ProMinent DULCOflex DFAa 003, DULCOflex DFAa 008 Assembly And Operating Instructions Manual

Page 1

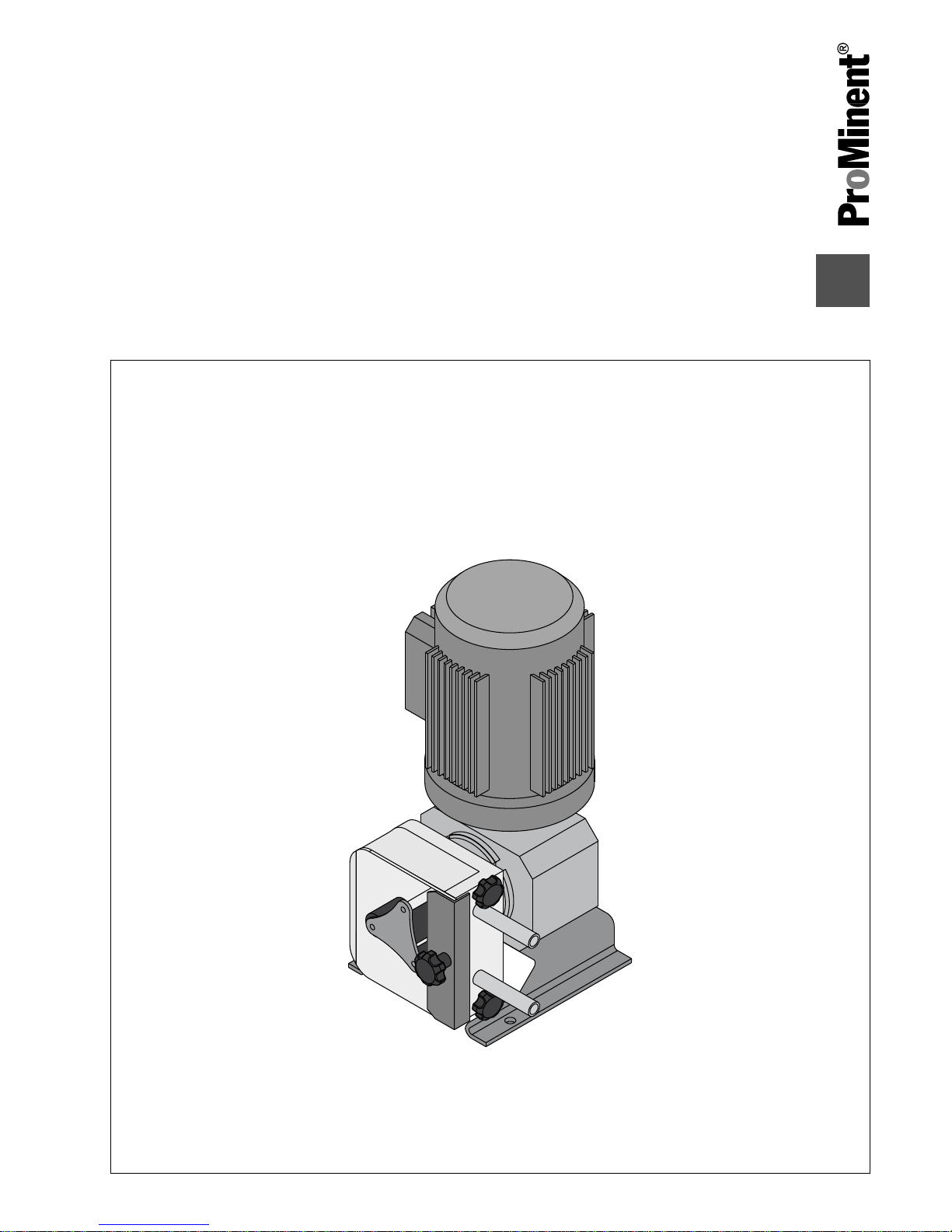

DULCO®flex DFAa

Hose Pump

Assembly and operating instructions

A0380

Original operating instructions (2006/42/EC)Part no. 986229 BA DX 013 04/11 EN

Please carefully read these operating instructions before use! · Do not discard!

The operator shall be liable for any damage caused by installation or operating errors!

Technical changes reserved.

Page 2

986229, 1, en_GB

© 2011

ProMinent Dosiertechnik Heidelberg GmbH

Im Schuhmachergewann 5 - 11

69123 Heidelberg

Telephone: +49 6221 842-0

Fax: +49 6221 842-419

email: info@prominent.de

Internet: www.prominent.com

2

Page 3

Table of contents

1

Introduction........................................................................... 4

1.1 Explanation of the safety information............................ 4

1.2 Users' qualifications...................................................... 6

1.3 ID Code......................................................................... 7

1.3.1

Identcode DULCO®flex DFAa 003............................. 7

1.3.2

Identcode DULCO®flex DFAa 008............................. 8

2 Safety and responsibility..................................................... 10

2.1 General safety information.......................................... 10

3 Functional description......................................................... 13

3.1 Construction................................................................ 13

3.2 Overview of the device............................................... 14

4 Transport, storage, assembly and Installation.................... 15

4.1 Transport.................................................................... 15

4.2 Storage....................................................................... 15

4.3 Assembly.................................................................... 15

4.3.1 Ambient conditions.................................................. 16

4.3.2 Alignment of the suction side................................... 16

4.3.3 Alignment of the discharge side............................... 16

4.3.4 Performance curves................................................. 17

5 Commissioning................................................................... 18

5.1 Testing prior to commissioning the pump................... 18

6 Operation of the peristaltic pump........................................ 19

7

Maintenance, repair, malfunctions, disposal and spare

parts.................................................................................... 20

7.1 Maintenance............................................................... 20

7.2 Exchanging the pump hoses...................................... 20

7.3 Troubleshooting.......................................................... 21

7.4 Disposal of Used Parts............................................... 22

7.5 Spare parts................................................................. 23

8 DFAa technical data............................................................ 26

8.1 Dimensions DFAa 003/008......................................... 26

9 DFAa technical appendices................................................ 28

9.1 Declaration of Conformity........................................... 28

10 Index................................................................................... 29

Table of contents

3

Page 4

1 Introduction

These operating instructions provide information on the technical

data and functions of the DULCO®flex DFAa series hose pump.

In order to make it easier to read, this document uses the male

form in grammatical structures but with an implied neutral sense. It

is aimed equally at both men and women. We kindly ask female

readers for their understanding in this simplification of the text.

1.1

Explanation of the safety information

These operating instructions provide information on the technical

data and functions of the product. These operating instructions pro‐

vide detailed safety information and are provided as clear step-bystep instructions.

The safety information and notes are categorised according to the

following scheme. A number of different symbols are used to

denote different situations. The symbols shown here serve only as

examples.

DANGER!

Nature and source of the danger

Consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger

Danger!

–

Denotes an immediate threatening danger. If this is

disregarded, it will result in fatal or very serious

injuries.

WARNING!

Nature and source of the danger

Possible consequence: Fatal or very serious injuries.

Measure to be taken to avoid this danger

Warning!

–

Denotes a possibly hazardous situation. If this is

disregarded, it could result in fatal or very serious

injuries.

General non-discriminatory approach

Introduction

Introduction

4

Page 5

CAUTION!

Nature and source of the danger

Possible consequence: Slight or minor injuries, mate‐

rial damage.

Measure to be taken to avoid this danger

Caution!

–

Denotes a possibly hazardous situation. If this is

disregarded, it could result in slight or minor inju‐

ries. May also be used as a warning about material

damage.

NOTICE!

Nature and source of the danger

Damage to the product or its surroundings

Measure to be taken to avoid this danger

Note!

–

Denotes a possibly damaging situation. If this is

disregarded, the product or an object in its vicinity

could be damaged.

Type of information

Hints on use and additional information

Source of the information, additional measures

Information!

–

Denotes hints on use and other useful information.

It does not indicate a hazardous or damaging sit‐

uation.

Introduction

5

Page 6

1.2 Users' qualifications

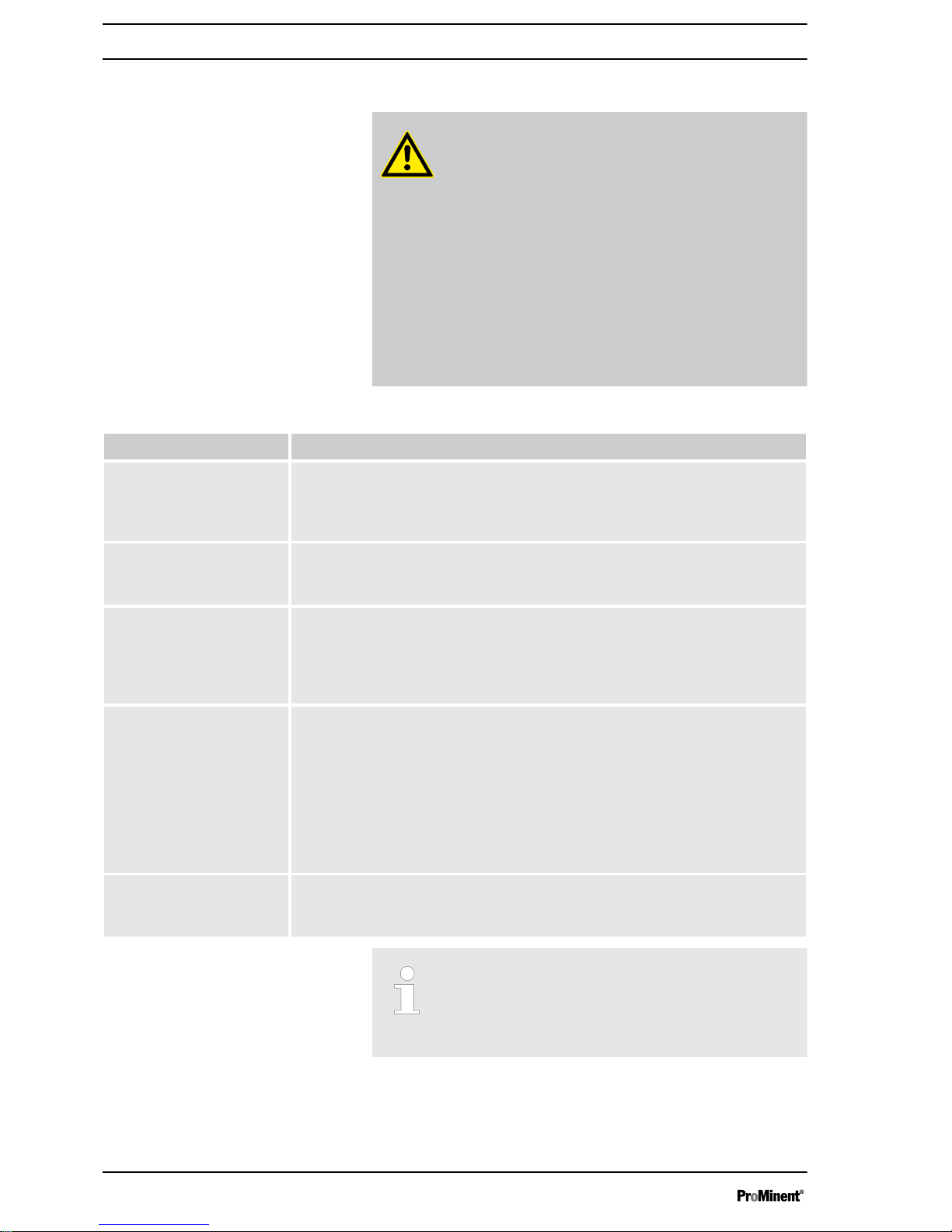

WARNING!

Danger of injury with inadequately qualified personnel!

The operator of the plant / device is responsible for

ensuring that the qualifications are fulfilled.

If inadequately qualified personnel work on the unit or

loiter in the hazard zone of the unit, this could result in

dangers that could cause serious injuries and material

damage.

– All work on the unit should therefore only be con‐

ducted by qualified personnel.

–

Unqualified personnel should be kept away from

the hazard zone

Training Definition

Instructed personnel An instructed person is deemed to be a person who has been instructed and,

if required, trained in the tasks assigned to him/her and possible dangers that

could result from improper behaviour, as well as having been instructed in the

required protective equipment and protective measures.

Trained user A trained user is a person who fulfils the requirements made of an instructed

person and who has also received additional training specific to the system

from ProMinent or another authorised distribution partner.

Trained qualified per‐

sonnel

A qualified employee is deemed to be a person who is able to assess the

tasks assigned to him and recognize possible hazards based on his/her

training, knowledge and experience, as well as knowledge of pertinent regula‐

tions. The assessment of a person's technical training can also be based on

several years of work in the relevant field.

Electrician Electricians are deemed to be people, who are able to complete work on elec‐

trical systems and recognize and avoid possible hazards independently based

on his/her technical training and experience, as well as knowledge of pertinent

standards and regulations.

Electricians should be specifically trained for the working environment in

which the are employed and know the relevant standards and regulations.

Electricians must comply with the provisions of the applicable statutory direc‐

tives on accident prevention.

Customer Service depart‐

ment

Customer Service department refers to service technicians, who have

received proven training and have been authorised by ProMinent to work on

the system.

Note for the system operator

The pertinent accident prevention regulations, as well

as all other generally acknowledged safety regulations,

must be adhered to!

Introduction

6

Page 7

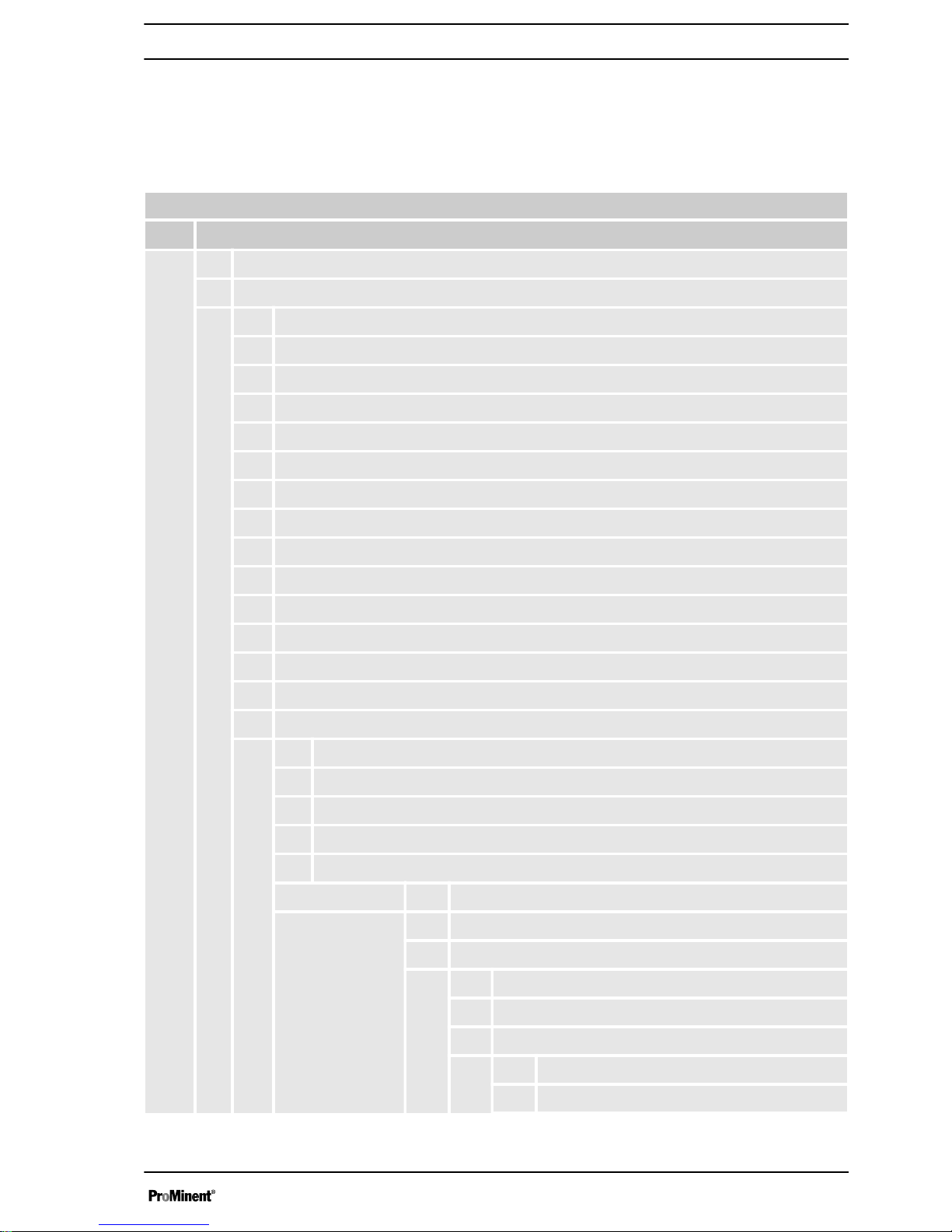

1.3 ID Code

1.3.1

Identcode DULCO®flex DFAa 003

Identcode

DFAa

DULCO®flex DFAa 003

Type

003 DFAa 003, with 3.2 mm hose, wall thickness 2.4 mm (1.66 ml/revolution)

Drive

000 Pump without drive

Step-down gears / 3 x 230 / 400 VAC

A10 0.09 kW, 14 rpm, 1.4 l/h, 2 bar

A11 0.12 kW, 35 rpm, 3.5 l/h, 2 bar

A12 0.12 kW, 70 rpm, 7.0 l/h, 2 bar

A13 0.18 kW, 93 rpm, 9.3 l/h, 2 bar

A14 0.18 kW, 140 rpm, 13.9 l/h, 2 bar

Manual adjustment gears / 3 x 230 / 400 VAC

A21 0.15 kW, 10.9-57 rpm, 1.1-5.7 l/h, 2 bar

A22 0.15 kW, 34-176 rpm, 3.4-17.5 l/h, 2 bar

Adjustment gears with integrated frequency converter / 1x 230 VAC

A31 0.18 kW, 13-130 rpm, 1.3-12.9 l/h, 2 bar

Adjustment gears (external frequency converter required) / 3 x 230 / 400 VAC

A41 0.18 kW, 0-93 rpm, 0-9.3 l/h, 2 bar

Hose material

A Norpren A60G

B Norpren A60F (food grade)

C Solva

D Silicone

Base plate

0 Base plate, lacquered steel

1 Base plate, stainless steel

Batch control

0 without batch control

R with batch control

Special version of motor

0 Standard (3 phase) 3x230/400 VAC

Device identification / Identcode

Introduction

7

Page 8

Identcode

DFAa

DULCO®flex DFAa 003

D Single phase motor, 0.12 kW (not suitable for

A21-A41) 1x230 VAC

E Single phase motor, 0.18 kW (not suitable for

A21-A41) 1x230 VAC

Pump head

0 Standard with one pump head

C Double head version

Certification

01 CE mark

1.3.2

Identcode DULCO®flex DFAa 008

Identcode

DFAa

DULCO®flex DFAa 008

Type

008 DFAa 008, with 8 mm hose, wall thickness 2.4 mm (10 ml/revolution)

Drive

000 Pump without drive

Step-down gears / 3 x 230 / 400 VAC

B10 0.09 kW, 14 rpm, 8.4 l/h, 2 bar

B11 0.12 kW, 35 rpm, 21 l/h, 2 bar

B12 0.12 kW, 70 rpm, 42 l/h, 2 bar

B13 0.18 kW, 93 rpm, 55.8 l/h, 2 bar

B14 0.18 kW, 140 rpm, 84 l/h, 2 bar

Manual adjustment gears / 3 x 230 / 400 VAC

B21 0.15 kW, 10.9-57 rpm, 6.5-34.2 l/h, 2 bar

B22 0,25 kW, 34-176 rpm, 20.4 - 105 l/h, 2 bar

Adjustment gears with integrated frequency converter / 1x 230 VAC

B31 0.18 kW, 13-130 rpm, 7.8-78 l/h, 2 bar

Adjustment gears (external frequency converter required) / 3 x 230 / 400 VAC

B41 0.18 kW, 0-93 rpm, 0-55.8 l/h, 2 bar

Hose material

A Norpren A60G

B Norpren A60F (food grade)

C Solva

Introduction

8

Page 9

Identcode

DFAa

DULCO®flex DFAa 008

D Silicone

Base plate

0 Base plate, lacquered steel

1 Base plate, stainless steel

Batch control

0 without batch control

R with batch control

Special version of motor

0 Standard (3 phase) 3x230/400 VAC

D Single phase motor, 0.12 kW (not suitable for

B21-B41) 1x230 VAC

E Single phase motor, 0.18 kW (not suitable for

B21-B41) 1x230 VAC

Pump head

0 Standard with one pump head

C Double head version

Certification

01 CE mark

Introduction

9

Page 10

2 Safety and responsibility

2.1

General safety information

WARNING!

Live parts

Possible consequence: Fatal or very serious injuries

– Measure: The device must be disconnected from

the power supply before it is opened

–

Isolate damaged, faulty or manipulated devices

from the mains in order to de-energise.

WARNING!

Emergency stop switch

Possible consequence: Fatal or very serious injuries

An emergency stop switch is to be connected for the

entire plant. This should enable the entire plant to be

shut down in the event on an emergency in such a way

that the overall plant can be brought into a safe condi‐

tion.

WARNING!

Unauthorised access

Possible consequence: Fatal or very serious injuries

– Measure: Ensure that there can be no unauthor‐

ised access to the unit

WARNING!

Hazardous media / contamination of persons and

equipment

Possible consequence: Fatal or very serious injuries.

material damage

– Ensure that the pump hoses are resistance against

the media being conveyed

–

Always observe the the safety data sheets for the

media to be conveyed. The system operator must

ensure that these safety data sheets are available

and that they are kept up-to-date

– The safety data sheets for the media being con‐

veyed are always decisive for initiating counter

measures in the event of leakage to the media

being conveyed

– Observe the general restrictions in relation to vis‐

cosity limits, chemical resistance and density

– Always switch the pump off before exchanging the

pump hose

Safety and responsibility

10

Page 11

WARNING!

Correct and proper use

Possible consequence: Fatal or very serious injuries

– The unit is not intended to convey or regulate gas‐

eous or solid media

–

Do not exceed the rated pressure, speed or tem‐

perature for the pump

– The unit may only be used in accordance with the

technical data and specifications provided in these

operating instructions and in the operating instruc‐

tions for the individual components

– The system is not designed for use in areas at risk

from explosion

– Only switch the pump on if it has been properly

fastened to the floor

– Only switch the pump on if it the front cover has

been attached.

WARNING!

Operational lifetime of the pump hoses

Possible consequence: Fatal or very serious injuries

The operational lifetime of the pump hoses cannot be

precisely specified. For this reason, the possibility of

fracture and consequential leakage of liquids must be

accounted for. If the hose rupture alarm (optional) is

fitted, then the pump can be stopped and / or an elec‐

trical valve can be actuated.

In addition, you must avoid particles from untight

hoses being introduced into the media being con‐

veyeed. This can be achieved e.g. by means of filtra‐

tion, a hose rupture alarm or other means suitable for

the respective process.

CAUTION!

CIP cleaning

In the event of CIP cleaning, it is necessary to obtain

information from the manufacturer about correct instal‐

lation of the pump (a special installation is required),

as well as regarding the compatibility of the cleaning

agents with the pump hoses of the pump and the other

hydraulic connections.

Cleaning should be undertaken at the recommended

maximum temperature.

Safety and responsibility

11

Page 12

CAUTION!

Direction of rotation / flow direction

Possible consequence: Material damage right through

to destruction of the unit

– The pump's direction of rotation in relation to the

desired flow direction must be checked prior to

every start.

CAUTION!

Environmental influences

Possible consequence: Material damage right through

to destruction of the unit

– The device is not suitable for outdoor operation

– Take suitable measures to protect the device from

environmental influences such as:

– UV rays

– Moisture

– Frost, etc.

Safety and responsibility

12

Page 13

3 Functional description

The package contents supplied with the DULCO®flex DFAa is

selectable via the identcode.

The DULCO®flex DFAa is a displacement pump. The feed chem‐

ical is transported by the rotor squeezing the hose in the direction

of flow. No valves are needed for this. This ensures gentle han‐

dling of the metered media.

The DULCO®flex DFAa has been designed for safe and uncompli‐

cated operation, as well as straightforward maintenance.

The DULCO®flex DFAa can be used for many different media.

However, this pump type is often the optimal solution for abrasive,

shear-sensitive and viscose media.

Typical areas of use include processes where only a low discharge

pressure is required (max. 2 bar).

3.1

Construction

Main modules:

n Drive Unit

n Housing

n Base frame

The pump housing is closed off with a screwed front cover in order

to avoid the risk of injury.

The motor serves to drive the rotor. Rollers at the ends of the rotor

serve to press the pump hose against the pump housing.

The rotary movement of the rotors alternately press and relax the

rollers in relation to the pump hose. This serves to suck the media

in and convey it into the metering line.

Brief functional description

Functional description

13

Page 14

3.2 Overview of the device

Fig. 1: Diagram of functional principle

1. Housing

2. Hose

3. Rotor

4. Rollers

Functional description

14

Page 15

4 Transport, storage, assembly and Installation

n User qualification, transport and storage:

instructed persons,

see

Ä Chapter 1.2 “Users' qualifications” on page 6

n User qualification, assembly: trained qualified personnel, see

Ä Chapter 1.2 “Users' qualifications” on page 6

n User qualification, electrical installation: Qualified electrician,

see

Ä Chapter 1.2 “Users' qualifications” on page 6

WARNING!

Safety data sheet

Possible consequence: Fatal or very serious injuries

Always observe the corresponding data sheets for the

media when carrying out any tasks which involve con‐

tact with the media that is to be conveyed.

4.1 Transport

Transport

n The pump is protected by means of cardboard packaging

n The packaging materials can be recycled

n For environmental conditions for storage and transportation

see

Ä Chapter 4.3.1 “Ambient conditions” on page 16

4.2 Storage

Storage

n The pump hose should be removed from the housing during

the duration of storage

n For storage durations longer than 60 days, the coupling sur‐

faces (terminals, reducing adaptors, motors) are to be pro‐

tected with suitable antioxidant agents

n For environmental conditions for storage and transportation

see

Ä Chapter 4.3.1 “Ambient conditions” on page 16

4.3 Assembly

CAUTION!

Possible consequence: Slight or minor injuries, mate‐

rial damage.

Carry out the assembly work before the electrical

installation is undertaken!

Observe the permissible environmental conditions!

Transport, storage, assembly and Installation

15

Page 16

4.3.1 Ambient conditions

NOTICE!

Ambient conditions

Possible consequence: Property damage and

increased wear and tear

Assembly is to be carried out in the following order. If

the pump has to be installed outdoors, then it is to be

equipped with protection against sunlight and weather

influences.

When positioning the pump, ensure that sufficient

room for access is provided for all types of mainte‐

nance work.

There are limit values for temperature and pressure, depending on

the type of hose selected. These limit values are described in the

following section:

Limit values for hose temperature and pressure

Material

Hose

min. temp. (°C)

Feed chemical

max. temp. (°C)

Feed chemical

min. temp. (°C)

Environment

max. pressure (bar)

Solva - - -40 2

Silicone - - -40 2

Tygon -10 70 -40 2

NORPREN -40 120 -40 2

Also observe the general safety information, see

Ä Chapter 2.1 “General safety information” on page 10

4.3.2 Alignment of the suction side

The pump is to be positioned as near as possible to the liquid con‐

tainer, so that the suction side is kept as short and straight as pos‐

sible.

The suction line must be absolutely airtight and made of a suitable

material, so that it is not squeezed together under vacuum.

The diameter must correspond to the rated diameter of the pump

hose. A larger diameter is recommended in the event of viscose

liquids.

The pump is self-priming and does not require an admission valve.

The pump is reversible and the suction connection can therefore

comprise of one of two options. Normally the option is selected

which is best suited to the physical conditions of the installation.

4.3.3

Alignment of the discharge side

The discharge line is to be kept as straight and short as possible,

in order to avoid performance reduction.

Transport, storage, assembly and Installation

16

Page 17

The diameter must correspond to the rated diameter of the pump

hose. A larger diameter is recommended in the event of viscose

liquids.

4.3.4

Performance curves

NOTICE!

Maximum pressure under continuous operation

The dotted line indicates the limit for maximum pres‐

sure under continuous operation

A0510

Fig. 2: DFAa 003 (3.2 mm) / DFAa 008 (8.0 mm)

Transport, storage, assembly and Installation

17

Page 18

5 Commissioning

n User qualification, commissioning: trained user, see

Ä Chapter 1.2 “Users' qualifications” on page 6

5.1 Testing prior to commissioning the pump

The following tests are to be carried out:

n Ensure that the pump has not been damaged during transpor‐

tation or storage. Immediately report any damage to the sup‐

plier

n Check that the mains voltage is suitable for the motor

n Ensure that the hose is suitable for the fluid to be conveyed

and that it is not damaged

n Make sure that the temperature of the liquid does not exceed

the recommended temperature range

n Only switch the pump on if it the front cover has been properly

attached

n Check that the rollers are correctly fitted and fastened

n Check that the hose and rollers are sufficiently lubricated

n Check that the thermal overload protection (not included in the

delivery scope) corresponds to the value specified on the

motor type plate

n Check whether the direction of rotation is correctly adjusted

n Check that the optional electrical components are connected

and are working properly

n Install a manometer in the pressure line if the back-pressure

value is unknown

n Check the operating instructions in order to ensure that the

flow values, pressures and power consumption of the motor do

not exceed the rated values

n Install a pressure relief valve in the pressure line in order to

protect the pump in the event that a valve is unintentionally

closed off or the line is blocked in another way.

Commissioning

18

Page 19

6 Operation of the peristaltic pump

n User qualification, operation:

instructed persons, see

Ä Chapter 1.2 “Users' qualifications” on page 6

The peristaltic pump is to be fully integrated into the customer's

designated plant and is then controlled by this plant. It is not pos‐

sible to operate the pump directly.

Operation of the peristaltic pump

19

Page 20

7 Maintenance, repair, malfunctions, disposal and spare parts

n User qualification, maintenance and disposal: instructed per‐

sons, see

Ä Chapter 1.2 “Users' qualifications” on page 6

n User qualification, repair and malfunctions: trained user, see

Ä Chapter 1.2 “Users' qualifications” on page 6

7.1 Maintenance

CAUTION!

Disconnect the pump from the mains

Possible consequence: Personal injury

You may only carry out work on the pump after it has

previously been switched off and disconnected from

the mains.

Lubrication

n Check that the rollers and the hose are sufficiently lubricated

–

Check every 200 operating hours

n Check whether the oil level is correct for the step-down gears

– Exchange the oil at regular intervals in accordance with the

step-down gear maintenance manual.

7.2 Exchanging the pump hoses

1. Close off all valves, in order to prevent leakage of the feed

chemical

2. Dismantle the pump hoses from both the discharge and suc‐

tion sides

3. Remove the front cover

4. Dismantle the pump housing

5. Remove the pump hose to be exchanged

1. Clean the interior surfaces of the pump housing

2. Lubricate the internal surfaces of the pump housing at the

contact surfaces to the pump hose

3. Check the rollers. Ensure that the roller surfaces are not

damaged

4. Lay the pump hose into the pump

5. Reassemble the pump housing again

6. Attach the front cover to the pump housing together with the

integrated hose clip. In doing so, hold the pump hose so that

it is lightly prestressed.

7. Tighten the knurled thumb screw for the integrated hose clip

just enough that the pump hose is sufficiently compressed

and so that it doesn't come loose during operation

Exchanging the pump hoses - dis‐

mantling

Exchanging the pump hoses - installa‐

tion

Maintenance, repair, malfunctions, disposal and spare parts

20

Page 21

8. Mount the pump hoses from both the discharge and suction

sides

9. Open all of the valves

7.3

Troubleshooting

Problem Possible cause Solution

Increased pump temperature Pump hose has no lubricant Lubricate pump hose

Increased product temperature Reduce product temperature

Insufficient or poor suction condi‐

tions

Check suction line for blockages

Pump speed too high Reduce pump speed

Reduced flow or pressure Valves on discharge and or suc‐

tion side completely or partially

closed

Open valves

Pump hose insufficiently com‐

pressed

Check roller fastening

Pump hose rupture (the product

leaks out into the housing)

Exchange pump hose

Partial blockage of the suction line Clean pipe

Insufficient product quantity in

storage container

Fill storage container or exchange

pump

Insufficient diameter on the suc‐

tion side

Increase the diameter on the suc‐

tion side, as far as possible

Suction line too long Shorten the suction line, as far as

possible

High viscosity of medium Reduce viscosity, as far as pos‐

sible

Air introduction in the suction con‐

nections

Check connections and accesso‐

ries for air tightness

Vibration in the pump Pump speed too high Reduce pump speed

Pump base plate loose Fasten base plate

Short operational lifetime of the

hoses

Chemical stress Check the compatibility of the

hose with the liquid being con‐

veyed, the cleaning fluid and the

lubricant

High pump speed Reduce pump speed

High conveying temperature Reduce product temperature

High operating pressure Reduce operating pressure

Pump cavitations Check the suction conditions

Pump hose pulled into the pump

housing

High inlet pressure (> 3 bar) Reduce inlet pressure

Pump hose filled with deposits Clean or replace the pump hose

Maintenance, repair, malfunctions, disposal and spare parts

21

Page 22

Problem Possible cause Solution

Front cover with integrated hose

clip insufficiently tightened up

Tighten up the holder

The pump does not start up Insufficient motor performance Check motor and replace if neces‐

sary

Insufficient output from frequency

converter

The frequency converter must

match the motor

Check voltage. Start occurs at

minimum 10 Hz

Blockage in the pump Check if the suction or discharge

side is blocked. Rectify blockage

7.4 Disposal of Used Parts

WARNING!

Danger due to feed chemicals

Possible consequence: Fatal or serious injuries

In the event that damage to the pump hose causes the

pump to be contaminated with feed chemicals, then it

is to be decontaminated with suitable agents (refer to

the feed chemical safety data sheets).

NOTICE!

If no Declaration of Decontamination is affixed to the

delivery, acceptance of the devices will be refused.

(also available as download from: www.promi‐

nent.com)

A signed "Declaration of Decontamination" is required

by law and in order to protect our staff, before you

order can be processed.

Please ensure that this is attached to the outside of the

package. Otherwise we are unable to accept your

delivery.

NOTICE!

Regulations governing disposal of used parts

– Note the current national regulations and legal

standards which apply in your country

The pump hose is to be removed and disposed of on-site before

sending the pump to ProMinent Dosiertechnik GmbH, Heidelberg /

Germany.

ProMinent Dosiertechnik, Heidelberg/Germany is prepared to take

back clean used parts.

Maintenance, repair, malfunctions, disposal and spare parts

22

Page 23

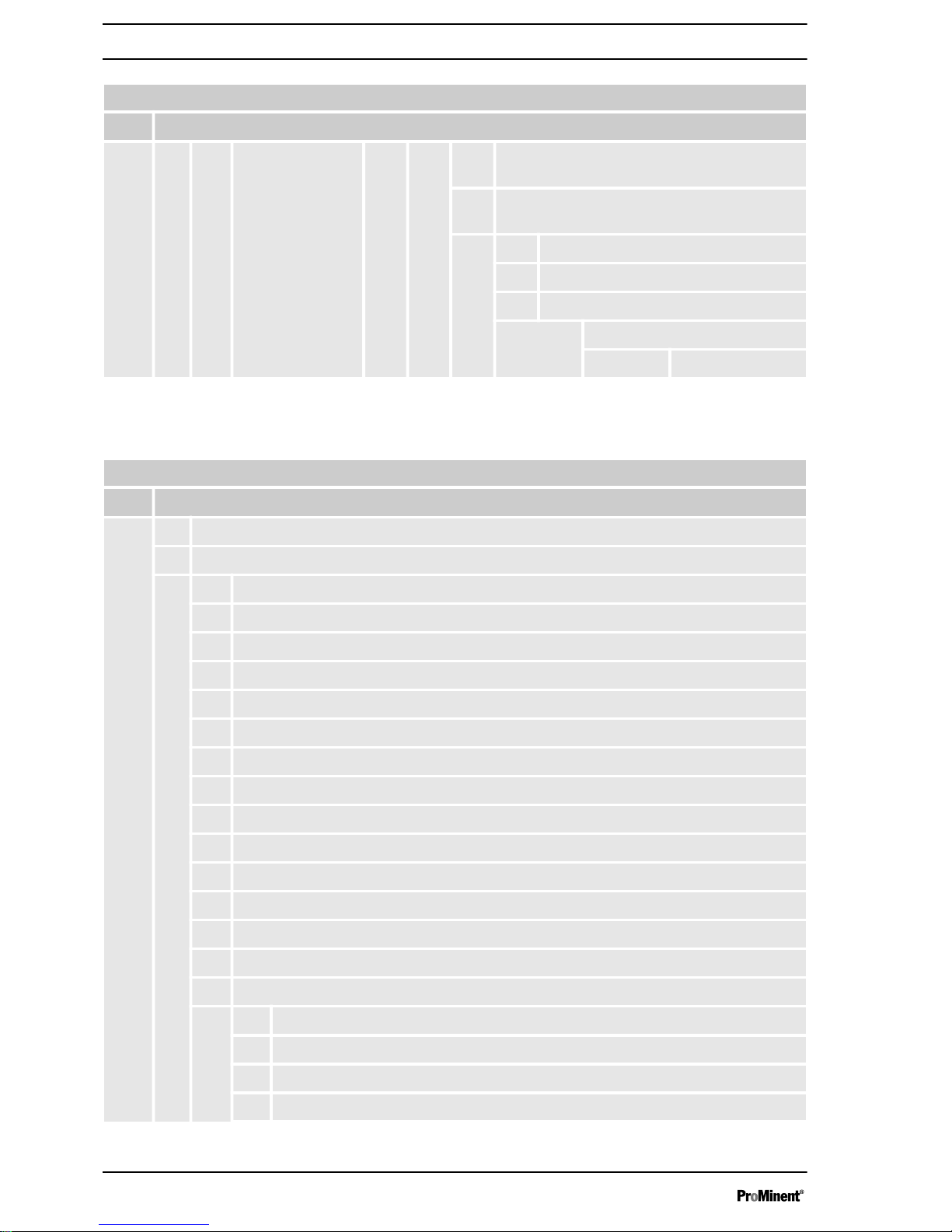

7.5 Spare parts

9

1

2

3

18

4

5

6

7

13

19

10

11

12

8

14

15

16

17

A0511

Fig. 3: Spare parts exploded view DFAa 003/008

DFAa 003

refer to Fig. 3

Pos. Description Quantity Reference Part number

1 Mount pump housing 1 115.00.01

2 Pump housing 1 115.00.02

3 Rotor with steel shaft 1 115.00.03

Rotor with stainless steel shaft 1 115.00.04

4 Roller for pump hose with 2.4 mm wall

thickness / Plastic A

3 115.00.05

Roller for pump hose with 2.4 mm wall

thickness / Plastic B

3 115.00.06

5 Shaft for roller 3 115.00.09

6 Safety ring for rotor shaft 1 115.00.10

7 Pump housing screws 2 115.00.11

Stainless steel pump housing screws 2 115.00.12

Maintenance, repair, malfunctions, disposal and spare parts

23

Page 24

DFAa 003

refer to Fig. 3

Pos. Description Quantity Reference Part number

8 Pump housing nuts 2 115.00.13

9 Base plate 1 115.00.14

Base plate, stainless steel 1 115.00.15

10 Front cover, polycarbonate 1 115.00.16

11 Pump hose clamping pad 1 115.00.17

Stainless steel pump hose clamping pad 1 115.00.18

12 Front cover fascia, steel 1 115.00.19

Front cover fascia, stainless steel 1 115.00.20

13 Adjustment screw, steel 1 115.00.21

Adjustment screw, stainless steel 1 115.00.22

14 Adjustment screw grip, plastic 1 115.00.23

15 Coil spring 1 115.00.24

16 Safety ring adjustment screw 1 115.00.25

17 Thread insert 1 115.00.26

Thread insert, stainless steel 1 115.00.27

18 Drive 1

19 Pump hose silicone 1 1037107

Pump hose Norprene A-60-F 1 1037144

Pump hose Solva 1 1037145

DFAa 008

refer to Fig. 3

Pos. Description Quantity Reference Part number

1 Mount pump housing 1 115.00.01

2 Pump housing 1 115.00.02

3 Rotor with steel shaft 1 115.00.03

Rotor with stainless steel shaft 1 115.00.04

4 Roller for pump hose with 2.4 mm wall

thickness / Plastic A

3 115.00.05

Roller for pump hose with 2.4 mm wall

thickness / Plastic B

3 115.00.06

5 Shaft for roller 3 115.00.09

6 Safety ring for rotor shaft 1 115.00.10

7 Pump housing screws 2 115.00.11

Maintenance, repair, malfunctions, disposal and spare parts

24

Page 25

DFAa 008

refer to Fig. 3

Pos. Description Quantity Reference Part number

Stainless steel pump housing screws 2 115.00.12

8 Pump housing nuts 2 115.00.13

9 Base plate 1 115.00.14

Base plate, stainless steel 1 115.00.15

10 Front cover, polycarbonate 1 115.00.16

11 Pump hose clamping pad 1 115.00.17

Stainless steel pump hose clamping pad 1 115.00.18

12 Front cover fascia, steel 1 115.00.19

Front cover fascia, stainless steel 1 115.00.20

13 Adjustment screw, steel 1 115.00.21

Adjustment screw, stainless steel 1 115.00.22

14 Adjustment screw grip, plastic 1 115.00.23

15 Coil spring 1 115.00.24

16 Safety ring adjustment screw 1 115.00.25

17 Thread insert 1 115.00.26

Thread insert, stainless steel 1 115.00.27

18 Drive 1

19 Pump hose silicone 1 1037146

Pump hose Norprene A-60-G 1 1037147

Pump hose Norprene A-60-F 1 1037148

Pump hose Solva 1 1037149

Lubricant

Pos. Description Quantity Reference Part number

1 0.5 kg silicone grease 1 1037255

2 1.0 kg silicone grease 1 1037256

Maintenance, repair, malfunctions, disposal and spare parts

25

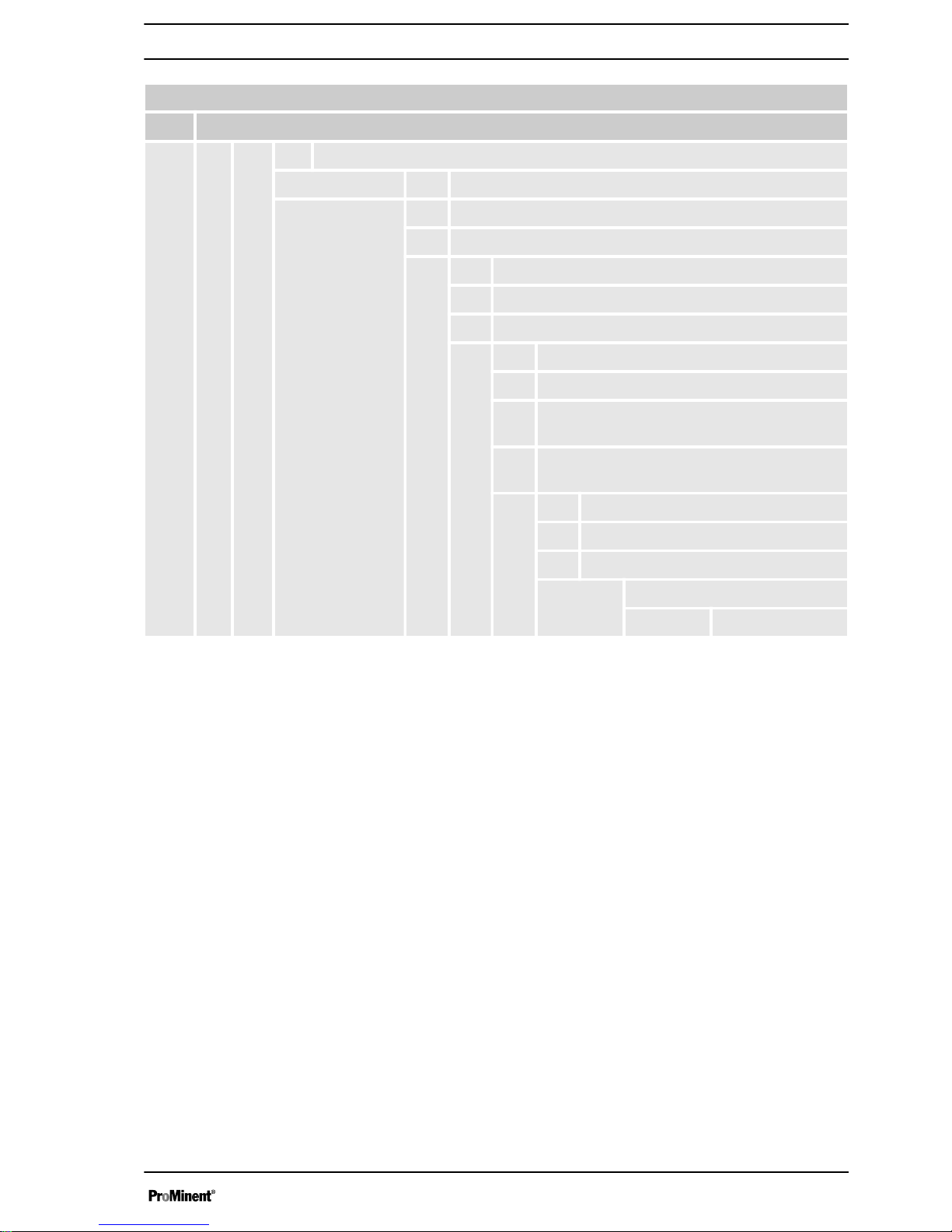

Page 26

8 DFAa technical data

Type

DFAa

Feed rate

in ml/rev‐

olution

P max.

in bar

Flow rate

at max.

pressure

in l/h

Rollers/

shoes

Shoes

Hose

interior

⌀ in mm

Solids

max.

⌀ in mm

Weight

without

drive

in kg

Con‐

nector

003 1,66 2 17,5 Rollers 3,2 - 2 -

008 10 2 105 Rollers 8 - 2 -

8.1 Dimensions DFAa 003/008

A

D

E

C

B

F

G

H

A0512

Fig. 4: Dimensions DFAa 003/008

A 180 mm

B 200 mm

C 36 mm

D 95 mm

E 36 mm

G 47 mm

H 76 mm

DFAa technical data

26

Page 27

Drive Position

“F”

in mm

A10/B10 323

A11/B11 323

A12/B12 323

A13/B13 325

A14/B14 325

A21/B21 439

A22/B22 457

A31/B31 355

A41/B41 340

The drive version is specified by means of an Identcode, please

refer to

Ä Chapter 1.3 “ID Code” on page 7

DFAa technical data

27

Page 28

9 DFAa technical appendices

9.1

Declaration of Conformity

Fig. 5: EC Declaration of Conformity

DFAa technical appendices

28

Page 29

10 Index

C

Correct and proper use........................................ 11

Counter measures

................................................ 11

D

Displacement pump............................................. 13

Disposal............................................................... 22

E

Emergency stop switch........................................ 10

G

General non-discriminatory approach.................... 4

L

Live parts.............................................................. 10

N

Non-discriminatory approach................................. 4

S

Safety data sheet................................................. 11

Safety information............................................ 4, 10

U

Unauthorised access............................................ 10

Users' qualifications............................................... 6

Index

29

Loading...

Loading...