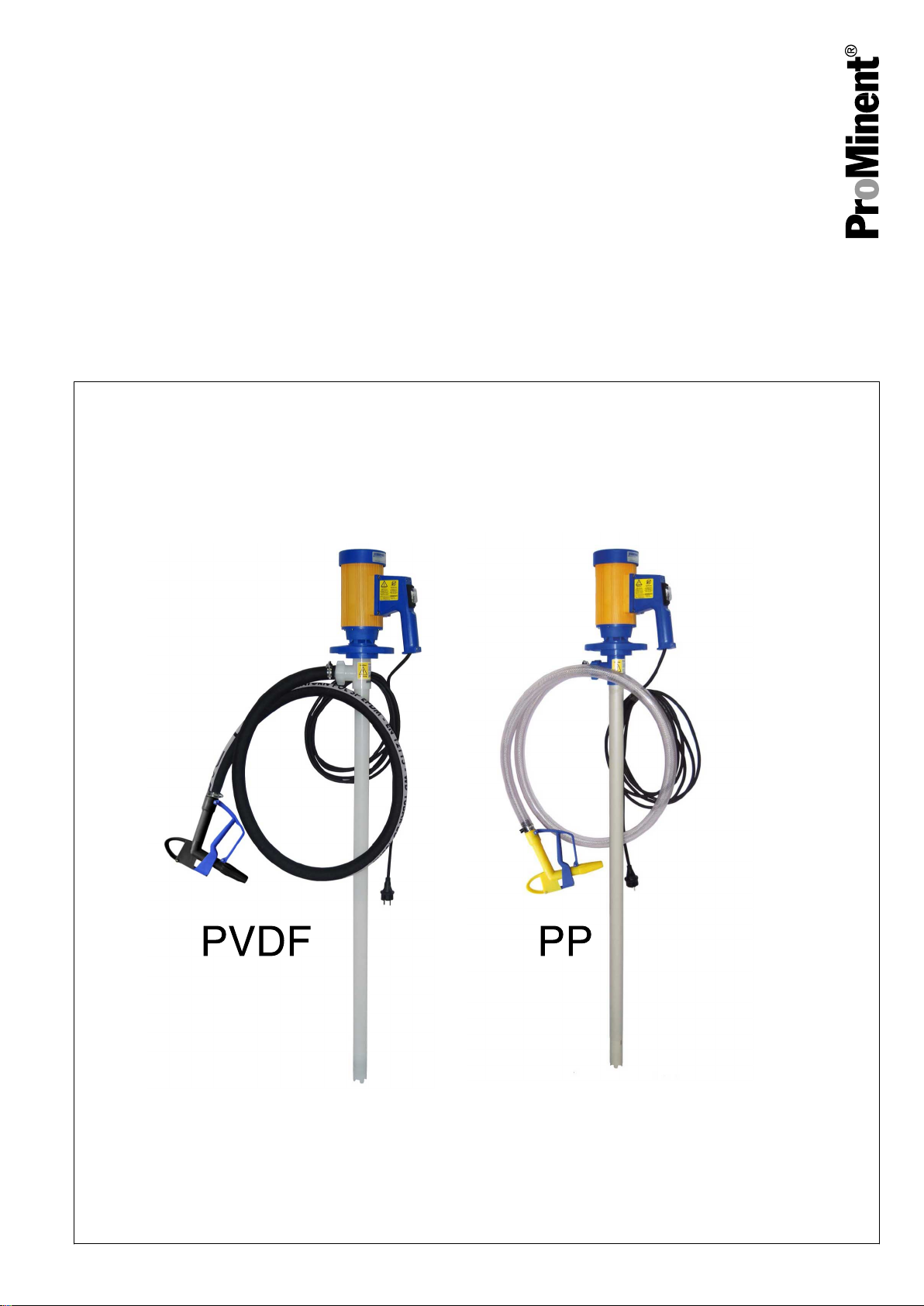

ProMinent DULCO Trans 41/1000 PVDF, DULCO Trans 41/1000 PP, DULCO Trans 32/700 PVDF, DULCO Trans 32/700 PP Assembly And Operating Instructions Manual

Page 1

Assembly and operating instructions

A2670

Barrel pump

DULCO®Trans 41/1000 PVDF or PP

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Original Operating Instructions (2006/42/EG) / Target group: commercial use982028 BA DTR 005 01/19 EN

Page 2

Supplemental directives

General non-discriminatory approach

Supplementary information

In order to make it easier to read, this document uses the male

form in grammatical structures but with an implied neutral sense. It

is aimed equally at both men and women. We kindly ask female

readers for their understanding in this simplification of the text.

Please read the supplementary information in its entirety.

Information

This provides important information relating to the

correct operation of the unit or is intended to make

your work easier.

Warning information

Warning information includes detailed descriptions of the haz‐

ardous situation, see

tion’ on page 7

Ä Chapter 2.1 ‘Labelling of Warning Informa‐

.

The following symbols are used to highlight instructions, links, lists,

results and other elements in this document:

Tab. 1: More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other applicable documents.

n

[Button]

List without set order.

Display element (e.g. indicators).

Operating element (e.g. button, switch).

‘Display /GUI’

CODE

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

2

Page 3

Table of contents

Table of contents

1 Function, resistance and scope of delivery........................... 4

2 Safety chapter....................................................................... 7

2.1 Labelling of Warning Information.................................. 7

2.2 User qualification.......................................................... 9

2.3 Intended Use................................................................ 9

2.4 Foreseeable Misuse................................................... 10

2.5 Safety.......................................................................... 10

2.5.1 Safety information for pump and motor................... 10

2.5.2 Safety information for the pump nozzle................... 12

2.6 Sound pressure level.................................................. 13

3 Storage and Transport........................................................ 14

3.1 Transport.................................................................... 14

3.2 Disposal of Packaging................................................ 14

4 Assembly and commissioning............................................. 15

4.1 Assembly of the pump................................................ 15

4.2 Motor description and overcurrent tripping................. 15

5 Operation............................................................................ 16

6 Cleaning after each use...................................................... 18

7 Repair, faults and spare parts............................................. 19

7.1 Checks/repairs............................................................ 19

7.2 Troubleshooting.......................................................... 21

7.3

Spare parts for the DULCO®Trans............................. 21

7.3.1

7.3.2

7.3.3 Spare parts for the motor......................................... 23

7.3.4 Spare parts for the pump......................................... 25

7.3.5 Spare parts for the pump nozzle.............................. 27

7.3.6 Accessories............................................................. 28

8 Disposal of used parts........................................................ 29

9 Technical data at a glance.................................................. 30

9.1 Technical data, PP version......................................... 30

9.2 Technical data, PVDF version.................................... 31

9.3 Performance diagram................................................. 32

9.4 Dimensional drawing with main dimensions............... 32

10 EC / EU Declaration of Conformity for Machinery............... 33

11 Index................................................................................... 34

Spare parts kit for DULCO®Trans 41/1000 PP........ 22

Spare parts kit for DULCO®Trans 41/1000 PVDF... 22

3

Page 4

Function, resistance and scope of delivery

1 Function, resistance and scope of delivery

Function

Device Max. pump capacity Max. delivery height Order number

DULCO®Trans 41/1000 PP

DULCO®Trans 41/1000 PVDF

* The pump capacity is also measured with water at 20 °C, a 1” pressure pipe and an oval wheel meter.

Chemical resistance

Barrel pumps are the ideal solution when liquids have to be moved.

The unit is used for bottling, draining and transferring non-flam‐

mable and non-explosive liquids from canisters, hobbocks, drums,

storage tanks and containers.

93 l/min* 11.0 m 1098491

93 l/ min* 11.0 m 1098493

The field of application of the unit depends on the

chemical resistance of the materials used.

Tab. 2: Wetted materials of the unit, PP version:

Component Material

External and internal pipe, pump nozzle PP

Drive shaft

Rotor PP

Metering hose PVC with woven inner layer

The resistance list, which is continually updated, can be found on the manufacturer’s homepage

www.prominent.com

Hastelloy® C

Tab. 3: Wetted materials of the unit, PVDF version:

Component Material

External and internal pipe, pump nozzle PVDF

Drive shaft

Rotor PVDF

Metering hose Cross-linked PE

The resistance list, which is continually updated, can be found on the manufacturer’s homepage

www.prominent.com

Hastelloy® C

4

Page 5

A2678

1

6

5

4

3

2

A2679

Nameplate

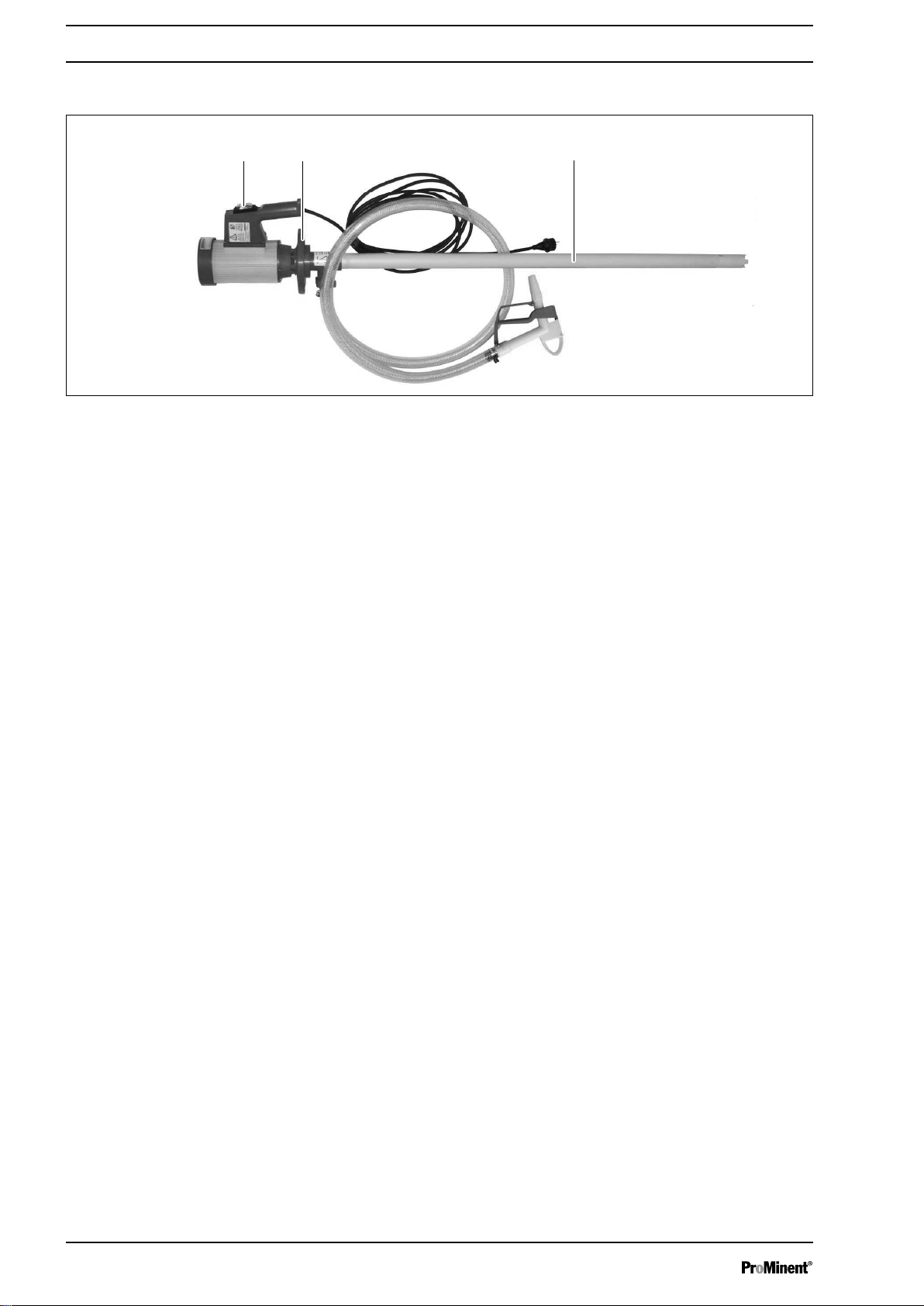

Scope of delivery

Function, resistance and scope of delivery

Fig. 1: Nameplate on the pump housing, PP version.

Fig. 2: A2679

1 Barrel pump motor

2 Pump

3 Pump nozzle assembled on the metering hose

4 Metering hose

5 Packaging

6 Assembly and operating instructions

5

Page 6

1 2

3

A2681

Function, resistance and scope of delivery

Overview of the key components

Fig. 3: Overview of the key components, PP version.

1 On/off switch.

2 Connecting nut.

3 Suction tube.

6

Page 7

2 Safety chapter

2.1 Labelling of Warning Information

Safety chapter

Introduction

These operating instructions provide information on the technical

data and functions of the product. These operating instructions pro‐

vide detailed warning information and are provided as clear stepby-step instructions.

The warning information and notes are categorised according to

the following scheme. A number of different symbols are used to

denote different situations. The symbols shown here serve only as

examples.

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger.

Description of hazard

– Denotes an immediate threatening danger. If

the situation is disregarded, it will result in fatal

or very serious injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very serious inju‐

ries.

Measure to be taken to avoid this danger.

– Denotes a possibly hazardous situation. If the

situation is disregarded, it could result in fatal

or very serious injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor injuries.

Material damage.

Measure to be taken to avoid this danger.

– Denotes a possibly hazardous situation. If the

situation is disregarded, it could result in slight

or minor injuries. May also be used as a

warning about material damage.

NOTICE!

Nature and source of the danger

Damage to the product or its surroundings.

Measure to be taken to avoid this danger.

– Denotes a possibly damaging situation. If the

situation is disregarded, the product or an

object in its vicinity could be damaged.

7

Page 8

Safety chapter

Type of information

Hints on use and additional information.

Source of the information. Additional measures.

–

Denotes hints on use and other useful informa‐

tion. It does not indicate a hazardous or dam‐

aging situation.

8

Page 9

2.2 User qualification

Safety chapter

WARNING!

Danger of injury with inadequately qualified per‐

sonnel

The operator of the system / equipment is respon‐

sible for ensuring that the qualifications are ful‐

filled.

If inadequately qualified personnel work on the unit

or loiter in the hazard zone of the unit, this could

result in dangers that could cause serious injuries

and material damage.

– All work on the unit should therefore only be

conducted by qualified personnel.

– Unqualified personnel should be kept away

from the hazard zone.

The pertinent accident prevention regulations, as

well as all other generally acknowledged safety

regulations, must be adhered to.

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been instructed and,

if required, trained in the tasks assigned to him and possible dangers that

could result from improper behaviour, as well as having been instructed in the

required protective equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of an instructed

person and who has also received additional training specific to the system

from the manufacturer or another authorised distribution partner.

Trained, qualified per‐

sonnel

Electrical technician An electrical technician is able to complete work on electrical systems and rec‐

A trained, qualified employee is deemed to be a person who is able to assess

the tasks assigned to him and recognize possible hazards based on his

training, knowledge and experience, as well as knowledge of pertinent regula‐

tions. A trained, qualified employee must be able to perform the tasks

assigned to him independently with the assistance of drawing documentation

and parts lists. The assessment of a person's technical training can also be

based on several years of work in the relevant field.

ognise and avoid possible dangers independently based on his technical

training and experience as well as knowledge of pertinent standards and regu‐

lations. An electrical technician must be able to perform the tasks assigned to

him independently with the assistance of drawing documentation, parts lists,

terminal and circuit diagrams. The electrical technician must be specifically

trained for the working environment in which the electrical technician is

employed and be conversant with the relevant standards and regulations.

Service The Service department refers to service technicians, who have received

proven training and have been authorised by the manufacturer to work on the

system.

2.3 Intended Use

n The barrel pump is used for the fast and safe drainage or

transfer of storage tanks, drums and container.

n Depending on its design, the barrel pump can pump non-flam‐

mable liquids of all kinds.

9

Page 10

Safety chapter

2.4 Foreseeable Misuse

n The collector motor is used to drive the barrel pump in areas

not at risk of explosion and is used for non-flammable liquids.

n The pump nozzle is used for the bottling of liquids.

n Barrel pump, motor and pump nozzle are suitable for protected

use indoors and may not be exposed to weathering.

n The barrel pump, motor and pump nozzle are intended for

commercial use.

n The barrel pump and its accessories are not intended to be

used by untrained people and by people with restricted phys‐

ical, sensory or mental capabilities.

n Children should be supervised to ensure that they do not play

with the unit.

n The use of the pump nozzle is not permitted in petrol filling sta‐

tions (TRBF40).

n The pumping of flammable liquids is not permitted.

n Operation in areas at risk of explosion is not permitted.

2.5 Safety

This chapter gives an overview of all the important safety aspects

for the protection of individuals as well as for safe and fault-free

operation of the product. Other task-specific warning information

can be found in the individual action sequences.

The following chapters describe the residual risks that use of this

unit presents even when used as intended. Please refer to the

safety information listed here and comply with the warning informa‐

tion in the later chapters of these instructions to reduce these risks

of personal injury and material damage and avoid hazardous situa‐

tions.

2.5.1 Safety information for pump and motor

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

10

Page 11

Safety chapter

Non-observance of the safety information

Non-observance of the safety information can lead

to damage to people and the environment and also

result in damage to the motor and pump.

n In the event of an emergency, disconnect from the mains

power supply.

n The motor is not explosion-protected.

n Do not leave the pump operating unsupervised.

n Do not use the pump in areas at risk from explosion.

n Never pump flammable liquids.

n Only use the pump for its intended purpose, see

Ä Chapter 2.3

‘Intended Use’ on page 9

n The pump is operated vertically.

n Set up the pump so that it cannot fall into the storage tank.

n Regularly check the pump and hose for operational safety.

n Regularly check the motor in accordance with statutory/

country-specific regulations and accident prevention regula‐

tions, in Germany such as in accordance with BGV A3.

n Secure the motor against accidental start-up. The pump can

start up as soon as the mains plug has been inserted.

n Before plugging in the mains plug, turn the On/Off switch to "0".

n The motor does not restart automatically following power

failure.

n Only immerse the pump in the liquid as far as the pressure

nozzle.

n Only allow the pump to stand in the liquid while it is pumping.

n Use the pump up to a maximum liquid temperature of 50 °C(PP

version) or a maximum liquid temperature of 90 °C (PVDF ver‐

sion).

n Ambient temperature: + 1 °C ... + 40 °C.

n Note any escaping air and displace volume when immersing

the pump in the water. Immerse the pump carefully and slowly.

n Use a spray guard with open drums or storage tanks.

n Remove any spilled liquid and dispose of it in an environmen‐

tally-friendly manner, referring to the material safety data

sheets issued by the manufacturer of the hazardous material.

n Note any internal instructions.

n Wear protective clothing, referring to the material safety data

sheets issued by the manufacturer of the hazardous material.

n Do not expose the pump to weathering.

n Clean the pump after each use, referring to the material safety

data sheets issued by the manufacturer of the hazardous

material.

n Do not store the pump in aggressive fumes.

11

Page 12

Safety chapter

2.5.2 Safety information for the pump nozzle

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

Non-observance of the safety information

Non-observance of the safety information can lead

to damage to people and the environment and also

result in damage to the pump nozzle.

n Only pump clean liquids.

n When using, note the maximum operating pressure of 2 bar at

50 °C (PP design) or 2 bar at 60 °C (PVDF design). The pump

nozzle can bounce back.

n When filling into a storage tank, make sure that no overpres‐

sure can build up in this storage tank. Danger from spraying

liquids.

n Do not fill up too quickly to prevent the liquids from splashing

out of the storage tank.

n Only bend the hose slightly to prevent too high mechanical

stresses being exerted on the pump nozzle

n Only fill up using the pump nozzle under supervision, as the

nozzle does not automatically shut off.

n Check during commissioning whether the manual lever returns

automatically into its starting position.

n Use visual controls to regularly monitor the external condition

of the pump nozzle.

n Allow the pump nozzle to drain at the end of the filling process.

n Regularly check to make sure that the hose clips are fixed

securely.

n Remove any spilled liquid and dispose of it in an environmen‐

tally-friendly manner, referring to the material safety data

sheets issued by the manufacturer of the hazardous material.

n Note any internal instructions.

n Wear protective clothing, referring to the material safety data

sheets issued by the manufacturer of the hazardous material.

n Do not expose the pump nozzle to weathering.

n Clean the pump nozzle after each use, referring to the material

safety data sheets issued by the manufacturer of the haz‐

ardous material.

n Do not store the pump nozzle in aggressive fumes.

12

Page 13

2.6 Sound pressure level

Safety chapter

The sound pressure level is < 70 dB (A). This value was measured

on the manufacturer's test stand.

13

Page 14

Storage and Transport

3 Storage and Transport

3.1 Transport

3.2 Disposal of Packaging

n User qualification: instructed user, see

Ä Chapter 2.2 ‘User

qualification’ on page 9

Environmental conditions for storage and transport:

n Permissible ambient temperature: +1 °C ... +40 °C.

n Humidity: maximum 90 % relative air humidity, non-con‐

densing.

n Other: No dust, no direct sunlight.

The sensor should be transported in its original packaging and in

compliance with the permissible environmental conditions. No fur‐

ther special conditions have to be observed in relation to transport.

Packaging material

Dispose of packaging material in an environmen‐

tally responsible way. All packaging components

carry the corresponding recycling code .

14

Page 15

4 Assembly and commissioning

6

2

5

4

3

1

A2682

Assembly and commissioning

4.1 Assembly of the pump

n User qualification: instructed user,

cation’ on page 9

Ä Chapter 2.2 ‘User qualifi‐

Fig. 4: Assembly.

1. Use the connecting nut (3) to connect the pump (2) and the

2. Place the hose (4) (PVC = transparent, PE = black) on the

4.2 Motor description and overcurrent tripping

Inner-ventilated universal motor with overcurrent switch and zero

voltage trigger.

Repeated overloading can damage the motor. Overloading can be

caused by high-viscosity liquids or liquids with a higher density

than water.

Overcurrent trip:

n The motor switches off if the maximum current is exceeded.

motor (1).

hose plug (6) of the pump and use the hose clamp (5) to fix

the hose in place.

If the motor switches off due to overloading, reduce the vis‐

cosity and/or the density of the liquid.

You can immediately switch on the motor again by actuating

the On/Off switch.

15

Page 16

Operation

5 Operation

n User qualification: instructed user,

cation’ on page 9

WARNING!

Electrical voltage

Possible consequence: Fatal or very serious inju‐

ries.

– Before using, check the mains connection

cable for damage.

– Keep the mains connection cable away from

solvents.

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

Ä Chapter 2.2 ‘User qualifi‐

Threaded connector (union nut)

–

Only operate the pump when the threaded con‐

nector (union nut) between the hose and pump

is manually tightened, see Ä Chapter 4

‘Assembly and commissioning’ on page 15.

–

Only switch on the motor if the pump's suction

pipe is in the liquid.

16

Page 17

2

1

A2683

Operation

Fig. 5: Operating the pump

1. Fix the barrel threaded connector (2) to the barrel. Insert the

pump into the liquid.

2. Check whether the manual lever of the pump nozzle returns

automatically to its starting position.

Never switch the pump on should this not be the case, as

ð

the pumping process could not therefore be regulated.

3. Compare the operating voltage observed with the data on the

nameplate.

4. Before plugging in the mains plug, turn the On/Off switch (1)

to "0".

5. Insert the mains plug.

The pump is now ready for operation.

ð

6. Use the On/Off switch to switch on the pump.

7. Press the pump nozzle's manual lever to pump the medium.

Measures after use

Drain the pump, hose and fittings after each use.

Allow the pump nozzle to drain in a controlled

manner after filling, as there can still be liquid in

the outlet tube, which would otherwise flow out in

an uncontrolled manner.

17

Page 18

A2684

Cleaning after each use

6 Cleaning after each use

Cleaning using a suitable cleaning

agent

n User qualification: instructed user, see

Ä Chapter 2.2 ‘User

qualification’ on page 9

WARNING!

Change of medium = Clean the pump

Hazard from the chemical incompatibility of the

media.

Possible consequence: Health risk and/or damage

to the pump and/or medium.

Remedy: Always thoroughly clean the pump when

the medium is changed. If you do not clean the

pump, it can lead to incompatibility between the

medium and pump or old medium and new

medium. Refer to the material safety data sheet on

the feed chemical.

Regular cleaning of the pump increases its service life and main‐

tains the performance of the pump.

1. Note the resistance of the pump and the hose to the cleaning

agent, referring to the reference list.

2. Use a suitable cleaning agent to rinse the pump, referring to

the material safety data sheet for the medium. Never use

flammable or explosive liquids.

Fig. 6: Lip (arrow) of the outlet nozzle.

3. Only immerse the pump in the cleaning agent as far as the lip

(arrow) of the outlet nozzle and never immerse the pump

fully.

4. Rinse the pump until the pump is clean.

The pump is now ready for further use, also with a dif‐

ð

ferent medium.

18

Page 19

7 Repair, faults and spare parts

4

3

2

1

A2669

7.1 Checks/repairs

Repair, faults and spare parts

Replacing the hose connection or

seal:

n User qualification: trained user,

tion’ on page 9

–

Regularly check the pump in accordance with

statutory/country-specific regulations and acci‐

dent prevention regulations (in Germany

such as in accordance with BGV A3).

It is essential that all faulty parts are replaced.

Preferably use genuine spare parts.

Ä Chapter 2.2 ‘User qualifica‐

Fig. 7: Components of the pump nozzle (PP = yellow and Blue,

PVDF = Black).

1. Housing.

2. Hose connection.

3. Protective mounting bracket.

4. Manual lever.

19

Page 20

A2671

Repair, faults and spare parts

Fig. 8: Components of the pump nozzle (PP = yellow and Blue, PVDF = Black).

1. Disconnect the pump from the mains power supply.

2. Allow the hose and pump nozzle to run empty.

3. Clean the pump.

Please proceed as follows to replace

the seals of the pump nozzle.

4. Remove the three grooved pins (5, 6 and 7) by pushing them

out using a small pin. The stainless steel pin is wider at one

side and can therefore only be removed in the direction of the

wider end

5. Then first remove the bracket (14), the manual lever (13) and

then the hose plug (12) on which the first (11) of a total of

three seals is located.

6. Then block the hexagonal opening at the rear end of the

valve rod (10) by inserting a long Allen key (size 8) into the

nozzle body from the rear side of the pump nozzle on which

you have removed the hose plug and blocking the hexagonal

opening.

7.

A compression spring (2) sits behind the

domed nut. When removing the domed nut,

make sure that you are not injured by the

spring when removing it as it is pressurised.

20

Page 21

7.2 Troubleshooting

Repair, faults and spare parts

Whilst holding the Allen key firmly with one hand, remove the

domed nut (1) from the other side with a size 10 socket.

8. A seal mount (3) is located behind the spring at the rear end

of which is located the second seal (4).

9. After removing the domed nut, the spring and the seal mount

with the second seal, you can push out the valve rod (10)

from this side towards the hose connection already removed

and replace the third seal (9).

10. Clean and check all components.

11. Replace all faulty or defective parts.

12. Finally fit the pump nozzle in the reverse order to that already

described and test the leak-tightness of the pump nozzle at

the end of a water line with 3 ... 4 bar pressure.

The pump nozzle is ready for use again.

ð

n User qualification: trained user, see

Ä Chapter 2.2 ‘User quali‐

fication’ on page 9

Fault Cause Solution

Manual lever on pump

nozzle sticking.

Pump starts but does not

pump.

Please contact Service with all other faults. For contact data see the Legal Notices.

Check on the manufacturer's website www.prominent.com whether a more recent version of the operating

instructions is available, as further remedies may have been developed in the meantime.

7.3

Spare parts for the DULCO®Trans

Joint stuck. Dismantle the pump nozzle, clean it and

replace any faulty components if neces‐

sary.

Maximum delivery height and/or

viscosity/density exceeded.

Inner tube blocked. Check and possibly clean inner tube.

Couplings, rotor faulty. Check the couplings and rotor and

n User qualification: Service, see

tion’ on page 9

Spare parts should only be ordered and fitted through Service.

Adjust the delivery height and/or viscosity.

replace if necessary.

Ä Chapter 2.2 ‘User qualifica‐

.

21

Page 22

Repair, faults and spare parts

7.3.1

Spare parts kit for DULCO®Trans 41/1000 PP

Tab. 4: Spare parts kit (order number 1098500) for DULCO®Trans 41/1000 PP, parts list

Pos. Description Material Quantity Order no.

16 a Carbon brushes Carbon 2 8080

21 a Motor coupling PA 1 8333

1 b V-seal PTFE 1 4000

2 b Pump factory coupling PA 1 1004

5 b Bearing unit Steel 1 1038

10 b Pump housing with PTFE bearing PP/PTFE 1 1524

12 b Rotor PP 1 1608

13 b Pump foot PP 1 1609

7.3.2

Spare parts kit for DULCO®Trans 41/1000 PVDF

Tab. 5: Spare parts kit (order number 1098498) for DULCO®Trans 41/1000 PVDF, parts list

Pos. Description Material Quantity Order no.

16 a Carbon brushes Carbon 2 8080

21 a Motor coupling PA 1 8333

1 b V-seal PTFE 1 4000

2 b Pump factory coupling PA 1 1004

5 b Bearing unit Steel 1 1038

10 b Pump housing with PTFE bearing PVDF/PTFE 1 4607

12 b Rotor PVDF 1 4608

13 b Pump foot PVDF 1 4609

22

Page 23

7.3.3 Spare parts for the motor

A2685

Repair, faults and spare parts

Fig. 9: Spare parts drawing for the motor.

23

Page 24

Repair, faults and spare parts

Tab. 6: Spare parts list for the motor

Position Description Quantity Order number

1a Lower part of handle 1 8001

2a Screw 2 8015

3a Screw 2 8016

4a Screw 4 8017

5a Motor cover 1 8026

6a Screw 8 8035

7a Handle cover 1 8037

8a Switch frame 1 8038

9a 5 m cable with earthed plug 1 8039

10a Screw 1 8045

11a Tension relief clamp 1 8046

12a Screw 2 8047

13a Spark interference filter 1 8056

14a Impeller 1 8070

15a Switch cover, transparent 1 8073

16a Carbon brush 2 8080

17a M5x110 screw 2 8081

18a Motor housing 1 8082

19a Lower bearing label 1 8083

20a Motor package 230 V, 50 Hz 1 8180

21a Motor coupling 1 8333

22a Switch 230 V, 3.5 A, 50 Hz with USP 1 8708

24

Page 25

7.3.4 Spare parts for the pump

A2686

Repair, faults and spare parts

Fig. 10: Spare parts drawing for the pump.

25

Page 26

Repair, faults and spare parts

Tab. 7: Spare parts list for the pump (PP design)

Position Description Quantity Order number Materials

1b V-seal 1 4000 PTFE

2b Coupling 1 1004 PA

3b

Drive shaft, Hastelloy

©

1 1006

Hastelloy

4b Outlet piece 1 1028 PP

5b Bearing unit (assembled) 1 1038 Steel

6b Hose plug DN 19 1 1051 PP

7b Wing nut 1 1106 PP

8b Retainer 1 1508 Spring steel

9b Teflon hose 1 1514 PTFE

©

10b Pump housing with PTFE

1 1524 PP, PTFE

bearing

11b Inner tube 1 1601 PP

12b Rotor 1 1608 PP

13b Pump foot 1 1609 PP

14b Outer tube 1 1611 PP

15b Manual adjustment wheel 1 1842 PP

Tab. 8: Spare parts list for the pump (PVDF version)

Position Description Quantity Order number Materials

1b V-seal 1 4000 PTFE

2b Coupling 1 1004 PA

3b

Drive shaft, Hastelloy

©

1 1006

Hastelloy

4b Outlet piece 1 4028 PVDF

5b Bearing unit (assembled) 1 1038 Steel

6b Hose plug DN 19 1 4051 PVDF

©

7b Wing nut 1 4106 PVDF

8b Retainer 1 1508 Spring steel

9b Teflon hose 1 1514 PTFE

10b Pump housing with PTFE

1 4607 PVDF, PTFE

bearing

11b Inner tube 1 4601 PVDF

12b Rotor 1 4608 PVDF

13b Pump foot 1 4609 PVDF

14b Outer tube 1 4591 PVDF

15b Manual adjustment wheel 1 1842 PP

26

Page 27

7.3.5 Spare parts for the pump nozzle

A2674

Repair, faults and spare parts

Fig. 11: Spare parts drawing for the pump nozzle.

Tab. 9: Spare parts list for the pump nozzle (PP design)

Position Description Quantity Order number Materials

1c Domed nut 1 1135 PP

2c Compression spring 1 1136 Stainless steel

3c Seal mount 1 1137 PP

4c O-ring 1 1138 FKM

5c Distance pin Ø 5x40 1 1141 Stainless steel

6c Distance pin Ø 5x25 1 1142 Stainless steel

7c Distance pin Ø 4x25 1 1143 Stainless steel

8c Housing 1 1144 PP

9c O-ring 1 1145 FKM

10c Valve rod 1 1148 PP

11c O-ring 1 1149 FKM

12c Hose plug DN19 1 1153 PP

13c Manual lever 1 1155 PP

27

Page 28

Repair, faults and spare parts

Position Description Quantity Order number Materials

14c Bracket 1 1156 PP

15c Nozzle Ø 20 1 1157 PP

16c Nozzle Ø 9 1 1158 PP

Tab. 10: Spare parts list for the pump nozzle (PVDF version)

Position Description Quantity Order number Materials

1c Domed nut 1 1159 PVDF

2c Compression spring 1 1136 Stainless steel

3c Seal mount 1 1160 PVDF

4c O-ring 1 1138 FKM

5c Distance pin Ø 5x40 1 1141 Stainless steel

6c Distance pin Ø 5x25 1 1142 Stainless steel

7c Distance pin Ø 4x25 1 1143 Stainless steel

8c Housing 1 1161 PVDF

9c O-ring 1 1145 FKM

10c Valve rod 1 1162 PVDF

11c O-ring 1 1149 FKM

12c Hose plug DN19 1 1164 PVDF

13c Manual lever 1 1155 PP

14c Bracket 1 1156 PP

15c Nozzle Ø 20 1 1166 PVDF

16c Nozzle Ø 9 1 1167 PVDF

7.3.6 Accessories

Tab. 11: Accessories

Description Quantity Order number

Barrel threaded connector (PP) Ø 41, with thread G 2 1 9001

28

Page 29

8 Disposal of used parts

Disposal of used parts

Sign indicating EU collection system

n User qualification: instructed user, see

Ä Chapter 2.2 ‘User

qualification’ on page 9

NOTICE!

Regulations governing the disposal of used parts

– Note the national regulations and legal stand‐

ards that currently apply in your country

The manufacturer will take back decontaminated used devices pro‐

viding they are covered by adequate postage.

Decontaminate the device before returning it for repair. To do so,

remove all traces of hazardous substances. Refer to the Material

Safety Data Sheet for your feed chemical.

A current Declaration of Decontamination is available to download

on the ProMinent website.

In accordance with the European Directive 2012/19/EU on waste

electrical and electronic equipment, this device features the symbol

showing a waste bin with a line through it. The device must not be

disposed of along with domestic waste. To return the device, use

the return and collection systems available and observe the local

legal requirements.

29

Page 30

Technical data at a glance

9 Technical data at a glance

9.1 Technical data, PP version

Tab. 12: Part no. 1098491. PP version

Parameter Value/Design

Pump type

Feed rate*) 93 l/min

Max. delivery height 11 m

Max. viscosity 600 mPas

Max. medium temperature < 50 °C

Max. medium density 1.5 kg/dm³

Immersion tube length, measured from the end of

the pump foot to the middle of the pressure nozzle

Suction tube outer diameter 41 mm

Wetted materials

Pump housing PP

Shaft

Rotor PP

Axial face seal none

Seals PTFE (pump), FKM (pump nozzle)

Hose PVC 2 m, DN 19

DULCO©Trans 41/1000 PP

1000 mm

PP, Hastelloy©, PTFE, FKM, PVC

Hastelloy

©

Pump nozzle PP, DN 19

Hose connection DN 19

Hose clamps 2 no., stainless steel 1.4301

Drum adapter Ø 41, with G 2 thread

Motor performance 640 W

Motor IP protection IP 24

Voltage 230 VAC; 1~; 50 Hz / 60 Hz

Nominal current 2.82 A

Undervoltage trigger with

Overcurrent protection switch with

speed control none

Connecting cable 5 m, with standard European plug

Motor colour yellow

Colour of top part of housing blue

Weight 7.6 kg

Dimensions HxWxD 1315 x 270 x 170 mm

*) Measured values ± 5 %, test medium: water 20 °C, 1” pressure pipe, oval wheel meter

30

Page 31

Technical data at a glance

9.2 Technical data, PVDF version

Tab. 13: Part no. 1098493. PVDF version

Parameter Value/Design

Pump type DULCO Trans 41/1000 PVDF

Feed rate*) 93 l/min

Max. delivery height 11 m

Max. viscosity 600 mPas

Max. medium temperature < 90 °C max.

Medium density 1.5 kg/dm³

Immersion tube length, measured from the end of

1000 mm

the pump foot to the middle of the pressure nozzle

Suction tube outer diameter 41 mm

Wetted materials

PVDF, PTFE, Hastelloy©, PE, FKM, PVC

Pump housing PVDF

Shaft

Hastelloy

©

Rotor PVDF

Axial face seal none

Seals PTFE (pump), FKM (pump nozzle)

Hose PE 2 m, DN19

Pump nozzle PVDF, DN19

Hose connection DN19

Hose clamps 2 no., stainless steel 1.4301

Drum adapter Ø 41, with G 2 thread

Motor performance 640 W

Motor IP protection IP 24

Voltage 230 VAC; 1~; 50 Hz / 60 Hz

Nominal current 2.82 A

Undervoltage trigger with

Overcurrent protection switch with

speed control none

Connecting cable 5 m with earthed plug

Motor colour yellow

Colour of top part of housing blue

Weight 9.2 kg

Dimensions HxWxD 1315 x 270 x 170 mm

*) Measured values ± 5 %, test medium: water 20 °C, 1” pressure pipe, oval wheel meter

31

Page 32

A2687

A2688

A2689

Technical data at a glance

9.3 Performance diagram

Fig. 12: Performance diagram. Measured values ± 5 %, test medium: water 20 °C, 1” pressure pipe, oval

wheel meter.

I. For version: Rotor

9.4 Dimensional drawing with main dimensions

Fig. 13: PP version: Dimensional drawing with main dimensions, all measurements in mm.

Fig. 14: PVDF version: Dimensional drawing with main dimensions, all measurements in mm.

32

Page 33

EC / EU Declaration of Conformity for Machinery

10 EC / EU Declaration of Conformity for Machinery

In accordance with DIRECTIVE 2006/42/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL, Appendix I, BASIC

HEALTH AND SAFETY REQUIREMENTS, section 1.7.4.2. C.

We,

n ProMinent GmbH

n Im Schuhmachergewann 5 - 11

n D - 69123 Heidelberg, Germany,

hereby declare that the product specified in the following, complies

with the relevant basic health and safety requirements of the Direc‐

tive, on the basis of its functional concept and design and in the

version distributed by us.

Any modification to the product not approved by us invalidates this

declaration.

Tab. 14: Extract from the EC/EU Declaration of Conformity

Designation of the product: Barrel pump

Product type:

Serial number: see nameplate on the device

Relevant EC Directives: EC Machinery Directive (2006/42/EC)

Harmonised standards applied,

in particular:

Place, Date: Heidelberg, 1.02.2019

DULCO®trans

Compliance with the protection targets of the Low Voltage Directive

2014/35/EU according to Appendix I, No. 1.5.1 of the Machinery Direc‐

tive 2006/42/EC.

EMC Directive (2014/30/EU)

RoHS Directive (2011/65/EU)

EN ISO 12100:2010

EN 809:1998 + A1:2009 + AC:2010

EN 60335-2-41:2003 + A1:2004 + A2:2010

EN 55014-1:2006 + A1:2009 + A2:2011

EN 55014-2:1997 + A1:2001 + A2:2008

EN 50581:2012

The EC Declaration of Conformity is available to download on our

website www.prominent.com.

33

Page 34

Index

11 Index

A

Accessories .............................28

Action, step by step ........................2

Ambient temperature, permitted ............. 14

Applied harmonised standards .............. 33

Assembly of the pump .....................15

C

Change of medium = Clean the pump .........18

Cleaning after each use ................... 18

Cleaning using a suitable cleaning agent ...... 18

Collector motor .......................... 15

D

Danger from hazardous substances! ..........10

Designation of the product ................. 33

E

Environmental conditions for storage and trans‐

port ................................... 14

F

Foreseeable Misuse ...................... 10

G

General non-discriminatory approach .......... 2

H

Humidity: maximum 90 % relative air humidity,

non-condensing. .........................14

I

Non-discriminatory approach ................ 2

Non-observance of the safety information ...... 11

O

Overcurrent protection switch ............... 15

P

Performance diagram ..................... 32

Permissible ambient temperature ............ 14

Pump starts but does not pump. ............. 21

R

Recycling .............................. 14

Relevant EC/EU directives ................. 33

Repair ................................. 19

Replacing the hose connection or seal ........ 19

Resistance, chemical ...................... 4

S

Safety ................................. 10

Safety information for pump and motor ........ 10

Safety information for the pump nozzle ........ 12

Scope of delivery ......................... 5

Seal ...................................15

Serial number ........................... 33

Sound pressure level ..................... 13

Spare parts list for the motor ................ 23

Spare parts list for the pump ................ 25

Spare parts list for the pump nozzle .......... 27

Storage and Transport .................... 14

Intended Use .............................9

L

Links to elements or sections of these instruc‐

tions or other applicable documents ........... 2

M

Main dimensions ......................... 32

Mains connection cable ....................16

Manual lever on pump nozzle sticking. ........ 21

Measured values ±10% ....................32

Measures after use ....................... 17

More symbols ............................ 2

N

Nameplate .............................. 5

T

Technical data ........................30, 31

Threaded connector ...................... 15

Transport .............................. 14

Troubleshooting ......................... 21

U

Union nut .............................. 16

User qualification ......................... 9

W

Warning information ....................... 7

Wetted materials of the unit ..................4

34

Page 35

35

Page 36

ProMinent GmbH

Im Schuhmachergewann 5 - 11

D-69123 Heidelberg, Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

982028, 1, en_GB

© 2019

Loading...

Loading...