Page 1

Drive unit

Orlita® Evolution

Operating instructions

These operating instructions form part of an operating manual and are only valid if used in conjunction with the documents

in this operating manual.

EN

983748 BA ORL 008 06/16 EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Page 2

Table of contents

1

Safety.................................................................................... 3

2 Functional Description of the Drive Unit................................ 9

3 Assembly............................................................................ 10

4 Installation, Electrical.......................................................... 15

5 Start Up and Operation....................................................... 20

5.1 Tests Prior to Start Up of the Pump............................ 22

5.2 Testing Directly After the Pump has Started Up......... 24

5.3 Testing 0.5 to 1 Hour After the Pump has Started...... 25

5.4 Bleeding the Diaphragm Holder.................................. 25

6 Maintenance....................................................................... 26

7

Carrying out repairs............................................................ 27

8 Remedying Faults on the Drive Unit................................... 28

9 Decommissioning and Disposal.......................................... 30

10 Index................................................................................... 31

Table of contents

2

Page 3

1 Safety

WARNING!

Observe the safety chapter and safety information in

the other documents.

Note the information on the "Technical Data Sheet" for

the pump.

The following signal words are used in these operating instructions

to identify different severities of a hazard:

Signal word Meaning

WARNING Denotes a possibly hazardous situation. If this is

disregarded, you are in a life-threatening situation

and this can result in serious injuries.

CAUTION Denotes a possibly hazardous situation. If this is

disregarded, it could result in slight or minor inju‐

ries or material damage.

The following warning signs are used in these operating instruc‐

tions to denote different types of danger:

Warning signs Type of danger

Warning – high-voltage.

Warning – hot surface.

Warning – danger zone.

n Only operate the pump in premises at risk from explosion with

the appropriate nameplate for pumps for use in areas at risk of

explosion in accordance with the European guidelines.

Ensure that the explosion group, category and degree of pro‐

tection specified on the label corresponds to or is superior to

the conditions prevalent in the intended application.

n Only use the pump after it has been correctly installed and

started up in accordance with the technical data and specifica‐

tions contained in the operating manual.

n The pump is intended for use in dry, ventilated rooms with a

non-aggressive atmosphere.

The pump has to have a different design for other environ‐

ments, such as outdoors, areas at risk from explosion, drilling

rigs etc... .

n All other uses or modifications are prohibited.

Explanation of the safety information

Warning signs denoting different

types of danger

Intended use

Safety

3

Page 4

n Never operate pumps in premises at risk from explosion

without the relevant nameplate (and the respective EC Decla‐

ration of Conformity) for pumps for use in areas at risk from

explosion.

n Do not expose the ATEX design to ionising radiation, electro‐

magnetic high frequency radiation within the range of 104 ...

3x1015 Hz or ultrasound without putting in place measures in

line with EN 1127-1.

n The pump is not suitable for portable operation.

n The pump is only intended for industrial use.

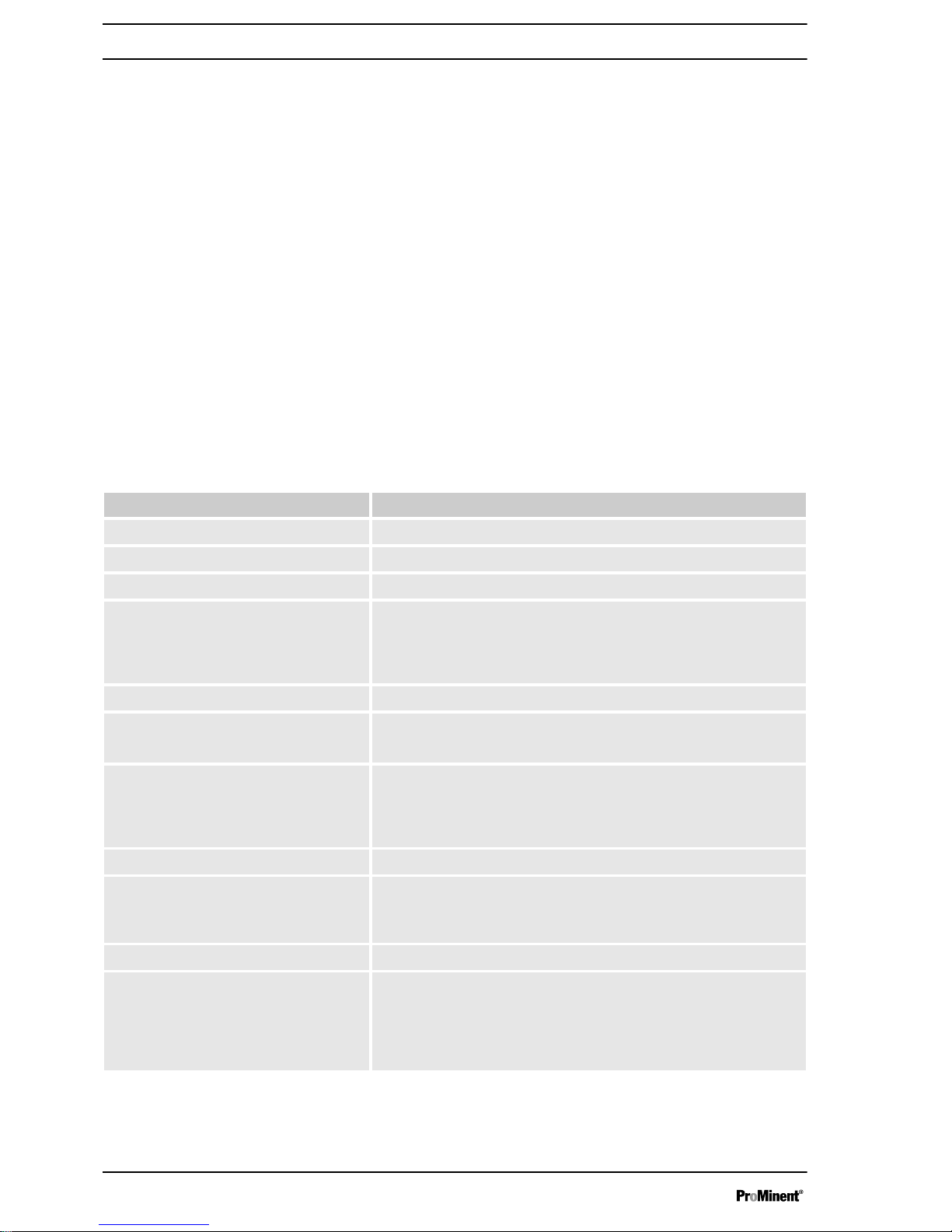

n Only allow trained and authorised personnel to operate the

pump - see the following table.

n This pump is designed to be operated in an upright position by

an adult who does not suffer from impaired vision.

n You have a responsibility to adhere to the information con‐

tained in the operating instructions at the different phases of

the unit's service life.

n You have a responsibility to observe the information contained

in the operating instructions for the auxiliary equipment at the

different phases of their respective service lives.

Task Qualification

Transport Qualified personnel

Storage, unpacking Instructed person

Assembly Technical personnel, Service

Planning the hydraulic installation Qualified personnel who have a thorough knowledge of oscillating

metering pumps

In areas at risk from explosion: ATEX qualified person, ATEX

electrical technician

Hydraulic installation Technical personnel, Service

Installation, electrical Electrical technician,

In areas at risk from explosion: ATEX electrical technician

Start up Qualified personnel

In areas at risk from explosion: Qualified personnel with ATEX

training; checking of the electrical installation: recognised compe‐

tent person

Operation Instructed person

Maintenance, repair Technical personnel, Service

In areas at risk from explosion: ATEX qualified person, ATEX

electrical technician

Decommissioning, disposal Technical personnel, Service

Troubleshooting Qualified person, electrical technician, instructed person, service

- depending on the requirement

In areas at risk from explosion: ATEX electrical technician;

checking of the electrical installation: recognised competent

person

Explanation of the table:

Qualified personnel

Qualification of personnel

Safety

4

Page 5

A qualified employee is deemed to be a person who is able to

assess the tasks assigned to him and recognise possible dangers

based on his technical training, knowledge and experience, as well

as knowledge of pertinent regulations.

Qualified personnel who open the hydraulic components of the

pump have to be able to recognise sealing surfaces so that they do

not become scratched.

Note:

A qualification of equal validity to a technical qualification can also

be gained by several years of employment in the relevant field of

work.

Electrical technician

An electrical technician is able to complete work on electrical sys‐

tems and recognise and avoid possible dangers independently

based on his technical training and experience, as well as knowl‐

edge of pertinent standards and regulations.

The electrical technician should be specifically trained for the

working environment in which he is employed and be conversant

with the relevant standards and regulations.

Make sure that the electrical technician complies with the provi‐

sions of the applicable statutory directives on accident prevention.

A qualification of equal validity to a technical qualification can also

be gained by several years of employment in the relevant field of

work.

Electrical technician with knowledge of ATEX explosion protection

The electrical technician with an additional explosion protection

qualification should be specifically trained for the work area in

which he is employed and be familiar with the relevant standards

and regulations. The electrical technician with an additional explo‐

sion protection qualification can work on electrical systems and

independently recognise and avoid possible dangers based on his

technical training and experience.

The electrical technician with an additional explosion protection

qualification is familiar with all the standards and regulations appli‐

cable to explosion protection, in particular, but not however exclu‐

sively, with all parts of EN 60079 [Electrical equipment for areas at

risk of a gas explosion].

The electrical technician with an additional explosion protection

qualification must comply with the provisions of the applicable stat‐

utory directives on accident prevention.

Recognised competent person

To carry out explosion hazard inspections the competent person

must have:

n Completed a relevant course of study or

n Have a comparable technical qualification or

n Another technical qualification combined with long-term experi‐

ence of safety technology.

Make sure that the person is familiar with the relevant body of

standards and regulations and has worked in the area for at least

one year. The person needs to have opportunities for an exchange

of experience.

Specific requirements are placed on competent persons who per‐

form tests on repaired devices/parts. They have to be recognised

by the responsible authorities (e.g. district council) in this respect.

Instructed person

Safety

5

Page 6

An instructed person is deemed to be a person who has been

instructed and, if required, trained in the tasks assigned to him and

possible dangers that could result from improper behaviour, as well

as having been instructed in the required protective equipment and

protective measures.

Service

The Service department refers to service technicians, who have

received proven training and have been authorised by ProMinent

to work on the system.

CAUTION!

These operating instructions include notes and

extracts from German regulations relating to the opera‐

tor's scope of responsibility. This information does not

discharge the operator from his responsibility as an

operator and is intended only to remind him or make

him aware of specific problem areas. This information

does not lay claim to being complete, nor applicable to

every country and every type of application, nor to

being unconditionally up-to-date.

WARNING!

Only use ATEX pumps in areas at risk from explosion

– Note the relevant regulations for the installation

and operation of equipment in areas at risk from

explosion.

– Observe the guidelines for intrinsically safe power

circuits.

– Adhere to the respective national regulations out‐

side of the EU.

– Ensure that installations in areas at risk from explo‐

sion are checked by a "recognised competent"

person. This applies specifically to intrinsically safe

power circuits.

– Only clean the pump outside of / in the absence of

explosive atmospheres.

WARNING!

Danger of injury to personnel and material damage

The pump must only be opened at those points

required to be opened by these operating instructions.

It may only be opened in other positions upon receipt

of written authorisation from the ProMinent head office,

Heidelberg.

WARNING!

Danger of slippage on the pump

Danger of injury from slipping.

– Never climb on the pump.

Safety information

Safety

6

Page 7

CAUTION!

Danger of personnel injury and material damage

The use of untested third party parts can result in per‐

sonnel injuries and material damage.

– Only fit parts to metering pumps, which have been

tested and recommended by ProMinent.

CAUTION!

Danger from incorrectly operated or inadequately

maintained pumps

Danger can arise from a poorly accessible pump due

to incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

–

Adhere to the maintenance intervals.

In the event of an electrical accident, disconnect the mains cable

from the mains or press the emergency cut-off switch fitted on the

side of the system!

If feed chemical escapes, also depressurise the hydraulic system

around the pump as necessary. Adhere to the safety data sheet for

the feed chemical.

Prior to commissioning the system or system component, it is the

responsibility of the system operator to obtain the latest safety data

sheet for the chemicals / equipment to be used with the system

from the supplier. Based on the information provided in the data

sheets concerning health and safety, water and environmental pro‐

tection, and taking into consideration the actual operating environ‐

ment on site, it is the responsibility of the operator to create the

legal framework for the safe operation of the system or system

component, such as for example the preparation of operating

instructions (operator's duties).

Secure all these parts in their place when using the pump.

Protective equipment May only be removed by*:

Protective cowling over the motor fan Service

Motor terminal box cover Electrical technician, ATEX electrical technician,

Service

Drive unit cover Technical personnel, Service

Only with multiple pumps: Connecting flange for

drive units

Technical personnel, Service

Other units and ancillary equipment: Their corre‐

sponding parts

Technical personnel, Service

Information in the event of an emer‐

gency

Safety information for operating

instructions

Safety equipment

Fixed, isolating protective equipment

Safety

7

Page 8

* Only if required by the operating instructions and if the mains

cable remains disconnected from the mains voltage. Make sure

that all protective equipment is refitted during operation.

Safety equipment May only be removed by*:

Only in areas at risk from explosion: Vent screw with

filter

Qualified employee, electrical technician, ATEX

electrical technician, Service

"Hot surface" label -

Earthing lines from motor and third-party electrical

parts

Electrical technician, ATEX electrical technician,

Service

Only with multiple pumps: Potential equalisation

lines between the drive units and base plate

Electrical technician, ATEX electrical technician,

Service

Other units and ancillary equipment: Their corre‐

sponding parts

Technical personnel, Service

* Only if required by the operating instructions and if the mains

cable remains disconnected from the mains voltage. Make sure

that all protective equipment is refitted during operation.

The operator must be able to:

n Perform a risk assessment

n Produce and attach a nameplate

n Issue an EC Declaration of Conformity

n Adapt the operating instructions, if necessary

n Correctly install the motor

n With ATEX motors: perform an ignition hazard assessment

Sound pressure level at maximum stroke length, maximum stroke

rate, maximum back pressure (water) - see "Evolution Data Sheet".

Small amounts of gear oil can evaporate out of the vent screws.

We recommend that you slightly ventilate the installation site.

Gear oil can escape from the pump in the event of specific faults,

damage, neglected maintenance, during commissioning and during

maintenance and repair work.

Additional safety equipment

Requirements, if the motor is installed

independently

Sound pressure level

Other emissions

Safety

8

Page 9

2 Functional Description of the Drive Unit

The stroke length of a drive unit can be set via its stroke adjust‐

ment wheel or an actuator (optional) or control drive (optional).

The pump's stroke rate can be changed by a frequency converter

(optional) if required.

One or more add-on drive units can be attached to the main drive

unit using 1 connecting set with a claw coupling.

General

Add-on drive unit

Functional Description of the Drive Unit

9

Page 10

3 Assembly

WARNING!

Danger of toppling over

The centre of gravity of the single pump with standing

motor is relatively high.

– Only remove the pump from the crane hook once it

is firmly connected to the base.

–

Compare the dimensions on the dimension sheet

with those of the pump.

1. Select a suitable motor - make sure that it corresponds to the

data from the "Motor data" table.

WARNING!

This is EX-relevant in areas at risk from explo‐

sion!

2. Fit the motor correctly on the flange (qualified personnel).

Observe the coupling operating instructions!

WARNING!

This is EX-relevant in areas at risk from explo‐

sion!

With a claw coupling: Make sure that the claw on the motor

shaft is fixed at the correct height – see Fig. Fig. 1.

3. ATEX pumps only: Ensure that there is also potential equali‐

sation between the motor and drive unit.

4. As you have converted an "incomplete machine" into a com‐

plete machine, you must:

n Perform an assessment of conformity

n Perform a risk assessment

n Produce an EC Declaration of Conformity

n Fit your own nameplate

n With ATEX pumps: additionally perform an ignition

hazard assessment.

n Complete the pump documentation / operating instruc‐

tions.

n ...

Motor installation - with designs

without a motor

Assembly

10

Page 11

QQ

P_HY_0060_SW

Fig. 1: Correct heigh of the clutch claw on the motor shaft

EF1a

Motor Motor flange Rotex Q

1.1 kW F200 24 1a 40

0.75 kW F200 24 1a 40

0.55 kW F160 19 1b 41

0.35 kW F160 19 1b 41

EF2a

Motor Motor flange Rotex Q

1.5 kW F200 24 1a 40

1.1 kW F200 24 1a 40

0.75 kW F200 24 1a 40

0.55 kW F200 24 1a 40

EF3a

Motor Motor flange Rotex Q

2.2/3.0 kW F250 38 59

2.2/3.0 kW F250 28 68

0.75 kW F200 28 67

1.1/1.5 kW F250 28 67

Assembly

11

Page 12

EF4a

Motor Motor flange Rotex Q

11 / 15 kW F350 42 1b 89.5

5.5 / 7.5 kW F300 42 Typ 1 65.5

2.2 / 3.0 / 4.0 kW F250 38 1b 72.5

WARNING!

The pump can break through the base or slide off it

– Ensure that the base is horizontal, flat and perma‐

nently load-bearing.

Capacity too low

Vibrations can disturb the liquid end valves.

–

Do not allow the base to vibrate.

WARNING!

Motor may overheat

If the necessary cooling air supply is not guaranteed,

the motor may overheat. In an area at risk from explo‐

sion, it could trigger an explosion.

– Maintain sufficient clearance between the air

intake opening and the walls. The distance should

be greater than 1/4 of the diameter of the air intake

opening.

–

The fan must not suck in the exhaust air from other

devices.

WARNING!

Danger with high pressure

Feed chemicals at pressures above 100 bar can seri‐

ously injure people standing nearby in the event of a

discharge-side leak - particularly if energy stores, such

as pulsation dampers, are used.

– Use appropriate guard panels to shield the dis‐

charge-side components if necessary.

Base

h

P_MOZ_0016_SW

Fig. 2

Space requirement

Assembly

12

Page 13

CAUTION!

Danger from incorrectly operated or inadequately

maintained pumps

Danger can arise from a poorly accessible pump due

to incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

–

Adhere to the maintenance intervals.

WARNING!

Risk of injury from feed chemical at extreme tempera‐

tures

People could be injured if feed chemical at extreme

temperatures can heat up or cool down the liquid ends

above or below the permitted surface temperatures.

– Avoid contact with the unit.

–

If necessary, mount a guard plate.

Position the pump so that control elements, such as the oil inspec‐

tion windows, are easily accessible.

Make sure that there is sufficient room to carry out an oil change or

perform other maintenance work and repairs.

1 Discharge valve

2 Dosing head

3 Suction valve

Ensure there is sufficient free space (f) around the dosing head

and hydraulic end so that maintenance and repair work can be car‐

ried out easily on these components.

Capacity too low

Vibrations can disturb the liquid end valves.

–

Secure the metering pump so that no vibrations

can occur.

1. Take the dimensions of the fastening holes - refer to the

appropriate dimensional drawings or data sheets.

2. Use screws (strength class 8.8) to fix the pump base to the

foundation.

Pumptype Screw size

EF1a M12

EF2a M12

EF3a M12

EF4a M16

1

3

2

f

f

f

P_MOZ_0017_SW

Fig. 3

Fastening

Assembly

13

Page 14

Protect the pump from lightening.

Install a guard if the pump is exposed to direct sunlight or another

heat source.

Lightning protection

Direct sunlight

Assembly

14

Page 15

4 Installation, Electrical

CAUTION!

Danger of injury to personnel and material damage

Disregarding the technical data when installing can

lead to personal injuries or damage to property.

– Refer to the Technical Data - see the "Evolution

Data Sheet" chapter and the operating instructions

for the other components.

WARNING!

ATEX pumps in areas at risk from explosion

– Only connect potential-free as well as non-isolating

low voltage switch accessories, such as diaphragm

rupture indicators, stroke rate instruments etc., to

an intrinsically safe power circuit in areas at risk

from explosion.

– Only use motor protection switches, mains

switches and fuses permitted for use in areas at

risk from explosion in line with the manufacturer's

information, as electrical components in areas at

risk from explosion.

– Electrically wire all electrical units cleanly and per‐

manently to an electrically clean earthing point, e.g. with an earthing bar on your system.

– Electrically wire the earthing point on the pump

cleanly and permanently to an electrically clean

potential equalisation point - e.g. with a potential

equalisation bar on your system.

– Note the enclosed documentation for the individual

electrical components.

– Please note the relevant national regulations

during installation!

WARNING!

ATEX pumps in areas at risk from explosion

Static electricity can cause ignition sparks.

– Consider potential equalisation before you

approach any pump equipment that could be at a

different electrical potential (such as pipes or tools)

WARNING!

Danger of fire with flammable feed chemicals

– The ATEX diaphragm rupture sensor and a dis‐

charge-side flow control must both stop the pump

as soon as a diaphragm rupture or no flow is

detected.

Installation, Electrical

15

Page 16

WARNING!

Danger of electric shock

Unprofessional installation may lead to electric shocks.

– Crimp cable end sleeves onto all shortened cable

cores.

–

Only allow technically trained personnel to under‐

take the electrical installation of the device.

WARNING!

Danger of electric shock

In the event of an electrical accident, it must be pos‐

sible to quickly disconnect the pump, and any electrical

ancillaries which may possibly be present, from the

mains.

– Install an emergency cut-off switch in the mains

supply line to the pump and any electrical ancilla‐

ries which may be present or

–

Integrate the pump and electrical ancillaries which

may be present in the emergency cut-off manage‐

ment of the system and inform personnel of the

isolating option.

WARNING!

Danger of electric shock

This pump is equipped with a protective earth con‐

ductor, to reduce the risk arising from an electric

shock.

– Connect the PE conductor to "earth" with a clean

and permanent electrical connection.

WARNING!

Danger of electric shock

A mains voltage may exist inside the motor or elec‐

trical ancillaries.

– If the housing of the motor or electrical ancillaries

has been damaged, you must disconnect it from

the mains immediately. The pump must only be

returned to service after an authorised repair.

What requires electrical installation?:

n Motor

n External fan (optional)

n A frequency converter (bought-in part) if necessary

n Electric diaphragm rupture sensor (optional)

n Diagnostic equipment for bearing damage (bought-in part) if

necessary

n Stroke sensor (optional)

n Earthing wires (to be provided on site)

n Potential equalisation line (to be provided on site)

Installation, Electrical

16

Page 17

WARNING!

ATEX pumps in areas at risk from explosion

– Use a suitable motor protection switch to protect

power end motors. Use motor protection approved

for this application with Ex"e" motors. (Protection

against warming caused by overloading)

–

Provide a time-delay residual current device.

– Ensure that motors are only installed and checked

by a "recognised competent" person in areas at

risk from explosion.

– Cleanly earth the motor via the mains cable.

– Observe the enclosed operating instructions for the

Ex motor, especially the maintenance plan.

CAUTION!

The motor can be damaged

Provide appropriate motor protection devices (e.g.

motor protection switch with thermal overcurrent trip)

to protect the motor against overloading. Fuses do not

provide motor protection.

CAUTION!

Pump can be damaged

The pump can be damaged if the motor drives the

pump in the wrong direction.

– When connecting the motor, pay attention to the

correct direction of rotation - refer to the "Start Up"

chapter.

Use an electrical isolating device in the mains supply

cable, such as a mains switch, to switch off the pump

independently of the entire installation (e.g. for

repairs).

1. Install a motor protection switch, as the motors have no fuse.

2. Install an emergency cut-off switch or include the motor in the

system's emergency cut-off management scheme.

3. Connect the motor to the power supply.

–

Key motor data can be found on the nameplate.

–

The terminal wiring diagram is located in the ter‐

minal box.

CAUTION!

Provide a separate power supply for the external fan

with motors with external fan.

Motor

External fan (optional)

Installation, Electrical

17

Page 18

Connect the motor as per the wiring diagram for the controller, if it

is controlled by an electronic control unit (such as direct current

motors by a frequency converter).

WARNING!

Danger of electric shock

In event of a defect, there is a risk of electric shock

when conductive feed chemicals are present.

– For safety reasons we recommend connecting to

protective low voltage, e.g. in accordance with EN

60335-1 (SELV ).

WARNING!

Risk of fire after a diaphragm rupture

With seriously oxidising feed chemicals: Make sure

that the electric diaphragm rupture sensor switches off

the pump immediately after a diaphragm rupture.

– Connect the pump and the diaphragm rupture

sensor to a control so that the pump stops immedi‐

ately in the event of a diaphragm rupture.

CAUTION!

Danger resulting from unnoticed diaphragm rupture

All pumps ordered with an electric diaphragm rupture

sensor need to be electrically installed.

– Electrically wire the enclosed diaphragm rupture

sensor to a suitable monitoring device.

CAUTION!

Additional damage with a ruptured diaphragm

Never allow the diaphragm to rupture fully if damage

can be caused by hydraulic oil mixing with the feed

chemical.

– The diaphragm rupture sensor must switch off the

pump immediately.

Only restart the pump once the diaphragm has

been replaced.

Refer to the operating instructions for the diaphragm rupture

sensor.

Connect the stroke sensor to a suitable monitoring device in

line with the details in the "Technical Data" chapter - also

refer to their technical data!

Make sure that the monitoring/feed equipment installed by

the customer is capable of evaluating the current variations

of the Namur sensor to indicate a diaphragm rupture!

Frequency converter (to be provided

on site)

Electric diaphragm rupture sensor

(optional)

Stroke sensor (optional)

Installation, Electrical

18

Page 19

WARNING!

In areas at risk from explosion:

– Note the details of the type examination certificate

PTB 00 ATEX 2048 X for the Namur sensor

NJ1.5-8GM-N.

CAUTION!

Danger from unnoticed bearing damage

If the pump is intended for operation with diagnostic

equipment for bearing damage (e.g. for areas area at

risk from explosion), then it also has to be electrically

installed.

– Electrically connect the diagnostic equipment for

bearing damage to a suitable monitoring device.

CAUTION!

The pump's earthing concept is not suitable for active

cathodic corrosion protection with external current.

Wire the earthing lines of all electrical components for the supplied

installation cleanly and permanently to an electrically clean

earthing point, e.g. with an earthing bar on site - see earthing dia‐

grams in the appendix.

Connect the partial potential equalisation points of the pump, motor

and, if necessary further units, which are not connected electrically

cleanly to the pump, electrically cleanly via potential equalisation

lines - see dimensional drawing. Electrically wire an additional

potential equalisation cable from the potential equalisation cables

from this system cleanly and permanently to an electrically clean

potential equalisation point, e.g. to a potential equalisation bar on

site.

Install the other units in line with their documentation.

Diagnostic equipment for bearing

damage (provided on site)

Earthing lines

Potential equalisation lines (manda‐

tory with ATEX)

Other units

Installation, Electrical

19

Page 20

5 Start Up and Operation

WARNING!

ATEX pumps in areas at risk from explosion

– Make sure that a suitably competent person

checks whether the appropriate installation infor‐

mation from the "Installation " chapter has been

implemented correctly.

–

Make sure that a "recognised competent person"

checks the electrical installation and in particular

the intrinsically safe power circuits.

– Set the opening pressure of the relief valve to a

maximum of no more than 1.5 times the nominal

pressure of the pump.

WARNING!

ATEX pumps in areas at risk from explosion

Static electricity can cause ignition sparks.

– Consider potential equalisation before you

approach any pump equipment that could be at a

different electrical potential (such as pipes or tools)

WARNING!

Danger of fire with flammable feed chemicals

– Combustible media may only be transported using

stainless steel dosing heads.

–

The ATEX diaphragm rupture sensor and a dis‐

charge-side flow control must both stop the pump

as soon as a diaphragm rupture or no flow is

detected.

– During filling and draining of the liquid end, an

expert must ensure that feed chemical does not

come into contact with oxygen.

– If necessary, the operator must implement further

measures.

WARNING!

Hot surface

In event the power end motor is loaded excessively, its

surface may become very hot.

– Avoid contact.

–

If necessary, mount a guard plate.

Safety Information

Start Up and Operation

20

Page 21

WARNING!

Risk of burns with hot feed chemicals

If hot feed chemicals can heat the liquid ends above

the permissible surface temperatures, persons can

suffer burns from them.

– Consider attaching a "Hot surface" label to the

liquid end or ...

–

fitting a guard plate.

WARNING!

Danger with high pressure

Feed chemicals at pressures above 100 bar can seri‐

ously injure people standing nearby in the event of a

discharge-side leak - particularly if energy stores, such

as pulsation dampers, are used.

– Wear protective goggles and protective clothing if

no protective panels are fitted.

WARNING!

Only with frequency control unit: Danger of electric

shock

There is still the risk of an electric shock on conducting

parts of the frequency control unit (e.g. frequency con‐

verter), the motor and the cables even after the mains

voltage has been switched off.

– Once switched off, allow the device to stand for as

long as is required in the operating instructions for

the frequency control unit and only then open the

terminal box.

WARNING!

Observe other operating instructions

Observe the safety information in the other operating

instructions.

CAUTION!

Do not permit the maximum permissible priming pres‐

sure on the suction side to be more than 10% of the

maximum allowable operating pressure. Otherwise the

pump will wear out quickly.

CAUTION!

Use the clamp lever to fix the manual adjustment

wheel following every adjustment of the stroke length.

Start Up and Operation

21

Page 22

CAUTION!

Prior to commissioning, check that the power end

motor and corresponding ancillary equipment is con‐

nected in compliance with the regulations!

CAUTION!

Adhere to the instructions in the frequency converter

operating instructions when using pumps with speed

control

CAUTION!

Danger of material damage

Note all information on the "Evolution data sheet".

Note all information in the operating instructions and

on the data sheets.

CAUTION!

Feed chemical can escape unnoticed

Feed chemical can escape unnoticed if the electric dia‐

phragm rupture sensor does not stop the pump or no

alarm is triggered.

– Trigger the electric diaphragm rupture sensor - see

"Operating Instructions for Electric Diaphragm

Rupture Sensor..." and thus check the reaction of

the monitoring unit and/or the pump.

CAUTION!

Only restart the pump once the diaphragm has been

replaced after a diaphragm rupture if damage can be

caused by hydraulic oil mixing with the feed chemical.

CAUTION!

Never adjust the pressure relief valve.

5.1 Tests Prior to Start Up of the Pump

Check whether the gear oil covers up to a quarter to three-quarters

of the oil inspection window (020).

Check whether the oil level in the turrets lies between the marks

and the end of the dipstick.

Observe the technical data

Testing the electric diaphragm rupture

sensor (option)

Pressure relief valve

Checking the oil levels and oil quali‐

ties

Start Up and Operation

22

Page 23

Check whether water is in the dosing head - if it would interfere.

Check whether the accessories supplied loose are correctly

assembled and installed. Use the operating instructions for the

loosely fitted accessories.

Check whether the safety equipment is correctly assembled and

working properly.

Check whether the entire electrical installation is correctly installed

and in accordance with local regulations. Also potential equalisa‐

tion and earthing lines.

Check whether the supply voltage from the drive motor,

actuator ...is correct.

Check whether the system is protected from overpressure.

Only in areas at risk from explosion: Set the opening pressure of

the (on site) relief valve downstream of the pressure manifold to a

maximum of 1.5 times the nominal pressure of the pump.

Check whether the suction line and discharge line are free from

tension and connected tightly.

Replace the closing screws on the oil filler neck with the vent

screws supplied.

Slight oil marks on the pump do not indicate leaks with

a new product.

Remove any oil stains and note their position.

Set the stroke length to start at 0 mm.

Check whether all obstacles have been removed in the suction and

discharge manifold and that the shut-off valves are open.

Check whether the actuator is working correctly over the entire

stroke length. This is also the case with drive units that are not

working.

Is the clamp of the stroke adjustment wheel working?

EF3a and EF4a only:

Check whether the scale bushing with the round scale is correctly

fitted.

Checking for water

Checking for accessories supplied

loose

Checking the safety equipment

Checking the electrical installation

Checking the supply voltage

Adjusting the relief valve (on site)

Checking the suction line and dis‐

charge line

Installing the vent screws with filter

Setting the stroke length to 0 mm

Checking the flow in discharge and

suction lines

Checking the stroke length adjust‐

ment

Checking the scale bushing

Start Up and Operation

23

Page 24

5.2 Testing Directly After the Pump has Started Up

With the pump running, check whether bubbles are rising in the oil

inspection window (336) above the bleed valve in the diaphragm

holder (300) - no foam!

Check whether liquids are escaping at any point.

Ensure that the back pressure on the discharge side is perma‐

nently above 1.5 bar (2.5 bar absolute).

Check whether the ratio of stroke length / metering frequency is

appropriate to the process.

Set the stroke length to prime to the maximum value on the scale.

WARNING!

Risk of injury from the fan impeller

The fan impeller beneath motor's fan cowling can

cause severe injuries while it is turning.

– The pump must only be connected to the mains

voltage with the fan cowling closed.

With upright motors:

Check whether the drive motor is rotating correcting – refer to the

arrow on the motor flange.

1. Unscrew the screw from the control opening on the motor

flange.

2. Push a long thin piece of cardboard a little way into the

opening with the motor running.

3. Remove the cardboard from the opening.

ð

The bend of the cardboard shows the direction of rota‐

tion.

With multiple pumps:

Check whether the drive shaft is rotating correctly - refer to the

arrow on the connecting flange between the drive units.

1. Unscrew the drive unit cover when the motor is at a standstill.

2. Carefully place a long thin piece of cardboard onto the end of

the shaft with the motor running.

WARNING!

Risk of injury

Never touch the end of the shaft with your fin‐

gers.

ð

The cardboard indicates the direction of rotation.

3. When the motor is stopped: Screw the drive unit cover onto

the drive unit.

Checking the hydraulic oil flow

Checking for leaks

Setting the back pressure

Checking the stroke length / metering

rate

Setting the stroke length to the max‐

imum value on the scale

Checking the direction of rotation

Start Up and Operation

24

Page 25

5.3 Testing 0.5 to 1 Hour After the Pump has Started

With the pump running, check whether oil is rising in the oil inspec‐

tion window (336) above the bleed valve (356) in the diaphragm

holder (300) - a few bubbles are permitted.

Check whether liquids are escaping at any point.

With the pump idle, check whether the drive unit oil level slightly

covers a quarter to three-quarters of the oil inspection window

(020).

With the pump idle and the stroke length 0 mm, check whether the

oil level in the turrets lies between the marks and the end of the

dipstick - screw in the vent screw with the measuring dipstick to do

so.

5.4

Bleeding the Diaphragm Holder

Bleed the hydraulics once to start up:

1. Set a stroke length of 0 mm.

2. Unscrew the oil inspection window (336) and the bleed valve

(356) from the diaphragm holder (300).

3. Re-fit the oil inspection window (336).

4. Start up the pump at a low speed.

5. Slowly increase the speed until hydraulic oil flows into the

feed of the bleed valve (356).

The hydraulic system is adequately bled when only isolated

air bubbles rise from the feed of the bleed valve (356) within

1 minute.

6. Re-fit the bleed valve (356) with the pump stopped.

Checking the hydraulic oil flow

Checking for leaks

Checking the oil levels and oil quali‐

ties

Start Up and Operation

25

Page 26

6 Maintenance

- refer to the "Operating Instructions for the Liquid Ends Orlita

®

Evolution"

Maintenance

26

Page 27

7 Carrying out repairs

- refer to the "Operating Instructions for the Liquid Ends Orlita

®

Evolution"

Carrying out repairs

27

Page 28

8 Remedying Faults on the Drive Unit

WARNING!

ATEX pumps in areas at risk from explosion

Immediately stop the pump in the event of leakages,

unusual noises, high temperatures, unusual smells,

vibrations and rectify the cause.

WARNING!

Danger of an electric shock

Personnel working on electrical parts can be electro‐

cuted if all electrical lines carrying current have not

been disconnected.

– Disconnect the supply cable before working on the

motor and prevent it from being reconnected acci‐

dentally.

–

Any separately driven fans, servo motors, speed

controllers or diaphragm rupture sensors fitted

should also be disconnected.

– Check that the supply cables are de-energised.

WARNING!

Risk of injury from the fan impeller

The fan impeller beneath motor's fan cowling can

cause severe injuries while it is turning.

– The pump must only be connected to the mains

voltage with the fan cowling closed.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pres‐

sure in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

–

Depressurise the system before commencing any

work on hydraulic parts.

Rectify functional faults on the liquid ends and boughtin parts as per their operating instructions.

Remedying Faults on the Drive Unit

28

Page 29

Electrical faults

Description of fault Cause Remedy Personnel

Drive unit does not rotate Faulty or missing contact

to power supply

Check the power supply

connector

Electrical technician,

ATEX electrical techni‐

cian

Drive motor rotates in the

wrong direction

The phases have been

swapped

Swap the phases Electrical technician,

ATEX electrical techni‐

cian

Various sensors do not

react

Incorrect installation,

faulty contacts, faulty

sensor

Correct installation, if

necessary, check con‐

tacts and repair if

required, replace sensor

Electrical technician,

ATEX electrical techni‐

cian

Mechanical faults

Description of fault Cause Remedy Personnel

Gear motor makes loud

noises

Bearing damage on the

motor shaft

Replace bearings or

motor

Service

Overload Monitor the process

parameters

Qualified employee

Monitor the process

parameters, makes loud

noises

Too great axial play in

the cam shaft bearing

Tighten / monitor adjust‐

ment nuts

Service

Overload Monitor the process

parameters

Qualified employee

Mechanics sluggish Too little axial play in the

cam shaft bearing (tight)

Monitor the adjustment

nut

Service

A piston is too tight in its

socket

n Loosen the hydraulic

end screws

n Press the hydraulic

end manually

upwards and

n Re-tighten the

screws

Qualified employee

No stroke movement

despite motor running

Check mechanical com‐

ponents for breakage

Replace defective com‐

ponents

Service

Remedying Faults on the Drive Unit

29

Page 30

9 Decommissioning and Disposal

- refer to the "Operating Instructions for the Liquid Ends Orlita

®

Evolution"

Decommissioning and Disposal

30

Page 31

10 Index

A

Add-on drive unit ..........................9

Assembling the motor independently ........8,

10

Assembly ..............................10

B

Base ..................................12

C

Carrying out repairs ....................27, 30

Claw coupling ...........................10

D

Diaphragm holder ........................25

Diaphragm rupture sensor ...............18, 22

Direct sunlight ...........................14

Direction of rotation ....................17, 24

E

Earthing lines ...........................19

Electrical faults ..........................29

Emergency ..............................7

Emissions ...............................8

Explanation of the safety information ..........3

External fan .............................17

F

Fastening ..............................13

Frequency converter ......................18

Functional description ......................9

H

Hydraulic oil flow .........................24

I

Information in the event of an emergency .......7

Installation, Electrical .....................15

Intended use .............................3

L

Lightning protection .......................14

M

Maintenance ............................26

Mechanical faults ........................29

Motor ..................................17

O

Oil level ................................22

Operation ..............................20

P

Potential equalisation cables ................19

Pressure relief valve ......................22

Protective equipment ......................7

Q

Qualification of personnel ...................4

S

Safety ..................................3

Safety equipment .........................7

Sound pressure level ......................8

Space requirement .......................12

Start Up ................................20

Stroke sensor ...........................18

T

Troubleshooting .........................28

V

Vent screw .............................23

W

Warning sign .............................3

Index

31

Page 32

Heidelberg, 3, en_GB

© 2015

ProMinent GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg, Germany

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

Loading...

Loading...