ProMinent DULCOTEST DO 3-mA-20 ppm Assembly And Operating Instructions Manual

Assembly and operating instructions

A2613

DULCOTEST® sensors for dissolved oxygen

Type: DO 3-mA-20 ppm

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Target group: Instructed person982373 BA DT 061 12/18 EN

Supplemental directives

General non-discriminatory approach In order to make it easier to read, this docu‐

ment uses the male form in grammatical struc‐

tures but with an implied neutral sense. It is

aimed equally at both men and women. We

kindly ask female readers for their under‐

standing in this simplification of the text.

Supplementary information

Please read the supplementary information in its entirety.

Information

This provides important information relating to the correct operation of the unit or is intended

to make your work easier.

Warning information

Warning information includes detailed descriptions of the hazardous situation, see

‘Labelling of Warning Information’ on page 8

The following symbols are used to highlight instructions, links, lists, results and other elements in

this document:

.

Ä Chapter 2.1

Tab. 1: More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other applicable docu‐

ments.

n

[Button]

List without set order.

Display element (e.g. indicators).

Operating element (e.g. button, switch).

2

Symbol Description

Supplemental directives

‘Display /GUI’

CODE

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

3

Table of contents

Table of contents

1 Function.................................................................................................................................. 5

1.1 Measuring principle........................................................................................................ 5

1.2 Construction and function............................................................................................... 6

1.3 Scope of delivery............................................................................................................ 7

2 Safety...................................................................................................................................... 8

2.1 Labelling of Warning Information.................................................................................... 8

2.2 User qualification.......................................................................................................... 10

2.3 General safety information........................................................................................... 11

2.4 Intended use................................................................................................................. 11

3 How to store and transport the sensor.................................................................................. 12

3.1 Storage......................................................................................................................... 12

3.2 Transport...................................................................................................................... 12

4 Assembly and installation...................................................................................................... 13

4.1 Installation on a PVC immersion tube.......................................................................... 14

4.2 Installation in the bypass fitting DGMa......................................................................... 15

4.3 Installation in bypass fitting DLG III.............................................................................. 16

4.4 Electrical connection.................................................................................................... 18

5 Preparation for the measurement......................................................................................... 20

6

Calibration with the DULCOMETER ® DACb........................................................................ 21

6.1 Calibration on air.......................................................................................................... 21

6.2 Calibration in water using a reference measurement................................................... 21

6.3 Calibrating the zero point............................................................................................. 21

7 Maintenance and troubleshooting......................................................................................... 22

7.1 Dismantling the sensor................................................................................................. 22

7.2 Replacing the sensor cap............................................................................................. 22

7.3 Cleaning....................................................................................................................... 23

7.4 Troubleshooting............................................................................................................ 23

8 Disposal of used parts........................................................................................................... 24

9 Parts and accessories........................................................................................................... 25

10 Technical data....................................................................................................................... 26

10.1 Standards and regulations complied with................................................................... 27

11 Index..................................................................................................................................... 28

4

1 Function

The DULCOTEST® sensor, type DO 3, is used

for measurement of the partial pressure of dis‐

solved oxygen and the measured variables

derived from this:

n Oxygen concentration in aqueous liquids

in mg/l or ppm,

n Degree of oxygen saturation in aqueous

liquids in %

The sensor type DO 3 is used for measurement

of the concentration of dissolved oxygen in

fresh water and salt water. The applications

specifically include

n The control and monitoring of aeration pro‐

cesses in clarification plants,

n Monitoring of fish farming facilities

n The aeration of raw water in water works

n Assessment of the quality of surface

water.

All wetted materials are suitable for fresh water

and salt water.

Function

1.1 Measuring principle

The sensor type DO 3 is based on the optical

measurement of a fluorescence beam. The flu‐

orescence beam is weakened depending on

the partial pressure of the oxygen in the water.

The measurement is done in pulsed mode, with

the relaxation time of the fluorescence beam

being determined.

5

A2646

4

3

2

1

5

Function

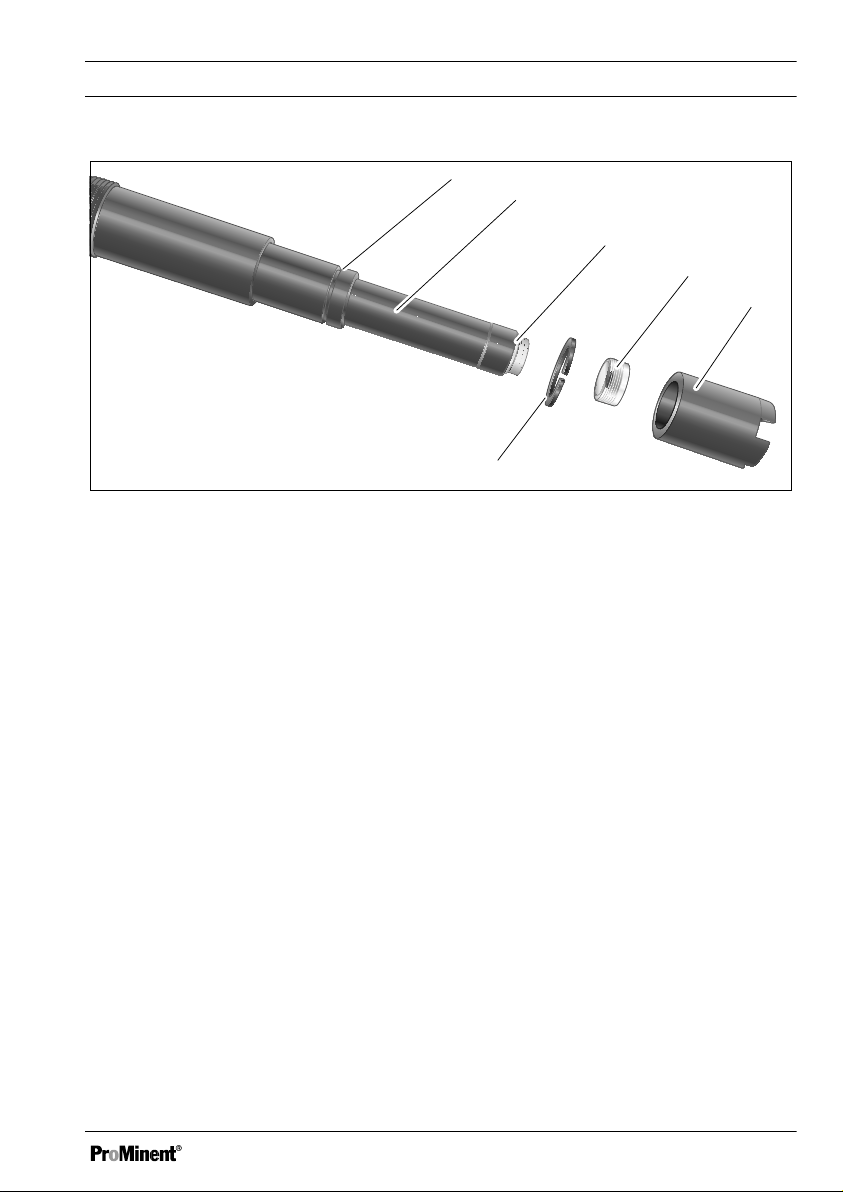

1.2 Construction and function

A sensor cap is screwed onto the optical window of the sensor type DO 3 integrated in the sensor

shaft. The sensor cap contains fluorescence dye immobilised on a carrier. A black protective cap is

attached to the sensor cap. The sensor has a 10-metre long fixed cable. The sensor can be

immersed under water. The sensor shaft has an Rp1” thread on the cable side. The adapter

included in the scope of delivery is screwed onto the thread to enable the sensor to be connected to

an immersion tube at an angle of 45°. The middle part of the sensor shaft has a groove for a clamp

disc. The clamp ring threaded connection is used to fix the sensor into a suitable ProMinent bypass

fitting. The sensor shaft contains a temperature sensor (Pt 1000). The temperature sensor is used

for internal temperature correction of the measuring signal. The temperature sensor is connected to

the measuring equipment. The sensor is factory calibrated. The temperature-corrected, calibrated

and galvanically isolated 4 ... 20 mA measuring signal leaves the sensor along 2 lines. The supply

voltage is also fed along the same lines (two-line technology).

Fig. 1: Construction of the sensor

1 Fixed cable, 10 metres

2 Rp1” thread

3 Sensor shaft with groove for the clamp disc

4 Sensor head area with protective cap

5 Clamp disc

6

A2643

3

2

1

5

4

6

Fig. 2: Construction in the sensor head area

1 Groove for the clamp disc for connection to

the bypass fitting

2 Sensor shaft

3 O-ring

Function

4 Sensor cap with fluorescence dye

5 Protective cap (bite protection for the appli‐

cation: fish farming)

6 Clamp disc

1.3 Scope of delivery

Please first check the scope of delivery of

sensor type DO 3, order number 1094609

n 1 no. clamp disc,

n 1 no. clamp disc, replacement,

n 1 no. protective cap on the sensor head,

n 1 no. adapter: with Rp1” thread, PVC-U,

n 1 no. 45° angle, PVC, DN32,

n 1 no. assembly and operating instructions.

7

Safety

2 Safety

2.1 Labelling of Warning Infor‐

mation

Introduction

These operating instructions provide informa‐

tion on the technical data and functions of the

product. These operating instructions provide

detailed warning information and are provided

as clear step-by-step instructions.

The warning information and notes are categor‐

ised according to the following scheme. A

number of different symbols are used to denote

different situations. The symbols shown here

serve only as examples.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very

serious injuries.

Measure to be taken to avoid this

danger.

– Denotes a possibly hazardous sit‐

uation. If the situation is disre‐

garded, it could result in fatal or

very serious injuries.

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious

injuries.

Measure to be taken to avoid this

danger.

Description of hazard

– Denotes an immediate threatening

danger. If the situation is disre‐

garded, it will result in fatal or very

serious injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor

injuries. Material damage.

Measure to be taken to avoid this

danger.

– Denotes a possibly hazardous sit‐

uation. If the situation is disre‐

garded, it could result in slight or

minor injuries. May also be used

as a warning about material

damage.

8

NOTICE!

Nature and source of the danger

Damage to the product or its surround‐

ings.

Measure to be taken to avoid this

danger.

– Denotes a possibly damaging sit‐

uation. If the situation is disre‐

garded, the product or an object in

its vicinity could be damaged.

Type of information

Hints on use and additional information.

Source of the information. Additional

measures.

–

Denotes hints on use and other

useful information. It does not indi‐

cate a hazardous or damaging sit‐

uation.

Safety

9

Safety

2.2 User qualification

WARNING!

Danger of injury with inadequately qualified personnel

The operator of the system / equipment is responsible for ensuring that the qualifications are

fulfilled.

If inadequately qualified personnel work on the unit or loiter in the hazard zone of the unit,

this could result in dangers that could cause serious injuries and material damage.

– All work on the unit should therefore only be conducted by qualified personnel.

– Unqualified personnel should be kept away from the hazard zone.

The pertinent accident prevention regulations, as well as all other generally acknowledged

safety regulations, must be adhered to.

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been

instructed and, if required, trained in the tasks assigned to him and pos‐

sible dangers that could result from improper behaviour, as well as

having been instructed in the required protective equipment and protec‐

tive measures.

Trained user A trained user is a person who fulfils the requirements made of an

instructed person and who has also received additional training specific

to the system from the manufacturer or another authorised distribution

partner.

Trained, qualified per‐

sonnel

A trained, qualified employee is deemed to be a person who is able to

assess the tasks assigned to him and recognize possible hazards

based on his training, knowledge and experience, as well as knowledge

of pertinent regulations. A trained, qualified employee must be able to

perform the tasks assigned to him independently with the assistance of

drawing documentation and parts lists. The assessment of a person's

technical training can also be based on several years of work in the rel‐

evant field.

10

Loading...

Loading...