Page 1

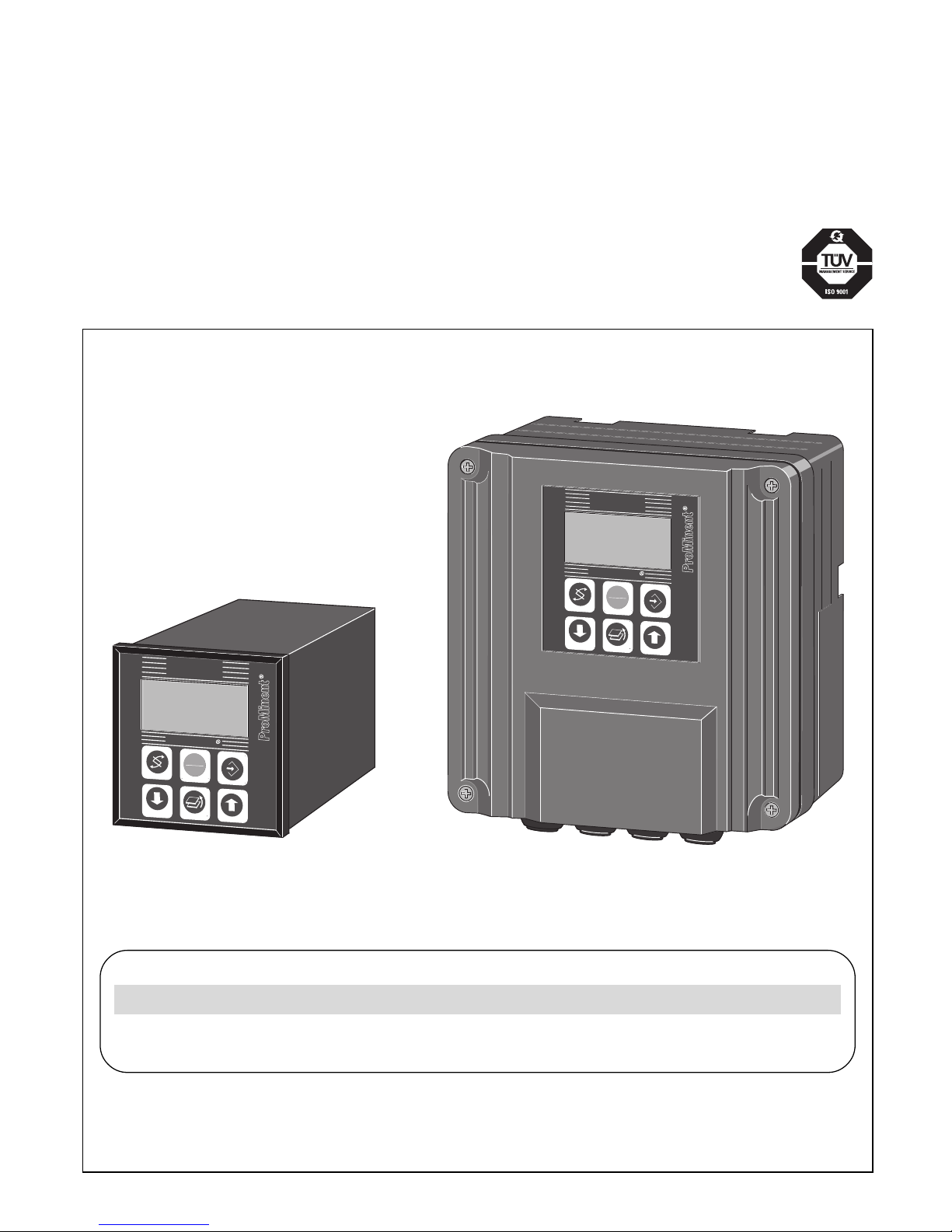

Typ/type W

Operating Instructions

DULCOMETER® D1C

Part 1: Mounting and installation instructions for wall-mounted and

control panel-mounted devices

ProMinent

®

T. Nr./P. No.: 987725 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany BA DM 123 04/03 G/GB/F/E

Identcode

D1C A

___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___ ___

pH

7.43

pH

START

STOP

Temp.: 24.7

° C

DULCOMETER

pH

7.20

pH

START

STOP

DULCOMETER

DED1C1S001 DED1C1W001

G/GB/F/E

Typ/type D

Page 2

2

Betriebsanleitung in deutsch

von Seite 1 bis 21

Operating Instructions in English

from Page 23 to Page 41

GB

E

Page 3

23

1 Contents / General User Information

Please completely read through these operating instructions. Do not discard!

The warranty shall be invalidated by damage caused by operating errors!

Page

General User Information ............................................................................................................................ 23

Device Identification / Identity Code ........................................................................................................... 24

Device Overview / Controls ......................................................................................................................... 25

Functional Description ................................................................................................................................. 26

Mounting / Installation.................................................................................................................................. 27

Safety information ............................................................................................................................... 27

Technical Data .............................................................................................................................................. 33

Maintenance / Repair ................................................................................................................................... 37

Applicable Types of Enclosure / Standards ................................................................................................ 39

Spare Parts / Accessories............................................................................................................................ 40

Used Part Disposal....................................................................................................................................... 40

EC Declaration of Conformity ...................................................................................................................... 41

Overview of terminal arrangement ............................................................................................................... 42

Terminal diagrams ........................................................................................................................................ 44

General User Information

Please read the following information carefully and thoroughly. Knowledge of this information will greatly

increase the benefit you gain from the operating instructions.

Particular attention is drawn to:

• Lists

Instructions

Setting menus

NOTE

The information provided in a note is intended to make your work easier.

and safety information:

WARNING

This symbol draws attention to possible hazardous situations. Disregard of this information

may result in the direct threat to life and serious injuries.

CAUTION

This symbol draws attention to a possibly dangerous situation. Disregard of this

information may result in serious injuries or damage to property.

IMPORTANT

This symbol is used to draw attention to possible damaging situations. Disregard of this

information may result in damage to property.

SAFETY INFORMATION

CAUTION

• Please observe the parts of these operating instructions applicable to your specific type

of equipment! Applicable parts are listed in the device identification/ID code list!

• Correct measurement and metering is possible only with the probe in perfect working

order! The probe must be calibrated/checked at regular intervals!

Probe failure may cause the uncontrolled metering of chemicals.

Page 4

24

2 Device Identification / Identity Code

D1C A

Please enter the identity code of your device here.

D1C DULCOMETER® Controller Series D1C

W Wall mounting

D Control panel installation, 96 x 96 mm

Operating voltage

0 230 V 50/60 Hz

1 115 V 50/60 Hz

2 200 V 50/60 Hz (control panel installation only)

3 100 V 50/60 Hz (control panel installation only)

4 24 V AC/DC

Measured variable

B Bromine (0.1...13 mg/l) (3rd quarter 2001)

C Chlorine (0...0.5/2/10/20 mg/l)

L Conductivity (0…20/200/2000 µS/cm; 0…20/200 mS/cm)

P pH (0...14 pH)

R Redox (-1000...1000 mV)

H Hydrogen peroxide (1…20; 10…200; 100…2000 mg/l)

S Standard signal (0/4-20 mA)

A Peracetic acid (10…200; 100…2000 mg/l)

D Chlorine dioxide (0...0.5/2/10/20 mg/l)

Z Ozone (0...2 mg/l)

X Dissolved Oxygen (0.1...10/20 ppm)

T Temperature (0...100 °C)

Connection of measured variable

1 Terminal, standard signal 0/4-20 mA (signal converters necessary for controllers

with measured variable connection, standard signal 0/4-20 mA

2 SN6 connector for P or R

3 Terminal for L

4 Terminal PT 100 for T

5 Terminal mV for P or R

Correction variable

0 None

1 pH for chlorine

2 Temperature for P, D, H, A or L via terminal

3 Temperature for P, D, H, A or L via standard signal 0/4-20 mA

4 manual temperature entry for P, H, A or L

Feedforward control

0 None

1 Flow as standard signal 0/4-20 mA

2 Flow as frequency 0 - 500 Hz

3 Flow as frequency 0 - 10 Hz

Control input

0 None

1 Pause

Signal output

0 None

1 Standard signal 0/4-20 mA measured value

2 Standard signal 0/4-20 mA controlled variable

3 Standard signal 0/4-20 mA correction variable

42 standard signal outputs 0/4-20 mA, freely programmable (not for H, A)

Power control

G Alarm and 2 limit value relays

M Alarm and 2 solenoid valve relays (pulse length control)

R Alarm relay and actuator with feedback

Pump control

0 None

2 Two pumps

Control characteristic

0 None

1 Proportional control

2 PID control

Log output

0 None

Language

D German (E, F, N)

E English (D, F, N)

F French (D, E, N)

I Italian (D, F, S)

N Dutch (D, E, F)

S Spanish (D, I, F)

P Polish (D, E, A)

A Swedish (D, E, P)

B Portuguese (E, S, F)

U Hungarian (P, A, E)

G Czech

Page 5

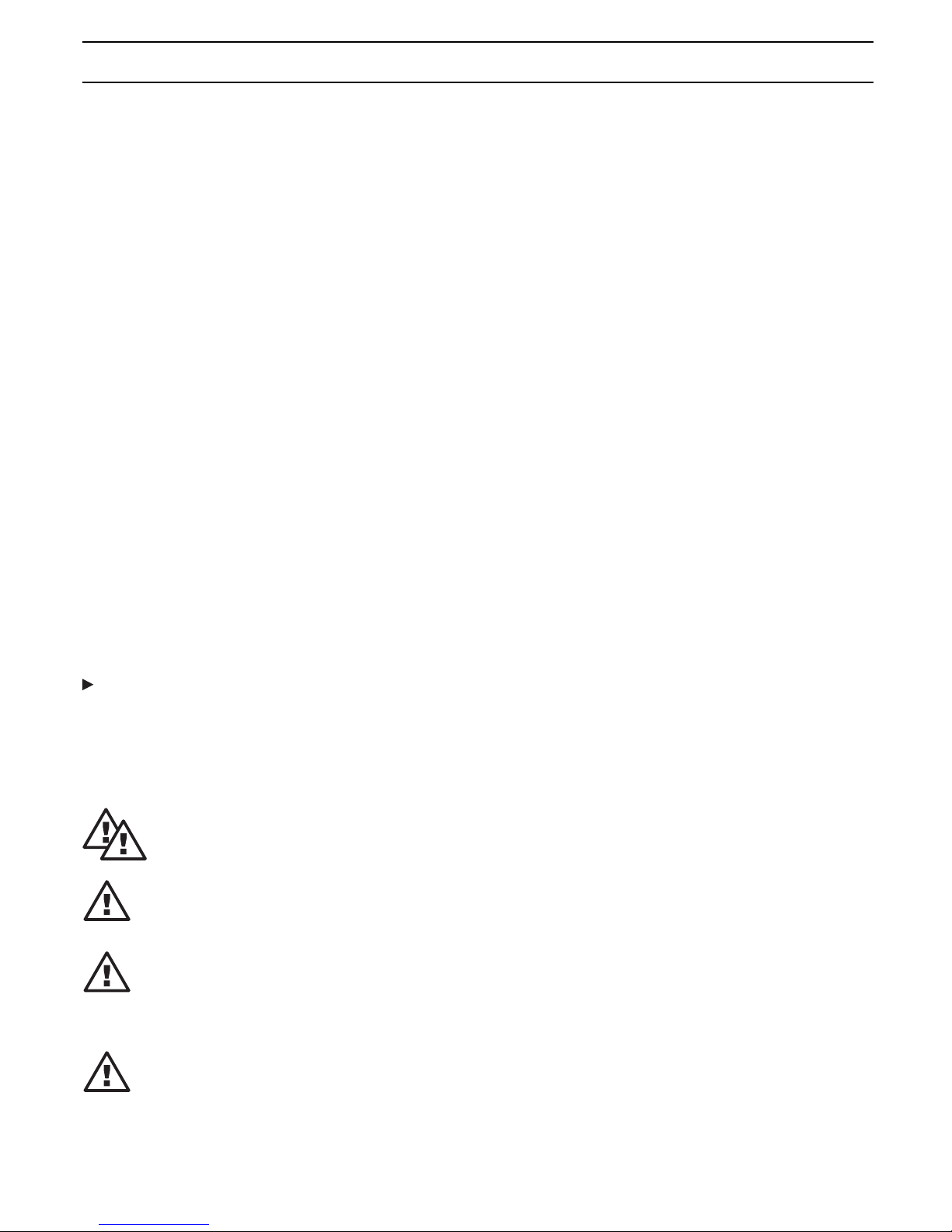

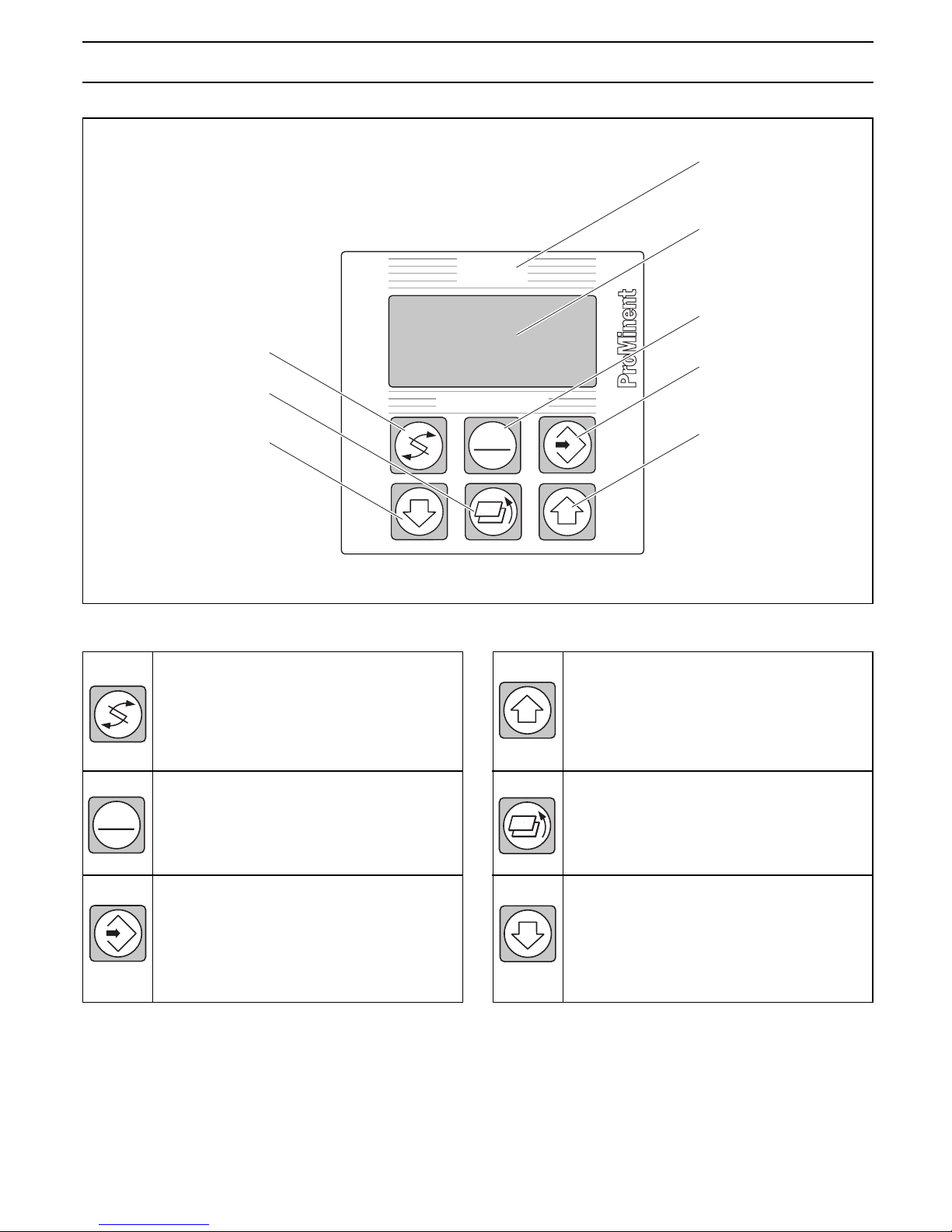

25

®

DULCOMETER

®

STOP

START

Display field

measured

variable

Graphic display

START/STOP

Button

ENTER

Button

UP

Button

CHANGE

Button

DOWN

Button

RETURN

Button

D1C

CHANGE button

To change over within a menu level

and to change from one variable to

another within a menu point.

START/STOP button

Start/stop of control and metering

function

ENTER button

To accept, confirm or save a displayed

value or status. For alarm acknowledgement.

3 Device Overview / Controls

D1C2-Cl-002-GB

STOP

START

UP button

To increase a displayed numerical

value and to change variables (flashing

display).

RETURN button

To exit operating menu (back to start

of relevant setting menu).

DOWN button

To decrease a displayed numerical

value and to change variables (flashing

display).

Page 6

26

4.1 Brief functional description

The DULCOMETER® D1C is a device designed for measuring, displaying and controlling measures

variables. With the corresponding expansion stage it can also process disturbance variables.

The measured variables to be processed are:

- pH, ORP

- Standard signal, Temperature

- Dissolved Oxygen

- Chlorine, ClO2, Br, O

3

- Conductivity

- H2O2 , peracetic acid

4.2 Mechanical design

The DULCOMETER® D1C is supplied in versions suitable for control panel installation and wall mounting.

4.2.1 Control panel installation in accordance with DIN 43700 (96 x 96 mm)

The DULCOMETER® D1C is a device suitable for control panel installation in accordance with DIN 43700

with the format 96 x 96 mm, depth 140 mm. In this installation arrangement, the device is completely

integrated in the control panel or installed in a housing. The device is electrically connected directly via

terminals at the rear.

The terminals as well as an SN6 socket for pH or redox input project beyond the rear panel.

Retaining brackets for mounting the device in the control panel are provided on the housing.

The display pc-board with the graphic display is located at the front. It features 6 operating buttons and a

transparent display window.

4.2.2 Wall mounting

The DULCOMETER® D1C W is suitable both for wall mounting as well as for installation in a control panel

(control panel installation kit, Part No. 792908). The durable plastic housing is made up of an upper section

and lower section. The graphic display and transparent display window are accommodated in the upper

section while the lower section houses the processor, power supply and options board. The connection to

the display is made by means of a ribbon cable. Electrical connection is made via the originally closed,

punch-out cable leadthroughs on the underside of the housing. On devices with an SN6 input (dependent

on identity code), the standard SN6 socket is located on the left-hand side. A wall mounting bracket is

provided at the rear of the device to facilitate simple wall mounting.

4.3 Electrical design

The device processes an input signal while taking into consideration disturbance variables and operator

inputs. The result is displayed and made available to other devices via a standard signal or a serial interface.

When equipped with corresponding actuators, the device can undertake control functions. It is designed to

activate metering pumps, solenoid valves, servo motors with feedback as well as mA standard signal. The

activation variable is recalculated every second.

The controller does not feature a separate power switch. It is therefore immediately ready for operation

after being connected to the power supply.

The devices correspond to relevant requirements concerning electrical operating equipment. For this

purpose, the following standards are complied with:

• Supply voltage in accordance with - DIN IEC 38

• Electrical safety in accordance with - EN 61010-1

• Emitted electromagnetic interference in accordance with - EN 55011 Gr. 1/Cl. A

4 Functional Description

Page 7

27

5.1 Safety information

WARNING

The device is suitable for installation in a control panel or in a corresponding housing (see

accessories). The device must not be placed into operation if not installed as intended!

CAUTION

• The generally applicable safety precautions must be observed for installation.

Corresponding national regulations must be complied with!

• The operating instructions must be read through carefully before starting any installation

and start-up procedures!

• Only specially trained and qualified personnel are permitted to carry out electrical

installation of the device!

• The power ratings specified on the device must agree with those of the supply voltage!

• The power connection line and the data lines must not be installed together with

interference-prone lines! If low electrical disturbance cannot be guaranteed in the

working environment, special interference suppression measures must be implemented!

Severe disturbances can cause malfunctions through to irreparable damage of the

device!

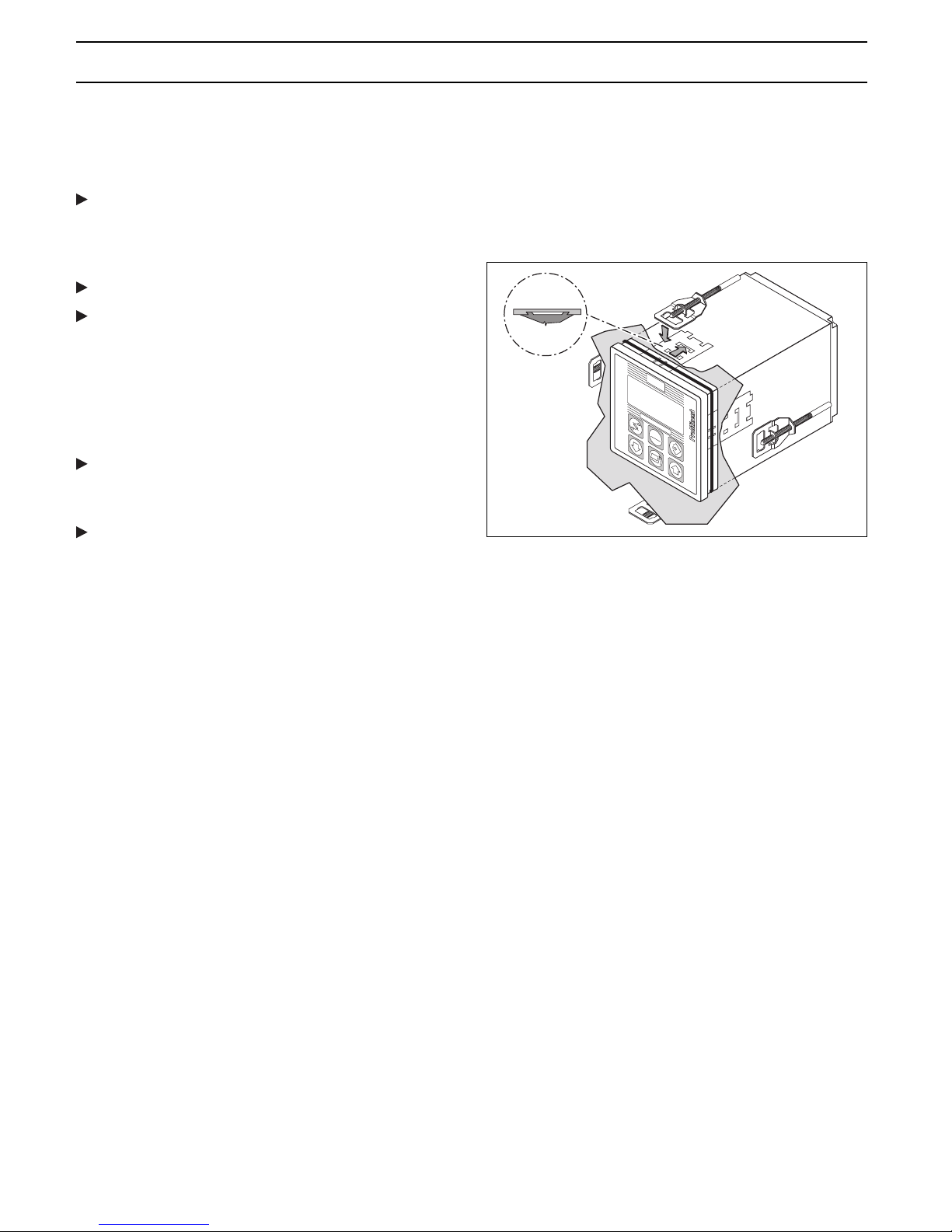

5.2 Mounting description, mechanical

Please remove the protective film from the display!

5.2.1 Mounting DULCOMETER® D1C D (control panel installation)

This device is designed specifically for installation in a control panel. The housing corresponds to DIN

43700.

The aperture in the control panel for installing the device is defined in DIN 43700.

We recommend a smaller aperture. In this way, the device is held more securely in place (reduced lateral

play) and the seal is pressed more evenly.

5 Mounting / Installation

92

+0,6

92

+0,6

90

+0,5

90

+0,5

DED1C1S003

Aperture to ProMinent

recommendation

Aperture to

DIN 43700

Page 8

28

To make aperture:

As an installation aid, a drill/punch template at a scale of 1:1 is provided with the device for the purpose of

optimally positioning the device on the control panel.

With the aid of a spirit level, align the template in the corresponding position on the control panel and

secure in this position. Mark the corner points with a centre punch and drill out with a 6 mm Ø twist drill.

Then saw out the intermediate web with a compass saw. Neatly rework the surfaces until the dimensions

are within the specified tolerances.

Cleanly deburr edges.

Before fitting the device into the control panel

aperture, check the position of the seal (must rest

on front shoulder). Working from the outside, fit the

device in the aperture, attach the retaining brackets

and slide back as far as it will go. All four retaining

brackets must be fitted otherwise the enclosure

class IP54 will not be complied with.

Using a suitable screwdriver, screw the threaded

pins forward until the seal is evenly pressed all

round.

Check once again that the seal is fitted correctly, if

necessary, release the threaded pins and correct

the position.

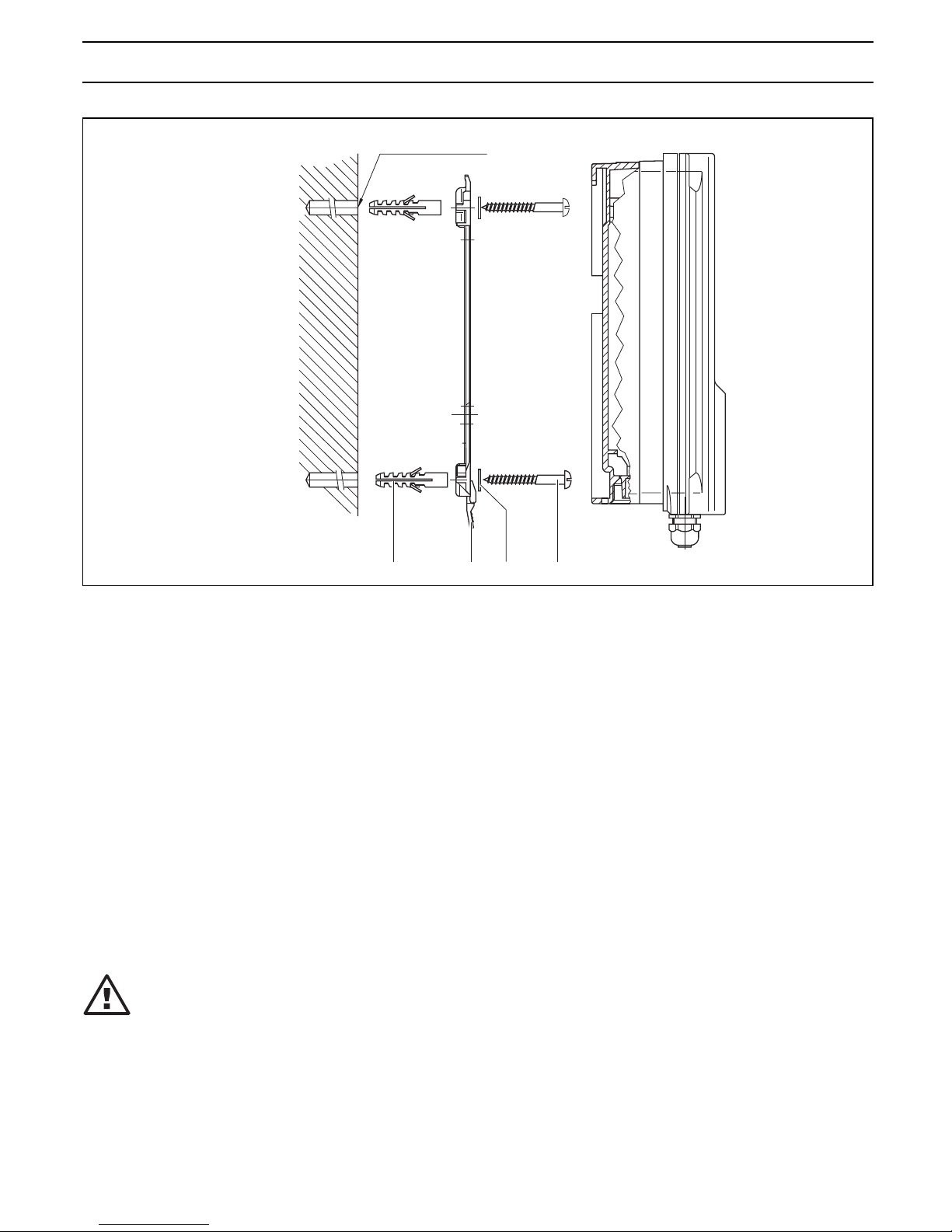

5.2.2 Mounting DULCOMETER® D1C W (wall mounting)

NOTE

The device should be mounted in such a position as to facilitate easy read-off and

operation (at eye-level where possible).

The device can be screwed directly onto the wall with the aid of the wall mounting bracket provided (drilling

template enclosed).

Securing material for wall mounting:

• Item (1) 3x button head screws 5x45

• Item (2) 3x U-washer 5.3

• Item (3) 3x plastic wall plug d8

The wall mounting bracket (4) can also be used as a drilling aid. For this purpose, set up the mounting

bracket in the corresponding position on the wall.

NOTE

Take particular care when setting up to ensure that sufficient space is available for the

purpose of installing the cables. A space of approx. 120 mm must be left at the top for the

“park position”.

Mark and drill the holes. Insert wall plugs (3) and secure mounting bracket with screws (1) and U-washers

(2). Mount device from above on mounting bracket, press slightly against the wall and slide upward by

approx. 4 mm until it is heard to engage in position.

DED1C1S004

®

S

TO

P

START

DULCOMETER

®

D1C

Mounting / Installation

Page 9

29

5.2.3 Control panel installation D1C W

A 4 mm wide flange acting as the stop for the control panel together with an all-round groove for a seal is

provided on the perimeter of the device. When mounted in a control panel, the entire front section

protrudes by approx. 35 mm from the control panel. The device is mounted from the outside in a prepared

aperture in the control panel. The device can be secured to the control panel from the inside with the

securing material provided.

Securing material for control panel installation:

• Item (1) 1x cellular rubber seal d3

• Item (2) 6x retaining bracket, galvanised steel

• Item (3) 6x PT self-tapping screw, galvanised

Procedure

Using the cut-out template provided, first mark the exact position of the device on the control panel. Where

possible, it should be positioned at eye-level. Ensure sufficient space is left at the top to allow for the “park

position”. Mark and drill the corners. Hole diameter 12 - 13 mm.

IMPORTANT

Dimensional deviations may occur as the result of photocopying the cut-out template.

Now make the aperture as specified in the drawing with the aid of a punch or compass saw. The control

panel should be 2 - 3 mm thick. Before fitting the device in the aperture, evenly press the seal into the

groove on the outside of the housing. With the aid of a second person if necessary, the controller can then

be firmly secured with the retaining brackets and screws to the control panel.

3421

D1C1(W) 003 D

Ø 8 x 50 deep drilled hole

Mounting / Installation

Page 10

30

Mounting with SN6 socket (depending on identity code)

Corresponding to the order, an SN6 input socket may be

preassembled on the device. This socket must first be removed

in order to facilitate installation in the control panel. For this

purpose, open device as described under Point 5.3.

By pressing the orange-coloured levers simultaneously,

disconnect connection cable from terminals No. 11 and 12.

Unscrew SN 6 socket (WAF 22) complete with O-ring.

After installing the controller in the control panel, the SN6

socket can be re-fitted together with the coaxial cable and

O-ring.

IMPORTANT

Ensure the O-ring is fitted correctly!

Reconnect cable to terminals 11 and 12.

5.3 Electrical installation

WARNING

• Electrical connection must not be carried out before the device has been installed in the

control panel!

• The supply voltage must be disconnected when removing the device together with the

connection lines!

• Generally, the device may only be opened by qualified personnel.

• Particular care must be taken before opening the device for the purpose of possible

service work to ensure that no voltage is applied to the device and the voltage supply

cannot be switched on while carrying out service work.

IMPORTANT

Tie together stranded wires with cable ties at a distance of 30 mm from the terminals! If

they work loose in the event of a defect, stranded wires carrying mains voltage must be

prevented from coming in contact with low voltage terminals!

5.3.1 Electrical installation D1C D (control panel installation)

Terminals are provided at the rear of the device to facilitate electrical connection. The number and type of

terminals depend on the type of device.

Not all devices are equipped with terminal row X1 (left).

Among other things, terminal row X2 (centre) serves the purpose of connecting the measured variable. The

measured variables pH and redox can be connected directly to the terminals with SN6 connectors or, as

other measured variables, via a mA signal. The jumper must be connected at terminals 9 and 10 of terminal

row X2 if pH or redox probes are connected to SN6 connectors or to the terminal without connection of

equipotential bonding!

Terminals rows XR1, XR2 and XR3 (right) serve the purpose of connecting power relays. The mains power

connection XP is located at the bottom right. An earthing cable is not necessary.

The connectors XHK are provided for service purposes.

Refer to the terminal connection diagrams for the connection terminals (see Page 42-53).

3 2 1

D1C1(W) 004 D

Control panel

Mounting / Installation

Page 11

31

a) b) c)

d)

e)

3

2

1

4

Cable ties

16 15 1413 12 11 10 9 8 7 6 5 4 3 2 1

123456789101112

21

2

1

N

21

321

L1

pH

®

pH

DULCOMETER

®

S

T

O

P

S

T

A

R

T

1) 2) 5)

3) 4)

D1C1(W) 005 D

a) b)

c) d)

6

5

DED1C1W 006 DED1C1W 007

Fig. 1: Rear row Fig. 2: Front row

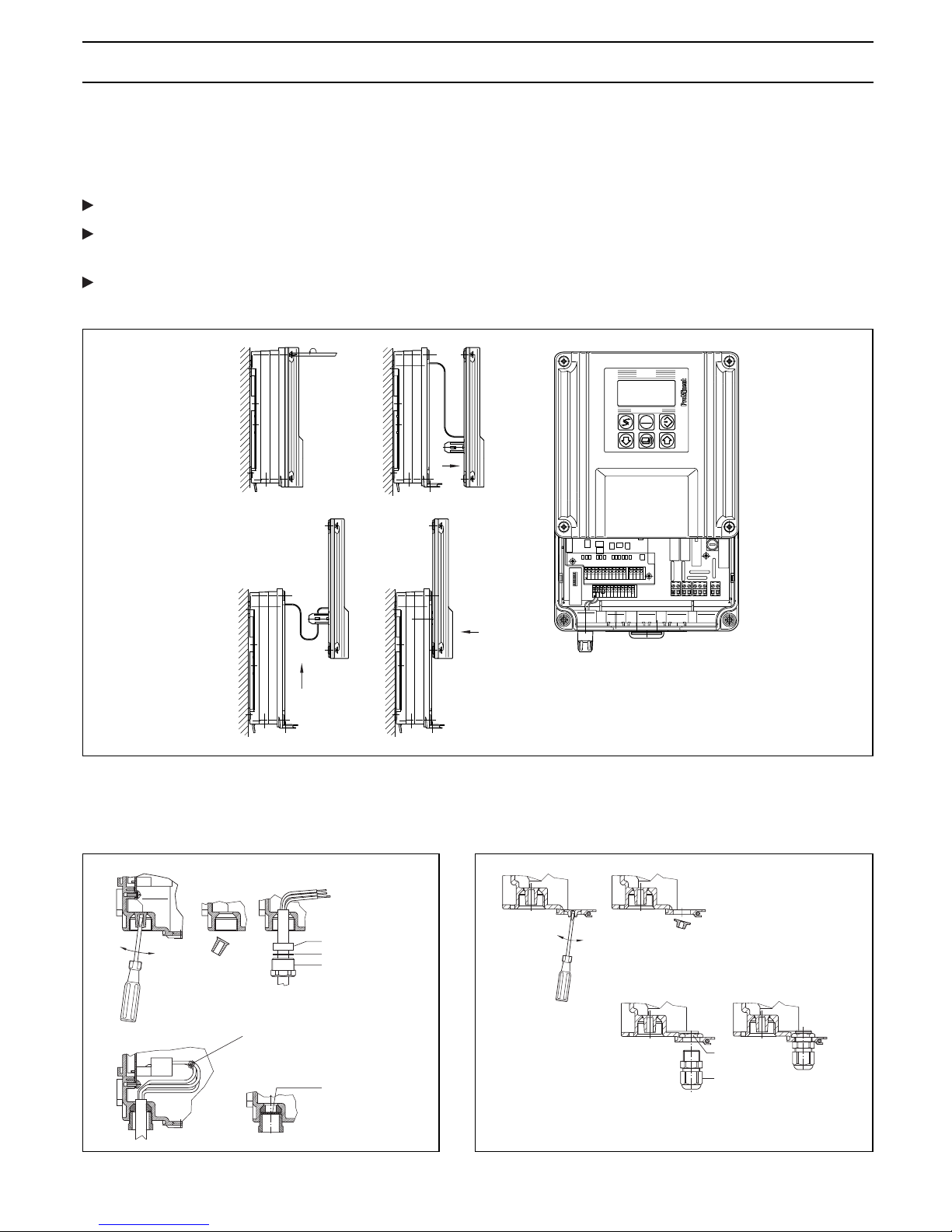

5.3.2 Electrical installation D1C W (wall mounting)

Opening the housing

The device should only be opened when it is mounted on a wall or installed in a control panel.

To open the housing, initially, the four captive countersunk screws must be released.

The upper section is additionally locked to the bottom section by means of snap hooks. The housing can

be opened by pulling the upper section forward thus releasing the snap hooks.

With the aid of the two guide rails, the upper section can be moved to the approx. 100 mm higher “park

position”. The fuse and all connection terminals are freely accessible in the park position.

Electrical installation for wall mounting

Initially, threaded holes must be broken out corresponding to the number of cables.

• Punch aids are provided to break out the individual threads.

Mounting / Installation

Page 12

32

• Use following tools to punch out holes:

Rear row (Fig. 1): Screwdriver DIN 5262-B, size 1 (Ø 4.5 mm)

Front row (Fig. 2): Screwdriver DIN 5262-B, size 0 (Ø 3.0 mm)

Remove cable sheathing over a sufficient length (corresponding to length of terminals). Fit screwed

gland (1), thrust ring (2) and seal (3) over cable and insert in threaded hole.

Screw in screwed gland and firmly tighten with WAF 19 spanner. Shorten stranded wires to the exact

overall length, then strip approx. 7 mm insulation and connect to terminals corresponding to the electrical

connection diagram.

Core sleeves may be used for the stranded wires. If too many threaded holes are punched out, they can

be closed off again with the dummy washers PG 11 (4) supplied with the device.

If the controller features an SN6 input (corresponding to identity code), the corresponding input socket is

located in the rear row on the left side in a PG 11 threaded hole. Any ProMinent cable combination coax

SN6 can be connected to this input.

Packing list, cable screwed glands

5x screwed gland PG 11 Item (1)

5x thrust ring PG 11 Item (2)

5x seal PG 11 inside Ø 9 mm Item (3)

3x seal PG 11 inside Ø 7 mm Item (3)

3x seal PG 11 inside Ø 5 mm Item (3)

2x seal PG 11 inside Ø 4 mm Item (3)

5x seal PG 11 2 x Ø 5 mm Item (3)

2x seal PG 11 2 x Ø 4 mm Item (3)

3x dummy washer PG 11 Item (4)

Additionally for expansion version

4 Stck. 4x screwed gland PG 7 Item (5)

4x lock nut PG 7 brass, nickel-plated Item (6)

The four additional cut-outs in the front row can be used for PG 7 screwed glands. All commercially

available PG 7 screwed glands (suitable for type of enclosure IP65) with lock nut (brass, galvanised, nickelplated) can be used as cable screw fittings.

Available from ProMinent under:

1x cable screwed gland PG 7, black Part No. 703896

1x lock nut PG 7 brass, nickel-plated Part No. 703819

Fit lock nut PG 7 (6) on the inside and mount PG 7 screwed gland (5) from outside and firmly tighten

(WAF 15).

Electrical connection for control panel installation

Normally, only the rear row of threaded holes should be used on devices mounted in a control panel. The

front row (PG 7 cut-outs) are located outside the control panel. The cable screw fittings supplied with the

device are not required for control panel installation. In this case, the individual stranded wires (without pullrelief and seal) are routed directly through the holes and connected to terminals corresponding to the

electrical connection diagram. The holes are broken out as described above.

Mounting / Installation

Page 13

33

Temperature specifications D1C D Control panel Wall mounting

Permissible ambient temperature installation

Basic version: 0 °C...50 °C -5 °C...45 °C

Expansion version: with position feedback

or with correction value via mA

or with disturbance variable via mA 0 °C...45 °C -5 °C...40 °C

D1C W

Permissible ambient temperature

Basic version: -5 °C...50 °C

Expansion version: with position feedback

or with correction value via mA

or with d isturbance variable via mA -5 °C...40 °C

Permissible storage temperature: -10 °C...70 °C

Material specifications / chemical resistance

Part Material

Housing and frame D1C D PPO GF 10

Housing D1C W PPE GF 10

Rear panel D1C D PPE GF 20

Membrane keypad Polyester film PET

Seal Cellular rubber CR

Inner seal, D1C D Silicon-based sealing compound

Retaining bracket and screws Galvanised, zinc-plated steel

M5 screws A2

Chemical resistance:

The device is resistant to normal atmospheres in installation rooms.

Dimensions and weights

D1C D

96 x 96 mm in accordance with DIN 43700, depth 140 mm

Device weight without packing: approx. 850 g

Gross weight of device with packing: approx. 1200 g

D1C W

198 x 200 x 76 mm (W x H x D) Wall mounting

198 x 200 x 35 mm (W x H x D) Control panel installation, external

198 x 200 x 38 mm (W x H x D) Control panel installation, internal

Device weight without packing: approx. 1.2 kg

Net weight of device with packing: approx. 2.0 kg

Electrical data

Probe input via terminals

(X2.12 ... X2.9): Input resistance: > 5 x 1011 Ω

Input resistance of reference electrode with respect to

chassis ground: <1 kΩ

Input range: ±1 V

Accuracy: ±0.5 % of input range

Resolution: 0.0625 % of input range

Connection option for one equipotential bonding electrode

(alternatively, two connection terminals are to be connected

by a wire jumper).

6 Technical Data

Page 14

34

Probe input via

SN6 socket (X2.12 ... X2.9): Input resistance: 1012 Ω

Other data same as for “Probe input via terminals”

Standard signal input

(all measured variables)

(X2.12 ... X2.9): Input range: 0/4…20 mA (programmable)

Input resistance: 50 Ω

Accuracy: 0.5 % of input range

Resolution: 0.014/0.012 mA

Supply voltage and current for external electronics:

19 V ±1.5 V, 20 mA

Conductivity input via

terminals (X2.12 ... X2.9): 2 electrode measuring cells via 2-conductors

2 electrode measuring cells via 4-conductors

4 electrode measuring cells via 4-conductors

Measuring range: 20, 200, 2000 µS/cm

20, 200 µS/cm

Measuring span: 1 : 100

Cell constant: 0.006…12.0 cm-1 depending on measuring range

Probe activation: Sinusoidal 56 Hz or 2.7 kHz

depending on measuring range

Pt 100 input (X2.8, X2.7): Input range: 0 °C…100 °C

Accuracy: ±0.5 °C

Resolution: 0.1 °C

Frequency outputs

(2 reed relays)

for pump activation

(X2.6, X2.5 and X2.4, X2.3): Type of contact: n/o contact noise-suppressed with Varistors

Load capacity: 25 V peak, 0.100 A switching current

Contact lifespan: >50 x 106 switching operations at

contact load 10 V, 10 mA

Max. frequency: 8.33 Hz (500 strokes/min)

Closing time: 100 ms

Standard signal output mA

(X2.2, X2.1): Galvanically isolated from remaining inputs and outputs

Insulation voltage: 500 V

Output range: 0/4...20 mA (programmable)

Max. load: 600 Ω current output 1

400 Ω current output 2

Accuracy: 0.5 % of output range referred to

displayed value

Technical Data

Page 15

35

Standard signal input

for correction variable or

disturbance variable mA

(X1.16 ... X1.14): Galvanically isolated from other inputs and outputs

Insulation voltage: 500 V

Input range: 0/4…20 mA (programmable)

Input resistance: 50 Ω

Accuracy: 0.5 % of input range

Resolution: 0.014/0.012 mA

Supply voltage and current for external electronics:

22 V ±1.5 V, 20 mA

Standard signal output mA

(X1.13, X1.12): Galvanically isolated from other inputs and outputs

Insulation voltage: 500 V

Output range: 0/4…20 mA (programmable)

Max. load: 600 Ω current output 1

400 Ω current output 2

Accuracy: 0.5 % of output range referred to displayed value

Digital input (X1.10, X1.9 Common reference potential and with RS interface but galvanically

and X1.7, X1.6): isolated from remaining inputs and outputs

Insulation voltage: 500 V

- Pause

- Disturbance variable up to 10 Hz or up to 500 Hz

(according to identity code/programmable)

Position feedback input

(X1.3 ... X1.1): Galvanically isolated from other inputs and outputs

Insulation voltage: 500 V

Potentiometer to be connected: 900 Ω...10 kΩ

Accuracy (not including potentiometer error):

1 % of input range

Resolution: 0.5 % of input range

Actuating time: min.: 25 s

max.: 180 s

Power relay output for

controlled variable output (M, R)

or limit value signalling (G)

(XR1 and XR2): Type of contact: Changeover contact, noise-suppressed

with varistors

Load capacity: 250 V AC, 3 A, 700 VA

Contact lifespan: >20 x 106 switching operations

IMPORTANT

The supply voltage applied at relays XR1-XR3 must be identical to the supply voltage

of XP.

Technical Data

Page 16

36

Power relay output

for alarm triggering (XR3): Type of contact: Changeover contact, noise-suppressed

with varistors

Load capacity: 250 V AC, 3 A, 700 VA

Contact lifespan: >20 x 106 switching operations

IMPORTANT

The supply voltage applied at relays XR1-XR3 must be identical to the supply voltage

of XP.

Rated voltage (XP): 100/200 V AC, 50/60 Hz (D1C D only)

Maximum current intake: 150 mA at 100 V AC

75 mA at 200 V AC

Internal fuse protection with: 5 x 20 mm miniature fuse

160 mA, 250 V slow-blow

Rated voltage (XP): 115/230 V AC, 50/60 Hz

Maximum current intake: 140 mA at 115 V AC

70 mA at 230 V AC

Internal fuse protection with: 5 x 20 mm miniature fuse

160 mA, 250 V slow-blow

Rated voltage (XP): 24 V DC or 24 V AC, 50/60 Hz

(operation with safety extra-low voltage only!)

Internal fuse protection with: 5 x 20 mm miniature fuse

315 mA, 250 V slow-blow

Technical Data

Page 17

37

Input /

Output

terminals

Power supply

pc-board on rail 1

Fuse

Rear cover

Terminal block with

flange screw fitting

Pin strip

SN6-connector

Safety information

WARNING

• The device or system must be disconnected from the power supply before starting any

maintenance work. The DULCOMETER® D1C does not feature a separate power switch!

The power supply must therefore be interrupted by means of an external master switch

or by a main fuse. General safety regulations are applicable at all times!

Even when the voltage supply is switched off, mains power may still be applied at

terminals XR 1-3!

• Only use fuses of the specified manufacturer!

Only use 5 x 20 mm miniature fuses!

Fuse rating at mains voltage 100…240 V: 0.160 A slow-blow, Part No. 712048

24 V: 0.315 A slow-blow, Part No. 712026

Fuse change D1C D:

The device can be opened from the rear. For this purpose:

Release flange screw connections of plug-in terminal strips

Unplug terminal strips together with electrical connections

Release SN6 connector (if fitted) and unplug from socket

Unscrew rear panel and remove; the captive screws are located on the rear cover

The power board is located on the right-hand side (viewed from rear); pull out towards rear

If necessary, remove fuse and replace by new fuse

Take particular care when re-inserting the card to ensure that it is fitted in the same rail otherwise

electrical connection to the display board will not be established

Press card fully forward onto plug contacts

Reinstall rear housing cover and firmly tighten

Reconnect terminal strips with electrical lines to corresponding pin strips and firmly tighten.

Maintenance / Repair

DED1C1S005

Page 18

38

Fuse change D1C W:

• The above-specified safety measures must be implemented (disconnection from mains!) before replacing

the device fuse:

The mains power fuse is located in a closed fuse holder (6) in the terminal box.

Open device and set in “park position”

Release bayonet catches of fuse holder

Remove fuse and replace by new fuse

Lock bayonet catch and close housing

Maintenance / Repair

6534

2

1

......

D1C-..

FW-_._

DED1C1W010

Upper section of housing

inside

Lower section of housing

inside

Sectional

side view

Item (1) Electrical assembly, display Item (4) Ribbon cable

Item (2) Ribbon cable Item (5) Electrical assembly, processor

Item (3) Electrical assembly I/O/S Item (6) Fuse holder

Page 19

39

8.1 Electric shock and moisture protection (IP)

D1C D: Device in installed condition: Type of enclosure DIN 40050 - IP 54

D1C W: Device in sealed housing type of enclosure IP 65 in accordance with DIN VDE 0470 corresponding

to EN 60529 and IEC 529

outer seal (control panel installation): type of enclosure IP 54 in accordance with DIN VDE 0470

corresponding to EN 60529 and IEC 529.

8.2 Electrical safety/interference suppression

EC low voltage guideline (73/23/EEC) consequently 93/44/EEC

EC EMC guideline (89/336/EEC) consequently 92/31/EEC being prepared

Supply voltage in accordance with DIN IEC 38

Electrical safety in accordance with EN 61010-1

Electromagnetic emitted interference in accordance with EN 55011 Gr. 1/Cl. B

Interference immunity in accordance with IEC 801-2, -3, -4 or DIN VDE 0843, Part 2, Part 3, Part 4 or EN

50082-2

EN 60335-1 Safety of electrical devices for household use

EN 50081-1 EMC, emitted interference, residential areas

EN 50082-2 EMC, emitted interference, industrial areas

EN 60555-2 EMC, reactions in power supply networks, harmonics

EN 60555-3 EMC, reactions in power supply networks, voltage fluctuations

8.3 Test in moist changeable climate

D1C D: Permissible relative humidity: max. 80 % (condensation not permitted)

WARNING

The device is not suitable for use in a moist changeable climate as there is no sealed

housing and constant exchange of air!

D1C W: Moist changeable climate in accordance with FW DIN 50016.

8 Applicable Types of Enclosure / Standards

Page 20

40

9 Spare Parts / Accessories

- Housing for wall mounting, including securing material, Order No. 790235

- Mounting kit for control unit installation, Order No. 792908

- Sensors, instrument leads, see product catalogue, chap. 6

- Measuring transducers, see product catalogue, chap. 5

10 Used Part Disposal

NOTE

Plastics and scrapped electronic components are special waste and must be recycled!

Used electronic components are accepted by municipal collection points set up by towns

and municipal districts or ProMinent branches!

With the exception of the electrical assemblies, the design of the device comprised few

mechanical parts. They are relatively easy to separate into specific materials; e.g. no

metallic thread inserts were used in the housing. With the exception of the membrane

keypad, these parts can be re-introduced to the material recycling system (see under

Chap. 6 “Material Specifications”)!

The membrane keypad is to be classified and disposed of in compliance with applicable

municipal guidelines!

9 Spare Parts / Accessories

10 Used Part Disposal

Page 21

41

EC Declaration of Conformity

Page 22

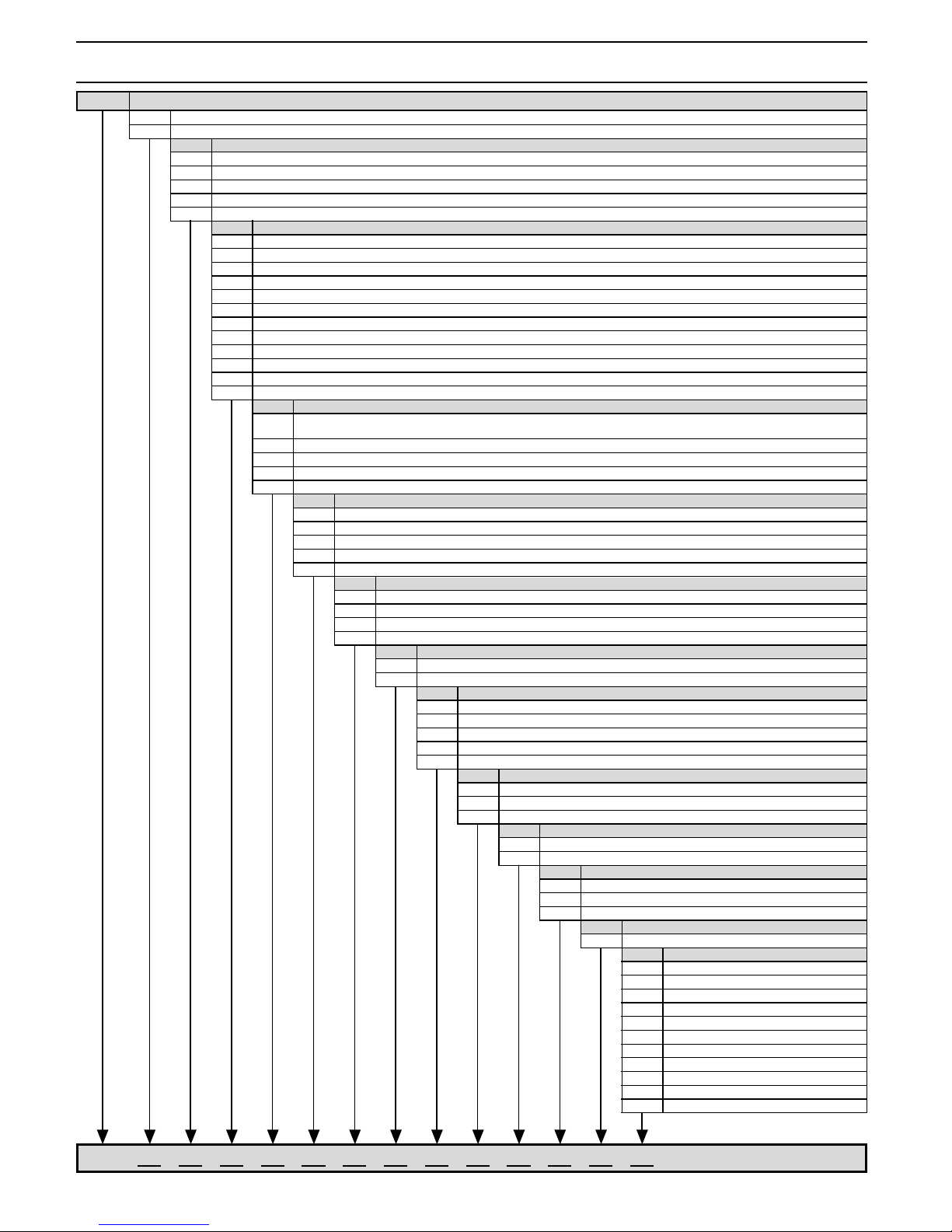

42

Übersicht Klemmenanordnung / Overview of terminal arrangement

Klemmenanordnung

Schalttafelgerät

Terminal order

switchboard mounting

X1

X2

XR1

XP

XR2

XR3

X2

Page 23

43

Klemmenanordnung

Wandgerät

Terminal order

wall mounting

X1

X2

XR1 XR3XR2 XP

ACHTUNG

Nicht die Klemmenbezeichnungen von X2 und X1

verwechseln!

IMPORTANT

Do not confuse the terminal designations X2 and X1!

Page 24

44

pH/Redox über Klemme / pH/ORP via terminals

Pt 100 (temperature)***

Mains power Mains power

Netz

Extern Pumpe 2 senken

Extern Pumpe 1 heben

Normsignal-Ausgang 1

0/4-20mA

Standard signal output 1

0/4-20mA

Netz

external

Extern

(potentialfrei)

(potentialfrei)

with

without

Liquid reference potential

mV-input terminal

Terminal connection for pH / ORP via terminals

mV

Ref.

Pt 100 (Temperatur)***

87

65 43

21

Ref.

mV

Potentialausgleich

pH/Redox (ORP)

pH/Redox (ORP)

mV-Eingang-Klemme

ohne/

mit/

Potentialausgleich

Liquid reference potential

Klemmenanschluss für pH / Redox über Klemme

X2

1211109

1211109

+

-

pH/Redox (ORP)

**

Te mperature

input (Pt 100)

Temperatur-

Eingang (Pt 100)

Frequency outputs

(pumps)

Frequenz-Ausgänge

(Pumpen)

i. e. recorder

z. B. Schreiber

internal

Intern

External pump 2 decrease (potencial free)

External pump 1 increase (potencial free)

*** Correction variable for pH (see also p. 53)

*** Korrekturgröße für pH (vgl. auch S. 53)

** IMPORTANT: When connecting the electrode without liquid reference potential

clamp terminal X2.9 and X2.10 have to be closed.

** ACHTUNG: Bei Anschluss der Sonde ohne Potenzialausgleich

die Klemmen X2.9 u. X2.10 brücken.

Page 25

45

pH/Redox über SN6-Eingang / pH/ORP via SN6 socket

Pt 100 (temperature)***

Mains power Mains power

Netz

Extern Pumpe 2 senken

Extern Pumpe 1 heben

Normsignal-Ausgang 1

0/4-20mA

Standard signal output 1

0/4-20mA

Netz

external

Extern

(potentialfrei)

(potentialfrei)

with

without

SN6-input

Pt 100 (Temperatur)***

87

65 43

21

pH/Redox (ORP)

SN6-Eingang

ohne/

mit/

Potentialausgleich

Liquid reference potential

Klemmenanschluss für pH / Redox über SN6-Eingang

Terminal connection for pH / ORP via SN6 socket

X2

1211109

1211109

+

-

pH/Redox (ORP)

**

Te mperature

input (Pt 100)

Temperatur-

Eingang (Pt 100)

Frequency outputs

(pumps)

Frequenz-Ausgänge

(Pumpen)

i. e. recorder

z. B. Schreiber

internal

Intern

Liquid reference potential

SN6

Potentialausgleich

SN6

pH/Redox (ORP)

*

*

clamp terminals X2.12 and X2.11 are connected internaly.

* Bei Version D (Schalttafeleinbau) sind

die Klemmen X2.12 und X2.11 intern verdrahtet.

* Version D (Control panel installation) only:

External pump 2 decrease (potencial free)

External pump 1 increase (potencial free)

*** Correction variable for pH (see also p. 53)

*** Korrekturgröße für pH (vgl. auch S. 53)

** ACHTUNG: Bei Anschluss der Sonde ohne Potenzialausgleich

die Klemmen X2.9 und X2.10 brücken.

** IMPORTANT: When connecting the electrode without liquid reference potential

clamp terminal X2.9 and X2.10 have to be closed.

Page 26

46

F, Br2, Cl2, ClO2, O2, O3, mA, mS/cm, pH*, Redox / ORP*, ºC*

Pt 100 (temperature)***

Mains power Mains power

** See also D1C, part 2 "Measured value setting"-

"range adjustment" and operating instructions DMT!

Netz

Extern Pumpe 2 senken

Extern Pumpe 1 heben

Normsignal-Ausgang 1

0/4-20 mA

Standard signal output 1

0/4-20 mA

Netz

external

** Siehe auch D1C, Teil 2 "Messbereich einstellen"

"Bereichzuordnung" und Betriebsanleitung DMT!

Extern

(potentialfrei)

(potentialfrei)

Assignment variants

Measured variable

Standard signal input (mA)

Pt 100 (Temperatur)***

87

65 43

21

Normsignal-Eingang (mA)

Belegungsvarianten

Klemmenanschluss für

Terminal connection for

F, Br2, Cl2, ClO2, O2, O3, mA, mS/cm, pH*, Redox*, ˚C*

X2

1211109

1211109

+

-

Messgröße

Temperature

input (Pt 100)

Temperatur-

Eingang (Pt 100)

Frequency outputs

(pumps)

Frequenz-Ausgänge

(Pumpen)

***Correction variable for pH, ClO2, mS/cm (see also p. 53)

*** Korrekturgröße für pH, ClO2, mS/cm (vgl. auch S. 53)

i. e. recorder

z. B. Schreiber

internal

Intern

External current source

1211109

ProMinent transducer

2

1

ProMinent Umformer

+

-

+

-

+

-

+

-

+

-

+

-

ProMinent DMT

8

7

**

passives Normsignal 4 - 20 mA

aktives Normsignal 0/4 - 20 mA

Externe Stromquelle

active standard signal 0/4 - 20 mA

passive standard signal 4 - 20 mA

External pump 2 decrease (potencial free)

External pump 1 increase (potencial free)

X1

* Nur mit Umformer

* Only with transducer

Page 27

47

Leitfähigkeit / conductivity

Normsignal-Ausgang 1

0/4-20mA

Standard signal output 1

0/4-20mA

External pump 2 decrease (potencial free)

External pump 1 increase (potencial free)

Pt 100 (temperature)***

Mains power Mains power

Netz

Extern Pumpe 2 senken

Extern Pumpe 1 heben

Netz

external

Extern

(potentialfrei)

(potentialfrei)

Conductivity input

Terminal connection for conductivity

Pt 100 (Temperatur)***

87

65 43

21

Leitfähigkeits-

Eingang

Klemmenanschluss für Leitfähigkeit

X2

1211109

+

-

Temperature

input

Temperatur-

Eingang

Frequency outputs

(pumps)

Frequenzausgänge

(Pumpen)

***Correction variable for mS/cm (see also p. 53)

*** Korrekturgröße für mS/cm (vgl. auch S. 53)

i. e. recorder

z. B. Schreiber

internal

Intern

2-Elektroden-

Messzelle

2-Elektroden-

Messzelle,

4-Leiter-Anschluss

4-Elektroden-

Messzelle

current b

current a

voltage b

voltage a

Strom b /

Strom a /

Spannung b /

Spannung a /

four wire connection

two electrodes

measuring cell,

measuring cell

two electrodes

measuring cell

four electrodes

Page 28

48

mit Grenzwertrelais / with limit value relays

Klemmenanschluss mit Grenzwertrelais

Leistungsrelais-

Ausgänge

Power relay output

for alarm triggering

Leistungsrelais-

Ausgang zur

Alarmgabe

Internal

power supply

Interne Spannungs-

versorgung

XR2

XR1

XP

XR3

Terminal connection with limit value relay

Power relay

output

1

2

12

L1

N

1

23

external

Extern

internal

Intern

Horn

Hupe

limit relay 1

limit relay 2

Grenzwertrelais 1

Grenzwertrelais 2

Speise-

spannung*

Speise-

spannung**

Speise-

spannung**

Speise-

spannung**

HINWEIS: zu Relais XR3: Das Gerät ist in betriebs-

bereitem Zustand und es steht kein Alarm an.

NOTE: to relay XR3: The device is shown ready and no

alarm is present.

feed

voltage**

feed

voltage**

feed

voltage*

feed

voltage**

is not relevant !

* With 24V DC polarity on feed voltage

Speisespannung ohne Bedeutung !

Bei 24 V DC ist die Polarität der

*

ACHTUNG: Die Speisespannung, die an

die Relais XR1 - XR3 gelegt wird, muss

identisch mit der Speisespannung von XP sein!

** IMPORTANT: The feed voltage to be connected to

the relays XR1 - XR3, has to be identically

with the feed voltage of XP.

**

Page 29

49

mit Magnetventilen / with solenoid valves

Klemmenanschluss mit Magnetventilen

Interne Spannungs-

versorgung

Terminal connection with solenoid valves

Leistungsrelais-

Ausgänge

Leistungsrelais-

Ausgang zur

Alarmgabe

Power relay

output

Power relay output

for alarm triggering

Internal

power supply

XR2

XR1

XP

XR3

1

2

12

L1

N

1

23

external

Extern

internal

Intern

Horn

Hupe

solenoid valve 1

solenoid valve 2

Magnetventil 1

Magnetventil 2

Speise-

spannung*

Speise-

spannung**

Speise-

spannung**

feed

voltage**

feed

voltage**

feed

voltage*

Speise-

spannung**

feed

voltage**

ACHTUNG: Die Speisespannung, die an die Relais

XR1 - XR3 gelegt wird, muss identisch

mit der Speisespannung von XP sein!

is not relevant !

* With 24V DC polarity on feed voltage

Speisespannung ohne Bedeutung !

Bei 24 V DC ist die Polarität der

*

**

NOTE: to relay XR3: The device is shown ready and no

alarm is present.

HINWEIS: zu Relais XR3: Das Gerät ist in betriebs-

bereitem Zustand und es steht kein Alarm an.

** IMPORTANT: The feed voltage to be connected to

the relays XR1 - XR3, has to be identically

with the feed voltage of XP.

Page 30

50

mit Stellmotor / with servomotor

Klemmenanschluss mit Stellmotor

Leistungsrelais-

Ausgänge

Power relay

output

Leistungsrelais-

Ausgang zur

Alarmgabe

Power relay output

for alarm triggering

Interne Spannungs-

versorgung

Internal

power supply

Terminal connection with servomotor

Stellungsrückmelde-

Eingang

Position feedback

input

XR2

XR1

XP

XR3

X1

1

2

12

L1

N

1

23

321

-

+

S

external

Extern

internal

Intern

S...Schleifer / S...slider

geschlossen / closed

offen / open

Öffner / to open

Schließer / to close

S

Actuator motor

Stellmotor

Horn

Hupe

Speise-

spannung*

Speise-

spannung**

feed

voltage**

feed

voltage*

Speise-

spannung**

feed

voltage**

M

is not relevant !

* With 24V DC polarity on feed voltage

Speisespannung ohne Bedeutung !

Bei 24 V DC ist die Polarität der

*

NOTE: to relay XR3: The device is shown ready and no

alarm is present.

HINWEIS: zu Relais XR3: Das Gerät ist in betriebs-

bereitem Zustand und es steht kein Alarm an.

ACHTUNG: Die Speisespannung, die an die Relais

XR1 - XR3 gelegt wird, muss identisch

mit der Speisespannung von XP sein!

**

** IMPORTANT: The feed voltage to be connected to

the relays XR1 - XR3, has to be identically

with the feed voltage of XP.

Page 31

51

mit Normsignal-Ausgang 2, mit Pause / with standard signal

output 2, with pause

Standard signal

output 2

0/4-20mA

Digital-

Eingang

Anschlussdetails Normsignalausgang 2 / Digitaleingang Pause

Connection details Standard signal output 2 / Digital input pause

X1

Intern

Normsignal-

Ausgang 2

Digital input

-

13+12

10 9 8

external

Extern

internal

-

+

Potenzialfreier

Kontakt nötig!

potential free connection

necessary.

i. e. recorder

z. B. Schreiber

Pause

-

+

Page 32

52

mit Störgröße / with disturbance variable

Anschlussdetails Störgröße

Digital-

Eingang

Digital input

Normsignal-Eingang

für Korrekturgröße oder Störgröße (mA)

Connection details disturbance variable

X1

external

Extern

internal

Intern

Standard signal input

correction variable or disturbance variable (mA)

Assignment variants

Belegungsvarianten

Disturbance variable (mA) i. e. flow signal from:

765

-

+

16 15 14

16 15 14

External current source

Measuring transducer

2

1

Messumformer

+

-

+

-

+

-

+

-

passives Normsignal 4 - 20 mA

aktives Normsignal 0/4 - 20 mA

Externe Stromquelle

active standard signal 0/4 - 20 mA

passive standard signal 4 - 20 mA

-

+

disturbance variable frequency

Störgröße Frequenz

X1

Störgröße (mA) z.B. Durchfluss-Signal von:

potential free connection

necessary.

Potenzialfreier

Kontakt nötig!

Electromagnetic

flow meters

Magnetisch-induktivem

Wassermesser

Contact water meter*

Kontaktwassermesser *

* IMPORTANT: Note maximum frequency.

* ACHTUNG: Maximalfrequenz beachten!

Page 33

53

mit Korrekturgröße / with correction variable

Anschlussdetails Korrekturgröße

Connection details correction variable

Normsignal-Eingang

für Korrekturgröße oder Störgröße (mA)

Temperature

input (Pt 100)

Temperatur-

Eingang (Pt 100)

X1

external

Extern

internal

Intern

Standard signal input

correction variable or disturbance variable (mA)

Assignment variants

Belegungsvarianten

87

X2

1615 14

1615 14

1615 14

+

-

+

-

+

-

ProMinent transducer

2

1

+

-

+

-

+

-

ProMinent DMT

aktives Normsignal 0/4 - 20 mA

active standard signal 0/4 - 20 mA

passive standard signal 4 - 20 mA

X1

ProMinent Umformer

8

7

**

passives Normsignal 4 - 20 mA

Externe Stromquelle

External current source

Pt 100 (temperature)

Pt 100 (Temperatur)

** Siehe auch D1C, Teil 2 "Messbereich einstellen"

"Bereichzuordnung" und Betriebsanleitung DULCOMETER

®

DMT!

** See also D1C, part 2 "Measured value setting"-

"range adjustment" and operating instructions DULCOMETER

®

DMT!

Page 34

54

Page 35

108

©1999 ProMinent Dosiertechnik GmbH · 69123 Heidelberg · Germany

Operating Instructions DULCOMETER® D1C, Part 1, issue 04/03

Subject to technical modifications · Printed in Germany

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11 · 69123 Heidelberg · Germany

Postfach 101760 · 69007 Heidelberg · Germany

Tel.: +49 6221 842-0 · Fax: +49 6221 842-419

info@prominent.de · www.prominent.de

Loading...

Loading...