Page 1

Ultrasonic Flow Meter

DulcoFlow® DFMa

Operating instructions

Part no. 986007 BA MAZ 014 01/11 EN

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Technical changes reserved.

Page 2

986007, 1, en_GB

© 2010

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5-11

69123 Heidelberg

Germany

Telephone: +49 6221 842-0

Fax: +49 6221 842-617

email: info@prominent.com

Internet: www.prominent.com)

2

Page 3

Supplementary information

Read the following supplementary information

in its entirety! Should you already know this

information, you have an even greater need of

the Operating Instructions.

The following are highlighted separately in the

document:

n Enumerated lists

Instructions

ð

Outcome of the instructions

- see (reference)

Information

This provides important information

relating to the correct operation of the

system or is intended to make your work

easier.

Safety information

Safety information is identified by pictograms see "Safety Chapter".

General non-discriminatory approach

In order to make it easier to read, this docu‐

ment uses the male form in grammatical struc‐

tures but with an implied neutral sense. It is

aimed equally at both men and women. We

kindly ask female readers for their under‐

standing in this simplification of the text.

Supplemental instructions

3

Page 4

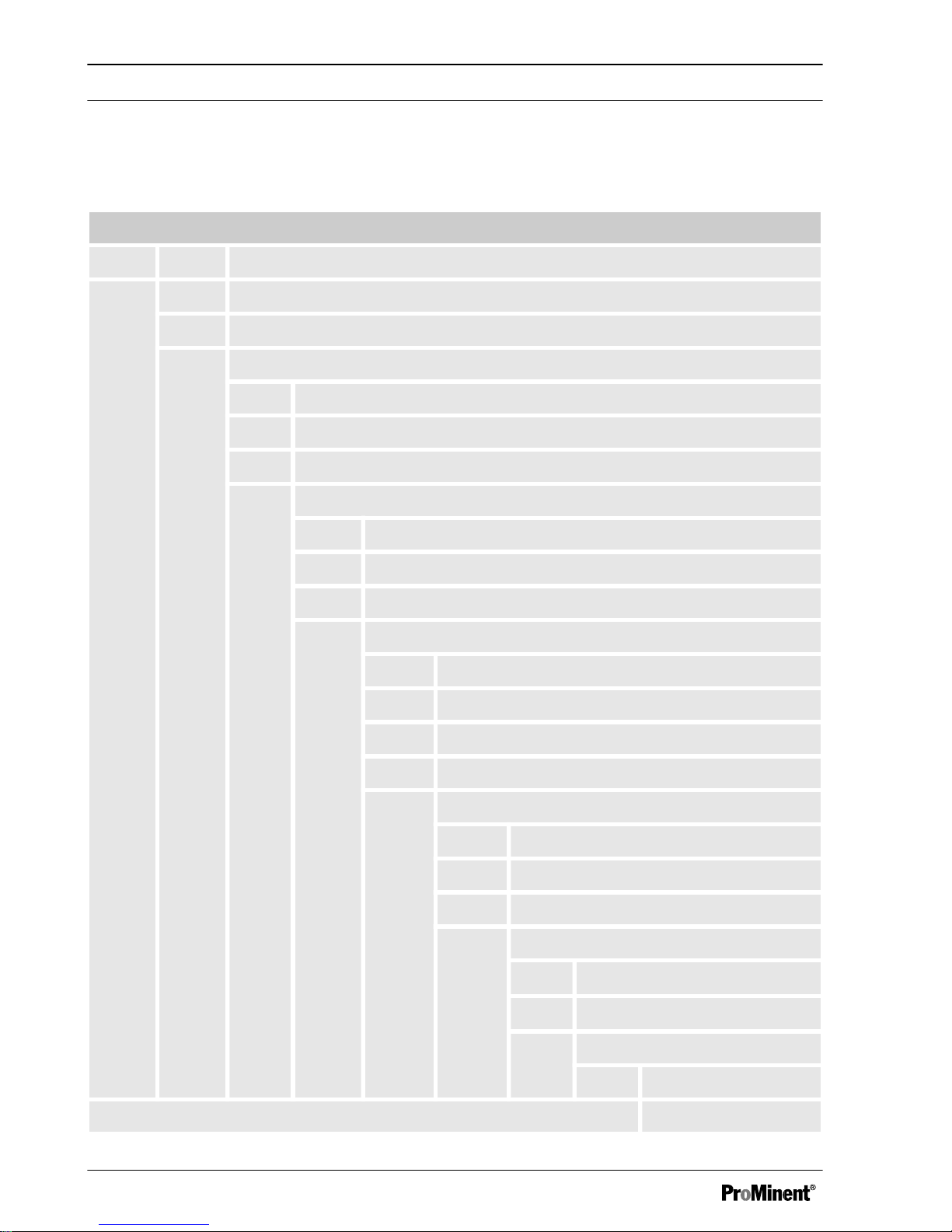

Table of contents

1 Identity code............................................................................................................................ 6

2

About this product................................................................................................................... 8

3 Safety chapter......................................................................................................................... 9

4 Storage and transport........................................................................................................... 12

5 Device overview.................................................................................................................... 13

6 Functional description........................................................................................................... 14

7 Assembly and installation...................................................................................................... 15

7.1 Installation.................................................................................................................... 15

7.2 Hydraulic Installation.................................................................................................... 15

7.3 Electrical Installation..................................................................................................... 17

8 Settings ................................................................................................................................ 20

8.1 Operating unit............................................................................................................... 20

8.1.1 LCD screen............................................................................................................... 20

8.1.2 LEDs.......................................................................................................................... 20

8.1.3 Control keys.............................................................................................................. 20

8.2 Checking adjustable variables...................................................................................... 23

8.3 Operating menu overview............................................................................................ 24

8.4 Changing to adjustment mode..................................................................................... 25

8.4.1 "Mode" main menu.................................................................................................... 25

8.4.2 "Set-up" main menu.................................................................................................. 25

8.4.3 "Calibration" main menu............................................................................................ 29

8.4.4 "Zero set" main menu................................................................................................ 40

8.4.5 "Info" main menu....................................................................................................... 41

8.4.6 "Language" main menu............................................................................................. 41

9 Start up.................................................................................................................................. 42

10 Maintenance, repair and disposal......................................................................................... 44

10.1 Maintenance............................................................................................................... 45

10.2

Repairs....................................................................................................................... 45

10.3 Disposal...................................................................................................................... 45

11 Troubleshooting.................................................................................................................... 46

11.1

DulcoFlow® error........................................................................................................ 47

11.2 Pump error................................................................................................................. 48

11.3 All Other Faults........................................................................................................... 49

Table of contents

4

Page 5

12 Technical data....................................................................................................................... 50

13 Dimensions sheet.................................................................................................................. 53

14 EC Declaration of Conformity................................................................................................ 54

15

Decontamination declaration................................................................................................. 55

16 Index..................................................................................................................................... 56

Table of contents

5

Page 6

1 Identity code

Product range DulcoFlow® flow meter

DFMa Type For pump product ranges

05 Beta, gamma/ L: 1000 - 0413/0713; delta: 1608 - 1612

08 Beta, gamma/ L: 0220/0420 - 0232; delta: 1020 - 0280

Seal material

E EPDM

T PTFE

V FPM

Hydraulic connection

1 6/4 mm

2 8/5 mm

3 12/9 mm

Electrical connection

A 2 m European

B 2 m Swiss

C 2 m Australian

D 2 m USA

Signal output

0 No output

1 Current output

2 Counter output

Version

0

With ProMinent®

Logo

2

Without ProMinent® Logo

Accessories

0 No accessories

Identity code

6

Page 7

Identity code

7

Page 8

2 About this product

The flow meter DulcoFlow® is intended for use

in measuring pulsing volume flows in the range

from 0.1 to 80 l/h. All parts coming into contact

with flow media are made from PVDF. This

ensures that aggressive media can also be

measured without problem. The device is

installed approximately 30 cm after the pump in

the metering line. Interfering influences, such

as air bubbles, are identified and forwarded to

the analysis unit as an error message. With the

delta, it can only be used with the fast metering

stroke version.

The DulcoFlow® flow meter can not only be

used for recording and measurement of volume

flows, but also for monitoring individual

metering strokes. In this case the pump is cali‐

brated to the lifting volume set at the pump. A

lower and upper limit can be entered, which if

exceeded or undershot, results in no feedback

to the pump. This creates an error message.

The connection to the pump takes place via the

input for the "Flow Control" dosing monitor

The device is designed for wall mounting.

About this product

8

Page 9

3 Safety chapter

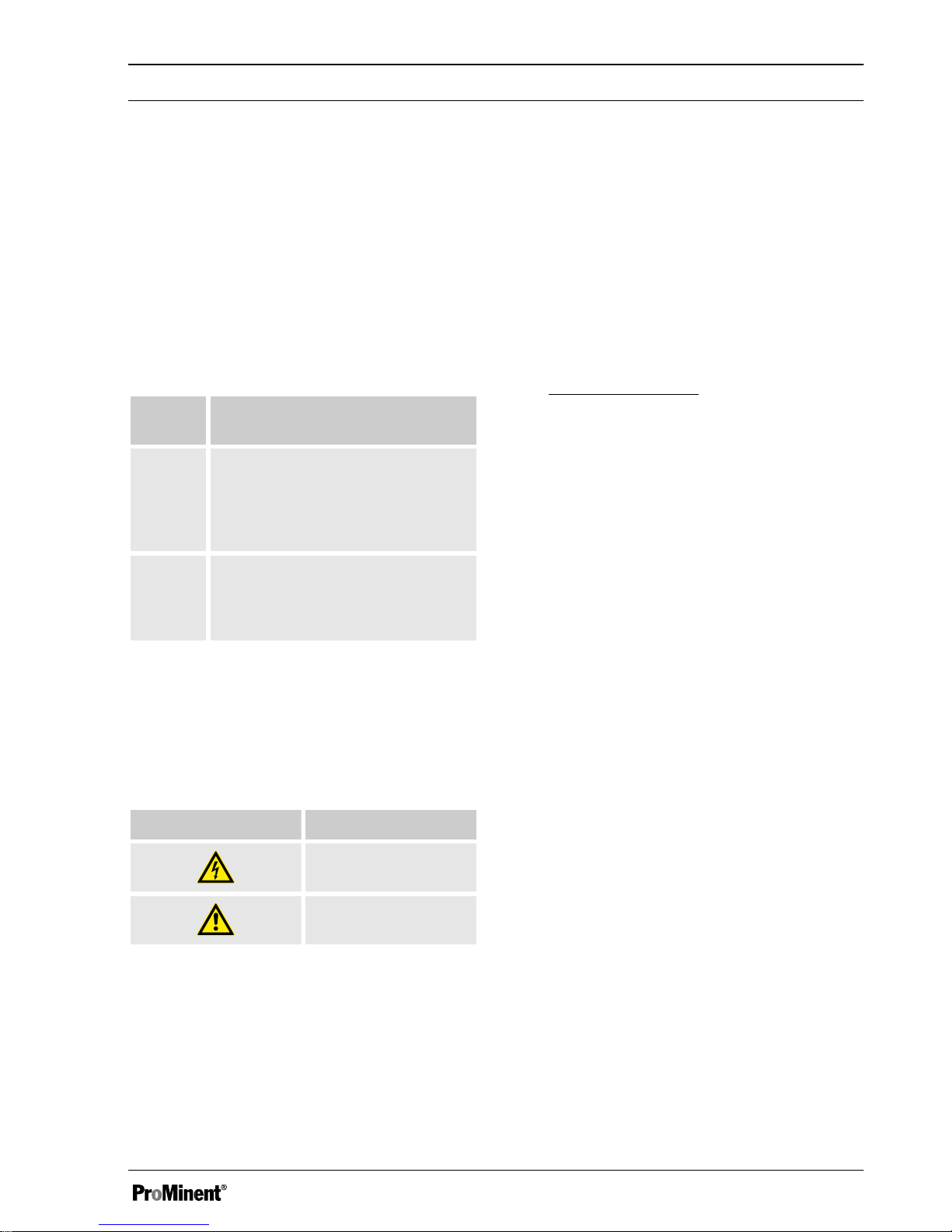

Explanation of the safety information

The following signal words are used in these

operating instructions to identify different

severities of a hazard:

Signal

word

Meaning

WARNINGDenotes a possibly hazardous sit‐

uation. If this is disregarded, you

are in a life-threatening situation

and this can result in serious inju‐

ries.

CAU‐

TION

Denotes a possibly hazardous sit‐

uation. If this is disregarded, it

could result in slight or minor inju‐

ries or material damage.

Warning signs denoting different types of

danger

The following warning signs are used in these

operating instructions to denote different types

of danger:

Warning signs Type of danger

Warning – highvoltage.

Warning – danger

zone.

Correct and proper use

n The device may only be used with liquid

metering chemicals.

n The device can only be used with pulsing

liquid flows with a clear zero flow.

n The device may only be used after it has

been correctly installed and commissioned

in accordance with the technical data and

specifications contained in the operating

instructions.

n Observe the general limitations with regard

to viscosity limits, chemical resistance and

density - see also ProMinent resistance list

(In the product equipment catalogue or at

www.prominent.com

)!

n Any other uses or modifications are pro‐

hibited.

n The device is not suitable for measuring

continuous liquid flows.

n The device may not be used to measure

gaseous media or solids.

n The device may not be used with combus‐

tible media without appropriate protective

measures.

n The device may not be used with explo‐

sive media.

n The device may not be used with radioac‐

tive media.

n The device is not intended for exterior

applications without use of suitable protec‐

tive equipment.

n The device should only be operated by

trained and authorised personnel, see the

following "Qualifications" table.

n You are obliged to observe the information

contained in the operating instructions at

the different phases of the system's

service life.

Safety chapter

9

Page 10

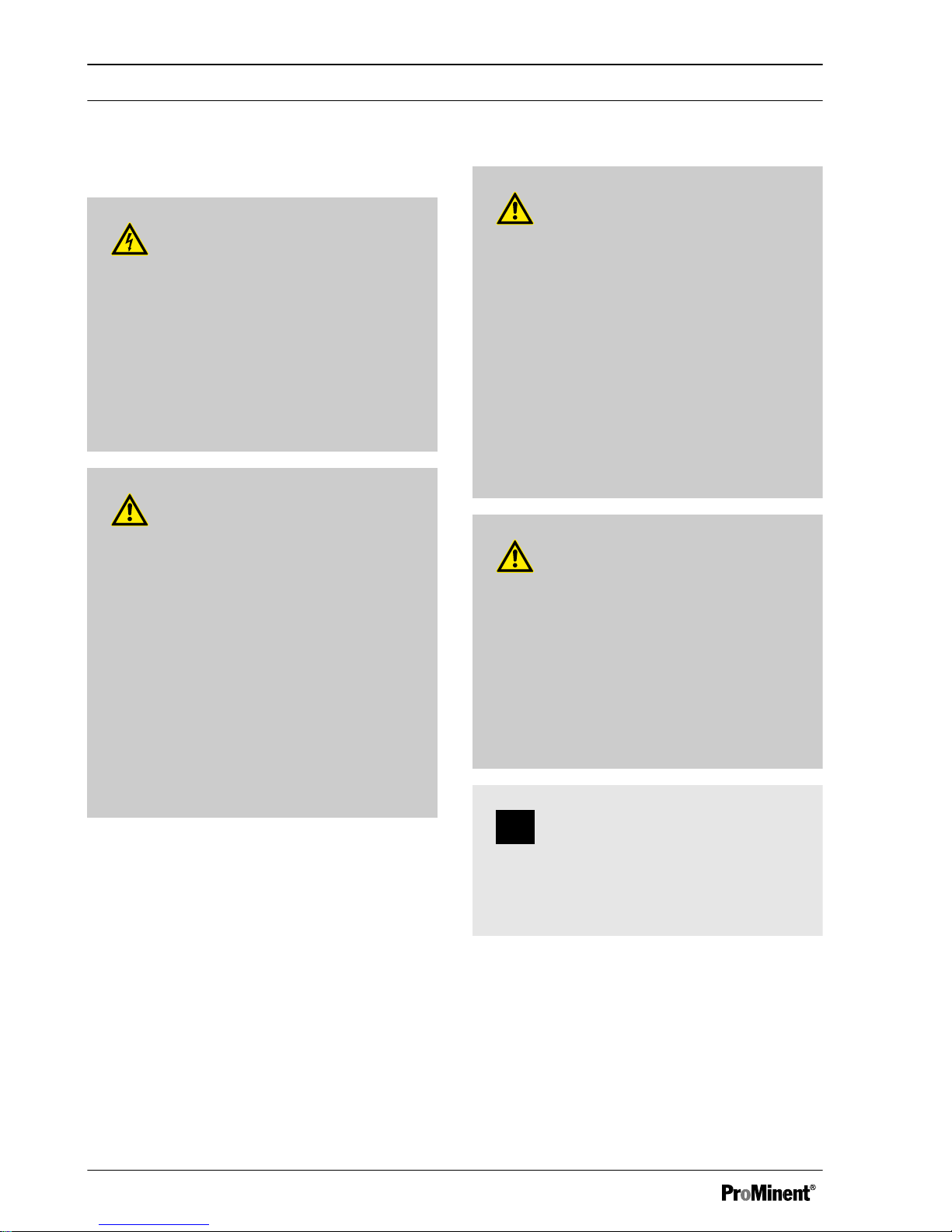

Safety information

WARNING!

Danger of electric shock

A mains voltage may exist inside the

housing.

– If the housing has been damaged,

you must disconnect the device from

the mains immediately. It may only be

returned to service after an authorised

repair.

WARNING!

Warning of dangerous or unknown feed

chemical

Should a dangerous or unknown feed

chemical be used: It may escape from the

hydraulic components during maintenance

work.

– Take appropriate protective measures

before working on the device (safety

glasses, safety gloves, ...). Observe

the safety data sheet for the feed

chemical.

–

Drain and flush the hydraulic parts

before working on the device.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the

hydraulic components if they are manipu‐

lated or opened due to pressure in the

hydraulic and adjacent parts of the system.

– Disconnect the pump of the device

hydraulic system from the mains

power supply and ensure that it

cannot be switched on again by unau‐

thorised persons.

– Depressurise the system before com‐

mencing any work on hydraulic parts.

CAUTION!

Danger of personnel injury and material

damage

The use of untested third party parts can

result in personnel injuries and material

damage.

– Only fit parts to the device, which

have been tested and recommended

by ProMinent.

NOTICE!

Warning of illegal operation

Observe the regulations that apply where

the device is installed.

Information in the event of an emergency

In an emergency, disconnect the device from

the mains!

If feed chemical escapes, also depressurise the

device hydraulic system. Adhere to the safety

data sheet for the feed chemical.

Safety chapter

10

Page 11

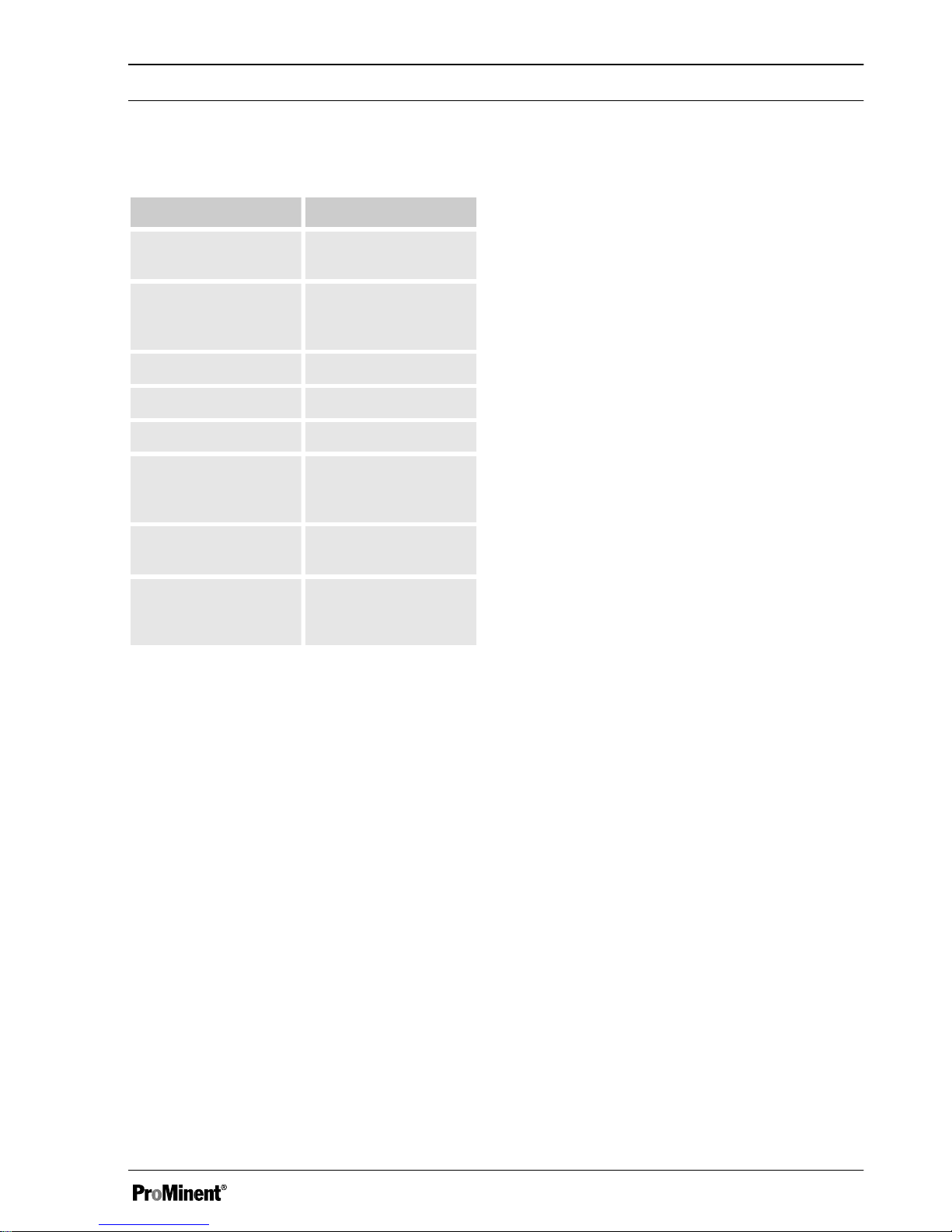

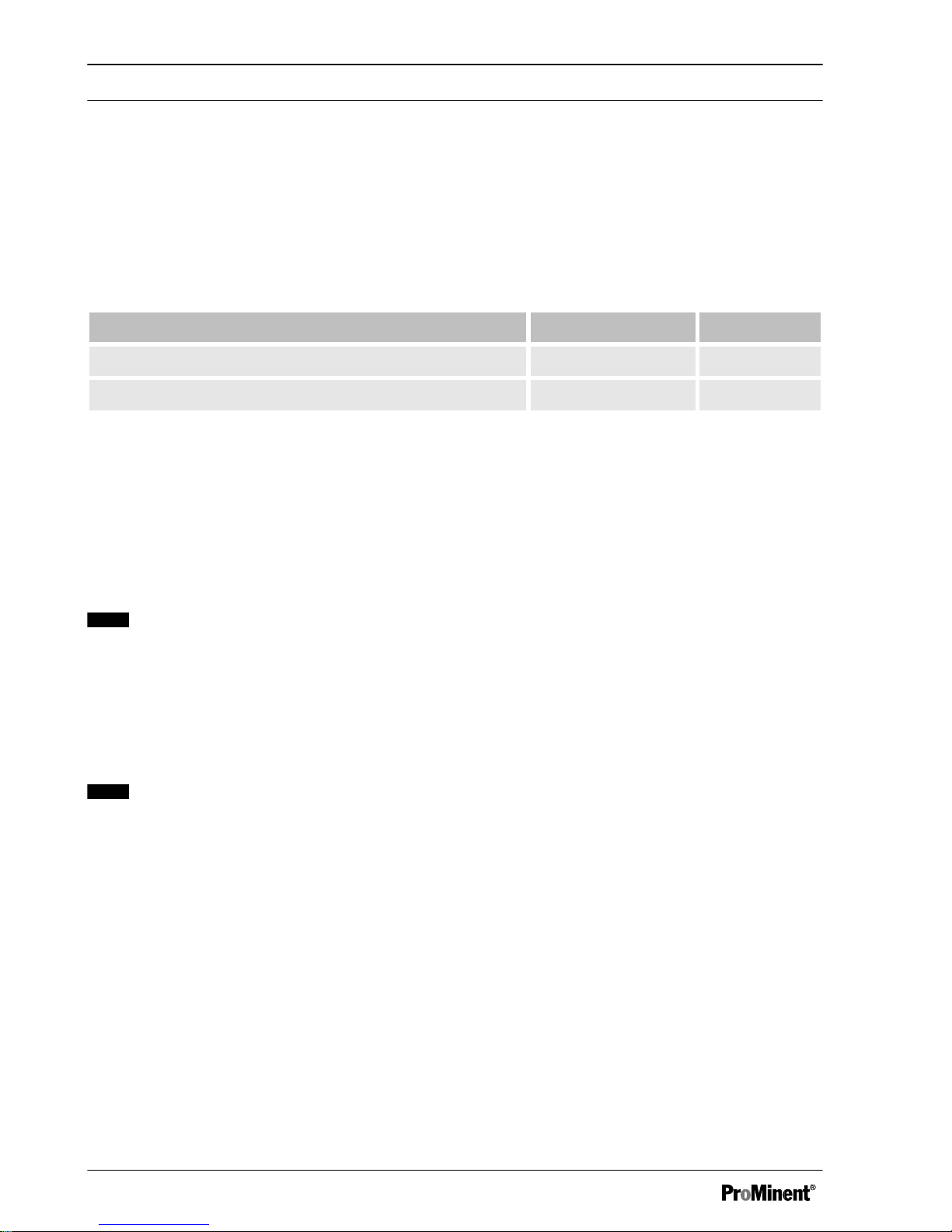

Qualification of personnel

Activity Qualification level

Storage, transport,

unpacking

Instructed personnel

Installation, installa‐

tion of hydraulic

system

Technical personnel

Electrical installation Electrician

Operation Instructed personnel

Maintenance Technical personnel

Repairs Customer service -

authorised by ProMi‐

nent

Decommissioning,

disposal

Technical personnel

Troubleshooting Technical personnel,

electrician, instructed

personnel

Technical personnel

A qualified employee is deemed to be a person

who is able to assess the tasks assigned to him

and recognise possible hazards based on his/

her technical training, knowledge and experi‐

ence, as well as knowledge of pertinent regula‐

tions.

Electrician

Electricians are deemed to be people, who are

able to complete work on electrical systems

and recognize and avoid possible hazards

independently based on their technical training

and experience, as well as knowledge of perti‐

nent standards and regulations. Electricians

should be specifically trained for the working

environment in which the are employed and

know the relevant standards and regulations.

Electricians must comply with the provisions of

the applicable statutory directives on accident

prevention.

Instructed personnel

An instructed person is deemed to be a person

who has been instructed and, if required,

trained in the tasks assigned to him/her and

possible dangers that could result from

improper behaviour, as well as having been

instructed in the required protective equipment

and protective measures.

Customer Service department

Customer Service refers to service technicians,

who have received proven training and have

been authorised by ProMinent® to work on the

system.

Safety chapter

11

Page 12

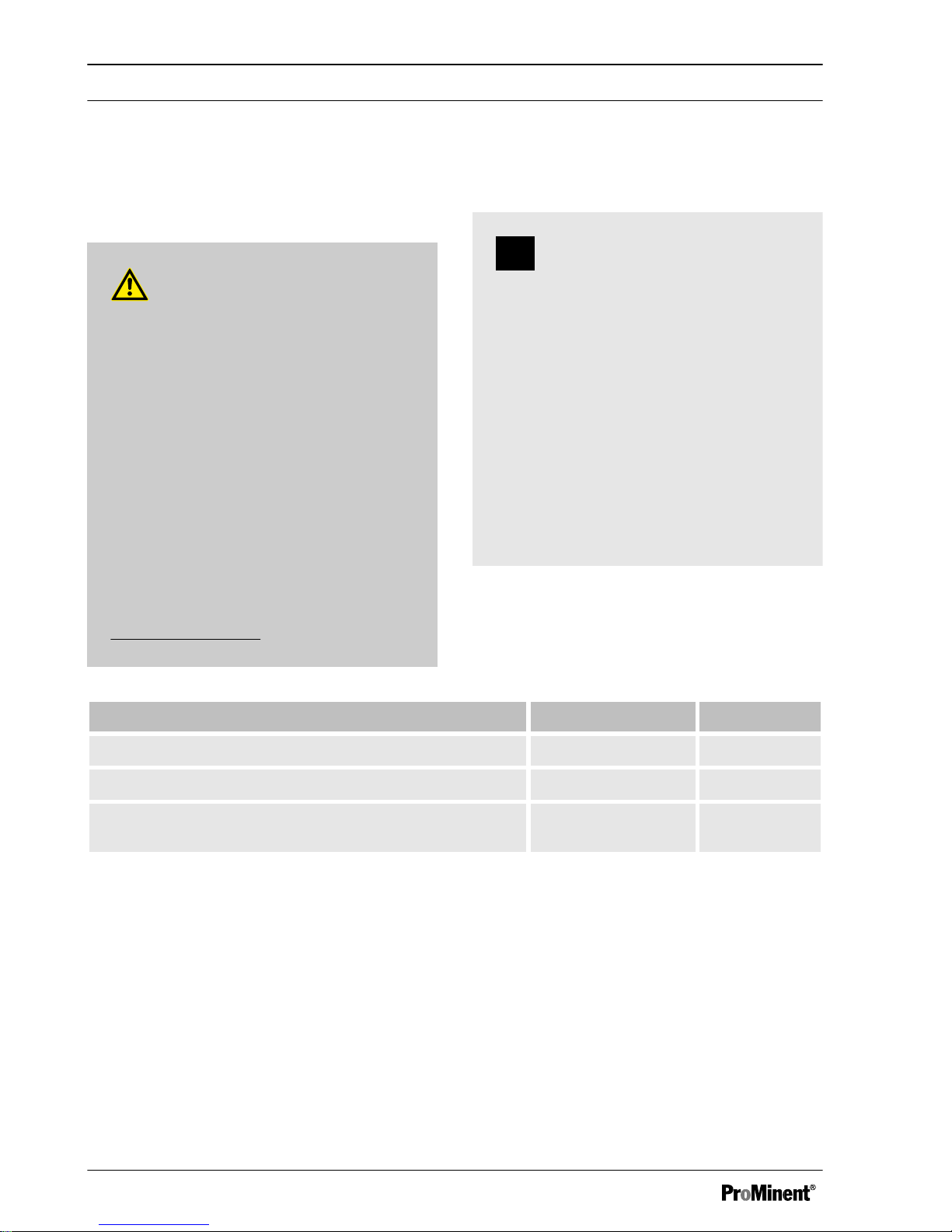

4 Storage and transport

Safety information

WARNING!

Only return the device for repair in a

cleaned state and with flushed hydraulic

parts - refer to the chapter "Decommis‐

sioning"!

Only send the unit complete with a filled in

Decontamination Declaration form. The

Decontamination Declaration constitutes

an integral part of an inspection / repair

order. A unit can only be inspected or

repaired when a Decontamination Declara‐

tion Form is submitted that has been com‐

pleted correctly and in full by an authorised

and qualified person on behalf of the oper‐

ator.

The "Decontamination Declaration Form"

can be found in the Appendix or under

www.prominent.com

.

NOTICE!

Danger of material damage

The device can be damaged by incorrect

or improper storage or transportation!

– The device should only be stored or

transported in a well packaged state preferably in its original packaging.

– The packaged unit should also only

be stored or transported in accord‐

ance with the stipulated storage con‐

ditions.

– The packaged unit should be pro‐

tected from moisture and the ingress

of chemicals.

Ambient conditions

Data Value Unit

Minimum storage and transport temperature -10 °C

Maximum storage and transport temperature +50 °C

Air humidity < 95 % rel.

humidity*

* non-condensing

Storage and transport

12

Page 13

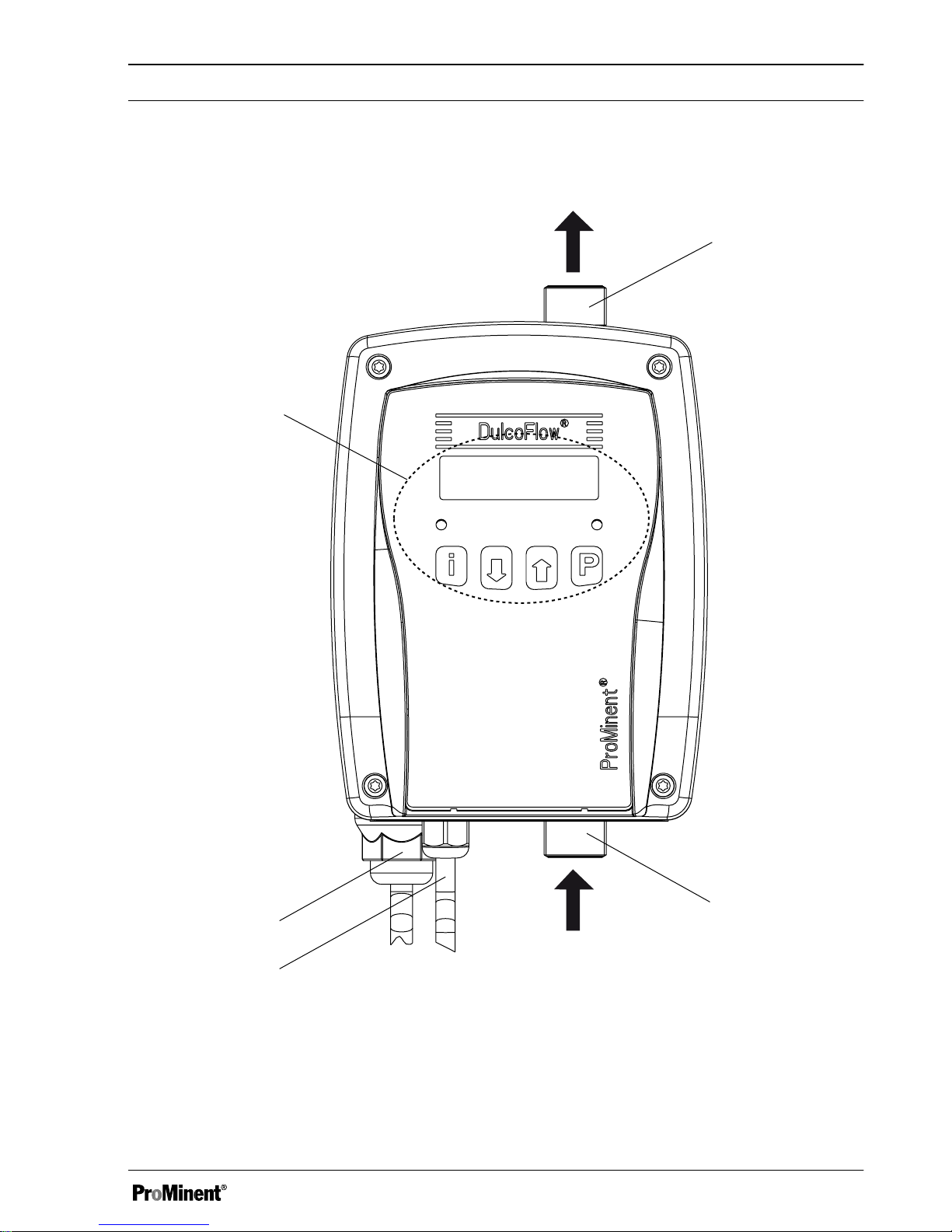

5 Device overview

1

2

4

5

3

Fig. 1: Overview of equipment DulcoFlow® with arrows showing flow

1 Control elements - see chapter "Settings" -

"Operating unit"

2 Mains connection

3 Signal output (option)

4 Feed chemical inlet

5 Feed chemical outlet

Device overview

13

Page 14

6 Functional description

The DulcoFlow ® flow meter measures the

volume flow of pulsing flows. The ultrasonic,

time of flight measurement method is used. For

the time of flight measurement, a sound signal

is alternately transmitted in and against the

direction of flow. The time difference is then a

measure of the mean flow velocity. Use of the

ultrasound measurement method automatically

compensates any temperature induced

changes in the medium. Operation without

moving parts guarantees a long service life and

wear-free operation.

The DulcoFlow® calculates the mass flow from

the volume flow and the density of the feed

chemical.

Additionally the DulcoFlow® can measure the

pressure surges of the metering pump and

hence replace a dosing monitor such as the

Flow Control. A metering pump such as the

gamma/ L or delta®

can use these signals as

acknowledge pulses for its individual strokes. If

the acknowledge pulses are missing or if the

capacity exceeds the specified limit values, the

metering pump stops after an adjustable

number of missing pulses and goes into fault

mode - see metering pump operating instruc‐

tions.

The DulcoFlow® gives the flow reading, stroke

feedback, or error messages via the various

output types.

Functional description

14

Page 15

7 Assembly and installation

Safety information

WARNING!

Carry out the assembly work before the

electrical installation is undertaken.

WARNING!

Observe the information in the "Technical

data" chapter.

WARNING!

Danger of an electric shock

If the device is used outdoors without a

cover or weatherproof roof, water may be

able to collect on the seals and penetrate

the housing or direct sunlight may cause

the housing to be corroded.

– Always use a cover or weatherproof

roof when using the unit outdoors.

CAUTION!

Warning of illegal operation

Observe the regulations that apply where

the unit is to be installed.

The device is resistant to normal atmos‐

pheres in plant rooms.

7.1 Installation

Install the device so that the hose between

it and the pump is approximately 30 cm

long.

This ensures it measures accurately.

Mount the device vertically.

This ensures it measures accurately.

Mount the device vertically on the wall

using both eyes on the housing.

Do not forget the washers.

7.2 Hydraulic Installation

CAUTION!

Warning of escaping feed chemical

Feed chemicals can escape in the event

that the hose lines are incorrectly installed.

– Only use original hoses with the

specified hose dimensions.

– Avoid reducing the hose sizes.

Assembly and installation

15

Page 16

Flow direction

The flow direction through the device goes

from the bottom to the top.

Injection valves, back pressure

valves, relief valves

Injection valves, back pressure valves or

relief valves must not have any effect on

the measurement.

Relief valves

It is best to install a relief valve before the

flow meter, so that the displayed flow or

flow volume actually corresponds to the

value which is being metered into the

system if the relief valve triggers.

Hydraulic Dampers

Hydraulic dampers, like accumulators,

inline dampers or bladder accumulators /

diaphragm accumulators must not have

any effect on the measurement.

A zero flow must be available.

The damping must not push the flow mean

value beneath the measurement threshold.

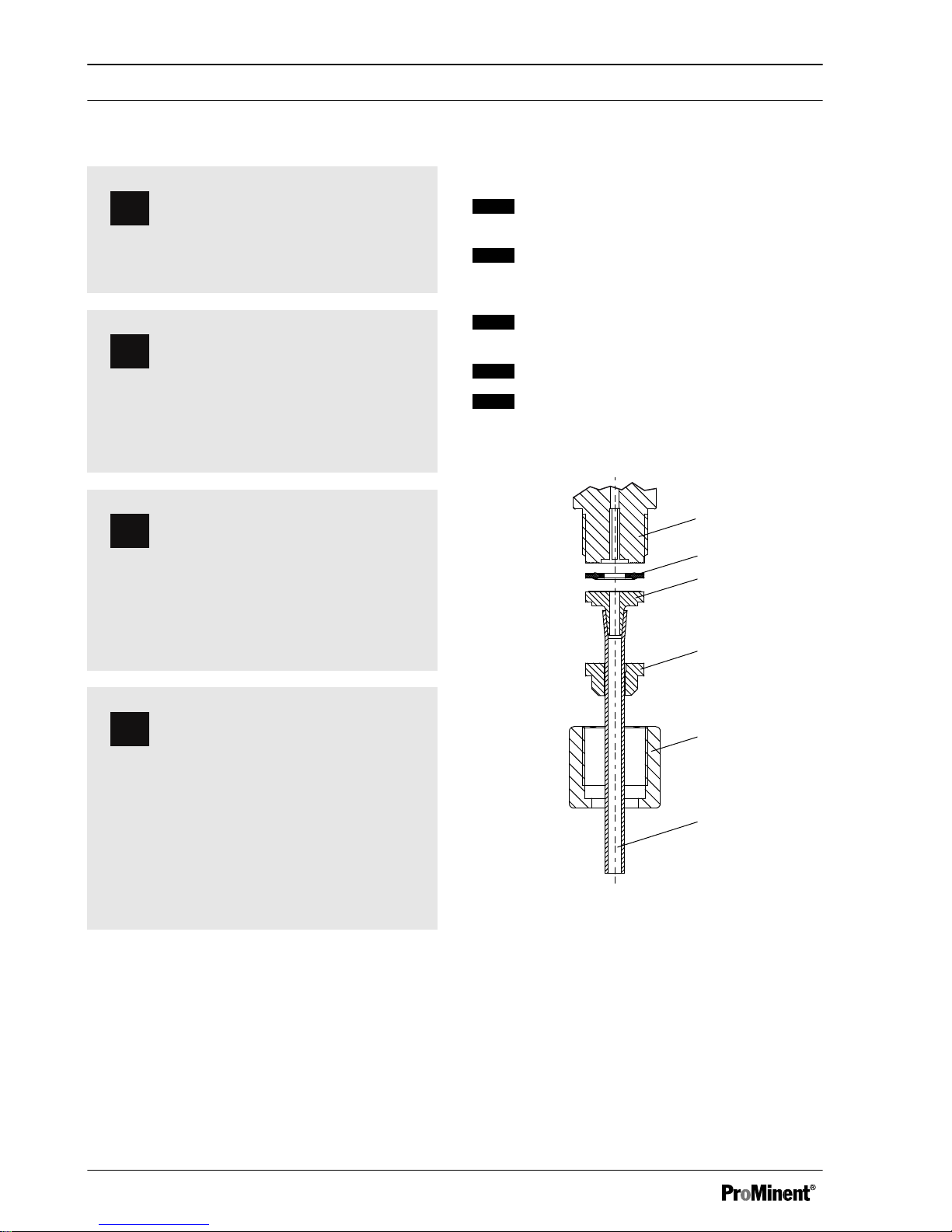

Installing the hosing:

1. Cut off the ends of the hoses (6) so that

they are straight.

2. Unscrew the union nut (5) and push

over the hose together with the clamp

ring (4).

3. Push the hose end (6) up to the stop

over the nozzle (3).

4. Tighten the union nut (5).

5. Pull on the hose (6) and tighten up the

union nut (5).

1

3

2

4

5

6

P_MAZ_0041_SW

Fig. 2: Installing the hose line

1 Connector

2 Seal

3 Nozzle

4 Clamp ring

5 Union nut

6 Hose

Assembly and installation

16

Page 17

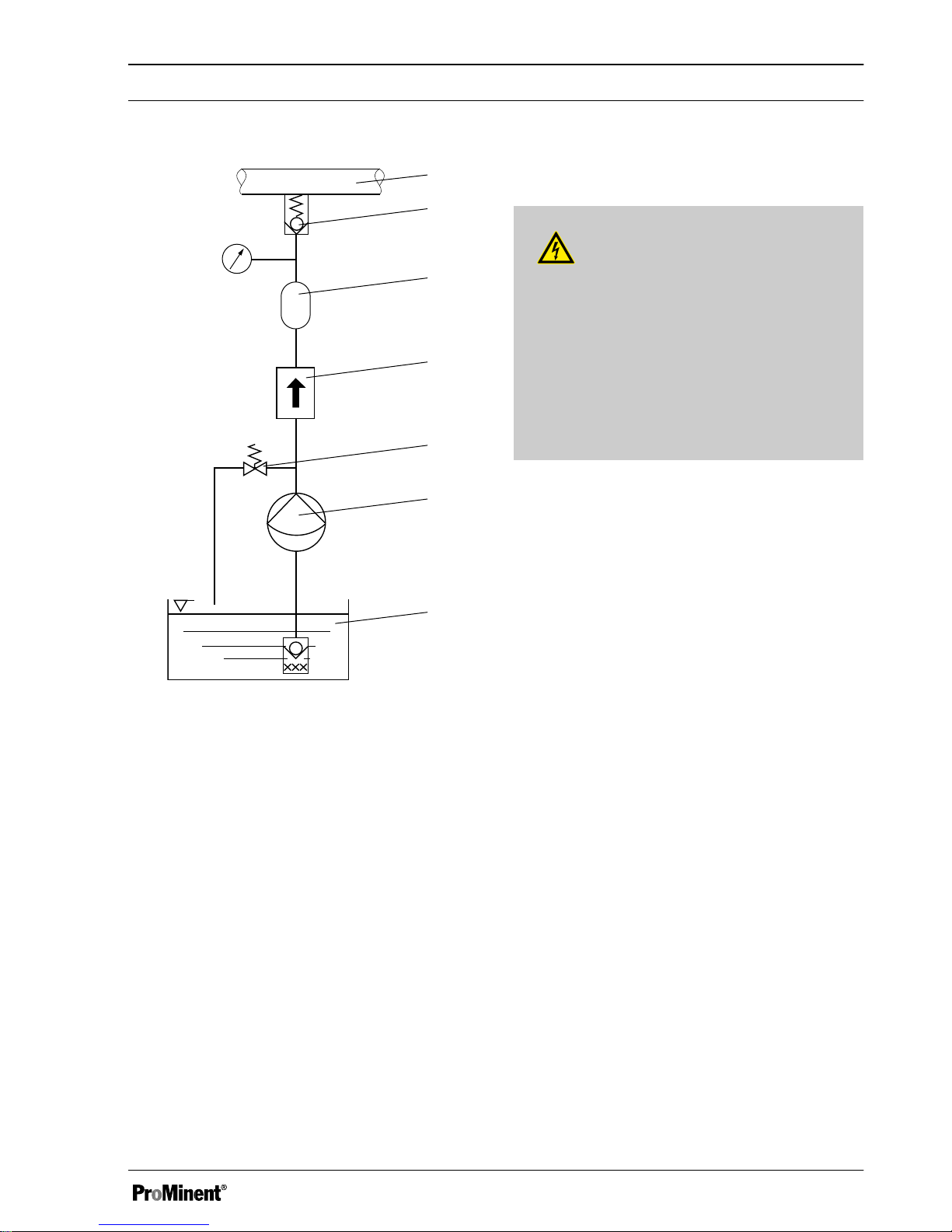

P_MAZ_0040_SW

2

PD

1

3

4

5

6

7

Fig. 3: DulcoFlow® hydraulic system

1 Target use

2 Pressure maintenance device

3 Hydraulic Damper

4

DulcoFlow

®

5 Overflow device

6 Metering pump

7 Storage tank

7.3 Electrical Installation

WARNING!

Danger of electric shock

The use of a residual current circuit

breaker drastically increases survival

chances should persons come into contact

with the mains voltage due to an electrical

accident.

– Always fit a residual current circuit

breaker on-site.

A metering pump, PLC or other devices can be

connected to the flow meter.

The following alternative electrical outputs are

available via cable:

n Current output (identity code characteristic

"signal output "1"):

n Counter output (identity code characteristic

"signal output "2"):

Assembly and installation

17

Page 18

Current output

The following can be signalled via the current output (standard signal output (mA)):

n Instantaneous flow

n Fault

Technical data:

Data Value Unit

Current* 0/4 .. 20 mA

Maximum load 400 Ω

* zero volt connection

Counter output as stroke feedback output

The counter output as stroke feedback output

can be used to signal stroke feedback, pro‐

vided it is set accordingly - see chapter "Set‐

tings".

1. To report stroke feedback at the

metering pump such as gamma/ L and

delta® , plug the cable from the flow

meter to the pump in the "dosing mon‐

itor" terminal.

ð

The identifier for the dosing monitor

must appear on the LCD screen of

the pump.

2. If it does not appear, make the neces‐

sary settings at the metering pump.

Assembly and installation

18

Page 19

Counter output as frequency output

The counter output as frequency output can be used to signal flow or an error, provided it is set

accordingly - see chapter "Settings".

1. Remove the connected socket.

2. Remove the insulation of the leads to match the terminals of the other device.

3. Crimp on a suitable cable end sleeve.

ð

In this format, the cable can be connected to another device.

4.

Connect the cable to both devices in accordance with the wiring diagram. DulcoFlow® wiring

diagram - see appendix.

Technical data:

Data Value Unit

Voltage with open contacts < 30 V

Current with closed contacts < 10 mA

Residual voltage with closed contacts < 0.7 V

Switching frequency < 10 kHz

Lead Function

brown Supply Voltage

white Error signal

blue Frequency signal

black Mass

Assembly and installation

19

Page 20

8 Settings

8.1 Operating unit

P_MAZ_0039_SW

V: 1145.69 mL

Q:

502.13

mL/h

i

DulcoFlow

®

1

2

3

4

Fig. 4: Operating unit DulcoFlow

®

1 LCD display

2 Status LED

3 Control keys

4 Stroke feedback LED

8.1.1 LCD screen

The LCD screen comprises a two-line display.

8.1.2 LEDs

The status LEDs (left) shows the following

information:

LED Information

green Status OK

orange Warning

red Error

The stroke feedback LED (right) shows the fol‐

lowing information:

LED Information

off No pressure surge identified

green, illumi‐

nated

Pressure surge detected within tolerance

red, illumi‐

nated

Pressure surge detected outside tolerance

8.1.3 Control keys

The control keys are designated as follows:

Key Designation

i

[ i ]

[DOWN]

[UP]

[P]

Settings

20

Page 21

P

P

3 s

P

P

3 s

cont.

display

main menu

set-up

set-up

display

= set-up

option

Fig. 5: Navigation within the operating menu

The control keys have different functions in the continuous display, in the operating menu and in the

menu branches.

In the continuous display

Key Functions

i

Changes to continuous dis‐

play

Changes into the operating

menu

In the operating menu

Key Functions

Change to the previous menu

branch

Change to the next menu

branch

Open menu branch (switch to

the first item of the selected

menu branch).

Settings

21

Page 22

In a menu item of a menu branch

Key Functions

i

Switches between the continuous changing of a number and digit

by digit changing

Increase/change the set value

Reduce/change the set value

Accept the configured value and change to the next menu item of

the menu branch.

In digit by digit changing: Within a number change to the next

figure.

B0210

density

1.3425 g/mL

density

1.3425 g/mL

density

1.3425 g/mL

a) b)

Fig. 6: a) Change between continuous changing of a number and digit by digit changing; b) Changes

the position within the number

Key [P] - additional generally-applicable func‐

tions:

Press dura‐

tion

Function

approx. 2 s Open the operating menu

approx. 3 s Quit the operating menu

without saving the configured

values and return to the con‐

tinuous display

A modified set value is only adopted, if it

has previously been confirmed by brief

pressing of the [P] key.

Settings

22

Page 23

8.2 Checking adjustable varia‐

bles

Before you adjust the flow meter, you can

check the actual settings of the adjustable vari‐

ables:

Press the key

[ i ]

("i" for "Info"), if the

LCD screen is displaying a continuous

display - i.e. no display of the operating

menu.

ð

After every press on the

[ i ]

key,

you see a different continuous dis‐

play.

The number and appearance of the continuous

displays depends on the selected measured

variable and whether a setpoint has been

entered - see below.

The key [ i ] is used to change between

continuous displays.

Continuous display for the "Volume" measured

variable

Continuous display Description

V: 243,32 mL

Q: 171,05 mL/h

Total quantity* V and

instantaneous volume

flow Q

V: 243,32 mL

N: 637

Total quantity* V and

number of strokes* N

V/H: 0,382 mL

%SH: 102,3 %

Volume per stroke V/

H and deviation from

the set point of the

lifting volume** %SH

* since the last reset

** if a

„volume (stroke)“

has been entered under

„Calibration è Stroke feedback è Set-point“

Continuous displays for the "Mass" measured

variable

(If

„mass“

was set under

„Mode

è

Measured variable“

.)

Continuous display Description

m: 326,05 g

Q: 229,21 g/h

Total quantity* m and

instantaneous mass

flow Q

m: 326,05 g

N: 527

Total quantity* m and

number of strokes* N

m/H: 0,619 g

%SH: 97,8 %

Mass per stroke m/H

and deviation from the

set point of the stroke

mass** %SH

* since the last reset

** if a

„mass (stroke)“

has been entered under

„Calibration è Stroke feedback è Set-point“

Reset values

–

To reset the total quantity and

strokes, press both [arrow keys]

simultaneously.

–

In the main menu "Zero set", the total

quantity and the strokes can be set to

"zero" independently of each other.

Settings

23

Page 24

8.3 Operating menu overview

B0209

P

P

P

cont.

display

2 s

set to zero quantity and strokes

acknowledge error

main menu

mode

menu

measurandmeasurand

P

main menu

calibrationcalibration

menu

stroke feedb.stroke feedb.

menu

quantityquantity

P

main menu

zero setzero set

menu

quantityquantity

menu

strokesstrokes

P

main menu

set-upset-up

menu

displaydisplay

menu

serviceservice

menu

counter outp.*counter outp.*

menu

current output*current output*

* Dependent on identity code

Settings

24

Page 25

main menu

infoinfo

main menu

languagelanguage

Fig. 7

8.4 Changing to adjustment

mode

If the

[P]

key is pressed for 2 seconds in a con‐

tinuous display, the device changes to adjust‐

ment mode.

The following main menus can be selected in

adjustment mode:

1 - Mode

2 - Set-up

3 - Calibration

4 - Zero set

5 - Info

6 - Language

8.4.1 "Mode" main menu

main menu

mode

The measured variables can be selected from

the "Operation" main menu:

n

„Volume“

(-flow)

n

„Mass“

(-flow)

The appearance of a few menus is dependent

on this.

8.4.2 "Set-up" main menu

main menu

set-up

The following menus can be selected from the

"set-up" main menu:

1 -

„Display“

3 -

„Current output“

(identity code character‐

istic "signal output" "1")

2 -

„Counter output“

(identity code character‐

istic "signal output" "2")

4 -

„Service“

(for customer service only)

Settings

25

Page 26

8.4.2.1 "Display" menu

P P P P

B0228

set-up

display

flow unit

mL/h

quantity unit

mL

damping flow

30.00

s

In the

„display“

menu, the units can be selected for the quantities and flow.

Moreover, the damping of the displayed flow values can be changed (not for quantities), if they

change too quickly / slowly in the display.

The greater the set integration constant in the menu item

„damping flow“

, the greater the damping of

the displayed flow values.

Non-metric units and their conversion

Unit Meaning Conversion

1 gal 1 US liquid gallon = 3.785421 l

1 lb(s) 1 Pound = 453.59237 g

8.4.2.2 "Counter output" menu

(identity code characteristic "signal output" "2")

P

P

P

P P

P

P P

P P

B0235

set-up

counter output

puls/freq.

open-collector

counter output

puls/freq.

counter output

stroke feedback

open-collector

NPN

K factor

5000 1/mL

puls/freq.

signal

output

K factor unit

1/mL

puls/freq.

error output

error

bubbles

In the

„counter output“

menu the counter output can be set either as a pulse/frequency output to

output the instantaneous flow, as an error signal or as a feedback message.

Settings

26

Page 27

puls/freq. (frequency output)

Firstly the type of the output (

„Open-Collector“

)

can be selected so that it is suitable for the con‐

nected device (NPN / PNP).

The K factor can be set via the

„signal output“

menu, and is then used by the DulcoFlow® to

convert the instantaneous flow prior to output

via the counter output to an external device.

In the

„error output“

menu a setting can be

made to determine whether the DulcoFlow

®

outputs an error signal via the counter output to

an external device. It works like a relay in

status NO.

stroke feedback

For stroke feedback, e.g. to a Prominent

metering pump, as with a Flow Control® dosing

monitor, the cable must be fed from the counter

output to the "dosing monitor" terminal of the

metering pump.

Then the

„stroke feedback“

must be calibrated

under

„calibration“

, see chapter "Calibration".

Settings

27

Page 28

8.4.2.3 "Current output" menu

(identity code characteristic "signal output" "1")

P P P P

P P

P P

B0234

set-up

current output

current range

4...20 mA

current output

signal current

flow unit

mL/h

0/4 mA value

0.68 mL/h

20 mA value

897.65 mL/h

current output

error current

error current

bubbles

In the

„current output“

menu the standard signal output (mA) can be set either to output the instanta‐

neous flow or as a feedback message.

In the

„signal current“

menu a setting can be

made to determine how the DulcoFlow® outputs

the instantaneous flow via the current output to

an external device.

In the

„error output“

menu a setting can be

made to determine whether the DulcoFlow

®

outputs an error signal via the current output to

an external device (23 / 3.6 mA).

Settings

28

Page 29

8.4.2.4 "service" menu

P P

B0229

set-up

service

service code

0000

The "service" menu is password protected and only for customer service.

8.4.3 "Calibration" main menu

main menu

calibration

From the "calibration" menu either the flow

measurement can be calibrated or the stroke

feedback set up.

8.4.3.1

Calibrate "stroke feedback"

8.4.3.1.1

For "volume"

The permitted range for the lifting volume V/H

can be specified in this menu. If the lifting

volume moves outside of this range, e.g. due to

a changed back pressure, the DulcoFlow® no

longer gives any stroke feedback to the

metering pump and the right LED now illumi‐

nates as a steady red instead of green. ProMi‐

nent metering pumps such as the gamma/ L or

delta® go into fault mode after a series of defec‐

tive strokes (pump set up).

Settings

29

Page 30

About setpoint and tolerances

P P P P

P P P

B0230

calibration

stroke feedback

volume (stroke)

0.347 mL

stroke feedback

set-point

volume

(stroke)

0.347 mL

lower tolerance

-010.00 %

tolerance

tolerance (%)

upper tolerance

+020.00

%

Specify the allowed range for the lifting volume V/H via the setpoint of the lifting volume V/H and

tolerances in %:

1.

Follow the menu path

„calibration è stroke feedback è set-point“

and press the key

[P]

.

ð

The menu item

„volume (stroke)“

displays the currently stored setpoint.

2. Start the metering pump.

ð

The actual measured value is displayed.

3. Turn the stroke length adjustment knob until the desired setpoint is displayed.

4. Press key

[P]

.

ð

The displayed measured value is saved as a setpoint and the menu item

„tolerance

tolerances“

appears.

The setpoint is valid as 100%.

5. Stop the metering pump.

6. Press key

[P]

.

7. Set the

„lower tolerance“

with the

[arrow keys]

and press the

[P]

.

8. Set the

„upper tolerance“

with the

[arrow keys]

and press the

[P]

.

ð

The continuous display appears again.

The desired setpoint can also be entered, without having to use the stroke adjustment dial or

the pump having to be running, directly under „volume (stroke)“ using the [arrow keys] .

Settings

30

Page 31

Upper limit values

B0231

calibration

stroke feedback

volume (stroke)

0.347 mL

stroke feedback

set-point

P P P P

volume (stroke)

0.347 mL

tolerance

tolerance (%)

P

lower limit

0.312 mL

tolerance

limits

P P P

upper limit

0.416

mL

Alternatively, the desired limits for the allowed range of the lifting volume can be entered under

„lower limit“

and

„upper limit“

:

1.

Follow the menu path

„calibration è stroke feedback è set-point“

and press the key

[P]

.

ð

The menu item

„volume (stroke)“

displays the currently stored setpoint.

2. Start the metering pump.

ð

The actual measured value is displayed.

3. Turn the stroke length adjustment knob until the desired setpoint is displayed.

4. Press key

[P]

.

ð

The displayed measured value is saved as a setpoint and the menu item

„tolerance

tolerances“

appears.

The setpoint is valid as 100%.

5. Using the

[arrow keys]

change to the menu item

„limits“

and press key

[P]

.

6. Turn the stroke length adjustment dial down until the desired lower limit is reached and press

key

[P]

.

7. Proceed analogously for the upper limit.

ð

The continuous display appears again.

8. Stop the metering pump.

Settings

31

Page 32

The desired setpoint can also be entered, without having to use the stroke adjustment dial or

the pump having to be running, directly under „volume (stroke)“ using the [arrow keys] .

8.4.3.1.2 For "mass"

The permitted range for the mass per stroke m/

H can be specified in this menu. If the mass per

stroke moves outside of this range, e.g. due to

a changed back pressure, the DulcoFlow® no

longer gives any stroke feedback to the

metering pump and the right LED now illumi‐

nates as a steady red instead of green. ProMi‐

nent metering pumps such as the gamma/ L or

delta® go into fault mode after a series of defec‐

tive strokes (pump set up).

Settings

32

Page 33

About setpoint and tolerances

B0232

P P P P

P P P

calibration

stroke feedback

mass (stroke)

0.347 g

stroke feedback

set-point

mass (stroke)

0.347 g

lower

tolerance

-010.00

%

tolerance

tolerance (%)

upper tolerance

+020.00 %

Specify the allowed range for the mass per stroke m/H via the setpoint of the lifting volume m/H and

tolerances in %:

1.

Follow the menu path

„calibration è stroke feedback è set-point“

and press the key

[P]

.

ð

The menu item

„volume (stroke)“

displays the currently stored setpoint.

2. Start the metering pump.

ð

The actual measured value is displayed.

3. Turn the stroke length adjustment knob until the desired setpoint is displayed.

4. Press key

[P]

.

ð

The displayed measured value is saved as a setpoint and the menu item

„tolerance

tolerances“

appears.

The setpoint is valid as 100%.

5. Press key

[P]

.

6. Set the

„lower tolerance“

with the

[arrow keys]

and press the

[P]

.

7. Set the

„upper tolerance“

with the

[arrow keys]

and press the

[P]

.

ð

The continuous display appears again.

8. Stop the metering pump.

The desired setpoint can also be entered, without having to use the stroke adjustment dial or

the pump having to be running, directly under „mass (stroke)“ using the [arrow keys] .

Settings

33

Page 34

Upper limit values

B0233

P P P P

P

P P P

calibration

stroke feedback

mass (stroke)

0.347 g

stroke feedback

set-point

mass (stroke)

0.347 g

tolerance

tolerance (%)

lower

limit

0.312 g

tolerance

limits

upper

limit

0.416 g

Alternatively, the desired limits for the allowed range of the stroke mass can be entered under

„lower

limit“

and

„upper limit“

:

1.

Follow the menu path

„calibration è stroke feedback è set-point“

and press the key

[P]

.

ð

The menu item

„volume (stroke)“

displays the currently stored setpoint.

2. Start the metering pump.

ð

The actual measured value is displayed.

3. Turn the stroke length adjustment knob until the desired setpoint is displayed.

4. Press key

[P]

.

ð

The displayed measured value is saved as a setpoint and the menu item

„tolerance

tolerances“

appears.

The setpoint is valid as 100%.

5. Using the

[arrow keys]

change to the menu item

„limits“

and press key

[P]

.

6. Turn the stroke length adjustment dial down until the desired lower limit is reached and press

key

[P]

.

7. Analogously, proceed in the same way for the upper limit.

ð

The continuous display appears again.

8. Stop the metering pump.

Settings

34

Page 35

The desired setpoint can also be entered, without having to use the stroke adjustment dial or

the pump having to be running, directly under „mass (stroke)“ using the [arrow keys] .

8.4.3.2 Calibrate "quantity"

Only calibrate the quantity flow if the dis‐

played values do not attain the expected

accuracy.

Settings

35

Page 36

8.4.3.2.1 By corr. factor

B0244

P P P

calibration

quantity

corr. factor

101.23 %

quantity

corr. factor

calibration

stroke

feedback

If the new correction factor is know in %, it can be entered directly here.

It is obtained by dividing a value you have measured yourself by the displayed value and multiplying

the result by 100.

1.

Follow the menu path

„calibration è stroke feedback“

.

2. Using the

[arrow keys]

change to the menu item

„calibration quantity“

and press key

[P]

2x.

3. Using the

[arrow keys]

Enter the

„corr. factor“

and press the key

[P]

.

ð

The continuous display appears again.

8.4.3.2.2 By meas. Value

CAUTION!

Danger with dangerous feed chemicals

Provided the following handling instruc‐

tions are followed, contact with the feed

chemical is possible.

– If the feed chemical is dangerous,

take appropriate safety precautions

when carrying out the following han‐

dling instructions.

–

Observe the feed chemical safety

data sheet.

Depending on the set measured variable, a cal‐

ibration menu appears for:

n Volume

n Mass

Settings

36

Page 37

Volume

B0226

P P

P P P

P

calibration

quantity

quantity

corr. factor

actual volume

54.72 mL

quantity

meas. Value

corr. factor

95.27 %

nominal volume

52.13 mL

calibration

stroke feedback

Settings

37

Page 38

Requirements:

n 1 measuring cylinder which can be read sufficiently accurately

n The metering pump suction line is fed, bubble-free into the measuring cylinder.

1. Record the fluid level in the measuring cylinder.

2. Change from the menu item

„calibration stroke feedback“

using the

[arrow keys]

to the menu

item

„calibration quantity“

and press key

[P]

.

ð

The menu item

„quantity corr. factor“

appears.

3. Change from the menu item

„quantity corr. factor“

using the

[arrow keys]

to the menu item

„quantity meas. Value“

and press key

[P]

.

ð

The menu item

„actual volume“

appears.

4. Start the metering pump.

Select the number of strokes so that the reading error at the measuring cylinder (half of

the smallest readable volume graduation divided by the metered total volume) is smaller

than the Dulcoflow measurement error.

5. Stop the metering pump.

6. Record the fluid level in the measuring cylinder and calculate the difference.

7. Press key

[P]

.

ð

The menu item

„nominal volume“

appears.

8. Adjust the value in the menu item

„nominal volume“

using the

[arrow keys]

based on this dif‐

ference and press the

[P]

key.

ð

The menu item

„corr. factor“

appears. It shows the calculated correction factor.

9. Press key

[P]

, to return to the continuous display.

It is also possible to manually calculate the correction factor and enter it directly under

„entry“

-

„corr.

factor“

.

Settings

38

Page 39

Mass

B0227

P P

P P P

P

calibration

quantity

quantity

corr. factor

actual mass

54.72 g

quantity

meas. Value

corr. factor

95.27 %

nominal mass

52.13 g

calibration

stroke feedback

Settings

39

Page 40

Requirements:

n 1 weighing instrument which can be read sufficiently accurately

n 1 vessel with feed chemical

n the suction line is fed, bubble-free into the measuring vessel.

1. Zero the weighing instrument.

2. Change from the menu item

„calibration stroke feedback“

using the

[arrow keys]

to the menu

item

„calibration quantity“

and press key

[P]

.

ð

The menu item

„quantity corr. factor“

appears.

3. Change from the menu item

„quantity corr. factor“

using the

[arrow keys]

to the menu item

„quantity meas. Value“

and press key

[P]

.

ð

The menu item

„actual mass“

appears.

4. Start the metering pump.

Select the number of strokes so that the reading error at the weighing instrument (half of

the smallest readable mass graduation divided by the metered total mass) is smaller

than the Dulcoflow measurement error.

5. Stop the metering pump.

6. Read off the weight from the weighing instrument.

7. Press key

[P]

.

ð

The menu item

„nominal mass“

appears.

8. Adjust the value in the menu item

„nominal mass“

using the

[arrow keys]

to the read-off

weight and press the key

[P]

.

ð

The menu item

„corr. factor“

appears. It shows the calculated correction factor.

9. Press key

[P]

, to return to the continuous display.

It is also possible to manually calculate the correction factor and enter it directly under

„entry“

-

„correction factor“

.

8.4.4 "Zero set" main menu

main menu

zero set

In the main menu "Zero set", the total quantity

and the strokes, which are displayed in the con‐

tinuous display, can be set to "zero" independ‐

ently of each other.

Settings

40

Page 41

8.4.5 "Info" main menu

main menu

info

This information can be read-off in the "info"

main menu:

Code Meaning

ID Identity code

SN Serial number

HW Hardware version

SW Software version

BL Bootloader

8.4.6 "Language" main menu

main menu

language

The operating language can be selected from

the "language" main menu.

Settings

41

Page 42

9 Start up

1. Connect the device hydraulically to the

installation.

2. Connect the device to the supply

voltage.

3. If necessary set:

n the language - see

Ä Chapter 8.4.6

„"Language" main

menu“ on page 41

n the measured variable to "mass"

and density of the feed chemical see

Ä on page 25

n the units - see

Ä Chapter 8.4.2.1

„"Display" menu“ on page 26

n the current output - see

Ä Chapter

8.4.2.3 „"Current output"

menu“ on page 28

n the counter output - see

Ä Chapter

8.4.2.2 „"Counter output"

menu“ on page 26

4. Allow the metering pump to prime press both

[arrow keys]

simultaneously

at the pump control unit.

5. At the device acknowledge the error

„bubbles“

by pressing the key

[P]

.

6. Allow the metering pump to run.

7. Check whether the displayed values are

plausible.

8. Check whether the stroke feedback to

the metering pump is plausible.

9. Check whether the frequency signals

and the mA signals of the device have

the expected effect if these signals are

being used.

If the metering pump goes into fault mode

during start up, press the [P] key to

acknowledge.

Use with the metering pump delta® is only

possible if the pump is set to "dosing" "set-up" (discharge stroke)" - "fast".

Operation as a flow meter

1. In the menu

„calibration“

calibrate the

„quantity“

- see

Ä Chapter 8.4.3.2 „Cali‐

brate "quantity"“ on page 35

2. Check whether the displayed values are

plausible.

Operation as a dosing monitor

1.

Under

„set-up è set counter output“

to

„stroke feedback“

.

2. Connect the device cable with the

"dosing monitor" terminal of the pump.

3. In the menu

„calibration“

set the

„stroke

feedback“

- see

Ä Chapter 8.4.3.1 „Cali‐

brate "stroke feedback"“ on page 29

Function "transmit error signal"

(for identity code characteristic "signal output"

"1")

1.

Under

„set-up è current output

è

error current“

set the desired error

result and set the

„error current“

.

2. Cause the error to occur and check

whether everything functions as desired.

Start up

42

Page 43

(for identity code characteristic "signal output"

"2")

1.

Under

„set-up è counter output

è

puls/freq. è error output“

set the

desired error result.

2. Cause the error to occur and check

whether everything functions as desired.

Start up

43

Page 44

10 Maintenance, repair and disposal

WARNING!

Danger from chemical residues

There is normally chemical residue in the

measurement pipe and housing after ope‐

ration. This chemical residue could be haz‐

ardous to people.

– It is mandatory that the safety infor‐

mation relating to the "Storage, trans‐

port and unpacking" chapter is read

before shipping or transporting the

unit.

– Thoroughly clean the measurement

pipe and the housing to remove

chemicals and dirt. Adhere to the

safety data sheet for the feed chem‐

ical.

Maintenance, repair and disposal

44

Page 45

10.1 Maintenance

Interval Maintenance work

Regularly Check whether the correct flow value is displayed.

If this is not the case, recalibrate the flow - see chapter "calibrate".

If stroke feedback is used: Adjust the stroke length with the metering pump run‐

ning and set just above the programmed upper limit - the flow identifier at the

pump should no longer flash.

Adjust the stroke length with the metering pump running and set just below the

programmed lower limit - the flow identifier at the pump should no longer flash.

If this is not the case, check for the cause and as necessary readjust the Dulco‐

Flow® - see

Ä Chapter 8.4.3.1 „Calibrate "stroke feedback"“ on page 29

If stroke feedback is used: Check whether the stroke feedback LED (right-hand

side of the device) illuminates in time with the strokes.

If this is not the case, check for the cause and rectify as necessary.

Check whether feed chemical is coming out.

If necessary, carefully wipe the device with a soft cloth and soapy water.

10.2 Repairs

Only ProMinent of customer service authorised

by ProMinent may repair the DulcoFlow® flow

meter.

10.3 Disposal

CAUTION!

Environmental hazard due to electronic

waste

There are electronic components in the

device, which can have a toxic effect on

the environment.

– Separate the electronic components

from the remaining parts.

– Observe the current applicable regu‐

lations in your country.

Maintenance, repair and disposal

45

Page 46

11 Troubleshooting

WARNING!

Warning of dangerous or unknown feed

chemical

Should a dangerous or unknown feed

chemical be used: It may escape from the

hydraulic components during maintenance

work.

– Before maintenance work, take

appropriate protective measures

(safety glasses, safety gloves, ...).

Observe the safety data sheet for the

feed chemical.

– Drain and flush the liquid end of the

metering pump before working on it.

Troubleshooting

46

Page 47

11.1

DulcoFlow® error

Faults with error messages

The left device LED lights up red if an error exists.

Fault description Cause Remedy

Bubbles detected There are too many bubbles or particles

in the feed chemical.

Avoid bubbles or particles in the

feed chemical.

Warning with error message

The left device LED lights up orange if a

warning exists.

LED signals

For further information about LED signals,

see the "Settings" chapter.

Troubleshooting

47

Page 48

11.2 Pump error

To return the pump to operating status after one of the following errors, press the key [P] .

In the event of an error an LED lights up red and the flow identifier flashes.

Fault description Cause Remedy

The pump stops

during priming.

Due to air in the liquid end,

the DulcoFlow® has not

output an acknowledge

pulse.

During priming pull the cable to the DulcoFlow

®

out - the function "Flow" is disabled which the

cable is out.

The pump stop

during Dulco‐

Flow®

set-up.

The DulcoFlow® has given

out too few sequential

acknowledge pulses.

Press key

[P]

.

The pump stops

while running.

There is air in the liquid end,

gaseous feed chemical.

n Pull out the cable to the DulcoFlow® from

the pump.

n Bleed the liquid end.

n Plug the cable to the DulcoFlow® into the

socket on the pump.

n Increase the number of acknowledge

pulses in the pump's menu.

Troubleshooting

48

Page 49

Fault description Cause Remedy

There is air in the liquid end,

the chemical feed container

is empty.

n Fill the metering tank.

n Pull out the cable to the DulcoFlow® from

the pump.

n Bleed the liquid end.

n Plug the cable to the DulcoFlow® into the

socket on the pump.

There is gas in the dosing

head - leaks in the path

between the chemical feed

container and the Dulco‐

Flow®.

n Repair the leak.

n Pull out the cable to the DulcoFlow® from

the pump.

n Bleed the liquid end.

n Plug the cable to the DulcoFlow® into the

socket on the pump.

Blockage between Dulco‐

Flow® and metering tank

n Clear the blockage.

n Pull out the cable to the DulcoFlow® from

the pump.

n Bleed the liquid end.

n Plug the cable to the DulcoFlow® into the

socket on the pump.

The stroke adjustment dial

is mis-set

- see metering pump operating instructions

The feed chemical is too

viscous

- see metering pump operating instructions

11.3 All Other Faults

All other faults:

Inform your customer service department or

your ProMinent branch.

Troubleshooting

49

Page 50

12 Technical data

Performance data

Data Value Unit

Measuring range, pulsing, type 05: 0.1... 13 L/h

Measuring range, pulsing, type 08: 0.6... 80 L/h

Smallest measurable lifting volume, pulsing approx. 0.03 mL/stroke

Accuracy over at least 100 strokes: ± 2 %*

* relative to the measured value

Electrical data

Data Value Unit

Stroke feedback, output**: 1 Contact/stroke

Frequency output**: < 10 kHz

Current output, max. load: 400 Ω

Protective system: IP 65

Supply voltage: 100...230 V AC

Mains supply frequency: 50/60 Hz

** open collector

Media requirements

Material compatibility with: PVDF, sealing material

Data Value Unit

Medium pressure: 0...16 bar

Medium temperature: -10...+45 °C

Dynamic viscosity (η): 0.5...2000 mPas

Sound pressure level: 1000 ... 2500 m/s

Technical data

50

Page 51

Ambient conditions

Data Value Unit

Minimum storage and transport temperature -10 °C

Maximum storage and transport temperature +50 °C

Ambient temperature in operation, min. -10 °C

Ambient temperature in operation, max. +50 °C

Maximum air humidity * 95 % rel. humidity

* non-condensing

Material

Component Material

Measurement pipe PVDF

Seals, hydraulic - see identity code

Housing PPE+GF20

Screws, etc. A2

Electronics Electronic components

Dimensions

Data Value Unit

Hose connection - nominal widths: 6/4, 8/5, 12/9 mm

Dimensions (HxBxD): 183.6 x 121 x 122.7 mm

Technical data

51

Page 52

Compatibility

Type Pumps

05 Beta, gala: 1000 - 0413/0713

delta: 1608 - 1612

08 Beta, gala: 0220/0420 - 0232

delta: 1020 - 0280

Technical data

52

Page 53

13 Dimensions sheet

107

183.6

35.5

121.6

160.5

80.4

18

5.4

10

121

91.9

M20x1,5

Fig. 8: Dimensional drawing DulcoFlow® - dimensions sheet in mm

Dimensions sheet

53

Page 54

14 EC Declaration of Conformity

- Original -

EC Declaration of Conformity

We,

ProMinent Dosiertechnik GmbH

Im Schuhmachergewann 5 - 11

DE - 69123 Heidelberg

hereby declare that, the product specified in the following complies with the relevant basic health and safety

rules of the EC Directive, on the basis of its functional concept and design and in the version marketed by us.

This declaration loses its validity in the event of a modification to the product not agreed with us.

Description of the product:

DulcoFlow ultrasonic flow meter

Product type:

DFMa...

Serial no.:

Please refer to type plate on the device

Relevant EC

Directives:

EC Low Voltage Directive (2006/95/EC)

EC EMC Directive (2004/108/EC)

Harmonised standards applied, in

particular:

EN 60335-1, EN 61010-1

EN 55011, EN 61000-6-3, EN 61326-1

Other applicable national

standards and specifications:

EN 60529, EN 61000-4-2/3/4/5/6/11

Technical documents have been

compiled by documentation

specialists:

Norbert Berger

Im Schuhmachergewann 5-11

DE-69123 Heidelberg

Date / manufacturer's signature:

Details of the signatory:

09.12.2010

Dr. Johannes Hartfiel, Assistance Development Director

EC Declaration of Conformity

54

Page 55

15 Decontamination declaration

Decontamination declaration

55

Page 56

16 Index

A

About this product.......................................... 8

B

BL................................................................. 41

bubbles......................................................... 28

C

Calibration.................................................... 29

Checking...................................................... 23

Checking adjustable variables..................... 23

Control keys................................................. 20

corr. factor

.................................................... 36

Correct and proper use.................................. 9

Correction factor............................... 36, 37, 39

Counter output....................................... 18, 26

Current output........................................ 18, 28

D

damping....................................................... 26

Display......................................................... 26

Disposal....................................................... 44

dosing monitor.............................................. 27

Dosing monitor....................................... 18, 42

E

Emergency................................................... 10

error output............................................. 27, 28

Error signal................................................... 42

Explanation of the safety information ............ 9

F

Fault............................................................. 18

Flow.............................................................. 18

Flow meter................................................... 42

frequency output.......................................... 27

Frequency output......................................... 19

Functional description.................................. 14

H

HW............................................................... 41

Hydraulic system.......................................... 17

I

ID.................................................................. 41

Identity code................................................... 6

Info............................................................... 41

Information in the event of an emergency.... 10

Installation.................................................... 15

L

Language..................................................... 41

LCD screen.................................................. 20

Leads........................................................... 19

LEDs............................................................ 20

Limit values............................................ 31, 34

M

Main menu................................................... 25

Maintenance................................................. 44

Mass................................................. 25, 32, 39

Mass flow..................................................... 25

meas. Value................................................. 36

Mode............................................................ 25

O

Operating unit............................................... 20

P

puls/freq....................................................... 27

Q

Qualification of personnel............................. 11

R

Repair........................................................... 44

S

Safety chapter................................................ 9

Service......................................................... 29

Setpoint.................................................. 30, 33

Set-up........................................................... 25

Index

56

Page 57

SN................................................................ 41

Standard signal output (mA)........................ 18

Start up......................................................... 42

Storage......................................................... 12

stroke feedback...................................... 27, 29

Stroke feedback........................................... 18

Supplementary information............................ 3

SW

............................................................... 41

T

Technical data.............................................. 50

Tolerances............................................. 30, 33

Transport...................................................... 12

Troubleshooting........................................... 46

U

Units............................................................. 26

V

Volume....................................... 25, 29, 35, 37

Volume flow.................................................. 25

W

Warning sign.................................................. 9

Z

Zero set........................................................ 40

Index

57

Loading...

Loading...