ProMinent EXtronic EXBb Series, EXtronic EXBbG Series, EXtronic EXBbM Series Operating Instructions Manual

Page 1

Operating Instructions

0158

Metering Pump ProMinent EXtronic® EXBb

®

ProMinent

EXBb

The operating instructions contain changes in the electrical safety parameters.

Please carefully read through these operating instructions in full! Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Part No. 987094 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany BA EX 014 01/12 EN

___ ___ ___ ___ ___ ___ ___ ___

Please enter identcode of the device here!

It replaces all earlier operating instructions.

Page 2

Publishing details

Page 2

Publishing details:

Operating Instructions Metering Pump ProMinent EXtronic® EXBb

© ProMinent Dosiertechnik GmbH, 2003

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

info@prominent.com

www.prominent.com

Subject to technical modificatios.

ProMinent

®

Page 3

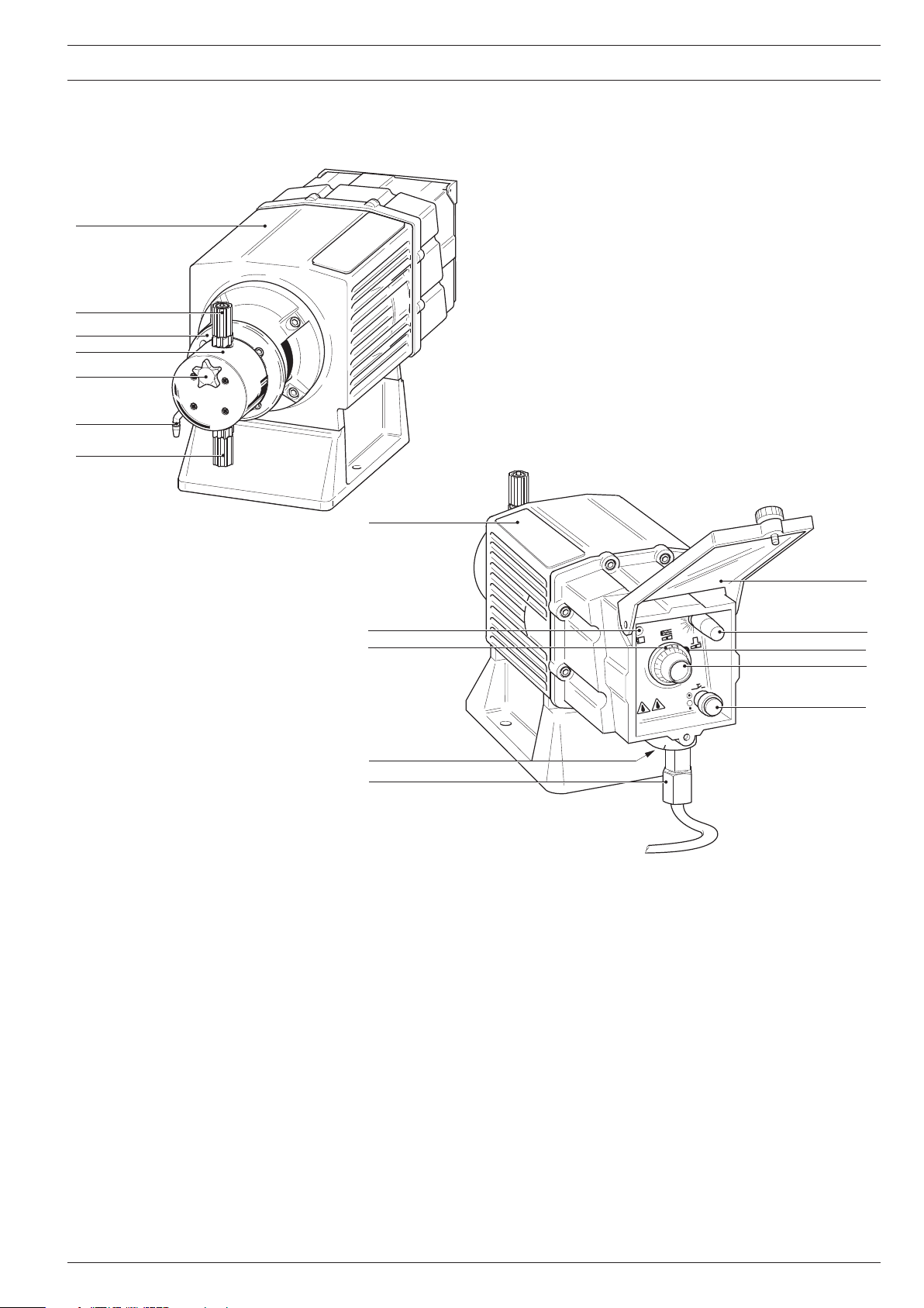

View of Metering Pump

1

2

3

4

5

6

7

8

9

12

14

15

13

11

16

10

17

View of Metering Pump

Description of Functional Elements

1 Drive unit with electronic control and solenoid

2 Delivery connection

3 End ring

ProMinent

®

4 Liquid end

5Vent valve (only on types 1000 - 0417 NP and PP, refer to identcode on Page 13)

6 Socket for bypass hose (only on types 1000 - 0417 NP and PP, refer to identcode on Page 13)

7 Intake connection#

8Type identification plate

9 Operating/impulse display

10 Inspection window

11 External connection

12 Power connection

13 Mains switch (not for 500 V version)

14 Control for stroke length

15 Locking lever

16 Control knob for stroke rate or pushbutton/pushbutton switch for priming

17 Transparent cover

Page 3

Page 4

Page 4

ProMinent

®

Page 5

Contents

View of Metering Pump ......................................................................................................................................................... 3

Description of Functional Elements

Notes for User

.............................................................................................................................................................................. 7

Metering Pump Applications

............................................................................................................................ 3

............................................................................................................................................. 8

Contents

1 Safety

2 Design and Function

.................................................................................................................................................................................................. 9

1.1 Notes on Safety

1.2 Reference Guidelines/Standards

1.3 Tests and Approvals

2.1 Functional principle

............................................................................................................................................................. 9

..................................................................................................................... 9

................................................................................................................................................... 10

............................................................................................................................................................ 10

.................................................................................................................................................... 10

2.2 Construction / functional description, diaphragm rupture detector

2.3 Delivery capacity

2.4 Versions

................................................................................................................................................................................ 12

3Technical Data

3.1 Identcode

3.2 Dimensions and Weights

3.3 Capacity data

3.4 Accuracies

3.5 Material Specifications

3.6 Electrical Data

3.6.1 Electrical data, control current circuit

........................................................................................................................................................... 11

............................................................................................................................................................................ 13

............................................................................................................................................................................ 13

........................................................................................................................................ 14

.................................................................................................................................................................. 15

......................................................................................................................................................................... 16

............................................................................................................................................. 16

................................................................................................................................................................. 16

.......................................................................................... 16

3.6.1.1 for “non-intrinsically safe” version and

“intrinsically safe” version

3.6.1.2 under “intrinsically safe” version

3.6.2 Electrical data, supply current circuit

3.6.2.1 for “not intrinsically safe” version

3.6.2.2 for the “intinsically safe” version

.............................................................................................. 16

............................................................................... 17

........................................................................................... 17

............................................................................. 17

............................................................................... 17

3.6.3 Electrical data for the intrinsically safe (optional)

diaphragm rupture indicator

3.6.4 Electrical data, details

3.7 Mechanical data, cables

3.8 Ambient conditions

..................................................................................................................................................... 19

......................................................................................................................................... 18

................................................................................................................ 18

................................................................................................................................. 18

.................................... 10

ProMinent

4 Unpacking

5 Mounting and Installation

5.1 Installing Metering Pump

5.2 Installing Hose Lines

5.3 Installation Examples, Mechanical/Hydraulic

5.4 Electrical Installation

®

...................................................................................................................................................................................... 19

................................................................................................................................................ 20

....................................................................................................................................... 20

.................................................................................................................................................. 20

5.2.1 Installing the Intake Line

5.2.2 Installing the Delivery Line

5.2.3 Installing the Bypass Vent Line (see fold-out page)

.................................................................................................................................................. 25

......................................................................................................................... 21

.................................................................................................................... 22

.......................................................... 22

........................................................................................ 23

Page 5

Page 6

Contents

6 Operation ........................................................................................................................................................................................ 26

6.1 Start-Up

6.2 Determining the Delivery Capacity

6.3 Nomograms

6.4 Setting the Delivery Capacity

............................................................................................................................................................................... 26

................................................................................................................. 27

...................................................................................................................................................................... 29

............................................................................................................................. 37

7 Maintenance

8 Repairs

8.1 Replacing working diaphragm / safety diaphragm

8.2 Servicing diaphragm rupture detector

................................................................................................................................................................................ 37

.............................................................................................................................................................................................. 38

............................................................................ 38

......................................................................................................... 39

8.3 Replacing separating diaphragm in the diaphragm rupture detector

8.4 Checking diaphragm rupture detector

9 Malfunctions

................................................................................................................................................................................ 40

9.1 Operation/pulse indicator does not light, no stroke movement

........................................................................................................ 39

.............................................. 40

9.2 Pump intake no longer operable despite full stroke movement and venting

9.3 Pump no longer meters, although operation/pulse indicator lights

9.4 Liquid Emerges from end ring

............................................................................................................................ 40

9.5 Pump does not reach high pressures

or no suction despite max. stroke action

9.6 Diaphragm rupture indicator triggers alarm

10 Used Part Disposal

11 Spare parts

.................................................................................................................................................................................... 43

Installation data

................................................................................................................................................................ 42

........................................................................................................................................................................... 46

Guarantee claim for metering pumps

Declaration of Complete Dafety

EC Declaration of Conformity

EC Model Certificate

............................................................................................................................................................... 50

..................................................................................................................................... 48

.......................................................................................................................................... 49

........................................................................................................................ 47

.................................................................................................. 42

................................................................................................. 42

................................. 39

............... 40

..................................... 40

Page 6

ProMinent

®

Page 7

Notes for User

Notes for User

Please read the following instructions carefully. They will help you make the best use of this

manual.

The following are highlighted in the text:

• Numbered points

왘 Instructions

Operating guidelines:

NOTE

Notes are intended to make your work easier.

and safety instructions:

WARNING

Describes a potentially hazardous situation.

If not avoided may result in fatal or severe injury.

CAUTION

Describes a potentially hazardous situation.

If not avoided, could result in slight or minor injury or damage to property.

IMPORTANT

Describes a potentially damaging situation.

If not avoided may result in damage to property.

ProMinent

®

Page 7

Page 8

Metering Pump Applications

Metering Pump Applications

The ProMinent EXtronic® EXBb is an electronically controlled, explosion-proof diaphragm

metering pump with a short-stroke solenoid.

Liquid media The pump is used for metering liquid media:

• in explosion-threatened workplaces in zone 1, device category II 2 G of explosion group II C

(EXBbG) according to VDE guidelines

• for firedamp-threatened underground excavations in explosion group I, device category

1 M 2 (EXBbM) according to VDE guidelines

• in industrial premises at risk of explosion according to FM and CSA standards

Liquid ends made of various materials cover virtually all applications:

• Polypropylene (PP)

• PVC

• Acrylic

• PTFE-Teflon

• Stainless steel

Gas-emitting media Self-venting liquid ends made of Acrylic or PVC are available for metering gas-emitting media.

Combustible media

®

WARNING

For combustible media only use the "SB” dosing head.

IMPORTANT

The pump is not designed to meter gaseous media as well as solids.

Voltages Versions are available for various voltages and frequencies:

230 V, 115 V, 500 V, 100 V und 200 V;

50/60 Hz.

Compatibility The ProMinent EXtronic

®

EXBb is a continuation of the former EXBa series:

The external dimensions and securing holes are identical and the hydraulic accessories of these

series can be used.

The liquid ends are compatible with the other diaphragm metering pumps, with the exception of

versions „SB _“ and „_ _ M“ (see Identcode page 13).

Page 8

ProMinent

®

Page 9

Safety

1 Safety

1.1 Notes on Safety

WARNING

• Immediately switch off the pump in the case of emergency!

Use the pump power switch or an emergency stop switch in your working environment!

• When installing the metering pump also observe the installation instructions for

devices in explosive areas; for Europe the European operator directive 99/92/EC

(ATEX137) and the ATEX Product Directive 94/9/EC (ATEX 95), implemented in Germany

by the new health and safety legislation!

• When using the metering pump for metering flammable media, observe (in Europe) the

European Operator Guideline 99/92/EC (ATEX 137, previously ATEX118a), implemented

in Germany with the new operating safety directive and the German dangerous

chemicals directive.

• Observe also all relevant standards e.g. DIN EN 60079-10/14 and DIN VDE 60079-11 for

installations in explosion-threatened areas and DIN VDE 0118 for the installation of

electrical equipment in explosion-threatened areas by day.

• Note all national directives which apply to the installation when installing outside

Germany.

CAUTION

• Pumps must be accessible at all times to facilitate operation and maintenance.

Do not obstruct or block access routes!

• Only specially trained and authorized persons are permitted to maintain and repair

metering pumps and their peripheral equipment!

• Always depressurize the liquid end first before carrying out any work on the pump!

• If hazardous or unknown metering media are used, discharge and flush the liquid end

before carrying out any work on the pump!

• Observe the safety data sheets of the metering liquids!

• Always wear protective clothing (goggles, gloves) when handling hazardous or

unknown liquids! This applies in particular to working on the liquid end!

®

• Assembly of ProMinent

metering pumps with parts not tested and approved by

ProMinent is prohibited and can result in damage to persons and property, for which

no liability will be accepted!

IMPORTANT

• Adjust the stroke length only with the pump running when the load on the stroke length

setting pin is relieved temporarily!

Release the lock before adjusting the stroke length!

• Only use clamping rings and hose sockets suitable for the relevant hose diameter as

well as genuine ProMinent hoses with the specified hose dimensions and wall

thickness, otherwise the stability of the connection cannot be guaranteed!

ProMinent

NOTE

•Avoid reducing the hose sizes!

• Use the next higher pipe cross-section or a pulsation damper for long hose lines and

media with higher viscosity!

1.2 Reference Guidelines/Standards

see EC conformity declaration

®

Page 9

Page 10

Safety / Design and Function

1.3 Tests and Approvals

Explosions protection The conformity certificate of the DMT-Gesellschaft für Forschung und Prüfung mbH, department

for the safety of electric resources, exploring drifts, can be found in the appendix.

Device type Identification mark Approval

EXBbG II 2G Ex d IIC T6 Gb II 2G c IIC T6 Gb DMT 03 ATEX E 023

EXBbG, intrinsically safe II 2(1)G Ex d [ia Ga] IIC T6 Gb II 2G c IIC T6 Gb DMT 03 ATEX E 023

EXBbM I M2 Ex d I Mb I M2 c I Mb DMT 03 ATEX E 023

ExBbM, intrinsically safe I M2(M1) Ex d [ia Ma] I Mb I M2 c I Mb DMT 03 ATEX E 023

EXBbG Class l, Div.1, Group B, C and D, T6 FMR

EXBbG Class l, Div.1, Group B, C and D, T6 CSA

2 Design and Function

You will find the view of the metering pump and the description of the function units on the foldout page of the cover.

®

The metering pump ProMinent EXtronic

Drive unit (1) With electronic control and solenoid,

power connection (10)

Input “external control” (optional) (11);

Delivery unit End ring (3) with diaphragm which is stabilised by a steel core.

Liquid end (4) with delivery connection (2) and intake connection (7),

on types 1000-0417 NP and PP with bypass hose socket (6) and vent valve (5);

Operator control unit with operating/pulse display (9),

Mains switch (not for 500 V version) (13),

Stroke length control knob (14) with observation window (10),

Locking lever (15),

Control knob for stroke rate or pushbutton/pushbutton switch for priming (16) and

transparent cover (17).

consists of the main components

2.1 Functional principle

Metering is based on the pulse burst principle:

A pulse produces a magnetic field around the solenoid,

the solenoid attracts a moving thrust piece,

as a result, the diaphragm displaces the medium in the liquid end via a pressure control valve,

the valve closes on the intake side.

The magnetic field decays on completion of the switch-on pulse,

the thrust piece of the solenoid is reset by a reset spring,

the diaphragm returns to its initial position, thus initiating an intake stroke,

which closes the pressure valve and the media is drawn in on the intake side.

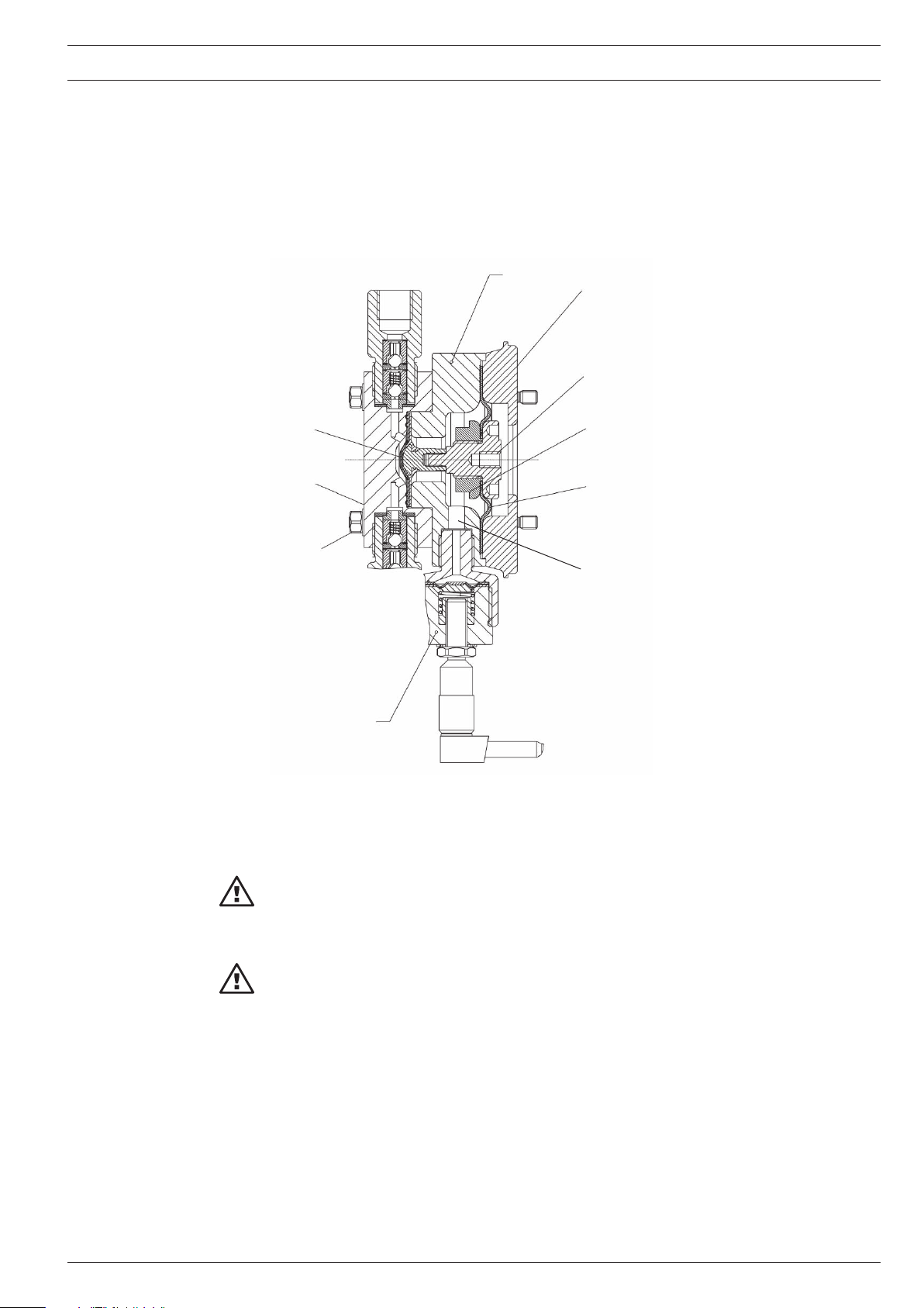

2.2 Construction / functional description diaphragm rupture indicator (optional)

The diaphragm rupture signalling system monitors the leak-tightness of the operating

diaphragm.

The liquid end of EXBb with diaphragm rupture signalling has instead of only one operating

diaphragm an additional diaphragm comprising the operational diaphragm and an additional

safety diaphragm, and is equipped with an intrinsically safe diaphragm rupture sensor (see

figure 1).

Page 10

ProMinent

®

Page 11

Design and Function

The safety diaphragm is situated between the top plate and the spacer plate and forms a sealed

interim chamber with the working diaphragm.

Function It serves to monitor ruptures in the working diaphragm and protects the power end from

corrosion and the environment from chemical leaks in the case of diaphragm rupture.

Even after diaphragm rupture, this liquid end can continue to operate in emergency mode at full

working pressure and without leaks until the diaphragm is changed.

5

1

2

6

3

1Top plate

7

4

2Adapter

3 Intermediate bush

8

10

4 Safety diaphragm

(Backup diaphragm)

5 Spacer

6Working diaphragm

7 Liquid end

8 Locking screw

9

9 Diaphragm rupture indicator

10 Intake line

fig.: 1

IMPORTANT

If the diaphragm ruptures, an electrical signal is triggered when the system back pressure

reaches approx. 2 bar.

IMPORTANT

Precise pump feed cannot be guaranteed after a working diaphragm rupture.

2.3 Feed rate

The delivery capacity is determined by the stroke length and the stroke frequency (rate).

The stroke length can be steplessly adjusted with the control knob for stroke length (14) during

operation from 100 % to 10 % and then locked. The maximum stroke length is 1.25 mm, 0.63

mm for type EXBb_1000.

A setting of 0 to 110 (120) stroke/min can be set manually with the control knob for stroke

frequency (rate) (16).

At a maximum stroke length and rate and a max. backpressure of 1.5 bar to 25 bar, the

diaphragm-operated metering pumps deliver at a rate of 0.2 l/h to 60 l/h.

ProMinent

®

Page 11

Page 12

Design and Function

2.4 Control types

Version “Internal stroke rate setting” (identity code characteristic “Control type”: 0):

The controlling pulse is internally generated, stroke length and stroke rate can be manually

adjusted using the control buttons on the operating panel.

Versions “External contact control” (identity code characteristic “Control type”: 1, 4):

The controlling pulse is externally generated, from potential-free or semiconductor contacts and

fed to the drive unit via the “external control” jack; examples are contact water meter or

DULCOMETER® controls.

Versions “Analog control x - 20 mA”

(Identity code characteristic “Control type”: 2, 3, 5, 6):

An external, analogue signal is fed to the drive unit via the “External control” jack;

the stroke rate changes proportionally according to the 0 .. 20 mA or 4 .. 20 mA signal.

Versions “Internal stroke rate setting with pause function”

(Identity code characteristic “Control type”: 7, 8):

As for version “Internal stroke rate setting”, however there is also the possibility of switching the

metering on and off via an external semiconductor contact or potential-free contact.

NOTE

All control types, that can be controlled via an input, can be supplied with an “External

control” input of “non-intrinsically safe” or “intrinsically safe” type [i, a].

Page 12

ProMinent

®

Page 13

3Technical Data

3.1 Identcode

EXBb Series ProMinent EXtronic® Version b

Type of enclosure

G Gas-explosion protection, explosion group IIC, device group/category II 2G;

M Mining/firedamp, and gas-explosion protection, expl. value I/IIC) device size/category I M2 U. II 2G)

1000 1601 1201 0803 1st and 2nd digit: Backpressure [bar]

1002 0308 2501 2502 3rd and 4th digit: Capacity [l/h]

1006 0613 0417 2505

1310 0814 0430 0260

Technical Data

Pump type

Liquid end material

NP1 Acrylic with vent, Viton

NP3 Acrylic with vent, Viton®-B O-Ring

NS3 Acrylic self-degassing, Viton®-B O-Ring

PP1 PP with vent, EPDM O-Ring

PP4 PP without vent/HV, EPDM O-Ring

PS3 PVC self-degassing, Viton®-B O-Ring

SB1 Stainless steel* with internal thread, Rp 1/4 bzw. 1/2 *) Material No. 1.4571

SS1 Stainless steel* with clamping rings PTFE-gasket *) Material No. 1.4571

SSM as SS1, with diaphragm rupture detector

SBM as SB1, with diaphragm rupture detector

SS2 Stainless steel* w. internal thread. 1/4"-NPT, PTFE-gasket *) Material No. 1.4571

TT1 PTFE +25 % carbon, PTFE-gasket

Valve spring

0 no valve spring

1 with 2 valve springs (1.4571) 0,1 bar

A 230 V 50/60 Hz open End

B 115 V 50/60 Hz open End

C 200 V 50/60 Hz open End

D 100 V 50/60 Hz open End

E 500 V 50/60 Hz open End

®

-A O-Ring

Electrical connection

Control type

0 internal stroke rate adjustment

1 external contact activation

2 analogue activation 0–20 mA

3 analogue activation 4–20 mA

4 external contact activation [i,a]

5 analogue activation 0–20 mA [i,a]

6 analogue activation 4–20 mA [i,a]

7 internal stroke rate adjustment with pause function

8 external stroke rate adjustment with pause function [i,a]

Control variant

0 with potentiometer

1 with push-button for ma. frequency

2 with switch for ma. frequency

Approval/voltage/language

0 BVS-Europa/100–500 V/German

1 BVS-Europa/100–500 V/English

2 FM-USA/100–500 V/English

3 CSA-Kanada/100–500 V/English

EXBb ___ ______ ____ ___ ___ ___ ___ ___

Viton® is a registered trademark of DuPont Dow Elastomers.

ProMinent

®

Page 13

Page 14

10

20

30

40

50

60

70

100

1

0

19

0

50

10

20

30

40

60

70

80

90

125

144

G

Technical Data

PP=11,5

Nicht u nter

Spannun g

öffnen !

D

NP=13

C

E

B

Ø 5,8

226

141

306

A

149

F

31

32

93

F

81

Version ,,NS, PS“ Version ,,SB“

*) Vent valve and bypass only on

Typs 1000 – 0417 NP and PP

*) see diagram

Page 14

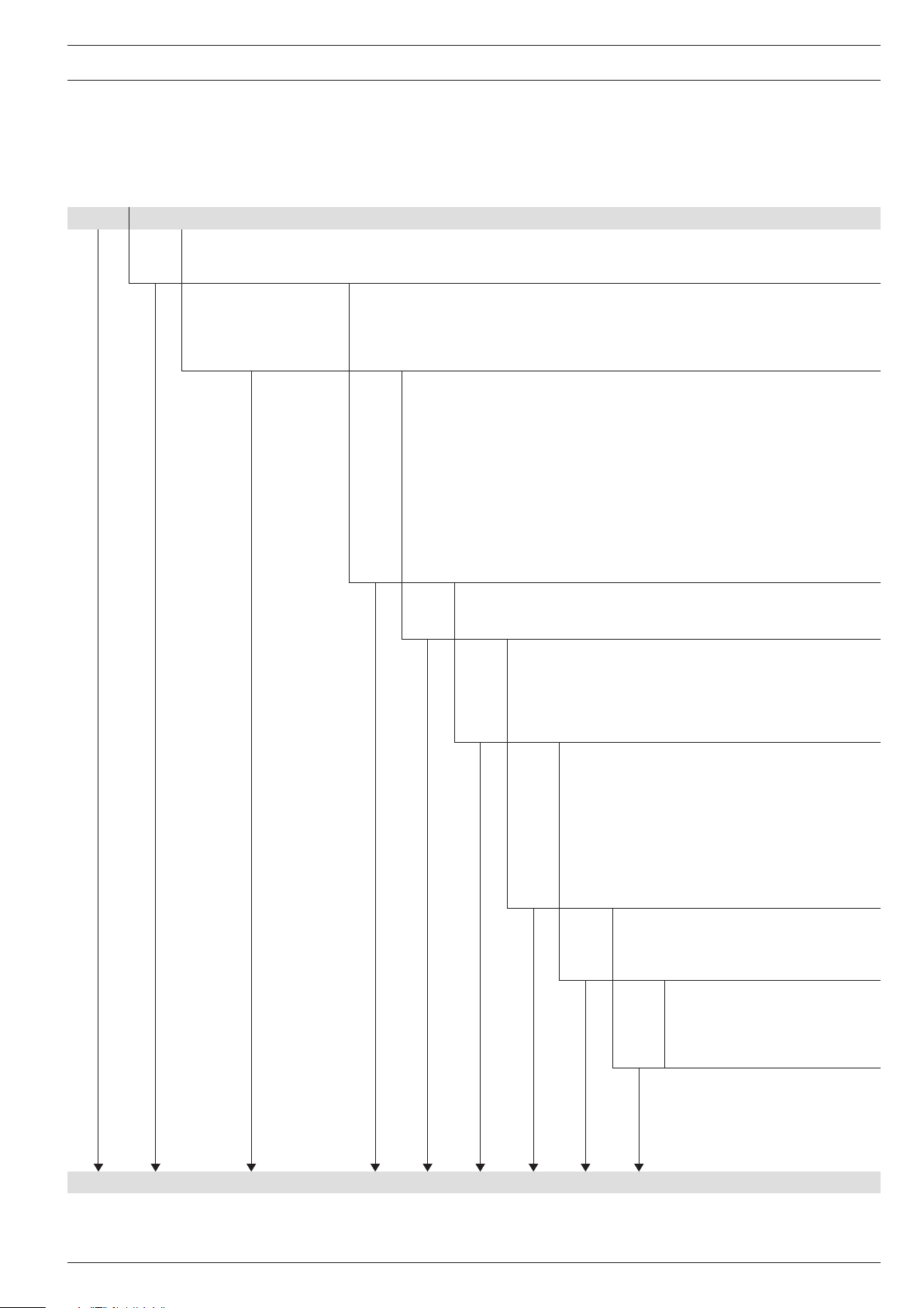

3.2 Dimensions and Weights

fig.: 2

ProMinent EXtronic® EXBb dimensions in mm

Pump type / material A B C ø D E ø F G

1000,1601, 1201, 0803 NP1 391 136 69 70 6x4 38 229

1002, 0308, 2502, 2505, 1006 NP3 391 136 61 85 8x5 50 237

1310, 0613 391 136 52 100 8x5 66 244

0814, 0417 391 136 52 100 12x9 66 244

0430 381 137 46 135 DN10 117 304

0260 398 142 -16 135 DN15 117 314

1000, 1601, 1201, 0803 PP1 393 136 67 70 6x4 38 236

1002, 0308, 1006 393 136 67 70 8x5 50 236

0613 393 136 57 90 8x5 66 246

0814, 0417 393 136 57 90 12x9 66 246

0430 381 137 46 135 DN10 117 304

0260 398 142 -16 135 DN15 117 314

1002 PP4 389 138 46 85 DN10 50 222

1006 398 145 76 85 DN15 50 222

1310 398 145 76 85 DN15 66 222

0814 398 145 69 100 DN15 66 229

1000, 1601, 1201 TT1 378 134 75 60 6x4 38 223

0803 378 134 70 70 6x4 38 228

1002, 0308, 1006 388 138 42 80 8x5 50 256

0613 388 138 32 95 8x5 66 266

0814, 0417 388 138 32 95 12x9 66 266

0430 388 137 35 135 DN10 117 263

0260 398 142 31 135 DN15 117 268

1000, 1601, 1201 SS1 376 134 84 60 6x5 38 214

0803 376 134 79 70 6x5 38 219

1002, 0308, 2502, 2505, 1006 386 138 48 80 8x7 50 250

1310, 0613 386 138 39 95 8x7 66 259

0814, 0417 386 138 39 95 12x10 66 259

0430 386 137 35 135 DN10 117 263

0260 390 142 28 135 DN15 117 271

1601, 2501 SSM 391 149 84 60 6x5 38 214

1000 SB1 373 134 87 70 Rp 1/4 38 211

1601, 1201, 0803 373 134 79 85 Rp 1/4 38 219

1002, 0308, 2502, 2505, 1006 381 138 56 80 Rp 1/4 50 242

1310, 0613 381 138 48 95 Rp 1/4 66 250

0814, 0417 381 138 48 95 Rp 1/4 66 250

0430 381 138 22 145 Rp 1/4 117 275

0260 383 139 27 145 Rp 1/2 117 279

1601, 2501 SBM 388 149 79 85 Rp 1/4 38 219

ProMinent

®

Page 15

Technical Data

1601, 1201, 0803 NS3 383 136 67 * 6x4 38 243

1002 383 136 67 * 6x4 50 243

1601, 1201, 0803 PS3 383 136 67 * 6x4 38 243

1002 383 136 67 * 6x4 50 243

Pump type Material Weight

EXBbG EXBbM

1000, 2501,1601, 1201, 0803, 1002, 0308 NP, PP, TT, SS, SB approx. 12/16 kg approx. 26/30 kg

2502, 1006, 0613, 0417 NP, PP, TT, SS, SB approx. 13/17 kg approx. 27/31 kg

2505, 1310, 0814, 0430, 0260 NP, PP, TT, SS, SB approx. 16/20 kg approx. 30/34 kg

3.3 Capacity data

Pump max. Capacity max. Capacity Stroke rate Connection- Suction Priming Perm. adtype at max. at medium size lift* lift** mission pres.

backpressure backpressure ä Ø x i Ø intake side

EXBb bar l/h ml/stroke bar l/h ml/stroke strokes/min mm m Wc m Wc bar

1000 10 0.19 0.27 5 0.27 0.038 120 6x4 1.5 0.5 8.0

2501 SSM 25 1.14 0.16 12 1.4 0.18 120 6x4 5 1.8 8.0

1601 SSM 16 1.31 0.18 8 1.68 0.23 120 6x4 5 1.8 8,0

1601 16 1.00 0.14 8 1.3 0.18 120 6x4 5 1.8 8.0

1201 12 1.70 0.24 6 2.0 0.28 120 6x4 5 2.5 5.5

0803 8 3.70 0.51 4 3.9 0.54 120 6x4 5 2.8 3.0

1002 10 2.30 0.32 5 2.7 0.38 120 8x5 5 1.0 3.0

0308 3 8.60 1.20 1.5 10.3 1.43 120 8x5 5 1.8 1.5

2502 25 2.00 0.28 12 2.4 0.31 120 8x5 5 1.0 8.0

2505 25 4.20 0.64 12 5.3 0.73 110 8x5 5 1.5 3.5

1006 10 6.00 0.83 5 7.2 1.00 120 8x5 5 1.3 3.5

1310 13 10.50 1.59 6 11.9 1.80 110 8x5 5 1.9 2.0

0613 6 13.10 1.82 3 14.9 2.07 120 8x5 5.5 1.9 2.0

0814 8 14.00 2.12 4 15.4 2.33 110 12x9 5 2.0 1.5

0417 3.5 17.40 2.42 2 17.9 2.49 120 12x9 4.5 2.0 1.5

0430 3.5 27.00 4.09 2 29.5 4.7 110 DN10 5 1.8 0.8

0260 1.5 60.00 9.09 - - - 110 DN15 1.5 1.5 0.8

Type 1000

Type 2502, 2505, 1310 only in version NP and SS

Metering pumps for high viscosity media “HV”

EXBb bar l/h ml/stroke bar l/h ml/stroke strokes/min mm m Wc m Wc bar

1002 10 2.30 0.31 5 2.7 0.38 120 DN10 1 - 3.0

1006 10 6.00 0.83 5 7.2 1.00 120 DN15 1.3 - 3.5

1310 10 10.50 1.59 6 11.9 1.80 110 DN15 1.9 - 2.0

0814 8 14.00 2.12 5 15.4 2.33 110 DN15 2 - 1.5

Metering pumps with self-degassing liquid end***

EXBb bar l/h ml/stroke bar l/h ml/stroke strokes/min mm m Wc m Wc bar

1601 16 0.66 0.09 - - - 120 6x4 - 1.8 0.2

1201 12 1.0 0.14 - - - 120 6x4 - 2.0 0.2

0803 8 2.4 0.33 - - - 120 6x4 - 2.8 0.2

1002 10 1.8 0.25 - - - 120 6x4 - 2.0 0.2

*) Suction lift: with intake line filled

**) Priming lift: with intake line not filled

***) The specified performance data are guaranteed minimum values determined with water at room temperature.

ProMinent

®

Page 15

Page 16

Technical data

3.4 Accuracies

min.: -5 %, max.: not specified

at max. stroke length and max. backpressure,

in all material versions.

Better than ± 2 %

under constant conditions and min. 30 % stroke length;

observe following notes:

• All specifications refer to metering measurements with water at 20 °C.

• Constant backpressure, above 1 bar if possible.

• If metering takes place via a free outlet, a pressure retention valve must be used to generate

a backpressure of min. 1.5 bar (refer to the installation examples).

• Wherever possible, lay intake and metering lines with a constant rising gradient.

• If the liquid level of the supply tank is above the pump during operation, admission pressure

will be applied on the intake side; in this case, the backpressure should be so high that there

is a minimum differential pressure of 1.5 bar otherwise a pressure retention valve or a springloaded injection valve with corresponding admission pressure must be used.

NOTE

A pressure retention valve or a spring-loaded injection valve is not an absolutely tightclosing shut-off element. For this reason, an intake valve which is closed when the

metering pump is at a standstill, must be installed if admission pressure is applied on the

intake side.

Liquid end

Intake- / delivery

connection

Seals

Balls Ø 6–Ø 12

Balls DN10–DN15

3.5 Material Specifications

PP1 PP4 PC5 NP1/NP3 NS3 PS3 TT1 SS

Polypropylene Polypropylene PVC Acrylic Acrylic PVC PTFE with Stainless steel

Polypropylene Polypropylene PVC PVC PVC PVC PTFE with Stainless steel

EPDM EPDM FPM-A FPM-A/B FPM-B FPM-B PTFE PTFE

Ceramic — Ceramic Ceramic Ceramic Ceramic Ceramic Ceramic

Duran Ceramic — Duran — — Ceramic 1.4401

Type 1000 with ceramic seat rings in all material versions

PP4 with Hastelloy C valve springs

DEVELOPAN

FPM-A (Viton®-A), FPM-B (Viton®-B) and Duran (laboratory glass) are registered trademarks.

®

metering diaphragm with PTFE base in all versions

carbon 1.4404

carbon 1.4404

3.6 Electrical Data

3.6.1 Electrical data, control current circuit

3.6.1.1 for “non-intrinsically safe” version and “intrinsically safe” version

mA input, identity code feature “control type”: 2, 3, 5*, 6*

Voltage max. 6 V

Current max. 30 mA

Input apparent ohmic resistance, approx. 94 Ω

Page 16

ProMinent

®

Page 17

Contact/pause input, identity code feature “control type”: 1, 4*, 7, 8*

Voltage with open contact approx. 5 V

Input resistance approx. 4.7 kΩ

Control using potential-free contact or semiconductor switch:

Residual current max. (contact open): 70 µA

Contact resistance (closed) max.: 10 kΩ or

Voltage drop max.: 3 V

Pulse frequency max.: 40 pulses/sec.

Pulse width min.: 10 ms

* For the ensuring of intrinsic-safety, see chapter 3.6.1.2 under "intrinsically safe" version

3.6.1.2 under “intrinsically safe” version

Control circuit Default value of all types “(ia)”,

• Maximum output voltage: U

• Maximum output current: I

• Maximum output power: P

• Internal resistance R

• Maximum external inductance: L

• Maximum external capacity: C

= 7.14 V

0

= 5 mA

0

= 23.3 mW

0

= 4296 Ω

i

=1 H

0

= 13.5 µF

0

Technical data

For connection of an intrinsically safe circuit

• Maximum input current: I

• Maximum input voltage: U

• Maximum input power P

•Effective inner self-inductance L

•Effective inner capacity C

= 280 mA

i

= 30 V

i

=2 W

i

= negligible

i

= negligible

i

3.6.2 Electrical data, supply current circuit

3.6.2.1 for “not intrinsically safe” version

Measurement voltage 100,115, 200, 230 and 500 + - 10 % VAC

Maximum current consumption I

Max. peak current during a stroke I

Maximum power consumption P

* 1.5 A

eff

peak

* 50 W

wirk

8 A

* obtained by averaging over several strokes at the maximum stroke rate

3.6.2.2 for the “intinsically safe” version

Supply current circuit Intrinsically safe rated voltage: 100, 115, 200, 230 + - 10%, 500 +6% -10% VAC

Maximum current consumption I

Max. peak current during a stroke I

* 1.5 A

eff

peak

8 A

Maximum power consumption Pwirk* 50 W

* obtained by averaging over several strokes at the maximum stroke rate

ProMinent

®

Page 17

Page 18

Technical data

3.6.3 Electrical data for the intrinsically safe (optional) diaphragm rupture indicator

Diaphragm rupture detector Type Pepperl+Fuchs, NJ1,5-8GM-N-V1

Nominal voltage 8.2 V (Ri approx. 1 kOhm)

Normal power consumption ≤ 1mA

Power consumption in the event of a diaphragm rupture ≥ 3mA

Please observe the Operating Manual and the Type Examination Certificate of the diaphragm

rupture sensor for detailed data and for use in areas at risk of explosion.

3.6.4 Electrical data, details

Pump type 1000, 2501,1601, 1201, 2502, 1006, 0613, 0417, 2505, 1310, 0814, 0430, 0260

Mains connection (V) 100 115 200 230 500 100 115 200 230 500 100 115 200 230 500

Max. current consumption*** (A) 1.6 1.4 0.7 0.8 0.3 3.0 2.7 1.8 1.8 0.6 4.1 3.6 2.2 2.5 1.1

Effective. current

consumption*** (A)

Mean power consumption (W) 16 16 16 16 16 35 35 35 35 35 47 47 47 47 47

Fuse item 65* value (A)/Type 1.0T 0.63T 0.4T 0.315T 0.319 2.5T 2.0T 1.25T 0.8T 0.63 3.15T 2.5T 1.6T 1.25T 1.25

Value (A)/Type 0.16T 0.16T 0.16T 0.16T - 0.16T 0.16T 0.16T 0.16T - 0.16T 0.16T 0.16T 0.16T -

0.27 0.29 0.14 0.17 0.09 0.70 0.70 0.33 0.41 0.14 0.95 0.84 0.47 0.53 0.25

0803, 1002, 0308 1002*****

* special fuse with high switching capacity: only use original fuse

** use only original fuse

*** effective value during a stroke

**** obtained by averaging over several strokes at the maximum stroke rate

*****with material version PP4

Fuse order numbers, see chapter 11

NOTE

Only the effective power consumption is specified on the rating plate

3.7 Mechanical data, cables

Pump type Voltage V Cable Cable type Colour outer Ø mm

EXBbG to 250 power cable H 07 RNF 3G1.5 black 10.0

EXBbG > 250 power cable NSSHÖU 3x1.5 yellow 12.5

EXBbM all power cable NSSHÖU 3x1.5 yellow 14.0

+3x1.5/3E

EXBbG < 60 external/analogue cable Ölflex 110 grey 6.3

EXBbG < 60 external/analogue cable Ölflex EB blue 5.9

EXBbM < 60 external/analogue cable L-YY (zg) Y grey 11.4

EXBb_ 8 diaphragm rupture detector blue

In “FM”- and “CSA” version H07 RNF up to 500 V, the cable aperture has

a 1/2" NPT internal thread for connection to the North American supply system.

Page 18

ProMinent

®

Page 19

3.8 Ambient conditions

Admissible storage temperature -20 °C to +50 °C

Admissible ambient temperature -20 °C to +45 °C

Admissible chemical temperature -10 °C to +35 °C (in accordance with IEC 335-2-41)

Temperature resistance of material versions

Long term at max. back pressure 50 °C 45 °C 50 °C 50 °C

Max. 15 min at max. 2 bar 100 °C 60 °C 120 °C 120 °C

Climate admissible humidity 92 % non condensing

Behaviour in damp alternating climate DIN IEC 60068-2-78

Enclosure rating IP 65

Sound intensity level ≤ 70 dB (A), 1 m Abstand

4 Unpacking

NOTE

Polystyrene parts are recyclable. They do not belong in the household waste!

Technical data / Unpacking

PP NP TT SS

왘 It is advisable to keep the outside packing complete with the polystyrene parts in order to

be able to return the metering pump in the case of repairs and warranty claims.

왘 Compare your delivery note with the packed contents.

왘 Check whether the data on the type identification plate (8) of the metering pump agree with

your order data!

왘 Should any problems arise, contact your ProMinent dealer or representative. You will find the

addresses on the back page of these operating instructions.

왘 Always specify the identity code and the serial number which you will find on the type identi-

fication plate when making any inquiries or ordering spare parts. In this way, the pump type

and material variants can be clearly identified.

Scope of delivery • Metering pump with power cable

• Operating instructions with conformity certificate

• Conformity declaration for Namur-Sensor (only with diaphragm rupture indicator)

ProMinent

®

Page 19

Page 20

Mounting and Installation

5 Mounting and Installation

WARNING

• When installing the metering pump also observe the installation instructions for devices

• When using the metering pump for metering flammable media, observe (in Europe) the

• Observe valid national regulations when installing the pump abroad!

• Remove all traces of water from the liquid end before starting operation with media

5.1 Installing Metering Pump

IMPORTANT

• Secure the pump such that no vibrations can occur.

• Ensure free access to facilitate operation and maintenance.

• The valves of the liquid end must be in vertical position!

왘 The metering pump must be secured with screws and washers Ø 6 mm on a horizontal, firm

in explosive areas; for Europe the European operator directive 99/92/EC (ATEX137) and

the ATEX Product Directive 94/9/EC (ATEX 95), implemented in Germany by the new

health and safety legislation!

European Operator Guideline 99/92/EC (ATEX 137, previously ATEX118a), implemented

in Germany with the new operating safety directive and the German dangerous chemicals directive.

which must not come in contact with water! The metering pump may still have water

residue in the liquid end from the tests carried out at the factory.

base.

5.2 Installing Hose Lines

IMPORTANT

• Lay and secure intake and delivery lines such that they cannot chafe.

• Lay intake and delivery lines such that they are free of mechanical stress.

• Arrange all lines such that the pump and liquid end can be removed laterally if required.

• When metering extremely aggressive or hazardous media, a venting facility with return

into the supply tank as well as a shut-off valve must be provided on the delivery and

intake sides.

• Ensure all connections are tight:

only use the clamping rings and hose sockets as specified for the relevant hose

diameter, only use original hoses with specified hose dimensions and wall

thickness.

•Avoid reductions in hose sizes: use the next higher line cross-section for long hose

lines and viscous media or install a compressed air vessel or diaphragm pulsation

damper!

Page 20

ProMinent

®

Page 21

Fitting Hose lines 왘 Remove plug if fitted in the intake/delivery connection.

Union nut

Clamping ring

Hose

Socket

Valve

Pipe

Union nut

Rear

clamping ring

Front

clamping ring

Valve

fig.: 3

Fitting stainless steel pipe

connections 왘 Fit union nut and clamping rings on to pipe with a projection of approx. 10 mm.

Mounting and Installation

왘 Cut end of hose straight.

왘 Fit union nut and clamping ring over hose.

왘 Fit end of hose as far as it will go over socket widen end if necessary.

왘 Fit hose with socket on to valve.

왘 Clamp hose connection:

Firmly tighten union nut while at the same time pressing down hose.

왘 Retighten hose connection:

Pull the hose line secured at the liquid end and then tighten the union nut once again.

왘 Fit pipe as far as it will go into valve.

왘 Firmly tighten union nut.

fig.: 4

Fitting PE or PTFE lines on

stainless steel

valves 왘 Additionally fit a stainless steel support sleeve in the plastic sleeve.

5.2.1 Installing the Intake Line

NOTE

• The intake line should be as short as possible.

• Fit intake line in upright position in order to avoid air bubbles forming.

• Wherever possible use pipe bends and not elbows for bends in the intake line.

• Select cross section and length such that the vacuum which occurs during intake does

not reach the vapour pressure of the medium to be metered. In extreme cases,

excessively high vacuum on the intake side is reflected in collapse of the liquid column

or by an incomplete return stroke.

• Do not exceed the permissible admission pressure on the intake side.

• Note: Suction lift x medium density ≤ max. suction lift in m water column

• Refer to the installation examples.

ProMinent

®

Page 21

Page 22

Mounting and Installation

Installing foot valve 왘 Cut the free end of the intake line to size such that the foot valve just hangs over the bottom

5.2.2 Installing the Delivery Line

IMPORTANT

•A multiple of the maximum operating pressure can build up if the metering punp is

• Install the delivery line such that the pressure peaks during the metering stroke do

• Refer to installation examples!

When metering with atmospheric discharge, a metering valve with 0.5 bar response pressure

should be mounted at the end of the line. Or a back-pressure valve should be mounted directly

onto the liquid end in order to create and maintain a counter-pressure of approx. 1.5 bar.

If the level of the fluid of the supply tank is above the pump in operating condition, the response

pressure is on the suction end. In this case the counter-pressure should be sufficiently high such

that a minimum differential pressure of 1.5 bar exists. If this is not the case a back-pressure

valve or a spring-loaded metering valve with the respective response pressure should be used.

of the tank. In the case of metered solutions with impurities or bottom deposits, the foot

valve should be located at an adequate distance above the tank bottom or bottom deposits.

operated against a closed shut-off element on the delivery side.This can cause the

delivery line to burst!

An overflow valve should be installed in order to avoid this, e.g. a ProMinent multifunction valve.

not exceed the max. permissible operating pressure. Check length and cross-section.

If necessary, install an overflow valve, compressed air vessel or diaphragm pulsation

damper.

NOTE

A back-pressure valve or a spring-loaded metering valve is not an absolutely leakproof

shut-off device!

On the suction end a stop valve is therefore to be installed which is closed when the

metering pump is idle.

5.2.3 Installing the Bypass Vent Line (see fold-out page)

The liquid end of the pump types 1000 - 0417 NP and PP is equipped with a vent valve (5) with

bypass (6).

The admission pressure on the intake side must be at least the same pressure as in the bypass

line. Operation is not possible with admission pressure in the bypass and no pressure on the

intake side

왘 Fit hose line with Ø

PVC-soft 6x4 is recommended.

= 4 mm (max. 6 mm) on to bypass hose socket,

internal

왘 For PE lines, secure against slipping using a quick fastener.

왘 Route the free end of the line back into the metering tank.

왘 Cut the bypass line to size such that it is not submerged in the metering medium.

Page 22

ProMinent

®

Page 23

Mounting and Installation

5.3 Installation Examples, Mechanical/Hydraulic

Symbols Oscillating diaphragm metering pump Injection valve

Foot valve Pressure retention valve/

overflow valve

Shut-off valve Pressure retention valve (adjustable)

Standard installation

Metering with free outlet and

small delivery head

Pressure gauge

Solenoid Valve

(closed when pump switched off)

.... and large delivery head

Compressed air vessel

... and admission pressure

on intake side

Installation to avoid lift-

through of hazardous media

ProMinent

®

Page 23

Page 24

Mounting and Installation

Installation togeher with air

vessel with long lines and for

low-pulsation metering

... in a delivery line

... with free outlet

... without after-running

Delivery line

DHV-S

Nozzle

To protect against

overpressure

Do not install like this:

Intake line cannot be vented!

Do not install like this:

Free flow!

Metering in vacuum

or intake line

Do not install like this:

Intake line too high!

Do not install like this:

Compressed air vessel

not effective!

injection valve

with re-inforced

spring or DHV

Page 24

ProMinent

®

Page 25

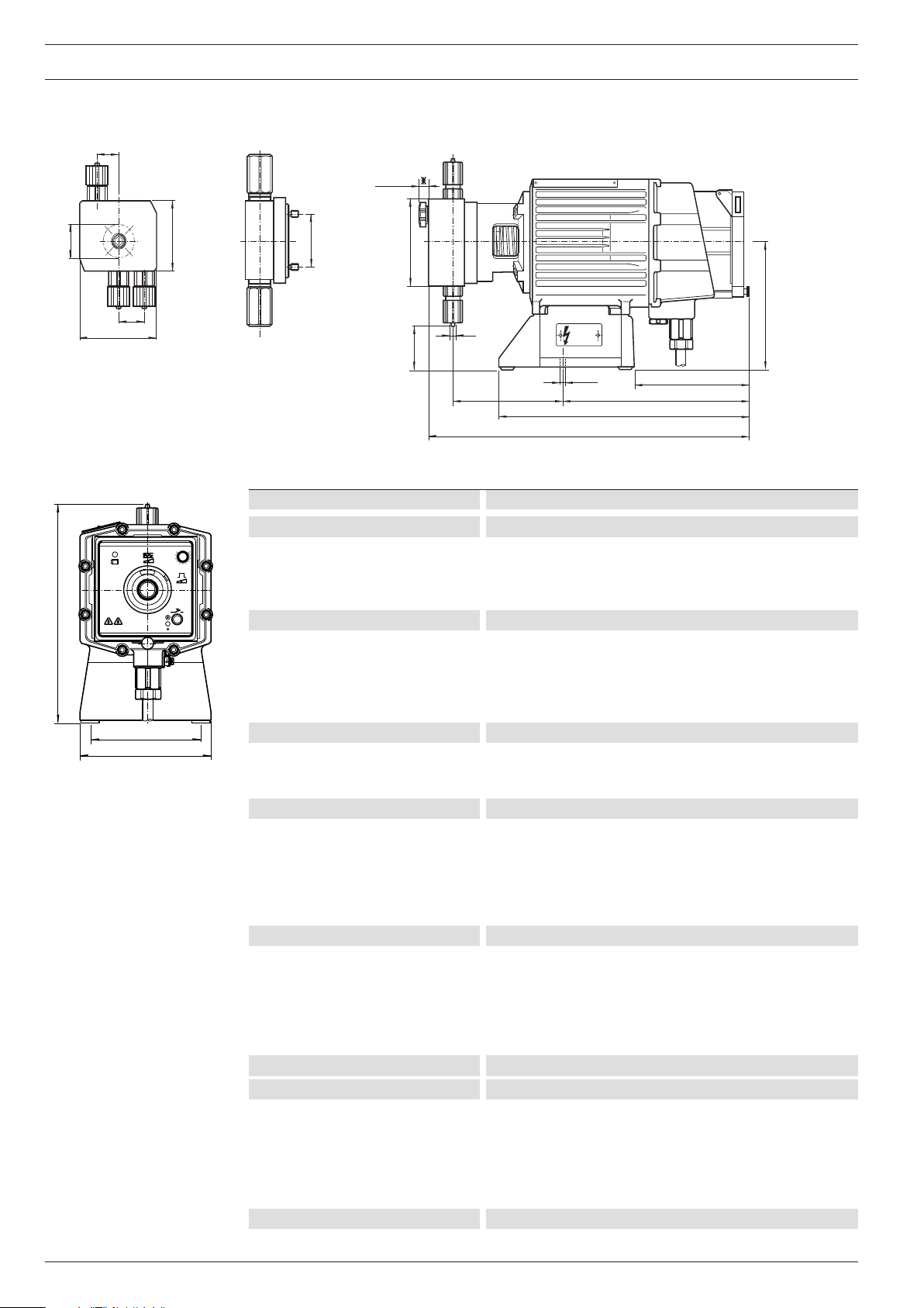

5.4 Electrical Installation

10

20

30

40

50

60

70

100

1

0

19

0

50

10

20

30

40

60

70

80

90

23

12

IMPORTANT

• The metering pump must be electrically installed by authorised, “skilled” personnel

only.

• When installing the metering pump also observe the installation instructions for

devices in explosive areas; for Europe the European operator directive 99/92/EC

(ATEX137) and the ATEX Product Directive 94/9/EC (ATEX 95), implemented in Germany

by the new health and safety legislation!

• Observe the relevant standards e.g. DIN EN 60079, DIN EN 60079-11, DIN VDE and/or

0118 “Erecting electrical equipment in explosion-threatened areas” DIN EN 60079-14!

• Note all national directives which apply to the installation when installing outside

Germany.

• Intrinsically safe installations must be checked by persons with “recognised

qualifications“.

• Do not connect mains power supply to the external terminal (11).

• The internally used fusible link has a breaking capacity of 1,500A. If the short-circuit

current in the supply network ma be larger than 1,500A, the pump is to be protected

with a suitable back-up fuse with a higher breaking capacity (rated current smaller

than 1,500A).

Power connection Electrical data see 3.6

The connection terminal (23) for the equipotential bonding conductor is located on the housing

next to the power supply terminal (12).

Mounting and Installation

fig.: 5

12 Power supply

23 Connection terminal for

equipotential bonding

Induction voltage If the pump is connected to the power supply parallel to inductive loads (e.g. solenoid valve,

EXBbG L1: Phase, brown

N: Zero wire, blue

PE: Earth lead, yellow/green

EXBbM L1: Phase, brown

N: Zero wire, blue

-: free, black*

PE: Earth lead, yellow/green**

* Internally insulated, connect to a free terminal on the outside.

** Twist the three single coaxial earth leads together, fit yellow/green sleeve and attach to the

earth lead terminal.

motor), it must be electrically isolated from these loads in order to avoid damage caused by

induction voltages when switching off.

왘 Use several contacts for power supply via auxiliary contactor or relay.

왘 In the 100-V- to 230-V-versions, connect a varistor (U

(0,22 uF/220 Ohm) in parallel.

= 275 V) or RC-element

N

ProMinent

Varistor

Inductive

load

ProMinent

Metering pump

ProMinent

Metering pump

Varistor

Inductive

load

Abb.: 6

Switching on With power switch (13), a power switch must be provided by the customer for the 500 V version.

®

Page 25

Page 26

Mounting and Installation / Operation

External, contact, analogue and pause input, not intrinsically safe

EXBbG input+ black (1)

Input- black (2)

EXBbM input+ blue

Input- black

External, contact, analogue and pause input intrinsically safe, sheath colour blue.

EXBbG und EXBbM: Input (+) = brown (1)

El. terminal for diaphragm rupture detector, intrinsically safe, sheath colour blue.

ExBbG and EXBbM: Alarm, blue

6 Operation

6.1 Start-Up

Input (+) = blue (2)

GND+, brown

WARNING

• Always wear protective goggles and protective clothing when handling hazardous

media!

• The metering pump may still contain water residue in the liquid end from the tests

carried out at the factory. All water must be removed from the liquid end before startup in the case of media which must not come in contact with water!

NOTE

• Carry out all settings only with the pump in operation.

Release the lock before adjusting the stroke length!

• The intake head with the liquid end empty is dependent on the stroke volume:

The pump intake should be set at stroke length = 100 %. Select the intake head

correspondingly smaller if the pump is to be discharged at a lower setting without

changing the stroke length and is to be placed into operation again self-priming.

• Pump intake is not possible against backpressure

• Absolutely reliable metering cannot be guaranteed after a pump down period.

Regular monitoring is necessary!

Before start-up 왘 Check function of pressure relief valves.

왘 Check pump connections and pipe connections for leaks.

Remove water from liquid end when handling media which must not come in contact with water:

왘 Tu rn pump through 180°.

왘 Empty liquid end.

왘 Flush with a suitable medium from above through the intake connection.

Page 26

Filling liquid end without vent valve:

왘 Connect intake line but do not yet connect the delivery line to the liquid end.

왘 Switch on pump with power switch (13) and operate at max. stroke length and stroke rate

until liquid end is filled completely and free of bubbles.

왘 Switch off pump with power switch (13).

왘 Connect delivery line to liquid end.

The pump is now ready for operation.

ProMinent

®

Page 27

Filling liquid end liquid end with vent valve and bypass:

Rough venting

왘 Connect intake and delivery line to liquid end.

왘 Connect bypass line.

왘 Open vent valve (5) by one turn of the star knob in counterclockwise direction; the routes

for rough venting via the bypass (6) is now clear.

왘 Switch on pump with power switch (13) and operate at max. stroke length and stroke rate

until liquid end is filled completely and free of bubbles (when the medium is visible in the

venting or metering line).

왘 Close vent valve.

왘 Switch off pump with power switch (13).

The pump is now ready for operation

Setting fine vent metering gas-emitting media:

NOTE

•A part of the metered quantity is constantly routed back into the supply tank.

The return quantity should be approx. 20 % of the metered quantity.

• The media must be low-viscous (thin-bodied) and without solids.

• If the return flow line ends above the liquid level, the precision vent valve acts as a

vacuum breaker and prevents discharge of the supply tank if a vacuum builds up in

the metering line.

• Retighten the screws in the liquid end after 24 hours of operation.

Operation

왘 Remove star knob from vent valve (5).

왘 Using a screwdriver, turn screw in vent valve approx. 1 turn in counterclockwise direction.

왘 Fit star knob on vent valve (5).

Venting liquid end HV version:

Initial intake and venting is impaired to a certain extent by the valves and valve springs which

are still dry. Therefore select the shortest possible intake head or vent the liquid end with inlet

or admission pressure on the intake side.

If not successful, shortly operate pump without valve spring in the pressure valve:

왘 Unscrew delivery connection and press away ball from O-ring.

왘 Fill liquid end with water or suitable liquid.

왘 Fit delivery connection without valve spring.

왘 Fit short piece of PVC hose (100 mm) on to hose socket, half fill with water.

왘 Operate pump at max. stroke length until metering is visible in the hose.

왘 Re-install valve spring – avoid twisting by fitting an approx. 4 mm Ø drift through the

pressure valve in order to hold the spring in the centre position.

왘 Reconnect delivery line.

Venting liquid end when pump delivers in a pressure system and has drawn in air:

왘 Set venting on delivery side: Release metering line or open vent valve.

왘 Switch on pump and vent at stroke length 100 %.

ProMinent

6.2 Determining the Delivery Capacity

The actual delivery capacity is dependent on the stroke length, stroke frequency (rate) and

backpressure in the metering line. The relationship between capacity/stroke length/stroke

frequency (rate) is illustrated in the nomogram for each type of pump. A correction factor can

be read off from the diagram which shows the change in capacity referred to backpressure.

The measurements for determining the nomograms were conducted with water and the

correction factor was determined at a stroke length of 70 %. The capacity scatter over all

material versions is -5 % (for max. value: not specified).

®

Page 27

Page 28

Operating

왘 Select the required capacity within the value range of the pump type (see capacity data).

왘 Select the nomogram and diagram of the pump type.

왘 Mark the backpressure in the metering system on the abscissa and read off the

corresponding correction factor on the ordinate.

왘 Divide the required capacity by the correction factor.

왘 Using a ruler, mark the determined capacity on the middle scale of the nomogram.

왘 Draw a line across all three scales – as horizontal as possible, however, such that the line

intersects at least one of the two outer scales; where possible, select a graduation with a

large value on the stroke length scale.

The point of intersection of the line with the right-hand scale shows the stroke frequency (rate)

to be set, the point of intersection of the line with the left-hand scale shows the stroke length to

be set.

Capacity with mean backpressure: 11.9 l/h (see capacity data)

Required capacity: 6 l/h

Backpressure: 8 bar

→ Correction factor as per diagram: 0.9

→ Capacity to be set: 6 l/h

0.9

= 6,66 l/h

→ Stroke length as per nomogram: 80 %

→ Stroke rate as per nomogram: 80 stroke/min

NOTE

• Select large stroke length and low stroke rate for highly viscous and gas-emitting

media.

• Use self-venting liquid end for gas-emitting media with viscosity ≤ 20 mPa s.

• Select a shorter stroke length and high stroke rate for effective mixing.

• For a precise dosing, choose metering-stroke of not less than 30 %.

At max. pressure stroke length

≥ 60 % for type 1601,

≥ 40 % for type 1201 and 1002,

≥ 20 % for type 0803;

the stroke length can be reduced further at lower pressure.

• Set the stroke length greater for pumps with the precision vent open

Page 28

ProMinent

®

Page 29

EXBb_1000

0.30

0.25

0.20

0.15

0.12

0.09

0.07

0.05

0.04

0.03

0.02

0.015

0.012

0.01

0.005

0.004

5.04

4.00

3.00

2.00

1.50

1.00

0.70

0.50

0.40

0.30

0.20

0.15

0.10

0.07

1.5

1.0

0.5

0 1.5 3 4 5 6 7 8 9 10

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

0.625

0.563

0.500

0.438

0.375

0.313

0.250

0.188

100

90

80

70

60

50

40

30

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 0.27 l/h at medium backpressure of 5 bar

Capacity 0.19 l/h at max. backpressure of 10 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (stroke/min)

1,125

1,250

1,000

0,875

0,750

0,625

0,500

0,375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

1,30

0,90

0,60

0,40

0,26

0,18

0,13

0,10

0,08

0,06

0,04

0,03

0,02

0,015

0,01

21,67

16,00

13,00

10,00

8,00

6,50

5,50

4,33

3,50

2,70

2,17

1,50

1,00

0,80

0,60

0,40

0,30

0,20

Stroke length (mm)

Stroke length (%)

Capacity (ml/min)

Capacitiy (l/h)

Stroke rate (Scale)

Stroke rate (stroke/min)

Backpressure (bar)

Capacity 1,30 l/h at medium backpressure of 16 bar

Capacity 1,10 l/h at max. backpressure of 25 bar

Capacity dependent on backpressure

Correction factor

Operating

6.3 Nomograms

EXBb_2501

ProMinent

®

Page 29

Page 30

Operating

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

1.5

1

0.5

0

1.5

21

34567

8

910

11

12

2.00

1.60

1.30

1.00

0.76

0.60

0.50

0.35

0.25

0.20

0.15

0.10

0.08

0.06

0.04

0.03

33.33

28.00

24.00

20.00

17.00

15.00

12.67

9.50

7.50

6.00

4.50

3.33

2.50

2.00

1.50

1.25

1.00

0.80

0.70

0.60

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 2.00 l/h at medium backpressure of 6 bar

Capacity 1.70 l/h at max. backpressure of 12 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (stroke /min)

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

1.30

0.90

0.60

0.40

0.26

0.18

0.13

0.10

0.08

0.06

0.04

0.03

0.02

0.015

0.01

21.67

16.00

13.00

10.00

8.00

6.50

5.50

4.33

3.50

2.70

2.17

1.50

1.00

0.80

0.60

0.40

0.30

0.20

1.5

1

0.5

0

1.5

4

6

8

10

12 14

16

Stroke length (mm)

Stroke length (%)

Capacity (ml/min)

Capacitiy (l/h)

Stroke rate (Skale)

Stroke rate (stroke/min)

Backpressure (bar)

Correction factor

Capacity 1.30 l/h at medium backpressure of 8 bar

Capacity 1.00 l/h at max. backpressure of 16 bar

Capacity dependent on backpressure

EXBb_1601

EXBb_1201

Page 30

ProMinent

®

Page 31

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

3.90

3.40

3.00

2.50

2.00

1.70

1.42

1.20

1.00

0.80

0.60

0.50

0.39

0.30

0.25

0.20

0.15

0.12

0.10

0.08

0.06

65.00

58.00

50.00

40.00

35.00

27.00

23.67

20.00

15.00

11.50

10.00

8.00

6.50

5.00

4.00

3.00

2.50

2.00

1.60

1.30

1.00

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

1.5

1

0.5

0

1

1.5 2

3

4

5

6

78

Stroke length (mm)

Stroke length (%)

Capacity (ml/min)

Capacity (l/h)

Stroke rate (scale)

Stroke rate (stroke/min)

Backpressure (bar)

Correction factor

Capacity 3.90 l/h at medium backpressure of 4 bar

Capacity 3.70 l/h at max. backpressure of 8 bar

Capacity dependent on backpressure

EXBb_0803

2.70

2.30

1.80

1.50

1.20

1.00

0.83

0.70

0.60

0.50

0.40

0.33

0.27

0.20

0.15

0.10

0.08

0.06

0.04

45.00

38.00

30.00

25.00

20.00

17.00

13.30

10.00

8.00

6.00

4.50

3.60

3.00

2.50

2.00

1.50

1.00

0.80

1.5

1

0.5

0 1.5 2 3 4 5 6 7 8 9 10

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 2.70 l/h at medium backpressure of 5 bar

Capacity 2.30 l/h at max. backpressure of 10 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (Stroke /min)

Operating

EXBb_1002

®

ProMinent

Page 31

Page 32

10.30

8.00

6.00

5.00

4.00

3.42

2.50

2.00

1.50

1.03

0.80

0.60

0.50

0.40

0.30

0.20

0.15

171.67

150.00

120.00

100.00

80.00

65.00

57.00

47.00

40.00

30.00

25.00

20.00

17.17

13.00

10.00

8.00

6.00

5.00

4.00

3.00

1.5

1

0.5

0

0.5

1

1.5

2

2.5

3

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 10.30 l/h at medium backpressure of 1.5 bar

Capacity 8.70 l/h at max. backpressure of 3 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke lenght (%)

Stroke rate (scale)

Stroke rate (stroke /min)

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

3

2.5

2

1.5

0.5

0

1

0

2.5 5 7.5 10 12.5 15 17.5 20 22.5 25

1.250

1.125

1.000

0.875

0.750

0.625

100

90

80

70

60

50

2.20

1.40

1.00

0.70

0.50

0.39

0.25

0.19

0.15

0.10

0.06

0.04

0.03

0.02

36.66

22.00

15.00

10.00

6.50

4.50

3.17

2.20

1.50

1.00

0.70

0.50

0.40

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 2.20 l/h at medium backpressure of 20 bar

Capacity 2.00 l/h at max. backpressure of 25 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (stroke/min)

Operating

EXBb_0308

EXBb_2502

Page 32

ProMinent

®

Page 33

1.250

1.125

1.000

0.875

0.750

0.625

100

90

80

70

60

50

3

2.5

2

1.5

1

0

02.557.5 10 12.5 15 17.5 20 22.5 25

0.5

4.80

3.80

3.00

2.50

2.00

1.65

1.30

1.00

0.85

0.60

0.45

0.35

0.25

0.20

0.15

0.10

80.00

60.00

45.00

35.00

25.00

19.00

14.17

10.00

7.57

6.00

4.00

3.00

2.00

1.50

1.00

0.08

0.08

0.06

0.04

100

90

80

70

60

50

40

30

20

10

5

110

88

99

77

66

55

44

33

22

11

5.5

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 4.80 l/h at medium backpressure of 20 bar

Capacity 4.20 l/h at max. backpressure of 25 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (stroke/min)

EXBb_2505

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

7.20

6.00

5.00

4.00

3.00

2.00

1.53

1.20

0.90

0.72

0.50

0.40

0.30

0.20

0.15

0.10

0.06

120.00

100.00

80.00

60.00

50.00

40.00

30.00

25.50

20.00

16.00

12.00

10.00

8.00

6.00

5.00

4.00

3.00

2.00

1.50

1.00

1.5

1

0.5

0

1

2

3

4

5

6

78

9

10

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 7.20 l/h at medium backpressure of 5 bar

Capacity 6.00 l/h at max. backpressure of 10 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (stroke /min)

Operating

EXBb_1006

ProMinent

®

Page 33

Page 34

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

11.90

10.00

8.00

6.00

5.00

4.00

3.00

2.30

1.80

1.50

1.19

0.90

0.70

0.50

0.40

0.30

0.20

0.15

0.10

198.33

160.00

120.00

100.00

80.00

60.00

50.00

38.33

28.00

19.83

15.00

10.00

8.00

6.00

4.00

3.00

2.00

1.50

100

90

80

70

60

50

40

30

20

10

5

110

88

99

77

66

55

44

33

22

11

5.5

1.5

1

0.5

0

1

2

34567 9810

11

12

13

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 11.90 l/h at medium backpressure of 6 bar

Capacity 10.50 l/h at max. backpressure of 13 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (stroke/min)

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0 0.5

1 1.5

2 2.5 3

3.5

4

4.5

5 5.5

6

14.90

12.00

9.00

6.50

5.00

3.60

2.80

2.00

1.49

1.20

0.90

0.70

0.50

0.40

0.30

0.20

0.15

248.33

190.00

150.00

120.00

100.00

80.00

60.00

45.00

35.00

24.83

18.00

14.00

10.00

8.00

6.00

4.00

3.00

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 14.90 l/h at medium backpressure of 3 bar

Capacity 13.10 l/h at medium backpressure of 6 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (scale)

Stroke rate (stroke /min)

Operating

EXBb_1310

EXBb_0613

Page 34

ProMinent

®

Page 35

100

90

80

70

60

50

40

30

20

10

5

110

88

99

77

66

55

44

33

22

11

5,5

1,125

1,250

1,000

0,875

0,750

0,625

0,500

0,375

100

90

80

70

60

50

40

30

15,40

12,50

10,00

8,00

6,00

4,11

3,00

2,00

1,54

1,00

0,80

0,60

0,40

0,30

0,20

256,67

200,00

160,00

120,00

90,00

68,50

55,00

40,00

25,67

20,00

15,00

11,00

8,00

6,00

4,00

3,00

0,5

1

012 3 45

6

78

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 15,40 l/h at medium backpressure of 5 bar

Capacity 14,00 l/h at max. backpressure of 8 bar

Capacity dependent on backpressure

Stroke length (mm)

Stroke length (%)

Stroke rate (Skale)

Stroke rate (Hübe/min)

EXBb_0814

1.125

1.250

1.000

0.875

0.750

0.625

0.500

0.375

100

90

80

70

60

50

40

30

100

90

80

70

60

50

40

30

20

10

5

120

108

96

84

72

60

48

36

24

12

6

17.90

13.00

10.00

8.00

6.00

4.50

3.00

2.40

1.79

1.30

1.00

0.80

0.60

0.40

0.30

0.20

298.33

250.00

200.00

150.00

120.00

90.00

75.00

60.00

40.00

29.83

20.00

15.00

10.00

8.00

6.00

4.00

3.00

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0

0.5 1

1.5

2 2.5

3 3.5

Capacity (ml/min)

Capacity (l/h)

Backpressure (bar)

Correction factor

Capacity 17.90 l/h at medium Backpressure of 2 bar