Page 1

Operating instructions

Diaphragm Metering Pump

ProMinent® Makro/ 5 M5Ma

Two sets of operating instructions are required for the safe, correct and proper operation of the metering pumps: The

product-specific operating instructions and the "General Operating Instructions for ProMinent® motor-driven metering

pumps and hydraulic accessories".

Both sets of operating instructions are only valid when read together.

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Technical changes reserved.

Original Operating Instructions (2006/42/EC)Part no. 985753 BA MAK 005 10/11 EN

Page 2

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-617

email: info@prominent.com

Internet: www.prominent.com

985754, 1, en_GB

© 2010

2

Page 3

Supplementary information

Supplemental instructions

Read the following supplementary information in its entirety!

Should you already know this information, you have an even

greater need of the Operating Instructions.

The following are highlighted separately in the document:

Fig. 1: Please read!

General user instructions

n Enumerated lists

Instructions

Outcome of the handling instructions

ð

- see (reference)

Information

This provides important information relating to the cor‐

rect operation of the device or is intended to make

your work easier.

Safety notes

Safety notes are identified by pictograms - see Safety Chapter.

Two sets of operating instructions are required for the safe, correct

and proper operation of the metering pumps: The product-specific

operating instructions and the "General Operating Instructions for

ProMinent® motor-driven metering pumps and hydraulic accesso‐

ries".

State the identity code and serial

number

General non-discriminatory approach

Both sets of operating instructions are only valid when read

together.

Please read these operating instructions carefully before use! Do

not discard!

Please state identity code and serial number, which you can find

on the nameplate when you contact us or order spare parts. This

enables the device type and material versions to be clearly identi‐

fied.

In order to make it easier to read, this document uses the male

form in grammatical structures but with an implied neutral sense. It

is aimed equally at both men and women. We kindly ask female

readers for their understanding in this simplification of the text.

3

Page 4

Table of contents

Table of contents

1 Identity code.......................................................................... 5

About this pump.................................................................... 7

2

3 Safety chapter....................................................................... 8

4 Storage, transport and unpacking....................................... 14

5 Overview of equipment, control elements........................... 16

6 Functional description......................................................... 19

7 Assembly............................................................................ 21

8 Installation........................................................................... 24

8.1 Installation, hydraulic.................................................. 24

8.2 Installation, electrical.................................................. 26

9 Start up............................................................................... 29

10 During use........................................................................... 31

11 Maintenance....................................................................... 32

Repairs................................................................................ 37

12

12.1 Replacing the membrane.......................................... 38

12.2 Valve repair............................................................... 40

12.2.1 Double ball valves.................................................. 40

12.2.2 Single ball valves................................................... 41

12.2.3 Plate valves........................................................... 42

13 Troubleshooting.................................................................. 45

14 Decommissioning and disposal.......................................... 48

14.1 Decommissioning..................................................... 48

14.2 Disposal.................................................................... 50

15 Technical data..................................................................... 51

15.1 Performance data..................................................... 51

15.2 Accuracy................................................................... 52

15.2.1 Reproducibility....................................................... 52

15.2.2 Metering precision................................................. 52

15.3 Viscosity.................................................................... 52

15.4 Wetted materials....................................................... 53

15.5 Ambient conditions................................................... 53

15.5.1 Temperatures........................................................ 53

15.5.2 Air humidity............................................................ 54

15.6 Housing degree of protection.................................... 54

15.7 Stroke sensor (option), intrinsically safe................... 55

15.8 Filling volumes.......................................................... 55

15.8.1 Gear oil.................................................................. 55

15.9 Sound pressure level................................................ 55

15.10 Compatibility........................................................... 56

15.11 Supplement for modified versions.......................... 56

16 EC Declaration of Conformity............................................. 57

17 Index................................................................................... 59

4

Page 5

1 Identity code

M5Ma Makro/ 5 diaphragm metering pump

Power end type

H Main power end

D Main power end, doubled

A Add-on power end

B Add-on power end doubled

Type:

bar l/h

041540 4 1540

041900 4 1900

042600 4 2600

043400 4 3400

Identity code

044000 4 444000

Dosing head material

PC PVC

PV PVDF

TT PTFE + 25 % carbon

SS Stainless steel

Seal material

T PTFE

Displacement body material

T Metering diaphragm with PTFE coating

Dosing head version

1 with valve spring, Hastelloy C; 0.1 bar

Hydraulic connector

0 Standard connection

1 Union nut and PVC insert

2 Union nut and PP insert

3 Union nut and PVDF insert

4 Union nut and SS insert

Version

0

With ProMinent® logo, no frame

1

Without ProMinent® logo, no frame

A

With ProMinent® logo, with single frame

B

With ProMinent® logo, with double frame

5

Page 6

Identity code

M5Ma Makro/ 5 diaphragm metering pump

C

With ProMinent® logo, with triple frame

D

With ProMinent® logo, with quadruple frame

M Modified* * order-related version, for pump

features see order paperwork

Electric power supply

S 3 ph, 230 V/400 V 50/60 Hz (WBS)

L 3 ph, 460 V, 60 Hz, (Exe, Exd)

P 3 ph, 230 V/400 V 50 Hz (Exe, Exd)

R Variable speed motor 4 pole, 230/400 V (R 1:5)

N 1 ph, 115 V, 60Hz

V(0) Motor with integral frequency converter

V(2) Motor with integral frequency converter (Exd)

Z Speed control 230/400 V assy.

5 No motor, with gear IEC 100

6 No motor, with gear IEC 112

0 No motor, no gear

Motor version

0 IP 55 (Standard) ISO class F

1 Exe version ATEX-T3

2 Exd version ATEX-T4

A Power end ATEX design

Stroke sensor

0 No stroke sensor

1 Stroke sensor (Namur), intrinsically safe

Stroke length adjustment

0 Stroke length adjustment, manual

3 Control drive 230 V 0-20 mA

4 Control drive 230 V 4-20 mA

5 Control drive 115 V 0-20 mA

6 Control drive 115 V 4-20 mAz

Applications

0 standard

6

Page 7

2 About this pump

About this pump

All pumps

Externally mounted pumps

Double head version

The ProMinent® Makro/ 5 diaphragm metering pump is fitted as

standard with a 3 kW wide range AC motor. The stroke length can

be adjusted between 0...20 mm. The spheroidal graphite housing

can be combined with up to 7 liquid end sizes and 5 gear reduction

ratios (integrated in the spur geared motor). The liquid ends are

available in various material combinations which can be matched

to the feed chemicals being metered.

The ProMinent® Makro/ 5 externally mounted metering pump can

be combined with the Makro/ 5 main power end to form a double or

multiple pump. A main power end can be combined with up to four

add-on power ends. One power end can be used both as a single

or a double head version.

The double head versions are fitted with a second liquid end which

operates in push-pull mode (Boxer principle).

7

Page 8

Safety chapter

3 Safety chapter

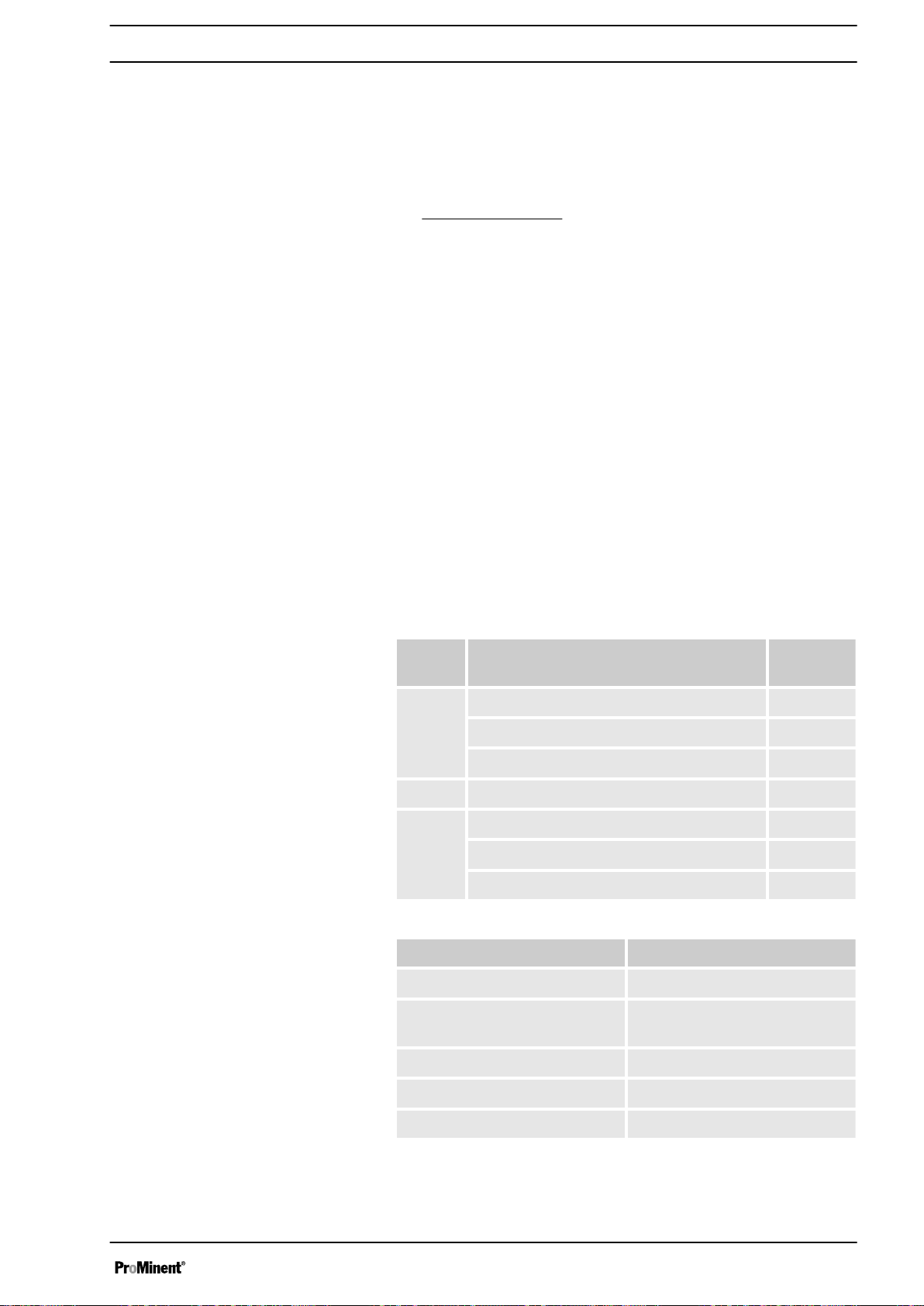

Identification of safety notes

Warning signs denoting different

types of danger

The following signal words are used in these operating instructions

to denote different severities of danger:

Signal word Meaning

WARNING Denotes a possibly dangerous

situation. If this is disregarded,

you are in a life-threatening sit‐

uation and this can result in

serious injuries.

CAUTION Denotes a possibly dangerous

situation. If this is disregarded,

it could result in slight or minor

injuries or material damage.

The following warning signs are used in these operating instruc‐

tions to denote different types of danger:

Warning signs Type of danger

Warning – hand injuries.

Correct and proper use

Warning – high-voltage.

Warning – flammable sub‐

stances.

Warning – hot surface.

Warning – danger zone.

n The pump may only be used to meter liquid metering chemi‐

cals.

n In potentially explosive atmospheres in zone 1, device category

II 2G of explosion group II C, the pump must only be operated

according to the with the relevant nameplate (and the respec‐

tive EC Declaration of Conformity) for pumps for potentially

explosive atmospheres complying with Directive 94/9/EC in

accordance with the European guidelines. The explosion

group, category and degree of protection identified on the

marking must correspond with or be better than the given con‐

ditions in the intended field of application.

8

Page 9

Safety chapter

n The pump may only be started up after it has been correctly

installed and commissioned in accordance with the technical

data and specifications contained in the operating instructions.

n The general limitations with regard to viscosity limits, chemical

resistance and density must be observed - see also ProMinent

resistance list (In the product catalogue or at

www.prominent.com

n Any other uses or modifications are prohibited.

n Pumps without the relevant nameplate (and the respective EC

Declaration of Conformity) for pumps for potentially explosive

atmospheres must never be operated in potentially explosive

atmospheres.

n The pump is not intended for the metering of gaseous media or

solids.

n The pump is not intended for unprotected outside use.

n The pump is only approved to meter flammable liquids, if the

operator takes appropriate safety measures.

n The pump should only be operated by trained and authorised

personnel, see also

n You are obliged to observe the information contained in the

operating instructions at the different phases of the device's

service life.

)!

Ä ‘Qualification of personnel’ on page 9

.

Qualification of personnel

In hazardous locations only the following combinations of identity

code variants is permitted:

Combi‐

Identity code specification values

nations

1 Electric power supply L, P

Motor version 1,2, V(2)

Stroke length adjustment 0, G, H

2 Electric power supply 0, 5.6

Motor version A

Stroke length adjustment 0, G, H

Activity Qualification level

Storage, transport, unpacking Instructed person

Assembly, installation of

Technical personnel, service

hydraulic system

Installation, electrical Electrical technician

Operation Instructed person

Maintenance, repair Technical personnel, service

9

Page 10

Safety chapter

Activity Qualification level

Decommissioning, disposal Technical personnel, service

Troubleshooting Technical personnel, electrical

technician, instructed person,

service

Explanation of the terms:

Technical personnel

A qualified employee is deemed to be a person who is able to

assess the tasks assigned to him and recognise possible dangers

based on his/her technical training, knowledge and experience, as

well as knowledge of pertinent regulations.

Note:

A qualification of equal validity to a technical qualification can also

gained by several years employment in the relevant work area.

Electrical technician

Electrical technicians are deemed to be people, who are able to

complete work on electrical systems and recognize and avoid pos‐

sible dangers independently based on their technical training and

experience, as well as knowledge of pertinent standards and regu‐

lations.

Safety notes

Electrical technicians should be specifically trained for the working

environment in which the are employed and know the relevant

standards and regulations.

Electrical technicians must comply with the provisions of the appli‐

cable statutory directives on accident prevention.

Instructed person

An instructed person is deemed to be a person who has been

instructed and, if required, trained in the tasks assigned to him/her

and possible dangers that could result from improper behaviour, as

well as having been instructed in the required protective equipment

and protective measures.

Service

Customer Service department refers to service technicians, who

have received proven training and have been authorised by ProMi‐

nent or ProMaqua to work on the system.

WARNING!

Warning of dangerous or unknown feed chemical

Should a dangerous or unknown feed chemical be

used: It may escape from the hydraulic components

when working on the pump.

– Take appropriate protective measures before

working on the pump (e.g. safety glasses, safety

gloves, ...). Observe the safety data sheet for the

feed chemical.

– Drain and flush the liquid end before working on

the pump.

10

Page 11

Safety chapter

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious injuries.

Please ensure when handling hazardous substances

that you have read the latest safety data sheets pro‐

vided by the manufacture of the hazardous substance.

The actions required are described in the safety data

sheet. Check the safety data sheet regularly and

replace, if necessary, as the hazard potential of a sub‐

stance can be re-evaluated at any time based on new

findings.

The system operator is responsible for ensuring that

these safety data sheets are available and that they

are kept up to date, as well as for producing an associ‐

ated hazard assessment for the workstations affected.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pres‐

sure in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

– Depressurise the system before commencing any

work on hydraulic parts.

CAUTION!

Warning of feed chemical spraying around

An unsuitable feed chemical can damage the parts of

the pump contacted by the chemical.

– Take into account the resistance of the materials

which will come into contact with the chemical

when selecting the feed chemical - see the ProMi‐

nent product catalogue or under

www.prominent.com

.

CAUTION!

Danger of personnel injury and material damage

The use of untested third party parts can result in per‐

sonnel injuries and material damage.

– Only fit parts to metering pumps, which have been

tested and recommended by ProMinent.

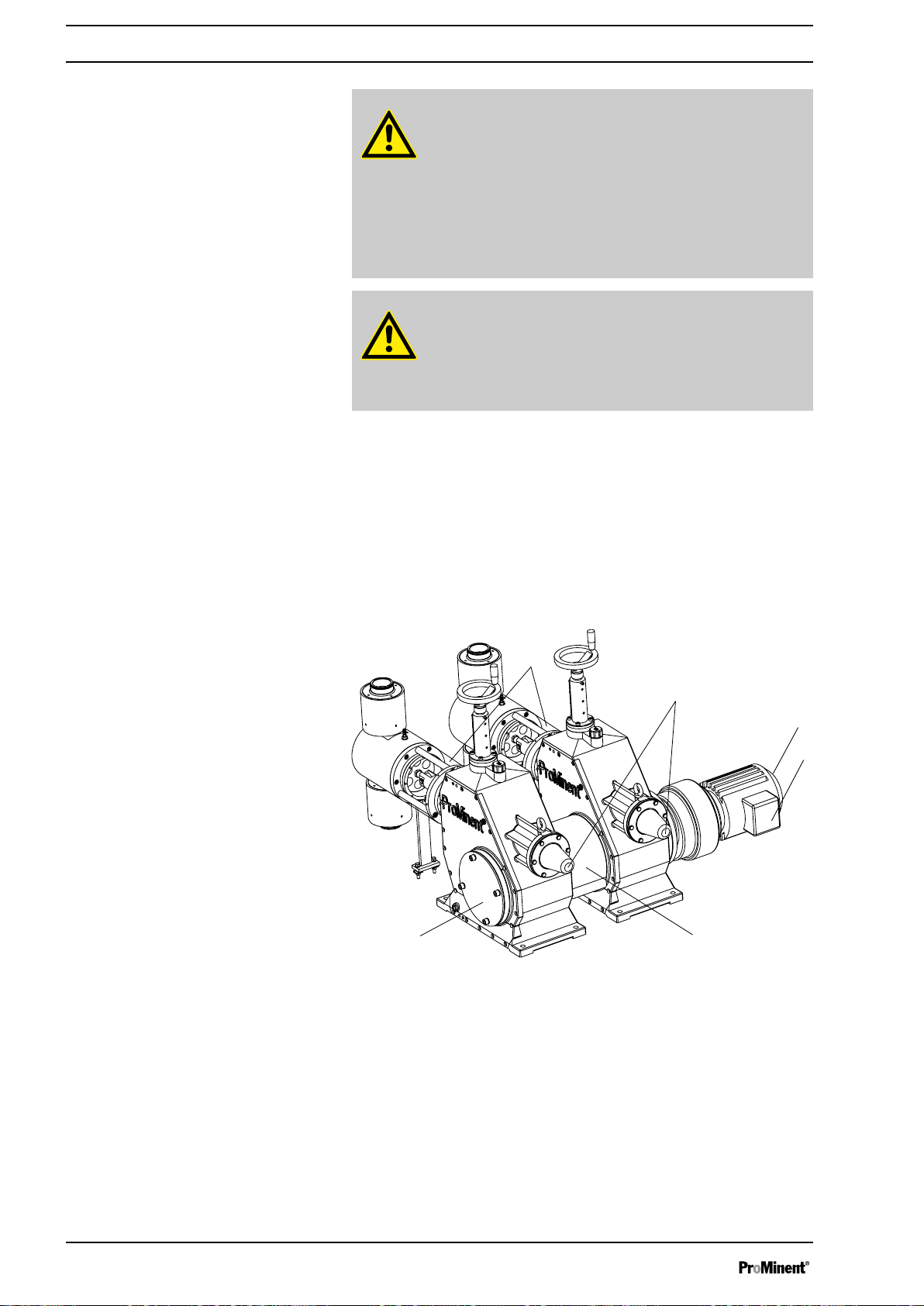

11

Page 12

1

6

5

2

3

4

P_MAK_0025_SW

Safety chapter

CAUTION!

Danger from incorrectly operated or inadequately

maintained pumps

Danger can arise from a poorly accessible pump due

to incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

– Adhere to the maintenance intervals.

CAUTION!

Warning of illegal operation

Observe the regulations that apply where the unit is to

be installed.

Information in the event of an emer‐

gency

Protective equipment

In the event of an electrical accident, disconnect the mains cable

from the mains or press the emergency cut-off switch fitted on the

side of the system!

If feed chemical escapes, also depressurise the hydraulic system

around the pump as necessary. Adhere to the safety data sheet for

the feed chemical.

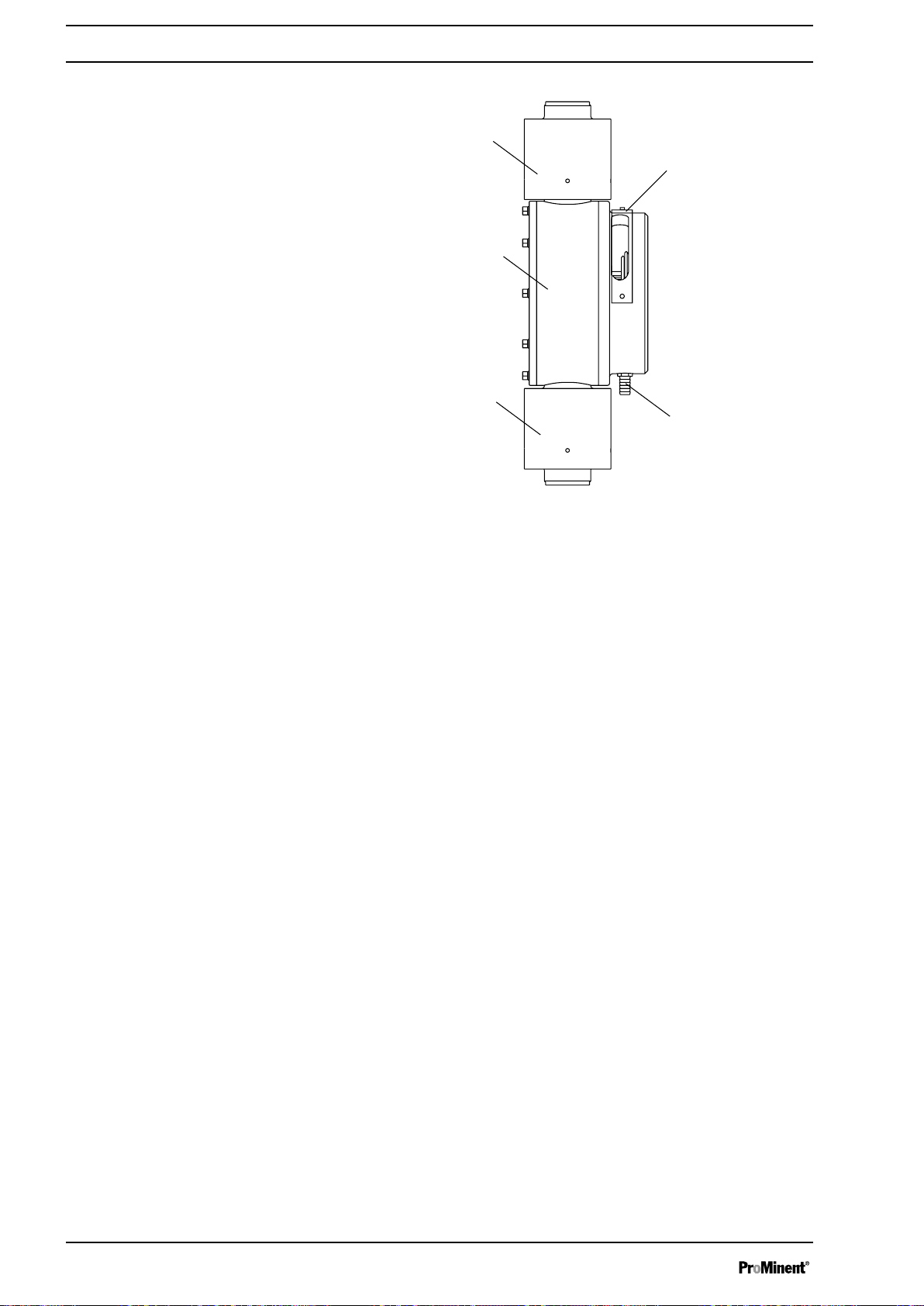

Fig. 2: Isolating protective equipment Makro/ 5 with add-on power

end (shown here for piston version)

1 Cap (only single head version)

2 Fan impeller hood

3 Terminal box cover, motor

4 Cover plate (only with add-on power end)

5 Flange cover

6 Protective cover (only diaphragm and piston versions)

12

Page 13

Safety chapter

WARNING!

Warning of personal injury and material damage

– The customer must only remove the protective

equipment if requested to do so by the operating

instructions.

– The pump must not operate without fitted protec‐

tive equipment.

Sound pressure level

Sound pressure level LpA < 75 dB in accordance with EN ISO

20361:2010-10

at maximum stroke length, maximum stroke rate, maximum back

pressure (water)

13

Page 14

Storage, transport and unpacking

4 Storage, transport and unpacking

Safety notes

WARNING!

The transporting of pumps which have been used with

radioactive feed chemicals is forbidden!

They will also not be accepted by ProMinent!

WARNING!

Only return metering pumps for repair in a cleaned

state and with a flushed liquid end - refer to the section

on decommissioning!

Only send metering pumps with a filled in Decontami‐

nation Declaration form. The Decontamination Decla‐

ration constitutes an integral part of an inspection /

repair order. A unit can only be inspected or repaired

when a Declaration of Decontamination Form is sub‐

mitted that has been completed correctly and in full by

an authorised and qualified person on behalf of the

pump operator.

Scope of supply

You can find the "Decontamination Declaration" form

under

www.prominent.com

CAUTION!

Danger of environmental and material damage

The unit can be damaged or oil may escape due to

incorrect or improper storage or transportation!

– The unit should only be stored or transported in a

well packaged state - preferably in its original

packaging.

– Only transport the unit with the locking screw - not

the bleed plug - fitted to the oil filling opening.

– The packaged unit should also only be stored or

transported in accordance with the stipulated

storage conditions.

–

The packaged unit should be protected from mois‐

ture and the ingress of chemicals.

Compare the delivery note with the scope of supply:

or on the CD.

n Metering pump with mains power cable

n Connector kit for tube/pipe connection

n Product-specific operating instructions with EC Declaration of

Conformity

n CD with order information, exploded diagrams, performance

diagrams, motor data sheet and dimension sheets

n Optional accessories if ordered

14

Page 15

Storage

Storage, transport and unpacking

Personnel:

1. Place the caps on the valves.

2. Check whether the seal screw is screwed into oil filler

opening instead of the vent screw.

3. Preferably place the pump standing vertically on a pallet and

secure against falling over.

4. Cover the pump with a tarpaulin cover - allowing rear ventila‐

tion.

Store the pump is a dry, sealed place in the following ambient con‐

ditions.

Technical personnel

n

Ambient conditions

Data Value Unit

Minimum storage and transport tem‐

-10 °C

perature

Maximum storage and transport tem‐

+50 °C

perature

Maximum air humidity * 95 % rel.

humidity

* non-condensing

15

Page 16

P_MAK_0027_SW

1

2

3

1

4

A

5

C

P_MAK_0027_SW

7

6

Overview of equipment, control elements

5 Overview of equipment, control elements

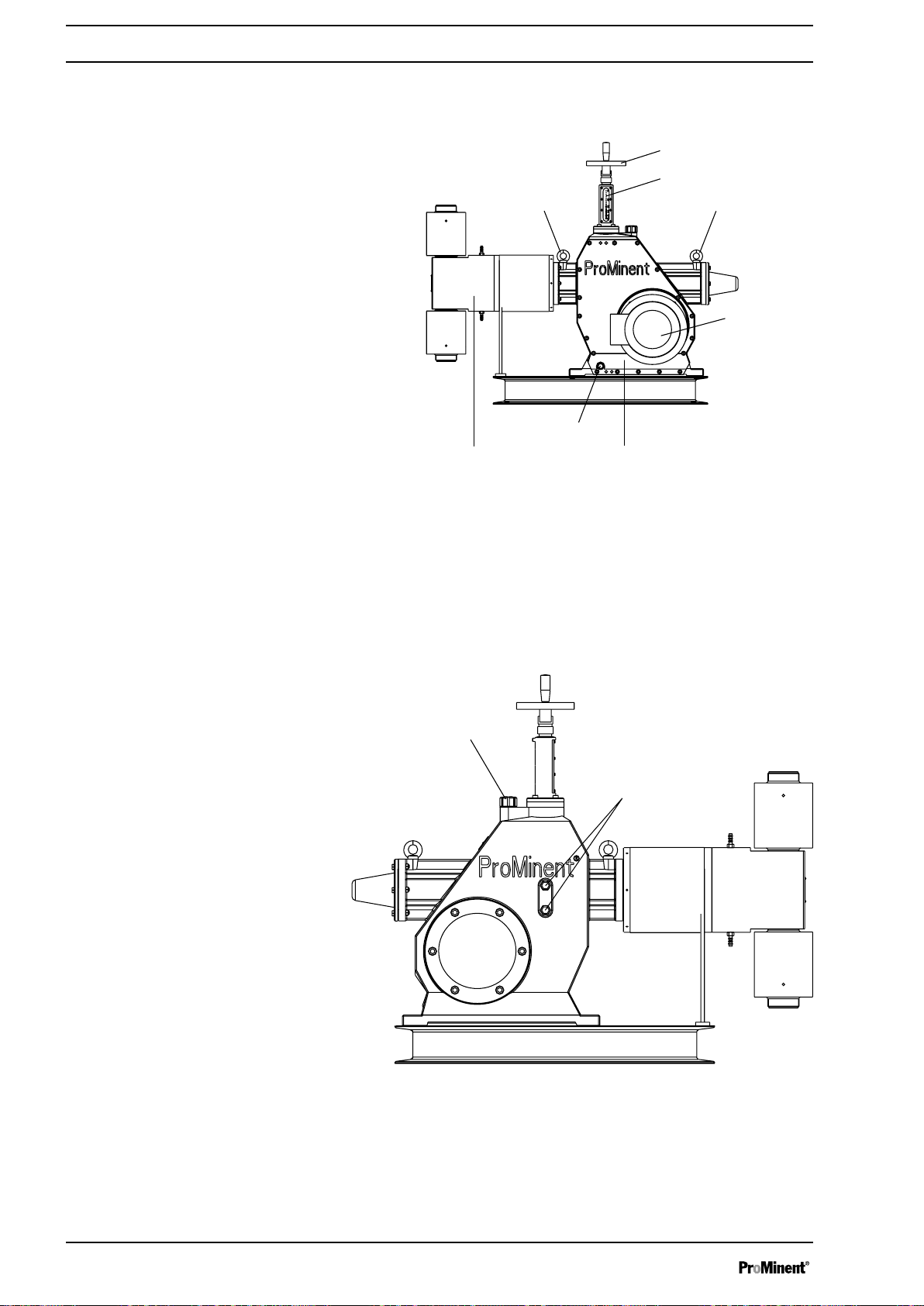

Power end, single head

Fig. 3: View from the motor side (here M5Ka H)

A Power end

C Liquid end

1 Lifting eye

2 Stroke length adjustment wheel

3 Indicating dial

4 motor

5 Oil drain plug

Fig. 4: View away from the motor (here M5Ka H)

6 Vent screw

7 Oil inspection window

16

Page 17

P_MAK_0029_SW

1 1

2

3

5

C A C

4

P_MAK_0030_SW

6

7

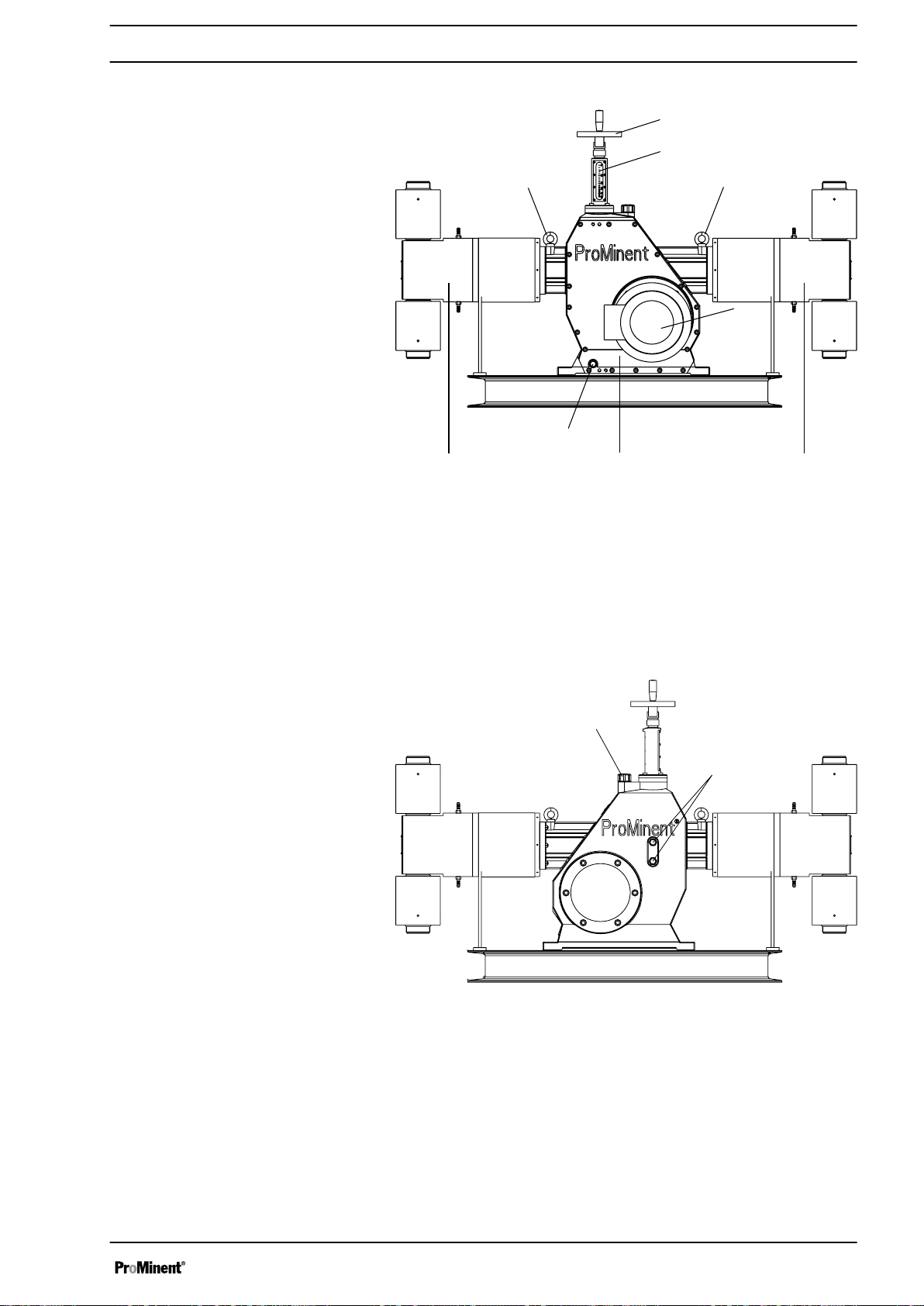

Power end, double head

Overview of equipment, control elements

Fig. 5: View from the motor side (here M5Ka D)

A Power end

C Liquid end

1 Lifting eye

2 Stroke length adjustment wheel

3 Indicating dial

4 motor

5 Oil drain plug

Fig. 6: View away from the motor (here M5Ka D)

6 Vent screw

7 Oil inspection window

17

Page 18

1

2

5

3

4

P_MAK_0031_SW

Overview of equipment, control elements

Liquid end

Fig. 7

1 Discharge valve

2 Dosing head

3 Suction valve

4 Tube nozzle for leakage

5 Protective cover

18

Page 19

6 Functional description

P_MAK_0035_SW

6

5

4

3

1

2

8

7

Functional description

Power end functional description

The Makro/ 5 metering pump is a motor-driven metering pump with

a kinematic gear.

A motor drives the cam shaft (1). A connecting rod (2) rests on the

cam shaft (1) which allows the oscillating crank (4) to rotate about

a variable pivot point, see

Fig. 8. The lifting arm of the oscillating

crank, which lies above the pivot point, moves the slide rod (8)

which itself drives the liquid end.

The stroke is adjusted using the manual adjustment wheel (7). This

causes a spindle (6) to move the fork (5; shown in cutaway view in

the diagram). The fork (5) moves the sliding block (3) in a groove

cut into the oscillating crank (4). The sliding block (3) determines

the pivot point of the oscillating crank (4). This determines the

stroke length. When the pivot point of the sliding block (3) is

directly above the axle of the slide rod (8) the lifting arm of the

oscillating crank above the pivot point is at zero and the slide rod

stops. When the sliding block (3) is pushed down, the lifting arm of

the oscillating crank (4) above the pivot point is greater than zero

so that the slide rod (8) is driven

Liquid ends can be fitted to both ends of the slide rod. They then

operate in push-pull mode (Boxer principle).

Fig. 8: Cross-section through the power end

1 Cam shaft

2 Connecting rod

3 Sliding block

4 Oscillating crank

5 Fork

6 Spindle

7 Manual adjustment wheel

8 Slide rod

19

Page 20

1

2

3

4

P_MAK_0036_SW

Functional description

Functional description of the dia‐

phragm liquid end (for M5Ma)

The diaphragm (3) hermetically shuts off the pump volume of the

dosing head (2) from the outside. The suction valve (4) closes as

soon as the diaphragm (3) is moved in to the dosing head (2) and

the feed chemical flows through the discharge valve (1) out of the

dosing head. The discharge valve (1) closes as soon as the

metering diaphragm (3) is moved in the opposite direction due to

the vacuum pressure in the dosing head and fresh feed chemical

flows through the suction valve (4) into the dosing head. One cycle

is thus completed.

Fig. 9: Cross-section through the liquid end

1 Discharge valve

2 Dosing head

3 Diaphragm

4 Suction valve

20

Page 21

7 Assembly

Safety notes

Assembly

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

CAUTION!

Warning about personal and material damage

Also observe the "General Operating Instructions for

ProMinent

®

Motor-Driven Metering Pumps and

Hydraulic Accessories"!

®

Motor-Driven Metering

CAUTION!

Danger of environmental and material damage

The unit can be damaged or oil may escape due to

incorrect or improper storage or transportation!

– The unit should only be stored or transported in a

well packaged state - preferably in its original

packaging.

– Only transport the unit with the locking screw - not

the bleed plug - fitted to the oil filling opening.

– The packaged unit should also only be stored or

transported in accordance with the stipulated

storage conditions.

–

The packaged unit should be protected from mois‐

ture and the ingress of chemicals.

CAUTION!

Warning about personal and material damage

Personal and material damage may be caused if the

unit is operated outside of the permissible ambient

conditions.

– Please observe the permissible ambient conditions

- refer to the chapter entitled "Technical Data".

21

Page 22

h

P_MOZ_0016_SW

A

A

P_MOZ_0018_SW

1

3

2

f

f

f

P_MOZ_0017_SW

Assembly

Supporting floor

Fig. 10

WARNING!

Risk of electric shock

If water or other electrically conducting liquids pene‐

trate into the drive housing, an electric shock may

occur.

– Position the pump so that drive housing cannot be

flooded.

WARNING!

The pump can break through the supporting floor or

slide off it

– The supporting floor must be horizontal, smooth

and permanently load-bearing.

Space requirement

Fig. 11

Capacity too low

Vibrations can disturb the valves of the liquid end.

–

The supporting floor must not vibrate.

CAUTION!

Danger from incorrectly operated or inadequately

maintained pumps

Danger can arise from a poorly accessible pump due

to incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

– Adhere to the maintenance intervals.

Position the pump so that control elements such as the stroke

length adjustment knob, the indicating dial A or the oil inspection

window are accessible.

In so doing, ensure there is enough space to carry out an oil

change (vent screws, oil drain plugs, oil trough ...).

Fig. 12

1 Discharge valve

Dosing head

2

3 Suction valve

Ensure there is sufficient free space (f) around the dosing head as

well as the suction and discharge valve so that maintenance and

repair work can be carried out on these components.

22

Page 23

Liquid end alignment

DNm

m

P_MOZ_0015_SW

Fastening

Assembly

Capacity too low

If the valves of the liquid end do not stand upright, they

cannot close correctly.

–

The discharge valve must be upright.

Capacity too low

Vibrations can disturb the valves of the liquid end.

–

Secure the metering pump so that no vibrations

can occur.

Take the dimensions (m) for the fastening holes from the appro‐

priate dimensional drawings or data sheets.

Fasten the pump base to the supporting floor using suitable

screws.

Fig. 13

Instruction

Screw the pump to a support surface with 4 sufficiently

strong screws through the 4 holes in the frame.

Nothing more need be fitted to the pump itself: the pump is filled

with gear oil and completely assembled on a frame.

23

Page 24

Installation

8 Installation

8.1 Installation, hydraulic

CAUTION!

Danger of personnel injury and material damage

The disregard of technical data during installation may

lead to personal injuries or damage to property.

– Observe the technical data- refer to chapter "Tech‐

nical Data" and, where applicable, the operating

instructions of the accessories.

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

WARNING!

Warning of feed chemical reactions to water

Feed chemicals that should not come into contact with

water may react to residual water in the liquid end that

may originate from works testing.

– Blow the liquid end dry with compressed air

through the suction connector.

– Then flush the liquid end with a suitable medium

through the suction connector.

WARNING!

The following measures are an advantage when

working with highly aggressive or hazardous feed

chemicals:

®

Motor-Driven Metering

– Install a bleed valve with recirculation in the

storage tank.

– Install an additional shut-off valve on the discharge

or suction ends.

24

Page 25

Installation

CAUTION!

Warning about personal and material damage

Also observe the "General Operating Instructions for

ProMinent

Hydraulic Accessories"!

CAUTION!

Suction problems possible

For feed chemicals with a particle size greater than 0.3

mm, the valves may no longer close properly.

– Install a suitable filter in the suction line.

CAUTION!

Warning against the discharge line bursting

With a closed discharge line (e.g. due to a clogged dis‐

charge line or by closing a valve), the pressure that the

metering pump generates can reach several times the

permissible pressure of the system or the metering

pump. This could lead to lines bursting resulting in

dangerous consequences with aggressive or toxic feed

chemicals.

®

Motor-Driven Metering Pumps and

– Install a relief valve that limits the pressure of the

pump to the maximum permissible operating pres‐

sure of the system.

CAUTION!

Warning against the discharge line bursting

Tube lines with insufficient pressure rating may burst.

– Only use tube lines with the required pressure

rating.

CAUTION!

Warning against lines disconnecting

With suction, discharge and relief lines installed incor‐

rectly can loosen / disconnect from the pump connec‐

tion.

– Only use original tubing with the specified tube

diameter and wall thickness.

– Only use clamp rings and tube nozzles that corre‐

spond with the respective hose diameter.

– Always connect the lines without mechanical ten‐

sion.

25

Page 26

Installation

Precise metering is only possible when the back

–

pressure is maintained above 1 bar at all times.

–

If metering at atmospheric pressure, a back pres‐

sure valve should be used to create a back pres‐

sure of approx. 1.5 bar.

Route the leakage liquid drainage line

8.2 Installation, electrical

Personnel:

The leakage liquid is drained off via the flushing collar and a tube

nozzle, without other parts of the liquid end coming into contact

with the medium.

1. Connect a tube to the lower tube nozzle.

2. Route the tube into a collection device for the leakage liquid.

WARNING!

Danger of electric shock

Unprofessional installation may lead to electric shocks.

– All cable cores cut to length must be provided with

cable end sleeves.

– The Installation, electrical of the device may only

be undertaken by technically trained personnel.

Technical personnel

n

WARNING!

Danger of electric shock

In the event of an electrical accident, it must be pos‐

sible to quickly disconnect the pump, and any electrical

ancillaries which may possibly be present, from the

mains.

– Install an emergency cut-off switch in the mains

supply line to the pump and any electrical ancilla‐

ries which may be present or

– Integrate the pump and electrical ancillaries which

may be present in the emergency cut-off manage‐

ment of the system and inform personnel of the

isolating option.

WARNING!

Danger of electric shock

This pump is equipped with a protective earth con‐

ductor, to reduce the risk arising from an electric

shock.

– Connect the PE conductor to "earth" with a clean

and permanent electrical connection.

26

Page 27

Installation

WARNING!

Danger of electric shock

A mains voltage may exist inside the pump housing.

– If the pump housing has been damaged, you must

disconnect it from the mains immediately. It may

only be returned to service after an authorised

repair.

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

®

Motor-Driven Metering

motor

CAUTION!

Warning about personal and material damage

Also observe the "General Operating Instructions for

ProMinent

®

Motor-Driven Metering Pumps and

Hydraulic Accessories"!

Personnel:

Electrician

n

What requires electrical installation?

n motor

n External fan (option)

n Stroke control drive (Option)

n Stroke adjusting drive (Option)

n Diaphragm rupture sensor

n Stroke sensor (Option)

n Frequency converter (option)

CAUTION!

Pump can be damaged

The pump can be damaged if the motor drives the

pump in the wrong direction.

– When connecting the motor, pay attention to the

correct direction of rotation indicated by the arrow

on the fan cover, as shown in Fig. 14.

27

Page 28

P_SI_0012_SW

Installation

Fig. 14: Direction of rotation of motor

CAUTION!

The motor may be damaged

The motor is not equipped with a fuse.

– Install a suitable motor protection switch.

1. Use a suitable cable between the motor terminal box and

power supply.

2. Install an emergency cut-off switch or include the motor in the

emergency cut-off management of the system.

–

Key motor data can be found on the unit name‐

plate.

–

Motor data sheets can be requested for more infor‐

mation.

–

The terminal wiring diagram is located in the ter‐

minal box.

–

Notes on the speed controlled motor with external

fan and temperature monitoring can be found in

the "General operating instructions for ProMinent

®

motor-driven metering pumps and hydraulic acces‐

sories"!

The external fan requires an independent mains con‐

nection.

Stroke sensor (Option)

Other units

Connect the stroke sensor to a suitable monitoring device

according to the details in the chapter "Technical Data". Also

observe its technical data.

Install the other units according to their documentation.

28

Page 29

9 Start up

Safety notes

Start up

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

WARNING!

Hot surface

In event the power end motor is loaded excessively, its

surface may become very hot.

– Avoid contact.

– If necessary, mount a guard plate.

®

Motor-Driven Metering

CAUTION!

Possible environmental and material damage

The screw plug in the oil filler neck is factory-fitted and,

during operation, prevents any pressure equalisation

between the power end housing and the surroundings.

This ensure that oil can be pushed from the power end

housing.

– Replace the screw plug on the oil filler neck by the

air vent plug supplied.

– Retain the sealing plug for subsequent transport of

the unit.

CAUTION!

Single head version only: Oil may escape

The screw plug in the oil filler neck is factory-fitted and,

during operation, prevents any pressure equalisation

between the power end housing and the surroundings.

This ensure that oil can be pushed from the power end

housing.

– Ensure that the hole in the metal cap on the drive

flange is always clear - see "Overview of equip‐

ment, control elements".

CAUTION!

Warning about personal and material damage

Also observe the "General Operating Instructions for

ProMinent

®

Motor-Driven Metering Pumps and

Hydraulic Accessories"!

29

Page 30

Start up

Installing a vent screw

Replace the sealing screw at the oil filler neck with the supplied

vent screw - see chapter "Overview of equipment and control ele‐

ments".

Checking the oil level

Checking the direction of rotation

When the pump is idle, check whether the pump oil level slightly

covers the lower oil inspection window.

This indicates that the pump has not lost oil and consequently

been damaged.

When commissioning the unit, check whether the drive motor is

rotating correctly - check this against the arrow on the motor

housing or the diagram in the chapter entitled "Electrical Installa‐

tion."

Eliminating suction problems (only for single ball

valves with PTFE ball seat)

For suction problems occurring during start up:

–

Exclude the possibility that there are foreign bodies

in the valve.

–

Place the valve on a stable surface.

–

Using a hammer (1) and a brass bar (2), gently tap

the PTFE ball seat above the valve ball - see figure

below.

–

Then with the valve in a damp condition allow it to

prime.

Fig. 15: Tapping the valve set disc

Adjusting the stroke length

Only adjust the stroke length when the pump is run‐

ning. This is easier and also better for the pump.

Correctly adjusting the pump:

n Select as large a stroke length as possible for viscous feed

chemicals.

n Select as large a stroke length as possible for outgassing feed

chemicals.

n Select as high a stroke rate as possible for good mixing.

n For precise metering using quantity-proportional metering, do

not set the stroke length to less than 30 %.

The pump can now be released for operation.

30

Page 31

10 During use

During use

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

WARNING!

Personnel injury and material damage may occur

During use all units, protective equipment, additional

devices must be fitted, operational and tightly closed.

®

Motor-Driven Metering

WARNING!

Hot surface

In event the power end motor is loaded excessively, its

surface may become very hot.

– Avoid contact.

– If necessary, mount a guard plate.

WARNING!

Sparking caused by dry running

If the bearings in the power end run dry, sparks can be

formed.

– Check for oil leaks.

– When the pump is idle, the pump oil level must

slightly cover the lower oil inspection window.

Observe the instructions in the "Start up" chapter and

the operating instructions for the other machine com‐

ponents.

31

Page 32

Maintenance

11 Maintenance

Safety notes

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

®

Motor-Driven Metering

Pumps and Hydraulic Accessories" must be

observed in all cases.

WARNING!

It is mandatory that you read the safety information

and specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

WARNING!

Hot surface

In event the power end motor is loaded excessively, its

surface may become very hot.

– Avoid contact.

– If necessary, mount a guard plate.

WARNING!

Warning of hazardous or unknown feed chemical

Should a hazardous or unknown feed chemical be

used, it may escape from the hydraulic components

when working on the pump.

– Take appropriate protective measures before

working on the pump (protective eyewear, protec‐

tive gloves, ...). Read the safety data sheet on the

feed chemical.

– Drain and flush the liquid end before working on

the pump.

WARNING!

Risk of fingers being crushed

Under unfavourable conditions, the stroke axle or dis‐

placement body can cause crushing of the fingers.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

32

Page 33

Maintenance

WARNING!

Risk of injury from the fan impeller

The fan impeller beneath motor's fan cowling can

cause severe injuries while it is turning.

– The pump must only be connected to the mains

voltage with the fan cowling closed.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pres‐

sure in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

– Depressurise the system before commencing any

work on hydraulic parts.

Maintenance work

Under heavy loading (e.g. continuous operation)

shorter maintenance intervals are recommended than

those given.

Keep a spare parts kit in stock ready for maintenance

work.

Order numbers are contained on the CD.

33

Page 34

3

1

(30 Nm)

2

(25 Nm)

P_MAK_0040_SW

Maintenance

Interval Maintenance work

Quarterly* EX pumps only: For special maintenance work see chapter "Important supplements for

metering pumps in hazardous locations" of the "General Operating Instructions for ProMi‐

nent® motor-driven metering pumps and hydraulic accessories"

Check the tightening torques for the dosing head screws (1) (30 Nm) and the drive flange

screws (2) (25 Nm).

Check that the discharge valve and suction valve are correctly seated.

Check the correct seating and state of the metering lines at both discharge and suction

ends.

Check for firm seating of the diaphragm rupture sensor.

Check the tightness of the entire liquid end - particularly around the leakage hole!

Check the oil level.

Single head versions only: Check that the hole in the metal cap on the drive flange is

clear - see the figure in the "Safety Chapter".

Check that the electrical connections are intact

Check whether the pump is transporting media correctly - run briefly at high power.

Observe the maximum permissible operating pressure!

Check, whether moisture can be detected at the tube nozzle (3); if so a diaphragm rupture

has probably occurred.

Fig. 16: Liquid end

1 Dosing head screws

2 Drive flange screws

3 Tube nozzle

Interval Maintenance work

After approx. 5,000 operating hours Change the gear oil.

After approx. 10,000 operating hours ** Replace the diaphragm - refer to the "Repair" chapter -

"Changing the diaphragm".

* Under normal loading (approx. 30 % of continuous operation)

Under heavy loading (e.g. continuous operation): Shorter intervals.

** under normal loading.

With very unfavourable metering parameters: Shorter intervals.

34

Page 35

P_MAK_0043_SW

1

2

Changing the gear oil

Maintenance

WARNING!

Risk of burns due to hot gear oil

The gear oil may become very hot when the pump is

heavily loaded

– When draining oil, avoid contact with the oil run‐

ning out.

Gear oil

Gear oil Supplied quantity Part no.

Mobilgear 634 VG 460 20.0 l 1006284

Gear oil filling volumes

Types Volume, approx.

All 16.5 l

Draining the gear oil:

1. Remove the vent screw (1).

2. Place an oil trough under the oil drain plug (2). Expected oil

quantity - see filling volumes, above.

3. Unscrew the oil drain plug (2) out of the power end housing.

4. Allow the gear oil to run out of the power end.

5. Screw in the oil drain plug (2) with a new seal.

Fig. 17: Oil change 1

1 Vent screw

2 Oil drain plug

35

Page 36

P_MAK_0044_SW

3

Maintenance

Filling with gear oil:

1. Start the pump.

2. Slowly pour gear oil through the vent screw (1) opening until

the upper oil inspection window (3) is slightly covered.

3. Allow the pump to run for a further 1... 2 minutes.

4. Replace the vent screw (1).

Fig. 18: Oil change 2

3 Oil inspection windows

36

Page 37

12 Repairs

Safety notes

Repairs

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

WARNING!

It is mandatory that you read the safety information

and specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

®

Motor-Driven Metering

WARNING!

Hot surface

In event the power end motor is loaded excessively, its

surface may become very hot.

– Avoid contact.

– If necessary, mount a guard plate.

WARNING!

Warning of hazardous or unknown feed chemical

Should a hazardous or unknown feed chemical be

used, it may escape from the hydraulic components

when working on the pump.

– Take appropriate protective measures before

working on the pump (protective eyewear, protec‐

tive gloves, ...). Read the safety data sheet on the

feed chemical.

– Drain and flush the liquid end before working on

the pump.

WARNING!

Risk of fingers being crushed

Under unfavourable conditions, the stroke axle or dis‐

placement body can cause crushing of the fingers.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

37

Page 38

Repairs

WARNING!

Risk of injury from the fan impeller

The fan impeller beneath motor's fan cowling can

cause severe injuries while it is turning.

– The pump must only be connected to the mains

voltage with the fan cowling closed.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pres‐

sure in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

– Depressurise the system before commencing any

work on hydraulic parts.

12.1 Replacing the membrane

WARNING!

Observe the safety notes at the beginning of the

chapter.

1. Flush the suction line, discharge lines and liquid end (activate

flushing equipment or immerse suction lance in a suitable

medium and pump for a while (consider the effect of the

medium on your system first!)) or proceed, as described

below.

2. Set the stroke length to 0 % stroke with the pump running.

3. Switch off the pump.

4. Secure the pump to prevent it being switched back on.

5. If the liquid end has not been flushed according to the above

processes, then protect yourself against the feed chemical -

protective clothing, safety glasses, ... .

After dismantling immediately place parts that have been

wetting with the medium in a trough with a suitable medium

for flushing, in dangerous media were used flush and rinse

thoroughly.

6. Unscrew the hydraulic connectors on the discharge and suc‐

tion side.

38

Page 39

1

2

3

4

5

6

7

8

9

P_MAK_0045_SW

Fig. 19: Cross-section through the liquid end

1 Dosing head

2 Diaphragm

3 Reinforce plate

4 Screw

5 Protective cover

6 Backplate

7 Bellows

8 Slide rod

9 Tube nozzle

Repairs

7. Undo the screws (4) on the reinforce plate.

8. Remove the dosing head (1) with the screws from the back‐

plate (6).

While doing this, do not damage the black bellows (7)

on the slide rod.

10. Remove the protective cover (5) from the backplate (6).

11. Unscrew the diaphragm (2) on the grooves of its shaft from

the slide rod (8) and remove. Use a sickle spanner inserted

through the slot in the backplate (6).

12. Clean the sealing surfaces.

13. Check the state of the bellows (7).

14. Screw the new diaphragm (5) up to the stop on the slide rod

(8).

This must be done correctly to ensure the pump meters

ð

accurately.

15. Place the dosing head (1) and the reinforce plate (3) onto the

backplate (6).

16. Position the screws

39

Page 40

Repairs

12.2 Valve repair

17. Start the pump and tighten the screws crosswise at a 100%

stroke.

Tightening torque 30 Nm

18. Position the protective cover (5) on the backplate (6).

–

Check the tightening torque of the screws after 24hours' operation.

–

With PP dosing heads, recheck the tightening

torque again after three months.

Unsuitable spare parts for the valves may lead to prob‐

lems for the pumps.

12.2.1 Double ball valves

Cleaning a discharge valve

–

Only use new components that are especially

adapted to fit your valve (both in terms of shape

and chemical resistance).

–

Use the correct spare part kits. In case of doubt,

refer to the exploded views and ordering informa‐

tion contained in the "Supplementary information

CD for ProMinent® pump operating instructions".

Clean the discharge and suction valves only one after

another as they cannot be differentiated using the

arrow markings.

Taking the discharge valve apart

1. Unscrew the discharge valve from the dosing head and rinse

out.

2. Dismantle the discharge valve.

3. Rinse and clean all parts.

4. Replace the worn parts and seals.

Assembling the discharge valve

40

Page 41

When assembling, take note of the orientation of the

1

2

3

4

*

5

*

6

7

valve seats (3). The valve seats (3) are used as a ball

seat on the fine machined side and as a ball cage and

spring guide on the other side. The fine machined side

must point in the flow direction with all valve seats.

When assembling the valves, take note of the

sequence:

Teflon – Metal – Teflon – Metal - ...

1. Slide into the valve body (1) one after another:

n one seal (2) and one valve seat (3) - correct!

n one seal (2) and one valve bushing (4)

n (If fitted: one spring (*) into the spring guide of the valve

seat (3)

n one ball (5) into the valve body (1)

n one seal (2) and the second valve seat (3, correct!)

n one seal (2) and the second valve bushing (4)

n (If fitted: the second spring (*) into the spring guide of the

valve seat (3))

n the second ball (5) into the valve body (1)

n one seal (2), the third valve seat (3) - (correct!) and a fur‐

ther seal (2)

Repairs

2. Position the insert disc (6) with the flare on the packing.

The distance between the edge of the valve body

and the insert disk (6) is due to the construction.

3. Place the larger seal (7) between the insert disk (6) and the

dosing head.

Fig. 20: Discharge valve (double ball

4. Screw in the valve until the stop.

valve).

Cleaning a suction valve

A suction valve is dismantled, cleaned and assembled in the same

way as a discharge valve.

Please note, however, that when assembling, the

valve seat (3) must be aligned in the other direction.

The fine machined side must point in the flow direction

with all valve seats (3).

12.2.2 Single ball valves

1. Screw the valve cap (5) on to the suction side - see Fig. 21.

2. Carefully remove the parts from the valve body (2).

3. Replace the worn parts.

4. Clean the remaining parts.

5. Check all parts.

41

Page 42

1

2

3

4

5

P_MAK_0054_SW

Repairs

6. If available: Place the compression spring inside the valve

body (2).

7. Insert the valve ball (3 and the valve seat (4).

8. Screw on the valve cap (5).

Pay attention to the flow direction of the discharge and

suction connectors when fitting the valve.

12.2.3 Plate valves

Fig. 21: Cross-section through the single ball valve

1 Seal

2 Valve body

3 Valve ball

4 Valve seat

5 Valve cap

Do not scratch the finely machined sealing surfaces on

the valve plates (5) and valve inserts (6).

42

Page 43

1

2

3

4

5

6

7

P_MAK_0055_SW

Fig. 22: Section through a plate valve (DN65 shown)

V

N

P_MAK_0056_SW

1 Valve cap II (only DN 65)

2 Perforated disc (only DN 65)

3 Compression spring

4 Valve body

5 Valve plate

6 Valve insert

7 Valve cap

Repairs

1. Screw the valve cap (7) on to the suction side - see Fig. 22.

2. Carefully remove the parts from the valve body (4).

3. Replace the worn parts.

4. Clean the remaining parts.

5. Check all parts.

6. Only DN 65: Insert the perforated disc (2) in the valve body

(4).

7. Place the compression spring (3) inside the valve body (4).

Position the compression spring with the end

(see figure: arrow N, at the bottom) as shown on

one of the lugs in the valve body.

Otherwise the valve plate may knock when in

operation.

8. Insert the valve plate (5) and the valve insert (6).

9. Screw on the valve cap (7).

Pay attention to the flow direction of the discharge and

suction connectors when fitting the valve.

43

Page 44

Repairs

Fig. 23: Inserting the compression

spring

44

Page 45

13 Troubleshooting

Safety notes

Troubleshooting

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

WARNING!

Fire danger

Only with combustible media: These may start to burn

when combined with oxygen.

– When filling and draining the liquid end, the feed

chemical must not come into contact with oxygen.

®

Motor-Driven Metering

WARNING!

Hot surface

In event the power end motor is loaded excessively, its

surface may become very hot.

– Avoid contact.

– If necessary, mount a guard plate.

WARNING!

Danger of an electric shock

Personnel working on electrical parts can be electro‐

cuted if all electrical lines carrying current have not

been disconnected.

– Disconnect the supply cable before working on the

motor and prevent it from being reconnected acci‐

dentally.

– Any separately driven fans, servo motors, speed

controllers or diaphragm rupture sensors fitted

should also be disconnected.

– Check that the supply cables are de-energised.

45

Page 46

Troubleshooting

WARNING!

Warning of hazardous or unknown feed chemical

Should a hazardous or unknown feed chemical be

used, it may escape from the hydraulic components

when working on the pump.

– Take appropriate protective measures before

working on the pump (protective eyewear, protec‐

tive gloves, ...). Read the safety data sheet on the

feed chemical.

– Drain and flush the liquid end before working on

the pump.

WARNING!

Risk of injury from the fan impeller

The fan impeller beneath motor's fan cowling can

cause severe injuries while it is turning.

– The pump must only be connected to the mains

voltage with the fan cowling closed.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pres‐

sure in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

– Depressurise the system before commencing any

work on hydraulic parts.

Tasks

Fault description Cause Remedy Personnel

Pump does not prime in

spite of full stroke

The valves are

dirty or worn.

Repair the valves - see chapter entitled

"Repair".

Technical

personnel

motion and bleeding

Pump does not reach

high pressure rates.

The valves are

dirty or worn.

The feed chemical

has particles larger

Repair the valves - see chapter entitled

"Repair".

Technical

personnel

Install a suitable filter in the suction line. Technical

personnel

than 3 mm.

The motor is wired

incorrectly.

The mains voltage

has failed.

1. Check the mains voltage and mains fre‐

Electrician

quency.

2. Wire the motor correctly.

Eliminate the cause. Electrician

46

Page 47

Troubleshooting

Fault description Cause Remedy Personnel

The diaphragm rupture

warning system gener‐

ates an alarm.

No hydraulic oil flows

The multi-layer dia‐

phragm is rup‐

tured.

- - - - Immediately switch off the pump and inform

through the tube at the

bleed valve

The power end motor is

very hot.

The discharge line

is seriously con‐

stricted.

All other faults. Other causes.

n Replace the multi-layer diaphragm

immediately - refer to the "Repair"

chapter - "Changing the diaphragm".

n If necessary replace the separating dia‐

phragm of the diaphragm rupture sensor

- see "Replacing the separating dia‐

phragm, diaphragm rupture sensor" in

the chapter "Repair".

n Check the diaphragm rupture warning

system for correct operation.

customer service.

n Rectify any constriction of the discharge

line.

n Have the safety relief valve checked.

Call ProMinent®

or ProMaqua® service.

Technical

personnel

Technical

personnel

47

Page 48

Decommissioning and disposal

14 Decommissioning and disposal

14.1 Decommissioning

WARNING!

Warning about personal and material damage

EX pumps only: When operating in EX areas, certain

subjects must be observed.

– The chapter "Important supplements for metering

pumps in EX zones" of the "General Operating

Instructions on ProMinent

Pumps and Hydraulic Accessories" must be

observed in all cases.

WARNING!

Danger of an electric shock

When working on the motor or electrical auxiliary

equipment, there is a danger of an electric shock.

®

Motor-Driven Metering

– Before working on the motor, take note of the

safety instructions in its operating instructions!

– Should external fans, servomotors or other auxil‐

iary equipment be installed, these should also be

disconnected and checked that they are voltage

free.

WARNING!

Danger from chemical residues

There is normally chemical residue in the liquid end

and on the housing after operation. This chemical res‐

idue could be hazardous to people.

– It is mandatory that the safety note relating to the

"Storage, Transport and Unpacking" chapter is

read before shipping or transporting the unit.

– Thoroughly clean the liquid end and the housing of

chemicals and dirt. Adhere to the safety data sheet

for the feed chemical.

WARNING!

Warning of hazardous or unknown feed chemical

Should a hazardous or unknown feed chemical be

used, it may escape from the hydraulic components

when working on the pump.

– Take appropriate protective measures before

working on the pump (protective eyewear, protec‐

tive gloves, ...). Read the safety data sheet on the

feed chemical.

– Drain and flush the liquid end before working on

the pump.

48

Page 49

Decommissioning and disposal

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pres‐

sure in the liquid end and adjacent parts of the system.

– Disconnect the pump from the mains power supply

and ensure that it cannot be switched on again by

unauthorised persons.

– Depressurise the system before commencing any

work on hydraulic parts.

WARNING!

Hot oil and hot components

The hydraulic oil and the hydraulic end may become

very hot when the pump is exposed to heavy loading.

– Allow the pump to cool before starting work.

Final decommissioning

CAUTION!

Danger of damage to the device

The device can be damaged by incorrect and improper

storage or transportation.

– Take into account the information in the "Storage,

Transport and Unpacking" chapter if the system is

decommissioned for a temporary period.

Personnel:

Technical personnel

n

1. Disconnect the pump from the mains power supply.

2. Depressurise and bleed the hydraulic system around the

pump.

3. Flush the liquid end with a suitable medium - Observe the

safety data sheet! Flush the dosing head thoroughly when

using hazardous feed chemicals!

4. Drain the gear oil - refer to the chapter entitled "Mainte‐

nance".

Temporary decommissioning

5. Thoroughly clean the liquid end and the housing of chemicals

and dirt.

6. Possible additional work - see chapter "Storage, Transport

and Unpacking".

In addition:

1. Place the caps on the valves.

2. Push the caps into place on the tube nozzles.

49

Page 50

Decommissioning and disposal

3. Preferably place the pump on a pallet.

4. Cover the pump with a tarpaulin cover - allowing rear ventila‐

tion!

5. Store the pump is a dry, sealed place under storage condi‐

tions according to the chapter "Storage, Transport and

Unpacking".

14.2

Disposal

Personnel:

Technical personnel

n

CAUTION!

Environmental hazard due to gear oil

The pump contains gear oil, which can cause damage

to the environment.

– Drain the gear oil from the pump.

– Note the local guidelines currently applicable in

your country!

CAUTION!

Note the local guidelines generally currently applicable

in your country!

50

Page 51

15 Technical data

Only for "M - modified" version:

15.1 Performance data

Main pumps with motor 1500 rpm

under 50 Hz operation

Technical data

WARNING!

Risk of personal injuries

Please observe the ”Supplement for modified ver‐

sion“ at the end of the chapter!

It replaces and supplements the technical data!

Type Minimum pump capacity at max‐

imum back pressure

bar l/h ml/stroke Strokes/min m WS G-DN kg

41540 4 1540 427 60 3 2 1/2"-50 320

41900 4 1900 427 75 3 2 1/2"-50 320

42600 4 2600 427 103 3 2 1/2"-50 320

43400 4 3400 427 133 3 2 1/2"-50 320

44000 4 4000 427 156 3 2 1/2"-50 320

* Stainless steel material version Shipping weight 340 kg

The shipping weight is applicable to single head pumps without an

add-on power end.

The permissible priming pressure at the suction side is approxi‐

mately 50% of the max. permitted back pressure

All figures refer to water at 20 °C.

The suction lift applies to filled suction line and filled liquid end when installed correctly.

The priming lift of 2 m applies for clean and moistened valves and

a clear outlet

Maximum

stroke rate

Suction

lift

Connector

size

Shipping

weight*

51

Page 52

Technical data

Main pumps with motor 1800 rpm

under 60 Hz operation

Type Minimum pump capacity at max‐

imum back pressure

psi l/h gph Strokes/min m WS G-DN kg

41540 58 1822 482 71 3 2 1/2"-50 320

41900 58 2254 597 89 3 2 1/2"-50 320

42600 58 3104 822 123 3 2 1/2"-50 320

43400 58 4064 1076 159 3 2 1/2"-50 320

44000 58 - - - 3 2 1/2"-50 320

* Stainless steel material version Shipping weight 340 kg

The permissible priming pressure at the suction side is approxi‐

mately 50% of the max. permitted back pressure

All figures refer to water at 20 °C.

The suction lift applies to filled suction line and filled liquid end when installed correctly.

The priming lift of 2 m applies for clean and moistened valves and

a clear outlet

Maximum

stroke rate

Suction

lift

Connector

size

Shipping

weight*

15.2

15.2.1

Accuracy

Reproducibility

15.2.2 Metering precision

Data Value Unit

Reproducibility ±2 % *

* for measurements taken under constant conditions, minimum 10

% stroke rate and water at 20 °C - when installed correctly, p< 1

bar

Data Value Unit

Metering precision ±1 % *

* at maximum stroke length and maximum back pressure

15.3 Viscosity

The liquid ends are generally suitable for the following viscosity

ranges:

52

Page 53

Version Range Unit

no valve springs 0 ... 200 mPas

with valve springs 200 ... 500 mPas

Technical data

with appropriately

laid out installation

with appropriately

laid out installation

and advice from

ProMinent

* Only when the installation is correctly adjusted

500 ... 1000 mPas

> 1000 mPas

15.4 Wetted materials

Material ver‐

sion

PPT Polypropylene Polypropylene PTFE Ceramic / Hast. C

PCT PVC PVC PTFE Ceramic / Hast. C

Liquid end Suction/dis‐

charge con‐

nector

Seals Valve plates /

valve spring

+ CTFE**

+ CTFE**

Valve seat

PTFE

PTFE

TTT PTFE with

carbon

SST Stainless steel

1.4571//1.44041

.4404

15.5 Ambient conditions

15.5.1 Temperatures

Pump, compl.

PC liquid end

PTFE with

carbon

Stainless steel

1.45711.4404

DEVELOPAN® metering diaphragm with PTFE coating.

** The valve spring is coated with CTFE (similar to PTFE)

Data Value Unit

Storage and transport temperature -10 ... +50 °C

Ambient temperature in operation

(drive + motor):

Data Value Unit

PTFE Ceramic / Hast. C

+ CTFE**

PTFE Stainless steel

1.4404/ Hast. C

-10 ... +40 °C

PTFE

PTFE

Max. temperature long-term at max.

operating pressure

Max. temperature for 15 min at max. 2

bar

53

45 °C

60 °C

Page 54

Technical data

Data Value Unit

Minimum temperature -10 °C

PP liquid end

TT liquid end

SST liquid end

Data Value Unit

Max. temperature long-term at max.

60 °C

operating pressure

Max. temperature for 15 min at max. 2

100 °C

bar

Minimum temperature -10 °C

Data Value Unit

Max. temperature long-term at max.

90 °C

operating pressure

Max. temperature for 15 min at max. 2

120 °C

bar

Minimum temperature -10 °C

Data Value Unit

Max. temperature long-term at max.

90 °C

operating pressure

Max. temperature for 15 min at max. 2

bar

Minimum temperature -10 °C

15.5.2 Air humidity

Data Value Unit

Maximum air humidity *: 95 % rel.

*non-condensing (according to DIN IEC 60068-2-30)

15.6 Housing degree of protection

Data Value

Protection against contact and humidity* IP 55

*according to DIN VDE 470 (EN IEC 60529)

120 °C

humidity

54

Page 55

15.7 Stroke sensor (option), intrinsically safe

Namur sensor (identity code specifica‐

tion "Stroke sensor": 1)

Install the sensor according to the chapter "Installation,

electrical".

Technical data

Namur sensor (Specified for EX

zones)

5–25 V DC, in accordance with Namur or DIN 19234, potential-free

design.

Data Value Unit

Rated voltage * 8 VDC

Power consumption - active surface

uncovered

Power consumption - active surface

covered

Rated switching distance 1.5 mm

* Ri ~ 1 kΩ

Cable colour Polarity

blue -

brown +

> 3 mA

< 1 mA

15.8 Filling volumes

15.8.1 Gear oil

15.9 Sound pressure level

Sound pressure level

Gear oil

Gear oil Supplied quantity Part no.

Mobilgear 634 VG 460 20.0 l 1006284

Required amount of oil

Pump type Oil change, compl.

All: 16.5 l

Sound pressure level LpA < 75 dB in accordance with EN ISO

20361:2010-10

at maximum stroke length, maximum stroke rate, maximum back

pressure (water)

55

Page 56

Technical data

15.10 Compatibility

The hydraulic accessories of the Makro/ 5 metering pump Hydro

are compatible with the Sigma and Makro TZ piston pumps.

The connecting dimensions of valves and dosing heads are the

same size but have different materials. (This does not apply with

different diaphragm materials).

15.11

Technical data

motor

Spare parts

Supplement for modified versions

(With Identcode specification "Version": "M" - "modified")

Technical data of pumps in the modified version can deviate from

those of the standard pumps. They can be queried by stating the

details of the serial number.

The motor data sheets for the modified version are valid. They may

deviate from the standard motor data sheets.

With a modified version, it is absolutely necessary to specify the

details of the serial number requesting and ordering the spare and

replacement parts.

56

Page 57

16 EC Declaration of Conformity

- Original -

EC Declaration of Conformity for Machinery

We,

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

DE - 69123 Heidelberg

hereby declare that the product specified in the following complies with the relevant basic health and safety rules of the

EC Directive, on the basis of its functional concept and design and in the version marketed by us.

This declaration loses its validity in the event of a modification to the product not agreed with us.

Description of the product:

Metering pump, Makro 5 series

Product type:

M5Ma..., M5Ka..., M5Ha...

Serial no.:

Please refer to nameplate on the device

Relevant EC

Directives:

EC - Machinery Directive (2006/42/EC)

EC EMC Directive (2004/108/EC)

The safety objectives of the Low Voltage Directive 2006/95/EC are complied

with

in accordance with Appendix I, No. 1.5.1

of the Machinery Directive 2006/42/EC

Harmonised standards applied, in

particular:

EN ISO 12100, EN 809,

EN ISO 13732-1, EN 60034-5, EN 60034-6, EN 60034-9,

EN 60204-1, EN 61000-6-2, EN 61000-6-3

Technical documents have

been compiled by documentation

specialists:

Norbert Berger

Im Schuhmachergewann 5-11

DE-69123 Heidelberg

05/10/2011

Date / Manufacturer's signature:

Joachim Schall, Head of Development

Details of the signatory:

For pumps without explosion protec‐

tion:

EC Declaration of Conformity

57

Page 58

EC Declaration of Conformity

For pumps with explosion protection:

The EC Declaration of Conformity for pumps for potentially explo‐