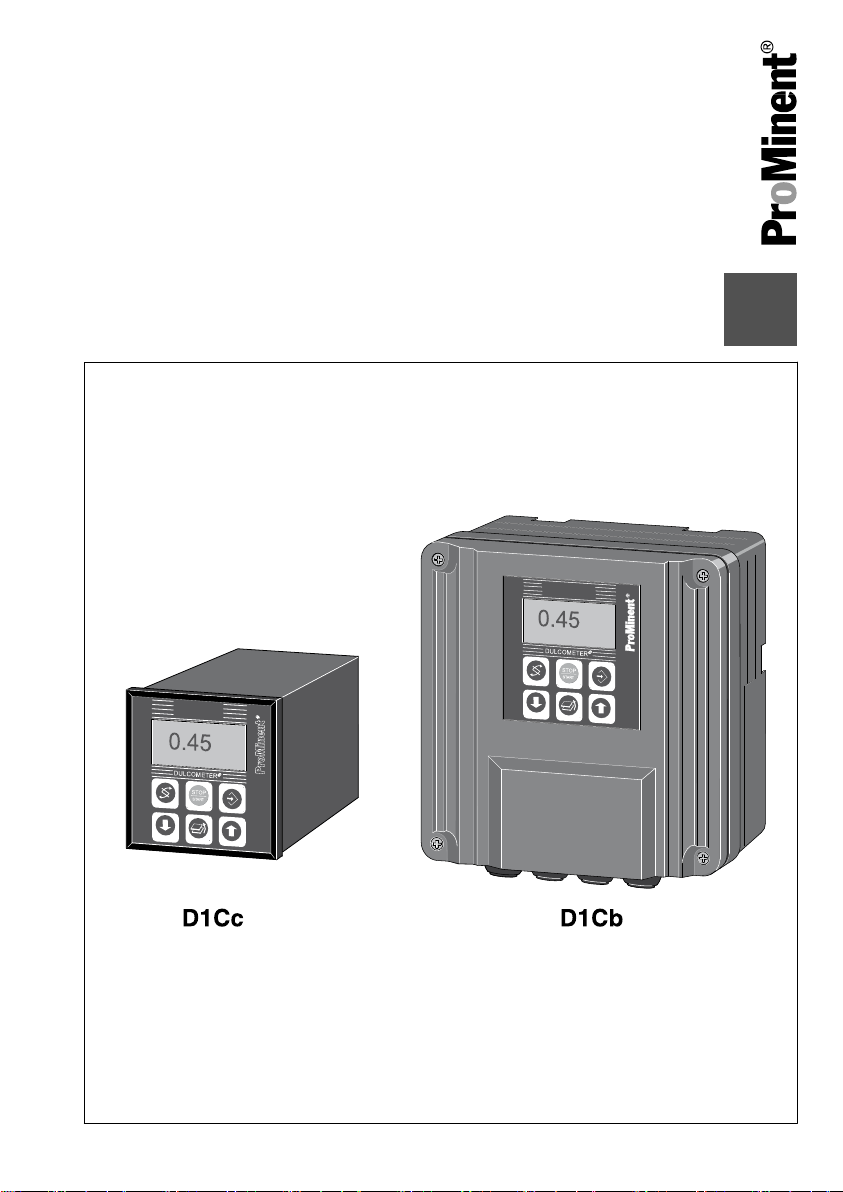

Page 1

Assembly and operating instructions

DULCOMETER® D1Cb / D1Cc

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Technical changes reserved.

Teile Nr. 986362 BA DM 187 09/11 EN

Page 2

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

email: info@prominent.de

Internet: www.prominent.com

986362, 4, en_GB

© 2011

2

Page 3

General non-discriminatory approach

In order to make it easier to read, this

document uses the male form in grammat‐

ical structures but with an implied neutral

sense. It is aimed equally at both men and

women. We kindly ask female readers for

their understanding in this simplification of

the text.

Supplementary information

Read the following supplementary infor‐

mation in its entirety!

The following are highlighted separately in

the document:

n Enumerated lists

Instructions

Results of the instructions

ð

Supplemental instructions

Information

This provides important information

relating to the correct operation of the

system or is intended to make your

work easier.

Safety information

Safety information are provided with

detailed descriptions of the endangering

situation, see

Ä Chapter 1.1 ‘Explanation

of the safety information’ on page 8

3

Page 4

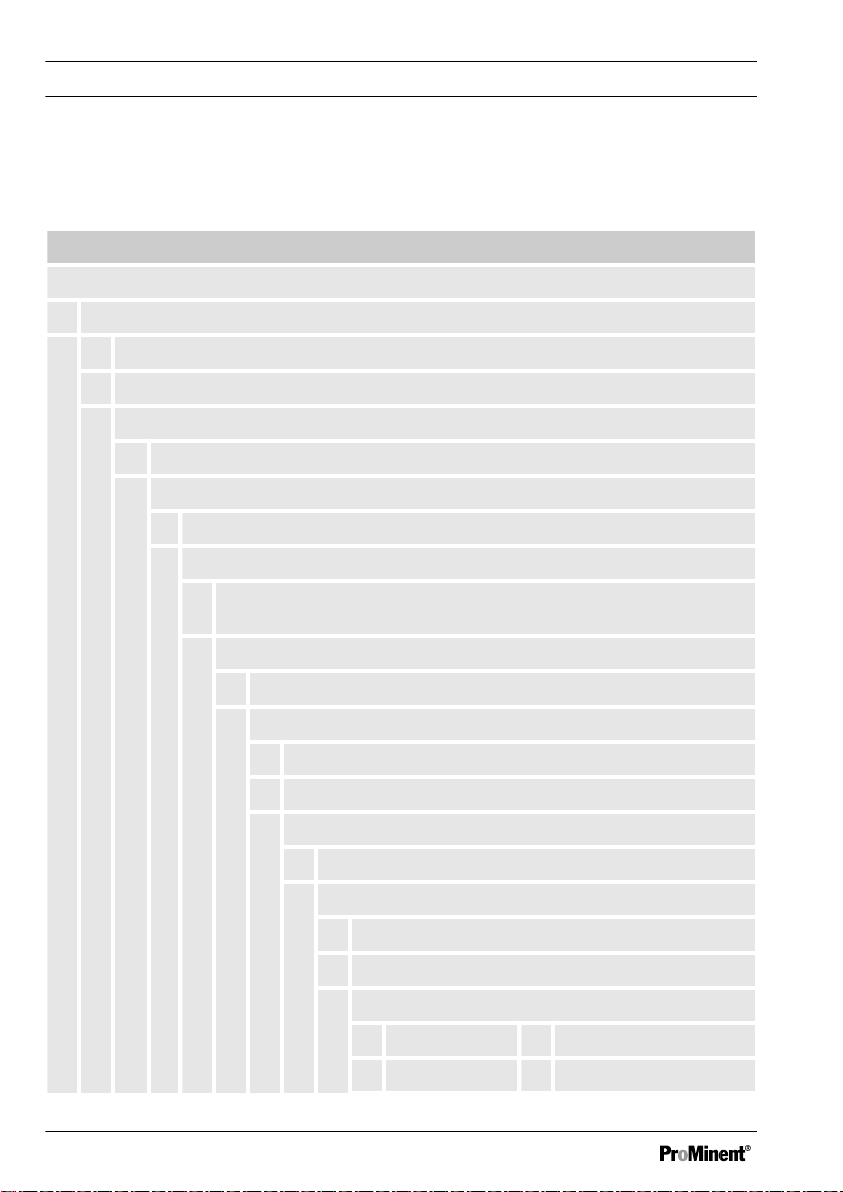

Table of contents

Table of contents

1 Introduction............................................................................................................. 8

1.1 Explanation of the safety information............................................................. 8

1.2 Users' qualifications...................................................................................... 10

1.3 General Safety Information.......................................................................... 11

1.4 Correct and proper use................................................................................ 13

1.5 ID Code........................................................................................................ 14

2 Functional description........................................................................................... 17

2.1 Wall mounting/control panel installation....................................................... 18

2.2 Electrical construction.................................................................................. 19

2.2.1 Block circuit diagram................................................................................. 20

2.2.2 Galvanic Isolation ..................................................................................... 21

3 D1Cb mounting..................................................................................................... 22

3.1 Scope of supply............................................................................................ 23

3.2 Installation (Wall Mounted) .......................................................................... 24

3.3 Installation - Control Panel Mounted (Optional) .......................................... 25

3.4 Wall Mounted Installation of D1Cb (Electrical) ............................................ 27

3.4.1 Opening the device................................................................................... 28

3.4.2 Electrical Installation (Wall Mounted) ....................................................... 29

3.4.3 Electrical Installation (Control Panel Mounted) ........................................ 30

3.4.4 Installation of Coaxial Cable to Guard Terminal XE1 ............................... 31

3.4.5 Cable Cross-Sections and Cable End Sleeves......................................... 32

3.4.6 Protective RC Circuit (Optional) ............................................................... 33

3.4.7 Terminal Wiring Diagram .......................................................................... 34

3.5 Switching of inductive loads......................................................................... 38

4 D1Cc mounting..................................................................................................... 40

4.1

DULCOMETER® D1Cc scope of supply...................................................... 41

4.2

Mounting - control panel installation DULCOMETER®

4.3 Electrical Installation (Control Panel Mounted)............................................ 44

4.3.1 Installation of Coaxial Cable to Guard Terminal XE1................................ 45

4.3.2 Cable Cross-Sections and Cable End Sleeves......................................... 47

4.3.3 Terminal diagram ..................................................................................... 48

4.4 Switching of inductive loads......................................................................... 50

D1Cc....................... 41

4

Page 5

Table of contents

5 Commissioning..................................................................................................... 52

5.1 Initial commissioning ................................................................................... 52

5.1.1 Selection of the Operating Language........................................................ 52

5.1.2 Selection of the Measured Variable and Measuring Range...................... 54

5.2 Activation Code for Extended Functions...................................................... 55

5.2.1 Extended Functions Obtainable with the Activation Code......................... 55

6 Operating diagram/ Display Symbols................................................................... 59

6.1 Overview of equipment/Control elements.................................................... 59

6.2 Display Symbols........................................................................................... 60

6.3 Permanent Display 1 ................................................................................... 61

6.4 Continuous display 2.................................................................................... 62

6.5 Continuous display 3.................................................................................... 62

6.6 Operating diagram........................................................................................ 64

6.7 Reduced / Complete Operating Menu ......................................................... 67

6.8 Fault Messages............................................................................................ 67

6.8.1 Fault display.............................................................................................. 67

6.9 General settings........................................................................................... 68

6.9.1 Access code.............................................................................................. 68

7 Measured Variables and Operating Menus for Amperometric Sensors............... 69

7.1 Reduced / Complete Operating Menu ......................................................... 70

7.2 Description of All Amperometric Measured Variables ................................. 70

7.3 Reduced Operating Menu ........................................................................... 71

7.4 Complete Operating Menu / Description of All Measured Variables............ 73

7.5 Calibration of All Amperometric Measured Variables .................................. 74

7.6 Calibration of the Sensor for Amperometric Measured Variables................ 75

7.6.1 Preparation for Calibration of the Sensors for Amperometric Measured

Variables .................................................................................................. 75

7.6.2 Calibration of Zero Point and Slope.......................................................... 76

7.7 Setting the Measured value.......................................................................... 79

7.8 Correcting value........................................................................................... 79

8 Measured Variables and Operating Menus for Potentiometric Sensors............... 81

8.1 Reduced / Complete Operating Menu ......................................................... 82

8.2 Description of pH, Redox and Fluoride Measured Variables ...................... 82

8.3 Reduced pH / Redox / Fluoride Operating Menu ........................................ 83

8.4 Complete Operating Menu/Description of pH / ORP / Fluoride.................... 85

8.5 Calibration of pH, ORP and Fluoride Sensors.............................................. 87

5

Page 6

Table of contents

8.5.1 Description of the Calibration of pH Sensors ........................................... 88

8.5.2 Calibration of pH Sensors. Description of the Setting Ranges ................. 91

8.5.3 Calibration of pH Sensors. Description of the Error Messages ................ 91

8.5.4 Testing the Redox Sensor ........................................................................ 92

8.5.5 Description of the Calibration of Fluoride Sensors.................................... 95

8.6 Temperature correction value for pH and fluoride sensors.......................... 99

9 Measured Variables and Operating Menus for the Standard Signal General..... 101

9.1 Explanation of the Standard Signal General.............................................. 101

9.2 Changing the Measured Variable .............................................................. 103

9.3 Reduced / Complete Operating Menu ....................................................... 104

9.4 Setting the Reading ................................................................................... 104

9.5 Description of All Standard Signal Measured Values/Measured

Variables ................................................................................................... 105

9.6 Reduced Operating Menu ......................................................................... 106

9.7 Complete Operating Menu / Description of All Measured Variables ......... 108

9.8 Calibrating the Standard Signal ................................................................. 109

9.8.1 Calibration of the Zero Point of the Standard Signal General................. 110

9.8.2 Two-Point Calibration of the Standard Signal General............................ 111

10 Operating Menus Independent of Measured Variables...................................... 113

10.1 Pumps ..................................................................................................... 114

10.2 Setting the Relays.................................................................................... 116

10.2.1 Setting and Functional Description of the Relays.................................. 117

10.3 Setting the Limits...................................................................................... 122

10.4 Setting the Control.................................................................................... 125

10.5 Set mA output........................................................................................... 129

10.6 General settings....................................................................................... 131

10.6.1 Setting the Measured Variable/Measuring Range................................. 131

10.6.2 Sub-Functions of the "General Settings" Menu..................................... 132

11 Maintenance....................................................................................................... 136

11.1

Fuse replacement DULCOMETER®

11.2 Summary of Error Texts .......................................................................... 138

12 Technical data.................................................................................................... 141

12.1

Ambient conditions DULCOMETER® D1Cb / D1Cc ................................ 141

12.2 Sound Pressure Level.............................................................................. 141

12.3 Material Data............................................................................................ 142

D1Cb / D1Cc ................................. 136

6

Page 7

Table of contents

12.4 Chemical Resistance................................................................................ 142

12.5 Dimensions and weights.......................................................................... 143

13 Electrical Data .................................................................................................... 144

14

Spare parts and accessories DULCOMETER® D1Cb / D1Cc............................ 148

Standards Complied With .................................................................................. 150

15

16 Disposal of Used Parts....................................................................................... 151

17 Declaration of Conformity................................................................................... 152

18 Index................................................................................................................... 154

7

Page 8

Introduction

1 Introduction

These operating instructions provide infor‐

mation on the technical data and functions

DULCOMETER® controllers of the

of the

series D1Cb / D1Cc.

The controllers DULCOMETER

D1Cb and DULCOMETER® D1Cc

differ from each other only in their

type of housing and mounting loca‐

tion, not in their functionality.

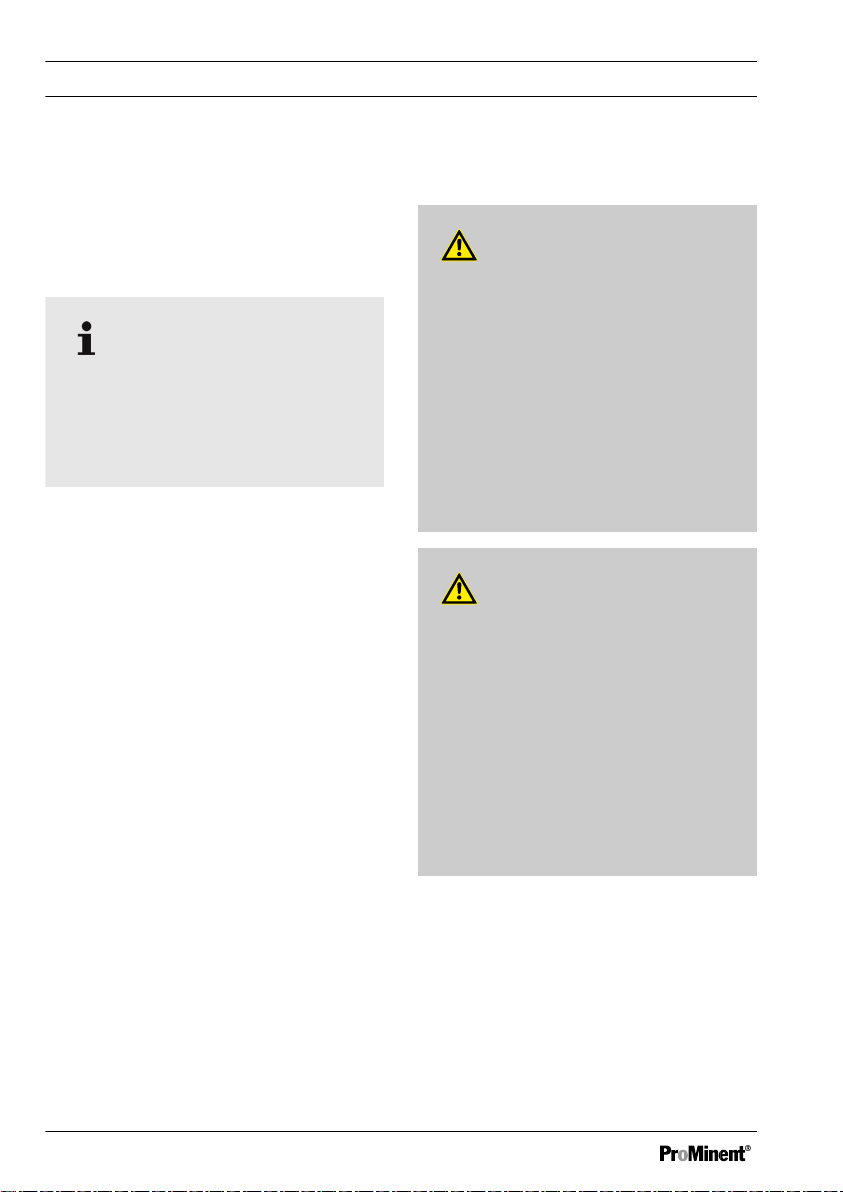

1.1 Explanation of the safety information

Introduction

These operating instructions provide infor‐

mation on the technical data and functions

of the product. These operating instruc‐

tions provide detailed safety information

and are provided as clear step-by-step

instructions.

The safety information and notes are cate‐

gorised according to the following

scheme. A number of different symbols

are used to denote different situations.

The symbols shown here serve only as

examples.

®

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious

injuries.

Measure to be taken to avoid this

danger

Danger!

Denotes an immediate threat‐

–

ening danger. If this is disre‐

garded, it will result in fatal or

very serious injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very

serious injuries.

Measure to be taken to avoid this

danger

Warning!

Denotes a possibly hazardous sit‐

–

uation. If this is disregarded, it

could result in fatal or very

serious injuries.

8

Page 9

Introduction

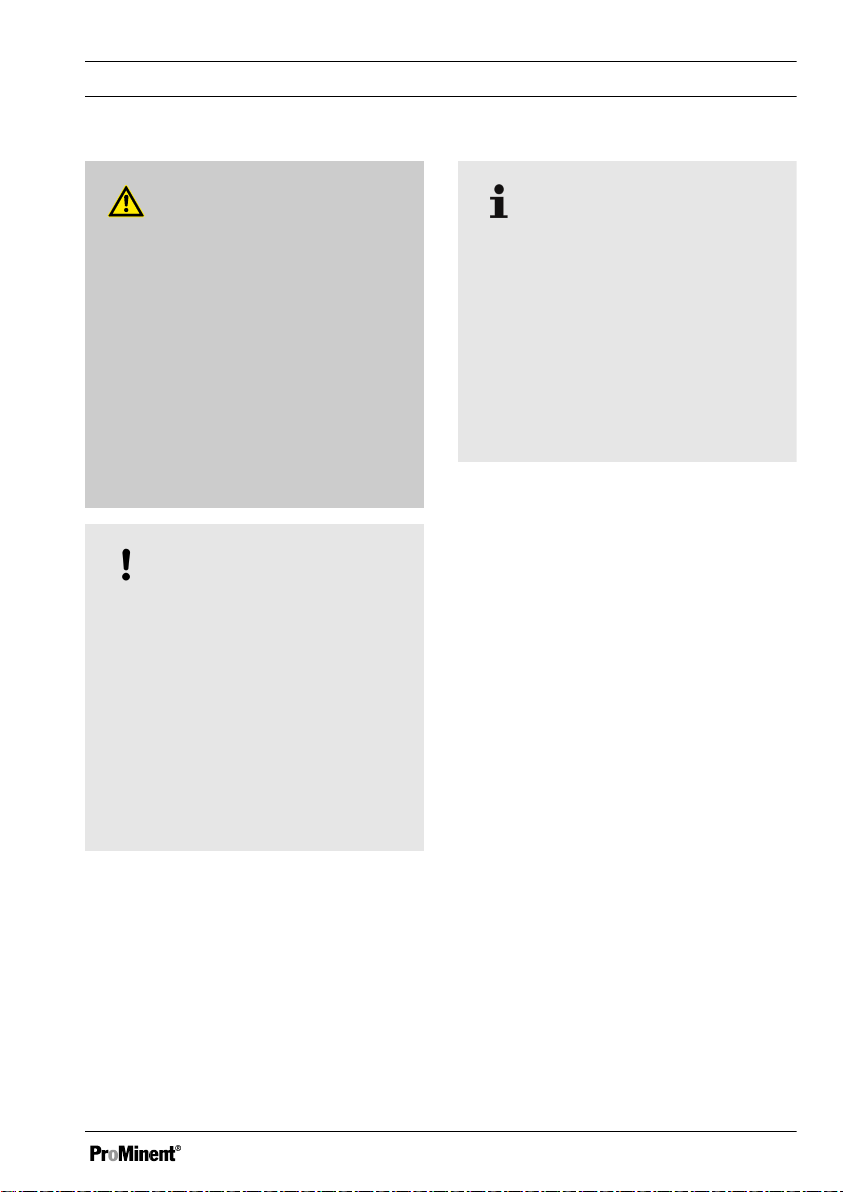

CAUTION!

Nature and source of the danger

Possible consequence: Slight or

minor injuries, material damage.

Measure to be taken to avoid this

danger

Caution!

Denotes a possibly hazardous sit‐

–

uation. If this is disregarded, it

could result in slight or minor inju‐

ries. May also be used as a

warning about material damage.

NOTICE!

Nature and source of the danger

Damage to the product or its sur‐

roundings

Measure to be taken to avoid this

danger

Note!

Denotes a possibly damaging sit‐

–

uation. If this is disregarded, the

product or an object in its vicinity

could be damaged.

Type of information

Hints on use and additional informa‐

tion

Source of the information, additional

measures

Information!

–

Denotes hints on use and other

useful information. It does not

indicate a hazardous or dam‐

aging situation.

9

Page 10

Introduction

1.2 Users' qualifications

WARNING!

Danger of injury with inadequately qualified personnel!

The operator of the plant / device is responsible for ensuring that the qualifications

are fulfilled.

If inadequately qualified personnel work on the unit or loiter in the hazard zone of the

unit, this could result in dangers that could cause serious injuries and material

damage.

– All work on the unit should therefore only be conducted by qualified personnel.

Unqualified personnel should be kept away from the hazard zone

–

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been

instructed and, if required, trained in the tasks assigned to him/

her and possible dangers that could result from improper

behaviour, as well as having been instructed in the required

protective equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of

an instructed person and who has also received additional

training specific to the system from ProMinent or another

authorised distribution partner.

Trained qualified per‐

sonnel

A qualified employee is deemed to be a person who is able to

assess the tasks assigned to him and recognize possible haz‐

ards based on his/her training, knowledge and experience, as

well as knowledge of pertinent regulations. The assessment of

a person's technical training can also be based on several

years of work in the relevant field.

10

Page 11

Training Definition

Introduction

Electrician Electricians are deemed to be people, who are able to com‐

plete work on electrical systems and recognize and avoid pos‐

sible hazards independently based on his/her technical training

and experience, as well as knowledge of pertinent standards

and regulations.

Electricians should be specifically trained for the working envi‐

ronment in which the are employed and know the relevant

standards and regulations.

Electricians must comply with the provisions of the applicable

statutory directives on accident prevention.

Customer Service

department

Customer Service department refers to service technicians,

who have received proven training and have been authorised

by ProMinent to work on the system.

Note for the system operator

The pertinent accident prevention regulations, as well as all other generally acknowl‐

edged safety regulations, must be adhered to!

1.3 General Safety Information

WARNING!

WARNING!

Live parts!

Possible consequence: Fatal or very

serious injuries

– Measure: Disconnect the mains

power supply prior to opening the

housing

De-energise damaged, defective

–

or manipulated units by discon‐

necting the mains plug

Unauthorised access!

Possible consequence: Fatal or very

serious injuries

– Measure: Ensure that there can

be no unauthorised access to the

unit

11

Page 12

Introduction

WARNING!

Operating errors!

Possible consequence: Fatal or very

serious injuries

– The unit should only be operated

by adequately qualified and tech‐

nically expert personnel

Please also observe the oper‐

–

ating instructions for controllers

and fittings and any other compo‐

nent groups, such as sensors,

measuring water pumps ...

– The operator is responsible for

ensuring that personnel are quali‐

fied

CAUTION!

Electronic malfunctions

Possible consequence: Material

damage to destruction of the unit

– The mains connection cable and

data cable should not be laid

together with cables that are

prone to interference

Measure: Take appropriate inter‐

–

ference suppression measures

NOTICE!

Correct and proper use

Damage to the product or its sur‐

roundings

– The unit is not intended to

measure or regulate gaseous or

solid media

The unit may only be used in

–

accordance with the technical

details and specifications pro‐

vided in these operating instruc‐

tions and in the operating instruc‐

tions for the individual

components

NOTICE!

Correct sensor operation / Run-in

time

Damage to the product or its sur‐

roundings

– Correct measuring and dosing is

only possible if the sensor is

working perfectly

It is imperative that the run-in

–

times of the sensors are adhered

to

– The run-in times should be

allowed for when planning initial

operation

– It may take a whole working day

to run-in the sensor

– Please read the operating instruc‐

tions for the sensor

12

Page 13

Introduction

NOTICE!

Correct sensor operation

Damage to the product or its sur‐

roundings

– Correct measuring and dosing is

only possible if the sensor is

working perfectly

Check and calibrate the sensor

–

regularly

NOTICE!

Compensation of control deviations

Damage to the product or its sur‐

roundings

– This controller cannot be used in

control circuits which require

rapid compensation (< 30 s)

1.4 Correct and proper use

NOTICE!

Correct and proper use

The unit is intended to measure and

regulate liquid media. The marking of

the measured variables is located on

the controller and is absolutely

binding.

The unit may only be used in accord‐

ance with the technical details and

specifications provided in this oper‐

ating manual and in the operating

manuals for the individual compo‐

nents (such as, for example, sensors,

fittings, calibration devices, metering

pumps etc.).

Any other uses or modifications are

prohibited.

NOTICE!

Compensation for control deviations

Damage to the product or its sur‐

roundings

– The controller can be used in pro‐

cesses, which require compensa‐

tion of > 30 seconds

13

Page 14

Introduction

1.5 ID Code

Device identification / Identcode

DULCOMETER® controller series D1Cb / D1Cc

D1Cb / D1Cc

Type of mounting

W Wall mounted D1Cb (IP 65)

D Control panel installation D1Cc (IP54)

Version

00 with LCD and keypad / with ProMinent logo

Operating voltage

6 90...253 V, 50/60 Hz (wide voltage power unit)

Certification

01CE mark

Hardware extension I

14

0 none

Hardware extension II

0 none

1 Protective RC circuit for power relay

External connection

0 none

Software default setting

U Default setting

V Software preset

Default measured variable

0 Universal I Chlorite

A Peracetic acid P pH

Page 15

DULCOMETER® controller series D1Cb / D1Cc

B Bromine R ORP

Introduction

C Chlorine S 0/4...20 mA standard

signal general

D Chlorine

X Dissolved oxygen

dioxide

F Fluoride Z Ozone

H Hydrogen per‐

L Conductivity

oxide

Connection of the measured variable

1 mA input (standard signal 0/4-20 mA, all

measured variables)

5 mV input (pH/ORP)

Correction variable

0 none

2 Temperature Pt 100/PT1000 (for

pH, conductivity, fluoride, ClO2 CDP

sensor)

4 Manual temperature input (for pH,

conductivity, fluoride, ClO2 CDP

sensor)

Control input

0 none

1 Pause

Signal output

0 none

1 Analogue signal output

0/4...20 mA

Power activation

G Alarm and 2 limit relays

15

Page 16

Introduction

DULCOMETER® controller series D1Cb / D1Cc

M Alarm and 2 solenoid

valve relays

Pump activation

0 none

2 2 pumps via pulse

frequency

Control character‐

istic

0 none

1 Proportional

control

2 PID control

16

Page 17

Functional description

2 Functional description

Brief functional description

The DULCOMETER® D1Cb / D1Cc 4-wire measuring transducer/controller is a device

designed to measure/control a measured variable.

In the mA measuring version, the measured variable can be changed without restrictions

in the device menu. In the mV measurement version, the menu of the

DULCOMETER®

Depending on the measured variable, sensors for pH or redox potential (ORP) or

amperometric sensors can only be connected to the measured variables in line with

Ä ‘Allocation of the measurement inputs of the DULCOMETER® D1Cb / D1Cc’ Table

on page 17

measured using a Pt 100/1000. This means that automatic temperature compensation is

possible with pH-value, conductivity and fluoride measured variables. Temperature com‐

pensation is performed in the sensor (with the exception of the chlorine dioxide sensor

type CDP) with amperometric measured variables (chlorine etc.). Operation of the

DULCOMETER® D1Cb / D1Cc takes place via the menu keys. and the data is displayed

by means of an illuminated LCD display. The LCD display ensures that the measured

value, correction variable, control value and error messages can be clearly read.

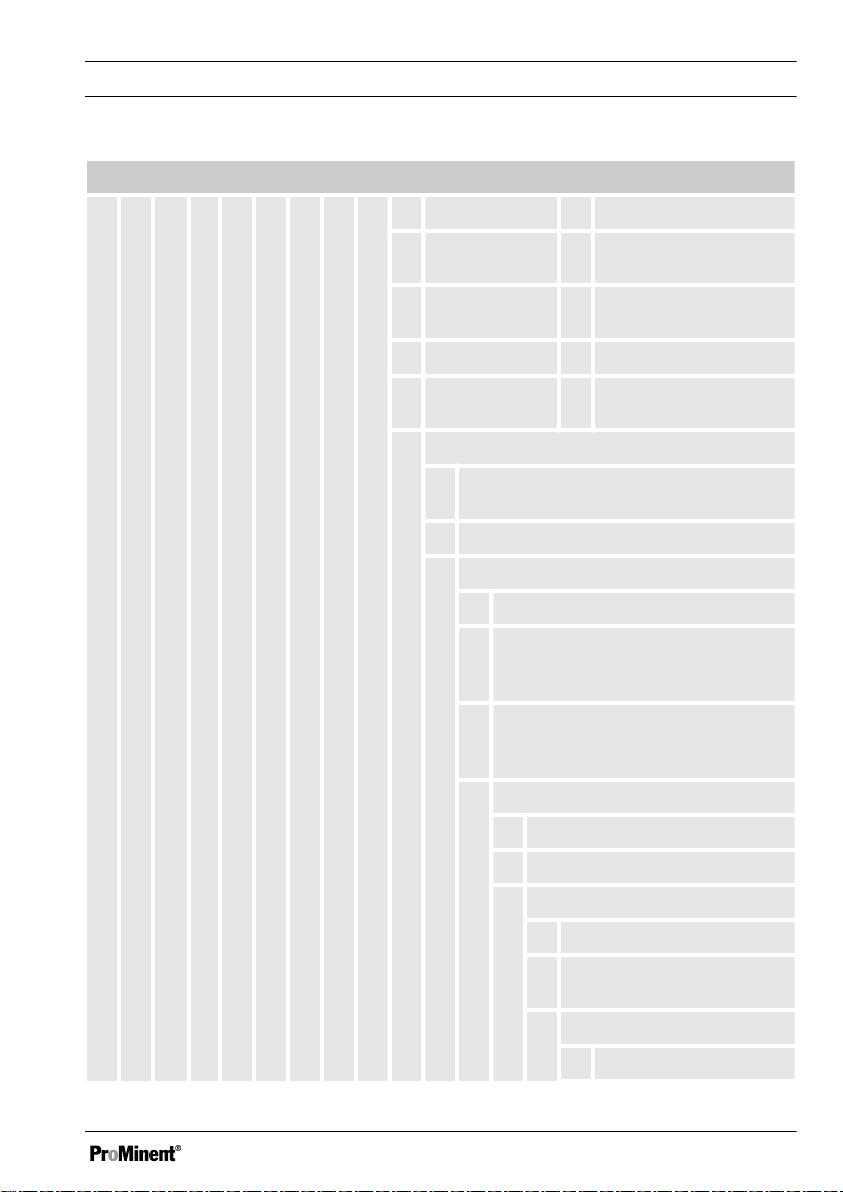

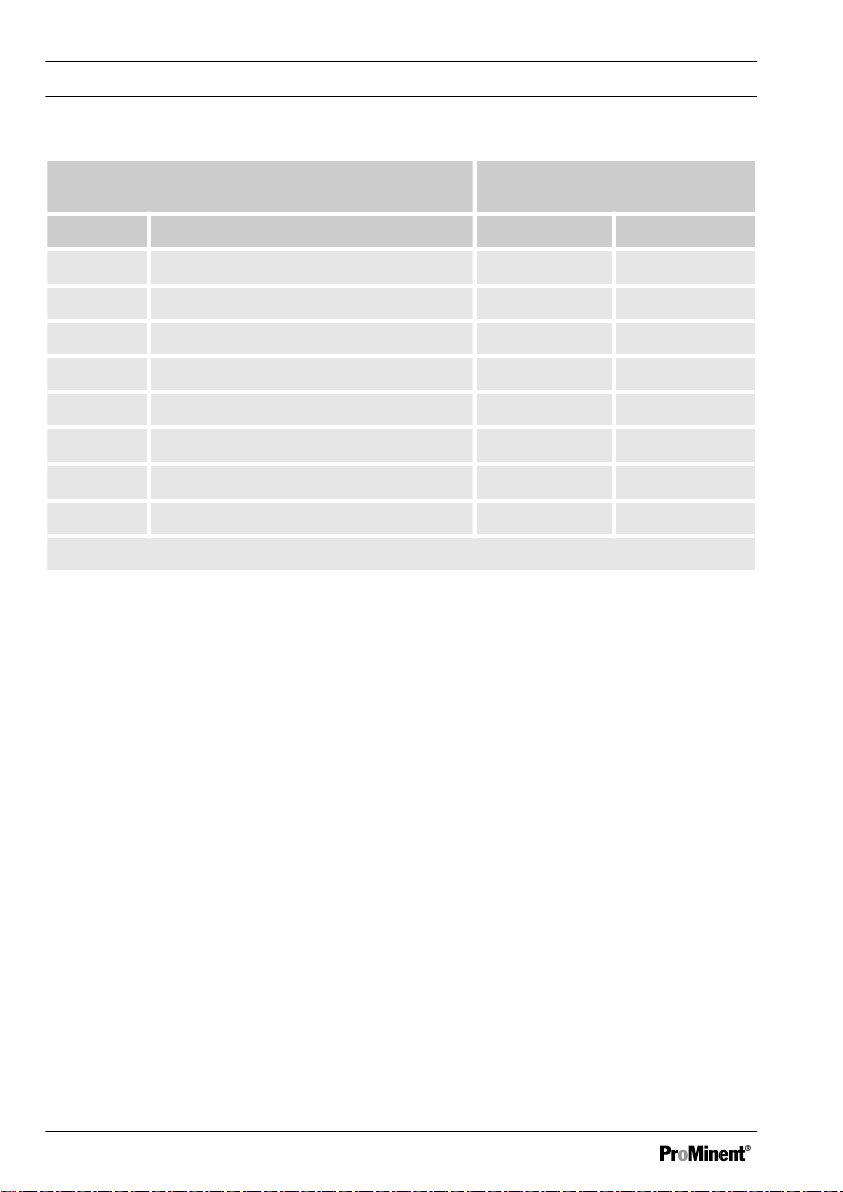

Allocation of the measurement inputs of the DULCOMETER® D1Cb / D1Cc

D1Cb / D1Cc only permits choice between pH and ORP.

. The temperature measurement serves as a correction variable and can be

Connection of the measured vari‐

able to:

Character Measured variable mV input mA input

0 no default setting

of the measured variable

X

(pH and redox can be selected)

A PES (peracetic acid) X

B Bromine X

C Chlorine X

D Chlorine dioxide X

F Fluoride X

*with measured value transducer

17

Page 18

Functional description

Connection of the measured vari‐

able to:

Character Measured variable mV input mA input

H H2O2 (hydrogen peroxide) X

I Chlorite X

P pH X X*

R ORP X X*

S 0/4...20 mA standard signal general X

X O

Z O

2

3

X

X

L Conductivity X

*with measured value transducer

Description of the terminal connections for mA and mV: see Fig. 11 and Fig. 12

Description of the operating menu of the measured variables via mV connection:

see

Ä Chapter 8 ‘Measured Variables and Operating Menus for Potentiometric Sensors’

on page 81

Description of the operating menu of the measured variables via mA connection: see

Ä Chapter 7 ‘Measured Variables and Operating Menus for Amperometric Sensors’

on page 69

Description of the operating menu of the measured variables via mA standard signal: see

Ä Chapter 9 ‘Measured Variables and Operating Menus for the Standard Signal General’

on page 101

2.1 Wall mounting/control panel installation

DULCOMETER® D1Cb

The DULCOMETER®

both for wall-mounting, as well as for

installation in a control panel (with addi‐

tional control panel mounting kit).

D1Cb W is suitable

The plastic housing comprises a housing

upper section and lower section. The LCD

display and membrane keypad are

accommodated in the upper section of the

housing.

The lower section of the housing accom‐

modates the processor and power units

and any optional assemblies. A ribbon

cable connects to the LCD display and the

membrane keypad.

18

Page 19

The electrical connection is made through

originally sealed, push-out cable cut-outs

on the underside of the lower section of

the housing.

A wall bracket for wall mounting is located

on the rear of the lower section of the

housing.

DULCOMETER® D1Cc

The DULCOMETER® D1Cc is suitable for

control panel installation. In this respect if

fulfils the same functions as the D1Cb.

However, the D1Cc also has an option for

upgrading with a protective RC circuit.

When correctly installed, the D1Cc has an

IP54 protection rating.

Electrical construction

2.2

The device does not have a mains switch.

It is therefore immediately ready for ope‐

ration once connected to the power

supply.

The device processes an input signal

whilst taking into consideration operator

inputs. The result is displayed and made

available to other devices via a standard

signal. When equipped with actuators, the

device can also provide control functions.

It is designed to activate metering pumps,

solenoid valves, as well as an mA

standard signal output. The activation var‐

iable is recalculated every second.

Functional description

19

Page 20

externer Speicher /

EEROM/Flash

mV Eingang /

mA Eingang /

Kontakteingang

Netzteil

Temperatureingang /

Relaisausgang 3 /

Relaisausgang 2 /

Relaisausgang 1 /

Kontaktausgang 1 /

Kontaktausgang 2 /

Stromausgang /

Functional description

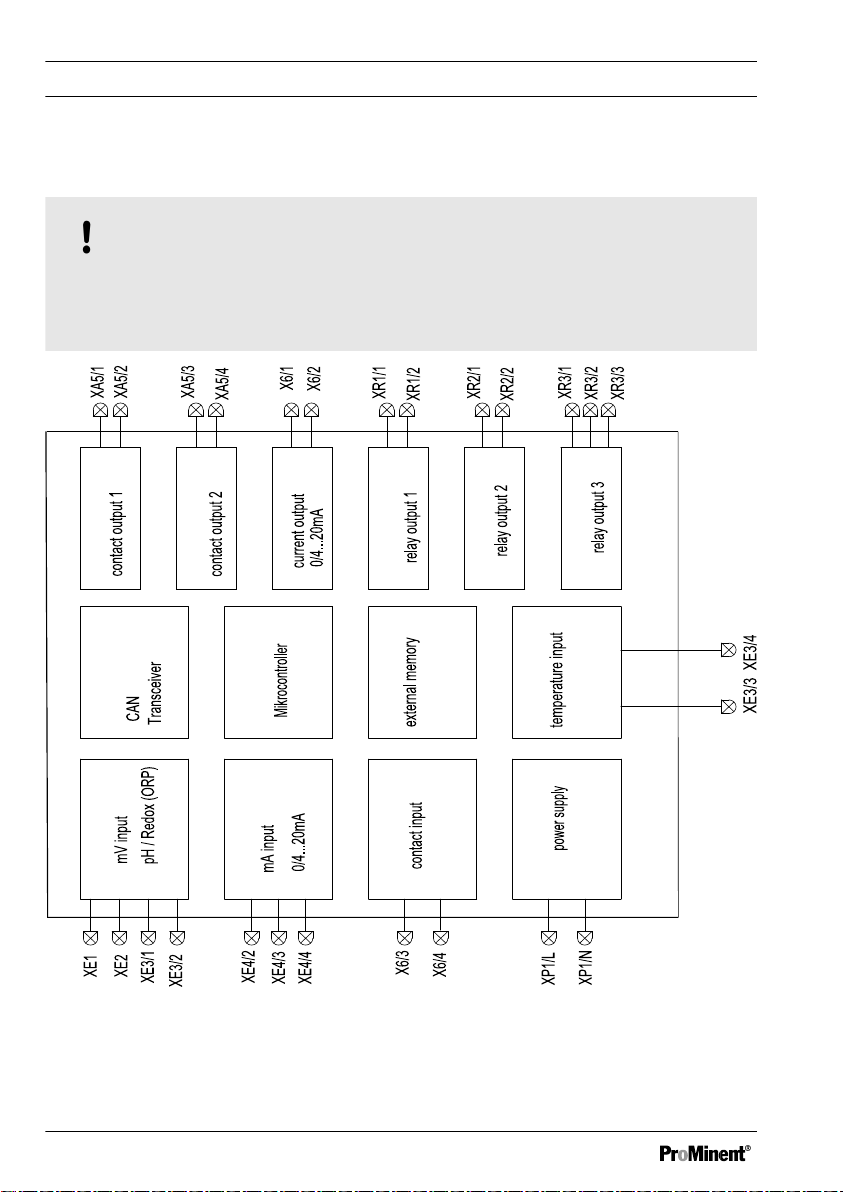

2.2.1 Block circuit diagram

NOTICE!

Connection of mV or mA sensors

The DULCOMETER® D1Cb / D1Cc is suitable for the connection of mV or mA sen‐

sors. It is not possible to connect mV and mA sensors simultaneously.

Fig. 1: Block circuit diagram

20

Page 21

Netzeingang /

Netzanschluss

pH Eingang /

mA Eingang /

Kontakteingang /

Temperatureingang /

Kontaktausgang 2 /

Kontaktausgang 1 /

mA Ausgang /

Alarmausgang /

Relaisausgang 1-2 * /

Functional description

2.2.2 Galvanic Isolation

WARNING!

Protective low voltage/Mains voltage

Possible consequence: Fatal or very serious injuries

If relay 1 or 2 is operated with protective low voltage, no mains voltage may be con‐

nected to the other relay.

Fig. 2: Galvanic Isolation

* If relay 1 or 2 is operated with protective low voltage, no mains voltage many be con‐

nected to the other relay.

** No galvanic isolation between mA and mV input and temperature input.

21

Page 22

D1Cb mounting

3 D1Cb mounting

n User qualification, mechanical

mounting: trained qualified personnel,

see

Ä Chapter 1.2 ‘Users' qualifica‐

tions’ on page 10

n User qualification, electrical installa‐

tion: Electrical technician, see

Ä Chapter 1.2 ‘Users' qualifications’

on page 10

NOTICE!

Mounting position and conditions

– Ensure that there is unimpeded

access for operation

Secure, low-vibration fixing

–

– Avoid direct sunlight

– Permissible ambient temperature

at fixing position: 0 ... 50 °C at

max. 95 % relative air humidity

(non-condensing)

NOTICE!

Material damage to electrostatically

sensitive components

Components can be damaged or

destroyed by electrostatic voltages.

– Before any work, on electrostati‐

cally sensitive components, dis‐

connect the power supply.

When working on electrostatically

–

sensitive components, wear an

earthed anti-static wrist band.

– Always hold components by their

corners and never touch conduc‐

tors, ICs, etc.

– Only place components on anti-

static supports or the original

packaging.

22

Ablese- und Bedienposition

–

Das Gerät in einer günstigen

Ablese- und Bedienposition

(möglichst in Augenhöhe) mon‐

tieren

Montageposition

–

Ausreichend Freiraum für die

Kabel vorsehen

–

Für die ‘Parkstellung’ des

Reglers, nach oben mindestens

120 mm Platz freihalten

Page 23

3.1 Scope of supply

The following parts belong to the standard

scope of supply of a

DULCOMETER

series D1Cb controller.

Identifier Quantity

D1Cb controller 1

®

D1Cb mounting

Half screw connection, com‐

plete (set)

M12 x 1.5 threaded connec‐

tion, complete (set)

Assembly material, complete,

3P Universal (set)

Measured variable labels

D1C/D2C

Operating Manual 1

General safety notes 1

1

1

1

1

23

Page 24

D1Cb mounting

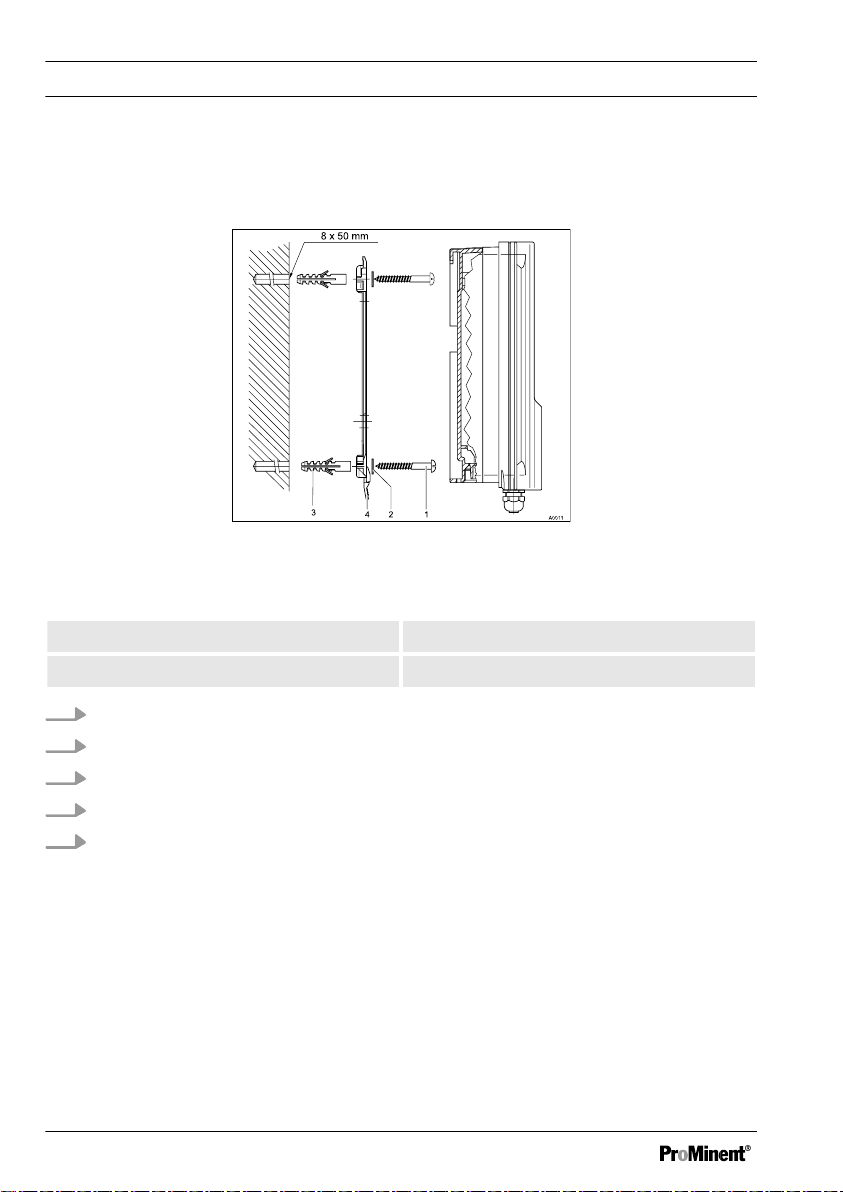

3.2 Installation (Wall Mounted)

The device can be installed directly on the wall with the aid of the wall bracket.

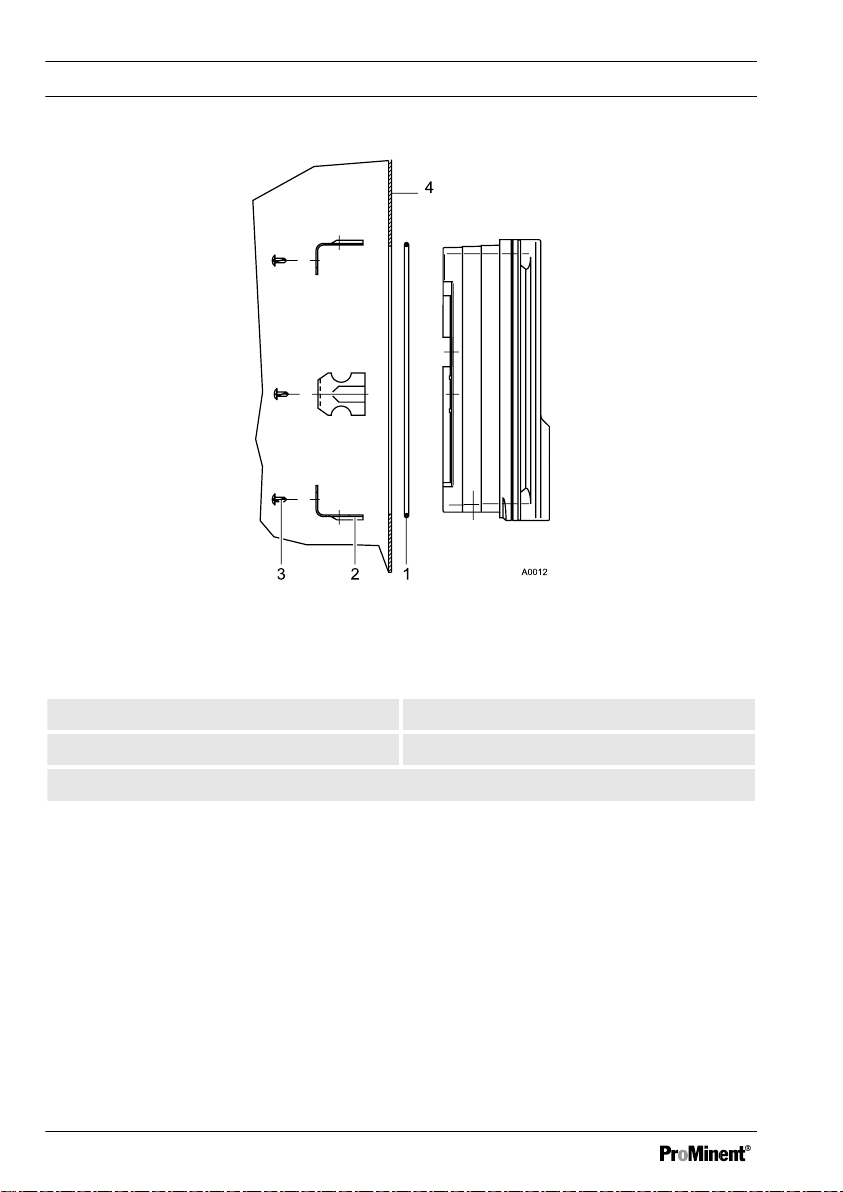

Fig. 3: Fixing material for wall mounting

1. 3 x Round head screws 5x45 2. 3 x Washers 5.3

3. 3 x Plastic wall plugs d8 4. Wall bracket

1. Mark the holes using the wall bracket and drill them

2. Insert wall plugs

3. Secure wall bracket in place with washers and round head screws

4. Place the device from above onto the wall bracket

5. Press the device gently against the wall bracket and slide it approx. 4 mm upwards

until you hear it engage in position

24

Page 25

D1Cb mounting

3.3 Installation - Control Panel Mounted (Optional)

CAUTION!

Dimensional variations

Possible consequence: material damage

– Photocopying the punched template can result in dimensional deviations

Use the dimensions shown in Fig. 4 and mark on the control panel

–

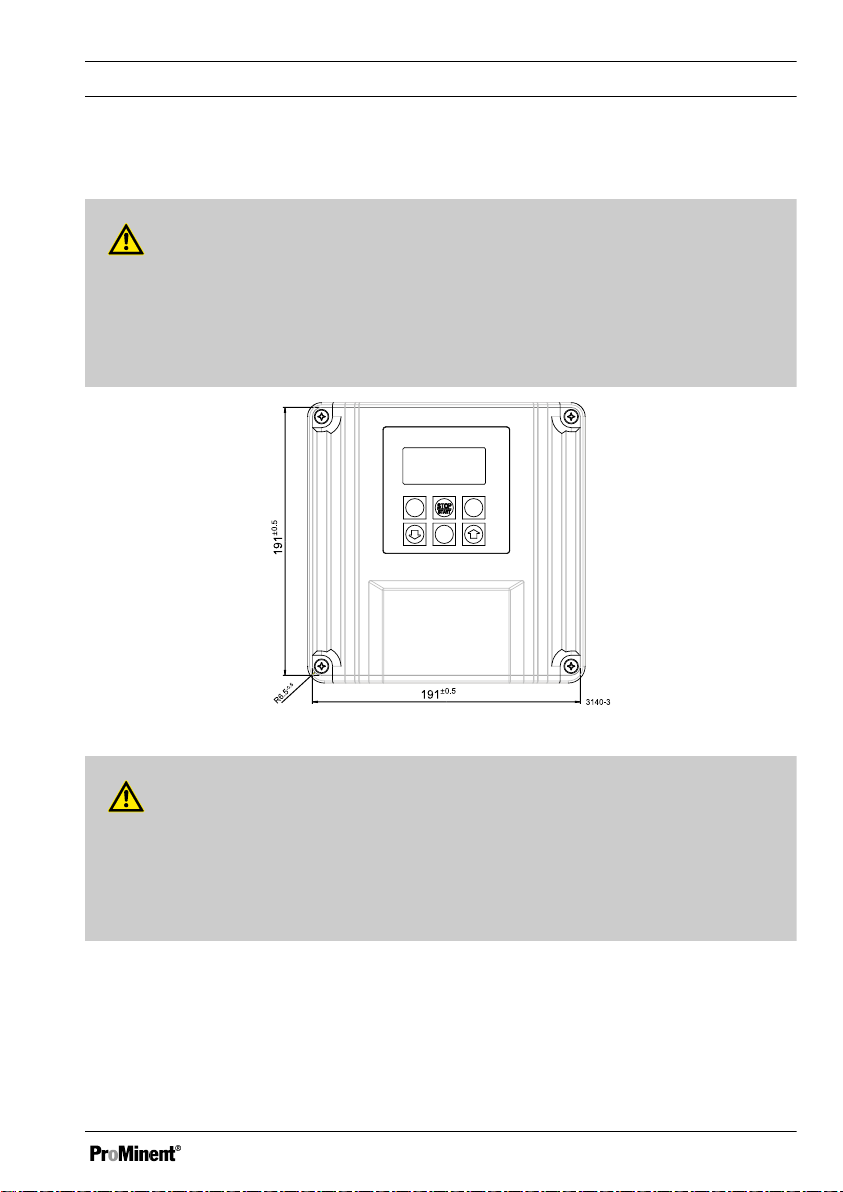

Fig. 4: Punched template, drawing number 3140-3 /not to scale

CAUTION!

Material thickness of control panel

Possible consequence: material damage

– The material thickness of the control panel must be at least 2 mm to ensure

secure fixing

25

Page 26

D1Cb mounting

Fig. 5: The material thickness of the control panel must be at least 2 mm to ensure

secure fixing

1. 1 x Foam rubber caulk strip d3 2. 6 x Galvanised steel retaining brackets

3. 6 x Galvanised PT cutting screws 4. Control panel

For the part number of the assembly set, refer to

26

Ä Table on page 149

Page 27

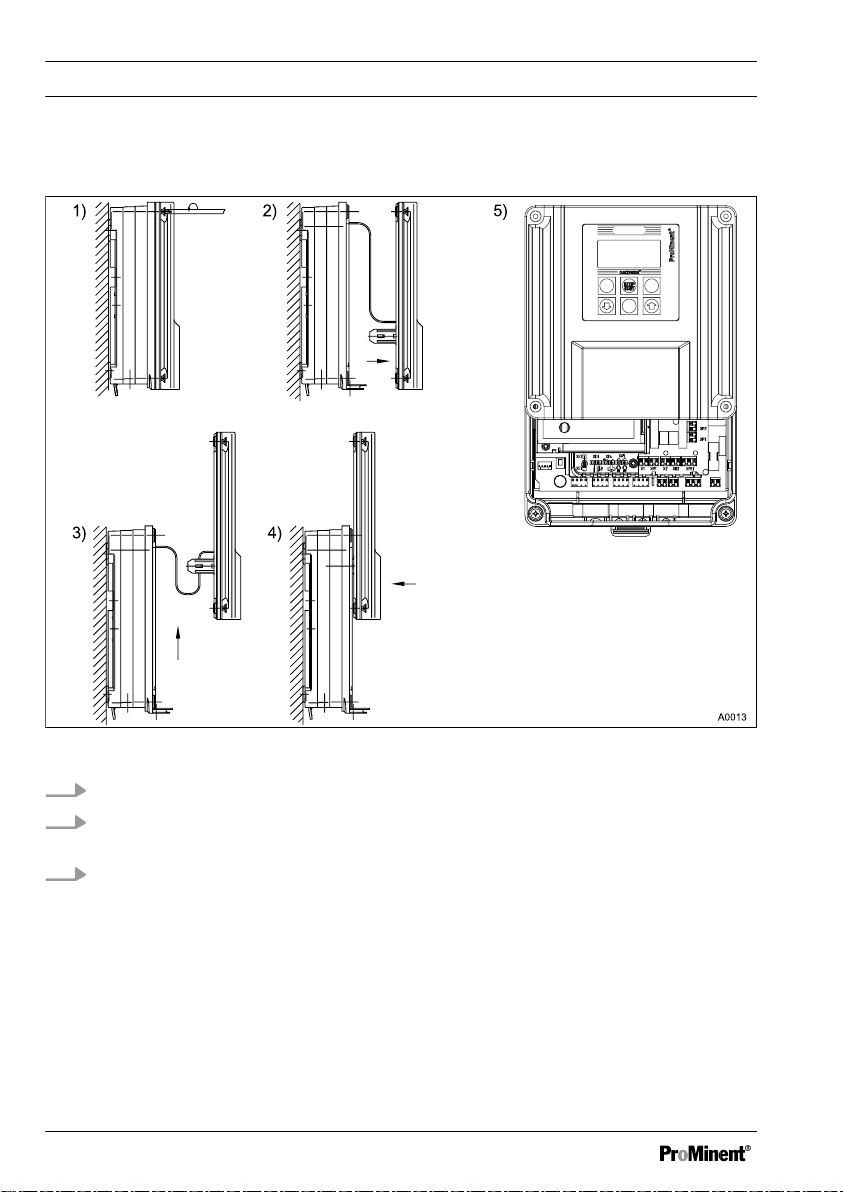

D1Cb mounting

1. Using the dimensions shown in

Fig. 4 mark the precise position of the device on

the control panel

2. Mark the corner points and drill (drill diameter 12 - 13 mm)

3. With a punching tool or jigsaw make the opening as per the punched template

drawing

4. Chamfer the cut edges and check whether the sealing surfaces are smooth for the

caulk strip

Otherwise the seal cannot be guaranteed

ð

5. Press the caulk strip evenly into the groove running around the device

6. Place the device into the control panel and fix in place at the rear by means of the

retaining brackets and PT cutting screws

The device should project approx. 35 mm from the control panel

ð

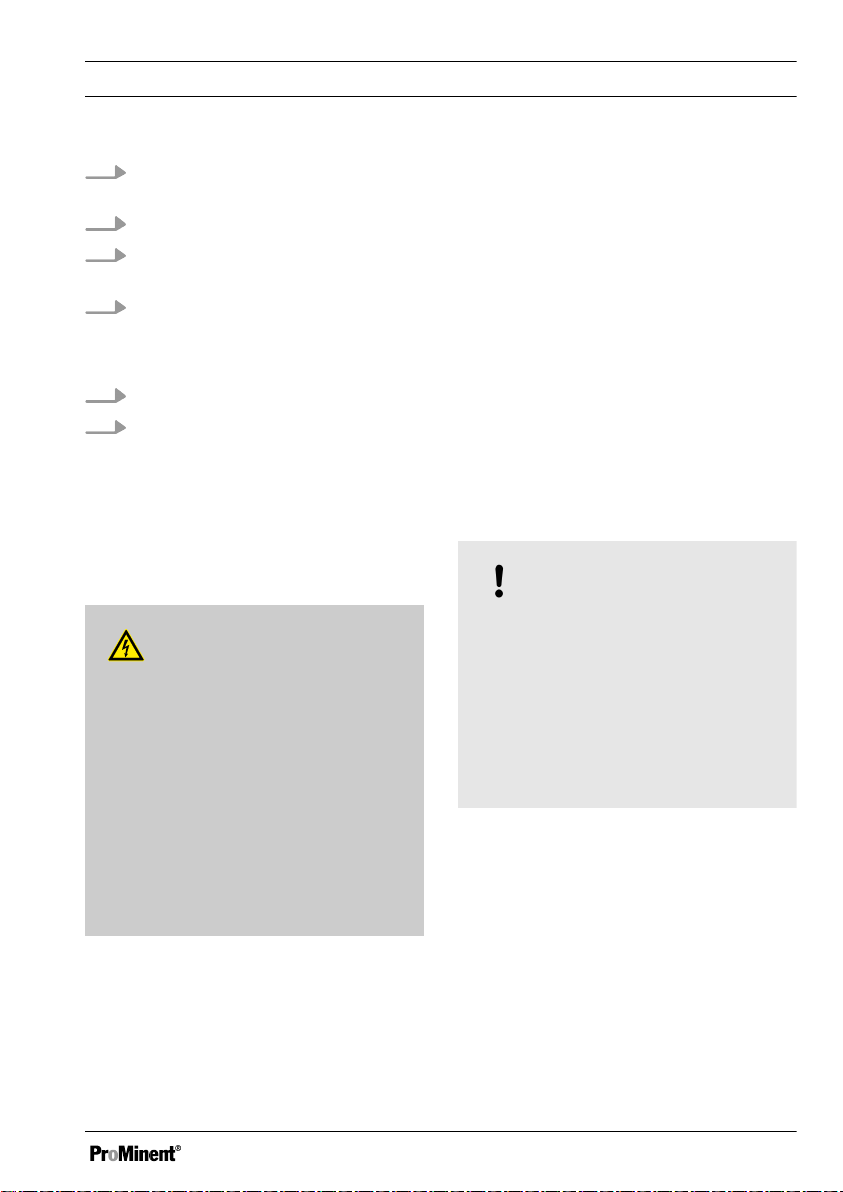

3.4 Wall Mounted Installation of

D1Cb (Electrical)

WARNING!

Electrical voltage

Possible consequence: Fatal or very

serious injuries

– The electrical connection to the

device should only be made once

it has been fitted to the wall or

control panel

The device must be electrically

–

disconnected before it is opened

– Ensure that the device cannot be

reconnected accidentally

NOTICE!

Opening the device

Damage to the product or its sur‐

roundings

– The device may only be opened

by qualified personnel

The device should only be

–

opened when fitted to the wall or

control panel

27

Page 28

D1Cb mounting

3.4.1 Opening the device

Fig. 6: Opening the device

1. Loosen the 4 captive screws (1).

2. Lift the upper section of the device from the lower section (2). A wide flathead

screwdriver may be of assistance.

3. Insert the upper section with both guide rails into the lower section (3 and 4)

(parked position)

28

Page 29

A0014

D1Cb mounting

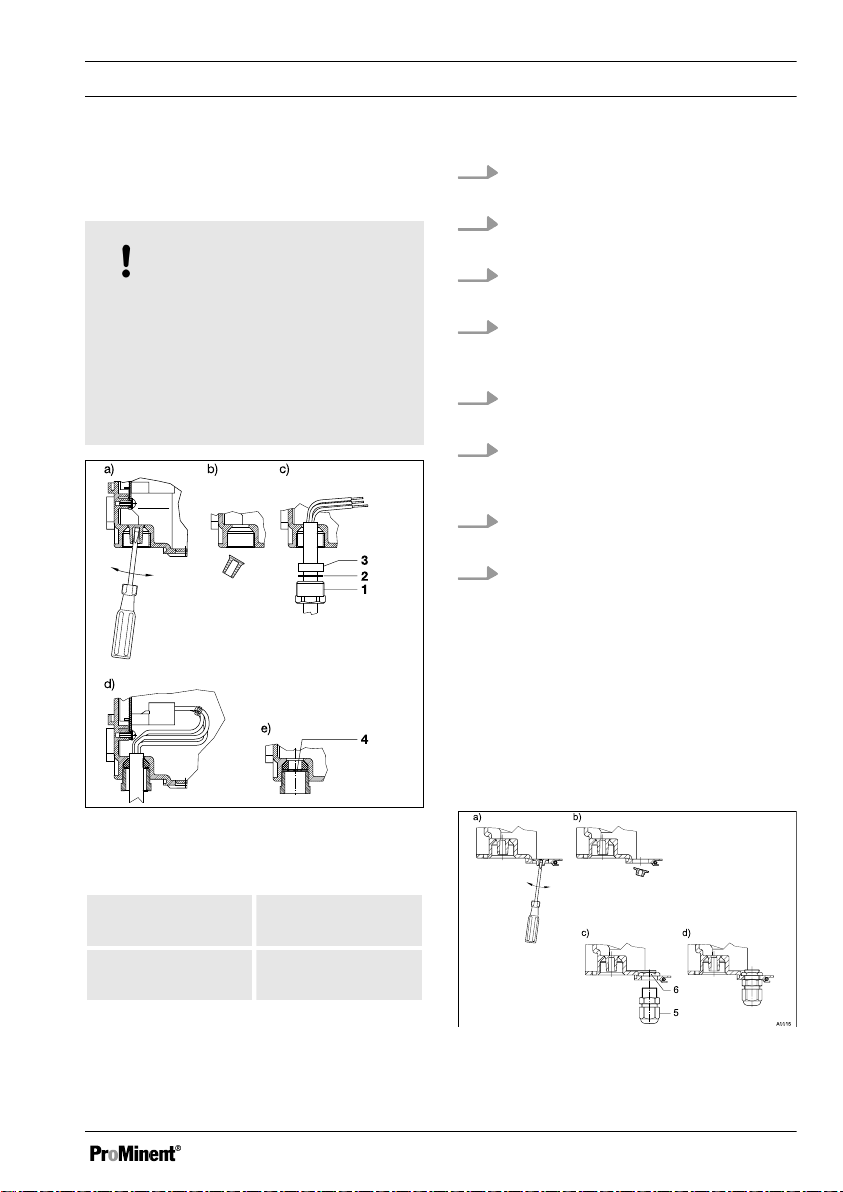

3.4.2 Electrical Installation (Wall Mounted)

NOTICE!

Threaded holes

Using a suitable tool, punch out the

threaded holes according to the

number of cables ( Æ approx. 4 mm).

– Punch aids are provided to punch

out the threaded holes

1. Remove cable sheathing over a

sufficient length

2. Fit screw connection (1), pressure

ring (2) and seal (3) onto cable

3. Insert cable and fittings into the

threaded hole

4. Align the cable and push in until

enough cable is in the control

housing

5. Screw in screw connection and

tighten firmly

6. Shorten cable wires to the precise

overall length and strip off approx. 8

mm insulation

7. Fit cable end sleeves to the wires.

Refer to

Ä on page 32

8. Connect up the wires to the termi‐

nals according to the electrical

wiring diagram Fig. 11

Punched out threaded holes can be

resealed with the M20 dummy washers

(4) provided.

The M12 x 1.5 screw connections and

brass lock nuts are used for the 4 open‐

ings in the front row.

Fig. 7: Punching out the threaded holes

1. Screw connec‐

tion M20 x 1.5

3. Pressure ring

M20

2. Pressure ring

M20

4. Dummy washer

M20

Fig. 8: M12x1.5 screw connections

29

Page 30

D1Cb mounting

5. Screw connec‐

tion M12 x 1.5

6. Lock nut

M12x1.5

1. Fit lock nut M12x1.5 (6) on the

inside

2. Fit screw connection M12x1.5 (5)

from the outside and tighten firmly

3.4.3

Electrical Installation (Control Panel Mounted)

Proceed as described under "Electrical

Installation (Wall Mounted)". Refer to

Ä Chapter 3.4.2 ‘ Electrical Installation

(Wall Mounted) ’ on page 29

Only the rear row of threaded holes

(M20x1.5) should be used when the

device is mounted in a control panel. The

front row (M12x1.5) lies outside of the

control panel.

Connect up as per the electrical terminal

wiring diagram. Refer to

Ä Chapter 3.4.7

‘Terminal Wiring Diagram ’ on page 34

30

Page 31

D1Cb mounting

3.4.4 Installation of Coaxial Cable to Guard Terminal XE1

CAUTION!

Maximum length of the coaxial cable 10 m

Incorrect reading due to too long a coaxial cable

Possible consequence: Slight or minor injuries, material damage

The maximum length of the coaxial cable may not exceed 10 m when using redox or

pH sensors. The measured signal can otherwise be falsified by the effects of interfer‐

ence.

If the gap between the pH/redox measuring point and the

more than 10 metres, then the use of an interposed DULCOTEST ® transducer 4-20

mA pH V1, rH V1 is recommended. The connection is then made via terminal XE4 of

the DULCOMETER ® D1Cb.

The XE4 (mA input) terminal is a chargeable additional function!

DULCOMETER ® D1Cb is

When installing the coaxial cable for the guard terminal XE 1, the allowances shown on

the diagram for stripping insulation from the coaxial cable should be adhered to.

Fig. 9

The guard terminal should be tightened until "hand-tight".

31

Page 32

optional

RC-Schutzbeschaltung

Sicherung

Programmierschnittstelle

Schirmklemme

Klemmenanordnung Ausführung Wandgerät

Konfektionierung Koaxialkabel zum Anschluss an D1Cb

oder vorkonfektioniert in den Varianten

Detail Anschluss Koaxialkabel D1Cb

D1Cb mounting

Fig. 9: Preparation of coaxial cable

3.4.5 Cable Cross-Sections and Cable End Sleeves

Minimum cross-sec‐

Without cable end

tion

0.25 mm

2

sleeve

Cable end sleeve

without insulation

Cable end sleeve

0.20 mm

0.20 mm

2

2

with insulation

32

Maximum crosssection

1.5 mm

1.0 mm

1.0 mm

Stripped insulation

length

2

2

2

8 - 9 mm

10 - 11 mm

Page 33

3.4.6 Protective RC Circuit (Optional)

A protective RC circuit is recommended

for operation with consumers, which

present an inductive load (e.g. motor

metering pumps or solenoid metering

pumps). In these applications a protective

RC circuit prevents wear and tear of the

relay contacts. Refer to

Ä ‘Spare parts

and accessories DULCOMETER® D1Cb’

on page 148

D1Cb mounting

33

Page 34

Klemmenanordnung

Ausführung: Wandmontage

Schirmklemme

Sicherung 5x20

D1Cb mounting

3.4.7 Terminal Wiring Diagram

Fig. 10: Terminal layout

34

Page 35

Netz

Netz

Magnetventil 2(senken)

Magnetventil 1(heben)

Netz Netz

Relais 3 / Alarm

Grenzwertrelais 1

Grenzwertrelais 2

Extern

Belegungsvarianten

Variante 1

Magnetventil

Grenzwertrelais, Timer, Stellglied

(ohne RC-Schutzbeschaltung)

Variante 2

Variante 2

Variante 1

D1Cb mounting

Fig. 11: Terminal diagram with assignment options 1

35

Page 36

Netz

Normsignal-Eingang

Temperatur

Digital Eingang "Pause" oder Störgröße

Offen/geschl.

Potenzialfreier Kontakt nötig!

Drahtbrücke

-

ProMinent Umformer

Normsignal-Eingang

Stromquelle

Extern Pumpe 2,senken (potenzialfrei)

Extern Pumpe 1,heben (potenzialfrei)

Normsignal-Ausgang1

1

Belegungsvarianten

Temperatur

Potenzialausgleich

Belegungsvarianten

D1Cb mounting

Fig. 12: Terminal diagram with assignment options 2

36

Page 37

Extern

Netz

Pumpe 2 (senken)

Pumpe 1 (heben)

RC-Schutzbeschaltung

(optional)

D1Cb mounting

Fig. 13: Protective RC circuit terminal diagram

37

Page 38

A0842

D1Cb mounting

3.5 Switching of inductive loads

If you connect an inductive load, i.e. a

consumer which uses a coil (e.g. an

alpha motorised pump), then you

must protect your controller with a

protective circuit. If in doubt, consult

an electrical technician for advice.

The RC member protective circuit is a

simple, but nevertheless very effective,

circuit. This circuit is also referred to as a

snubber or Boucherot member. It is pri‐

marily used to protect switching contacts.

When switching off, the connection in

series of a resistor and capacitor means

that the current can fade out in a damped

oscillation.

Also when switching on, the resistor acts

as a current limiter for the capacitor

charging process. The RC member pro‐

tective circuit is highly suited to AC

voltage supplies.

C=k * I

L

k=0,1...2 (dependent on the application).

Only use capacitors of class X2.

Units: R = Ohm; U = Volt; IL = Ampere;

C = µF

If consumers are connected which

have a high starting current (e.g. plugin, switched mains power supplies),

then a means of limiting the starting

current must be provided.

The switching-off process can be investi‐

gated and documented using an oscillo‐

scope. The voltage peak at the switch

contact depends on the selected RC com‐

bination.

The magnitude of the resistance R of

the RC member is determined according

to the following equation:

R=U/I

L

(U= Voltage divided by the load // IL =

load current)

The magnitude of the capacitor is deter‐

mined using the following equation:

Units: R = Ohm; U = Volt; IL = Ampere;

C = µF

38

Fig. 14: Switching-off process shown on

the oscillogram.

Page 39

WARNING!

A0835

Mains voltage

Possible consequence: Fatal or very

serious injuries

If mains voltage is connected to one

of the terminals XR1-XR3 or XP, then

no protective low voltage may be con‐

nected to any other of these terminals

(SELV).

D1Cb mounting

Fig. 15: RC protective circuit for the relay

contacts

Typical AC current application with an

inductive load:

n 1) Load (e.g. alpha motorised pump)

n 2) RC-protective circuit

– Typical RC protective circuit at

230 V AC:

– Capacitor

– Resistor

[0.22µF/X2]

[100 ohm / 1 W]

(Metal-

oxide (pulse-resistant))

n 3) Relay contact (XR1, XR2, XR3)

39

Page 40

D1Cc mounting

4 D1Cc mounting

n User qualification, mechanical

mounting: trained qualified personnel,

see

Ä Chapter 1.2 ‘Users' qualifica‐

tions’ on page 10

n User qualification, electrical installa‐

tion: Electrical technician, see

Ä Chapter 1.2 ‘Users' qualifications’

on page 10

NOTICE!

Mounting position and conditions

– Ensure that there is unimpeded

access for operation

Secure, low-vibration fixing

–

– Avoid direct sunlight

– Permissible ambient temperature

at fixing position: 0 ... 50 °C at

max. 95 % relative air humidity

(non-condensing)

NOTICE!

Material damage to electrostatically

sensitive components

Components can be damaged or

destroyed by electrostatic voltages.

– Before any work, on electrostati‐

cally sensitive components, dis‐

connect the power supply.

When working on electrostatically

–

sensitive components, wear an

earthed anti-static wrist band.

– Always hold components by their

corners and never touch conduc‐

tors, ICs, etc.

– Only place components on anti-

static supports or the original

packaging.

40

Ablese- und Bedienposition

–

Das Gerät in einer günstigen

Ablese- und Bedienposition

(möglichst in Augenhöhe) mon‐

tieren

Montageposition

–

Ausreichend Freiraum für die

Kabel vorsehen

Page 41

D1Cc mounting

4.1

DULCOMETER®

The following parts belong to the standard scope of supply of a DULCOMETER® series

D1Cc controller.

Identifier Quantity

D1Cc controller 1

Retaining bracket 4

Measured variable labels D1C/D2C 1

Operating Manual 1

General safety notes 1

4.2

Mounting - control panel installation DULCOMETER® D1Cc

CAUTION!

Dimensional variations

Possible consequence: material damage

– Photocopying the punched template can result in dimensional deviations

Use the dimensions according to Fig. 16 and mark on the control panel

–

D1Cc scope of supply

CAUTION!

Material thickness of control panel

Possible consequence: material damage

– The material thickness of the control panel must be at least 2 mm to ensure

secure fixing

The device is designed for installation in a control panel. The housing corresponds to DIN

43700. The control panel opening for installation of the device is specified in DIN 43700.

We recommend a smaller opening. Fixing of the device is then better (less sideways

play) and the seal is uniformly compressed.

41

Page 42

92

+0,6

92

+0,6

90

+0,5

90

+0,5

I. II.

A0696

D1Cc mounting

Fig. 16: Mounting - control panel installation DULCOMETER® D1Cc

I. DIN 43700 instruction

II. ProMinent recommendation

42

Page 43

®®

STOP

S

T

A

RT

DULCOM

ETER

®

D

1

C

A0697

D1Cc mounting

Fabricating the opening:

Fig. 17: Screw the studs forward

A drilling punched 1:1 template is enclosed with the device as a mounting aid. Its use

will ensure optimal positioning of the device on the control panel.

1. Align and secured the punched drilling template in the appropriate position on the

control panel using a spirit level

2. Mark the four corners using a centre punch and drill four holes using a 6 mm Ø bit

3. Then saw out the connected bridges with a jigsaw

4. Dress the surfaces so they are smooth and the dimensions are within the specified

tolerance.

5. Finally ensure the edges are fully de-burred

6. Before inserting the device in the control panel opening, check the position of the

seal (must lie against the front collar)

IP54 protection rating

43

Page 44

D1Cc mounting

7. Insert the device from the outside in the opening, attach the retaining bracket and

push backwards up to the stop

All four holes retaining brackets must be attached, as otherwise protection

ð

rating IP54 cannot be adhered to.

8. Using a suitable screw driver, screw the studs forwards, see

Fig. 17, until the seal

is completely and uniformly compressed

9. Check the correct seating of the seal, as necessary loosen the studs and correct

the position

4.3 Electrical Installation (Con‐

trol Panel Mounted)

Connect up as per the electrical terminal

wiring diagram. Refer to

‘Terminal diagram ’ on page 48

Ä Chapter 4.3.3

44

Page 45

D1Cc mounting

4.3.1 Installation of Coaxial Cable to Guard Terminal XE1

CAUTION!

Maximum length of the coaxial cable 10 m

Incorrect measured value due to too long a coaxial cable

Possible consequence: Slight or minor injuries. Material damage.

The maximum length of the coaxial cable may not exceed 10 m when using redox or

pH sensors. The measurement signal can otherwise be falsified by the effects of

interference.

If the distance between the pH/ORP measuring point and the

is more than 10 m, the use of a DULCOTEST® measuring transducer 4-20 mA pH

V1, rH V1 is recommended. Connection is then via terminal XE4 of the

DULCOMETER® D1Cc

The XE4 (mA input) terminal is an auxiliary function that incurs an extra charge.

When installing the coaxial cable for the guard terminal XE 1, the allowances shown in

the diagram Fig. 18 for stripping insulation from the coaxial cable must be adhered to.

The guard terminal should be tightened until "hand-tight".

DULCOMETER® D1Cc

45

Page 46

Terminal order panel type mounting

Fabrication of the coaxial cable connection to the D1Cc

or pre-fabricated for the variants

A0698

D1Cc mounting

Fig. 18: Preparation of coaxial cable

46

Page 47

4.3.2 Cable Cross-Sections and Cable End Sleeves

D1Cc mounting

Minimum cross-sec‐

tion

Without cable end

0.25 mm

2

sleeve

Cable end sleeve

0.20 mm

2

without insulation

Cable end sleeve

0.20 mm

2

with insulation

Maximum crosssection

1.5 mm

1.0 mm

1.0 mm

2

2

2

Stripped insulation

length

8 - 9 mm

10 - 11 mm

47

Page 48

Netz

Netz

Magnetventil 2(senken)

Magnetventil 1(heben)

Netz Netz

Relais 3 / Alarm

Grenzwertrelais 1

Grenzwertrelais 2

Extern

Belegungsvarianten

Variante 1

Magnetventil

Grenzwertrelais, Timer, Stellglied

(ohne RC-Schutzbeschaltung)

Variante 2

Variante 2

Variante 1

D1Cc mounting

4.3.3 Terminal diagram

Fig. 19: Terminal diagram with assignment options 1

48

Page 49

Netz

Normsignal-Eingang

Temperatur

Digital Eingang "Pause" oder Störgröße

Offen/geschl.

Potenzialfreier Kontakt nötig!

Drahtbrücke

-

ProMinent Umformer

Normsignal-Eingang

Stromquelle

Extern Pumpe 2,senken (potenzialfrei)

Extern Pumpe 1,heben (potenzialfrei)

Normsignal-Ausgang1

1

Belegungsvarianten

Temperatur

Potenzialausgleich

Belegungsvarianten

D1Cc mounting

Fig. 20: Terminal diagram with assignment options 2

49

Page 50

A0842

D1Cc mounting

4.4 Switching of inductive loads

If you connect an inductive load, i.e. a

consumer which uses a coil (e.g. an

alpha motorised pump), then you

must protect your controller with a

protective circuit. If in doubt, consult

an electrical technician for advice.

The RC member protective circuit is a

simple, but nevertheless very effective,

circuit. This circuit is also referred to as a

snubber or Boucherot member. It is pri‐

marily used to protect switching contacts.

When switching off, the connection in

series of a resistor and capacitor means

that the current can fade out in a damped

oscillation.

Also when switching on, the resistor acts

as a current limiter for the capacitor

charging process. The RC member pro‐

tective circuit is highly suited to AC

voltage supplies.

C=k * I

L

k=0,1...2 (dependent on the application).

Only use capacitors of class X2.

Units: R = Ohm; U = Volt; IL = Ampere;

C = µF

If consumers are connected which

have a high starting current (e.g. plugin, switched mains power supplies),

then a means of limiting the starting

current must be provided.

The switching-off process can be investi‐

gated and documented using an oscillo‐

scope. The voltage peak at the switch

contact depends on the selected RC com‐

bination.

The magnitude of the resistance R of

the RC member is determined according

to the following equation:

R=U/I

L

(U= Voltage divided by the load // IL =

load current)

The magnitude of the capacitor is deter‐

mined using the following equation:

Units: R = Ohm; U = Volt; IL = Ampere;

C = µF

50

Fig. 21: Switching-off process shown on

the oscillogram.

Page 51

WARNING!

A0835

Mains voltage

Possible consequence: Fatal or very

serious injuries

If mains voltage is connected to one

of the terminals XR1-XR3 or XP, then

no protective low voltage may be con‐

nected to any other of these terminals

(SELV).

D1Cc mounting

Fig. 22: RC protective circuit for the relay

contacts

Typical AC current application with an

inductive load:

n 1) Load (e.g. alpha motorised pump)

n 2) RC-protective circuit

– Typical RC protective circuit at

230 V AC:

– Capacitor

– Resistor

[0.22µF/X2]

[100 ohm / 1 W]

(Metal-

oxide (pulse-resistant))

n 3) Relay contact (XR1, XR2, XR3)

51

Page 52

language

Deutsch

english

A0201_GB

Commissioning

5 Commissioning

n Users' qualification: Trained user

WARNING!

Sensor run-in periods

This can result in hazardous incorrect

metering

Take into consideration run in periods

when commissioning

Correct measuring and dosing is

–

only possible if the sensor is

working perfectly

– It is imperative that the run in

periods of the sensors are

adhered to

– The run in periods should be

allowed for when planning com‐

missioning

– It may take a whole working day

to run-in the sensor

– Please read the operating manual

for the sensor

Start menu during initial commis‐

sioning

The "Language setting during initial

commissioning" menu appears only

once.

Later changes to the operating lan‐

guage can then be made via the

"General Settings/Information" menu

item.

Fig. 23: Initial commissioning display

This is followed by the selection of the

measured variable and the measuring

range in the "General Settings/Informa‐

tion" menu item.

Following completion of mechanical and

electrical assembly, the controller should

be integrated into the measuring point.

Initial commissioning

5.1

During initial commissioning the device's

display will be in "English". The display

will show "language english". Exception:

the language has been factory-preset to

the customer's requirement.

52

5.1.1 Selection of the Operating Language

With devices, which have not been pre‐

configured to the customer's specific

requirement, the operating language

required has to be selected in the "Gen‐

eral Settings / Operating Menu/" menu.

Refer to

Ä Chapter 10.6 ‘General settings’

on page 131

Page 53

NOTICE!

Resetting the operating language

In the event that a foreign and thus

non-comprehensible operating lan‐

guage has been set, the

DULCOMETER® D1Cb / D1Cc can

be reset to the basic "English" setting.

If you find yourself in the continuous

display 1, then by simultaneously

pressing the keys

, , the

DULCOMETER® D1Cb / D1Cc can

be made to ask again for the oper‐

ating language. Refer to

Ä Chapter 6.3 ‘Permanent Display 1 ’

on page 61

Should you no longer know where

you are in the operating menu,

because you cannot read the strange

operating language, then press key

10 times. Then you will definitively

find yourself in continuous display 1.

Commissioning

53

Page 54

general setting

Information

Identcode:

Vxxxxxxxxxxxx

D1CBxxxxxxxxxxx

Srnr: xxxxxxxxxx

add. functions

Software version

measure change

wash timer chlorit

Br

O3

O2

effective range

A0032

0...2.00ppm

Commissioning

5.1.2 Selection of the Measured Variable and Measuring Range

WARNING!

Incorrect metering due to incorrect measuring range

Possible consequence: Fatal or serious injuries.

– The measuring range of the sensor is essential for the measuring range!

If the assignment of the measuring range is modified, the settings must be

–

checked in all menus

– If the assignment of the measuring range is changed, the sensor must be recali‐

brated

With devices, which have not been preconfigured to the customer's specific requirement,

the measured variable required has to be selected in the complete operating menu "Gen‐

eral Settings / Change Measured Variable". The DULCOMETER® D1Cb / D1Cc then has

to be labelled with the label corresponding to the measured variable selected. The rele‐

vant labels are enclosed with the DULCOMETER® D1Cb / D1Cc.

Fig. 24: Selection of measured variable and measuring range

The measuring range required has to be selected and set in the complete operating

menu General Settings / Change Measured Variable, see

Measured Variable/Measuring Range’ on page 131

54

Ä Chapter 10.6.1 ‘Setting the

.

Page 55

general setting

informationen

Identcode:

Vxxxxxxxxxx

D1CB xxxxxxxxx

Srnr: xxxxxxxxxx

add. functions

software version

measure change

wach timer

function

unlocking

yes

no

Code input:

_ _ _ _ - _ _ _ _ _ _ _ _ - _ _ _ _

A0010_GB

Code ok!

wrong code!

Commissioning

5.2 Activation Code for Extended Functions

Activation code

Access to further functions can optionally be provided by means of an activation

code.

Should you require additional operating literature for these functions, this can be

obtained on the homepage of ProMinent Dosiertechnik, Heidelberg.

Fig. 25: Activation code / Serial number

The activation code is entered one digit at a time using the

next position using the

5.2.1 Extended Functions Obtain‐

Extended functions

The DULCOMETER® D1Cb / D1Cc con‐

troller functionality can be extended or

modified by means of a 16-digit activation

code. Functions can be enabled several

times.

and keys. Move to the

key.

The newly activated functions must be configured or parameterised in the relevant

menu or new measured variables must be calibrated. Information on this can be

found in the relevant complete operating menu.

able with the Activation Code

D1Cb / D1Cc software upgrade

To provide an activation code, ProMi‐

nent requires the 10-digit serial

number (Srnr) and the required soft‐

ware upgrade identity code, which

can both be found in the table below.

55

Page 56

Commissioning

NOTICE!

Activation code

When ordering the activation code, it

is imperative that you ensure that the

serial number (Srnr) corresponds

exactly to that of the DULCOMETER

D1Cb / D1Cc. Otherwise a charge‐

able activation code will be provided,

which will not work.

NOTICE!

"Incorrect code" message

If the code has been entered incor‐

rectly then the "Incorrect code" mes‐

sage will appear. You can enter the

activation code as many times as you

need to. If this is still not successful,

then check the serial number of the

controller.

®

56

Page 57

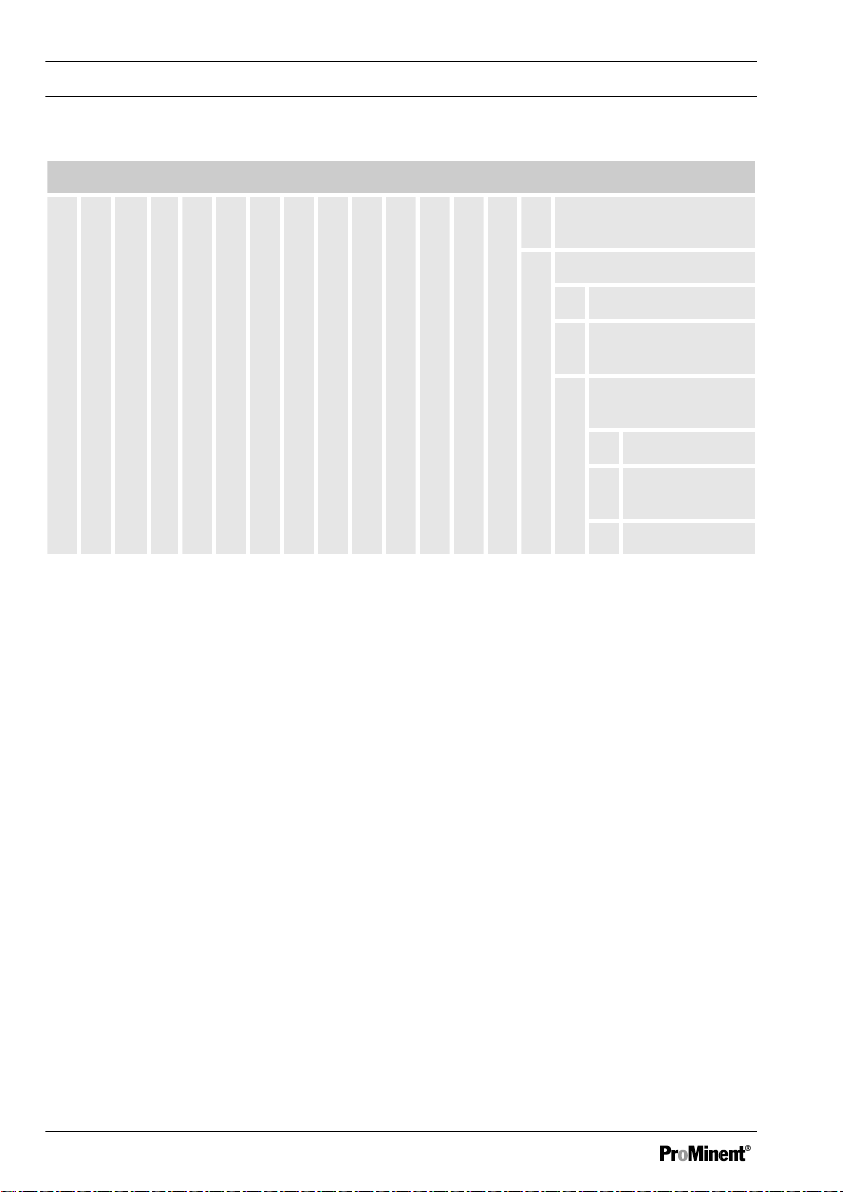

DULCOMETER® D1Cb / D1Cc software upgrade

D1UbSoftware default setting

V Software preset

Default setting - measured variable

0 Universal

A Peracetic acid

B Bromine

C Chlorine

D Chlorine dioxide

F Fluoride

H Hydrogen peroxide

I Chlorite

P pH

R ORP

Commissioning

S 0/4-20 mA standard signal general

X Oxygen

Z Ozone

L Conductivity

Connection of the measured variable

1* Standard signal 0/4-20 mA, all measured variables

5 mV input for pH/redox via guard terminal

Correction variable

0 none

2* Temperature Pt100/PT1000 (for pH and conductivity)

4* Manual temperature input (for pH and conductivity)

* = chargeable option

57

Page 58

Commissioning

DULCOMETER® D1Cb / D1Cc software upgrade

Control input

0 none

1* Pause

Signal output

0 none

1* Analogue signal output 0/4-20 mA

Power activation

G Alarm and 2 limit relays

M* Alarm and 2 solenoid valve relays

Pump activation

0 none

2* 2 pumps via pulse fre‐

quency

Control characteristic

* = chargeable option

58

0 none

1* Proportional control

2* PID control

Language

00 no default

setting

Page 59

Operating diagram/ Display Symbols

6 Operating diagram/ Display Symbols

Overview of equipment/Control elements

6.1

Fig. 26: Overview of equipment/Control elements

Function Description

1st respective measured variable Affix the measured variable label here.

2. Display

3. START/STOP key Start/Stop the control and metering functions

4. ENTER key To apply, confirm or save a displayed value or

status or to acknowledge an alarm

59

Page 60

Operating diagram/ Display Symbols

Function Description

5. UP key To increase a displayed numerical value and to

change the variables (flashing display). move up in

the operating menu.

6. DOWN key To lower a displayed numerical value and to

change the variables (flashing display). To move

down in the operating menu.

7. BACK KEY Back to the continuous display or to the start of the

respective setting menu

8. CHANGE key To change within a menu level and to move from a

changeable variable to another changeable vari‐

able within a menu option. When inputting numer‐

ical values, the cursor moves one space on

6.2 Display Symbols

The display of the DULCOMETER® D1Cb / D1Cc

Meaning Comment Symbol

Limit transgression - relay 1 upper Symbol left

Limit transgression - relay 1 lower Symbol left

uses the following symbols:

Limit transgression - relay 2 upper Symbol right

Limit transgression - relay 2 lower Symbol right

Metering pump 1 activation off Symbol left

Metering pump 1 activation on Symbol left

Metering pump 2 activation off Symbol right

Metering pump 2 activation on Symbol right

Solenoid valve 1 activation off Symbol left

Solenoid valve 1 activation on Symbol left

60

Page 61

Operating diagram/ Display Symbols

Meaning Comment Symbol

Solenoid valve 2 activation off Symbol right

Solenoid valve 2 activation on Symbol right

Stop key pressed

Manual dosing

Fault

Measured value rises very quickly Trend of measured value dis‐

play

Measured value rises quickly Trend of measured value dis‐

play

Measured value rises slowly Trend of measured value dis‐

play

Measured value falls very quickly Trend of measured value dis‐

play

Measured value falls quickly Trend of measured value dis‐

play

Measured value falls slowly Trend of measured value dis‐

play

Measured value steady Trend of measured value dis‐

play

6.3 Permanent Display 1

1. Reading

2. Mass unit ("ppm" in this example)

3. Status of the actuators

4. Display of reading trend - falling /

rising

Fig. 27: Permanent Display 1

Not all symbols are visible simultane‐

ously in the permanent display 1. The

scope of the symbols depends on what

is required.

61

Page 62

100%

2.3

A0095_GB

0%

mea. val

feedfwd:

ctrlout:.

w =

5.0 ppm

Operating diagram/ Display Symbols

5. Measured variable ("chlorine" in this

example)

6. Status line

Not all symbols are visible simultane‐

ously in the permanent display 1. The

scope of the symbols depends on what

is required.

6.4 Continuous display 2

Fig. 28: Continuous display 2

The continuous display 2 shows all the

currently required information from the

DULCOMETER® D1Cb / D1Cc controller.

Switch to other displays by pressing

or .

or

6.5 Continuous display 3

Fig. 29: Continuous display 3

1. Current measured value in plain text

2. Bar graph display shows the current

measured value in relation to the

lower and upper measured value

limits

3. Displays the upper and lower limit of

the display

Switch to other displays by pressing or

or .

To set the lower and upper value (3) press

. The left-hand value will flash and can

be set using the or . Confirm the

entry with . Likewise, switching

between the left- and right-hand values (3)

occurs by pressing the key

This setting only changes the display

range of the bar graph, as it were

"zooming in" to a smaller range to obtain a

better resolution of the display in the main

display range of the measurement.

.

62

Page 63

This setting only changes the display

range of the bar graph! A change to

the measuring range of the

DULCOMETER® D1Cb / D1Cc is not

possible using this function.

Operating diagram/ Display Symbols

63

Page 64

Operating diagram/ Display Symbols

6.6 Operating diagram

Access code

–

Access to the setting menu can be blocked with an access code

–

If the access code has been correctly selected for a setting menu, then all of the

other setting menus are also accessible

Fundamentally the continuous displays 1 - 3 and the calibration menu are freely

accessible. All of the other menus can be disabled by the access code in such a

way that the set values are displayed but cannot be changed. The default value

of the access code is "5000".

–

If no key is pressed within 60 seconds, the device will return to the continuous

display 1, the access code is re-enabled and access is restricted

64

Page 65

Access code, correct

Parameter

setting

Calibration notes

Permanent

display 1

Permanent

display 3

Calibration

menu

V

arious

Access code

Setting menus

A0001_GB

Permanent

display 2

Operating diagram/ Display Symbols

Fig. 30: Access code

The number and scope of the setting menus depends on the design of the device.

65

Page 66

1

Text 1

Text 2

Selection 1

Selection 2

Text 1

Text 2

Selection 1

Selection 2

A0007_GB

Operating diagram/ Display Symbols

You can set and change numerical values as follows:

Fig. 31: Settable values flash on and off

1. Settable values flash on and off

You can lower or increase values using the keys

and .

You can switch between the settable values using the key.

1. The setpoint (e.g. 7.20 pH) flashes

2.

The the or key once

The first figure of the numerical value now flashes.

ð

3.

Using the

key you can go back to the figure you want to change

By pressing the key multiple times, you can return to the first figure of the

numerical value which is to be set.

The figure of the numerical value which can be changed flashes.

4.

66

You can lower or increase the numerical value using the keys and

Page 67

general setting

information

Identcode:

D1CB xxxxxxxxxx

Vxxxxxxxxxx

Srnr: xxxxxxxxxxx

alarm relay

access c.:

5000

operating menu

english

reduced

A0088_GB

operating menu

Calib timer

wash timer

_

_

Operating diagram/ Display Symbols

ð

You can now save the entire modified numerical value using the key.

5.

By multiple pressing of the

6.7

Reduced / Complete Operating Menu

key you access the next menu point

The DULCOMETER® D1Cb / D1Cc allows settings to be made in two different compre‐

hensive menus (reduced / complete). All of the parameters of the controller are preset

and can be changed in the complete operating menu.

The controller is delivered with a restricted operating menu. If adjustments are neces‐

sary, the parameters can be changed by switching to the complete operating menu.

Fig. 32: Reduced / complete changeover

6.8 Fault Messages

Any fault messages and notes which arise

are shown in the bottom line of the perma‐

nent display 1. Faults which have to be

acknowledged (acknowledging them

switches the alarm relay off) are shown by

the

Faults/notes, which remain after acknowl‐

edgement, will be displayed alternately. If

a correction variable is being processed,

the value will be displayed in the same

line as the faults/notes. Faults, which are

rectified automatically by changing oper‐

ating situations, are removed from the

permanent display 1 without the need for

acknowledgement.

symbol.

6.8.1 Fault display

Fig. 33: Fault display

1. Stop function

2. Fault

3. Fault in plain text

67

Page 68

general setting

information

Identcode:

D1CB xxxxxxxxxx

Vxxxxxxxxxx

Srnr: xxxxxxxxxxx

alarm relay

access c.:

5000

operating menu

english

reduced

A0088_GB

operating menu

Calib timer

wash timer

_

_

Operating diagram/ Display Symbols

6.9 General settings

6.9.1

Access code

Access to the setting menu can be prevented by an access code. The

DULCOMETER® D1Cb / D1Cc is delivered with the access code "5000". Even a security

lock is applied using the access code, the calibration menu remains freely accessible.

Fig. 34: Access code

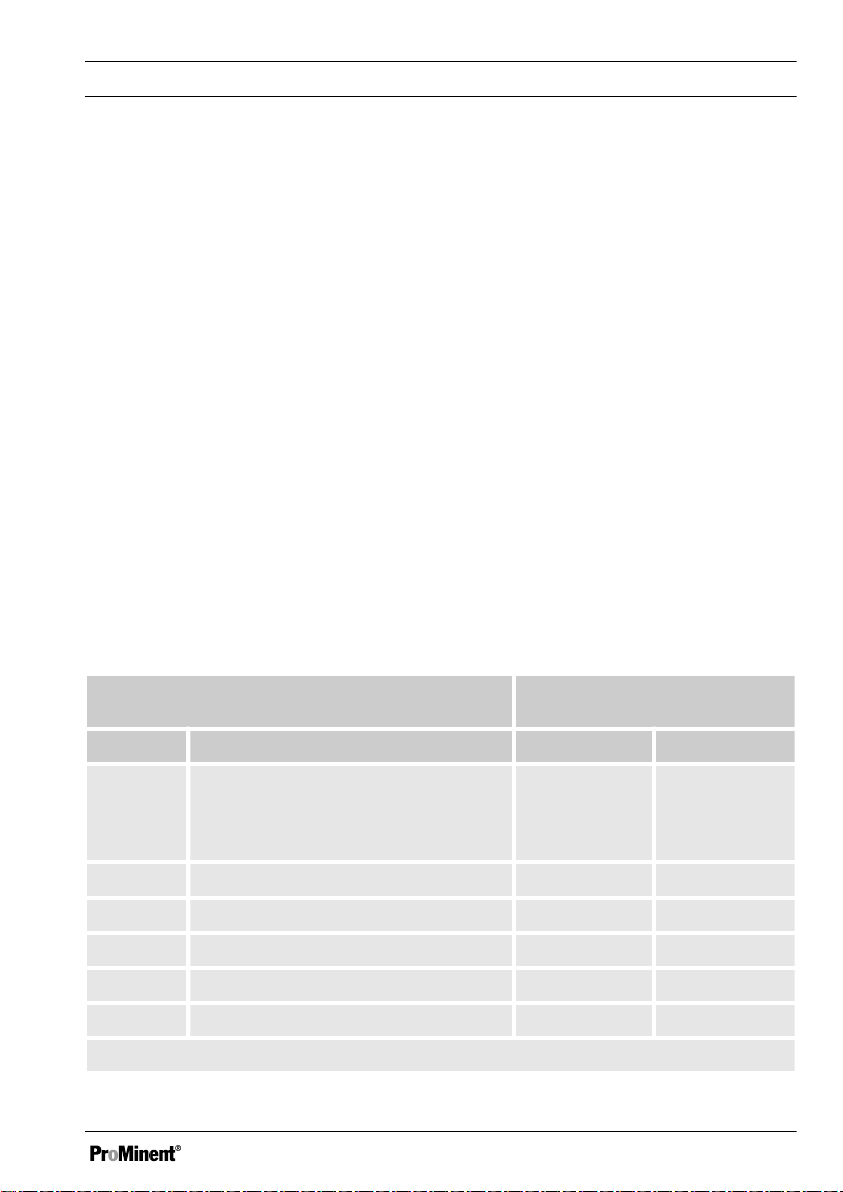

Possible values

Factory set‐

Increment Lower value Upper value Remarks

ting

Access code 5000 1 0000 9999

68

Page 69

Measured Variables and Operating Menus for Amperometric Sensors

7 Measured Variables and Operating Menus for Ampero‐

metric Sensors

n Users' qualification: instructed per‐

sons, see

ifications’ on page 10

Ä Chapter 1.2 ‘Users' qual‐

69

Page 70

general setting

information

Identcode:

D1CB xxxxxxxxxx

Vxxxxxxxxxx

Srnr: xxxxxxxxxxx

alarm relay

access c.:

5000

operating menu

english

reduced

A0088_GB

operating menu

Calib timer

wash timer

_

_

Measured Variables and Operating Menus for Amperometric Sensors

7.1 Reduced / Complete Operating Menu

The DULCOMETER® D1Cb / D1Cc allows settings to be made in two different compre‐

hensive menus (reduced / complete). All of the parameters of the controller are preset

and can be changed in the complete operating menu.

The controller is delivered with a restricted operating menu. If adjustments are neces‐

sary, the parameters can be changed by switching to the complete operating menu.

Fig. 35: Reduced / complete changeover

7.2 Description of All Amperometric Measured Variables

WARNING!

Danger of incorrect metering

This can result in hazardous incorrect metering

During initial commissioning, the measured variable and the measuring range of the

sensor must be set prior to calibration. Refer to

Measured Variable and Measuring Range’ on page 54

Ä Chapter 5.1.2 ‘Selection of the

Measured variable Default measuring range

Chlorine, chlorine dioxide, ozone 2 ppm

Bromine 10 ppm

Oxygen 20 ppm

Peracetic acid 2000 ppm

Hydrogen peroxide 200 ppm

Chlorite 0.5 ppm

70

Page 71

Measured Variables and Operating Menus for Amperometric Sensors

The measuring ranges can be selected in the following ppm increments: 0.5, 2, 5, 10, 20,

50, 100, 200, 1000, 2000, 5000, 10000, 20000.

Reduced Operating Menu

7.3

The reduced operating menu allows the key parameters to be set. The following overview

shows the settings that can be selected:

71

Page 72

Positive values of setting variable:

Measured value lift

Negative values of setting variable:

Measured value lower

auto.: 30.0 °C

Permanent display 1

Permanent display 2

only with control

(w = setpoint

)

Control with dead zone

For normal control

PID Control

Proportional control

Only with control

ppm

0.60

mea. val 0.60

ppm

feed fwd: 70 %

ctrlout: 59 %

w=

0.60

ppm

calibration

zero p.: 4.00 mA

slope:

6.50 mA/ppm

calibration

DPD-value:

0.60 ppm

temp.: 30.0 °C

calibration

zero p.: 4.00 mA

slope:

6.75 mA/ppm

limits

setting ?

control

setting ?

control

control output

positive

negative

control

control value

set point

0.60 ppm

ctrl parameter

xp = 10 %

control

control value

set point 2 upper

0.80 ppm

set point 1 lower

0.60 ppm

control

control value

30 %

manual dosing

15 %

regulated range

general setting

information

identcode

D1CBxxxxxxxxx

Vxxxxxxxxxx

Srnr: xxxxxxxxxx

alarm relay

active

access c.:

5000

operating menu

English

-

reduced

Setting in

complete

operating

menu

For manual control

or

or

ctrl parameter

xp = 10 %

Ti = off

Td = off

limit 1 lower

0.10 ppm

limit 2 upper

1.50 ppm

limits fault

0.50 ppm

0001s

hyst.:

∆t

off

off

control

A0003_GB

0.60 ppm

0.0 10.0

Permanent display 3

normal

normal

30%

30%

control value

control value

p-control

PID-control

30 %

30 %

normal

with dead band

manual