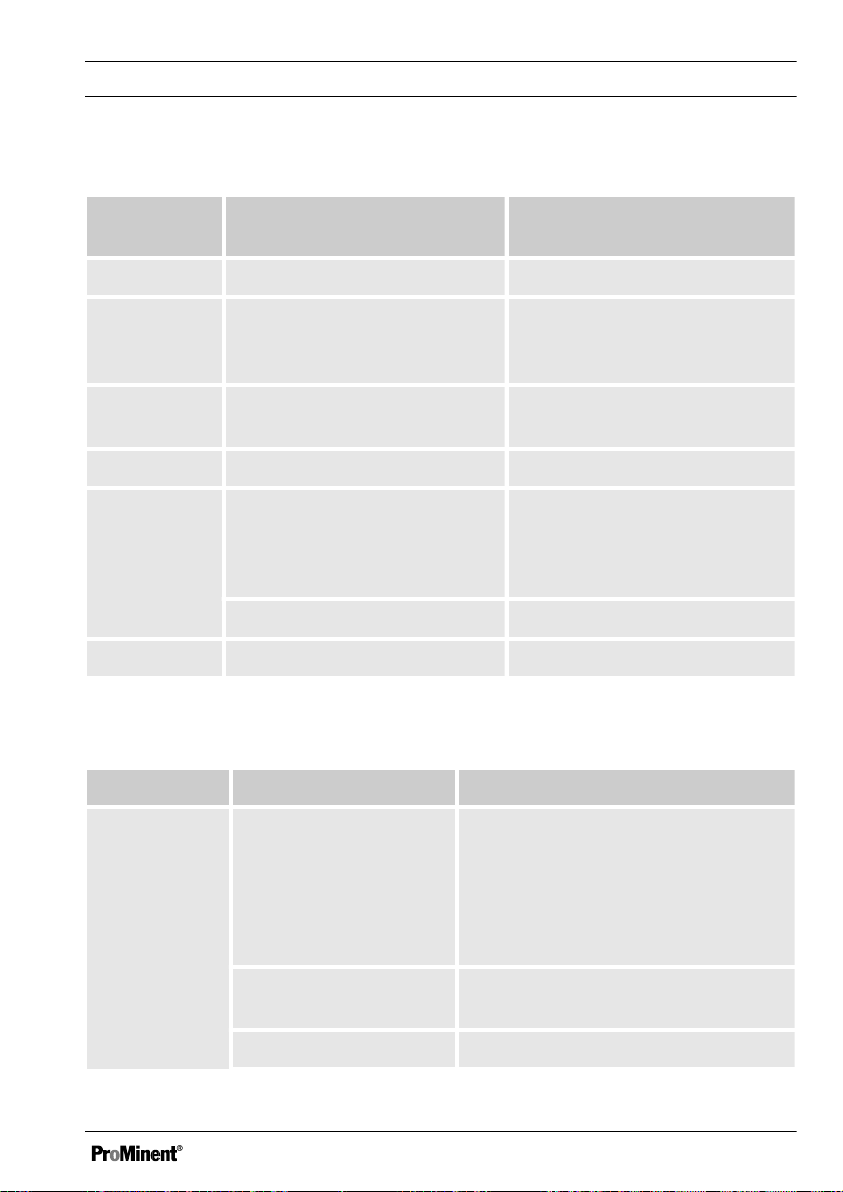

8.1.1 System error messages

Maintenance, troubleshooting and repair

Fault mes‐

Possible cause Measure

sage

[MA]

[DESC]

4 ... 20 mA circuit open Check cabling

Drying agent saturated Exchange drying agent. Refer

to

Ä Chapter 6.1 „Load drying

agent“ on page 30

[LAMP]

Lamp failure Exchange lamp. Contact cus‐

tomer service

[FLOW]

[CLN]

Flow interrupted Establish flow

Cuvette ultrasound trans‐

ducer has no contact

Rotate the cuvette slightly in

order to improve contact.

Exchange the cuvette if the

problem persists.

Cuvette removed Insert cuvette

[FAIL]

Fatal system errors Contact customer service

8.1.2 Faults in the process

Fault Possible cause Process error

Displayed

values higher

Air bubbles in the

sample water

than expected

Condensate or cuvette

not airtight

Cuvette soiled Clean cuvette

Ensure that the outlet bleed valve is

open and not blocked

Create backpressure

Install air bubble trap, accessories,

order number 1037790

Check cuvette for condensate or

leaks

67

Page 68

Maintenance, troubleshooting and repair

Fault Possible cause Process error

Displayed

values incor‐

rect

Displayed

values lower

than expected

Upper row of

display

flashes

Sensor not correctly

calibrated

Air bubbles in the

sample water

Particles of dirt in the

cuvette

Sensor not correctly

calibrated

Sample has exceeded

the permissible meas‐

urement range

Calibrate sensor, see

Ä Chapter

7.1.2 „Perform calibra‐

tion“ on page 59

Ensure that the outlet bleed valve is

open and not blocked

Create backpressure

Install air bubble trap, accessories,

order number 1037790

Clean the cuvette of any particles of

dirt.

Calibrate sensor, see

Ä Chapter

7.1.2 „Perform calibra‐

tion“ on page 59

Check sample. Turbidity of the

sample may be too high in order to

be read by the sensor

68

Page 69

Spare parts and accessories

9 Spare parts and accessories

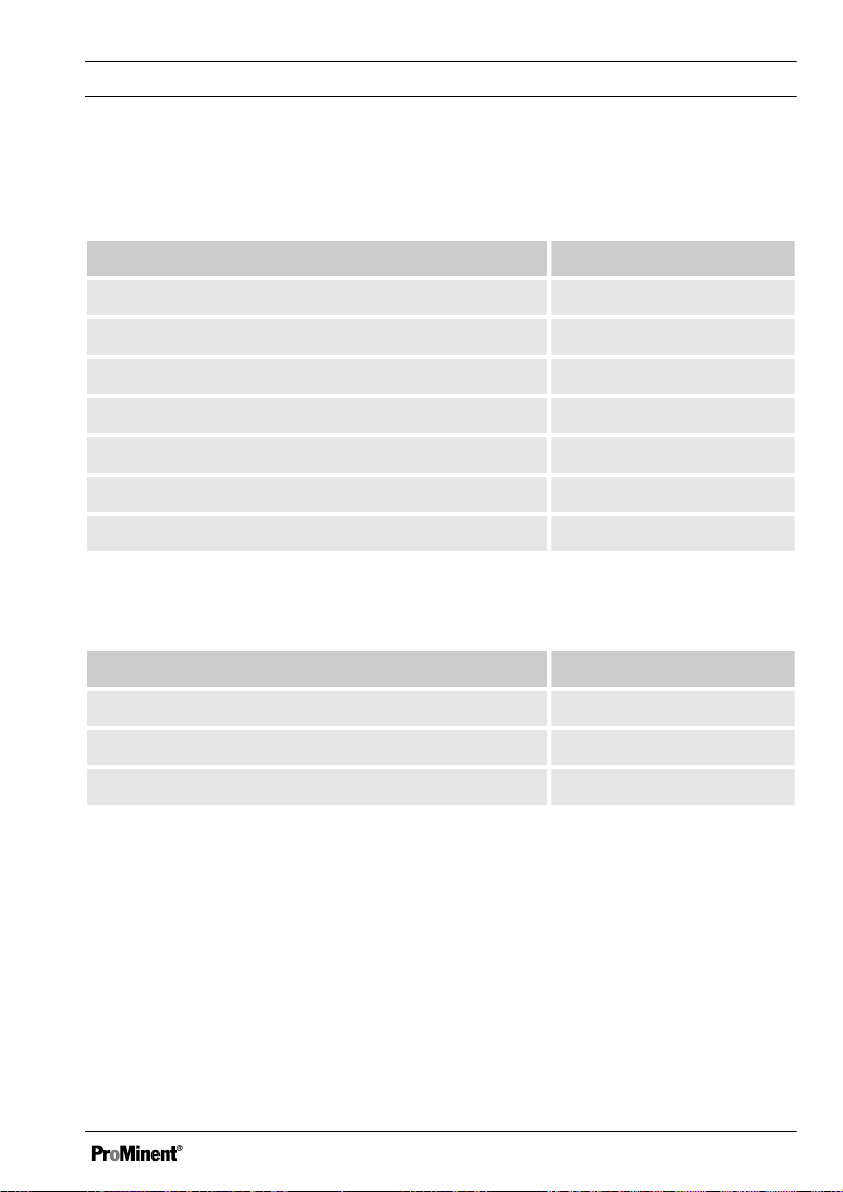

Spare parts

Spare part Part number

Drying agent 1037701

Cuvette TUC1 / TUC2 1037877

Cuvette TUC3 / TUC4 1037878

Infrared lamp TUC1 / TUC3 1037702

White light lamp TUC2 / TUC4 1037703

Hose kit 1037879

Pressure regulating valve 1037885

Accessories

Accessories Part number

Calibration set 1037699

Flow controller 1037880

Air bubble trap 1037700

69

Page 70

Standards complied with

10 Standards complied with

EN 60529 Specification for degrees of

protection provided by enclosures (IPCode)

EN 60746-1 Expression of perform‐

ance of electrochemical analyzers Part 1: General

EN 61000 Electromagnetic compati‐

bility (EMC)

EN 61010 Safety requirements for

electrical equipment for measure‐

ment, control and laboratory use Part 1: General requirements

EN 61326 Electrical equipment for

measuring, control and laboratory use

- EMC requirements (for class A and

B devices)

70

Page 71

11 Disposal of used parts

n Users' qualification: instructed

persons, see

„Users' qualifications“ on page 8

NOTICE!

Regulations governing disposal of

used parts

– Note the current national reg‐

ulations and legal standards

which apply in your country

ProMinent Dosiertechnik GmbH, Hei‐

delberg will take back decontami‐

nated used devices providing that

they are covered by adequate

postage.

Ä Chapter 1.2

Disposal of used parts

71

Page 72

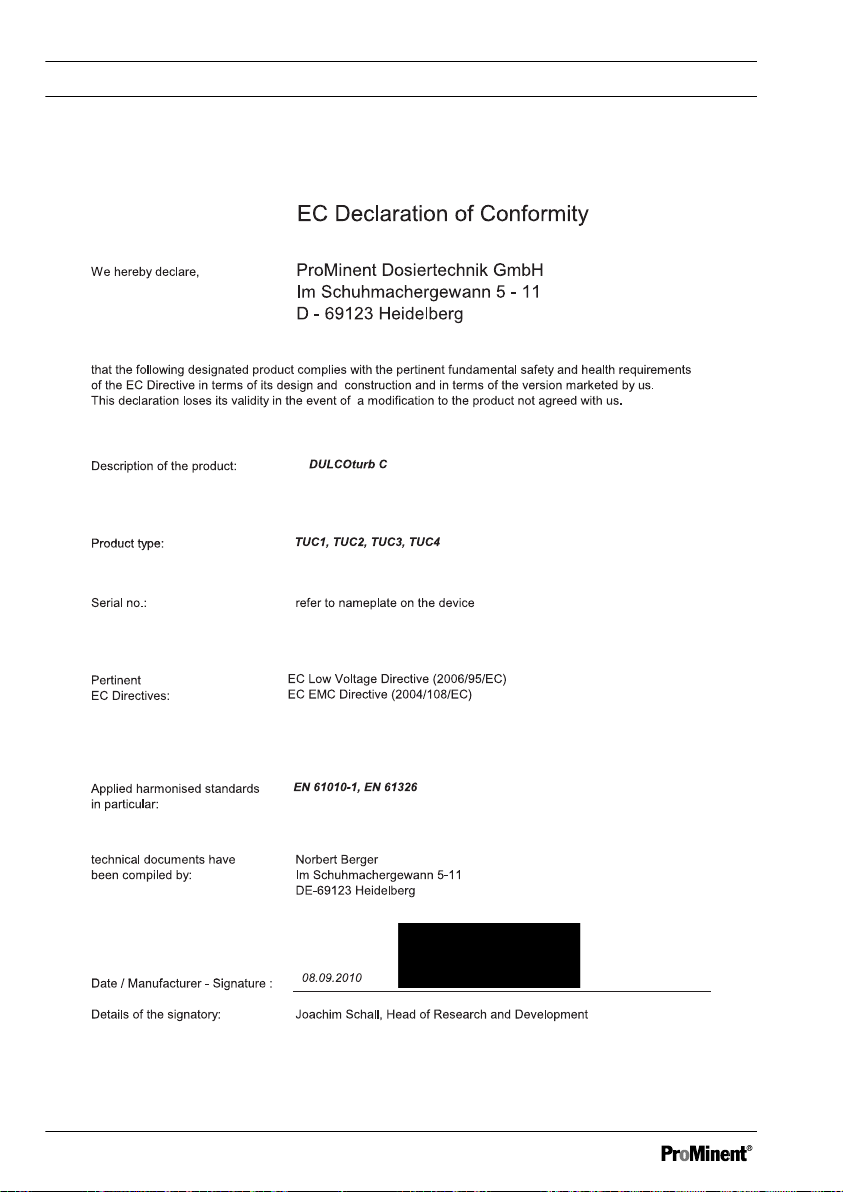

Declaration of Conformity

12 Declaration of Conformity

Fig. 31: Declaration of Conformity

72

Page 73

13 Index

Index

A

Accessibility................................... 17

Accessories................................... 69

Alarm delay period........................ 39

Alarm ERROR............................... 39

Alarm function............................... 38

Alarm HI........................................ 39

Alarm limit value............................ 39

Alarm LO....................................... 39

Alarm menu................................... 40

Ambient temperature..................... 17

C

Calibration erroneous.................... 65

D

Data................................................. 6

Delay period alarm........................ 39

F

Flow............................................... 21

FNU............................................... 30

Functions......................................... 6

G

General non-discriminatory

approach......................................... 3

I

Incorrect calibration....................... 65

L

Limit value alarm........................... 39

Liquid temperature........................ 21

M

Menu Alarm................................... 40

Mounting position.......................... 17

N

non-discriminatory approach........... 3

NTU............................................... 30

O

Operating position......................... 17

P

Pressure........................................ 21

Protection class IP 66 ...................

25

R

Radiant exposure.......................... 17

Reading position............................ 17

Recycling................................. 16, 17

S

Safety information........................... 6

Spare parts.................................... 69

Strain relief.................................... 24

T

Turbidity threshold......................... 39

U

Unit NTU ....................................... 30

Users' qualifications......................... 8

73

Page 74

Page 75

Page 76

Loading...

Loading...