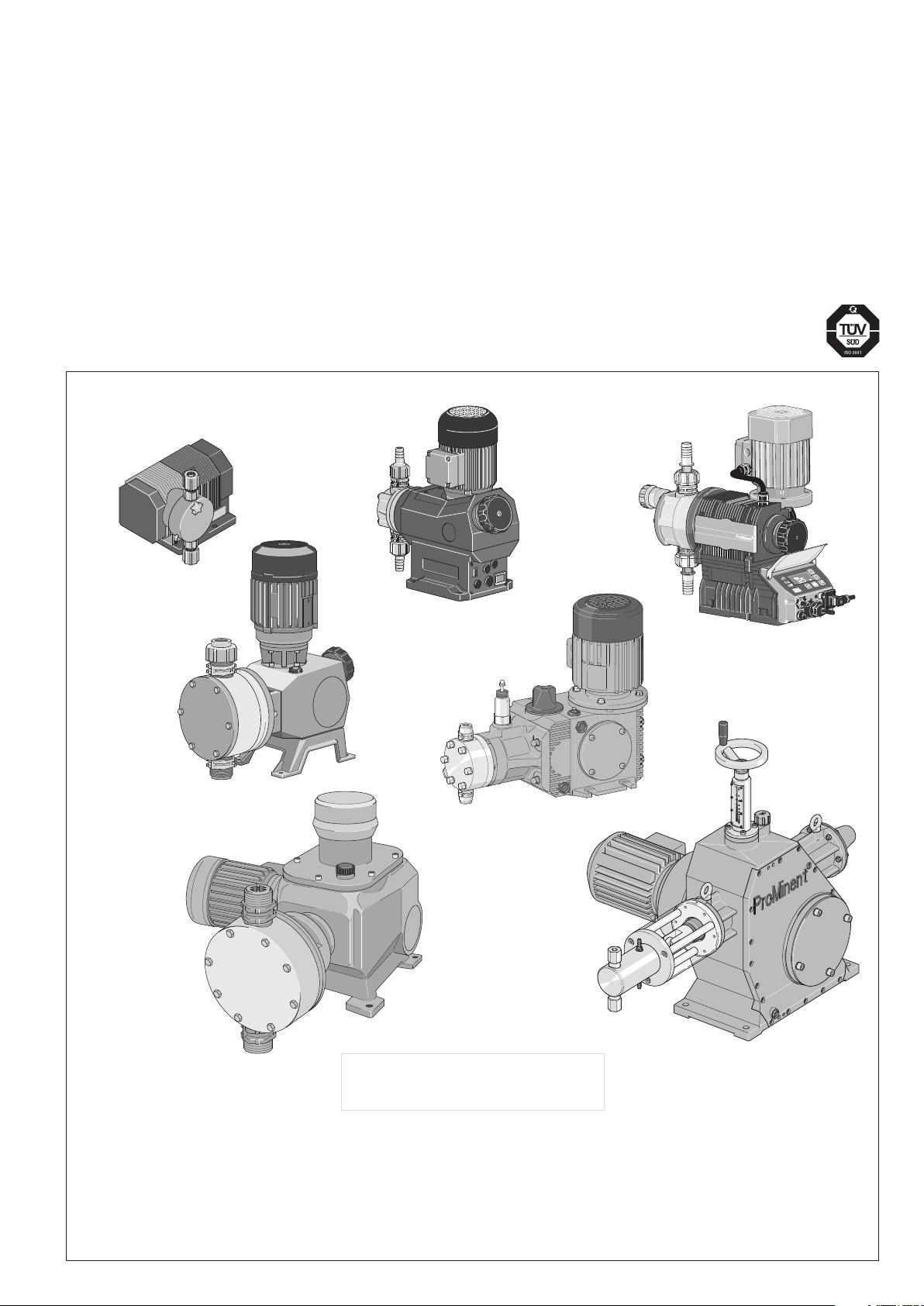

ProMinent alpha Series, Hydro Series, Meta Series, Vario Series, Sigma Series General Operating Instructions

...Page 1

General Operating Instructions

ProMinent® Motor-Driven Metering Pumps

and Hydraulic Accessories

®

ProMinent

alpha

Meta

Vario

Sigma

Hydro

Makro/ 5

Makro TZ

Two sets of operating instructions are necessary to ensure safe operation of the metering pumps corresponding to their

intended purpose: The product-specific operating instructions (e.g. for Sigma) and the general operating instructions

for ProMinent

Both are only applicable in conjunction with each other.

Please completely read through these operating instructions first! Do not discard!

The warranty shall be invalidated by damage caused by operating errors!

Part No. 987702 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany BA MOZ 015 05/06 GB

®

motor-driven metering pumps.

Page 2

Legal notice

Page 2

Legal notice:

General Operating Instructions for

ProMinent® Motor-Driven Metering Pumps

© ProMinent Dosiertechnik GmbH, 1995

Address:

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

info@prominent.com

www.prominent.com

Subject to technical modifications.

ProMinent

ProMinent

®

®

Page 3

Table of Contents

Table of Contents

User Information ................................................................................................................................................................................ 4

1 Application of Motor-Driven Metering Pumps

2 Safety Notes

3 Mounting

4 Installation, hydraulic

4.1 Standard Installation

4.2 Notes on Installation on Intake Side

4.3 Notes on Installation on Delivery Side

4.4 How not to install pumps

4.5 Special Notes on Installation

5 Installation, electrical

5.1 Motor

6 Start-Up

7 Maintenance

8Troubleshooting

................................................................................................................................................................................. 5

......................................................................................................................................................................................... 6

.......................................................................................................................................................... 7

.................................................................................................................................................. 8

............................................................................................................. 9

......................................................................................................... 10

....................................................................................................................................... 12

............................................................................................................................... 13

.......................................................................................................................................................... 15

...................................................................................................................................................................................... 15

............................................................................................................................................................................................ 17

................................................................................................................................................................................ 18

........................................................................................................................................................................ 18

............................................................................................. 5

9 Other important considerations for dosing pumps in ex-zones

9.1 Application in accordance with regulations

9.2 Safety instructions

9.2.1 Safety equipment

....................................................................................................................................................... 19

.......................................................................................................................................... 19

9.2.2 EU declaration of conformity / certification

9.3 Assemble

9.4 Installation, hydraulic

9.5 Installation, electrical

9.6 Commissioning

9.7 Maintenance

9.8 Troubleshooting

9.9 Repair

9.10 Decommissioning

10 Hydraulic Accessories

............................................................................................................................................................................ 19

................................................................................................................................................. 20

................................................................................................................................................. 21

.............................................................................................................................................................. 21

..................................................................................................................................................................... 22

............................................................................................................................................................. 23

..................................................................................................................................................................................... 23

......................................................................................................................................................... 23

........................................................................................................................................................ 24

10.1 Overview and Notes on Accessories

10.2 Back pressure valve / relief valve

10.3 Pulsation Dampers

Appendix

.......................................................................................................................................................................................... 28

...................................................................................................................................................... 26

.................................................................................................................... 26

Warranty Application for Metering Pumps and Accessories

Data for Calculating Metering Line

Installing Drawing

Safety declaration form

...................................................................................................................................................................... 30

......................................................................................................................................................... 31

.............................................................................................................................. 29

............................................................................................ 19

............................................................................. 19

............................................................................................................ 24

................................................................... 28

................................................. 19

ProMinent

ProMinent

®

®

Page 3

Page 4

User Information

User Information

Please read through the following user guidelines. Familiarity with these points ensures optimum

use of the operating instructions.

Key points in the text are indicated as follows:

• Enumerated points,

왘 Hints

Working Guidelines:

NOTE

Notes on operation.

Safety Guidelines:

WARNING

There is a danger to life or the risk of serious injury if the notes on safety are disregarded!

CAUTION

There is a danger of slight injury and damage to property if the notes on safety are

disregarded!

IMPORTANT

There is a danger of damage to property if the notes on safety are disregarded.

These general operating instructions for motor-driven metering pumps and hydraulic assemblies

apply only in conjunction with the product-related pump operating instructions for e.g. alpha,

Vario, Meta, Sigma, Hydro, Makro/ 5 and Makro TZ motor-driven metering pumps.

Page 4

ProMinent

ProMinent

®

®

Page 5

Application of Motor-Driven Metering Pumps / Safety Notes

1 Application of Motor-Driven Metering Pumps

ProMinent® motor-driven metering pumps and accessories are to be used solely for the purpose

of metering liquid media!

In explosion-threatened workplaces in zone 1, device category II 2G of explosion group II C

the pump may not be operated without the corresponding rating plate (and the corresponding

EC conformity declaration) for pumps for explosion-threatened workplaces in accordance with

guideline 94/9/EC of the European guidelines. The explosion group, category and type of

protection shown on the marking must correspond to or exceed the conditions prevailing in the

intended area of application.

All other uses or modifications are prohibited!

Pumps may never be operated in explosion-threatened workplaces without a corresponding

rating plate (and the corresponding EC conformity declaration) for pumps for explosionthreatened workplaces.

®

ProMinent

metering gasses and solids!

Refer to the relevant product-related operating instructions and product cataloque for the

technical data of the type of motor-driven metering pump used!

Decisive criteria relating to the intended use of the pumps are

• EX-protection of the pump

• Resistance of parts coming in contact with metered medium

• Pressure and temperature of metered medium

motor-driven metering pumps and accessories are not to be used for the purpose of

2 Safety Notes

WARNING

• Explosion-proof pump only: it is essential that you observe the contents of section 9!

• Immediately switch off the pump in case of emergency! Use the power switch on

the pump or an emergency switch in your immediate operating environment!

• Pumps for radioactive medium must not be shipped through standard channels!

• Observe applicable national regulations for installation abroad!

CAUTION

• Do not obstruct or block access areas!

Pumps must be accessible at all times to facilitate operation and maintenance.

• Only specially trained and authorized persons are permitted to carry out maintenance

and repairs on metering pumps and their periphery!

• Always depressurize the liquid end first before carrying out any work on the pump!

• If hazardous or unknown metering media are used, discharge and flush the liquid end

before carrying out any work on the pump!

• Observe safety specifications for liquid metered media! Corresponding protection and

emergency measures must be implemented prior to initial operation.

• Always wear protective clothing (safety goggles, gloves,...) when handling hazardous or

unknown liquid media! This applies particularly when working on the liquid end!

• Do not use parts which have not been tested and approved by ProMinent for assembly of

ProMinent

property, for which no liability will be accepted!

• Install safety devices in the system, e.g. overflow valves!

ProMinent

whether the delivery line is closed, e.g. by closing off the delivery line or by closing a valve,

the pressure produced by the pump can reach a multiple of the permissible working

pressure of the system or of the metering pump. This can result in lines bursting with

dangerous consequences particularly in the presence of aggressive or toxic media!

• Piston pumps must always be equipped with a dry-run protection facility to avoid the

pump packing running dry as this may cause overheating and thus premature wear.

®

motor-driven metering pumps since this can result in damage to persons and

®

motor-driven pumps are oscillating displacement pumps. Irrespective of

ProMinent

ProMinent

®

®

Page 5

Page 6

Safety Notes / Mounting

DN

fig.1

m

m

fig. 2

fig. 3

Head valve

Intake valve

Liquid end

f

f

f

IMPORTANT

• Based on state-of-the-art technology, the manufacturer carefully selects the materials

•Avoid over-feed with positive pressure difference (at least 1 bar) between discharge

• Only specially trained personnel are permitted to operate the metering pump.

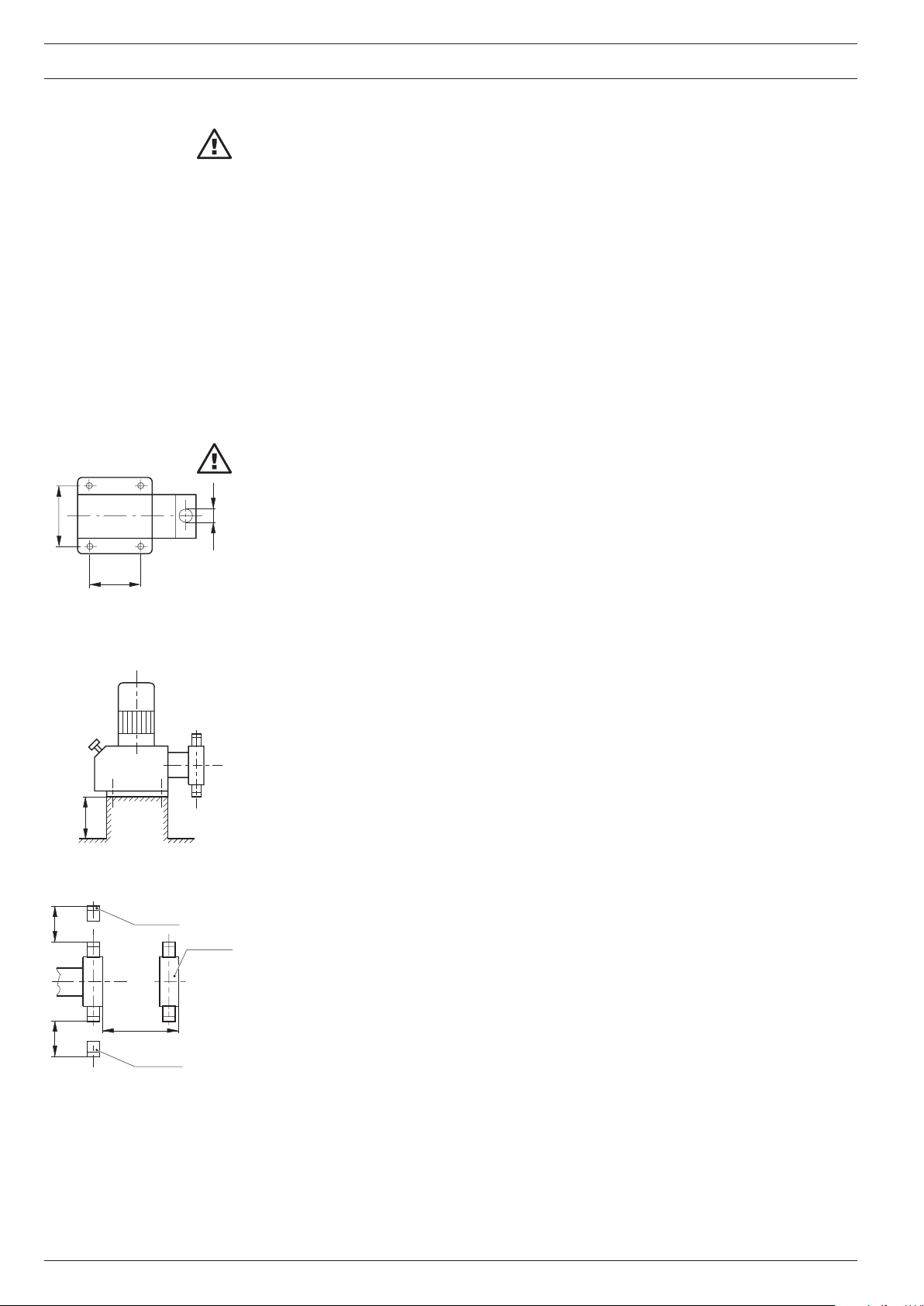

3 Mounting

IMPORTANT

• Mount the metering pump upright with the feet on a horizontal base. Refer to the

• The frame or the foundation for mounting the pump must be designed such as to

for parts coming into contact with the medium as specified by the customer.

The manufacturer shall not be liable for any damage caused by metering other media

or media which has been modified with regard to its properties (concentration, density,

temperature, additives, impurities etc.).

and suction sides.

The operator must ensure by applying appropriate accident prevention measures that

operating personnel are not endangered under given operating conditions (pressure,

temperature, aggressivity etc.).

corresponding data sheets for the dimensions (m) of the securing holes.

ensure the unit is free of vibration and stable.

• Install pump at convenient operating level and mount such that the valves are vertical:

head valve always at top and intake valve always at bottom.

• Ensure adequate clearance (f) in area of liquid end as well as intake valve and head

valve so that these parts can be easily removed if required.

Page 6

ProMinent

ProMinent

®

®

Page 7

Mounting / Installation, hydraulic

fig. 4

A

A

fig. 5

DN

pipe

DN

pump valve

DN

pump valve

fig. 6

Pressure

gauge sleeve

Pipe

(delivery line)

Pressure

control valve

Intake valve

Pipe

(intake line)

Pressure

gauge sleeve

fig. 7

Steel/stainless steel

pipe

Flexible pipe adapter

Plastic connecting piece

• Set up the pump such that the stroke length adjustment, indicator scale A, oil level

indicator, oil filler and drain plugs as well as the valves are easily accessible for

servicing.

• Ensure nominal diameters of pipes and installed fittings are the same size or larger

than the nominal diameters of the pump valves (intake and head valves).

4 Installation, hydraulic

WARNING

• Explosion-proof pump only: it is essential that you observe the contents of section 9!

IMPORTANT

• Observe the relevant national directives with regard to installation!

• In order to verify the pressure conditions in the piping system it is recommended to

provide connection options for manometer close to the suction and pressure port.

• Connect pipes to the pump such that there is no stress or strain whatsoever acting

on the pump, such as offset, weight or expansion of the pipe. Only use a flexible pipe

adapter for connecting steel/stainless steel pipes to plastic pump housings.

ProMinent

ProMinent

®

®

Page 7

Page 8

Mounting

Delivery line

Metering tank

PD

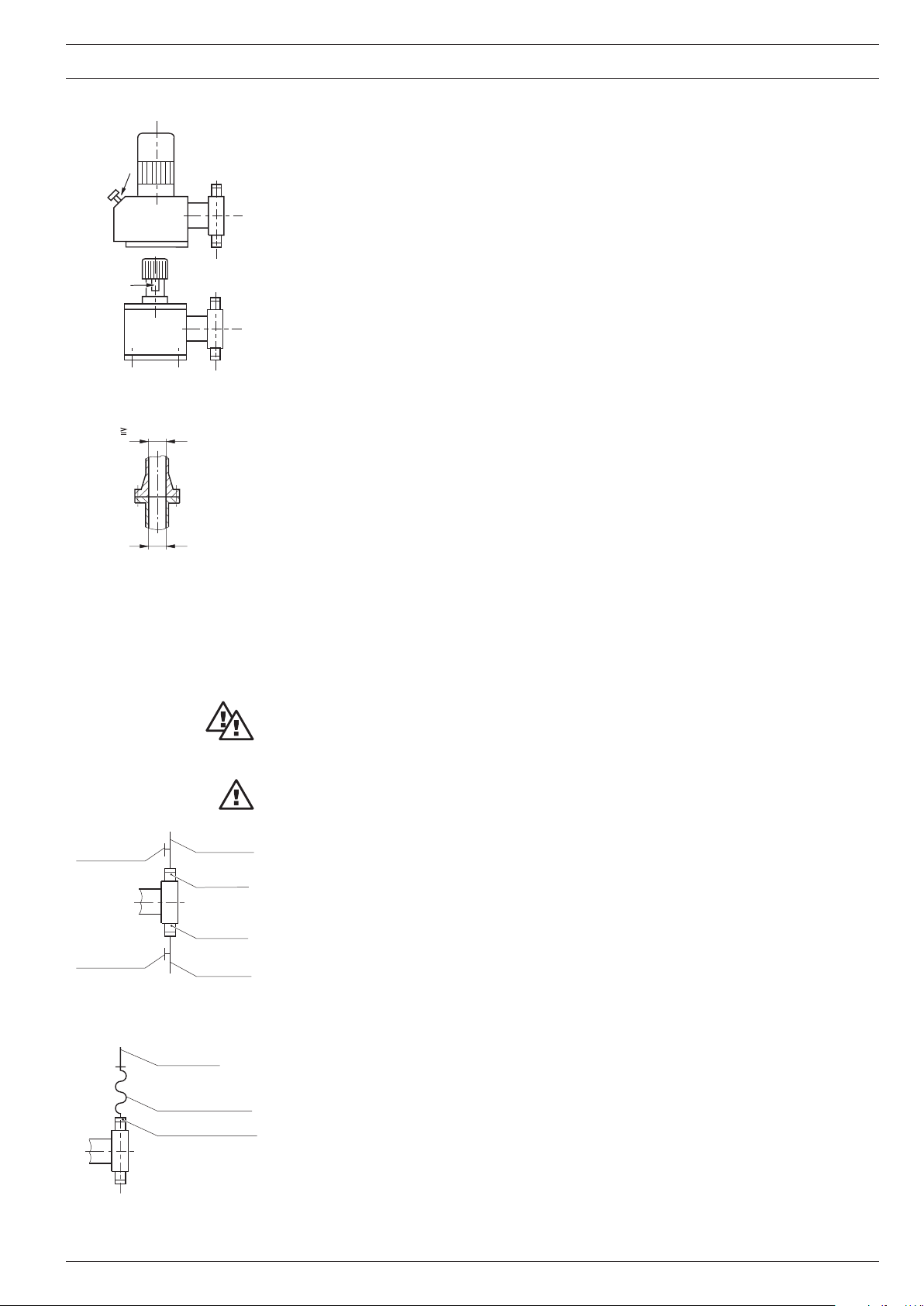

4.1 Standard Installation

Diagram 8

Metering pump Dirt trap

Metering valve Solenoid valve

Adjustable pressure control valve

Pulsation damper

(Overflow valve)

Foot valve with sieve filter Float valve

Pressure gauge Filler device

Ball check valve Siphon vessel

Shut-off cock valve

Page 8

ProMinent

ProMinent

®

®

Page 9

Installation, hydraulic

h

fig. 9

fig. 10

fig. 11

fig. 12

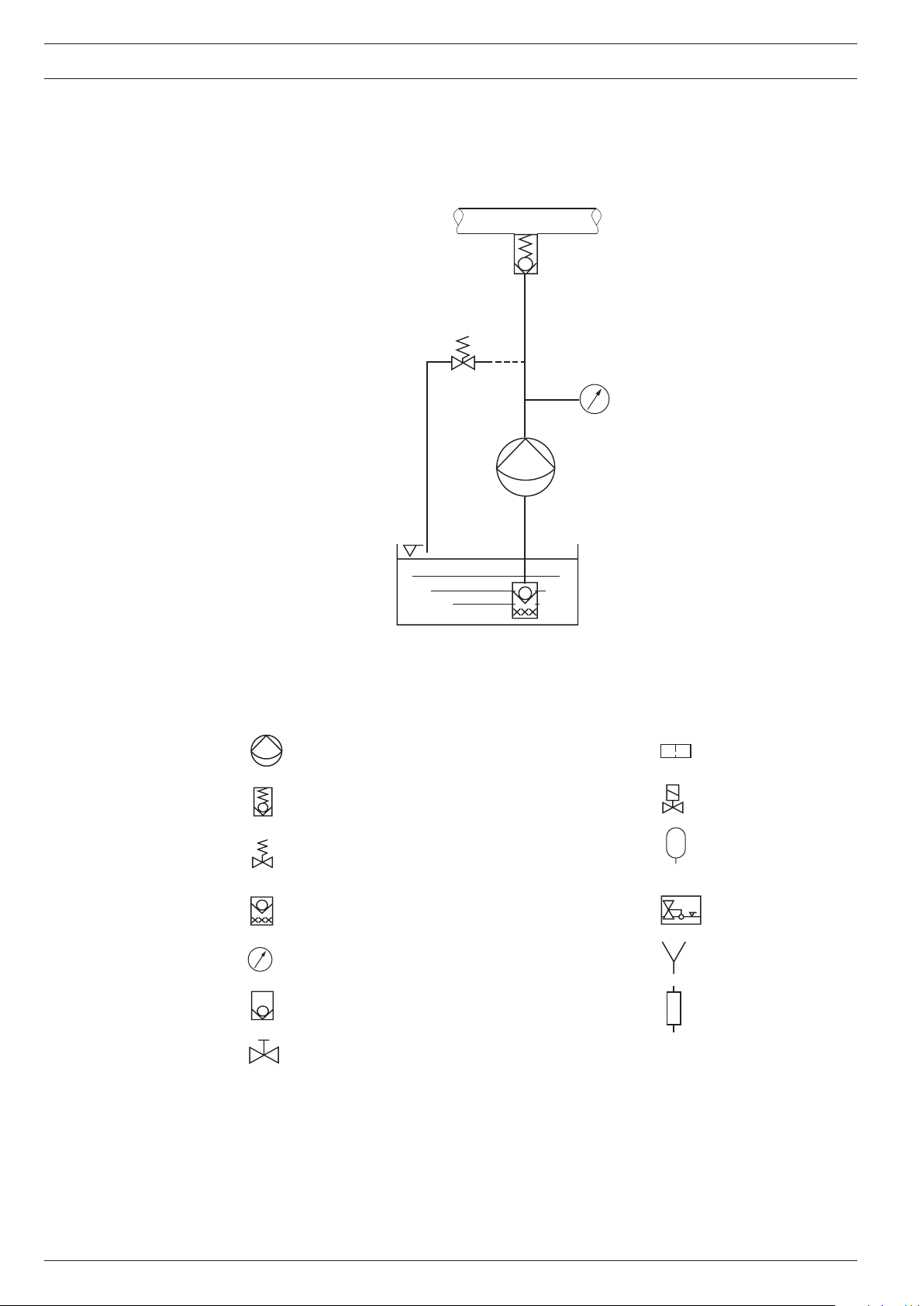

4.2 Notes on Installation on Intake Side

NOTE

Avoid the intake line running empty:

• Install foot valve at end of intake line when the pump is higher than the max. liquid level

in the intake tank.

• The calculated size h (see diagram) must not be greater than the specified pump

suction head divided by the density of the delivered medium.

• Use short intake line and avoid thin-walled hoses.

NOTE

Connect intake line to tank slightly above the base of the tank.

IMPORTANT

Provide suitable means for retaining impurities!

Otherwise they can cause faults in the pump and system!

E.g. install a dirt trap (mesh size 100–400 µm depending on medium and type of metering

pump).

NOTE

Install pump with inlet on intake side for gas-emitting media.

NOTE

Intake via siphon line for high-level tanks without connection facilities at base of tank:

• Install filler facility for siphon line (intake line).

• Observe acceleration pressures due to the longer intake line.

ProMinent

ProMinent

®

®

Page 9

Page 10

fig. 15

Installation, hydraulic

fig. 13

fig. 14

4.3 Notes on Installation on Delivery Side

IMPORTANT

Do not exceed permissible nominal pressure! Otherwise the pump may be damaged!

Provide an overpressure facility if the permissible pressure in the pump head can be

exceeded, e.g. by closing a shut-off element or a blockage in the line:

• Install overflow valve in the delivery line or

• use an overflow valve integrated in the pump housing (depending on type, refer to

data sheet of the type of pump used).

The following points must be observed with regard to the overflow line when using an

overflow valve:

• Route the overflow line with a drop into the supply tank under atmospheric pressure

or into an open runoff channel.

• Connect the overflow line to the intake line, however, only if there is no check valve in

the intake line.

IMPORTANT

Do not use a non-return check valve on the intake side for the overflow return as it may

cause the intake line to tear off.

IMPORTANT

Cut off the return flow from the main line!

Otherwise unwanted mixing in the metering line can occur.

• Install the metering valve at the injection point.

IMPORTANT

Dampen pulsation by installing pulsation dampers if

• low-pulsation delivery flow is required for process reasons;

• acceleration forces have to be reduced due to the geometry of the piping system.

Page 10

The following can occur if acceleration forces are not dampened

• Fluctuations in delivery, metering faults, pressure surges, valve knocking and wear

as a result of cavitation on the intake and delivery side of the pump.

• Mechanical destruction of pump, leakages and knocking of valves as a result of the

permissible maximum pressure being exceeded on the pump delivery side.

ProMinent

ProMinent

®

®

Page 11

Installation, hydraulic

fig. 16

*

PD

fig. 17

*

PD

fig. 18

*

PD

Pulsation damper in delivery line

(refer to section 5.3)

Pulsation damper for free outlet:

• Install pressure control valve or metering valve at end of metering line.

Pusation damper without trails

(e.g. together with nozzles):

• Interlock the solenoid valve electrically with the voltage supply of the metering pump.

* Accumulators without diaphragm: fit a vent valve

ProMinent

ProMinent

®

®

Page 11

Page 12

Installation, hydraulic

fig. 19

fig. 20

PD

2

1

fig. 21

fig. 22

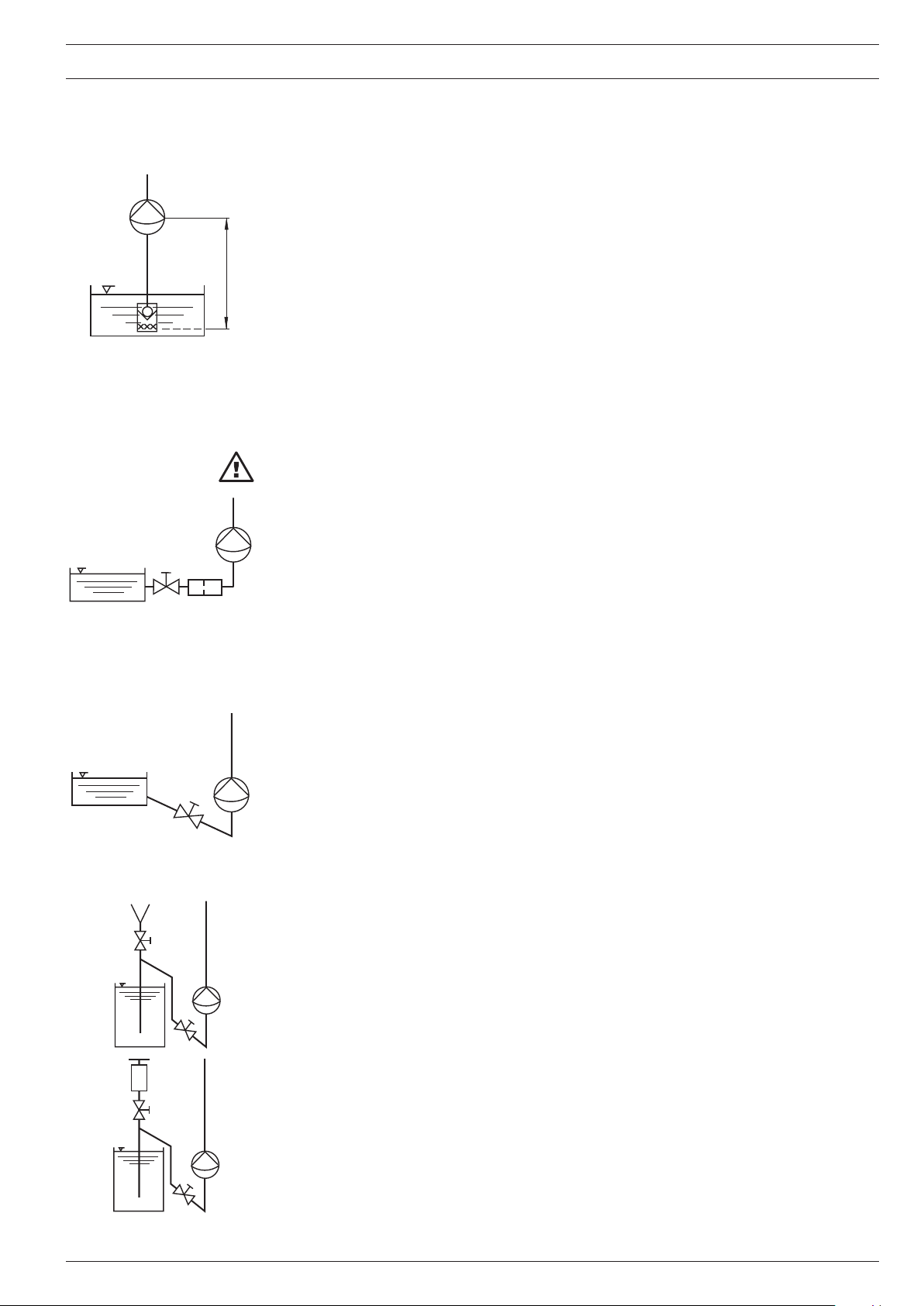

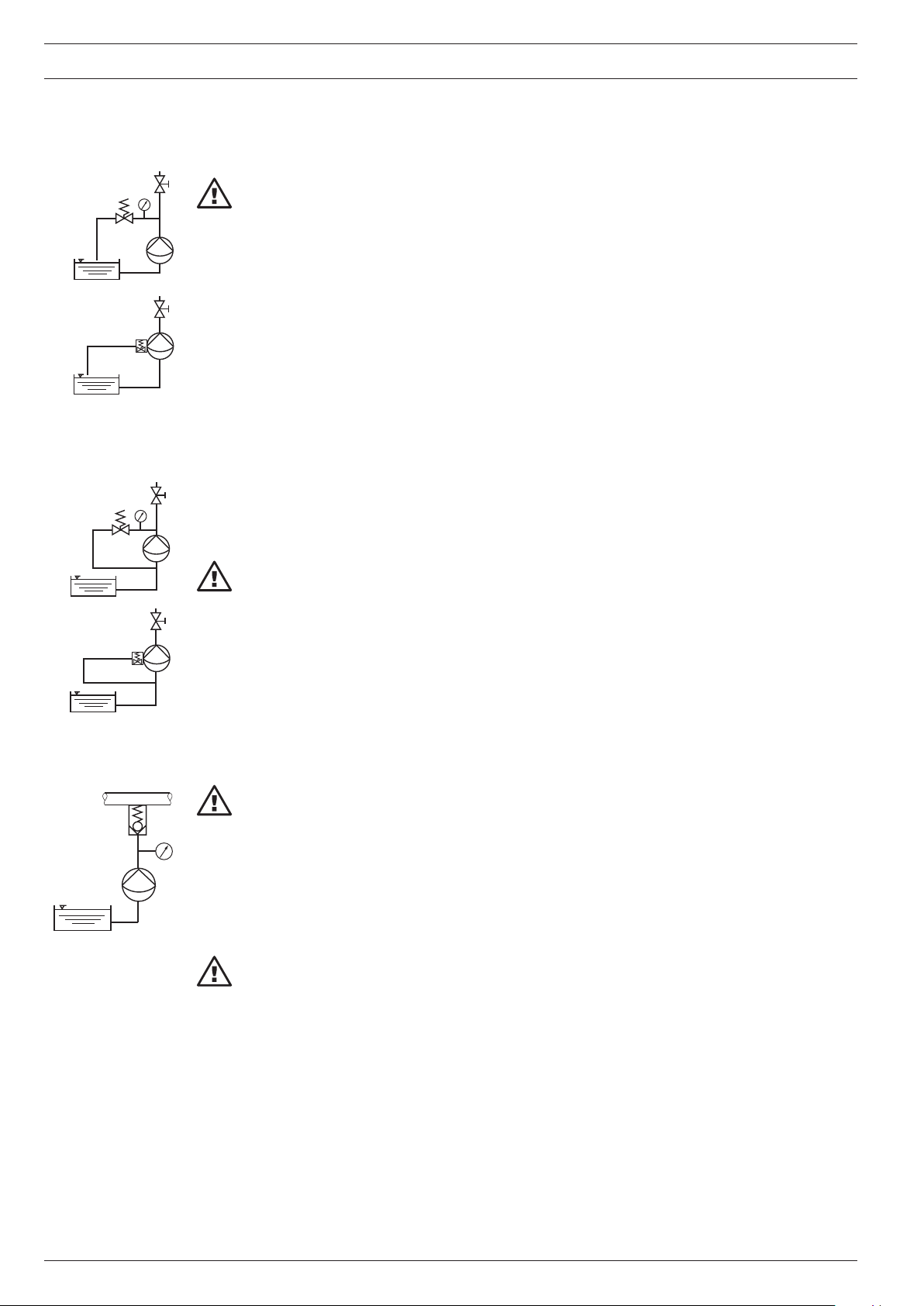

4.4 How not to install pumps

IMPORTANT

Intake line cannot be bled

• Air pocket in intake line.

Pulsation damper not effective

• Arrangement of pulsation damper (2) and pressure retension valve (1) incorrect.

Siphon effect

Admission pressure on intake side too high

Page 12

®

ProMinent

ProMinent

®

Page 13

Installation, hydraulic

fig. 23

fig. 24

fig. 25

fig. 26

fig. 27

4.5 Special Notes on Installation

IMPORTANT

Avoid overloading by positive pressure difference between delivery side and intake side:

• Install end of delivery line higher than the liquid level in the intake tank.

or:

• Install the discharge line outlet of the pump such that its position is higher than the

level of liquid in the chemical storage tank

or:

• Install pressure control valves in the pump delivery line.

IMPORTANT

Ensure constant pressure in the intake line!

Irregular pump flow can occur if the pressure from the take-off line or the intake tank

is transmitted.

• Ensure constant supply height when pump intake is from pressurized lines!

ProMinent

ProMinent

• Ensure constant supply level if intake is from high supply level!

®

®

Page 13

Page 14

Installation, hydraulic

fig. 28

Flushing water

Flushing device

fig. 29

Flushing water

Timer

autom. flushing device

fig. 30

•Avoid siphon (suction) effect when metering into a main line under vacuum:

Install pressure control valve (DHV-SR) or metering valve in the metering line!

NOTE

When metering suspensions it is necessary to flush the pump head in order to avoid

deposits forming

• as intermittent flushing or

• flushing after switching off the pump.

IMPORTANT

Switch off metering pump before flushing!

Maximum permissible flushing pressure: 2 bar

Manual flushing device

Automatic flushing device

Page 14

ProMinent

ProMinent

®

®

Page 15

Installation, hydraulic

- circuit

circuit

-

L1 L2 L3

L1

L2 L3

W1

U2 V2

V1U1

W2

W1V1U1

U2 V2W2

Low voltage

High voltage

fig. 31

5 Installation, electrical

WARNING

• Explosion-proof pump only: it is essential that you observe the contents of section 9!

5.1 Motor

IMPORTANT

• Connect electric motor in accordance with VDE regulations as illustrated in the circuit

diagram provided.

• Check that the mains voltage and frequency agree with the values specified on the

motor ratings plate.

•Provide corresponding motor protection devices in order to protect the motor from

overload (e.g. motor protection switch with thermal overcurrent release).

Fuses are not motor protection devices!

• The specified rated motor output applies at a maximum ambient temperature of 40 °C

and installation altitudes below 1000 m above sea level.

The motor output will be reduced if these values are exceeded (refer to VDE 0530).

• Ensure unobstructed supply of cooling air!

• Installation in wet rooms or in the open:

왘 Arrange terminal box such that the cable lead-ins point downwards (can be taken into

account when ordering).

왘 Select PG screw glands suitable for the supply line, use reducer if necessary.

Seal cable lead-in well otherwise all other measures will be of little use.

왘 Apply sealing compound to PG screw glands and thread of dummy plugs, firmly tighten and

coat once again with sealing compound.

왘 Thoroughly clean sealing surfaces of terminal box and terminal box cover before re-

installing.

Seals must be bonded on one side.

After a longer operating period, replace brittle seals by new ones.

Different types of motors are used depending on the application and required output.

ProMinent will send you the motor data sheets for the desired motor versions on request.

Motors connected to three-phase AC network

Three-phase squirrel-cage motor

ProMinent

ProMinent

®

®

Example:

Specified rating 230/400 V

Three-phase network available 400 V:

Correct motor connection Y-circuit

Direction of rotation reversal: Interchange 2 supply lines

Page 15

Page 16

Installation, hydraulic

L1 L2 L3

W1

V2 W2

V

1

U1

U2

L1 L2 L3

W1V1U1

V2 W2U2

Low speed

High speed

fig. 32

L1 N

CB

W1

V2W2

V1U1

U2

fig. 33

Pole-changing three-phase AC motor (2 speeds in Dahlander circuit)

When changing over speed with pole selector switch, the star bridge 1U-1V-1W is realized

externally (in switch).

Motors connected to alternating current network

Any three-phase AC motor can be operated in conjunction with a corresponding running

capacitor on the alternating current network. However, care must be taken to ensure that the

starting torque is only approx. 30 % of the rated torque.

Three-phase AC motor with running capacitor (Steinmetz circuit)

Page 16

Motors with electronic speed adjustment

Refer to the circuit diagram of the control system for connection of the motor if electric motors

are driven by electronic control devices, e.g. three-phase AC motors by frequency converters or

DC motors by thyristor controllers.

External fans

IMPORTANT

For motors with separate cooling fan (identification code feature “R“ or “Z“), a separate

power supply is used for the separate cooling fan!

Actuators/servomotors for stroke length adjustment

Electrical connection of the motors is shown on the enclosed terminal connection diagram and

on the connection diagram provided on the inside of the housing.

IMPORTANT

Stroke length adjustment/control drives must only be operated with the pump running!

ProMinent

ProMinent

®

®

Page 17

Start-Up

6 Start-Up

WARNING

• Explosion-proof pump only: it is essential that you observe the contents of section 9!

IMPORTANT

• Based on state-of-the-art technology, the manufacturer carefully selects the materials

for parts coming in contact with the medium as specified by the customer.

The manufacturer shall not be liable for any damage caused by metering other media

or media which has been modified with regard to its properties (concentration, density,

temperature, additives, impurities etc.).

• Only specially trained personnel are permitted to operate the metering pump.

The operator must ensure by applying appropriate accident prevention measures that

operating personnel are not endangered under given operating conditions (pressure,

temperature, aggressivity etc.).

• Refer to the information provided in the product-specific operating instructions.

• Before starting up, check correct connection of the drive motor as well as the

corresponding additional equipment!

• Check intake and delivery lines for leaks!

• Check whether necessary flushing lines are connected!

•Provide suitable type of safety overflow valves in all delivery lines!

왘 Bleed delivery side:

Switch on pump and run at 100 % stroke length until liquid end is full.

Switch off pump.

왘 Close bleeder on delivery side.

Pump is now ready for operation.

왘 Open shut-off valve in metering line, operate pump.

왘 Check cut-in pressure of overflow valve.

왘 Check delivery capacity and correct if necessary.

IMPORTANT

• If a compressed air vessel is installed on the delivery side, vent at regular intervals!

• Ensure the correct gas admission pressure (approx. 60–80 % of the mean operating

pressure).

• Observe the information provided in the operating instructions of the frequency

converter if using pumps with speed control.

ProMinent

ProMinent

®

®

Page 17

Page 18

Maintenance/Troubleshooting

7 Maintenance

WARNING

• Explosion-proof pump only: it is essential that you observe the contents of section 9!

IMPORTANT

• Refer to notes in product-specific operating instructions!

• If metering pumps are sent for repair to the manufacturer or a ProMinent dealer,

clean all parts which come into contact with the medium before shipping.

Essentially, maintenance is restricted to checking the metering capacity and for leaks.

Diaphragm failure:

왘 Change diaphragm as described in Section “Diaphragm-type metering unit” in the

product-specific operating instructions.

Impermissibly high leakage from piston-type liquid ends:

왘 Replace packing as described in Section “Piston-type metering unit“ and “Notes on packing

seal” in the product-specific operating instructions.

Replace packing as described in Section “Piston-type metering unit” and “Notes on packing

seal” in the product-specific operating instructions. In order to maintain the delivery unit, we

recommend to keep a spare parts kit in stock, consisting of the wearing parts such as

diaphragm or piston packing and the necessary valve parts, balls and seals. We can quote a

spare parts package for your metering system.

8Troubleshooting

WARNING

• Explosion-proof pump only: it is essential that you observe the contents of section 9!

IMPORTANT

Follow instructions in the product’s operating manual!

Fault Cause Corrective measures

No metering pump intake Suction head too high 왘 Install pump closer to

(during initial operation) intake tank

Backpressure in metering line 왘 Eliminate backpressure

(delivery side) (e.g. via bypass line)

No metering although drive is Stroke setting 0 % 왘 Increase stroke length

running (after longer period of ( 씮 100 %)

operation) Intake tank empty 왘 Top up medium and restart

Gas cushion in intake line and 왘 Bleed intake line, check for

liquid end leaks and restart

Metered liquid emerges from Diaphragm defective 왘 Replace diaphragm

leakage opening of delivery

unit

Loss of metering capacity Wearing parts in valves 왘 Replace wearing parts

(after longer period of defective

operation)

Deposits in valves 왘 Clean or replace valve parts

Page 18

ProMinent

ProMinent

®

®

Page 19

Other important considerations for dosing pumps in ex-zones

ATTENTION

Because of electrostatical flammable

danger, use damp cloth only to wipe

off plastic parts !

9 Other important considerations for dosing pumps in ex-zones

9.1 Application in accordance with regulations

• In areas of operation where there is a risk of explosion, the pump may only be operated with

the appropriate nameplate and the corresponding EU declaration of conformity for areas of

operation where there is a risk of explosion in accordance with directive 94/9/EU concordant

with the European directives. The explosion group, category and protection system stated

on the label must be equivalent to or better than the conditions specified in the designated

area of application.

• Any other application or modification is prohibited!

• Pumps which do not have the appropriate nameplate and the corresponding EU declaration

of conformity for areas of operation where there is a risk of explosion may under no

circumstances be operated in areas of operation where there is a risk of explosion.

9.2 Safety instructions

WARNING

• When installing and operating equipment in ex-zones in Europe, you must observe the

European directive 99/92/EU (ATEX 137). In Germany this is incorporated within the

occupational safety regulations and German regulations on hazardous materials.

•You must observe the European standards EN 1127-1, EN 60079-10, EN 60079-14, EN

60079-17 as well as EN 50020 and EN 50039 for intrinsically safe electrical circuits. (In

Germany, these standards are partly covered by VDE 0165 and VDE 0118.)

• For countries outside the EU, you should observe the appropriate national directives.

• Installations in ex-zones must be checked by a “recognised qualified” person. This

particularly applies to intrinsically safe electrical circuits.

• The information detailed below chiefly refers to particular features found in ex-zones. It does

not replace the standard information in the operating instructions manual!

• When cleaning plastic components, you should ensure that no electrostatic charge is

created through excessive friction. - see warning sign

9.2.1 Safety equipment

WARNING

• Please adhere to the following safety instructions for pumps containing non-

9.2.2 EU declaration of conformity / certification

The EU declaration of conformity is attached for the whole pump (also for pumps without

motors).

The EU declarations of conformity, EU design inspection reports and the operating instructions

manuals for the individual components are attached.

9.3 Assemble

No specific notes.

ProMinent

ProMinent

®

®

conductive components.

Page 19

Page 20

Other important considerations for dosing pumps in ex-zones

9.4 Installation, hydraulic

WARNING

• Dosing pumps used in ex-zones must be fitted with an appropriate safety relief valve

on the output side of the dosing pump (serves to protect against overheating resulting

from overloading and arcing due to interruption of drive components as a result of

overloading.)

• Piston dosing pumps are designed for use in temperature class T3. The pumps can be

used in T4 if they are fitted with an additional flow controller on the output side (serves

to protect against a rise in temperature resulting from dry running) or with an

appropriate temperature controller.

• Similarly, dosing pumps whose diaphragm is driven hydraulically must be fitted with a

temperature or flow controller for use in T4. (The internal relief valve protects against

overheating in the event of extended operation.) Without this protection, temperature

class T3 is applicable.

• With different temperature classes being available for different components, the

possible application of the entire pump corresponds to the component with the lowest

temperature class.

• Combustible media may only be extracted using stainless steel dosing heads. In

exceptional circumstances, where stainless steel is not available, PTFE with carbon

can also be used. Our TT designs are manufactured from this conductive synthetic

material. The operator should take special care in this instance due to reduced

mechanical stability.

• Piston dosing pumps may not be used for combustible media. Where it is impossible to

avoid the use of piston pumps, additional control measures should be implemented to

ensure the required level of safety. This includes flow controller + piston leakage

controller, and an additional temperature controller on the dosing head for media with

critical friction characteristics.

• Hydraulic diaphragm pumps are perfectly suitable, however it is compulsory to have

those whose construction includes diaphragm-rupture controller Ex “i” and flow

controller.

• Diaphragm pumps with mechanically linked diaphragm, e.g. Zt. MTMa..., TZMa...,

Sigma’s S1Ba..., S2BaHM..., S3Ba: no additional measures are required, although it is

essential to use the construction with diaphragm-rupture indicator, in the Ex “i”

construction.

• Installations in ex-zones must be checked by a “recognised qualified” person.

• The following applies to all dosing pumps when metering combustible media: Start up

and drain only under the supervision of an appropriately qualified person.

• Observe the relevant national directives with regard to installation!

Page 20

ProMinent

ProMinent

®

®

Page 21

Other important considerations for dosing pumps in ex-zones

9.5 Installation, electrical

WARNING

• Zero-volts switches can be rated as simple electrical equipment (EN 60079-14 or

EN 50020).

• Both zero-volts and extra-low voltage circuit-breaking accessories such as diaphragm

–rupture indicator, stroke rate equipment, etc. may only be connected to an intrinsically

safe electrical circuit in ex-zones.

• If several electrical components are connected together, the safety of the entire

connection needs to be tested and confirmed in accordance with safety regulations.

This can be evidenced by means of a declaration of conformity from the supplier

(ProMinent) for the equipment in its entirety, or if components are delivered

individually, by means of a document from the operator confirming the components to

be explosion-proof.

• For electrical components in ex-zones you may only use the approved motor

protection switch, mains switch and fuses in accordance with the manufacturer’s

specifications for the application in the relevant ex-zone!

• Observe the documentation attached for the individual electrical components!

• Observe the relevant national directives with regard to installation!

For hydraulic equipment switches in macro-hydraulic diaphragm dosing pumps

(diaphragm rupture sensor, excess pressure sensor):

These switches may be used in areas where there is a risk of gas explosions, category II 2G.

WARNING

• The switches may only be connected to an intrinsically safe electrical circuit! Only use

switches with a blue connection cable!

• The data in the operating instructions manuals is specific to the design of the switches!

Lower values apply in an intrinsically safe electrical circuit, according to the ex-zone!

NOTE

You may disregard the inductivity and capacity of the cable (cable length less than 10m).

Motor

WARNING

• Drive motors should be protected by a suitable motor protection switch. For Ex”e”

motors you should use a motor protection that has been approved for this application.

(Protection against overheating due to overload)

• Motors may only be installed and checked in ex-zones by a “recognised qualified”

person!

• Observe the attached operating instructions manual for EX motors!

9.6 Commissioning

ProMinent

ProMinent

WARNING

• The following applies to all dosing pumps when metering combustible media: Start up

and drain only under the supervision of an appropriately qualified person.

• Combustible media may only be extracted with stainless steel dosing heads. In

exceptional circumstances, where stainless steel is not available, PTFE with carbon

can also be used. Our TT designs are manufactured from conductive synthetic

material. The operator should take special care in this instance due to reduced

mechanical stability.

®

®

Page 21

Page 22

Other important considerations for dosing pumps in ex-zones

• Piston dosing pumps may not be used for combustible media.

Where it is impossible to avoid the use of piston pumps, additional control measures

should be used to ensure the required level of safety: flow controller + piston leakage

controller, and an additional temperature controller on the dosing head for media with

critical friction characteristics.

• Hydraulic diaphragm pumps are perfectly suitable, however it is compulsory to have

those whose construction includes diaphragm-rupture controller Ex “i” and flow

controller.

• Diaphragm pumps with mechanically linked diaphragm, e.g. MTMa..., TZMa..., Sigma’s

S1Ba..., S2BaHM..., S3Ba: no additional measures are necessary, although it is essential to use the construction with diaphragm-rupture indicator, in the Ex “i”* construction.

• Dosing pumps used in ex-zones must be fitted with an appropriate safety relief valve

on the output side of the dosing pump (serves to protect against overheating resulting

from overloading and arcing due to interruption of drive components as a result of

overloading).

• Piston dosing pumps are designed for use in temperature class T3.

The pumps are suitable for use in T4 if they are fitted with an additional flow controller

on the output side (serves to protect against a rise in temperature resulting from dry

running) or with an appropriate temperature controller.

• Similarly, dosing pumps whose diaphragm is driven hydraulically must be fitted with a

temperature or flow controller for use in T4. (The internal relief valve protects against

overheating in the event of extended operation.) Without this protection, temperature

class T3 is applicable.

• With different temperature classes being available for different components, the

possible application of the entire pump corresponds to the component with the lowest

temperature class.

9.7 Maintenance

WARNUNG

•You should make regular checks (on leakages, noise, temperatures, odours, etc.) to

ensure general regular operation, particularly with regard to the actuator and bearing.

• Do not allow the pump to overheat due to a lack of oil!

For lubricated dosing pumps, you should make regular checks to ensure sufficient

lubricant is present, e.g. by checking the level of lubricant, visual check for leakages,

etc. If oil is leaking, you must locate the point of leakage immediately and eliminate

the cause of the leak.

• Check the regular operation of the relief valve behind the pump!

In the event of a fault in areas of operation where there is a risk of explosion, the relief

valve must prevent the gears from being overloaded and overheating!

• When cleaning plastic components, you should ensure that no electrostatic charge is

created through excessive friction. - see warning sign

• The following applies to all dosing pumps when metering combustible media: Start up

and drain only under the supervision of an appropriately qualified person.

• Expendable parts, such as bearings, must be replaced when there are visible signs of

unacceptable wear. (It is not possible to calculate the nominal service life for lubricated

bearings.)

• Original spare parts must be used as replacements.

• Inspection and repair must be carried out in compliance with DIN EN IEC 60079-17

and should only be done by “experienced personnel with the necessary expertise”

(section 4.2).

• These measures are prescribed by ProMinent as the minimum required for protection.

If the operator is aware of other risks, it is his responsibility to eliminate these by

implementing the appropriate measures.

Page 22

ProMinent

ProMinent

®

®

Page 23

Other important considerations for dosing pumps in ex-zones

9.8 Troubleshooting

WARNING

•You should make regular checks (on leakages, noise, temperatures, odours, etc.) to

ensure general regular operation, particularly with regard to the actuator and bearing.

• Do not allow the pump to overheat due to a lack of oil!

For lubricated dosing pumps, you should make regular checks to ensure sufficient

lubricant is present, e.g. by checking the level of lubricant, visual check for leakages,

etc. If oil is leaking, you must locate the point of leakage immediately and eliminate

the cause of the leak.

• When cleaning plastic components, you should ensure that no electrostatic charge is

created through excessive friction. - see warning sign

• The following applies to all dosing pumps when metering combustible media: Start up

and drain only under the supervision of an appropriately qualified person.

• Expendable parts, such as bearings, must be replaced when there are visible signs of

unacceptable wear. (It is not possible to calculate the nominal service life for lubricated

bearings.)

• Original spare parts must be used as replacements.

• Inspection and repair must be carried out in compliance with DIN EN IEC 60079-17 and

should only be done by “experienced personnel with the necessary expertise” (section

4.2).

9.9 Repair

WARNING

• The following applies to all dosing pumps when metering combustible media: Start up

and drain only under the supervision of an appropriately qualified person.

•You should make regular checks (on leakages, noise, temperatures, odours, etc.) to

ensure general regular operation, particularly with regard to the actuator and bearing.

9.10 Decommissioning

WARNING

• The following applies to all dosing pumps when metering combustible media: Start up

and drain only under the supervision of an appropriately qualified person.

ProMinent

ProMinent

®

®

Page 23

Page 24

Hydraulic Accessories

Metering pump A

external activation and

control facility A1

Metering valve B

Shut-off fitting C

Flow meter D

Pulsation damper E

Pressure control valve F

Overflow valve

in bypass line G

Level switch H

Foot valve I

Pressure gauge J

fig. 34

Filling

Venting

Intake line

Bypass

System line

A

B

C

D

E

F

G

H

I

J

A1

C

10 Hydraulic Accessories

10.1 Overview and Notes on Accessories

To ensure trouble-free operation of metering systems, not only is correct selection of the

metering pump decisive but also of the individually compiled hydraulic and electrical

accessories. On the following pages, many accessories are illustrated which are not always

necessary but which provide a general overview of the various possibilities.

We would be pleased to be of assistance in selecting the right accessories for your metering

task and e.g. offer our advisory services for calculating the piping system.

Page 24

ProMinent

ProMinent

®

®

Page 25

Hydraulic Accessories

System Components

Function Application

Metering pump* A Metering of a defined quantity of liquid in a Variable adjustment of metered quantity and

system; external activation facility enable optimum

Activation: Manual or automatic (external adaptation to any metering applications.

signal)

Metering valve* B Check valve (non-return valve) ...in closed piping system, to prevent mixing

and return flow in delivery line.

As backpressure generator ...in systems with free outlet in order to

produce a defined backpressure.

Shut-off fittings C To cut off the pipe system in individual sections ...for maintenance, conversion or repair work

(function sections) in order to shut down parts of the system.

Visual flow meter D Visual indication of metered quantity ...for control of the adjusted metering volume.

((volumetric flow)

Pulsation damper

compressed air vessel E Elimination of pulsation in piping system ...in long piping systems in order to keep

(delivery side), produces low-pulsation flow pressure loss at a minimum.

..for producing a continuous flow (metering).

...for avoiding troublesome vibrations in the

piping system.

Pressure control valve* F Produces a defined backpressure (adjustment ...in piping systems with free outlet to ensure

range as specified in technical data) trouble-free operation of the metering pump.

...use together with a pulsation damper in

order to produce a constant backpressure.

Overflow valve* G Opens a bypass line at a set pressure limit ...as safety device for protecting the metering

value system or metering pump from overload.

Level switch H Signals level of supply tank ...for trouble-free operation of the system.

One-stage or (with early warning) ...to indicate when the intake tank needs to

two-stage version be topped up or a tank change.

...to protect the system from running empty.

Foot valve* I Check valve (non-return valve) ...to protect the intake line from running

empty (e.g. during tank change).

With integrated sieve as coarse filter ...to protect the metering pump from coarse

solid particles.

Pressure gauge J Indicates the actual pressure in the metering ...absolutely recessary

line for setting of pressure control valve resp.

overflow vave.

...for determining actual operating pressure in

metering line.

Intake air vessel Elimination of pulsation in piping system ...for avoiding pressure loss in long intake line.

(intake side), produces low-pulse flow ...as intake aid together with a vacuum pump.

Filter Filters coarse solid particles out of intake flow ...to protect metering pump and system from

dirt and increased wear.

Solenoid valve Automatic shut-off fitting ...as safety device for shutting off (tight)

Activation: e.g. electrically interlocked with delivery line when system at standstill.

power supply of metering pump

ProMinent

ProMinent

IMPORTANT

* Not absolutely tight-closing shut-off elements.

®

®

Page 25

Page 26

Diaphragm type pulsation damper

(bubble accumulator)

Compressed air vessel

In-line damper

fig. 36

Hydraulic Accessories

fig. 35

Protective cap

Pressure setting screw

Lock nut

10.2 Back pressure valve / relief valve

ProMinent® DHV-DL (DHV-S, DHV-S-DL, DHV-SR, DHV-RM)

Pressure control/overflow valves for installation in metering line:

• Adjustable pressure control valve for installation in metering lines.

• Used to produce a constant backpressure to ensure precision delivery

when metering with free outlet,for admission pressure on intake side, for fluctuating

backpressure or metering to vacuum.

• Also used as safety overflow valve.

• If used as pressure control valve for avoiding resonance:

Installation at end of metering line or set pressure (set pressure / line pressure) loss.

IMPORTANT

Pressure control/overflow valves are shut-off elements which do not close absolutely tight.

The DHV-S, DHV-S-DL series is used in conjunction with pulsation dampers only with free

outlet and a short metering line.

The DHV-SR/RM series is not subject to the effect of backpressure and is therefore particularly

suitable for use in cases of fluctuating backpressure at the pipe outlet and for use in

conjunction with pulsation dampers or longer metering lines. The DHV-SR/RM series can be

installed at any point along the metering line.

Type DHV-RM 1-10 bar

왘 Remove protective cap.

왘 Prior to pump operation:

Unscrew pressure setting screw for pressure relief until it turns easily.

왘 During pump operation: Produce required operating pressure by turning in pressure setting

screw:

Read off set pressure at pressure gauge installed in pipe system.

왘 Secure pressure setting screw:

왘 Tighten lock nut.

왘 At required pressure relief, release lock nut and unscrew pressure setting screw until it

moves easily.

10.3 Pulsation Dampers

Pulsation dampers are often used in conjunction with oscillatory displacement pumps.

They are necessary when:

• Low-pulsation flow is required, for example, for process reasons.

• Depending on the piping situation, it is necessary to reduce impermissibly high pressure

peaks during operation of oscillatory displacement pumps or pressure loss must

be avoided; in this case, it is necessary to use pulsation dampers both on the intake

side as well as the delivery side.

Page 26

ProMinent

ProMinent

®

®

Page 27

Hydraulic Accessories

Intake valve

Safety overflow valve

Metering line

In-line damper

fig. 39

Intake line

Safety overflow valve

Metering line

Diaphragm pulsation damper

fig. 38

fig. 37

p

V

0

12

pp

VV

0

1

2

V

1

2

3

p=

p=

p=

V=

V=

V=

0

1

2

0

1

2

V= Change in volume for

pulsation compensation

Schematic:

Diaphragm-type pulsation damper

Gas filling pressure

Minimum operating pressure

Maximum operating pressure

Effective gas volume

Gas volume at p

1

Gas volume at p

2

Function

Their function is based on compression and expansion of a gas cushion in order to release

energy.

As the pressure increases, a part of the medium to be delivered is stored and then released to

the pipe network as the pressure decreases.

In principle, a differentiation is made between pulsation dampers with and without a separating

diaphragm.

In pulsation dampers without a separating diaphragm (e.g. air tank), the medium has direct

contact with the gas cushion which is formed by feeding in compressed air. After start-up, the

compressed air is compressed to the damping volume. Since the compressed air is gradually

released in the medium, venting is necessary from time to time with the system depressurized.

This disadvantage is avoided by using pulsation dampers with a separating diaphragm.

In this case, the damping gas cushion is separated from the delivered medium by a flexible

diaphragm and thus protected from absorption.

Installation

IMPORTANT

Observe the regulations valid at the place of installation prior to initial operation and

during operation of pulsation dampers!

The Pressure Vessel Ordinance (Druckbeh.V.) is applicable in the Federal Republic of

Germany.

ProMinent

ProMinent

®

®

IMPORTANT

Pulsation dampers can only fulfil their task of damping pressure peaks and pulses if they

are installed correctly.

• Integrate pulsation dampers in the system so that they are well accessible and free

of vibration!

• Install pulsation damper in the immediate vicinity of the point where pressure peaks

are to be dampened. For metering pumps this means installation at the shortest

possible distance after the head valve of the liquid end (or immediately before the

intake valve if a suction-air vessel is installed).

• Install connection line straight and corresponding to the connection diameter of the

pulsation damper in order to avoid unnecessary deflection and pipe friction losses.

IMPORTANT

Do not use oxygen for preloading diaphragm-type pulsation dampers (or bubble accumulators) for air or nitrogen!

The greatest efficiency of pulsation dampers is achieved when the preload pressure is approx.

60–80 % of the subsequent mean operating pressure.

If the pulsation damper is not equipped with a pressure gauge, it is recommended to check the

preload pressure (pv):

• After 500 hours of operation.

• Before resuming operation after a prolonged downtime.

A regular check every three months is recommended.

Page 27

Page 28

Warranty Application for Metering Pumps and Accessories

No.: .........................................................................................................................................................................................................................

Please fill in completely!

Company:

..........................................................................................................................................................................................................

Tel.No.: ............................................................................................... Date: ............................................................................................

Address: .............................................................................................................................................................................................................

Compiler (customer): ................................................................................................................................................................................

Order No.: ....................................................................................... Date of delivery: ..................................................................

Pump type/

Identity code: ............................................................................... Serial No.: ................................................................................

Short fault description: .......................................................................................................................................................................

...................................................................................................................................................................................................................................

...................................................................................................................................................................................................................................

Type of fault:

1 Mechanical fault 2 Electrical fault

Abnormal wear Connections (connector or cable) loose

Wearing parts Operating element (e.g.switch)

Breakage/other damage Control

Corrosion

Damage during transport

3Leaks 4 None or poor delivery capacity

Connections Diaphragm defective

Liquid end Others

®

Operating conditions of ProMinent

Location/system description:

............................................................................................................................................................

pumps:

Pump accessories used: .......................................................................................................................................................................

...................................................................................................................................................................................................................................

...................................................................................................................................................................................................................................

...................................................................................................................................................................................................................................

Commissioning (initial operation/date): .....................................................................................................................................

Operating period (approx. operating hours):.........................................................................................................................

Installation data/system schematic (provided by customers)

Page 28

(Please completely fill in enclosed form "Data for calculating metering line"!)

ProMinent

ProMinent

®

®

Page 29

Data for Calculating Metering Line

Customer: .........................................................................................................................................................................................................

Project No.: .................................................................................... Date : ............................................................................

Diagram/remarks

Metering pump

Type –

Capacity l/h ...........................................................................................

Stroke rate stroke/min ...........................................................................................

Type of valve (ball/plate) – ...........................................................................................

Valve spring pressure, intake side bar ...........................................................................................

Valve spring pressure, delivery side bar ...........................................................................................

Max. permissible operating pressure bar ...........................................................................................

Medium

Designation, concentration %

Proportion of solids/grain size %/mm ...........................................................................................

Material solids/hardness (Mohs Scale) ...........................................................................................

Dynamic viscosity mPa s (cP) ...........................................................................................

Density kg/m≈ ...........................................................................................

Vapour pressure at operating temp. bar/°C ...........................................................................................

...........................................................................................

...........................................................................................

System intake side

Pressure in intake tank

...........................................................................................

Nominal diameter intake line DN/mm ...........................................................................................

Intake hight min/max. m

nlet hight min/max. m

...........................................................................................

Intake line length m ...........................................................................................

Pipe condition** Smooth and clean plastic

Seamless, smooth steel

Galvanized steel pipe

Number of brackets/valves

...........................................................................................

Pulsation damper Diaphragm accumulator ........................... ltr.

Compressed air vessel .............................. ltr.

System delivery side

Static system pressure min/max bar

...........................................................................................

Nominal diameter delivery line DN/mm ...........................................................................................

Delivery line length m ...........................................................................................

Delivery hight* m ...........................................................................................

Pipe condition** Smooth and clean plastic

Seamless, smooth steel

Galvanized steel pipe

Number of brackets/valve

...........................................................................................

Pulsation damper Diaphragm accumulator ........................... ltr.

Compressed air vessel .............................. ltr.

ProMinent

ProMinent

* When calculating:

Observe sign, tank level below liquid end = negative intake head H

Metering line outlet level under liquid end = negative delivery head HD

** The pipe properties should be specified for precise calculation at viscosities below 50 mPas.

®

®

Page 29

Page 30

Installing Drawing

Customer: ............................................................................................................................................................................................................................................................................................

Project No.: ................................................................................................................................................................. Date: ..................................................................................................

Page 30

ProMinent

ProMinent

®

®

Page 31

Safety declaration form

Safety declaration form

A completed form must always be returned with the equipment!

This declaration must only be completed and signed by an authorized member of the technical

staff!

The equipment or its parts will only be repaired or serviced if it is accompanied by a correctly

completed and signed safety declaration form. The work could be delayed if no form is returned.

Legally binding declaration

We hereby assure that:

1. The enclosed equipment

Type: _______________________________________________________________________________________________________

Serial No.: __________________________________________________________________________________________________

is free from any

toxic

corrosive

microbiological

carcinogenic

explosive

radioactive substances

or other substances that may be harmful to health.

2. The equipment was thoroughly cleaned before being shipped.

3. There is no hazard due to residual contamination.

4. The details given in this form are correct and complete.

Company / Institute: _______________________________________________

Street: ____________________________________________________________________ Postcode, Town: ___________________________________________________

Tel: _________________________________________________________________________ Fax: _______________________________________________________________________

Surname, First name: ____________________________________________ Position: ________________________________________________________________

Date: ______________________________________________________________________

________________________________________________________________________________ __ _____________________________________________________________________________

Legally binding signature Company stamp

Part No. 986715 / AL_017_03/06 GB

ProMinent

ProMinent

®

®

Page 31

Page 32

Die ProMinent Firmengruppe / The ProMinent Group

Stammhaus / Head office

ProMinent Dosiertechnik GmbH · Im Schuhmachergewann 5-11 · 69123 Heidelberg · Germany

info@prominent.com · www.prominent.com

Tel.: +49 6221 842-0 · Fax: +49 6221 842-617 Chemical Fluid Handling · Fax -431 Water Treatment Solutions

Niederlassungen weltweit / Affiliated Companies Worldwide

ProMinent Fluid Controls Pty. Ltd.

Unit 4, Narabang Way

Belrose, NSW 2085 (Australia)

Tel.: +61 2 94500995, Fax: 94500996

sales@prominentfluid.com.au

ProMinent Dosiertechnik Ges. mbH

Gewerbepark-Rosenau/Sonntagberg

3332 Rosenau (Austria)

Tel.: +43 7448 30400, Fax: 4205

office@prominent.at

ProMinent Fluid Controls (Bangladesh) Ltd.

House No. 9, Road No. 17

Block D, Banani Model Town

Dhaka-1213 (Bangladesh)

Tel.: +8802 8818713, Fax: 9889071

info@prominent-bd.com

ProMinent Belgium S.A., N.V.

Parc Industriel de Saintes

Avenue Landas 11

1480 Tubize (Belgium)

Tel.: +32 2 3914280, Fax: 3914290

info@prominent.be

ProMinent Brasil Ltda.

Rua Alfredo Dumont Villares 115

09672-070 Sao Bernardo do Campo-SP (Brazil)

Tel.: +55 11 43610722, Fax: 43632292

prominent@prominent.com.br

ProMinent Fluid Controls BG

8 Kr. Sarafov

1164 Sofia (Bulgaria)

Tel.: +359 2 9631921, Fax: 8660447

prominent@abv.bg

ProMinent Fluid Controls Ltd.

490, Southgate Drive

Guelph, Ontario N1G 4P5 (Canada)

Tel.: +1 519 8365692, Fax: 8365226

info@prominent.ca

ProMinent Fluid Controls China Co. Ltd.

No. 14, Road Liaohe Xisan

Dalian Economic & Techn. Development Zone

116600 Dalian (P.R. of China)

Tel.: +86 411 87315738, Fax: 87315730

dr.r.hou@prominent.com.cn

ProMinent Dosiertechnik CS s.r.o.

Sobieského 1, P.O. Box 53

77010 Olomouc (Czech Republ.)

Tel.: +420 585 757011, Fax: 757023

info@prominent.cz

ProMinent Finland OY

Orapihlajatie 39

00320 Helsinki (Finland)

Tel.: +35 89 4777890, Fax: 47778947

prominent@prominentfinland.fi

ProMinent France S.A.

8, rue des Frères Lumière

B.P. 39, Eckbolsheim

67038 Strasbourg Cedex 2 (France)

Tel.: +33 3 88101510, Fax: 88101520

contact@prominent.fr

ProMinent Fluid Controls (UK) Ltd.

Resolution Road, Ashby de la Zouch

Leicestershire LE65 1DW (Great Britain)

Tel.: +44 1530 560555, Fax: 560777

sales@prominent.co.uk

ProMinent Hellas Ltd.

24, Mitrodorou Str. + Athinon Ave.

10441 Athens (Greece)

Tel.: +30 210 5134621, Fax: 5134500

promin@hol.gr

Vertretungen weltweit / Distributors Worldwide

Argentina · Bahrain · Bolivia · Botswana · Chile · Columbia · Costa Rica · Croatia · Cuba · Cyprus · Denmark · Egypt · El Salvador · Guatemala · Hong Kong · Indonesia ·

Iceland · Iran · Ireland · Israel · Jordan · Kenya · Kuwait · Macedonia · Malta · Namibia · New Zealand · Nigeria · Norway · Oman · Pakistan · Panama · Paraguay · Peru ·

Philippines · Qatar · Romania · Russia-Ural Region · Saudi Arabia · Senegal · Serbia/Montenegro · Slovenia · Sudan · Syria · Tanzania · Tunisia · Turkey · Turkmenistan ·

Uganda · Uruguay · United Arab Emirates · Venezuela · Vietnam · White Russia · Zimbabwe

Anschriftennachweise erhalten Sie durch: / Addresses of distributors are available from: ProMinent Dosiertechnik GmbH, Germany

12/05

ProMinent Magyarország Kft.

Íves u. 2

9027 Győr (Hungary)

Tel.: +36 96 511400, Fax: 329981

prominent@prominent.hu

Heidelberg ProMinent Fluid Controls India Pvt. Ltd.

#2/2, MES Road, Yeshwanthpur

Bangalore 560 022 (India)

Tel.: +91 80 23578872, Fax: 23477984

prominent@hpfcindia.com

ProMinent Fluid Controls Ltd.

Finisklin Industrial Estate

Sligo, Co. Sligo (Ireland)

Tel.: +353 71 9151222, Fax: 9151225

sconvay@prominent.ie

ProMinent Italiana S.R.L.

Via Albrecht Dürer, 29

39100 Bolzano (Italy)

Tel.: +39 0471 920000, Fax: 920099

info@prominent.it

ProMinent Japan Ltd.

Toyu Bldg., 528 Wasedatsurumaki-cho

Shinjuku-Ku

Tokyo 162-0041 (Japan)

Tel.: +81 3 32073470, Fax: 32073119

info@prominent.co.jp

ProMinent Korea Co., Ltd.

Sungnam P.O. Box 72

Kyoungki-Do 461-600 (Republic of Korea)

Tel.: +82 31 7018353, Fax: 7072621

info@prominent.co.kr

ProMinent Office Kazakhstan

ul. Timiryaseva 42, „Atakent“

Building 15/1, Office 13

480057 Almaty (Kazakhstan)

Tel.: +7 3272 504130, Fax: 695466

prominent@ducatmail.kz

ProMinent Office Kaunas

Gedimino st. 47

3000 Kaunas (Lithuania)

Tel.: +370 37 325115, Fax: 325116

prominent1@takas.lt

ProMinent Fluid Controls (M) Sdn. Bhd.

92-1 Jalan Radin Anum Satu

Seri Petaling

57000 Kuala Lumpur (Malaysia)

Tel: +60 3-905 77 224, Fax: 3-905 77 219

info@pfc-prominent.com.my

ProMinent Fluid Controls Ltd.

BT 7 - 12, Bulebel Industrial Estate

Bulebel (Malta)

Tel.: +356 21693677, Fax: 21693547

info@pfc.com.mt

ProMinent Fluid Controls de Mexico S.A. de C.V.

Centro Aleman, Av. Santa Fé No. 170 Ofic. 0-4-12

Col. Lornas de Santa Fé

C.P. 01210 Mexico D.F. (Mexico)

Tel.: +52 55 917 29300-302, Fax: 29303

pfc-mexico@prominent.com.mx

ProMinent Verder B.V.

Utrechtseweg 4a

3451 GG Vleuten (Netherlands)

Tel.: +31 30 6779280, Fax: 6779288

info@prominent.nl

ProMinent Dozotechnika Sp. z o.o.

Ul. Jagiellonska 2B

55-095 Mirkow k/Wroclawia (Poland)

Tel.: +48 71 3980600, Fax: 3980629

prominent@prominent.pl

ProMinent Portugal Controlo de Fluídos, Lda.

Estrada de Barrosa, Elospark 16

Algueirao

2725-193 Mem Martins (Portugal)

Tel.: +35 121 9267040, Fax: 9267049

geral@prominent.pt

ProMinent Dositechnika OOO

Lyusinovskaya ul. 36, str. 1

115093 Moskow (Russia)

Tel.: +7 095 7874501, Fax: 7874502

evg.bogatykh@prominent.ru

Proshield Ltd.

Unit 2, 18 Albert Street

Motherwell ML1 1 PR (Scotland)

Tel.: +44 1698 260260, Fax: 260441

pcp@proshield.co.uk

ProMinent Fluid Controls (Far East) Pte. Ltd.

50 Kallang Pudding Road

#08-01 Golden Wheel Industrial Building

Singapore 349326 (Singapore)

Tel.: +65 67474935, Fax: 67452240

pfc@prominent.com.sg

ProMinent Slovensko s.r.o.

Rol’nícka 21

83107 Bratislava-Vajnory (Slovak. Republ.)

Tel.: +421 2 48200111, Fax: 43711030

prominent@prominentsk.sk

ProMinent Fluid Controls Pty. Ltd.

Unit E7, Cnr. Jack + Refinery Roads

Germiston

P.O. Box 15413

Lambton ZA-1414 (South Africa)

Tel.: +27 11 8254142, Fax: 8254132

promsa@mweb.co.za

ProMinent Gugal S.A.

Polígono Industrial, s/n

17853 Argelaguer/Girona (Spain)

Tel.: +34 972 287011/12, Fax: 287107

prominent@prominentspain.com

ProMinent Doserteknik AB

S.a. Hildedalsgatan 10, Box 8933

40273 Göteborg (Sweden)

Tel.: +46 31 656600, Fax: 508960

info@prominent.se

ProMinent Dosiertechnik AG

Trockenloostrasse 85

8105 Regensdorf (Switzerland)

Tel.: +41 44 8706111, Fax: 8706161

info@prominent.ch

ProMinent Fluid Controls (Taiwan) Ltd.

8 F 2, No. 288-9 Hsinya Road

Kaohsiung (Taiwan)

Tel.: +886 7 8135122, Fax: 8135121

richard@prominent.com.tw

ProMinent Fluid Controls (Thailand) Co. Ltd.

2991/7 Visuthanee Office Park

Ladprao Road, Klongchan, Bangkapi

Bangkok 10240 (Thailand)

Tel.: +66 2 3760008, Fax: 37600130

pfc@prominent.co.th

ProMinent Office Kiev

ul. Schorsa 31, office 403

01133 Kiev-133 (Ukraine)

Tel.: +380 44 2696933, Fax: 5311438

prominent@i.com.ua

ProMinent Fluid Controls, Inc.

R.I.D.C. Park West, 136 Industry Drive

Pittsburgh, PA, 15275 (USA)

Tel.: +1 412 7872484, Fax: 7870704

sales@prominent.cc

Loading...

Loading...