Page 1

Operating Manual

P_PL_0001_SW

Plasma PSMa

Motorised Diaphragm Metering Pump

Two sets of operating instructions are required for the safe, correct and proper operation of the metering pumps: The

product-specific operating instructions and the

and Hydraulic Accessories".

Both sets of operating instructions are only valid when read together.

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Translation of Original operating instructions (2006/42/EC) Vers. 10/2009

"General Operating Instructions ProMinent® Motor-Driven Metering Pumps

Technical changes reserved.

Page 2

Heidelberg ProMinent Fluid Controls India Pvt. Ltd.

2/2 M.E.S. Road

Yeshwanthpur

India

Telephone: 080 - 2357 8872 / 73 / 74

Fax: 080 - 2357 3743 / 2347 7984

email: prominent@hpfcindia.com

Internet: www.prominentindia.com

BA PL 001, 1, en_GB

, Bangalore – 560 022

© 2009

2

Page 3

Supplementary information

Fig. 1: Please read carefully!

Supplemental directives

Please read the following supplementary information in its entirety!

This information will enable you to make better use of the operating

instructions.

The following are highlighted separately in the document:

n Enumerated lists

. Operating instructions

Information

This provides important information relating to the

correct operation of the unit or is intended to make your

work easier.

Safety information

Safety information is identified by pictograms - see Safety Chapter.

User information

State the identcode and serial number

Two sets of operating instructions are required for the safe, correct

and proper operation of the metering pumps: The product-specific

operating instructions and the "General Operating Instructions ProM‐

inent® Motor-Driven Metering Pumps and Hydraulic Accessories".

Both sets of operating instructions are only valid when read

together.

Please read these operating instructions carefully before use! Do not

discard!

Please state the identcode and the serial number that you find on the

specification label in all correspondence or when you order spare

parts. This enables us to clearly identify the unit type and material

version.

3

Page 4

Table of contents

Table of contents

1 Identcode ............................................................................. 5

2 About this Pump ................................................................... 6

3 Safety Chapter ..................................................................... 7

4 Storage, Transport and Unpacking .................................... 10

5 Overview of the Unit and Control Elements ....................... 12

6 Functional Description ....................................................... 13

6.1 Drive Unit ................................................................... 13

6.2 Liquid End .................................................................. 14

7 Assembly ........................................................................... 15

8

Installation .......................................................................... 16

8.1 Hydraulic Installation .................................................. 16

8.2 Electrical Installation .................................................. 16

9 Commissioning .................................................................. 18

10 Maintenance ...................................................................... 20

11 Repair ................................................................................ 22

11.1 Cleaning Valves ....................................................... 22

11.2 Replacing the Diaphragm ........................................ 24

12 Troubleshooting ................................................................. 26

13 Decommissioning ............................................................... 27

14 Technical Data ................................................................... 29

14.1 Performance Data .................................................... 29

14.2 Degree of Protection and Safety Requirements ...... 29

14.3 Ambient Conditions .................................................. 30

14.3.1 Temperatures ....................................................... 30

14.3.2 Climate .................................................................. 31

14.4 Gear Oil ................................................................... 31

14.5 Sound Pressure Level.............................................. 31

15 Appendix ............................................................................ 32

15.1 Dimensional Drawings ............................................. 32

15.2 Diagrams for Setting the Metering Capacity ............ 33

15.3 Ordering Information ................................................ 34

15.3.1 Spare Parts Sets ................................................... 34

15.3.2 Diaphragms .......................................................... 35

15.4 EC Declaration of Conformity .................................. 36

15.5 Decontamination Declaration ................................... 37

16 Index................................................................................... 38

4

Page 5

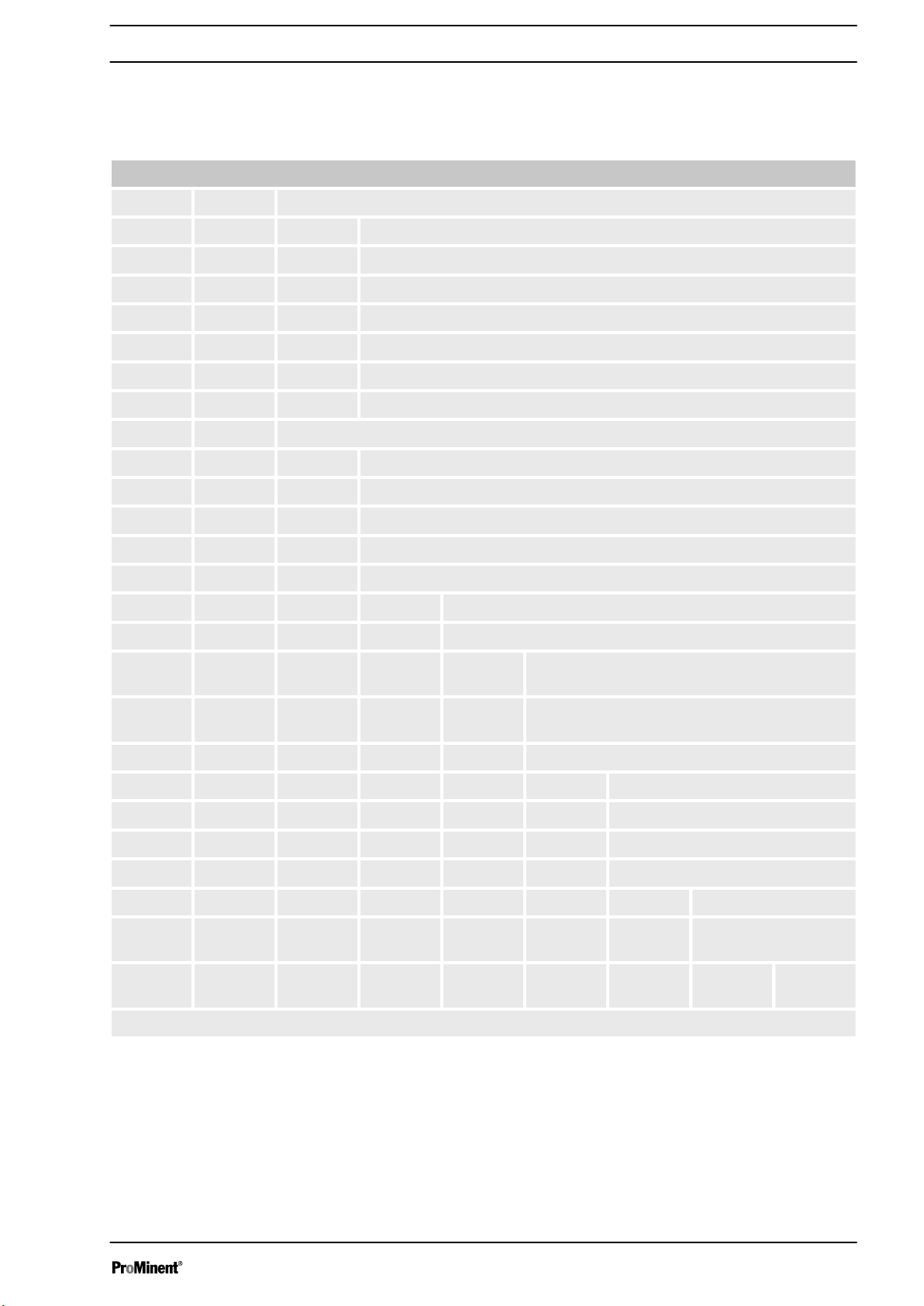

1 Identcode

Plasma Series, Version I

PSMa Type Power

bar l/h

05050 5 50

05065 5 65

05100 5 90

05120 5 120

05200 5 200

05260 5 260

Material of dosing head/valves

PC PVC with EPDM sealing material

PP Polypropylene with EPDM sealing material

Identcode

TT PTFE with PTFE sealing material

SS Stainless steel with PTFE sealing material

Dosing head design

0 Standard

Hydraulic connection

0 Standard connection - cap nut with hose

connection

1 Cap nut with stainless steel insert (standard

with stainless steel)

Motor connection

S 3-ph, 400 V ± 10 %, 50 Hz

(60 Hz versions on request)

1 without motor

Stroke sensor

0 no stroke sensor

Stroke length adjust‐

ment

0 manual

(standard)

5

Page 6

About this Pump

2 About this Pump

ProMinent

effective diaphragm metering pumps

®

Plasma PSMa motorised metering pumps are very

. They are compact, energysaving, provide excellent precision and reflect the high standards of

quality of ProMinent motorised metering pumps.

ProMinent

®

Plasma PSMa motorised metering pumps are available

up to metering outputs of 260 l/h. There are six different maximum

metering output levels available.

6

Page 7

3 Safety Chapter

Safety Chapter

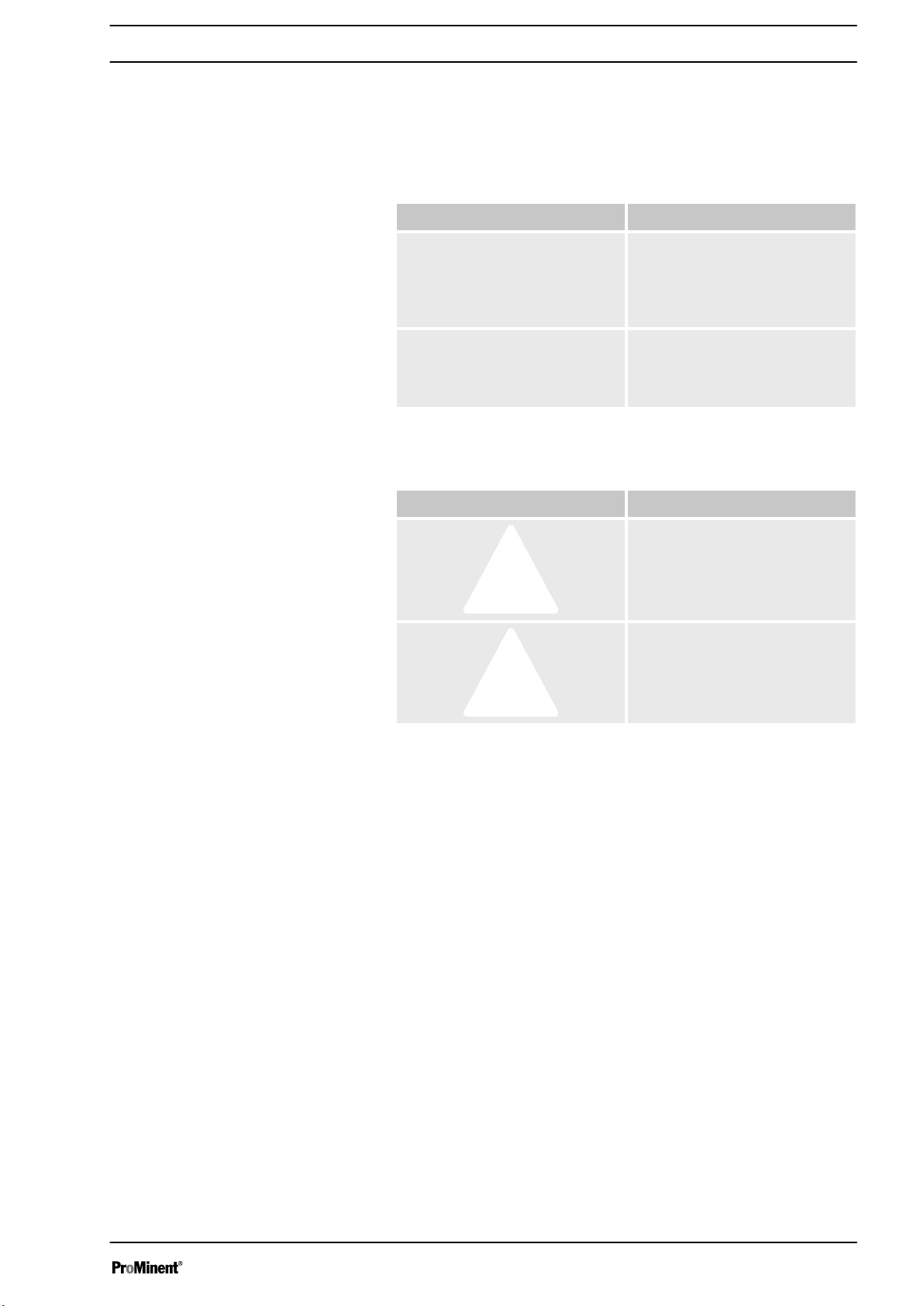

Explanation of the safety information

Warning signs denoting different types

of hazard

The following signal words are used in these operating instructions

to identify different severities of a hazard

Signal word Meaning

WARNING Denotes a possibly hazardous

CAUTION Denotes a possibly hazardous

The following warning signs are used in this operating instructions to

denote different types of hazard:

Warning sign Type of hazard

:

situation. If this is disregarded

you are in a life-threatening

situation and this can result in

serious injuries.

situation.

could result in slight or minor

injuries or material damage.

Warning of a hazardous area

If this is disregarded, it

,

Correct and Proper Use

Safety information

Warning of hazardous electrical

voltage

n The pump may only be used to dose liquid feed chemicals

n The pump may only be used after it has been correctly installed

and commissioned in accordance with the technical data and

specifications contained in the operating instructions.

n Any other uses or modifications are prohibited.

n The pump is not intended to dose gaseous media or solids.

n The pump is not intended for operation in EX zones.

n The pumps is not intended to dose combustible fluids.

n The pump should only be operated by trained and authorised

personnel.

n You are obliged to observe the information contained in the oper‐

ating instructions at the different phases of the device''s service

life.

.

7

Page 8

Safety Chapter

Safety information

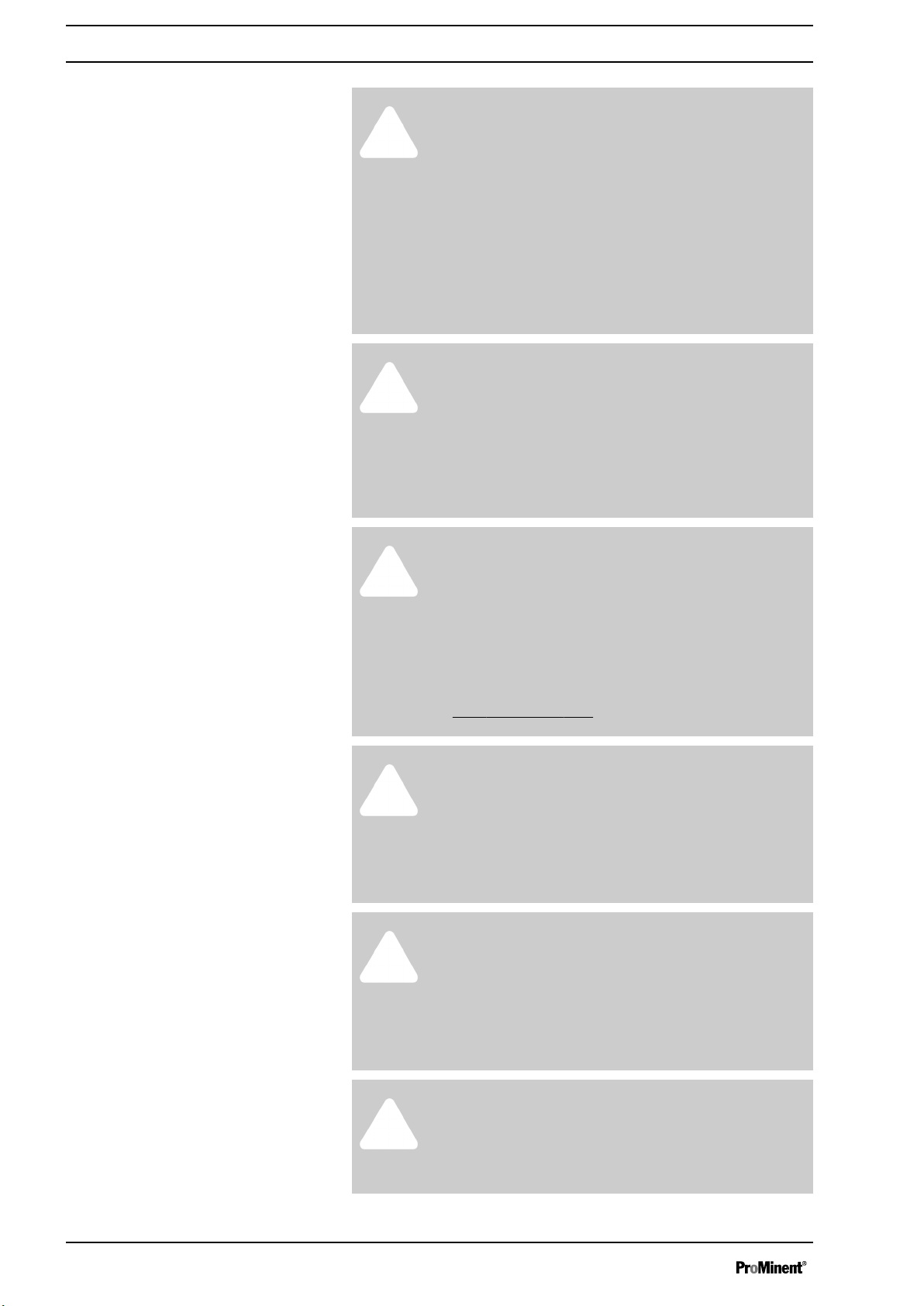

WARNING!

Warning of hazardous or unknown feed chemical

Should a hazardous or unknown feed chemical be

used, it may escape from the hydraulic components

when working on the pump

.

– Take appropriate protective measures before

working on the pump (protective eyewear, protective

gloves, ...). Read the safety data sheet on the feed

chemical.

– Drain and flush the liquid end before working on the

pump.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Depressurise the system prior to undertaking any

maintenance or repair work!

CAUTION!

Warning of feed chemical spraying around

An unsuitable feed chemical can damage the parts of

the pump contacted by the chemical

.

– Take into account the resistance of the material

contacted by the chemical when selecting the feed

chemical - refer to the ProMinent

®

resistance list

in the product equipment catalogue or at

www.prominent.com

.

CAUTION!

Danger of personal and material damage

The use of untested third party parts can result in

damage to personnel and material damage

.

– Only fit parts to dosing pumps, which have been

tested and recommended by ProMinent.

CAUTION!

Danger

from incorrectly operated or inadequately main‐

tained pumps

Danger can arise from a poorly accessible pump due to

incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

CAUTION!

Warning of illegal operation

Observe the regulations that apply where the unit is to

be installed

.

8

Page 9

Information in the event of an emer‐

gency

Safety Chapter

The pump cannot be de-energised!

In

the event of an electrical accident, disconnect the mains cable from

the mains or press the emergency cut-off switch fitted on the side of

the system!

Should feed chemical leak out, refer to the feed chemical's safety

data sheet. To switch off the pump in such an event, disconnect the

mains cable from the mains or press the emergency cut-off switch

fitted on the side of the system. If necessary depressurise the

hydraulic system around the pump.

Qualification of personnel

Activity Qualification

Storage, transport, unpacking Technical personnel

Installation, installation of

hydraulic system

Electrical Installation Electrician

Operation Instructed personnel

Maintenance, repair Technical personnel

Decommissioning, disposal Technical personnel

Troubleshooting Technical personnel, electri‐

Electrician

Electricians

on electrical systems and recognise and avoid possible hazards

independently based on his/her technical training and experience, as

well as knowledge of pertinent standards and regulations.

Electricians should be specifically trained for the working environ‐

ment in which the are employed and know the relevant standards

and regulations.

Electricians must comply with the provisions of the applicable statu‐

tory directives on accident prevention.

Instructed personnel

The instructed personnel have been instructed by the operator in a

training session about the tasks allocated to them and potential

hazards with incorrect and improper conduct.

Technical personnel

Technical personnel are deemed to be people, who are able to

complete the tasks allocated to them and recognise and avoid

hazards independently based on his/her technical training and expe‐

rience, as well as knowledge of pertinent regulations.

are deemed to be people, who are able to complete work

Technical personnel

cian, instructed personnel

Sound Pressure Level

9

The sound pressure level is < 70 dB (A)

at a maximum stroke length, maximum stroke rate, maximum

counter pressure (water) according to:

DIN EN 12639 (Noise testing on liquid pumps).

Page 10

Storage, Transport and Unpacking

4 Storage, Transport and Unpacking

Safety information

WARNING!

It is prohibited to ship pumps for radioactive media

They will also not be accepted by ProMinent!

WARNING!

Only return metering pumps for repair in a cleaned state

and with a flushed liquid end - refer to the chapter on

decommissioning! Should safety precautions neverthe‐

less be necessary, in spite of carefully cleaning the

pumps, the requisite information must be entered on the

Decontamination Declaration form.

The Decontamination Declaration form constitutes an

integral part of an inspection/repair order. A unit can only

be inspected or repaired if a Decontamination Declara‐

tion form has been completed correctly and in full by an

authorised and qualified person on behalf of the pump

operator.

The "Decontamination Declaration" form can be found

in the Appendix or at

www.prominent.com

!

.

Scope of delivery

CAUTION!

Danger of environmental and material damage

The unit can be damaged or oil may escape due to

incorrect or improper storage or transportation

– The unit should only be stored or transported in a

well packaged state - preferably in its original pack‐

aging.

– Only transport the unit with the locking screw - not

the bleed plug - fitted to the oil filling opening.

– The packaged unit should also only be stored or

transported in accordance with the stipulated

storage conditions.

– The packaged unit should be protected from mois‐

ture and the ingress of chemicals.

Compare the delivery note with the shipment:

n Metering pump

n Product-specific operating instructions with EC Declaration of

Conformity

n "General Operating Instructions ProMinent® Motor-Driven

Metering Pumps and Hydraulic Accessories".

!

Storage

Personnel:

1. Place the caps on the valves.

2. Preferably place the pump on a pallet

n

Technical personnel

.

10

Page 11

Storage, Transport and Unpacking

3. Cover

Store the pump in a dry, sealed place in the following ambient condi‐

tions.

the pump with a tarpaulin cover - allowing for rear venti‐

lation.

Ambient Conditions

Specification Value Unit

Minimum storage and transport

temperature

Maximum storage and transport

temperature

Maximum air humidity * 95 % rel.

* non-condensing

-10 °C

+50 °C

humidity

11

Page 12

1

3

4

P_PL_0002_SW

2

5

6

Overview of the Unit and Control Elements

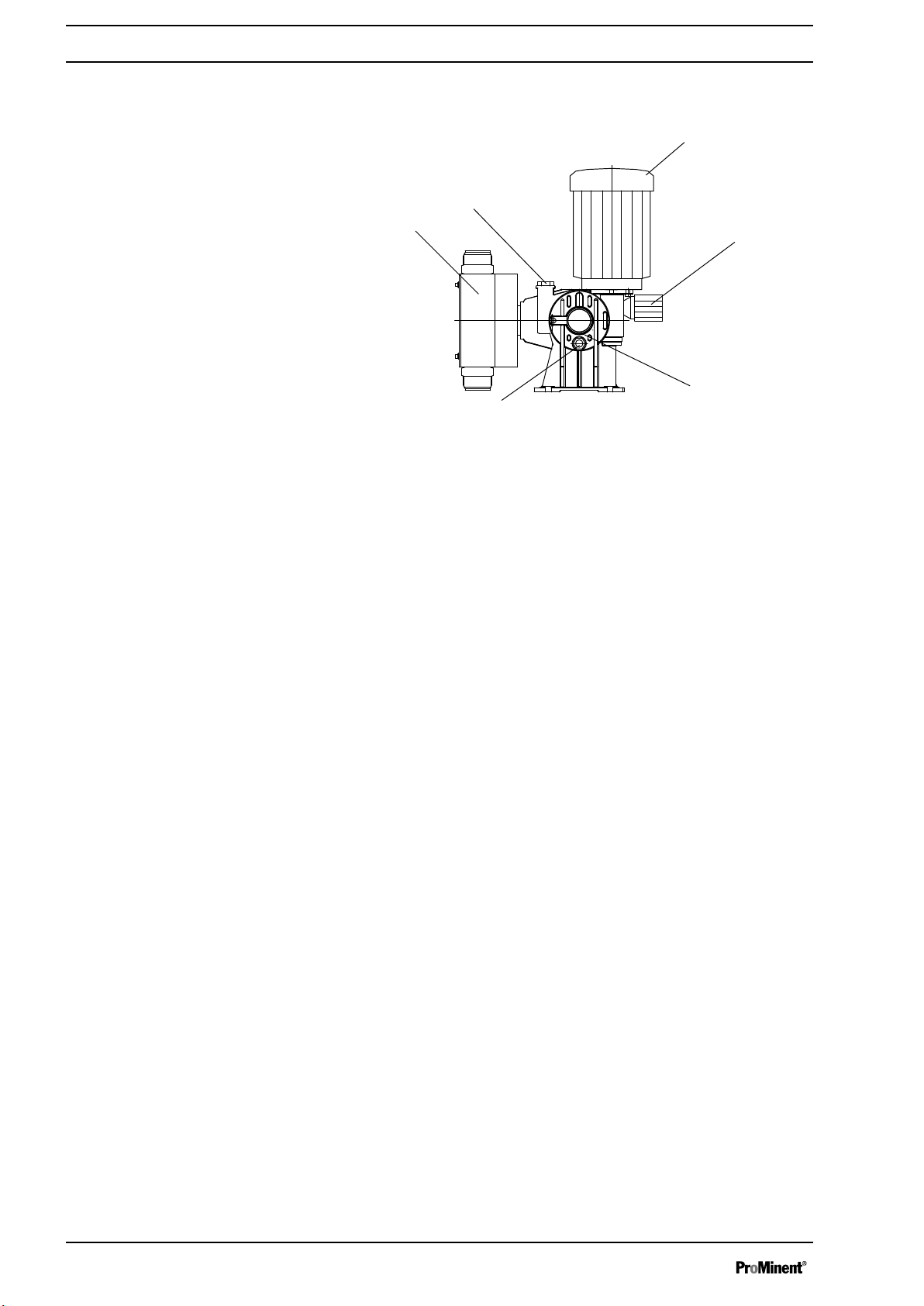

5 Overview of the Unit and Control Elements

Fig. 2: Complete overview

1 Drive motor

2 Bleed plug / Locking plug

3 Liquid end

4 Oil drain screw

5 Drive unit

6 Stroke length adjustment knob

not shown Oil level indicator (on rear)

12

Page 13

6 Functional Description

1

2

3

6

4

5

7

P_PL_0003_SW

0

s s

a)

180 360 0

b)

180 360

ω ω

P_PL_0009_SW

6.1 Drive Unit

Functional Description

The metering pump is an oscillating displacement pump, the stroke

length of which can be adjusted

pump. A worm gear (2) reduces the drive rotation of the pump. An

eccentric cam (3) converts it together with the receiving fork (8) into

an oscillating movement of the driving rod (4). A return spring (5)

presses the receiving fork together with the driving rod in a force-fit

manner against the eccentric cam and thus triggers the return

stroke. The stroke length can be adjusted by the stroke adjustment

knob (6) and the shaft (7). The different stroke lengths are in effect

caused by the limitation of the return stroke (cf.

stroke movement ” on page 13

motion to the diaphragm.

. An electric motor (1) drives the

Ä “Illustration of the

). The driving rod transmits the stoke

Illustration of the stroke movement

Fig. 3: Cross-section through drive unit

1 Electric motor

2 Worm gear

3 Eccentric cam

4 Driving rod

5 Return spring

6 Stroke adjustment knob

7 Shaft

8 Receiving fork

Fig. 4: Stroke movement at a) maximum stroke length and b) reduced

stroke length.

s Stroke velocity

⍵ Angle of rotation of eccentric cam

+ Pressure stroke

- Suction stroke

13

Page 14

Functional Description

6.2 Liquid End

The diaphragm (3) hermetically closes the pump volume of the

dosing

soon as the diaphragm (3) is moved in the dosing head and the feed

chemical flows out of the dosing head through the discharge valve

(1). As soon as the diaphragm (3) is moved in a counter direction,

the discharge valve (1) closes due to the negative pressure in the

dosing head and fresh feed chemical flows through the suction valve

(4) into the dosing head. One cycle is thus completed.

head (2) towards the outside. The suction valve (4) closes as

Fig. 5: Cross-section through the liquid end

1 Discharge valve

2 Dosing head

3 Diaphragm

4 Suction valve

14

Page 15

7 Assembly

Assembly

CAUTION!

Maintenance to prevent personal and material damage

Also refer to the "General Operating Instructions ProM‐

inent® Motor-Driven Metering Pumps and Hydraulic

Accessories"!

CAUTION!

Danger of environmental and material damage

The unit can be damaged or oil may escape due to

incorrect or improper storage or transportation

– The unit should only be stored or transported in a

well packaged state - preferably in its original pack‐

aging.

– Only transport the unit with the locking screw - not

the bleed plug - fitted to the oil filling opening.

– The packaged unit should also only be stored or

transported in accordance with the stipulated

storage conditions.

– The packaged unit should be protected from mois‐

ture and the ingress of chemicals.

!

CAUTION!

Warning about personal and material damage

Personal

is operated outside of the permissible ambient condi‐

tions.

– Please observe the permissible ambient conditions

and material damage may be caused if the unit

- refer to the chapter entitled "Technical Data".

15

Page 16

Installation

8 Installation

8.1 Hydraulic Installation

WARNING!

Warning of feed chemical reactions to water

Feed chemicals that should not come into contact with

water may react to residual water in the liquid end that

may originate from works testing

– Blow the liquid end dry with compressed air through

the suction connector.

– Then flush the liquid end with a suitable medium

through the suction connector.

CAUTION!

Maintenance to prevent personal and material damage

Also refer to the "General Operating Instructions ProM‐

inent® Motor-Driven Metering Pumps and Hydraulic

Accessories"!

.

8.2 Electrical Installation

Personnel:

n

Technical personnel

WARNING!

Risk of electric shock

The

electrical installation of the unit may only be under‐

taken by technically trained personnel with a proven

qualification.

CAUTION!

Maintenance to prevent personal and material damage

Also refer to the "General Operating Instructions ProM‐

inent® Motor-Driven Metering Pumps and Hydraulic

Accessories"!

CAUTION!

The pump can be damaged

pump can be damaged if the motor drives the pump

The

in the wrong direction.

– When wiring the motor, pay due care and attention

to the correct direction of rotation indicated by the

arrow on the motor housing (cf. diagram below).

16

Page 17

P_SI_0012_SW

Fig. 6: Direction of rotation of motor

–

Key motor data can be found on the unit specification

label.

–

The terminal wiring diagram is located in the terminal

box.

–

The motor can only be wired in star (Y) configura‐

tion.

Installation

Personnel:

n

Electrician

17

Page 18

0

1

9

P_PL_0006_SW

Commissioning

9 Commissioning

Safety information

Fitting the bleed plug

CAUTION!

Maintenance to prevent personal and material damage

Also refer to the "General Operating Instructions ProM‐

inent® Motor-Driven Metering Pumps and Hydraulic

Accessories"!

CAUTION!

Possible environmental and material damage

The locking screw on the oil filling opening is factory

fitted and, during operation, prevents any pressure

compensation between the drive housing and the

surroundings. This ensures that oil can be pushed out of

the drive housing.

– Replace the locking screw on the oil filling opening

with the bleed plug supplied.

– Retain the locking screw for subsequent transporta‐

tion of the unit.

-

Checking the oil level

Checking the direction of rotation

Adjusting the stroke length

When the pump is idle, check whether the oil level in the pump is in

the middle of the oil level indicator

This will rule out the pump losing oil and suffering damage.

When commissioning the unit, check whether the drive motor is

rotating correctly - check this against the arrow on the motor housing

or the diagram in the chapter entitled "Electrical Installation."

CAUTION!

– Only adjust the stroke length when the pump is

running.

–

Only turn the stroke adjustment knob one revolu‐

tion, corresponding to 100% stroke length. The

figures on the stroke adjustment knob x 10 corre‐

spond to the stroke length set in % - see diagram

below.

.

Fig. 7: 1 revolution = 100 % stroke length

18

Page 19

Commissioning

Correctly adjusting the pump:

n Select as large a stroke length as possible for viscous feed

chemicals.

n Select as large a stroke length as possible for outgassing feed

chemicals.

n Select as high a stroke rate as possible for good mixing

n Do not set the stroke length at less than 30 % for precise

dosing.

.

Eliminating priming problems (only with TTT and SST)

Should you experience priming problems during

commissioning, unscrew the valves from the liquid

end, place on a solid surface and, using a brass bar

(2), gently tap with a hammer (1) the PTFE ball seat disc

through the valve ball - see diagram below. Then allow

the valves to prime in a damp state.

Fig. 8: Tapping the valve seat disc

1 Hammer, approx. 300 g

2 Brass bar Ø 9 x approx. 200 mm

19

Page 20

Maintenance

10 Maintenance

WARNING!

is mandatory that you read the safety information and

It

specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Depressurise the system before commencing work

on hydraulic parts!

Standard liquid ends:

Interval Maintenance task Personnel

After approx.

ating hours

Quarterly* n Check that the dosing lines are fixed firmly to the liquid

Changing gear oil

5,000 oper‐

Change gear oil - refer to "Changing gear oil" in this chapter. Instructed

end.

n Check

n Check the tightness of the entire liquid end - particularly

around the leakage hole!

n Check that the flow is correct: allow the pump to prime

briefly.

n Check that the electrical connections are intact

n Check that the dosing head screws are tight

that the suction valve and discharge valve are tight.

* under normal loading (approx. 30 % of continuous operation)

Under heavy loading

Draining gear oil

1. Remove the bleed plug

2. Place an oil tray under the oil drain screw

3. Unscrew the oil drain screw

4. Allow the gear oil to run out of the drive

5. Replace the oil drain screw

(e.g. continuous operation): Shorter intervals.

(1).

(2) from the drive housing.

(2) with a new seal.

personnel

Technical

personnel

(2).

.

Filling gear oil

1. Start up the pump.

2. Slowly fill gear oil through the opening for the bleed plug

until the oil level indicator (3) is half-covered.

3. Allow the pump to run for a further 1... 2 minutes.

4. Replace the bleed plug

(1).

(1)

20

Page 21

Tightening torque

Maintenance

Specification Value Unit

Tightening torque for screws: 9.0 Nm

21

Page 22

Repair

11 Repair

Safety information

WARNING!

is mandatory that you read the safety information and

It

specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

WARNING!

Contact with the feed chemical

Parts that come into contact with the feed chemical

become uncovered and touched during repairs.

– Protect yourself from the feed chemical should it be

hazardous. Read the safety data sheet on the feed

chemical.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents

if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Depressurise the system prior to undertaking any

maintenance or repair work!

11.1 Cleaning Valves

Repairing ball valves

Personnel:

CAUTION!

Warning about personal and material damage

Feed chemical may escape from the liquid end

example, if ball valves not repaired correctly.

– Only use new components that fit your valve - both

– Pay attention to the flow direction of the discharge

1. Screw on the valve cap (5) on the suction side

2. Carefully remove the parts from the valve body

3. Replace the worn parts

4. Clean the remaining parts

5. Check all parts.

6. Insert the valve ball (3) and the valve seat

7. Screw on the valve cap (5).

n

Technical personnel

in terms of shape and chemical resistance!

and suction connections when fitting the valve.

.

.

(4).

, for

- see diagram.

(2).

22

Page 23

1

2

3

4

5

P_SI_0013_SW

Fig. 9: Simple cross-section through ball valve

1 Flat seal

2 Valve body

3 Valve ball

4 Valve seat

5 Valve cap

Repair

23

Page 24

Repair

11.2 Replacing the Diaphragm

WARNING!

Depending on the design

feed chemical may have accumulated behind the

diaphragm in the backplate following a leak!

– Take this feed chemical into consideration when you

are planning a repair - especially if it is hazardous!

, a few cubic centimetres of

Personnel:

n If necessary take protective measures.

n Read the safety data sheet on the feed chemical.

n Depressurise the system.

1. Empty

the feed chemical to run out; flush out with a suitable

medium; flush the liquid end thoroughly when using hazardous

feed chemicals!

2. With

end position at 0 % stroke length (the drive shaft is then difficult

to turn).

3. Switch off the pump.

4. Unscrew the hydraulic connectors on the discharge and

suction side.

5. Remove the 6 screws on the dosing head

6. Remove the dosing head

7. Loosen

wards turn in a clockwise direction.

8. Unscrew the diaphragm fully from the drive shaft

9. Tentatively screw the new diaphragm anticlockwise onto the

drive shaft as far as its stop position.

ð

10. Should this not work, remove dirt or swarf out of the threads

and screw the diaphragm correctly onto the drive shaft this

time.

11. Place the dosing head with the screws onto the diaphragm

the suction connector must be pointing downwards when the

pump is installed later.

the liquid end: Turn the liquid end upside down and allow

the pump running, move the stroke adjustment knob to its

the diaphragm from the drive shaft with a gentle back‐

The diaphragm is now sitting at the end position of the

thread.

n

Technical personnel

.

.

.

-

12. Tighten the screws gently to start with.

13. Start up the pump and adjust the stroke length to 100

14. Now

further tighten the screws crosswise. See below for tight‐

ening torque.

CAUTION!

Warning of escaping feed chemical

The liquid end may leak should it not be possible to

check the tightening torque of the screws.

» see next page

%.

24

Page 25

Repair

– Check the tightening torque of the screws after 24-

hours of operation

– Recheck the tightening torque again after three

months with PP dosing heads!

!

Tightening torque

Specification Value Unit

Tightening torque for screws: 9.0 Nm

25

Page 26

Troubleshooting

12 Troubleshooting

Safety information

WARNING!

Warning of hazardous or unknown feed chemical

Should a hazardous or unknown feed chemical be

used, it may escape from the hydraulic components

when working on the pump

– Take appropriate protective measures before

working on the pump (protective eyewear, protective

gloves, ...). Read the safety data sheet on the feed

chemical.

– Drain and flush the liquid end before working on the

pump.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Depressurise the system prior to undertaking any

maintenance or repair work!

.

WARNING!

Danger of an electric shock

Personnel working on electrical parts can be electro‐

cuted

if all electrical lines carrying current have not been

disconnected.

– Disconnect the supply cable before working on the

motor and prevent it from being reconnected acci‐

dentally.

– Any separately driven fans, servo motors, speed

controllers or diaphragm rupture sensors fitted

should also be disconnected.

– Check that the supply cables are de-energised.

Tasks

Error description Cause Solution Personnel

Pump does not prime in spite of

full

stroke motion and bleeding.

Pump does not reach high pres‐

sure rates.

The valves are dirty or

worn.

The valves are dirty or

worn.

The motor is wired incor‐

rectly.

Repair the valves - see chapter

entitled "Repair".

Repair the valves - see chapter

entitled "Repair

1.

Check the mains voltage and

mains frequency.

2. Wire the motor correctly.

".

Technical

personnel

Technical

personnel

Electrician

The mains voltage has

failed.

The drive motor is very hot. The discharge line is seri‐

ously constricted.

Eliminate the cause. Electrician

Rectify any constriction of the

discharge line

.

Technical

personnel

26

Page 27

13 Decommissioning

Decommissioning

Decommissioning

WARNING!

Danger from chemical residues

is normally chemical residue in the liquid end and

There

on the housing after operation. This chemical residue

could be hazardous to individuals.

– It is mandatory that the safety information relating to

the "Storage, Transport and Unpackaging" chapter

is read before shipping or transporting the unit.

– Thoroughly clean the liquid end and the housing of

chemicals and dirt. Read the safety data sheet on

the feed chemical.

WARNING!

Warning of hazardous or unknown feed chemical

Should a hazardous or unknown feed chemical be

used, it may escape from the hydraulic components

when working on the pump.

– Take appropriate protective measures before

working on the pump (protective eyewear, protective

gloves, ...). Read the safety data sheet on the feed

chemical.

– Drain and flush the liquid end before working on the

pump.

Final decommissioning

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents

if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Depressurise the system prior to undertaking any

maintenance or repair work!

CAUTION!

Danger of damage to the unit

into account the information in the "Storage, Trans‐

Take

port and Unpackaging" chapter if the system is decom‐

missioned for a temporary period.

Personnel:

1. Disconnect the pump from the mains power supply

2. Empty the liquid end by turning the pump upside down and

allowing the feed chemical to run out

3. Flush the liquid end with a suitable medium

head thoroughly when using hazardous feed chemicals!

4. Drain

the gear oil - refer to the chapter entitled "Maintenance".

n

Technical personnel

.

.

; flush the dosing

Temporary decommissioning

27

Page 28

Decommissioning

Disposal

Additional work: refer to the chapter on "Storage, Transport and

Unpacking

Personnel:

".

n

Technical personnel

CAUTION!

Environmental hazard due to gear oil

The pump contains gear oil that can cause damage to

the environment.

– Drain the gear oil from the pump.

– Note

the pertinent regulations currently applicable in

your country!

28

Page 29

14 Technical Data

14.1 Performance Data

Plasma with 0.2 kW motor, 400 V, 50

Hz, 1440 rpm

Technical Data

Type Minimum flow rate at maximum back

pressure

bar l/h ml/stroke Strokes/

05050 5 50 8.0 105 2 1.5 1 1/4" - 20

05065 5 65 7.8 140 2 1.5 1 1/4" - 20

05090 5 90 14.3 105 2 1.5 1 1/4" - 20

05120 5 120 14.3 140 2 1.5 1 1/4" - 20

05200 5 200 31.8 105 4 1.5 1 1/4" - 20

05260 5 260 31.0 140 4 1.5 1 1/4" - 20

All figures apply to water at 20 °C.

The suction lift applies to a filled suction line and filled liquid end

when installed correctly.

Accuracy

Specification Value Unit

Reproducibility ± 2 % *

* - at constant conditions and min. 30 % stroke length

Maximum

stroke rate

min

Stroke

length

mm m WS G-DN

Suction lift Connector

size

-

Materials that come into contact with

the feed chemical

Material version Liquid end Suction/

Discharge

connector

PC PVC PVC EPDM PTFE EPDM

PP Polypropylene Polypropylene EPDM PTFE EPDM

TT PTFE with

carbon

SS Stainless steel

SS 316

Shipping weight

PTFE with

carbon

Stainless steel

SS 316

Material version Shipping weight in kg

PP, PC, TT 12.1

SS 14.5

Seals Valve balls Valve seats

PTFE Ceramics PTFE

PTFE Stainless steel

SS 316

PTFE

14.2 Degree of Protection and Safety Requirements

Degree of protection

Protection against contact and humidity:

IP

55 in accordance with IEC 529, EN 60529, DIN VDE 0470 Part 1

29

Page 30

Technical Data

Safety requirements

Degree of protection:

1 - Mains power connection with protective earth conductor

14.3

Ambient Conditions

14.3.1 Temperatures

Pump, compl.

PP liquid end

PC liquid end

Specification Value Unit

Storage and transport temperature -10 ... +50 °C

Ambient temperature in operation

(drive):

Specification Value Unit

Max. temperature long-term at max.

operating pressure

Max. temperature for 15 min at max. 2

bar

Minimum temperature -10 °C

Specification Value Unit

Max. temperature long-term at max.

operating pressure

Max. temperature for 15 min at max. 2

bar

-10 ... +45 °C

45 °C

70 °C

45 °C

60 °C

TT liquid end

SS liquid end

Minimum temperature -10 °C

Specification Value Unit

Max. temperature long-term at max.

operating pressure

Max. temperature for 15 min at max. 2

bar

Minimum temperature -10 °C

Specification Value Unit

Max. temperature long-term at max.

operating pressure

Max. temperature for 15 min at max. 2

bar

Minimum temperature -10 °C

45 °C

120 °C

45 °C

120 °C

30

Page 31

14.3.2 Climate

14.4 Gear Oil

Technical Data

Specification Value Unit

Maximum air humidity *: 95 % rel.

humidity

* non-condensing

14.5 Sound Pressure Level

Sound Pressure Level

Manufacturer Name Viscosity class

(ISO 3442)

Shell Omala HD 320 0.25 l

The sound pressure level is < 70 dB (A)

at a maximum stroke length, maximum stroke rate, maximum

counter pressure (water

DIN EN 12639 (Noise testing on liquid pumps).

) according to:

Oil volume

31

Page 32

410

45

138

310

222

95

218

1 1/4" BSP

56

110

198

126

80

61

130

Ø 9

Ø25

3/4" BSP

Ø25

230

45

138

310

222

95

218

1 1/4" BSP

56

110

183

110

80

61

90 x 63

Ø 9

P_PL_0008_SW

Appendix

15 Appendix

15.1 Dimensional Drawings

Dimensional drawing of Plasma

Fig. 10: Dimensional drawing of Plasma PSMa - dimensions in mm

Dimensional drawing of Plasma

without motor

Fig. 11: Dimensional drawing of Plasma PSMa without motor - dimensions in mm

32

Page 33

15.2 Diagrams for Setting the Metering Capacity

10 20 30 40 50 60 70 80 90 100

10

20

30

40

50

60

70

1 2 3 4 5

50

60

70

80

90

100

10 20 30 40 50 60 70 80 90 100

10

20

30

40

50

60

70

80

90

100

1 2 3 4 5

100

110

120

130

140

150

110

120

10 20 30 40 50 60 70 80 90 100

5

10

15

20

25

30

35

40

45

50

s [%]

s [%]

s [%]

s [%]

C [l/h] PSMa 05050

C [l/h]

C [l/h]

C [l/h]

C [l/h]

C [l/h] PSMa 05065

C [l/h] PSMa 05090

C [l/h] PSMa 05120

1 2 3 4 5

50

55

60

65

70

p [bar]

p [bar]

p [bar]

p [bar]

55

10 20 30 40 50 60 70 80 90 100

10

20

30

40

50

60

70

80

90

100

1 2 3 4 5

80

90

100

110

B

A

B

A

B

A

B

A

Appendix

Fig. 12: A) Metering capacity C at medium back pressure according to the stroke length for maximum stroke

rate. B) Metering capacity C at medium back pressure according to the back pressure p.

33

Page 34

10 20 30 40 50 60 70 80 90 100

20

40

60

80

100

120

140

160

180

200

1 2 3 4 5

260

270

280

290

300

220

240

260

10 20 30 40 50 60 70 80 90 100

20

40

60

80

100

120

140

160

180

200

1 2 3 4 5

180

200

220

s [%]

C [l/ h] PSMa 05200

C [l/ h]

p [bar]

B

A

s [%]

C [l/ h] PSMa 05260

C [l/ h]

p [bar]

B

A

Appendix

Fig. 13: A) Metering capacity C at medium back pressure according to the stroke length for maximum stroke

rate. B) Metering capacity C at medium back pressure according to the back pressure p.

15.3 Ordering Information

15.3.1 Spare Parts Sets

Spare parts sets normally include the wearing parts of a liquid end.

Standard delivery for material version PPE

1 - Diaphragm

1 - Suction valve

1 - Discharge valve

2 - Valve balls

1 - Seal set

Standard delivery for material version SST

Spare parts sets for types 05050,

05065

1 - Diaphragm

2 - Valve balls

1 - Seal set

Liquid end Material version Part no.

FM 130 - DN 20 PP PMIN-3303001

FM 130 - DN 20 PC PMIN-3303002

FM 130 - DN 20 SS PMIN-3303003

FM 130 - DN 20 TT PMIN-3303004

34

Page 35

Spare parts sets for types 05100,

05120, 05200

, 05260

Appendix

Liquid end Material version Part no.

FM 260 - DN 20 PP PMIN-3303005

FM 260 - DN 20 PC PMIN-3303006

FM 260 - DN 20 SS PMIN-3303007

FM 260 - DN 20 TT PMIN-3303008

PMIN = Heidelberg ProMinent Fluid Controls India Pvt. Ltd.

15.3.2

Diaphragms for types 05050, 05065

Diaphragms for types 05100, 05120,

05200, 05260

Diaphragms

Liquid end Part no.

FM 130 PMIN-3301019

Liquid end Part no.

FM 260 PMIN-3301020

PMIN = Heidelberg ProMinent Fluid Controls India Pvt. Ltd.

35

Page 36

Appendix

15.4 EC Declaration of Conformity

Fig. 14

36

Page 37

15.5 Decontamination Declaration

Declaration of Decontamination

(see download: www.prominent.com)

Because of legal regulations and for the safety of our employees and operation equipment, we need the „declaration of decontamination”, with your signature, before your order can be handled.

Please make absolutely sure to include it with the shipping documents, or – even better – attach it to the

outside of the packaging.

Please return your products to:

ProMinent Dosiertechnik GmbH

Department: Reparaturabteilung

Im Schuhmachergewann 5-11

69123 Heidelberg, Germany

Please direct your inquiry to:

0049 6221 8420

customercare@prominent.de

Type of instrument / sensor: _________________________ Serial number: __________________________

Process data: Temperature: ___________________ [° C] Pressure: _________________ [bar]

Mediums and warnings:

Medium/

Concentration

Identi

-

fication

flammable

toxic

corrosive

harmful

/

irritant

other*harmless

Process

medium

Medium

for pro-

cess-

cleaning

Returned

part

cleaned

with

* explosive; oxidising; dangerous for the environment; biological risk; radioactive

Please tick should one of the above be applicable, include security sheet and, if necessary, special handling instructions.

Reason for return:

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

Company data:

Company: ______________________ Phone number: ______________________

Contact person: ______________________ Fax: ______________________

Straße: ______________________ E-Mail: ______________________

Address: ______________________ Your order No: ______________________

„We hereby certify that the returned parts have been carefully cleaned. To the best of our knowledge they

are free from any residues in dangerous quantities.”

_________________________ _________________________________________________

Place, date Company stamp and legally binding signature

Appendix

Fig. 15

37

Page 38

Index

16 Index

A

About this Pump .................................................... 6

Accuracy ............................................................. 29

Air humidity ......................................................... 31

Ambient Conditions ............................................. 30

Appendix ............................................................. 32

Assembly .............................................................

B

Bleed plug ........................................................... 12

C

Capacity diagrams .............................................. 33

Cleaning Valves .................................................. 22

Climate ................................................................ 31

Commissioning .................................................... 18

Connector size .................................................... 29

Control Elements ................................................. 12

Correct and Proper Use......................................... 7

D

Declaration of Conformity .................................... 36

Decommissioning ................................................ 27

Decontamination Declaration .............................. 37

Degree of protection ............................................ 29

Diagrams ............................................................. 33

Diaphragm ........................................................... 14

Diaphragms ......................................................... 35

Dimensional Drawings ........................................ 32

Direction of rotation of ......................................... 17

Discharge valve ................................................... 14

Disposal .............................................................. 28

Dosing head ........................................................ 14

Drive Unit ............................................................ 13

E

EC Declaration of Conformity .............................. 36

Emergency ............................................................ 9

Emptying the liquid end ....................................... 27

Explanation of the safety information .................... 7

F

Flow rate ............................................................. 29

Functional Description ......................................... 13

G

Gear Oil ............................................................... 31

I

Identcode .............................................................. 5

Information in the event of an emergency ............. 9

Installation ........................................................... 16

IP ......................................................................... 29

15

L

Leakage hole ....................................................... 20

Liquid end ............................................................ 12

Liquid End ........................................................... 14

Locking screw ..................................................... 12

M

Maintenance ........................................................ 20

Materials that come into contact with the feed

chemical .............................................................. 29

motor ................................................................... 17

O

Oil drain screw .................................................... 12

Ordering Information ........................................... 34

Overview of the Unit ............................................ 12

P

Protection against contact and humidity ............. 29

Q

Qualification of personnel....................................... 9

R

Radioactive ......................................................... 10

Repair .................................................................. 22

Replacing the Diaphragm .................................... 24

S

Safety Chapter ...................................................... 7

Safety Declaration Form ..................................... 10

Safety requirements ............................................ 29

Scope of delivery ................................................. 10

Shipping weight ................................................... 29

Sound Pressure Level...................................... 9, 31

Spare Parts Sets ................................................. 34

Storage ................................................................ 10

Storage and transport temperature ..................... 30

Stroke length ....................................................... 18

Stroke length adjustment knob ........................... 12

Suction lift ............................................................ 29

Suction valve ....................................................... 14

T

Temperatures ...................................................... 30

Transport ............................................................. 10

Troubleshooting .................................................. 26

U

Unpacking ........................................................... 10

W

Warning sign.......................................................... 7

Weight ................................................................. 29

38

Loading...

Loading...