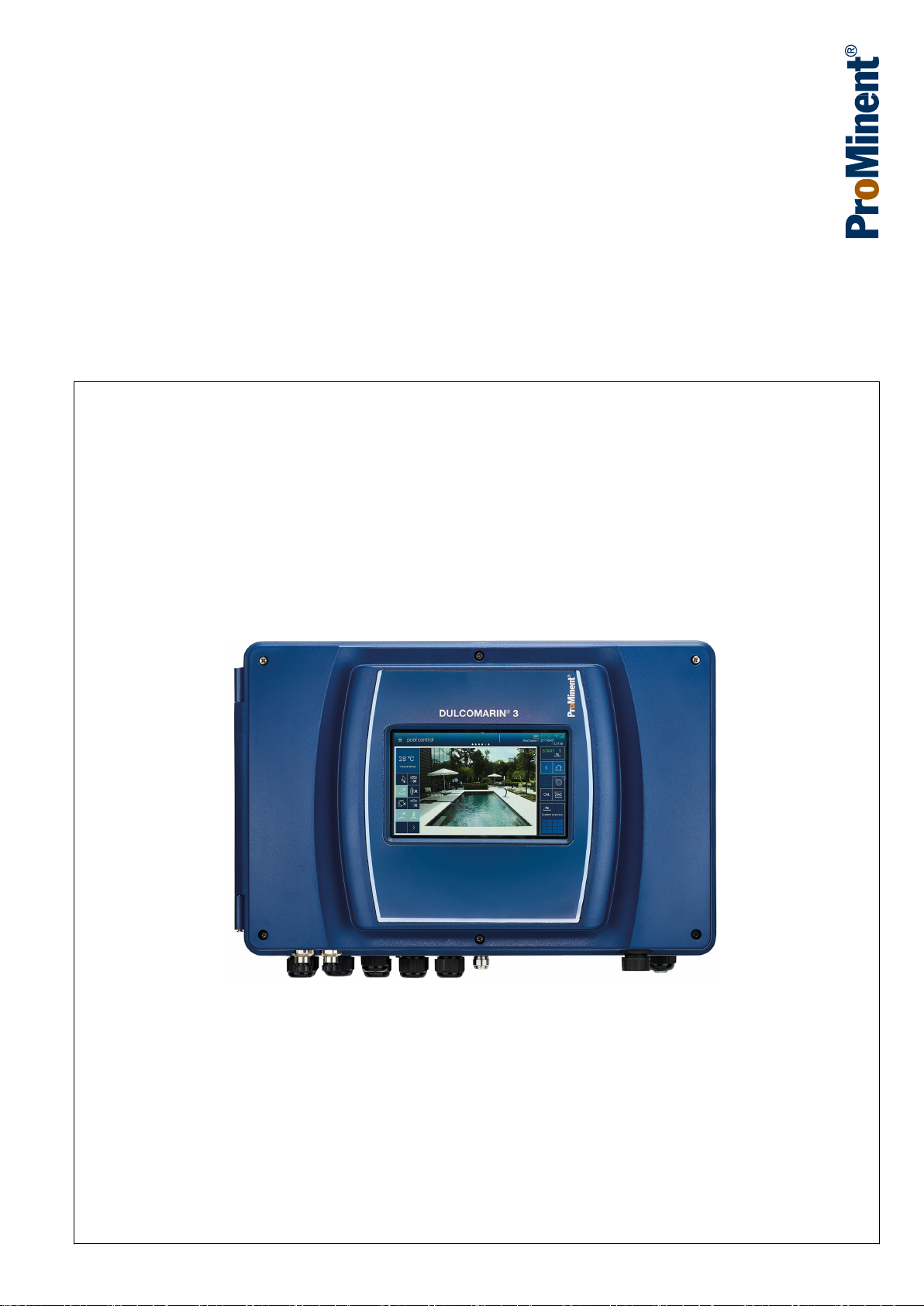

Page 1

Assembly and operating instructions

A2600

Multi-channel measuring and control system

DULCOMARIN® 3 Compact

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Target group: Trained user.Part number: 982801 Version: BA DC 089 09/18 EN

Page 2

Supplemental directives

General non-discriminatory approach

Supplementary information

In order to make it easier to read, this document uses the male

form in grammatical structures but with an implied neutral sense. It

is aimed equally at both men and women. We kindly ask female

readers for their understanding in this simplification of the text.

Please read the supplementary information in its entirety.

Information

This provides important information relating to the

correct operation of the unit or is intended to make

your work easier.

Warning information

Warning information includes detailed descriptions of the haz‐

ardous situation, see

tion’ on page 6

Ä Chapter 1.2 ‘Labelling of Warning Informa‐

.

The following symbols are used to highlight instructions, links, lists,

results and other elements in this document:

Tab. 1: More symbols

Symbol Description

Action, step by step.

⇨ Outcome of an action.

Links to elements or sections of these instructions or other applicable documents.

n

[Button]

List without set order.

Display element (e.g. indicators).

Operating element (e.g. button, switch).

‘Display /GUI’

CODE

Screen elements (e.g. buttons, assignment of function keys).

Presentation of software elements and/or texts.

2

Page 3

Table of contents

Table of contents

1 Safety and responsibility....................................................... 6

1.1 Introduction................................................................... 6

1.2 Labelling of Warning Information.................................. 6

1.3 General safety information............................................ 7

1.4 Intended use................................................................. 9

1.5 User qualification........................................................ 10

1.6 Warranty..................................................................... 10

1.7 Network security......................................................... 11

2 Functional description......................................................... 12

2.1 Open-source software licences.................................. 13

3 Operating concept............................................................... 14

3.1 Operating elements.................................................... 14

3.2 Navigation levels......................................................... 17

3.2.1 Interactions.............................................................. 18

3.2.2 Navigation levels...................................................... 19

4 Access to the setting menus............................................... 26

4.1

Hamburger menu with access to the system......... 26

4.2

Hamburger menu with access to the selected

pool............................................................................. 27

4.3

Cog wheel icon ....................................................... 28

4.4 Swiping and tapping on the display............................ 29

5 Storage and transport......................................................... 30

6 Assembly and installation................................................... 31

6.1 Scope of delivery........................................................ 31

6.2 Installation, mechanical.............................................. 32

6.2.1 Wall mounting.......................................................... 32

6.3 Electrical installation................................................... 35

6.3.1 Dimensioning/ arrangement of threaded connec‐

tors........................................................................... 36

6.3.2 Connection labels, base module.............................. 37

6.3.3 Terminal layout........................................................ 46

6.3.4 Terminal diagram..................................................... 47

6.3.5 Cable Cross-Sections and Cable End Sleeves....... 55

6.3.6 Switching of inductive loads..................................... 55

6.3.7 Connect the sensors electrically to the controller.... 56

6.4 Compact system, arrangement of components, CAN

connectivity................................................................. 61

6.4.1 Principles................................................................. 61

6.4.2 T-connectors............................................................ 62

6.4.3 Terminal resistances................................................ 62

6.5 CAN construction........................................................ 63

6.5.1 Determine the requirement for cables and accesso‐

ries........................................................................... 65

6.5.2 Routing the CAN bus backbone.............................. 66

7 Interfaces............................................................................ 68

7.1 SD card....................................................................... 68

7.2 USB port..................................................................... 69

7.3 LAN interface.............................................................. 69

7.3.1 Digital certificate...................................................... 70

3

Page 4

Table of contents

7.4 Wi-Fi interface (optional)............................................. 70

8 Data logger......................................................................... 72

9 Operating the device........................................................... 73

9.1 Home.......................................................................... 73

9.2 System settings.......................................................... 73

9.2.1 Login/logout............................................................. 73

9.2.2 Setting the language................................................ 73

9.2.3 Display..................................................................... 73

9.2.4 System > System settings....................................... 74

9.2.5 Network.................................................................... 75

9.2.6 Web services > NETWORK settings....................... 76

9.2.7 User administration.................................................. 76

9.2.8 Screen recorder....................................................... 77

9.2.9 E-mail....................................................................... 77

9.2.10 Bar graphs............................................................. 77

9.2.11 Network CAN......................................................... 78

9.2.12 Wizards.................................................................. 78

9.2.13 Gateway (planned extension)................................ 78

9.2.14 Functional test....................................................... 78

9.2.15 Default settings...................................................... 78

9.3 Help topics.................................................................. 79

9.4 Information.................................................................. 79

9.5 Calibrating................................................................... 79

9.6 Screen recorder.......................................................... 79

9.7 Pool control (attractions)............................................. 79

9.8 Single pool > Measured values pool........................... 79

9.9 Measured values pool................................................. 80

9.10 Process flowchart..................................................... 80

9.11 Connectivity.............................................................. 80

9.12 Pool settings............................................................. 80

9.12.1 ECO mode parameters.......................................... 80

9.12.2 Timer details operating mode................................ 80

9.12.3 Background image, pool geometry, pool name..... 80

9.12.4 Superchlorination................................................... 81

10 Application-specific settings................................................ 82

11 Calibrating........................................................................... 84

11.1 Calibrate: measured variable, pH............................. 85

11.2 Calibrate: measured variable, ORP.......................... 87

11.3 Calibrate: measured variable, free chlorine.............. 88

11.4 Calibrate: measured variable, total available

chlorine..................................................................... 89

11.5 Calibrate: measured variable, total chlorine............. 89

11.6 Calibrate: measured variable, total available bro‐

mine.......................................................................... 90

11.7 Calibrate: measured variable, total bromine............. 90

11.8 Calibrate: measured variable, chlorine dioxide......... 91

11.9 Calibrate: measured variable, chlorite...................... 91

11.10 Calibrate: Temperature measured variable............ 92

12 Flocculant treatment........................................................... 93

4

Page 5

Table of contents

13 Factory settings of device................................................... 94

13.1 Factory settings for free chlorine measured vari‐

able........................................................................... 94

13.2 Factory settings for combined chlorine measured

variable..................................................................... 95

13.3 Factory settings for pH measured variable............... 96

13.4 Factory settings for ORP measured variable............ 97

13.5 Factory settings for temperature measured vari‐

able........................................................................... 98

14 Commissioning................................................................... 99

15 Diagnostics, error and warning messages........................ 101

16 Software update................................................................ 102

17 Maintenance..................................................................... 103

18 Technical data................................................................... 104

18.1 General information................................................ 104

18.2 Electrical data......................................................... 104

19 Spare parts and accessories............................................ 107

19.1 Spare parts............................................................. 107

19.2 Accessories............................................................ 107

20 Formal information and standards.................................... 109

20.1 Disposal of used parts............................................ 109

20.2 Standards complied with and Declaration of Con‐

formity..................................................................... 109

21 Index................................................................................. 110

5

Page 6

Safety and responsibility

1 Safety and responsibility

1.1 Introduction

Target group of document

General knowledge of measuring and control technology and

swimming pool technology is required in order to understand the

document. Furthermore, the planning and use of measuring and

control technology and swimming pool technology require technical

specialist knowledge, which is not communicated in this document.

The minimum requirement of personnel is “trained user”, see

Ä Chapter 1.5 ‘User qualification’ on page 10

specified.

Assembly and operating instructions

The printed version of the assembly and operating instructions is

naturally not updated. We would therefore ask you to regularly visit

the manufacturer’s homepage www.prominent.com to find out

about the new electronic versions of the assembly and operating

instructions. These versions may contain, among other things,

information about new fault remedies or spare parts.

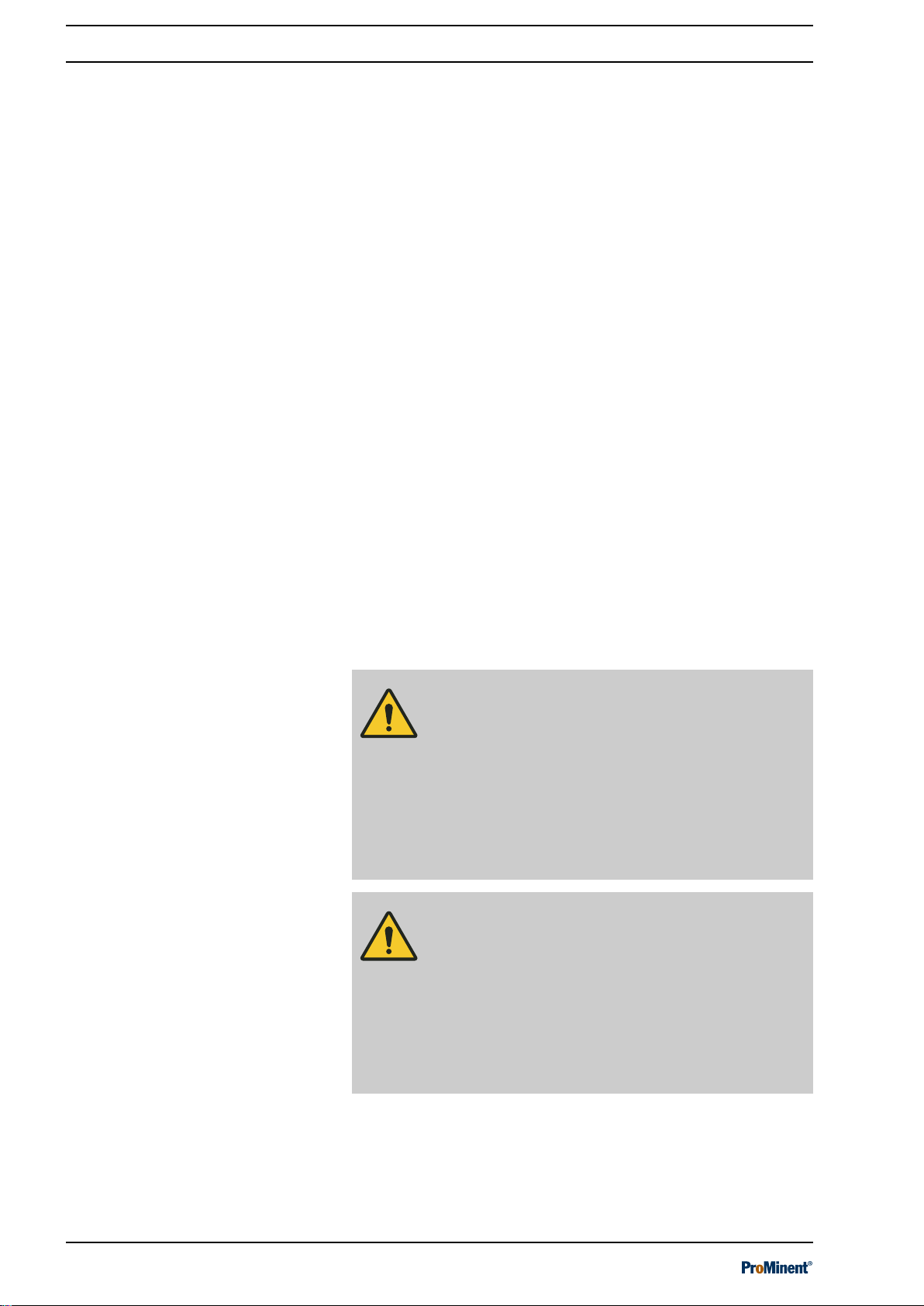

1.2 Labelling of Warning Information

Introduction

These operating instructions provide information on the technical

data and functions of the product. These operating instructions pro‐

vide detailed warning information and are provided as clear stepby-step instructions.

The warning information and notes are categorised according to

the following scheme. A number of different symbols are used to

denote different situations. The symbols shown here serve only as

examples.

, unless otherwise

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger.

Description of hazard

– Denotes an immediate threatening danger. If

the situation is disregarded, it will result in fatal

or very serious injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very serious inju‐

ries.

Measure to be taken to avoid this danger.

– Denotes a possibly hazardous situation. If the

situation is disregarded, it could result in fatal

or very serious injuries.

6

Page 7

Safety and responsibility

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor injuries.

Material damage.

Measure to be taken to avoid this danger.

– Denotes a possibly hazardous situation. If the

situation is disregarded, it could result in slight

or minor injuries. May also be used as a

warning about material damage.

NOTICE!

Nature and source of the danger

Damage to the product or its surroundings.

Measure to be taken to avoid this danger.

– Denotes a possibly damaging situation. If the

situation is disregarded, the product or an

object in its vicinity could be damaged.

1.3 General safety information

Type of information

Hints on use and additional information.

Source of the information. Additional measures.

–

Denotes hints on use and other useful informa‐

tion. It does not indicate a hazardous or dam‐

aging situation.

WARNING!

Live parts!

Possible consequence: Fatal or very serious inju‐

ries

– Measure: Before undertaking installation work

on the open device, ensure that it is discon‐

nected from the power supply.

– Regularly monitor the devices and de-energise

damaged or defective devices, or devices that

have been tampered with, from the power

supply.

– The operator must install a suitable circuit

breaker (e.g. IEC 60947-1 and IEC 60947-3)

for this.

– When switching off the device, the operator

must ensure that the entire process remains

safe.

– The operator should fit a residual current

device (RCD) or another suitable measure to

protect personnel and equipment.

7

Page 8

Safety and responsibility

WARNING!

Danger from hazardous substances!

Possible consequence: Fatal or very serious inju‐

ries.

Please ensure when handling hazardous sub‐

stances that you have read the latest safety data

sheets provided by the manufacture of the haz‐

ardous substance. The actions required are

described in the safety data sheet. Check the

safety data sheet regularly and replace, if neces‐

sary, as the hazard potential of a substance can be

re-evaluated at any time based on new findings.

The system operator is responsible for ensuring

that these safety data sheets are available and that

they are kept up to date, as well as for producing

an associated hazard assessment for the worksta‐

tions affected.

WARNING!

Unauthorised access!

Possible consequence: Fatal or very serious inju‐

ries.

– Measure: Ensure that there can be no unau‐

thorised access to the device.

WARNING!

Operating faults!

Possible consequence: Fatal or very serious inju‐

ries.

– Ensure that the device is only operated by ade‐

quately qualified and technically expert per‐

sonnel.

– Please also observe the operating instructions

for sensors and fittings and any other units

which may be fitted, such as sample water

pumps etc.

– The operator is responsible for ensuring that

personnel are qualified.

NOTICE!

Correct sensor operation

Damage to the product or its surroundings.

– Correct measurement and metering is only

possible if the sensor is working perfectly.

– Check and calibrate the sensor regularly.

8

Page 9

1.4 Intended use

Safety and responsibility

Protection of radio reception

This equipment is not intended to be used in resi‐

dential areas and cannot guarantee appropriate

protection of radio reception in these environ‐

ments.

The control’s limit values need to be permanently activated with

swimming pool controllers.

The unit is designed to measure and regulate water treatment in a

swimming pool with one or more pools.

The unit’s range of application extends to industry and residential.

Only use the unit in accordance with the technical details and

specifications provided in these operating instructions and in the

operating instructions for the individual components (such as sen‐

sors, fittings, calibration devices, metering pumps, etc.).

The controller can be used in processes, which have a time con‐

stant of > 30 seconds.

All other uses or modifications are prohibited.

Interference resistance

The device complies with the interference resistance provisions in

accordance with EN 61326-1 and is intended for use in industrial

electromagnetic environments and in residential areas.

WARNING!

Disturbance signal emissions class A or B / Protec‐

tion for radio reception

The device complies with the disturbance signal

emissions test requirements for residential areas

as a Class B (Residential area), Group 1 unit.

With devices with communication interface

– B = Profibus,

– E = LAN,

– G = Profinet,

the unit only complies with the limit values for a

class A device (other areas apart from residential),

Group 1.

This device is then not intended to be used in resi‐

dential areas and cannot guarantee appropriate

protection of radio reception in these environ‐

ments.

9

Page 10

Safety and responsibility

1.5 User qualification

WARNING!

Danger of injury with inadequately qualified per‐

sonnel

The operator of the system / equipment is respon‐

sible for ensuring that the qualifications are ful‐

filled.

If inadequately qualified personnel work on the unit

or loiter in the hazard zone of the unit, this could

result in dangers that could cause serious injuries

and material damage.

– All work on the unit should therefore only be

conducted by qualified personnel.

– Unqualified personnel should be kept away

from the hazard zone.

The pertinent accident prevention regulations, as

well as all other generally acknowledged safety

regulations, must be adhered to.

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been instructed and,

if required, trained in the tasks assigned to him and possible dangers that

could result from improper behaviour, as well as having been instructed in the

required protective equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of an instructed

person and who has also received additional training specific to the system

from the manufacturer or another authorised distribution partner.

Trained, qualified per‐

sonnel

Electrical technician An electrical technician is able to complete work on electrical systems and rec‐

A trained, qualified employee is deemed to be a person who is able to assess

the tasks assigned to him and recognize possible hazards based on his

training, knowledge and experience, as well as knowledge of pertinent regula‐

tions. A trained, qualified employee must be able to perform the tasks

assigned to him independently with the assistance of drawing documentation

and parts lists. The assessment of a person's technical training can also be

based on several years of work in the relevant field.

ognise and avoid possible dangers independently based on his technical

training and experience as well as knowledge of pertinent standards and regu‐

lations. An electrical technician must be able to perform the tasks assigned to

him independently with the assistance of drawing documentation, parts lists,

terminal and circuit diagrams. The electrical technician must be specifically

trained for the working environment in which the electrical technician is

employed and be conversant with the relevant standards and regulations.

Service The Service department refers to service technicians, who have received

proven training and have been authorised by the manufacturer to work on the

system.

1.6 Warranty

The general terms and conditions of business, contracts and

national laws and regulations apply in the relevant order of priority.

10

Page 11

1.7 Network security

Safety and responsibility

The product is suitable for use in networks. Users are responsible

for taking appropriate security measures for their own network and

all components contained therein, in particular their computer sys‐

tems and other systems. They must protect these adequately from

unauthorised access by third parties, viruses, harmful software and

any other forms of harmful elements. In particular, the user under‐

takes to set up an appropriate firewall and wherever possible to

use automatically generated passwords of an adequate length,

which should be regularly changed, or to take other appropriate

measures to establish or maintain network security. Responsibility

for network security lies with the operator of the system.

ProMinent GmbH in particular is not liable for any consequences

resulting from inadequate security measures and the potential

misuse of the user’s identification features.

11

Page 12

Functional description

2 Functional description

The measuring and control system DULCOMARIN® 3 controls the

entire range of swimming pools – from private pools to public

adventure pools.

The measuring and control system DULCOMARIN® 3 is used to

treat swimming pool water. Eco!Mode® adapts the circulation

capacity for on-demand energy use.

The system is operated either via the 7” touchscreen with graphic

user interface or using mobile smart devices by means of the inte‐

grated web server while maintaining full functionality. Explanatory

videos guide the user step-by-step through operation.

By using industrial bus systems, up to 16 pool circuits can be net‐

worked and the amount of wiring needed is reduced at the same

time. Local operating devices can be added to each pool circuit.

This simplifies regular maintenance of the swimming pool system

(e.g. sensor calibration). The modular construction allows existing

systems to be extended.

Field of application

Overview of the functions

n Water parks,

n public swimming pools,

n private pools.

Measurement and control of all relevant hygiene parameters.

n pH,

n ORP,

n chlorine, total / combined / free,

n bromine,

n chlorine dioxide,

n temperature,

n conductivity,

n turbidity.

Control of the swimming pool technology:

n circulating pumps, on-demand thanks to Eco!Mode®,

n filter backflushing,

n lighting,

n covers,

n whirlpool functions,

n attractions such as counterflow systems.

Evaluation and reporting functions:

n high-resolution screen recorders with zoom function,

n comprehensive data logger for evaluations on a PC,

n sending configurable status messages by e-mail.

Communication options:

n linking to building management systems by means of KNX /

OPC standard,

n PLC linking by means of PROFIBUS® DP and Modbus RTU,

n LAN and Wi-Fi connections for operation using a PC, tablet or

smartphone etc.

12

Page 13

2.1 Open-source software licences

The DULCOMARIN® 3 controller may contain firmware with opensource software packages. You will find a list in table format of the

possible software packages, the licensing conditions for these

packages and the source code on the data carrier provided with

the controller and on the product and download page for the DUL‐

COMARIN® 3.

Functional description

13

Page 14

System overview

System designation

System 1... 3

Pool overview

2018-06-22

14:21:28

Pool name 1

1

ECO

2

ECO

Pool name 3

3

CAL

Input screen locked!

Swipe to unlock.

A2495

Operating concept

3 Operating concept

3.1 Operating elements

Operating elements

The device is operated by a touchscreen as a combined input and

output interface between man and machine (HMI).

The capacitative touchscreen display provides a quick overview of

all functions. It responds like a smartphone, which ensures simple

and intuitive operation.

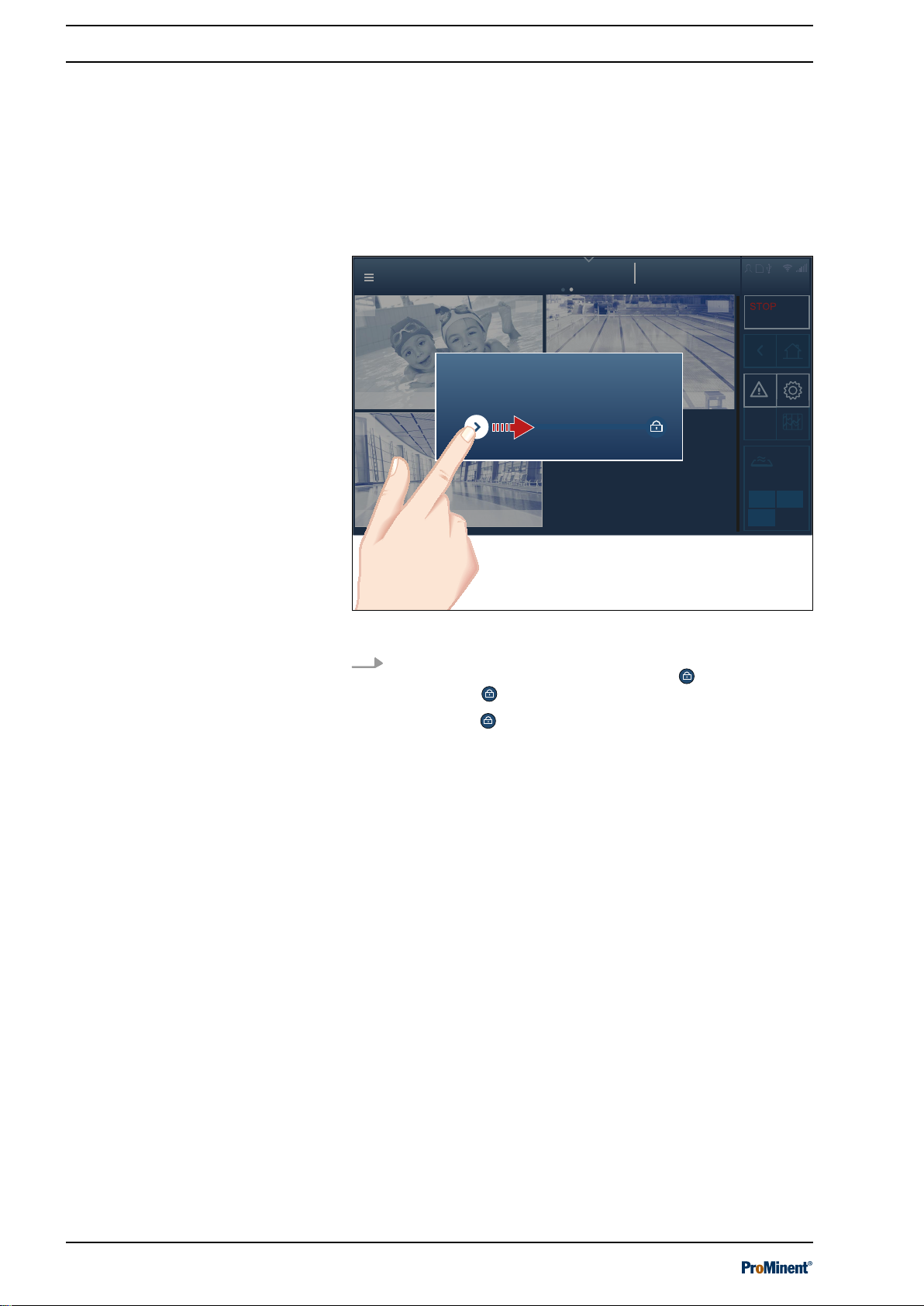

Fig. 1: Locked screen

To unlock: use the tip of your finger to move the left icon and

drag the icon to the right towards the lock . Cover the lock

with the icon .

The lock

ð

opens.

14

Page 15

Operating elements

Help topics

System overview

2018-11-06

14:21:28

CAL

Pool name

System 1... 3

STOPSTOP

Pool measured value

Pool name

Off

System overview

pH

Target

0.00

pH

Dosing

ON

Dosing

-100.0 %

ON

Target 0

ORP

mV

Dosing

Target 0.0

Temperature

Dosing

Target 0.00

Free chlorine

ppm

Dosing

Target 0.00

Total chlorine

m3/h

Dosing

Cl combined

Target 0.00

OFF

START 1

System information

Start/Stop

Pool

Home

Start screen

Settings

Recorder

System overview

Status display of

pools and link to

start screen

back

Alarms

Errors & warnings

Calibrate

active pool

Page index

Menu

Pool name 1

OFF

START

1

06/11/2017

System overview

CAL

active pool

14:21:28

A2519

ON

Operating concept

Fig. 2: The individual operating elements

Reciprocal

n

‘ON’

n

‘OFF’

‘ON/ OFF’

status ➨

status ➨

to

‘START/STOP’

‘STOP’

pool display (at pool level)

‘START’

pool display (at pool level)

If the status display for a pool is indicating the

[STOP]

key can be used to stop the control and outputs of this

pool.

If the status display for a pool is indicating the

the

[START]

key can be used to start the control and outputs of

this pool.

All pools can be stopped at system level using the

[system 1 ... n]

. Each pool can then only be started individually.

status

[ON]

status, then the

[OFF]

status, then

[STOP]

key

15

Page 16

Becken 1...3

2018-06-22

14:21:28

Operating concept

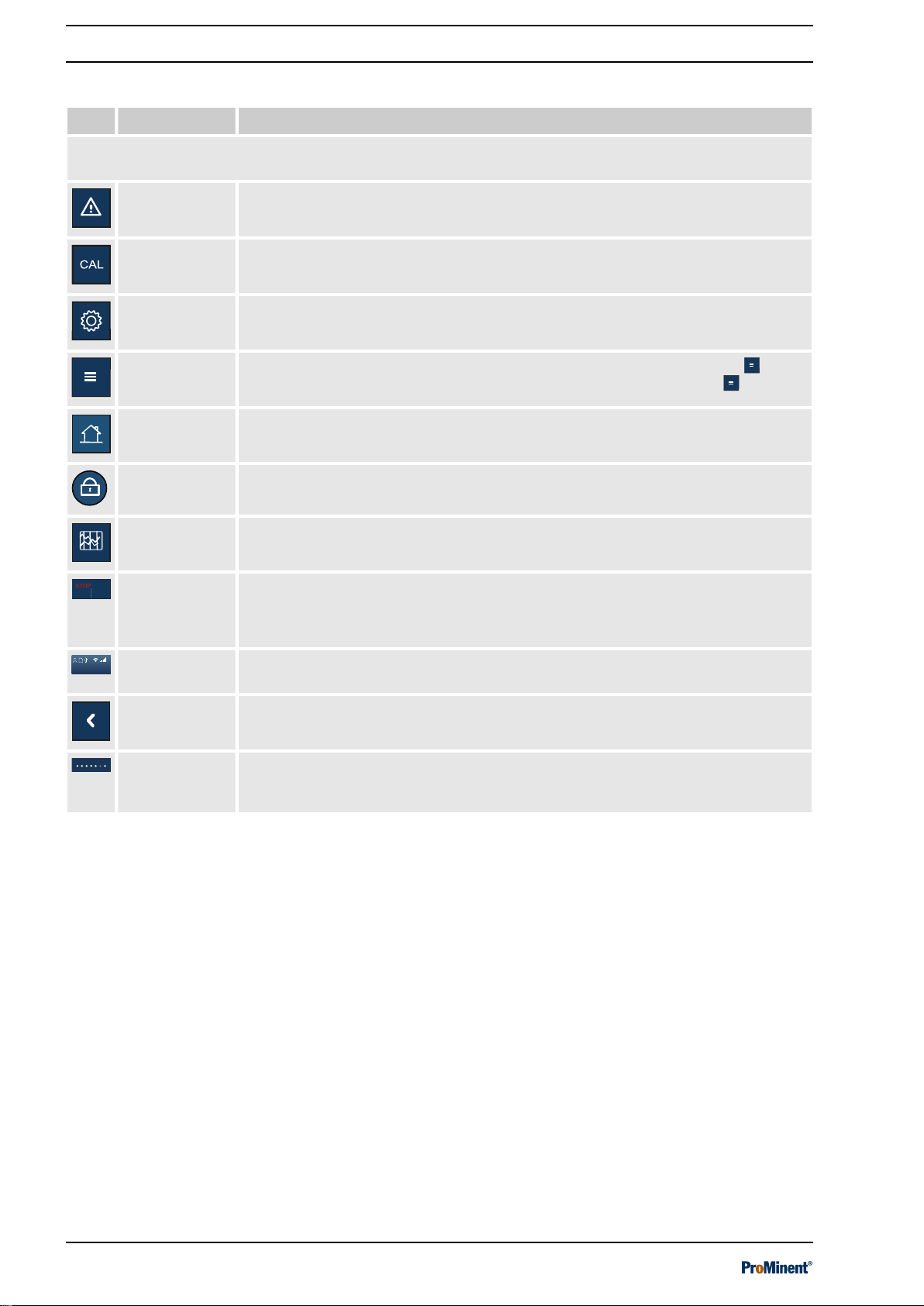

Tab. 2: Pictograms as operating elements.

Picto. Name Meaning and function

Active pictograms are highlighted, while inactive pictograms remain dimmed. Only the active pictograms

can be actuated.

System alarms This key immediately opens the global list with all system alarms.

Calibration

This key immediately opens the calibration menu.

menu

System set‐

This key immediately opens the list with all system settings.

tings

Quick access

menu

[Home]

This key immediately opens the quick access menu (

can then select from the various sub-menus in the

This key takes you straight back to the screen defined as

Locked lock This icon indicates that the display is locked.

Screen

recorder

Pool status Reciprocal

General infor‐

mation

This key immediately opens the view with the recorder. The screen recorder logs

all the device’s activities and measured values.

‘ON/ OFF’

n

‘ON’

status➨

n

‘OFF’

status ➨

to

‘STOP’

‘START’

‘START/STOP’

display

display

status

You will find all information about the date, time and links between the various

interfaces displayed here.

‘hamburger’

‘hamburger’

[Home]

menu) . You

menu .

.

Back This key takes you one level back in the menu.

Page index These points at the top of the display indicate that there are more pages. You can

access these pages by swiping to the left or right. The dark point marks the posi‐

tion of the visible page in the entire system.

16

Page 17

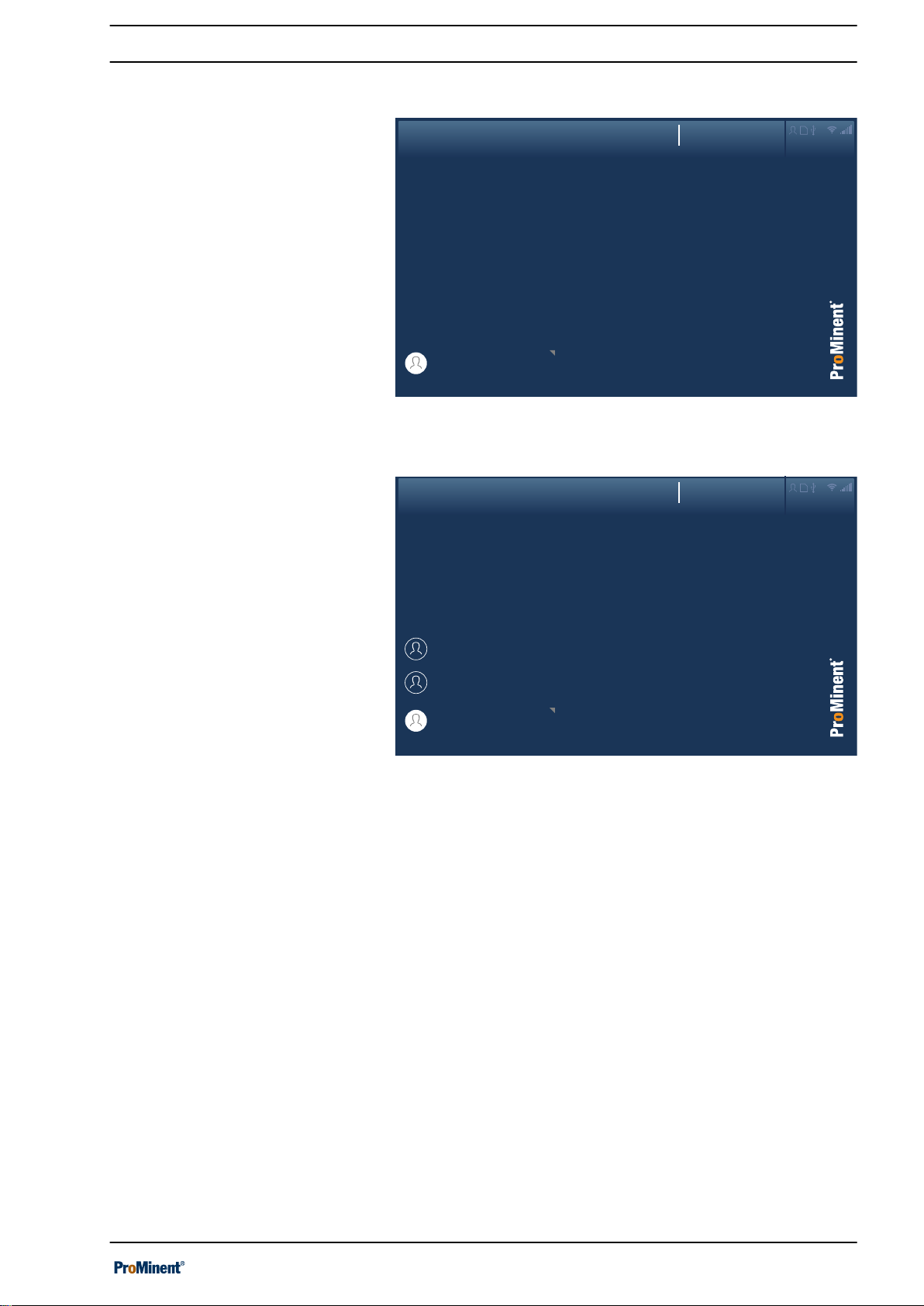

3.2 Navigation levels

Login

System designation

2018-06-22

14:21:28

Select user

A2532

Login

System designation

2018-06-22

14:21:28

Select user

Name User2

User

alias User1

Service

A2533

Login

Select user

Operating concept

Fig. 3: Login interface

Fig. 4: User selection interface

17

Page 18

Login

System designation

2018-06-22

14:21:28

alias User1

Service

1 2 3

4 5 6

987

0

A2534

Help topics

System overview

2018-06-22

14:21:28

System designation

System 1... 3

Navigation principle, interaction

Swipe

Navigate to

next screen on the same

level.

Scroll

Display further content on the

same screen

.

Tap

Navigate to

following screen on

the next level.

A2518

Operating concept

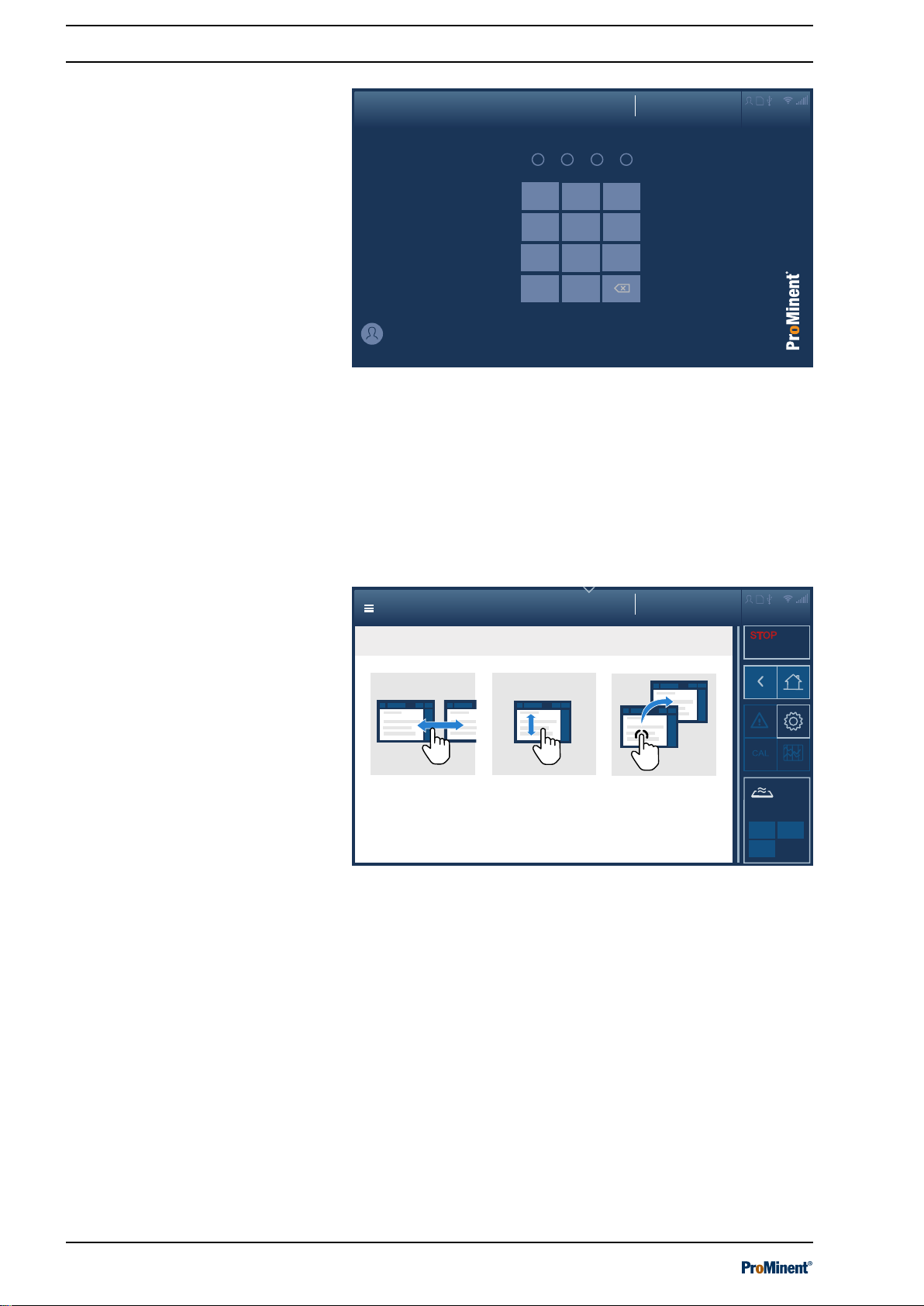

Entering a PIN/PUK

Fig. 5: PIN entry interface

You can enter the PIN you have assigned here. If you can’t

remember your PIN, you can enter the PUK. The PUK is supplied

with the device and can be found in a sealed envelope. It is the

responsibility of the operator to ensure that the PUK is kept safe

and is available when needed.

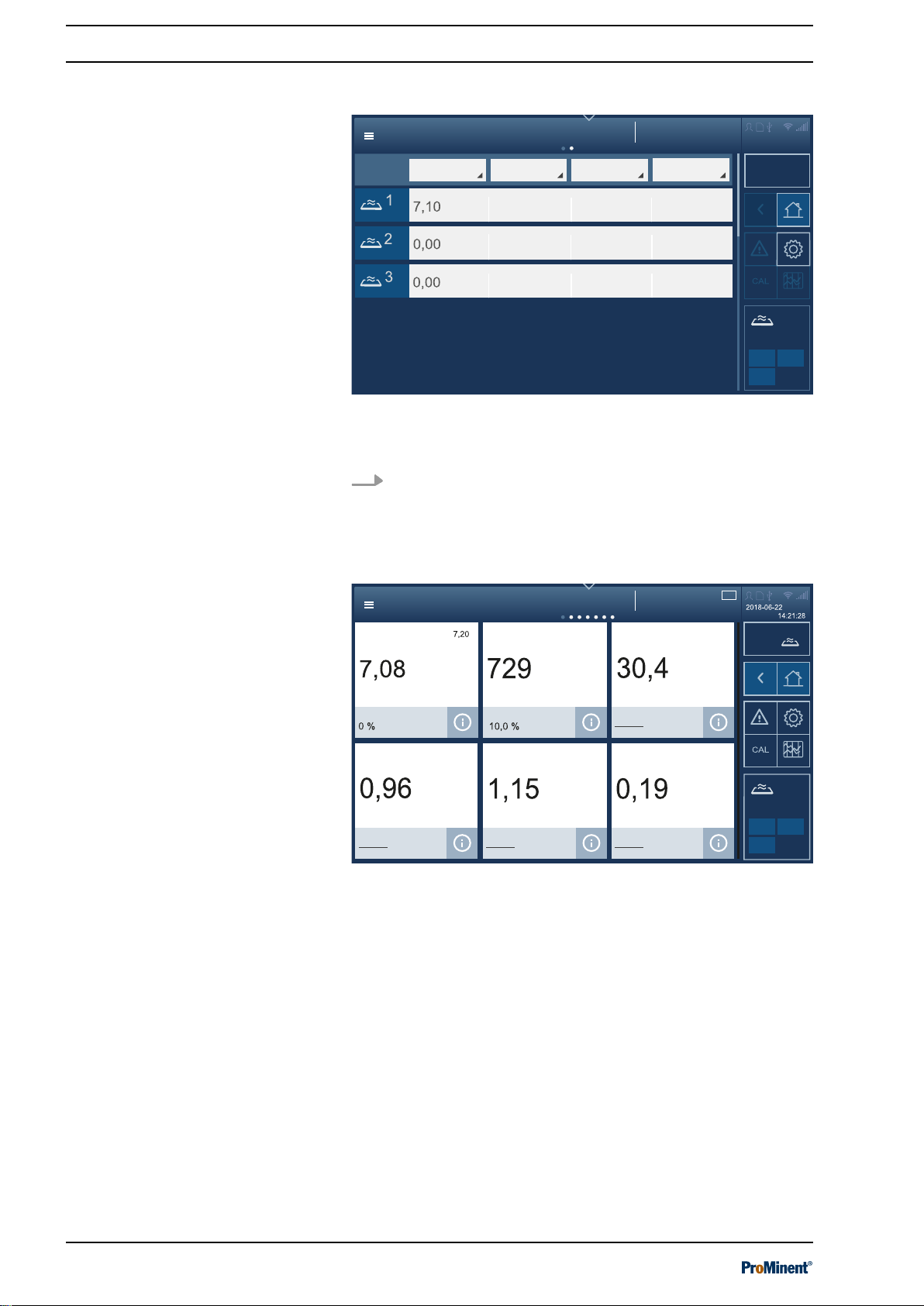

3.2.1 Interactions

Fig. 6: Swiping, scrolling and tapping

18

Page 19

3.2.2 Navigation levels

Help topics

System overview

2018-06-22

14:21:28

CAL

System designation

System 1... 3

STOPSTOP

System level

Pool level

Detail level

Navigation levels (principle)

1.1

1.3

1.2

2.1

2 x

2.2

2 y

3.1

3 x

3.2

3 y

A2517

System overview

System designation

System 1... 3

System overview

2018-06-22

14:21:28

1

ECO

ECO

2

ECO

Rehabilitation

Children's pool

3

Competition pool

A2494

Operating concept

Fig. 7: Principle of navigation levels

Swipe between the pages of a level e.g. 1.1-1.3.

Tapping on a level takes you one level lower in the menu if this is

possible.

3.2.2.1 System level

System overview

Press to go back one level.

The Home key returns you to the

[Home]

screen.

Fig. 8: [Home] screen, here with the individual system overview.

You can set the layout and assignment in the

menu. Tapping on the

[Home]

You now have two options:

n Swipe over the display to move to the next display, or

n tap on the respective pool to view the measured value display.

screen.

[Home]

icon always takes you to the

[System settings]

19

Page 20

System measured values

System designation

System 1... 3

System overview

1.0 %

729

1.0 %

30.8

0.0 %

0.96

8.0 %

0.0 % 0.0 % 0.0 %0.0 %

0.0 % 0.0 % 0.0 %0.0 %

0.00

0.00

0.0

0.0

0

0

pH ORP Temp

Free chlorine

2018-06-22

14:21:28

STOP

A2504

Measured values pool

System 1

OFF

System overview

pH

Target

pH

Dosing

ON

Dosing

ON

Target 750

ORP

mV

Dosing

Target 30.0

Temperature

°C

Dosing

Target 1.15

Free chlorine

ppm

Dosing

Target 1.20

Total chlorine

ppm

Dosing

Combined chlorine

ppm

OFF

START 1

A2505

OFFOFF

Target 0.05

Operating concept

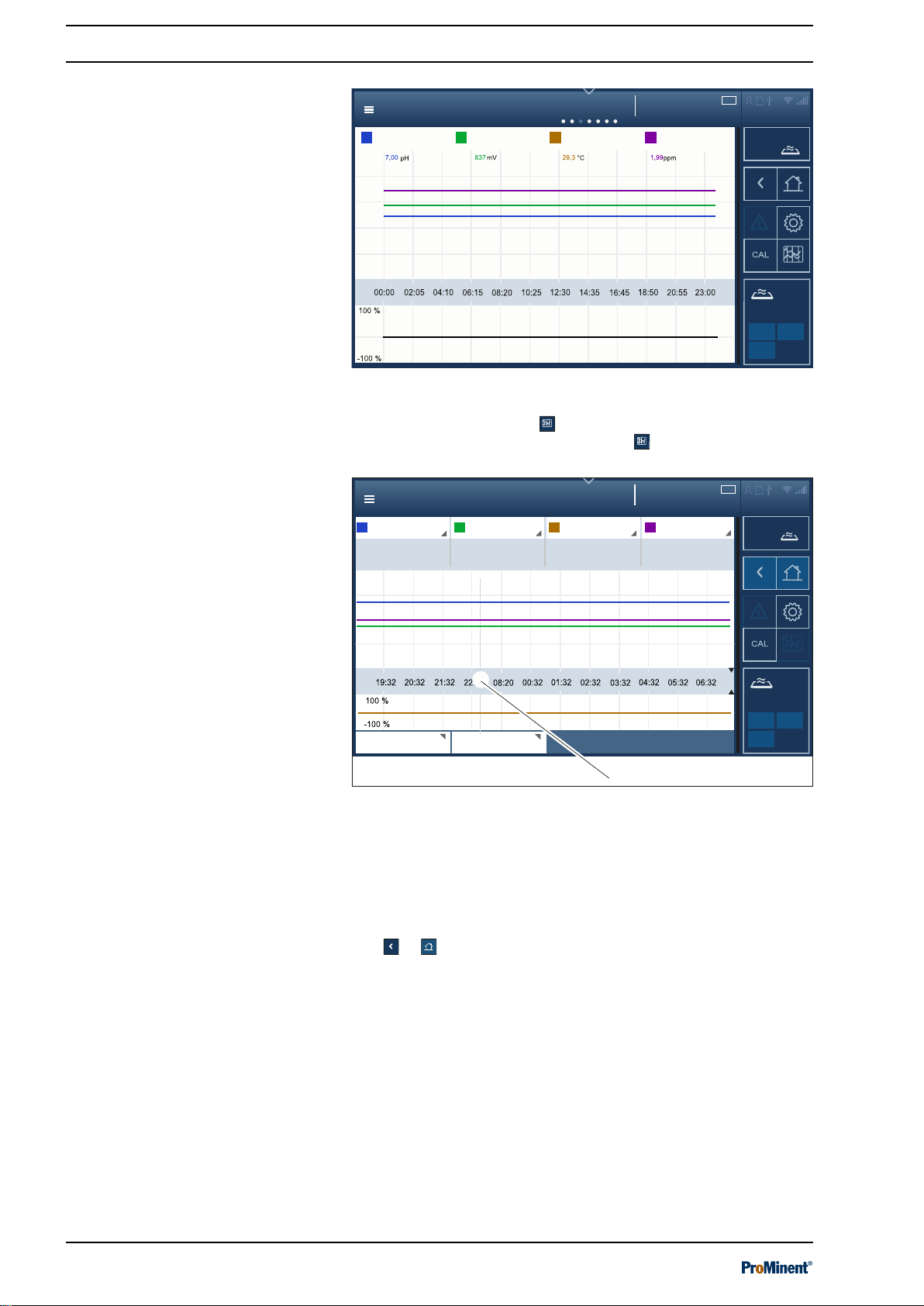

System measured values

Fig. 9: Measured values interface.

You can view all the system’s measured values for pools 1 to n.

Scrolling up or down over the display allows you to display all

pools.

3.2.2.2 Pool level

Measured values of pools

Fig. 10: Measured values interface for the selected pool.

Up to 12 measured values = tiles can be displayed. The 7 points in

the centre at the top indicate that it is possible to swipe on this dis‐

play.

20

Page 21

Measured values pool

System overview

2018-06-22

14:21:28

pH

pH

Setpoint

pH

7.09

7.00 7.20 10.0%

On

Dosing

6.00

0.00

9.00

729

1.0 %

Dosing

On

ORP

mV

Setpoint

mV

730

600

900

0

Setpoint

°C

°C

30.5

Temperature

30.0

OFF

System 1

START 1

A2507

Measured values of pools, details

Operating concept

Fig. 11: Detailed pool display interface.

This display is more detailed, the set limit values are also displayed

here. The measured value, setpoint and metering are displayed at

a glance. The scroll bar indicates that there are more measured

values below – you therefore need to scroll upwards.

21

Page 22

Recorder

System overview

2018-06-22

14:21:28

pH ORP

Temperature

Free chlorine

System 1

OFF

START 1

A2508

Value ValueValueValue

Recorder details

System overview

2018-06-22

14:21:28

7.19 pH Value

499 mV

Value

28.7 °C Value Value

1.98 ppm

Dosing 01.0 %Dosing 00.0 %

Dosing 12.0 %Dosing 02.0 %

15 minutes

22.06.2018

System 1

OFF

START 1

A2509

Free chlorine

Temperature

ORPpH

1.

Operating concept

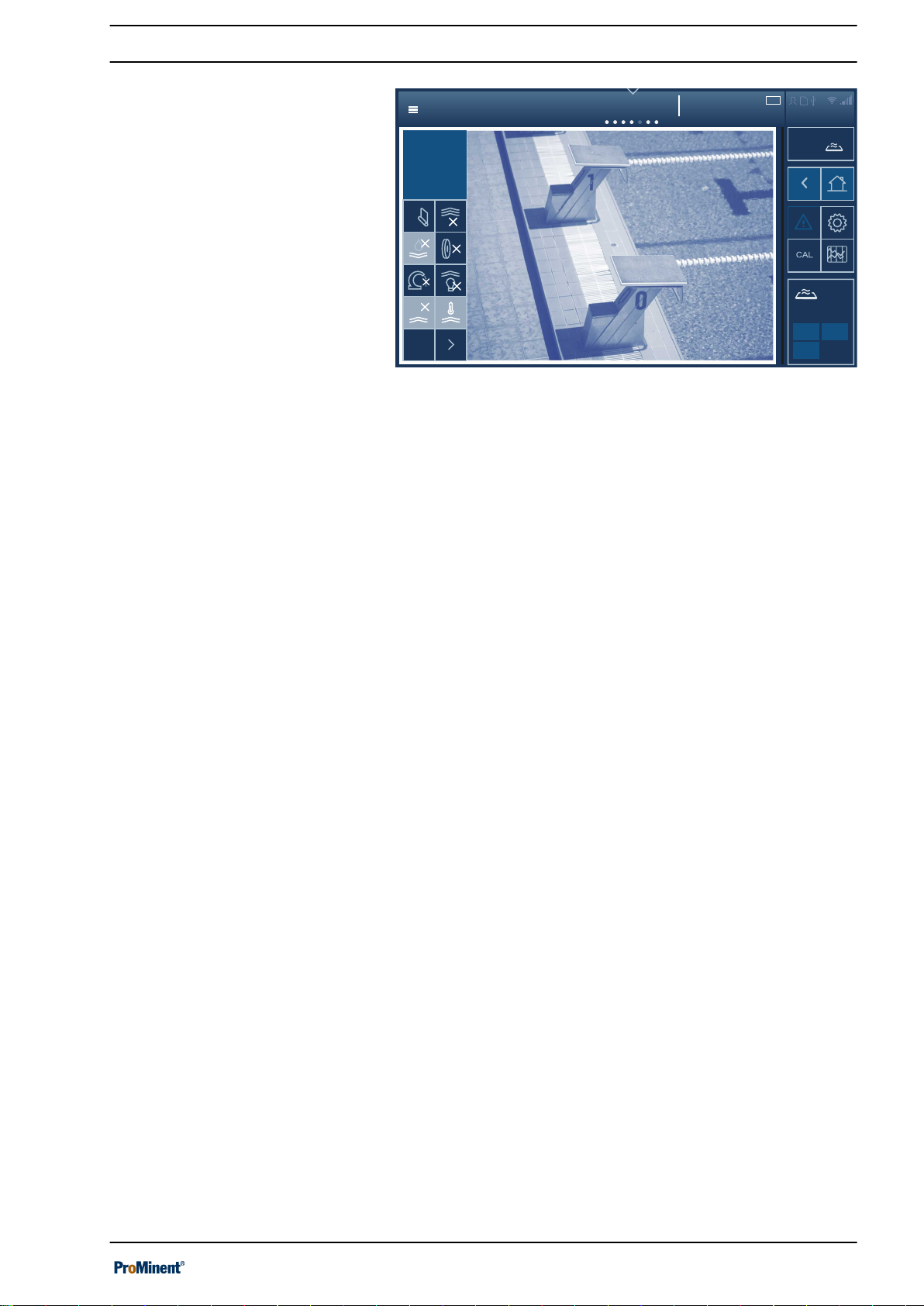

Screen recorder

Fig. 12: Screen recorder mode interface.

This is the screen recorder : tapping on it takes you to the next

page of the display. The screen recorder

logs all the device’s

activities and measured values.

Connectivity

Fig. 13: Interface of screen recorder with cursor (1.).

1 Cursor

The measured values at certain times can be displayed in this

screen recorder view by moving the cursor (1). By tapping on and

scrolling up/down the displays for measured variables, time and

date, you can also select other values or units, deactivate indi‐

vidual measured variables and adapt the time interval displayed.

Use or to go back.

Here you can monitor and configure the recognised CAN bus mod‐

ules and call up and read all the parameters required.

22

Page 23

Pool control

System 1

OFF

System overview

2018-06-22

14:21:28

START 1

Water temperature

30.6 °C

A2511

Pool control (attractions)

Operating concept

Fig. 14: Pool control interface (attractions)

You can switch the attractions (flood shower, fountains etc.) on and

off here.

23

Page 24

Process flowchart

System1

OFF

System overview

2018-06-22

14:21:28

START 1

Pump

Mode

Filter backflushing

Duration 0

Circulating pump

Normal mode...

50.0 m3/h

pH

ORP

Temp

Cl

Cl

comb.

7.10 pH

729

mV

30.5 °C

0.96 ppm

1.15 ppm

pH-

25.7 %

pH+

0 %

Cl

42.2 %

Floccculant

5.5 %

Auto

manual

1

A2512

Process flowchart

System 1

OFF

System overview

2018-06-22

14:21:28

CAL

START 1

Pump

Mode

Filter backflushing

Duration 0 s

Circulating pump

Normal mode...

50.0 m3/h

Cl

comb.

1.15 ppm

pH-

25.7 %

pH+

0 %

Cl

42.2 %

Floccculant

5.5 %

Auto

manual

Hydraulic details

Timer, circulating pump, level

A2513

Operating concept

Process flowchart

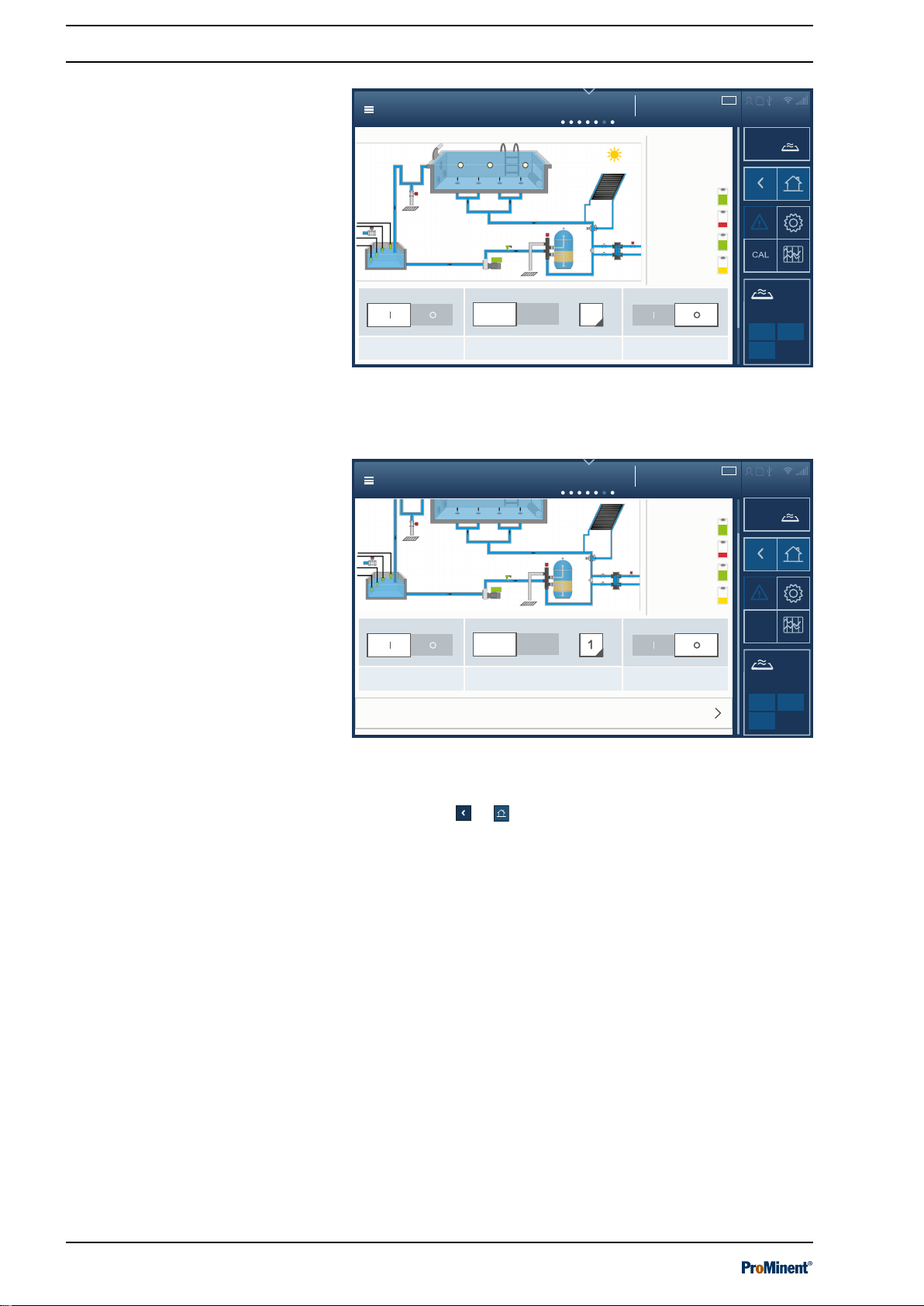

Fig. 15: Process flowchart interface

Here you can switch the circulating pump off and on by tapping on

the circulating pump, for instance.

Fig. 16: Process flowchart interface showing the hydraulic details.

Scrolling up takes you to the hydraulic details, timer, circulating

pump etc. Use

or to go back.

24

Page 25

Pool settings

System 1

OFF

System overview

2018-06-22

14:21:28

START 1

Settings

Settings

Settings

ECO! mode parameters

A2514

Settings

Control parameters for superchlorination

Timer, details, operating mode

Background image, select pool geometry,

pool name

6.00

Details of measured variables

System overview

2018-06-22

14:21:28

Screen recorder of the last 2 hours

14.00

0.00

7.00

7.10

7.2

14.00

6.8

min

Alarms

max.

7.8

Setpoints and control parameters

Setpoint, normal mode

Setpoint, Eco!Mode

Superchlorination

7.27.2 7.1

OFF

System designation

START 1

A2506

pH

pH

1.

2.

3.

4.

Pool settings

Operating concept

Fig. 17: Pool settings interface

You can set or select the parameters for Eco!Mode®, timer details,

operating modes, superchlorination and background images here.

3.2.2.3 Detail level

Measured variables, details

Fig. 18: Details of measured variables interface.

Tapping on the desired measured value of the measured variable

takes you to the details of measured variables, the measured value

screen recorder for the last 2 hours, the control parameters and

setpoints for the operating modes: Normal, Eco!Mode® and super‐

chlorination. Here you can select the normal, Eco!Mode® and

superchlorination operating modes in order to set the parameters

for them.

25

Page 26

Access to the setting menus

4 Access to the setting menus

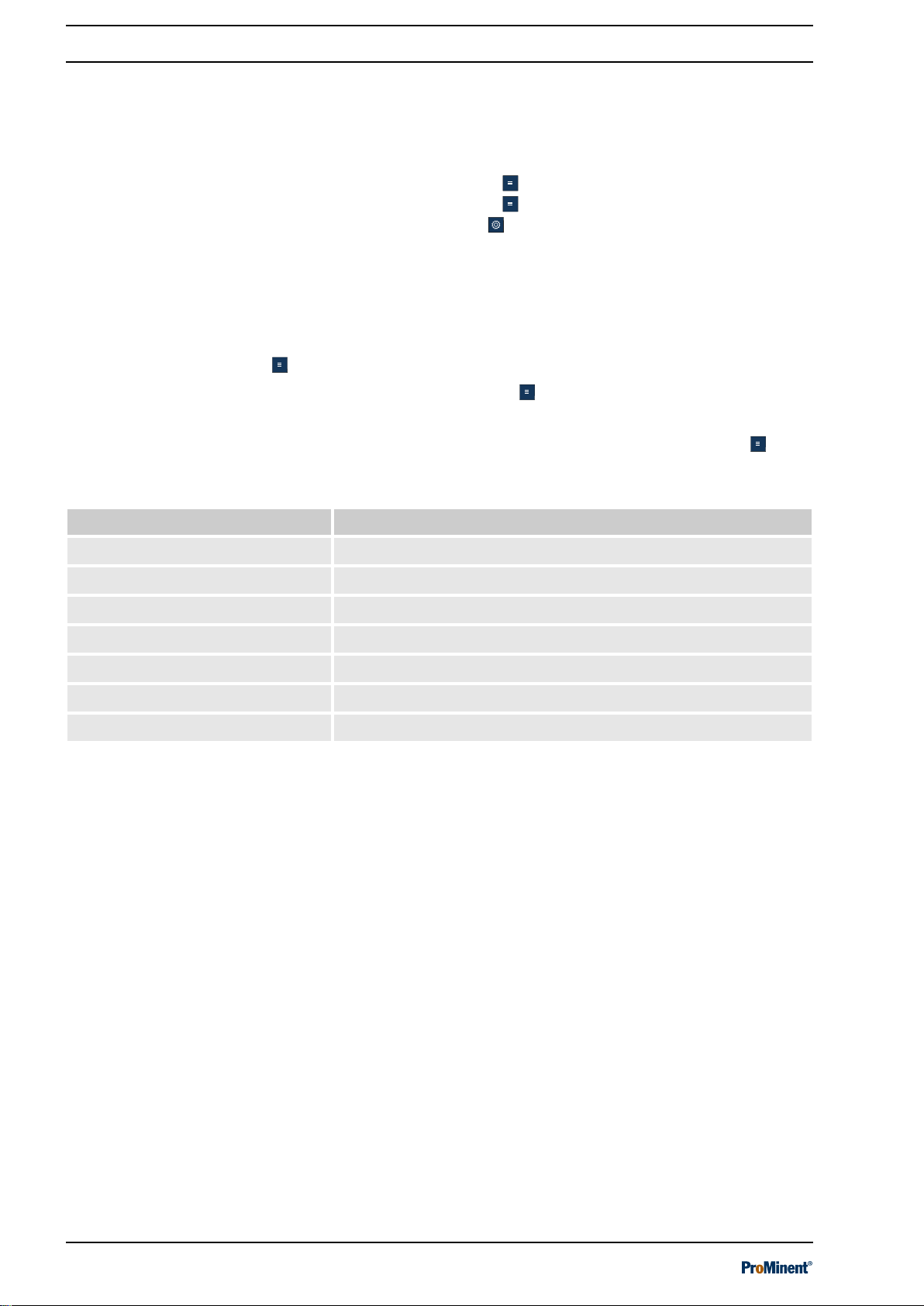

You can use various means of access to access the controller’s

setting menus:

n Hamburger menu with access to the system.

n Hamburger menu with access to the selected pool.

n Cog wheel icon .

n Swiping and tapping on the display.

For details of how to use all menus and interfaces, please consult

chapter

4.1 Hamburger menu with access to the system

In the Hamburger menu with access to the system, you can

undertake all settings, which affect the entire system and not cer‐

tain pools. More menu items only become visible once you select a

pool on the display, see

access to the selected pool’ on page 27

Ä Chapter 3 ‘Operating concept’ on page 14

.

Ä Chapter 4.2 ‘Hamburger menu with

.

Menu item Destination of the menu item

Login

Language settings

Safely remove the storage medium

System settings

Help topics

Info

Login.

Ä Chapter 9.2.1 ‘Login/logout’ on page 73

Ä Chapter 9.2.2 ‘Setting the language’ on page 73

Ä Chapter 9.2.8 ‘Screen recorder’ on page 77

Ä Chapter 9.2 ‘System settings’ on page 73

Ä Chapter 9.3 ‘Help topics’ on page 79

Ä Chapter 9.4 ‘Information’ on page 79

Ä Chapter 9.2.1 ‘Login/logout’ on page 73

26

Page 27

4.2 Hamburger menu with access to the selected pool

In the Hamburger menu with access to the selected pool, you

can undertake all settings, which affect a certain pool. The pool in

question is selected by tapping on the pool required before acti‐

vating the Hamburger menu .

Menu item Destination of the menu item

Access to the setting menus

Login

Language settings

Safely remove the storage

medium

System settings

Help topics

Info

Calibration

Screen recorder

Pool control

Single pool

Measured values pool

Process flowchart

Connectivity

Home

Login

Ä Chapter 9.2.1 ‘Login/logout’ on page 73

Ä Chapter 9.2.2 ‘Setting the language’ on page 73

Ä Chapter 9.2.8 ‘Screen recorder’ on page 77

Ä Chapter 9.2 ‘System settings’ on page 73

Ä Chapter 9.3 ‘Help topics’ on page 79

Ä Chapter 9.4 ‘Information’ on page 79

Ä Chapter 11 ‘Calibrating’ on page 84

Ä Chapter 9.6 ‘Screen recorder’ on page 79

Ä Chapter 9.7 ‘Pool control (attractions)’ on page 79

Ä Chapter 9.8 ‘Single pool > Measured values pool’ on page 79

Ä Chapter 9.9 ‘Measured values pool’ on page 80

Ä Chapter 9.10 ‘Process flowchart’ on page 80

Ä Chapter 9.11 ‘Connectivity’ on page 80

Ä Chapter 9.1 ‘Home’ on page 73

Ä Chapter 9.2.1 ‘Login/logout’ on page 73

27

Page 28

Access to the setting menus

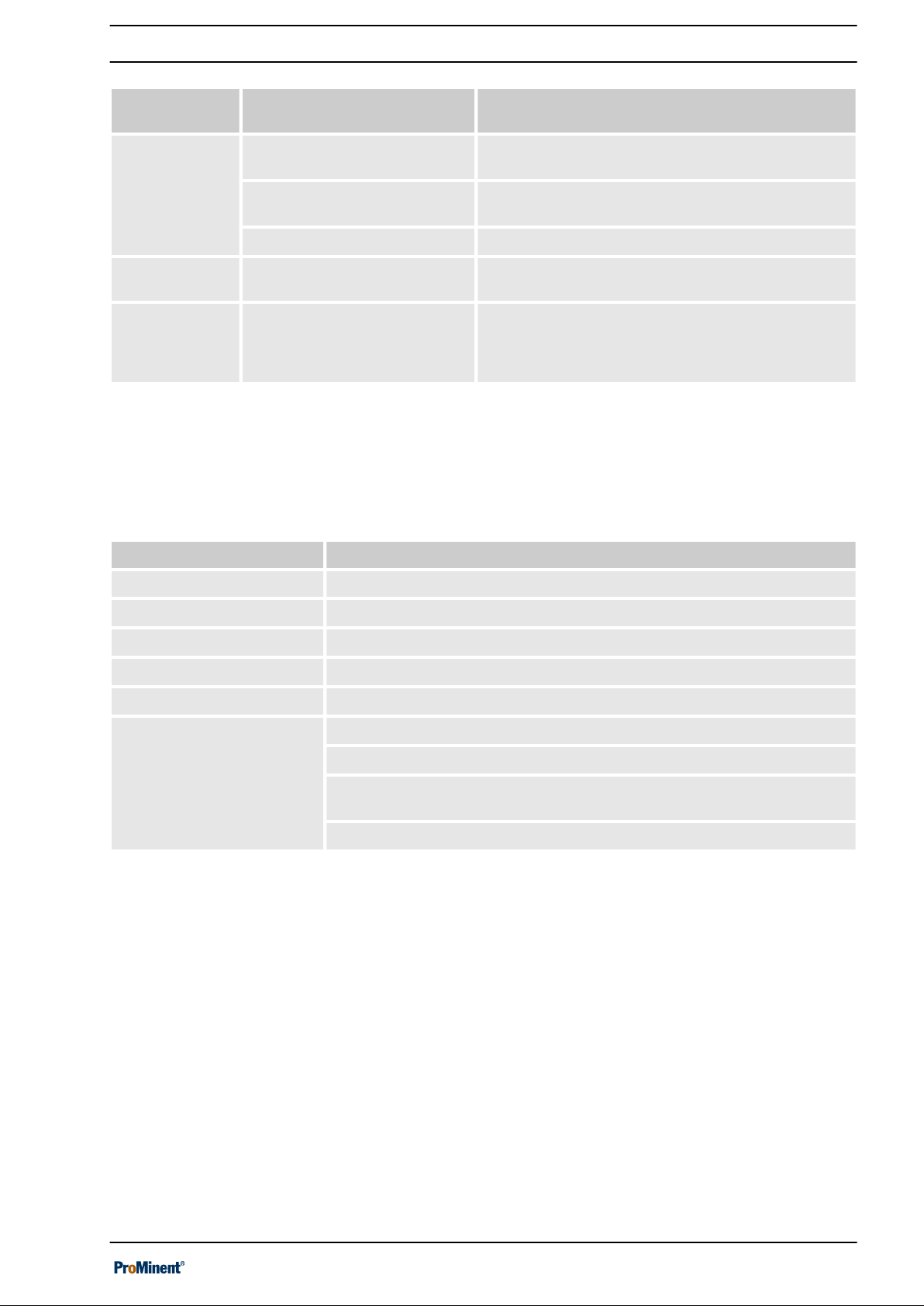

4.3 Cog wheel icon

The cog wheel icon takes you to the

Ä Chapter 9.2 ‘System settings’ on page 73

‘System settings’

Menu item Submenu item for which param‐

eters are to be set

Login free

Language Set the operating language

Display Display

Colour scheme

Screen lock

Maintenance interval

Date

Time

System Unit settings

Software update

‘System settings’

menu item. The

menu item contains the following submenus:

Destination of the menu item

Ä Chapter 9.2.1 ‘Login/logout’ on page 73

Ä Chapter 9.2.2 ‘Setting the language’ on page 73

Ä Chapter 9.2.3 ‘Display’ on page 73

Ä Chapter 9.2.3.4 ‘Colour scheme’ on page 74

Ä Chapter 9.2.3.5 ‘Screen lock’ on page 74

Ä Chapter 9.2.3.8 ‘Activating maintenance timer’

on page 74

Ä Chapter 9.2.3.1 ‘Date and time’ on page 73

Ä Chapter 9.2.3.2 ‘Setting units’ on page 74

Ä Chapter 9.2.4.1 ‘Unit settings’ on page 75

Ä Chapter 16 ‘Software update’ on page 102

Device restart

Network LAN

Wi-Fi

IP

DHCP client

DHCP server

Web services Intranet

Web server

FTP server

VNC server

User administra‐

tion

Recorder Recorder, settings

E-mail E-mail alarms, settings

Add/delete user

Change password

Ä Chapter 9.2.4 ‘System > System settings’

on page 74

Ä Chapter 7.3 ‘LAN interface’ on page 69

Ä Chapter 7.4 ‘Wi-Fi interface (optional)’

on page 70

Ä ‘DHCP client or DHCP server’ on page 75

Ä ‘DHCP client or DHCP server’ on page 75

Ä ‘DHCP client or DHCP server’ on page 75

Ä Chapter 9.2.6.1 ‘Web server settings’ on page 76

Ä Chapter 9.2.6.3 ‘Intranet’ on page 76

Ä Chapter 9.2.6 ‘Web services > NETWORK set‐

tings’ on page 76

Ä Chapter 9.2.6.2 ‘VNC server’ on page 76

Ä Chapter 9.2.7 ‘User administration’ on page 76

Ä Chapter 9.2.7 ‘User administration’ on page 76

Ä Chapter 9.2.8 ‘Screen recorder’ on page 77

Ä Chapter 9.2.9 ‘E-mail’ on page 77

Bar graphs Settings

Network CAN BUS details

Wizards Design wizard

Commissioning wizard

Calibration wizard

Ä Chapter 9.2.10 ‘Bar graphs’ on page 77

Ä Chapter 9.2.11 ‘Network CAN’ on page 78

Ä Chapter 9.2.12.1 ‘Design wizard’ on page 78

Ä Chapter 9.2.12.2 ‘Commissioning wizard’

on page 78

Ä Chapter 9.2.12.3 ‘Calibration wizard’ on page 78

28

Page 29

Access to the setting menus

Menu item Submenu item for which param‐

eters are to be set

Gateway KNX

OPC

IOT

Functional test Log books, network configura‐

tion

Default settings Complete system

User settings

Control parameter

4.4 Swiping and tapping on the display

Once you have selected a pool, you can select the following menu

items by swiping and tapping on the display.

Destination of the menu item

Ä Chapter 9.2.13 ‘Gateway (planned extension)’

on page 78

Ä Chapter 9.2.13 ‘Gateway (planned extension)’

on page 78

Ä Chapter 9.2.13.3 ‘IOT’ on page 78

Ä Chapter 9.2.14 ‘Functional test’ on page 78

Ä Chapter 9.2.15 ‘Default settings’ on page 78

Menu item Destination of the menu item

Measured values pool

Recorder

Connectivity

Pool control

Process flowchart

Pool settings

Ä Chapter 9.9 ‘Measured values pool’ on page 80

Ä Chapter 9.6 ‘Screen recorder’ on page 79

Ä Chapter 9.11 ‘Connectivity’ on page 80

Ä Chapter 9.7 ‘Pool control (attractions)’ on page 79

Ä Chapter 9.10 ‘Process flowchart’ on page 80

Ä Chapter 9.12.1 ‘ECO mode parameters’ on page 80

Ä Chapter 9.12.2 ‘Timer details operating mode’ on page 80

Ä Chapter 9.12.3 ‘Background image, pool geometry, pool name’

on page 80

Ä Chapter 9.12.4 ‘Superchlorination’ on page 81

29

Page 30

Storage and transport

5 Storage and transport

n User qualifications, storage and transport: trained personnel

Ä Chapter 1.5 ‘User qualification’ on page 10

CAUTION!

Danger of material damage

The device can be damaged by incorrect or

improper storage or transportation!

– The unit should only be stored or transported in

a well packaged state - preferably in its original

packaging.

– The packaged unit should also only be stored

or transported in accordance with the stipu‐

lated storage conditions.

– The packaged unit should be protected from

moisture and the ingress of chemicals.

Packaging material

If required, dispose of the packaging material in an

environmentally responsible way. All packaging

components carry the corresponding recycling

code .

Ambient conditions for storage and

transport

Storage period

Transport weight

Store and transport the system in its original packaging.

Also protect the packaged systems against damp, exposure to

chemicals and mechanical effects.

Storage temperature: - 20 ... 70 °C.

Air humidity: < 95% relative humidity, non-condensing.

Humidity: None. Avoid rain and condensation.

Other: No dust, no direct sunlight.

There is no limit to the storage period.

The transport weight depends on the device’s equipment and lies

between 4 ... 8 kg.

30

Page 31

6 Assembly and installation

n User qualification, mechanical installation: trained and qualified

personnel

n User qualification, electrical installation: electrical technician

Ä Chapter 1.5 ‘User qualification’ on page 10

Assembly and installation

Ä Chapter 1.5 ‘User qualification’ on page 10

NOTICE!

Installation site and ambient conditions

– The controller meets the requirements for IP 67

(housing, closed) or IP 20 (housing, open) and

leak-tightness (based on NEMA 4X). These

standards are only met if all seals and

threaded connectors are correctly fitted.

– Only carry out the (electrical) installation after

(mechanical) installation.

– Ensure that there is unimpeded access for

operation.

– Ensure safe and low-vibration fixing.

– No direct sunlight.

– Permissible ambient temperature of the con‐

troller at the installation location: - 5 ... 50 °C at

max. 95% relative air humidity (non-con‐

densing).

– Requires a low voltage cable with a tempera‐

ture resistance of ≧ 70 °C.

– Take into consideration the permissible

ambient temperature of the connected sensors

and other components.

– The controller is only suitable for operation in

closed rooms. If operating outdoors, use a suit‐

able protective enclosure to protect the con‐

troller from the environment.

Mounting position

–

As standard, a wall-mounted controller is used.

–

Always install the controller so that the cable

entries point downwards.

–

Leave sufficient free space for the cables.

6.1 Scope of delivery

Tab. 3: The following components are included as standard:

Description Quantity

Measuring/control system DULCOMARIN® 3 including wall bracket.

Assembly material, complete, 2P universal (set). 2

Threaded cable connector set, M20 DCPa. 1

Data DVD. 1

Operating instructions. 1

Access card with PUK. 1

1

31

Page 32

424

415

137

127

76

276

276

A2566

40317570

Assembly and installation

6.2 Installation, mechanical

n User qualification, mechanical installation: trained and qualified

personnel

Ä Chapter 1.5 ‘User qualification’ on page 10

Fig. 19: Dimensional drawing, all dimensions in millimetres.

Install the device so that it is at eye level and is easily accessible to

operating personnel. Leave enough free space on the left of the

device for it to be folded open.

6.2.1 Wall mounting

Mounting materials (contained in the scope of delivery)

n 1 x wall bracket

n 4 x PT screws 5 x 35 mm

n 4 x washers 5.3

n 4 x rawl plug Ø 8 mm, plastic

32

Page 33

A0490

Wall mounting

Assembly and installation

Take the wall bracket out of the housing

Fig. 20: Removing the wall bracket

1. Pull the two snap hooks (1) outwards

The wall brackets snaps slightly downwards.

ð

2. Push the wall bracket downwards (2) from the housing and

fold (3) it out

3. Use the wall bracket as a drilling template to mark the posi‐

tions of four drill holes

4. Drill the holes: Ø 8 mm, d = 50 mm

33

Page 34

A0491

A0492

1

2

3

Assembly and installation

Fig. 21: Fitting the wall bracket

5. Screw the wall bracket into position using the washers, see

Fig. 21

Fig. 22: Fitting the wall bracket

6. Hook the bottom of the housing (1) into the wall bracket

7. Lightly press the housing at the top (2) against the wall

bracket

8. Then check that the housing is hooked in at the top and

press down (3) until it audibly engages

34

Page 35

6.3 Electrical installation

Assembly and installation

n User qualification, electrical installation: electrical technician

Ä Chapter 1.5 ‘User qualification’ on page 10

WARNING!

Mains connection via mains plug is not permis‐

sible.

The device must not be connected to the mains

using a mains plug. If the socket is incorrectly

wired, there is a risk of the electric safety not being

met due to faulty potentials.

The device may only be connected via a terminal

box.

Lightning and surge protection

We recommend fitting lightning and surge protec‐

tion in the building. The lightning and surge protec‐

tion should consist of protection from high, medium

and low voltage power surges. The operator is

responsible for ensuring that the lightning and

surge protection required is implemented correctly.

Procedure for fitting the threaded

cable connector in a watertight

manner

The cabling system requires a low voltage cable with a tempera‐

ture resistance of ≧ 70 °C.

Only use the threaded cable connector set supplied with installa‐

tion to guarantee the degree of protection and UL® requirement.

The device should have no unsealed openings after installation.

1. Manually tighten the threaded cable connector’s union

nuts. ”Manually tighten” means ➨ tighten as far as possible

without tools.

Ensure that the rubber insert surrounds the cable or closure

cap in a snug manner. There must not be any gaps.

2. Then use an appropriate tool to tighten the union nuts by 90°.

35

Page 36

A2580

CAN

USB

I.

(4x33=)132

(4x33=)132

33

33

33

82

27,5

33,5

21

II.

Assembly and installation

6.3.1 Dimensioning/ arrangement of threaded connectors

Fig. 23: Dimensioning/ arrangement of threaded connectors

I. Bleeding (must not be removed or sealed)

II. Blanking plug

Remove the blind plugs on the device and insert the appro‐

priate threaded cable connectors. Use the appropriate

sealing inserts depending on the cable used. The appropriate

threaded cable connectors form part of the device’s scope of

delivery. The individual parts are specified in detail here

Ä Tab. 4 ‘Individual parts of threaded cable connector set

M20 DCPa. Part number: 1092176’ on page 36

Tab. 4: Individual parts of threaded cable connector set M20 DCPa. Part number: 1092176

Name Quantity in parts Part number

Threaded cable connectors, M20x1.5, (5-13) 9005 V0 10 1092175

Sealing ring, M20/4x, Ø5 5 1045172

Sealing ring M20/2x, Ø4 5 1045173

Sealing ring M20/2x, Ø6 5 1045194

Sealing stopper, Ø4 mm, PA, red 4 1092174

Sealing stopper, Ø5 mm, PA, red 4 1092122

Sealing stopper, Ø6 mm, PA, red 4 1092123

.

36

Page 37

6.3.2 Connection labels, base module

Tab. 5: DULCOMARIN® 3, connection labels, 100 ... 230 V AC

Description Terminal iden‐

tifier

Terminals Pin Signal Function

Assembly and installation

Power supply

100 ... 230 V AC

External supply

100 ... 230 V AC

External supply

100 ... 230 V AC

External supply

100 ... 230 V AC

Output relay 6

feeding NO

[Power IN]

[Power OUT]

[Powered

relays Rel 6]

XP1 12 (L) Phase AC voltage supply to

8 (N) Neutral conductor

4 (PE) Protective earth

11 (L) Phase Supply voltage to

7 (N) Neutral conductor

3 (PE) Protective earth

10 (L) Phase Supply voltage to

6 (N) Neutral conductor

2 (PE) Protective earth

9 (L) Phase Supply voltage to

5 (N) Neutral conductor

1 (PE) Protective earth

XR5 12 (L*)

switched

conductor

conductor

conductor

conductor

Phase switched Output relay 100 ...

unit

output

output

output

230 V AC

Output relay 6

feeding NC

Output relay 5

feeding NO

Output relay 5

feeding NC

Output relay 4

feeding NO

[Powered

relays Rel 5]

[Powered

relays Rel 4]

8 (N) Neutral conductor

4 (PE) Protective earth

11 (L*)

switched

7 (N) Neutral conductor

3 (PE) Protective earth

10 (L*)

switched

6 (N) Neutral conductor

2 (PE) Protective earth

9 (L*)

switched

5 (N) Neutral conductor

1 (PE) Protective earth

XR4 12 (L*)

switched

conductor

Phase switched

conductor

Phase switched Output relay 100 ...

230 V AC

conductor

Phase switched

conductor

Phase switched Output relay 100 ...

230 V AC

11 (L*)

switched

8 (N) Neutral conductor

37

Phase switched

Page 38

Assembly and installation

Description Terminal iden‐

tifier

Output relay 4

feeding NC

Potential-free

output relay 3

[Dry relays

Rel 3]

Terminals Pin Signal Function

7 (N) Neutral conductor

4 (PE) Protective earth

conductor

3 (PE) Protective earth

conductor

10 (L*)

Phase switched

switched

9 (L*)

Phase switched

switched

6 (N) Neutral conductor

5 (N) Neutral conductor

2 (PE) Protective earth

conductor

1 (PE) Protective earth

conductor

XR3 1 (COM) Root Potential-free output

2 (NO) Normally Open

relay 100 ... 230 V AC

or 24 V DC*

3 (NC) Normally Closed

Potential-free

output relay 2

[Dry relays

Rel 2]

XR2 1 (COM) Root Potential-free output

2 (NO) Normally Open

relay 100 ... 230 V AC

or 24 V DC*

3 (NC) Normally Closed

Potential-free

output relay 1

[Dry relays

Rel 1]

XR1 1 (COM) Root Potential-free output

2 (NO) Normally Open

relay 100 ... 230 V AC

or 24 V DC*

3 (NC) Normally Closed

* If XR1 to XR 3 is being supplied with 24 V, then the leads of the respective cable must also be fixed with

cable connectors (double insulation).

Control output 4

[Digital out‐

puts]

XA4 1 (A) Contact output A Digital output, control,

2 (B) Contact output B

OptoMos relay

Control output 3 XA3 1 (A) Contact output A Digital output, control,

2 (B) Contact output B

OptoMos relay

Control output 2 XA2 1 (A) Contact output A Digital output, control,

2 (B) Contact output B

OptoMos relay

Control output 1 XA1 1 (A) Contact output A Digital output, control,

2 (B) Contact output B

OptoMos relay

Digital input 8

[Digital inputs]

XK8 1 (-) Reference potential External contact input

2 (+) Contact input

with 15 V/10 mA

power supply

3 (+V) +15 V/10 mA

power supply

Digital input 7 XK7 1 (-) Reference potential External contact input

2 (+) Contact input

38

with 15 V/10 mA

power supply

Page 39

Assembly and installation

Description Terminal iden‐

Terminals Pin Signal Function

tifier

3 (+V) +15 V/10 mA

power supply

Digital input 6 XK6 1 (-) Reference potential External contact input

2 (+) Contact input

with 15 V/10 mA

power supply

3 (+V) +15 V/10 mA

power supply

Digital input 5 XK5 1 (-) Reference potential External contact input

2 (+) Contact input

with 15 V/10 mA

power supply

3 (+V) +15 V/10 mA

power supply

Digital input 4 XK4 1 (-) Reference potential External contact input

2 (+) Contact input

with 15 V/10 mA

power supply

3 (+V) +15 V/10 mA

power supply

Digital input 3 XK3 1 (-) Reference potential External contact input

2 (+) Contact input

with 15 V/10 mA

power supply

3 (+V) +15 V/10 mA

power supply

Digital input 2 XK2 1 (-) Reference potential External contact input

2 (+) Contact input

with 15 V/10 mA

power supply

3 (+V) +15 V/10 mA

power supply

Digital input 1 XK1 1 (-) Reference potential External contact input

2 (+) Contact input

with 15 V/10 mA

power supply

3 (+V) +15 V/10 mA

power supply

CAN bus 1

[CAN]

XC1 1 (CAN‐

SCHIRM)

2 (CANV+) CAN supply

3

(CANGND)

CAN shield with

connection to PE

voltage +20 V/400

mA

CAN reference

potential

CAN 1 local CANBUS with external

power supply 20 V /

0.4 A (powerrestricted) with CAN

shield to PE connector

4 (CANH) CAN high

5 (CANL) CAN low

XC3 1 (CAN‐

SCHIRM)

2 (CANV+) CAN supply

3

(CANGND)

CAN shield CAN 1 local CAN-

BUS with external

power supply 20 V /

voltage +20 V/400

mA

CAN reference

0.4 A (powerrestricted) without

CAN shield to PE con‐

nector

potential

4 (CANH) CAN high

39

Page 40

Assembly and installation

Description Terminal iden‐

Terminals Pin Signal Function

tifier

5 (CANL) CAN low

Modules 1 Module slot 1 for 2-

channel IO modules

Modules 2 Module slot 2 for 2-

channel IO modules

Modules 3 Module slot 3 for 2-

channel IO modules

Modules 4 Module slot 4 for 2-

channel IO modules

40

Page 41

Tab. 6: DULCOMARIN® 3, connector labels, 24 V DC

Description Terminal

Terminals Pin Signal Function

identifier

Assembly and installation

24 VDC supply

External power

supply 24 VDC

External power

supply 24 VDC

External power

supply 24 VDC

Output relay 6

feeding NO

[Power IN]

[Power

OUT]

[Powered

relays Rel 6]

XP1 12 (+) Phase DC supply to unit

8 (-) Neutral conductor

24 VDC, - 15% ...

+20 %

4 (PE) Protective earth

conductor

11 (+) Phase Supply voltage for

7 (-) Neutral conductor

output 24 VDC,

-15% ... +20 %

3 (PE) Protective earth

conductor

10 (+) Phase Supply voltage for

6 (-) Neutral conductor

output 24 VDC,

-15% ... +20 %

2 (PE) Protective earth

conductor

9 (+) Phase Supply voltage for

5 (-) Neutral conductor

output 24 VDC,

-15% ... +20 %

1 (PE) Protective earth

conductor

XR5 12 (+)

switched

8 (N) Neutral conductor

Phase switched Output relay 24

VDC, -15% ... +20

%

Output relay 6

feeding NC

Output relay 5

feeding NO

Output relay 5

feeding NC

Output relay 4

feeding NO

[Powered

relays Rel 5]

[Powered

relays Rel 4]

4 (PE) Protective earth

11 (+)

switched

7 (-) Neutral conductor

3 (PE) Protective earth

10 (+)

switched

6 (-) Neutral conductor

2 (PE) Protective earth

9 (+) switched Phase switched

5 (-) Neutral conductor

1 (PE) Protective earth

XR4 12 (+)

switched

11 (+)

switched

conductor

Phase switched

conductor

Phase switched Output relay 24

VDC, -15% ... +20

%

conductor

conductor

Phase switched Output relay 24

VDC, -15% ... +20

Phase switched

%

8 (-) Neutral conductor

7 (-) Neutral conductor

41

Page 42

Assembly and installation

Description Terminal

identifier

Output relay 4

feeding NC

Potential-free

output relay 3

[Dry relays

Rel 3]

Terminals Pin Signal Function

4 (PE) Protective earth

conductor

3 (PE) Protective earth

conductor

10 (+)

Phase switched

switched

9 (+) switched Phase switched

6 (-) Neutral conductor

5 (-) Neutral conductor

2 (PE) Protective earth

conductor

1 (PE) Protective earth

conductor

XR3 1 (COM) Root Potential-free

2 (NO) Normally Open

3 (NC) Normally Closed

output relay 100 ...

230 V AC or 24 V

DC

Potential-free

output relay 2

Potential-free

output relay 1

Control output 4

[Dry relays

Rel 2]

[Dry relays

Rel 1]

[Digital out‐

puts]

XR2 1 (COM) Root Potential-free

2 (NO) Normally Open

3 (NC) Normally Closed

output relay 100 ...

230 V AC or 24 V

DC

XR1 1 (COM) Root Potential-free

2 (NO) Normally Open

3 (NC) Normally Closed

output relay 100 ...

230V AC or 24 V

DC

XA4 1 (A) Contact output A Digital output, con‐

2 (B) Contact output B

trol, OptoMos

relay

Control output 3 XA3 1 (A) Contact output A Digital output, con‐

2 (B) Contact output B

trol, OptoMos

relay

Control output 2 XA2 1 (A) Contact output A Digital output, con‐

2 (B) Contact output B

trol, OptoMos

relay

Control output 1 XA1 1 (A) Contact output A Digital output, con‐

trol, OptoMos

relay

input with 15V/

10mA power

supply

Digital input 8

[Digital

inputs]

2 (B) Contact output B

XK8 1 (-) Reference potential External contact

2 (+) Contact input

3 (+V) +15 V/10 mA power

supply

Digital input 7 XK7 1 (-) Reference potential External contact

2 (+) Contact input

3 (+V) +15 V/10 mA power

input with 15V/

10mA power

supply

supply

Digital input 6 XK6 1 (-) Reference potential External contact

input with 15V/

10mA power

42

Page 43

Assembly and installation

Description Terminal

Terminals Pin Signal Function

identifier

2 (+)

Contact input

supply

3 (+V) 15 V/10 mA power

supply

Digital input 5 XK5 1 (-) Reference potential External contact

2 (+) Contact input

3 (+V) +15 V/10 mA power

input with 15V/

10mA power

supply

supply

Digital input 4 XK4 1 (-) Reference potential External contact

2 (+) Contact input

3 (+V) +15 V/10 mA power

input with 15V/

10mA power

supply

supply

Digital input 3 XK3 1 (-) Reference potential External contact

2 (+) Contact input

input with 15 V/10

mA power supply

3 (+V) +15 V/10 mA power

supply

Digital input 2 XK2 1 (-) Reference potential External contact

2 (+) Contact input

input with 15 V/10

mA power supply

3 (+V) +15V/10mA power

supply

Digital input 1 XK1 1 (-) Reference potential External contact

2 (+) Contact input

input with 15 V/10

mA power supply

3 (+V) +15V/10mA power

supply

CAN bus 1

[CAN]

XC1 1 (CAN‐

SCHIRM)

2 (CANV+) CAN supply voltage

3 (CANGND) CAN reference

CAN shield with

connection to PE

+20 V/400 mA

potential

CAN 1 local CANBUS with external

power supply 20

V / 0.4 A (powerrestricted) with

CAN shield to PE

connector

4 (CANH) CAN high

5 (CANL) CAN low

XC3 1 (CAN‐

SCHIRM)

2 (CANV+) CAN supply voltage

3 (CANGND) CAN reference

CAN shield CAN 1 local CAN-

BUS with external

power supply 20

+20 V/400 mA

V / 0.4 A (powerrestricted) without

CAN shield to PE

potential

connector

4 (CANH) CAN high

5 (CANL) CAN low

Modules 1 Module slot 1 for

2-channel IO mod‐

ules

43

Page 44

Assembly and installation

Description Terminal

Terminals Pin Signal Function

identifier

Modules 2 Module slot 2 for

2-channel IO mod‐

ules

Modules 3 Module slot 3 for

2-channel IO mod‐

ules

Modules 4 Module slot 4 for

2-channel IO mod‐

ules

Tab. 7: DULCOMARIN® 3, upper part of housing

Description Terminal identi‐

Terminals Pin Signal Function

fier

Modbus RTU

[RS485 IN]

XB1 1 (A) Cable A Modbus-RTU

2 (B) Cable B

input

3 (GND) RS485 reference

potential

4 (shield) RS485 shield

[RS485 OUT]

XB2 1 (A) Cable A Modbus RTU

2 (B) Cable B

output

3 (GND) RS485 reference

potential

4 (shield) RS485 shield

LAN Customer LAN

interface

cNet Internal ProMi‐

nent system

interface for dis‐

tributed system

USB USB interface

for customer’s

USB stick

SD card ProMinent

internal SD card

reader

44

Page 45

Assembly and installation

Tab. 8: Connection label on the base module

Connection label Function

Modules 1 Module slot 1 for 2-channel IO modules

Modules 2 Module slot 2 for 2-channel IO modules

Modules 3 Module slot 3 for 2-channel IO modules

Modules 4 Module slot 4 for 2-channel IO modules

XC1 Connector of CAN bus with CAN shield on PE

XC3 Connector of CAN bus without CAN shield on PE

XK1 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XK2 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XK3 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XK4 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XK5 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XK6 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XK7 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XK8 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XA1 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XA2 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XA3 Digital input for potential-free signals (e.g. contact water meter, status etc.)

XA4 Digital input for potential-free signals (e.g. contact water meter, status etc.)

Rel 1 XR1 Alternating relay, unpowered

Rel 2 XR2 Alternating relay, unpowered

Rel 3 XR3 Alternating relay, unpowered

Rel 4 XR4 Alternating relay, unpowered, fused, NO with RC circuit

Rel 5 XR5 Alternating relay, unpowered, fused, NO with RC circuit

Rel 6 XR5 Alternating relay, unpowered, fused, NO and NC with RC circuit

Power IN Feed 100 … 240 V AC, L, N, PE

Power OUT Outlet 100 …240 V AC, L, N, PE, max.10 A for feed Rel1, Rel2, Rel3

Tab. 9: Connection label on the upper part of the housing

Connection label Function

USB USB interface for customer’s USB stick.

cNet Internal ProMinent system interface for distributed systems.

LAN Customer LAN interface.

XB1 Modbus (RS485) interface, input.

XB2 Modbus (RS485) interface, output.

45

Page 46

A2567

4

3

2

1

5

Assembly and installation

6.3.3 Terminal layout

Fig. 24: Terminal layout

1 Base module

2 Internal connection to the HMI

3 Module plug-in contacts

4 Fan connector

5 Position of fuses under the cover

46

Page 47

6.3.4 Terminal diagram

A2591

To preserve the relay’s contacts, we recommend using a protective

RC circuit (e.g. part number 710802). This should be connected in

parallel to the load, also see

tive loads’ on page 55

6.3.4.1 Interfaces in the lower part of the housing - 1

Assembly and installation

Ä Chapter 6.3.6 ‘Switching of induc‐

.

Fig. 25: Interfaces in the lower part of the housing - 1

47

Page 48

A2592

Assembly and installation

6.3.4.2 Interfaces in the lower part of the housing - 2

Fig. 26: Interfaces in the lower part of the housing - 2

48

Page 49

6.3.4.3 Interfaces in the top part of the housing

A2594

Assembly and installation

Fig. 27: Interfaces in the top part of the housing

49

Page 50

SN-6 Anschlussbuchse

Belegungsvarianten

pH/Redox

Temperatur-Sensor

Potenzialaustausch

Temperatur-Sensor

Normsignal-Eingang

Stromquelle

2-Leiter-Normsignal-Eingang

Sensor

3-Leiter-Normsignal-Eingang

3-Leiter-Sensor

Drahtbrücke

A2384

Assembly and installation

6.3.4.4 Module interfaces

6.3.4.4.1 Module: mV temperature/mA input. Part number 734355

Fig. 28: Module: mV temperature/mA input. Part number 734355

A module for the direct measurement of a pH value or redox poten‐

tial via a coaxial cable and a sensor signal from an mA 2-wire

sensor, e.g. for chlorine, bromine or peracetic acid (PES).

mA interface:

n for use with ProMinent 2-wire transmitters and sensors with 2-

wire mA interface.

n Processing of active mA signals, type of connector: current

source.

n Driver voltage: 24 V DC.

n Max. current 50 mA.

n Input switches off at 70 mA.

n Protection against reverse polarity and overvoltage up to max.

30 V DC.

n Maximum cable length: 30 m, limited by the EMC specification.

2-wire control line for the connection of mA sensors to terminals

XE5.2 and XE5.3

Control line LiYY, 2 x 0.25 mm2, Ø 4 mm, part number 725122

mV interface:

n For the direct connection of pH and ORP sensors

n Maximum cable length: 10 m

50

Page 51

A2413

40215017

mV-Eingang

Belegungsvarianten

Temperatur

Temperatur

Potenzialausgleich

SN6-Anschlussbuchse

Optional:

Drahtbrücke

Assembly and installation

Tab. 10: Sensor connection cable, coaxial, for terminal XE1/XE2

Description Part number

Cable combination, coaxial, Ø 5 mm 0.8 m - SN6 – pre-assembled. 1024105

Cable combination, coaxial, Ø 5 mm 2 m - SN6 – pre-assembled. 1024106

Cable combination, coaxial, Ø 5 mm 5 m - SN6 – pre-assembled. 1024107

6.3.4.4.2 Module: 2x mV inputs/temperature input. Part number 734131

Fig. 29: Module: 2x mV inputs/temperature input. Part number 734131

Tab. 11: Sensor connection cable, coaxial, for terminal XE1/XE2 and X5/X6

Description Part number

Cable combination, coaxial, Ø 5 mm 0.8 m - SN6 – pre-assembled. 1024105

Cable combination, coaxial, Ø 5 mm 2 m - SN6 – pre-assembled. 1024106

Cable combination, coaxial, Ø 5 mm 5 m - SN6 – pre-assembled. 1024107

A module for the direct measurement of two pH values or two

redox potentials or pH value and redox potential via a coaxial

cable.

n For the direct connection of pH and ORP sensors

n Maximum cable length: 10 m

51

Page 52

A2385

Belegungsvarianten

2x Konduktive Leifähigkeit/

Temperatur

Temperatur

Konduktive Leifähigkeit

Temperatur

Konduktive Leifähigkeit

Kanal 1

Kanal 2

Assembly and installation

6.3.4.4.3 Module: 2x conductive conductivity/temperature sensors. Part number 734223

Fig. 30: Module: 2x conductive conductivity/temperature sensors. Part number 734223

A module for the direct measurement of the electrolytic conductivity

based on the conductive principle. For the direct connection of 2

electrode conductivity sensors.

n Maximum cable length: 30 m, screened.

52

Page 53

Assembly and installation

Electrical data

Parameter Value

Cell constant: 0.005 1/cm ... 15 1/cm

Measuring ranges dependent on the sensor type:

Specific conductivity: 0.001 µS/cm ... 200 mS/cm

Specific electrical resistance: 5 Ωcm ... 1000 MΩcm

TOS (total dissolved solids): 0 ... 9999 ppm (mg/l)

SAL (salinity): 0.0 ... 70.0 ‰ (g/kg)

Precision:

Specific conductivity: 1 µS/cm ... 20mS/cm: better 1% of the measured value

±1 µS/cm/±1 digit

Specific electrical resistance: 50 Ωcm ... 10 MΩcm: better 1% of the measured value ±1 digit