Page 1

Operating Instructions

DULCOMETER® DMT

On-site measurement transducer

Measured variables pH/redox/temperature

®

ProMinent

DMTa

The operator shall be liable for any damage caused by installation or operating errors!

Part no. 987426 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany BA DM 163 03/08 GB

___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Please enter the identity code of the device here.

Please read the operating instructions through completely before

commissioning this equipment! Do not discard!

Page 2

Publishing details

Publishing details:

Operating Instructions

DULCOMETER

®

DMT on-site measurement transducer

Measured variables pH/redox/temperature

© ProMinent Dosiertechnik GmbH, 2000

Address:

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

info@prominent.com

www.prominent.com

Subject to technical alterations.

Page 2

ProMinent

®

Page 3

Table of contents

Table of contents

Device identification/identity code: measured variable pH.......................... 5

Device identification/identity code: measured variable redox ..................... 6

Device identification/identity code: measured variable temperature .......... 7

1 General instructions for use ............................................................ 8

2 Safety .................................................................................................. 9

2.1 Correct use ............................................................................ 9

2.2 Safety guidelines ................................................................... 9

3 Storage and transport ...................................................................... 9

4 Assembly and installation ................................................................ 10

4.1 Assembly (mechanical) ......................................................... 10

4.1.1 Wall mounting ........................................................................ 10

4.1.2 Pipe mounting ........................................................................ 11

4.1.3 Panel mounting ...................................................................... 12

4.2 Installation (electrical) ........................................................... 13

4.2.1 Wall mounting ........................................................................ 14

4.2.2 Pipe mounting ........................................................................ 15

4.2.3 Panel mounting ...................................................................... 15

4.2.4 Connecting coaxial cable ...................................................... 16

4.2.5 Connecting terminals ............................................................. 16

5 Device overview and control elements .......................................... 17

6 Function description ......................................................................... 18

6.1 General .................................................................................. 18

6.2 Key functions ......................................................................... 19

6.3 Operating menu, schematic .................................................. 19

6.4 Negotiating operating menu ................................................. 20

6.4.1 Calibration menu (pH only) .................................................... 21

6.4.2 Info display ............................................................................ 21

6.4.3 Menu options ......................................................................... 21

6.4.4 Negotiating the menu options ............................................... 21

7 DMT settings ...................................................................................... 22

7.1 Measured variables pH and redox........................................ 23

ProMinent

®

Page 3

Page 4

Table of contents

8 Operating the DMT ............................................................................ 38

7.1.1 Menu overview: measured variable pH ................................ 23

7.1.2 Menu overview: measured variable redox ............................ 24

7.1.3 Parameter settings (pH only) ................................................ 25

7.1.4 Checking the ORP probe (redox only) .................................. 25

7.1.5 Parameters: Temperature ...................................................... 26

7.1.6 Parameter output .................................................................. 28

7.1.7 General settings .................................................................... 31

7.2 Measured variable temperature ............................................ 33

7.2.1 Menu overview measured variable, temperature ................. 33

7.2.2 Parameters temperature ....................................................... 34

7.2.3 Parameter output .................................................................. 34

7.2.4 General settings .................................................................... 36

8.1 Permanent display ................................................................ 38

8.1.1 Probe condition information (pH only) ................................... 38

8.1.2 Brightness of LC display ........................................................ 39

8.2 Calibrating the pH meter ....................................................... 39

8.2.1 Automatic buffer detection .................................................... 39

8.2.2 The calibration process ......................................................... 40

9Troubleshooting ................................................................................. 44

9.1 Error messages during operation ......................................... 44

9.2 Error messages while calibrating the pH meter ................... 45

10 Maintenance and repair .................................................................... 46

11 Disposal .............................................................................................. 46

12 Technical data .................................................................................... 47

13 Spare parts and accessories ........................................................... 48

Appendix ............................................................................................. 49

Conformity declarationdeclaration ...................................................... 49

Terminal connection plan pH/redox/temperature ................................ 50

Wiring example - two wire system ....................................................... 51

PROFIBUS

Index .................................................................................................... 53

Page 4

®

circuit board terminal connection ................................... 52

ProMinent

®

Page 5

Device identification/identity code: measured variable pH

DMTa DULCOMETER® DMT series measurement transducer

Mounting type

W wall/pipe mounted

S control panel mounted (not PROFIBUS®-DMT)

Version

0 with ProMinent logo

Electrical connection

9 4-20 mA (two wire) current loop, 24 V DC (16...40 V DC)

5 PROFIBUS®-DP, 24 V DC (16...30 V DC)

Communication interface

0 none

4 PROFIBUS®-DP

Measured variable

PpH

R redox (ORP)

T temperature

Correction variable

1 temperature (PT 1000/PT 100)

Enclosure rating

0 standard

Adjustable general settings:

Language

D German

E English

F French

P Polish

S Spanish

IItalian

Automatic buffer detection

0 ProMinent buffer set

D DIN 19226 buffer set

V automatic buffer adjustment

Temperature measurement

0 automatic

(PT 1000 or PT 100)

1 manual

2 automatic or manual

9 none

0 measured variable

1 manually adjustable

2 measured variable or manual

3 measured variable or manual

44 mA constant current

Output

(fault: 23 mA, calibration: 23 mA)

current value

(fault: 23 mA, calibration: 23 mA)

(fault: 23 mA, calibration: HOLD)

Other settings

0 standard

DMTa 0 P 1 0 0

Please enter the identity code for your device here.

ProMinent

®

Page 5

Page 6

Device identification/identity code: measured variable redox

DMTa DULCOMETER® DMT series measurement transducer

Mounting type

W wall/pipe mounted

S control panel mounted (not PROFIBUS®-DMT)

Version

0 with ProMinent logo

Electrical connection

9 4-20 mA (two wire) current loop, 24 V DC (16...40 V DC)

5 PROFIBUS®-DP, 24 V DC (16...30 V DC)

Communication interface

0 none

4 PROFIBUS®-DP

Measured variable

R redox

PpH

T temperature

Correction variable

1 temperature (PT 1000/PT 100) - measurement only

Enclosure rating

0 standard

Adjustable general settings:

Language

D German

E English

F French

P Polish

S Spanish

IItalian

Probe type

0 standard

Temperature measurement

0 automatic

(PT 1000 or PT 100)

9 none

0 measured variable

1 manually adjustable

2 measured variable or manual

3 measured variable or manual

44 mA constant current

Output

(fault: 23 mA, calibration: 23 mA)

current value

(fault: 23 mA, calibration: 23 mA)

(fault: 23 mA, calibration: HOLD)

Other settings

0 standard

DMTa 0 R 1 0 0 0

Please enter the identity code for your device here.

Page 6

ProMinent

®

Page 7

Device identification/identity code: measured variable temperature

DMTa DULCOMETER® DMT series measurement transducer

Mounting type

W wall/pipe mounted

S control panel mounted (not PROFIBUS®-DMT)

Version

0 with ProMinent logo

Electrical connection

9 4-20 mA (two wire) current loop, 24 V DC (16...40 V DC)

5 PROFIBUS®-DP, 24 V DC (16...30 V DC)

Communication interface

0 none

4 PROFIBUS®-DP

Measured variable

PpH

R redox (ORP)

T temperature

Correction variable

0 none

Enclosure rating

0 standard

Adjustable general settings:

Language

D German

E English

F French

P Polish

S Spanish

IItalian

Probe type

0 PT 100 or PT 1000

Temperature detection

0 Probe (PT 1000 or PT 100)

0 Output: measured variable

1 Output adjustable

2 measured variable or adjustable

3 measured variable + manual + HOLD

4 Output current = 4 mA

Output current

(fault: 23 mA, calibration: 23 mA)

(fault: 23 mA, calibration: 23 mA)

(fault: 23 mA, calibration: HOLD)

Other settings

0 standard

DMTa 0 T 0 0 0 0 0

Please enter the identity code for your device here.

ProMinent

®

Page 7

Page 8

General instructions for use

1 General instructions for use

Please read through these instructions for use carefully. They will enable you

to make the best possible use of this operating instructions manual.

The following sections are highlighted in the text:

• Enumerated points

왘 Instructions

Working instructions

NOTE

Guidelines are intended to make your work easier.

and safety instructions:

CAUTION

Describes a potentially dangerous situation.

Non-observance can lead to personal injury or damage

to property.

IMPORTANT

Describes a potentially dangerous situation.

Non-observance can lead to damage to property.

Page 8

ProMinent

®

Page 9

Safety / Storage and transport

2 Safety

2.1 Correct use

The DMT on-site measurement transducer is designed exclusively for the

• measurement of pH value resp. redox potential

• measurement of temperature

• display of measured variables

•production of an output signal

It is prohibited to use the device for any other applications or to modify it

in any way!

The device must not be used outdoors without added protection (housing,

weatherproof cover).

2.2 Safety guidelines

CAUTION

• The device must not be used in a possible explosion

area.

• The DMT must be operated by trained and authorised

personnel.

IMPORTANT

• The system must be suitably equipped and configured to

prevent overdosing of hazardous materials due to probe

failure.

• The DMT has no on/off switch. It starts to function as soon

as it is connected to a power supply.

3 Storage and transport

Store and transport the DMT in the original packaging.

IMPORTANT

• Protect the DMT from damp and the effects of chemicals

even when packed.

Ambient conditions for storage and transport:

Temperature: -20 °C to 70 °C

Humidity: max. 95 % relative humidity,

ProMinent

®

non condensing

Page 9

Page 10

Assembly and installation

4 Assembly and installation

IMPORTANT

• The DMT is fully resistant to normal environments control

rooms.

• The DMT must not be placed where it can come into

contact with rain or direct sunlight!

Use a protective housing or weatherproof cover if in use

out of doors.

4.1 Assembly (mechanical)

The DMT can be wall, pipe or panel mounted (not for PROFIBUS®-DMT).

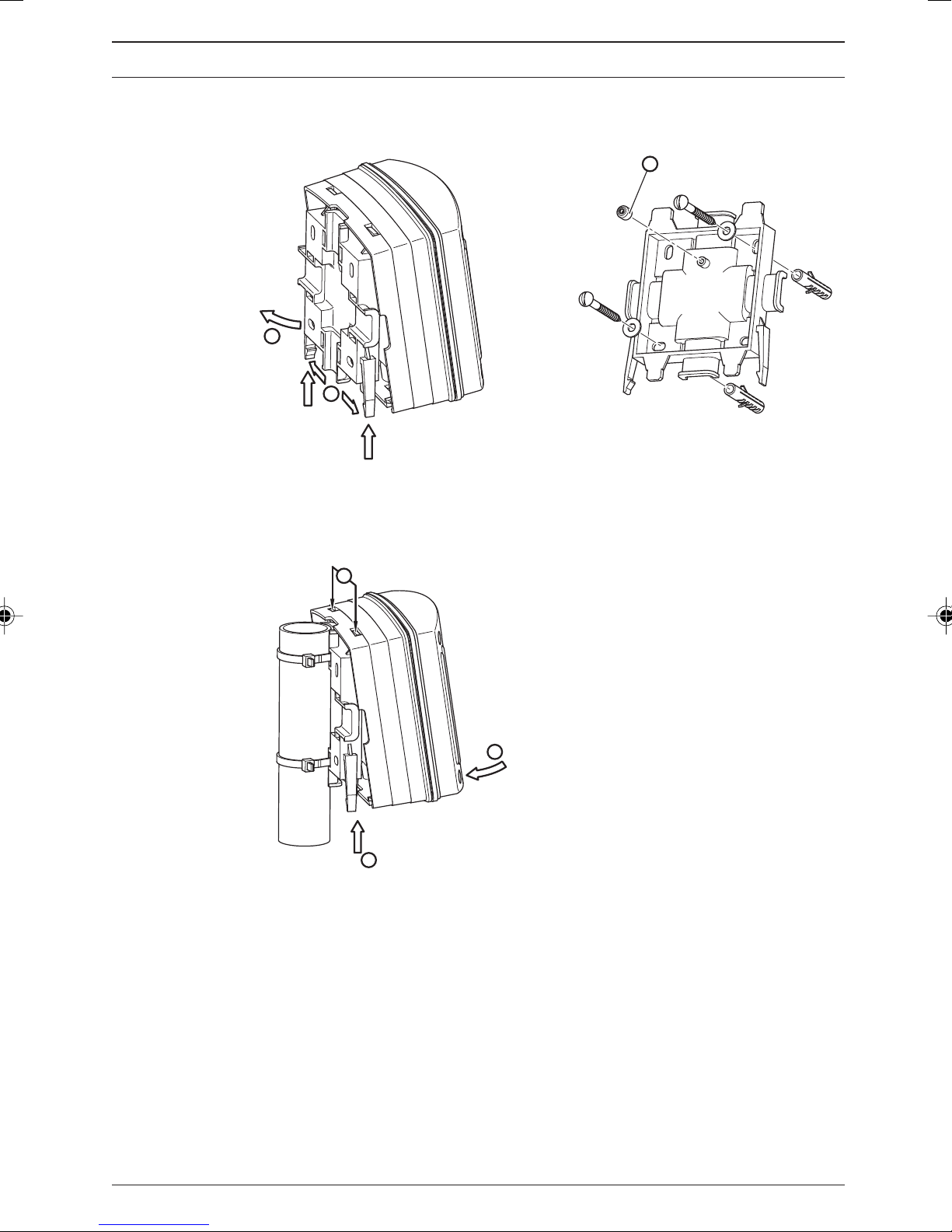

4.1.1 Wall mounting

Mounting materials (included in delivery):

1 x wall/pipe bracket

2 x 5x45 mm round headed screws

2 x 5.3 washers

2 x wall plugs Ø 8 mm, plastic

1 x rubber insert

1 x locking screw (PT)

Wall mounting, please follow the steps below:

왘 Remove wall/pipe bracket from DMT:

pull the two snap fasteners outwards and push upwards (fig. 1, ➀).

Swing the wall/pipe bracket away from the DMT and pull downwards

(fig. 1, ➁).

왘 Mark two drill holes diagonally opposite one another using the mounting

bracket as a template.

왘 Drill the holes: Ø 8 mm, depth = 50 mm.

왘 Screw the wall/pipe bracket in place inserting the washers (fig. 2).

왘 If the DMT is also to be secured with a screw, pierce the screw hole in the

back of the housing (housing must be open) and attach a rubber insert

(fig. 2, ➀) to the bracket.

왘 Hang the DMT onto the top of the bracket (fig. 3, ➀) and push down

gently against the bracket (fig. 3, ➁), then push upwards until you hear

a click (fig. 3, ➂).

왘 Tighten the locking screw to secure more firmly (housing is open).

Page 10

ProMinent

®

Page 11

Assembly and installation

Fig. 1 Fig. 2

2

1

3515_4

1

3461_4

Fig. 3

1

2

3

3464_4

4.1.2 Pipe mounting

Mounting materials (included in delivery):

1 x wall/pipe bracket

2 x cable ties

1 x sealing cap

1 x locking screw (PT)

Can be mounted onto pipes of diameters from 25 mm to 60 mm.

ProMinent

®

Page 11

Page 12

Assembly and installation

Pipe mounting, please follow the steps below:

왘 Remove wall/pipe bracket from DMT:

pull the two snap fasteners outwards and push upwards (fig. 1, ➀).

Swing the wall/pipe bracket away from the DMT and pull downwards

(fig. 1, ➁).

왘 Fasten the bracket to the pipe using the cable ties or pipe clamps (fig. 3).

왘 If the DMT is also to be secured with a screw, pierce the screw hole in the

back of the housing (housing must be open) and attach a rubber insert

(fig. 2, ➀) to the bracket.

왘 Hang the DMT onto the top of the bracket (fig. 3, ➀) and push down

gently against the bracket (fig. 3, ➁), then push upwards until you hear a

click (fig. 3, ➂).

왘 Tighten the locking screw to secure more firmly (housing is open).

4.1.3 Panel mounting

Fig. 4

IMPORTANT

• The control panel must be thick enough to withstand the

weight of the mounted DMT without buckling. (To achieve

enclosure rating IP 54, steel must be at least 2 mm thick;

plastic should be correspondingly thicker).

NOTE

The DMT will protrude from the control panel approx. 30 mm

once mounted.

Page 12

3463_4

ProMinent

®

Page 13

Assembly and installation

Panel mounting, please follow the steps below:

왘 Decide on the exact position of the DMT on the panel using the drill

template.

왘 Centre punch the holes for the screws and cut-out through the drilling

template.

왘 Drill the four screw holes with a Ø 3.5 mm diameter drill bit.

왘 Punch out the cut-out or drill the four inner holes using an Ø 8 mm

diameter drill bit and pierce out the cut-out with a keyhole saw.

CAUTION

Sharp edges can cause injury.

왘 File off cut edges.

왘 Insert the profile seal into the groove provided on the DMT.

왘 Place the DMT onto the cut-out and screw in place.

IMPORTANT

Check that the seal is located correctly.

IP 54 is only achieved when assembly has been carried out

correctly.

4.2 Installation (electrical)

IMPORTANT

• Installation must be carried out by specially trained

personnel.

• Installation can only be carried out after assembly has been

completed.

• The device must be connected to a protective low voltage

in accordance with EN 60335-1.

• Observe the relevant technical data in chapter 12

throughout installation procedures.

• The current loop must be disconnected from the power

supply during installation.

• The DMT signal cable must not be laid next to leads subject

to high levels of interference. Can lead to malfunction of

DMT.

• The hinge between the front and back sections of the

housing is not particularly strong. When working on the

front section it should be held securely in place.

ProMinent

®

Page 13

Page 14

Assembly and installation

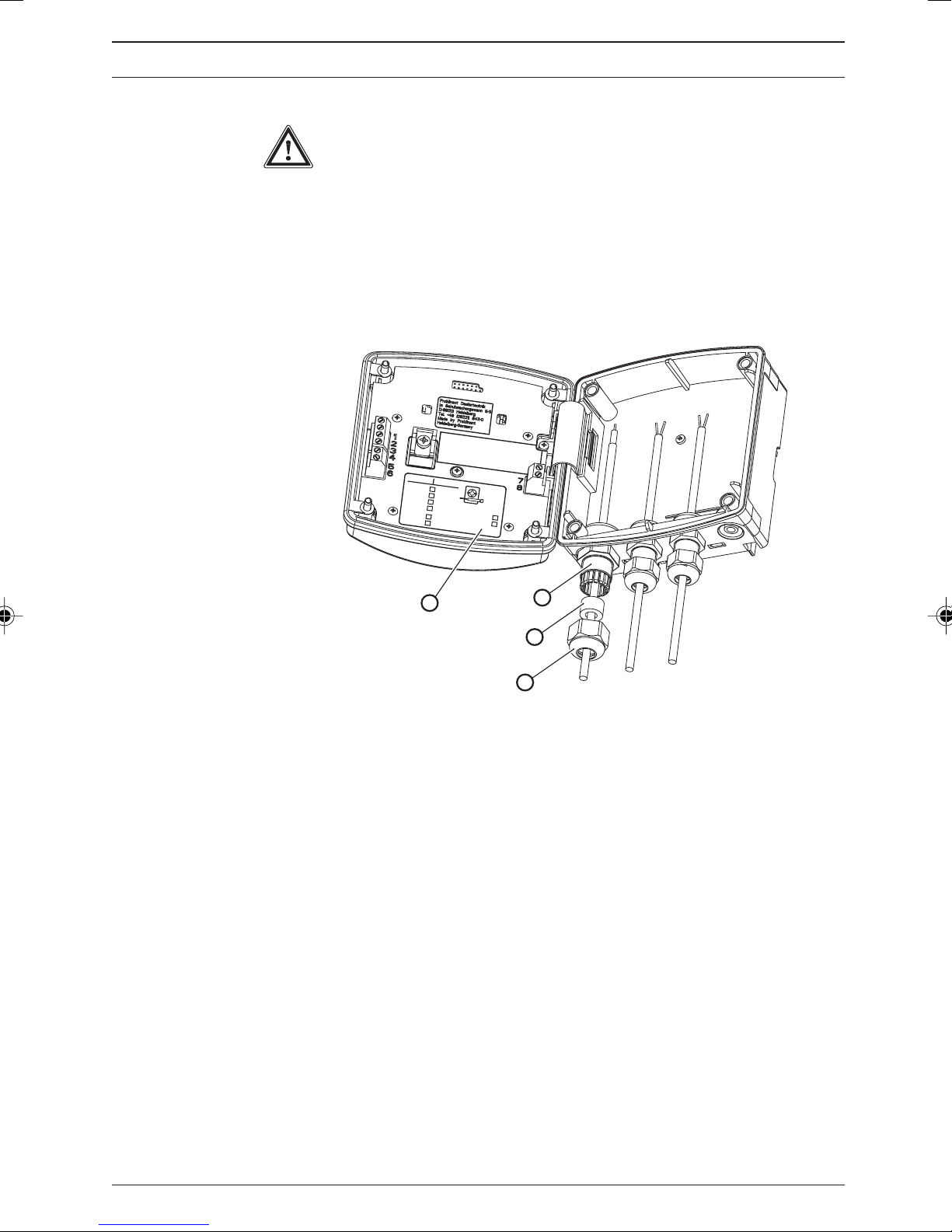

4.2.1 Wall mounting

왘 Unfasten the four housing screws

왘 Lift the front section slightly forwards and then swing open to the left.

왘 Pierce threaded cable apertures at the bottom of the rear side as required

(fig. 5).

Fig. 5

3468_4

NOTE

• The large gland (M 20 x 1.5) is intended for the sensor

cable.

• Feed the power cable leftwards through the smaller

threaded connector (M 16 x 1.5). Follow with the other

sensor cables (e.g. PT 1000).

왘 Tighten the threaded connectors (fig. 6, ➀) as required.

왘 Use reducers as required (fig. 6, ➁) to adapt the sizes of the threaded

connectors to the actual cable diameters.

왘 Feed the cables into the threaded connectors.

왘 Now proceed according to 4.2.4 Connecting coaxial cable and

4.2.5 Connecting terminals.

Then follow the steps below:

왘 Tighten the locking screws (fig. 6, ➂) for the threaded connectors.

왘 Swing the front section onto the back section.

Page 14

ProMinent

®

Page 15

Cl/ClO /O

-

+

4to20mA

shield

(gr) Pt1000 - /sig.gnd.

(wth) Pt1000 +

(bl) +U

---

(blk)-U

(br) meas.sig.

Pt100x -

Pt100x +

---

liquid pot.

r

ef.el.

glass el.

pH/OR

P

8

6

5

4

3

7

1

Assembly and installation

IMPORTANT

Check that the seal is located correctly. IP 65 is achieved only

when assembly has been carried out correctly.

(If necessary pull the front section forward in order to reduce

the stress on the seal.)

왘 Tighten the housing screws finger tight.

Fig. 6

pH/OR

Cl/ClO /O

P

2

3

liquid pot.

1

(blk)-U

---

Pt100x +

Pt100x -

glass el.

r

ef.el.

2

(bl) +U

3

---

4

(br) meas.sig.

5

(wth) Pt1000 +

6

(gr) Pt1000 - /sig.gnd.

4to20mA

shield

+

7

-

8

4

1

2

3

3465_3

4.2.2 Pipe mounting

See 4.2.1 Wall mounting

4.2.3 Panel mounting

NOTE

The cable must be laid in cable ducting on site to minimise

stresses.

Connect the cable from the back through the cut-out in the control panel:

왘 Follow the steps given in 4.2.4 Connecting coaxial cable and 4.2.5

Connecting terminals.

ProMinent

®

Page 15

Page 16

Assembly and installation

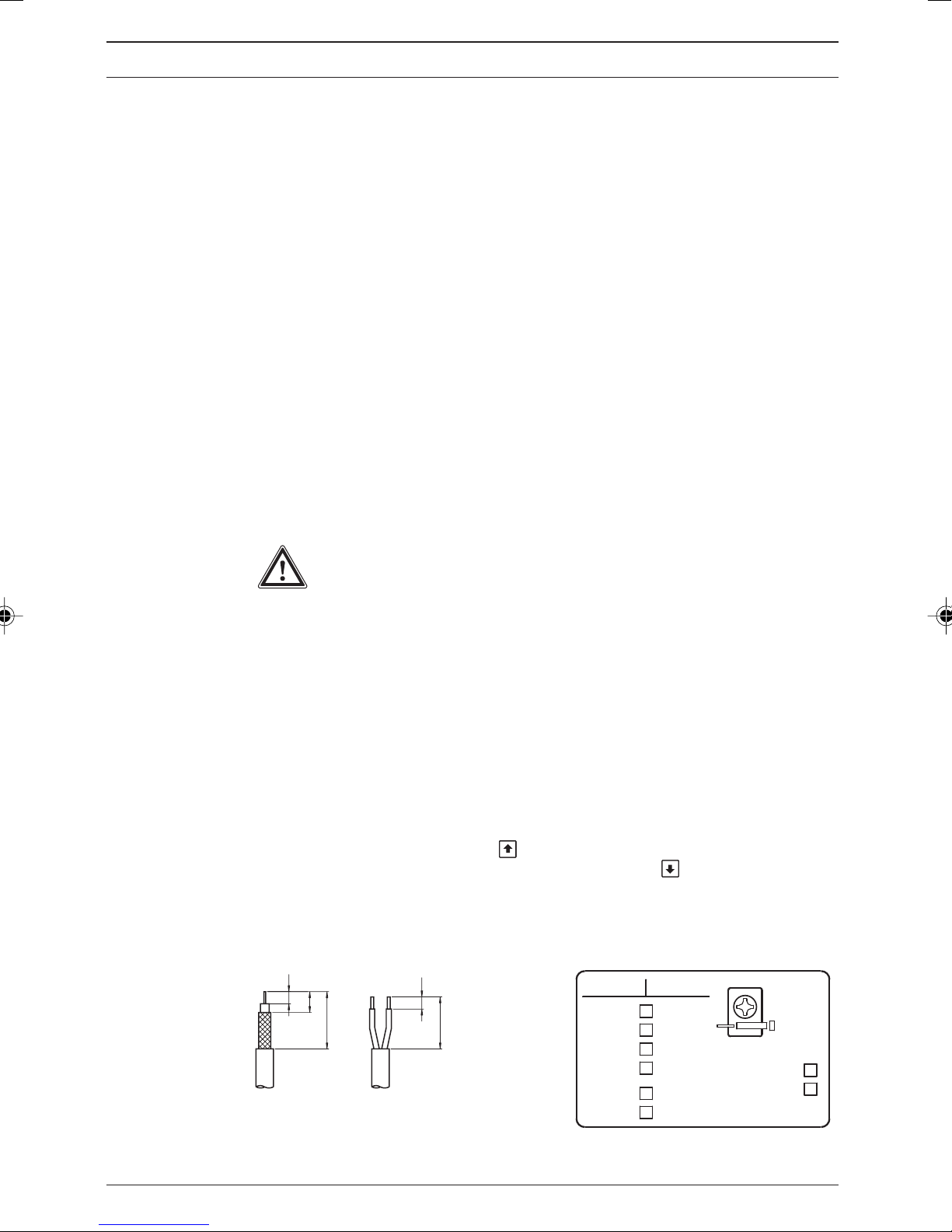

4.2.4 Connecting coaxial cable

The pH resp. redox probe is connected via a coaxial cable:

왘 Strip back to reveal cable shield (reference electrode) in accordance with

fig. 7 (left) and clamp using the shield clip.

The shield clip is connected internally to terminal 3.

Under normal circumstances measuring can be carried out without

connecting a liquid reference potential. In this case provide wire jumpers

between terminals 1 and 2.

When electrical conditions are more complex a potential plug should be

connected to terminal 1. Terminal 2 is left free.

The appendix contains an overview of connection options (terminal

connection plan).

4.2.5 Connecting terminals

왘 Remove insulation from cable ends as shown in fig. 7 (right) and attach

end crimps to each core.

왘 Connect the cables in accordance with the terminal connection plan.

IMPORTANT

• Do not operate PROFIBUS® variants at voltages over 30 V.

•

Connect PROFIBUS® variant power supplies via terminals 3

and 4 on the PROFIBUS® circuit board in the back section,

not terminals 7 and 8 in the front section.

NOTE

• The terminal connection plan is given in the appendix.

There is also a panel giving connection information affixed

to the housing near the terminals (fig. 6, and fig. 8).

• Push the cable through the housing until the front section

can be moved up and down easily.

• If the LC display is too weak, reduce the brightness using

the up arrow key

. If the display is too dark, increase the

brightness using the down arrow key .

Fig. 7 Fig. 8

7

12

33

7

3459_4

pH/ORP

liquid pot.

30

glass el.

Pt100 +

Pt100 -

---

ref.el.

Cl/ClO /O

3

2

(blk)-U

1

(bl) +U

2

---

3

4

(br) meas.sig.

(wth) Pt1000 +

5

(gr) Pt1000 - /sig.gnd.

6

shield

4to20mA

+

7

8

-

Page 16

ProMinent

®

Page 17

Device overview and control elements

5 Device overview and control elements

Fig. 9

Measured

variable label

LC-Display

Change key

Back key

Down key

CAL key

Enter Key

Up key

3456_4

ProMinent

®

Page 17

Page 18

Function description

6 Function description

6.1 General

The DULCOMETER® MEASUREMENT TRANSDUCER (DMT) is a microprocessor controlled on site measurement transducer. It displays the

selected measured variable and produces a proportional output signal. It can

also use temperature as a correction variable. The user can specify these

functions using the operating menu.

The user can switch between the measured variables pH value, redox

potential and temperature.

The inputs are collectively electrically insulated against the output.

In the event of a fault the DMT indicates an error message on the LC display

and produces an increased current (23 mA) through the ring circuit.

The DMT is also available for the following measured variables:

• Conductivity

• Chlorine

Measured

variable

temperature

Block circuit diagram

A

D

µP

Keypad LC display

EEPROM

(parameter memory)

FlashROM

(program memory)

D

A

Power supply,

current control

Signal

output

4 ... 20 mA

at

16 ... 40 V DC

and/or

30 V DC

(PROFIBUS

variant)

®

Page 18

ProMinent

®

Page 19

Function description

6.2 Key functions

The key are used to alter the DMT settings and have the following

functions:

In the permanent display / In the menu options

in the info display

Change key Toggles between permanent Scrolls through values of the

display and info display current menu option

modes

Back key Exits info display mode and Exits to info display without

returns to permanent display saving changes to values

mode

Enter key Accesses menu option Saves changes to values in

(from an info display) current menu option and

accesses the next info

display or another menu

option

CAL key Opens the calibration menu Activates calibration in

(from permanent display) calibration menu (pH only)

Down key Alters brightness of the Changes a value

LC display

Up key (in permanent display mode)

6.3 Operating menu, schematic

The operating menu comprises:

• the permanent display

• the calibration menu

• the info displays (info level)

for the display of pre-set parameters resp. general settings

• menu options (settings level)

for altering parameters resp. general settings

ProMinent

®

Page 19

Page 20

Function description

pH only

Permanent

display

Info display 1

Info display X

Info level Settings level

Calibration menu

Menu option 1

Menu option 1

Menu option 2

= Request access code

(only when activated by user)

6.4 Negotiating operating menu

NOTE

• The back key

any time. Depending upon where you are in the operating

menu, you will return either to the permanent display or to

the corresponding info level.

• The display will automatically return to permanent display

if you do not press a key within 5 min. (does not save

changes to values).

• If an access code has been activated by the user, access

code protection is applied to both the calibration menu and

the settings level menu options.

To access these menu options the access code must be

entered when it is requested and confirmed with the enter

key . Access restriction is reinstated each time you

return to the permanent display.

• The access code is factory set to 5000 (inactive).

can be used to exit the operating menu at

Page 20

ProMinent

®

Page 21

Function description

6.4.1 Calibration menu (pH only)

Access the calibration menu from the permanent menu using the CAL key

(further details given in 8.2 Calibrating the pH meter)

6.4.2 Info display

Access the first info display of the info level from the permanent display using

the change key .

Use the change key

the permanent display after the last info display.

6.4.3 Menu options

Use the enter key to access the menu options associated with that info

level.

6.4.4 Negotiating the menu options

input: sensor

unit: ˚C

offset = 0.00 ˚C

meas. val. = 21.00 ˚C

to access the other info displays in turn. Returns to

= adjustable numerical

values/texts flashing

Press the change key to activate all adjustable values in a menu option.

Flashing values can be altered. Use the arrow keys / to alter numerical

values or texts.

Keystrokes perform the following actions:

•1 x short keystroke reduces/increases a numerical value by one

increment or alters a text

• Holding the key down for longer alters numerical values increasingly

rapidly.

Use the enter key

to save changed values in the menu option. You will

then automatically enter the next info display or (if available) the next menu

option.

NOTE

Your entries become active immediately and are stored

permanently when you press the enter key .

If you do not wish to save changes, exit the menu option using the back

key

. You will then return to the info display for that menu.

ProMinent

®

Page 21

Page 22

DMT settings

Permanent display Calibration of pH probe Zero point and slope

7 DMT settings

NOTE

• Settings need only be changed if your process

requirements differ from factory general settings.

• If your DMT does not display the required settings option,

check the general settings of your device as described in

chapter 7.1.7.

Menu overview table

pH probe parameters Zero point, slope and probe

resistance

Redox probe test Compare with buffer Probe resistance

Parameter Detection means:

Temperature • sensor

measurement • manual (enter value)

Unit of measurement

• °C

• °F

Parameter Value:

Output current •

General settings Measured variable: Settings configuration Access

proportional measured variable:

measured variable at 4 mA

measured variable at 20 mA

• manual (enter value)

• pH code

• ORP (redox)

• temperature

= Request access code

(if activated by the user)

Page 22

ProMinent

®

Page 23

7.1 Measured variables pH and redox

7.1.1 Menu overview: measured variable pH

NOTE

The following menu is only an example.

The displays can vary depending upon the general settings.

DMT settings

pH

pH

7.12

12.5 mA 21.0 ˚C

param. measurement

zero point. = -0.1 mV

slope = 60.30 mV/pH

probe check: on

param. temperature

input: sensor

unit: ˚C

param. output signal

output: meas. value

4 mA: 2.00 pH

20 mA: 12.00 pH

general settings

DMTaW090P10E0220

2.1.06

zero point = -0.1 mV

slope = 60.30 mV/pH

probe check: on

meas. val. = 7.12 pH

input: sensor

unit: ˚C

offset = 0.00 ˚C

meas. val. = 21.00 ˚C

output: meas. value

4 mA: 2.00 pH

20 mA: 12.00 pH

device type

!! correct probe ??

type = pH

DMTaW090P10E0220

= Request access code

(if activated by the user)

general settings

language

DMTaW090P10E0220

E = english

ProMinent

®

general settings

change

access code = 5000

free access

Page 23

Page 24

DMT settings

7.1.2 Menu overview: measured variable redox

NOTE

The following menu is only an example.

The displays can vary depending upon the general settings.

Redox

mV

312

12.5 mA 21.0 ˚C

checking ORP-probe

param. temperature

input: sensor

unit: ˚C

param. output signal

output: meas. value

4 mA: 0 mV

20 mA: 1000 mV

general settings

DMTaW090R10E00220

2.1.06

probe in buffer!

faulty probe!!

buffer value: 465 mV

meas. value: 509 mV

unit: °C

offset = 0.00 °C

meas. val. = 21.00 °C

output: meas. value

4 mA: 0 mV

20 mA: 1000 mV

device type

!! correct probe ??

type = ORP (Redox)

DMTaW090R10E0220

= Request access code

(if activated by the user)

check dry probe

resistance = 1.23 MΩ

allowed > 2 MΩ

faulty probe !!

general settings

language

DMTaW090R10E0220

E= english

Page 24

general settings

change

access code = 5000

free access

ProMinent

®

Page 25

7.1.3 Parameter settings (pH only)

DMT settings

pH

param. measurement

zero point = -0.1 mV

slope = 60.30 mV/pH

probe check: on

zero point = -0.1 mV

slope = 60.30 mV/pH

probe check: on

meas. val. = 7.12 pH

or

zero point = -0.1 mV

slope = 60.30 mV/pH

probe check: on

resistance = 1.23 MΩ

The following settings options are available to you:

Zero point

and slope 왘 Enter the calibration values of the pH probe under “zero point” and

“slope” if these have been obtained by other means than via the DMT

calibration menu.

The current pH value is displayed under “meas. value” for monitoring

purposes.

Probe check 왘 Select on or off under “probe check” to activate/deactivate the pH

probe check.

If the probe check is active (on flashes) the resistance value of the pH

probe is displayed under “resistance”.

If the resistance value falls below 2 MΩ at any time during operation for

longer than 1 minute the error message “defective pH probe !!” appears in

the permanent display. Alternatively, if it is above 200 MΩ and the

measurement signal is fluctuating significantly, the error message “pH input

error!” is activated along with the display value “-2.00 pH” or “16.00 pH”.

7.1.4 Checking the ORP probe (redox only)

Redox

ProMinent

®

checking ORP-probe

NOTE

Sample liquid temperatures below 20 °C or above 60 °C can

cause incorrect signals during probe monitoring. In this case

we recommend that you switch off the probe check as long as

the pH probe is functioning correctly.

probe in buffer!

faulty probe!!

buffer value: 465 mV

meas. value: 509 mV

check dry probe

resistance = 1.23 MΩ

allowed > 2 MΩ

faulty probe !!

NOTE

The output current value is frozen during probe testing at,

depending upon the general settings, the last measured value

(HOLD) or at 23 mA (see chapter 7.1.7 General settings).

Page 25

Page 26

DMT settings

Two different test options are available:

Comparison

with buffer You can check the probe in the first menu option by measuring the redox

potential of a buffer solution:

The suggested “buffer value” (the redox potential for the buffer solution) is

220 mV or 465 mV. This value can be changed. The device compares the

buffer value with the measured variable and displays an error message

“faulty probe !!” if the difference is greater than 40 mV.

Probe

resistance The probe can be checked in the second menu option by measuring the

electrical resistance between the electrodes of the probe (must be dry):

It is particularly important that there is no residual moisture adhering to the

probe.

If the resistance measured is less than 2 MΩ the device will display the error

message “faulty probe !!”.

7.1.5 Parameters: Temperature

NOTE

• The DMT automatically detects whether a PT 1000 or

PT 100 is connected.

• If there is no temperature gauge connected the

temperature measurement should be set to “none”

or “manual” (see chapter 7.1.7 General settings).

Depending upon the “temp. meas.” general setting you have the following

options:

7.1.5.1 General setting: Temperature measurement = automatic

왘 Select the unit of measurement for temperature °C or °F under “unit”.

왘 Enter the difference ∆t under “offset” to a reference temperature

measurement (see chapter 7.5.5 Calibrating the Pt 100 temperature

gauge).

The actual temperature measured is displayed under “meas. val.”.

Page 26

ProMinent

®

Page 27

DMT settings

7.1.5.2 General setting: Temperature measurement = manual

(pH only)

pH

pH

param. temperature

input: manual

unit: ˚C

T = 22.6 ˚C

unit: ˚C

왘 Enter the process temperature under “T”.

왘 Select the temperature unit °C or °F under “unit”.

7.1.5.3 General setting: Temperature measurement = automatic or

manual (pH only)

param. temperature

input: manual

unit: ˚C

input: sensor

unit: ˚C

offset = 0.00 ˚C

meas. val. = 21.00 ˚C

or

input: manual

T = 22.6 ˚C

Unit: ˚C

왘 Under “input” select sensor or manual:

Select sensor if a temperature gauge is connected (temperature

measurement = automatic):

Select manual if the user is going to enter the process temperature

(temperature measurement = manual).

The selection made under “input” affects subsequent settings options.

Sensor If you have selected sensor in the “input” option:

왘 Select the unit of measurement for temperature °C or °F under “unit”.

왘 Enter the difference ∆t under “offset” to a reference temperature

measurement (see 7.1.5.5 Calibrating the Pt 100 temperature gauge).

The actual temperature measured is displayed under “meas. val.”.

Manual If you have selected manual in the “input” option:

왘 Enter the process temperature under “T”.

왘 Select the temperature unit °C or °F under “unit”.

7.1.5.4 General setting: Temperature measurement = none

No info display appears in the operating menu.

No temperature measurement is carried out.

ProMinent

®

Page 27

Page 28

DMT settings

7.1.5.5 Calibrating the PT 100 temperature gauge

NOTE

You need only calibrate the temperature gauge if

-You have a PT 100 temperature gauge and the sensor cable

is longer than 4 m.

-You have a precision measurement device (the DMT

measures to ±0.5 °C / ±0.9 °F accuracy).

• Do not replace the temperature sensor during calibration!

왘 Immerse the DMT temperature gauge and the reference measurement

device into the same liquid sample.

왘 Read off the value from the reference measurement device once the

temperature is stable.

왘 Set the correction value under “offset” until the temperature value is

identical to the reference value.

7.1.6 Parameter output

Depending upon the “output” general setting you have the following settings

options:

7.1.6.1 General setting: output current = measured value

(= 0 in identity code)

왘 Under “4 mA” enter the value at which the output current should be

4 mA.

왘 Under “20 mA” enter the value at which the output current should be

20 mA.

During calibration or checking of the ORP probe, the output current increases

to 23 mA.

Page 28

ProMinent

®

Page 29

DMT settings

7.1.6.2 General setting: output current = adjustable

(= 1 in identity code)

This setting serves as a function check.

왘 Enter under “l” any output current between 4 and 20 mA.

The current pH value or the current ORP are displayed in “meas. val.”

for verification purposes.

7.1.6.3 General setting: output current = measured value or adjustable

(= 2 in identity code)

pH

Redox

param. output signal

output: meas. value

4 mA: 2.00 pH

20 mA: 12.00 pH

param. output signal

output: meas. value

4 mA: 0 mV

20 mA: 1000 mV

output: meas. value

4 mA: 2.00 pH

20 mA: 12.00 pH

or

output: constant

I = 10.2 mA

meas. value = 7.11 pH

output: meas. value

4 mA: 0 mV

20 mA: 1000 mV

or

output: constant

I = 10.2 mA

meas. val. = 502 mV

왘 Under “output” select meas. value or constant:

Select meas. value if you require the output current to be proportional to

the measured value (output = meas. val.);

Select constant if you are going to enter the output current manually

(output = manual).

The “output” selection affects subsequent settings options:

Measured

variable If you have selected meas. value under “output”:

왘 Under “4 mA” enter the value at which the output current should be

4 mA.

왘 Under “20 mA” enter the value at which the Output current should be

20 mA.

ProMinent

®

Page 29

Page 30

DMT settings

Constant If you have selected constant under “output”

왘 Enter under “l” any output current between 4 and 20 mA.

The current pH/redox value is displayed under “meas. value” for

monitoring purposes.

This setting serves as a function check. During calibration or checking of the

ORP probe, the output current increases to 23 mA.

7.1.6.4 General setting: output current = measured value + adjustable +

HOLD

(= 3 in identity code)

In this general setting, the DMT can be adjusted as shown in 7.1.6.1 or

7.1.6.3. The following differences should be noted:

pH

For DMT pH, the output current remains at the output current value last

reported (HOLD function) during calibration. The output current freezes the

moment the menu option “input” is exited using the CAL key. This output

current corresponds to the last measured pH value. The HOLD value of the

output current is held until the calibration is completed. It is also possible to

set a certain HOLD value in the first measuring point of the calibration menu

(see 8.2.2).

Redox

With regard to DMT redox, the output current increases during calibration of

the ORP probe to the output current value last displayed (HOLD function)

upon activation of the ENTER key. This output current corresponds to the last

measured redox value. The HOLD value of the output current is held until the

menu “checking of redox probe” is exited.

7.1.6.5 General setting: output = 4 mA

(= 4 in identity code)

No info display appears in the operating menu.

The DMT emits a constant output current of 4 mA.

This setting serves as a function check and is selected if the DMT is to be

used purely as a display device (current consumption is minimal in this case!).

Page 30

ProMinent

®

Page 31

7.1.7 General settings

DMT settings

pH Redox

general settings

DMTaW090P10E0220

2.1.06

device type

!! correct probe ??

type = pH

DMTaW090P10E0220

general settings

change

access code = 5000

free access

general settings

language

DMTaW090P10E0220

E= english

7.1.7.1 Changing the device type

You can select the measured variables, pH or redox potential, in the first

menu option “device type”.

왘 Under “type” select pH or ORP (redox).

Depending upon your choice the corresponding identity code position alters:

pH = “P”, redox = “R”.

If you have confirmed the change of measured variable with the enter key

the output current will change immediately.

The settings for each measured variable are unaffected even after a different

selection has been made and are reinstated if the selection is reversed.

7.1.7.2 Changing general settings

You can adapt the DMT to your individual process requirements in the

second menu option “general settings”.

Access the individual identity code positions using the change key

.

Non-alterable features are automatically bypassed.

The following tables show the settings options depending upon the selected

measured value (the sequence from left to right corresponds to the identity

code position).

Measured variable pH

Language Automatic buffer Temperature Output Other

detection measurement settings

D = German 0 =ProMinent 0 = automatic 0 = measured variable; 0 =standard

E = English buffer set 1 = manual fault 23 mA,

F = French D = DIN 19266 2 = automatic or at calibration 23 mA

P = Polish buffer set manual 1 = manually adjustable

I = Italian V = automatic 9 = none current value

S = Spanish adjustment 2 = measured variable

or manual:

at fault 23 mA,

at calibration 23 mA

3 = measured variable

or manual:

at fault 23 mA,

when calibrating the last

measured value (HOLD)

4 = constant 4 mA

current

ProMinent

®

Page 31

Page 32

DMT settings

Measured variable redox

Language Probe type Temperature Output Other

measurement settings

D = German 0 =standard 0 = automatic 0 = measured variable: 0 =standard

E = English 9 = none at fault 23 mA,

F =French at calibration 23 mA

P = Polish 1 = manually adjustable

I = Italian current value

S = Spanish 2 = measured variable

or manual:

at fault 23 mA,

at calibration 23 mA

3 = measured variable

or manual:

at fault 23 mA,

when calibrating the last

measured value (HOLD)

4 = constant 4 mA

current

7.1.7.3 Changing access code

The factory pre-set access code is 5000. This setting allows unlimited access

to the calibration menu and the menu options in the settings level.

This code can be changed in the third menu option “change access code”.

Use the change key

to move to individual digits.

The new code is confirmed and activated with the enter key .

NOTE

• If an access code has been activated, both the calibration

menu and the menu options are access-protected.

To gain access, enter the access code when requested

to do so and confirm using the enter key

. Access

protection is reactivated when the DMT returns to

continuous display mode.

• Deactivate the access code by resetting the code to 5000

in the “change access code” menu option.

Page 32

ProMinent

®

Page 33

DMT settings

7.2 Measured variable temperature

7.2.1 Menu overview measured variable, temperature

NOTE

The following menu is only an example.

The displays can vary depending upon the general settings.

T

21.0

7.4 mA

param. temperature

unit: ˚C

param. output

output: meas. value

4 mA: 0.0 ˚C

20 mA: 100 ˚C

general settings

DMTaW090T10E0020

2.1.06

˚C

unit: ˚C

offset = 0.00 ˚C

meas. val. = 21.00 ˚C

output: meas. value

4 mA: 0.0 ˚C

20 mA: 100 ˚C

device type

!! correct probe ??

type = temp.

DMTaW090T00E0020

general settings

change

access code: 5000

free access

= Request access code

(only when activated by user)

general settings

language

DMTaW090T00E0020

E= english

ProMinent

®

Page 33

Page 34

DMT settings

7.2.2 Parameters temperature

왘 Select the temperature unit ˚C or ˚F under “unit”.

왘 Enter under “offset” the difference ∆t from a reference temperature

measurement (see 7.1.5.5 Calibrating the Pt 100 temperature gauge).

The actual measured temperature is displayed under “meas. val.”.

NOTE

• The DMT automatically recognises whether a PT 1000 or a

PT 100 has been connected.

7.2.3 Parameter output

You have the following settings options, depending on the “output” type you

selected under general settings:

7.2.3.1 General setting: output current = measured variable

(= 0 in the identity code)

왘

Under “4 mA”, enter the value at which the output current should be 4 mA.

왘 Under “20 mA”, enter the value at which the output current should be

20 mA.

7.2.3.2 General setting: output current = adjustable

(= 1 in the identity code)

왘 Under “l”, enter an output current between 4 and 20 mA.

This setting is used for the function check.

Page 34

ProMinent

®

Page 35

DMT settings

7.2.3.3 General setting: output current = measured value or adjustable

(= 2 in the identity code)

왘 Under “output”, select meas. value or constant:

Select meas. value if the output current should be proportional to the

measured value (output = measured value):

Select constant if the output current is to be entered manually

(output = adjustable).

The selection you make under “output” influences the subsequent settings

options:

If you selected “output” meas. value:

Under “4 mA”, enter the value at which the output current should be 4 mA.

왘

왘 Under “20 mA”, enter the value at which the output current should be

20 mA.

Entry If you selected “output” constant:

왘 Under “l”, enter any output current between 4 and 20 mA.

7.2.3.4 General setting: output = 4 mA

(= 4 in the identity code)

No information display will appear in the operating menu.

The DMT emits a constant output current of 4 mA.

This setting is used for the function check and/or is selected if the DMT is to

be used purely as a display device (the power consumption is minimal in this

case).

ProMinent

®

Page 35

Page 36

DMT settings

7.2.4 General settings

T

general settings

DMTaW090T10E0020

2.1.06

device type

!! correct probe ??

type = temp.

DMTaW090T10E0020

general settings

change

access code = 5000

free access

general settings

language

DMTaW090T10E0020

E = english

7.2.4.1 Changing device type

The first menu option, “device type”, is used to switch between the measured

variables pH value, redox voltage or temperature:

왘 Under “type”, select pH, ORP (redox) or Temperature.

The corresponding identity code position changes depending on your choice:

pH= “P”, redox = “R”, temperature = “T”.

If you confirm the change of measured variable using the enter key

,

the output current changes immediately.

The settings for each measured variable are unaffected by switching from one

to another, i.e. you do not need to re-set them when re-selecting a measured

variable.

7.2.4.2 Changing general settings

The second menu option; “general settings”, is used to adapt the DMT to

your specific process requirements.

Scroll through individual identity code positions using the “Change” key

until you reach the one you require. Non-adjustable features are automatically

bypassed.

The following tables show the settings options for each measured variable

(the sequence from left to right corresponds to the identity code positions).

Measured variable temperature

Language Probe type Temperature Output current Additional

input settings

D = German standard 0 = sensor 0 = measured variable; 0 =standard

E = English 0 =PT 100 or PT 1000 (100) at fault 23 mA

F = French PT 1000 at calibration 23 mA

P = Polish 1 = adjustable output

I = Italian 2 = measured variable

S = Spanish or adjustable;

at fault 23 mA

at calibration 23 mA

4 =4 mA constant current

Page 36

ProMinent

®

Page 37

DMT settings

7.2.4.3 Change access code

The factory-set default access code is 5000. This setting allows unlimited

access to the calibration menu and the settings level menu options.

This code can be changed in the third menu option; “change access code”.

Use the change key

enter key. Once all digits have been selected you can activate the code by

pressing the enter key once more.

NOTE

• If an access code has been activated, both the calibration

menu and the menu options are access-protected.

To gain access, enter the access code when requested to

do so and confirm using the enter key

protection is reactivated when the DMT returns to

continuous display mode.

• Deactivate the access code by resetting the code to 5000 in

the “change access code” menu option.

to bring up the individual digits and confirm using the

. Access

ProMinent

®

Page 37

Page 38

mV/pH

m

V

-60 +60+500-50

300

s

40 656345

The pre-set time depends upon the

temperature and the cable length.

Depending on the system the setting

time can be more than 60 seconds.

Pre-set time:

Slope:

Admissible range

Zero point:

visible = probe OK

not visible = on the limit of admissible range

and/or not in order

Condition:

Zero point

Slope

Pre-set time

Display:

59,16

Operating the DMT

8 Operating the DMT

8.1 Permanent display

pH

Redox

pH

Information about the probe condition

7.12

12.5 mA 21.0 ˚C

mV

312

12.5 mA 21.0 ˚C

The permanent display allows you to monitor the DMT measured values

during operation.

The permanent display can indicate the following (depending upon

general settings):

• Measured variable • Information about the probe condition

• Correction variable • Error messages

• Output current

8.1.1 Probe condition information (pH only)

Page 38

Optimum range

Admissible range

Optimum range

ProMinent

®

Page 39

Operating the DMT

8.1.2 Brightness of LC display

You can alter the brightness of the LC display in the permanent display:

왘 Increase brightness using the down arrow key

arrow key .

8.2 Calibrating the pH meter

The pH probe condition is a key factor in the quality of the measurement. The

pH probe must therefore be re-calibrated at regular intervals with the aid of

buffer solutions. The DMT incorporates automatic buffer detection.

8.2.1 Automatic buffer detection

The tables for the following two buffer solution sets are contained in the

program memory.

Temp. ProMinent buffer table DIN 19266 buffer table

°CpH pH

0 4.05 7.13 10.26

5 4.04 7.07 10.17 4.00 6.95 10.25

10 4.02 7.05 10.11 4.00 6.92 10.18

15 4.01 7.02 10.05 4.00 6.90 10.12

20 4.00 7.00 10.00 4.00 6.88 10.07

25 4.00 6.98 9.94 4.01 6.86 10.01

30 4.00 6.98 9.90 4.01 6.85 9.97

40 4.00 6.97 9.82 4.04 6.84 9.89

50 4.00 6.96 9.75 4.06 6.83 9.83

60 4.00 6.97 9.68 4.09 6.84

70 4.01 6.98 9.62 4.13 6.85

80 4.02 6.99 9.55 4.16 6.86

or reduce using the up

We recommend that you use the buffer solutions obtainable from ProMinent

for calibration purposes.

Select a buffer set which is higher than the general setting (see chapter 7.1.7)

If V = automatic adjustment has been selected the corrected values are

saved and used for buffer detection during the subsequent calibration

process.

On delivery the program memory contains the ProMinent buffer table as the

V-table.

ProMinent

®

Page 39

Page 40

Operating the DMT

8.2.2 The calibration process

Calibration menu overview

8.2.2.1 2 point calibration

NOTE

• The back key can be used to exit the calibration menu at

any time. You will then return to the permanent display.

• The output current is frozen for the duration of the calibration at, depending upon general settings, the last

measured value (HOLD) or at 23 mA (see chapter 7.1.7

General settings).

• Inadmissible values render the ongoing calibration invalid.

The previous calibration values are retained. The error

messages are explained in chapter 9.2.

• Please dispose of spent buffer solution.

Page 40

ProMinent

®

Page 41

8.2.2.2 1 point calibration

Operating the DMT

Proceed as follows to call up the calibration menu:

pH

7.12

12.5 mA 21.0 ˚C

pH

input: sensor

buffer temp. = 20.3 ˚C

HOLD 7.12 pH

HOLD 12.12 mA

input: manual

buffer temp. = 20.3 ˚C

or

HOLD 7.12 pH

HOLD 12.12 mA

Starting

calibration 왘 Press the CAL key when in the permanent display mode while the pH

probe is immersed in the liquid sample.

왘 Under “input” set the detection method of the buffer temperature

(correction value):

Sensor (if the pH sensor incorporates a temperature gauge) or

manual (if using a separate temperature gauge).

If you select manual, you must set the buffer temperatures under “buffer

temp.” using the up and down arrow

/ keys.

This setting is only valid during calibration.

왘 You can change the pH HOLD value under “HOLD”. This setting is only

valid during calibration.

왘 Remove the pH probe from the liquid sample, rinse and immerse in the

first buffer solution.

왘 Press the CAL key to start automatic buffer detection:

ProMinent

®

Page 41

Page 42

Operating the DMT

pH

pH cal1

4.02 4.01 4.04

recogn.

T = 20.3 ˚C

The progress of the buffer detection is indicated by a time bar. The calculation of the calibration parameters begins automatically after the buffer

detection. This is also indicated by a time bar.

If you have selected sensor as the detection method for the buffer temperature, the current measured buffer temperature is displayed under “T”. If you

have selected manual, the manually entered buffer temperature is displayed

under “T”.

The buffer value can be corrected during calibration using the / arrow

keys. If the sensor signal is unstable the time bar will wait until it becomes

stable.

왘 After completion of this calibration stage the display shows the next

menu option for 1 point calibration:

The buffer value can be corrected once again at this point using the arrow

keys / .

pH cal1

calibr.

T = 20.3 ˚C

pH cal1

end = or cal2 = CAL

T = 20.3 ˚C

Progress from this point onwards depends upon whether you have selected a

1 point calibration or a 2 point calibration (recommended!).

1 point

calibration 왘 Press the enter key

to end 1 point calibration.

The zero point is calibrated if the buffer value is between 5.5 pH and 8.0 pH.

The slope is calibrated if the buffer value is less than 5.5 pH or greater than

8.0 pH.

왘 Proceed as for “conclude calibration”.

2 point

calibration 왘 For a 2 point calibration remove the pH probe from the first buffer

solution, rinse and immerse in the second buffer solution.

왘 Press the CAL key

to restart automatic buffer detection.

Buffer detection and calibration take place as described above.

Page 42

ProMinent

®

Page 43

Operating the DMT

왘 After completion of this calibration stage the display shows the next

menu option for 2 point calibration:

The buffer value can be corrected once again at this point using the arrow

keys

왘 Press the enter key to end 2 point calibration.

왘 Proceed as for “conclude calibration”.

Conclude

calibration The calibration values (zero point and slope) are now displayed:

pH

zero point = -0.12 mV

slope = 58.32 mV/pH

acceptance

meas. val. = 7.21 pH

The current pH value is shown under “meas. val.”.

왘 Press the enter key

without saving the values.

/ .

to adopt the values or the back key to exit

The display changes to permanent display. The calibration is complete.

NOTE

Inadmissible values render the current calibration process

invalid.

The previous calibration values are retained.

The error messages during calibration are explained in

chapter 9.2.

ProMinent

®

Page 43

Page 44

Troubleshooting

9Troubleshooting

9.1 Error messages during operation

The following error messages can appear in the permanent display during

operation:

Message Displayed Cause of fault Remedy

value

Output overflow Measured Warning: detected current value Change configuration if

value greater than pre-set necessary

20 mA value

Output underflow Measured Warning: detected current value Change configuration if

value less than pre-set necessary

4 mA value

pH input error ! -2.00 pH Probe not present or lead Check probe connection

or damaged (switch off probe check if

16.00 pH necessary)

pH input error ! ~7.00 pH Short circuit Check probe connection

(probe resistance ≅ 0 Ω)

defective pH probe !! Measured Measured probe Replace probe (switch off

value resistance < 2 MΩ probe check if necessary)

ORP input error ! Measured value > 1200 mV or Check probe connection

< -1200 mV,

resp. fluctuating significantly

temp. input error ! 999.9 ° Probe not present or Check probe connection

lead damaged (set temperature measurement

to manual if necessary)

temp. input error ! -99.9 ° Short circuit Check probe connection

(set temperature measurement

to manual if necessary)

The error message disappears automatically once you have remedied the

fault.

Page 44

ProMinent

®

Page 45

Troubleshooting

9.2 Error messages while calibrating the pH meter

The following error messages can appear in the corresponding menu options

during calibration:

Error message Cause Effect

Zero point <-60mV !!! N < -60 mV Previous zero point and slope retained

Calibration failed Replace probe

Zero point > 60mV !!! N > +60 mV ”

Calibration failed

Slope < 40mV/pH ! S < 40 mV/pH ”

Calibration failed (S < 67 %)

Slope > 65mV/pH ! S > 65 mV/pH ”

Calibration failed (S > 111 %)

Warning Cause Effect

Measured value t

unstable !!!

Buffer differential < 2 pH ! ∆

False buffer value - Set correct buffer value

* The admissible setting time is: t

> 30 s *

cal

< pH 2 Use second buffer solution

Buffer

< 30 s for a value fluctuation ∆U < 2 mV/s

cal

IMPORTANT

The sensor monitoring is deactivated during the calibration

process!

ProMinent

®

Page 45

Page 46

Maintenance and repair / Disposal

10 Maintenance and repair

Maintenance The DMT requires no maintenance.

You should clean the housing with a damp, soapy cloth and then rub dry.

IMPORTANT

Solvents may attack the surfaces and must not be used.

Repair Please return the DMT to ProMinent Dosiertechnik GmbH for repair.

11 Disposal

IMPORTANT

Electronic waste is treated as special waste!

Observe current nationally and locally applicable directives.

Page 46

ProMinent

®

Page 47

12 Technical data

Electrical data

Device Protection class: III

Supply voltage: - 4-20 mA (two wire) current loop,

24 V DC (16...40 V DC), protective low voltage

- PROFIBUS®-DP, 24 V DC (16...30 V DC),

protective low voltage

The supply voltage level must not fall below

16 V at any time

Signal output: 4 … 20 mA in normal operation,

23 mA to signal fault,

Ohmic resistance 50 Ω

Enclosure

ratings When installed correctly the following enclosure ratings apply:

Wall/pipe mounted: IP 65 in accordance with DIN VDE 0470-1

Control panel mounted: IP 54 in accordance with DIN VDE 0470-1

Measured

variable, pH Measurement range: -1 … +15 pH at 0 … 100 °C

Reproducibility: 0.01 pH

Operating measurement

deviation: max. 0.02 pH at 25 °C ambient temperature

Insulation voltage: 500 VDC; electrically insulated against

ring circuit

Input resistance: Glass electrode: > 1012 Ω

Reference electrode: All reference electrodes can be connected

to diaphragm

Resolution: 0.01 pH

Measured

variable, redox Measurement range: -1200 … +1200 mV

Reproducibility: 1 mV

Operating measurement

deviation: max. 2 mV at 25 °C ambient temperature

Insulation voltage: 500 VDC: electrically insulated against

ring circuit

Input resistance: > 1012 Ω

Reference electrode: All reference electrodes can be connected

to diaphragm

Measured

variable/ Resolution: 1 mV

Correction

variable,

temperature Measurement range: -20 °C … 150 °C

Measurement deviation: max. 0.3 °C (PT 1000 at 25 °C ambient

temperature)

max. 0.5 °C (PT 100 at 25 °C ambient

temperature)

Resolution: 0.1 °C

Display Principle: LCD (liquid crystal display)

Technical data

ProMinent

®

Page 47

Page 48

Technical data / Spare parts and accessories

Ambient conditions

Operating temperature: 0 … 55 °C

Storage temperature: -20 … 70 °C

Air humidity: max. 95 % rel. humidity, non condensing

Control

panel

Dimensions and weight

Dimensions: Wall/pipe mounted version 126x136x78 mm

(WxHxD)

Panel mounted version 35 mm, 30 mm (D

Weight: Wall mounted, 450 g

D

o

, Do)*

i

Panel mounted, 300 g

*D

= depth inside, Do = depth outside

i

Admissible cable diameters: threaded connector:

M 20 x 1.5: Terminal area Ø 2 … Ø 7 mm

(SW 22)

M 16 x 1.5: Terminal area Ø 5 … Ø 10 mm

(SW 19)

reducers:

M 20: Terminal area Ø 4 … Ø 13 mm

M 16: Terminal area Ø 3 … Ø 9 mm

D

i

Admissible lead

cross sections: 0.14 … 0.75 mm

Admissible screen diameters:

Ø 2 … Ø 5 mm

2

Material information

Housing: PPE-GF10

Wall/pipe bracket: PPE-GF20

Keypad: Silicon

Housing seal: Silicon

13 Spare parts and accessories

Assembly kit for wall/pipe mounting Order no. 1003205

Pipe clamps for pipe mounting Order no. 1002777

Plug-in power supply 90-264 V AC/24 V DC Order no. 1006100

Probes See product catalogue

Probe cable See product catalogue

Page 48

NOTE

Please give the identity code when ordering electronic

component kits.

ProMinent

®

Page 49

Conformity declaration

ProMinent

®

Page 49

Page 50

Terminal connection plan pH/redox/temperature

Inputs, Output

connection variations

Internal

External

pH/redox ORP

combination probe

without liquid

reference potential

5566

44332211

-

+

pH/redox ORP

combination probe

with liquid

reference potential

--

+

XY

Signal

Shield

ϑ

Pt 1000/

Pt 100

pH/redox pH/redox

ϑ

Pt 1000/

Pt 100

Signal

Shield

Potential plug

pH/redox ORP

separate probe system

564321

+

Z

Signal

Shield

ϑ

Pt 1000/

Pt 100

pH/redox

Ref. electrode

(not PROFIBUS

variants)

87

-

+

Current loop

4-20 mA/

Supply voltage

16-40 V DC

®

3

Shield to shield clip

421 21

Shield to shield clip

Internal

External

Detail ZDetail YDetail X

3344

21

Wire jumperWire jumper

Shield to shield clip

Connection variant temperature

Resistance thermometer

564321

-

+

(not PROFIBUS

Output

variants)

87

+

®

-

Page 50

ϑ

Pt 1000/

Pt 100

Current loop

4-20 mA

Supply voltage

16-40 V DC

ProMinent

®

Page 51

Wiring example - two wire system

1

=

2

3

4

+

-

+

-

+

-

5

=

-

+

6

-

+

~

1 DMT transducer

2 Controller

3 Meter

4 Recorder

5 24 V DC (16...30 V DC/40 V DC) power supply unit

6 4-20 mA current loop

IMPORTANT

• The signal inputs of all devices in the current loop must be

electrically isolated from the current output.

• Take into account the sum of the ohmic resistances of all

devices in the current loop (excluding power supply).

The input voltage of the transducer must never drop below

16 V during operation.

The measured value will otherwise be wrong.

ProMinent

®

Page 51

Page 52

+ - + -

Intern Extern

1 2 3 4

+ - + -

PROFIBUS® circuit board terminal connection

PROFIBUS

Ribbon cable

®

-DMT power supply

Supply voltage

16-30 V DC

NOTE

To operate the PROFIBUS

®

-DMT temporarily without the

PROFIBUS®, unplug the ribbon cable (see fig.) and briefly

disconnect from the power supply.

To operate the PROFIBUS

®

-DMT with the PROFIBUS® again,

plug the ribbon cable back in (plug in the connector on the

side of the PROFIBUS® circuit board with the red edge of the

ribbon cable facing upwards (see fig.)). Briefly disconnect

from the power supply.

Page 52

ProMinent

®

Page 53

Index

A

Access code 32

B

Buffer detection 39, 41

General settings 31

C

Calibration

fault messages 44

pH meter 39

Pt 100 28

Calibration menu 40

menu overview 40

Conformity declaration 48

Control elements 17

Check ORP probe 25

D

Device type 31

F

Fault message

during operation 43

during calibration 44

G

General settings 31

changing 31

M

Menu option 21

Menu overview

calibration menu 40

measured variable pH 23

measured variable redox 24

measured variable temperature 33

tabular 22

Mounting 10

O

Operating 38

Operating menu 20

schematic 19

Output

General settings 31, 32, 36

parameters 28, 34

P

Parameters

output 28, 34

measurement 25

temperature 26, 34

Permanent display 38

Probe check (pH) 25

Probe condition (pH) 38

Probe type (temperature)

general settings 36

®

PROFIBUS

16, 50

I

Identity code

measured variable pH 5

measured variable redox 6

measured variable temperature 7

Info display 20, 21

Installation 13

K

Key functions 19

L

Language

general settings 31

LC display

brightness 39

S

Settings 22

Slope 25, 42

T

Temperature measurement

parameters 26, 34

Temperature gauge

general settings 31, 32, 36

Terminal connection plan 49

Troubleshooting 43

2-wire system 51

Typical wiring for a 2-wire system 51

Z

Zero point 25, 42

ProMinent

®

Page 53

Page 54

Page 54

ProMinent

®

Page 55

Drilling template for DMT

Page 55

ProMinent

®

4 x 3.5 mm diam. holes

3460-4.1

108

100

5

100

60

R 4

ATTENTION: Photocopying the template can change the scale!

3460-4.1

Page 56

Addresses and delivery information

from the manufacturer:

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

info@prominent.com

www.prominent.com

ProMinent

®

Loading...

Loading...