Page 1

®

Operating Instructions

DULCOMETER® D2C

Part 2: Adjustment and Operation,

Measured Variables chlorine/chlorine

CI

/

CI

2

2

ppm

0.50

CLE

ppm

0.20

∆CI

DULCOMETER

STOP

ST

AR

T

CI

0.50

0.20

DULCOMETER

2

STOP

ST

/Cl

AR

T

ppm

CLE

ppm

∆CI

ProMinent

D2C2-001-chlorine/chlorine-GB

2

Typ WTyp D

D2C A

___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

Please enter the identity code of your device here!

Please completely read through operating instructions! • Do not discard!

The operator shall be liable for any damage caused

by installation or operating errors!

Part No. 986846 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany BA DM 169 10/08 GB

Page 2

1 Device Identification / Identity Code

D2C A DULCOMETER® controller Series D2C

W Wall mounting

D Panel mounting (96 x 96 mm)

Operating voltage

0 230 V 50/60 Hz

1 115 V 50/60 Hz

4 24 V AC/DC

Measured variable 1/Measured variable 2

CC Chlorine/Chlorine (0...2/5/10 ppm)

Connection of measured variable 1 (connection measured variable 2: 4-20 mA)

1 Terminal standard signal 4–20 mA (signal converters are necessary)

Correction variable (Temperature for pH)

0 None

0 None

Disturbance variable connection

Signal output

0 None

42 Standard signal outputs 0/4-20 mA, free programmable

Power control

G Alarm and 2 limit relay

M Alarm and 2 solenoid valve relays

(pulse length control)

Control characteristic

1 Proportional control

2 PID control

0 None

Protocol output

Language

D German

E English

F French

S Spanish

A Swedish

N Dutch

D2C A

2

Please enter the identity code of your device here!

Page 3

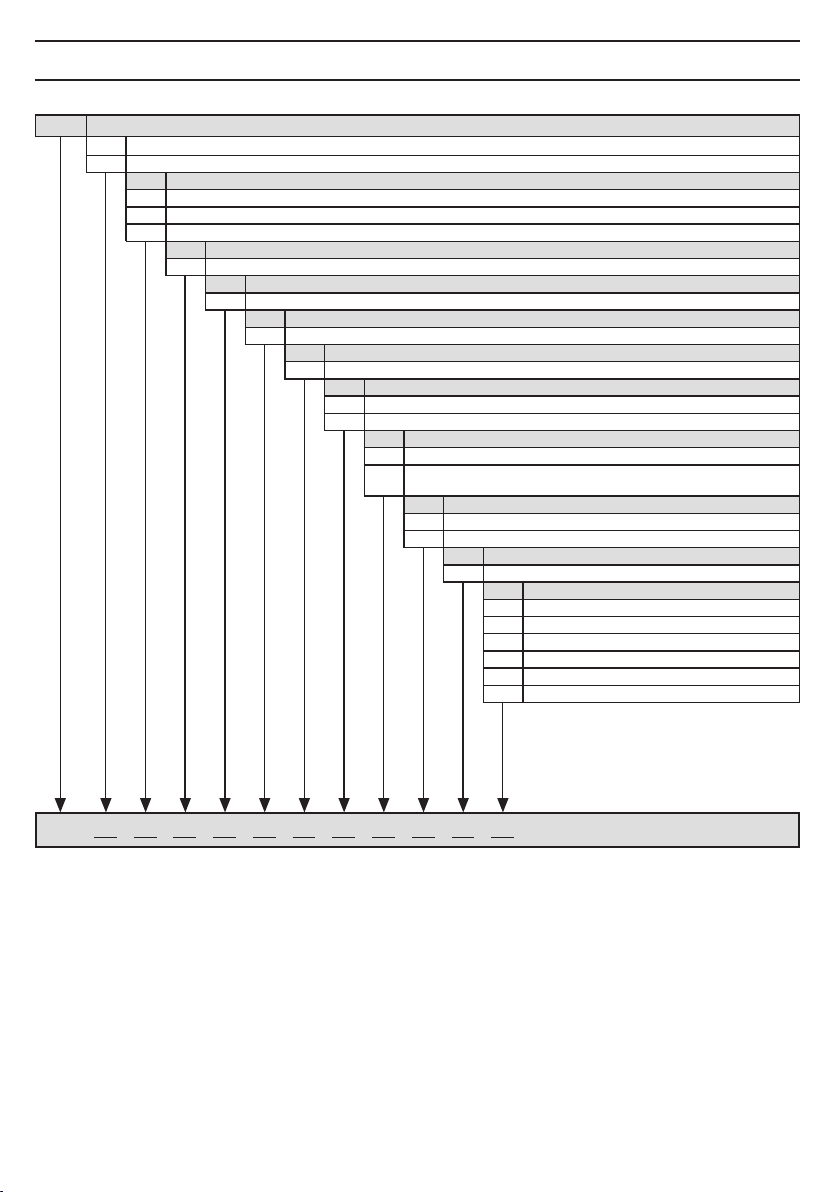

2 General User Information

Page

1 Device Identification / Identity Code ...................................................................................................... 2

2 General User Information ......................................................................................................................... 3

3 Device Overview / Controls ..................................................................................................................... 4

4 Functional Description ............................................................................................................................ 5

5 Display Symbols ..................................................................................................................................... 6

6 Operating ................................................................................................................................................. 7

7 Operating Menu / Overview ..................................................................................................................... 8

8 Operating Menu / Description ............................................................................................................... 12

9 Technical Terms ..................................................................................................................................... 22

10 Faults / Notes / Troubleshooting ........................................................................................................... 23

General User Information

These operating instructions describe the technical data and function of the series DULCOMETER® D2C

controller, provide detailed safety information and are divided into clear steps.

IMPORTANT

• Please observe the parts of these operating instructions applicable to your particular

version! This is indicated in the Section “Device Identification/Identity Code”.

• Correct measuring and dosing is only possible in the case of impeccable operation of the

probe. The probe has to be calibrated/checked regularly!

• In the event of a probe failure, uncontrolled chemicals addition may result. We therfore

recommend urgently to activate “check out time limits” with automatic control shut-off!

3

Page 4

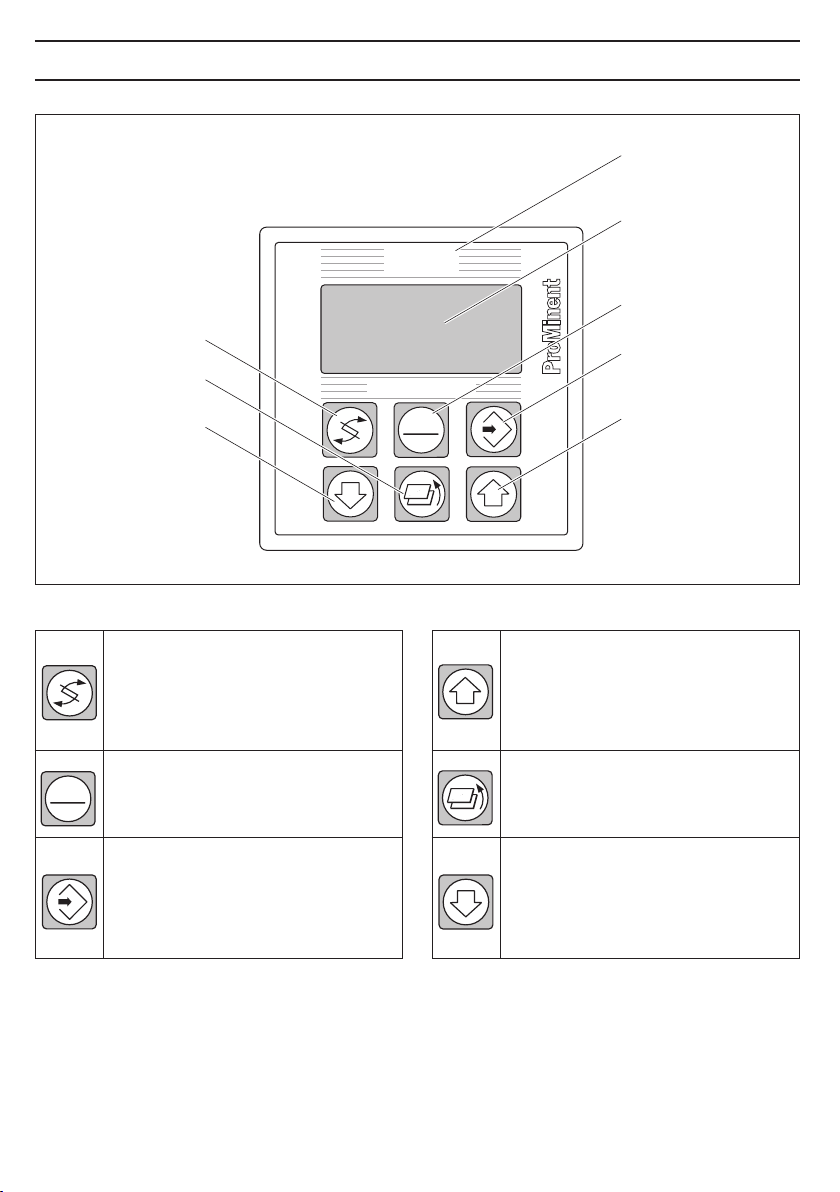

3 Device Overview / Controls

"Change"

button

"Branch back"

button

"Down"

button

DULCOMETER

CI2/CI

STOP

START

Display field

Measured variable

chlorine/chlorine

Graphic display

2

®

®

"Start/Stop"

button

"Enter"

button

"Up"

button

D2C2-002-chlorine/chlorine-GB

4

STOP

START

CHANGE button

To change over within a menu level

and to change from one variable to

another within a menu point.

START/STOP button

Start/stop of control and metering

function.

ENTER button

To accept, confirm or save a displayed

value or status. For alarm acknowledgement.

UP button

To increase a displayed numerical value

and to change variables (flashing

display)

BRANCH BACK button

Back to permanent display or to start

of relevant setting menu.

DOWN button

To decrease a displayed numerical

value and to change variables (flashing

display).

Page 5

4 Functional Description

NOTE

Please refer to the description of the operating menu for a detailed description of the

individual characteristics of the DULCOMETER

4.1 Operating Menu

The DULCOMETER® D2C controller permits settings to be made in two different menus. All values are

preset and can be changed in the complete operating menu.

The controller is delivered with a restricted operating menu so that the D2C controller can be used

effectively in many applications from the very onset. If adaptations prove to be necessary, all relevant

parameters can then be accessed by switching over to the complete operating menu.

4.2 Access Code

Access to the setting menu can be prevented by setting up an access code. The D2C controller is supplied

with the access code 5000 which permits free access to the setting menu. The calibration menu remains

freely accessible even when access to the setting menu is blocked by the code.

4.3 Control

The D2C can operate as a proportional controller or as a PID controller - dependent on the device version

(see identity code) and the setting.

The controlled variable is recalculated once a second. Control procedures which require rapid correction of

setpoint deviations (less than approx. 30 seconds) cannot be processed with this controller. The solenoid

valve control (pulse on-time) must take account of the cycle times.

The control function (reference variable output) can be switched off through the pause function and the

water control input. The calculation of the regulated variable starts again with the cessation of the "pause"

after expiry of the adjustable delay time "td". No fault treatment is performed with active "pause" function.

®

D2C controller!

4.4 Fault messages

Faults to be acknowledged are shown in the permanent displays by the symbol "

fault messages and notes are shown in the permanent display 2. Faults/notes continuing after

acknowledgement are shown alternatively. Faults automatically remedied throught changing operating

conditions are removed from the permanent display without necessitating acknowledgement. Chapter 10

includes an overview of fault messages and causes.

". The corresponding

5

Page 6

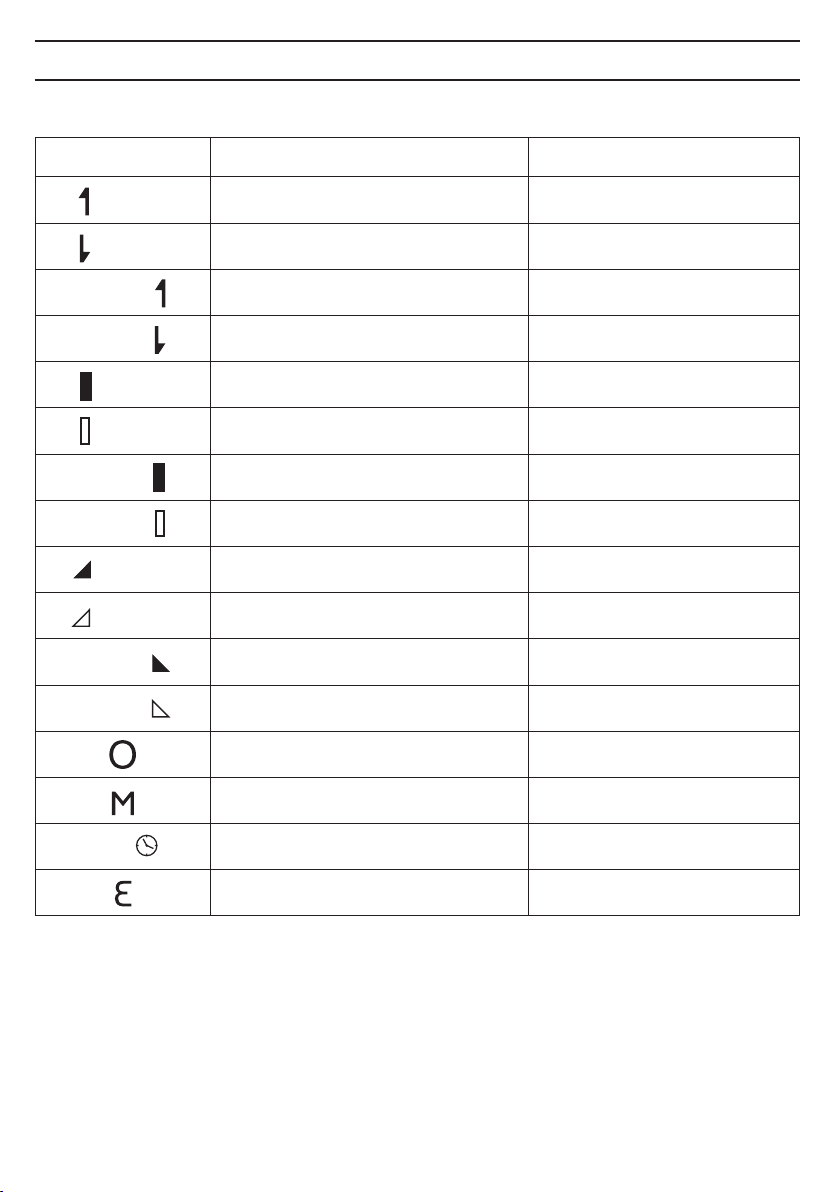

5 Display Symbols

The display of the DULCOMETER® D2C controller uses the following symbols:

Symbol Description Comment

Limit value transgression measured value 1

Relay 1 upper or zone left

Relay 1 lower left

Limit value transgression measured value 2

Relay 2 upper or zone right

Relay 2 lower right

Metering pump measured value 1 Symbol

Control off left

Control on left

Metering pump measured value 2 Symbol

Control off right

Controll on right

Solenoid valve measured value 1 Symbol

Controll off left

Controll on left

Solenoid valve measured value 2 Symbol

Controll off right

Control on right

Stop button pressed

Symbol

Symbol

Symbol

Symbol

Symbol

Symbol

Symbol

Symbol

pause

6

Manual metering

Delay time "td" Control starts after

expiry of "td"

Fault

Page 7

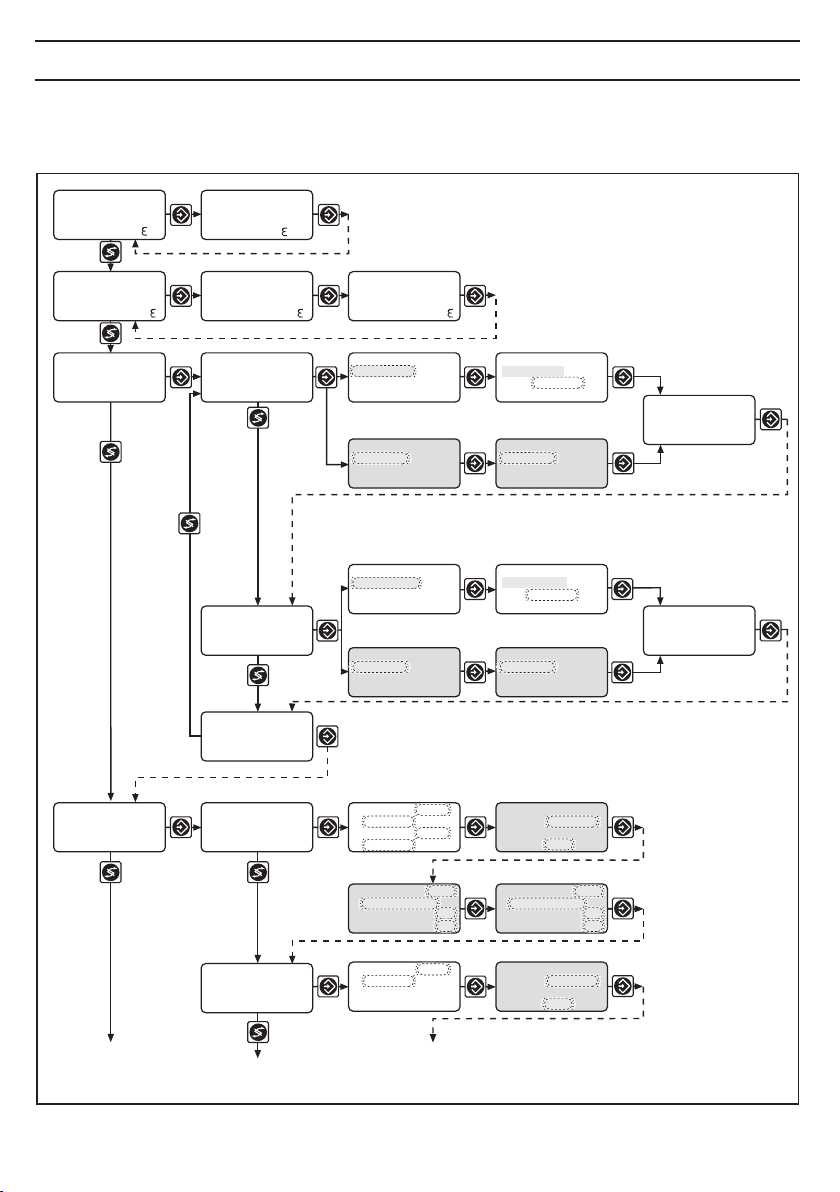

6 Operation

Permanent

display 1

Permanent

display 3

Calibration

menu

Various

Setting menus

Access code

NOTE

Access to the setting menus can be barred with the access code!

The number and scope of setting menus is dependent on the device version!

If the access code is selected correctly in a setting menu, then the following setting menus are also

accessible!

If within a period of 10 minutes no button is pushed, the unit automatically branches back from the

calibrating menu or a setting menu to the permanent display 1.

Permanent

display 2

Permanent

display 4

Calibration notes

Access code, correct

Parameter

setting

The various menus are

selected with the CHANGE

button

The menu is started with

the ENTER button

BRANCH BACK to

permanent display or to

relevant setting menu

D2C2-007-chlorine/chlorine GB

BRANCH BACK without

saving setting

BRANCH BACK to

start of setting

Variables flash

Text 1

Selection 1

Text 2

Selection 2

Text 1

Selection 1

Text 2

Selection 2

CHANGE from selection to selection

Change numbers or

settings of selection

ENTER and save setting,

continue to next menu

D2C2-008-chlorine/chlorine-GB

7

Page 8

7 Operating Menu / Overview

The setting menus highlighted in grey and the adjustable parameters are only visible in the complete

operating menu.

0.50

0.20

free CL 0.50 ppm

s. point 0.40 ppm

ctrlout 50 %

calibration ?

ppm o

CLE

ppm

∆Cl

free CL 0.50 ppm

comb. CL 0.20 ppm

total CL 0.70 ppm

stop key

comb. CL 0.20 ppm

s.point 0.20 ppm

ctrlout 0 %

cal. free chlor.

zero p.: 4.00 mA

slope:

6.00 mA/ppm

cal. total chlor.

zero p.: 4.00 mA

slope:

6.00 mA/ppm

calibration

end

total CL 0.70 ppm

cal. free chlor.

DPD1-value

0.45 ppm

cal. free chlor.

zero point

0.45 ppm

cal. total chlor.

DPD4-value:

0.45 ppm

cal. total chlor.

zero point

1.28 ppm

cal. free chlor.

DPD1-value

0.45 ppm

cal. free chlor.

zero point

value take over?

4.01 mA

cal. total chlor.

DPD4-value

0.45 ppm

cal. total chlor.

zero point

value take over?

4.01 mA

cal. free chlor.

zero p.: 4.00 mA

slope:

6.01 mA/ppm

cal. total chlor.

zero p.: 4.00 mA

slope:

6.01 mA/ppm

8

limits

setting ?

limit

free chlorine

limit

comb. chlorine

limit 2: upper

0.60 ppm

limit 1: lower

0.10 ppm

LV-relay 1: LV1

- active closed

∆t on 0 s

∆t off 0 s

limit 2: upper

0.10 ppm

hysteresis

limits: 0.04 ppm

checkout time

limits: off

Only with limit value relay

LV-relay 2: LV2

- active closed

∆t on 0 s

∆t off 0 s

hysteresis

limits: 0.04 ppm

checkout time

limits: off

Page 9

Operating Menu / Overview

control

setting ?

limit

total chlorine

limit

end

control

free chlorine

LV-relay 2: LV2

- active closed

∆t on 0 s

∆t off 0 s

limit 2: upper

0.60 ppm

limit 1: lower

0.10 ppm

LV-relay 1: LV1

- active closed

∆t on 0 s

∆t off 0 s

control

automatic

dosing direction

free chlorine

ctrl parameter

xp = 10 %

Ti= off

Td= off

LV-relay max.

time: 0000 s

hysteresis

limits: 0.04 ppm

checkout time

limits: off

Only with limit value relay

LV-relay 2: LV2

- active closed

∆t on 0 s

∆t off 0 s

set point

value: 0.40 ppm

dosing direction

free chlorine

set point 2 upper

value: 0.40 ppm

set point 1 lower

value: 0.40 ppm

manual dosing

value: 0 %

dosing direction

free chlor.

additional load

value: 0 %

dosing direction

free chlorine

control

comb. chlorine

control

end

control

automatic

dosing direction

comb. chlorine

ctrl parameter

xp = 10 %

Ti= off

Td= off

set point

value: 0.20 ppm

dosing direction

comb. chlorine

manual dosing

value: 0 %

dosing direction

comb. chlorine

additional load

value 0 %

dosing direction

comb. chlorine

9

Page 10

Operating Menu / Overview

pumps

setting ?

relay

setting ?

measuring range

setting ?

meas. value free

chlorine setting

pump 1

pump 2

pump end

relay 1

relay 2

relay end

free chlorine

0...2.00 ppm

total chlorine

0...2.00 ppm

free chlorine

range adjustment

4 mA = 0.00 ppm

20 mA = 2.00 ppm

pump 1

- free chlorine

pump 2

- comb. chlorine

relay 1

- free chlorine

relay adjustment

- solenoid valve

relay 2

- comb. chlorine

relay adjustment

- solenoid valve

pump

- free chlor.

dosing pump max.

pulse/min: 180

pump

- comb. chlor.

dosing pump max.

pulse/min: 180

solenoid valve 1

- free chlor.

period 10 s

min. time 1 s

solenoid valve 2

- comb. chlor.

period 10 s

min. time 1 s

10

mA outputs

setting ?

mA output 1

mA output 2

mA output end

mA output 1

- free chlorine

adjustment

-

measured value

mA output 2

- comb. chlorine

adjustment

- control output

mA output 1

0 mA = 0.00 ppm

20 mA = 2.00 ppm

mA output 2

4 mA = 0 %

20 mA = 100 %

Page 11

Operating Menu / Overview

general setting

information

ident-code: D2CA

M0CC1004M20A

software version

D2C-Cl FW-01.00

pause free Cl

- active closed

- alarm off

- td: 10 min.

access c.: 5000

operating menu:

- english

- complete

alarm relay

active

pause total Cl

- active closed

- alarm off

- td: 10 min.

Permanent display 1

11

Page 12

8 Operating Menu / Description

Permanent displays

0.50

0.20

free CL 0.50 ppm

s. point 0.40 ppm

ctrlout 50 %

ppm o

CLE

ppm

∆Cl

free CL 0.50 ppm

comb. CL 0.20 ppm

total CL 0.70 ppm

stop key

comb. CL 0.20 ppm

s.point 0.20 ppm

ctrlout 0 %

total CL 0.70 ppm

The permanent displays 1 to 4 serve information on fault messages/causes (see also table on page 23) as

well as on operating values/settings.

Calibrate

The chlorine probe is calibrated (slope adjustment) using the DPD method (free chlorine: DPD1, total

chlorine: DPD1+3 or DPD4). The frozen measured value is suggested at the start of the calibration; this can

be adjusted to the measured DPD value with the up / down keys. A calibration is only possible if the DPD

value is ≥ 2% of the range. The control function stops during the calibration and the dosing goes over to

base load. After a successful calibration, the error diagnostics related to the measured value are restarted.

In the complete operating menu, the zero can be adjusted as well as the slope. The zero adjustment must

be made under realistic operating conditions with chlorine-free water! In this case control is stopped and

the dosing is reduced to the set base load.

The 0/4 ... 20 mA output (measured value) is frozen at the start of the calibration.

ATTENTION

• The range of the chlorine measuring cell must match the set range of the DULCOMETER® D2C

(factory setting 0 - 2.00 ppm). Any range adjustment (see “Measuring ranges” and “Free

chlorine measured value” sections, Page 19) must be made before the calibration. When

the range is changed, all settings are reset to the factory settings.

• The D2C Cl

maintains the pH at a constant value with a maximum deviation of Xm = 0.05 pH! Only then

/Cl2 must only be operated in conjunction with a pH control system which

2

can the D2C Cl2/Cl2 control the chlorine concentration with sufficient accuracy, as the

chlorine measured value is pH-dependent.

12

Page 13

Operating Menu / Description

calibration ?

cal. free chlor.

zero p.: 4.00 mA

slope:

6.00 mA/ppm

cal. total chlor.

zero p.: 4.00 mA

slope:

6.00 mA/ppm

calibration

end

cal. free chlor.

DPD1-value

0.45 ppm

cal. free chlor.

zero point

0.45 ppm

cal. total chlor.

DPD4-value:

0.45 ppm

cal. total chlor.

zero point

1.28 ppm

cal. free chlor.

DPD1-value

0.45 ppm

cal. free chlor.

zero point

value take over?

4.01 mA

cal. total chlor.

DPD4-value

0.45 ppm

cal. total chlor.

zero point

value take over?

4.01 mA

cal. free chlor.

zero p.: 4.00 mA

slope:

6.01 mA/ppm

cal. total chlor.

zero p.: 4.00 mA

slope:

6.01 mA/ppm

Possible values

Initial value Increment Lower value Upper value

DPD value Measured value 0.01 ppm -0.20 ppm 2.20 ppm

0.01 ppm -0.50 ppm 5.50 ppm

0.01 ppm -1.00 ppm 11.00 ppm

Zero point Measured value (mA) – – –

Error message Condition Remarks

Cl calibration not possible! Cl slope too low Repeat calibration

Slope too low (<25 % of the standard slope)

Cl calibration not possible! Cl slope too high Repeat calibration

Slope too high (>300 % of the standard slope)

DPD value too small! DPD <2 % of measuring range Repeat calibration after

DPD > x.xx ppm addition of chlorine

Zero point high Sensor signal > 5 mA Repeat calibration in

chlorine-free water

Zero point low Sensor signal < 3 mA Check sensor connection

Possibly change sensor

13

Page 14

Operating Menu / Description

Limits

When setting the check out time, metering of the corresponding pump is stopped and an alarm is triggered

through the alarm relay in the event of limit violations exceeding the set check out time.

For devices with limit relays, a limit value or a zone may be set for each measuring value, where the relay will

switch.

limits

setting ?

limit

free chlorine

limit

comb. chlorine

limit

total chlorine

limit

end

limit 2: upper

0.60 ppm

limit 1: lower

0.10 ppm

LV-relay 1: LV1

- active closed

∆t on 0 s

∆t off 0 s

limit 2: upper

0.10 ppm

LV-relay 2: LV2

- active closed

∆t on 0 s

∆t off 0 s

limit 2: upper

0.60 ppm

limit 1: lower

0.10 ppm

LV-relay 1: LV1

- active closed

∆t on 0 s

∆t off 0 s

hysteresis

limits: 0.04 ppm

checkout time

limits: off

Only with limit value relay

LV-relay 2: LV2

- active closed

∆t on 0 s

∆t off 0 s

hysteresis

limits: 0.04 ppm

checkout time

limits: off

LV-relay max.

time: 0000 s

hysteresis

limits: 0.04 ppm

checkout time

limits: off

Only with limit value relay

LV-relay 2: LV2

- active closed

∆t on 0 s

∆t off 0 s

14

Page 15

Operating Menu / Description

Initial value Step interval Lower value Upper value Remarks

Type of limit infringement Limit infringement when value

Free chlorine upper upper

Combined chlorine lower upper

Total chlorine upper upper

Limit value 1 0.10 ppm 0.01 ppm -0.20 ppm 2.20 ppm

0.25 ppm 0.01 ppm -0.50 ppm 5.50 ppm

0.50 ppm 0.01 ppm -1.00 ppm 11.00 ppm

Limit value 2 0.60 ppm 0.01 ppm -0.20 ppm 2.20 ppm

1.50 ppm 0.01 ppm -0.50 ppm 5.50 ppm

3.00 ppm 0.01 ppm -1.00 ppm 11.00 ppm

Hysteresis limit 0.04 ppm 0.01 ppm 0 ppm 2.20 ppm Works towards clearing the

0.10 ppm 0.01 ppm 0 ppm 5.50 ppm infringement of the limit.

0.20 ppm 0.01 ppm 0 ppm 11.00 ppm

Checkout time limit Off 1 s 1 s 9999 s Leads to message and alarm

Limit relay 1 LV-relay 1 LV-relay 1

Limit relay 2 LV-relay 1 LV-relay 1

Limit relays 1, 2 active active

closed closed

Turn-on delay ∆t On 0 s 1 s 0 s 9999 s

Turn-off delay ∆t Off 0 s 1 s 0 s 9999 s

Limit relay Off 1 s 1 s / Off 9999 s Function can be switched off

max. (turn-on) time

Possible values

exceeds or falls below limit

lower

lower

lower

and shutdown of the

corresponding dosing.

Off: function switched off,

no message, no alarm.

LV-relay 2

Zone* *With the “Zone” setting

Off the gap between the limits

must be ≥ 3 times the set

LV-relay 2

Zone*

Off

active

open

hysteresis.

15

Page 16

Operating Menu / Description

Control

control

setting ?

control

free chlorine

control

dosing direction

free chlorine

automatic

set point

value: 0.40 ppm

dosing direction

free chlorine

set point 2 upper

value: 0.40 ppm

set point 1 lower

value: 0.40 ppm

manual dosing

value: 0 %

dosing direction

free chlor.

additional load

value: 0 %

dosing direction

free chlorine

set point

value: 0.20 ppm

dosing direction

comb. chlorine

manual dosing

value: 0 %

dosing direction

comb. chlorine

additional load

value 0 %

dosing direction

comb. chlorine

control

comb. chlorine

control

end

ctrl parameter

xp = 10 %

Ti= off

Td= off

control

automatic

dosing direction

comb. chlorine

ctrl parameter

xp = 10 %

Ti= off

Td= off

Possible values

Initial value Step interval Lower value Upper value Remarks

Control automatic automatic

auto with dead zone

manual

off

Dosing direction free chlorine free chlorine

free chlorine

free chlorine /

Setpoint 1/2 0.40 ppm 0.01 ppm 0 ppm 2.00 ppm setpoint1 ≤ setpoint2

1.00 ppm 0.01 ppm 0 ppm 5.00 ppm

2.00 ppm 0.01 ppm 0 ppm 10.00 ppm

16

Page 17

Operating Menu / Description

Possible values

Initial value Step interval Lower value Upper value Remarks

Control parameter xp 10 % 1 % 1 % 500 % xp relative to measuring

Control parameter Ti Off 1 s 1 s 9999 s

Control parameter Td Off 1 s 1 s 2500 s

Additive base load 0 % 1 % 0 % +100 %

Manual dosing 0 % 1 % -100 % +100 %

(free chlorine)

Manual dosing

(combined chlorine) 0 % 1 % 0 % +100 %

Pumps

The maximum stroke value of the metering pumps should correspond to the stroke frequency of the

metering pump used.

range

pumps

setting ?

pump 1

pump 2

pump end

pump 1

- free chlorine

pump 2

- comb. chlorine

pump

- free chlor.

dosing pump max.

pulse/min: 180

pump

- comb. chlor.

dosing pump max.

pulse/min: 180

Possible values

Initial value Step interval Lower value Upper value Remarks

Assignment of

measured variables

Pump 1 free chlorine free chlorine

combined chlorine

Off

Pump 2 combined chlorine free chlorine

combined chlorine

Off

Dosing direction free chlorine free chlorine Selection only available

Pump free chlorine with free chlorine

Max. no. of strokes/min 180 1 1 500 Off = 0 strokes/min

of pumps 1 and 2

17

Page 18

Operating Menu / Description

Relays

The two relays can be freely assigned with regard to function (limit, correcting element, solenoid valve).

If the function is set to correcting element or solenoid valve, the relays are de-energised on fault to prevent

faulty dosing.

Relay output 2 for combined chlorine is used to control devices for minimising combined chlorine.

relay

setting ?

relay 1

relay 2

relay end

relay 1

- free chlorine

relay adjustment

- solenoid valve

relay 2

- comb. chlorine

relay adjustment

- solenoid valve

solenoid valve 1

- free chlor.

period 10 s

min. time 1 s

solenoid valve 2

- comb. chlor.

period 10 s

min. time 1 s

Possible values

Initial value Increment Lower value Upper value Remarks

Measured variable

assignment

Relay 1 free chlorine free chlorine

comb. chlorine

total chlorine

Off

Relay 2 comb. chlorine free chlorine

comb. chlorine

total chlorine

Off

Function in accordance with limit value

1)

not with total chlorine

assignment Identity Code correcting element * measured variable

Relay solenoid valve

1)

* e.g. motor-driven pump

Relay is de-energised

on fault and during

the calibration

Dosing direction free chlorine free chlorine Selection only available

Solenoid valve 1 free chlorine with free chlorine

Cycle time 10 s 1 s 10 s 9999 s

Minimum time 1 s 1 s 1 s cycle/2

18

Page 19

Operating Menu / Description

Measuring ranges

ATTENTION

• The ranges (factory setting 0 – 2.00 ppm) must match the ranges of the chlorine measuring

cells used.

• If the range is changed, all settings (limits, setpoints ....) are reset to the factory settings!

measuring range

setting ?

free chlorine

0...2.00 ppm

total chlorine

0...2.00 ppm

Possible values

Initial value Increment Lower value Upper value Remarks

Measuring range 0...2 ppm 0...2 ppm

0...5 ppm

0...10 ppm

Free chlorine measured value

The measurement signal for free chlorine is connected to the standard signal input of X2. As the

measurement signal can come from an external device or a D1C with a different range, you can adjust the

range of this standard signal input separately in this setting menu.

ATTENTION

• If the range is changed, all setting values must be checked!

• If the measurement signal does not come directly from a sensor, but comes from a device

such as a D1C, for example, only the ranges of the D2C and the device have to be matched

to one another – do not calibrate the D2C for free chlorine!

• If the range changes, the controller range also changes with it!

meas. value free

chlorine setting

free chlorine

range adjustment

4 mA = 0.00 ppm

20 mA = 2.00 ppm

Possible values

Initial value Step interval Lower value Upper value Remarks

Lower limit of 4 mA 4 mA Upper limit is 20 mA

standard signal range 0 mA

Range assigned 0...2.00 ppm 0.01 ppm -0.20 ppm 2.20 ppm

to the standard 0...5.00 ppm 0.01 ppm -0.50 ppm 5.50 ppm

signal 0...10.00 ppm 0.01 ppm -1.00 ppm 11.00 ppm

19

Page 20

Operating Menu / Description

Outputs 0/4 - 20mA

The mA outputs may be used either for documentation of the measuring value or as regulated value. When

the regulated value is set, the metering direction selected in "control" will be automatically used!!

mA outputs

setting ?

mA output 1

mA output 2

mA output end

mA output 1

- free chlorine

adjustment

measured value

-

mA output 2

- comb. chlorine

adjustment

- control output

mA output 1

0 mA = 0.00 ppm

20 mA = 2.00 ppm

mA output 2

4 mA = 0 %

20 mA = 100 %

Possible values

Initial value Increment Lower value Upper value Remarks

Measured variables

assignment

mA output 1 free chlorine free chlorine

comb. chlorine

total Cl

Off

mA output 2 comb. chlorine free chlorine

comb. chlorine

total Cl

Off

Functions measured value

assignment control variable

1)

1)

not with total chlorine

measured variable

output1 measured value

output2 measured value

Lower limit 4 mA 4 mA Upper limit is 20 mA

Standard signal range 0 mA

Measured value

range 0…2 ppm 0.01 ppm -1.00 ppm 11.00 ppm Minimum range 0.1 ppm

Control variable range 0 %…+100 % 1 % 0 % +100 % Minimum range 1 %

20

Page 21

Operating Menu / Description

General settings

Alarm relay

The alarm relay may be activated / deactivated. When deactivated, no fault message is displayed.

Pause function

With regard to the pause, a delay time "td" may be set. The control will start again only after cessation of the

pause contact and expiry of the preset delay time. When the delay time is elapsing, a clock symbol will be

displayed. The pause function may be reset by pressing the start / stop button.

The mA output measuring value will be frozen when the pause function is activated.

Operating menu

All setting menus may be accessed by switching from reduced to complete. We recommend to set the

reduced menu again after commissioning.

Access code

If the access code (factory-set to 5000) is altered, no settings (with the exception of cali-bration) may be

carried out without entering the correct code.

general setting

information

ident-code: D2CA

M0CC1004M20A

software version

D2C-Cl FW-01.00

pause free Cl

- active closed

- alarm off

- td: 10 min.

access c.: 5000

operating menu:

- english

- complete

alarm relay

active

pause total Cl

- active closed

- alarm off

- td: 10 min.

Permanent display 1

Possible values

Initial value Increment Lower value Upper value Remarks

Alarm relay active active

not active

Pause closed closed

open

Alarm off Alarm off

Alarm on

td: 10 min 1 min 0 min 60 min

Access code 5000 1 1 9999

Language as per identity German

code Englisch

French

Spanish

Swedish

Dutch

Operating menu restricted restricted

complete

21

Page 22

9 Technical Terms

Calibration: By calibrating (adjusting), the measuring value readout will be adjusted to the actual

Solenoid valve: Activation of solenoid valves (motor-driven pumps) is defined by the cycle time and

Zero point: The zero point of pH probes is theoretically 0 mV. In practice, for a good probe

Slope: The slope of pH probes should always be ≥ 50 (better: ≥ 55) mV/pH. The slope of the

Set point: The set point is the value which is to be continuously maintained stable throughout

Regulated value: The regulated value is the value (e.g. frequency, mA signal) the controller sends to the

Control parameter: The control parameters (xp, Ti, Td) determine the control characteristic (PID).

Manual control: In this setting, the controller produces a controlled variable corresponding to the

xp value: This value influences the proportional control behaviour. In case of a deviation of 1.4

Ti (integral This value defines the integral (I) control behaviour. The greater Ti, the lower the

action time): I proportion.

Td (differential This value defines the differential (D) control behaviour. The lower Ti, the lower the

action time): D proportion.

Metering direction: This value determines in which direction the controller is active. In case of the

Additive base load: This results in the fact that the controller always generates a manipulated value

Relay: The relay (alarm, limit relay) switch when the corresponding prerequisites (e.g. alarm

probe signal. Without calibration, a correct measurement is not possible. A calibration

should be performed regularly (depending on application).

the minimum on-state interval (minimum time) (pulse length control). The on-state

interval always corresponds to at least the minimum time. However, it is increased up

to the cycle time at a maximum depending on the control deviation and the control

response. The cycle time itself defines the maximum possible on-state operations.

For instance, an actuator is switched on a maximum of 60 times per hour when the

cycle time is at 60 seconds. The minimum time defines the minimum on-state interval

duration. It should be selected as small as possible while, however, ensuring that

metering is still possible within this time.

function a zero point of ± 25 mV is acceptable.

The zero point of chlorine probes is 4 mA. A calibration is not necessary.

chlorine measuring cell is given in mA/ppm. For a good probe function, the values

accepted by the controller are sufficient.

the process via controlling.

final controlling element (e.g. metering pump) to reach again the set point.

entry. It is retained up to the next change. It is independent of the measured variable

and the set control parameters. This setting can be used for determining the time

response (e.g. dead time...) of the controlled system.

pH (=10 % of 14 pH) or 0.2 ppm (=10 % of 2 ppm), a xp value of 10 %, for example,

leads to a regulated value of 100 %. If the xp value has to be increased to 20 %, the

deviation must be double the value in order to reach a regulated value of 100 %. In

case of control overshooting, the set xp value must be doubled.

metering direction "acid", the controller generates a manipulated value when the

specified value for pH is exceeded.

corresponding to the additive base load. This load may only be reset to 0 using the

stop button. This function should not be activated when using PI or PID controllers.

condition, limit violation) are given. The relay function can be set either as make

contact (active closed) or break contact (active open). The relay may be reset pressing

the stop button. (Exception: limit value).

22

Page 23

10 Faults / Notes / Troubleshooting

2)

3)

5)

the dosing for combined chlorine goes onto base load as well (except for limit infringement)

the control for combined chlorine stops as well (except for limit infringement)

the delay period td of the pause function is deleted

Electronics error EEPROM faulty none stop Yes Return device

Operating step Info text Symbol Effect Alarm with Remarks Remedy

Pause contact pause none stop Yes, Delay time td Deselect pause,

Stop key

5)

Limit infringement comb CI limit

after check time switched off

Faulty calibration cal. total CI base load

Combined chlorine comb CI negativ continues No < -10 % Optimise pH controller,

negative value of measuring range recalibrate free Cl

after check time total CI limit

Faulty calibration cal. free CI base load

Total chlorine

signal too high total CI inputa base load

/ too low transmitter and connection

Limit infringement total CI limit

Free chlorine

signal too high free CI inputaaa base load

/ too low transmitter and connection

Limit infringement free CI limit

after check time free CI limit

Error Error text Symbol Effect Alarm with Remarks Remedy

switchable adjustable: shows delay time td

current „td“

stop key none stop No Start device

on dosing on control acknowledge

2 /

a none stop Yes Function can be

and total Cl

not possible! possibly renew.

1 /

2 /

aaa none stop

aaa switched off

2)

stop

3)

3)

Yes function can be

No Check sensor, clean,

Repeat calibration

not possible! possibly renew.

2)

stop

3)

Yes 3 mA>signal>23 mA Check sensor,

Repeat calibration

1 /

2 /

aaa none stop

aaa switched off

2)

stop

3)

No Check sensor, clean,

2)

stop

3)

3)

Yes 3 mA>signal>23 mA Check sensor,

Yes Function can be

on dosing on control acknowledge

23

Page 24

24

'

©2005 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany

Operating Instructions DULCOMETER® D2C, Part 2, Chlorine/Chlorine

Subject to modifications · Printed in Germany

Addresses and delivery information may be obtained from the manufacturer:

ProMinent Dosiertechnik GmbH · Im Schuhmachergewann 5-11 · 69123 Heidelberg

Telephone: +49 6221 842-0 · Telefax: +49 6221 842-419

info@prominent.com · www.prominent.com

Loading...

Loading...