Page 1

Assembly instructions

A0507

Multi-Channel Measuring and Control System

DULCOMARIN® II Swimming Pool Controller and

Disinfection Controller DXCa

Part 1: Assembly and installation

Please enter the identity code of your device here! DXCa _ _ _ _ _ _ _ _ _ _ _ _ _

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Technical changes reserved.

Part no. 986907 BA DC 080 04/12 EN

Page 2

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

email: info@prominent.de

Internet: www.prominent.com

986907, 2, en_GB

© 2012

2

Page 3

Supplemental instructions

Further applicable documents

These operating instructions and supplementary instructions are

only valid in combination with the following operating and supple‐

mentary instructions:

n Multi-channel measuring and control system operating instruc‐

tions DULCOMARIN® II

, Swimming Pool Controller and Disin‐

fection Controller DXCa Part 2: Operation

n Supplementary instructions DULCOMARIN® II, Screen plotter

operation

n Supplementary instructions DULCOMARIN® II, M-Module

(measuring module for pH, redox [ORP], temperature) DXMaM

connection

n Supplementary instructions DULCOMARIN® II, A-Module (con‐

trol module, pump and standard signal outputs mA) DXMaA

n Supplementary instructions DULCOMARIN® II, N-Module

(power supply module without relay) DXMaN

n Supplementary instructions DULCOMARIN® II, P-Module

(power supply module with relay) DXMaP

n Supplementary instructions DULCOMARIN® II, I-Module (cur‐

rent input module, standard signal inputs mA) DXMal

3

Page 4

Table of contents

Table of contents

Device identification / identity code....................................... 5

1

2 Introduction........................................................................... 8

2.1 Explanation of the safety information............................ 8

2.2 Users' qualifications...................................................... 9

3 Safety and responsibility..................................................... 11

3.1 General safety information.......................................... 11

3.2 Correct and proper use............................................... 11

4 Planning aids and requirements for the installation site ..... 13

4.1 Requirements for the installation site.......................... 13

4.2 Determine the requirement for cables and accesso‐

ries.............................................................................. 14

4.3

Allocate power supply modules (DULCOMARIN® II

DULCO-Net)............................................................... 18

4.4 Routing the CAN bus backbone................................. 19

5 Assembly and installation................................................... 20

5.1 Procedure with DXC housing (large).......................... 20

5.1.1 Wall mounting.......................................................... 20

5.1.2 Control panel mounting............................................ 22

5.1.3 Installation (electrical).............................................. 23

5.1.4 Connect the coaxial cable........................................ 26

5.1.5 Connecting the terminals......................................... 26

5.2 Procedure with DXM housing (small)......................... 27

5.2.1 Mounting (mechanical)............................................ 27

5.2.2 Installation (electrical).............................................. 28

5.3 install the CAN bus cable............................................ 30

5.3.1 Connections outside the housing............................. 31

5.3.2 Connections inside the DXC housing...................... 34

6 Device overview and operating elements........................... 36

Functional description (general).......................................... 38

7

8 Maintenance, repairs and disposal..................................... 41

8.1 Disposal of used parts................................................ 42

9 Technical data spare parts and accessories....................... 43

10 EC Declaration of Conformity and fulfilled standards......... 44

11

Wiring diagram DULCOMARIN® II compact ...................... 45

12 Index................................................................................... 49

4

Page 5

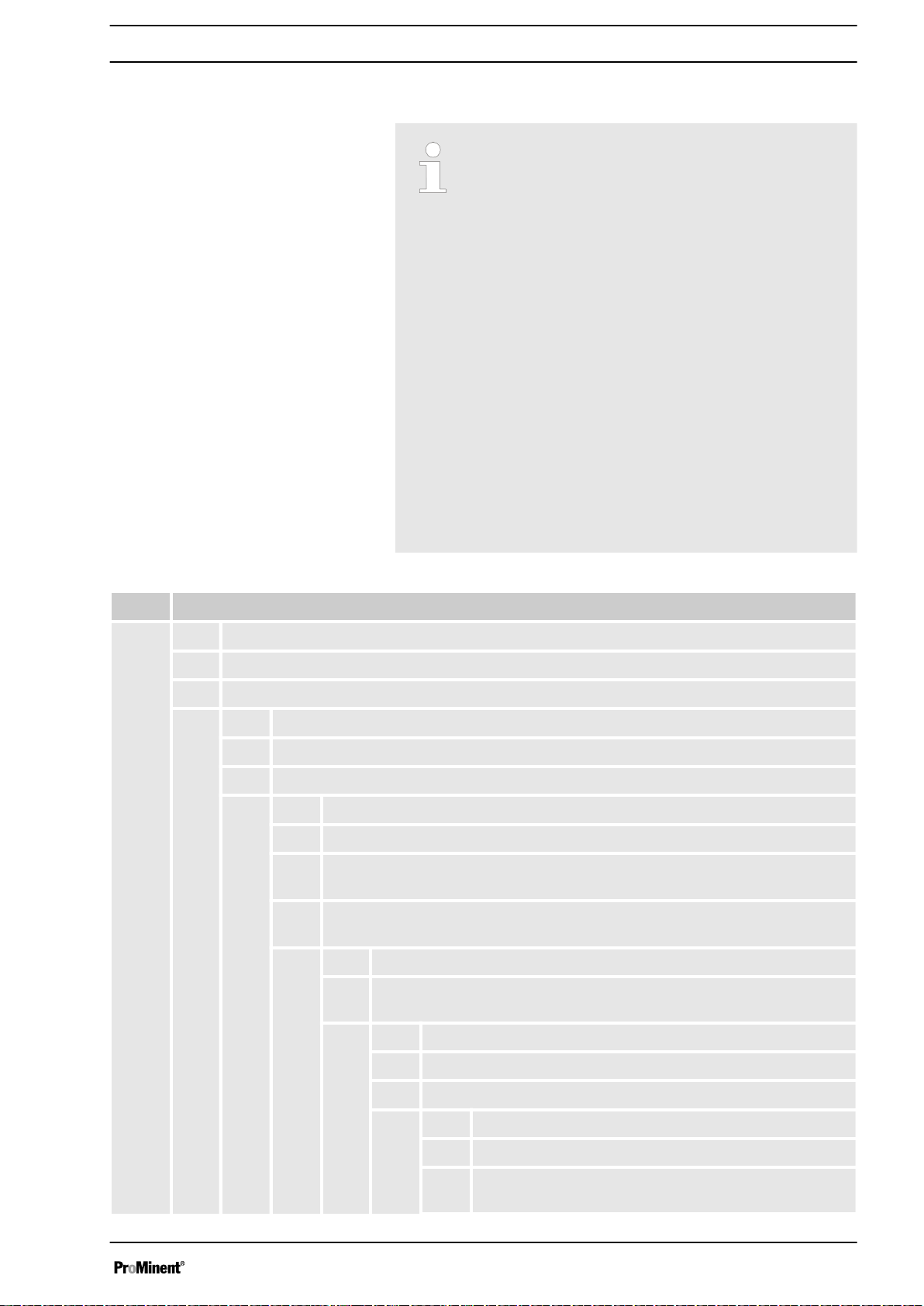

1 Device identification / identity code

The identity code describes the DULCOMARIN® II,

compact controller

1)

The supplied cable is for connection to a hub, switch,

router or an intranet.

For direct connection of the DULCOMARIN® II to a PC/

MAC, the supplied LAN coupling and category 5 crossover cable are required.

The maximum LAN cable length is approximately 100

m.

To operate the web server on a PC we recommend

Microsoft® Internet Explorer 5 or higher as the

browser.

The scope of supply of the DXCa includes:

–

1 T-coupler

–

1 CAN connection cable

–

1 terminating resistance coupling and 1 terminating

resistance plug

–

1 SD memory card 64 MB or greater

–

1 card reader suitable for PCs

Device identification / identity code

DXCa

Multi-channel measuring and control system - DULCOMARIN

Mounting type:

W Wall mounted (IP 65)

S Control cabinet (IP 54)

Version:

0 With operating elements

D With operating elements for use in drinking water/disinfection applications

Communication interfaces:

0 none

5 Embedded Web-Server, LAN incl. 5 m LAN patch cable 1:1, LAN coupling,

6 OPC-Server + Embedded Web-Server, LAN incl. 5 m LAN patch cable 1:1,

Option:

® II Series DXC

5 m cross-over cable

LAN coupling, 5 m cross-over cable

1)

1)

1 Screen plotter with data logger incl. SD card and USB card reader

for PC

Module 1:

M M module, measuring module pH, redox, temperature

I I module, current input module, 3x mA, 0/4 ... 20 mA

Module 2:

0 not occupied

A A module, control module: 3 pumps and 4 analog out‐

puts

5

Page 6

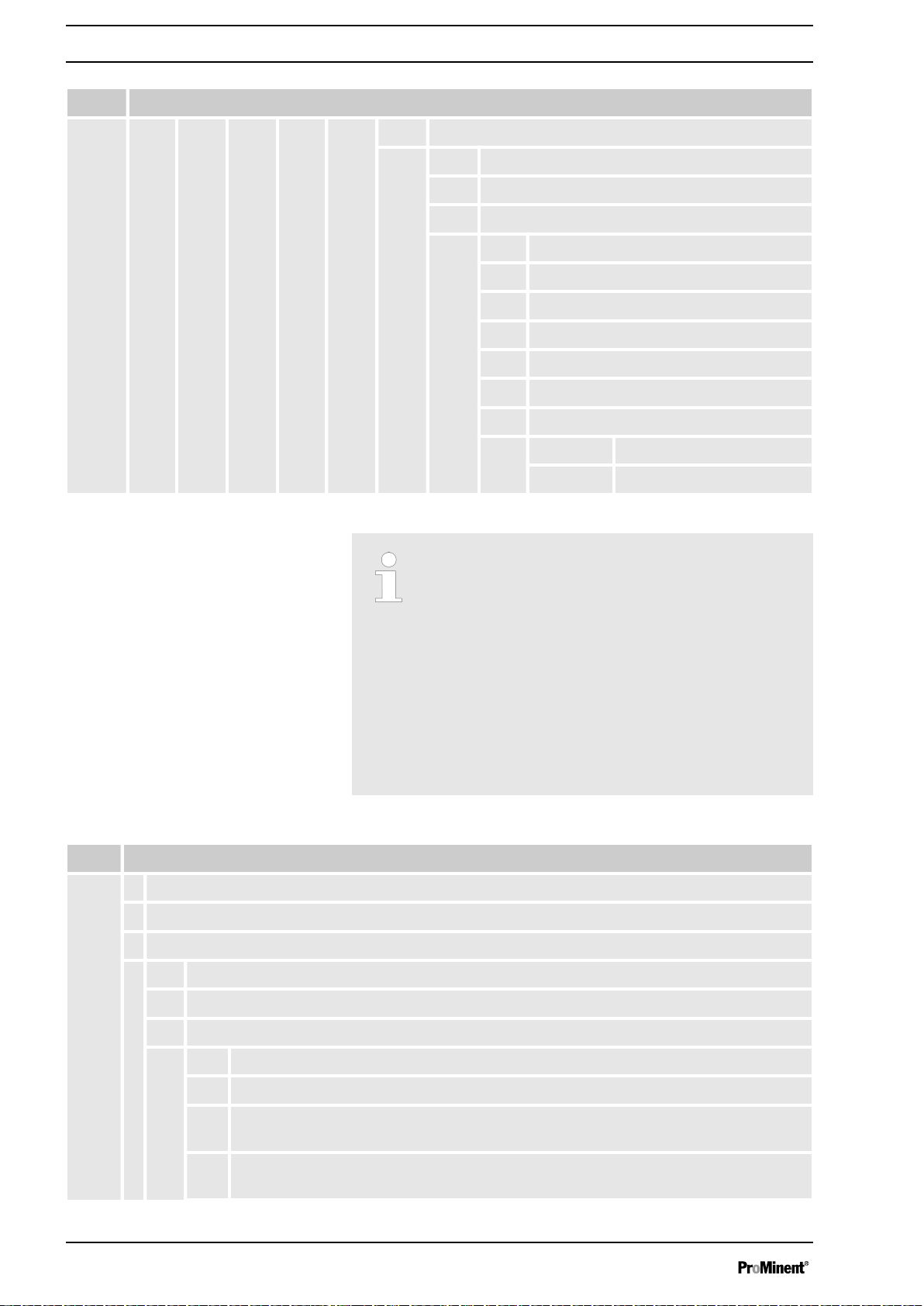

Device identification / identity code

DXCa

Multi-channel measuring and control system - DULCOMARIN

® II Series DXC

I I module, current input module, 3x mA, 0/4 ... 20 mA

Application:

S Swimming Pools

D Disinfection, general

Preset language:

DE German

EN English

ES Spanish

FR French

IT Italian

PL Polish

Certification:

01 CE mark

DXCa

Multi-channel measuring and control system - DULCOMARIN

Mounting type:

W Wall mounted (IP 65)

S Control cabinet (IP 54)

Version:

0 With operating elements

The identity code describes the complete DULCO‐

MARIN® II DULCO® Net Central Unit.

If the central unit is populated with modules, then the

following applies:

Module 1 preferably as M module

Module 2 preferably allocated to the A module.

Module 3 must always be allocated to the P or N

module.

1)

Module 1 preferably as M module

2)

only in version: "2" without controls

® II Series DXC

2 Without operating elements

Communication interfaces:

0 none

5 Embedded Web-Server, LAN incl. 5 m LAN patch cable 1:1, LAN-coupling, 5 m

cross-over-cable

1)

6 OPC-Server + Embedded Web-Server, LAN incl. 5 m LAN patch cable 1:1, LAN-

coupling, 5 m cross-over-cable

1)

6

Page 7

DXCa

Multi-channel measuring and control system - DULCOMARIN

Option:

0

Without screen plotter

1 Screen plotter with data logger incl. SD card and USB card reader for PC

Module 1:

0 not occupied

M M module, measuring module pH, redox, temperature

A A module, control module: 3 pumps and 4 analog outputs

I I module, current input module, 3x mA, 0/4 ... 20 mA

Module 2:

0 not occupied

A A module, control module: 3 pumps and 4 analog outputs

M M module, measuring module: pH, redox, temperature

I I module, current input module, 3x mA, 0/4 ... 20 mA

Device identification / identity code

® II Series DXC

2)

Module 3:

0 not occupied

P P module, power supply, 1 alarm relay, 3 solenoid

valve relays

N N module, power supply without relay

A A module, control module: 3 pumps and 4 analog out‐

puts

M M module, measuring module: pH, redox, temperature

Application:

S Swimming Pools

D Disinfection, general

Preset language:

DE German

EN English

ES Spanish

FR French

IT Italian

PL Polish

Certification:

01 CE mark

7

Page 8

Introduction

2 Introduction

The operating instructions describe the technical data and func‐

tions of the multi-channel measuring and control system

DULCOMARIN®

troller DXCa. The operating instructions subsequently refer to the

system merely as DXCa.

2.1 Explanation of the safety information

II Swimming Pool Controller and Disinfection Con‐

Introduction

These operating instructions provide information on the technical

data and functions of the product. These operating instructions pro‐

vide detailed safety information and are provided as clear step-bystep instructions.

The safety information and notes are categorised according to the

following scheme. A number of different symbols are used to

denote different situations. The symbols shown here serve only as

examples.

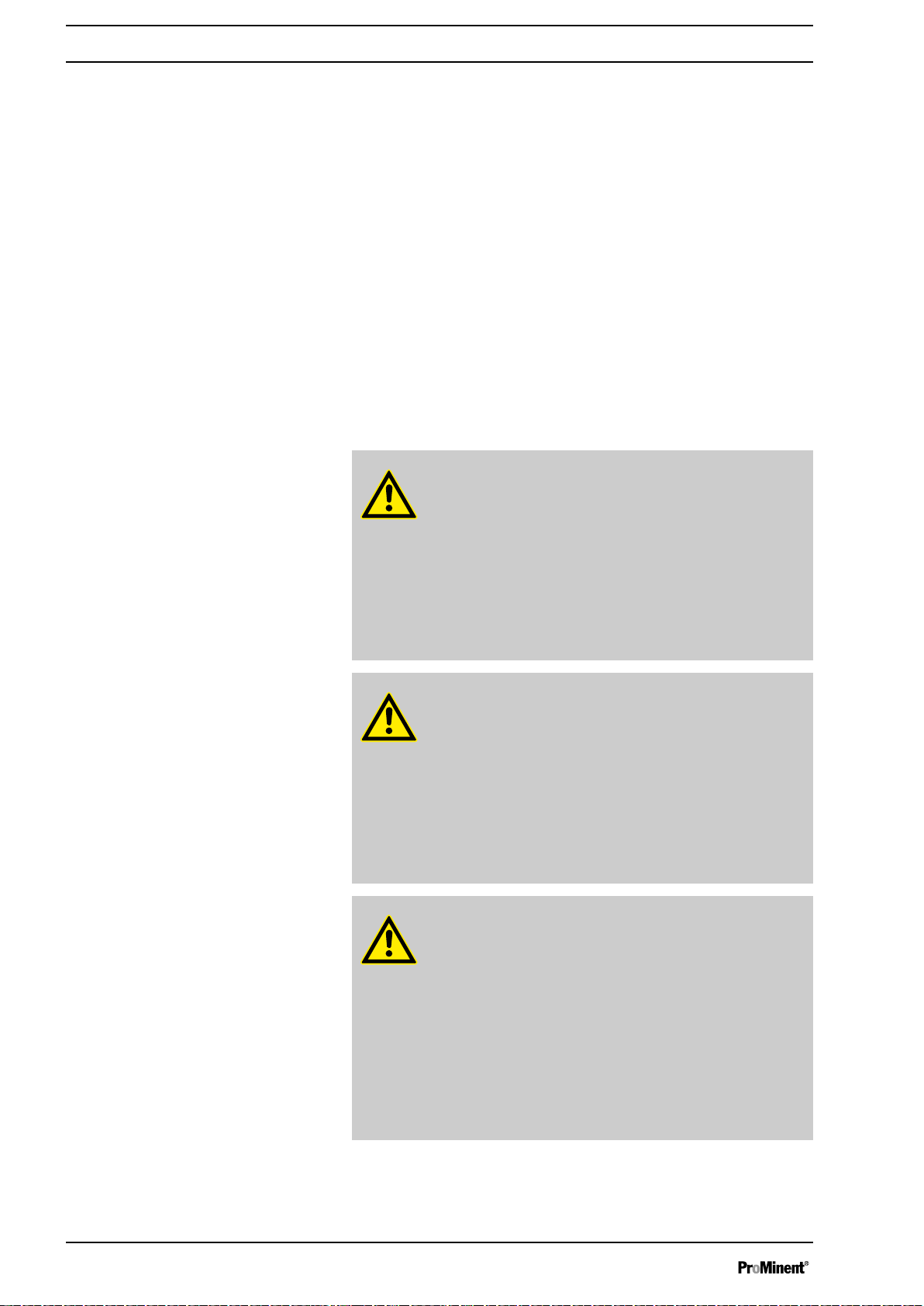

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger

Danger!

–

Denotes an immediate threatening danger. If this is

disregarded, it will result in fatal or very serious

injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger

Warning!

Denotes a possibly hazardous situation. If this is

–

disregarded, it could result in fatal or very serious

injuries.

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor injuries, mate‐

rial damage.

Measure to be taken to avoid this danger

Caution!

Denotes a possibly hazardous situation. If this is

–

disregarded, it could result in slight or minor inju‐

ries. May also be used as a warning about material

damage.

8

Page 9

Introduction

NOTICE!

Nature and source of the danger

Damage to the product or its surroundings

Measure to be taken to avoid this danger

Note!

Denotes a possibly damaging situation. If this is

–

disregarded, the product or an object in its vicinity

could be damaged.

Type of information

Hints on use and additional information

Source of the information, additional measures

Information!

–

Denotes hints on use and other useful information.

It does not indicate a hazardous or damaging sit‐

uation.

2.2 Users' qualifications

WARNING!

Danger of injury with inadequately qualified personnel!

The operator of the plant / device is responsible for

ensuring that the qualifications are fulfilled.

If inadequately qualified personnel work on the unit or

loiter in the hazard zone of the unit, this could result in

dangers that could cause serious injuries and material

damage.

– All work on the unit should therefore only be con‐

ducted by qualified personnel.

–

Unqualified personnel should be kept away from

the hazard zone

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been instructed and,

if required, trained in the tasks assigned to him/her and possible dangers that

could result from improper behaviour, as well as having been instructed in the

required protective equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of an instructed

person and who has also received additional training specific to the system

from ProMinent or another authorised distribution partner.

Trained qualified per‐

sonnel

A qualified employee is deemed to be a person who is able to assess the

tasks assigned to him and recognize possible hazards based on his/her

training, knowledge and experience, as well as knowledge of pertinent regula‐

tions. The assessment of a person's technical training can also be based on

several years of work in the relevant field.

9

Page 10

Introduction

Training Definition

Electrician Electricians are deemed to be people, who are able to complete work on elec‐

trical systems and recognize and avoid possible hazards independently based

on his/her technical training and experience, as well as knowledge of pertinent

standards and regulations.

Electricians should be specifically trained for the working environment in

which the are employed and know the relevant standards and regulations.

Electricians must comply with the provisions of the applicable statutory direc‐

tives on accident prevention.

Customer Service depart‐

ment

Customer Service department refers to service technicians, who have

received proven training and have been authorised by ProMinent to work on

the system.

Note for the system operator

The pertinent accident prevention regulations, as well

as all other generally acknowledged safety regulations,

must be adhered to!

10

Page 11

A0487

Planning aids and requirements for the installation site

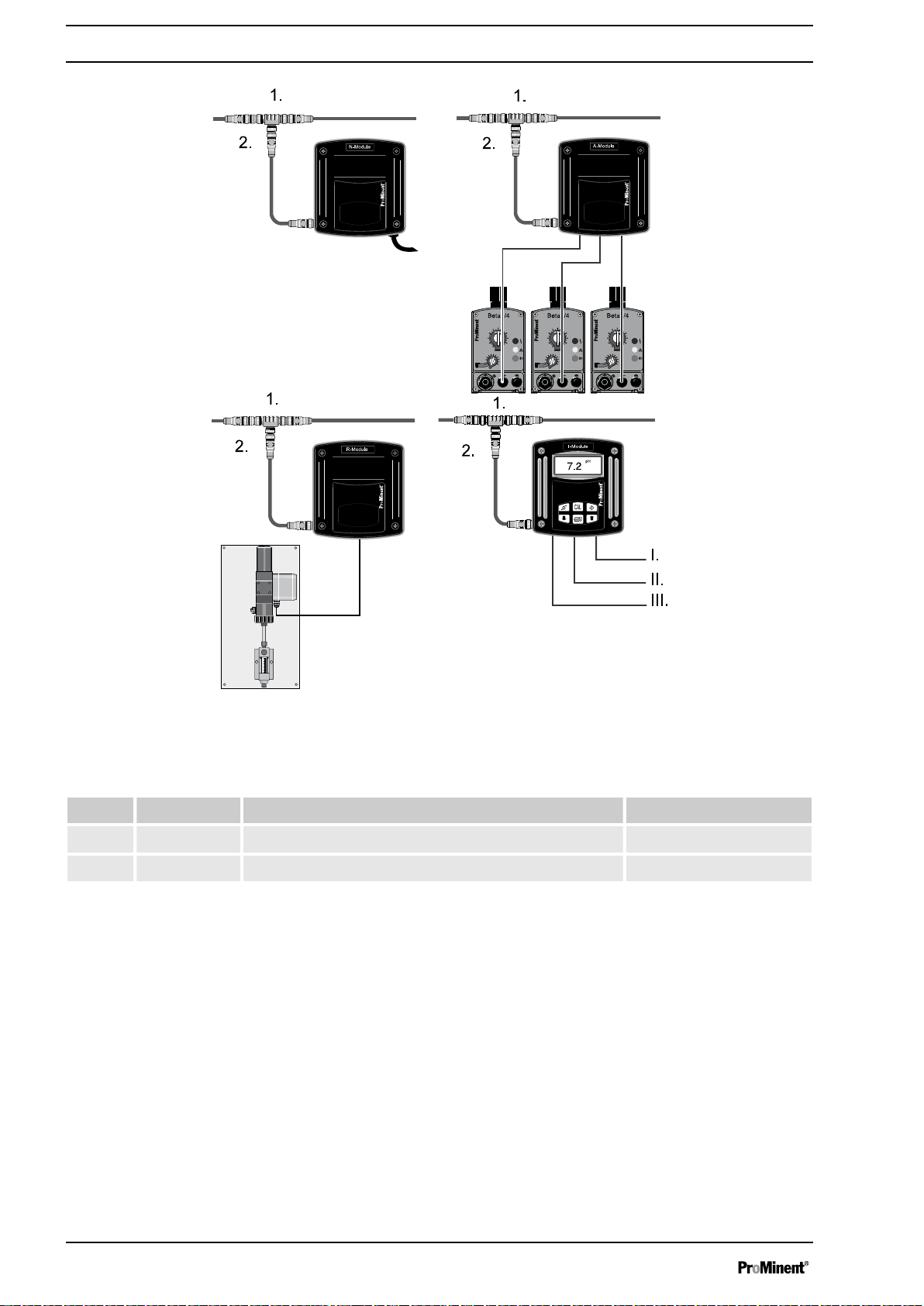

Fig. 3: External modules DXMa

Accessories, supplied

Item. Quantity Description Part no.

1 1 T-coupler, M12,5-pole CAN 1022155

2 1 Connecting cable - CAN, M12, 5 pole 0.5 m 1022137

16

Page 12

Planning aids and requirements for the installation site

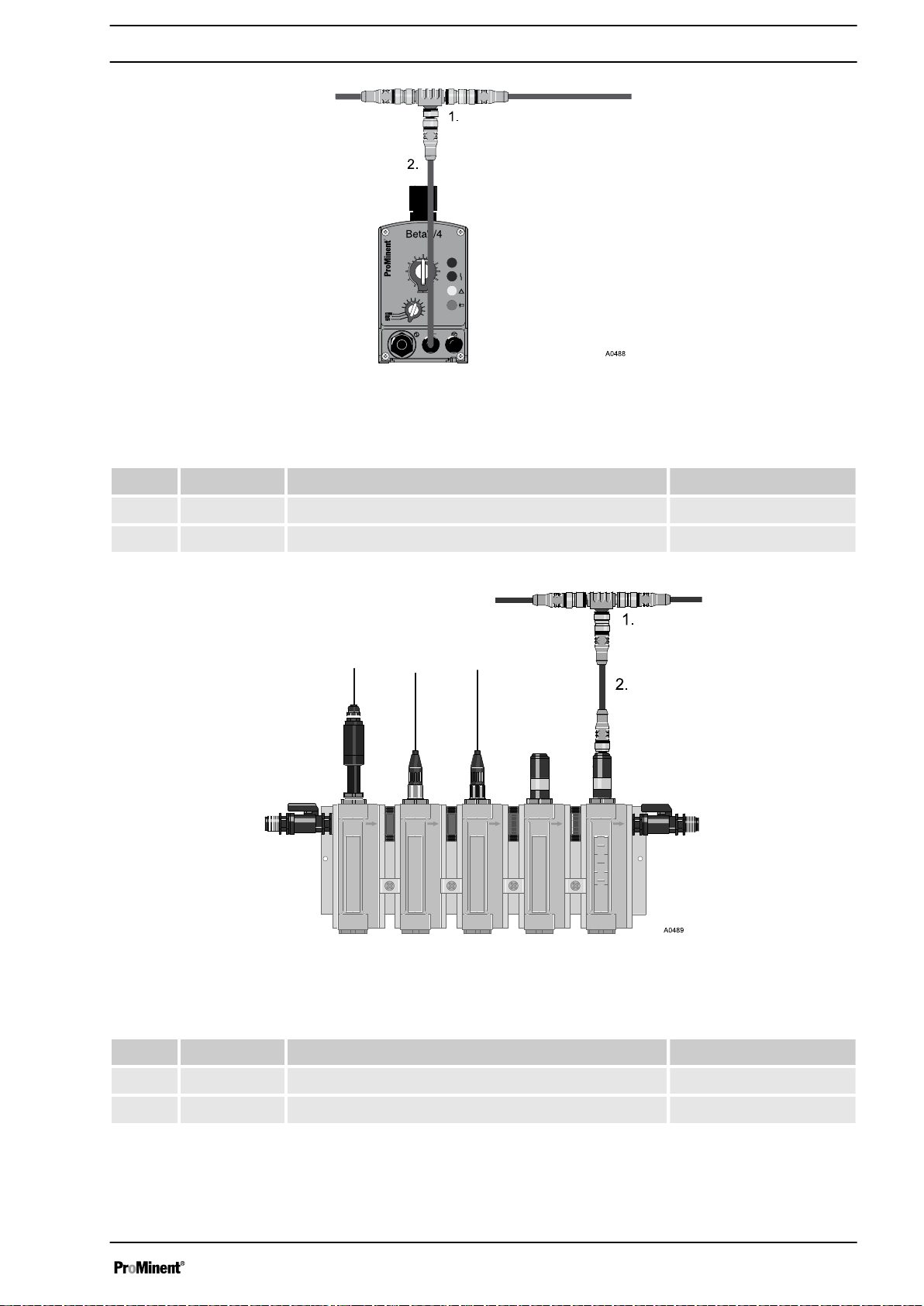

Fig. 4: Beta/4 CANopen

Accessories, supplied

Item. Quantity Description Part no.

1 1 T-coupler, M12,5-pole CAN 1022155

2 1 Connecting cable - CAN, M12, 5 pole 1 m 1022139

Fig. 5: Sensors DXUa

Accessories, supplied

Item. Quantity Description Part no.

1 1 T-coupler, M12,5-pole CAN 1022155

2 1 Connecting cable - CAN, M12, 5 pole 0.5 m 1022137

17

Page 13

Planning aids and requirements for the installation site

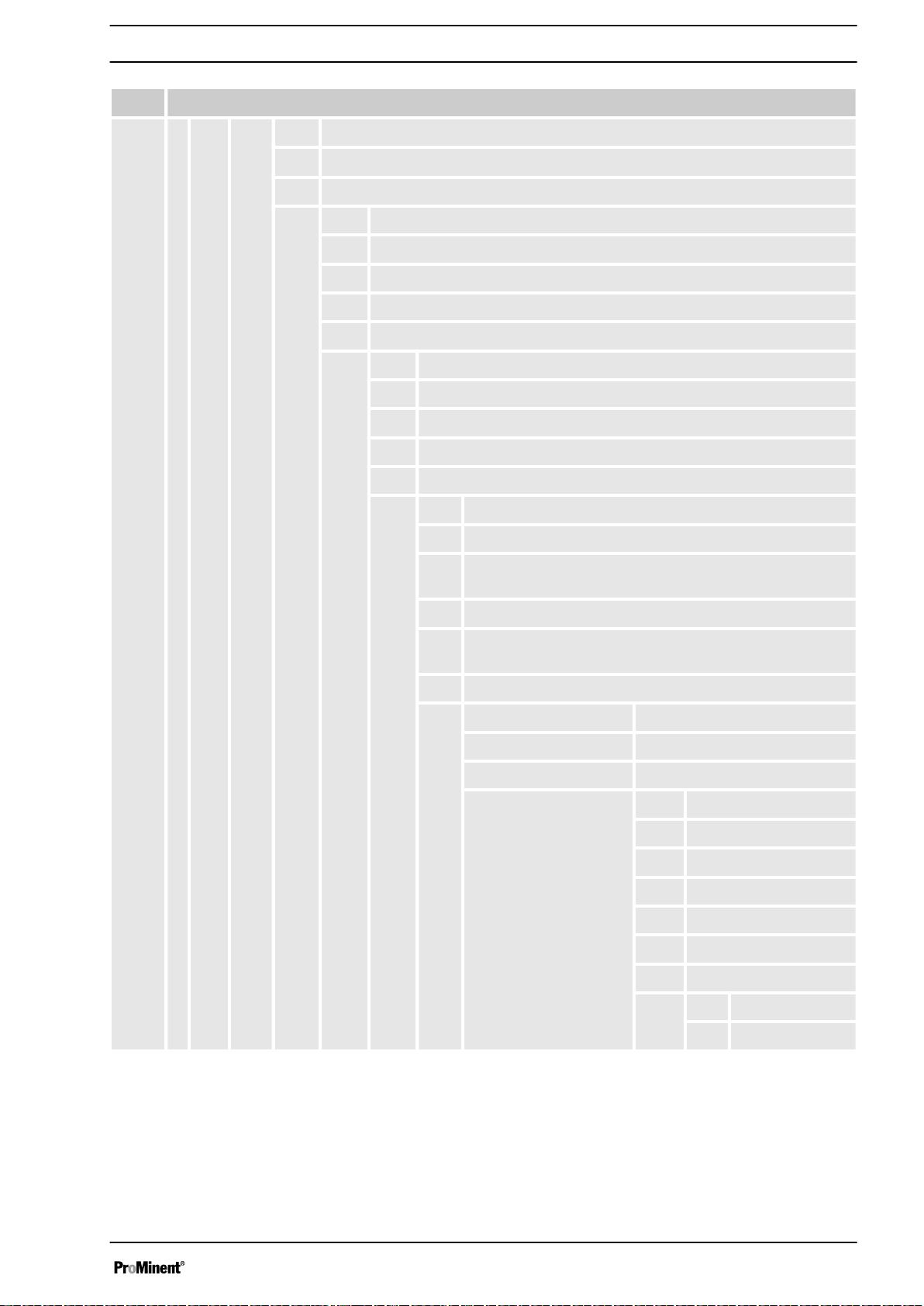

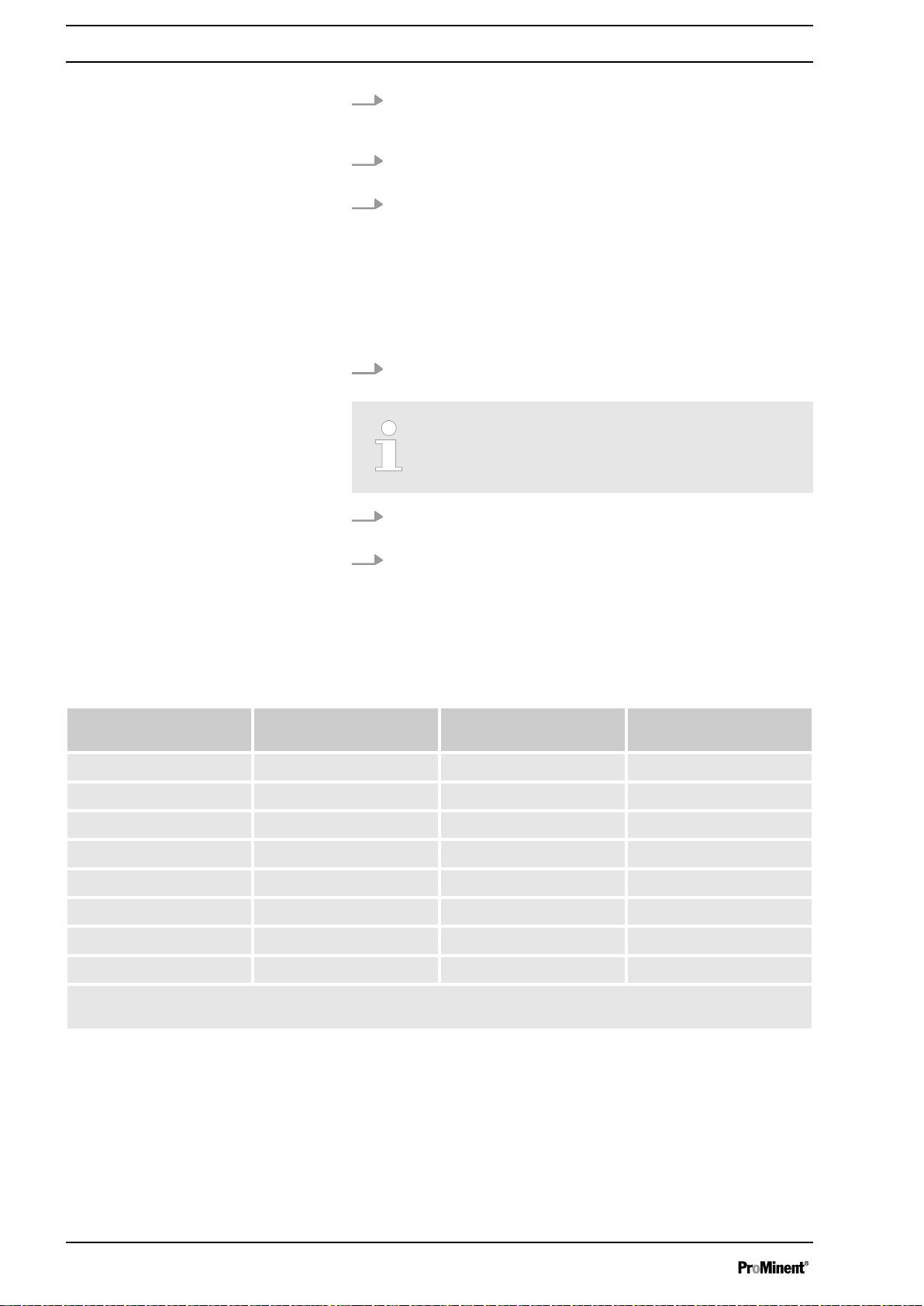

1. Determine the requirement for power supply modules, see

Ä Chapter 4.3 ‘Allocate power supply modules (DULCO‐

MARIN® II DULCO-Net)’ on page 18

2. Determine the requirement for connection cables between

the external modules

3. Determine the requirement for holding clamps for the con‐

nection cables (ASV pipe clips, 16 mm, order no. 359904

4.3

Allocate power supply modules (DULCOMARIN® II DULCO-Net)

Determine the number of additionally required power supply mod‐

ules (N modules and P modules).

1. Ensure that for each power supply module there is a power

outlet

The distance between the power supply modules

should not exceed 50 m.

2. Distribute the power supply modules as uniformly as possible

over the CAN bus line.

3. With an A module with connected plotters: arrange one of the

power supply modules as close as possible to the A module

Locate the power supply module in

the CAN bus backbone (main line)

(DULCOMARIN® II DULCO-Net)

The central unit always contains a power supply module.

Number of pools Additional N- or P-mod‐

ules

1 - 9 4

2 - 10 5

3 1 11 5

4 2 12 6

5 2 13 6

6 3 14 7

7 3 15 7

Number of pools Additional N- or P-mod‐

ules

8 4 16 8

Divide the number of pools by

2)

‘2’

. If a remainder is obtained, round down: (Exception: number of pools =

18

Page 14

4.4 Routing the CAN bus backbone

Planning aids and requirements for the installation site

CAUTION!

Maximum backbone length

Possible consequence: Malfunctions.

– The maximum backbone length (without branching

cables) must be less than 400 m

CAUTION!

Maximum length of branching cables

Possible consequence: Malfunctions.

The T-pieces and connecting cables (branching

cables) enclosed with the modules (M-, A-, G-, N-, R-,

I- modules, CAN sensors and metering pumps with

CAN bus must be used.

Branching cables are the connections branching from

the CAN bus backbone to the modules.

The external modules can be placed in any sequence

along the CAN bus backbone. The operating instruc‐

tions show for example possible sequences of the

external modules.

Each CAN cable has a plug or coupling on each end

so that these can be coupled together in sequence to

create longer cables.

Rule

Arrange the external modules in groups for each pool.

First assemble and install the external modules and

their attachments. Only then should you connect the

external modules with the CAN bus backbone and with

each other via the the shortest route.

Description Part no.

Connecting cable - CAN, M12, 5 pole, 0.5 m 1022137

Connecting cable - CAN, M12, 5 pole, 1 m 1022139

Connecting cable - CAN, M12, 5 pole, 2 m 1022140

Connecting cable - CAN, M12, 5 pole, 5 m 1022141

Connecting cable - CAN sold by the metre 1022160

19

Page 15

A0490

Assembly and installation

5 Assembly and installation

Procedure with DXC housing (large)

5.1

The DXC housing is suitable for mounting on a wall or in a control

panel

5.1.1 Wall mounting

Mounting materials (contained in the scope of delivery)

n 1 x wall bracket

n 4 x PT screws 5 x 35 mm

n 4 x washers 5.3

n 4 x rawl plug Ø 8 mm, plastic

Wall mounting

Take the wall bracket out of the DXC housing

Fig. 6: Removing the wall bracket

1. Pull the two snap hooks (1) outwards

The wall brackets snaps slightly downwards.

ð

2. Push the wall bracket downwards (2) from the DXC housing

and fold (3) it out

3. Use the wall bracket as a drilling template to mark the posi‐

tions of four drill holes

4. Drill the holes: Ø 8 mm, d = 50 mm

20

Page 16

Page 17

5.1.2 Control panel mounting

CAUTION!

Thickness of the control panel

The control panel must be sufficiently thick to ensure

that after fitting it does not bend. With steel panels it

must be at least 2 mm thick; select plastic correspond‐

ingly thicker.

Only in this way can the IP 54 rating be attained.

When fitted, the DXC housing extends approx. 45 mm

from the control panel. A drilling template is enclosed.

Page 18

Assembly and installation

8. Remove the front part

9. Now break out the necessary threaded holes of the lower

series, see

Ä Chapter 5.1.3 ‘Installation (electrical)’

on page 23

10. Screw the back part to the control panel (using the supplied

PT screws)

11. Plug the ribbon cable back on

12. Move the front part into the

Now first electrically install the DULCOMARIN® II and

ð

‘park position’

then complete the control panel mounting.

13. Place the front part on the rear part of the DXC housing and

screw it in

14.

CAUTION!

Protection class IP 54

Once again check the seating of the seal. Pro‐

tection class IP 54 is only achieved if the control

panel mounting is correct.

5.1.3 Installation (electrical)

WARNING!

Failure of the circulating pumps

In the event that the circulating pump fails, it is not suf‐

ficient to use the sample water limit contact of the inline probe housing on its own in order to stop the con‐

trol for the corresponding pool (contact K1 of the M

module).

The pool controller must also be set to Pause using

the contact K2

‘Pause control ’

of the M module.

Suitable triggers are:

– the zero volt contact of the filter control

– the zero volt contact of the circulation pump's

motor protection switch

– a flow monitor in the circulation line

WARNING!

Safe operating status

Both hardware and software safety precautions must

be taken to ensure that the DULCOMARIN® II adopts a

safe operating status in the event of a fault. E.g. use

limit switches, mechanical locks, ...

During installation the device must not be electrically

live.

The installation must only be carried out by technically

trained personnel.

Observe the technical data in these instructions.

23

Page 19

A0494

Assembly and installation

NOTICE!

Cable strain relief

With control panel mounting, the cables must be

routed in a site-provided cable duct to ensure strain

relief.

1. Plan which threaded holes shall be broken out (mark the

desired threaded holes)

CAUTION!

When breaking open the threaded holes, avoid

pushing the screwdriver deep into the housing. Parts

inside the device could be damaged.

Fig. 10: Breaking out threaded holes

2. To break out the threaded holes, punch the slit in the middle

of the threaded holes using a screwdriver (tip width 3.5 - 4

mm, see Fig. 10) and lever the material out

3. De-burr the resulting edges

24

Page 20

A0495

1.

2.

3.

4.

5.

Assembly and installation

Fig. 11: Fitting the threaded cable glands

1. Blanking plug

2. Union nut

3. Multiple seal insert

4. Threaded cable gland

5. Lock nut

4. Screw in the appropriate threaded cable glands (4) using

suitable lock nuts (5) and tighten firmly

5. Insert multiple seal inserts (3) depending on the cable diam‐

eter being used

6. Guide the cables into the threaded cable glands

7.

Further steps are contained in

coaxial cable’ on page 26

the terminals’ on page 26

Ä Chapter 5.1.4 ‘Connect the

and

Ä Chapter 5.1.5 ‘Connecting

.

8. Tighten the union nuts (2) of the threaded cable glands so

that they are properly sealed

9. Place the front part on the rear part

10. Manually tighten the four housing screws

11.

CAUTION!

Protection class IP 54

Once again check the seating of the seal. Pro‐

tection class IP 54 is only achieved if the control

panel mounting is correct.

25

Page 21

A0496

A0508

Assembly and installation

5.1.4 Connect the coaxial cable

The pH or redox sensor is connected

using a coaxial cable

Fig. 12: Removing the cable insulation

5.1.5

Connecting the terminals

1. Uncover the cable shielding according to

2. Tightly clamp the shielding

The wiring diagram is contained in the appendix.

Additionally there is an info field on the modules adja‐

cent to the terminals containing connection informa‐

tion.

Fig. 12

Fig. 13: Removing the cable insulation

1. Remove the insulation from the fork ends according to

Fig. 13 and press on the corresponding cable end sleeves

2. Pull off the terminal blocks P1 to P4 for installation

3. To fit the cable, push the supplied screwdriver right into the

square opening of the corresponding terminal in order to plug

the cable end into the terminal block

4. Connect the cables according to the wiring diagram

5. Push the pulled-off terminal blocks back onto the circuit

board after connecting the cables

26

Page 22

5.2

2

1

A0273

Procedure with DXM housing (small)

5.2.1 Mounting (mechanical)

For wall mounting, please observe the

following steps:

Assembly and installation

6. Check the cabling using the wiring diagram

Mounting materials (contained in the scope of delivery):

n 1 x wall/pipe bracket

n 2 x half-round head screws 5x45 mm

n 2 x washers 5.3

n 2 x rawl plug Ø 8 mm, plastic

n 1 x sealing cap

n 1 x safety screw (PT)

1. Remove the wall/pipe bracket from the DXM

2. Pull the two snap hooks outwards and push them upwards

(1)

3. Fold the wall/pipe bracket away and pull it out (2) in a down‐

wards direction

4. Mark two drill holes diagonal to each other by using the wall/

pipe bracket as a drilling template

5. Drill the holes: Ø 8 mm, d = 50 mm

27

Page 23

A0274

Assembly and installation

6. Tighten the wall/pipe bracket

7. Hook in the housing at the top in the wall/pipe bracket and

push it using light pressure at the bottom against the wall/

pipe bracket. Then press the housing upwards, until it audibly

engages

5.2.2

Installation (electrical)

For wall mounting

WARNING!

Safe operating status

During installation the device must not be electrically

live.

The installation must only be carried out by technically

trained personnel.

Observe the technical data in these instructions.

NOTICE!

Cable strain relief

With control panel mounting, the cables must be

routed in a site-provided cable duct to ensure strain

relief.

1. Undo the four housing screws.

2.

NOTICE!

The hinge between the front and rear part of the

housing cannot absorb high mechanical loading.

When working on the front part of the housing

you must support it.

Raise the front part slightly forwards and then fold out to the

left.

28

Page 24

A0272

3.

A0497

Assembly and installation

The large threaded cable gland (M20 x 1.5) is

only for use with the coaxial cable.

Punch out as many threaded holes on the bottom side of the

rear part as required

Fig. 14

1. Threaded cable gland

2. Reducing insert

3. Clamping nut

4. Terminal diagram

4. Screw the corresponding threaded cable glands (1) in and

tighten

5. Insert the reducing inserts (2) in the threaded cable glands

according to the cable cross section used

6. Guide the cables into the threaded cable glands

29

Page 25

Assembly and installation

7.

Further steps are contained in

coaxial cable’ on page 26

Ä Chapter 5.1.4 ‘Connect the

and

Ä Chapter 5.1.5 ‘Connecting

the terminals’ on page 26

Thereafter please continue with the following steps:

ð

8. Tighten the union nuts (3) of the threaded cable glands so

that they are properly sealed

9. Fold the front part onto the rear part

10.

NOTICE!

Protection class IP 65

Once again check the seating of the seal. Pro‐

tection class IP 65 is only achieved if the control

panel mounting is correct.

As necessary, pull the front part slightly forwards

to relieve the strain on the seal.

Manually tighten the housing screws

For control panel mounting (internal

module)

5.3 install the CAN bus cable

NOTICE!

Cable strain relief

With control panel mounting, the cables must be

routed in a site-provided cable duct to ensure strain

relief.

Connect the cables as follows:

coaxial cable’ on page 26

Ä Chapter 5.1.4 ‘Connect the

and

Ä Chapter 5.1.5 ‘Connecting

the terminals’ on page 26

CAUTION!

Maximum backbone length

Possible consequence: Malfunctions.

– The maximum backbone length (without branching

cables) must be less than 400 m

CAUTION!

Maximum length of branching cables

Possible consequence: Malfunctions.

The T-pieces and connecting cables (branching

cables) enclosed with the modules (M-, A-, G-, N-, R-,

I- modules, CAN sensors and metering pumps with

CAN bus must be used.

Branching cables are the connections branching from

the CAN bus backbone to the modules.

30

Page 26

5.3.1 Connections outside the housing

Assembly and installation

CAUTION!

T-coupling

Never connect a T-coupling directly to the housing.

The panel plug at the housing can break off.

CAUTION!

IP65 protection rating

Screw in the CAN cable threaded cable glands by

hand up to the stop. Otherwise the IP65 rating is not

achieved.

NOTICE!

Sequentially screw together the individual parts of the

CAN bus line starting from one side. Otherwise it can

occur that at one or several points socket is aligned

with socket or plug with plug.

CAN devices always have plugs, never sockets.

CAN bus line

External modules, CAN version of chlorine sensor and

DULCOMARIN® II are connected with each other via a

CAN bus line. The individual CAN devices are inserted

in this CAN bus line. There is a terminating resistance

at each end of the CAN bus line.

1. Connect the supplied branching cables (e.g. 0.5 m) with a Tpiece on the end to each module and the

DULCOMARIN® II

2. Screw the T-pieces of the CAN modules sequentially

together using CAN cables or directly one after the other

3. On each of the remaining ends of the CAN bus line screw on

a terminating resistance (1 x with a plug connector, 1 x with a

socket connector).

31

Page 27

Assembly and installation

Fig. 15: Inserting modules in the CAN bus line, compact version

1. CAN connection cable (branching cable 0.5 m)

2. Terminating resistance, M12 socket

3. T-coupling

4. CAN connection cable

6. Chlorine sensor CLE

7. CAN connection cable (branching cable 0.5 m)

8. T-coupling

9. Terminating resistance, M12 plug

5. Chlorine sensor CTE

32

Page 28

I.

II.

III.

A0499

Assembly and installation

Fig. 16: Inserting modules in the CAN bus line

I. Control room

II. Plant room, e.g. pool 1

III. Plant room, e.g. pool 2

A. Terminating resistance at the end of the CAN

bus line (the system can be extended from

here)

33

Page 29

A0501

1.

2.

3.

4.

Assembly and installation

If there is no P module or N module in the DXC housing:

n Use a so-called L circuit board as a distributor for the CAN bus

lines

Fig. 18: Use of an L circuit board

1. Cable connection to the A and M modules

2. Cable connection to the display and operating

module

3. Cable connection to the panel plug CAN 1

4. Panel plug CAN 1

35

Page 30

A0502

Device overview and operating elements

6 Device overview and operating elements

Keys

Fig. 19: Keys

1. Enter key

2. Start/Stop key

3. ESC key

4. Arrow keys

5. Function keys, variably assigned

36

Page 31

A0503

Displays

Device overview and operating elements

Fig. 20: Displays

1. LCD display

2. CAN 1-LED

3. Device LED

37

Page 32

A0504

Functional description (general)

7 Functional description (general)

Fig. 21: Measurement and control system for a filter circuit

1. Multi-channel measuring and control system

DULCOMARIN® II

2. In-line probe housing DGMa

3. Chlorine sensor CLE

4. Chlorine sensor CTE

5. T-coupling

6. Terminating resistance, M12 socket

7. Terminating resistance, M12 plug

9. pH sensor

10. ORP sensor

11. Coaxial cable

12. Control line

13. Metering pump 1

14. Metering pump 2

15. Signal horn

I. Plant room

8. CAN connection cable

The multi-channel measuring and control system

DULCOMARIN® II

(filtration circuits, pools ...) (version dependent).

The base functions are distributed over the following modules:

n M module (measurement module)

n I module (current input module)

n A module (control module)

n R module (control module for chlorine gas metering devices)

38

is suitable for controlling one or more systems

Page 33

Functional description (general)

n P module (power supply module with relay)

n N module (power supply module)

M module (measurement module)

n Measuring and control of the pH value

n Measuring and display (optional rules) of the redox potential

n Measuring and display of the temperature of the sample water

n Measuring and display of the circulating flow

n Monitoring the sample water

n Measuring the temperature of the sample water

n Measuring of free chlorine

n Measuring of total chlorine chlorine

n Displaying of combined chlorine

–

optional; calculated from total chlorine and free chlorine

Chlorine sensors:

n Measuring of free chlorine and temperature

n Measuring of total available chlorine and temperature

n Measuring of combined chlorine as a chlorine difference meas‐

urement

I module (current input module)

n Measurement monitoring and pause (2 contact inputs)

n Connection of 3 sensors

–

(3 standard signal inputs 0/4...20 mA, of which 2 as 2-con‐

ductor connection)

n Measuring and control of fluoride

n Measuring and control of ClO

2

n Measuring and control of chlorite

n Measuring and control of H2O

2

n Measuring of PES (peracetic acid)

n Measuring and display of dissolved oxygen2

n Measuring and display of ammonia

n Measuring and display of conductive conductivity

n Measuring and display of flow

n Measuring and display of turbidity

n Measuring and display of UV intensity

A module (control module)

n Control of metering pumps for pH correction and disinfectant

metering (over 3 frequency outputs, 3 contact inputs for pump

errors or container level monitoring)

n Output of measured values for pH value, redox potential, free

chlorine or total chlorine or combined chlorine or temperature

(4 analog outputs 0/4...20 mA, freely programmable and scal‐

able)

R module (control module for chlorine gas metering devices)

n Control of a servomotor with response signal for disinfectant

metering (2 relay outputs, position feedback input)

P module (power supply module with relay)

n Control of solenoid valve or hose pump for pH correction (via

pulse length output)

n Control of solenoid valve or hose pump for disinfectant (via

pulse length output)

n Control of hose pump for flocculant (via pulse length output) on

minimisation of the combined chlorine (via relay output)

39

Page 34

Functional description (general)

n Alarm (via relay output)

n Provision of the CAN bus with supply voltage

N module (power supply module)

n Provision of the CAN bus with supply voltage

CANopen metering pumps (Beta/4a, delta DLTa, Sigma S1CaS2Ca-S3Ca)

n Metering of pH correction agents, disinfectants or flocculants

40

Page 35

8 Maintenance, repairs and disposal

A0505

Maintenance

CAUTION!

Solvent

Do not under any circumstances use solvent to clean

the surfaces. Solvent can attack the surfaces.

Clean the housing with a damp cloth. Then rub dry.

Maintenance, repairs and disposal

The DULCOMARIN® II

is maintenance free. Replace the batteries

after 10 years as a precautionary measure. The DULCOMARIN® II

displays a warning should replacement be necessary sooner.

Battery type: CR2032, 3 V approx. 190 mAh

The battery is clamped in a holder on the rear side of the DXC

housing upper section.

Fig. 22: Removing the battery

Repairs

1. Unscrew the four retaining screws at the front on the housing

upper section and take the housing upper section off from the

housing lower section.

NOTICE!

Hazardous waste

The battery is hazardous waste. It must be disposed of

separately. Observe the conditions which apply on

your site.

2. Press on the holder lug to release the battery from the

holder, see

Fig. 22

3. Insert a new battery in the holder

In so doing avoid pressing with the fingers on the battery

ð

poles. This will result in poor contacts.

4. Place the housing upper section on the housing lower section

5. Manually tighten the four retaining screws

For repair please send the

DULCOMARIN® II to the manufacturer.

41

Page 36

Maintenance, repairs and disposal

8.1 Disposal of used parts

n Users' qualification: instructed persons, see

Ä Chapter 2.2

‘Users' qualifications’ on page 9

NOTICE!

Regulations governing disposal of used parts

– Note the current national regulations and legal

standards which apply in your country

ProMinent Dosiertechnik GmbH, Heidelberg will take back decon‐

taminated used devices providing that they are covered by ade‐

quate postage.

42

Page 37

Technical data spare parts and accessories

9 Technical data spare parts and accessories

Technical data

Spare parts and accessories

Description: Part no.

T-coupler M12 5-pole CAN 1022155

Terminating resistance, M12 socket 1022154

Terminating resistance, M12 plug 1022592

Connecting cable - CAN M12, 5 pole 0.5 m 1022137

Connecting cable - CAN M12, 5 pole 1m 1022139

Connecting cable - CAN M12, 5 pole 2 m 1022140

Connecting cable - CAN M12, 5 pole 5 m 1022141

Connecting cable - CAN M12, 5 pole Sold by the metre 1022160

Plug-CAN M12 5 pole Screwed connection 1022156

Coupling - CAN M12 5 pole Screwed connection 1022157

Cable combination coaxial 0.8 m-SN6, pre-assembled 1024105

You can find the technical data in the operating instructions of the

individual modules, see also the section "Further applicable docu‐

ments".

Cable combination coaxial 2 m-SN6, pre-assembled 1024106

Cable combination coaxial 5 m-SN6, pre-assembled 1024107

Control cable by the metre 2x0.25 mm2 725122

Fuse 5x20 slow-acting 0.63 AT VDE 712030

Battery 3 V approx. 190 mAh Li cell BR2032 732829

Buffer solution pH 4, red, 50 ml 506251

Buffer solution pH 7, green, 50 ml 506253

Buffer solution redox 465 mV, 50 ml 506240

Redox sensor RHES-Pt-SE 150703

pH sensor PHES 112 SE 150702

Chlorine sensor CLE 3-CAN-10 ppm* 1023425

Chlorine sensor CLE 3.1-CAN-10 ppm* 1023426

Chlorine sensor CTE 1 CAN-10 ppm* 1023427

Chlorine sensor CGE 2-CAN-10 ppm* 1024420

* Membrane caps and electrolyte for chlorine sensors, see the respective operating instructions of the

sensor

43

Page 38

EC Declaration of Conformity

We,

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

D - 69123 Heidelberg

hereby declare that the product identified below conforms to the basichealth and safety

requirementsof the ECDirective, by virtueof its design and construction, and in the configuration

placed on the market by us.

This declaration is no longerapplicable if changesaremade tothe product without our authorisation.

Productdescription:

DULCOMARIN II measuring and control unit

Producttype:

Serial no.:

see type plate on the unit

Applicable

EC Low Voltage Directive (2006/95/EC)

ECDirectives:

EC EMC Directive (2004/108/EC)

Date/ Manufacturer signature:

Name/ positionof the signatory:

Joachim Schall, Manager Innovation and Technology

Applied harmonised

standards,

especially:

EC Declaration of Conformity and fulfilled standards

10 EC Declaration of Conformity and fulfilled standards

Fig. 23: EC Declaration of Conformity

44

Page 39

A0506

Wiring diagram DULCOMARIN® II compact

11

Wiring diagram DULCOMARIN® II compact

Fig. 24: Wiring diagram DULCOMARIN® II compact (typical arrangement of modules)

I. M module (measurement module) DXMaM

II. A module (control module) DXMaA

III. P module (power supply module with relay) DXMaP

45

Page 40

Wiring diagram DULCOMARIN® II compact

Comprehensive module populating options are listed in the "Sup‐

plementary instructions DULCOMARIN® II, DXMa Modules".

M module (measurement module) DXMaM

Description Terminal

identifier

Temp. input

RTD 1 + Temp.- sensor d 5 1/M16

Pt1000/100

Ter‐

minal

no.

2 -

Pole Function Cable⌀Drill hole

no.

Size

Remarks

Redox input 1 ORP(pH) 3 Ref. Redox - sensor d3/d5 2/M20 Guide cable

through multiple

seal inserts 2x5

or 2x4

Potential equali‐

4 meas

sig.

Pot.1 5 11/M12

sation 1

Potential equali‐

Pot.2 6 pH - sensor 11/M12

sation 2

pH input 2 ORP(pH) 7 Ref. d3/d5 2/M20 Guide cable

8 meas

sig.

Contact input 1 K1 9 + Fault sample

10 -

water

Contact input 2 K2 11 + Pause (back‐

12 -

washing)

d4 3/M16 Guide cable

d4 3/M16 "

through multiple

seal inserts 2x5

through multiple

seal inserts 2x4

Contact input 3 K3 13 + ECO!Mode d4 12/M12

14 -

46

Page 41

A module (control module) DXMaA

Wiring diagram DULCOMARIN® II compact

Description Terminal

identifier

Ter‐

minal

Pole Function* Cable⌀Drill hole

no.

Relay output 1 R1 1 + Control acid pump

2 -

or

Control alkali

pump

Relay output 2 R2 3 + Control chlorine

4 -

pump

Control acid pump

Control redox

pump

Relay output 3 R3 5 + Control flocculant

6 -

pump

Control chlorine

pump

Control redox

pump

Contact input 1 K1 7 + Pump error

8 -

or

Filling level

Remarks

no.

Size

d5 13/M12

d5 14/M12

d5 15/M12

d4 4/M20 Guide 2 cables

through multiple

seal inserts 2x4

Contact input 2 K2 9 + Pump error

10 -

or

Filling level

Contact input 3 K3 11 + Pump error

12 -

or

Filling level

Current output

0/4-20mA 1

Current output

0/4-20mA 2

Current output

0/4-20mA 3

Current output

0/4-20mA 4

I out 1 13 + pH plotter connec‐

14 -

tion

I out 2 15 + Redox plotter con‐

16 -

nection

I out 3 17 + Chlorine free

18 -

plotter connection

I out 4 19 + Comb. chlorine

20 -

plotter connection

or

Temperature

plotter connection

d4 4/M20 Guide 2 cables

through multiple

seal inserts 2x4

d4 5/M16 Guide 2 cables

through multiple

seal inserts 2x4

d4 6/M16 Guide 2 cables

through multiple

seal inserts 2x4

d4 6/M16 Guide 2 cables

through multiple

seal inserts 2x4

d4 /M16 Guide 2 cables

through multiple

seal inserts 2x4

d4 7/M16 Guide 2 cables

through multiple

seal inserts 2x4

47

Page 42

Wiring diagram DULCOMARIN® II compact

P module (power supply module with relay) DXMaP

Description Terminal

identifier

Terminal

no.

Pole Function Cable⌀Drill hole

no.

Size

Alarm relay P1 1 Horn control d6.5 8/M16

2

3

Power relay 1 P2 4 Control acid solenoid valve

5

or

d6.5 9/M16

Control alkali solenoid valve

Power relay 2 P3 6 Control chlorine solenoid valve

7

or

d6.5 18/M12

Control redox solenoid valve

or

Control acid solenoid valve

or

Control alkali solenoid valve

Power relay 3 P4 8 Control UV (ozone, active

9

carbon)

d6.5 19/M12

or

Control redox solenoid valve

or

Control chlorine solenoid valve

or

Control heating

Mains X1 10 PE d6.5 10/M16

11 N

12 L(1)

CAN connection module

Description Terminal iden‐

tifier

CAN 1 - bus connection CAN 1 1 Shielding Plug

Terminal no. Pole Cable ⌀ Drill hole no.

Size

16/M12

2 24 V

A coding

3 ground

4 CAN high

5 CAN low

48

Page 43

12 Index

Index

1, 2, 3 ...

10 pole ribbon cable............................................. 34

16 pole ribbon cable............................................. 34

A

Accessories.......................................................... 43

Ambient conditions............................................... 13

Automatic start-up................................................ 11

B

Battery type: CR2032, 3 V approx. 190 mAh....... 41

Branching cables

C

Cable strain relief................................................. 23

CAN bus backbone.............................................. 19

CAN bus line........................................................ 31

CANopen third party devices............................... 11

Central unit........................................................... 18

CR2032................................................................ 41

D

Degree of protection............................................. 11

DIN IEC 60068-2-30............................................. 13

Displays................................................................ 37

Disposal............................................................... 41

DULCO-Net.......................................................... 18

E

External modules in the CAN bus backbone....... 19

F

Failure of the circulating pumps........................... 23

H

Hazardous substances......................................... 11

Hazardous waste................................................. 41

I

Identity code........................................................... 5

Internet Explorer..................................................... 5

.................................................. 19

IP 54..................................................................... 25

IP65 protection rating........................................... 31

K

Keys..................................................................... 36

L

LAN coupling.......................................................... 5

L circuit board....................................................... 35

M

Maximum length of branching cables.................. 19

Microsoft Internet Explorer..................................... 5

Mounting materials (contained in the scope of

delivery)................................................................ 27

P

Power supply module........................................... 18

R

Repairs................................................................. 41

Requirements for the installation site .................. 13

S

Safe operating status........................................... 23

Safety information.................................................. 8

Screwdriver.......................................................... 23

Sold by the metre................................................. 19

Spare parts........................................................... 43

T

T-coupling............................................................ 31

Terminating resistance......................................... 32

U

Users' qualifications............................................... 9

W

Wall/pipe bracket.................................................. 28

Wall mounting...................................................... 27

49

Loading...

Loading...