Page 1

Assembly and operating instructions

A2632

DULCOTEST® sensor ICT 5 and ICT 5-IMA

Sensor for electrical conductivity

EN/DE

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

982358 BA DT 157 10/18 DE/EN

Page 2

Overall Table of Contents

Overall Table of Con‐

tents

EN

DULCOTEST® sensor ICT 5 and ICT

5-IMA Sensor for electrical conduc‐

tivity..................................................... 4

1 Introduction.................................... 8

1.1 Measuring principle.................... 8

1.2 Construction and function of

the sensor................................... 9

1.3 Nameplate................................ 12

1.4 Scope of delivery...................... 12

2 Safety and responsibility............. 13

2.1 Labelling of Warning Informa‐

tion............................................ 13

2.2 User qualification...................... 15

2.3 General safety information....... 16

2.4 Intended use............................. 17

2.5 Information in the event of an

emergency................................ 17

3 How to store and transport the

sensor.......................................... 18

3.1 Storage..................................... 18

3.2 Transport.................................. 18

4 Assembly and installation............ 19

4.1 Installation of sensor type ICT

5............................................... 20

4.2 Installation of sensor type ICT

5-IMA........................................ 23

4.3 Electrical installation................. 24

5 Maintenance................................ 26

6 Rectifying faults and malfunc‐

tions............................................. 27

7 Disposal of used parts................. 28

8 Accessories................................. 29

9 Technical data............................. 30

9.1 General data............................. 30

9.2 Certification/Test marks............ 31

9.3 Permitted process pressure..... 32

10 Dimensions................................ 33

DE

DULCOTEST® Sensor ICT 5 und

ICT 5-IMA Sensor für elektrolytische

Leitfähigkeit....................................... 36

1 Einleitung..................................... 40

1.1 Messprinzip.............................. 40

1.2 Aufbau und Funktion des Sen‐

sors........................................... 41

1.3 Typenschild.............................. 44

1.4 Lieferumfang............................ 44

2 Sicherheit und Verantwortung..... 45

2.1 Kennzeichnung der Warnhin‐

weise........................................ 45

2.2 Benutzer-Qualifikation.............. 47

2.3 Allgemeine Sicherheitshin‐

weise........................................ 48

2.4 Bestimmungsgemäße Verwen‐

dung......................................... 49

2.5 Angaben für den Notfall............ 49

3 So lagern und transportieren Sie

den Sensor.................................. 50

3.1 Lagerung.................................. 50

3.2 Transport.................................. 50

4 Montage und Installation............. 51

4.1 Montage des Sensortyps ICT

5............................................... 52

4.2 Montage des Sensortyps ICT

5-IMA........................................ 55

4.3 Elektrische Installation.............. 56

5 Wartung....................................... 58

6 Fehler und Störungen beheben... 59

7 Altteileentsorgung........................ 60

8 Zubehör....................................... 61

9 Technische Daten....................... 62

9.1 Allgemeine Daten..................... 62

9.2 Zulassungen/Prüfzeichen......... 63

9.3 Zulässiger Prozessdruck.......... 64

2

Page 3

10 Abmessungen........................... 65

Overall Table of Contents

3

Page 4

Assembly and operating instructions

A2632

DULCOTEST® sensor ICT 5 and ICT 5-IMA

Sensor for electrical conductivity

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

982358 BA DT 157 10/18 DE/EN

Page 5

Supplemental directives

General non-discriminatory approach In order to make it easier to read, this docu‐

ment uses the male form in grammatical struc‐

tures but with an implied neutral sense. It is

aimed equally at both men and women. We

kindly ask female readers for their under‐

standing in this simplification of the text.

Supplementary information

Please read the supplementary information in its entirety.

Information

This provides important information relating to the correct operation of the unit or is intended

to make your work easier.

Warning information

Warning information includes detailed descriptions of the hazardous situation, see

‘Labelling of Warning Information’ on page 13

The following symbols are used to highlight instructions, links, lists, results and other elements in

this document:

.

Ä Chapter 2.1

Tab. 1: More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other applicable docu‐

ments.

n

[Button]

5

List without set order.

Display element (e.g. indicators).

Operating element (e.g. button, switch).

Page 6

Supplemental directives

Symbol Description

‘Display /GUI’

CODE

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

6

Page 7

Table of contents

Table of contents

1 Introduction............................................................................................................................. 8

1.1 Measuring principle........................................................................................................ 8

1.2 Construction and function of the sensor......................................................................... 9

1.3 Nameplate.................................................................................................................... 12

1.4 Scope of delivery.......................................................................................................... 12

2 Safety and responsibility....................................................................................................... 13

2.1 Labelling of Warning Information.................................................................................. 13

2.2 User qualification.......................................................................................................... 15

2.3 General safety information........................................................................................... 16

2.4 Intended use................................................................................................................. 17

2.5 Information in the event of an emergency.................................................................... 17

3 How to store and transport the sensor.................................................................................. 18

3.1 Storage......................................................................................................................... 18

3.2 Transport...................................................................................................................... 18

4 Assembly and installation...................................................................................................... 19

4.1 Installation of sensor type ICT 5................................................................................... 20

4.2 Installation of sensor type ICT 5-IMA........................................................................... 23

4.3 Electrical installation..................................................................................................... 24

5 Maintenance.......................................................................................................................... 26

6 Rectifying faults and malfunctions......................................................................................... 27

7 Disposal of used parts........................................................................................................... 28

8 Accessories........................................................................................................................... 29

9 Technical data....................................................................................................................... 30

9.1 General data................................................................................................................. 30

9.2 Certification/Test marks................................................................................................ 31

9.3 Permitted process pressure......................................................................................... 32

10 Dimensions........................................................................................................................... 33

7

Page 8

Introduction

1 Introduction

These operating instructions provide informa‐

tion on the technical data and functions of the

DULCOTEST® sensor for inductive conduc‐

tivity, ICT 5 and ICT-IMA.

Sensor type ICT 5 is designed for continuous

flow operation.

Sensor type ICT 5-IMA is integrated in an

immersion tube for immersion in a storage tank

and in an open channel.

The sensor records the electrolytic conductivity

of an aqueous process liquid online. Both types

of sensor work on the basis of an inductive

measuring principle. The sensor is almost

maintenance-free due to the inductive meas‐

uring process. Solid deposits and fatty or oily

films on the surface of the sensor have no

impact on its measuring precision. The sensor

is particularly suitable for measuring high con‐

ductivities of up to 2000 mS/cm. A stand-alone

temperature sensor (Pt1000) with a short

response time records the process tempera‐

ture. The temperature sensor is enclosed within

a protective stainless steel sleeve. Tempera‐

ture correction of the conductivity measurement

in the connected controller is provided for by

the temperature sensor (Pt1000).

You can also use both types of sensor in conta‐

minated water or in aggressive media, which is

chemically inert to PVC/EPDM and/or PP/

EPDM (depending on the design of the sensor).

1.1 Measuring principle

The electrolytic conductivity is measured with

an inductive sensor. The sensor contains a

transmission and receiver coil. Sine alternating

voltage feeds the transmission coil. A sample

flow is induced into the receiver coil depending

on the conductivity of the liquid to be meas‐

ured. The sample flow is proportional to the

conductivity of the medium.

Typical applications

The sensor is predominantly designed for appli‐

cations in water treatment and for water moni‐

toring, e.g.:

n Contaminated waste water and process

water

n Air conditioning plants and chillers

n Blowdown control in cooling towers,

n Flushing baths,

n Vehicle washing systems,

n Salt water desalination (feed),

n Swimming pool water control.

8

Page 9

A2617

4

3

2

1

5

Introduction

1.2 Construction and function of the sensor

The inductive transducer of the two types of sensor ICT 5 and ICT 5-IMA consists of a hermetically

sealed polypropylene (PP) body. A transmission coil and a receiver coil are incorporated in the

transducer. A flow opening in the sensor (sensor eye) permits the measuring medium to flow

through. There is galvanic isolation between the sample medium and the signal output. A standalone temperature sensor (Pt1000) with a short response time records the process temperature. The

temperature sensor is enclosed within a protective stainless steel sleeve.

Fig. 1: Components

1 PP sensor body

2 Transmission coil

3 Sensor eye through which the sample

medium flows

4 Receiver coil

5 Temperature sensor, stand-alone, enclosed

within a stainless steel sleeve

9

Page 10

A2641

Introduction

Sensor type ICT 5

The sensor type ICT5 is connected to a standard DN40 T-piece (on site) using a threaded socket

and a union nut for operation in the flow.

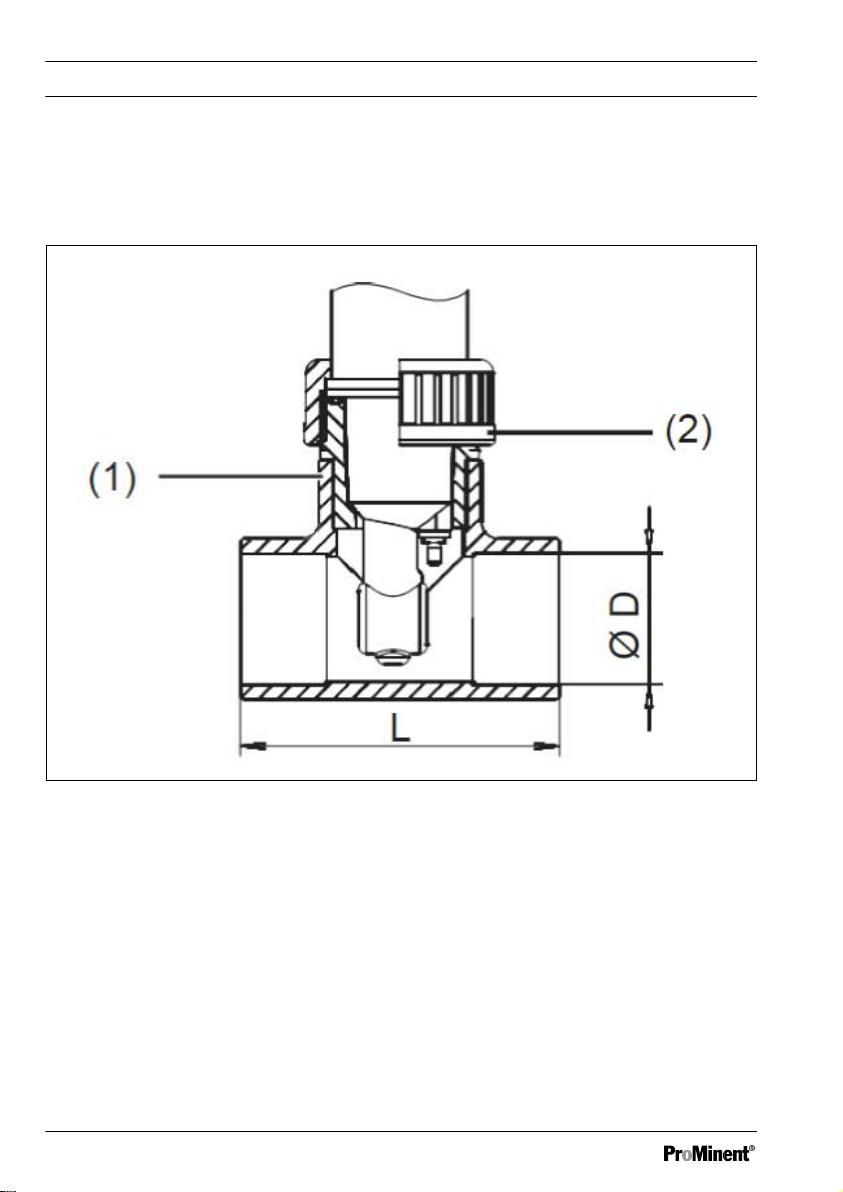

Fig. 2: Sensor type ICT 5

1. Threaded socket, G 1 1/2” (PVC or PP)

2. Union nut (PVC or PP)

10

Page 11

A2642

Introduction

Sensor type ICT5-IMA

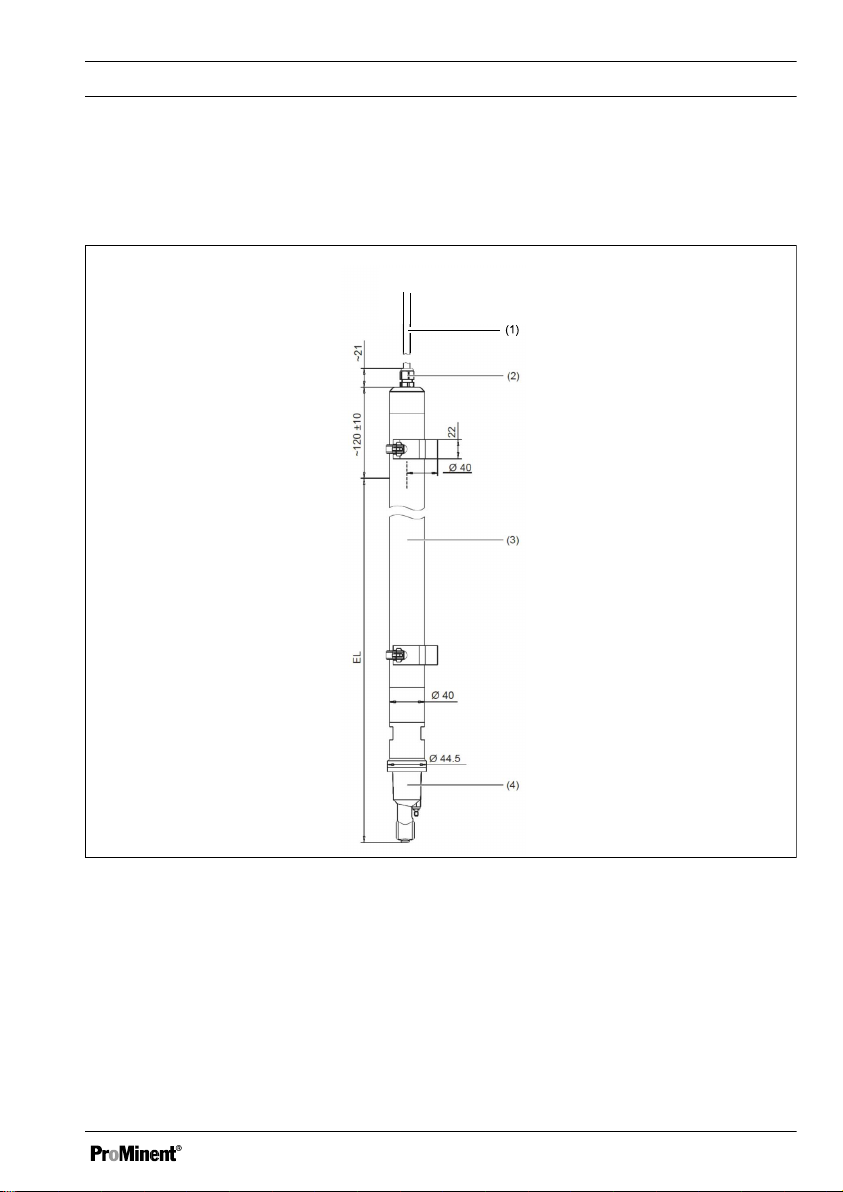

The sensor type ICT5-IMA is immersed by the fully assembled immersion tube (1 m) in the storage

tank and channel.

Fig. 3: Sensor type ICT 5-IMA

1. Fixed cable, 10 m

2. Threaded connector M16, degree of protec‐

tion, IP68 (up to 0.2 m)

3. PP

4. PP

11

Page 12

A2637

A2638

Introduction

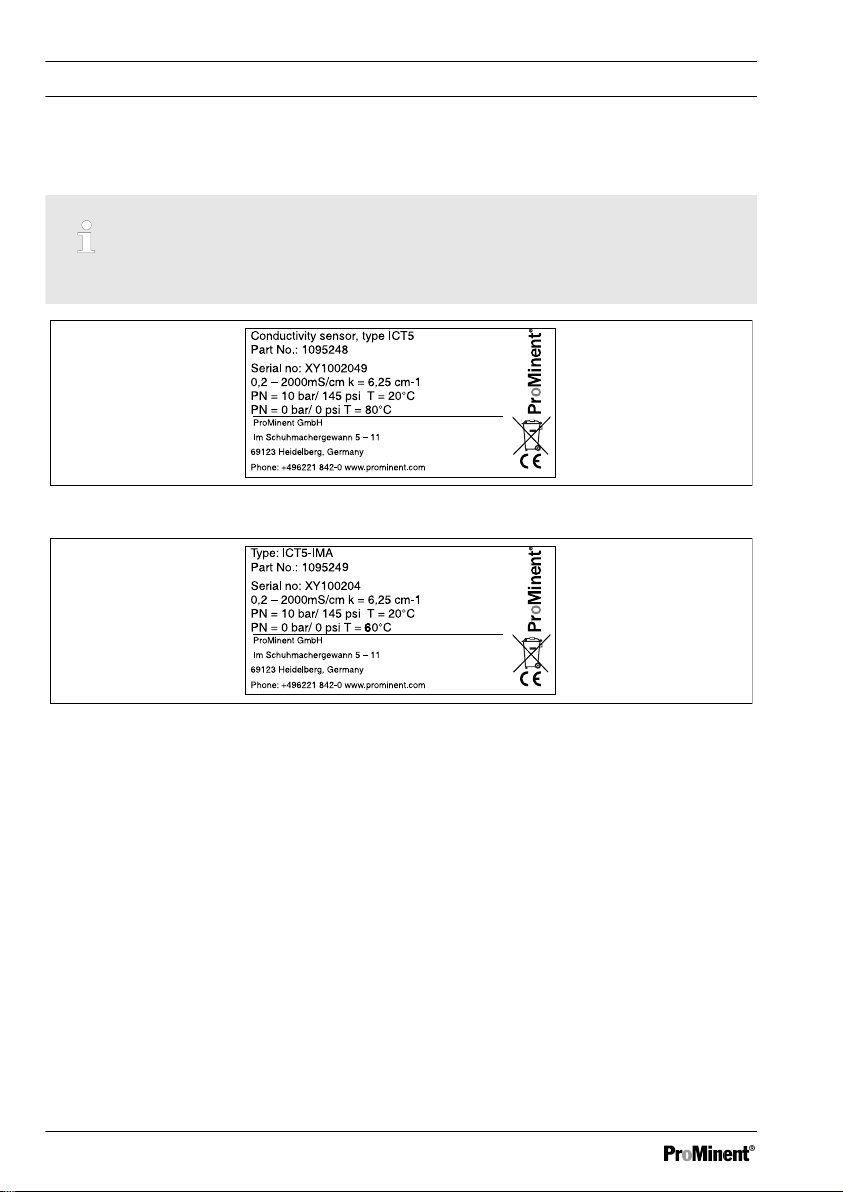

1.3 Nameplate

The cell constant K is needed for calibration on the transmitter/controller.

Fig. 4: ICT5 nameplate

Fig. 5: ICT5-IMA nameplate

1.4 Scope of delivery

Scope of delivery of sensor type ICT 5:

n Sensor type ICT 5, order number 1095248

n Straight solvent union PVC for adaptation

of the sensor to a standard T-piece DN40,

PVC (T-piece not included in the scope of

delivery)

n Assembly and operating instructions

Scope of delivery of sensor type ICT 5-IMA:

n Sensor type ICT 5-IMA, order number

1095249

n Assembly and operating instructions

12

Page 13

2 Safety and responsibility

2.1 Labelling of Warning Infor‐

mation

Introduction

These operating instructions provide informa‐

tion on the technical data and functions of the

product. These operating instructions provide

detailed warning information and are provided

as clear step-by-step instructions.

The warning information and notes are categor‐

ised according to the following scheme. A

number of different symbols are used to denote

different situations. The symbols shown here

serve only as examples.

Safety and responsibility

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very

serious injuries.

Measure to be taken to avoid this

danger.

– Denotes a possibly hazardous sit‐

uation. If the situation is disre‐

garded, it could result in fatal or

very serious injuries.

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious

injuries.

Measure to be taken to avoid this

danger.

Description of hazard

– Denotes an immediate threatening

danger. If the situation is disre‐

garded, it will result in fatal or very

serious injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor

injuries. Material damage.

Measure to be taken to avoid this

danger.

– Denotes a possibly hazardous sit‐

uation. If the situation is disre‐

garded, it could result in slight or

minor injuries. May also be used

as a warning about material

damage.

13

Page 14

Safety and responsibility

NOTICE!

Nature and source of the danger

Damage to the product or its surround‐

ings.

Measure to be taken to avoid this

danger.

– Denotes a possibly damaging sit‐

uation. If the situation is disre‐

garded, the product or an object in

its vicinity could be damaged.

Type of information

Hints on use and additional information.

Source of the information. Additional

measures.

–

Denotes hints on use and other

useful information. It does not indi‐

cate a hazardous or damaging sit‐

uation.

14

Page 15

Safety and responsibility

2.2 User qualification

WARNING!

Danger of injury with inadequately qualified personnel

The operator of the system / equipment is responsible for ensuring that the qualifications are

fulfilled.

If inadequately qualified personnel work on the unit or loiter in the hazard zone of the unit,

this could result in dangers that could cause serious injuries and material damage.

– All work on the unit should therefore only be conducted by qualified personnel.

– Unqualified personnel should be kept away from the hazard zone.

The pertinent accident prevention regulations, as well as all other generally acknowledged

safety regulations, must be adhered to.

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been

instructed and, if required, trained in the tasks assigned to him and pos‐

sible dangers that could result from improper behaviour, as well as

having been instructed in the required protective equipment and protec‐

tive measures.

Trained user A trained user is a person who fulfils the requirements made of an

instructed person and who has also received additional training specific

to the system from the manufacturer or another authorised distribution

partner.

Trained, qualified per‐

sonnel

15

A trained, qualified employee is deemed to be a person who is able to

assess the tasks assigned to him and recognize possible hazards

based on his training, knowledge and experience, as well as knowledge

of pertinent regulations. A trained, qualified employee must be able to

perform the tasks assigned to him independently with the assistance of

drawing documentation and parts lists. The assessment of a person's

technical training can also be based on several years of work in the rel‐

evant field.

Page 16

Safety and responsibility

Training Definition

Electrical technician An electrical technician is able to complete work on electrical systems

and recognise and avoid possible dangers independently based on his

technical training and experience as well as knowledge of pertinent

standards and regulations. An electrical technician must be able to per‐

form the tasks assigned to him independently with the assistance of

drawing documentation, parts lists, terminal and circuit diagrams. The

electrical technician must be specifically trained for the working environ‐

ment in which the electrical technician is employed and be conversant

with the relevant standards and regulations.

Service The Service department refers to service technicians, who have

received proven training and have been authorised by the manufacturer

to work on the system.

2.3 General safety information

CAUTION!

WARNING!

Unauthorised access!

Possible consequence: Fatal or very

serious injuries

– Measure: Ensure that there can be

no unauthorised access to the

device

– Only trained personnel may fit,

install, service and operate this

sensor

Functional limitations

Possible consequence: Slight or minor

injuries. Material damage

– Check the sensor regularly for dirt

and contamination

– Observe all applicable national

regulations relating to mainte‐

nance, service and calibration

intervals

16

Page 17

2.4 Intended use

n Only use the sensor to measure and regu‐

late electrolytic conductivity in aqueous

media, which are used in the applications

described in these operating instructions.

n All other uses or modifications are pro‐

hibited.

n The sensor is not a safety component in

the sense of DIN EN ISO

13849-1:2008-12. If there is a critical

process in your measurement and control

circuit, then it is your responsibility to make

sure this process is safe.

2.5 Information in the event of

an emergency

n In the event of an emergency, switch off

the controller

n If liquid escapes from the continuous flow

gauge, close the stopcocks on the inlet

and outlet installed by the customer

n Observe the plant operator's safety infor‐

mation before opening the continuous flow

gauge

Safety and responsibility

17

Page 18

How to store and transport the sensor

3 How to store and transport the sensor

Original packaging

User qualification: instructed user, see

Ä Chapter 2.2 ‘User qualification’ on page 15

Damage to the product.

n Only transport, ship and store the sensor

in its original packaging.

n Retain the packaging in its entirety

including the polystyrene inserts.

3.1 Storage

Storage and transport temperature:

n complete sensor -20 °C ... 75 °C.

Humidity: maximum 90 % relative air humidity,

non-condensing.

Other: No dust, no direct sunlight.

3.2 Transport

The sensor should be transported in its original

packaging and in compliance with the permis‐

sible environmental conditions. No further spe‐

cial conditions have to be observed in relation

to transport.

18

Page 19

4 Assembly and installation

n User qualification, mechanical installation:

trained and qualified personnel

2.2 ‘User qualification’ on page 15

n User qualification, electrical installation:

electrical technician

Ä Chapter 2.2 ‘User

qualification’ on page 15

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very

serious injuries.

Please ensure when handling haz‐

ardous substances that you have read

the latest safety data sheets provided

by the manufacture of the hazardous

substance. The actions required are

described in the safety data sheet.

Check the safety data sheet regularly

and replace, if necessary, as the

hazard potential of a substance can be

re-evaluated at any time based on new

findings.

The system operator is responsible for

ensuring that these safety data sheets

are available and that they are kept up

to date, as well as for producing an

associated hazard assessment for the

workstations affected.

Ä Chapter

Assembly and installation

Make sure that the medium flows correctly

through and around the sensor.

Maintain a minimum distance of 20 mm from

the sensor to the tube wall when installing in

pipework.

Minimum compensation will be achieved with

the “Installation factor” parameter if you cannot

adhere to these minimum spacings.

Provide a representative installation site for typ‐

ical conductivity and/or concentration when

immersing in a tank.

Installation site

Ensure that there is unimpeded access for sub‐

sequent calibration.

The mounting must be secure and low-vibra‐

tion.

Avoid direct sunlight.

19

Page 20

1

1

3

2

A2618

Assembly and installation

4.1 Installation of sensor type ICT 5

Fitting position

You can operate the sensor at any angle (0 ... 360°). The sensor is installed in a DN40 standard Tpiece, as shown in Fig. 6 with regard to its flow and the minimum distances from the walls.

Fig. 6: Fitting position of sensor type ICT5 in the T-piece (DN40)

1 ≧ 20 mm

2 Flow direction

3 Sensor

20

Page 21

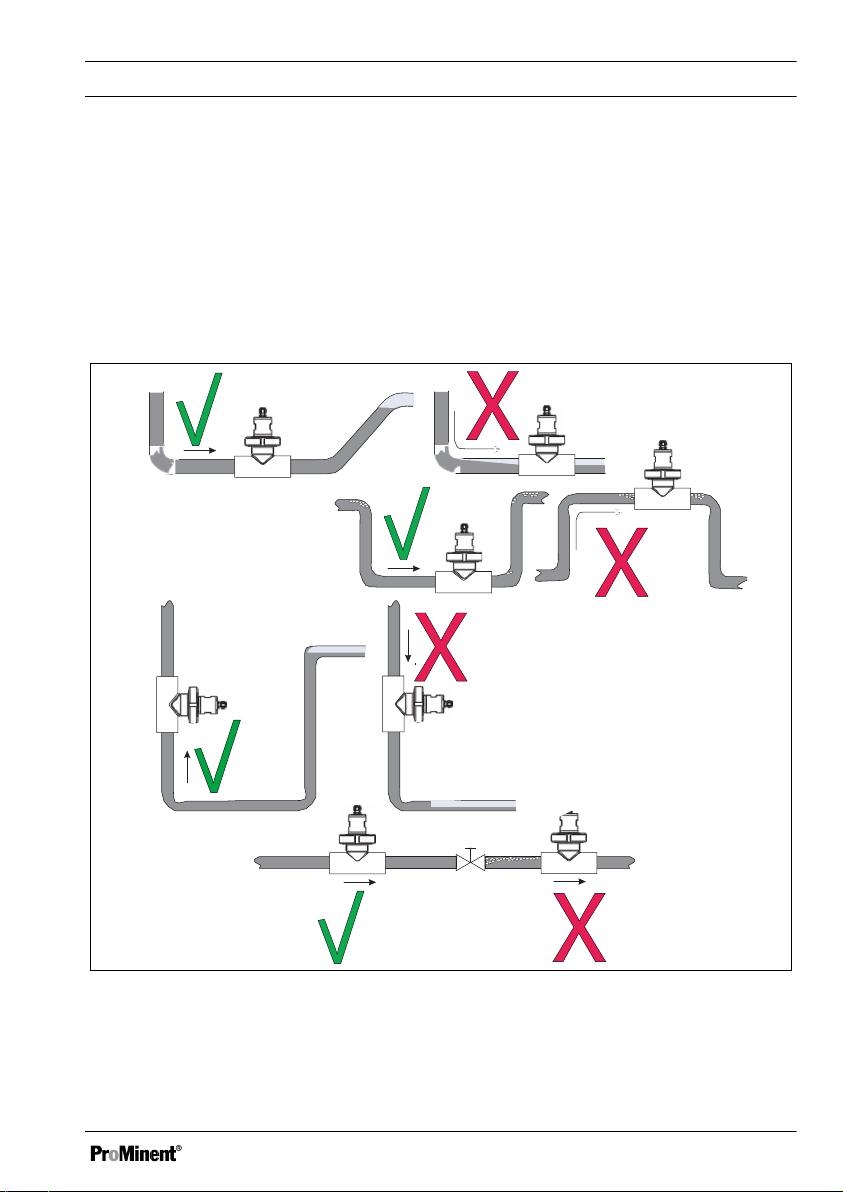

Hydraulic installation situation

A2619

Please note the hydraulic fitting position indicated in Fig. 7.

It is essential that the following are avoided:

n Formation of gas bubbles

n The device running dry

n Stalling

n Turbulence

Assembly and installation

Fig. 7: Hydraulic fitting position / tick = OK, cross = not OK

21

Page 22

A2639

5

4

3

2

1

Assembly and installation

Bonding the straight solvent union into a T-piece

Installing the sensor type ICT5 into PVC pipework. You can install the sensor into a PVC section

using the PVC straight solvent union supplied

Colour Material

Beige PP

Grey PVC

Use suitable adhesive, resistant to the media, for the materials to be bonded.

Fig. 8: Sensor and straight solvent union in a T-piece

1. Bond the straight solvent union (2) supplied into a standard T-piece (3) (on site).

When doing so, adhere to the minimum distances from the walls.

22

Page 23

Assembly and installation

Align the straight solvent union so that the sample medium flows through the sensor eye (5).

Align the guide lip (1) of the adhesive connector towards the T-piece in the flow direction.

Installing the sensor type ICT5 into polypropylene (PP) pipework

2. You can install the sensor directly into an optionally available PP T-piece (order number

1096349, not included in the scope of delivery). The PP T-piece already includes the sensor

adapter.

Assembling the sensor into the T-piece

3. Place the sensor (5) into the T-piece so that the groove (4) on the sensor shaft engages with

the guide lip of the sensor adapter.

4. Manually screw the union nut tightly onto the thread of the sensor adapter.

5. Check the leak-tightness.

4.2 Installation of sensor type

ICT 5-IMA

Installation place

The transducer of sensor type ICT 5-IMA is

fully integrated in the immersion pipe. The

immersion pipe can either be connected to a

storage tank or channel using the holes pro‐

vided or using pipe clamps (on site).

Select a suitable installation site for the repre‐

sentative sample measurement.

23

Page 24

Assembly and installation

4.3 Electrical installation

Do not shorten or mechanically damage the connecting cable.

Once connected, calibrate the inductive conductivity and temperature sensor.

Tab. 2: Terminal assignment, Dulcometer Compact

Terminal Function Sensor ICT5 lead colours

X1.1 Transmission coil, signal

X1.2 Transmission coil, signal, earth

X2.1 Receiver coil, signal

X2.2 Receiver coil, signal, earth Cable shield for X2.1, transparent

XE2.2 Earth Complete cable shield, black

XE4.1 Pt100x

XE4 Pt100x

The descriptions of the terminals refer to the ProMinent measuring and control unit, type DCCa. The

information about the colours relates to the leads of the sensor’s fixed data line.

Connect the data line to the terminals of your ProMinent measuring and control unit, type DCCa. In

doing so, refer to the relevant operating instructions

Connect the data line to the terminals of your measuring/control unit. Refer to the operating

instructions for your measuring/control unit

[bn]

[wh]

[pk]

[gn]

[ye]

, brown

, white

, pink

green

yellow

24

Page 25

Assembly and installation

Tab. 3: General assignment for further measuring/control units

Function Sensor ICT5 lead colours

Transmission coil, signal

Transmission coil, signal, earth

Receiver coil, signal

Receiver coil, signal, earth Cable shield for X2.1, transparent

Earth Complete cable shield, black

Pt100x

Pt100x

Connect the data line to the terminals of your measuring/control unit. Refer to the operating

instructions for your measuring/control unit

[bn]

[wh]

[pk]

[gn]

[ye]

, brown

, white

, pink

green

yellow

25

Page 26

Maintenance

5 Maintenance

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very

serious injuries.

Please ensure when handling haz‐

ardous substances that you have read

the latest safety data sheets provided

by the manufacture of the hazardous

substance. The actions required are

described in the safety data sheet.

Check the safety data sheet regularly

and replace, if necessary, as the

hazard potential of a substance can be

re-evaluated at any time based on new

findings.

The system operator is responsible for

ensuring that these safety data sheets

are available and that they are kept up

to date, as well as for producing an

associated hazard assessment for the

workstations affected.

3. Check the complete measuring chain

(sensor, connecting line and transmitter/

controller) should there be deviations of

the measured values with an unknown

cause.

NOTICE!

Solvent

Only use water rather than a volatile

organic solvent to clean the sensor.

1. Clean the sensor with water and a soft

brush.

2. Loosen tough films or deposits with

diluted hydrochloric acid and remove

with a soft brush.

26

Page 27

Rectifying faults and malfunctions

6 Rectifying faults and malfunctions

Problem Possible cause Measure

No display of measured value

or signal output

Display of measured value is

000 or signal output is 0% (e.g.

4 mA)

Incorrect or fluctuating meas‐

ured value display

No power supply Check power supply, check

terminals

Sensor not immersed in the

medium; storage tank level too

low

Flow fitting blocked Clean flow fitting

Sensor faulty

Sensor not immersed deeply

enough

No mixing Ensure that the sample is

Air bubbles Refer to the installation instruc‐

Top up storage tank

Top up storage tank

mixed well, ensuring that there

is approx. 18 mm of free circu‐

lation on all sides of the sensor

tions

27

Page 28

Disposal of used parts

7 Disposal of used parts

n User qualification: instructed user, see

Ä Chapter 2.2 ‘User qualification’

on page 15

NOTICE!

Regulations governing the disposal of

used parts

– Note the national regulations and

legal standards that currently

apply in your country

The manufacturer will take back decontami‐

nated used devices providing they are covered

by adequate postage.

Decontaminate the device before returning it for

repair. To do so, remove all traces of haz‐

ardous substances. Refer to the Material Safety

Data Sheet for your feed chemical.

A current Declaration of Decontamination is

available to download on the ProMinent web‐

site.

Sign indicating EU collection system

In accordance with the European Directive

2012/19/EU on waste electrical and electronic

equipment, this device features the symbol

showing a waste bin with a line through it. The

device must not be disposed of along with

domestic waste. To return the device, use the

return and collection systems available and

observe the local legal requirements.

28

Page 29

Accessories

8 Accessories

Description Part

number

Straight solvent union (PVC) + O-ring, for installation of sensor type ICT5 into a PVC

T-piece DN40

Union nut G 1 1/2”, PVC 1096351

T-piece, PP, DN40 with integral sensor adapter* 1096349

Union nut G 1 1/2”, PP 1096353

* Features an anti-turn locking device; the sensor can only be installed in the right direction.

1096348

29

Page 30

Technical data

9 Technical data

9.1 General data

Parameter ICT 5 ICT 5-IMA

Design For operation in the flow For immersion

Measuring principle inductive

Measuring range 0 ... 2000 mS/cm

Precision within the measuring range

0 ... 1 mS/cm ≤ 1%

0 ... 10 mS/cm ≤ 0.5%

0 ... 50 mS/cm ≤ 0.5%

0 ... 100 mS/cm ≤ 0.5%

0 ... 1000 mS/cm ≤ 1%

0 ... 2000 mS/cm ≤ 1%

Cell constant k = 6.25 1/cm

Temperature sensor Pt1000, Class A

t90 Temperature

Permissible ambient temperature -10 ... +60 °C

Permissible storage temperature -20 ... +75 °C

Degree of protection

Permitted medium temperature

when operating in pipework made

of:

Maximum process pressure with PP design

at 20 °C 10 bar 0 bar

at 60 °C 6 bar 0 bar

at 80 °C 0 bar

a

b

PVC: -10 ... +60 °C

PP: -10 ... +80 °C

≤ 6 seconds

IP68

-10 ... +60 °C

30

Page 31

Technical data

Parameter ICT 5 ICT 5-IMA

at -10 ... +80 °C minimum -0.1 bar minimum -0.1 bar

Sensor material, wetted

Sensor body PP

Protective sleeve, temperature

Stainless steel 1.4571

sensor

Seal EPDM

Electrical connection Fixed cable, 10 m, PUR, lead

Threaded cable connector M16, PBT/PA

Length of immersion fitting 1000 mm

a

DIN EN 60751

b

DIN EN 60529

9.2 Certification/Test marks

The materials wetted by the sample medium

are approved for use with food, physiologically

harmless and listed by the FDA.

31

Page 32

0

8

0

4

2

10

50403020

10

0-10 60 70 80

I

II

A2624

Technical data

9.3 Permitted process pressure

Temperature, pressure and the sample medium have an impact on the service life of the sensor.

Fig. 9: Permitted process pressure type ICT 5 fitted in PP pipework

I Pressure in bar.

II Temperature in °C.

32

Page 33

10 Dimensions

I. II. III. IV.

Ø40

Ø44,5

Ø40

22

21

120 ± 10

EL

A2620

Fig. 10: Dimensions, all dimensions in mm. Type ICT 5-IMA... Immersion version

I Fixed cable, 10 m

II Threaded connector M16, degree of protec‐

tion IP68 (up to 0.2 m), PBT/PA

III PP

IV Stainless steel 1.4301, AISI 304

Dimensions

33

Page 34

I.

II.

145

~81

118

36,5

A2622

Ø41

Ø44,5

67

Dimensions

Fig. 11: Dimensions, all dimensions in mm. Type ICT 5

I Threaded connector M16, degree of protec‐

tion IP68 (up to 0.2 m), PBT/PA

II PP

34

Page 35

ProMinent GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

982358, 1, en_GB

© 2018

Page 36

Montage- und Betriebsanleitung

A2632

DULCOTEST® Sensor ICT 5 und ICT 5-IMA

Sensor für elektrolytische Leitfähigkeit

DE

Betriebsanleitung bitte zuerst vollständig durchlesen. · Nicht wegwerfen.

Bei Schäden durch Installations- oder Bedienfehler haftet der Betreiber.

Die neueste Version einer Betriebsanleitung ist auf unserer Homepage verfügbar.

982358 BA DT 157 10/18 DE

Page 37

Ergänzende Anweisungen

Allgemeine Gleichbehandlung Dieses Dokument verwendet die nach der

Grammatik männliche Form in einem neutralen

Sinn, um den Text leichter lesbar zu halten. Es

spricht immer Frauen und Männer in gleicher

Weise an. Die Leserinnen bitten wir um Ver‐

ständnis für diese Vereinfachung im Text.

Ergänzende Anweisungen

Lesen Sie bitte die ergänzenden Anweisungen durch.

Infos

Eine Info gibt wichtige Hinweise für das richtige Funktionieren des Geräts oder soll Ihre

Arbeit erleichtern.

Warnhinweise

Warnhinweise sind mit ausführlichen Beschreibungen der Gefährdungssituation versehen, siehe

Ä Kapitel 2.1 „Kennzeichnung der Warnhinweise“ auf Seite 45

Zur Hervorhebung von Handlungsanweisungen, Verweisen, Auflistungen, Ergebnissen und anderen

Elementen können in diesem Dokument folgende Kennzeichnungen verwendet werden:

.

Tab. 1: Weitere Kennzeichnung

Kennzeichen Beschreibung

Handlung Schritt-für-Schritt.

⇨ Ergebnis einer Handlung.

Links auf Elemente bzw. Abschnitte dieser Anleitung oder mitgeltende Doku‐

mente.

n

[Taster]

37

Auflistung ohne festgelegte Reihenfolge.

Anzeigeelemente (z. B. Signalleuchten).

Bedienelemente (z. B. Taster, Schalter).

Page 38

Ergänzende Anweisungen

Kennzeichen Beschreibung

„Anzeige/GUI“

CODE

Bildschirmelemente (z. B. Schaltflächen, Belegung von Funktionstasten).

Darstellung von Softwareelementen bzw. Texten.

38

Page 39

Inhaltsverzeichnis

Inhaltsverzeichnis

1 Einleitung.............................................................................................................................. 40

1.1 Messprinzip.................................................................................................................. 40

1.2 Aufbau und Funktion des Sensors............................................................................... 41

1.3 Typenschild.................................................................................................................. 44

1.4 Lieferumfang................................................................................................................ 44

2 Sicherheit und Verantwortung............................................................................................... 45

2.1 Kennzeichnung der Warnhinweise............................................................................... 45

2.2 Benutzer-Qualifikation.................................................................................................. 47

2.3 Allgemeine Sicherheitshinweise................................................................................... 48

2.4 Bestimmungsgemäße Verwendung............................................................................. 49

2.5 Angaben für den Notfall................................................................................................ 49

3 So lagern und transportieren Sie den Sensor....................................................................... 50

3.1 Lagerung...................................................................................................................... 50

3.2 Transport...................................................................................................................... 50

4 Montage und Installation....................................................................................................... 51

4.1 Montage des Sensortyps ICT 5.................................................................................... 52

4.2 Montage des Sensortyps ICT 5-IMA............................................................................ 55

4.3 Elektrische Installation.................................................................................................. 56

5 Wartung................................................................................................................................. 58

6 Fehler und Störungen beheben............................................................................................ 59

7 Altteileentsorgung................................................................................................................. 60

8 Zubehör................................................................................................................................. 61

9 Technische Daten................................................................................................................. 62

9.1 Allgemeine Daten......................................................................................................... 62

9.2 Zulassungen/Prüfzeichen............................................................................................. 63

9.3 Zulässiger Prozessdruck.............................................................................................. 64

10 Abmessungen....................................................................................................................... 65

39

Page 40

Einleitung

1 Einleitung

Diese Betriebsanleitung beschreibt die techni‐

schen Daten und Funktionen des

DULCOTEST® Sensors für Induktive Leitfähig‐

keit, ICT 5 und ICT-IMA.

Der Typ ICT 5 ist für den Durchflussbetrieb

ausgelegt.

Der Typ ICT 5-IMA ist in ein Eintauchrohr integ‐

riert, für das Eintauchen im Behälter und im

offenen Gerinne.

Der Sensor erfasst online die elektrolytische

Leitfähigkeit einer wässrigen Prozessflüssig‐

keit. Beide Sensortypen arbeiten nach dem

induktiven Messprinzip. Durch das induktive

Messverfahren ist der Sensor nahezu war‐

tungsfrei. Feste Ablagerungen und Fett- oder

Ölfilme auf der Sensoroberfläche haben kaum

Einfluss auf die Messgenauigkeit. Der Sensor

sind insbesondere zum Messen von hohen

Leitfähigkeiten bis 2000 mS/cm geeignet. Ein

freistehender Temperatursensor (Pt1000) mit

kurzer Ansprechzeit erfasst die Prozesstempe‐

ratur. Der Temperatursensor ist in einer Edel‐

stahlhülse geschützt. Durch den Temperatur‐

sensor (Pt1000) kann die Temperaturkorrektur

der Leitfähigkeitsmessung im angeschlossenen

Mess- und Regelgerät erfolgen.

Sie können die beiden Sensortypen auch in

verschmutzten Wässern oder in aggressiven

Medien einsetzen die sich gegenüber PVC/

EPDM bzw. PP/EPDM (ja nach Ausführung des

Sensors) chemisch inert verhalten.

1.1 Messprinzip

Die Messung der elektrolytischen Leitfähigkeit

erfolgt mit einen induktiven Sensor. Der Sensor

enthält im Sensorkopf eine Sende- und Emp‐

fangsspule. Eine Sinus-Wechselspannung

speist die Sendespule. In Abhängigkeit von der

Leitfähigkeit der zu messenden Flüssigkeit wird

ein Messstrom in die Empfangsspule induziert.

Der Messstrom ist proportional zur Leitfähigkeit

des Mediums.

Typische Anwendungsgebiete

Der Sensor ist vornehmlich für die Anwendung

in der Wasseraufbereitung und zur Wasserü‐

berwachung konzipiert, z. B.:

n verschmutzte Ab- und Brauchwasser

n Klima- und Kühlanlagen

n Absalzkontrolle in Kühltürmen,

n Spülbäder,

n Fahrzeugwaschanlagen,

n Meerwasserentsalzung (Zulauf),

n Schwimmbadwasserkontrolle.

40

Page 41

A2617

4

3

2

1

5

Einleitung

1.2 Aufbau und Funktion des Sensors

Der induktive Messwertaufnehmer der beiden Sensortypen ICT 5 und ICT 5-IMA besteht aus einem

hermetisch verschlossenen Körper aus Polypropylen (PP). Im Innerem des Messwertaufnehmers

befindet sich eine Sende- und eine Empfängerspule. Eine Durchflussöffnung in dem Sensor (Sen‐

sorauge) erlaubt die Durchströmung mit dem Messmedium. Bedingt durch das Messprinzip besteht

eine galvanische Trennung zwischen Messmedium und Signalausgang. Ein freistehender Tempera‐

tursensor (Pt1000) mit kurzer Ansprechzeit erfasst die Prozesstemperatur. Der Temperatursensor

ist in einer schützenden Edelstahlhülse integriert.

Abb. 1: Bauteile

1 Sensorkörper aus PP

2 Sendespule

3 Sensorauge, durchströmt vom Messme‐

dium

4 Empfängerspule

5 Temperatursensor, freistehend, integriert in

eine Edelstahlhülse

41

Page 42

A2641

Einleitung

Sensortyp ICT 5

Der Sensortyp ICT5 wird über eine Gewindebuchse und Überwurfmutter an ein Standard T-Stück

DN40 (bauseits) zum Betrieb im Durchfluss angebunden.

Abb. 2: Sensortyp ICT 5

1. Gewindebuchse G 1 1/2“ (PVC bzw.PP)

2. Überwurfmutter (PVC bzw. PP)

42

Page 43

A2642

Einleitung

Sensortyp ICT5-IMA

Der Sensortyp ICT5-IMA wird über das komplett montierte Tauchrohr (1 m) in Behälter und in

Gerinne eingetaucht.

Abb. 3: Sensortyp ICT 5-IMA

1. Festkabel, 10 m

2. Kabelverschraubung M16, Schutzart IP68

(bis 0,2 m)

3. PP

4. PP

43

Page 44

A2637

A2638

Einleitung

1.3 Typenschild

Die Zellenkonstante K wird für die Kalibrierung am Messumformer/Regler benötigt.

Abb. 4: Typenschild ICT5

Abb. 5: Typenschild ICT5-IMA

1.4 Lieferumfang

Lieferumfang Sensortyp ICT 5:

n Sensor Typ ICT 5, Bestellnummer

1095248

n Klebemuffe PVC zur Adaption des Sen‐

sors, an ein Standard-T-Stück DN40, PVC

(T-Stück nicht im Lieferumfang enthalten)

n Montage- und Betriebsanleitung

Lieferumfang Sensortyp ICT 5-IMA:

n Sensor Typ ICT 5-IMA, Bestellnummer

1095249

n Montage- und Betriebsanleitung

44

Page 45

2 Sicherheit und Verantwortung

2.1 Kennzeichnung der Warn‐

hinweise

Einleitung

Diese Betriebsanleitung beschreibt die techni‐

schen Daten und Funktionen des Produktes.

Die Betriebsanleitung gibt ausführliche Warn‐

hinweise und ist in klare Handlungsschritte auf‐

gegliedert.

Warnhinweise und Hinweise gliedern sich nach

dem folgenden Schema. Hierbei kommen ver‐

schiedene, der Situation angepasste, Piktogr‐

amme zum Einsatz. Die hier aufgeführten Pik‐

togramme dienen nur als Beispiel.

GEFAHR!

Art und Quelle der Gefahr

Folge: Tod oder schwerste Verlet‐

zungen.

Maßnahme, die ergriffen werden muss,

um diese Gefahr zu vermeiden.

Beschriebene Gefahr

– Bezeichnet eine unmittelbar dro‐

hende Gefahr. Wenn die Situation

nicht gemieden wird, sind Tod

oder schwerste Verletzungen die

Folge.

Sicherheit und Verantwortung

WARNUNG!

Art und Quelle der Gefahr

Mögliche Folge: Tod oder schwerste

Verletzungen.

Maßnahme, die ergriffen werden muss,

um diese Gefahr zu vermeiden.

– Bezeichnet eine möglicherweise

gefährliche Situation. Wenn die

Situation nicht gemieden wird,

können Tod oder schwerste Ver‐

letzungen die Folge sein.

VORSICHT!

Art und Quelle der Gefahr

Mögliche Folge: Leichte oder geringfü‐

gige Verletzungen. Sachbeschädigung.

Maßnahme, die ergriffen werden muss,

um diese Gefahr zu vermeiden.

– Bezeichnet eine möglicherweise

gefährliche Situation. Wenn die

Situation nicht gemieden wird,

können leichte oder geringfügige

Verletzungen die Folge sein. Darf

auch für Warnung vor Sach‐

schäden verwendet werden.

45

Page 46

Sicherheit und Verantwortung

HINWEIS!

Art und Quelle der Gefahr

Schädigung des Produkts oder seiner

Umgebung.

Maßnahme, die ergriffen werden muss,

um diese Gefahr zu vermeiden.

– Bezeichnet eine möglicherweise

schädliche Situation. Wenn die

Situation nicht gemieden wird,

kann das Produkt oder etwas in

seiner Umgebung beschädigt

werden.

Art der Information

Anwendungstipps und Zusatzinforma‐

tion.

Quelle der Information. Zusätzliche

Maßnahmen.

–

Bezeichnen Anwendungstipps und

andere besonders nützliche Infor‐

mationen. Es ist kein Signalwort

für eine gefährliche oder schäd‐

liche Situation.

46

Page 47

Sicherheit und Verantwortung

2.2 Benutzer-Qualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation des Personals

Der Betreiber der Anlage/des Gerätes ist für die Einhaltung der Qualifikationen verantwort‐

lich.

Wenn unqualifiziertes Personal Arbeiten an dem Gerät vornimmt oder sich im Gefahrenbe‐

reich des Gerätes aufhält, entstehen Gefahren, die schwere Verletzungen und Sachschäden

verursachen können.

– Alle Tätigkeiten nur durch dafür qualifiziertes Personal durchführen lassen.

– Unqualifiziertes Personal von den Gefahrenbereichen fernhalten.

Die einschlägigen Unfallverhütungsvorschriften sowie die sonstigen allgemein anerkannten

sicherheitstechnischen Regeln einhalten.

Ausbildung Definition

unterwiesene Person Als unterwiesene Person gilt, wer über die übertragenen Aufgaben und

möglichen Gefahren bei unsachgemäßem Verhalten unterrichtet und

erforderlichenfalls angelernt, sowie über die notwendigen Schutzein‐

richtungen und Schutzmaßnahmen belehrt wurde.

geschulter Anwender Als geschulter Anwender gilt, wer die Anforderungen an eine unterwie‐

sene Person erfüllt und zusätzlich eine anlagenspezifische Schulung

bei dem Hersteller oder einem autorisierten Vertriebspartner erhalten

hat.

ausgebildete Fachkraft Als ausgebildete Fachkraft gilt, wer aufgrund seiner Ausbildung, Kennt‐

nisse und Erfahrungen sowie Kenntnis der einschlägigen Bestim‐

mungen die ihm übertragenen Arbeiten beurteilen und mögliche

Gefahren erkennen kann. Eine ausgebildete Fachkraft muss in der

Lage sein, die ihr übertragenen Arbeiten unter Zuhilfenahme von Zeich‐

nungsdokumentation und Stücklisten selbständig durchzuführen. Zur

Beurteilung der fachlichen Ausbildung kann auch eine mehrjährige

Tätigkeit auf dem betreffenden Arbeitsgebiet herangezogen werden.

47

Page 48

Sicherheit und Verantwortung

Ausbildung Definition

Elektrofachkraft Die Elektrofachkraft ist aufgrund ihrer fachlichen Ausbildung, Kennt‐

nisse und Erfahrungen sowie Kenntnis der einschlägigen Normen und

Bestimmungen in der Lage, Arbeiten an elektrischen Anlagen auszu‐

führen und mögliche Gefahren selbstständig zu erkennen und zu ver‐

meiden. Eine Elektrofachkraft muss in der Lage sein, die ihr übertra‐

genen Arbeiten unter Zuhilfenahme von Zeichnungsdokumentation,

Stücklisten, Klemmen- und Schaltplänen selbständig durchzuführen.

Die Elektrofachkraft ist speziell für das Arbeitsumfeld, in dem die Elekt‐

rofachkraft tätig ist, ausgebildet und kennt die relevanten Normen und

Bestimmungen.

Kundendienst Als Kundendienst gelten Servicetechniker, die von dem Hersteller für

die Arbeiten an der Anlage nachweislich geschult und autorisiert

wurden.

2.3 Allgemeine Sicherheitshin‐

weise

WARNUNG!

Unbefugter Zugriff!

Mögliche Folge: Tod oder schwerste

Verletzungen

– Maßnahme: Sichern Sie das Gerät

gegen unbefugten Zugriff

– Der Sensor darf nur durch hierfür

ausgebildetes Personal montiert,

installiert, gewartet und betrieben

werden

VORSICHT!

Funktionseinschränkung

Mögliche Folge: Leichte oder geringfü‐

gige Verletzungen. Sachbeschädigung

– Den Sensor regelmäßig auf Ver‐

unreinigungen überprüfen

– Die gültigen nationalen Vor‐

schriften für Pflege-, Wartungsund Kalibrierintervalle einhalten

48

Page 49

2.4 Bestimmungsgemäße Ver‐

wendung

n Der Sensor darf nur zum Messen und

Regeln der elektrolytischen Leitfähigkeit in

wässrigen Medien, der in dieser Betriebs‐

anleitung beschriebenen Anwendungen

verwendet werden.

n Alle anderen Verwendungen oder ein

Umbau sind verboten.

n Der Sensor ist kein Sicherheitsbauteil im

Sinne der DIN EN ISO 13849-1:2008-12.

Sollte es sich bei Ihren Mess- und Regel‐

kreis um einen kritischen Prozess handeln,

dann liegt es in Ihrer Verantwortung

diesen Prozess abzusichern.

2.5 Angaben für den Notfall

n Im Notfall den Regler spannungsfrei

machen

n Falls aus der Durchlaufarmatur Flüssigkeit

austritt, die bauseitig installierten Absperr‐

hähne am Zu- und Ablauf schließen

n Vor dem Öffnen der Durchlaufarmatur die

Sicherheitshinweise des Anlagenbetrei‐

bers beachten

Sicherheit und Verantwortung

49

Page 50

So lagern und transportieren Sie den Sensor

3 So lagern und transportieren Sie den Sensor

Originalverpackung

Benutzer-Qualifikation: unterwiesene Person,

siehe

Ä Kapitel 2.2 „Benutzer-Qualifikation“

auf Seite 47

Schädigung des Produkts.

n Transportieren, versenden und lagern Sie

den Sensor nur in der Originalverpackung.

n Bewahren Sie die Verpackung komplett

mit den Styroporteilen auf.

3.1 Lagerung

Lager- und Transporttemperatur:

n kompletter Sensor -20 °C ... 75 °C.

Feuchtigkeit: maximal 90 % relative Luftfeuch‐

tigkeit, nicht kondensierend.

Sonstige: Kein Staub, kein direktes Sonnen‐

licht.

3.2 Transport

Der Transport sollte in der Originalverpackung

und innerhalb der zulässigen Umweltbedin‐

gungen erfolgen. Weitere Besonderheiten sind

beim Transport nicht zu beachten.

50

Page 51

4 Montage und Installation

n Benutzer-Qualifikation, mechanische Mon‐

tage: ausgebildete Fachkraft

„Benutzer-Qualifikation“ auf Seite 47

n Benutzer-Qualifikation, elektrische Installa‐

tion: Elektrofachkraft

„Benutzer-Qualifikation“ auf Seite 47

WARNUNG!

Gefährdung durch einen Gefahrstoff!

Mögliche Folge: Tod oder schwerste

Verletzungen.

Beachten Sie beim Umgang mit

Gefahrstoffen, dass die aktuellen

Sicherheitsdatenblätter der GefahrstoffHersteller vorliegen. Die notwendigen

Maßnahmen ergeben sich aus dem

Inhalt des Sicherheitsdatenblatts. Da

aufgrund neuer Erkenntnisse, das

Gefährdungspotenzial eines Stoffes

jederzeit neu bewertet werden kann, ist

das Sicherheitsdatenblatt regelmäßig

zu überprüfen und bei Bedarf zu

ersetzen.

Für das Vorhandensein und den aktu‐

ellen Stand des Sicherheitsdatenblatts

und die damit verbundene Erstellung

der Gefährdungsbeurteilung der betrof‐

fenen Arbeitsplätze ist der Anlagenbe‐

treiber verantwortlich.

Ä Kapitel 2.2

Ä Kapitel 2.2

Montage und Installation

Achten Sie auf eine gute Durch- und Umströ‐

mung des Sensors.

Halten Sie beim Einbau in eine Rohrleitung

einen Mindestabstand von 20 mm vom Sensor

zur Rohrwandung ein.

Wenn Sie diese Mindestabstände nicht ein‐

halten können, dann kann mit dem Parameter

„Einbaufaktor“ ein begrenzter Ausgleich

erreicht werden.

Beim Eintauchbetrieb in Becken müssen Sie

einen für die typische Leitfähigkeit bzw. Kon‐

zentration repräsentativen Einbauort vorsehen.

Montageort

Achten Sie auf eine leichte Zugänglichkeit für

die spätere Kalibrierung.

Die Befestigung muss sicher und vibrationsarm

sein.

Vermeiden Sie direkte Sonneneinstrahlung.

51

Page 52

1

1

3

2

A2618

Montage und Installation

4.1 Montage des Sensortyps ICT 5

Einbaulage

Sie können den Sensor in jeder Winkelorientierung (0 ... 360°) betreiben. Der Sensor wird bezüglich

seiner Anströmung und den Mindestabständen von Wandungen, wie in Abb. 6 gezeigt, in ein DN40

Standard-T-Stück eingebaut.

Abb. 6: Einbaulage des Sensorstyps ICT5 im T Stück (DN40)

1 ≧ 20 mm

2 Strömungsrichtung

3 Sensor

52

Page 53

Hydraulische Einbausituation

A2619

Beachten Sie die in Abb. 7 gezeigte hydraulische Einbausituation.

Unbedingt vermeiden:

n Bildung von Gasblasen

n Trockenlaufen

n Strömungsabrisse

n Verwirbelungen

Montage und Installation

Abb. 7: Hydraulische Einbausituation / Haken = OK, Kreuz = NOK

53

Page 54

A2639

5

4

3

2

1

Montage und Installation

Einkleben der Klebemuffe in ein T-Stück

Montage des Sensortyps ICT5 in einer Verrohrung aus PVC. Sie können den Sensor in ein PVC-TStück einbauen, unter Verwendung der mitgelieferten PVC-Klebemuffe

Farbe Material

Beige PP

Grau PVC

Verwenden Sie für die zu verklebenden Materialien geeignete und medienbeständige Kleber.

Abb. 8: Sensor und Klebemuffe in Standard-T-Stück

1. Kleben Sie die beiliegende Klebemuffe (2) in ein Standard-T-Stück (3) (bauseits) ein.

Halten Sie dazu den Mindestabstand zu den Wandungen ein.

54

Page 55

Montage und Installation

Richten Sie dazu die Klebemuffe so aus, dass das Messmedium durch das Sensorauge (5)

fließt.

Richten Sie dazu die Führungszapfen (1) des Klebestutzens in Durchflussrichtung zum TStück aus.

Montage des Sensortyps ICT5 in einer Verrohrung aus Polypropylen (PP)

2. Sie können den Sensor direkt in das optional erhältliche PP-T-Stück einbauen (Bestell‐

nummer 1096349, nicht im Lieferumfang). Das PP-T-Stück enthält bereits den Sensora‐

dapter.

Montage des Sensors in das T-Stück

3. Setzen Sie den Sensor (5) so in das T-Stück ein, dass die Nut (4) am Sensorschaft in den

Führungszapfen des Sensoradapters greift.

4. Schrauben Sie die Überwurfmutter per Hand fest auf das Gewinde des Sensoradapters auf.

5. Überprüfen Sie die Dichtigkeit.

4.2 Montage des Sensortyps ICT 5-IMA

Einbauort

Der Messwertaufnehmer des Sensortyps ICT

5-IMA ist vollständig in das Eintauchrohr integ‐

riert. Das Eintauchrohr kann entweder über die

vorhandenen Bohrungen oder mit Rohrschellen

(bauseits) an einen Behälter oder an ein

Gerinne angebunden werden.

Wählen Sie einen für die repräsentative Probe‐

messung einen geeigneten Installationspunkt.

55

Page 56

Montage und Installation

4.3 Elektrische Installation

Sie dürfen das Anschlusskabel nicht kürzen oder mechanisch beschädigen.

Nach dem Anschluss müssen Sie den induktiven Leitfähigkeits- und Temperatursensor

kalibrieren.

Tab. 2: Klemmenzuordnung, Dulcometer Compact

Klemme Funktion Sensor ICT5 Leiterfarben

X1.1 Sendespule, Signal

X1.2 Sendespule, Signal, Erde

X2.1 Empfangsspule, Signal

X2.2 Empfangsspule, Signal, Erde Kabelabschirmung für X2.1, trans‐

XE2.2 Masse Kabelabschirmung gesamt,

XE4.1 Pt100x

XE4 Pt100x

Die Bezeichnungen der Klemmen beziehen sich auf das ProMinent-Mess-/Regelgerät, Typ DCCa.

Die Angaben der Farben beziehen sich auf die Adern der fest installierten Datenleitung des Sen‐

sors.

Verbinden Sie die Datenleitung mit den Klemmen Ihres ProMinent-Mess-/Regelgerät, Typ DCCa.

Beachten Sie hierbei die entsprechende Betriebsanleitung

Verbinden Sie die Datenleitung mit den Klemmen Ihres Mess-/Regelgerätes. Beachten Sie

hierbei die Betriebsanleitung Ihres Mess-/Regelgerätes

[bn]

, Braun

[ws]

, Weiß

[pk]

, Pink

parent

schwarz

[gn]

Grün

[ge]

Gelb

56

Page 57

Montage und Installation

Tab. 3: Allgemeine Zuordnung für weitere Mess-/Regelgeräte

Funktion Sensor ICT5 Leiterfarben

Sendespule, Signal

Sendespule, Signal, Erde

Empfangsspule, Signal

Empfangsspule, Signal, Erde Kabelabschirmung für X2.1, transparent

Masse Kabelabschirmung gesamt, schwarz

Pt100x

Pt100x

Verbinden Sie die Datenleitung mit den Klemmen Ihres Mess-/Regelgerätes. Beachten Sie

hierbei die Betriebsanleitung Ihres Mess-/Regelgerätes

[bn]

[ws]

[pk]

[gn]

[ge]

, Braun

, Weiß

, Pink

Grün

Gelb

57

Page 58

Wartung

5 Wartung

WARNUNG!

Gefährdung durch einen Gefahrstoff!

Mögliche Folge: Tod oder schwerste

Verletzungen.

Beachten Sie beim Umgang mit

Gefahrstoffen, dass die aktuellen

Sicherheitsdatenblätter der GefahrstoffHersteller vorliegen. Die notwendigen

Maßnahmen ergeben sich aus dem

Inhalt des Sicherheitsdatenblatts. Da

aufgrund neuer Erkenntnisse, das

Gefährdungspotenzial eines Stoffes

jederzeit neu bewertet werden kann, ist

das Sicherheitsdatenblatt regelmäßig

zu überprüfen und bei Bedarf zu

ersetzen.

Für das Vorhandensein und den aktu‐

ellen Stand des Sicherheitsdatenblatts

und die damit verbundene Erstellung

der Gefährdungsbeurteilung der betrof‐

fenen Arbeitsplätze ist der Anlagenbe‐

treiber verantwortlich.

3. Sollten Messwertabweichungen unbe‐

kannter Ursache auftreten, müssen Sie

die komplette Messkette (Sensor,

Anschlussleitung und Messumformer/

Regler) überprüfen,

Ä Kapitel 6 „Fehler

und Störungen beheben“ auf Seite 59

.

HINWEIS!

Lösungsmittel

Verwenden Sie für die Reinigung des

Sensors keine flüchtigen organischen

Lösungsmittel, sondern ausschließlich

Wasser als Lösungsmittel.

1. Reinigen Sie den Sensor mit Wasser

und einer weichen Bürste.

2. Hartnäckige Beläge bzw. Ablagerungen

können Sie z. B. mit verdünnter Salz‐

säure anlösen und mit einer weichen

Bürste entfernen.

58

Page 59

Fehler und Störungen beheben

6 Fehler und Störungen beheben

Problem mögliche Ursache Maßnahme

Keine Messwertanzeige bzw.

Signalausgang

Messwertanzeige 000 bzw.

Signalausgang 0 % (z. B.

4 mA)

Falsche oder schwankende

Messwertanzeige

Spannungsversorgung fehlt Spannungsversorgung prüfen,

Klemmen überprüfen

Sensor nicht in Medium einge‐

taucht; Behälterniveau zu

niedrig

Durchflussarmatur verstopft Durchflussarmatur reinigen

Sensor defekt

Sensor nicht tief genug einge‐

taucht

keine Durchmischung für gute Durchmischung

Luftblasen Einbauhinweise beachten

Behälter auffüllen

Behälter auffüllen

sorgen, beim Sensor auf all‐

seitig ca. 18 mm freie Umspü‐

lung achten

59

Page 60

Altteileentsorgung

7 Altteileentsorgung

n Benutzer-Qualifikation: unterwiesene

Person, siehe

Qualifikation“ auf Seite 47

HINWEIS!

Vorschriften Altteileentsorgung

– Beachten Sie die zurzeit für Sie

gültigen nationalen Vorschriften

und Rechtsnormen

Der Hersteller nimmt die dekontaminierten Alt‐

geräte bei ausreichender Frankierung der Sen‐

dung zurück.

Bevor Sie das Gerät einschicken, müssen Sie

das Gerät dekontaminieren. Dazu müssen Sie

alle Gefahrenstoffe restlos entfernen. Beachten

Sie dazu das Sicherheitsdatenblatt ihres

Dosiermediums.

Eine aktuelle Dekontaminationserklärung steht

als Download auf der Homepage zur Verfü‐

gung.

Ä Kapitel 2.2 „Benutzer-

Hinweis auf Sammelsystem EU

Dieses Gerät ist entsprechend der europä‐

ischen Richtlinie 2012/19/EU über Elektro- und

Elektronik-Altgeräte mit dem Symbol der durch‐

gestrichenen Mülltonne gekennzeichnet. Das

Gerät darf nicht über den Hausmüll entsorgt

werden. Nutzen Sie für die Rückgabe die Ihnen

zur Verfügung stehenden Rückgabe- und Sam‐

melsysteme und beachten Sie die örtlichen

gesetzlichen Vorgaben.

60

Page 61

Zubehör

8 Zubehör

Bezeichnung Teile‐

nummer

Klebemuffe (PVC) + O-Ring, zum Einbau des Sensortyps ICT5 in ein PVC T-Stück

DN40

Überwurfmutter G 1 1/2", PVC 1096351

T-Stück aus PP, DN40 mit integriertem Sensoradapter* 1096349

Überwurfmutter G 1 1/2", PP 1096353

* Mit Verdrehsicherung; der Sensor kann nur in der richtigen Ausrichtung eingebaut werden.

1096348

61

Page 62

Technische Daten

9 Technische Daten

9.1 Allgemeine Daten

Parameter ICT 5 ICT 5-IMA

Ausführung Für Betrieb im Durchfluss Für Eintauchen

Messprinzip induktiv

Messbereich 0 ... 2000 mS/cm

Genauigkeit bei Messbereich

0 ... 1 mS/cm ≤ 1 %

0 ... 10 mS/cm ≤ 0,5 %

0 ... 50 mS/cm ≤ 0,5 %

0 ... 100 mS/cm ≤ 0,5 %

0 ... 1000 mS/cm ≤ 1 %

0 ... 2000 mS/cm ≤ 1 %

Zellenkonstante k = 6,25 1/cm

Temperatursensor Pt1000, Klasse A

t90 Temperatur

zulässige Umgebungstemperatur -10 ... +60 °C

zulässige Lagertemperatur -20 ... +75 °C

Schutzart

zulässige Mediumstemperatur bei

Betrieb in Rohrleitungen aus:

maximaler Prozessdruck bei Ausführung PP

bei 20 °C 10 bar 0 bar

bei 60 °C 6 bar 0 bar

bei 80 °C 0 bar

a

b

PVC: -10 ... +60 °C

PP: -10 ... +80 °C

≤ 6 Sekunden

IP68

-10 ... +60 °C

62

Page 63

Technische Daten

Parameter ICT 5 ICT 5-IMA

bei -10 ... +80 °C minimal -0,1 bar minimal -0,1 bar

Sensorwerkstoff, medienberührt

Sensorkörper PP

Schutzhülse, Temperaturfühler Edelstahl 1.4571

Dichtung EPDM

Elektrischer Anschluss Festkabel, 10 m, PUR, Litze

Kabelverschraubung M16, PBT/PA

Länge der Eintaucharmatur 1000 mm

a

DIN EN 60751

b

DIN EN 60529

9.2 Zulassungen/Prüfzeichen

Die vom Messmedium berührten Materialien

sind für Lebensmittel zugelassen, physiologisch

unbedenklich und von der FDA gelistet.

63

Page 64

0

8

0

4

2

10

50403020

10

0-10 60 70 80

I

II

A2624

Technische Daten

9.3 Zulässiger Prozessdruck

Temperatur, Druck und Messmedium beeinflussen die Lebensdauer des Sensors.

Abb. 9: Zulässiger Prozessdruck Typ ICT 5 montiert in PP-Rohrleitungen

I Druck in bar.

II Temperatur in °C.

64

Page 65

10 Abmessungen

I. II. III. IV.

Ø40

Ø44,5

Ø40

22

21

120 ± 10

EL

A2620

Abb. 10: Abmessungen, alle Maße in mm. Typ ICT 5-IMA... Eintauchversion

I Festkabel, 10 m

II Kabelverschraubung M16, Schutzart IP68

(bis 0,2 m), PBT/PA

III PP

IV Edelstahl 1.4301, AISI 304

Abmessungen

65

Page 66

I.

II.

145

~81

118

36,5

A2622

Ø41

Ø44,5

67

Abmessungen

Abb. 11: Abmessungen, alle Maße in mm. Typ ICT 5

I Kabelverschraubung M16, Schutzart IP68

(bis 0,2 m), PBT/PA

II PP

66

Page 67

ProMinent GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telefon: +49 6221 842-0

Telefax: +49 6221 842-215

E-Mail: info@prominent.com

Internet: www.prominent.com

982358, 1, de_DE

© 2018

Page 68

ProMinent GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

Email: info@prominent.com

Internet: www.prominent.com

982358, 1, en_GB

© 2018

Loading...

Loading...