Page 1

Operating manual

A0943

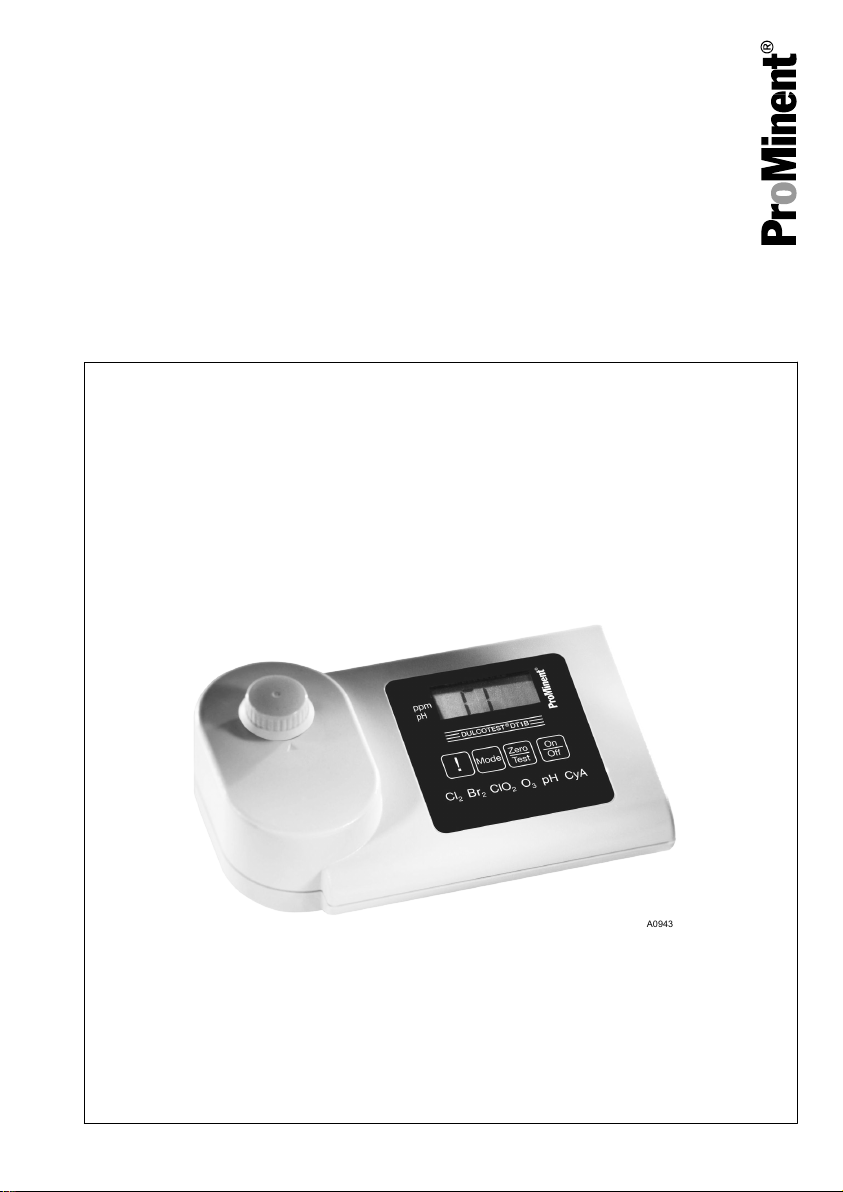

DULCOTEST® DT1B

Photometer

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Target group: instructed personnelPart number 985629 BA DT 057 03/17 EN

Page 2

Supplemental directives

General non-discriminatory approach In order to make it easier to read, this

document uses the male form in

grammatical structures but with an

implied neutral sense. It is aimed

equally at both men and women. We

kindly ask female readers for their

understanding in this simplification of

the text.

Supplementary information

Please read the supplementary information in its entirety.

Information

This provides important information relating to the correct operation of the

unit or is intended to make your work easier.

Warning information

Warning information include detailed descriptions of the hazardous situation.

The following symbols are used to highlight instructions, links, lists, results and

other elements in this document:

More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other

applicable documents.

n

List without set order.

2

Page 3

Symbol Description

Supplemental directives

[Button]

„Display /

GUI“

CODE

Display element (e.g. indicators).

Operating element (e.g. button, switch).

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

3

Page 4

Table of contents

Table of contents

1 General Information................................................................................... 5

1.1 Scope of delivery............................................................................... 6

1.2 Instructions for use............................................................................ 8

1.3 Adapter for 16 mm cuvettes............................................................. 11

1.4 Operations carried out on the device............................................... 12

2 Commissioning DT 1B............................................................................. 13

2.1 Commissioning................................................................................ 13

3 Operating Menu....................................................................................... 17

3.1 Operating Menu Options.................................................................. 17

3.2 Operating instructions...................................................................... 18

3.3 Error messages............................................................................... 18

4 Analysis methods..................................................................................... 20

4.1 Procedure instructions when using liquid reagents......................... 20

4.2 Quantitative determination using liquid reagents............................. 22

4.3 Procedure instructions when using tablets...................................... 29

4.4 Quantitative determination using tablets.......................................... 31

5 Calibration ............................................................................................... 44

6 Technical Data......................................................................................... 47

7 Consumables and Spare Parts................................................................ 49

8 Standards Complied with and Declaration of Conformity........................ 50

9 Index........................................................................................................ 51

4

Page 5

1 General Information

WARNING!

Danger from hazardous sub‐

stances!

Possible consequence: Fatal or

very serious injuries.

Please ensure when handling

hazardous substances that you

have read the latest safety data

sheets provided by the manu‐

facture of the hazardous sub‐

stance. The actions required

are described in the safety data

sheet. Check the safety data

sheet regularly and replace, if

necessary, as the hazard

potential of a substance can be

re-evaluated at any time based

on new findings.

The system operator is respon‐

sible for ensuring that these

safety data sheets are available

and that they are kept up to

date, as well as for producing

an associated hazard assess‐

ment for the workstations

affected.

General Information

5

Page 6

General Information

1.1 Scope of delivery

The following components are included as standard:

Description Quan‐

tity

n Case, blue with blue fasteners

– with ProMinent sticker, Photometer Dulcotest DT1B, code

1039315

– and hazard symbol

Foam insert for the case 1

Cover foam for the case 1

n Photometer DT1B

– Chlorine, bromine, chlorine dioxide, ozone, pH, CyA

– Battery compartment lid with O-ring

Screwdriver with clip, red 1

Countersunk screws 4

Batteries, 1.5 V alkali-manganese, type AA 4

Round cuvettes, 10 ml, d = 24 mm, h = 48 mm 3

Lid for round cuvette, 24 mm, grey 3

Sealing rings for cuvettes, grey 3

Round cuvettes, d = 16 mm, h = 90 mm 3

Lid for round cuvette, 16 mm, white 3

Adapter attachment, grey for 16 mm cuvettes 1

1

1

Syringe, 10 ml 1

Plastic mixing rod, 13 cm long 1

Cleaning brush 1

Operating instructions for Dulcotest DT1B 1

DPD -1 tablets 100

6

Page 7

General Information

Description Quan‐

tity

DPD -3 tablets 100

PHENOLRED PHOTOMETER tablets 100

CyA TEST tablets 100

CHLORINE HR (KI) tablets 100

ACIDIFYING GP tablets 100

Glycine tablets 20

7

Page 8

General Information

1.2 Instructions for use

–

Request the safety data sheets.

–

Reagents are intended for chemical analysis and access to them by

unauthorised persons must not be permitted.

–

You must dispose of reagent solutions properly.

–

Observe the application possibilities, analysis instruction and matrix

effects of the methods.

1. You must thoroughly clean the cuvettes, lids and stirring rod after each

analysis to avoid carry-over errors.

Even slight reagent residue can lead to incorrect measurement results.

For cleaning use the supplied brush.

If the fully reacted water sample is left for any length of time it may pro‐

duce stubborn coloured deposits, which you can remove using dilute (=

4 %) hydrochloric acid.

2. The outer walls of the cuvettes must be clean and dry before the analysis

is carried out. Fingerprints or water droplets on the light-entry surfaces of

the cuvette will result in faulty measurements. The cuvette should there‐

fore be wiped clean with a soft paper tissue (paper handkerchief) before

carrying out the measurement.

3. The zero correction and the analysis must both be carried out using the

same cuvette, as the cuvettes may have slightly varying tolerances.

8

Page 9

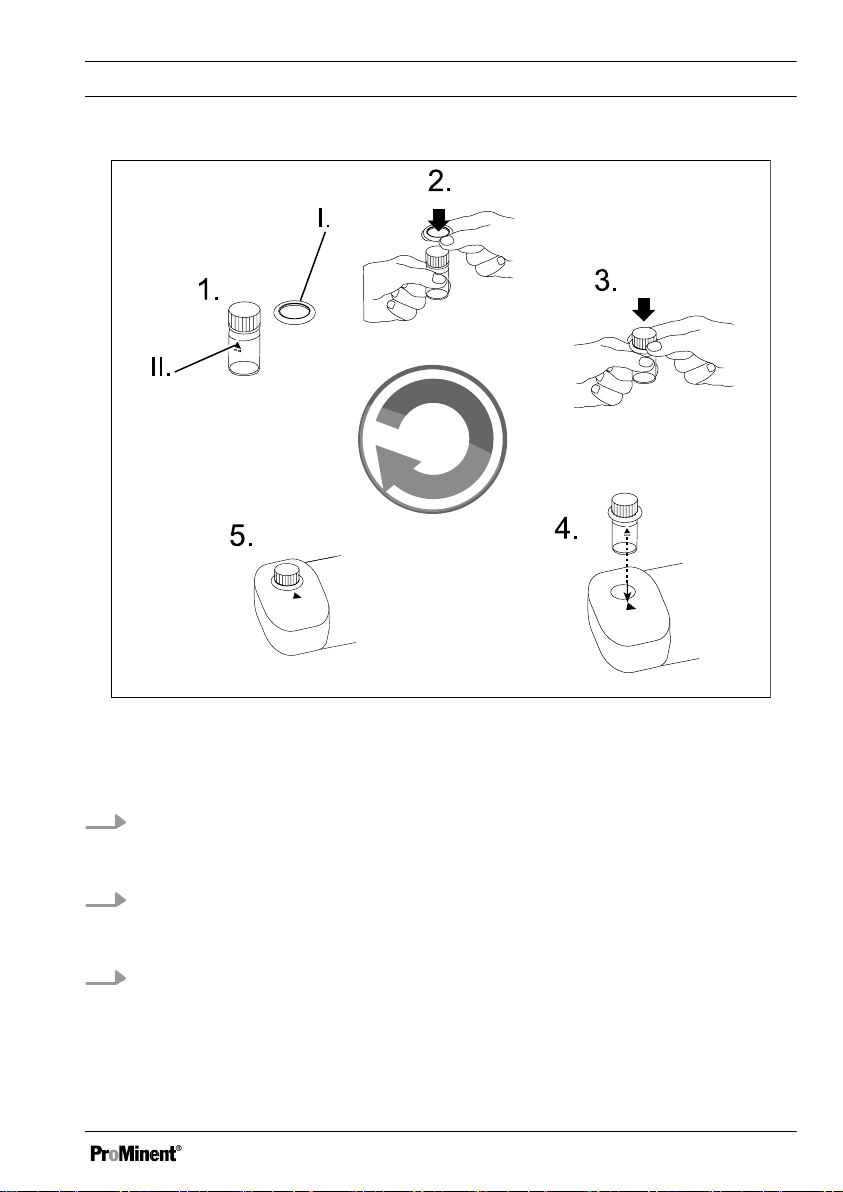

A0937

General Information

Fig. 1: Cuvette positioning (Ø 24 mm):

I. Seal

II. Marking with the white triangle

4. For the zero correction and test, the cuvette must be positioned in the

sample chamber in such a way that the marking with the white triangle (II.)

points towards the housing marking.

5. You must carry out the zero correction and test with the cuvette lid closed.

You must provide the cuvette lid with a sealing ring (I.) to prevent the

entrance of light into the sample chamber.

6. Formation of bubbles on the inside walls of the cuvette will result in faulty

measurements. Should this happen, seal the cuvette with the cuvette lid

and tip it back and forth to dissolve/remove the bubbles before carrying

out the test.

9

Page 10

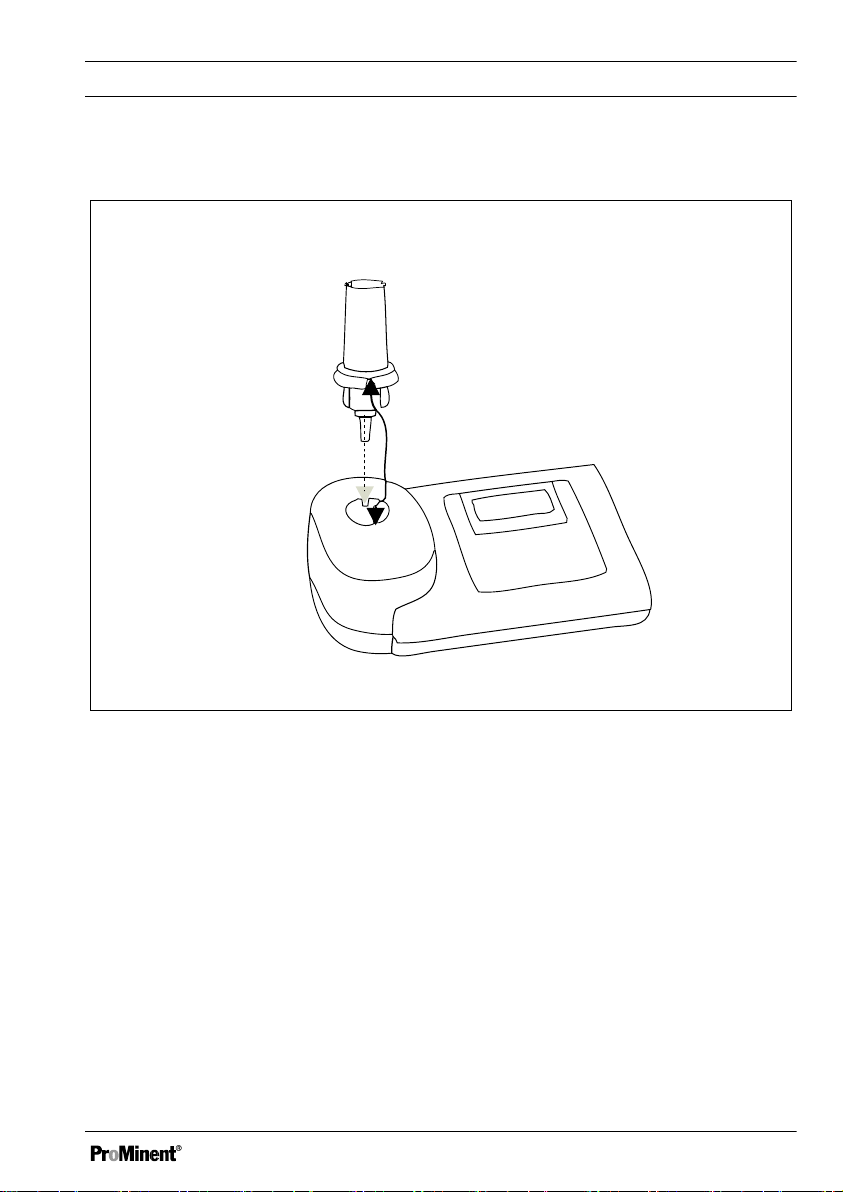

A0938

General Information

7. It is important to prevent water getting into the sample chamber because

this leads to incorrect measurement results.

8. Dirt in the transparent sample chamber leads to incorrect measurement

results. The light entry surfaces should be checked at regular intervals and

cleaned as necessary.

Standard spectacle cleaning cloths and cotton buds are suitable for

cleaning.

9. Pronounced differences in temperature between the photometer and the

surroundings can lead to incorrect measurements, e.g. due to the forma‐

tion of condensation in the sample chamber and on the cuvette.

10. Protect the device from direct sunlight.

Fig. 2: Correct filling of the cuvette: Left = correct / right = incorrect

11. Fill the cuvette as shown in Fig. 2.

12. Insert the reagent tablets directly from the blister pack into the water

sample, without touching them with your fingers.

13. After use immediately close the dropping bottles containing the liquid

reagents by closing them with the screw caps of the same colour.

14. You must observe the sequence for the addition of reagents without fail.

10

Page 11

1.3 Adapter for 16 mm cuvettes

A0941

General Information

Fig. 3: Place the adapter for 16 mm cuvettes on the sample chamber

Insert the adapter for the 16 mm cuvette as shown in Fig. 3.

This adapter is required for all analysis methods which must be carried out using

a 16 mm cuvette.

11

Page 12

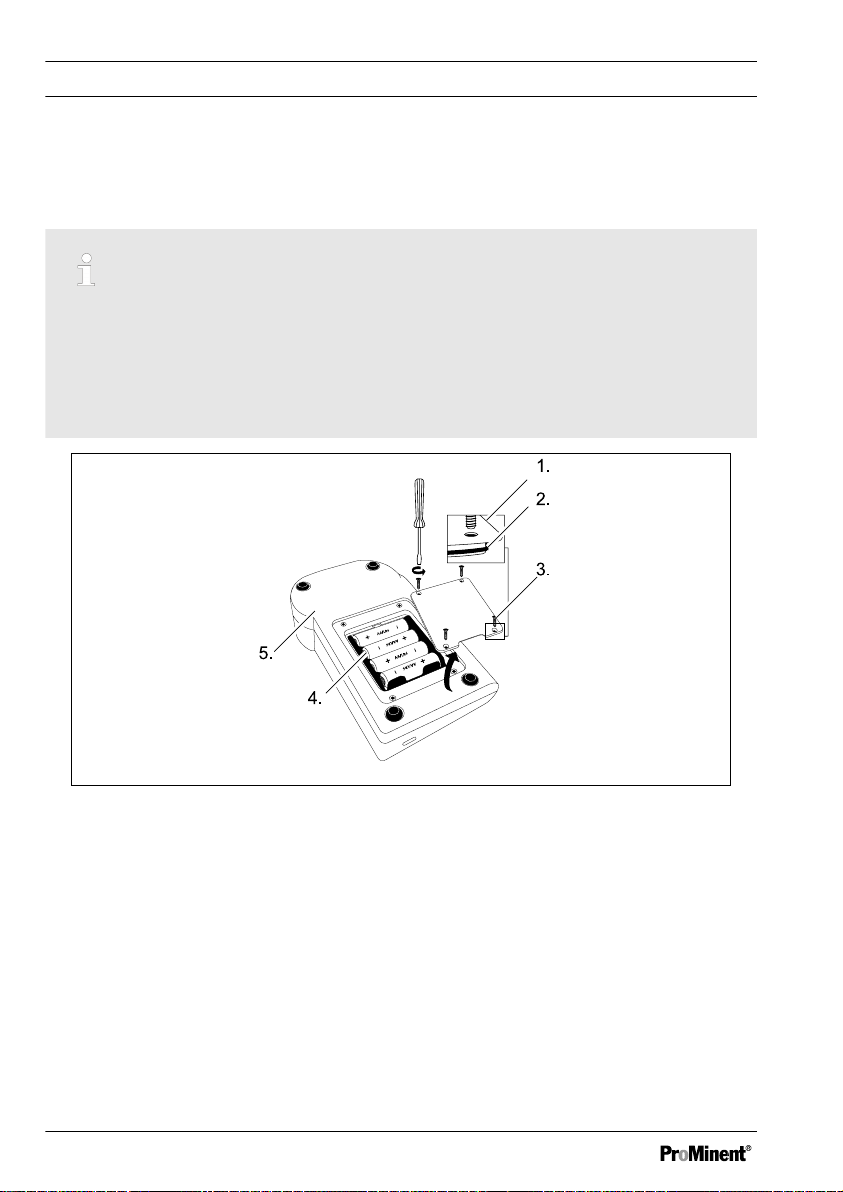

A0939

General Information

1.4 Operations carried out on the device

Battery replacement:

To ensure complete leak-tightness of the photometer, you must insert the

gasket (2) and screw on the battery compartment lid (1).

If the battery is removed for more than 1 minute from the device, then

when the device is switched on again with new inserted batteries, the

date/time program appears automatically.

Fig. 4: Battery replacement

1. Battery compartment cover

2. Seal

3. Screw

4. Batteries

5. Rear of the device

12

Page 13

2 Commissioning DT 1B

2.1 Commissioning

Switching on and zero correction

Scroll memory (SM)

With multi-parameter devices

the sequence of the various

methods is specified. After

switching on the device, the

method which was last selected

before the device was switched

off is automatically displayed.

This permits rapid access to a

favoured method.

1. Switch the device on using the

[ON/OFF]

ð

2. Select the

[MODE]

ð

Zero correction

3. Fill the cuvette up to the 10-ml

marking with the water sample,

see Fig. 2

4. Close the cuvette using the cuv‐

ette lid

5. Position the cuvette in the

sample chamber

ð

6. Press the key

key

The display outputs: The

last selected

key

The display outputs:

[METHOD]

Observe the correct posi‐

tioning of the cuvette.

[METHOD]

[METHOD]

.

using the

[ZERO/TEST]

.

Commissioning DT 1B

[METHOD]

ð

approximately 8 seconds.

[0.0.0]

play.

7. Remove the cuvette from the

sample chamber

Zero correction is ended.

ð

Analysis

8. Fill the cuvette up to the 10-ml

marking with the water sample,

see Fig. 2

9. Add reagents to the water

sample

The characteristic colouring

ð

develops.

10. Close the cuvette using the cuv‐

ette lid

11. Position the cuvette in the

sample chamber

12. Press the

so doing adhere to any possibly

required reaction time, see

flashes for

appears in the dis‐

[ZERO/TEST]

key, in

Ä „

Switching the countdown func‐

tion on“ on page 14

[METHOD]

ð

approximately 3 seconds.

The result is output to the

display.

flashes for

13

Page 14

Commissioning DT 1B

Switching the countdown function on

The result is automat‐

ically saved.

Repeating the analysis

Press the key

again

The process runs as

ð

described here

[ZERO/TEST]

on and zero correc‐

tion“ on page 13

New zero correction

Press the key

2 seconds

The process runs as

ð

described here

[ZERO/TEST]

on and zero correc‐

tion“ on page 13

Ä „Switching

.

for

Ä „Switching

.

NOTICE!

If reaction times are not

observed, the result may be

incorrect measurement results.

The countdown can only be

activated directly prior to a

measurement.

The countdown time equals 2

minutes and is non-adjustable.

The currently running count‐

down can be ended by

pressing the key [ZERO/TEST].

The measurement then takes

place immediately.

For methods with a reaction time, you

can optionally switch on a countdown

function:

1. Press the key

the key depressed

[!]

and then keep

2. Press the key

3. Release the

The countdown starts After

ð

the countdown has elapsed

(2 minutes), measurement

takes place automatically

[ZERO/TEST]

[!]

key

14

Page 15

Displaying stored data

The device has a ring buffer for 16 data records.

Fig. 5: Displaying stored data

1. Data record (n01 ... n16)

2. Year

3. Month/day

4. Time

5. Measured variable (e.g. chlorine,

dependent upon the device ver‐

sion)

6. Value in mg/l

Commissioning DT 1B

1. With the device switched on press the

[!]

key for more than 4 seconds then

release the key again

The display immediately switches to the memory menu.

ð

2. Press the

3. Press the

4. Press the

15

[MODE]

[ZERO/TEST]

[!]

key to scroll through the 16 data records

key to scroll through the values of a data record

key to return to the

[METHOD]

display

Page 16

Commissioning DT 1B

Display background lighting

Press the

ð

[!]

key

The display's background lighting switches on or off.

During measuring the background lighting switches off automati‐

cally.

16

Page 17

3 Operating Menu

3.1 Operating Menu Options

Operating menu selection

1. The device is switched off.

Press and hold down the

[MODE]

2. Use the

on the device

ð

3. Release the

4. The [!] key allows you to select

the following operating menu

items:

n

n Set date and time

n User adjustment

ð

5. Use the

date and time“

item (arrow at top right and

bottom left in the display)

key

[ON/OFF]

3 decimal points appear in

the display.

[diS]

= read out of stored

data

The selected operating

menu item is indicated by an

arrow in the display.

[!]

key to select the

key to switch

[MODE]

key

operating menu

„Set

Operating Menu

Setting date and time (24-hour

format)

Increase the value to be set by

pressing the [MODE] key.

Lower the value to be set by

pressing the [ZERO/TEST] key.

Pressing the [!] key takes you

to the next value to be set.

1. Press the

ð

2. Enter the year

3. Enter the month

4. Enter the day

5. Enter the hour

6. Enter the minutes

Enter the minutes in 10 minute

increments

Press the

Enter minutes in 1 minute incre‐

ments

7. After setting the minutes, press

the

ð

[MODE]

The parameter to be set

appears for 2 seconds.

key

[YYYY]

[MM]

[dd]

[hh]

[mm]

.

[!]

key

[!]

key

[IS SET]

play and the device auto‐

matically returns to meas‐

uring mode.

appears in the dis‐

17

Page 18

A1856

Operating Menu

3.2 Operating instructions

Display Meaning

Hi Measuring range exceeded or turbidity too

high.

Lo Measuring range undershot.

Change the batteries immediately, continuing

work impossible.

btLo Battery voltage for background lighting too low,

although measurement is possible.

With a method adjusted by the user, when the

result is shown in the display, an arrow appears

in the

[Cal]

position.

3.3 Error messages

Display Meaning

E 27/ E 28/

Light absorption too great. Cause e.g. dirty optics.

E 29

E 10 / E 11 Calibration factor outside the permissible range.

E 20 / E 21 Detector receives too much light.

E 23 / E24 /

Detector receives too much light.

E 25

E 22 The battery power was too low during the measurement.

Replace the battery.

E 70 Cl: Factory calibration not OK / deleted

E 71 Cl: User calibration not OK / deleted

E 72 Cl HR factory calibration not in order / deleted

E 73 Cl HR user calibration not OK / deleted

18

Page 19

Display Meaning

E 80 pH: Factory calibration not OK / deleted

E 81 pH: User calibration not OK / deleted

E 82 CyA: Factory calibration not OK / deleted

E 83 CyA: User calibration not OK / deleted

Operating Menu

19

Page 20

Analysis methods

4 Analysis methods

4.1 Procedure instructions when using liquid reagents

When calculating non-directly

determinable parameters from

individual measured values

error propagation based on the

possible tolerances of the indi‐

vidual methods must be consid‐

ered.

1. Cleaning the cuvettes Many

domestic cleaning agents con‐

tain reducing substances. Use

of these substances leads to

false low readings when meas‐

uring chlorine/bromine/chlorine

dioxide/ozone. To exclude this

measurement error, the cuv‐

ettes must not contain any sub‐

stances that have a chlorine

demand. Therefore the cuvettes

must be stored in a sodium

hypochlorite solution (0.1 g/l) for

one hour and then thoroughly

rinsed with deionised water.

2. For the relevant specification of

free chlorine and total chlorine

use a separate set of cuvettes

for each determination (see EN

ISO 7393-2, section. 5.3).

Label the cuvettes set on

the top and bottom so

that inadvertent inter‐

changing of the cuvettes

is not possible.

3. When preparing water samples

you must avoid the outgassing

of chlorine/bromine/chlorine

dioxide/ozone, e.g. by pipetting

and shaking. This applies partic‐

ularly for the dissolved gases

chlorine dioxide and ozone,

especially at temperatures >

30 °C. You must carry out the

analysis immediately after

taking the water sample.

4. The DPD colour development

takes place at a pH-value of 6.2

to 6.5. Therefore the reagents

contain a buffer for pH value

adjustment. You must ensure

strongly alkaline or acidic water

samples come within a pH

range between 6 and 7 (using

0.5 mol/l sulphuric acid solution

or 1 mol/l sodium hydroxide sol‐

ution).

5. Concentrations above the

measuring range with ...

n 4 mg/l chlorine when using

liquid reagents

n 9 mg/l bromine when using

liquid reagents

20

Page 21

Analysis methods

n 7.6 mg/l chlorine dioxide

when using liquid reagents

n 2.7 mg/l ozone when using

liquid reagents

may lead to results within

ð

the measuring range down

to 0 mg/l. In this case, you

must dilute the water

sample with water free from

oxidizing agent and repeat

the measurement (plausi‐

bility test).

6. Any turbidity that occurs during

the colour reaction leads to toohigh results. You can prevent

this error by pre-diluting the

sample with oxidizing agent-free

water. You must consider the

diluting ratio (e.g. 1:2) when cal‐

culating the measurement

result.

7. After use immediately close the

dropping bottles containing the

liquid reagents using the

respective screw caps of the

matching colour. Store the

reagent set at + 6 °C to + 10 °C.

8. The DPD method used

responds to many oxidising

media, hence you must ensure

that the selected oxidising agent

is present on its own. Mixtures,

e.g. from chlorine and chlorine

dioxide only yield total values.

These total values must then be

differentiated using additional

steps. To differentiate between

chlorine and chlorine dioxide,

see

[Chlorine with liquid reagent

method, section d.]

. To differen‐

tiate between chlorine and

ozone, see

[Chlorine with liquid reagent

method, section e.]

.

9. In water containing bromide and

iodide (primarily seawater), the

free and, as the case may be,

bound halogens formed by

chlorination are stated as

chlorine.

A steady increase in the meas‐

ured value of a water sample

therefore indicates that along‐

side the selected oxidising

agent (e.g. chlorine) a further

oxidising agent (e.g. bromide or

iodide) is present. This addi‐

tional oxidising agent (e.g. bro‐

mide or iodide) may due to cer‐

tain circumstances (many times

higher concentration, equilibria,

higher temperature) bleed

through into the measurement.

By working quickly and reading

off the measurement immedi‐

ately, the resulting error can be

minimised.

These interference effects

ð

are also known to occur with

these systems {combined

chlorine ⇛ free chlorine} and

{chloride ⇛ chlorine dioxide}.

21

Page 22

Analysis methods

4.2 Quantitative determination using liquid reagents

Chlorine with liquid reagents 0.01 ...

4.0 mg/l

Use the

[MODE]

key to select

[Cl]

.

a) Free chlorine

1. Take your cuvette set 1

2. In a 24 mm cuvette add a 10 ml

water sample and carry out a

zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

3. Remove the cuvette from the

sample chamber and empty the

cuvette completely

Hold the dropping bottle upright

4.

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

Fill the cuvette up to the 10 ml

marking with the water sample

5. Close the cuvette using the cuv‐

ette lid

6. Mix the contents of the cuvette

by tipping it back and forth

7. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette.

8. Press the key

[ZERO/TEST]

[METHOD]

ð

flashes for

approximately 3 seconds.

The result in mg/l of free

chlorine appears in the dis‐

play.

b) Total chlorine

1. Take your cuvette set 2

2. In a 24 mm cuvette add a 10 ml

water sample and carry out a

zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

3. Remove the cuvette from the

sample chamber and empty the

cuvette completely

Hold the dropping bottle upright

4.

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

n 3 drops ➨ DPD 3 solution

Fill the cuvette up to the 10 ml

marking with the water sample

5. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth

6. Place the cuvette in the sample

chamber

Observe the correct posi‐

ð

tioning of the cuvette.

22

Page 23

Analysis methods

7. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

tion time to elapse

8. The METHOD symbol flashes

for approximately 3 seconds

The result in mg/l of total

ð

chlorine appears in the dis‐

play.

c) combined chlorine

[!]

key

and

. To do

Combined chlorine = total

chlorine minus free chlorine

Calculate the combined chlorine

d) Chlorine together with chlorine

dioxide

1. Fill a cuvette with a 10 ml water

sample

2. Insert a

directly from the foil into the

water sample and crush the

[GLYCINE]

rod

3. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablet has dissolved

[GLYCINE]

tablet with a stirring

tablet

4. In a second 24 mm cuvette add

a 10 ml water sample and carry

out a zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

5. Remove the cuvette from the

sample chamber for the zero

correction and empty the cuv‐

ette out

Hold the dropping bottle upright

6.

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

7. Pour the contents of the first

cuvette (

into the prepared cuvette

8. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth

9. Place the cuvette in the sample

chamber

ð

10. Press the key

ð

11. Remove the cuvette from the

sample chamber

12. Thoroughly clean the cuvette

and the cuvette lid

[GLYCINE]

Observe the correct posi‐

tioning of the cuvette.

solution)

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The display value

chlorine dioxide reappears

in the display.

flashes for

[G]

=

23

Page 24

Analysis methods

13. Hold the dropping bottle upright

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

Fill the cuvette up to the 10 ml

marking with the water sample

14. Close the cuvette using the cuv‐

ette lid

15. Mix the contents of the cuvette

by tipping it back and forth

16. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette

17. Press the key

[METHOD]

ð

approximately 3 seconds.

The display value

of free chlorine plus chlorine

dioxide appears in the dis‐

play.

18. Remove the cuvette from the

sample chamber

19. Hold the dropping bottle upright

and by slow pressing, add equal

sized drops into the cuvette:

[ZERO/TEST]

flashes for

[A]

= sum

22. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette

23. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

tion time to elapse

24.

[METHOD]

mately 3 seconds.

The display value

ð

of free chlorine plus com‐

bined chlorine plus chlorine

dioxide appears in the dis‐

play.

Calculation:

25.

n Chlorine dioxide (mg/l) =

display value

n Free chlorine (mg/l) = dis‐

play value

value

n Combined chlorine (mg/l) =

display value

play value

[!]

and

key

flashes for approxi‐

[A]

[G]

[A]

. To do

[C]

= sum

[G]

x 1.9

minus display

[C]

minus dis‐

n 3 drops ➨ DPD 3 solution

20. Close the cuvette using the cuv‐

ette lid

21. Mix the contents of the cuvette

by tipping it back and forth

24

Page 25

Analysis methods

d) Chlorine together with ozone

1. In a 24 mm cuvette add a 10 ml

water sample and carry out a

zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette completely

Hold the dropping bottle upright

3.

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

n 3 drops ➨ DPD 3 solution

Fill the cuvette up to the 10 ml

marking with the water sample

4. Close the cuvette using the cuv‐

ette lid

5. Mix the contents of the cuvette

by tipping it back and forth

6. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette.

7. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

[!]

key

and

. To do

tion time to elapse

8. The METHOD symbol flashes

for approximately 3 seconds

The result of Total chlorine

ð

+ ozone = display value

[A]

appears in mg/l in the dis‐

play.

9. Remove the first cuvette from

the sample chamber

10. Thoroughly clean the cuvette

and the cuvette lid

11. Fill a second cuvette with a 10

ml water sample

12. Insert a

[GLYCINE]

tablet

directly from the foil into the

water sample and crush the

[GLYCINE]

tablet with a stirring

rod

13. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablet has dissolved

14. Hold the dropping bottle upright

and by slow pressing, add equal

sized drops into the first cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

n 3 drops ➨ DPD 3 solution

15. Pour the contents of the second

cuvette (

[GLYCINE]

solution)

into the prepared cuvette

16. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth

25

Page 26

Analysis methods

17. Place the cuvette in the sample

chamber

Observe the correct posi‐

ð

tioning of the cuvette.

18. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

tion time to elapse

19. The METHOD symbol flashes

for approximately 3 seconds

The result in mg/l of Total

ð

chlorine = display value

appears in the display.

Calculation:

20.

n Ozone (mg/l) = (Display

value

value

[!]

and

key

[A]

minus display

[G]

) x 0.67

. To do

[G]

Measuring tolerances when

determining the chlorine con‐

tent:

–

0 ... 1 mg/l: ± 0.05 mg/l

–

> 1 ... 2 mg/l: ± 0.10 mg/l

–

> 2 ... 3 mg/l: ± 0.20 mg/l

–

> 3 ... 4 mg/l: ± 0.30 mg/l

Bromine with liquid reagents 0.02 ... 9

mg/l

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[Br]

.

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette completely

Hold the dropping bottle upright

3.

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

n 3 drops ➨ DPD 3 solution

Fill the cuvette up to the 10 ml

marking with the water sample

4. Use the cuvette lid to seal the

cuvette

5. Mix the contents of the cuvette

by tipping it back and forth

6. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette.

7. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press

Wait for the 2 minutes reac‐

ð

tion time to elapse

[!]

and

. To do

[ZERO/TEST]

26

Page 27

8.

[METHOD]

mately 3 seconds.

The result in mg/l of bromine

ð

appears in the display.

9.

Measuring tolerances

when determining the

bromine content:

–

–

–

–

flashes for approxi‐

0 ... 2.3 mg/l: ± 0.12

mg/l

> 2.3 ... 4.5 mg/l:

± 0.25 mg/l

> 4.5 ... 6.8 mg/l:

± 0.45 mg/l

> 6.8 ... 9 mg/l: ± 0.68

mg/l

Analysis methods

Chlorine dioxide with liquid reagents

0.02 ... 7.6 mg/l

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[CdO]

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette completely

Hold the dropping bottle upright

3.

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

.

Explanatory notes, see

ð

Ä Further information

on page 20

27

.

Fill the cuvette up to the 10 ml

marking with the water sample

4. Close the cuvette using the cuv‐

ette lid

5. Mix the contents of the cuvette

by tipping it back and forth

6. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette.

7. Press the key

[METHOD]

ð

approximately 3 seconds.

The result in mg/l of chlorine

dioxide appears in the dis‐

play.

[ZERO/TEST]

flashes for

Page 28

Analysis methods

8.

Measuring tolerances

when determining the

chlorine dioxide content:

–

0 ... 1.9 mg/l: ± 0.1

mg/l

–

> 1.9 ... 3.8 mg/l:

± 0.2 mg/l

–

> 3.8 ... 5.7 mg/l:

± 0.4 mg/l

–

> 5.7 ... 7.6 mg/l:

± 0.6 mg/l

Ozone with liquid reagents 0.01 ... 2.7

mg/l

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[O3]

.

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette completely

Hold the dropping bottle upright

3.

and by slow pressing, add equal

sized drops into the cuvette:

n 6 drops ➨ DPD 1 buffer sol‐

ution

n 2 drops ➨ DPD 1 reagent

solution

n 3 drops ➨ DPD 3 solution

Fill the cuvette up to the 10 ml

marking with the water sample

4. Close the cuvette using the cuv‐

ette lid

5. Mix the contents of the cuvette

by tipping it back and forth

6. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette.

7. Press the key

[METHOD]

ð

approximately 3 seconds.

The result in mg/l of ozone

appears in the display.

[ZERO/TEST]

flashes for

28

Page 29

Analysis methods

8.

Measuring tolerances

when determining the

ozone content:

–

0 ... 0.67 mg/l: ± 0.03

mg/l

–

> 0.67 ... 1.3 mg/l:

± 0.07 mg/l

–

> 1.3 ... 2.0 mg/l:

± 0.13 mg/l

–

> 2.0 ... 2.7 mg/l:

± 0.20 mg/l

Explanatory notes, see

ð

Ä Further information

on page 20

.

4.3 Procedure instructions when using tablets

When calculating non-directly

determinable parameters from

individual measured values

error propagation based on the

possible tolerances of the indi‐

vidual methods must be consid‐

ered.

1. Cleaning the cuvettes Many

domestic cleaning agents con‐

tain reducing substances. Use

of these substances leads to

false low readings when meas‐

uring chlorine/bromine/chlorine

dioxide/ozone. To exclude this

measurement error, the cuv‐

ettes must not contain any sub‐

stances that have a chlorine

demand. Therefore the cuvettes

must be stored in a sodium

hypochlorite solution (0.1 g/l) for

one hour and then thoroughly

rinsed with deionised water.

2. For the relevant specification of

free chlorine and total chlorine

use a separate set of cuvettes

for each determination (see EN

ISO 7393-2, section. 5.3).

29

Page 30

Analysis methods

Label the cuvettes set on

the top and bottom so

that inadvertent inter‐

changing of the cuvettes

is not possible.

3. When preparing water samples

you must avoid the outgassing

of chlorine/bromine/chlorine

dioxide/ozone, e.g. by pipetting

and shaking. This applies partic‐

ularly for the dissolved gases

chlorine dioxide and ozone,

especially at temperatures >

30 °C. You must carry out the

analysis immediately after

taking the sample.

4. The DPD colour development

takes place at a pH-value of 6.2

to 6.5. Therefore the reagents

contain a buffer for pH value

adjustment. You must ensure

strongly alkaline or acidic water

samples come within a pH

range between 6 and 7 (using

0.5 mol/l sulphuric acid solution

or 1 mol/l sodium hydroxide sol‐

ution).

5. Concentrations above

n 10 mg/l chlorine when using

tablets

n 22 mg/l bromine when using

tablets

n 19 mg/l chlorine dioxide

when using tablets

n 6 mg/l ozone when using

tablets

may lead to results within

ð

the measuring range down

to 0 mg/l. In this case, you

must dilute the water

sample with water free from

oxidizing agent and repeat

the measurement (plausi‐

bility test).

6. Turbidity (causes incorrect

measurements): For water sam‐

ples with High Calcium content*

and/or high conductivity when

using the

[DPD no. 1 tablet]

result can be the rendering

turbid of the water sample and

consequently incorrect meas‐

urements. In this case, you

must you must use the alterna‐

tive reagent tablet

[DPD no. 1 High Calcium]

turbidity only appears after the

addition of the

[DPD No. 3]

tablet, you can prevent this by

use of the

[DPD no. 1 High Calcium]

the

[DPD no. 3 High Calcium]

tablet. The

[DPD No. 1 High Calcium]

should only be used in conjunc‐

tion with the

[DPD No. 3 High Calcium]

*exact values cannot be

ð

specified, as the formation

of turbidity depends on the

type and composition of the

water sample.

7. The DPD method used

responds to many oxidising

media, hence you must ensure

that the selected oxidising agent

is present on its own. Mixtures,

the

. If the

and

tablet

.

30

Page 31

Analysis methods

e.g. of chlorine and chlorine

dioxide only yield total values.

These total values must then be

differentiated using additional

steps. To differentiate between

chlorine and chlorine dioxide,

see

[Chlorine with tablet method,

section D "Chlorine together

with chlorine dioxide"]

entiate between chlorine and

ozone, see

To differ‐

[Chlorine with tablet method]

8. In water containing bromide and

iodide, the free and, as the case

may be, bound halogens formed

by chlorination are stated as

chlorine. A steady increase in

the measured value of a water

sample therefore indicates that

alongside the selected oxidising

agent a further oxidising agent

is present. This oxidising agent

may due to certain circum‐

stances (many times higher

concentration, equilibria, higher

temperature) bleed through into

the measurement. By working

quickly and reading off the

measurement immediately, the

resulting error can be mini‐

mised.

These interference effects

ð

are also known to occur with

these systems {combined

chlorine ⇛ free chlorine} and

{chloride ⇛ chlorine dioxide}.

4.4 Quantitative determination using tablets

Fully dissolve tablets

Make sure that the tablets have

fully dissolved before starting

measurements. Otherwise

incorrect measurements may

result.

31

Page 32

Analysis methods

Chlorine with tablets 0.01 ... 6.0 mg/l

Use the

a) Free chlorine

1. Take your cuvette set 1

2. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[Cl]

.

Ä „Switching on and zero cor‐

rection“ on page 13

3. Remove the cuvette from the

sample chamber and empty the

cuvette down to the last few

drops

4. Insert a

directly from the foil into the

water sample and crush the

[DPD No. 1]

rod

5. Fill the cuvette up to the 10 ml

marking with the water sample

6. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablet has dissolved

7. Position the cuvette in the

sample chamber

ð

8. Press the key

ð

[DPD No. 1]

tablet with a stirring

Observe the correct posi‐

tioning of the cuvette.

tablet

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

flashes for

The result in mg/l of free

chlorine appears in the dis‐

play.

b) Total chlorine

1. Take your cuvette set 2

2. In a 24 mm cuvette add a 10 ml

water sample and carry out a

zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

3. Remove the cuvette from the

sample chamber and empty the

cuvette down to the last few

drops

4. Insert a

directly from the foil into the

water sample and crush the

[DPD No. 1]

rod

5. Insert a

directly from the foil into the

water sample and crush the

[DPD No. 3]

rod

6. Fill the cuvette up to the 10 ml

marking with the water sample

7. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablets have dissolved

8. Place the cuvette in the sample

chamber

ð

[DPD No. 1]

tablet with a stirring

[DPD No. 3]

tablet with a stirring

Observe the correct posi‐

tioning of the cuvette.

tablet

tablet

32

Page 33

Analysis methods

9. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

tion time to elapse

10. The METHOD symbol flashes

for approximately 3 seconds

The result in mg/l of total

ð

chlorine appears in the dis‐

play.

c) combined chlorine

[!]

key

and

. To do

Combined chlorine = total

chlorine minus free chlorine

Calculate the combined chlorine

d) Chlorine together with chlorine

dioxide

1. Fill a cuvette with a 10 ml water

sample

2. Insert a

directly from the foil into the

water sample and crush the

[GLYCINE]

rod

3. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablet has dissolved

[GLYCINE]

tablet with a stirring

tablet

4. In a second 24 mm cuvette add

a 10 ml water sample and carry

out a zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

5. Remove the cuvette from the

sample chamber for the zero

correction and empty the cuv‐

ette out

6. Insert a

directly from the foil into the

water sample and crush the

[DPD No. 1]

rod

7. Pour the contents of the first

cuvette (

into the prepared cuvette

8. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablet has dissolved

9. Place the cuvette in the sample

chamber

ð

10. Press the key

ð

11. Remove the cuvette from the

sample chamber

12. Thoroughly clean the cuvette

and the cuvette lid

[DPD No. 1]

tablet with a stirring

[GLYCINE]

Observe the correct posi‐

tioning of the cuvette.

tablet

solution)

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The display value

(chlorine dioxide) reappears

in the display.

flashes for

[G]

33

Page 34

Analysis methods

13. Fill a cuvette with a few drops of

a water sample

14. Insert a

directly from the foil into the

water sample and crush the

[DPD No. 1]

rod

15. Fill the cuvette up to the 10 ml

marking with the water sample

16. Close the cuvette using the cuv‐

ette lid

17. Mix the contents of the cuvette

by tipping it back and forth, until

the tablet has dissolved

18. Position the cuvette in the

sample chamber

ð

19. Press the key

ð

20. Remove the cuvette from the

sample chamber

21. Insert a

directly from the foil into the

same water sample and crush

the

stirring rod

22. Close the cuvette using the cuv‐

ette lid

[DPD No. 1]

tablet with a stirring

Observe the correct posi‐

tioning of the cuvette.

tablet

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The display value

of free chlorine plus chlorine

dioxide) appears in the dis‐

play.

[DPD No. 3]

flashes for

[DPD No. 3]

tablet with a

[A]

tablet

(sum

23. Mix the contents of the cuvette

by tipping it back and forth, until

the tablet has dissolved

24. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette.

25. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

tion time to elapse

26. The METHOD symbol flashes

for approximately 3 seconds

The display value

ð

of free chlorine plus com‐

bined chlorine plus chlorine

dioxide) appears in the dis‐

play.

Calculation:

27.

n Chlorine dioxide (mg/l) =

display value

n Free chlorine (mg/l) = dis‐

play value

value

n Combined chlorine (mg/l) =

display value

play value

[G]

[!]

key

[A]

[A]

and

. To do

[C]

(sum

[G]

x 1.9

minus display

[C]

minus dis‐

34

Page 35

Analysis methods

d) Chlorine together with ozone

1. In a 24 mm cuvette add a 10 ml

water sample and carry out a

zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette down to the last few

drops

3. Insert a

a

from the foil into the water

sample and crush the tablets

using a stirring rod

4. Fill the cuvette up to the 10 ml

marking with the water sample

5. Close the cuvette using the cuv‐

ette lid

6. Mix the contents of the cuvette

by tipping it back and forth, until

the tablets have dissolved

7. Position the cuvette in the

sample chamber

ð

8. Switch the countdown on, see

[DPD No. 1]

[DPD No. 3]

Observe the correct posi‐

tioning of the cuvette.

tablet and

tablet directly

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

tion time to elapse

9. The METHOD symbol flashes

for approximately 3 seconds

[!]

key

and

. To do

The result of Total chlorine

ð

+ ozone = display value

appears in mg/l in the dis‐

play.

10. Remove the first cuvette from

the sample chamber

11. Thoroughly clean the cuvette

and the cuvette lid

12. Fill a second cuvette with a 10

ml water sample

13. Insert a

directly from the foil into the

water sample and crush the

[GLYCINE]

rod

14. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablet has dissolved

15. Insert a

a

from the foil into the water

sample and crush the tablets

using a stirring rod

16. Pour the contents of the second

cuvette (

into the prepared cuvette

17. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth

18. Place the cuvette in the sample

chamber

ð

[GLYCINE]

tablet with a stirring

[DPD No. 1]

[DPD No. 3]

[GLYCINE]

Observe the correct posi‐

tioning of the cuvette.

tablet

tablet and

tablet directly

solution)

[A]

35

Page 36

Analysis methods

19. Switch the countdown on, see

Ä „ Switching the countdown

function on“ on page 14

this, press the

[ZERO/TEST]

Wait for the 2 minutes reac‐

ð

tion time to elapse

20. The METHOD symbol flashes

for approximately 3 seconds

The result in mg/l of Total

ð

chlorine = display value

appears in the display.

Calculation:

21.

n Ozone (mg/l) = (Display

value

value

[!]

and

key

[A]

minus display

[G]

) x 0.67

. To do

[G]

Measuring tolerances when

determining the chlorine con‐

tent:

–

0 ... 1 mg/l: ± 0.05 mg/l

–

> 1 ... 2 mg/l: ± 0.10 mg/l

–

> 2 ... 3 mg/l: ± 0.20 mg/l

–

> 3 ... 4 mg/l: ± 0.30 mg/l

–

> 4 ... 6 mg/l: ± 0.40 mg/l

Chlorine HR with tablet 5 ... 200 mg/l

For the analysis method

with tablet 5 ... 200 mg/l“

contained in the scope of supply is

required, see

Ä Chapter 1.3 „Adapter

for 16 mm cuvettes“ on page 11

1. Insert the adapter for the 16 mm

round cuvette in the device, see

„Chlor HR

the adapter

.

Ä Chapter 1.3 „Adapter for 16

mm cuvettes“ on page 11

2. In a 16 mm cuvette add an 8 ml

water sample and carry out a

zero correction, see

Ä „Switching on and zero cor‐

rection“ on page 13

3. Insert a

tablet and an

tablet directly from the foil into

the water sample and crush the

tablets using a stirring rod

4. Close the cuvette with the cuv‐

ette lid and mix the contents by

tipping back and forth until the

tablet has dissolved

5. Position the cuvette in the

sample chamber

ð

6. Press the key

ð

[CHLORINE HR (KI)]

[ACIDIFYING-GP]

Observe the correct posi‐

tioning of the cuvette.

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The result in mg/l of chlorine

appears in the display.

flashes for

36

Page 37

Measuring tolerances

when determining

chlorine HR:

–

± 5 mg/l

Oxidising agents

lead to multiple

results

All the oxidising

agents contained in

the water sample

react like chlorine

which leads to mul‐

tiple findings.

Ensure, by using suit‐

able methods and

measures that for

your particular

process, such mul‐

tiple finding cannot

occur or that such

multiple findings can

be allowed for in

another manner.

Analysis methods

Bromine with tablet 0.02 ... 13 mg/l

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[Br]

.

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette down to the last few

drops

3. Enter a

[DPD No. 3]

the foil into the water sample

and crush the tablet with a stir‐

ring rod

4. Fill the cuvette up to the 10 ml

marking with the water sample

5. Use the cuvette lid to seal the

cuvette

6. Mix the contents of the cuvette

by tipping it back and forth, until

the tablet has dissolved

7. Position the cuvette in the

sample chamber

ð

8. Switch the countdown on, see

[DPD No. 1]

tablet directly from

Observe the correct posi‐

tioning of the cuvette.

tablet and a

Ä „ Switching the countdown

function on“ on page 14

this, press

9. Press

[METHOD]

ð

approximately 3 seconds.

[!]

[ZERO/TEST]

and

flashes for

. To do

[ZERO/TEST]

.

37

Page 38

Analysis methods

10.

The result in mg/l of bromine

appears in the display.

Measuring tolerances

when determining the

bromine content:

–

0 ... 2.3 mg/l: ± 0.12

mg/l

–

> 2.3 ... 4.5 mg/l:

± 0.25 mg/l

–

> 4.5 ... 6.8 mg/l:

± 0.45 mg/l

–

> 6.8 ... 9 mg/l: ± 0.68

mg/l

–

> 9 ... 13 mg/l: ± 0.90

mg/l

Explanatory notes, see

ð

Ä Further information

on page 29

.

Chlorine dioxide with tablet 0.02 ... 11

mg/l

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[CdO]

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette down to the last few

drops of the water sample

3. Insert a

directly from the foil into the

water sample and crush the

tablet with a stirring rod

4. Fill the cuvette up to the 10 ml

marking with the water sample

5. Close the cuvette using the cuv‐

ette lid

6. Mix the contents of the cuvette

by tipping it back and forth, until

the tablet has dissolved

7. Position the cuvette in the

sample chamber

ð

8. Press the key

ð

[DPD No. 1]

Observe the correct posi‐

tioning of the cuvette.

tablet

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The result in mg/l of chlorine

dioxide appears in the dis‐

play.

flashes for

.

38

Page 39

Analysis methods

9.

Measuring tolerances

when determining the

chlorine dioxide content:

–

0 ... 1.9 mg/l: ± 0.1

mg/l

–

> 1.9 ... 3.8 mg/l:

± 0.2 mg/l

–

> 3.8 ... 5.7 mg/l:

± 0.4 mg/l

–

> 5.7 ... 7.6 mg/l:

± 0.6 mg/l

–

> 7.6 ... 11 mg/l: ± 0.8

mg/l

Ozone with tablet 0.01 ... 4 mg/l

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[O3]

.

Ä „Switching on and zero cor‐

rection“ on page 13

2. Remove the cuvette from the

sample chamber and empty the

cuvette down to the last few

drops

3. Insert a

a

from the foil into the water

sample and crush the tablets

using a stirring rod

4. Fill the cuvette up to the 10 ml

marking with the water sample

5. Close the cuvette using the cuv‐

ette lid

6. Mix the contents of the cuvette

by tipping it back and forth, until

the tablets have dissolved

7. Position the cuvette in the

sample chamber

ð

8. Press the key

ð

[DPD No. 1]

[DPD No. 3]

Observe the correct posi‐

tioning of the cuvette.

tablet and

tablet directly

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The result in mg/l of ozone

appears in the display.

flashes for

39

Page 40

Analysis methods

9.

Measuring tolerances

when determining the

ozone content:

–

0 ... 0.67 mg/l: ± 0.03

mg/l

–

> 0.67 ... 1.3 mg/l:

± 0.07 mg/l

–

> 1.3 ... 2.0 mg/l:

± 0.13 mg/l

–

> 2.0 ... 2.7 mg/l:

± 0.20 mg/l

–

> 2.7 ... 4.0 mg/l:

± 0.27 mg/l

Explanatory notes, see

ð

Ä Further information

on page 29

.

pH value with tablet 6.5 ... 8.4

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[PH]

.

Ä „Switching on and zero cor‐

rection“ on page 13

2. Insert a

[PHENOL RED PHOTO‐

METER]

foil into the water sample and

crush the tablet with a stirring

rod

3. Fill the cuvette up to the 10 ml

marking with the water sample

4. Close the cuvette using the cuv‐

ette lid

5. Mix the contents of the cuvette

by tipping it back and forth, until

the tablets have dissolved

6. Position the cuvette in the

sample chamber

ð

7. Press the key

ð

tablet directly from the

Observe the correct posi‐

tioning of the cuvette.

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The result is output to the

display as a pH value.

flashes for

40

Page 41

Analysis methods

8.

Measuring tolerances

when determining pH:

–

up to ± 0.3 pH units

ð

Remarks:

–

For the photo‐

metric pH value

determination

only use

[PHENOL RED]

tablets with black

foil printing, which

are labelled with

the term

[PHOTOMETER].

–

Water samples

with low carbo‐

nate hardness*

may result in

incorrect pH

values.

*KS4.3 < 0.7

mmol/l ≜ Total

alkalinity < 35

mg/l CaCO3.

–

pH values under

6.5 and greater

than 8.4 may lead

to results within

the measuring

range. A plausi‐

bility test (pH

meter) is recom‐

mended.

–

The accuracy of

pH values based

upon colorimetric

determination

depends on var‐

41

Page 42

Analysis methods

ious boundary

conditions (buffer

capacity of the

water sample, salt

content, etc.).

–

The salt content

of the water

sample effects the

result of the pho‐

tometric pH

measurement

(salt error), hence

this method is not

suitable for

checking the func‐

tioning of a poten‐

tiometric pH

measurement

(DIN 19643-2 ff,

paragraph 4.2.4.

functional check).

Cyanuric acid with CyA test tablet 1 ...

80 mg/l

Use the

1. In a 24 mm cuvette add a 10 ml

[MODE]

water sample and carry out a

zero correction, see

key to select

[CyA]

.

Ä „Switching on and zero cor‐

rection“ on page 13

2. Insert a

directly from the foil into the

water sample and crush the

tablet with a stirring rod

3. Fill the cuvette up to the 10 ml

marking with the water sample

4. Close the cuvette using the cuv‐

ette lid

5. Mix the contents of the cuvette

by tipping it back and forth, until

the tablets have dissolved

6. Position the cuvette in the

sample chamber

ð

7. Press the key

ð

[CyA TEST]

Observe the correct posi‐

tioning of the cuvette.

tablet

[ZERO/TEST]

[METHOD]

approximately 3 seconds.

The result in mg/l of cya‐

nuric acid appears in the

display.

flashes for

42

Page 43

8.

Measuring tolerances

when determining the

cyanuric acid content:

–

0 ... 25 mg/l: ± 5 mg/l

–

25 ... 50 mg/l: ± 8

mg/l

–

50 ... 80 mg/l: ± 10

mg/l

ð

Remarks:

–

Cyanuric acid

causes a very

finely distributed

turbidity with a

milky appearance

in the water

sample. Individual

particles should

not be traced

back to the pres‐

ence of cyanuric

acid, rather are

due to impurities

in the water

sample.

–

Dissolve the

tablet completely

(tilt from side to

side for approx. 1

minute). Undis‐

solved particles

may result in mul‐

tiple findings.

Analysis methods

43

Page 44

Calibration

5 Calibration

1. The device is switched off.

Press and hold down the

[MODE]

2. Use the

on the device

ð

3. Release the

4. The [!] key allows you to select

the following operating menu

items:

n

n Set date and time

n User calibration

ð

5. Use the

[CAL]

(arrow top right in the display)

key

[ON/OFF]

3 decimal points appear in

the display.

[diS]

= read out of stored

data

The selected menu item is

indicated by an arrow in the

display.

[!]

key to select the

operating menu item

key to switch

[MODE]

key

Chlorine (Cl) adjustment range

User adjustment

NOTICE!

Separate adjustment of the bro‐

mine, chlorine dioxide or ozone

measuring ranges is impos‐

sible. The device relies on the

adjustment of the chlorine

measuring range (Cl).

User adjustment (display in Adjust‐

ment mode ) =

Factory calibration (display in Adjust‐

ment mode ) =

1. Confirm the selection with

[cCAL]

[CCAL]

[MODE]

The display toggles between

ð

[CAL / METHOD]

2. Select the method to be

adjusted using the

3. Fill the cuvette up to the 10-ml

marking with the standard solu‐

tion, without adding reagents

.

[MODE]

key

4. Use the cuvette lid to seal the

cuvette

5. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette

6. Press

[ZERO/TEST]

[METHOD]

ð

approximately 8 seconds.

flashes for

44

Page 45

Calibration

Confirmation of the zero cor‐

rection

with

7. Remove the cuvette from the

sample chamber and empty the

cuvette completely

8. Thoroughly clean the cuvette

and the cuvette lid

9. Fill the cuvette up to the 10-ml

marking with a standard solution

of known concentration and

introduce the reagents as

described under

[0.0.0]

[CAL]

alternates

.

Ä „Chlorine

with liquid reagents 0.01 ... 4.0

mg/l“ on page 22

or

Ä „a) Free

chlorine“ on page 32

10. Use the cuvette lid to seal the

cuvette

11. Position the cuvette in the

sample chamber

Observe the correct posi‐

ð

tioning of the cuvette.

12. Press

13. If the result matches the value

[ZERO/TEST]

[METHOD]

ð

approximately 3 seconds.

Confirmation of the result

alternates with

of the standard used, (within the

tolerance to be considered) you

can exit Adjustment mode by

pressing

flashes for

[ON/OFF]

[CAL]

.

Changing the displayed value:

Pressing the [MODE] key 1 x

increases the displayed result

by 1 digit.

Pressing the [ZERO/TEST] key

1 x reduces the displayed result

by 1 digit.

1. Repeatedly press the keys until

the displayed result matches the

value of the standard used

2. Press

[ON/OFF]

The new correction factor is

ð

calculated and saved in the

user adjustment level.

Confirmation of the adjust‐

ment appears in the display

for 3 seconds.

45

Page 46

Calibration

Return to the factory calibration

Returning from user adjustment

to factory calibration is only

possible simultaneously for all

methods.

With a method adjusted by the

user, when the result is shown

in the display, an arrow

appears in the [Cal] position.

Proceed as follows to return the

device to the factory calibration, pro‐

ceed as follows:

1. Device is switched off. Simulta‐

neously press

[MODE]

and

[ZERO/TEST]

2. Switch the device on using the

[ON/OFF]

ð

3. The display toggles between:

[SEL]

ð

4. or

5. The display toggles between:

[SEL]

key

After approximately 1

second, release

and

[ZERO/TEST]

and

[CAL]

The device is in the as-sup‐

plied condition (

for Select).

and

[cAL]

[MODE]

.

[SEL]

stands

The device operates with an

ð

adjustment performed by

the user. If the user adjust‐

ment is to be retained,

switch off the device using

[ON/OFF]

the

6. Pressing

simultaneously activate factory

calibration for all methods

7. The display toggles between

[SEL]

8. Switch the device off using the

[ON/OFF]

[MODE]

and

key

key.

lets you

[CAL]

46

Page 47

Technical Data

6 Technical Data

Device two wavelengths, automatic wavelength selection,

colorimeter with direct measured value display

Optics LEDs, interference filter (IF) and photo sensor at the

transparent sample chamber

Wavelength specifications of the interference filter:

n 530 nm Δλ = 5 nm

n 560 nm Δλ = 5 nm

Wavelength precision ± 1 nm

Photometric precision* 3% FS (Full Scale) (T = 20°C ... 25°C)

Photometric resolution 0.01 A (Absorption units)

Power supply 4 batteries (Mignon AA/LR 6)

Operating time approx. 53 h operating time or 15,000 measure‐

ments in continuous operation with background

lighting switched off

Auto-OFF Automatic device switch-off 10 minutes after the last

key was pressed

Display Backlit LCD (at the press of a key)

Memory internal ring buffer for 16 data records

Time Real time clock and date

Calibration (manufac‐

turer) / Adjustment

(user)

Factory calibration and user adjustment.

Return to factory calibration is possible.

Dimensions 190 x 110 x 55 mm (L x W x H)

Weight Basic device approx. 455 g (with batteries)

*measured with standard solutions

47

Page 48

Technical Data

Ambient conditions Temperature: 5 ... 40 °C

Relative humidity: 30 ... 90% (non-condensing)

Water-tight similar to IP 68 (1 hour at 0.1 m); buoyant device

*measured with standard solutions

The specified device precision is only obtained when the original reagent

systems are used.

48

Page 49

Consumables and Spare Parts

7 Consumables and Spare Parts

Consumables

Material Part number

DPD-1 tablets (100 no.) 1061892

DPD-3 tablets (100 no.) 1061893

Phenol red tablets R 175 (100 no.) 305532

Cyanuric acid tablets R 263 (100 no.) 1039744

CHLORINE HR (KI) tablets (100 no.) 1075056

ACIDIFYING GP tablets (100 no.) 1075057

Glycine tablets (20 no.) 1061944

Spare parts

Material Part number

3 no. round cuvettes (d = 24 mm, h = 48 mm) with lid

1007566

(replacement cuvettes) for:

n DPD identification

n Phenol red identification

n Cyanuric acid identification

5 no. round cuvettes (d = 16 mm, h = 90 mm) with lid

1024072

(replacement cuvettes) for:

n Chlorine HR identification with a tablet

49

Page 50

Standards Complied with and Declaration of Conformity

8 Standards Complied with and Declaration of Conformity

Declaration of Conformity

You will find the EC Declaration of

Conformity to download on our home‐

page.

Standards complied with

EC EMC Directive (2004/108/EC)

EN 61326 - 1

50

Page 51

9 Index

Index

1, 2, 3 ...

16 mm cuvette adapter ......... 11

A

Action, step by step .............2

B

Battery compartment cover ...... 12

Battery replacement ........... 12

Bromine with liquid reagents

0.02 ... 9 mg/l ................ 26

Bromine with tablet 0.02 ... 13

mg/l ........................37

C

Chlorine dioxide with liquid

reagents 0.02 ... 7.6 mg/l ....... 27

Chlorine dioxide with tablet

0.02 ... 11 mg/l ............... 38

Chlorine HR with tablet 5 ... 200

mg/l ........................36

Chlorine together with chlorine

dioxide (liquid reagents) ........ 23

Chlorine together with chlorine

dioxide (tablet) ............... 33

Chlorine together with ozone

(liquid reagents) .............. 25

Chlorine together with ozone

(tablet) ..................... 35

Combine chlorine (tablet) ....... 33

Combined chlorine (liquid

reagents) ................... 23

Consumables ................ 49

Countdown .................. 14

Cyanuric acid with CyA test tablet

1 ... 80 mg/l ..................42

D

Danger from hazardous sub‐

stances! ..................... 5

Date and time (24-hour format) ...17

Declaration of Conformity ....... 50

Degree of protection IP 68 ...... 47

Display background lighting ..... 16

Displaying stored data ......... 15

E

EN ISO 7393-2, section 5.3 ...20, 29

Error messages .............. 18

F

Free chlorine (liquid reagents) ... 22

Free chlorine (tablet) ...........32

G

General non-discriminatory

approach .....................2

I

IP 68 ....................... 47

51

Page 52

Index

L

Links to elements or sections of

these instructions or other appli‐

cable documents ...............2

M

Material safety data sheet ........5

More symbols ................. 2

N

Non-discriminatory approach ..... 2

O

Ozone with liquid reagents 0.01 ...

2.7 mg/l .....................28

Ozone with tablet 0.01 ... 4 mg/l .. 39

P

pH value with tablet 6.5 ... 8.4 ....40

Photometer leak-tightness ...... 12

Q

Question: For which measured

variable can I perform an adjust‐

ment? ...................... 44

Question: How can I read stored

data? .......................15

Question: How can I return to the

factory calibration? ............ 46

Question: How do I adjust the

date and time? ............... 17

Question: How do I carry out a

zero correction? .............. 13

Question: How do I carry out the

zero correction? ............... 8

Question: How do I change the

battery? .....................12

Question: How do I enter the

values determined by the adjust‐

ment into the device? .......... 45

Question: How do I perform a

user adjustment? ............. 44

Question: How do I switch the

background lighting of the display

off and on? .................. 16

Question: How do I switch the

countdown on? ............... 14

Question: What does the standard

scope of supply include? .........6

Question: What must it clean and

how? ........................8

Question: What sort of consuma‐

bles are available? ............ 49

Question: What spare parts are

available? ................... 49

Question: What type of error mes‐

sages are there? ..............18

Question: Where can I find the

Declaration of Conformity? ...... 50

Question: Which standards are

complied with? ............... 50

R

Repeating the analysis ......... 14

Return to the factory calibration .. 46

52

Page 53

Index

S

Safety data sheets ............. 8

Spare parts .................. 49

Standard scope of supply ........ 6

Standards complied with ........50

Switching on and zero correction . 13

T

Technical Data ............... 47

Total chlorine (liquid reagents) ... 22

Total chlorine (tablet) .......... 32

Z

Zero correction ............. 8, 13

53

Page 54

54 55

Page 55

Page 56

ProMinent GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg, Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

985629, 3, en_GB

© 2017

Loading...

Loading...